Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

177 results about "Alkali–aggregate reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali–aggregate reaction is a term mainly referring to a reaction which occurs over time in concrete between the highly alkaline cement paste and non-crystalline silicon dioxide, which is found in many common aggregates. This reaction can cause expansion of the altered aggregate, leading to spalling and loss of strength of the concrete.

Cement concrete

The invention discloses cement concrete, which has the advantages of fine particle, good fluidity, low hydration heat, low shrink, small water demand, high early strength and the like. Moreover, the alkalinity is low and the alkali-aggregate reaction of the cement concrete is inhibited; the compactness is high and the durability of the concrete is increased; the concrete interface surface and the gaps of gelled materials can be fully filled, the interface structure of the concrete is improved, the compressive property , the tensile property and the like are improved, the early cracks of the pumped concrete are effectively reduced, the later-stage desiccation is compensated, the crack resistance is improved, and the construction cost and the maintenance expense are reduced, i.e. the production cost is reduced; and the insolation resistance is high, the cement concrete is not apt to conduct heat, the external structure can be changed easily, the mechanism strength is good, the heat resistance, the compression resistance, the impact resistance and the humidity resistance are high, no condensation is caused because of cold and hot alternation, and the cement concrete can adopt to all kinds of climatic conditions.

Owner:赵国平

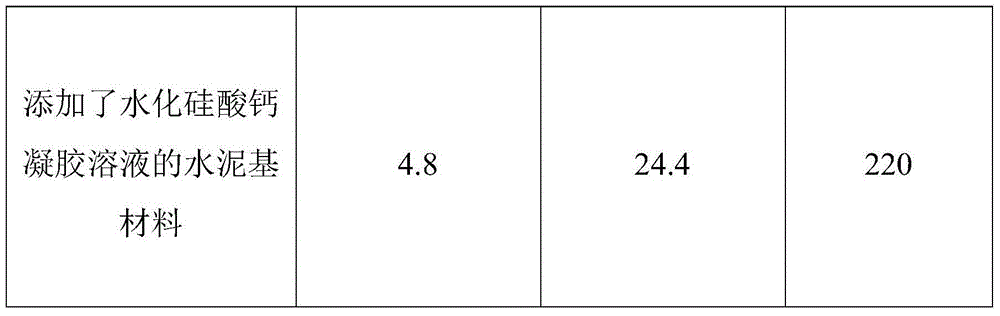

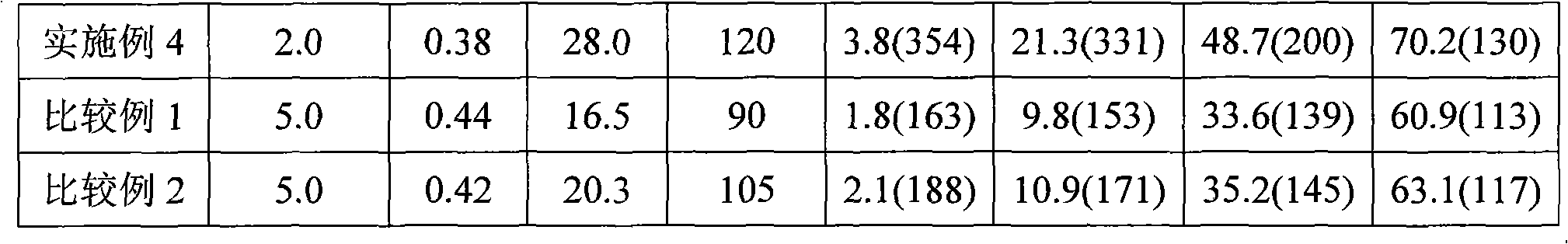

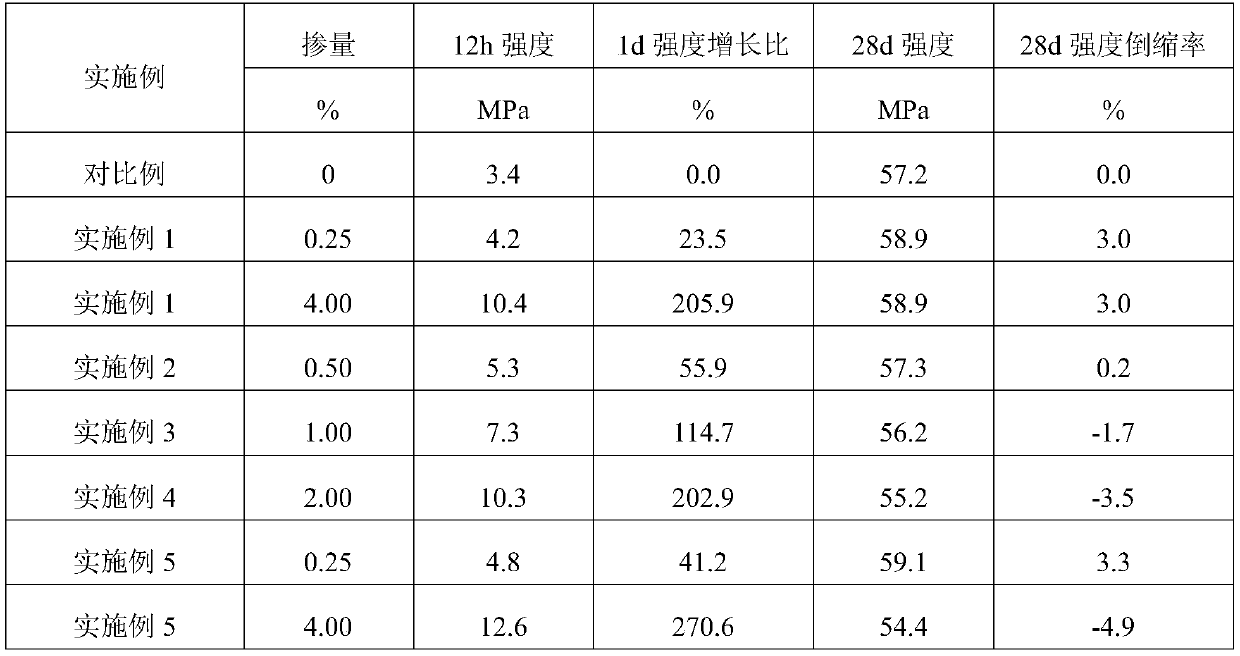

Calcium silicate hydrate gel solution early strength agent and preparation method thereof

