Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128 results about "Aluminite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminite is a hydrous aluminium sulfate mineral with formula: Al₂SO₄(OH)₄·7H₂O. It is an earthy white to gray-white monoclinic mineral which almost never exhibits crystal form. It forms botryoidal to mammillary clay-like masses. It has a very soft Mohs hardness of 1–2 and a specific gravity of 1.66–1.82.

Extraction of Sulfate from Water

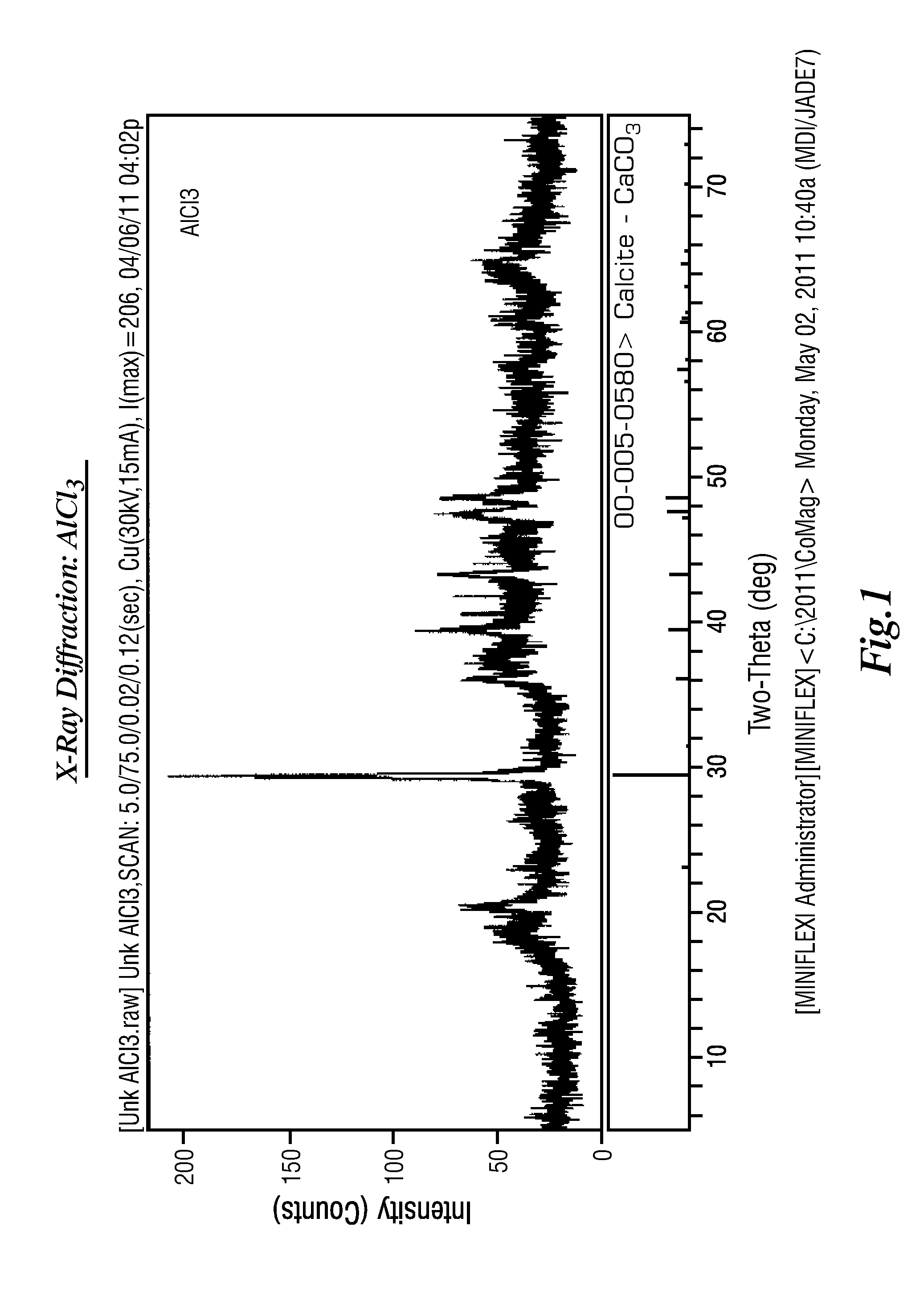

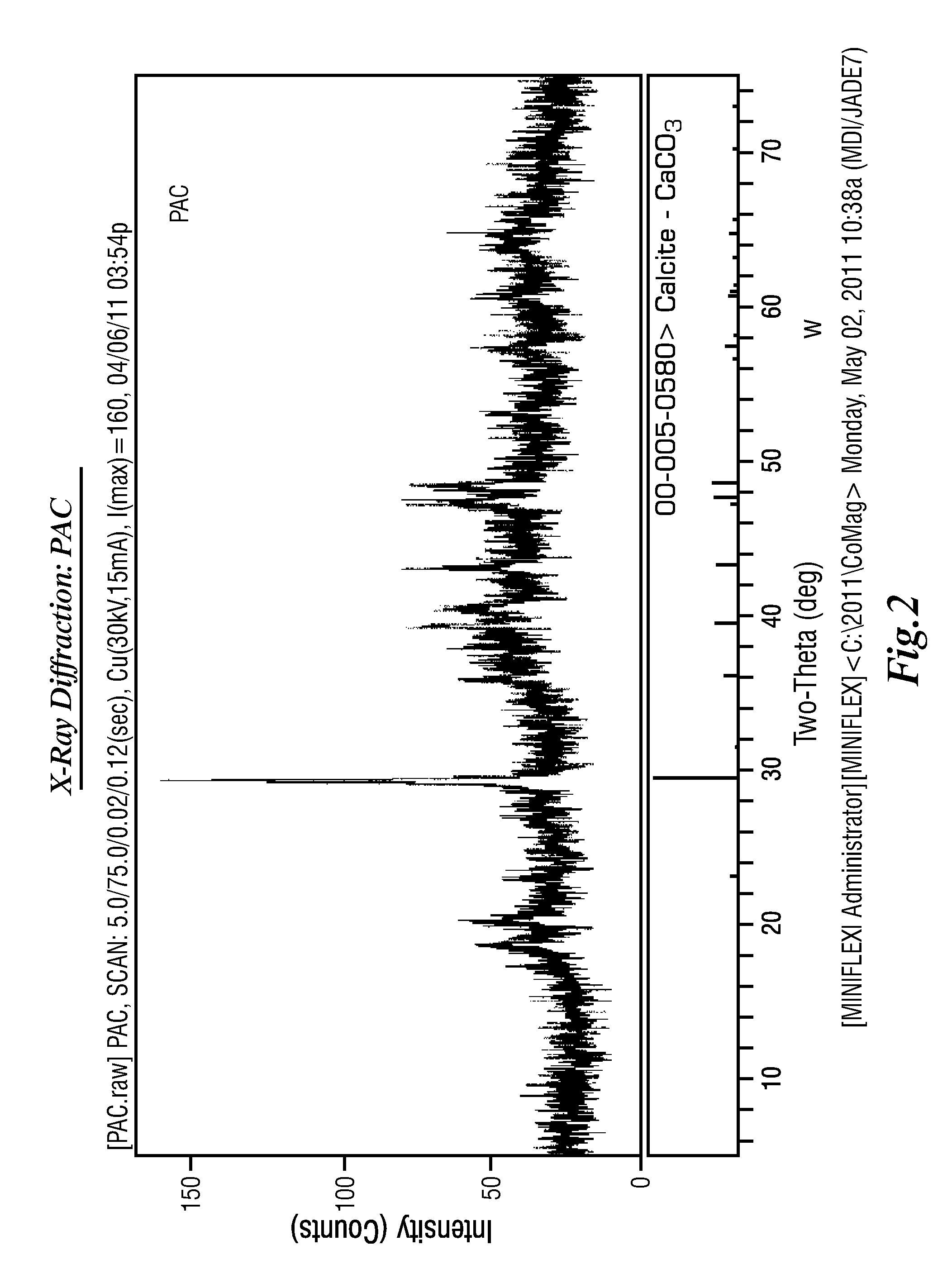

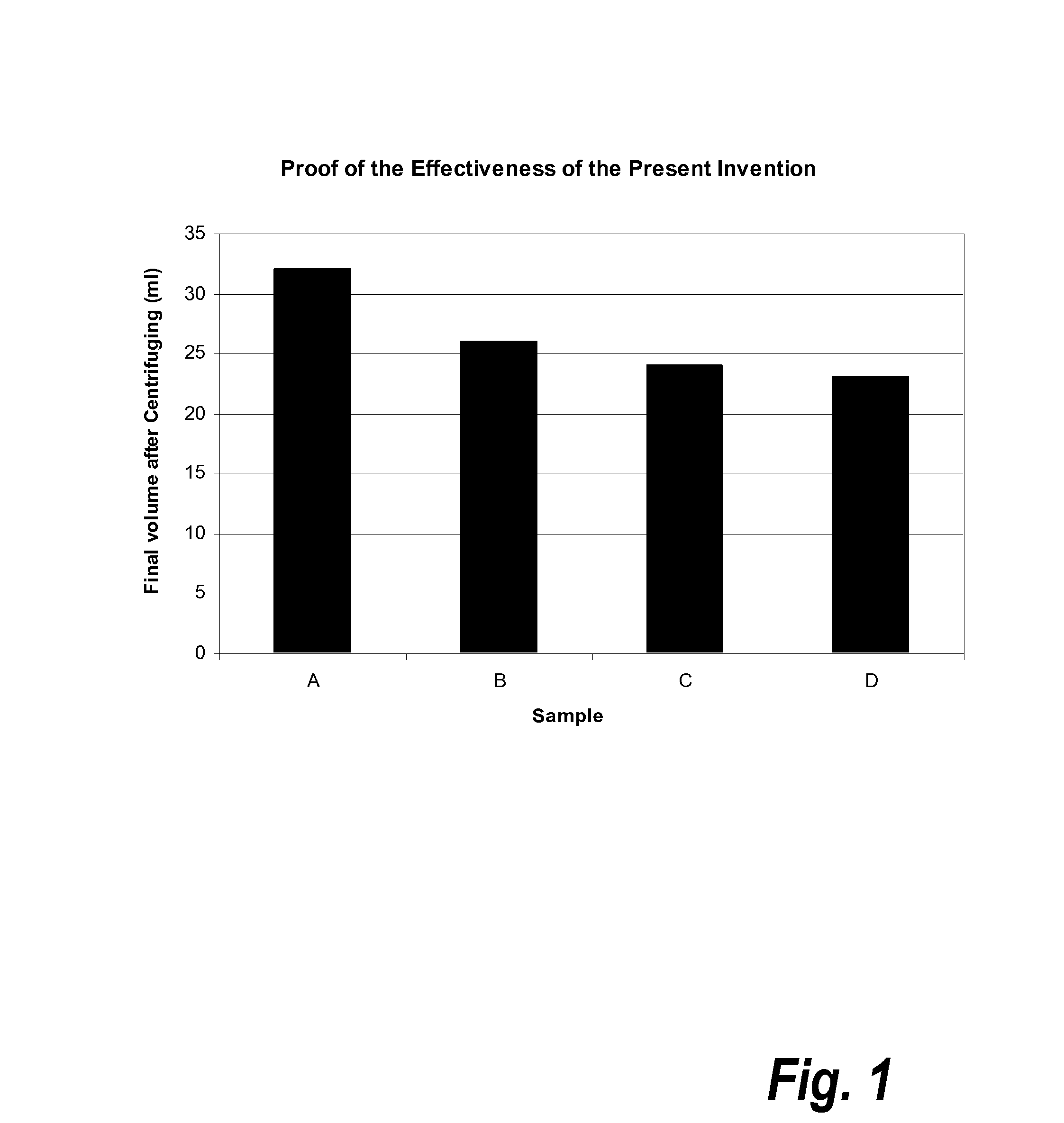

InactiveUS20120031850A1Reduce metal contentLess soluble in waterSedimentation separationRadioactive contaminantsAluminium chlorideAluminite

