Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209 results about "Alunite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alunite is a hydrated aluminium potassium sulfate mineral, formula KAl₃(SO₄)₂(OH)₆. It was first observed in the 15th century at Tolfa, near Rome, where it is mined for the manufacture of alum. First called aluminilite by J.C. Delamétherie in 1797, this name was contracted by François Beudant three decades later to alunite.

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

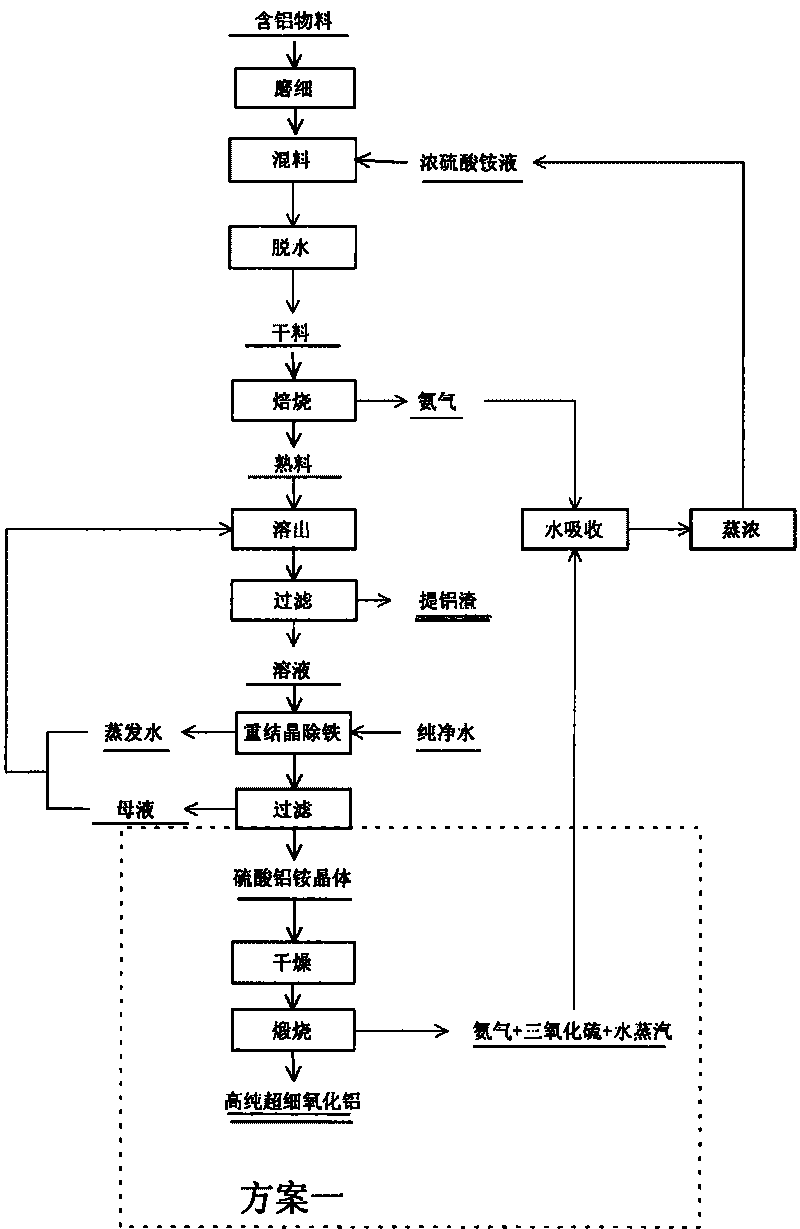

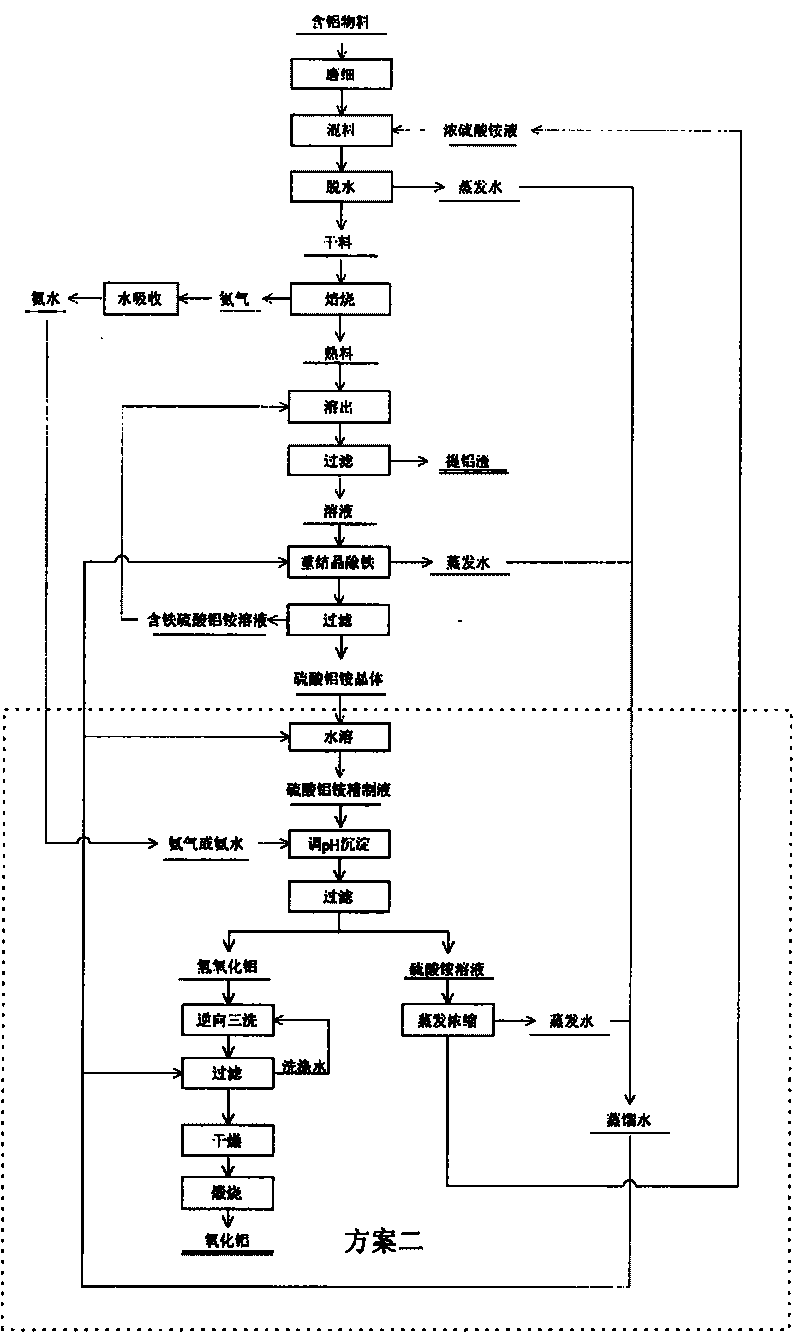

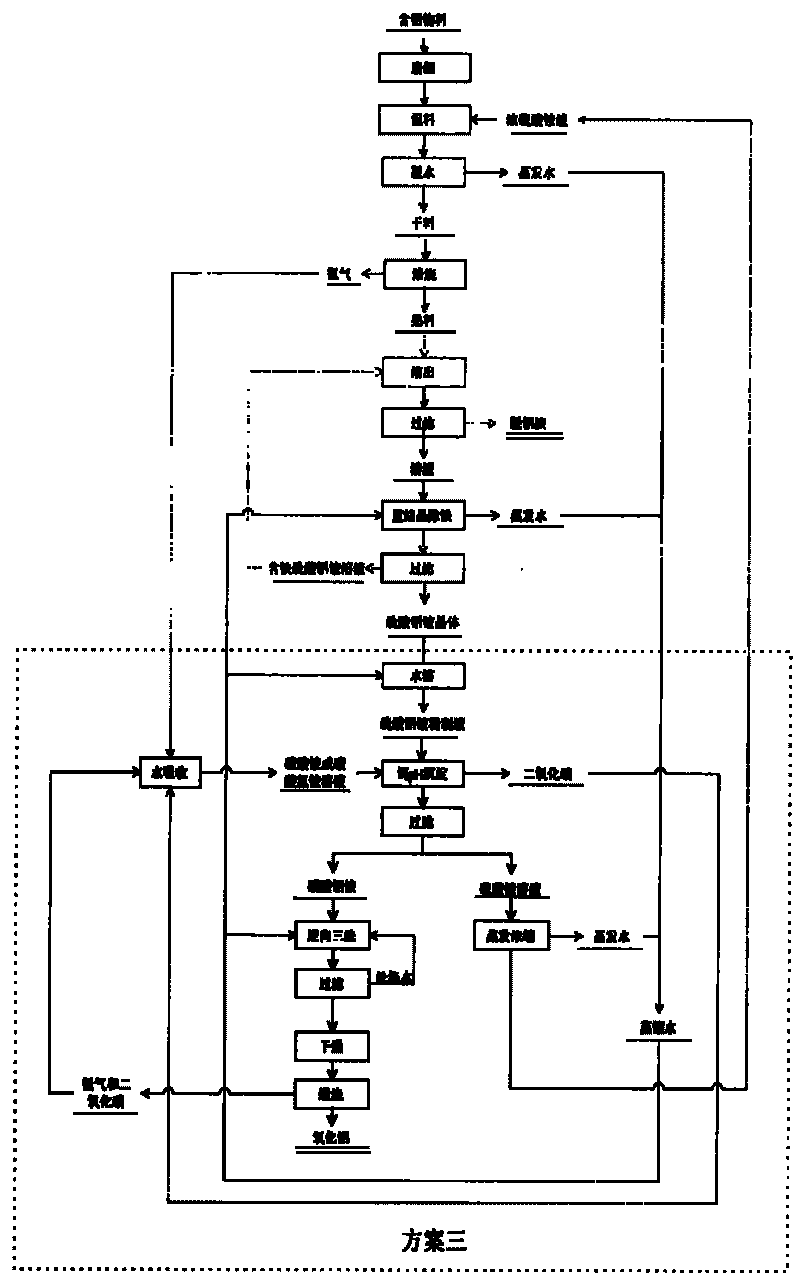

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

High performance expansible cement clinker expansion agent series prepared thereby