ActiveCN104402009ALong term storageGood dispersionAlkaline-earth metal silicatesCalcium in biologyCalcium silicate

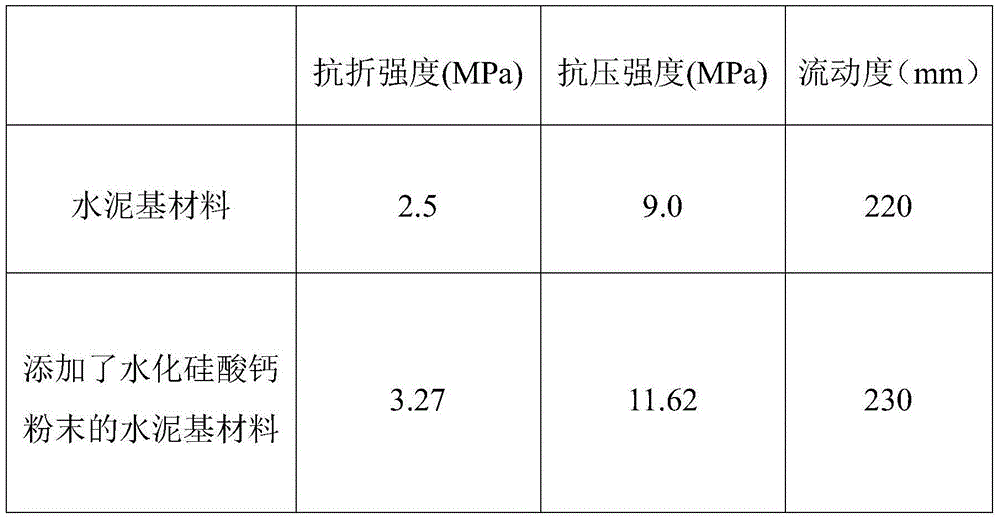

The invention discloses a calcium silicate hydrate gel solution early strength agent and a preparation method thereof, and relates to the technical field of construction material production. The early strength agent and the method are used for solving problems of complicated preparation process, high cost, storage difficulty, and poor early strength effect of traditional calcium silicate hydrate powder. The calcium silicate hydrate gel solution early strength agent comprises a calcareous material, a siliceous material, a gel dispersant, and water. A weight ratio of the calcareous material to the siliceous material is 0.3-3:1. A weight ratio of water to the total of the calcareous material and the siliceous material is 5-30:1. The mass percentage of the gel dispersant is 0.1-2.0%. The preparation method of the early strength agent comprises the following steps: reaction materials are weighed; a sodium silicate water solution and a calcium nitrate water solution are respectively prepared; the two are mixed and are subjected to a reaction, such that a gel mixture solution is obtained; suction filtration is carried out; and water and the dispersant are added for re-dispersion. The early strength agent is uniform and stable, and is convenient to store. The early strength agent is highly convenient to use, and has a good early strength effect. With the early strength agent, an alkali-aggregate reaction risk can be effectively reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

Alkali-free liquid accelerator, and preparation method and application method thereof

InactiveCN106082763AIncrease the concentration of aluminum ionsImprove solubilityShotcreteAlkali free

The invention discloses an alkali-free liquid accelerator, and a preparation method and an application thereof. The alkali-free liquid accelerator is prepared from, by weight, 35-60% of aluminum sulfate, 2-8% of aluminum hydroxide, 1-5% of alcohol amine, 0.5-1% of a dispersant, 0.1-0.5% of a stabilizer, and the balance of water. The accelerator is neutral, effectively avoids later alkali-aggregate reactions and avoids hidden safety troubles; the accelerator has low admixture and superior performances, and is far better than first-grade accelerators in initial setting time, final setting time and later strength; and the accelerator has the advantages of small rebounding amount, low dust concentration, provision of safe and healthy operating environment for construction personnel, engineering cost reduction, construction progress acceleration and good economic and social benefits in the concrete jet construction process.