Sulfate anions and divalent metal ions, such as magnesium, strontium and barium, in water are removed by treating the water with polyaluminum chloride, usually together with lime, to form ettringite and similar crystalline species which are readily removable by settling, filtration and the like. Iron is also removed by oxidation in a variation of the process. The process is particularly useful for treating aqueous solutions used in well treatment, where flowback fluids can provide some of the divalent metal ions necessary to form the ettringite-like materials, thus reducing the amount of lime otherwise necessary and further facilitating recycling of the fluid.

Owner:SMART CHEM SERVICES LP

Alkali-free chloride-free liquid concrete enhancer and preparation method thereof

The invention relates to an alkali-free chloride-free liquid concrete enhancer and a preparation method thereof, wherein the enhancer mainly comprises the following materials according to weight percentages: 20-80% of anhydrous aluminum sulfate, 5-20% of triethanolamine, 0-0.2% of stabilizer, and 15-60% of water. The concrete enhancer is lower in cost, the preparation process is simple, the production of the ettringite in the early stage is increased when the concrete enhancer is added into a concrete mixture, so that more chemical bonds with stronger binding forces are produced among cement hydration particles, the Van der Waals' force is replaced the binding force of a cementing material is increased, the strength of the cement and concrete is reached, the quality and the property of the concrete material are improved, and the amount of consumed concrete cement is reduced.

Owner:LUOYANG INST OF SCI & TECH

Effective Approach to Preventing and Remedying Distresses in Soils and Construction Materials

