Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about How to "High aluminum content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

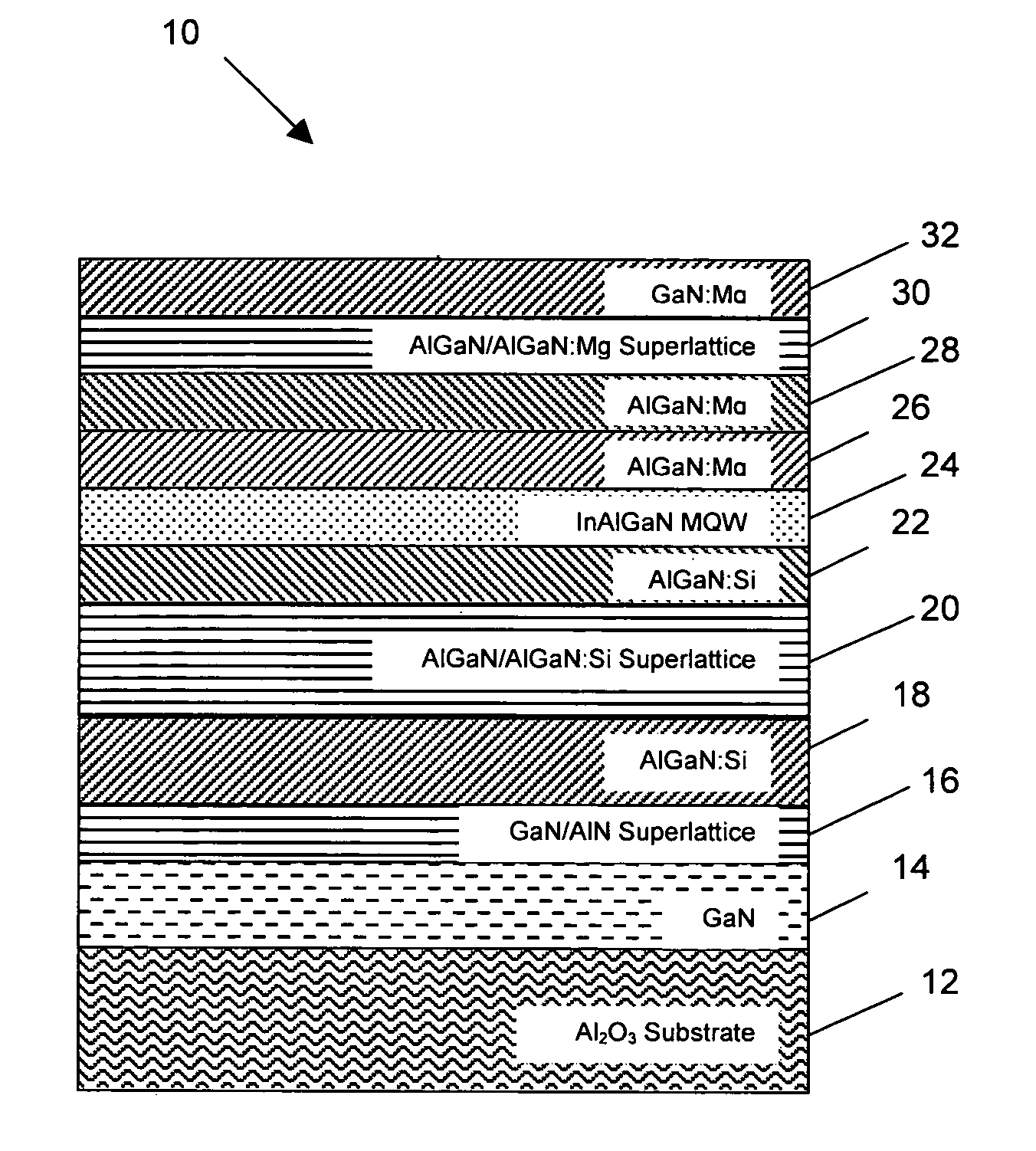

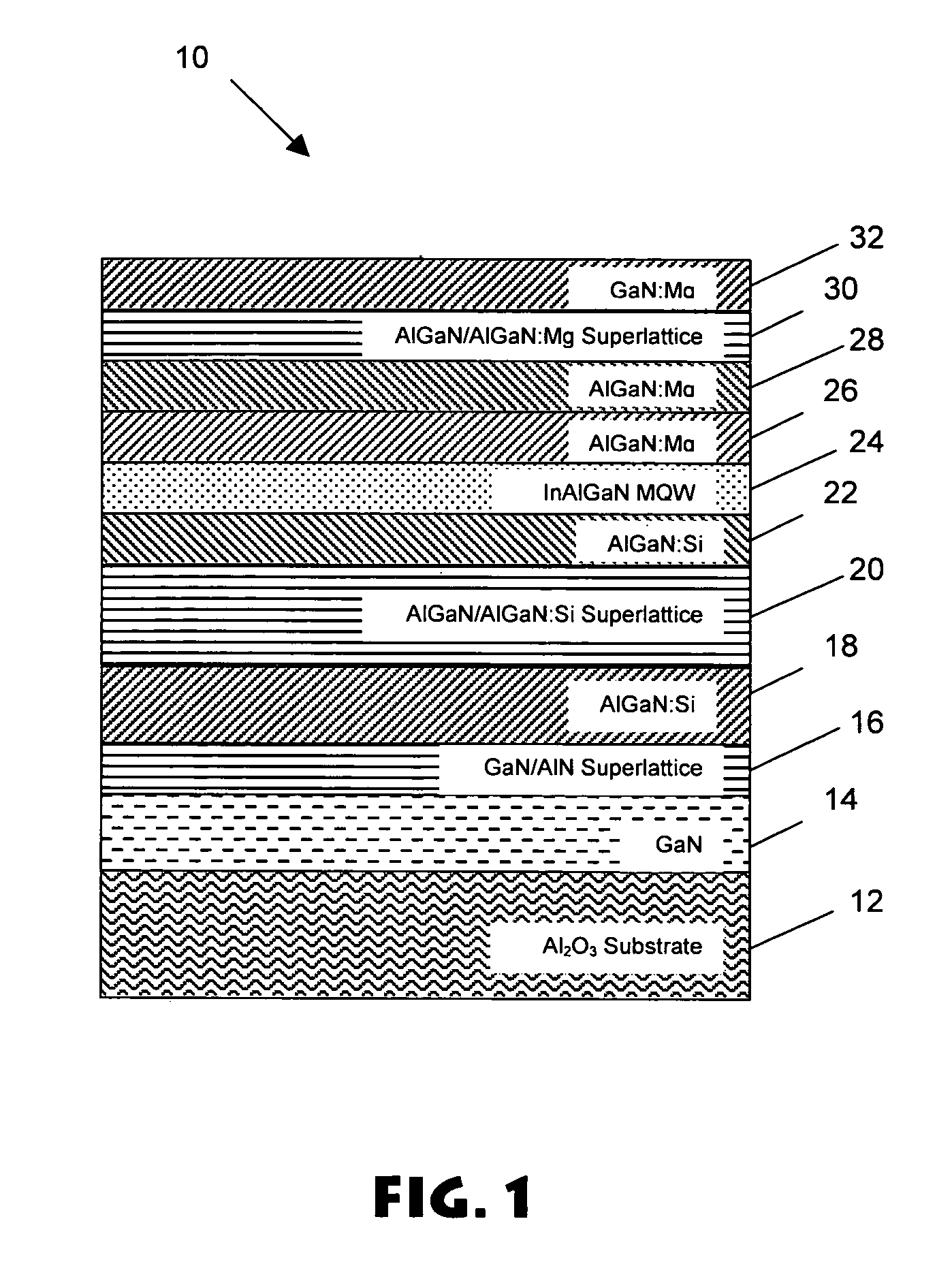

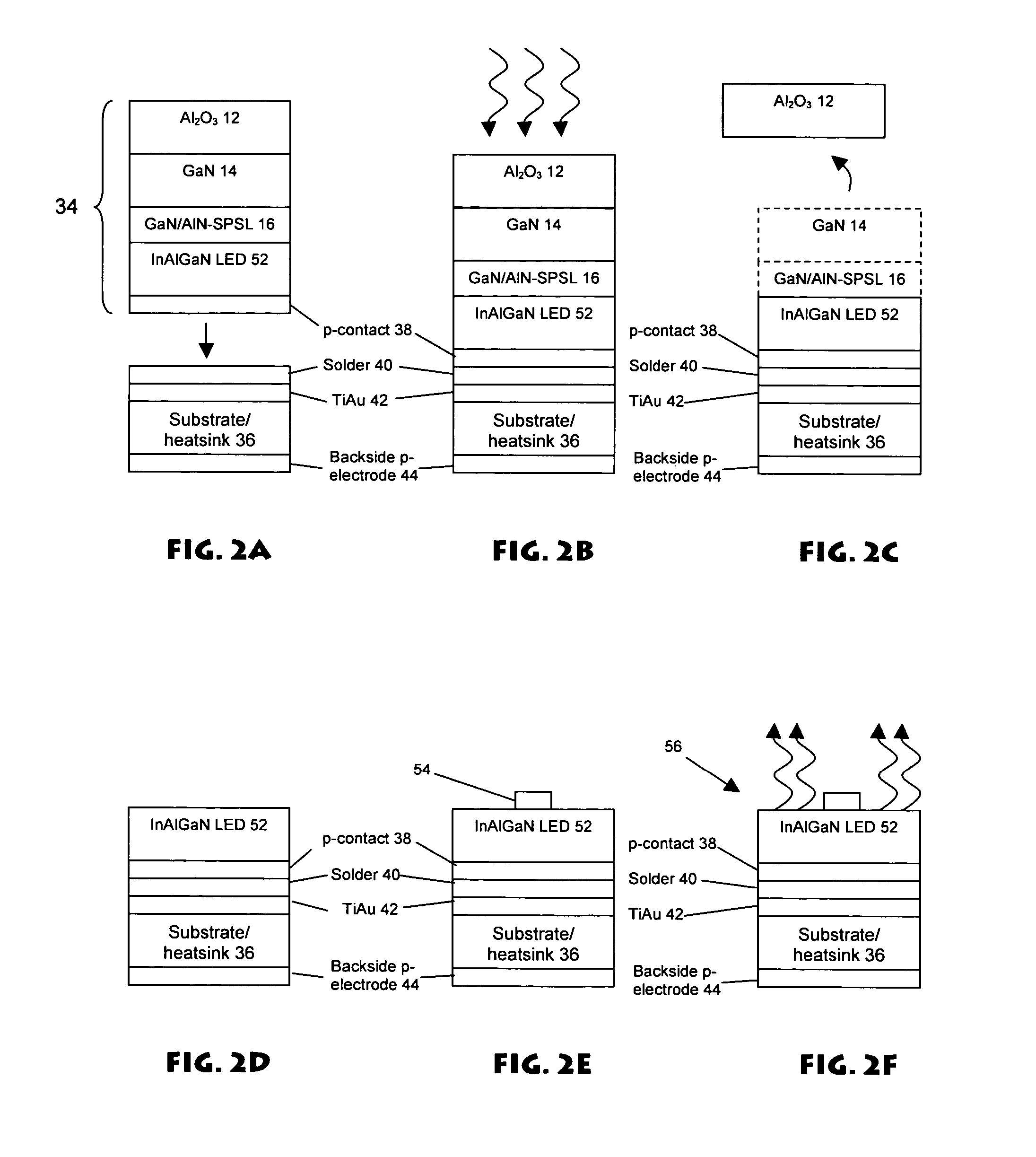

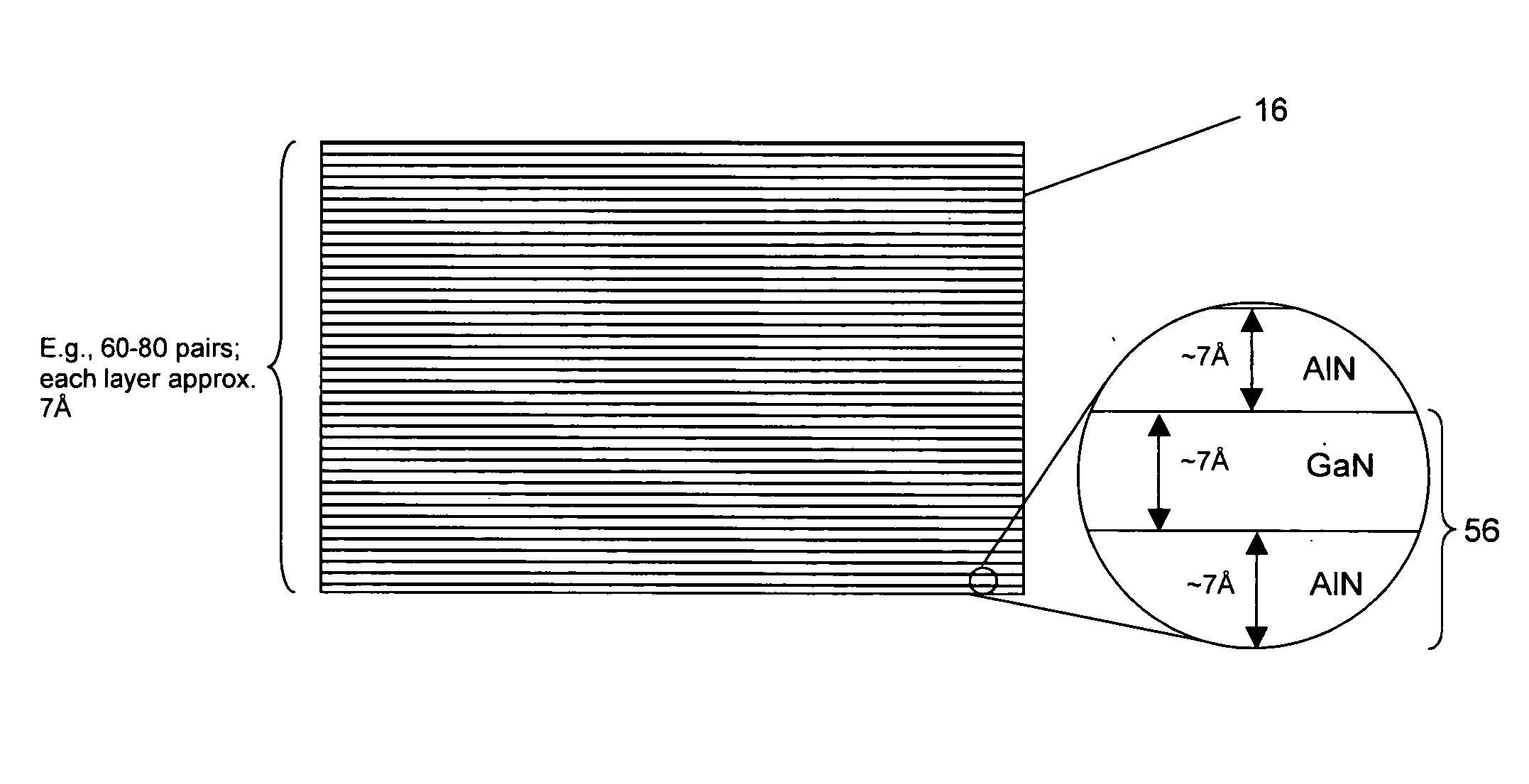

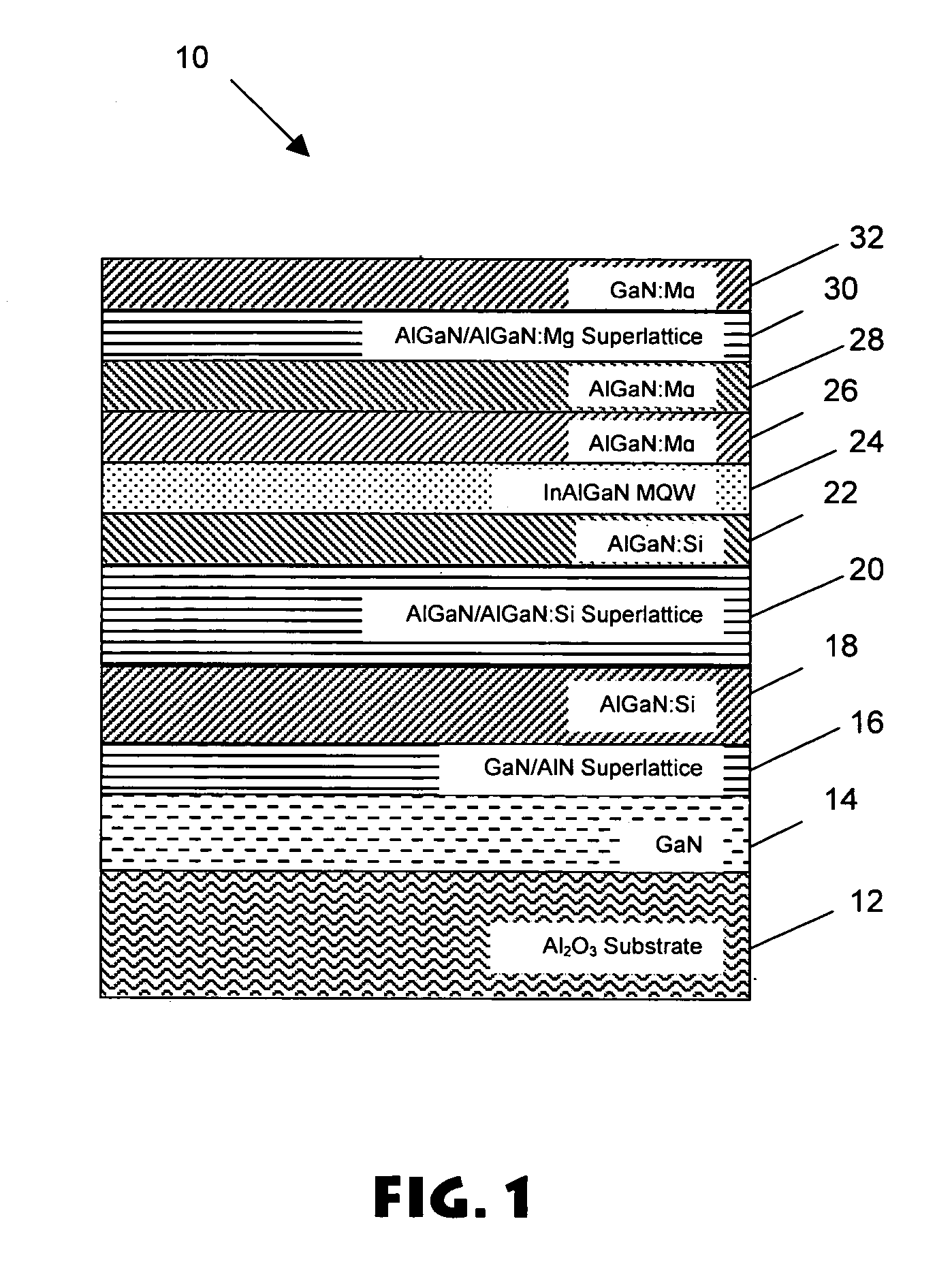

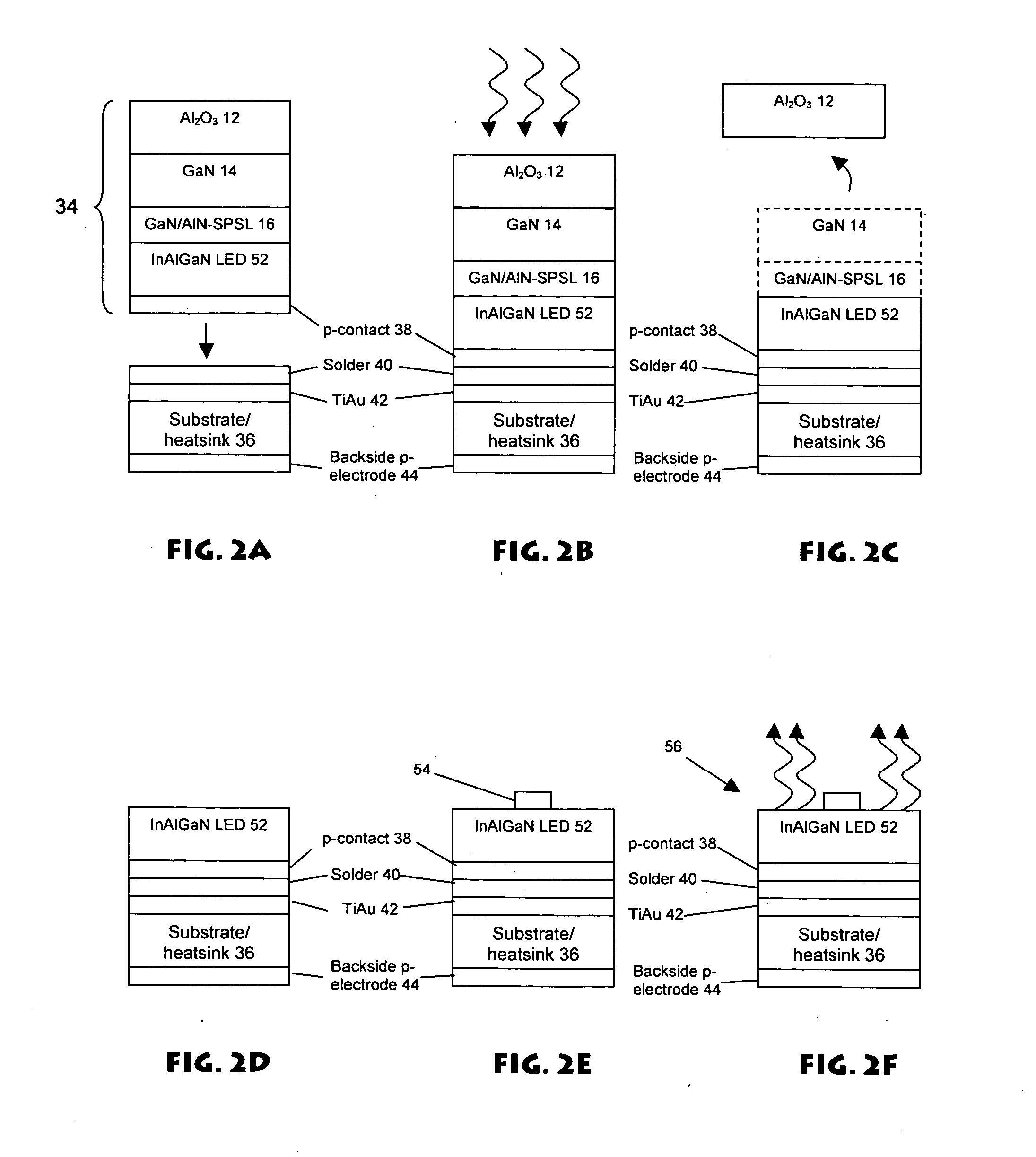

Superlattice strain relief layer for semiconductor devices

ActiveUS7547925B2High aluminum contentLow working voltageSolid-state devicesNanoopticsLength waveLight-emitting diode

A GaN / AlN superlattice is formed over a GaN / sapphire template structure, serving in part as a strain relief layer for growth of subsequent layers (e.g., deep UV light emitting diodes). The GaN / AlN superlattice mitigates the strain between a GaN / sapphire template and a multiple quantum well heterostructure active region, allowing the use of high Al mole fraction in the active region, and therefore emission in the deep UV wavelengths.

Owner:XEROX CORP

Superlattice strain relief layer for semiconductor devices

ActiveUS20070108456A1High aluminum contentEfficient productionSolid-state devicesNanoopticsLength waveLight-emitting diode

A GaN / AlN superlattice is formed over a GaN / sapphire template structure, serving in part as a strain relief layer for growth of subsequent layers (e.g., deep UV light emitting diodes). The GaN / AlN superlattice mitigates the strain between a GaN / sapphire template and a multiple quantum well heterostructure active region, allowing the use of high Al mole fraction in the active region, and therefore emission in the deep UV wavelengths.

