Installation construction method for large all-steel formwork at internal corner of shear wall

A construction method and shear wall technology, which are applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components, which can solve the problem that the rigidity of formwork at the inner corner cannot be guaranteed. and firm, large lateral pressure, unable to solve the problems of mass production, etc., to achieve the effect of accurate size, high bearing capacity and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

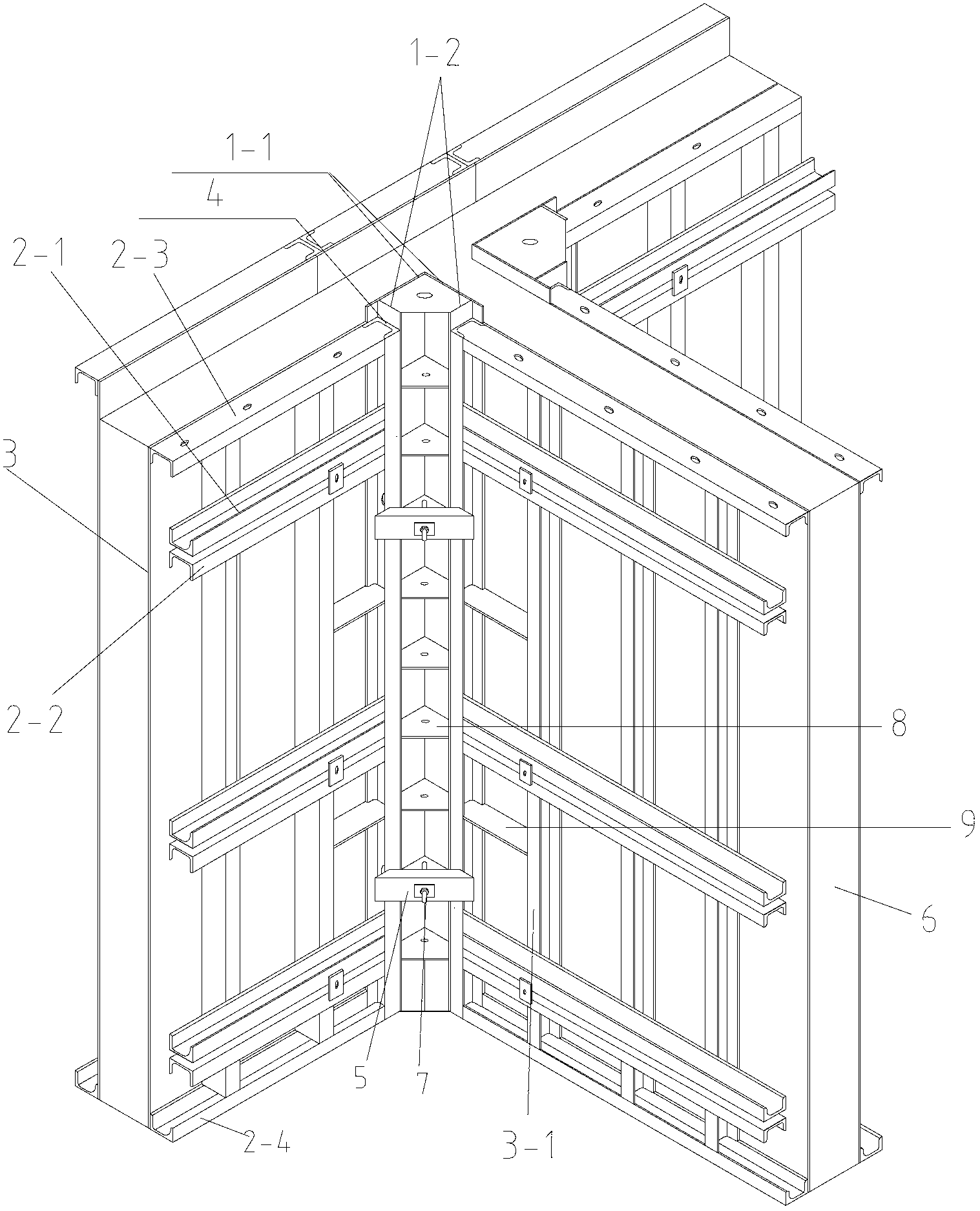

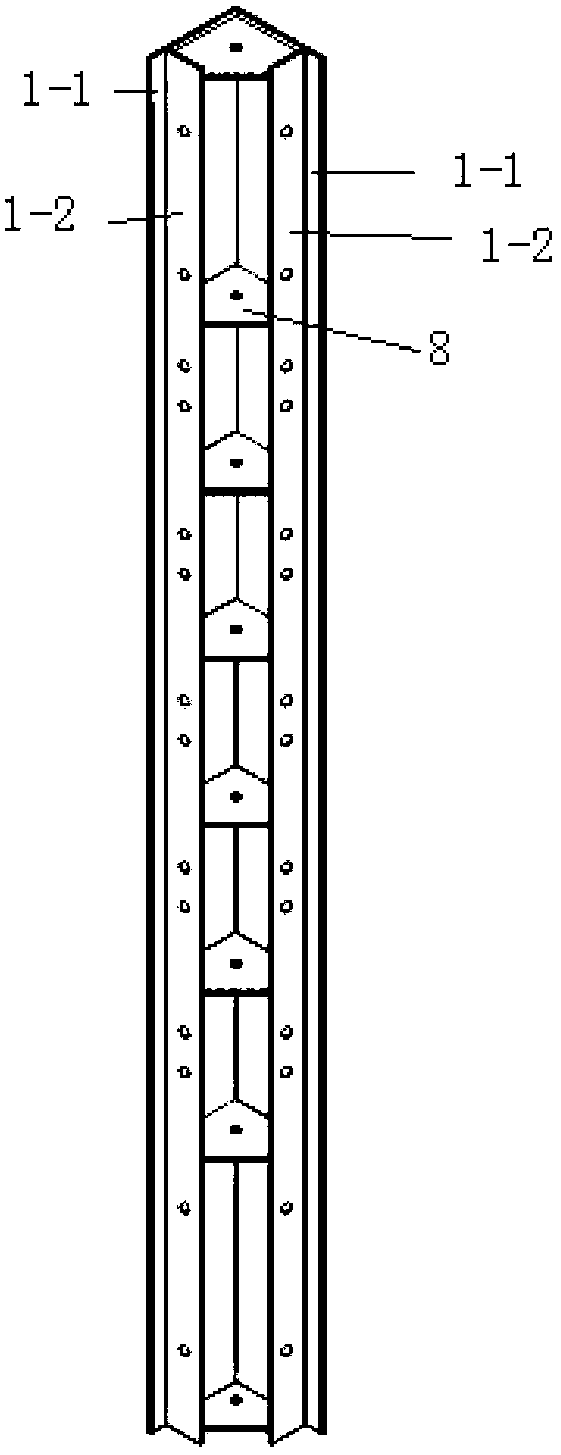

[0038] (1) Install the negative angle steel formwork at the internal corner of the wall, and the negative angle steel formwork includes two vertical steel plates 1-1 welded at right angles, and are connected at intervals along the height direction of the vertical steel plates 1-1 between the two vertical steel plates There are a plurality of reinforcing ribs 8 arranged in the horizontal direction, and a connecting steel plate 1-2 arranged in the vertical direction is respectively welded on both sides of the reinforcing ribs, and each of the connecting steel plates is respectively connected to the vertical The steel plates are vertically connected; (2) a grooved steel plate 4 is installed on the outer edge of each connecting steel plate 1-2 in the vertical direction through a screw rod connection; (3) the large steel templates on both sides of the inner corner of the installation wall 3; (4) On the large steel formwork 3, a plurality of formwork back flutes arranged along the ho...

Embodiment 2