Owner:SHANDONG YUANLIHUA MINING EQUIP

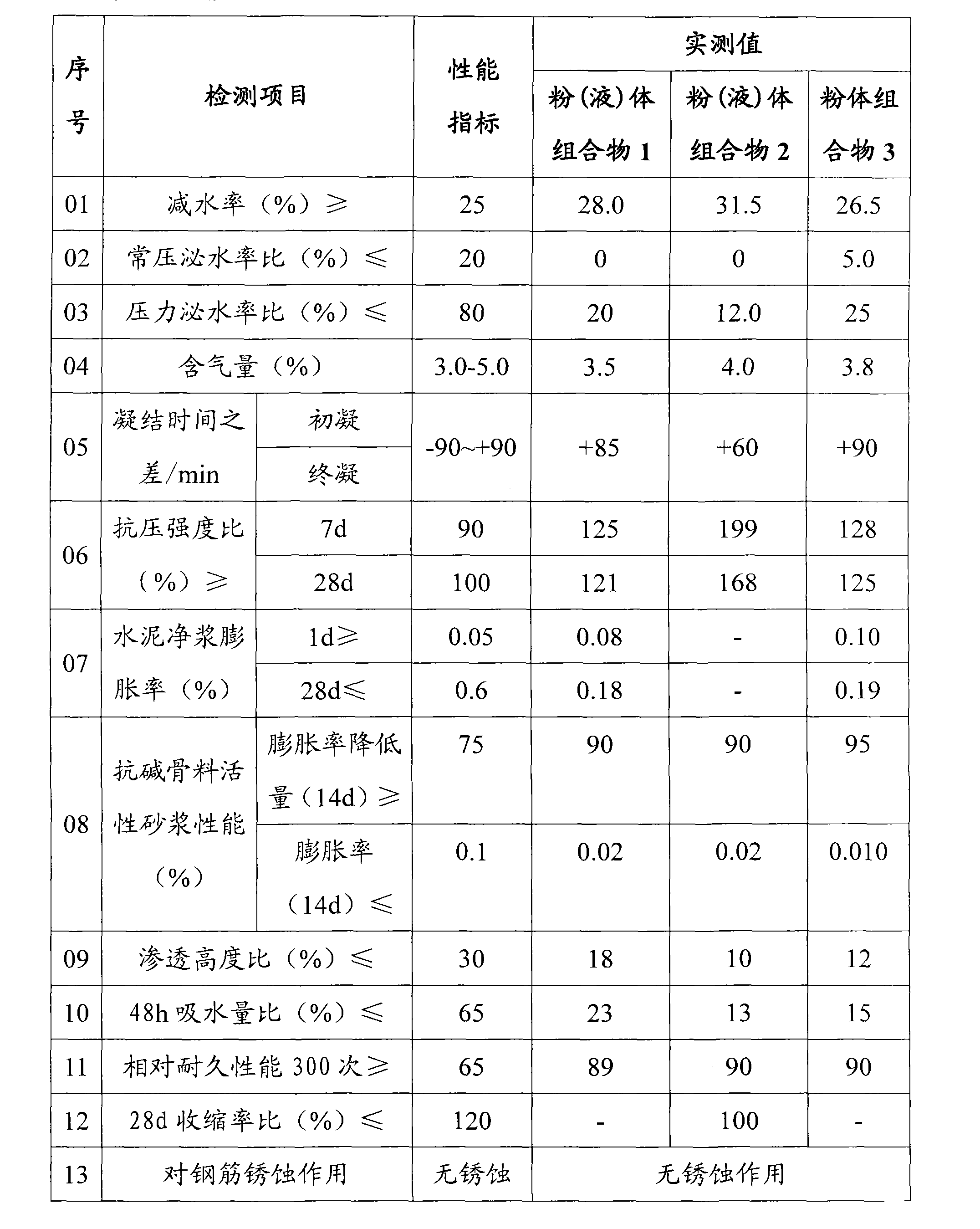

Early strength polycarboxylic acid high performance dehydragent and method for preparing same

InactiveCN101289292AImprove early strengthOvercoming steel bar corrosion prone to occurPolymer scienceCarboxylic acid

The invention relates to a high performance early-strength polycarboxylate water reducer and a preparation method thereof, which pertains to the water reducer field. The early-strength water reducer is prepared mainly based on graft copolymeric carboxylic polymer and compounded with a preferred early strength component; wherein, the copolymeric carboxylic polymer refers to the polymer polymerized by methoxy polyethylene glycol acrylate and acrylic acid / methyl acrylic acid through a free radical initiator in water. The high performance early-strength polycarboxylate water reducer prepared by the invention is characterized by small doping, low alkaline content, no chloride ion and no sulfate, etc., and does not result in the corrosion and alkali aggregate reaction, etc., of the steel bars in the concrete structure, which is helpful for guaranteeing the duration of the concrete structure. The high performance early-strength polycarboxylate water reducer manufactured by the invention can be widely applied to the construction of various concrete projects and the construction of concrete at low temperature, and is particularly suitable for the low energy consumptive production technique of prefabricated concrete members and has a promising application prospect.

Owner:BEIJING UNIV OF TECH

Geopolymer-like cement and preparation method thereof

ActiveCN102180606ASolve stacking problemsBroaden sources of raw materialsSolid waste managementCement productionEtchingSodium aluminate

The invention relates to geopolymer-like cement and a preparation method thereof. The geopolymer-like cement is prepared from the following components by weight percent: 62-73wt% of stone coal vanadium tailings, 5-10wt% of solid alkali metal hydroxide, 7-11wt% of solid sodium aluminate, 8-16wt% of superfine activated microsilica and 6-13wt% of metakaolin. The preparation method comprises the following steps: adding the solid alkali metal hydroxide in the stone coal vanadium tailings, stirring, performing dry ball milling and calcining; adding the solid sodium aluminate, the superfine activated microsilica and the metakaolin in the calcined mixture, stirring, and performing dry ball milling, so as to prepare the finished geopolymer-like cement; and when in use, adding water in the finishedcement, stirring and simultaneously grouting so that hardened slurry is formed at room temperature. According to the invention, the operation is simple, the cost is low, and the chemical corrosion degree on containers and human bodies is low; the hardened slurry of the prepared geopolymer-like cement has the advantages of high compression strength and folding strength, strong resistance to sulfate etching, water etching and alkali-aggregate reaction and good air shrinkage.

Owner:WUHAN UNIV OF TECH

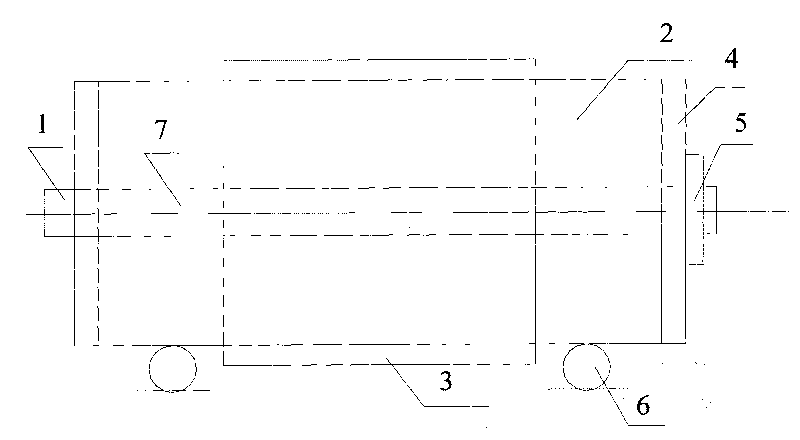

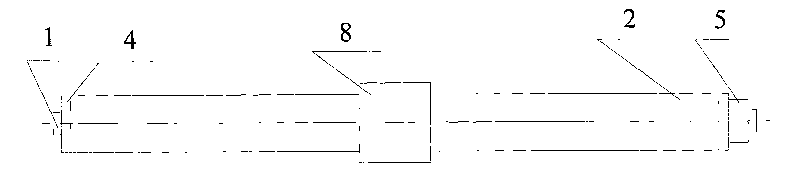

Method for testing concrete performance under pressure stress-chemical coupling effect and device thereof

InactiveCN101726439AConvenient performance testSmall footprintWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCarbonizationEngineering

The invention discloses a method for testing concrete performance under pressure stress-chemical coupling effect and a device thereof. The method applies a pressure stress to a test piece through a prestressing mode, and provides specific chemical corrosion action through a matched sealing device so as to apply a pull force to concrete and apply common chemical action at the same time. The internal stress of the concrete is monitored through a pressure sensor, the pressure stress is kept constant through secondary tension prestressing force, and the sealing device is arranged on the middle part of the concrete test piece to provide the chemical action, so the corrosion action of the chemical medium on a loading device is avoided; and a sealed box can provide one or more chemical erosion environments of carbonization, sulfate erosion, alkali-aggregate reaction, chloride ion erosion and corrosion. The device has a string structure, and can conveniently apply the pressure stress-chemical coupling effects of different conditions to a plurality of concrete test pieces.