Owner:XEROX CORP

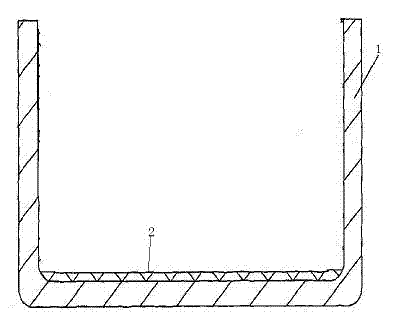

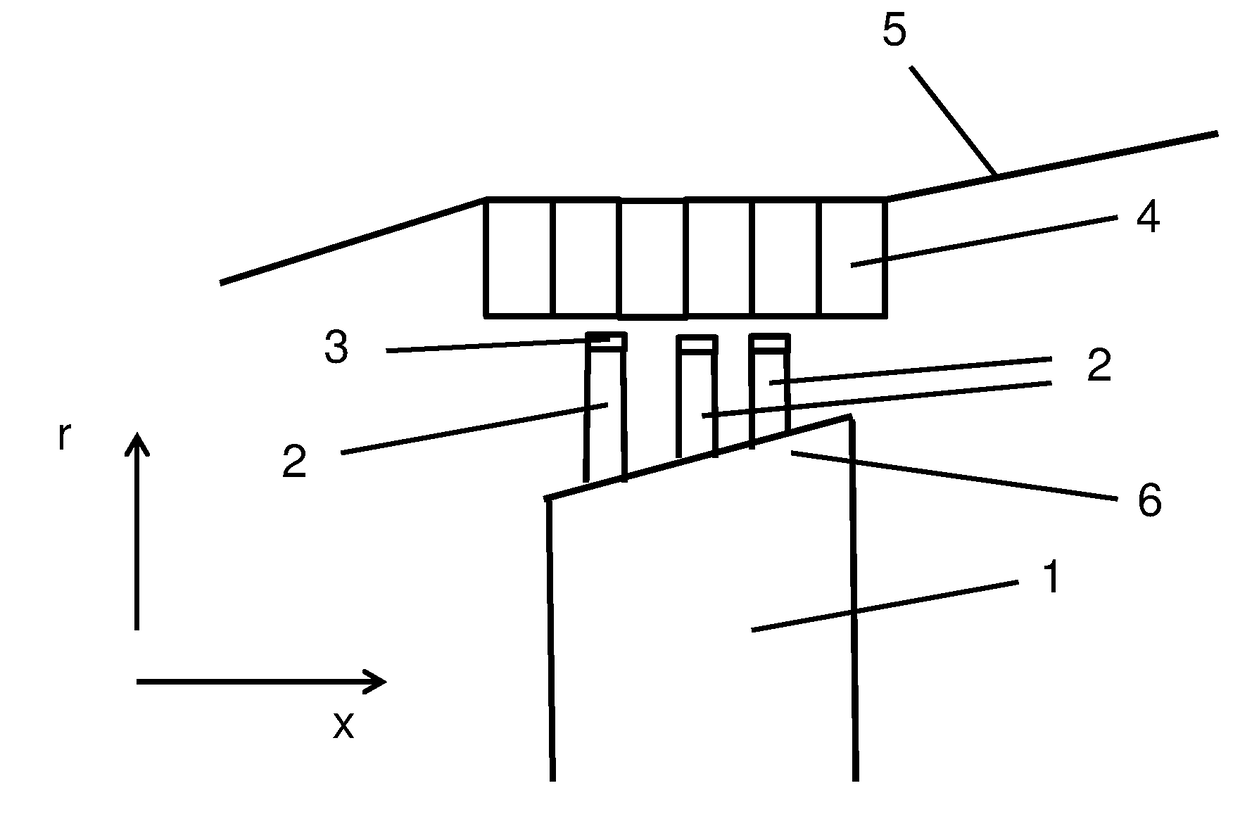

Lacunaris metal carrier and manufacturing method thereof

ActiveCN101229699AOvercome the defect of not resistance to oxidationImprove high temperature oxidation resistanceMolten spray coatingMetal layered productsPorous substrateRare-earth element

The invention discloses a porous metal carrier and a preparation method thereof. The porous metal carrier has a continuous micro-porous structure formed through mutual connection of polyhedron cabinets; a first layer is a substrate metal layer which comprises one or a plurality of the compositions: nickel, iron or copper; metal quantity of the substrate metal layer is more than or equal to 100g / m<2>; a function metal coating of MCrAl or MCrAlR is arranged on the substrate metal layer and M refers to Fe, Ni and Co or alloy of Fe, Ni and Co and R is rare earth element. The preparation method includes the following steps: first, metallization pretreatment is carried out for nonmetal porous substrate to form the substrate metal layer; second, the function metal layer with chromium and aluminum are sprayed on the substrate metal layer by adopting a thermal spraying process; at last, flame remelt and induction remelt are carried out for the function coating. The material provided by the invention has high porosity, large surface area, high strength, favorable flow disturbance, excellent high temperature and oxidization resistance, simple preparation method and process and low cost.

