Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

257 results about "Calcium sulfoaluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance expansible cement clinker expansion agent series prepared thereby

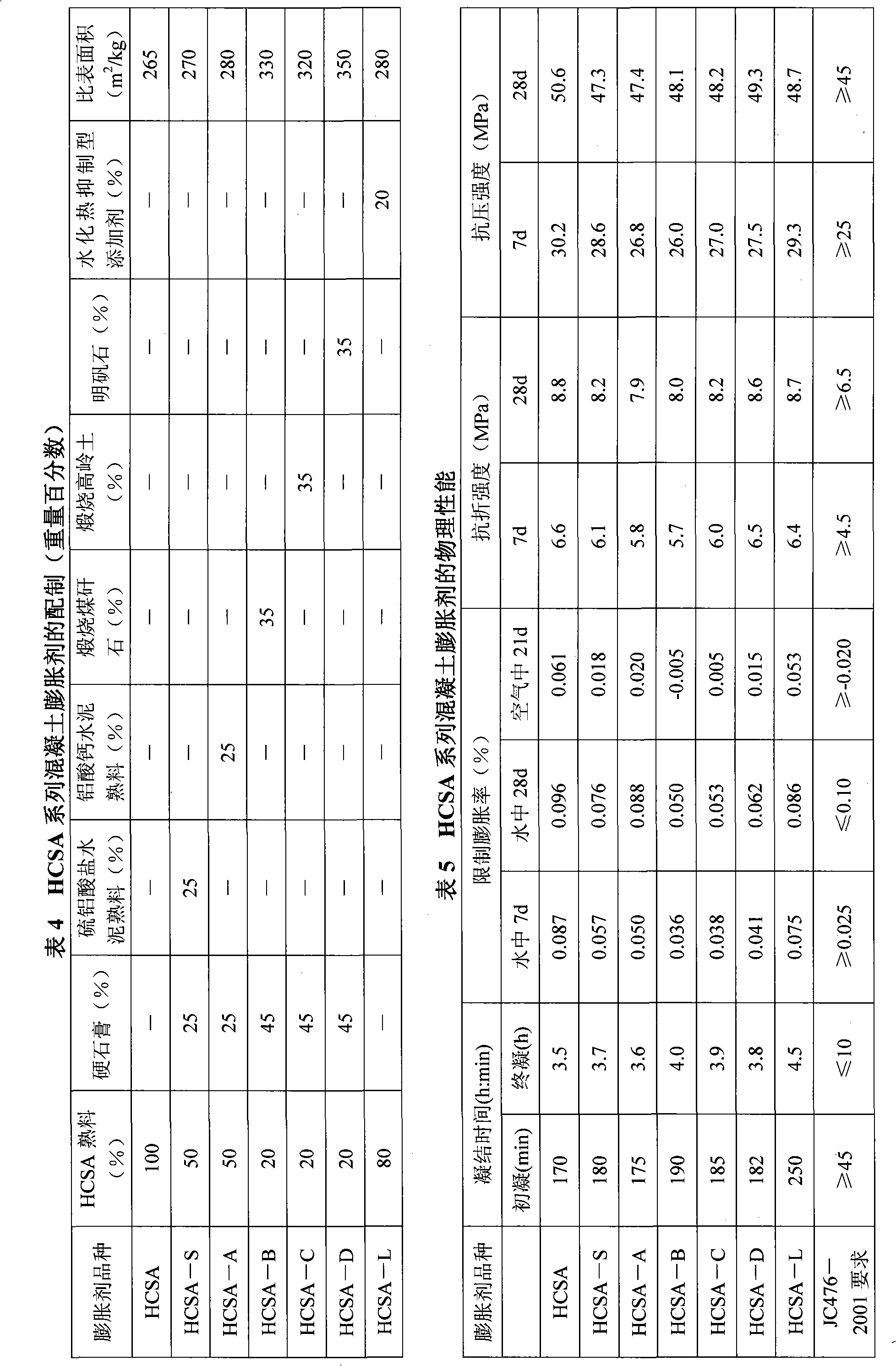

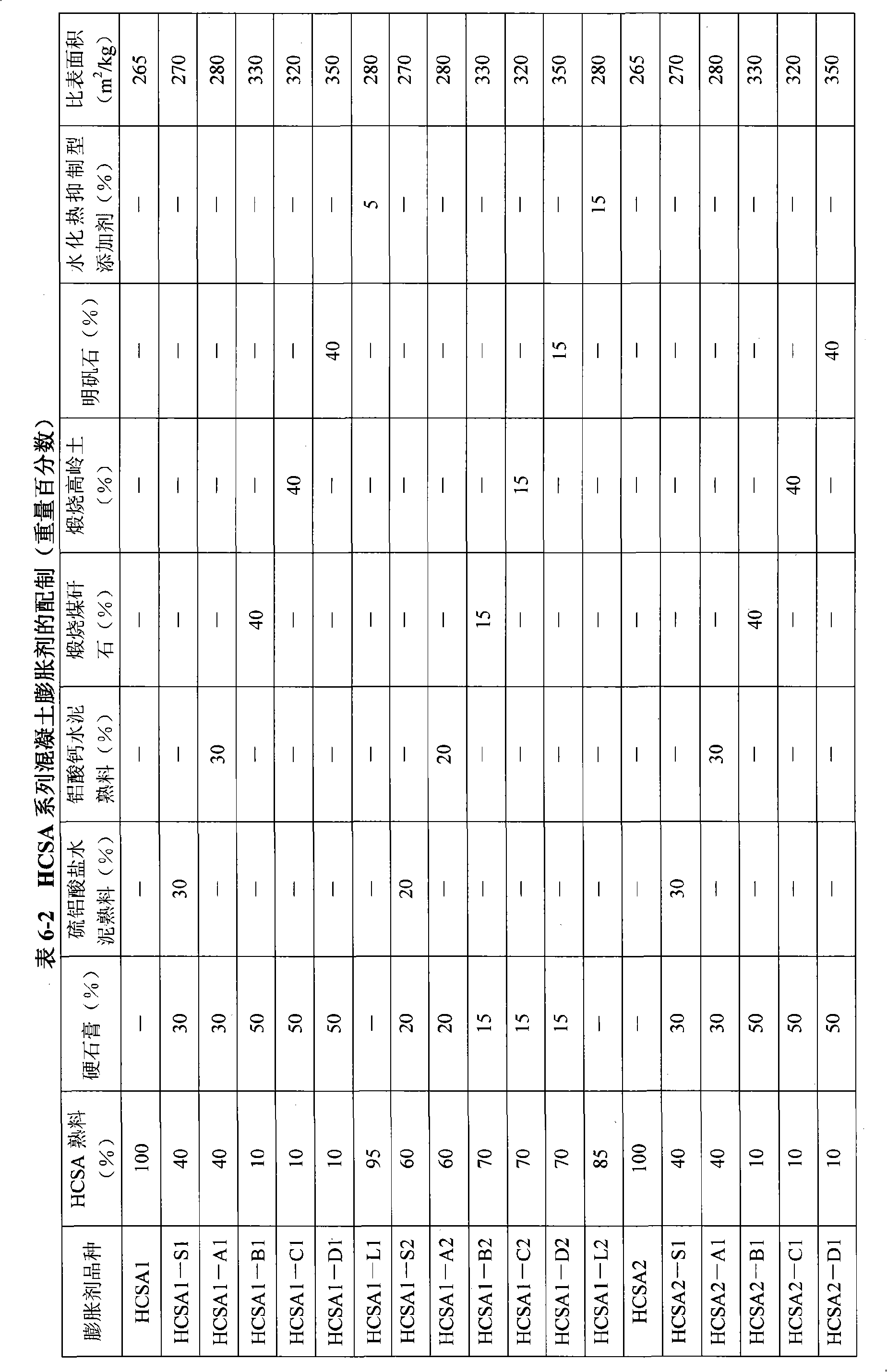

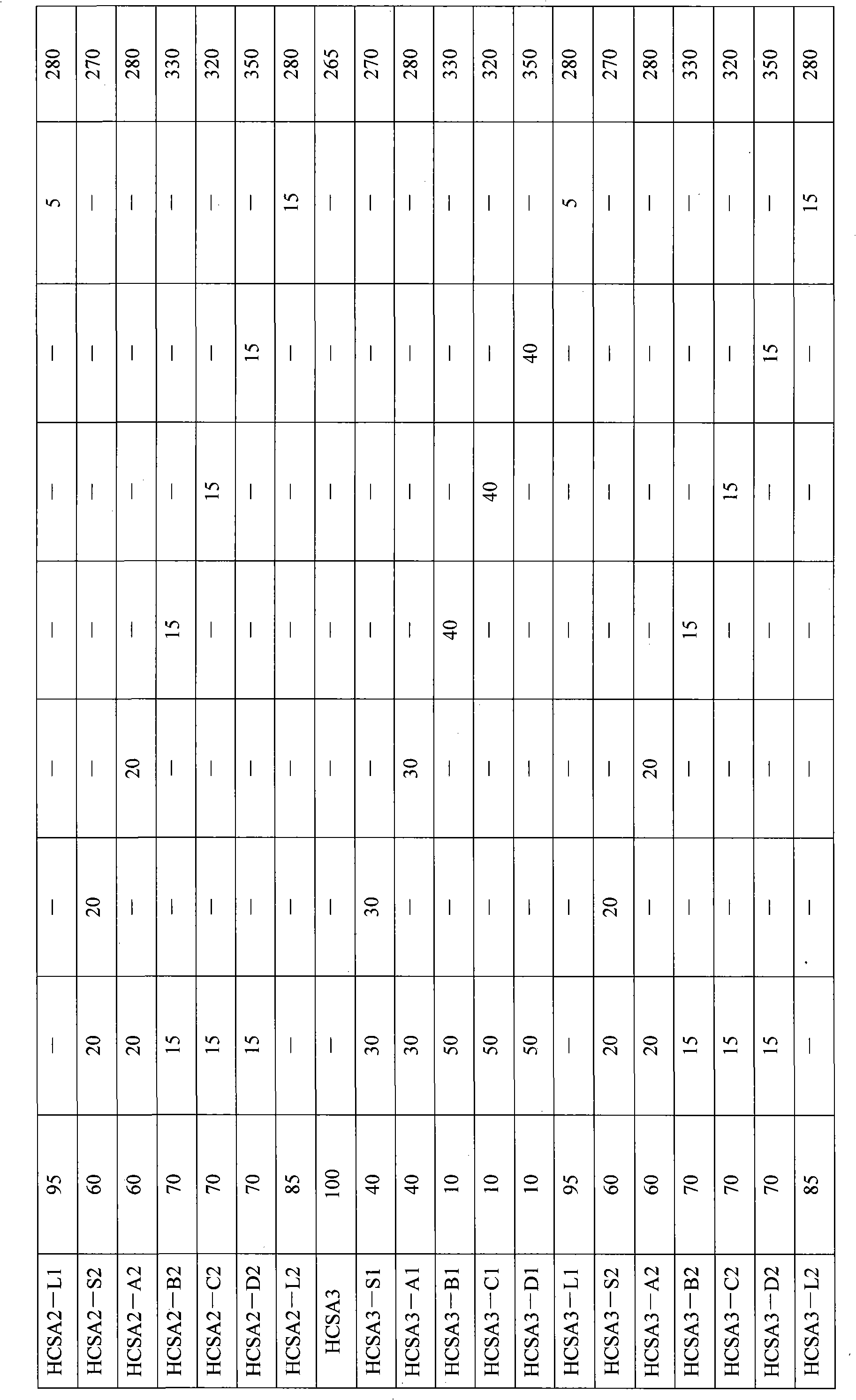

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

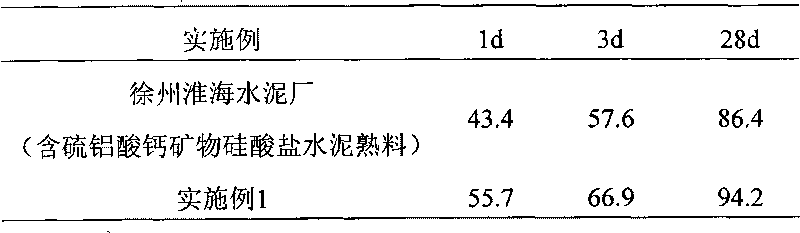

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS20170050882A1Increase heightHigh-strength rapid-hardeningSolid waste managementCement productionChemical compositionSlag

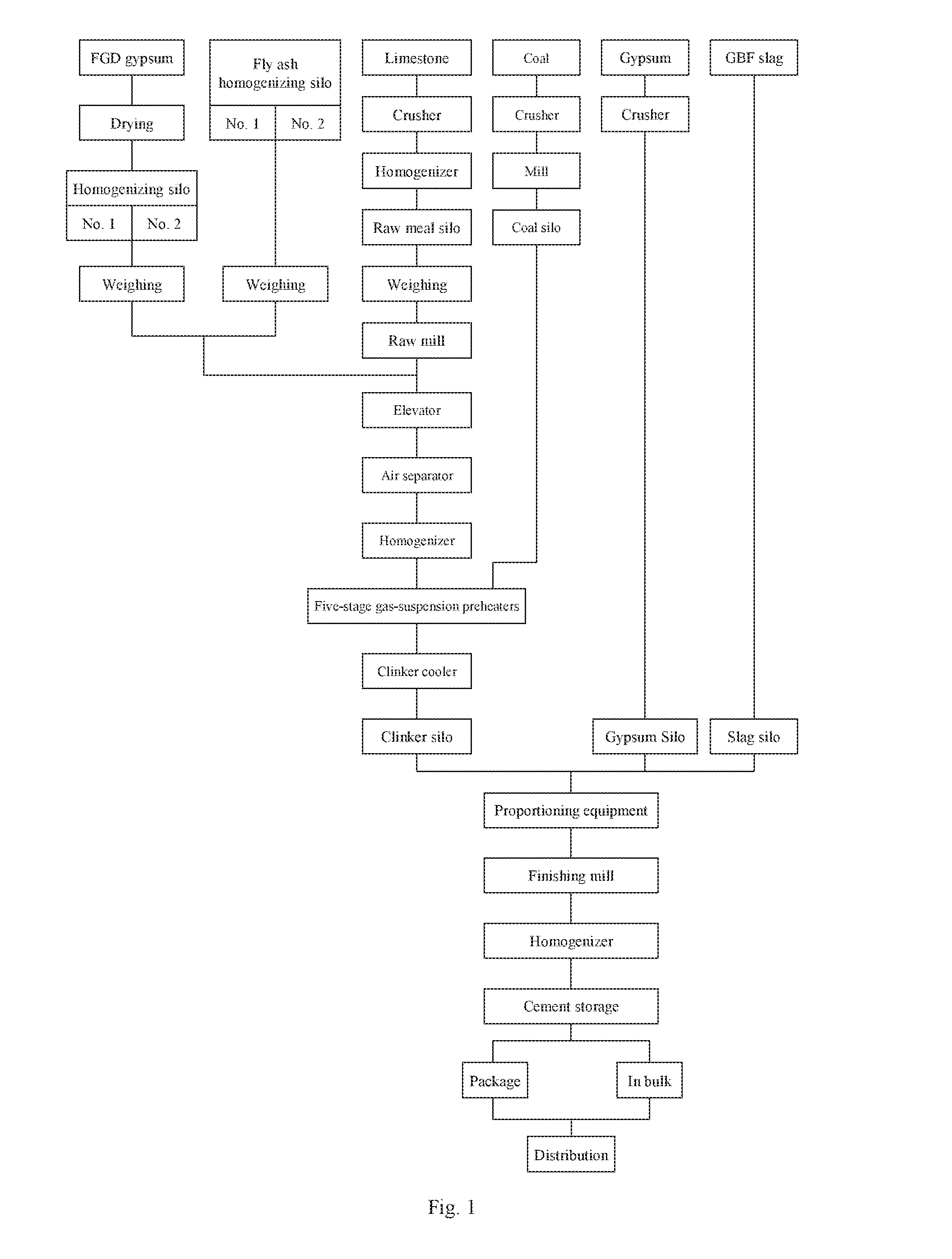

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-Ca° and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

Spraying material and spray technique employing the same

To provide a spraying material having an excellent quick-setting property and excellent adherability, a small alkali amount and excellent initial strength development, and a spraying method using it.The spraying material comprises a liquid quick-setting admixture containing an aluminum source, a sulfur source and a fluorine source, one or more quick-setting aids selected from the group consisting of calcium aluminate, calcium sulfoaluminate, calcium aluminosilicate, an alkali metal-containing substance, calcium hydroxide and aluminum hydroxide, and a cement concrete, and the method is to spray this spraying material.

Owner:DENKA CO LTD

High-strength micro-expansive grouting material and its preparation method

The invention provides a high-strength micro-expansive grouting material and its preparation method. Raw materials of the high-strength micro-expansive grouting material comprise Portland cement having a compressive strength of above 42.5MPa, sulphoaluminate cement or aluminous cement having a compressive strength of above 42.5MPa, a calcium sulphoaluminate expanding agent, quartz sand or corundum or iron tailings, an organic silicon antifoaming agent, a polycarboxylate