High-temperature andalusite push plate and preparation method

A technology of andalusite and push plate, which is applied in the field of andalusite push plate and its preparation, which can solve the problems of high-temperature calcination and short service life of the push plate, and achieve the effects of reducing porosity, prolonging service life, and eliminating volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

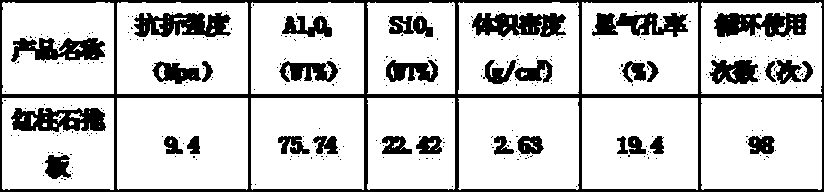

Image

Examples

Embodiment 1

[0030] By weight percentage as:

[0031] Andalusite particles 36%, of which 1mm andalusite particles 32.4% and 0.25mm andalusite powder 3.6%

[0032] White corundum powder 25%, of which 0.25mm white corundum powder 18% and 0.075mm white corundum powder 7%

[0033] Fused mullite powder 23%

[0034] Aluminum oxide powder 12%

[0035] Suzhou No. 2 kaolin 4%

[0036] Add 0.05% sodium methylcellulose as a binding agent, and the process steps are as follows:

[0037] Stir the above-mentioned raw material components evenly in a vertical stainless steel mixer according to the weight percentage, then put them into a horizontal Jiaolong machine for extrusion, store the trapped materials at room temperature for 10 days, and use them after cold pressing with a 500-ton press, and use them after natural drying The 16m-long high-temperature pusher oil kiln is calcined at 1550°C and kept for 8 hours.

Embodiment 2

[0039] By weight percentage as:

[0040] Andalusite particles 44%, of which 1mm andalusite particles 39.6% and 0.25mm andalusite powder 4.4%

[0041] White corundum powder 34%, of which 0.25mm white corundum powder 24% and 0.075mm white corundum powder 10%

[0042] Fused mullite powder 8%

[0043] Aluminum oxide powder 8%

[0044] Suzhou No. 2 kaolin 6%

[0045] Add 0.03% polyvinyl alcohol as a binding agent, and the process steps are as follows:

[0046] Stir the above-mentioned raw material components evenly in a vertical stainless steel mixer according to the weight percentage, then put them into a horizontal Jiaolong machine for extrusion, store the trapped materials at room temperature for 10 days, and use them after cold pressing with a 500-ton press, and use them after natural drying The 16m-long high-temperature pusher oil kiln is calcined at 1560°C and kept for 7 hours.

Embodiment 3

[0048] By weight percentage as:

[0049] Andalusite particles 50%, of which 1mm andalusite particles 45% and 0.25mm andalusite powder 5%

[0050] White corundum powder 22%, of which 0.25mm white corundum powder 24% and 0.075mm white corundum powder 10%

[0051] Fused mullite powder 15%

[0052] Aluminum oxide powder 8%

[0053] Suzhou No. 2 kaolin 5%

[0054] Add 0.07% maltodextrin as a binding agent, and the process steps are as follows:

[0055] Stir the above-mentioned raw material components evenly in a vertical stainless steel mixer according to the weight percentage, then put them into a horizontal Jiaolong machine for extrusion, store the trapped materials at room temperature for 10 days, and use them after cold pressing with a 500-ton press, and use them after natural drying The 16m-long high-temperature pusher oil kiln is calcined at 1580°C and held for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com