Owner:先进储能材料国家工程研究中心有限责任公司

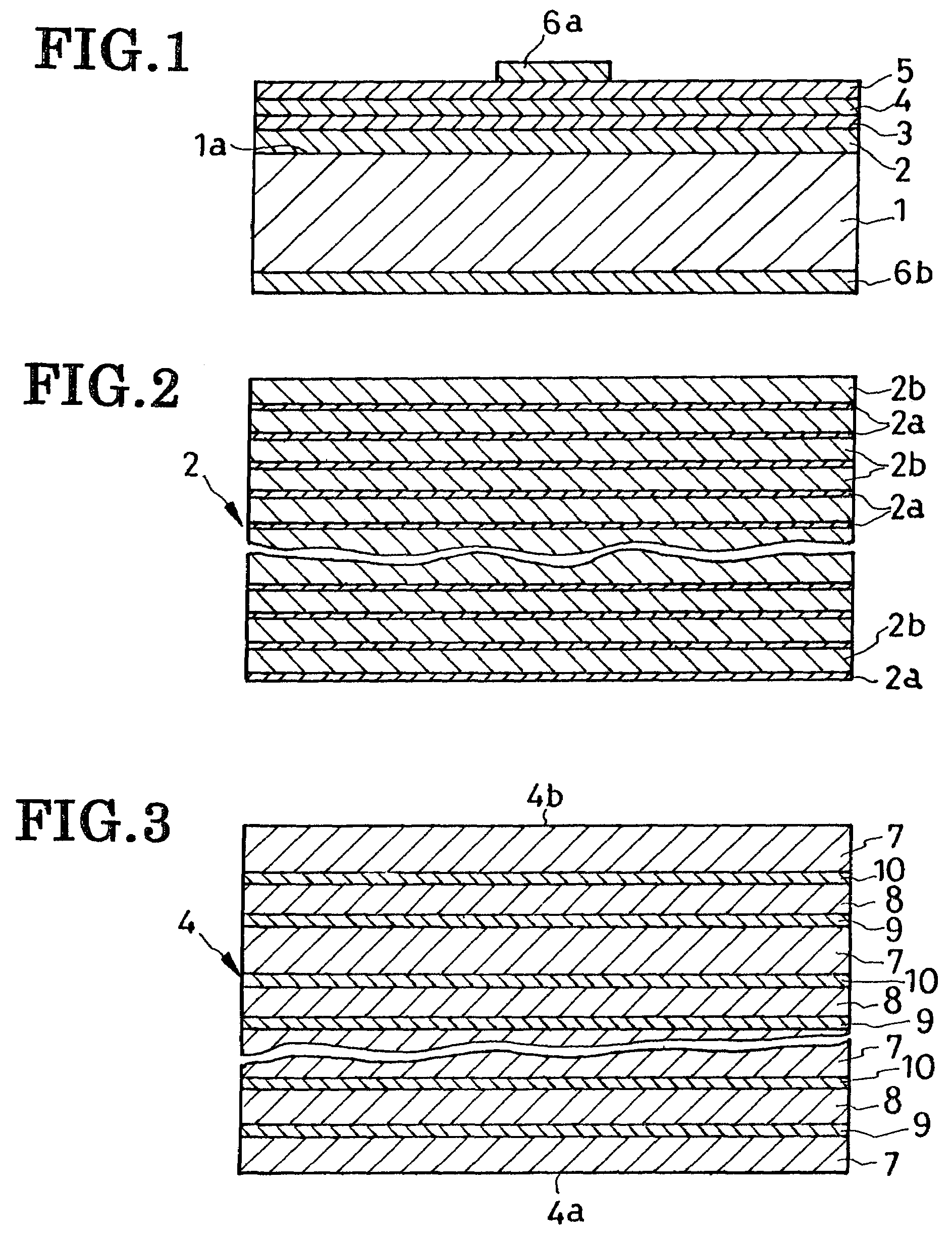

Light-emitting semiconductor device having a quantum well active layer, and method of fabrication

InactiveUS7176480B2High crystallinityPrevent evaporationSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumEvaporation

Owner:SANKEN ELECTRIC CO LTD

Preparation method of high-whiteness light-resistance rutile type titanium dioxide substrate

The invention discloses a preparation method of high-whiteness light-resistance rutile type titanium dioxide substrate. The preparation method includes steps of primary washing of metatitanic acid, preparation of metatitanic acid sizing, bleaching of metatitanic acid sizing, secondary washing of metatitanic acid, salt treating, roasting and smashing. In the bleaching of metatitanic acid sizing, 5wt% of rutile titanium dioxide roasted seed crystal and 0.2wt% of Ti3 and solution are added into the sizing. In the step of salt treating, potassium compound, phosphorous compound, aluminum compound and stibium oxide are added into the secondarily-washed metatitanic acid. By adding aluminum salt content, aluminum salt enters crystal lattice during growth of titanium dioxide crystal, light resistance performance of titanium dioxide pigment is substantially improved, and the yellowish problem caused by increment of aluminum slat content can be eliminated by adding antimonic salt, so that whiteness of dry powder is kept, whiteness and light resistance are kept balanced, and the high-whiteness light-resistance rutile type titanium dioxide substrate.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

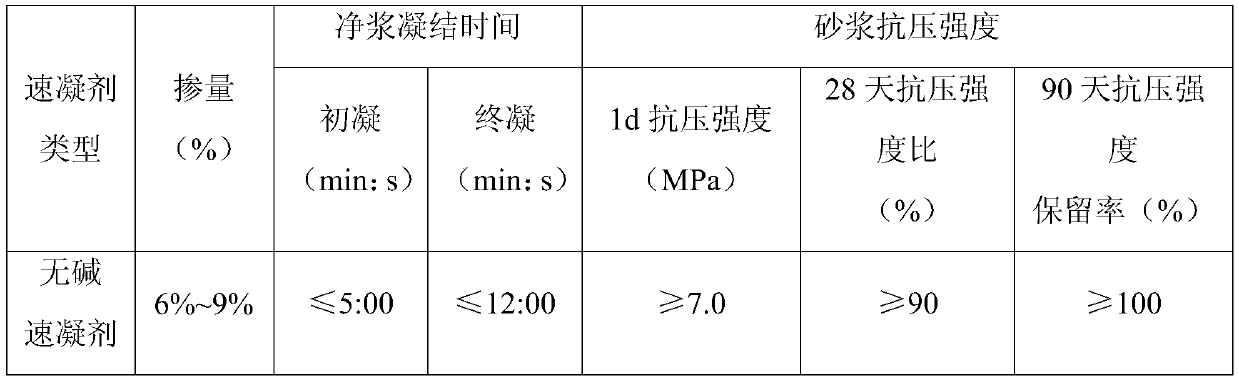

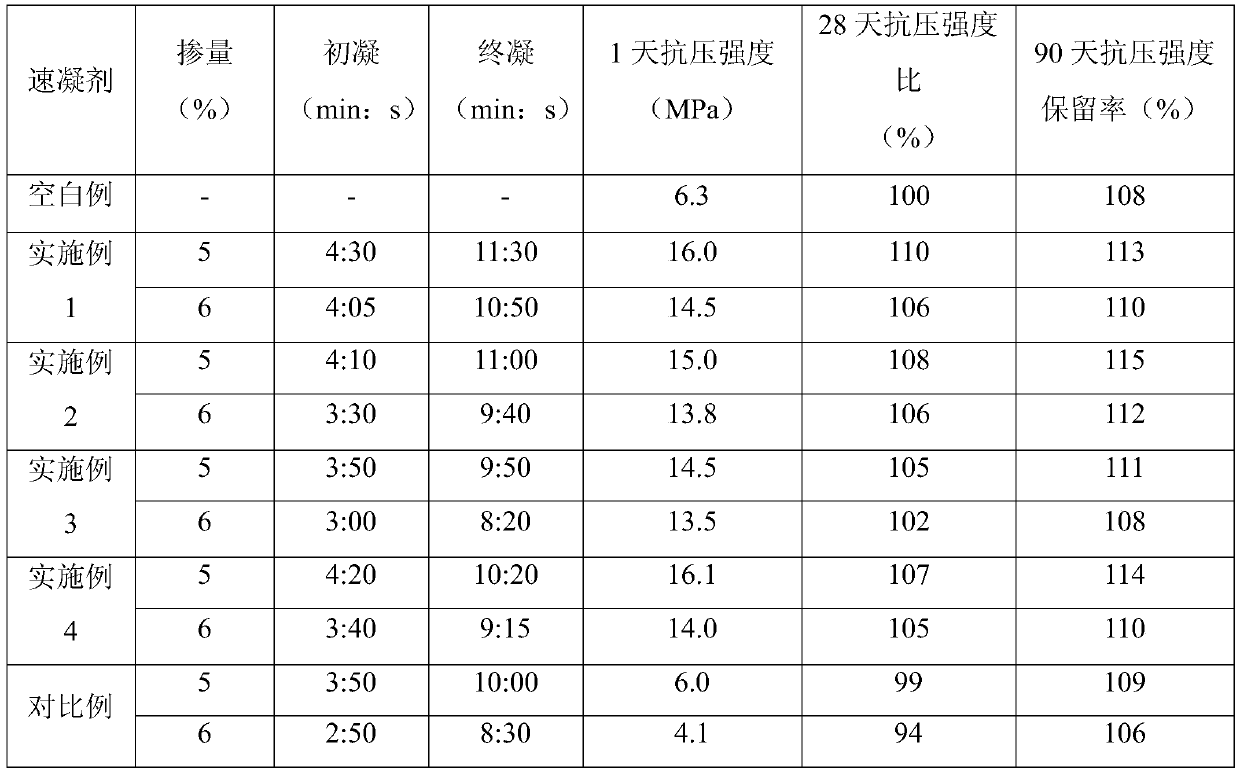

Low-dosage high-early-strength alkali-free liquid accelerator and preparation method thereof

The invention discloses a low-dosage high-early-strength alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from the following raw materials: 1, an alkali-free liquid accelerator; 50%-60% of modified aluminum sulfate, 2%-4% of a fluorine-aluminum complex solution, 3%-6% of an organic cosolvent, 1%-2% of a pH regulator, 0.5%-1.5% of an inorganic stabilizer, 0.3%-0.5% of a viscosity regulator, 4%-6% of a composite early strength agent and the balance of water, wherein the sum of the mass percentages of the components is 100%. The invention also provides a preparation method of the alkali-free liquid accelerator. The preparation process of the alkali-free liquid accelerator is simple; hydrofluoric acid-free process, alkali-free, chlorine-free, rust-free steel bar, non-polluting environment. Meanwhile, when the mixing amount of the alkali-free liquid accelerator is 5%-6%, the technical requirements of GB / T35159-2017 on the alkali-free accelerator can be met, the one-day compressive strength is larger than or equal to 13.0 MPa, and the alkali-free liquid accelerator has the advantages of being low in mixing amount, good in stability, high in early strength and large in later strength retention rate.