superplasticizer, calcium formate or lithium carbonate, sodium gluconate, and methyl cellulose ether or hydroxypropyl methyl cellulose ether or hydroxyethyl methyl cellulose ether. Compared with present cement-based grouting materials treating the sulphoaluminate cement and the aluminous cement as main cementing materials, the high-strength micro-expansive grouting material, which is obtained through treating the Portland cement as a main cementing material component, carrying out ultrafine crushing of the cementing material component via an ultrafine crushing technology, and processing, has the characteristics of high early-stage strength, excellent fluidity, increased long-term strength, and good durability; and compared with traditional epoxy mortars, the high-strength micro-expansive grouting material has the characteristics of micro-expansion, simple and fast construction, non-toxicity, and harmlessness.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Sulfoaluminous clinker without iron and without free lime, its process of preparation and its use in white binders

The lightly colored sulfoaluminous clinker contains: more than 55% by weight of calcium sulfoaluminate phase (C4A3S), more than 10% by weight of belite phase (C2S), less than 10% by weight of anhydrite (C{overscore (S), and contains practically no ferrite phase, nor a gehlenite phase (C2AS), nor free lime. It is prepared by a process of roasting carried out at temperatures comprised between about 1250° C. and 1350° C. It can be used for a wide range of applications by combining it with a source of calcium sulfate and / or Portland cement, to obtain binders having specific properties (color, setup time, mechanical strength, expansion or contraction . . . ).

Owner:SOC DES CIMENTS FR

Freeze-thaw durable geopolymer compositions and methods for making same

ActiveUS9624131B1Excellent freeze-thaw durability behaviorGood dimensional stabilityIn situ pavingsSolid waste managementFreeze thawingAnhydrous Calcium Sulfate