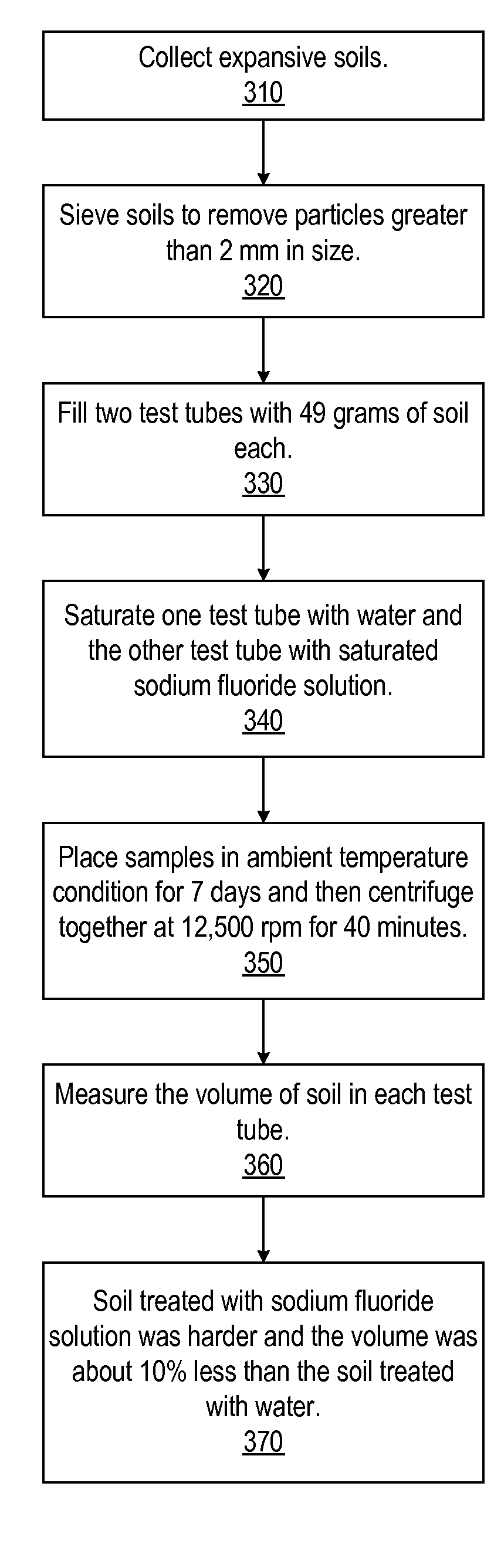

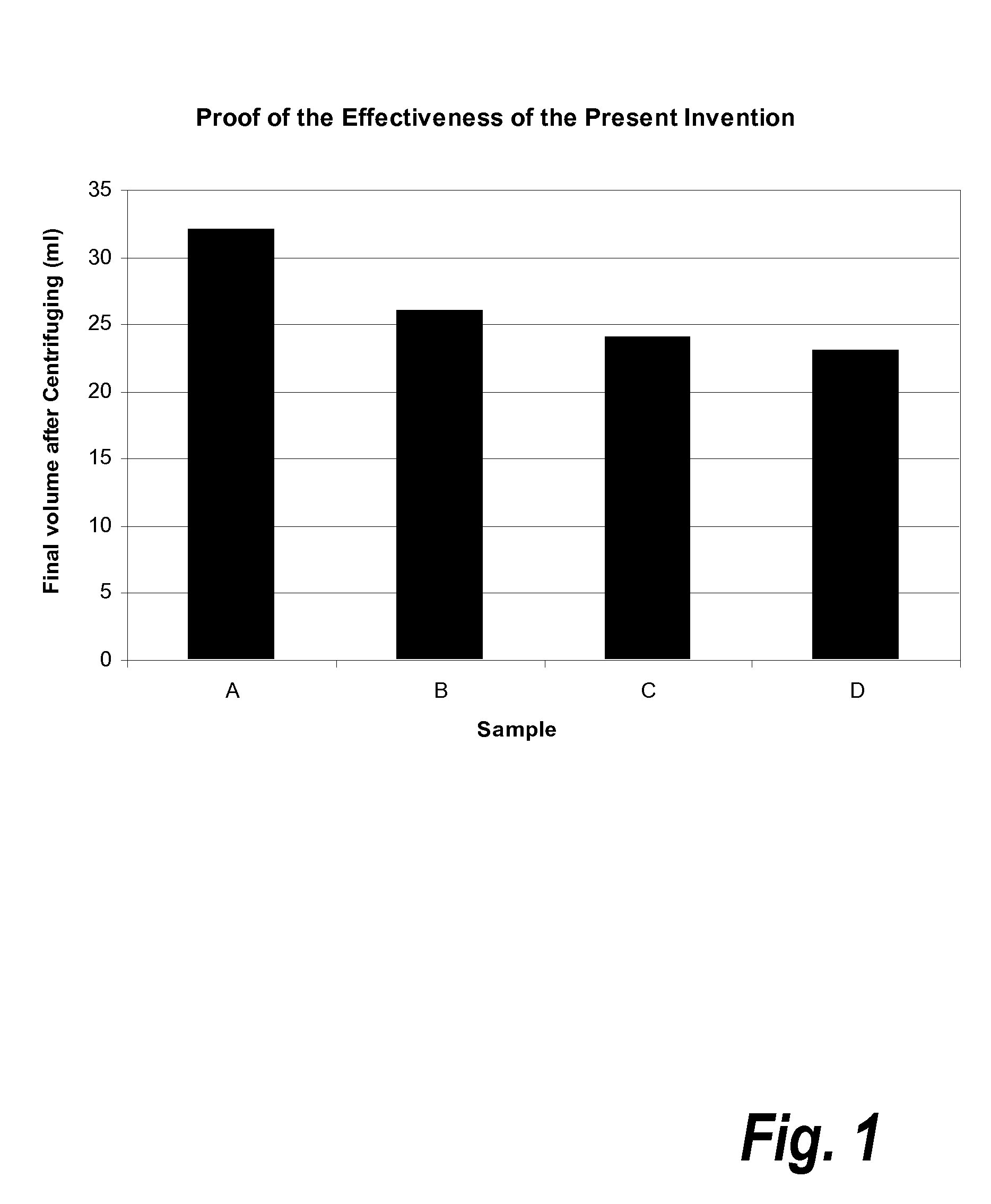

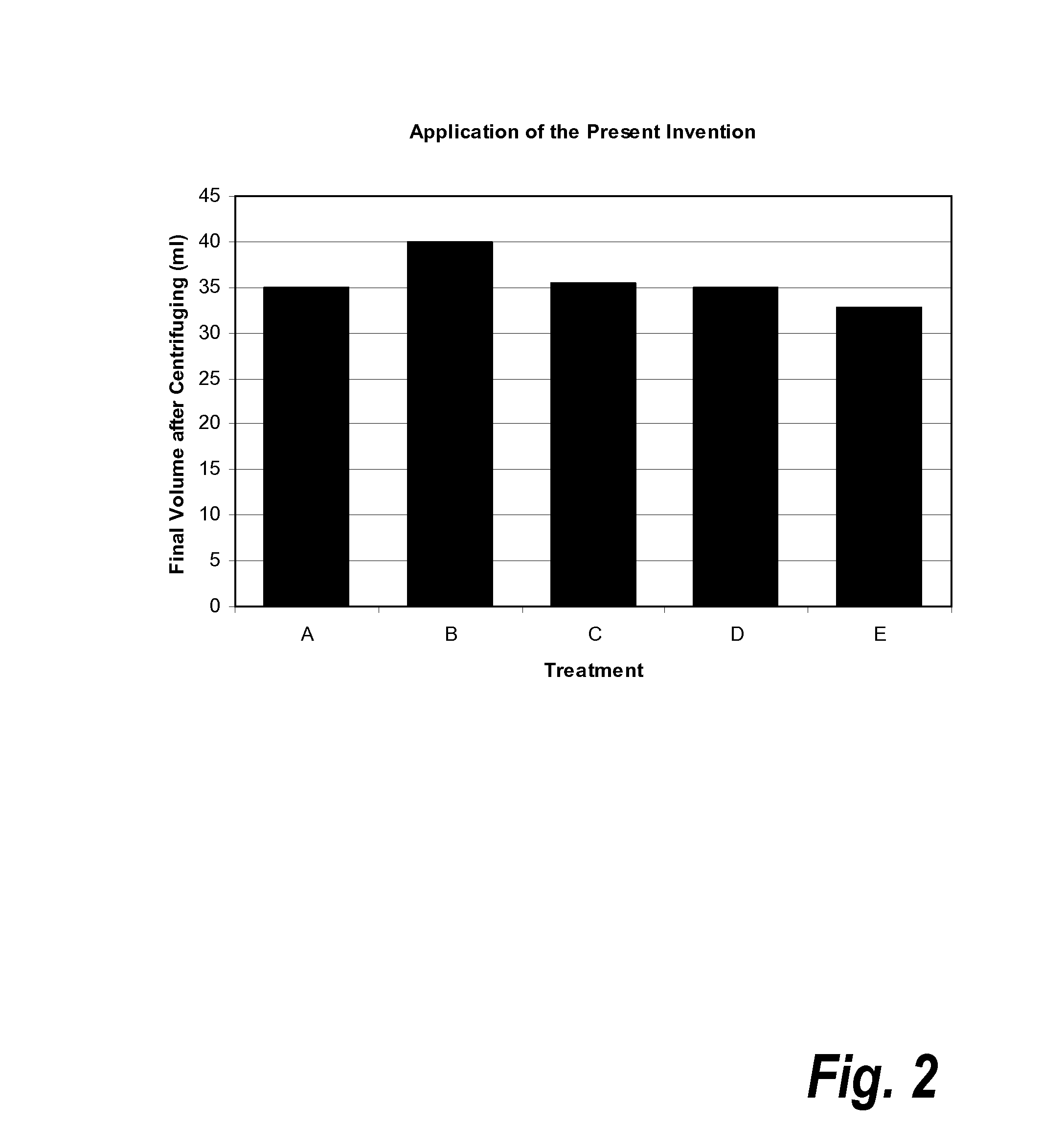

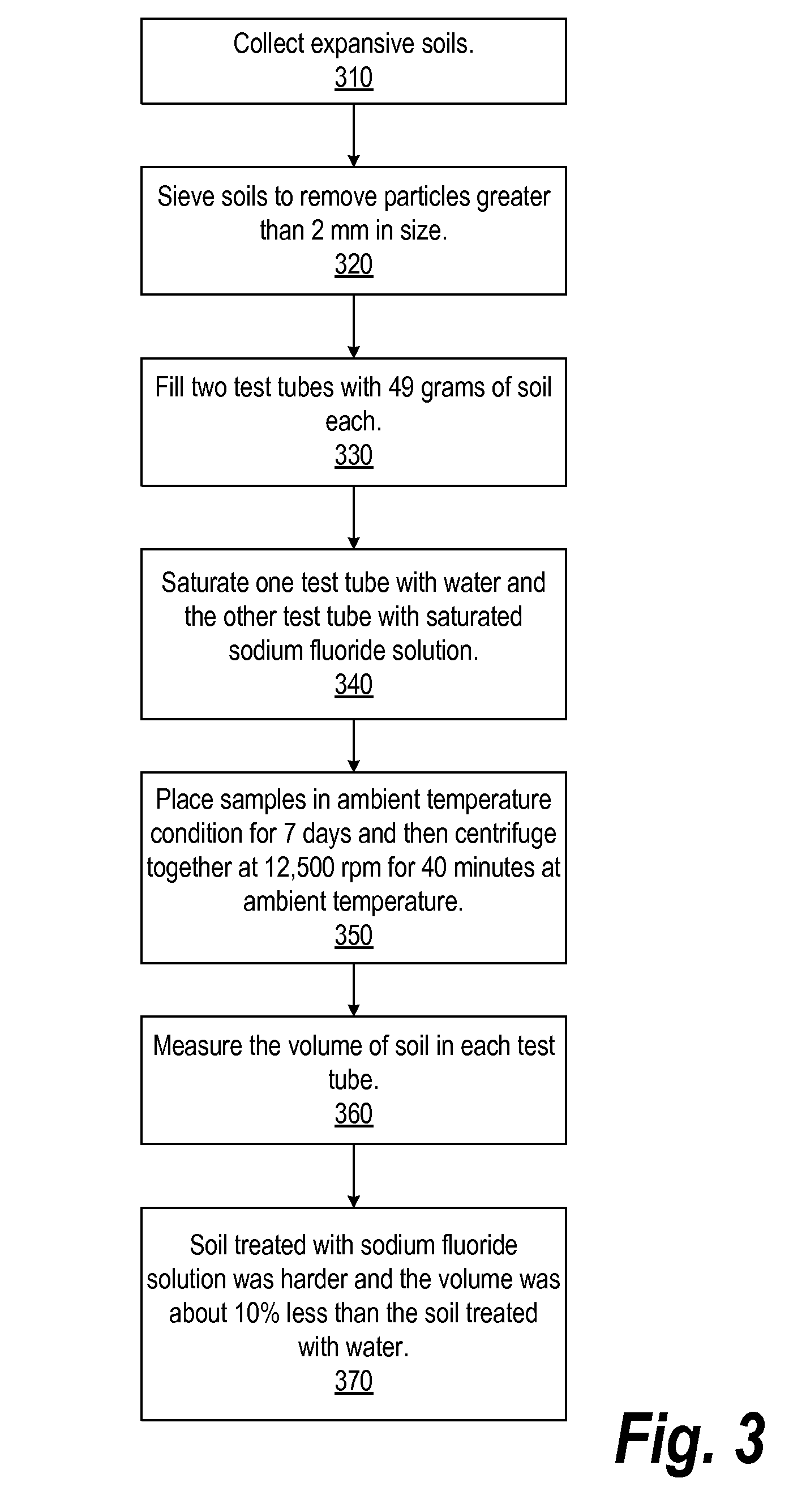

InactiveUS20110033247A1Efficient and effectiveReduce riskOrganic fertilisersSoil conditioning compositionsSulfateEngineering

This invention describes a simple and effective method, through introducing fluoride ion releasing agent / salt(s), such as sodium fluoride, for preventing, reducing or eliminating the undesirable construction heave / expansion / distresses / damage, characterized by loss of dimensional stability and integrity of expansive soil layers or concrete structural elements, primarily caused by the formation of ettringite or similar minerals. We demonstrated the technology that can be easily applied to new construction sites and to the sites where repair / retrofit of the existing or potential distresses in soil subgrade, base, subbase, or construction materials is needed. Experiments have demonstrated the effectiveness and efficiency of the technology with applications to stabilization of soils with all range of aluminum and sulfate contents including more than 3000 ppm of sulfate, and to treating cementitious construction materials. This invention can also extend the application of lime to stabilization of sulfate-rich soils and remedy of foundation movement or tilting of buildings caused by the formation of ettringite.

Owner:AMERICAN ACCUTECH

High efficiency cement composite grinding additive and preparation method thereof

InactiveCN101618955AIncrease incorporationIncrease productionSolid waste managementAluminiteSodium metasilicate

The invention discloses a high efficiency cement composite grinding additive, comprising the following raw materials by weight percent: 10-25% of calcined gypsum, 10-30% of calcined aluminite, 20-40% of sodium metasilicate, 2-4% of triethanolamine, 0.5-2% of polyacrylate, 0.5-3% of dispersant and 20-30% of zeolite powder. The preparation method of the high efficiency cement composite grinding additive comprises the following steps: first selecting raw materials, then dripping liquid raw materials-triethanolamine and polyacrylate TH-1100 with a liquid pump in zeolite powder, then preparing reinforced grinding component with a dry powder mixer, finally adding the reinforced grinding component, calcined gypsum, calcined aluminite, sodium metasilicate and dispersant in a kneader to mix for 20-30min and obtaining the product. The product has prominent grinding aid, and can increase the hourly output of mills by 10-15%, reduce the consumption of electricity, and increase the cement 3-day compression strength and the cement 7-day compression strength by more than 20% and the cement 28-day compression strength by 10-15%.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Coagulation controllable type cement based pore sealing material and application method thereof

InactiveCN106186976AExtended hydration timeCompensates for hydration shrinkageDrilling compositionAl powderAluminite

The invention relates to a coagulation controllable type cement based pore sealing material and application method thereof. A sulfoaluminate-silicate composite cement system with a certain ratio is adopted, a proper amount of industrial aluminum powder, a high efficient water reducer, and a resin type polymer material is added; an individual grinding technology is adopted, sulfoaluminate cement clinker and resin are grinded together at first so that fine resin particles can be adsorbed on the surface of the mineral particles in sulfoaluminate cement clinker; during the construction process, after the material is contacted with water, the resin wrapped on the surface of the clinker particles reacts with water to form a crosslinking coating film, the hydration of sulfoaluminate minerals is sustained-controlled therefore; the forming speed and forming amount of hydration products such as ettringite (Aft), hydrated aluminate, and the like can be adjusted; the setting time of sealing materials is effectively delayed; the construction becomes convenient, moreover, the sealing material can continuously and slightly expands in the sealed holes, a high early strength is provided for the material, the hydration shrinkage of silicate phase is compensated at the same time, and thus the pore sealing material can be used for a long time.

Owner:UNIV OF JINAN

Industrial solid waste autoclaved aerated concrete block and preparation method thereof

The invention discloses an industrial solid waste autoclaved aerated concrete block and a preparation method thereof. The concrete block uses fly ash, carbide slag, red mud, lime, desulfurized gypsumand cement as main raw materials and aluminum powder, sodium hydroxide, water glass and the dispersing agent silica fume as additives; the coal ash reacts with components in the carbide slag to generate ettringite, so the strength of the concrete block can be enhanced; a large amount of aluminum oxide contained in the red mud can a replace part of lime and undergo a hydration reaction with the cement, and the aluminum oxide in the red mud can react with calcium hydroxide in the carbide slag, so the strength of the block is enhanced; the coal ash, the carbide slag and the red mud react with oneanother to generate hydrated calcium silicate and hydrated calcium aluminate, so the structural compactness of the block can be improved; and the additives can enhance the foaming stability of the aluminum powder and improve the early strength of the block under an alkaline condition. The method is green and environment-friendly, and the waste of non-renewable resources is effectively reduced.