Owner:刘翠芬

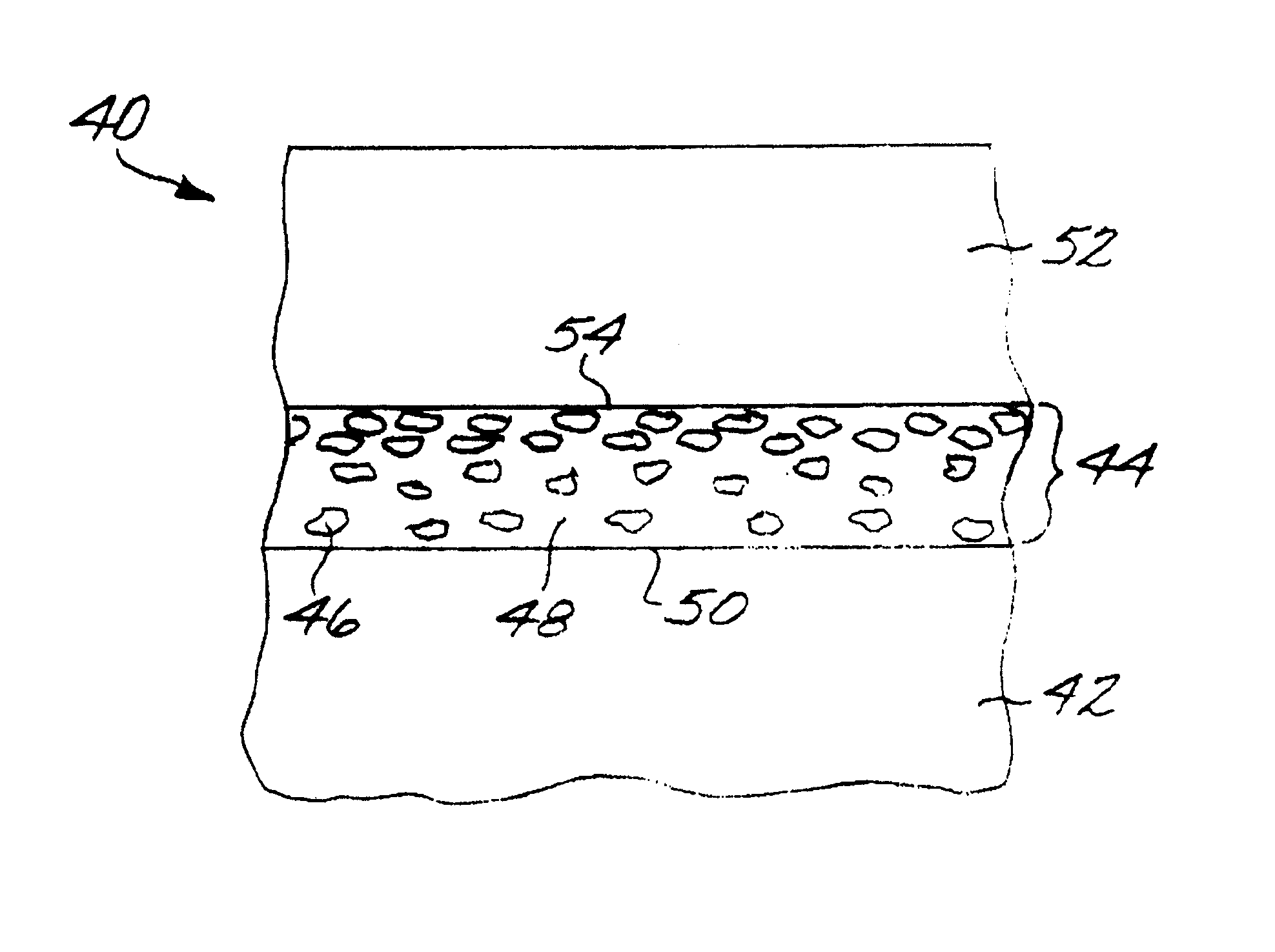

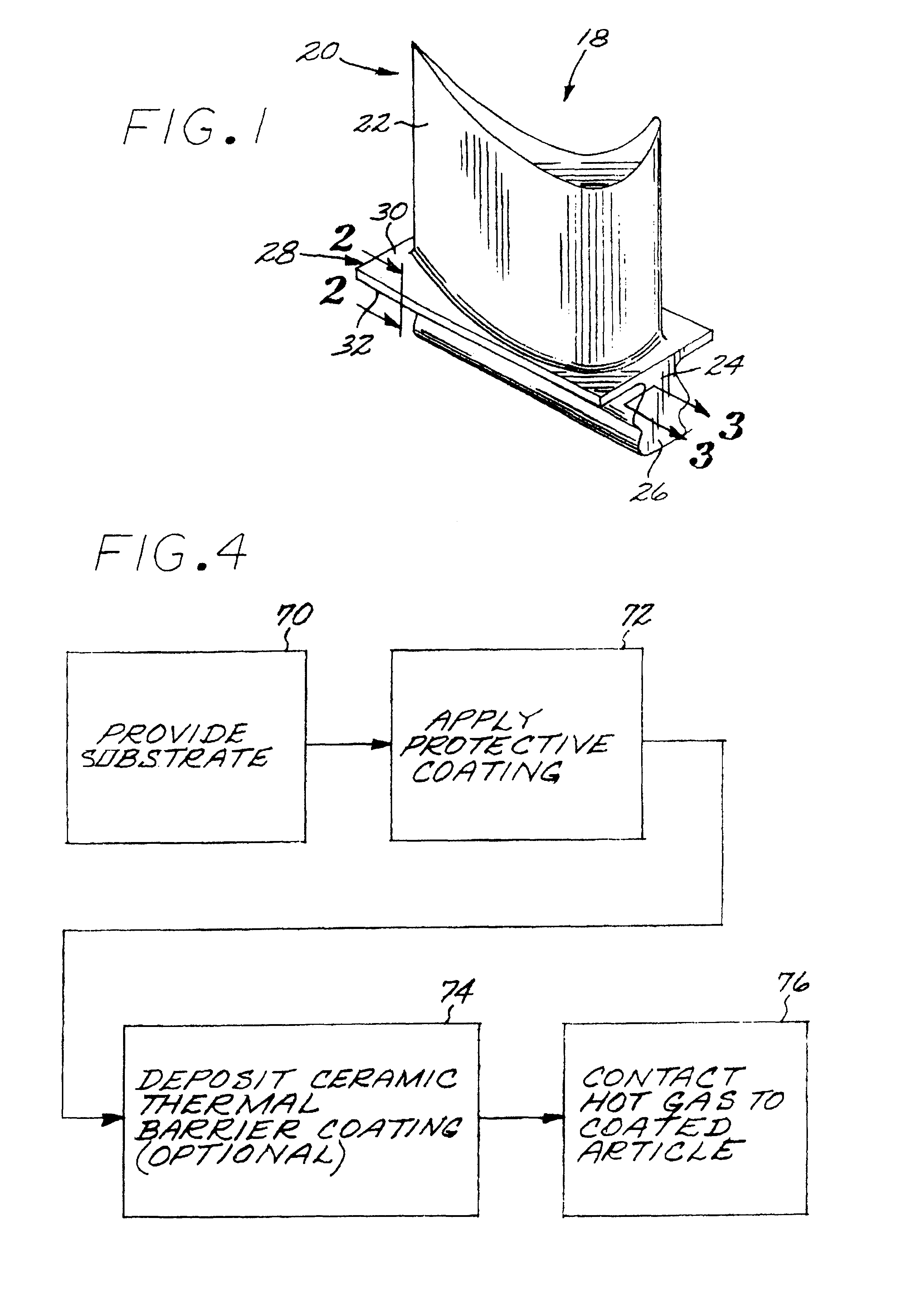

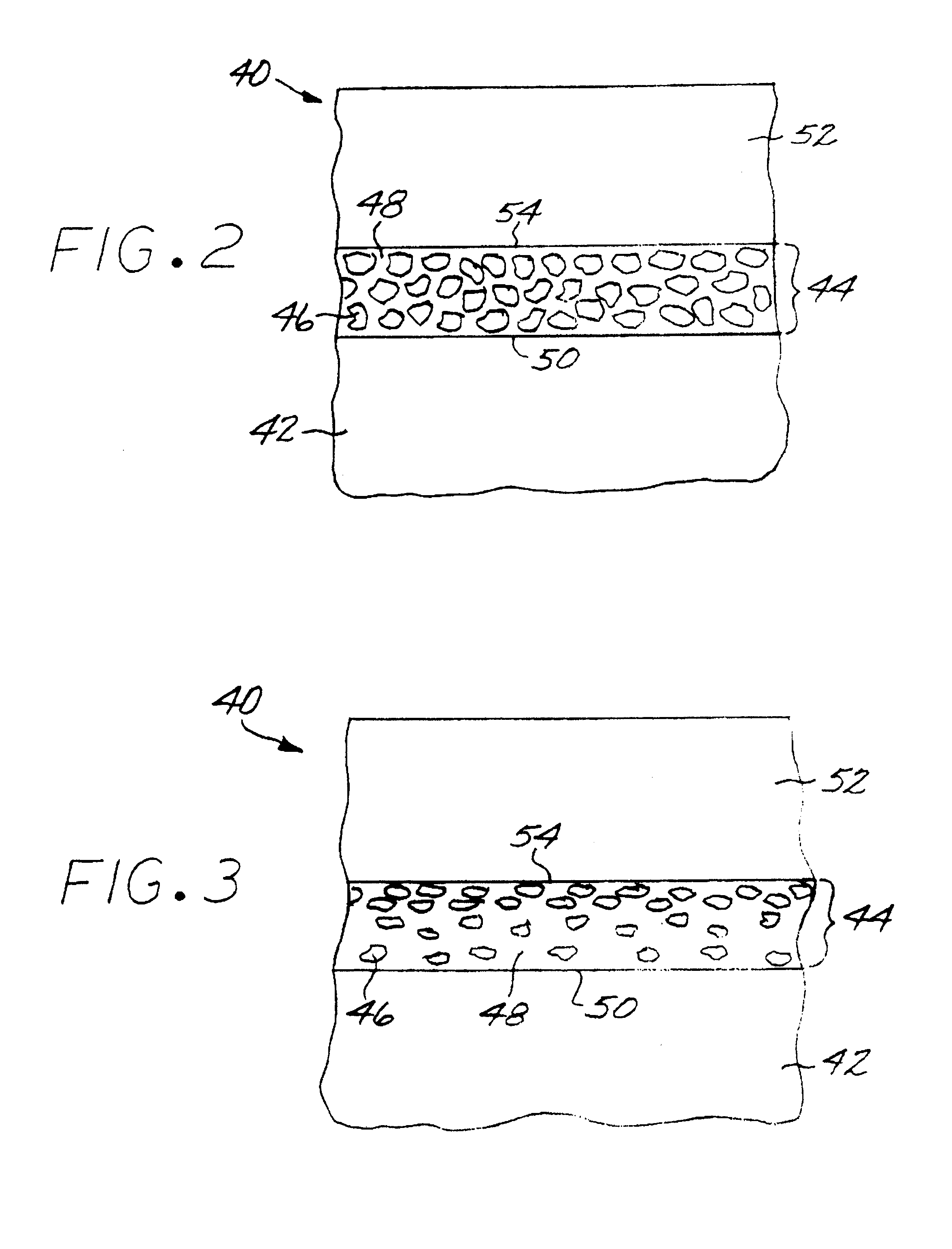

Thermal protection of an article by a protective coating having a mixture of quasicrystalline and non-quasicrystalline phases

InactiveUS6964818B1Minimize potential damageImprove protectionMolten spray coatingPropellersAlloyMetallic Nickel

A coated article includes formed of an alloy having a composition including nickel and aluminum, and a protective coating overlying and contacting the substrate. The protective coating is a mixture of a quasicrystalline metallic phase, and a non-quasicrystalline metallic phase comprising nickel and aluminum. The aluminum is present in an amount of from about 3 to about 35 percent by weight of the non-quasicrystalline metallic phase.

Owner:GENERAL ELECTRIC CO

Method for preparing polyaluminium chloride through catalyst of deposed molecular sieve

ActiveCN1686813AShort production cycleHigh aluminum contentAluminium chloridesMolecular sieveCalcium aluminates

The present invention discloses a method for preparing aluminium polychloride by utilizing waste molecular sieve catalyst. Said method includes the following steps: A. adopting catalytic cracked waste molecular sieve catalyst of oil refinery and adding hdyrochloric acid, making them react to prepare aluminum chloride solution; B. adding calcium aluminate into the above-mentioned aluminium chloride solution to coarsely regulate basicity; and C. adding calcium carbonate into aluminium polychloride with low basicity, regulating basicity of product, and curing so as to obtain the aluminium polychloride with high basicity.