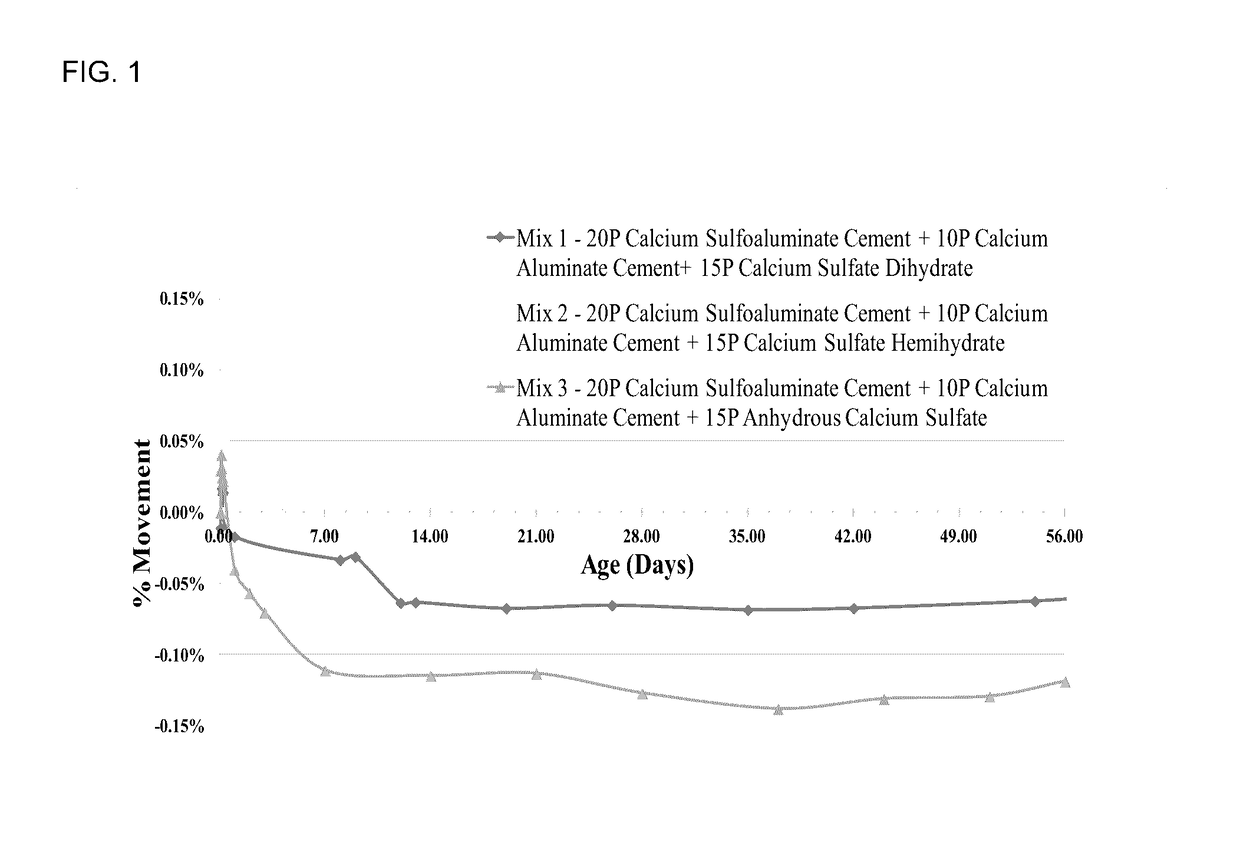

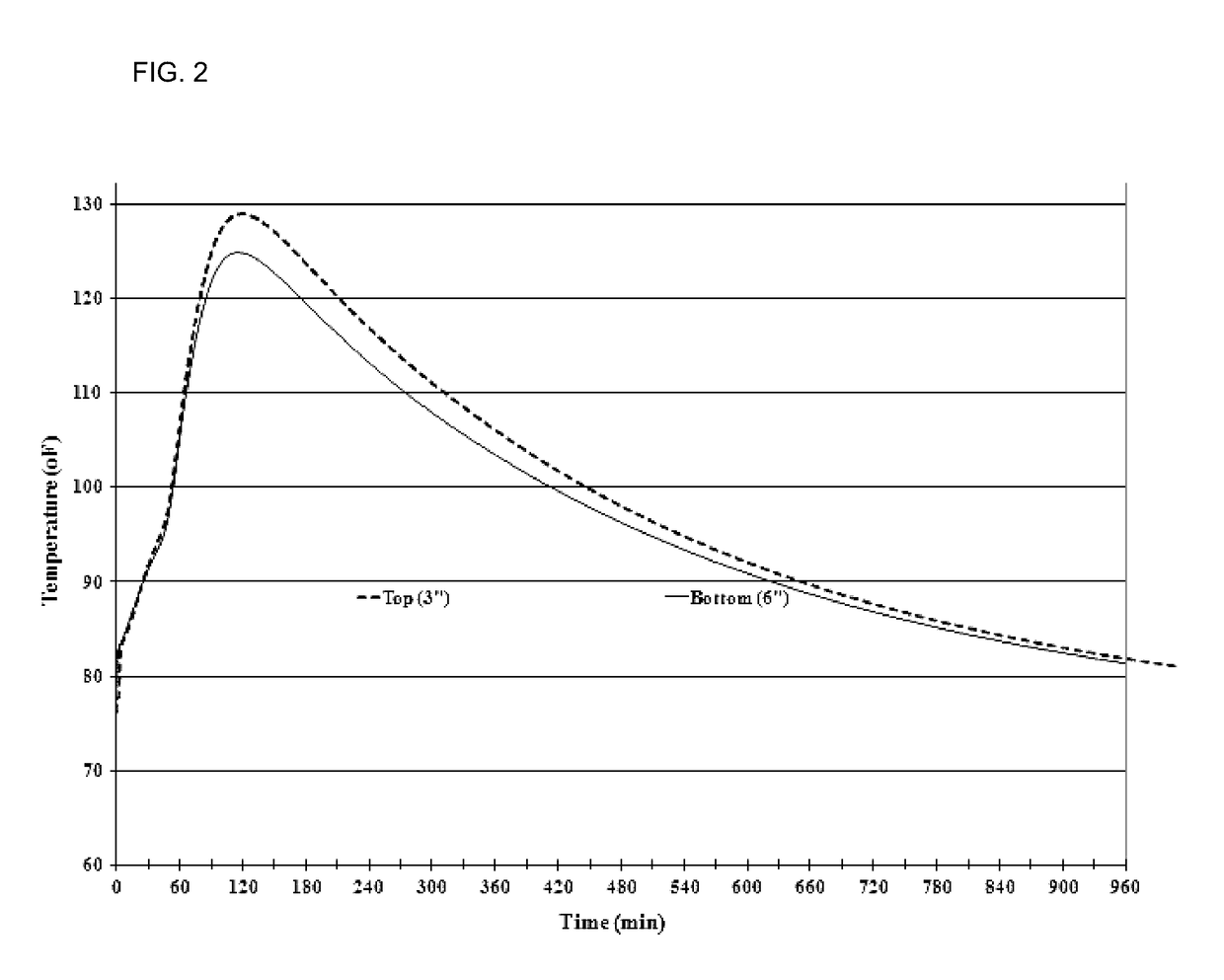

A freeze-thaw durable, dimensionally stable, geopolymer composition including: cementitious reactive powder including thermally activated aluminosilicate mineral, aluminate cement preferably selected from at least one of calcium sulfoaluminate cement and calcium aluminate cement, and calcium sulfate selected from at least one of calcium sulfate dihydrate, calcium sulfate hemihydrate, and anhydrous calcium sulfate; alkali metal chemical activator; and a freeze-thaw durability component selected from at least one of air-entraining agent, defoaming agent, and surface active organic polymer; wherein the composition has an air content of about 4% to 20% by volume, more preferably about 4% to 12% by volume, and most preferably about 4% to 8% by volume. The compositions are made from a slurry wherein the water / cementitious reactive powder weight ratio is 0.14 to 0.45:1, preferably 0.16 to 0.35:1, and more preferably 0.18 to 0.25:1. Methods for making the compositions are also disclosed.

Owner:UNITED STATES GYPSUM CO

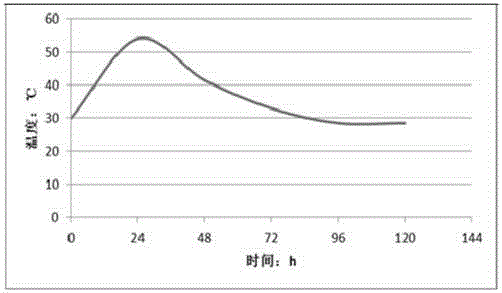

Coal mine gas extraction hole sealing material

InactiveCN104592962AHigh compressive strengthReduce fluidityDrilling compositionCeramicwareLiquid hydrogenCoal mine methane

The invention relates to a coal mine gas extraction hole sealing material. The coal mine gas extraction hole sealing material comprises, by mass, 60-80% of ordinary portland cement, 15-25% of an expanding agent (such as calcium sulphoaluminate and calcium sulphoaluminate-calcium oxide), 0-10% of gypsum, 0.1-0.3% of a foaming agent (such as solid aluminum powder or liquid hydrogen peroxide producing gas in an alkaline environment), and 0.2-0.5% of caustic soda, and the above materials and water are blended according to a mass ratio of 1: 0.6-1. The coal mine gas extraction hole sealing material has good expansibility, has an expansion coefficient greater than 10%, compressive strength greater than 10Mpa, good fluidity and short solidification time, is convenient for use and has a low cost.

Owner:HENAN SHENHUA ENERGY ENG

Spraying material and spray technique employing the same

ActiveUS20070054059A1Excellent initial strength developmentSmall amountLiquid surface applicatorsCoatingsAluminium hydroxideAlkali metal

To provide a spraying material having an excellent quick-setting property and excellent adherability, a small alkali amount and excellent initial strength development, and a spraying method using it. The spraying material comprises a liquid quick-setting admixture containing an aluminum source, a sulfur source and a fluorine source, one or more quick-setting aids selected from the group consisting of calcium aluminate, calcium sulfoaluminate, calcium aluminosilicate, an alkali metal-containing substance, calcium hydroxide and aluminum hydroxide, and a cement concrete, and the method is to spray this spraying material.

Owner:DENKA CO LTD

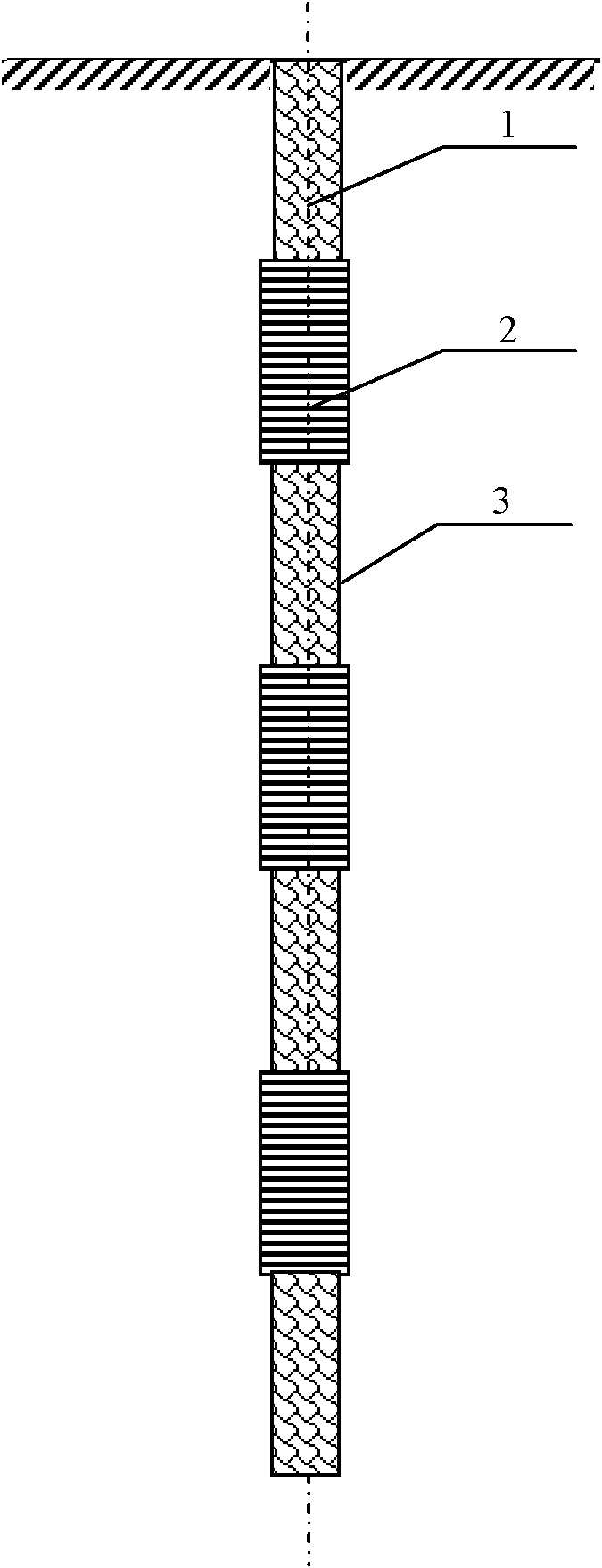

Expansive concrete caisson pile and manufacturing method thereof, and concrete expanding agent