Owner:SOUTHEAST UNIV

Retarding superplasticizer composition for roller compacted concrete

InactiveCN102659342AVC value loses quicklyVC value loss is smallRoller-compacted concreteSuperplasticizer

The invention relates to a retarding superplasticizer composition for roller compacted concrete, which is prepared from 40-80 percent of barium-containing naphthalene based superplasticizer, 10-30 percent of modified lignosulfonate, 3-7 percent of plastic retaining agent, 5-15 percent of composite retarder, 1-7 percent of layer silicate mineral material, 0.1-0.5 percent of polysiloxane and 0.1-0.2 percent of air entraining agent. The retarding superplasticizer composition does not contain alkali harmful to alkali-aggregate reaction, has a better inhibition effect to the alkali-aggregate reaction, and has the advantages of high water reducing rate, strong VC value retaining capacity, good water retaining property, small bleeding rate, remarkable retarding effect and the like, so that the prepared roller compacted concrete mixture has the characteristics of good workability, small VC value loss, small bleeding rate, long setting time, greatly reduced early hydration heat and delayed occurrence time of a hydration heat peak, so as to have better construction property, mechanical property and durability.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Marine durable cement concrete

The invention relates to a durable marine cement concrete. The invention is formed by stirring water, cementing material, aggregate, water reducer and admixture. The admixture comprises more than one of rosin and paraffin as well as rusty retardant agent and rosin pyrolytic polymer, wherein the mixing amount of the rosin, the paraffin or the mixtures of the rosin and the paraffin is 2 to 8 percent, of the rusty retardant agent is 1 to 5 percent, and of the rosin pyrolystic polymer is 0.01 to 0.04 percent, based on the gross weight of the cementing material. The cementing material comprises the cement and additive, wherein the additive includes mineral powder and fly ash. The mixing amount of the cement is 25 to 35 percent, of the mineral powder is 45 to 55 percent, and of the fly ash is 15 to 20 percent, based on the gross weight of the cementing material. The mixing amount of the water reducer is 0.80 to 0.99 percent based on the gross weight of the cementing material while of the aggregate is 74 to 76.4 percent. The ratio of the mixing amount of water to the cementing material is 0.30 to 0.40. The invention fundamentally improves the durability of the marine cement concrete, more particularly, the high resistance to corrosion of the alkali-aggregate reaction and Chloride ion erosion.

Owner:SHANDONG LUQIAO GROUP

Crystal nucleal procoagulant early strength agent for concrete and preparation method thereof

InactiveCN107555829ALowers the barrier to hydration nucleationImprove the coagulation effectSteel barConstruction aggregate

The invention discloses a crystal nucleal procoagulant early strength agent for concrete and a preparation method thereof. The crystal nucleal procoagulant early strength agent is prepared from calcium nitrate, sodium silicate and a 18# early strength polycarboxylate water reducing agent, and is characterized in that the parts of the materials used during preparation by weight are as follows: 1.55parts of calcium nitrate, 1.24 parts of sodium silicate and 1 part of 18# early strength polycarboxylate. The crystal nucleal procoagulant early strength agent has the beneficial effects as follows:a hydration nucleation barrier of cement is greatly reduced, the procoagulant effect is obvious, and the early strength increase is better than that of the conventional early strength agent; on one hand, a templating agent in the synthesis process is provided for controlling the growth and the morphology of crystals, and on the other hand, together with C-S-H crystal nuclei in concrete, the crystal nucleal procoagulant early strength agent achieves a synergistic effect on early strength; the crystal nucleal procoagulant early strength agent not only can effectively improve the early strength of the concrete, has no negative effect on late strength, but also can effectively avoid corrosion on steel bars and the concrete, can avoid efflorescence and an alkali-aggregate reaction, and has theadvantages of good cement adaptability, small dosage sensitivity and the like; the preparation process is simple, and the cost is low.

Owner:SHANXI GERUITE BUILDING TECH

Liquid accelerator for sprayed concrete and application thereof

The invention discloses liquid accelerator for sprayed concrete and application thereof. The liquid accelerator for sprayed concrete comprises, by weight percent, 30-50% of aluminum sulfate, 0.5-1.5% of triethanolamine, 10-30% of aluminate, 1.0-5.0% of cellulose, 5-10% of efficient water reducer, and the balance of water. In construction of the sprayed concrete, the accelerator 2-5% of cement is dosed. The accelerator is effective in setting acceleration, initial setting time is 2min-4min, final setting time is 4min-8min, early strength attains fast, 28d compressive strength ratio is over 95%, and the accelerator is high in cohesiveness and low in resilience. In addition, the accelerator is chloride-free and low in alkali and is capable of lowering the risk of concrete alkali-aggregate reaction and erosion of reinforced concrete.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Method for preparing water-based penetration type concrete protective agent

The invention relates to a method for preparing a water-based penetration type concrete protective agent. The concrete protective agent is prepared from the following raw materials: aluminum potassium sulfate dodecahydrate, sodium hydroxide, citric acid, a silane coupling agent, a sodium silicate aqueous solution and deionized water. The method comprises the following operation steps of: adding the aluminum potassium sulfate dodecahydrate into the deionized water, and stirring; adding sodium hydroxide, and stirring; adding the citric acid, and stirring; sequentially adding the sodium silicate aqueous solution and the silane coupling agent, stirring, and obtaining a mixed solution; and standing to obtain the water-based penetration type concrete protective agent. The concrete protective agent penetrates into the concrete to react with the concrete so as to form a whole protective layer, the penetration of moisture, salt and the like on the concrete can be reduced to the greatest degree, and freeze thawing, carbonization, erosion, alkali-aggregate reaction, crack and other damages and corrosions are reduced; and the protective agent is good in waterproof effect, simple in construction process, long in product storage period and wide in application range.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

Fly ash cement and preparation method thereof

InactiveCN103803821AReduce pollutionAnti-alkali-aggregate reactionCement productionActive agentRed mud