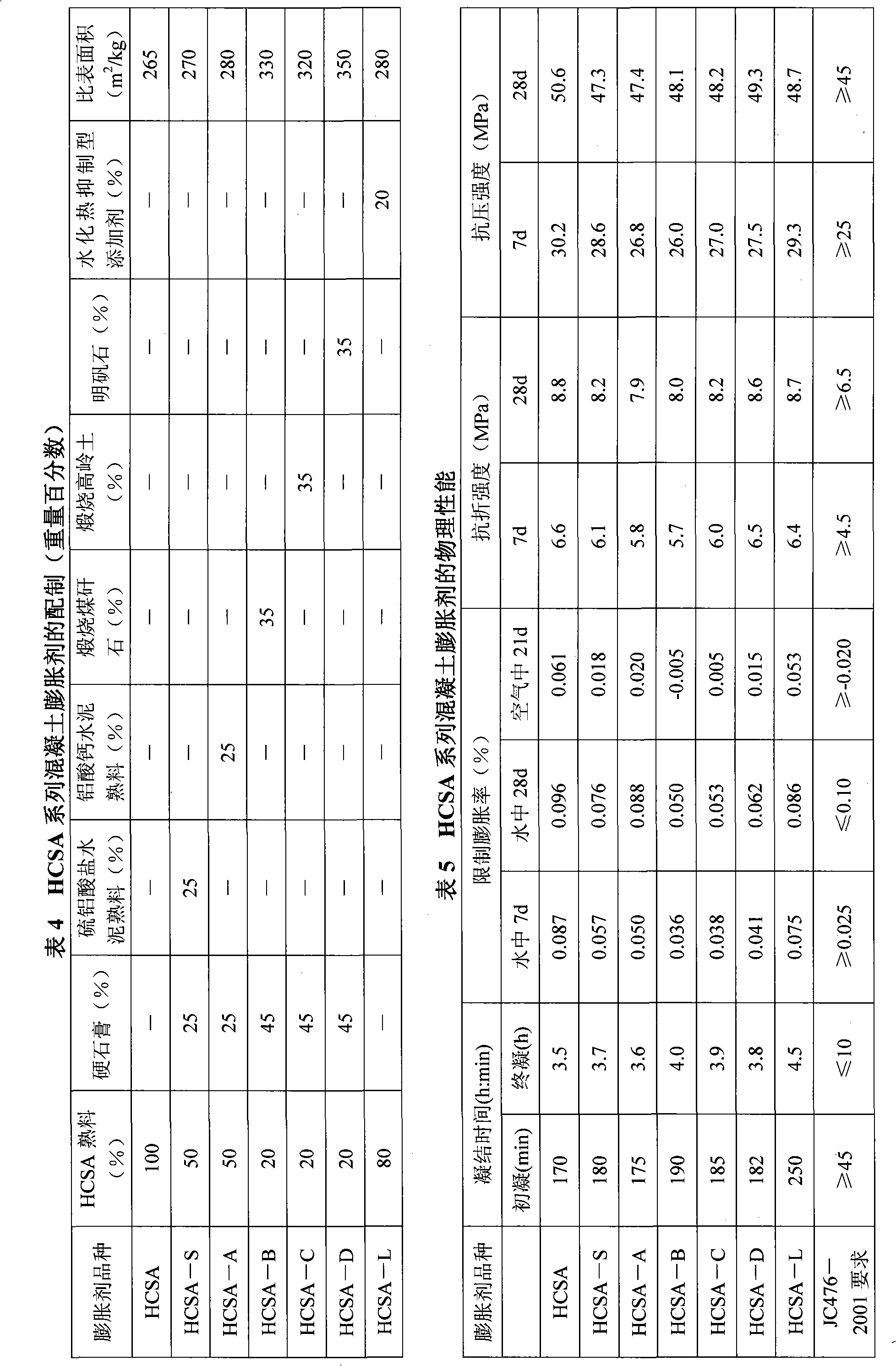

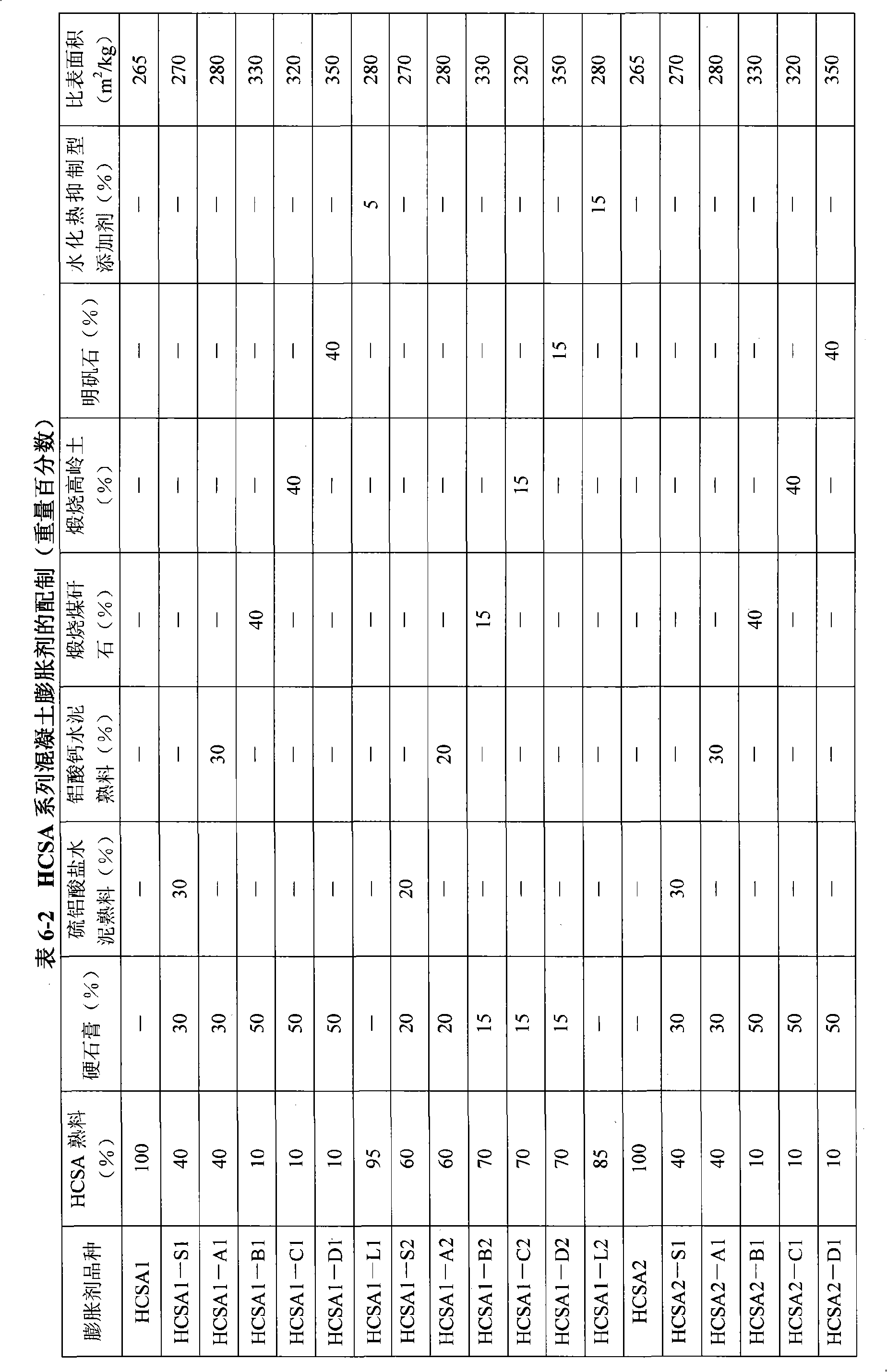

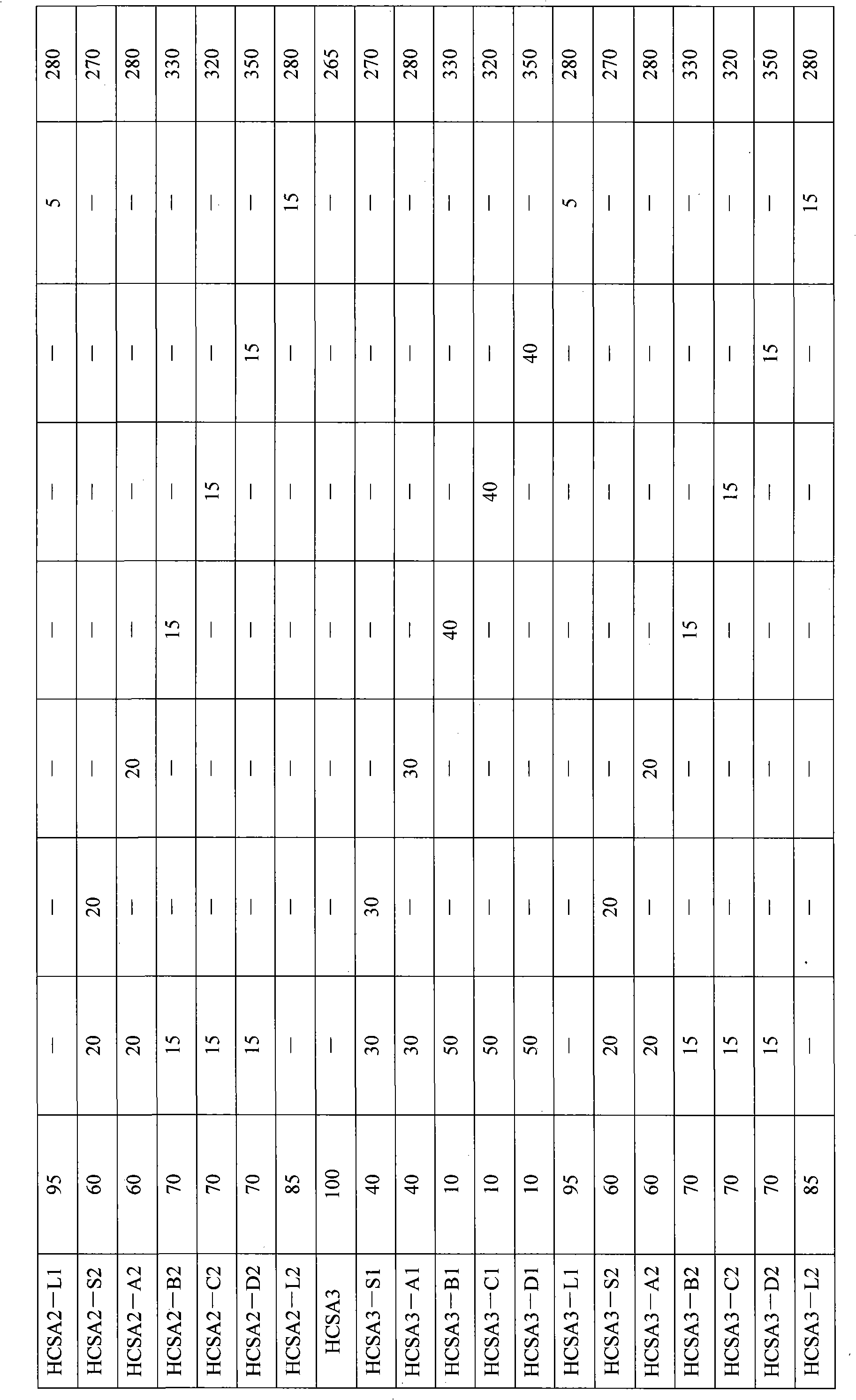

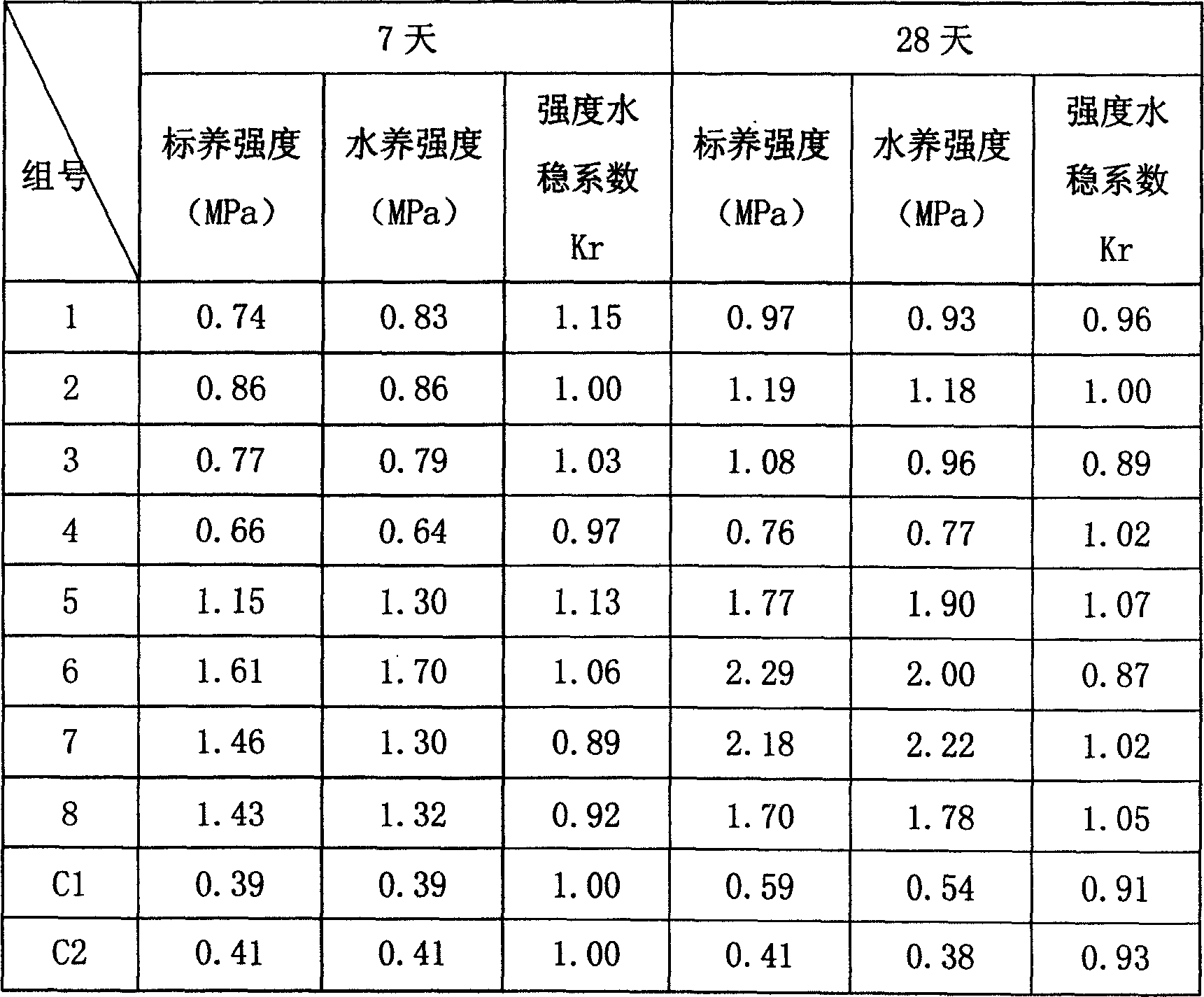

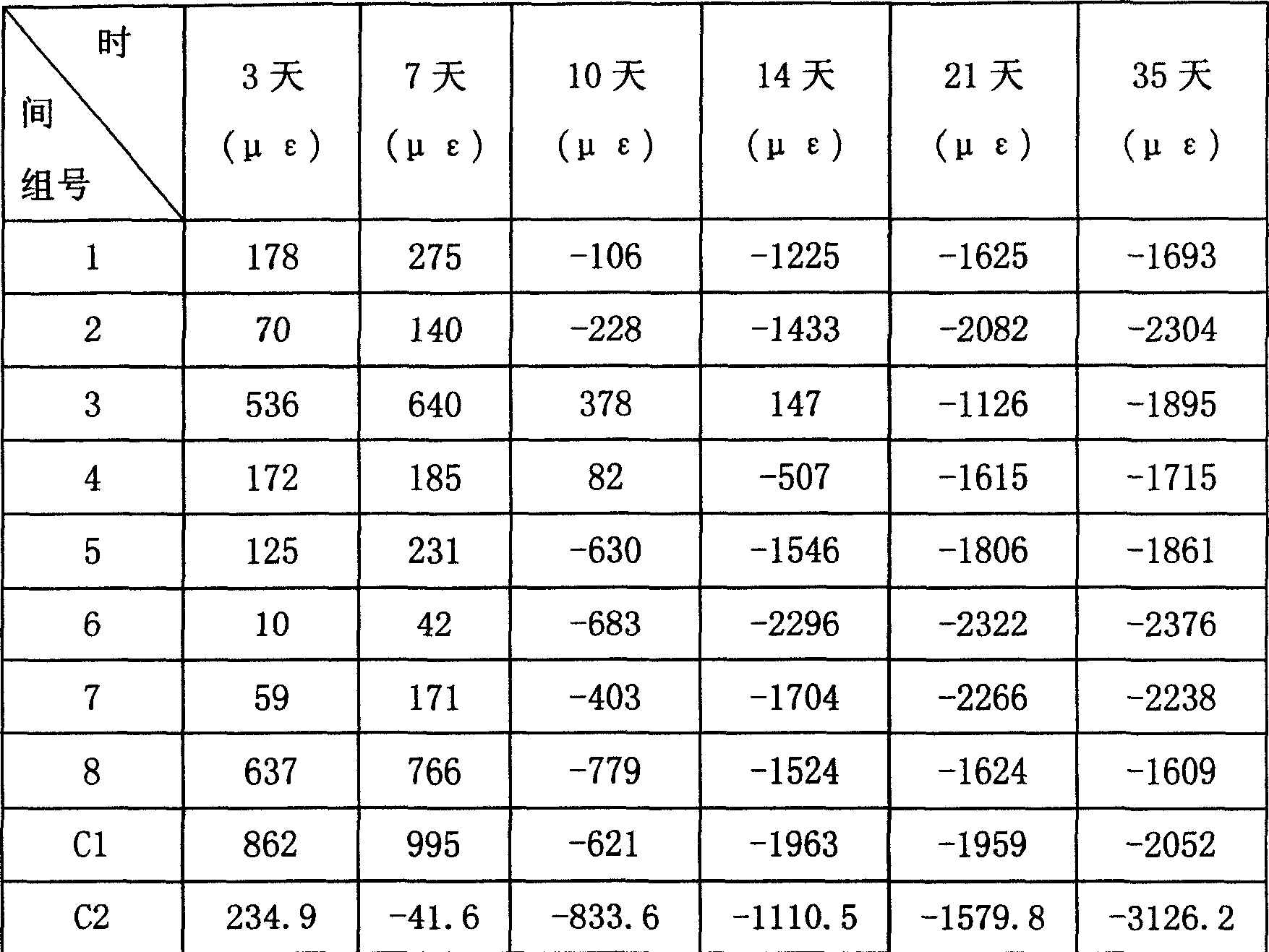

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

Soil solidifying agent

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

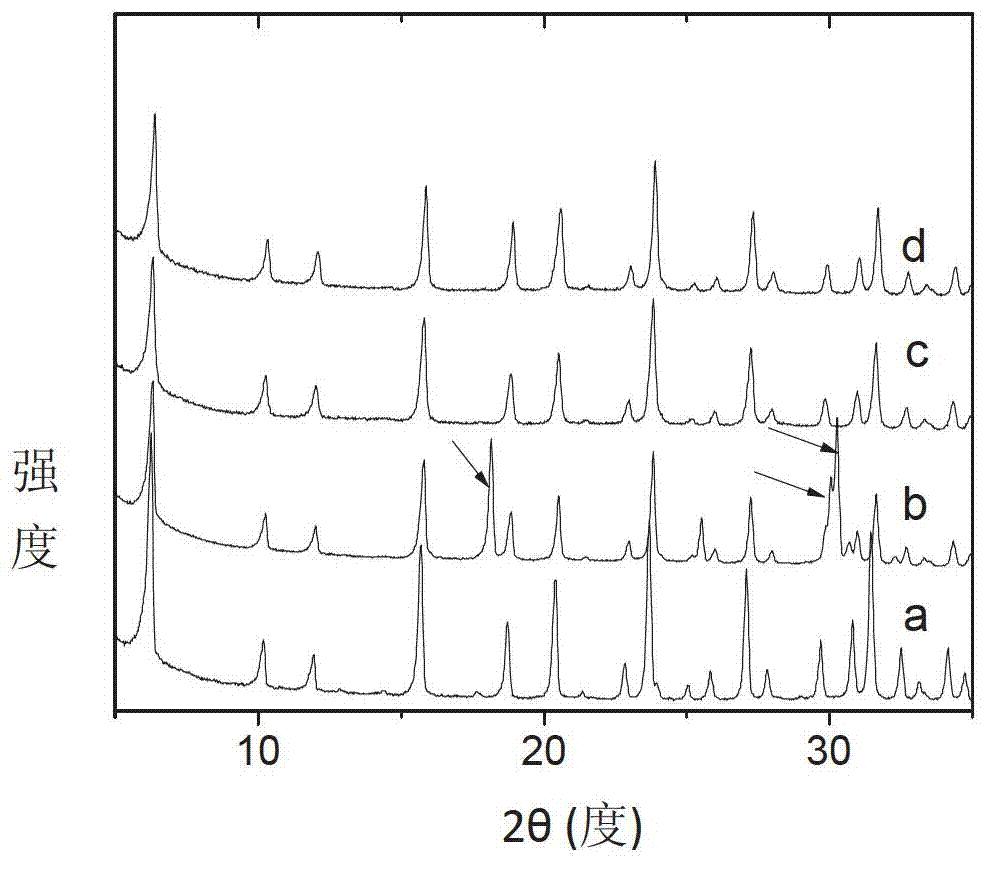

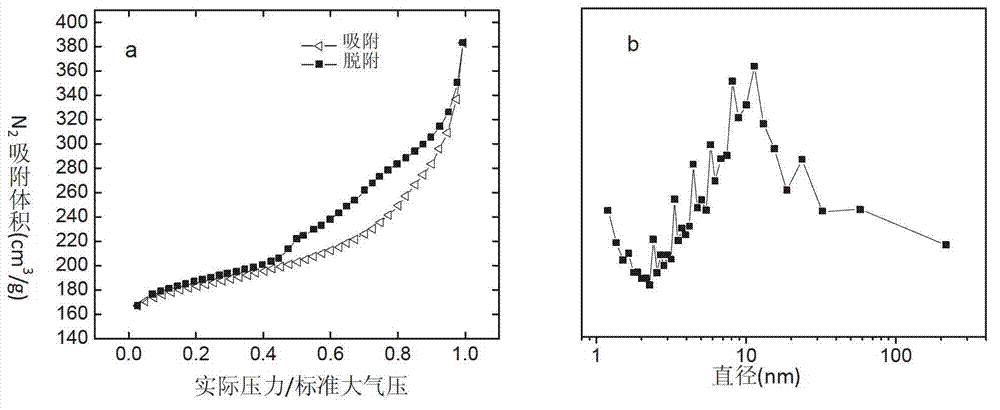

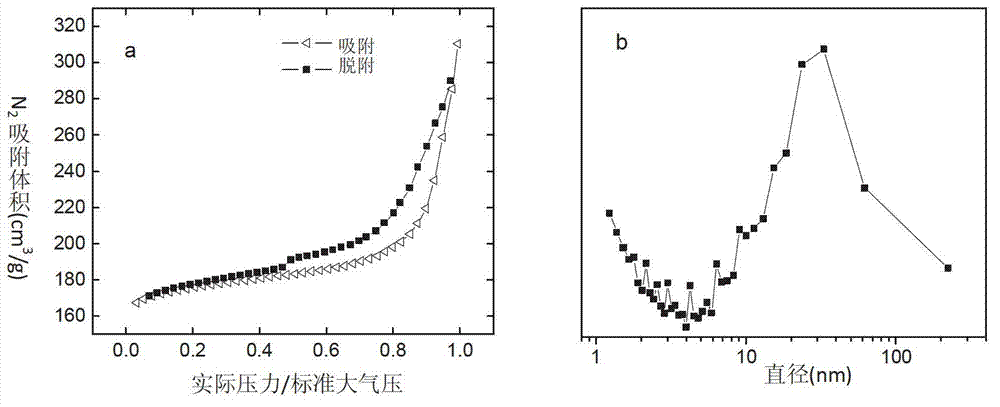

Modified method of Y-type molecular sieve

InactiveCN102951655AIncreased mesopore volumeFaujasite aluminosilicate zeoliteMolecular sieveAluminium sulfate

The invention discloses a modified method of a Y-type molecular sieve. The modified method comprises the following steps of: dissolving the Y-type molecular sieve and aluminum sulfate or aluminum sulfate containing crystal water into water, adding alcohol, reacting for 0-10 days at the temperature of 100-200 DEG C, filtering products after reaction, cleaning and obtaining mixture of an alunite-like phase and the Y-type molecular sieve; and adopting alkali compound to treat the mixture for 0-100 hours at the temperature of 0-100 DEG C and obtaining the modified Y-type molecular sieve. The modified method disclosed by the invention is wide in material source, low in cost and simple in reaction process, and is suitable for industrial production.

