Full-glass-reinforced-plastic box-type cable chute

A technology of cable trench and FRP, which is applied in the direction of cable installation, ground cable installation, pipe support, etc. It can solve the problems of inconvenient opening, inability to cross work, and large gaps, etc., so as to achieve a good working environment for cables and improve work efficiency. The effect of high surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

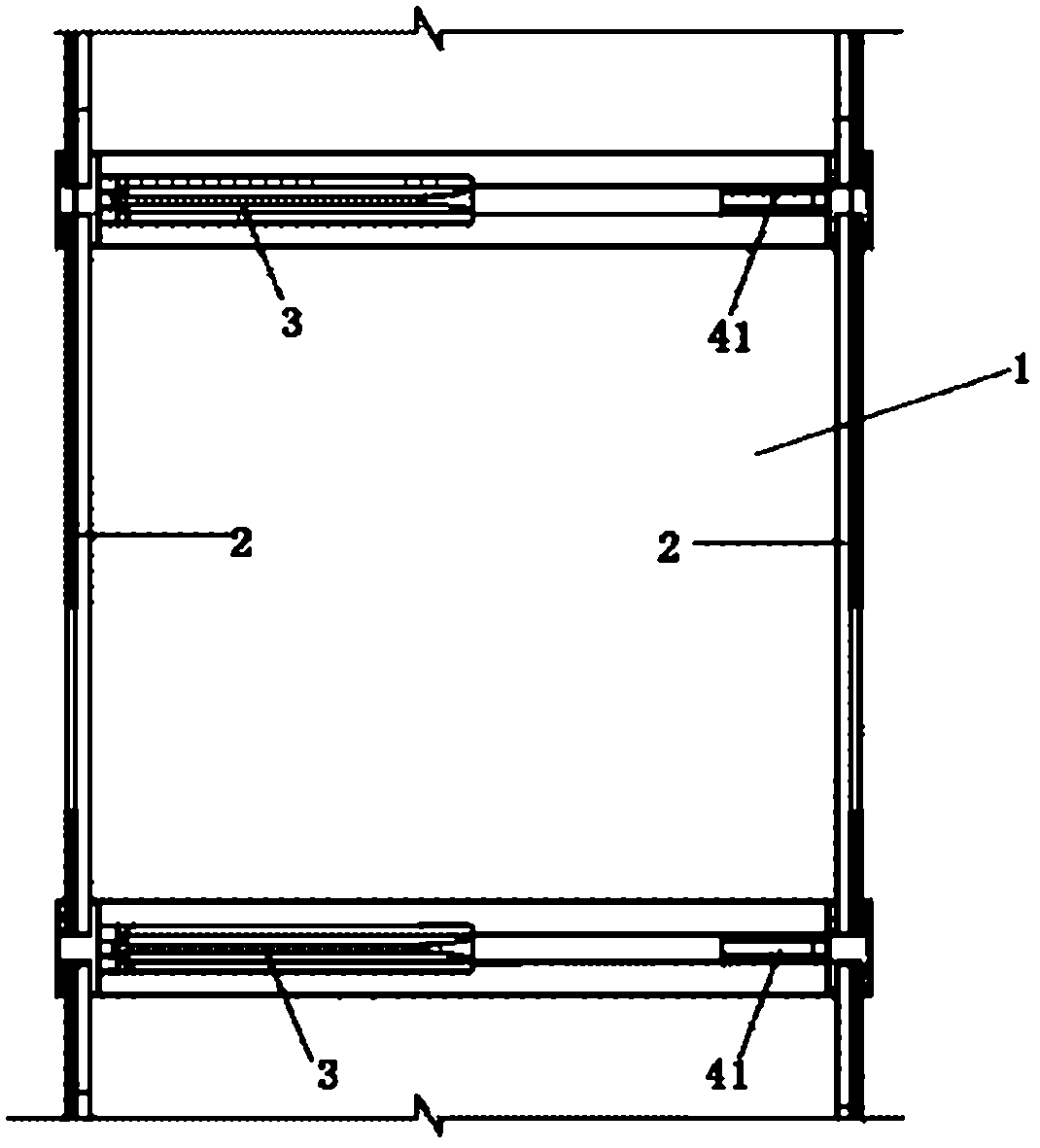

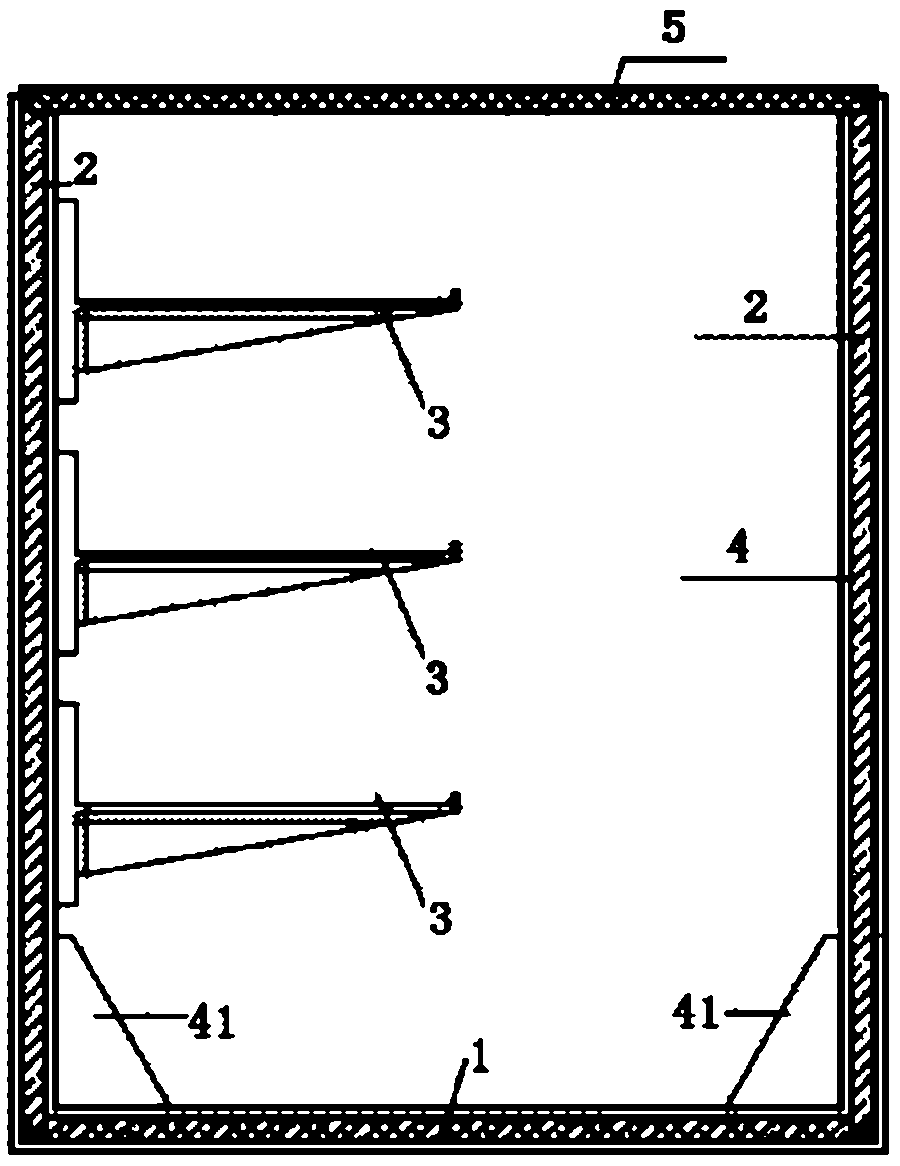

