Soil curing agent based on desulfurized fly ash activity and preparation method and application thereof

A technology of soil stabilizer and desulfurization ash, which is applied in soil protection, infrastructure engineering, construction, etc. It can solve the problems of large differences in calcium oxide and sulfur trioxide content, increase the difficulty of desulfurization ash, and consume large amounts of energy. The effect of reducing the risk of volume instability, avoiding the risk of volume instability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The method for preparing soil solidifying agent provided by the invention, the steps are:

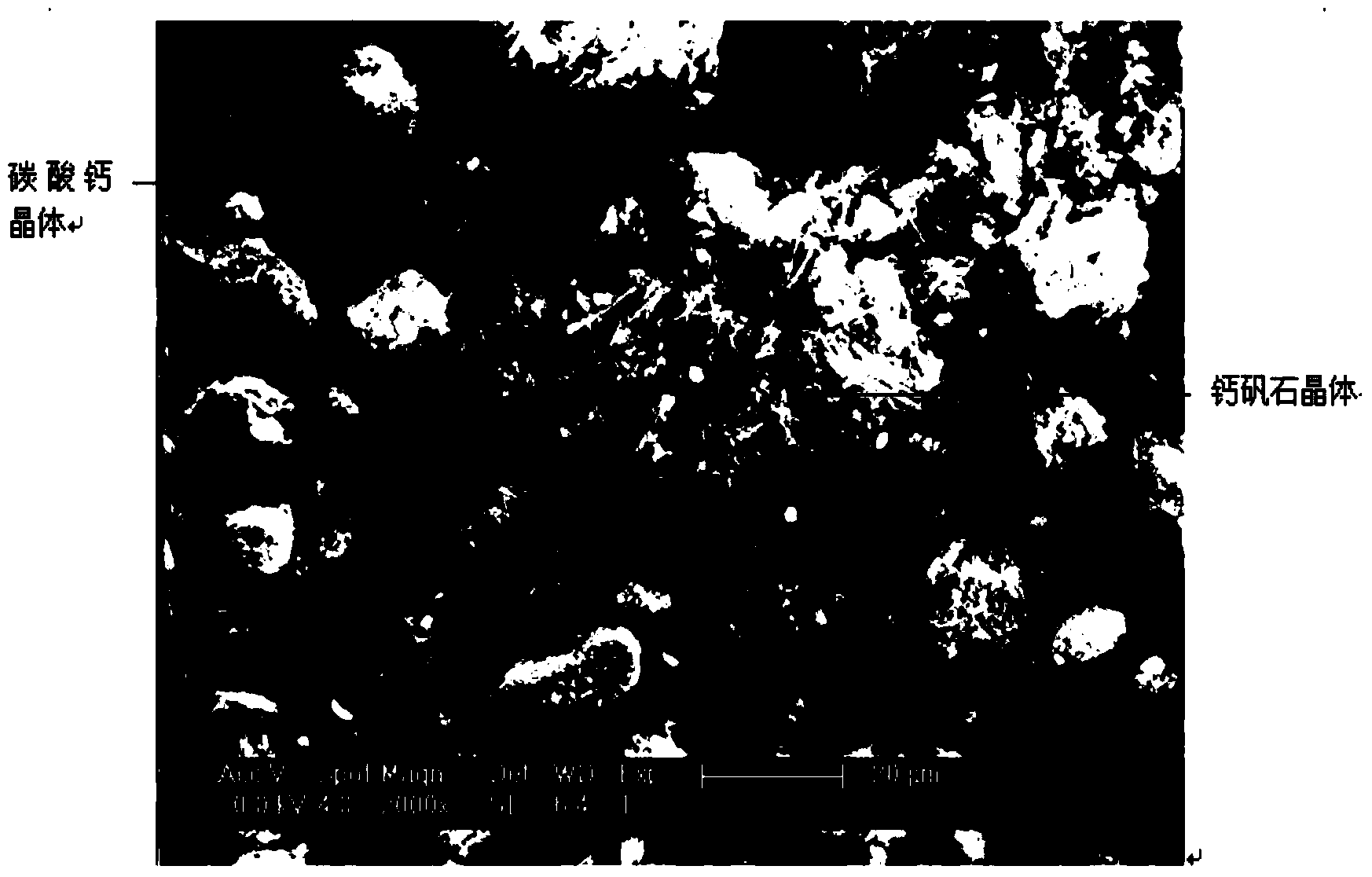

[0030] (1) Carry out chemical analysis or fluorescence analysis on desulfurization ash to obtain its main characteristic components, focus on testing the content of sulfur trioxide in desulfurization ash, and convert it into calcium sulfate content; test the content of alumina in slag powder; according to the molecular weight of ettringite Classical structure 3CaO·Al 2 o 3 · 3CaSO 4 32H 2 O, control the calcium sulfate in the desulfurization ash and the alumina in the slag powder, the molar ratio of the two should not exceed 3:1; eliminate the potential volume instability in the desulfurization ash from the source. In order to promote the formation of ettringite as soon as possible, the content of alumina can be increased appropriately. Due to the different desulfurization technologies in various places, there are certain differences in the composition ratio of desulfurizatio...