Owner:张延年

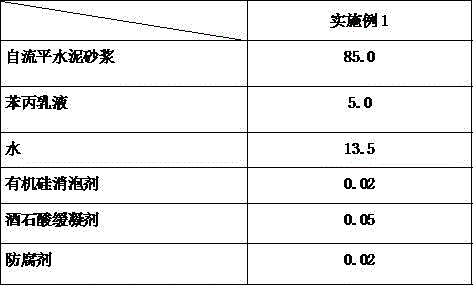

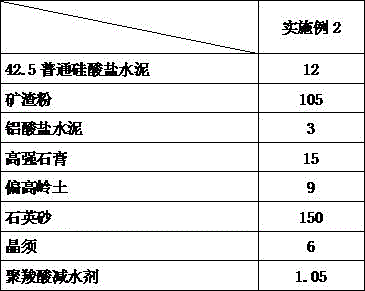

Whisker reinforcement-based self-leveling cement mortar and application thereof

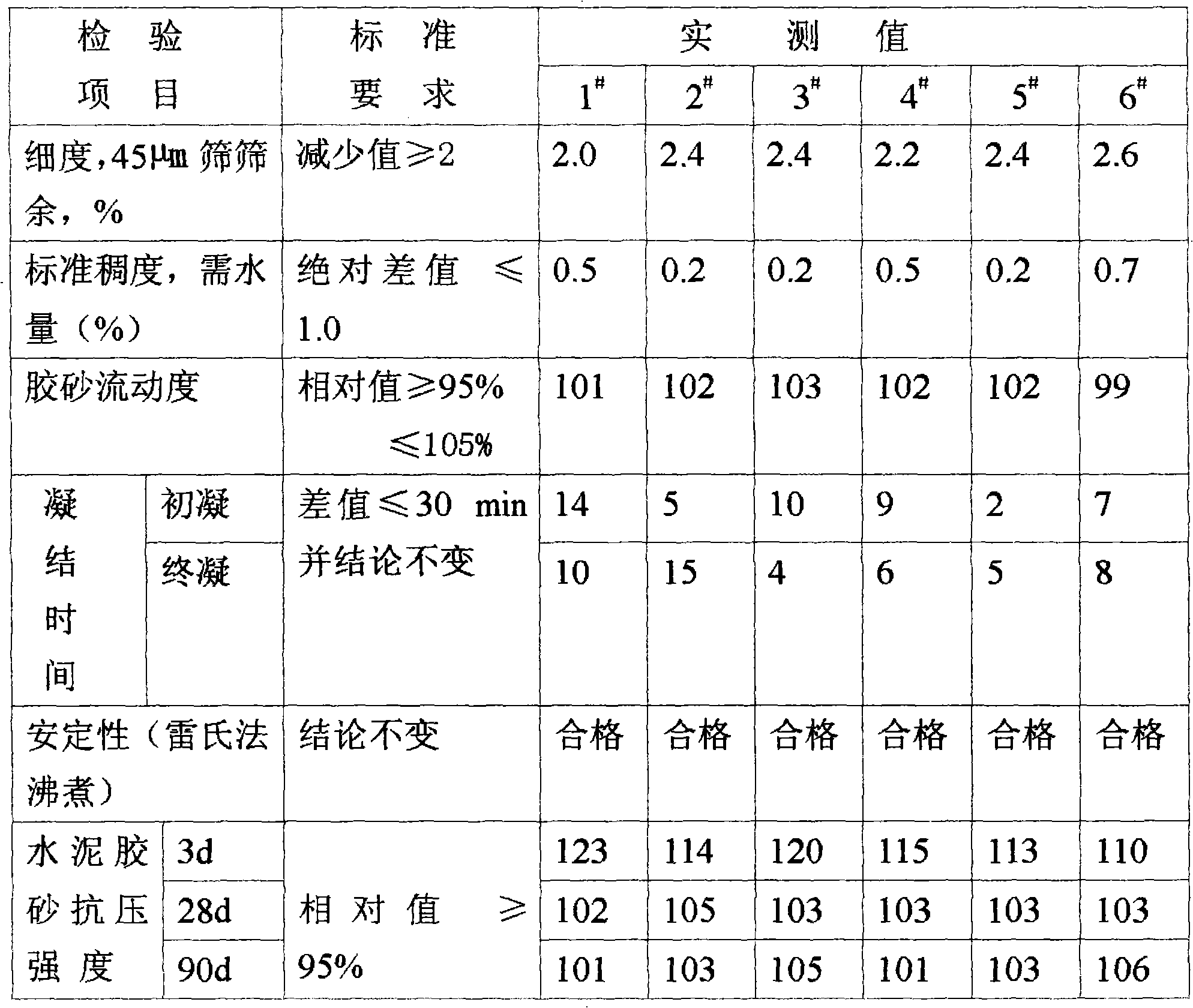

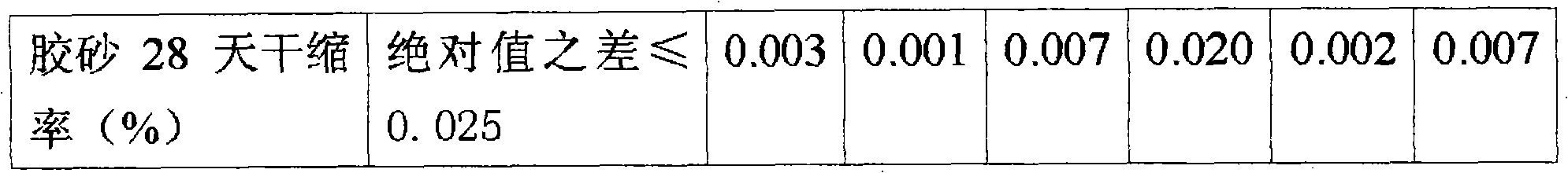

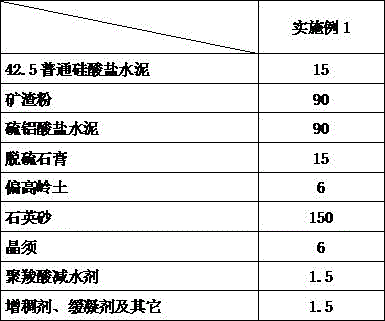

The invention discloses whisker reinforcement-based self-leveling cement mortar. The whisker reinforcement-based self-leveling cement mortar comprises the following components in parts by weight: 10 to 20 parts of ordinary Portland cement, 50 to 150 parts of slag powder, 3 to 20 parts of special cement, 10 to 20 parts of gypsum, 5 to 10 parts of metakaolin, 100 to 160 parts of quartz sand, 1 to 10 parts of a crystal whisker and 1 to 1.5 parts of a water-reducing agent, wherein the special cement adopts sulphoaluminate cement or aluminate cement; the gypsum adopts one of or a mixture of more than two of high-strength gypsum, fluorgypsum, desulfurized gypsum and citric acid gypsum; and the crystal whisker adopts one of or a mixture of more than two of gypsum crystal whiskers, a magnesium hydroxide crystal whisker, a magnesium oxide crystal whisker, an ettringite crystal whisker and a calcium carbonate crystal whisker. A terrace prepared from the whisker reinforcement-based self-leveling cement mortar has high surface hardness and high anti-compression and anti-bending strength, and can meet the wear-resistant requirement of most occasions.

Owner:江苏蓝圈新材料股份有限公司

Grounding calcium bentonite-based resistance-reducing agent

ActiveCN105957577AImprove conductivityHas a buffering effectLine/current collector detailsOther chemical processesAluminiteFiber

The invention provides a grounding calcium bentonite-based resistance-reducing agent, comprising(according to mass percent) 1-99%calcium bentonite; 1-30% carbon fiber; 0.1-30% ammonium chloride; 0.1-30% calcium oxide; 0.1-30% zinc powder; 0.1-30% nickel powder; 0.1-60%ammonium persulfate; 0.1-15% sodium molybdate; 5-60% electroconductive cement; 0.1-6% grapheme; 0.1-30%aluminite powder; 0.1-60% aniline; and 0.1-15% sodium tripolyphosphate. The grounding calcium bentonite-based resistance-reducing agent is a physical grounding resistance-reducing agent, overcomes the disadvantage of difficulty in package and construction of a present resistance-reducing agent, solves the problems of stronger corrosivity of the strong electrolyte and strong acid and strong base in the present resistance-reducing agent, and the problem of incapability of long-term normal service of a grounding body, and is suitable for acid soil regions, mountain regions, rock, sand and high corrosion regions.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +2

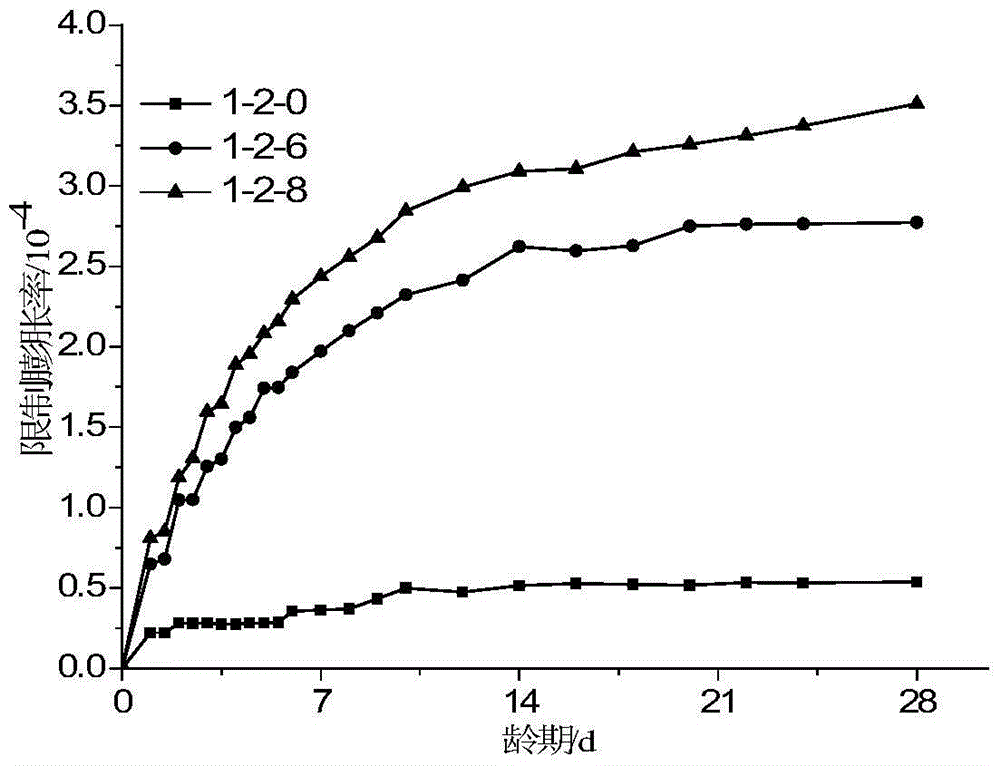

Secondary ettringite type expanding agent and preparation method and application thereof

ActiveCN102167536AReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

Preparation method of pressed aluminum-containing explosive

InactiveCN104725167AImprove response completenessFully contactedNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAcetic acidEthyl ester

The invention provides a preparation method of a pressed aluminum-containing explosive. According to the preparation method, the pressed aluminum-containing explosive is mainly prepared from 3,4-dinitrofurazanfuroxan and aluminite through direct granulation in the presence of a small amount of additives such as a binder and a desensitizing agent. The method comprises the following steps: firstly, dissolving 3,4-dinitrofurazanfuroxan by using ethyl acetate at a temperature of 50-60 DEG C; then, adding a surfactant, stirring for 20min, and adding the solution into aluminum powder while stirring; and finally, adding a binder and a desensitizing agent solution, stirring for 30min; after the obtained material becomes dough-shaped, sieving so as to form particles with a particle size of 1-2 mm, and drying, thus obtaining the aluminum-containing explosive modeling powder. By using the preparation method of an aluminum-containing explosive provided by the invention, a mixed explosive with good formability and high detonation velocity can be prepared, so that defects in traditional direct preparation methods in the background art are overcome.