Owner:EAST CHINA NORMAL UNIV

Earth cementation agent in use for roadway construction

InactiveCN1562851AImprove responseGood water hardnessSolid waste managementOrganic fertilisersPower stationRoad surface

In the invention, two kinds of waste material dry dust discharging coal ash and desulfurize gyp produced by power plant burning sub-bituminous coal or lignitous coal are used as main composition, shell and or cement, calcined gypsum and aluminum sulfate or alunite are used as secondary composition, they are prepared to dry powder soil curing agent by weighing, matching, forced stirring and mixing. The soil can be concreted by mixing a proper quantity of curing agent into the soil and processes of stirring, compacting, soaking and maintaining.

Owner:徐尔昌

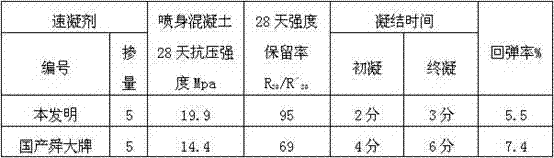

Cement concrete accelerator

The invention relates to a cement concrete accelerator. The accelerator comprises 50-65% of aluminium-oxygen clinker, 25-35% of calcined alunite, 3-8% of zinc sulfate and 6-8% of anhydrite. According to the accelerator, the resilience rate is low, the later strength is high, the compression strength retention rate for 28 days can reach more than 90%, and the alkali charge is low, and harm to an operating worker can be reduced greatly.