Owner:CCTEG SHENYANG RES INST

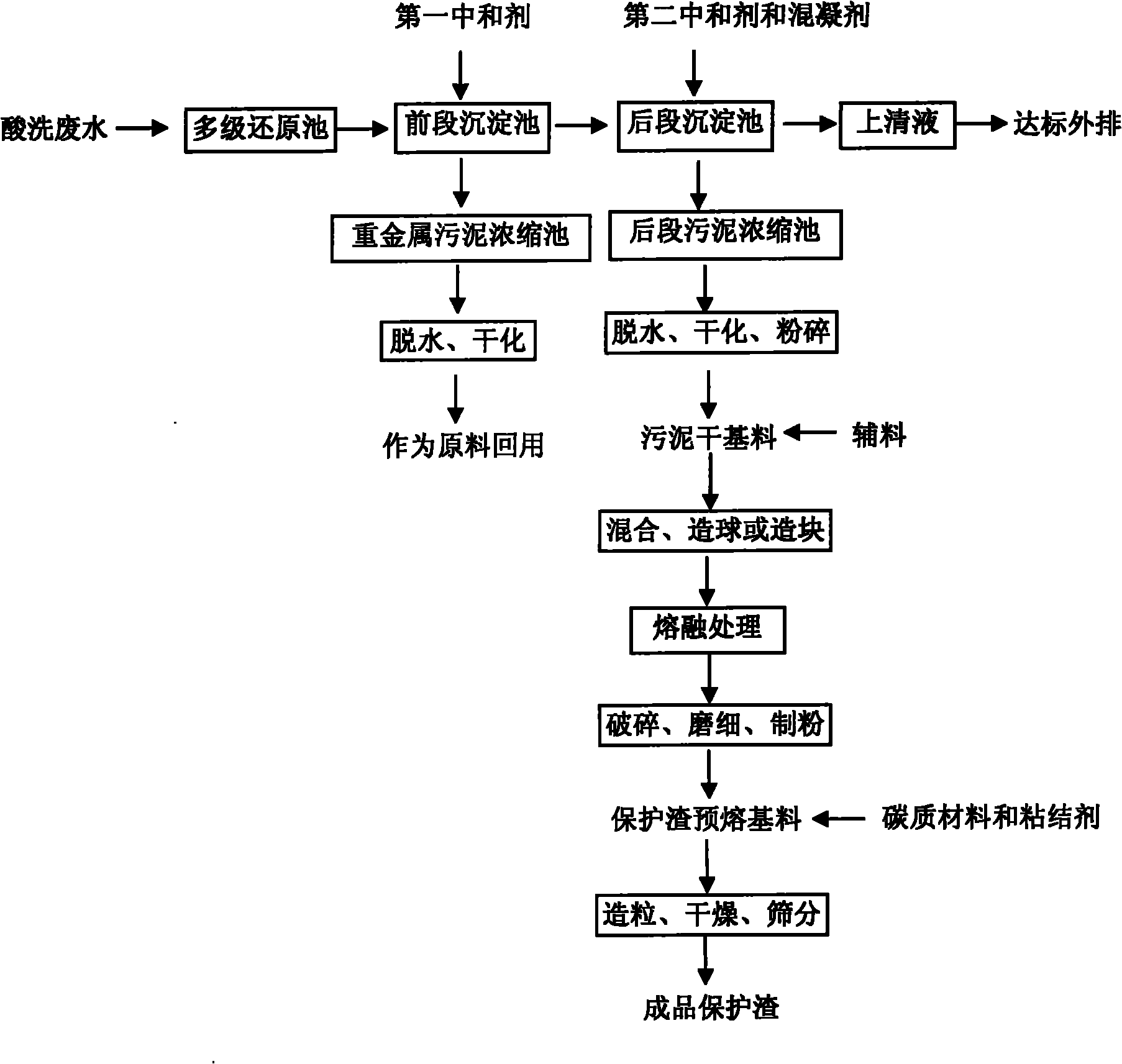

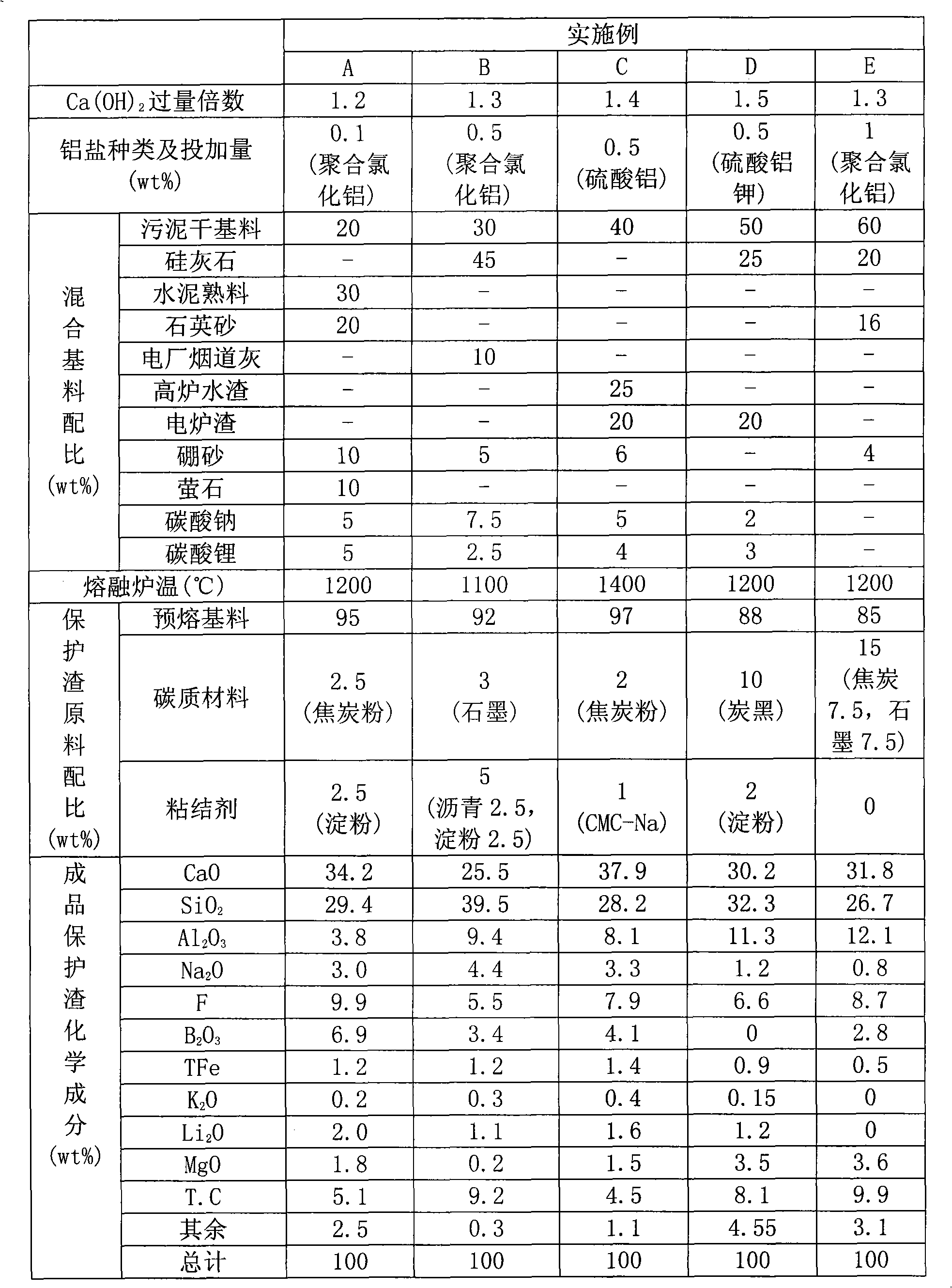

Method for preparing casting covering slag by utilizing stainless steel cold-rolling pickling wastewater

ActiveCN101837435ACost changeChange difficultySludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeSlag

The invention discloses a method for preparing casting covering slag by utilizing stainless steel cold-rolling pickling wastewater, which comprises the following steps of: after the stainless steel cold-rolling pickling wastewater is chemically reduced, adding a first neutralizing agent into a front-section precipitation tank to complex and precipitate heavy metal ions in the wastewater, concentrating, dehydrating and drying precipitates and returning the precipitates to a metallurgical process for reuse; making supernatant fluid enter a rear-section precipitation tank, adding a second neutralizing agent and a coagulant, discharging the supernatant fluid after the supernatant fluid meets the standard, and concentrating, dehydrating, drying and crushing rear-section sludge primarily comprising a calcium salt component to obtain a dry sludge base material; uniformly mixing 20 to 60 weight percent of dry sludge base material and 40 to 80 weight percent of auxiliary materials, melting the mixture in a high-temperature furnace after performing agglomeration or palletizing on the mixture, and crushing, grinding and milling the treated mixture to obtain a pre-melted base material of the covering slag; and adding 2 to 15 weight percent of carbonaceous material and 0 to 5 weight percent of bonding agent into the pre-melted base material of the covering slag, and then palletizing, drying and sieving the mixture to obtain the finished product of the covering slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Device and method for purifying water

ActiveUS20090045145A1Short timeEfficient solutionSemi-permeable membranesWater cleaningFiberMean diameter

A device and method for purifying waste water and stormwater flows by passage through a filter, which can be manufactured in various configurations. The filter has a broad range of thickness ranging from 1 mm to 20 meters. The filter is comprised of fibers from a melt of composition of 50% silicon dioxide, 15% aluminum oxide, 15% calcium oxide, 10% magnesium oxide, and other various oxides at lower percentages. At least the majority of fibers having a mean diameter of 4 microns and a mean length of 3 mm. The fiber solids of content of the material are at most 35% of the volume at a flow rate greater than 1 inch per hour to remove various pollutants from the water flow.

Owner:QUALCOMM INC +1

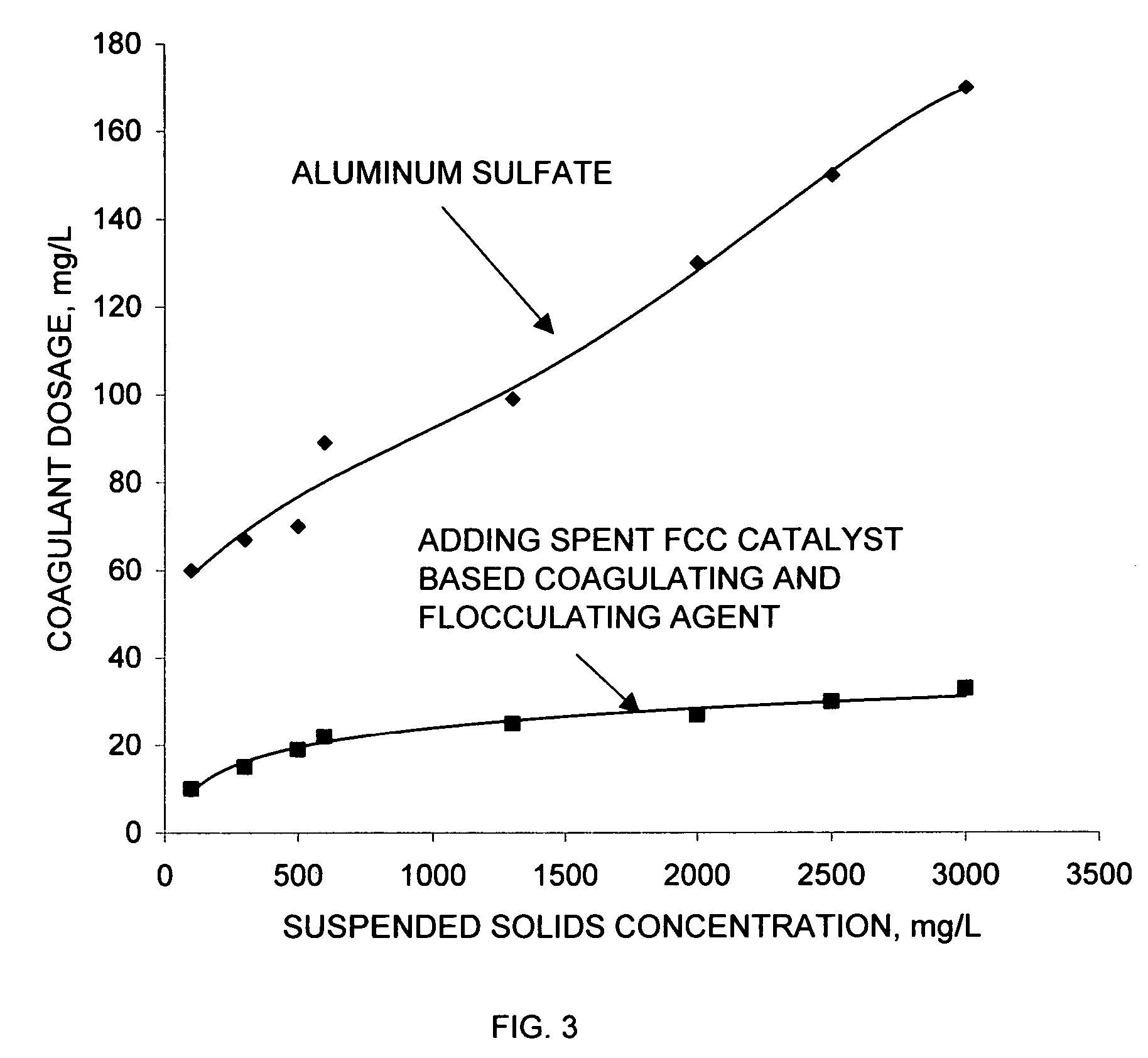

Spent FCC catalyst based coagulating and flocculating agent and method for making it

InactiveUS20060003891A1Short agent producing process timeAvoid problemsWaste water treatment from animal processingWaste water treatment from metallurgical processAluminium chlorohydrateSludge

The proposed coagulating and flocculating agent and the method for making it provide an efficient and economically attractive means for cleaning liquids, particularly water, and waste water and sludge. The spent FCC catalyst based coagulating and flocculating agent is a mineral material comprising polymeric aluminum chloride (PAC) [Al2(OH)nCl6-n]m, n<5, m<10, hydrated ferric chloride [FeCl3·6H2O] and extracted spent FCC catalyst. Furthermore, polymeric aluminum chloride and hydrated ferric chloride are evenly distributed inside the inter pores and outside surface of spent FCC catalyst, this unique feature of the proposed coagulating and flocculating agent leads to an excellent water treatment efficiency. In addition, the method of making it eventually convert spent FCC catalyst, currently being treated as semi-hazardous wastes produced by FCC process, into an environmental friendly new product without any byproduct in the making process.

Owner:ZHANG TAO +2

Steel-smelting alterant for molten steel refining

InactiveCN1807657AImprove performanceQuality improvementBlast furnace componentsBlast furnace detailsNon-metallic inclusionsSmelting

The invention discloses a composition alloy smelling method in mining heater in carbothermic method, which is characterized by the following: using alkaline earth alloy and rare earth alloy as raw material; adopting purified alterant of steel-smelting molten steel to deoxidize, sulfur removal and dispel harmful substance; making shape of non-metallic inclusion of steel balling, size smaller and adequate distribution. The method improves the mass of steel, which reduces steel-smelting cost by using the invention.