Owner:XIAN MODERN CHEM RES INST

Wear-resistant repairing additive of lubricating oil and production thereof

A wear-proofing and repairing additives of lubricant oil comprises Silica dust1-10wt%; MgO 0.5-5wt%; aluminite powder 20-70wt%; titanic powder 0.5-5wt%; nickel powder 0.1-1wt%; chrome oxide 0.1-1wt%; lithium nitration 1-5wt%; gold powder 0.1-1wt%; and boracic powder 5-20wt%. All the said components are milled be particles of 50um-3nm uniformly. They can increase hardness of friction pair surface, improve wear resistance, repair defects, and prolong operating life. They can be used for steam cylinders, compressors, etc.

Owner:王爱国 +1

Efficient expansion clinker for cement concrete, preparation method of efficient expansion clinker and application of efficient expansion clinker

ActiveCN105712642AHigh expansion efficiencyHigh strengthCement productionFerric hydroxideMechanical property

The invention relates to efficient expansion clinker for cement concrete, a preparation method of the efficient expansion clinker and application of the efficient expansion clinker. The efficient expansion clinker is composed of, by weight, 30-60wt% of f-CaO, 5-40wt% of Fe2O3, 3-10wt% of C2S, 2-10wt% of C4AF, 3-15wt% of SiO2, 3-12wt% of Fe and 1-8wt% of C4A3S. The preparation method of the efficient expansion clinker includes: grinding 60-80wt% of limestone, 15-30wt% of pyrite cinders and 5-10wt% of rice husk ash, and well mixing to obtain raw materials; calcining the raw materials for 30-120min at the temperature of 1100-1350 DEG C to obtain the efficient expansion clinker. The expansion clinker can be mixed with dispersive carriers (such as blast furnace slag and copper slag) to form an efficient expanding agent for cement concrete. The expansion clinker and the expanding agent integrate three expanding sources including calcium hydroxide, ferric hydroxide and ettringite and are greatly promoted in expanding performance as compared with an ettringite type expanding agent with a single expanding source; due to a hydraulic binder component, later-stage mechanical properties of the cement concrete can be enhanced to some extent.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Red mud steaming and pressurizing product and preparation method thereof

InactiveCN101628443AStrong and stable structureStrong densitySolid waste managementMixing operation control apparatusChemical LinkageCalcium silicate

The invention discloses a red mud steaming and pressurizing product and a preparation method thereof, which aim to solve the problem of comprehensive utilization limitation caused by alkali-contained red mud. The preparation method of the red mud steaming and pressurizing product comprises the following steps: premixing a raw material mainly comprising a low-temperature ceramic plaster material and red mud and pulverized fuel ash industrial waste residues to form a chemical bonding ceramic body, tobermorite and an ettringite crystal which adopt a silicon-aluminum long chains as a main structure; forcibly pugging the premixed product, carrying out secondary crushing dispersion and charging the premixed product into a vibration molding machine to mold; procuring a molded blank for a period of time and placing the blank into a steaming and pressurizing kettle to steam and pressurize so as to prepare the red mud steaming and pressurizing product. The product prepared by the method mainly comprises the chemical bonding ceramic body, the tobermorite and the ettringite crystal which adopt the silicon-aluminum long chain as the main structure and is divided into an inner layer and an outer layer, wherein an inner hollow cavity is formed between the inner layer and the outer layer; and the heavy metal and a radioactive substance in the red mud are partitioned and surrounded in the inner layer by the inner hollow cavity.

Owner:李为成

Bentonite binder of light batten for building partition

The invention discloses a bentonite binder of a light batten for a building partition. The binder comprises the following raw materials in parts by weight: 100-150 parts of 42.5 common silicate cement, 10-15 parts of vinyl acetate and styrene copolymerized gel powder, 100-120 parts of quartz sand, 4-6 parts of plant fiber, 3-4 parts of alunite powder, 3-5 parts of quick lime, 10-20 parts of instant powder sodium silicate, 8-12 parts of aluminite powder,10-15 parts of bentonite, 5-10 parts of coal ash and 1-2 parts of hydroxyethyl methyl cellulose. The bentonite binder of the light batten for the building partition provided by the invention is strong in binding force, the probability of layering and falling is reduced, the engineering quality is ensured, and the problems of hollowing, cracking and the like after long time use can be avoided, so that the durability is improved. The binder provided by the invention is pre-dry mixed and mixed and is stable in quality; when in use, the kaolin binder is mixed with a proper amount of water and is simple and convenient to construct. Wastes such as slag powder can be effectively utilized, and no toxic or harmful additives are generated, so that the binder completely satisfies the environmental-friendly demand, and is safe and pollution-free.

Owner:CHIZHOU BANZHU TECH

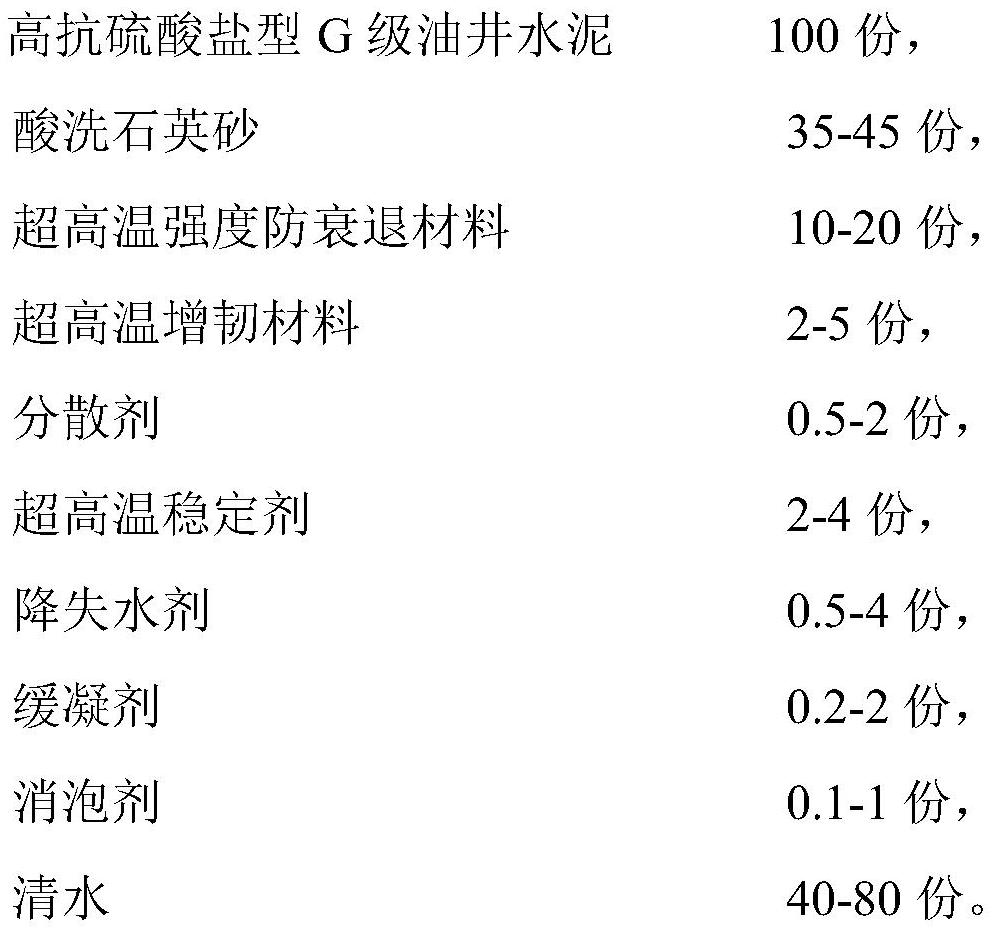

Ultrahigh-temperature high-strength tough cement paste system

The invention relates to an ultrahigh-temperature high-strength tough cement paste system which is composed of the following components in parts by weight: 100 parts of high-sulfate-resistance G-gradeoil well cement, 35-45 parts of acid-pickled quartz sand, 10-20 parts of an ultrahigh-temperature strength anti-recession material, 2-5 parts of an ultrahigh-temperature toughening material, 0.5-2 part of a dispersing agent, 2-4 parts of an ultrahigh-temperature stabilizer, 0.5-4 part of a fluid loss agent, 0.2-2 part of a retarder, 0.1-1 part of a defoaming agent and 40-80 parts of clear water.The acid-pickled quartz sand is refined quartz sand subjected to acid treatment, the ultra-high-temperature strength anti-recession material is a mixture of two or more of wollastonite, kyanite, calcined flint clay and aluminite, the ultra-high-temperature toughening material is a halloysite nanotube, the dispersing agent is a polycarboxylic acid dispersing agent for oil well cement, and the ultra-high-temperature stabilizer is a mixture of bentonite, magnesium aluminum silicate and welan gum. The strength of set cement does not decline under the ultra-high temperature condition, the toughnessis good, and the well cementation quality of unconventional oil and gas wells and high-temperature deep wells is effectively improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Soil curing agent based on desulfurized fly ash activity and preparation method and application thereof

InactiveCN104045293AAvoid the risk of volume instabilityRealize resource utilizationSoil preservationFluorescenceSlag

The invention discloses a soil curing agent based on desulfurized fly ash activity and a preparation method and application of the soil curing agent. The preparation method comprises the steps of performing chemical analysis or fluorescence analysis to obtain components of desulfurized fly ash and superfine slag powder characteristic substances, focusing on testing the content of sulfur trioxide in the desulfurized fly ash, and converting the content into the content of calcium sulfate; testing the content of aluminum oxide in the superfine slag powder; controlling calcium sulfate in the desulfurized fly ash and aluminum oxide in the superfine slag powder according to the classic structure 3CaO.Al2O3.3CaSO4.32H2O, of the ettringite molecule, wherein the mole ratio of calcium sulfate to aluminum oxide is no greater than 3:1; uniformly mixing the desulfurized fly ash and the superfine slag powder according to a pre-estimated ratio, and adding alkali excitant sodium hydroxide and zinc stearate, thereby preparing the novel soil curing agent. The activity of desulfurized fly ash is utilized, and meanwhile, the problem that the volume of the desulfurized fly ash is not stable is solved. The curing effect of the soil curing agent is better than that of a coal ash-lime stable roadbed material and is equivalent to that of a cement stable roadbed material, and the price is only 1 / 3 to 1 / 2 of that of the cement stable roadbed material.