Embodiment 1

[0036] (1) Weigh 5-10mm and 10-15mm of the second-grade crushed stones, the mass percentage of crushed stones is 85%, and this product accounts for 15%. The desulfurization ash used is from Nanjing, and the result of fluorescence analysis shows that the content of sulfur trioxide is 18.9% (mass ratio). The slag micropowder is S95 grade, in which the alumina content is 12.15% (mass ratio), sulfur trioxide is converted into calcium sulfate, and its proportion is about 27.45% (mass ratio), calculated according to the molecular structure of ettringite, the desulfurization The theoretical mass ratio of ash to slag fine powder should not exceed 1.8:1, and the actual use ratio is 1:1. Add a certain amount of sodium hydroxide and calcium stearate, that is, desulfurization ash: mineral powder: sodium hydroxide: calcium stearate = 1:1:0.13:0.08 (mass ratio).

[0037] (2) Take by weighing graded crushed stone (accounting for 85%) and this product (accounting for 15%), respectively selec...

Embodiment 2

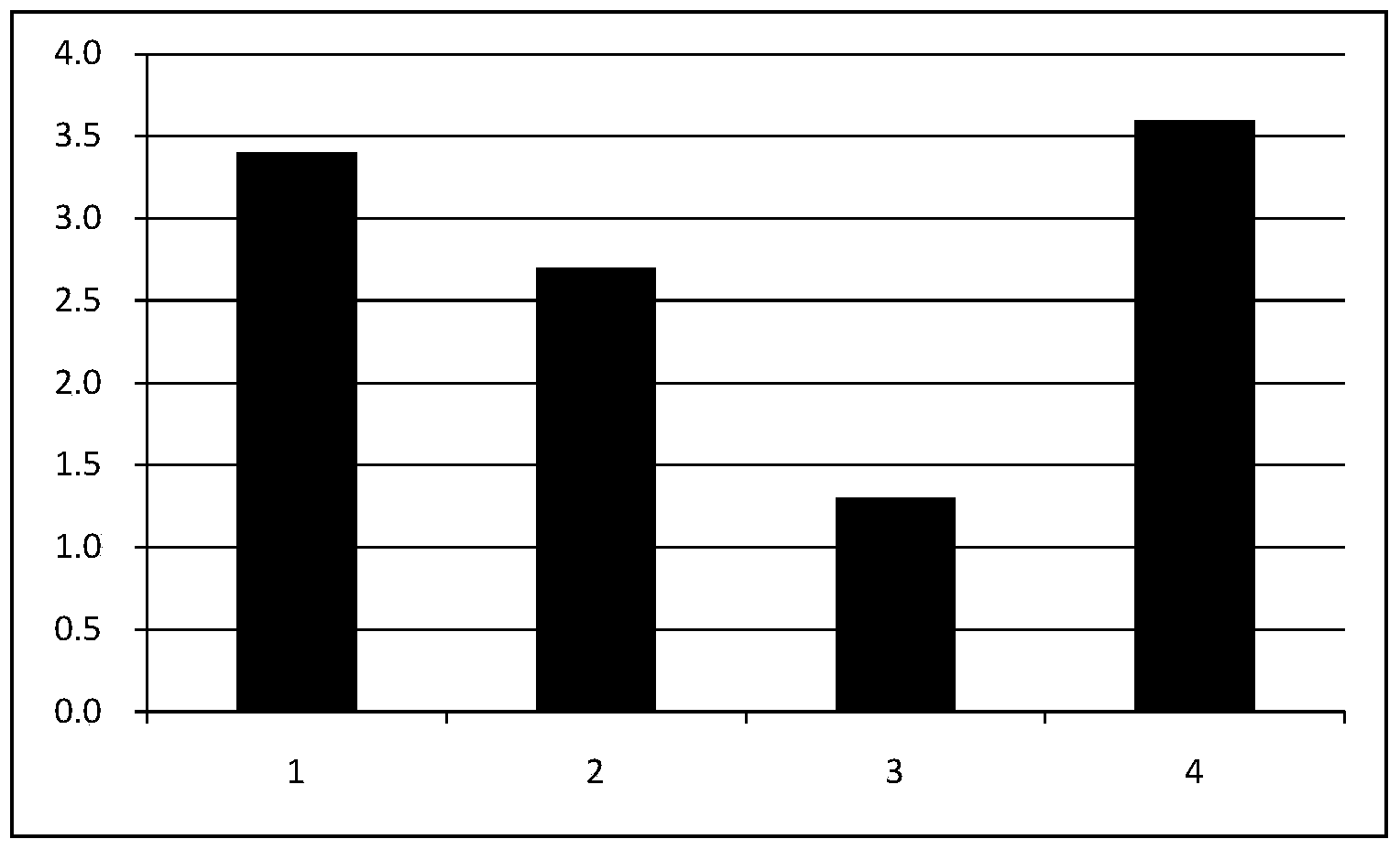

[0042] (1) In order to study the water stability of this product, desulfurization ash and slag powder were mixed according to the ratio (mass ratio) of 3:1, 1:1 and 1:3 respectively, and then the product with different ratios Add it into the soil at the dosage of 5%, 15%, 20% and 25%, and shape the sample according to the optimum moisture content of the plain soil. The appearance of the sample is the same as that of the sample in Example 1, which is a cylinder with a diameter and a height of 100 mm. Sodium hydroxide and calcium stearate were not spiked in this test.

[0043] (2) After standard curing for 7 days, dry it, then seal it with wax around it, stick a glass block on its upper end, place the sample in water, and use a dial gauge to test its volume change in water. The experimental process refers to the GB / T50082-2009 standard.

[0044] (3) Since the sides are sealed with wax, water mainly enters through the upper and lower end faces, and the volume changes of 1d, 3d,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com