The invention discloses fly ash cement comprising the following components in parts by weight: 30-40 parts of fly ashes, 53-65 parts of portland cement clinkers, 2-5 parts of dihydrate gypsum, 0.5-2 parts of excitants, 1-2 parts of active agents, 1.5-3 parts of early strength agents, 5-10 parts of lime, 6-12 parts of calcium-added slag and 15-25 parts of red mud. The fly ash cement disclosed by the invention can be used for also solving the problems of low early strength and long setting time, and the problem that later strength is still high besides that the fly ash cement has the excellent characteristics that the common flash ash cement is small in pollution, low in hydration heat, good in alkali-aggregate reaction resistance, sulfate corrosion resistance, dry shrinkage resistance, stability and the like, and especially, the excitants disclosed by the invention do not contain the substances such as sulfate, chloridion and the like, so that the latent instability of long-term durability of the cement and the concrete is effectively avoided, and meanwhile, the cost is greatly reduced due to adding of a lot of fly ashes and other slag. The obtained cement is extremely high in compressive strength, exceeds 40MPa after three days, and exceeds 70MPa after 28 days.

Owner:张家港市双林制墨涂装有限公司

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid belonging to the technical field of building materials and chemical engineering. The composite cement grinding aid comprises the following raw materials in parts by weight: 5-25 parts of reinforcing agent, 40-80 parts of grinding aid, 1-20 parts of surfactant, 1-20 parts of initiating agent, 1-20 parts of blender and 10-40 parts of water reducing agent. The composite cement grinding aid prepared by using the method is favorable for improving various properties of cement, has low blending quantity, is beneficial to environment protection, hardly causes alkali aggregate reaction of concrete and steel reinforcement corrosion, and is beneficial to the durability of the concrete.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Thin concrete repair composition for alkali-aggregate reaction affected concrete

A cement repair composition is provided for repairing thin concrete. The composition comprises, in weight percentages: fine aggregates, 50-80%; Portland cement, 10-20%; reinforcing fibers such as polyethylene, steel and fiberglass fibers, 0-5%; and a plurality of further additives. The additives preferably include a lithium admixture, an air entraining admixture and a water reducing chemical additive, and a shrinkage compensating chemical additive, in a combined weight percentage of 0.01 to 5%.

Owner:US DEPT OF THE INTERIOR

Composition for inhibiting concrete alkali aggregate reaction and preparation thereof

The invention belongs to the technical field of concrete engineering, and in particular relates to a composition for inhibiting concrete alkali-aggregate reaction and a preparation method thereof. The composition for inhibiting the concrete alkali-aggregate reaction comprises the following compositions: 10 to 50 percent of plasticizing agent, 10 to 70 percent of aluminate and 10 to 30 percent of alkali metal salt or alkaline-earth metal salt, wherein the alkali metal salt or the alkaline-earth metal salt is selected from at least one group of lithium compounds, barium compounds or calcium-magnesium compounds, and the total content of various compositions is 100 percent. The composition can cover or coat active elements of aggregate, prevent or isolate contact reaction between alkali metal ions such as K<+> and Na<+> and the active elements of the aggregate, prevent generation of soluble swelled gel and generation of insoluble compounds, and further eliminate alkali-aggregate reaction and improve the durability of concrete.

Owner:苏笮斌

Special additive for inhibiting concrete alkali-aggregate reaction

The invention relates to a concrete additive, particularly to a special additive for inhibiting a concrete alkali-aggregate reaction. Active fine powder is used as a carrier, and the multiple compounding technologies such as air entraining (lignosulfonate), water resistance (stearate), water reduction (lignin), early strengthening (nitrate) and the like are adopted. The cost of the additive is greatly lower than that of the foreign lithium salt additive. The doping amount of the inhibitor is 2-4% of cement aiming at high, medium and low activities of aggregate under different alkali content conditions, and the inhibitor has good inhibitory effect. The higher the activity of the aggregate alkali is, the more obvious the inhibitory effect is. The higher the content of concrete alkali is, the more obvious the inhibitory effect is. After the inhibitor is added into concrete, the overall performance is increased, the workability is improved, the slump loss is reduced, 28d strength is increased, the durability such as freezing resistance, seepage resistance and the like is increased, the harms of steel bar corrosion and the like do not occur, the service life of concrete is prolonged, the use safety of concrete is ensured, and the social benefit is great.

Owner:刘福战

An alkali-free chloride-free liquid accelerator

An alkali-free chloride-free liquid accelerator is disclosed. The liquid accelerator is prepared from following raw materials by weight: 35-55% of polyaluminium sulfate, 5-25% of magnesium oxide, a citrate type salt accounting for 15-30% by weight of the polyaluminium sulfate, 1-5% of an inorganic acid, 1-5% of a stabilizing agent, 1-5% of a defoaming agent and 1-5% of an antichlor, with the balance being water and the total weight percentage being 100%. The alkali content of the liquid accelerator is less than 1%, and the chlorine ion content is less than 1.1%, so that the liquid accelerator belongs to alkali-free chloride-free liquid accelerators. By using the liquid accelerator into concrete, the possibility of alkali-aggregate reactions is largely reduced, steel bar corrosion is prevented, and the durability of concrete is enhanced. The 2.28-d compressive strength ratio is higher than 111%. By using the liquid accelerator into the concrete, the early-stage strength is high, the later-stage strength does not loss lose and is increased, and the stable period is longer than 6 months.

Owner:CHANGAN UNIV

Environment-friendly anti-cracking waterproof agent for concrete and preparation method thereof

ActiveCN112110675AImprove pore structureImprove compactnessSolid waste managementSlagCarboxylic acid

The invention discloses an environment-friendly anti-cracking waterproof agent for concrete and a preparation method thereof. The anti-cracking waterproof agent comprises the following raw materials in percentage by weight: 1%-3% of graphite phase carbon nitride nanosheets, 5%-20% of modified ardealite powder, 10%-30% of ultrafine lithium slag powder, 5%-10% of nano titanium dioxide, 5%-15% of bauxite, 20%-50% of modified bentonite, 5%-15% of a magnesium oxide expanding agent, 1%-5% of zirconium silicone, 5%-15% of an organosilicon water repellent, 0.5%-2% of high alkali resistant water absorbent resin, and 1%-5% of a polycarboxylic acid water reducer. the waterproof agent provided by the invention not only can improve the pore structure of concrete, improve the compactness of concrete andenhance the impermeability of concrete, but also can reduce the risk of shrinkage cracking of concrete by utilizing the micro-expansion characteristic, and improves the crack resistance of concrete under the synergistic action of the waterproof agent and an alkali-aggregate reaction inhibition component; by utilizing the excitation effect of the nano titanium dioxide on the graphite-phase carbonnitride nanosheet, the nano titanium dioxide shows efficient photocatalytic performance under natural light, can effectively degrade harmful components such as nitric oxide in the air, and plays a positive role in purifying the environment.