Owner:贵州遵辉环保科技有限公司

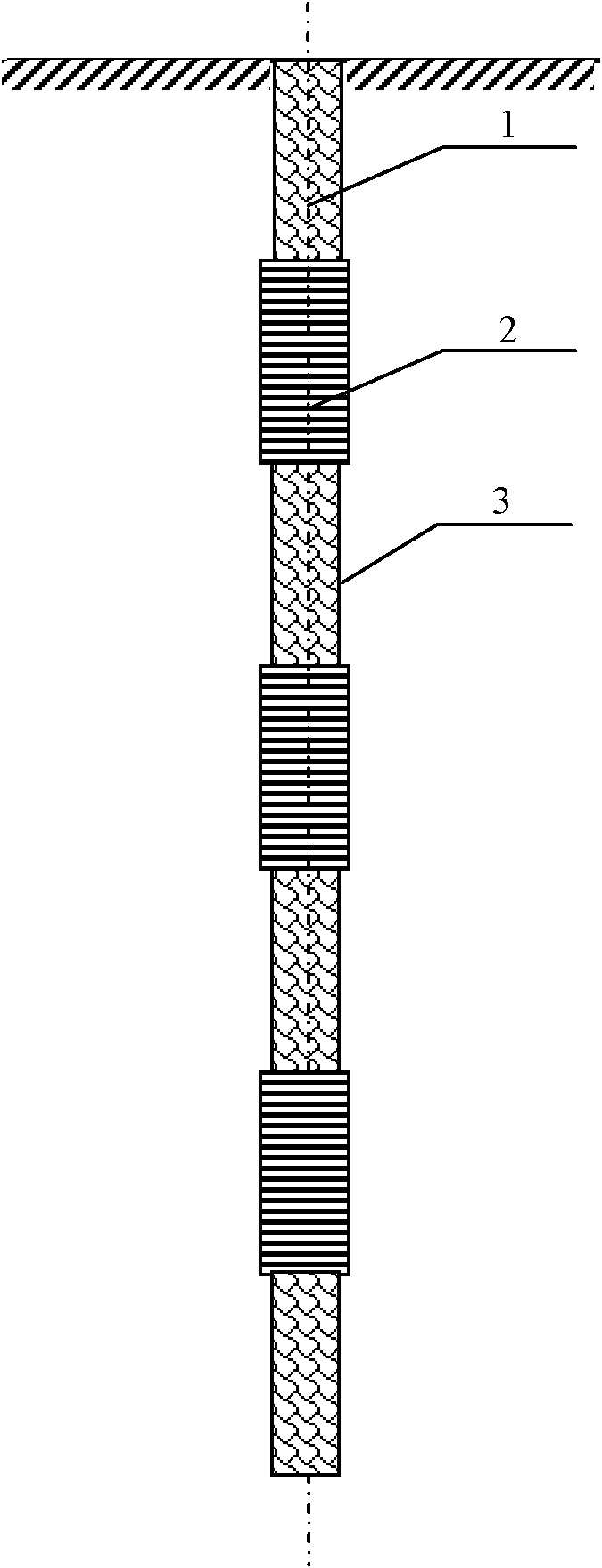

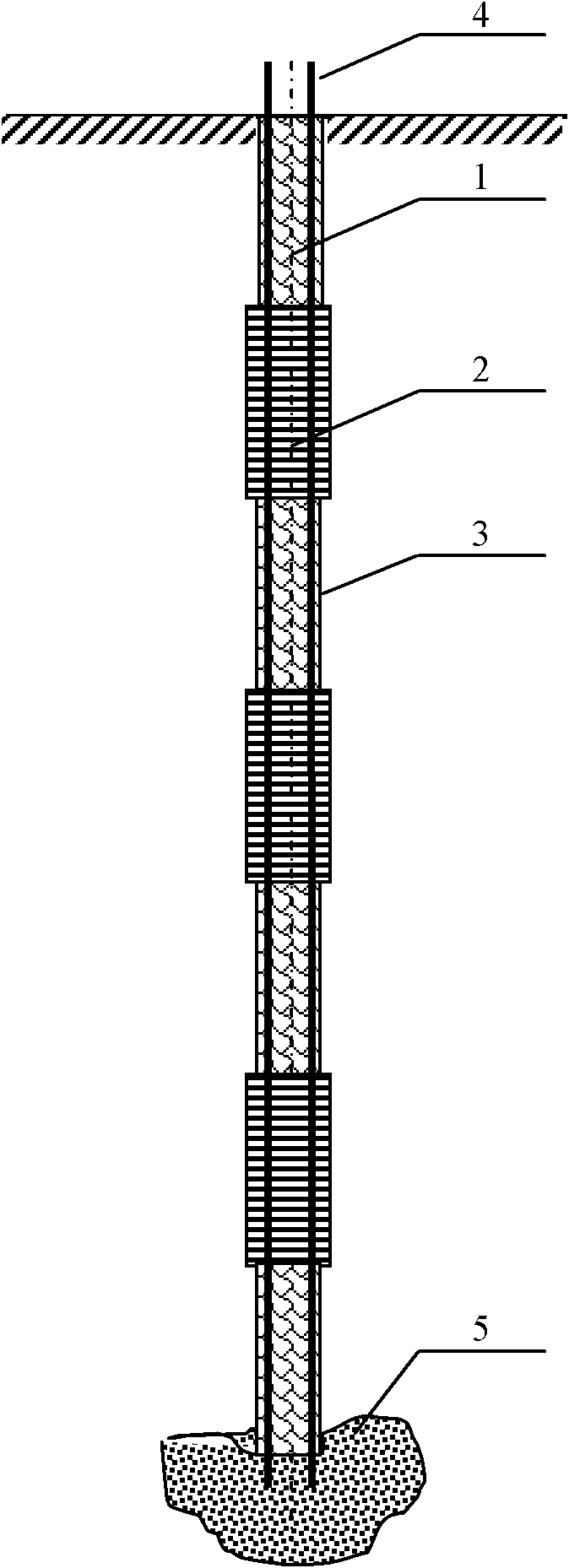

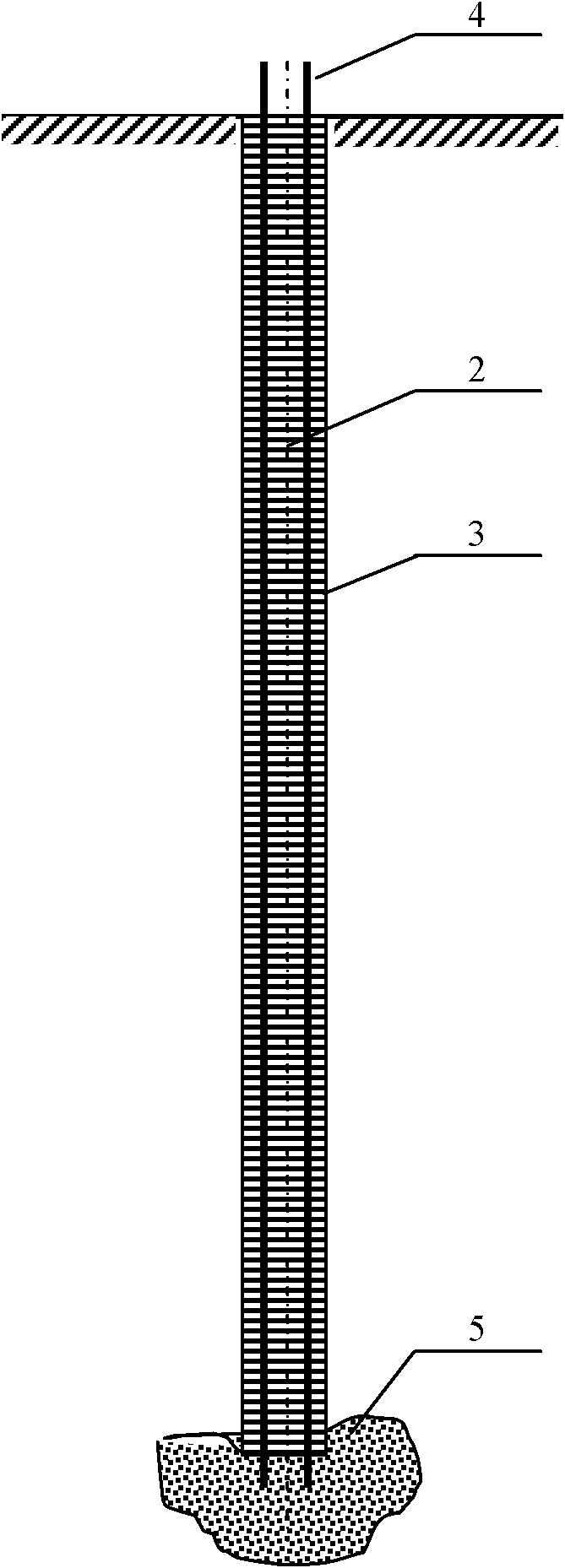

Expansive concrete caisson pile and manufacturing method thereof, and concrete expanding agent

ActiveCN102162244AIncrease relative resistance to motionImprove bearing capacityBulkheads/pilesSlurryJoints types

The invention provides an expansive concrete caisson pile and a manufacturing method thereof, and a concrete expanding agent, and belongs to the technical field of engineering materials and construction of concrete pile foundation. The method comprises the following steps of: alternatively pouring common concrete and expansive concrete into a caisson pile hole sequentially so as to form bamboo joint type I-shaped pile; and pouring slurry at the pile end of the I-shaped pile or the expansive concrete pile so as to form a II-shaped pile or a III-shaped pile. The expanding agent is manufactured by pulverizing 40 to 80 percent of limestone and 20 to 60 percent of gypsum, calcining the powder in a rotary kiln at the high temperature of 1,300 to 1,500 DEG C, and pulverizing 20 to 80 weight percent of the calcined substance and 20 to 80 weight percent of calcium sulfoaluminate cement or alunite or calcium aluminate cement or a mixture of the calcium sulfoaluminate cement, the alunite and the calcium aluminate cement until the specific surface area is 150 to 400 square meters per kilogram. By the method, the manufacturing cost of the expansive concrete caisson pile can be reduced obviously; and compared with the common expansive concrete caisson pile, the expansive concrete caisson pile has the advantage of obviously increasing the bearing capacity of a single caisson pile.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Concrete crack grouting repairing material prepared from calcium silicate hydrate crystal seed powder and use method of material

The invention relates to the field of building construction materials, in particular to a concrete crack grouting repairing material prepared from calcium silicate hydrate crystal seed powder and a use method of the material.The concrete crack grouting repairing material is prepared from ordinary Portland cement, the calcium silicate hydrate crystal seed powder, hydroxymethyl cellulose ether, dispersible adhesive powder, gypsum, a naphthalene sulfonated formaldehyde condensate water reducing agent, limestone powder and alunite.The concrete crack grouting repairing material can be used for rapidly repairing concrete cracks of a building structure, and therefore the mechanical property and durability of the concrete structure are improved, and the service life of the building is prolonged.The concrete crack grouting repairing material is suitable for repairing of cracks of concrete structures such as reinforced concrete structures, concrete pavements, bridges and water conservancy projects.

Owner:TONGJI UNIV

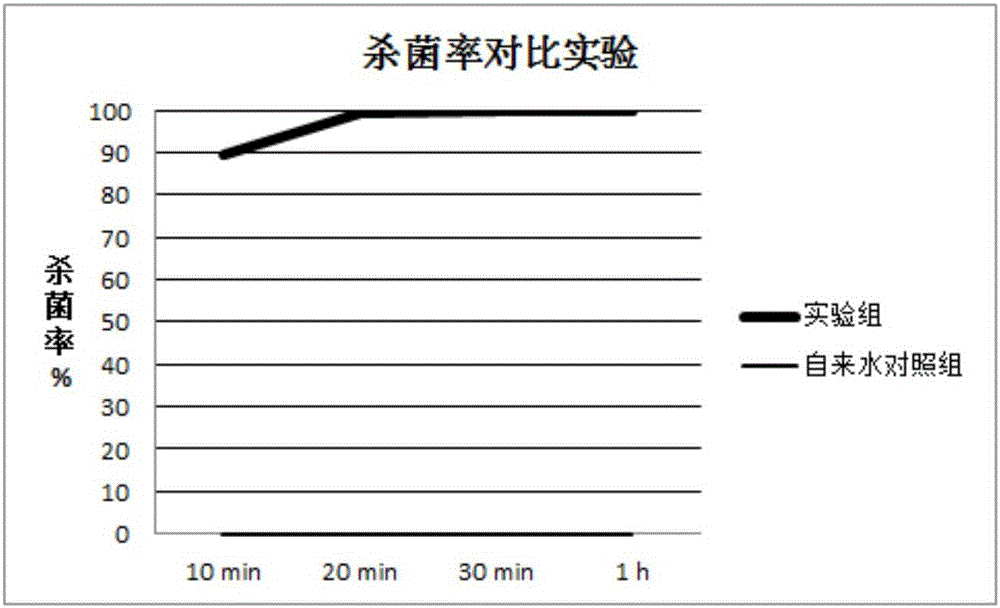

Dry powder modified disinfection agent

ActiveCN105052917AStrong water absorptionEfficient drying effectBiocideDisinfectantsAluniteLivestock

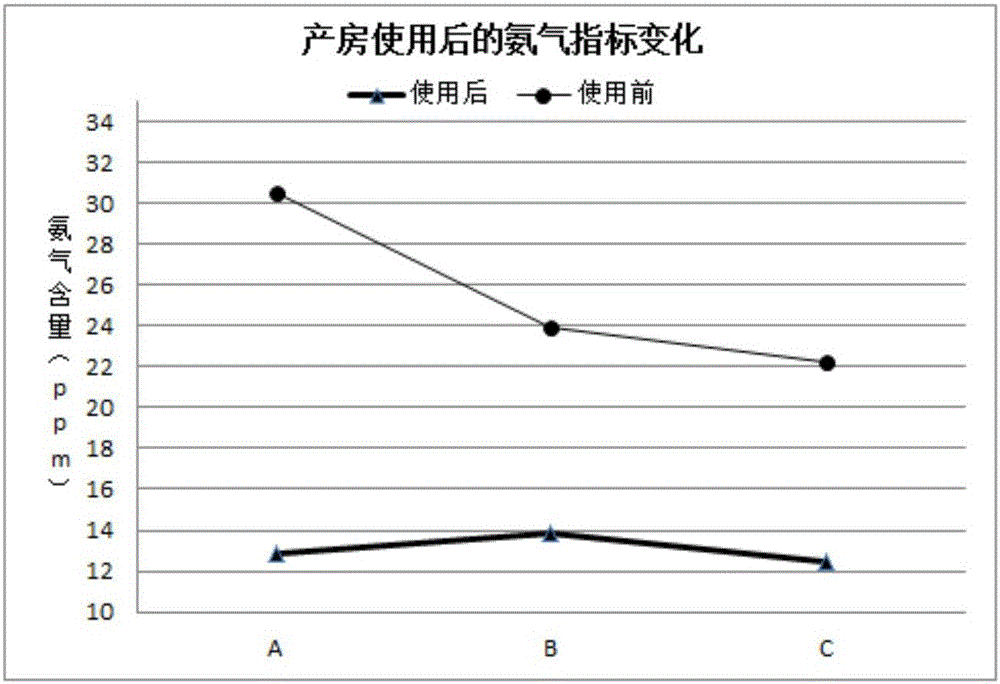

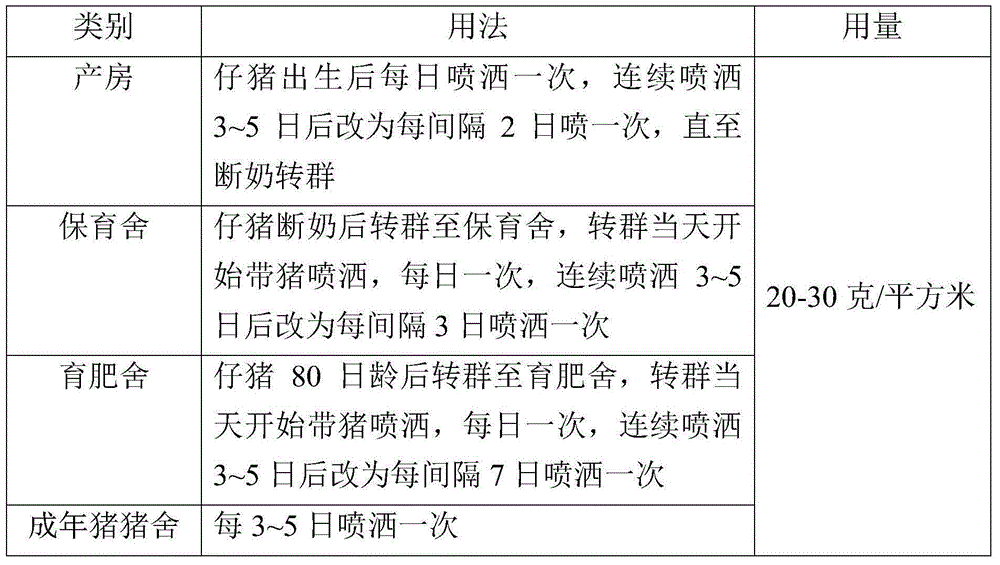

The invention discloses a dry powder modified disinfection agent which comprises adsorbents, an anti-bacterial agent and conditioning agents, wherein the adsorbents account for 93 to 95 percent by weight, the anti-bacterial agent accounts for 3 to 5 percent by weight, and the conditioning agents account for 1 to 4 percent by weight; the adsorbents are three or more of smectite, attapulgite, diatomite, gypsum, alunite, activated clay, kaolinite, talcum powder and activated carbon; the anti-bacterial agent comprises natural plant essential oil; the conditioning agents comprise perfume and borneol. The dry powder modified disinfection agent is used for adjusting and improving of the environment of a hog house, disinfection sterilization of piglet delivering and wounds, and disinfection drying of bacterial diarrhea, and further used for adjusting and improving of the internal environment of cowsheds, henhouses, duck sheds and other livestock breeding houses, disinfection sterilization of livestock wounds, and disinfection drying of bacterial diarrhea.

Owner:湖南幻影三陆零科技有限公司

Chloridizing roasting method of material containing alunite

The invention relates to a chloridizing roasting method of a material containing alunite, which is mainly used for comprehensively utilizing the alunite or tailing containing the alunite. The method adopts chloride as an additive for roasting dehydration of the alunite or the tailing containing the alunite; under the condition that dehydration rate is more than 90%, Al existing in the mode of Al2(SO4)3 in the alunite or the tailing containing the alunite volatilizes in the mode of AlCl3 and is enriched in a woven bag dust collector or a rotoclone collector, thus avoiding environment pollution by SO2 generated by decomposing the Al2(SO4)3; acid gas in smoke, such as HCl and the like, can be adsorbed by alkaline liquor or directly returned for roasting; clinker is leached by water; and leaching agent recovers K2SO4, and leaching slag recovers Al2O3 with a common leaching method. When being used for processing the alunite or the tailing containing the alunite, the method of the invention can respectively obtain AlCl3, K2SO4 and Al2O3, has the advantages of high comprehensive utilization ratio of resources, environmental friendliness and low production cost, and is suitable for alunite enterprises.

