Expansive concrete caisson pile and manufacturing method thereof, and concrete expanding agent

A technology of expansive concrete and a manufacturing method, which is applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of small increase in bearing capacity of cast-in-place piles, reduce concrete strength, and increase cost of cast-in-place piles, etc. The bearing capacity of a single pile, the effect of increasing pile tip resistance and increasing pile side resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

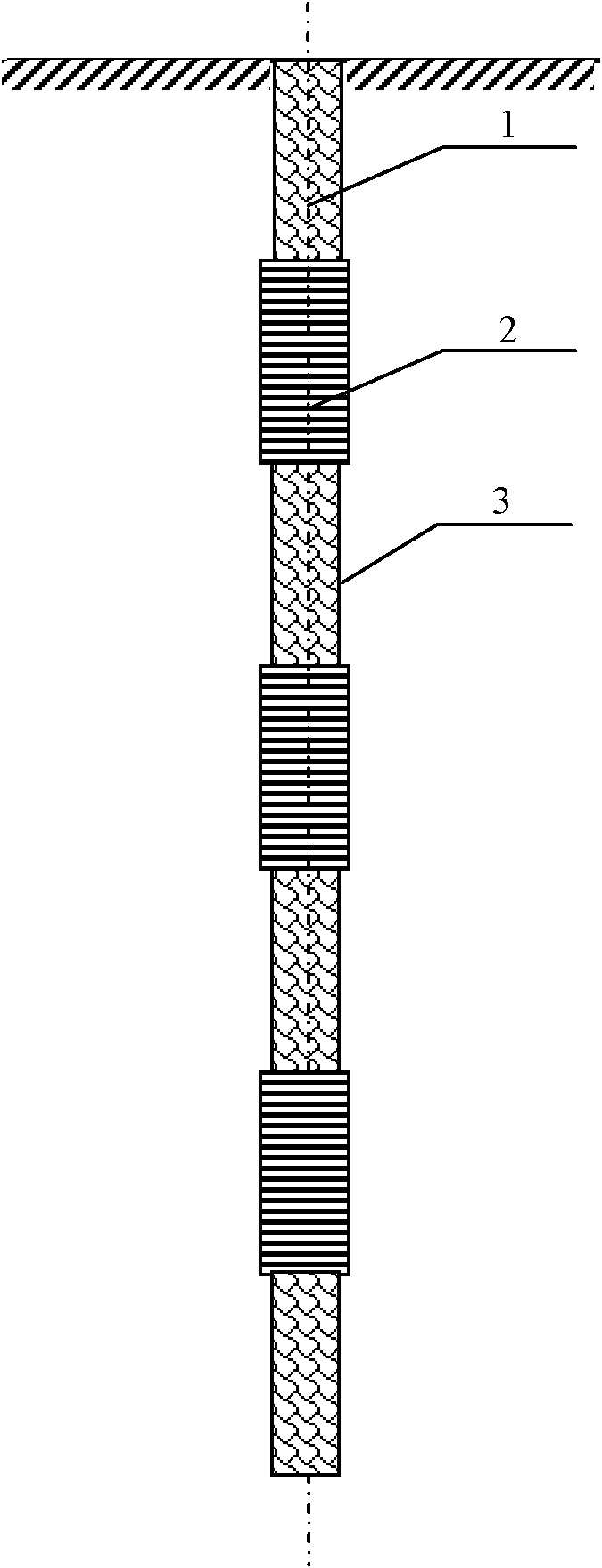

[0026] Embodiment 1: the manufacture of I type pile

[0027] see figure 1 As shown, in the cast-in-situ pile hole 3 where the reinforcement cage is installed below the ground, ordinary concrete and expanded concrete configured according to the strength grade required by the design are poured in sequence to form bamboo-shaped ordinary concrete section 1 and expanded concrete section 2, and each section The height of the concrete is not less than 1m; the pouring heights of ordinary concrete and expansive concrete can be the same or different, and ordinary concrete is preferred at the top of the pile. Wherein, the expansive concrete is formed by adding 15 to 30 wt% of an expansive agent to ordinary concrete, and the expansive agent can be a commercially available UEA expansive agent, but the expansive agent of the present invention is preferably used.