Owner:SOUTHEAST UNIV

Components for preparation of environment-friendly and efficient Yixing clay alkaline teapot

InactiveCN106145887AImprove temperature resistanceImprove high temperature resistanceClaywaresEnvironmental resistanceAluminite

The invention discloses components for preparation of an environment-friendly and efficient Yixing clay alkaline teapot. The components comprise 3-20 parts by weight of Yixing clay, 1-10 parts by weight of aluminite and 3-16 parts by weight of kaolin, wherein the Yixing clay is mainly used for keeping the temperature, color, aroma and taste of tea; the aluminite is mainly used for neutralizing a bleaching agent in tap water and is good for body health; meanwhile, the kaolin is a high temperature resistant material and can improve the high temperature resistance of the Yixing clay alkaline teapot when added to the Yixing clay, and the kaolin also has smaller particle size than the Yixing clay, thereby being capable of making up for the defect of bubbles produced by the Yixing clay and improving the thermal insulation property of the alkaline teapot.

Owner:欧仁平

Liquid cement synergist and preparation method thereof

The invention relates to a liquid cement synergist, which is prepared from the following raw materials by weight percent: 40-70% of sodium thiosulfate, 0-40% of sodium aluminate, 5-20% of triethanolamine, 0-0.2% of stabilizer and the balance of water. The liquid cement synergist disclosed by the invention is low in cost, and simple in preparation technology; when the liquid cement synergist is added to a concrete mixture, the production amount of early ettringite can be improved, more chemical bonds with stronger binding force are generated among cement hydration particles to replace Van der Waals force, the cementing force of the cementitious material is improved, the strength of the cement and the concrete is improved, the quality and the property of the concrete material are improved, and the consumption of the concrete cement is reduced.

Owner:LUOYANG INST OF SCI & TECH

Process for cold pressing-solving-vacuum sintering preparation of foamed aluminum

The invention designs a kind of cold-press - dissolved - vacuum to agglutinate the preparation froth aluminum method, is the froth aluminum the preparation technology. The method including below process: In the 180~~200 goal aluminite powder, compared to is 40~~70% joins the average grain diameter according to the quality is 0.45~~1.00mm NaCl makes the hole medicinal preparation, and compared to joins 5% absolute ethyl alcohol according to the aluminite powder and the NaCl quality to carry on the intensive mixing; Above will match the good mix aluminite powder to lay aside in will rub has, will suppress the semifinished product under the 250~~350MPa pressure, then will set at the semifinished materials in the 75~~85deg.C water bath soaks causes NaCl to dissolve, again will use the deionized water repeatedly to wash eliminates remaining NaCl; After will go to NaCl the pressure semifinished product to agglutinate as for the vacuum oven, maintains in the stove vacuum degree 1*10 -3 power of exponent ~~1*10 -4 power of exponent Pa, will control 8-10deg.C / min to heat up the speed temperature rise and keeps warm 2-3h the stove to 540~~560deg.C, then will cool along with the stove to the room temperature system results in the froth aluminum. The invention merit lies in, technological process simple, the manufacture froth aluminum blowhole size even, the opening wall intensity is high controllably factor of porosity.

Owner:TIANJIN UNIV

Concrete accelerator

The invention discloses a concrete accelerator comprising the following components in parts by weight: 12-14 parts of naphthalene sulfonated formaldehyde condensates, 3-5 parts of efficient water reducing agent, 6-8 parts of calcium formate, 3-8 parts of sodium fluoride, 25-30 parts of cellulose, 16-20 parts of sodium metaaluminate, 8-12 parts of aluminum sulfate, 3-6 parts of aluminite, 4-8 parts of gas mud and 2-6 parts of silicon powder. The concrete accelerator has the beneficial effects that 1, the setting time is short: the initial setting lasts for 1-5min, the final setting lasts for 5-10min, and the optimal proportion is 3-5% of the dosage of a cementing material; 2, the concrete accelerator contains 1% of alkaline metal and lt and is nontoxic, tasteless and nonirritant; 3, the fineness is up to 80mum, and the content of screen tailings is less than 10%; 4, the early strength of the sprayed concrete is high, and the compressive strength preserving rate of the sprayed concrete with the age of 28 days is up to 80-100%; and 5, the concrete accelerator is good in cohesiveness for a sprayed material, antirust for reinforcing steel bars, capable of increasing the anti-permeability grade, rapid in setting, thick in one-step spray layer and capable of achieving a 130-mm sprayed arch and an over 200-mm sprayed wall.

Owner:LIUZHOU ZHENGLING GROUP

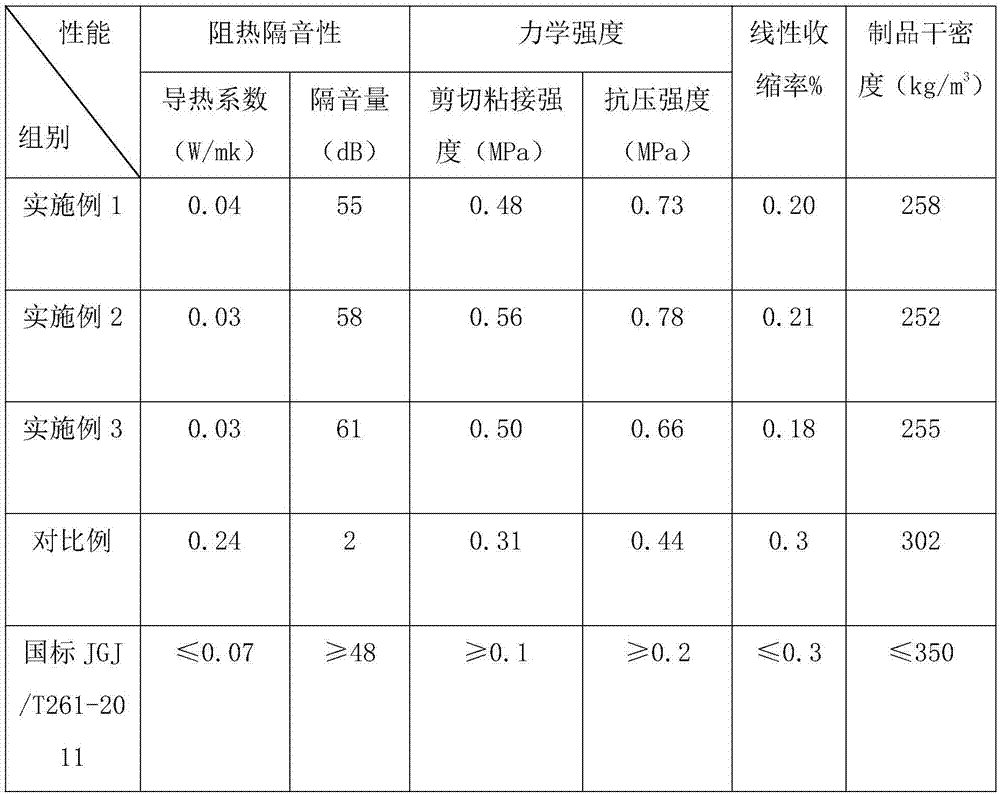

Modified diatomite thermal insulation mortar and preparation method thereof

The invention discloses modified diatomite thermal insulation mortar and a preparation method thereof. The mortar is prepared from the following raw materials in parts by weight: 80 to 100 parts of cement, 30 to 50 parts of modified diatomite, 15 to 25 parts of quartz sand, 10 to 20 parts of lime paste, 10 to 20 parts of alumina fiber, 8 to 12 parts of aerated aluminite powder, 5 to 15 parts of floating bead, 10 to 20 parts of phillipsite, 6 to 12 parts of mullite, 6 to10 parts of iron oxide powder, 4 to 8 parts of styrene-acrylic emulsion and 1 to 5 parts of auxiliary agent. The preparation method of the modified diatomite thermal insulation mortar comprises the following steps: firstly, crushing and grinding the quartz sand, the lime paste, the aerated aluminite powder, the floating bead, the phillipsite, the mullite and the iron oxide powder to obtain powder; secondly, mixing the cement, the alumina fiber and the styrene-acrylic emulsion with the powder, and adding the auxiliary agent to obtain slurry; finally, uniformly mixing the slurry. The thermal insulation mortar disclosed by the invention has the advantages of high mechanical strength, good insulating and soundproofing properties, low dry density of products, wide sources of raw materials, low cost and simple production process, thus the thermal insulation mortar has a positive impact on promoting the development of energy-saving and environmental-friendly building materials.

Owner:山东励仙电力工程有限公司

Effective Approach to Preventing and Remedying Distresses in Soils and Construction Materials

ActiveUS20120216720A1Efficient and effectiveStabilize expansive soilOrganic fertilisersSoil preservationSodium fluorideSoil horizon

Methods for preventing, reducing, or eliminating construction heave, expansion, distresses, and damage primarily caused by the formation of ettringite are disclosed including introducing fluoride ion releasing agent / salt(s), such as sodium fluoride, calcium fluoride, and potassium fluoride, to expansive soil layers or concrete structural elements and allowing the fluoride ion releasing agent / salt(s) at ambient temperature to react with formed ettringite and to prevent the formation of ettringite of the expansive soil layers or concrete structural elements. Other embodiments are described and claimed.

Owner:AMERICAN ACCUTECH

Method for preparing Al-Si alloy by AD-aluminite powder agent electrolytic process

The present invention is characterized by that it adopts Na3AlF6 cryolite as electrolyte, the molecular ratir of cryolite in the electrolyte is about 2.3-3.0, and the temperature range of electrolyteis 950-990 deg.C, and AD-aluminium powder agent can be added to the electrolyte in batches. This invention possesses the following advantages: AD-aluminium powder agent-by-product produced in secondary aluminium plant can be circularly used, and its Al-Si alloy possesses higher aluminium content, and can be made into cast alumnium alloy.