Owner:ZIJIN MINING GROUP

Extraction technology of alumina and potassium sulfate from alunite by using hot-pressing leaching process

ActiveCN101913633AReduce generation costShort processAlkali metal sulfites/sulfatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagPotassium hydroxide

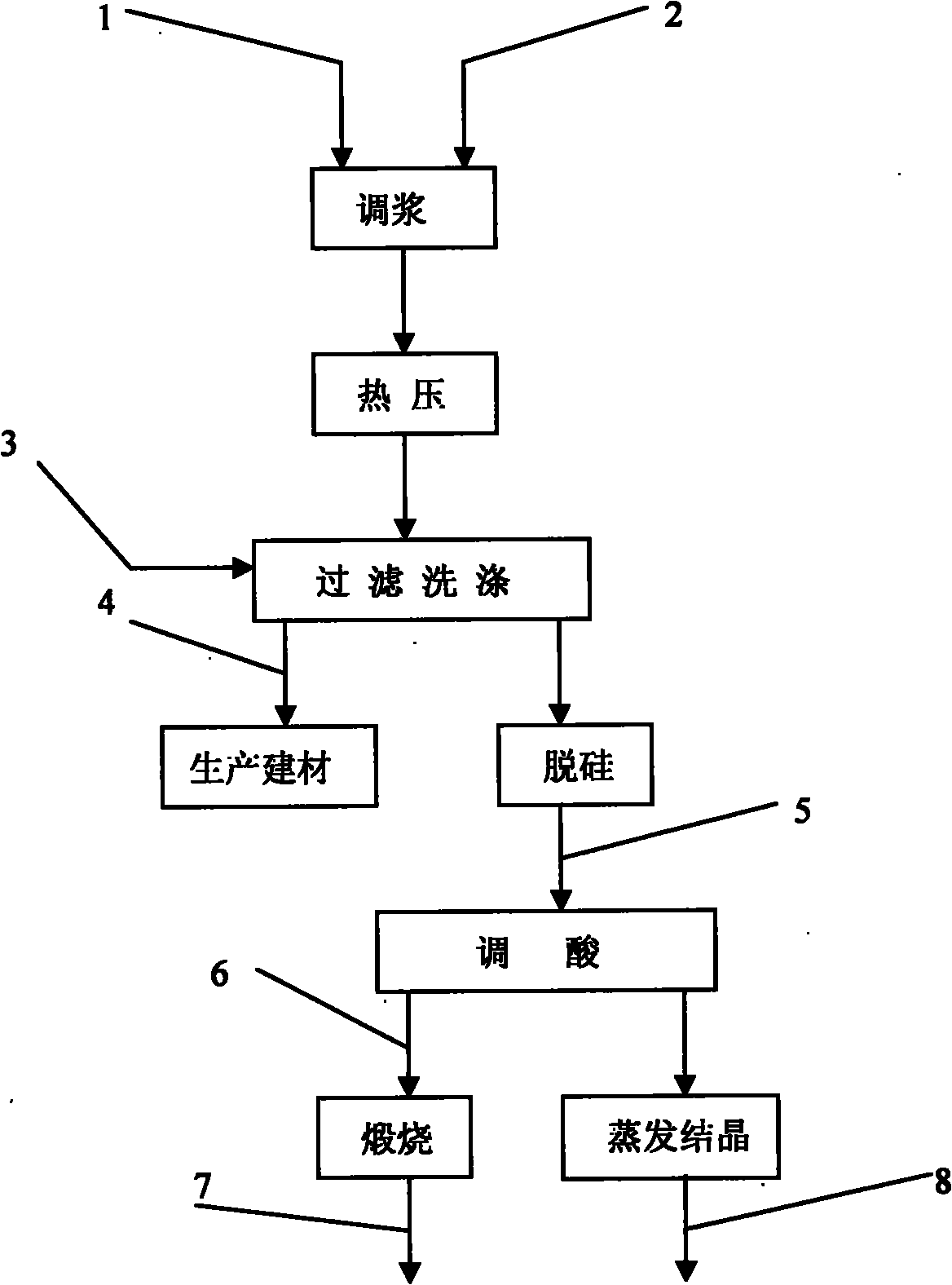

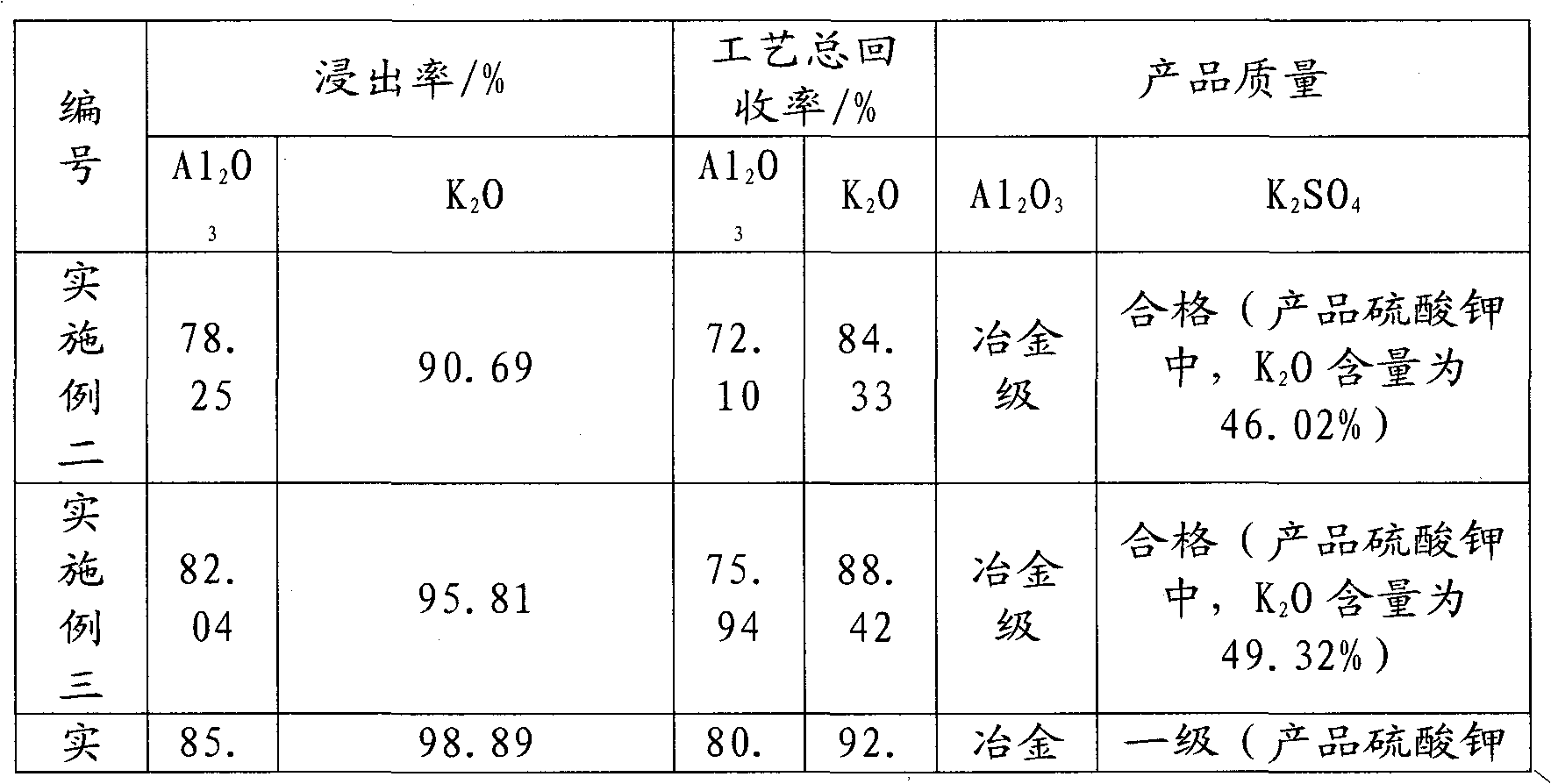

The invention discloses an extraction technology of alumina and potassium sulfate from alunite by using a hot-pressing leaching process, comprising the following steps: mixing the alunite with a potassium hydroxide solution to prepare pulp; transferring the pulp into a hot-pressing system, carrying out hot-pressing leaching at 100-300 DEG C, cooling the obtained leaching solution, and carrying out solid-liquid separation; transferring the leaching solution after solid-liquid separation into a desiliconization system for desiliconizing at 80-200 DEG C, and filtering and separating to obtain a desiliconized extracting solution and silica slag; transferring the desiliconized extracting solution into an acid regulating system, keeping adding sulfuric acid to the acid regulating system while stirring until white precipitate in the desiliconized extracting solution is not generated any more and disappears, and then filtering and separating out a solution mainly containing the potassium sulfate; transferring the solution mainly containing the potassium sulfate into a crystallization system, evaporating and crystallizing the solution mainly containing the potassium sulfate in the crystallization system, and filtering and separating to obtain potassium sulfate crystal. The extraction technology of the invention has lower production cost and relatively short process flow.

Owner:ZIJIN MINING GROUP

Application of modified calcium carbonate in plastics

InactiveCN107501891AHigh tensile strengthHigh elongation at breakFlexural strengthThermal deformation

The invention provides application of modified calcium carbonate in plastics. The plastics are prepared from the following raw materials in parts by weight: 3 to 5 parts of modified calcium carbonate, 1 to 3 parts of ethyl propionate, 4 to 6 parts of glass fibers, 40 to 50 parts of polycarbonate, 0.5 to 1 part of alunite, and 0.5 to 1 part of cross-linking agent. The modified calcium carbonate provided by the invention is added in the production process of the plastics, and the prepared plastics have good tensile strength, elongation at break, bending strength and brinell hardness, and high thermal deformation temperature.

