Box culvert pushing construction method integrating comprehensive grouting, pressure maintaining and pipe roof support

A technology of pipe curtain and box culvert, applied in the direction of road bottom layer, mining equipment, earthwork drilling, etc., can solve the problems of large settlement of road surface and difficult jacking, and achieve the effects of controlling settlement, effective water blocking and pressure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

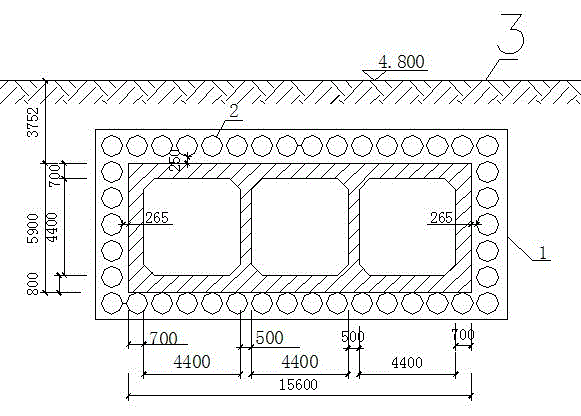

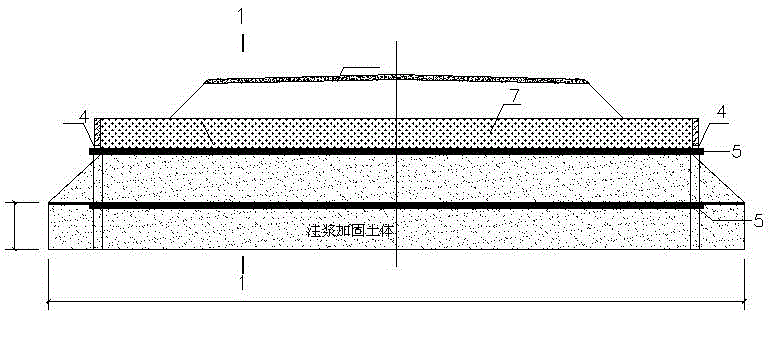

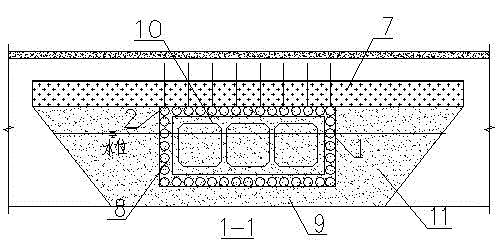

[0042] Such as Figure 1 to Figure 8 As shown, the water transfer box culvert of the South-to-North Water Diversion Project passes through the Tianjin-Baobao Expressway under Yangfen Port. The following innovative technologies have been adopted for the water transfer box culvert of the South-to-North Water Transfer Project, and it has been successfully promoted. The road surface settlement meets the design requirements.

[0043] 1. Multiple comprehensive grouting, see attached figure 1 Shown:

[0044] Multiple low-pressure pulse reinforcement grouting is performed on the top of the pipe curtain to form a cement-soil roof cover. The purpose is to prevent the muddy water tank of the shield head from being under high pressure during the construction of the pipe curtain, arching and cracking the road surface, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com