ActiveCN102162244AIncrease relative resistance to motionImprove bearing capacityBulkheads/pilesSlurryJoints types

The invention provides an expansive concrete caisson pile and a manufacturing method thereof, and a concrete expanding agent, and belongs to the technical field of engineering materials and construction of concrete pile foundation. The method comprises the following steps of: alternatively pouring common concrete and expansive concrete into a caisson pile hole sequentially so as to form bamboo joint type I-shaped pile; and pouring slurry at the pile end of the I-shaped pile or the expansive concrete pile so as to form a II-shaped pile or a III-shaped pile. The expanding agent is manufactured by pulverizing 40 to 80 percent of limestone and 20 to 60 percent of gypsum, calcining the powder in a rotary kiln at the high temperature of 1,300 to 1,500 DEG C, and pulverizing 20 to 80 weight percent of the calcined substance and 20 to 80 weight percent of calcium sulfoaluminate cement or alunite or calcium aluminate cement or a mixture of the calcium sulfoaluminate cement, the alunite and the calcium aluminate cement until the specific surface area is 150 to 400 square meters per kilogram. By the method, the manufacturing cost of the expansive concrete caisson pile can be reduced obviously; and compared with the common expansive concrete caisson pile, the expansive concrete caisson pile has the advantage of obviously increasing the bearing capacity of a single caisson pile.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

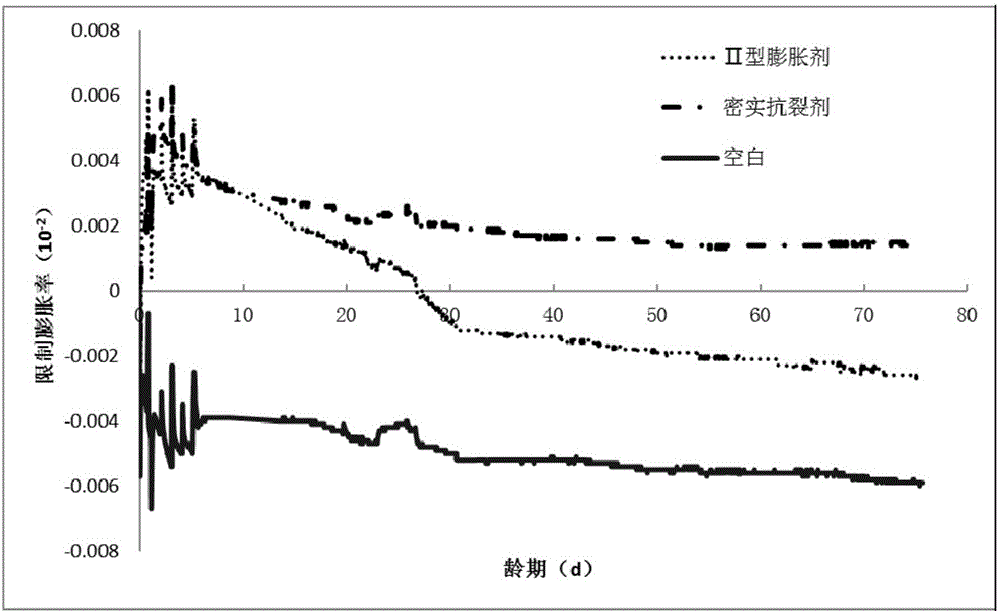

Concrete compaction anti-cracking agent

The invention discloses a concrete compaction anti-cracking agent which comprises 20.0-60.0% of light calcined magnesia, 10.0-30.0% of calcium oxide-calcium sulfoaluminate double-expansion source expanded clinker, 5.0-15.0% of gypsum and 20.0-50.0% of a fine powder material of which the specific surface area is greater than 300m<2> / kg, wherein the sum of the contents of all components is 100% based on the total mass of the concrete compaction anti-cracking agent. The concrete compaction anti-cracking agent can be used in concrete to effectively inhibit shrinkage of the concrete and improve the compactness and the durability of the concrete.

Owner:武汉三源特种建材有限责任公司

Anti-permeation concrete mixture and construction method thereof

The invention discloses an anti-permeation concrete mixture and a construction method thereof, aiming at solving the problems that an ocean environment contains a lot of chlorine ions, damages to steel bars in concrete and the concrete are caused and the use effect of anti-permeation concrete is influenced. According to technical scheme, the anti-permeation concrete mixture is prepared from the following raw materials in parts by weight: 250 to 420 parts of portland cement, 65 to 80 parts of fly ash, 650 to 850 parts of sand, 1000 to 1080 parts of crushed stones, 5 to 10 parts of a water reducing agent, 13 to 29 parts of a calcium sulfoaluminate expanding agent, 1 to 3 parts of other auxiliary agents and 160 to 190 parts of water; after the anti-permeation concrete mixture is cured, obtained concrete has a relatively good tolerance capability.

Owner:四川通德商品混凝土有限公司

Calcium sulphoaluminate-alite composite mineral phase cement clinker and its preparation method

The invention discloses calcium sulphoaluminate-Relit composite mineral phase cement and preparing method, which is characterized by the following: adopting coal ash, alumina, limestone and plaster as raw material and fluorite as mineralizer; designing MG and MS value; introducing new Relit mineral in the preparing course of common aluminium sulfate cement; preparing new clinker of new calcium sulphoaluminate-Relit composite mineral phase cement under 1200-1330 deg.c with 45%-65% C4A3S, 20%-36% C3S and residual C2S.

Owner:李金洪

Modified concrete expansive agent

The invention discloses a modified concrete expansive agent, made from, by weight, 10-20 parts of calcium silicoaluminate, 25-30 parts of calcium sulfoaluminate, 20-25 parts of sulfur fixing waste residue, 10-20 parts of modified red clay, 1-5 parts of tourmaline powder, 6-8 parts of iron slag, 4-6 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 3-5 parts of sodium methyl silicate, 2-4 parts of calcium formate, 0.1-0.3 part of azodicarbonamide, 0.4-0.7 part of maltodextrin, 1-4 parts of sodium lignin sulfonate, 0.3-0.6 part of polyglycol ether, 1-3 parts of a polycarboxylate superplasticizer, 2-5 parts of modified diatomite powder, and 0.5-0.8 part of nano calcium carbonate. The modified concrete expansive agent has the advantages of high strength, good compensating capacity and the ability to control calcium oxide reaction and is a promising concrete admixture.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Low-shrinkage ultra-high performance concrete and preparation method thereof

ActiveCN111285629ASmall self-shrinkage valueReduce the risk of later crackingCement productionAluminateWater reducer

The invention relates to low-shrinkage ultra-high performance concrete, which is prepared from the following raw materials in parts by weight: 800 to 900 parts of a special composite cementing material; 50 to 80 parts of silica fume; 200 to 250 parts of I-grade fly ash; 140 to 160 parts of copper-plated steel fibers; 15-20 parts of a water reducing agent; 1000 to 1100 parts of quartz sand; 160-180parts of water. The special composite cementing material is prepared by uniformly dry-mixing the following raw materials in parts by weight: 75-85 parts of Portland cement clinker powder; 10 to 20 parts of expansive high-belite calcium sulfoaluminate cement clinker powder; 5-10 parts of anhydrite powder. According to the invention, the UHPC self-shrinkage value is small; and the 7d self-shrinkage value ranges from 300 ppm to 350 ppm, the later cracking risk of the UHPC material is reduced, component deformation is reduced, the ultrahigh strength and durability are achieved, the 1d compressive strength reaches 60 MPa to 70 MPa, the 28d compressive strength reaches 160 MPa to 180 MPa, the liquidity is good, and the preparation cost is reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

