High performance expansible cement clinker expansion agent series prepared thereby

A technology of cement clinker and expansive cement, which is applied in the field of concrete expansive agents, can solve the problems of unsafe expansion, achieve fast expansion rate, inhibit carbonization, and improve the bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the manufacture of HCSA high performance expansive cement clinker

[0049] The chemical composition of each raw material is shown in Table 1, and the ingredients are prepared according to the design requirements:

[0050] Percentage by weight, limestone 72%, bauxite 8%, gypsum 17%, iron powder 3%. The raw materials were mixed and ground together to form raw meal powder, which was calcined in a rotary kiln at 1250°C. The product was HCSA clinker, whose chemical composition was shown in Table 2, and the calculated mineral composition of HCSA clinker was shown in Table 3.

[0051] Raw material chemical composition (%) of table 1 HCSA high performance expansive cement clinker

[0052] raw material name

loss

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

SO 3

TiO 2

15.31

6.05

70.68

2.07

0.97

0.12

-

1.63

limestone

41...

Embodiment 2

[0057] Embodiment 2: the manufacture of HCSA series expansion agent

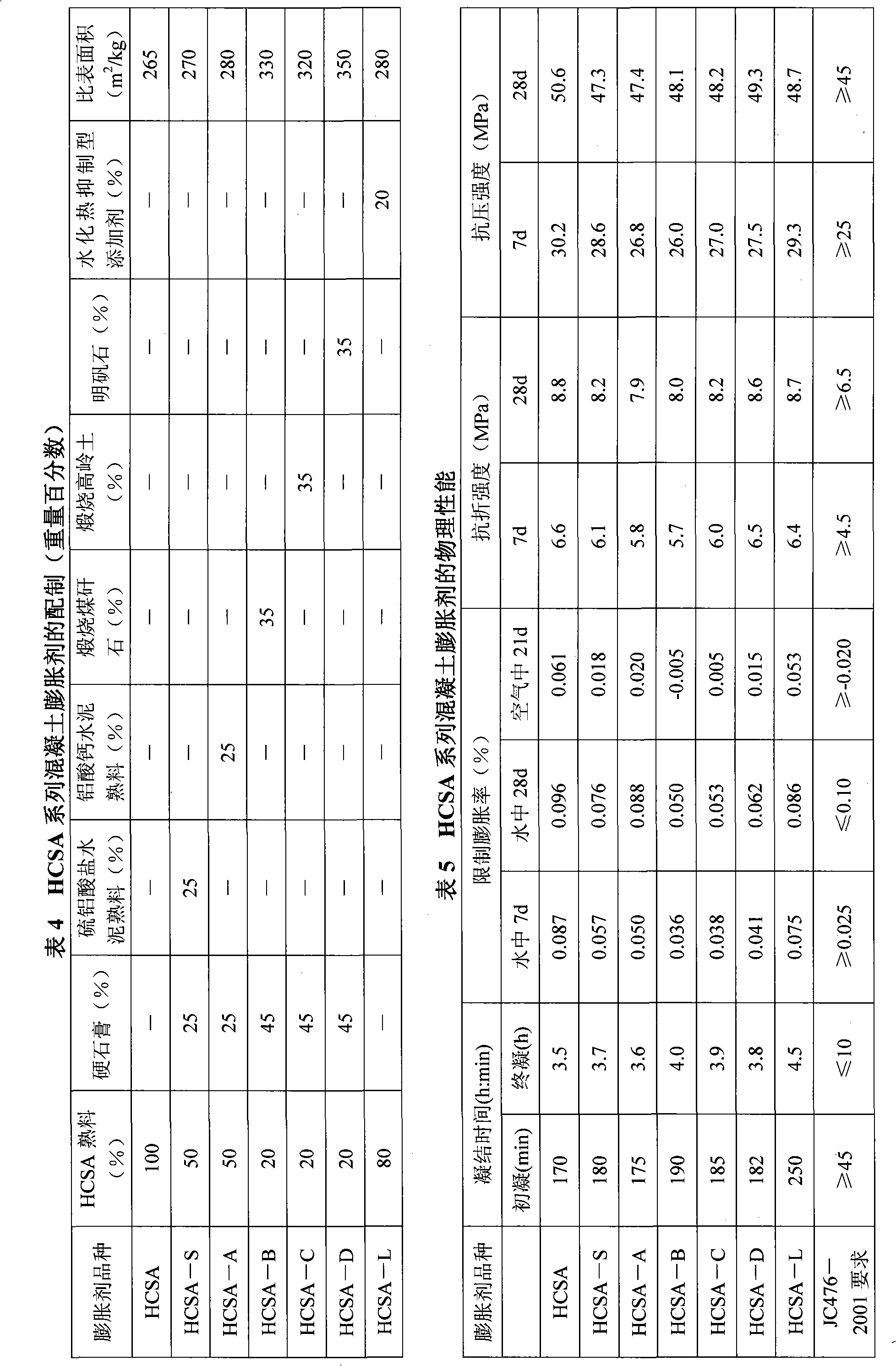

[0058] The HCSA high-performance expansive cement clinker of Example 1 was used to grind together with the corresponding raw materials according to the ratio in Table 4 to obtain a series of concrete expansive agents.