[0041] (1) Install the negative angle steel formwork at the internal corner of the wall, and the negative angle steel formwork includes two vertical steel plates 1-1 welded at right angles, and are connected at intervals along the height direction of the vertical steel plates 1-1 between the two vertical steel plates There are a plurality of reinforcing ribs 8 arranged in the horizontal direction, and a connecting steel plate 1-2 arranged in the vertical direction is respectively welded on both sides of the reinforcing ribs, and each of the connecting steel plates is respectively connected to the vertical The steel plates are vertically connected; (2) a grooved steel plate 4 is installed on the outer edge of each connecting steel plate 1-2 in the vertical direction through a screw rod connection; (3) the large steel templates on both sides of the inner corner of the installation wall 3; (4) Install reinforcing plates 9 at regular intervals between the channel steel plate 4 and ...

Embodiment 3

[0044] (1) Install the negative angle steel formwork at the internal corner of the wall, and the negative angle steel formwork includes two vertical steel plates 1-1 welded at right angles, and are connected at intervals along the height direction of the vertical steel plates 1-1 between the two vertical steel plates There are a plurality of reinforcing ribs 8 arranged in the horizontal direction, and a connecting steel plate 1-2 arranged in the vertical direction is respectively welded on both sides of the reinforcing ribs, and each of the connecting steel plates is respectively connected to the vertical The steel plates are vertically connected; (2) a grooved steel plate 4 is installed on the outer edge of each connecting steel plate 1-2 in the vertical direction through a screw rod connection; (3) the large steel templates on both sides of the inner corner of the installation wall 3; (4) Install reinforcing plates 9 at regular intervals between the channel steel plate 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com