Owner:谢廷声

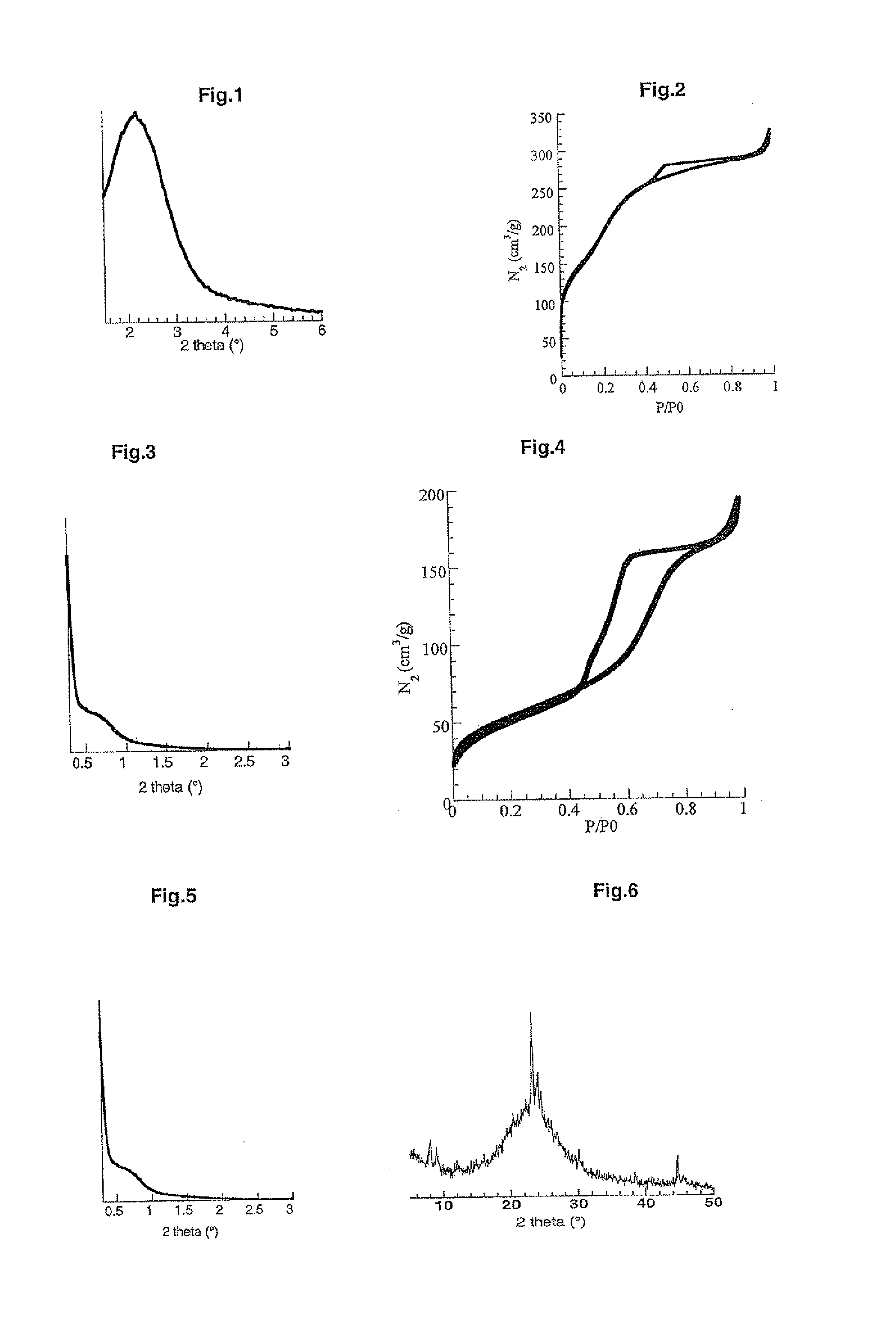

Mesostructured material with a high aluminium content

InactiveUS20090029847A1Advantageous acido-basicity propertyImprove developmentMaterial nanotechnologyMolecular sieve catalystsMaximum diameterPhysical chemistry

A mesostructured material that consists of at least two elementary spherical particles, each of said particles comprising a mesostructured matrix based on aluminum oxide and having a pore size of between 1.5 and 30 nm, an aluminum oxide content that represents more than 46% by weight relative to the mass of said matrix, which has amorphous walls with a thickness of between 1 and 30 nm and whereby said elementary spherical particles have a maximum diameter of 10 μm, is described. Said mesostructured matrix can also contain silicon oxide. Each of the spherical particles of the mesostructured material can also contain zeolitic nanocrystals so as to form a material with a mixed porosity that is both mesostructured and zeolitic in nature. The preparation of said material is also described.

Owner:INST FR DU PETROLE

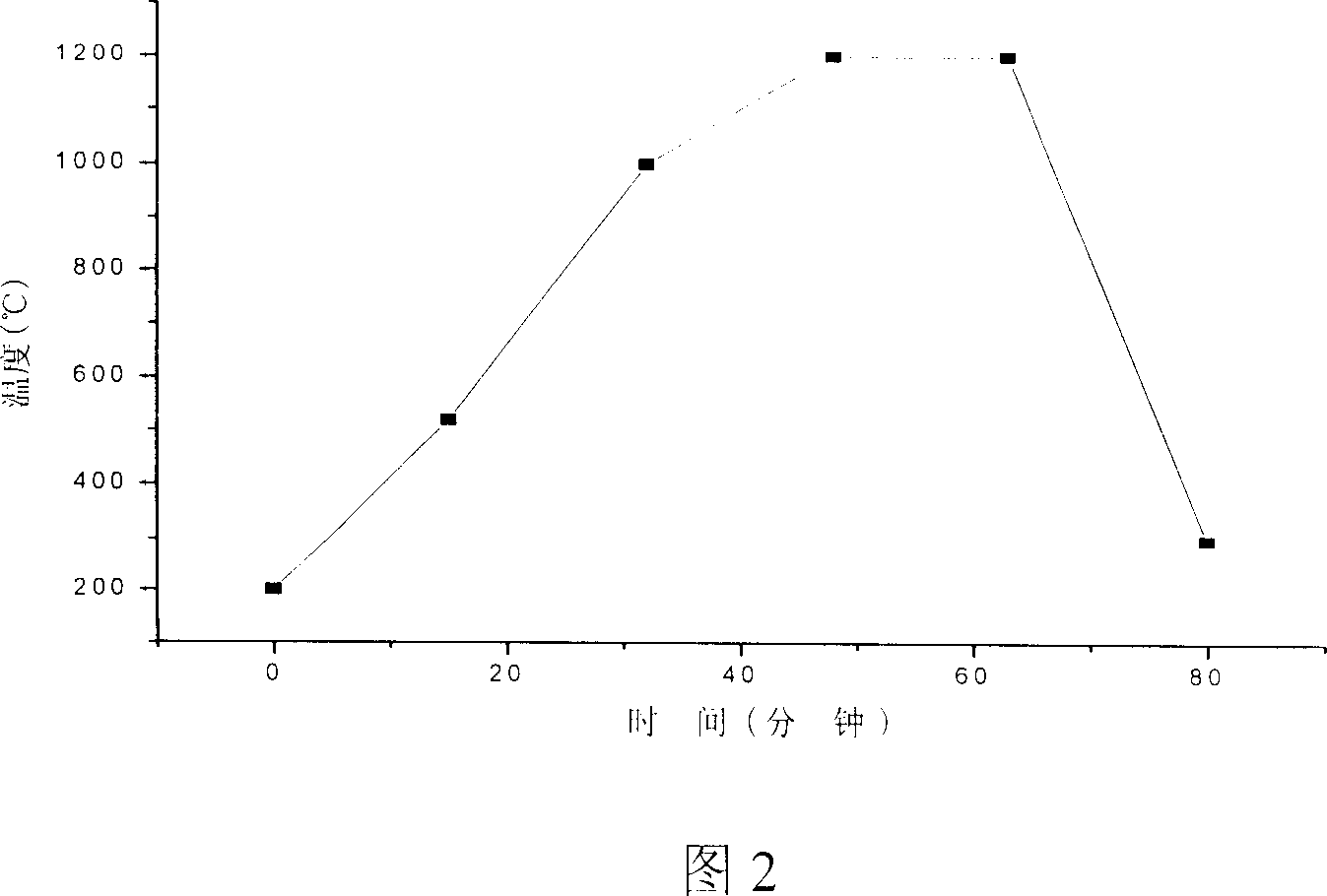

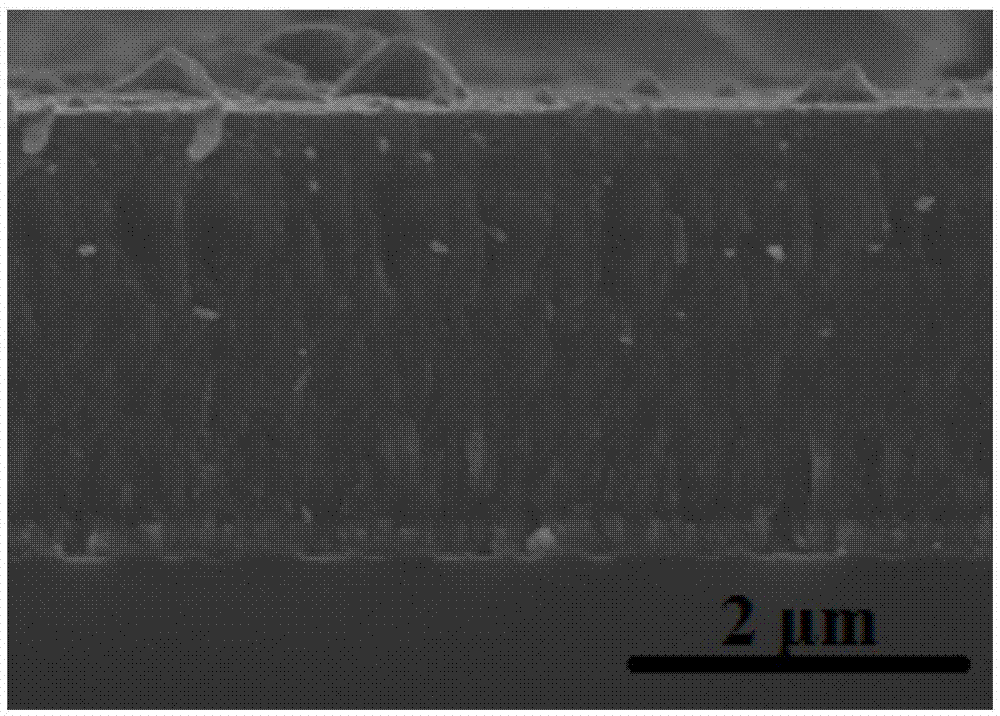

Low temperature baking process of heat conductive corundum-mullite ceramic tile

The present invention discloses low temperature baking process of heat conductive corundum-mullite ceramic tile. The process includes the steps of material treatment, powder preparation, pressing to form and sintering. The heat conductive corundum-mullite ceramic tile has certain energy saving effect, high mechanical performance and high heat conductivity. Using the heat conductive corundum-mullite ceramic tile can utilize geothermal resource effectively, lower energy consumption of building and protect ecological environment.

Owner:SOUTH CHINA UNIV OF TECH

A method for hot-dip aluminum plating of steel structure parts

InactiveCN102268625AImprove corrosion resistanceExcellent immersion performanceHot-dipping/immersion processesMelting tankRare earth

The invention relates to the technical field of metal surface coatings, in particular to a hot dipping method for a steel structure. A hot dipping alloy consists of the following components in percentage by mass: 75 to 85 percent of Al, 3 to 5 percent of Mg, 3 to 5 percent of Si, 0.01 to 0.02 percent of rare earth Y, 0.04 to 0.10 percent of Ni, 0.04 to 0.10 percent of Bi, 0.04 to 0.10 percent of V, and the balance of Zn and inevitable impurities; and in the hot dipping process, a pulsed electric field is applied to a weld pool, and the parameter ranges of the pulsed electric field are that: the pulse width is 80 to 100ms, the acting frequency is 1 to 2Hz and the peak density of pulse current introduced into the weld pool is 0.1 to 10A / cm<2>. By the synergism of the rare earth Y, Ni, Bi and V, the fluidity and wettability of aluminum are improved; the strength and corrosion resistance of a coating are improved by nano Si and Mg2Si phases separated under the action of the pulsed electric field; and the pulsed electric field also has effects of refining grains and improving the compactness of the coating. By the invention, the coating quality is improved, metal consumption is reduced, a process is simple, the conventional process and equipment are mature, the cost is low and the method is worth promoting.