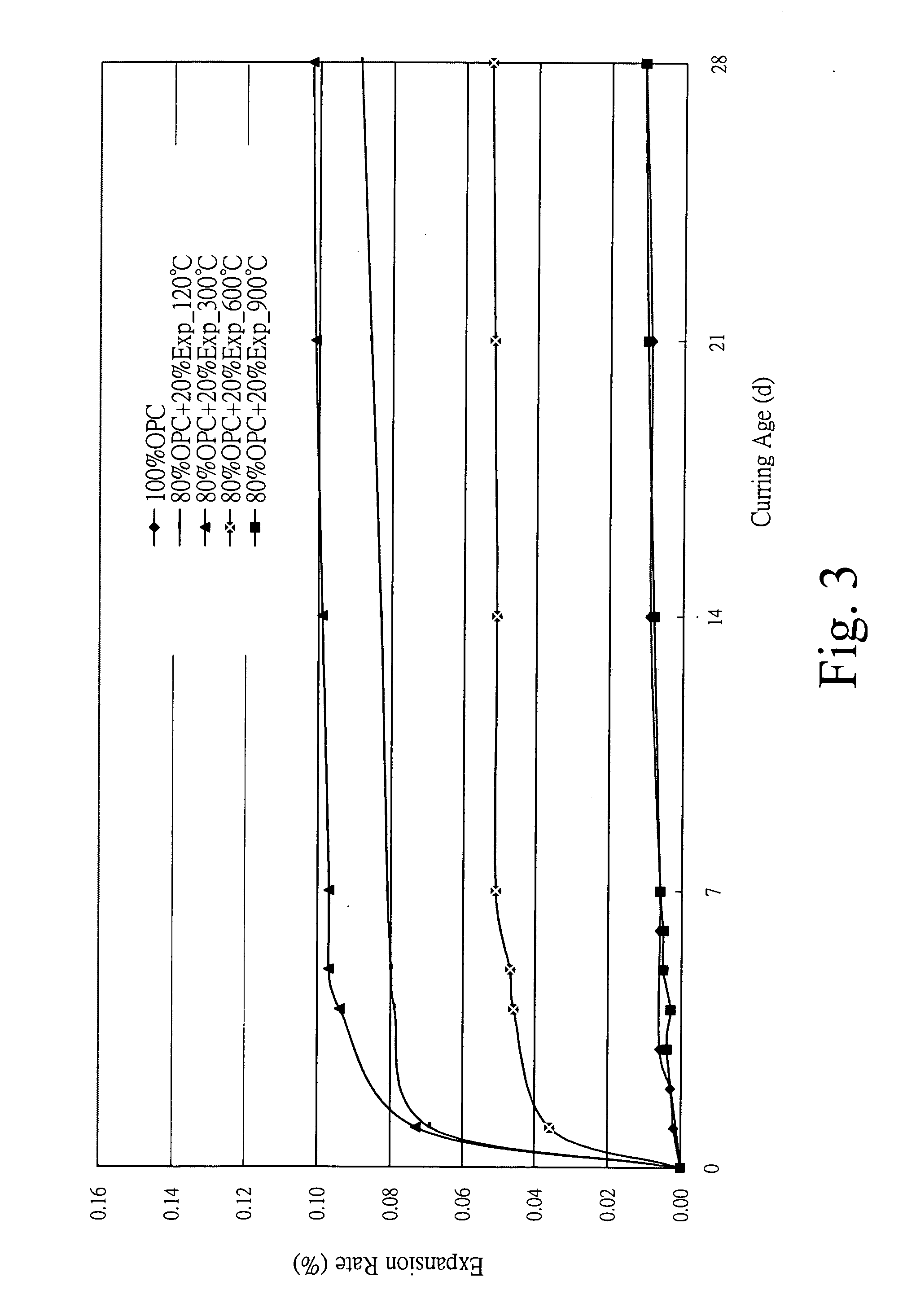

Process and composition for the manufacture of cement expansion additive

The present invention is related to the process and composition for the manufacture of cement expansion additive. The process comprises a blending step, a reaction step, and a calcination step. The blending step is to incorporate soluble calcium sulfate, soluble calcium oxide, and soluble aluminum compounds such as aluminum dross. The addition of water with the above incorporated materials to from ettringite is so-called reaction step. The calcination step is to calcine the products which are produced from reaction step at a temperature range between 60° C. and 900° C. by transforming ettringite from amorphous to calcium sulfoaluminate respectively. After calcinations, the final products can be used as expansive additives for cement or concrete. Further, this manufacturing method can effectively decrease raw material cost and production cost due to the raw material coming from recycling and no need to calcine at high temperature than other relative arts.

Owner:CHINA HI MENT CORP

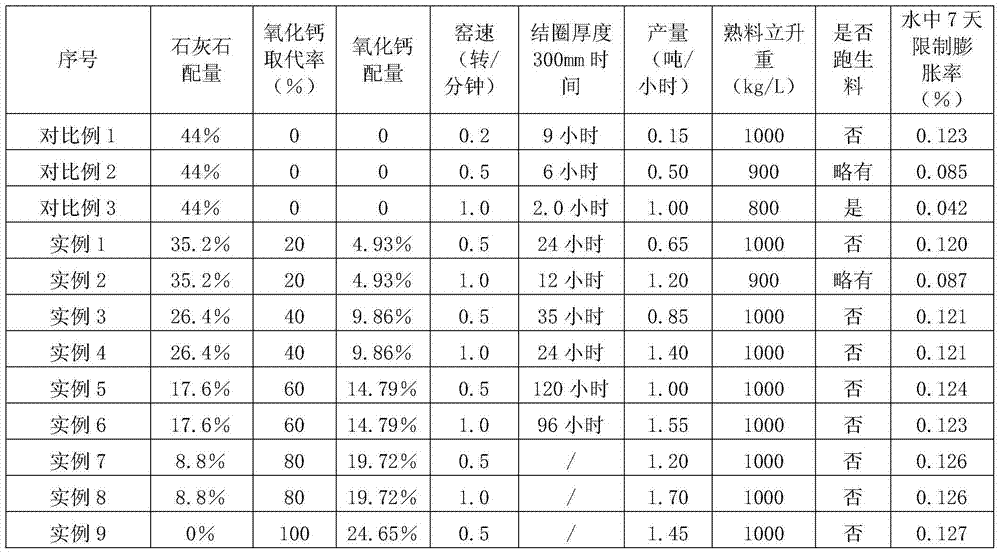

Calcium sulphoaluminate or calcium sulphoaluminate-calcium oxide concrete expanding agents as well as preparation method and application thereof

The invention discloses calcium sulphoaluminate or calcium sulphoaluminate-calcium oxide full-clinker concrete expanding agents as well as a preparation method thereof and application thereof in improving shrinkage resisting performance of concrete. A material formula of the expanding agents comprises the following components in percentage by weight: 40wt%-90wt% of limestone (calcium carbonate), 5wt%-50wt% of anhydrite and 2wt%-20wt% of alumina; moreover, limestone not lower than 20wt% (20wt%-100wt%) is replaced by calcium oxide (quicklime), and a calculation coefficient of the limestone replaced by the calcium oxide (quicklime) is 1.785 in mixture calculation, i.e., one part of calcium oxide used is equivalent to 1.785 parts of calcium carbonate. According to the invention, rotary-kiln industrial production of calcium sulphoaluminate or calcium sulphoaluminate-calcium oxide full-clinker concrete expanding agents is realized; moreover, expansion performance is improved, manufacturing cost is remarkably lowered, and application prospect is broad.

Owner:CHINA BUILDING MATERIALS ACAD

Additives for cement

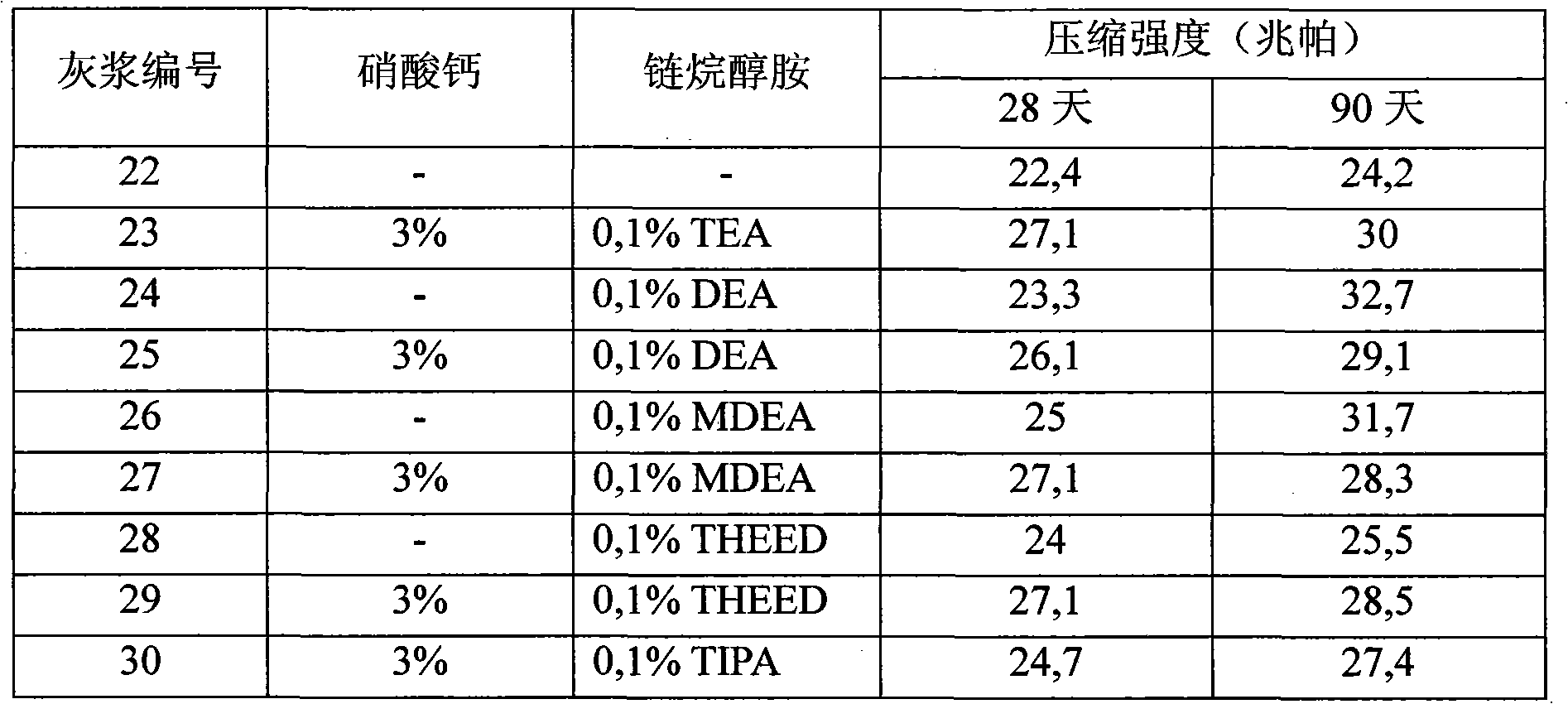

The invention provides a belite-calcium sulphoaluminate-ferrite (BCSAF) cement composition comprising: a BCSAF clinker which clinker has the following mineralogical composition, based on the total weight of the clinker: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase having the general formula C2AxF(1-X), wherein X is from 0.2 to 0.8; 15 to 35% of a calcium sulphoaluminate phase; 40 to 75% of belite (C2S); from 0.01 to 10% in total of one or more minor phases selected from calcium sulphates, alkali metal sulphates, perovskite, calcium aluminates, gehlenite, free lime and periclase and / or a vitreous phase; and an alkanolamine.

