High-durability gelatinization addition and preparation method thereof

A durable and admixture technology, applied in the field of gelled admixture and its preparation, can solve the problems of high price and expensive silica fume, achieve low cost, improve frost resistance and impermeability, and improve impermeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

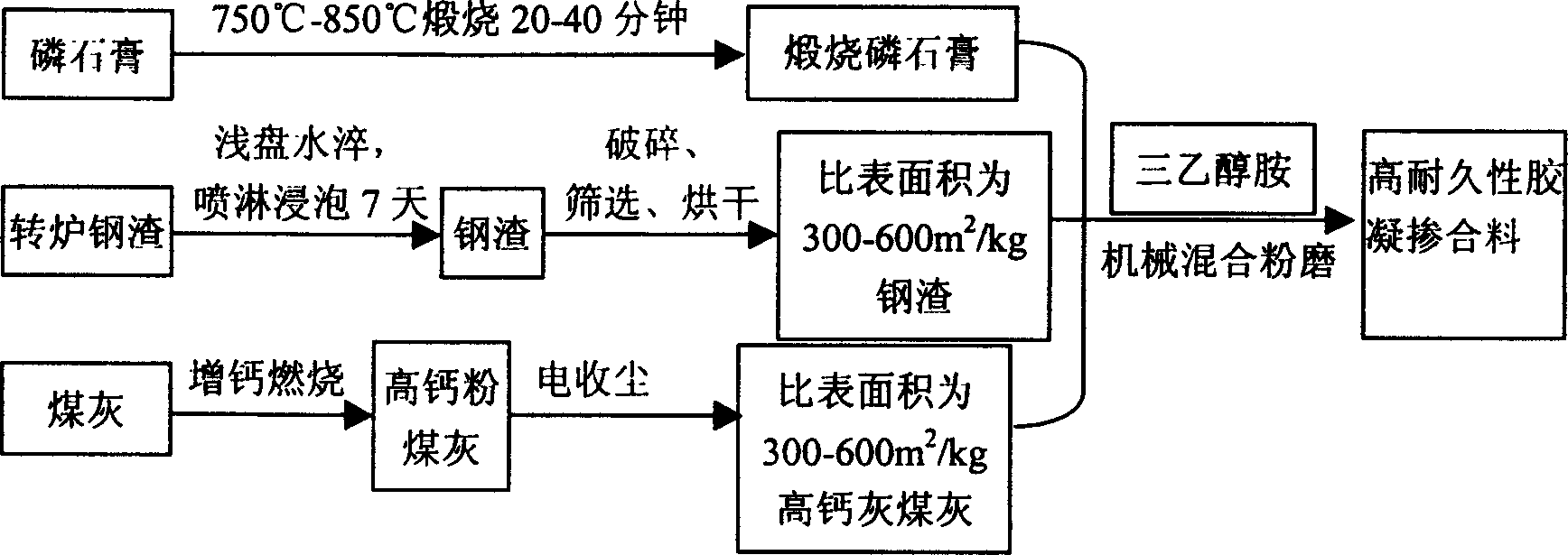

[0017] Embodiment 1: as figure 1 Shown, the preparation method of high-durability gelled admixture comprises the steps:

[0018] 1). Preparation of calcined phosphogypsum: Phosphogypsum (CaSO 4 Content 89.3%, P 2 o 5 content 2.16%), calcined at 780°C for 30 minutes to make calcined phosphogypsum powder.

[0019] 2). Preparation of steel slag powder: in the process of processing converter steel slag (with free CaO weight content of 5.12% and MgO weight content of 6.40% by shallow plate water quenching process) in the iron and steel industry, the steel slag was soaked in saturated water for 7 days. It is taken out of the slag pool, stacked naturally until the water weight content is 13.5%, and then crushed, screened, dried, and magnetically separated to remove iron before each process. The Blaine specific surface area is 400m 2 / kg.

[0020] 3). Selection of high-calcium fly ash: choose high-calcium fly ash with a CaO weight content of 39.8% and a free CaO weight content of...

Embodiment 2

[0029] The preparation method of high durability gelled admixture comprises the following steps: 1). The preparation of calcined phosphogypsum: CaSO 4 The weight content is 80%-95%, P 2 o 5 Phosphogypsum with a weight content of ≤2.6% is calcined at 750°C-850°C for 20-40 minutes to obtain calcined phosphogypsum powder, which is ready for use; 2). Preparation of steel slag powder: In the iron and steel industry, the converter is treated with a shallow pan water quenching process During the process of steel slag (free CaO weight content ≤ 6%, MgO weight content 4%-8%), when soaked in water for 7 days, steel slag is taken out from the slag pool, and naturally stacked until the water weight content is lower than 15%, and then crushed, screened, dried and made by magnetic separation and iron removal before each process. Blaine's specific surface area is 300-600m 2 / kg; 3). The selection of high-calcium fly ash: the high-calcium fly ash obtained by the dry coal ash of the power pl...

Embodiment 3

[0031] The preparation method of high durability gelled admixture comprises the following steps: 1). The preparation of calcined phosphogypsum: CaSO 4 The weight content is 80%-95%, P 2 o 5 Phosphogypsum with a weight content of ≤2.6% is calcined at 750°C-850°C for 20-40 minutes to obtain calcined phosphogypsum powder, which is ready for use; 2). Preparation of steel slag powder: In the iron and steel industry, the converter is treated with a shallow pan water quenching process During the process of steel slag (free CaO weight content ≤ 6%, MgO weight content 4%-8%), when soaked in water for 7 days, steel slag is taken out from the slag pool, and naturally stacked until the water weight content is lower than 15%, and then crushed, screened, dried and made by magnetic separation and iron removal before each process. Blaine's specific surface area is 300-600m 2 / kg; 3). The selection of high-calcium fly ash: the high-calcium fly ash obtained by the dry coal ash of the power pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com