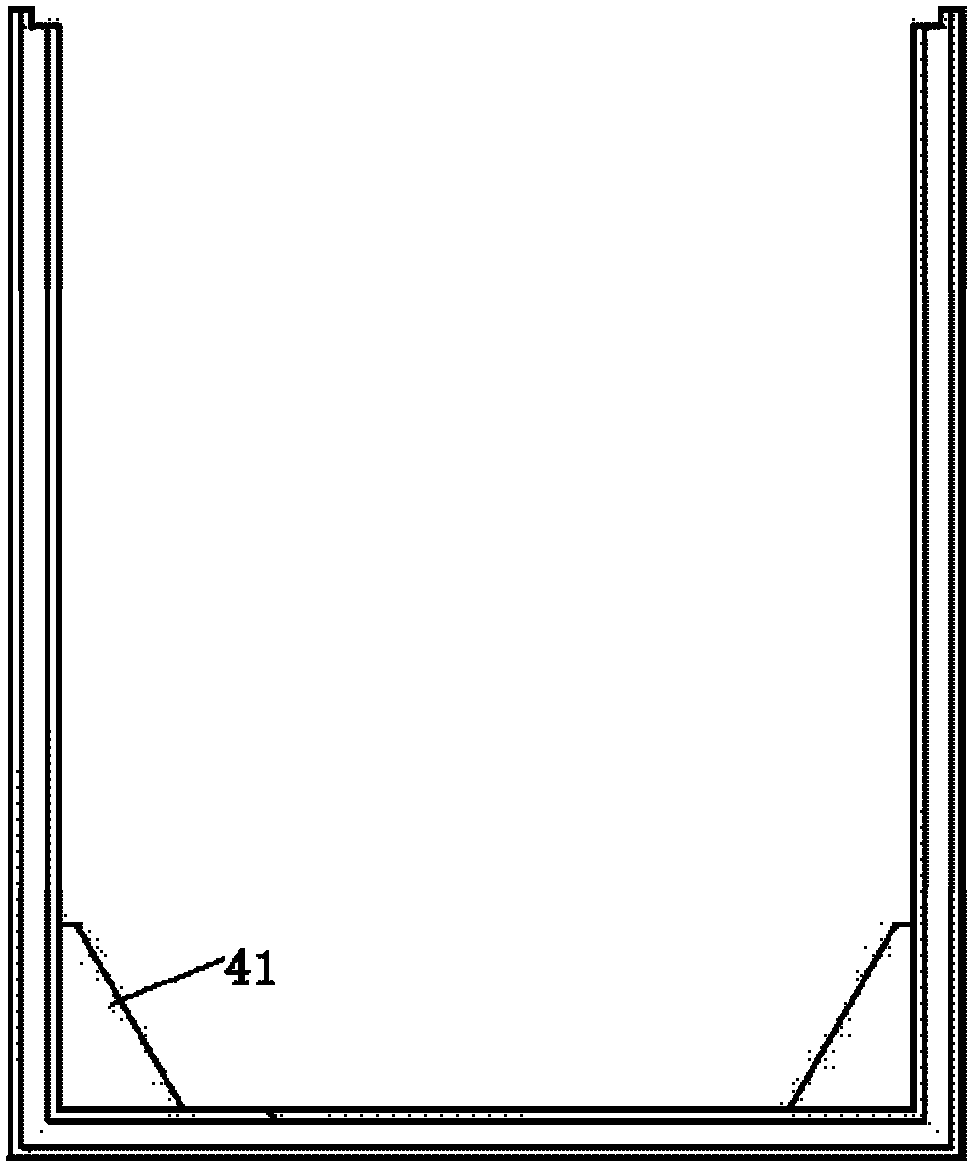

[0020] Such as figure 1 , figure 2 , image 3 As shown, an all-glass fiber reinforced plastic box-type cable trench, the cable trench is made of glass fiber reinforced plastic material, the cable trench includes a U-shaped column 4, a bottom plate 1, a side plate 2, a cover plate 5 and a bracket 3, and the U-shaped The lower end of the column 4 is fixed on the bottom plate 1, the left and right sides of the U-shaped column 4 are fixed on the side plate 2, the bracket 3 is fixed on the U-shaped column 4, and the cover plate 5 is fixed on the U-shaped column 4 upper end.

[0021] Divide the cable trench into 800mm long sections according to the distance between the cable brackets for design, the manufacturer mass-produces them, and splices them on site according to the required length. One U-shaped column 4 is arranged at a distance of 800mm. The U-shaped column 4 adopts an H-shaped slot. When installing, insert the side panels and bottom plates on both sides into the notch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com