Owner:贺州钟山县双文碳酸钙新材料有限公司

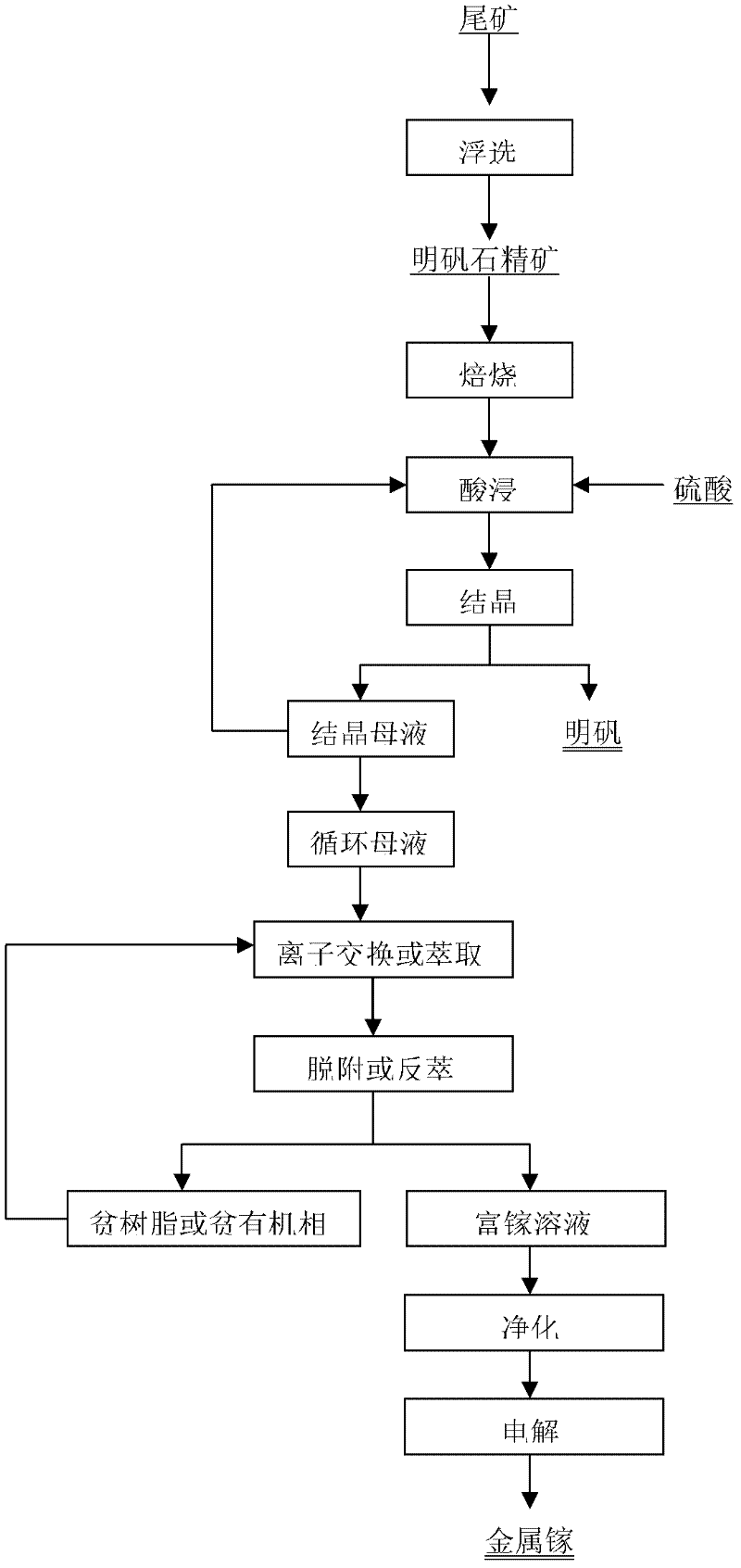

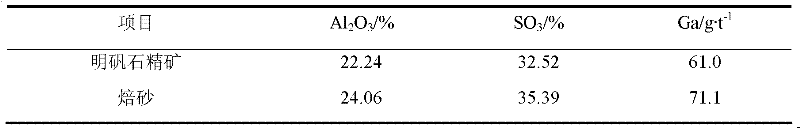

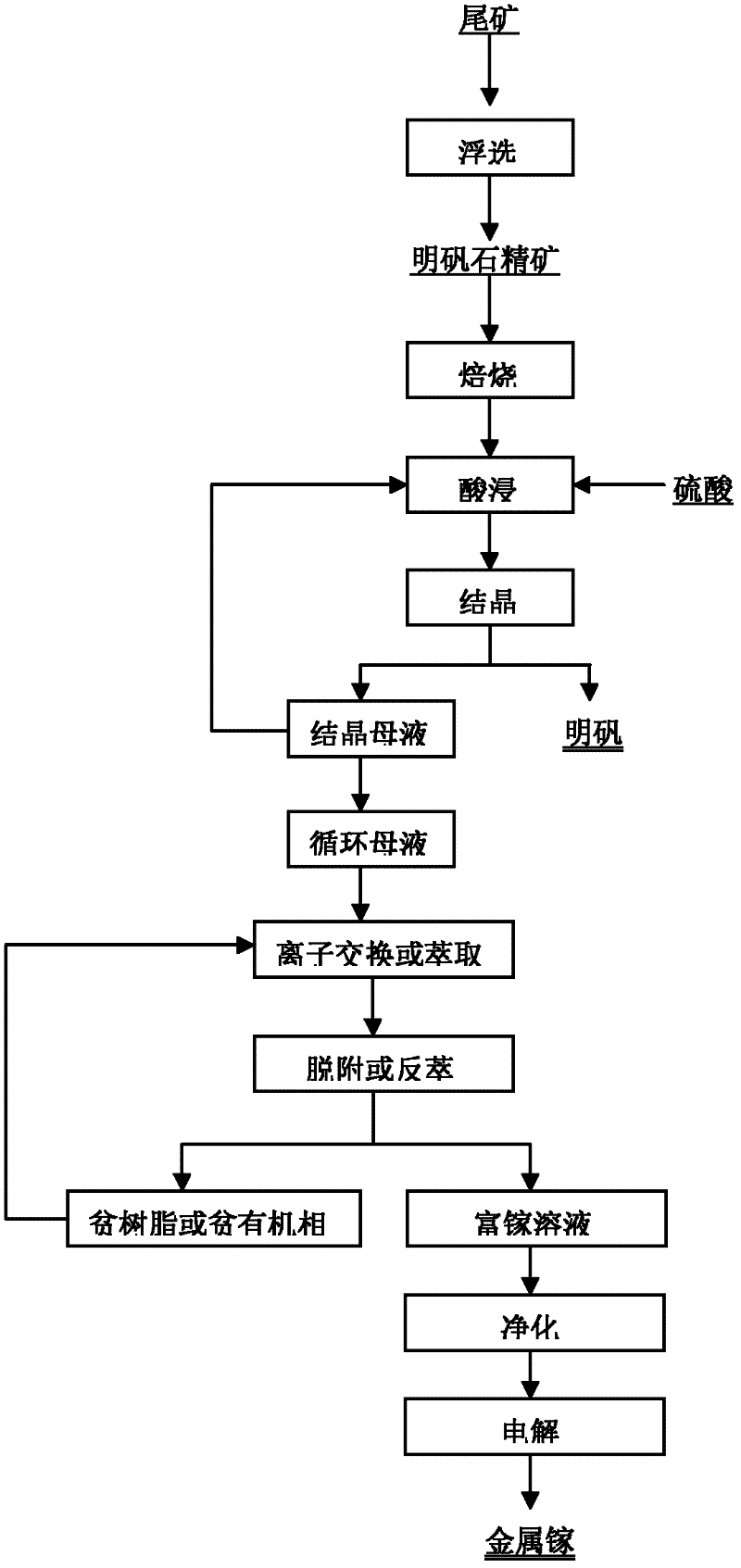

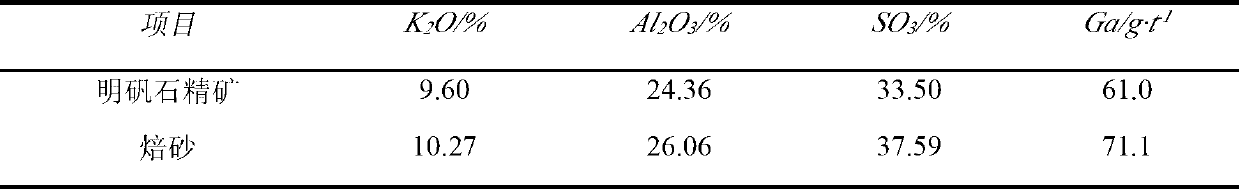

Method for recycling gallium in alunite concentrate

InactiveCN102517461ASolving the challenge of recycling galliumProcess efficiency improvementAluminium sulfatesSulfurIon exchange

The invention relates to a method for recycling gallium in alunite concentrate, characterized by comprising the steps of: floating the gangue of a copper ore with selected copper concentrate and sulfur concentrate to obtain the alunite concentrate; firstly, roasting the alunite concentrate to dewater the same, performing acid leaching and crystallization techniques on the dewatered calcine to obtain alum crystals and a crystallization mother solution, wherein the crystallization mother solution contains gallium, and the gallium content reaches to 100-300 mg / L after circulating the acid leaching technique on the calcine for multiple times; and performing such techniques as extraction and ion exchange, and the like, on the obtained mother solution containing gallium to extract the gallium. According to the invention, the comprehensive recoveries of the gallium and alum are respectively higher than 95%. The method of the invention has the advantages of simple technique, high recovery of gallium and alum, and good comprehensive recycle effect, etc.

Owner:ZIJIN MINING GROUP

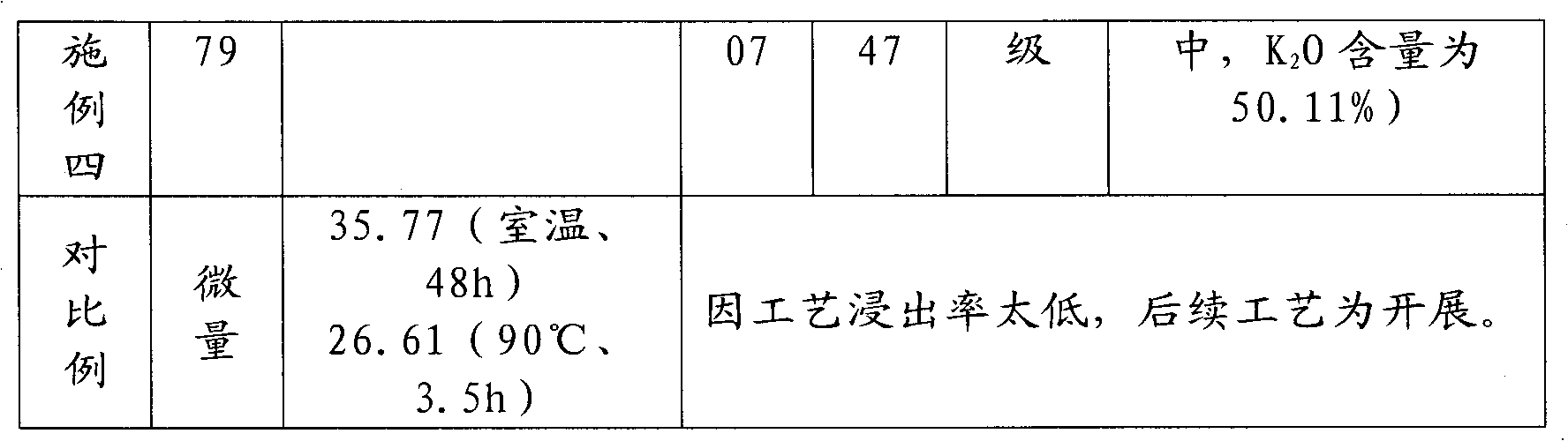

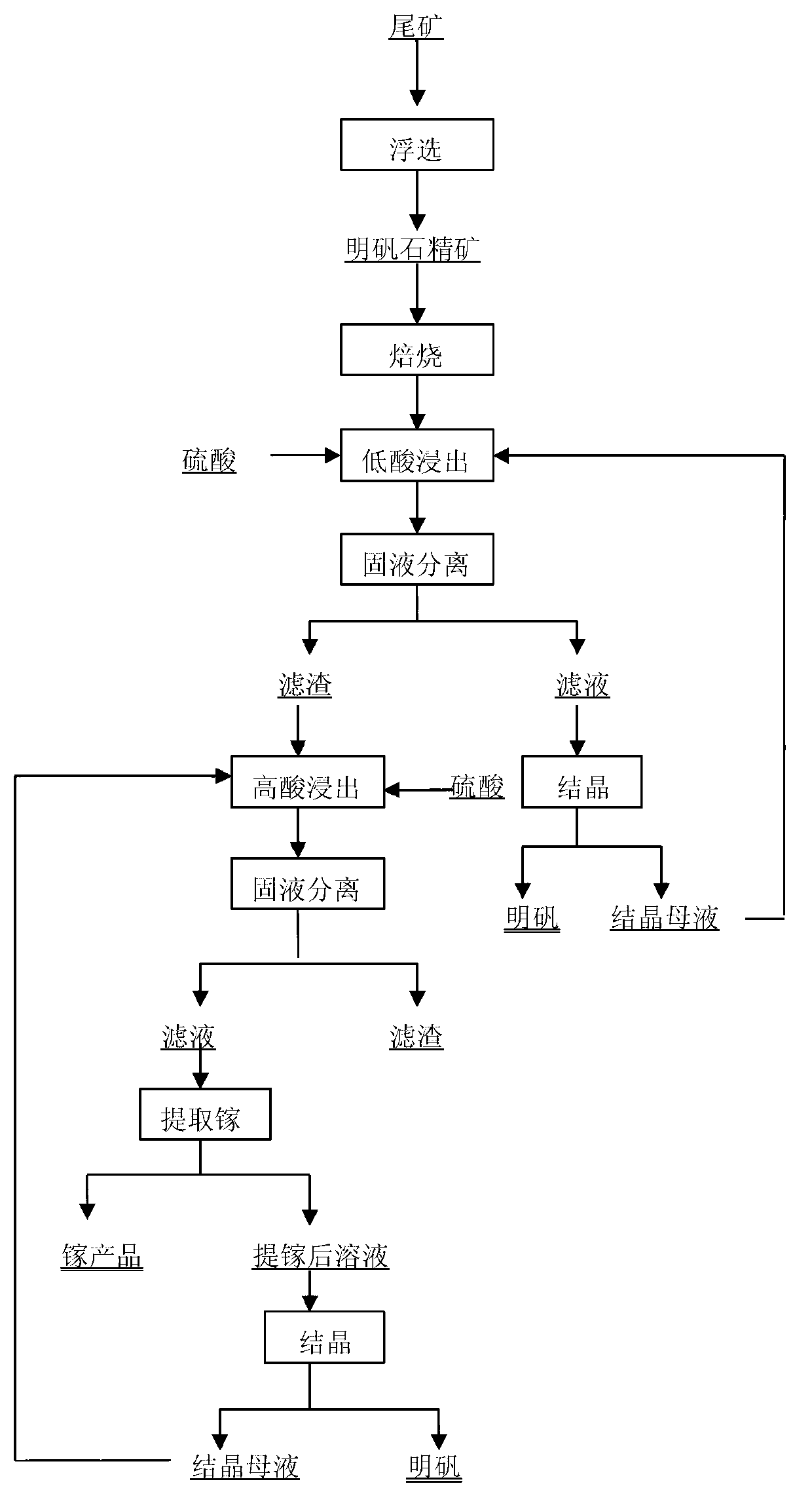

Method for selectively recovering alum and gallium from alunite concentrate

ActiveCN103103339ASolving Comprehensive Recycling AlumSolving the Difficulties of Scattered Gallium MetalProcess efficiency improvementAluminum IonIon exchange

The invention provides a method for selectively recovering alum and gallium from alunite concentrate, wherein the alunite concentrate is obtained through flotation from tailings after copper concentrate and sulfur concentrate are selected from copper ore. The method comprises the following steps of: calcining the alunite concentrate to obtain a calcine and leaching metal ions such as aluminum ions and potassium ions from the calcine under low sulfuric acid concentration firstly; after solid-liquid separation, crystallizing a filtrate to form alum and crystallization mother liquor; returning the mother liquor to the low sulfuric acid concentration for leaching to obtain leached residue, and leaching rare metal gallium from the leached residue under high sulfuric acid concentration after carrying out size mixing on the leached residue; after allowing the gallium to achieve a certain concentration by circulating leachate for multiple times, recovering the gallium in circulating solution by adopting an ion exchange or extraction method; and after gallium recovery, cooling the solution for crystallizing alum. Therefore the difficulties in recovering alum and scattered metal gallium from the alunite concentrate are solved.