Owner:JIANGSU UNIV

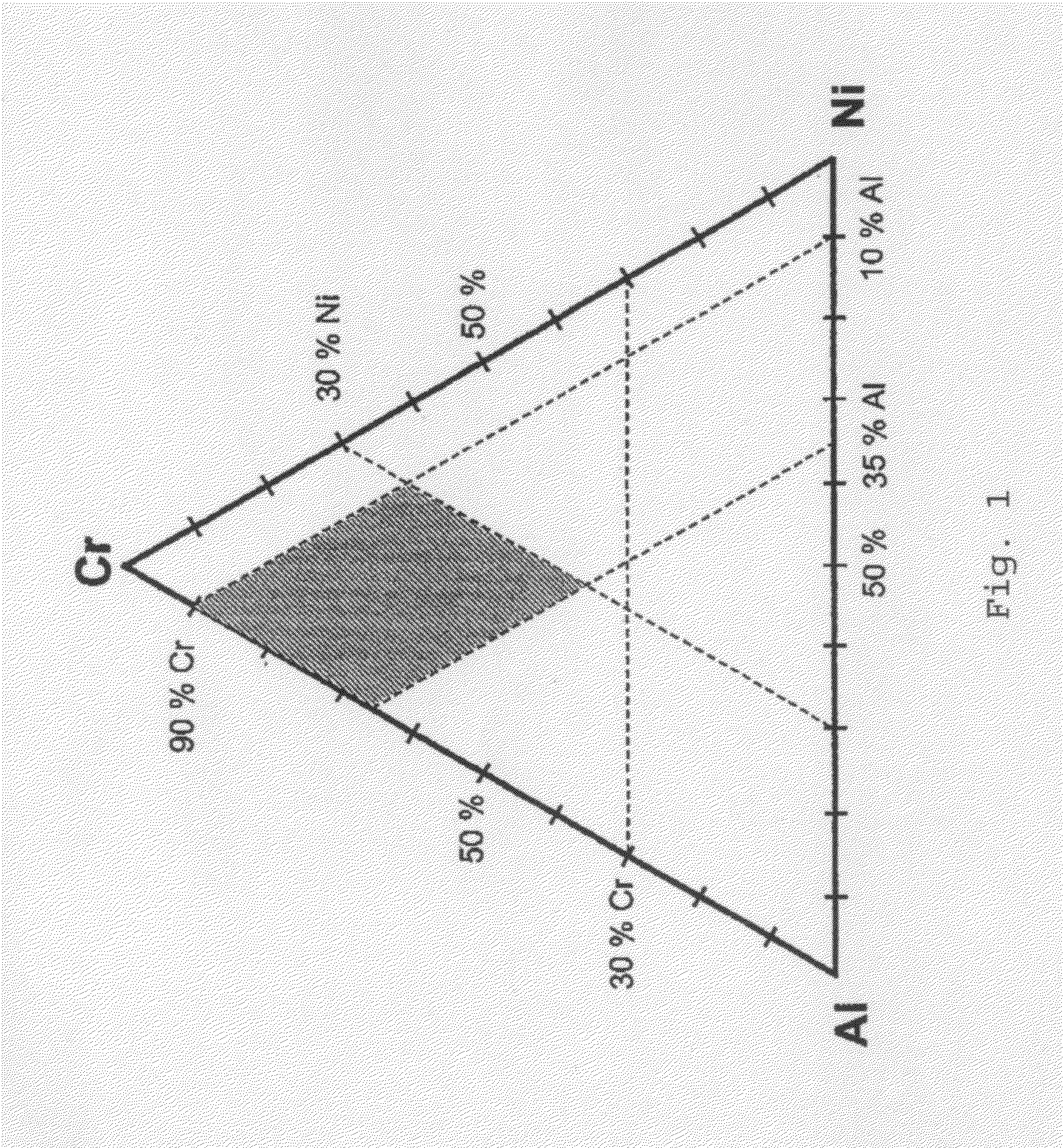

DUPLEX-PHASE CrAl COATING FOR IMPROVED CORROSION/OXIDATION PROTECTION

ActiveUS20140044986A1Improve corrosion resistanceSufficient protectionBlade accessoriesPretreated surfacesChromiumHigh heat

Disclosed is a coating for protecting a component against high temperatures and aggressive media, which coating has at least one subregion whose main constituent is chromium. The layer additionally comprises aluminum, the chromium content at least in the subregion in which chromium is the main constituent being greater than 30% by weight and the aluminum content being greater than or equal to 5% by weight. The invention further provides a process for producing such a coating, comprising chromizing the surface to be coated and subsequently alitizing the chromium-rich layer produced during chromizing.

Owner:MTU AERO ENGINES GMBH

Method for preparing high-strength, high-whiteness, high- thermal-shock-resistance petuntse

The present invention provides a method for preparing high-strength, high-whiteness, high-thermal-shock-resistance petuntse. The preparation method comprises the following production steps of (1) mechanically beating pyrophyllite, washing to remove mud and removing iron by magnetic separator and sieving; (2) mechanically beating kaolin, washing to remove mud and removing iron by magnetic separator and sieving; (3) according to the percentage by weight, weighting 28% of potassium feldspar, 12% of aluminum oxide, 10% of illite, 10% of montmorillonite and 30% of kaolin, mixing with 10% of pyrophyllite, ball milling, removing iron by magnetic separator and sieving to obtain petuntse materials; (4) press filtering the above sieved petuntse materials to obtain petuntse. The petuntse prepared by the invention is suitable for the production of ceramic products for daily use, product qualification rate is high. The strength, whiteness and thermal shock resistance of the product are superior to that of bone china, porcelain and highly siliceous magnesia porcelain, production cost is low, products are particularly applied in dishwashers, microwaves, refrigerators and sterilized cupboard.

Owner:CHAOZHOU RONGCHANG CERAMIC IND CO LTD

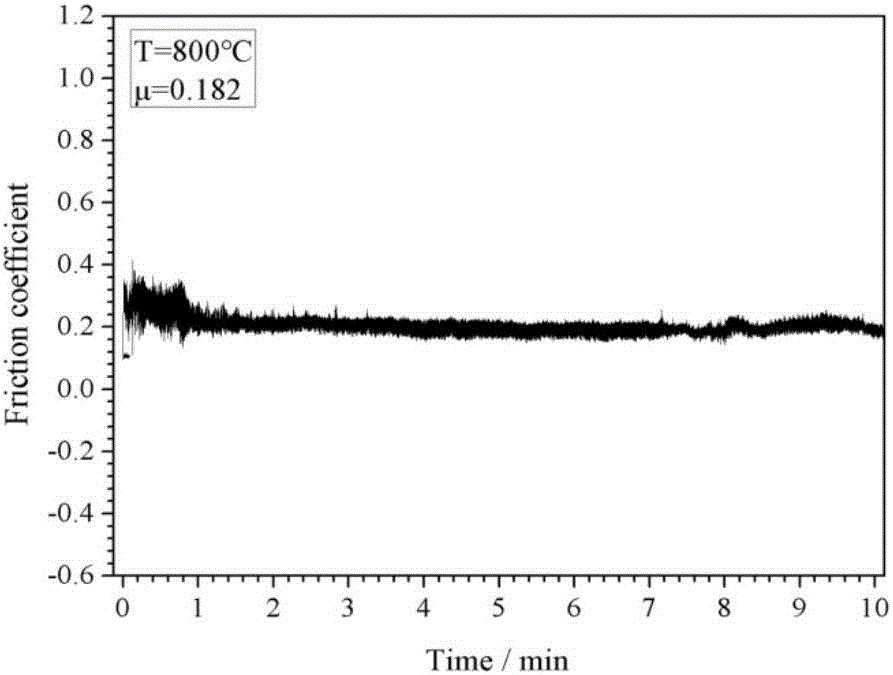

Preparation process for high-silicon super-hard PVD coating

InactiveCN104593737AWon't breakPrecise control of ingredientsVacuum evaporation coatingSputtering coatingVacuum pumpingPower flow

The invention provides a preparation process for a high-silicon super-hard PVD coating. The preparation process comprises the following steps: I, pre-processing a workpiece surface; II, clamping and loading a workpiece; III, performing vacuum-pumping on a furnace chamber; IV, heating the workpiece; V, etching and cleaning a target material and the workpiece; VI, preparing a high-silicon coating; VII, cooling the workpiece. The preparation process is used for obtaining the high-silicon super-hard PVD coating by controlling vacuum degree of a film-coating furnace chamber, bias voltage of a base body, a flow rate of nitrogen gas, target current and the like, wherein the flow rate of the reaction gas nitrogen gas (N2) ranges from 130 sccm to 210 sccm, the bias voltage of the base body ranges from 40 V to 120 V, and the vacuum degree of the furnace chamber ranges from 0.005 mbar to 0.060 mbar. By changing the element components of the coating, high silicon element content is obtained, so that the coating has characteristics of relatively high strength, hardness, wear resistance, high-temperature stability and corrosion resistance. A coating tool prepared by the process can be used for cutting a material with hardness of HRC65, and has relatively good using performances in comparison with a conventional coating.

Owner:SHANGHAI INST OF TECH

High-power arc spraying zinc aluminum pseudo-alloy protecting film and spraying method thereof

The invention relates to a zinc-aluminum pseudo-alloy protecting film of steel member anti-corrosion products and a spraying method thereof, in particular to a high-power arc-spray zinc-aluminum pseudo-alloy protecting film mainly applicable to the anti-corrosion products, such as, bridge steel structures, offshore platforms and other offshore steel structures and the spraying method thereof. The equipment of the invention comprises a high-power spraying power source, a refrigerated air dryer, a high-power arc-spray machine and a secondary atomized spray nozzle, which produces the zinc-aluminum pseudo-alloy protecting film. The method of the invention adopts zinc and aluminum metal lines for arc to spray the pseudo alloy protecting film on a workpiece or a steel surface; the method mainly solves the technical problem of how to obtain premium protecting films by adjusting equipment and technology process, etc. The invention has the beneficial effects that: the aluminum content in the zinc-aluminum pseudo-alloy protecting film is improved, the performance of the protecting film is enhanced, and the service lifetime of the steel structures is prolonged, thereby having the advantages of reducing cost and improving efficiency.

Owner:SHANGHAI RUNXIN CHEM ENG TECH DEV

Quartz ceramic crucible for producing high-efficiency polycrystals and preparation method thereof

ActiveCN102826737AHigh aluminum contentLow resistivityBy pulling from meltGlass shaping apparatusSilicon chipElectric properties

The invention discloses a quartz ceramic crucible for producing high-efficiency polycrystals, which comprises a crucible body, wherein the crucible body is a quartz ceramic crucible; and the internal surface of the crucible body comprises a high-purity quartz ceramic inner layer. The invention overcomes the following defects in the traditional quartz ceramic crucible: the traditional quartz ceramic crucible has high impurities, thereby influencing the electric properties of the downstream battery cells; high-content aluminum can be introduced into the crucible in the traditional ceramic production technique, thereby influencing the resistivity of the silicon wafer; and the traditional quartz ceramic crucible has poor thermal properties. The invention can lower the impurity content and aluminum content in the quartz ceramic crucible, and enhance the thermal properties of the quartz ceramic crucible, so that the quartz ceramic crucible can well satisfy the demands for real production.

Owner:CHANGSHU JIAHE DISPLAY TECH CO LTD

Lead-free free-cutting aluminum brass alloy and its manufacturing method

ActiveUS7776163B2Improve dezincification corrosion resistance of alloyDecrease castabilityRare-earth elementMetallic materials

Owner:XIAMEN LOTA INT CO LTD

Treatment method for purifying zinc pot in hot galvanizing production

The invention discloses a treatment method for purifying a zinc pot in hot galvanizing production. A purification treatment process comprises the steps that hot galvanizing production is carried out while aluminium content of molten zinc is maintained to be 0.025-0.030wt% and scummings in the zinc pot are cleaned in a hot galvanizing production process. The treatment method for purifying the zinc pot in the hot galvanizing production has the advantages that generation of iron in the zinc pot is inhibited by increasing the aluminium content in the molten zinc from 0.18-0.20% at ordinary times to 0.025-0.030%, so as to improve zinc layer adhesiveness and glossiness of a galvanized plate, and quality of the galvanized plate is effectively improved; iron content in the zinc pot after being purified by adopting the treatment method is obviously reduced, and thus a foundation is laid for follow-up generation.

Owner:HEBEI IRON AND STEEL

Foamed ceramic heat preservation board

InactiveCN109608167AImprove performanceHigh porosityCeramic materials productionCeramicwareEpoxyFiber

The invention relates to the technical field of new building materials, in particular to a foamed ceramic heat preservation board, which is composed of the following raw materials in parts by weight:20-40 parts of coal gangue, 10-20 parts of iron tailings, 10-30 parts of fly ash, 5-15 parts of dolomite, 4-10 parts of silicon carbide, 3-9 parts of far infrared ceramic powder, 4-10 parts of calcined talc, 8-12 parts of perlite, 3-9 parts of calcium carbonate, 10-20 parts of epoxy resin powder, 2-4 parts of crack resistant fiber, 1-3 parts of brucite nanofibers, 7-15 parts of modified diatomaceous earth, and 2-4 parts of graphene. The invention takes solid wastes such as coal gangue, iron tailings, fly ash and the like as main raw materials, provides an effective solution for resource reuse,and makes the foamed ceramic heat preservation board have high mechanical strength. Pearlite enveloped with calcium carbonate and epoxy resin powder can increase the overall strength and aging resistance of the heat preservation board, reduce water absorption and improve impermeability. The heat preservation board has the effects of crack resistance, impermeability, heat preservation, flame retardancy, abrasion resistance and compression resistance through the mutual assistance of the raw materials.

Owner:LIUZHOU LIUJING TECH CO LTD

Zinc-aluminum-silicon-rare earth alloy for hot-dip plating steel tube and preparation method thereof

InactiveCN102994929AHigh aluminum contentImprove corrosion resistanceHot-dipping/immersion processesRare earthAlloy

The invention relates to a zinc-aluminum-silicon-rare earth alloy for a hot-dip plating steel tube. The alloy consists of Zn, Al, Si and La. In percentage by weight, alloy consists of 20-30% of Al, 0.5-1.5% of Si, 0.05-0.6% of La and the balance of Zn. The alloy disclosed by the invention has the advantages of good mobility, even and smooth surfaces after a plating layer is formed, no skipping plate and good adhesion, so that the consumption of the raw materials is saved and the production cost is reduced. The corrosion resistance and abrasive resistance of the alloy plating layer are greatly enhanced; the corrosion resistance can reach 10 times to that of the common pure zinc plating layer; and the zinc-aluminum-silicon-rare earth alloy can be widely applied to the protection of steels in corrosive environments.