Owner:HOLCIM

Anticorrosion high-belit sulfoaluminate cement clinker and preparation method thereof, anticorrosion high-belit sulfoaluminate cement and preparation method of cement

ActiveCN107935423AImprove early strengthImprove seawater erosion resistanceCement productionSulfateUltimate tensile strength

The invention provides an anticorrosion high-belit sulfoaluminate cement clinker and a preparation method thereof, anticorrosion high-belit sulfoaluminate cement and a preparation method of the cement, and relates to the field of building material. The anticorrosion high-belit sulfoaluminate cement clinker comprises the following mineral components by the weight percentage: 12%-30% of anhydrous calcium sulfoaluminate, 9.04%-35% of tetracalcium aluminoferrite, 37%-49% of dicalcium silicate, 6%-26% of calcium sulfate and 0.5%-4.1% of free calcium oxide. The anticorrosion high-belit sulfoaluminate cement clinker is used in cement to alleviate the technical problems of poor seawater erosion resistance and poor corrosion resistance of conventional cement used in marine environments, has the advantages of high early strength and easy construction, and can be used for preparing high-corrosion-resistant marine cement concrete for marine environments.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

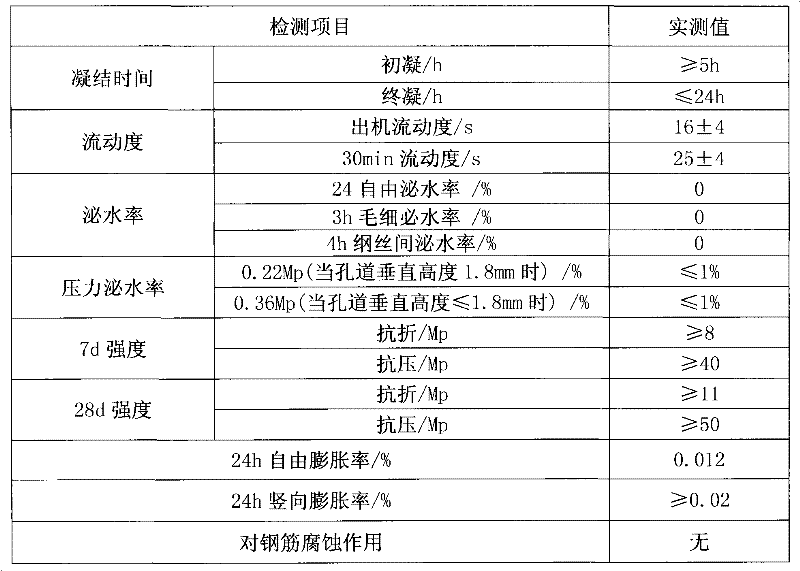

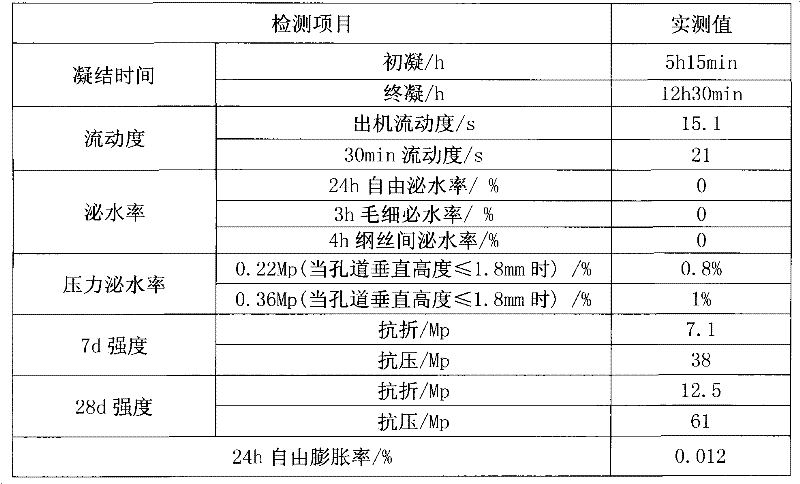

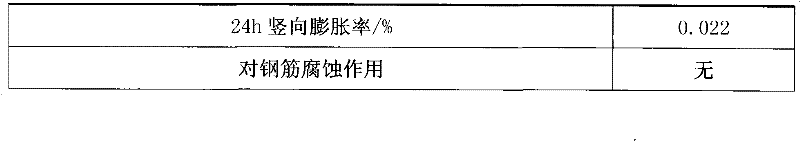

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

High performance concrete expanding agent

The invention which relates to a high performance concrete expanding agent belongs to the technical field of expansive cement. The high performance concrete expanding agent is characterized in that the high performance concrete expanding agent comprises, by weight, 40-60 parts of waterless calcium sulfoaluminate, 20-40 parts of calcium sulfate and 10-25 parts of calcium oxide. The high performance concrete expanding agent has the advantages of high expansion energy, good stability, safety and reliability, simple preparation process, low production cost, excellent product performance and the like. The expansion rate of the high performance concrete expanding agent is in harmony with the strength development of concrete, so the expansion rate is fast, the expansion stabilization phase is early, and the expanding agent has good anti-crack anti-seepage functions, thereby the expanding agent is an ideal material for preparing high performance expansive concrete.

Owner:TIANJIN BAOMING BUILDING ENG MATERIAL

Secondary synthesis method of calcium sulfoaluminate minerals in metasilicate cement clinker

The invention relates to a secondary synthesis method of calcium sulfoaluminate minerals in a metasilicate cement clinker, comprising the following steps of: mixing a plaster in a metasilicate cement raw material and calcining; and carrying out thermal treatment on the metasilicate cement clinker containing the calcium sulfoaluminate minerals to enable the decomposed calcium sulfoaluminate minerals in the clinker is re-formed at a high-temperature state. Therefore, the invention improves the content of the calcium sulfoaluminate minerals in the clinker, sufficiently develops the superiority of the calcium sulfoaluminate minerals in the cement clinker, improves the early and long-term perofmrance of the cement clinker and increases the mixture quantity of a mixed material in the cement.

Owner:NANJING TECH UNIV

Low-carbon cement clinker and preparation method and application thereof

ActiveCN105669056AIncreases hydration activityIncrease late strengthCement productionRed mudHigh activity

The invention discloses low-carbon cement clinker and a preparation method and application thereof.Raw materials for preparing the cement clinker are a silicon-aluminum containing material, limestone and industrial tailings, and the silicon-aluminum containing material is one of or a mixture of low-grade alumina, fly ash, red mud and gangue.The preparation method includes: well mixing the raw materials, and grinding, wherein a requirement on grain diameter after grinding is that screen residue of a 0.08-mm square-hole screen is less than 15%; calcining the raw materials after being ground at calcining temperature of 1150-1350 DEG C for 10-40 min, and cooling to obtain the low-carbon cement clinker.Content of high-activity beta type dicalcium silicate is greater than or equal to 50%, content of calcium sulfosilicate is 5-15%, and content of calcium sulfoaluminate is 15-25%.A finished cement product can be prepared by adding 0.01-10% of gypsum and 0.01-10% of limestone into the cement clinker.According to existing national detection standards, standard mortar of the cement is higher than 30 MPa in 3-day compressive strength and is 60+ / -5 MPa in 28-day compressive strength.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Expansive agent for building concrete

The invention discloses an expansive agent for building concrete. The expansive agent comprises, by weight, 10-20 parts of calcium silicoaluminate, 20-25 parts of calcium sulfoaluminate, 20-30 parts of sulfur fixation residues, 15-25 parts of red mud, 10-15 parts of magnesium slag, 4-8 parts of modified calcium oxide, 4-7 parts of magnesium oxide, 3-8 parts of methanesiliconic acid sodium salt, 3-5 parts of triisopropanolamine, 5-8 parts of aluminum potassium sulfate, 0.1-0.3 part of azodicarbonamide, 0.5-0.8 part of sodium citrate, 2-4 parts of sodium dodecyl benzene sulfonate, 0.4-0.6 part of ethylene-vinyl acetate copolymers and 1-3 parts of polycarboxylic acid water reducing agents. The expansive agent has the advantages that the expansive agent is high in strength and excellent in compensation capacity and calcium oxide regulation and control reaction and is a concrete admixture with a great prospect, and the like.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