Owner:ZIJIN MINING GROUP

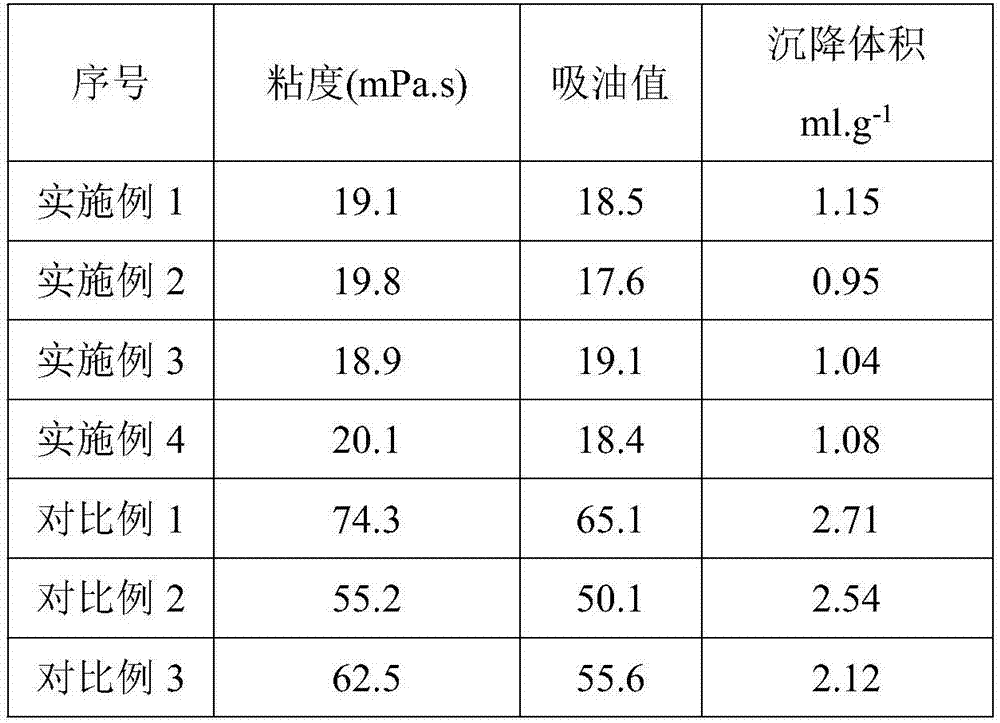

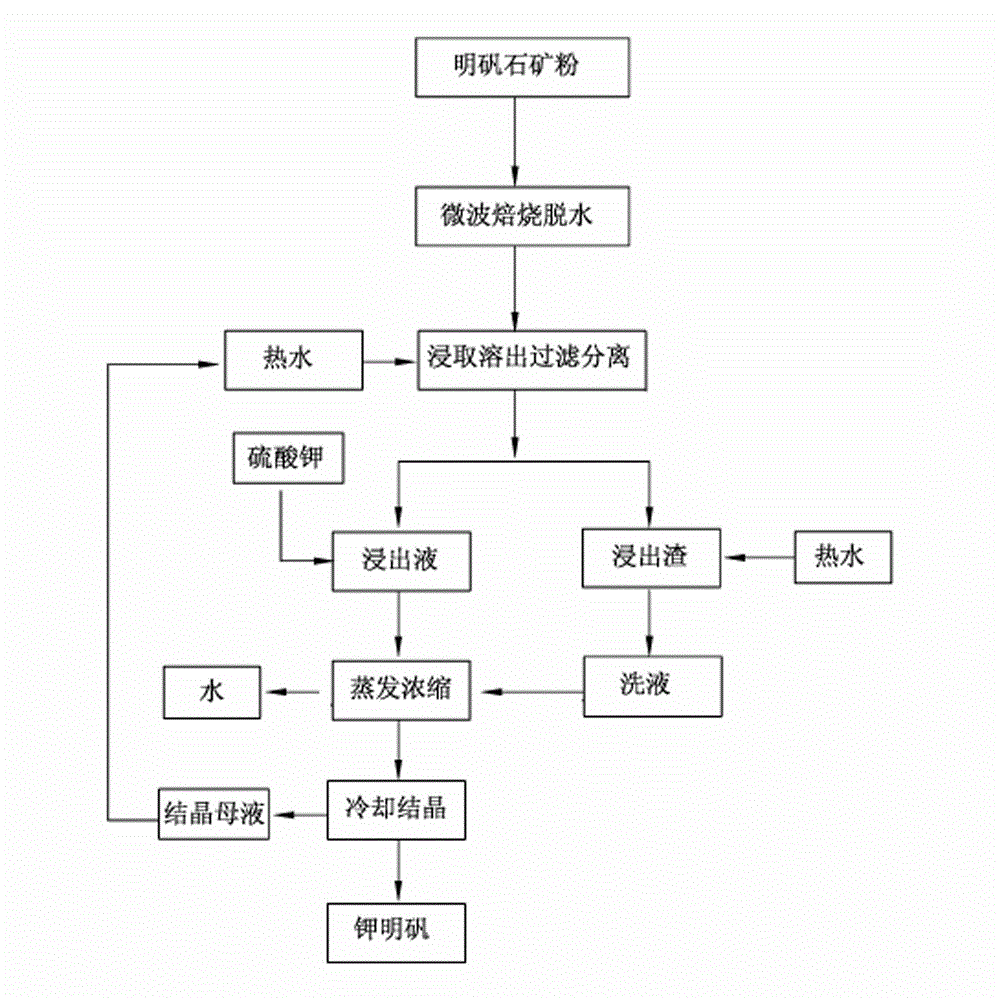

Method for producing alum by utilizing alunite

The invention relates to a method for producing alum by utilizing alunite, comprising the steps that alunite mineral powder is selected and used, the mineral powder is dehydrated by microwave roasting, sulfuric acid solution is leached and dissolved out, the filtering separation is carried out, the leaching agent is evaporated and concentrated, and the leaching agent is cooled and alum is crystallized. Potassium sulphate is added to the leaching agent, and potassium alum is completely produced; potassium sulphate is not added to the leaching agent, potassium alum is produced, and aluminum sulfate is co-produced; and crystallization mother liquor is recycled. Compared with the existing alum refining technology adopting 'water immersion method' and a vertical coal kiln, the method for producing alum by utilizing alunite has the beneficial effects that the utilization rate of resources is improved, the yield of alum is increased, the production cycle of the alum is shortened, energy sources are saved, the production cost is reduced, waste residues and waste gases are reduced, and the environment is protected.

Owner:广西北部湾粮油技术研究有限公司

A kind of phosphogypsum cement retarder and preparation method thereof

The invention relates to a phosphogypsum cement retarder. The cement retarder is composed of the following raw materials in weight percentage: 30%-65% of phosphogypsum, 3%-15% of lime, 5%-35% of alunite powder or 7%-40% of alunite, 8%-40% of slag . Compared with the prior art, the present invention has the beneficial effects that: the process of calcination into balls is omitted, and the processing of phosphogypsum is facilitated; the 28-day compressive strength value of cement is significantly improved, so that the same cement strength value is to be maintained. It can increase the amount of admixture in cement and bring economic benefits to cement enterprises.

Owner:安徽金刀水泥有限公司

Method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof

ActiveCN103011206AImprove the level of comprehensive utilizationAlleviate the contradiction between supply and demandSulfate/bisulfate preparationEngineeringPotassium sulfate

The invention provides a method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof. The method fully utilizes secondary resources, changes waste into treasure, achieves minimizing, harmlessness and recycling of solid waste, improves comprehensive utilizing level of tailings in China, relieves an acute contradiction of supply and demand of potassium sulfate, reduces loss on foreign exchange caused by mass importation of the potassium sulfate, improves guarantee age limit of kalium and the international competitiveness of the kalium salt industry, completely solves the key scientific and technical problem of economic, clean efficient and comprehensive utilization of the alunite in flotation, the tailings are utilized as resources, establishes tailing comprehensive utilization technical demonstration project, and promotes the development of the comprehensive utilization technique of the tailing in China.

Owner:ZIJIN MINING GROUP

Concrete composite expanding agent

The invention discloses a concrete composite expanding agent which is prepared from the following mixed substances in parts by weight: 35-42 parts of coal ash, 12-15 parts of gypsum powder, 3-5 parts of quick lime, 2-8 parts of alunite and 16-22 parts of calcium sulphoaluminate. The concrete composite expanding agent has the beneficial effects that the admixture amount is low, the expansion rate is more than the expansion rate of UEA (in market) with the admixture amount of 12%, the alkali amount is far lower than the alkali amount of 1.7-2.2% of a U-shaped expanding agent, which is of great significance; as the admixture amount is reduced, the early-stage strength and the later-stage strength are not affected, and the purpose of equivalent substitute for cement is achieved in deed; the concrete slump loss is not increased, and good construction properties are achieved.

Owner:LIUZHOU ZHENGLING GROUP

Accelerating agent

The invention relates to an accelerating agent prepared by the steps of preparing 35wt% of bauxite, 24wt% of sodium carbonate, 30wt% of limestone and 11wt% of coal into raw materials; grinding into powder; calcining into alumina clinker in a high temperature furnace section of 1250 DEG C; grinding the alumina clinker into powder, wherein the fineness is less than 15%; and uniformly stirring 40 to 60wt% of alumina clinker powder and 40 to 60wt% of coal ash. The coal ash is prepared by calcining coal gangue through a fluidized bed boiler, the active constituents of volcanic ash in the coal ash are much, and the content of Al2O3 reaches 27.39% (while the content of alunite is about 20%), so that the coagulation time is further shortened and the later strength of concrete is guaranteed under the active action of the volcanic ash. The accelerating agent has the advantages that wastes are changed into beneficial materials by utilizing the coal ash in power plants; the pollution of the coal ash to the environment is reduced; the alunite requiring high temperature calcining is simultaneously omitted; the electric energy is saved; the production cost is reduced; and the later strength of the concrete is guaranteed.

Owner:徐州华泰混凝土外加剂厂

Concrete reinforced water-retaining internal curing material and preparation method thereof

The invention discloses a concrete reinforced water-retaining internal curing material and a preparation method thereof. The method comprises the following steps: respectively weighing the following components in parts by weight: 10 parts of acrylic acid, 4 parts of acrylamide, 3 parts of ground zeolite powder, 2 parts of activated coal gangue powder, 0.005 part of N,N-methylene bisacrylamide and 0.1 part of potassium persulfate, adding the components into a container, uniformly stirring, dropwise adding a NaOH solution, uniformly stirring until the neutralization degree is 60 percent, reacting for 10 hours, and drying, thereby obtaining a solid cross-linking agent; weighing the solid cross-linking agent, coal ash beads, silica colloidal particles, phosphorus gypsum, natural alunite, magnesium oxide and calcium oxide according to the weight ratio of 82:5:4:3:3:2:1, adding the mixture into a ball mill, and grinding, thereby obtaining the concrete reinforced water-retaining internal curing material. The concrete reinforced water-retaining internal curing material disclosed by the invention is excellent in water retention capacity, pores reserved by water release inside concrete filled with the traditional internal curing material can be canceled, the compaction rate and strength of the concrete are guaranteed, the later maintenance cost is greatly reduced, the self-shrinkage within 28 days is reduced by 50-80 percent compared with that of common concrete, and the compressive strength is improved by 5-10 percent.

Owner:CHANGAN UNIV

Compound sulfate cement

InactiveCN101885589AExcellent resistance to sulfate corrosionImprove impermeabilitySolid waste managementSlagRoad surface

The invention provides compound sulfate cement which is characterized in that slag, plaster, aluminosilicate waste residues and cement clinker are taken as basic materials, and one kind of or various kinds of lime, limestone, alunite and zeolite are taken as auxiliary materials. The compound sulfate cement comprises the following components in parts by weight: 40 to 80 parts of slag, 5 to 20 parts of plaster, 10 to 30 parts of aluminosilicate waste residues, 3 to 8 parts of cement linker and 0 to 10 parts of auxiliary materials. The invention has the characteristics of high strength, low heat and no shrinkage or micro-expansion and is specifically suitable for the construction of mass concrete, such as large dams, cushion caps, concrete road surfaces, marine engineering, and the like. The cement has no dissociative calcium hydroxide, has excellent sulfate corrosion resistance performance, can fundamentally solve alkali-aggregate reaction due to extremely lower alkalinity, has important meaning for the durability of the construction of highway and railway across saline and alkaline land, and has good impermeability, and the strength and the impermeability of the cement in seawater can be continuously enhanced. Moreover, the corrosion of steel bars can be effectively resisted due to Fridel salt formed by the reaction of aluminum oxide in the slag and chloride ions.