Owner:CHANGZHOU UNIV

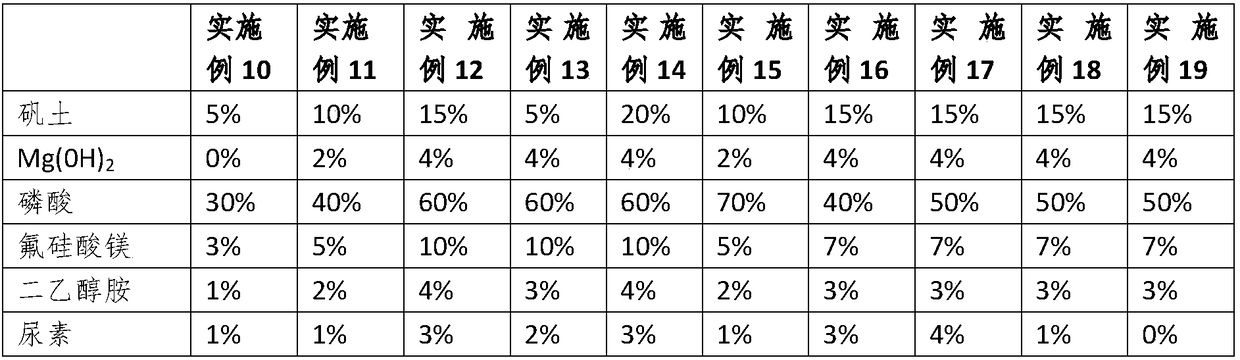

Polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and preparation method thereof

The invention discloses a polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and a preparation method thereof and relates to the technical field of alkali-free accelerators. The alkali-free accelerator comprises, by mass, 50-60% of phosphoric acid, 10-15% of alumina, 5-10% of magnesium fluorosilicate, 2-4% of magnesium hydroxide, 2-4% of diethanolamine, 2-6% ofa condensing agent and the balance of water. The accelerator is mainly used in shotcrete, and the use amount of the accelerator is 5 to 7% of that of a gelling material. The accelerator has good stability and does not produce layering and precipitation crystallization and use effect change after being placed at the room temperature and a low temperature (5 DEG C) for 3 months. The accelerator does not contain alkali metal ions, chloride ions and sulfate ions so that the corrosion of the steel bars in the concrete and the alkali aggregate reaction are reduced and the durability of the shotcrete is improved. Through a compatibility of the condensing agent, the compressive strength ratio measured at 28th days is greater than 100% and satisfies the requirement on the one-grade product in JC477-2005.

Owner:贵州天威建材科技有限责任公司

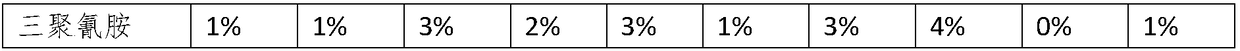

High-temperature-resistant and oxidation-resistant metal-based self-lubricating composite material and preparation method thereof

ActiveCN107177758AHigh aluminum contentGood high temperature oxidation resistanceCerium(IV) oxideAntioxidant

The invention relates to the fields of high-temperature corrosion resistance and self-lubrication, in particular to a high-temperature-resistant and oxidation-resistant metal-based self-lubricating composite material and a preparation method thereof. According to the composite material, high aluminum nickel based alloy serves as a matrix, calcium fluoride / barium fluoride co-crystals and enamel serve as a self-lubricating phase, aluminum oxide serves as a hard phase, rare earth oxides prepared from ceric oxide, yttria and the like at any ratio serve as an antioxidant, spark plasma sintering is conducted, and thus the composite material is prepared, specifically, the composite material comprises, by weight, 65-82% of high aluminum nickel based alloy, 8-15% of the self-lubricating phase, 6-15% of the aluminum oxide and 2-10% of the antioxidant, the weight percentage of the calcium fluoride / barium fluoride co-crystals is smaller than or equal to 10%, and the weight percentage of the enamel is 3-10%. Through high aluminum design of the nickel based alloy and addition of the antioxidant and the enamel serving as the novel high-temperature self-lubricating phase, the composite material integrates the properties of high-temperature resistance, oxidation resistance and excellent self-lubrication, and can be applied to part production under the oxidation-resistant, high-temperature-resistant and self-lubricating environment.

Owner:NORTHEASTERN UNIV

High temperature resistance protective coating and preparing method and application thereof

ActiveCN106929799AImprove high temperature oxidation performanceHigh Al contentVacuum evaporation coatingSputtering coatingOxidation resistantTemperature resistance

The invention discloses a high temperature resistance protective coating and a preparing method and application thereof. The high temperature resistance protective coating comprises a TiN transition layer and an AlTiN coating formed on the TiN transition layer; and in addition, in the AlTiN coating, and the ratio of the Al atom number to the sum of the Ti atom number and the Al atom number is larger than 0.67 and smaller than 0.9. The preparing method includes the steps that a Ti target is selected as a target material, the working atmosphere is N2, an arc ion plating technology is adopted for deposition of the TiN transition layer on the substrate surface; and meanwhile, an Al target and an Al67Ti33 target serve as target materials, and the arc ion plating technology is adopted for deposition of the AlTiN coating on the TiN transition layer continuously. According to the high temperature resistance protective coating, the aluminum content in the AlTiN coating is high, the Al / Ti proportion is adjustable, the oxidation resistance temperature can reach 900 DEG C, the excellent high-temperature oxidation resistant performance and corrosion resistant performance are achieved, and therefore the comprehensive performance of the AlTiN coating, a high-speed cutter and titanium alloy parts is effectively improved, and the service life of the AlTiN coating, the high-speed cutter and the titanium alloy parts is effectively prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

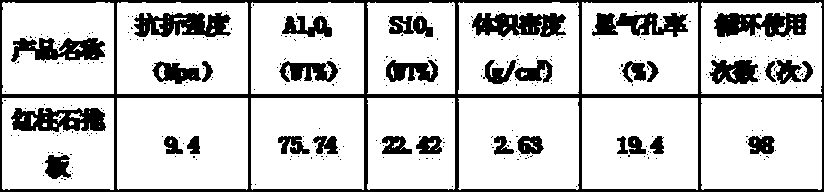

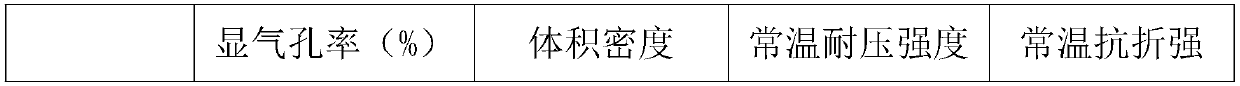

High-temperature andalusite push plate and preparation method

The invention relates to a high-temperature andalusite push plate and a preparation method. The preparation method comprises the following steps: sintering andalusite, white corundum, mullite, alumina micro powder and kaolin are used as main raw materials, and according to different weight percentage, the high-temperature andalusite push plate is prepared by sequentially performing mixing, ageing mixture, formation, drying and high-temperature sintering on the main raw materials. The high-temperature andalusite push plate overcomes the defects that the existing push plate has shorter service life, poor stability and low rupture strength, has the advantages of low apparent porosity, high rupture strength, fewer impurities and long service life, and can be recycled for more than 98 times at higher temperature.

Owner:长兴宏业高科高温耐火材料有限公司

Steel ladle bottom castable

InactiveCN110451998AReduce manufacturing costHigh aluminum contentMelt-holding vesselsCeramicwareMagnesium AluminateSlag

The invention discloses steel ladle bottom castable. The steel ladle bottom castable comprises 15-25% of precast blocks, 40-50% of black aloxite, 5-10% of fused magnesium aluminate spinel, 5-15% of white corundum, 1-5% of sintered spinel, 0.5-1.5% of fibers, 5-10% of activated aluminium oxide micro-powder, 5-10% of a binder, 0.5-1% of a superplasticizer, 2-5% of silica powder, 0.01-0.05% of citricacid and 0.01-0.05% of metal aluminum powder, wherein the particle size of aggregate of the precast blocks is 8-35 mm, and the particle size of the metal aluminum powder is 60 meshes. According to the steel ladle bottom castable, the main raw material aggregate is the industrial by-product black aloxite, thus slag is reused, waste discharge is reduced, the production cost of the steel ladle bottom castable is reduced, moreover, in the steel ladle bottom castable, the content of the black aloxite is high, a thermal shock effect is good, the service life of a fire-resistant product is prolonged, a heat conductivity coefficient of the black aloxite is small, a heat insulation effect is good, a safety factor of a steel ladle is high, and the scouring resistance of the steel ladle bottom castable is improved, so that better use prospects are brought.

Owner:北京利尔高温材料股份有限公司

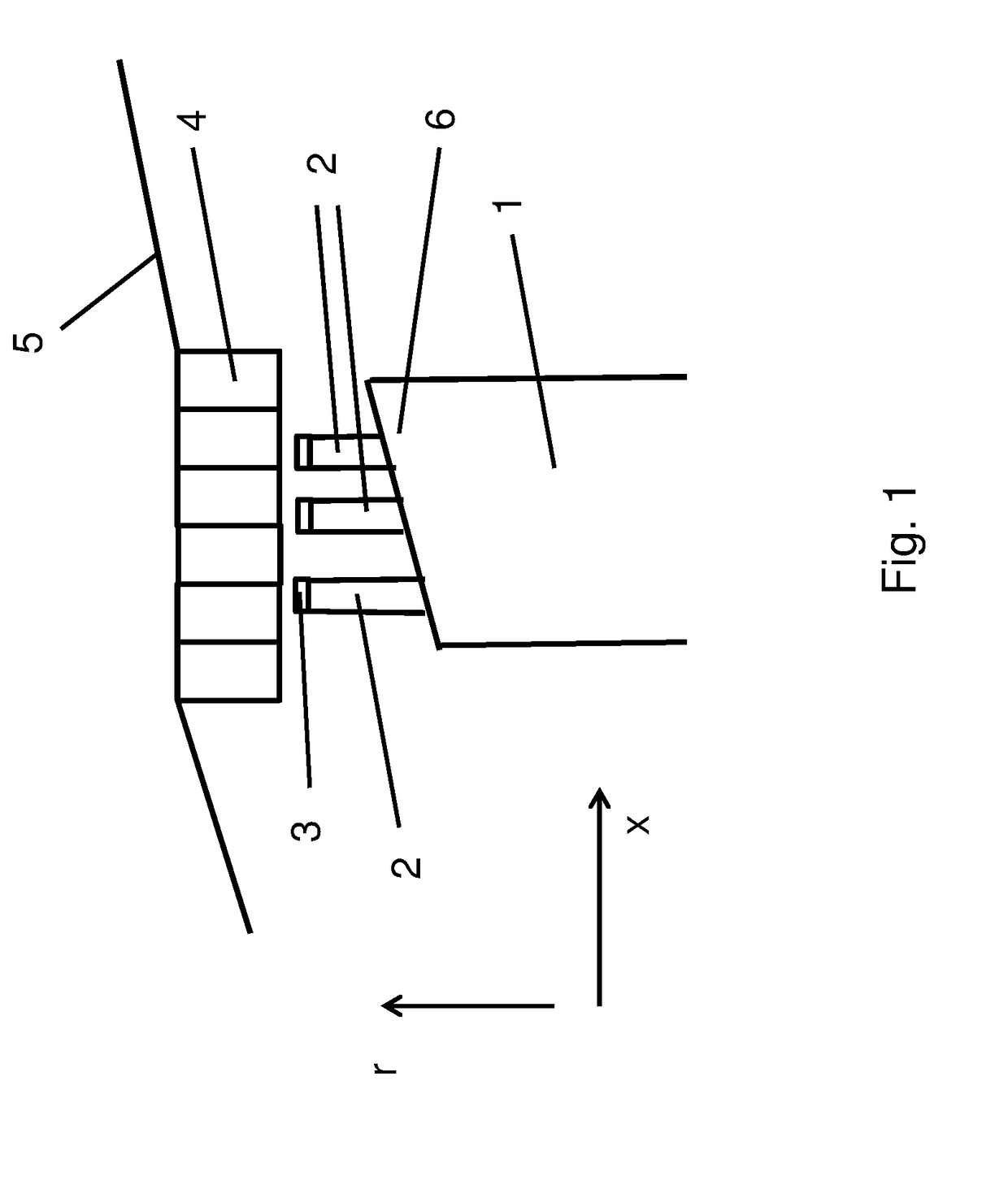

Sealing fin armoring and method for the production thereof

InactiveUS20170096906A1Improve antioxidant capacityHigh aluminum contentMolten spray coatingPump componentsEngineeringSlurry

A method for coating a sealing fin (2) on a component of a turbomachine, in particular on a blade tip (6) of a blade (1) of a turbomachine, with armoring (3, 30,300), and to a corresponding component, in which method a blade (1) having at least one sealing fin (2) and a slurry which comprises particles of MCrAlY or particles for forming an MCrAlY layer (31), where M is nickel and / or cobalt, are provided, the slurry is applied onto the sealing fin and dried, and the sealing fin with the applied slurry is subjected to an aluminizing process so that the MCrAlY layer comprises an Al-rich sublayer (32).

Owner:MTU AERO ENGINES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com