Owner:重庆源锦锦兴新材料科技有限公司

Alkali-activated binder, alkali-activated mortar, concrete products and wet red clay paving material using binder

InactiveUS20110287198A1Good effectMaintain compressive strengthEnvelopes/bags making machinerySolid waste managementAlkali activatedUltimate tensile strength

The present invention relates to an alkali-activated binder which can be used as a binder for replacing cement, and more particularly, to an alkali-activated binder, and to mortar, concrete, concrete products, and wet loess paving material comprising the binder, in which inorganic sodium-free alkaline materials are contained to reduce the total amount of Na2O and K2O in concrete, thus improving the workability and the strength stability and inhibiting the alkali-aggregate reaction.

Owner:IND FOUND OF CHONNAM NAT UNIV

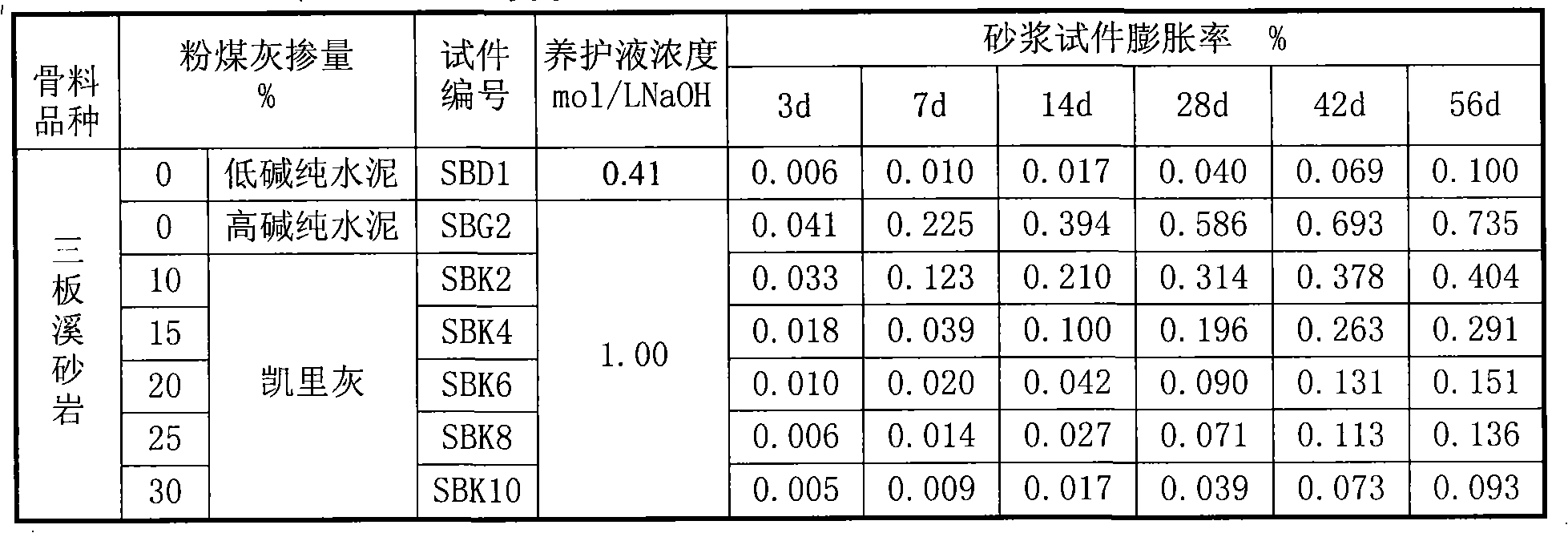

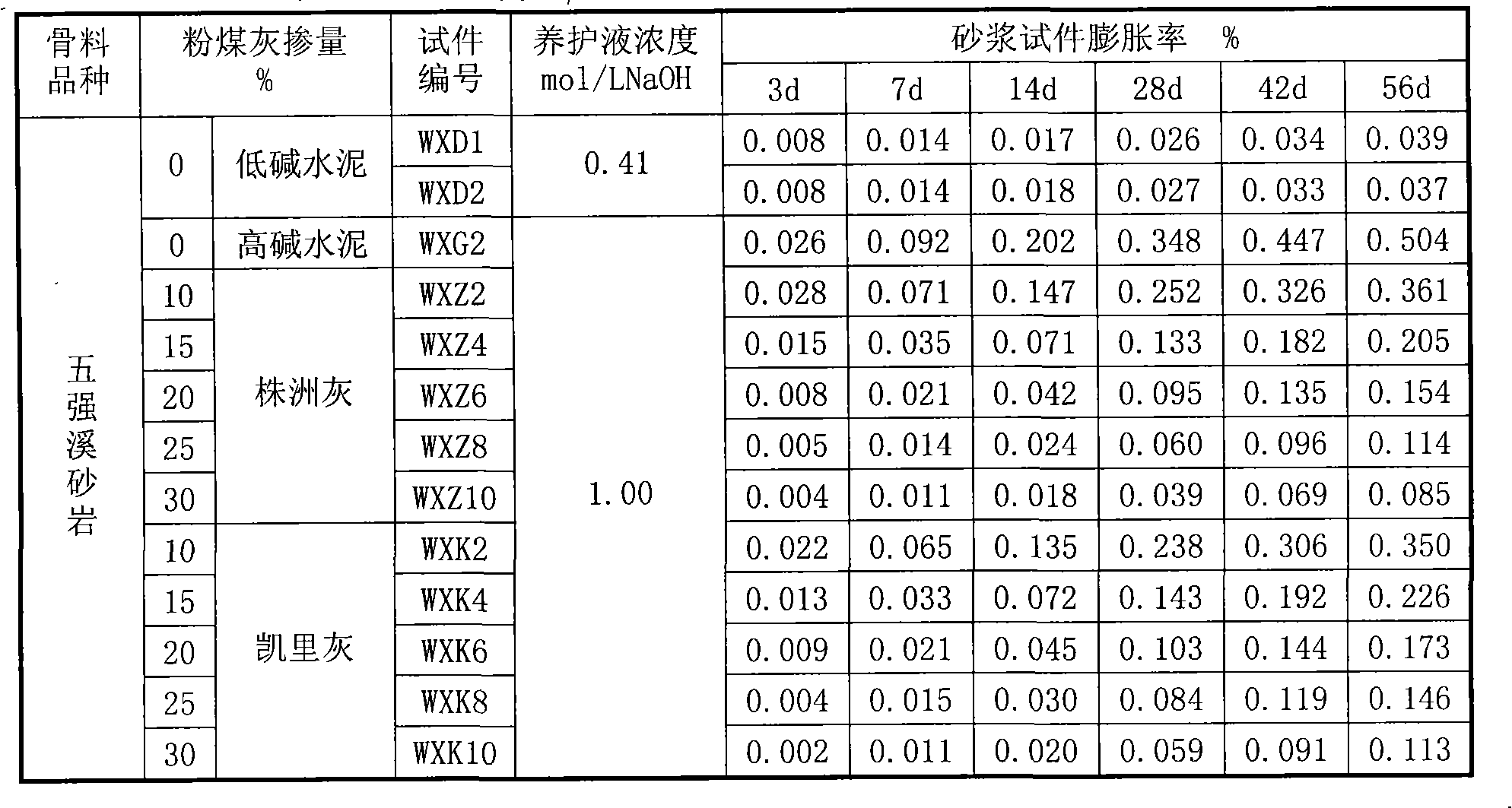

Method for evaluating effectiveness of measure for inhibiting alkali-silica active reaction of concrete aggregate

ActiveCN101514982AIneffective containmentMeet the needs of engineering constructionMaterial testing goodsCement mortarFly ash

A method for evaluating effectiveness of a measure for inhibiting alkali-silica active reaction of concrete aggregate comprises the following steps: using active aggregate used in actual works and low-alkali cement with available alkali Na2O content less than or equal to 0.60% or high-alkali cement with available alkali Na2O content of 0.90%+ / -0.1% to form mortar test pieces by mixing fly ash, and determining an inhibition measure effective where low-alkali cement mortar test pieces are formed and expansion rate of the mortar test pieces in 14 days is equal to or less than 0.040%, and determining the inhibition measure effective where high-alkali cement mortar test pieces mixed with the fly ash are formed and expansion rate of the mortar test pieces in 14 days is equal to or less than 0.050%. Thus, the method can help quickly determine the expansion rate of the mortar test pieces formed with the active aggregate used in actual works, and verify and evaluate the effectiveness of the measure for inhibiting the reaction of the concrete aggregate to meet engineering construction need.

Owner:POWERCHINA ZHONGNAN ENG

Compound sulfate cement

InactiveCN101885589AExcellent resistance to sulfate corrosionImprove impermeabilitySolid waste managementSlagRoad surface

The invention provides compound sulfate cement which is characterized in that slag, plaster, aluminosilicate waste residues and cement clinker are taken as basic materials, and one kind of or various kinds of lime, limestone, alunite and zeolite are taken as auxiliary materials. The compound sulfate cement comprises the following components in parts by weight: 40 to 80 parts of slag, 5 to 20 parts of plaster, 10 to 30 parts of aluminosilicate waste residues, 3 to 8 parts of cement linker and 0 to 10 parts of auxiliary materials. The