Owner:星野滋郎 +1

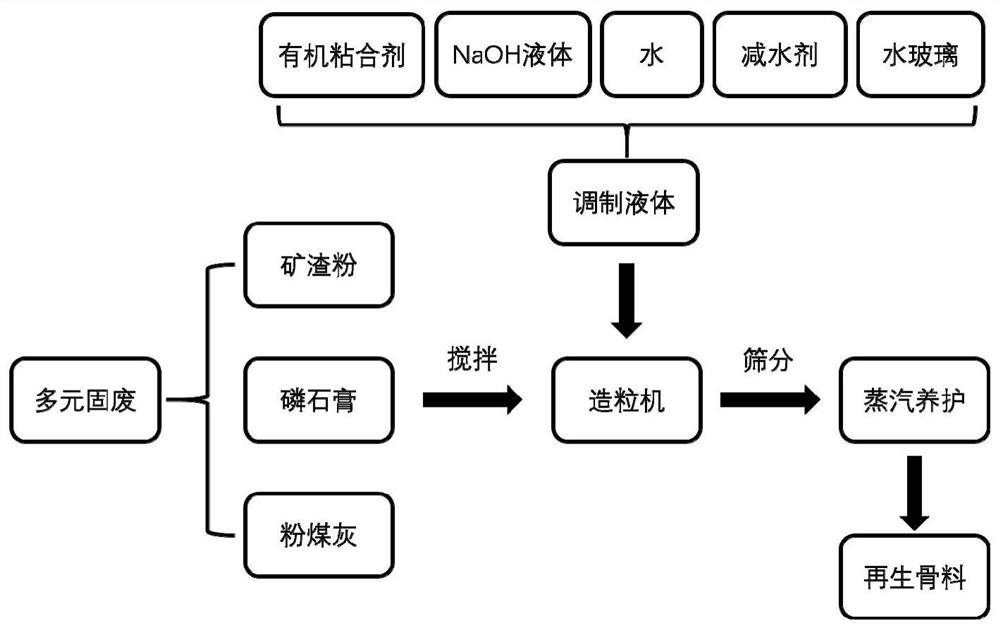

Multi-element solid waste recycled aggregate and preparation process thereof

The invention discloses a multi-element solid waste recycled aggregate and a preparation process thereof. The multi-element solid waste recycled aggregate is prepared by taking ardealite, fly ash, slag powder and a water reducing agent as raw materials and utilizing an alkaline activator, an active silicon-aluminum mineral admixture and an organic adhesive through a disc granulation balling process. Through carrying out a disc granulation pelletizing technology and natural hydration to generate ettringite and C-S-H gel to wrap and bond the remaining undissolved ardealite and the admixture together, thereby obtaining the novel building material. After the recycled aggregate is naturally hydrated and formed, the primarily formed aggregate is put into a steam curing box with the temperature being 100 + / -2 DEG C and the humidity being 95% or above so as to accelerate generation of C-S-H particles. The hydration rate is increased, the performance of the recycled aggregate is improved, the water absorption rate of the recycled aggregate is reduced, the water consumption of the recycled concrete is reduced, the strength of the recycled aggregate concrete is obviously improved, and the utilization rate of the recycled aggregate in the concrete is increased.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

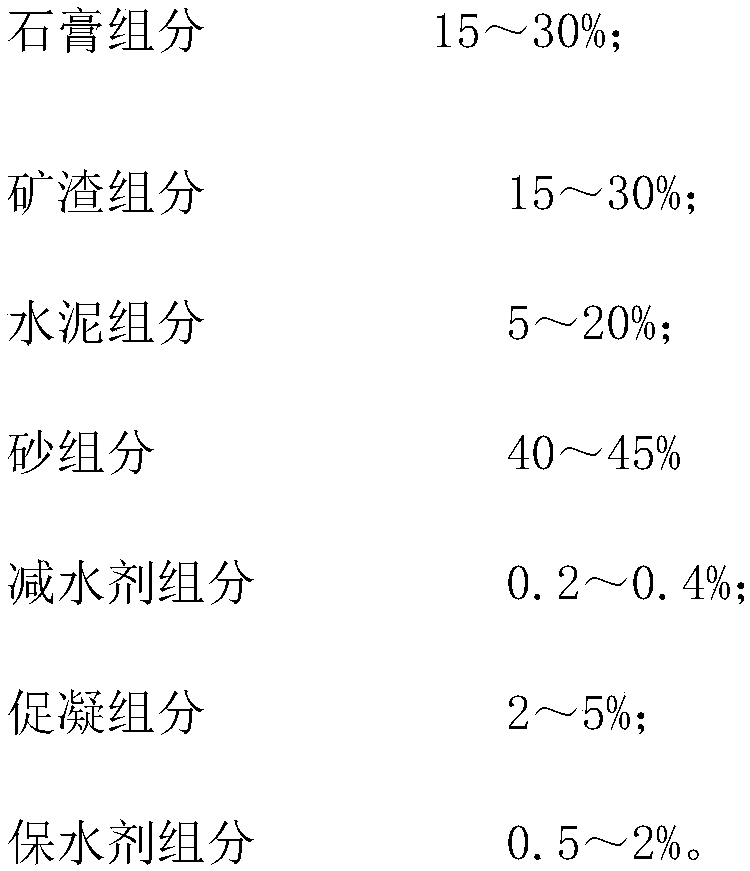

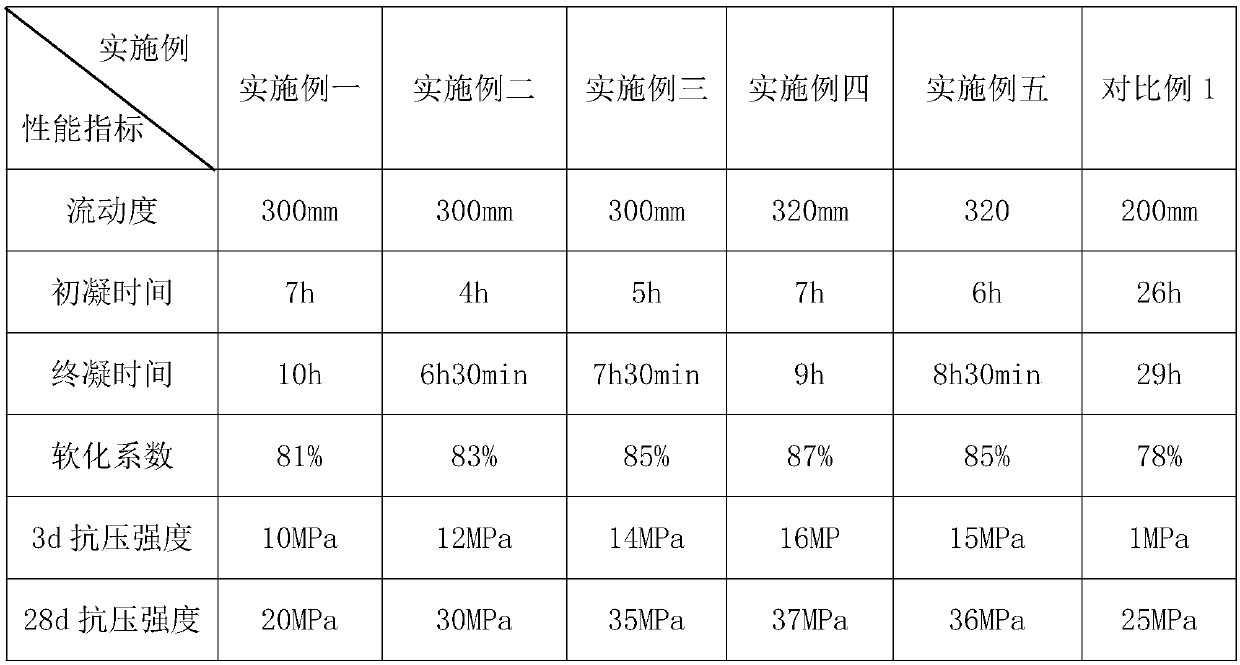

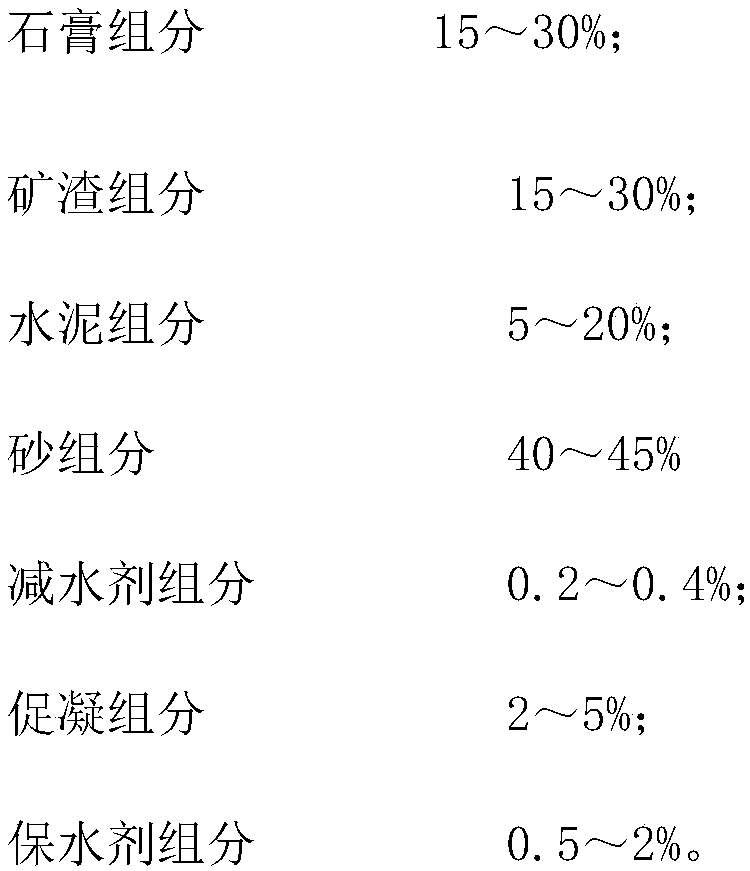

Gypsum-based hydraulic hard grouting material and preparation method and application thereof

InactiveCN109626936AGenerated in large quantities and stableImprove mechanical propertiesRoadwaysSoil preservationHydration reactionMineral reactions

The invention discloses a gypsum-based hydraulic grouting material and a preparation method and application thereof. The grouting material is mainly composed of a gypsum component, a slag component, acement component, a sand component, a water reducing agent component, a coagulation promoting component and a water retention agent component. According to the grouting material, hydrated calcium sulphoaluminate, namely ettringite is generated under a reaction of gypsum and slag, so that the quantity of generated hydraulic minerals is large and stable; meanwhile, the slag and cement are subjectedto a secondary hydration reaction to generate C-S-H gel so that grouting slurry can stably exist in a base body to provide another strength source for the base body, an overall structure is formed with ettringite, the mechanical properties of the foundation base body are improved, and the softening coefficient of the foundation base body is increased; in addition, through the common functions ofthe three gel materials including the gypsum, the slag and the cement, hydration and mineral reaction products in the foundation base body are stabilized, and the situation is avoided that after the local foundation base body encounters water, a lot of strength loss is caused; besides, the coagulation promoting component is added, and the problem of coagulation retarding of the gypsum component issolved.