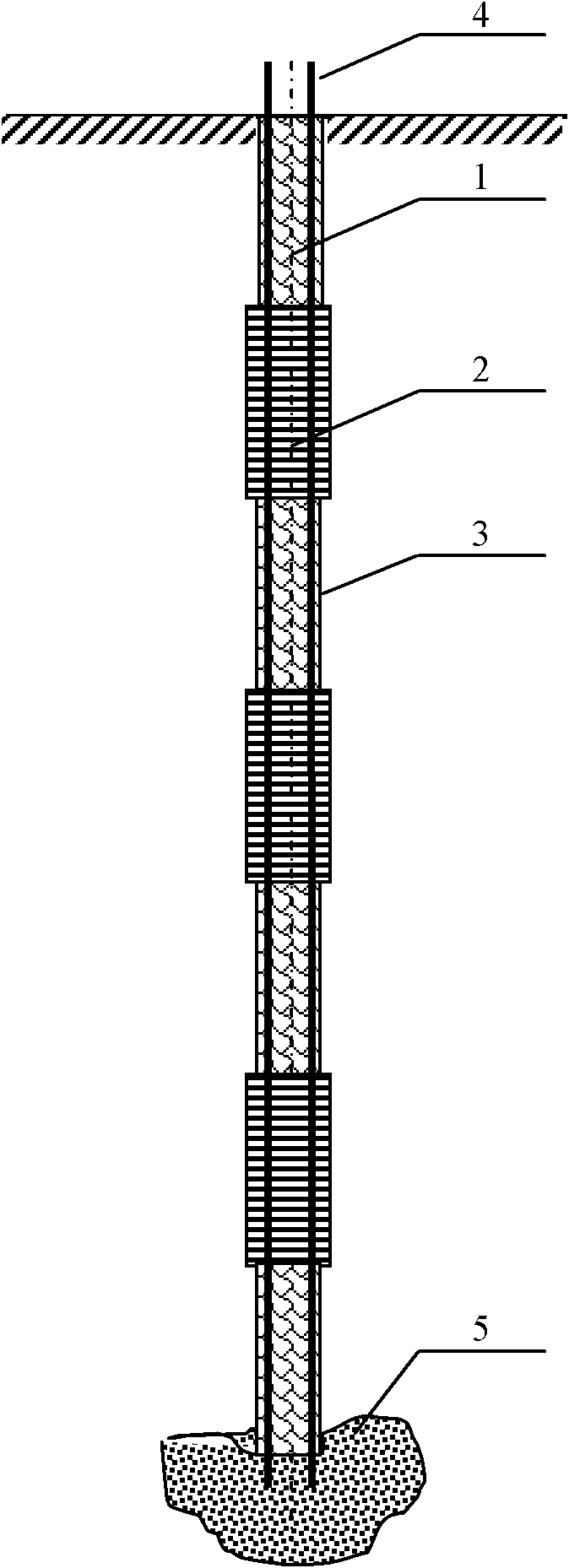

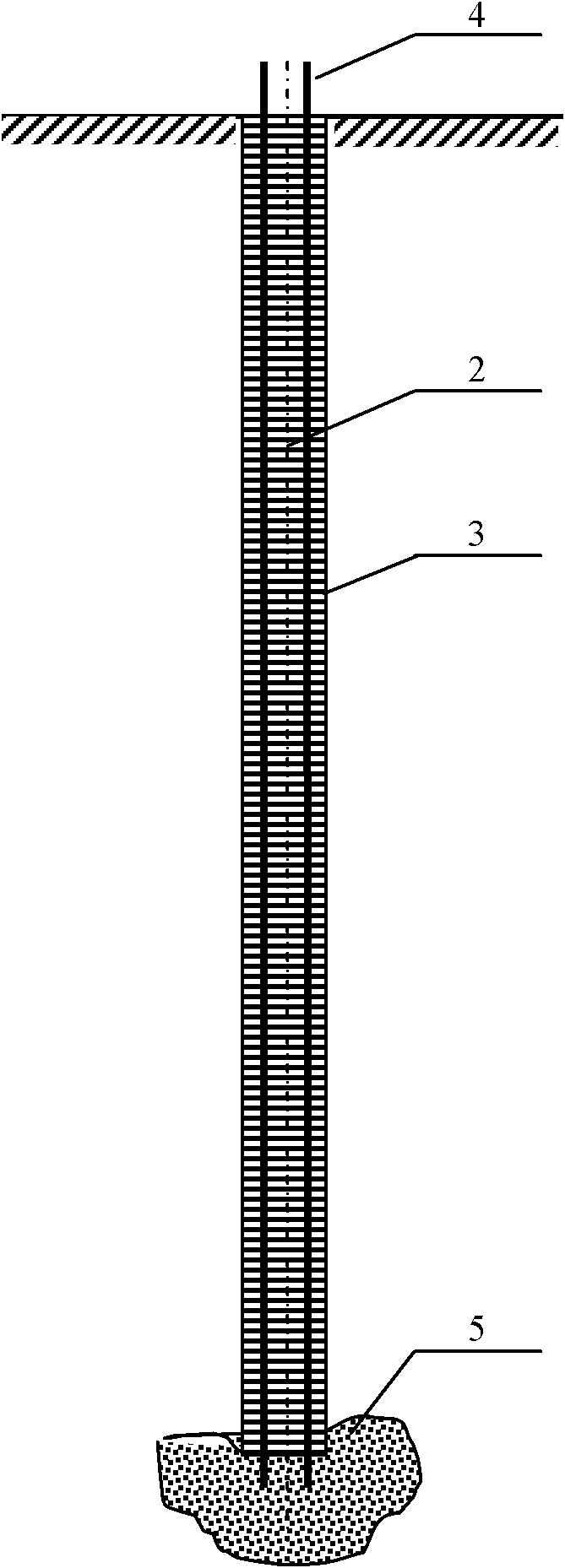

Coagulation controllable type cement based pore sealing material and application method thereof

InactiveCN106186976AExtended hydration timeCompensates for hydration shrinkageDrilling compositionAl powderAluminite

The invention relates to a coagulation controllable type cement based pore sealing material and application method thereof. A sulfoaluminate-silicate composite cement system with a certain ratio is adopted, a proper amount of industrial aluminum powder, a high efficient water reducer, and a resin type polymer material is added; an individual grinding technology is adopted, sulfoaluminate cement clinker and resin are grinded together at first so that fine resin particles can be adsorbed on the surface of the mineral particles in sulfoaluminate cement clinker; during the construction process, after the material is contacted with water, the resin wrapped on the surface of the clinker particles reacts with water to form a crosslinking coating film, the hydration of sulfoaluminate minerals is sustained-controlled therefore; the forming speed and forming amount of hydration products such as ettringite (Aft), hydrated aluminate, and the like can be adjusted; the setting time of sealing materials is effectively delayed; the construction becomes convenient, moreover, the sealing material can continuously and slightly expands in the sealed holes, a high early strength is provided for the material, the hydration shrinkage of silicate phase is compensated at the same time, and thus the pore sealing material can be used for a long time.