[0028] After the cast-in-situ piles are poured, it will be the test pile age. Refer to the current national industry standard ...

Embodiment 2

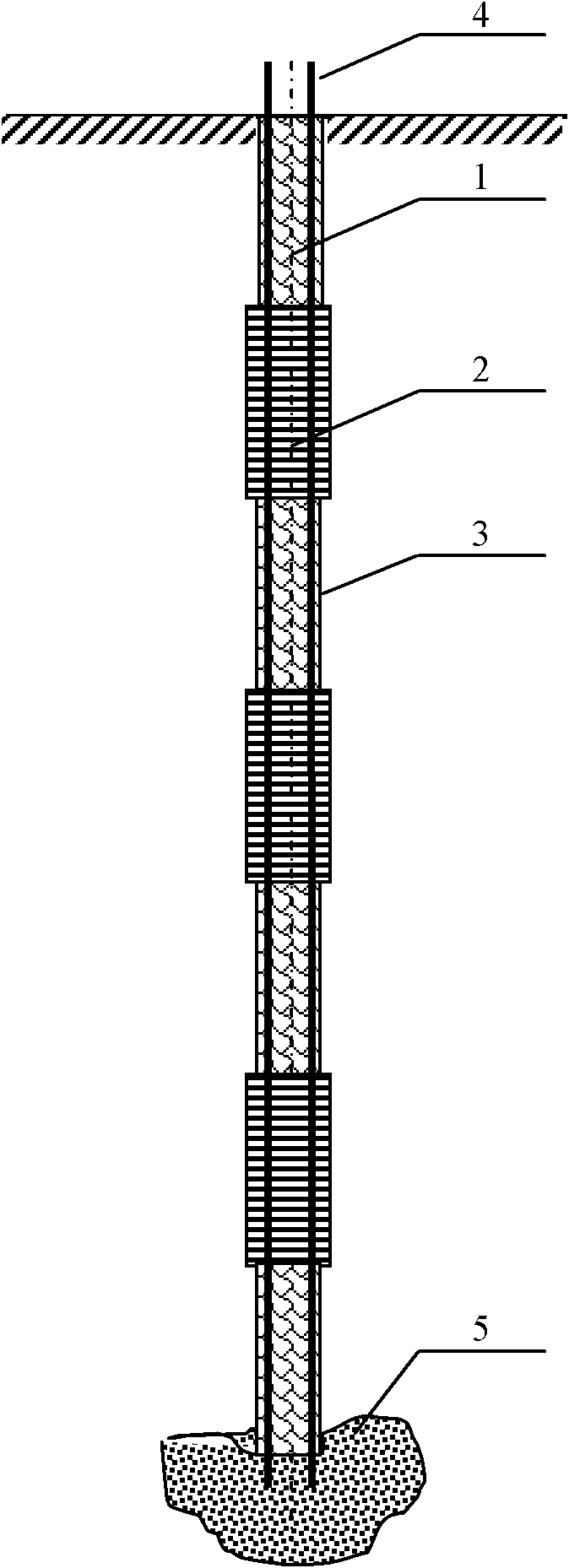

[0029] Embodiment 2: the manufacture of type II pile

[0030] see figure 2As shown, in the cast-in-situ pile hole 3 where the reinforcement cage is installed below the ground, the ordinary concrete 1 and the expanded concrete 2 configured according to the strength level required by the design are poured sequentially to form a bamboo joint in which the ordinary concrete section 1 and the expanded concrete section 2 are staggered. The height of each section of concrete is not less than 1m, and the pouring height of ordinary concrete and expansive concrete can be the same or different; 12 hours after the pile is poured, use a mud pump to pass The grout pipe 4 is pressure injected into the soft soil at the pile end and mixed with 5wt% (the expansion agent of the present invention can be added to the grouting liquid at the pile end with 5% to 10% of the expansion agent), or 12wt% cement of commercially available UEA expansion agent After 24 hours, the cement is solidified to form...