[0059] Physical performance test of concrete expansion agent: the expansion agent prepared in Table 4 was tested according to the current national industry standard JC476-2001 "Concrete Expansion Agent", and the dosage of the expansion agent was uniformly 8wt%. The physical properties are shown in Table 5.

[0060]

Embodiment 3

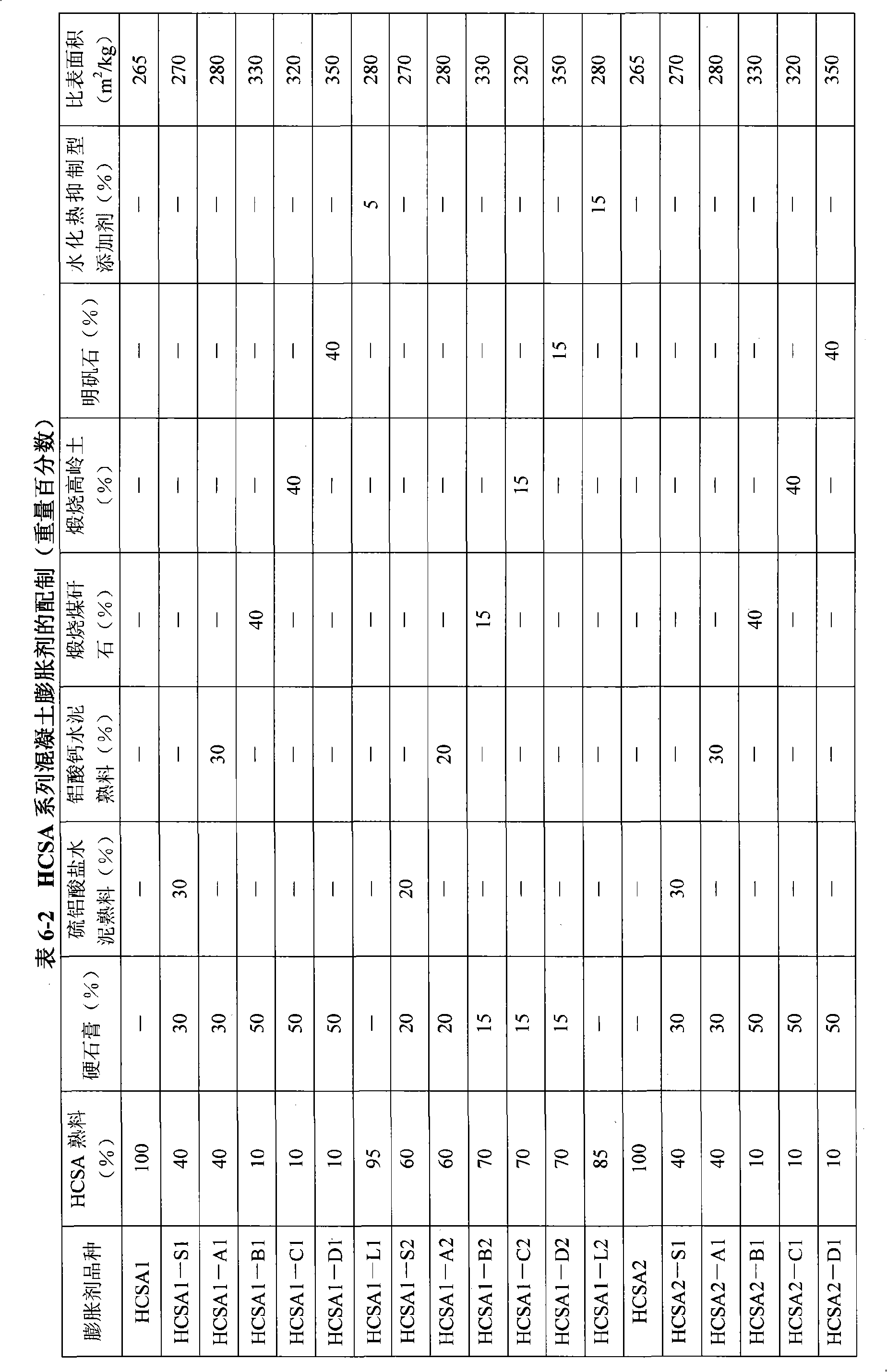

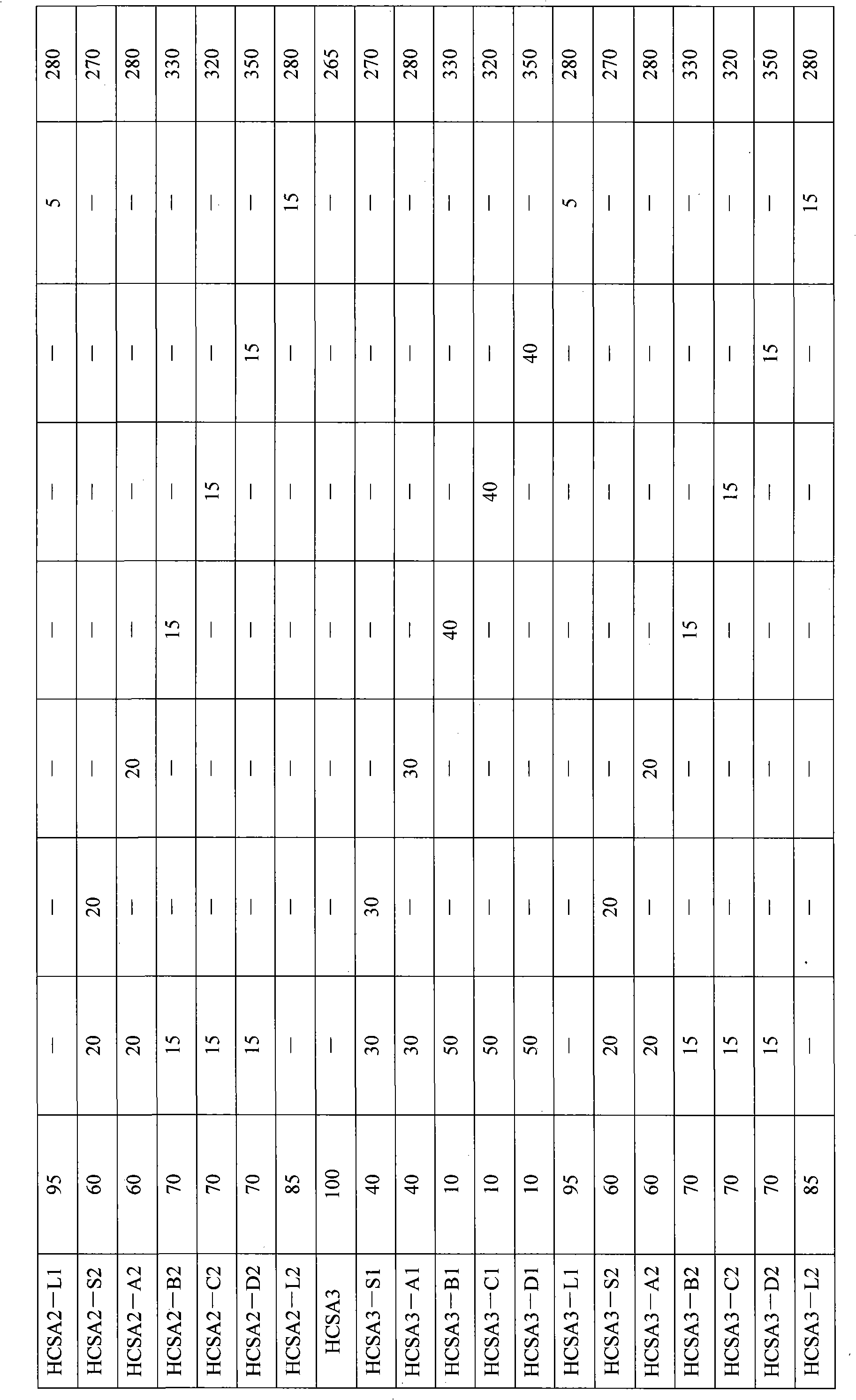

[0061] Example 3: Production of series HCSA high performance expansive cement clinker and series of expansion agents

[0062] Using the same raw materials as in Example 1, changing the ratio of raw materials according to the values in Table 6-1, a series of HCSA high-performance expansive cement clinkers were obtained. Then design and prepare a series of expansion agents according to Table 6-2 according to the same method as in Example 2, and the test results are listed in Table 6-3.

[0063] Table 6-1 Raw material ratio of HCSA cement clinker (weight percentage)

[0064] raw material

HCSA1

HCSA2

HCSA3

Limestone 50%~90%

50

90

59

Bauxite 1%~20%

20

1

10

Gypsum 5%~30%

25

5

30

Iron powder 1%~5%

5

4

1

[0065] As can be seen from the above examples, the present invention has the advantages that: the mineral composition of the HCSA high-performance expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com