Owner:UNIV OF JINAN

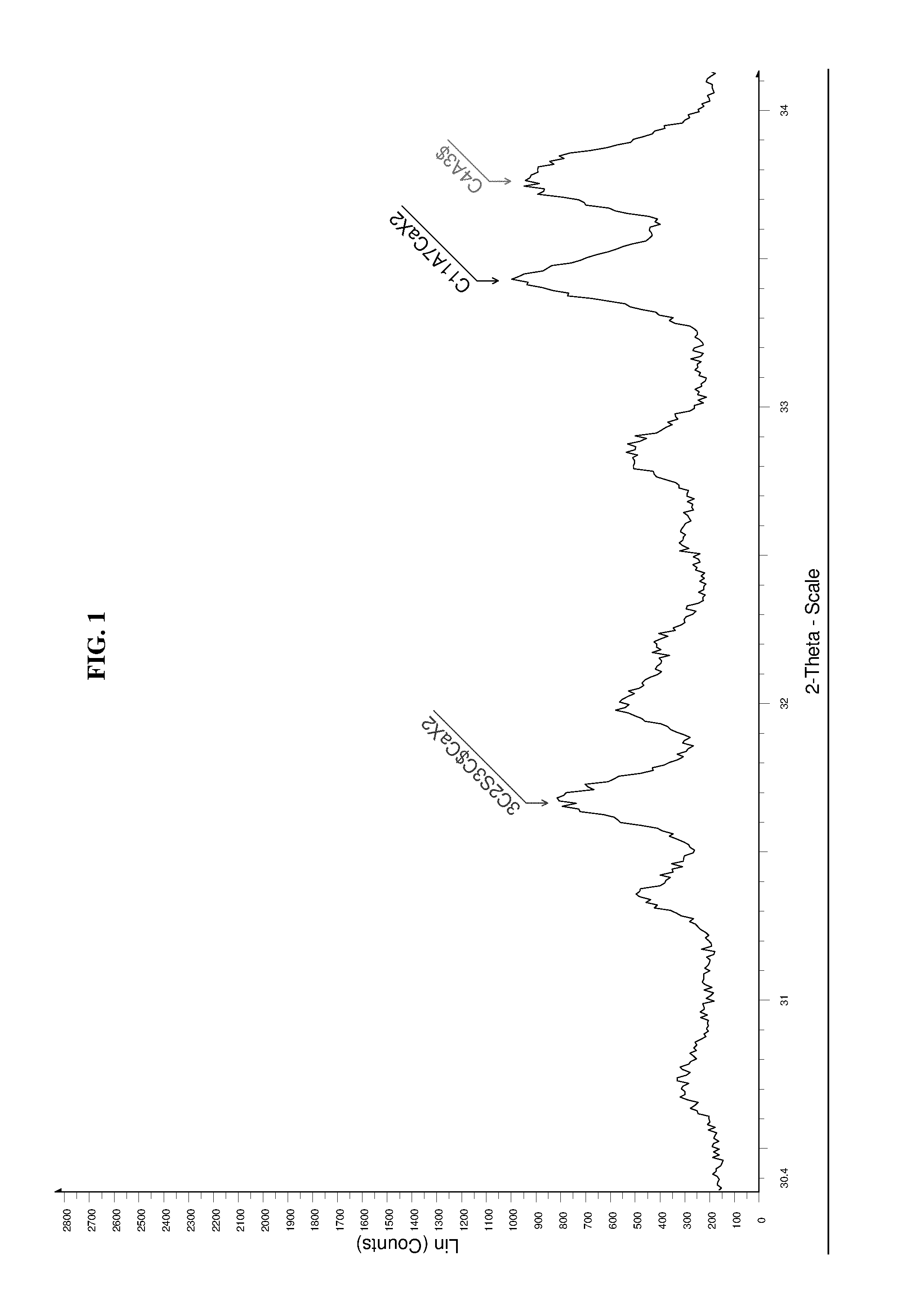

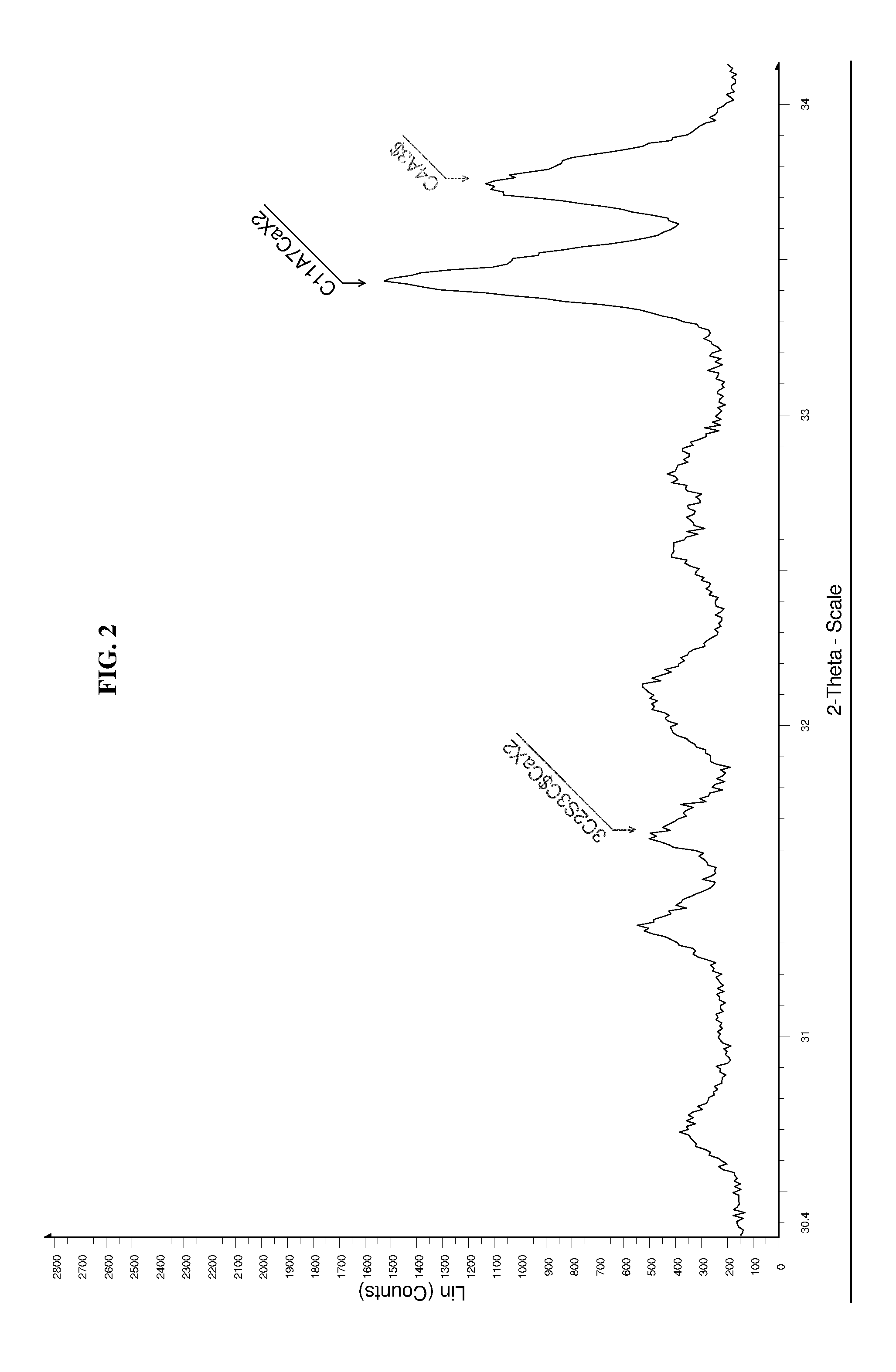

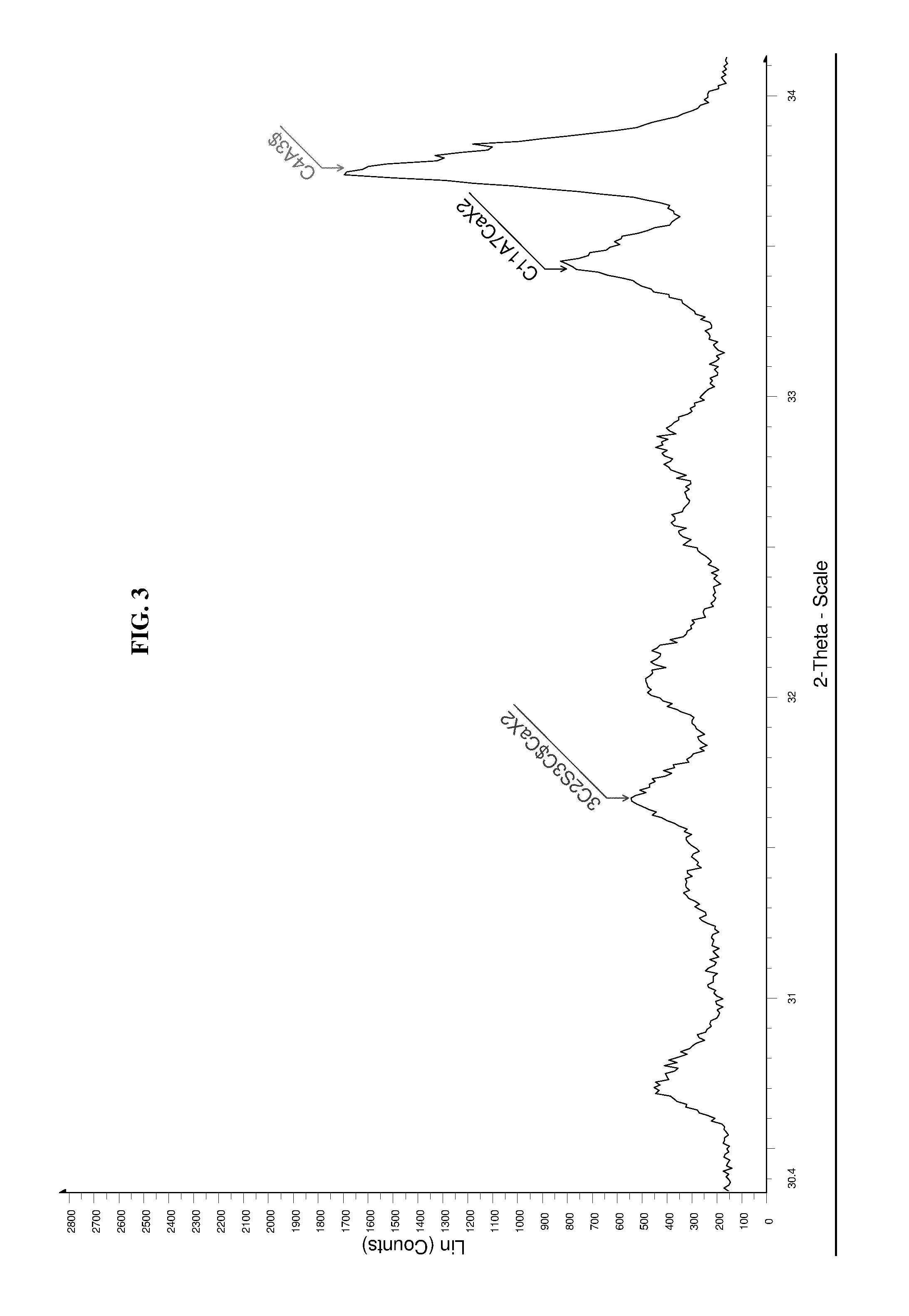

High performance sulfo-aluminous clinker

The invention relates to a sulfo-aluminous clinker with optimal setting time and short term compressive strengths, comprising a mixture of the following phases: —calcium sulfoaluminate, or C4A3$, in amounts higher than 50% by weight of the mixture, —belite, or C25, in amounts between 2 and 23%, —3C25 3C$ CaX2, X being fluorine or chlorine, between 3 and 15% —C11A7CaX2, X being fluorine or chlorine, between 2 and 12%, both fluorine and chlorine being altogether present in the mixture, and phase C5S2$ being absent. The invention also relates to a method for preparing this sulfo-aluminous clinker, and hydraulic binders comprising this clinker.

Owner:ITALCEMENTI

Treatment method for solidifying bed mud in river

ActiveCN101050045AReduce processing costsRealize resource utilizationSludge treatmentSolid waste managementBrickSlag

This invention relates to a method for solidifying river bottom sludge. The method utilizes coal slag, quicklime and gypsum to react with water in the river bottom sludge to solidify river bottom sludge. In addition, construction garbage including bricks and concrete chips are utilized as a supporting material to maintain the solidified river bottom sludge for a certain time. Quicklime as an alkali activator can react with SiO2 and Al2O3 in coal slag. The products can further react with gypsum to obtain calcium sulfoaluminate hydrate. The residual products are further subjected to hydration to solidify river bottom sludge. The solidified river bottom sludge can be used as a substitute for concrete blocks to construct road surface of parks.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing high-seepage-resistance calcium sulfoaluminate concrete

The invention relates to a method for preparing high-seepage-resistance calcium sulfoaluminate concrete. The high-seepage-resistance calcium sulfoaluminate concrete is prepared by steps: taking calcium sulfoaluminate cement accounting for 17.00%-25.00% of the total weight of concrete, retarder accounting for 0.01%-0.04% of the total weight of concrete and water accounting for 2.55%-5.25% of the total weight of concrete, and mixing for 20-40s; adding aggregates accounting for 65.00%-80.00% of the total weight of concrete, and mixing for 50-70s; and adding water reducing agent accounting for 0.10%-1.00% of the total weight of concrete and water accounting for 2.55%-5.25% of the total weight of concrete, and mixing for 50-70s, wherein the aggregates are proportionally composed of particles of different diameters. Operability of concrete compactness is realized by regulating mass fraction of the aggregates of each grade. The seepage resistance grade of the concrete prepared by the method is higher than P20, and the concrete has excellent seepage resistance and corrosion resistance.

Owner:UNIV OF JINAN

Concrete composite expanding agent

The invention discloses a concrete composite expanding agent which is prepared from the following mixed substances in parts by weight: 35-42 parts of coal ash, 12-15 parts of gypsum powder, 3-5 parts of quick lime, 2-8 parts of alunite and 16-22 parts of calcium sulphoaluminate. The concrete composite expanding agent has the beneficial effects that the admixture amount is low, the expansion rate is more than the expansion rate of UEA (in market) with the admixture amount of 12%, the alkali amount is far lower than the alkali amount of 1.7-2.2% of a U-shaped expanding agent, which is of great significance; as the admixture amount is reduced, the early-stage strength and the later-stage strength are not affected, and the purpose of equivalent substitute for cement is achieved in deed; the concrete slump loss is not increased, and good construction properties are achieved.

Owner:LIUZHOU ZHENGLING GROUP

Optimization of the properties of aluminous cements using inorganic fillers

The carefully controlled addition of inorganic fillers to calcium sulfoaluminate rapid-setting cements can lead to significant improvement and optimization of its properties. Generally, prior art achieves cement optimization using costly and unstable organic additives. In the present invention, the addition of three inorganic additives such as coal ash, limestone or kiln dust led to appreciable improvement in the properties of calcium sulfoaluminate-containing cements. The addition of coal fly ash led to increased compressive strength and freeze-thaw durability while decreasing shrinkage and autoclave expansion. The addition of limestone was shown to control the compressive strength while not affecting the setting time, and the addition of cement kiln dust was shown to control the compressive strength while increasing the setting time. And finally, the presence of a super plasticizing agent was shown to negatively affect both compressive strength and shrinkage when used in combination with fly ash.

Owner:MACAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com