Embodiment 3

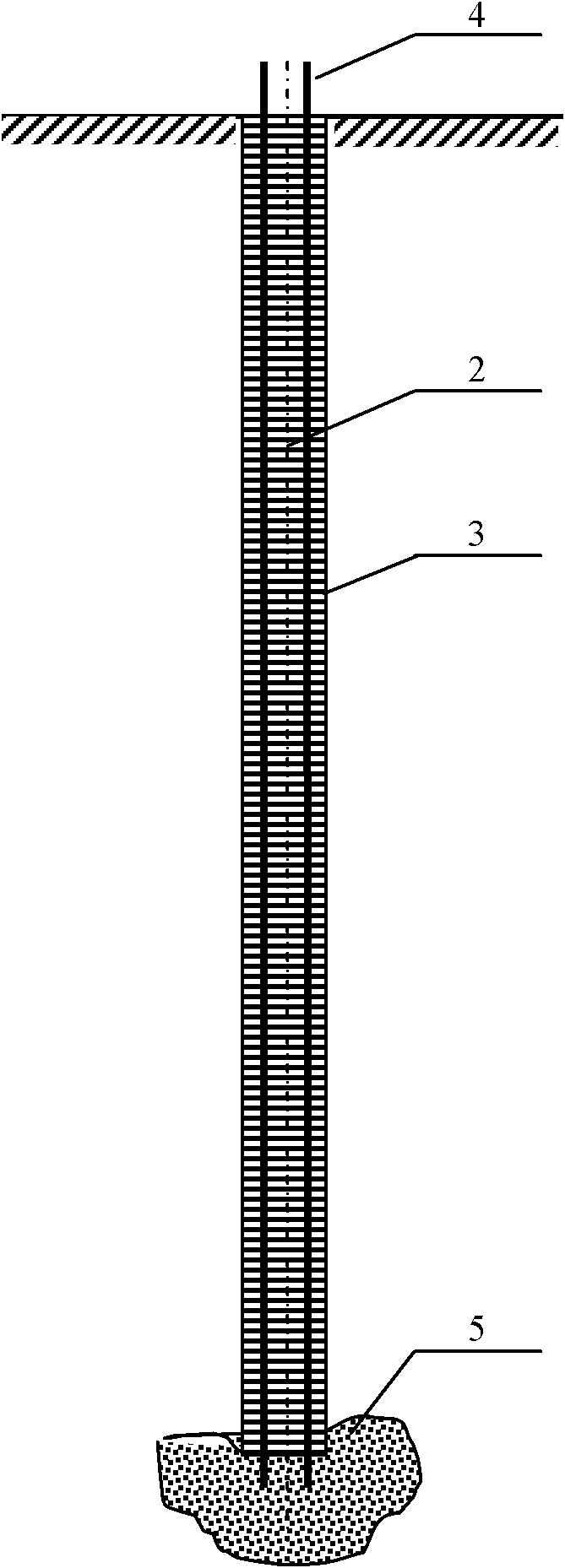

[0033] Example 3: Fabrication of Type III piles

[0034] see image 3 As shown, a Type III pile formation is shown. In the cast-in-situ pile hole 3 where the reinforcement cage is installed below the ground, all the expanded concrete is poured to form a pile body of a single material; In soft soil, add 5wt% of the expansion agent of the present invention (5% to 10% of the expansion agent can be added to the grouting liquid of the expansion agent of the present invention at the pile end), or cement slurry of 12wt% of the commercially available UEA expansion agent After 24 hours, the cement is solidified to form a solidified body 5 at the pile end. In pile casting, the expansive concrete is formed by adding 15-30wt% expansion agent to ordinary concrete. The expansion agent can be a commercially available UEA expansion agent, but the expansion agent of the present invention is preferably used.

[0035] Refer to the current national industry standard "Technical Specifications f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com