Owner:SHANDONG UNIV OF TECH

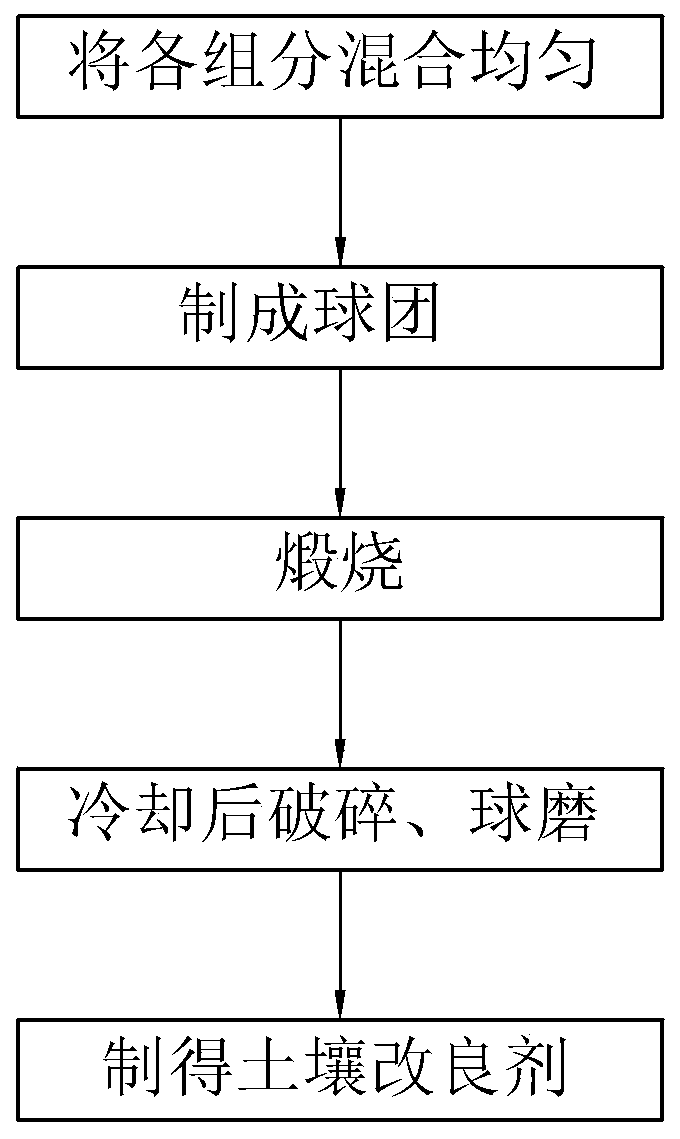

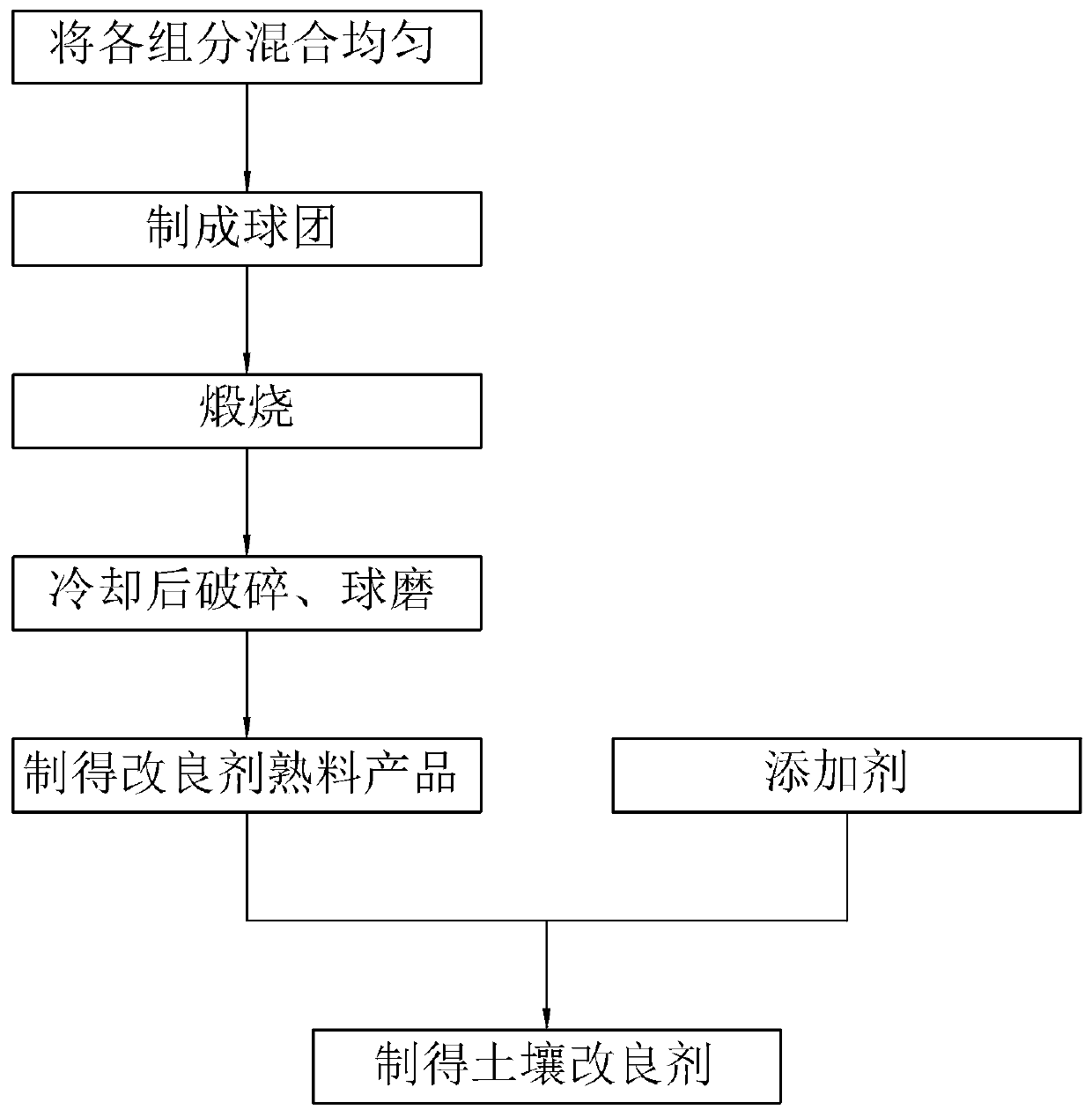

Soil conditioner as well as preparation method and use method thereof

ActiveCN110079332AWide variety of sourcesReduce typesCalcareous fertilisersAgriculture tools and machinesDickiteAlunite

The invention relates to the technical field of soil remediation, in particular to a soil conditioner as well as a preparation method and use method thereof. The soil conditioner comprises the following components in percentage by weight: 40-60% of copper tailings, 20-40% of fluorite tailings or limestone, 6-20% of talc, serpentine or dolomite, and 2-5% of a pellet curing agent, wherein the totalweight is 100%; and the copper tailings include quartz, alunite and dickite. The preparation method comprises the following steps: step 1, weighing the components and mixing the components uniformly;sep 2, preparing the mixture obtained in the step 1 into pellets; step 3, calcining the pellets at a temperature of at least 1000 DEG C for at least 1.5 hours; and step 4, cooling activated pellets and performing ball milling to obtain the soil conditioner. The soil container contains non-ferrous metal and non-metallic ores, various major, medium and trace elements necessary for the growth of crops, fruit trees and seedlings, and basically no additional major, medium and trace elements need to be added.

Owner:SHENZHEN MPD HITECH CO LTD

Composite waterproofing agent of gypsum

InactiveCN101050350AReduce capillary channelsEvenly dispersedOther chemical processesEmulsionPolyvinyl alcohol

This invention relates to a composite waterproof agent for gypsum. The composite waterproof agent is composed of: stearic acid, poly(vinyl alcohol), water, composite emulsifier, alunite, naphthaline-series water reducer and carboxylate at a ratio of (5-30):(2-10):(100-300):(0.05-0.5):(20-40):(5-8):(2-10). The composite waterproof agent is an emulsion that can be mixed with water at any ratio. The composite waterproof agent has such advantages as no toxicity, no stimulation, and high dispersion uniformity. The composite waterproof agent can improve the waterproof performance of gypsum by reducing the capillary pores of cured gypsum. The composite waterproof agent can be used on gypsum boards, gypsum wallboards and gypsum blocks.

Owner:UNIV OF JINAN

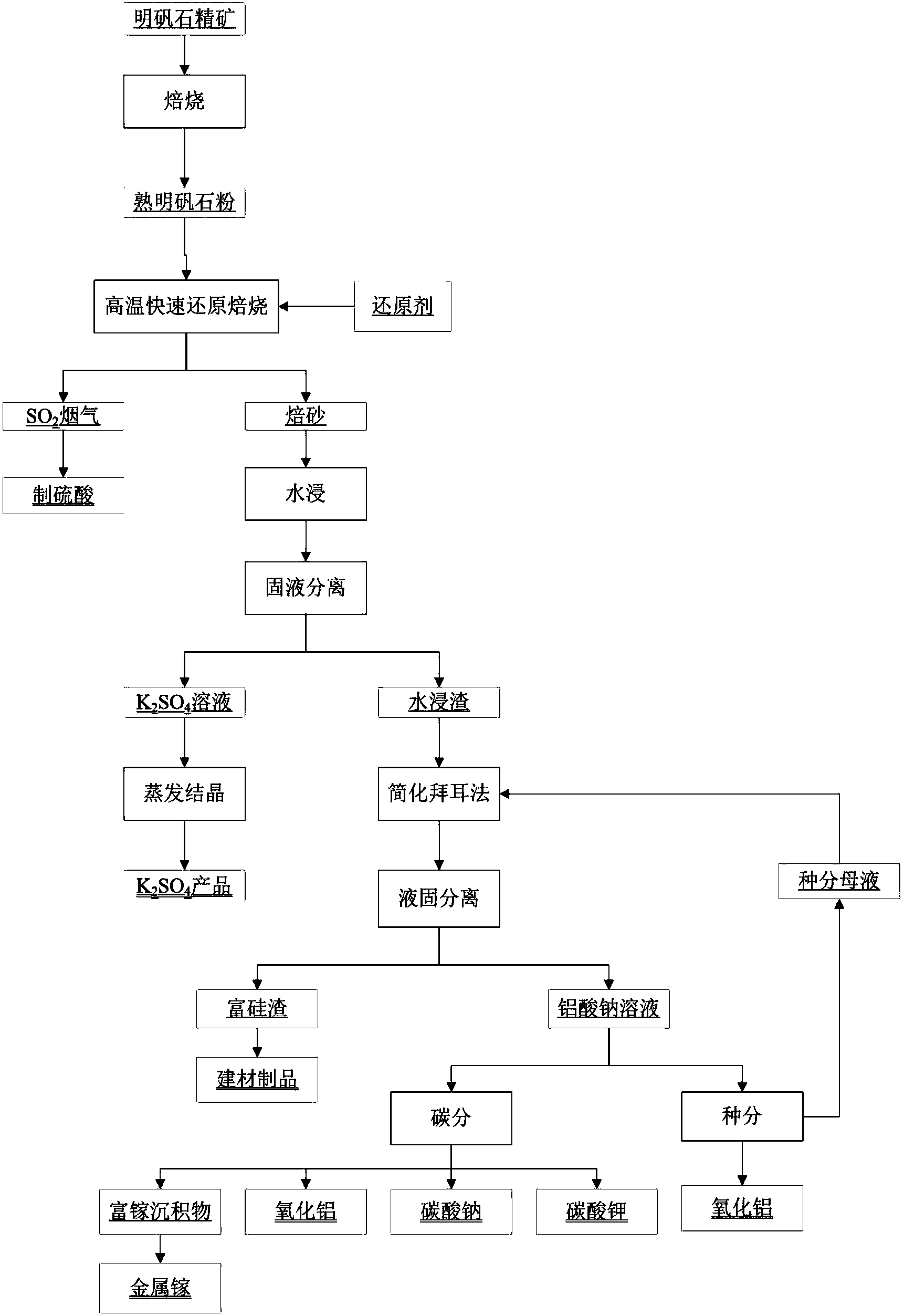

Process for recycling aluminum, potassium and gallium by quickly reducing and desulfurizing alunite at high temperature

ActiveCN104313346AReduce manufacturing costSimple processProcess efficiency improvementDecompositionDissolution

The invention discloses a process for recycling aluminum, potassium and gallium by quickly reducing and desulfurizing alunite at high temperature. The process comprises the following steps: roasting and dehydrating alunite ore powder at a certain temperature and within a certain time period to obtain alunite clinker; uniformly mixing with solid reductant coal according to a certain ratio, and carrying out fast high-temperature reduction roasting on alunite clinker the at a certain high temperature to realize desulfuration; extracting potassium from desulfurized calcine through water leaching, removing residual sulphur from the calcine; carrying out evaporative crystallization on water leaching solution to obtain a national standard product potassium sulfate; dissolving out aluminum and a small amount of potassium and metal gallium from water leaching residuals by a low-temperature low-alkali Bayer method; performing seed precipitation on leachate for recycling aluminum oxide, returning a seed precipitation mother solution to the dissolution process; regularly performing carbon decomposition on a part of the leachate for recycling the aluminum, potassium and gallium to obtain aluminum oxide, carbonate potassium and sodium carbonate and gallium-enriched precipitates, wherein the leaching residuals obtained through the low-temperature low-alkali Bayer method can be used as silicon raw materials for building products.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Concrete expansion agent

The present invention discloses a concrete expansion agent. The concrete expansion agent comprises the following components, by weight, 45-60 parts of fluorine gypsum, 25-35 parts of fly ash, 2-12 parts of slags, 2-5 parts of alunite, 15-25 parts of a high alumina clinker, 1-3 parts of phenol and 3-6 parts of a retarding and water reducing agent. The concrete expansion agent is prepared through steps of crushing and uniform mixing. According to the present invention, the concrete expansion agent provided by the present invention has a plurality of functions of expanding, water reducing, retarding, collapse protecting, enhancing and the like; only the treatment of grinding is required in the preparation process while the treatment of calcination is not required, the production process is simple, such that a large amount of the energy can be saved, the cost is low, the economic benefit is high, the concrete expansion agent provides more market competitiveness than similar products, the environmental pollution is reduced.

Owner:王琴

Molding sand for non-ferrous castings and preparation method thereof

InactiveCN103586396AImprove smoothnessImprove breathabilityFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention provides molding sand for non-ferrous castings. The molding sand is prepared from the following raw materials in parts by weight: 40-45 parts of alunite, 13-15 parts of plant ash, 20-30 parts of bentonite, 50-55 parts of mineral waste residue, 40-45 parts of medical stone powder, 12-15 parts of gypsum, 3-4 parts of zinc oxide, 3-5 parts of calcium lignosulphonate, 2-3 parts of diffusing agent MF2, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium carbonate, 2-3 parts of calcium oxide, 5-8 parts of magnesium oxide, 10-16 parts of aluminum sulfate slag, 5-8 parts of sodium metasilicate, 2-3 parts of glycerol triacetate, 1-2 parts of diethylene glycol benzoate and a proper amount of water. The molding sand prepared by calcining, smashing and carrying out high-temperature calcination on the alunite, the bentonite, the mineral waste residue, the gypsum and the like in combination with the dispersion and grinding of additives such as the calcium lignosulphonate has excellent smoothness, air permeability, caking property, toughness and plasticity. Meanwhile, the collapsibility of the molding sand is improved by using the powder such as the plant ash, the medical stone powder and the aluminum sulfate slag, so that the brightness of non-ferrous metals can be improved.

Owner:CHANGLI FORGING

Compound modified cement concrete internal-maintenance material and preparation method thereof

The invention provides a compound modified cement concrete internal-maintenance material and a preparation method thereof. The maintenance material is prepared by compounding inorganic hydrotalcite-like compounds with organic high water-absorbent resin through an intercalation modification technique. The material preparation by virtue of the preparation method has excellent water retention capacity, the shrinkage of concrete is reduced to a great extent, the compressive strengths in the days 7 and 28 are increased by above 10%, the relatively dynamic elasticity modulus after 300 freezing and thawing cycles is above 80%, the anti-freezing property is obviously improvided, and the chloride penetration resistance and sulfate corrosion resistance are remarkably improved.

Owner:西安华泽道路材料有限公司

Method for activating latent activity and improving the quality of fly ash

InactiveCN1837127AIncreased durabilityImprove bindingSolid waste managementSlagBiological activation

The invention discloses a compounding activation coal ash latent active and improving coal ash quality method in the building material domain, which is characterized by the following: using II, III degree coal ash for raw material; adding in 2.0-4.0% calcium sulfate, 3.0-4.0% alum stone, 5.0-10.0% industrial residue(such as steel scoria, slag), 1-2% inoculating crystal and a little disperser in coal ash weight; putting the above material and raw condition coal ash in ball grinder to jevigate; filling coal ash with 0.045 mum square hole screen in stocking yard by separation equipment; grinding the coal ash with larger 0.045 mum square hole screen until the fineness of coal ash (0.045 mum) is smaller than 10%. The method can make the low-grade coal ash to become I-grade or high grade coal ash, which meet the demand of the market.

Owner:UNIV OF SCI & TECH BEIJING

Compound mineral material for disposing landfill leachate as well as preparation method and application thereof

ActiveCN105129902AImprove adaptabilityLow priceAluminium silicatesWater contaminantsSodium BentoniteSewage treatment

The invention discloses a compound mineral material for disposing landfill leachate as well as a preparation method and application thereof, belonging to the technical field of sewage disposal. The compound mineral material is prepared from the following materials by weight percent: 25 to 35 percent of modified epidesmine, 25 to 35 percent of modified clinoptilolite, 10 to 15 percent of modified bentonite, 3 to 8 percent of alunite, 3 to 8 percent of kaolin, 6 to 18 percent of quartz sand, 3 to 8 percent of volcanic and 2 to 5 percent of water glass. The invention also discloses the preparation method and the application of the compound mineral material and a landfill leachate disposing method. The compound mineral material is low in cost, high in pertinence, high in treatment efficiency and small in secondary pollution, and the preparation method is simple, convenient to use, low in cost, wide in market prospect and suitable for scale production.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com