invention has the characteristics of high strength, low heat and no shrinkage or micro-expansion and is specifically suitable for the construction of mass concrete, such as large dams, cushion caps, concrete road surfaces, marine engineering, and the like. The cement has no dissociative calcium hydroxide, has excellent sulfate corrosion resistance performance, can fundamentally solve alkali-aggregate reaction due to extremely lower alkalinity, has important meaning for the durability of the construction of highway and railway across saline and alkaline land, and has good impermeability, and the strength and the impermeability of the cement in seawater can be continuously enhanced. Moreover, the corrosion of steel bars can be effectively resisted due to Fridel salt formed by the reaction of aluminum oxide in the slag and chloride ions.

Owner:SHANDONG UNIV OF TECH

Concrete anti-corrosion admixture

The invention discloses a concrete anti-corrosion admixture which is prepared by mixing the following raw materials in part by weight: 15 to 30 parts of poly carboxylic acid water reducing agent, 10 to 15 parts of organic amine, 0.1 to 0.15 part of triterpenoid saponins, 0.1 to 0.5 part of migration prevention agent, 2 to 3 parts of organic alkylol amine and 50 to 70 parts of water. The anti-corrosion admixture has no nitrite in the components, has no pollution to the environment and has chloridion content of lower than 0.07 percent. Due to the low chloridion content, the probability of concrete corrosion is reduced. The alkali content of the concrete anti-corrosion admixture is lower than 1.0 percent by weight, so that an alkali aggregate reaction is avoided, adverse effect of post cracking and the like of concrete are reduced, the service life of the concrete is prolonged and the durability is improved. The concrete anti-corrosion admixture is suitable for large-scale industrial production.

Owner:河北铁园科技发展有限公司

Nano cement-based crystal-nucleated early strength agent and preparation method and application thereof

ActiveCN110304857AAchieve the goal of early strengthGood compatibilityNanotechnologyAlkali–aggregate reaction

The invention provides a nano cement-based crystal-nucleated early strength agent and a preparation method and application thereof. The nano cement-based crystal-nucleated early strength agent mainlycomprises, by weight, 20-35 parts of cement, 1-3 parts of a dispersant, 0.5-1 part of a retarder, and 64.5-79.5 parts of water. Nano cement is used to provide a crystal nucleus for hydrating of the cement-based material herein, the crystal nucleus induces rapid hydration of the cement-based material; after the nano cement is added to the cement-based material, pore structure and induced nucleatingcan be improved to arrive at early strength; in addition, no harmful ions are introduced, the early strength agent herein is well compatible with cement and never causes alkali-aggregate reaction, scumming and the like.