Owner:GUIZHOU LANTU NEW MATERIALS

External curing agent for concrete

The invention discloses an external curing agent for concrete. The external curing agent for concrete is prepared from the following raw materials: a modified polyolefin wax emulsion, an organic emulsion, a silane coupling agent, a reinforcing agent and an inorganic densifying component. According to the concrete external curing agent, the modified polyolefin wax emulsion is adopted as a main rawmaterial and contains part of the reinforcing agent; water retention is conducted through the film forming effect of the wax emulsion and the organic emulsion, meanwhile, the reinforcing agent is added to serve as a catalyst, and hydration of the tricalcium aluminate content in concrete and formation of ettringite are accelerated, and a certain reinforcing effect is achieved. According to the concrete external curing agent, the curing cost of concrete is greatly saved, the water retention rate and the compressive strength are greatly improved, and secondary pollution to the surface of the concrete is avoided.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

General portland cement modifying agent containing high cementing property mineral* and application method thereof

The invention relates to a general portland cement modifying agent containing high cementing property mineral and an application method thereof. The modifying agent is formed by reasonably designing ingredient minerals by using waste residues with high aluminum content and natural or industrial by-product plaster as well as natural limestone as raw materials, the modifying agent is calcined for 15-60 min at 1250-1350 DEG C to prepare a modifying agent clinker; and the modifying agent clinker is added into the plaster to prepare the general portland cement modifying agent with higher mineral content. The application method comprises the steps of: doping the modifying agent clinker or the modifying agent into the general portland cement in the proper proportion to replace a part of clinkers to play a role in quick hydration of early strength minerals and excitation function to mixed materials, such as slag, flyash and the like, so as to form more hydration products, such as ettringite, alumina gel and the like and regulate the category and the proportion of the portland cement hydration product. The invention solves the problems of narrow coexistence temperature of C3S and minerals and non-matching of the temperature, and guarantees the effective utilization of the high cementing property mineral with early strength property to achieve the aims of improving the general portland cement performance and reducing the production cost.

Owner:UNIV OF JINAN

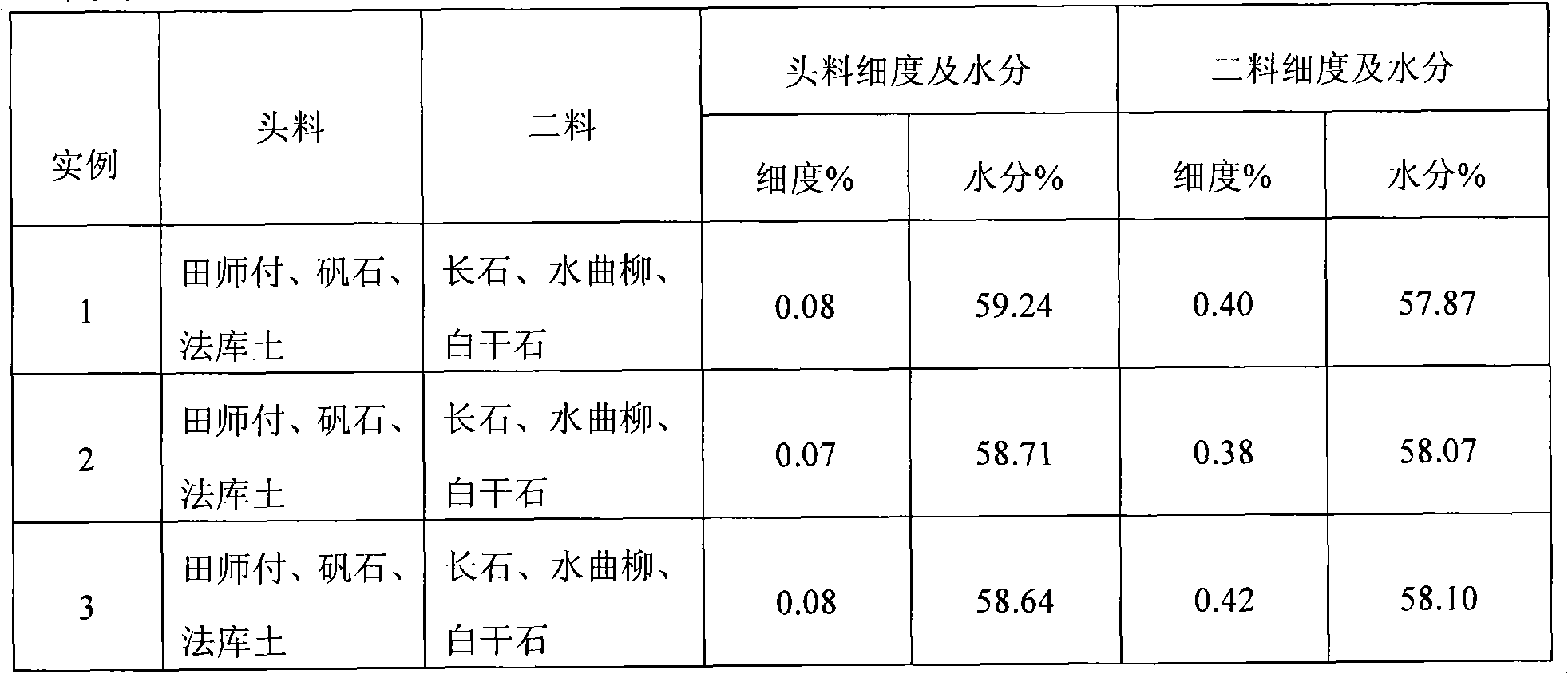

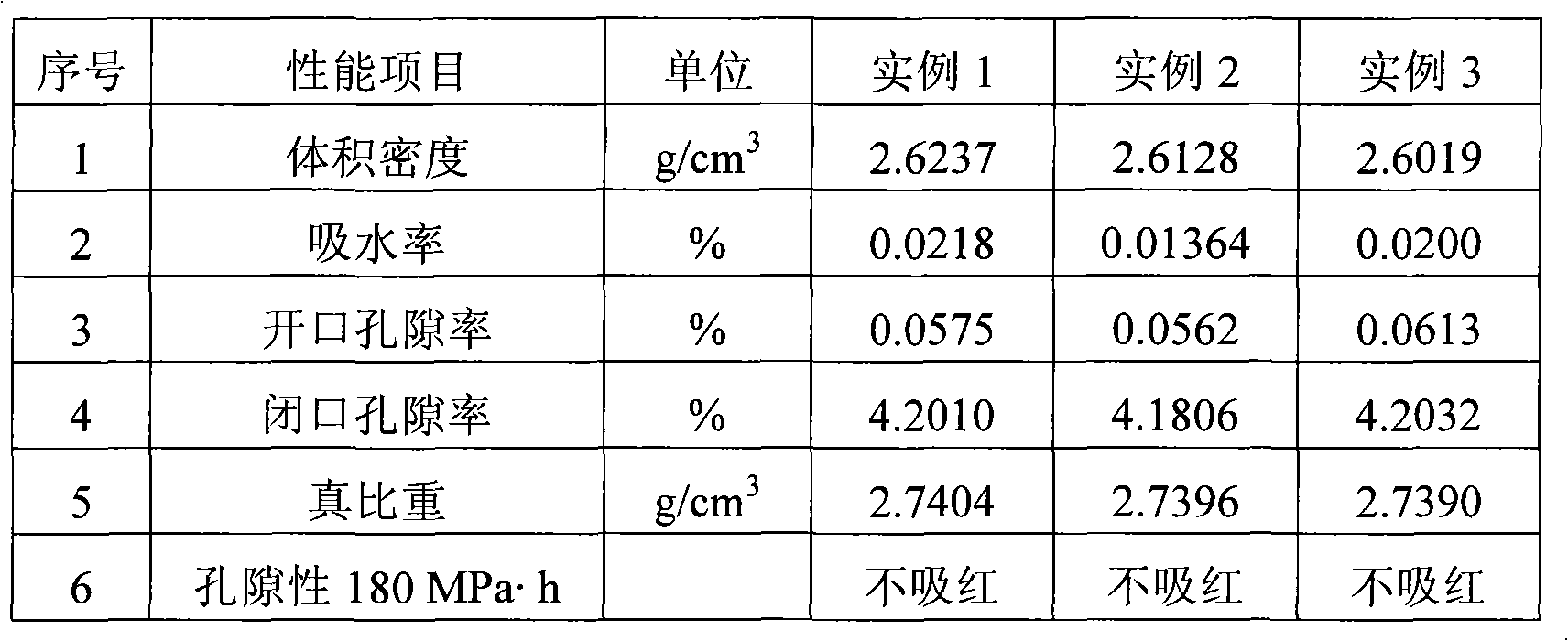

Cristobalite high strength porcelain formula

The invention provides a cristobalite high strength porcelain formula, aiming to solve the technical problem that in the traditional high strength electric porcelain formula, the proportion of aluminite reaches 35-45 percent and the proportion of feldspar is 15-20 percent, and if the high strength electric porcelain is expected to be obtained, the production cost of the electric porcelain is bound to increase because the price of the aluminite is highest in the raw materials used by the electric porcelain formula. In the cristobalite high strength porcelain formula, the key point is that the blank formula comprises 21-28 percent of aluminite, 5-10 percent of feldspar, 11-17 percent of kaolinites clay containing quartzose, 19-25 percent of hard kaolinites clay and the balance of illite clay. The invention is used for producing high-voltage electric porcelain.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

Filling permanent lining furnace fireproofing material

The invention relates to a filling permanent lining furnace fireproofing material, which is prepared by uniformly mixing composite brown corundum, silicon nitride powders, compound vitrified bond powders, magnesia powder, metal aluminite powders, alumina micro powders, tabular corundum powders and composite additives micro powders. The invention has the advantages of better heat preservation effects, stronger stability, longer service life, simple construction process and high efficiency and is beneficial to save resources and labor power.

Owner:鞍山尊克冶金材料有限公司

Glass paint

The invention discloses a glass paint, which consists of the following components in parts by weight: 20-30 parts of non-leafing aluminum powder slurry, 15-20 parts of hydroxyethyl cellulose, 5-10 parts of butyl stearate, 10-20 parts of epoxy polysulfide, 10-14 parts of water-soluble resin, 4-8 parts of petroleum, 80-100 parts of water. Compared with the prior art, the present invention has super strong adhesive force, so that the paint can adhere to the glass, the functionality of the paint is enriched, and people's use requirements are met.

Owner:NANJING GAOQI ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com