Owner:WUHAN UNIV OF TECH

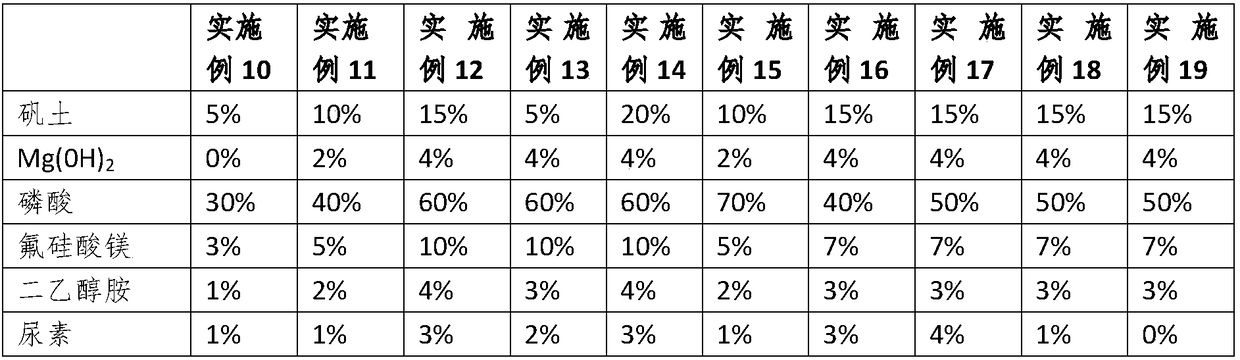

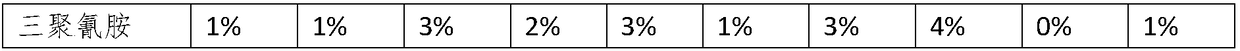

Polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and preparation method thereof

The invention discloses a polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and a preparation method thereof and relates to the technical field of alkali-free accelerators. The alkali-free accelerator comprises, by mass, 50-60% of phosphoric acid, 10-15% of alumina, 5-10% of magnesium fluorosilicate, 2-4% of magnesium hydroxide, 2-4% of diethanolamine, 2-6% ofa condensing agent and the balance of water. The accelerator is mainly used in shotcrete, and the use amount of the accelerator is 5 to 7% of that of a gelling material. The accelerator has good stability and does not produce layering and precipitation crystallization and use effect change after being placed at the room temperature and a low temperature (5 DEG C) for 3 months. The accelerator does not contain alkali metal ions, chloride ions and sulfate ions so that the corrosion of the steel bars in the concrete and the alkali aggregate reaction are reduced and the durability of the shotcrete is improved. Through a compatibility of the condensing agent, the compressive strength ratio measured at 28th days is greater than 100% and satisfies the requirement on the one-grade product in JC477-2005.

Owner:贵州天威建材科技有限责任公司

Test method for evaluating actual risk of alkali-aggregate reaction of hydraulic concrete

ActiveCN102565311AImprove distribution uniformityExtended pathMaterial testing goodsCalcium hydroxideAqueous solution

The invention relates to a test method for evaluating the actual risk of an alkali-aggregate reaction of hydraulic concrete. The test method comprises the following steps of: (1) mixing actual raw materials according to mix proportions to form concrete, adjusting equivalent Na2O content of cement to 1.00-1.50 percent by adding NaOH, screening aggregate with the grain size of being more than 40mm out, and forming a test piece from the concrete subjected to wet screening; (2) pre-burying stainless metal measuring heads in the test piece; (3) demolding the test piece and soaking the test piece in a saturated calcium hydroxide aqueous solution the equivalent Na2O concentration of which is close to that in a concrete hole solution, wiping the test piece till reaching a saturated and surface-dry state, and wrapping the test piece by aluminum foil in a sealed vessel for curing; (4) carrying out testing according ages of 7 days, 14 days, 28 days, 56 days and 90 days, taking the test piece out of a curing environment at 24h ahead of test age arrival, and measuring the length of the test piece after temperature is stable; and (5) evaluating the actual risk of the alkali-aggregate reaction of the hydraulic concrete. The test method disclosed by the invention can achieve the purposes of ensuring that the mix proportions, the raw materials and the test environment of the concrete are identical with those of the actual engineering to the greatest extent, and the test cycle can be shortened.

Owner:NANJING HYDRAULIC RES INST

Method of producing environmental friendly active cement-based composite material by utilization of iron-nickel alloy tailings

InactiveCN104163583AImprove mechanical propertiesHas a volcanic effectClinker productionBiological activationMechanical property

The invention discloses a method of producing an environmental friendly active cement-based composite material by utilization of iron-nickel alloy tailings. The method is characterized in that: the composite material is prepared by mixing 3-5% of iron-nickel alloy powder, 3-5% of clinker powder, 3-5% of dry coal ash and 3-5% of an activator. The beneficial effects of the method are that: addition of the iron-nickel alloy tailings into the cement clinker after the iron-nickel alloy tailings are modified by processing and activation is simple and easy to operate; the method plays a positive role for recycling of industrial solid waste, improvement of the comprehensive utilization rate of resources, and saving and reasonable effective utilization of the resources; and the obtained cement-based composite material is capable of 1) enhancing mechanical properties of concrete, 2) reducing the engineering cost of cement and concrete, 3) significantly reducing heat of hydration of concrete, improving concrete workability, reducing segregation and water bleeding, reducing temperature changes and internal pressure of large-volume concrete, and inhibiting cracks generated by temperature differences, 4) inhibiting concrete alkali-aggregate reactions, and 5) having a micro-aggregate effect.

Owner:把正春

Green high-early-strength low-alkali liquid accelerator and preparation method thereof

The invention discloses a green high-early-strength low-alkali liquid accelerator. The green high-early-strength low-alkali liquid accelerator is prepared from the following components in percentage by mass: 30-60% of aluminum sulfate, 5-20% of sodium fluoride, 4-10% of alcohol aluminum, 3-10% of a stabilizer, 1-5% of a suspending agent, 0-1% of a defoaming agent and the balance of water. The invention relates to the low-alkali liquid accelerator for sprayed concrete. The low-alkali liquid accelerator has the advantages of being low-alkali, chlorine-free, non-corrosive to human bodies or machines, free of pungent smell, high in early strength, high in later strength retention rate, good in durability and the like; the low-alkali liquid accelerator can greatly reduce the risk of alkali-aggregate reaction in concrete and the erosion to reinforced concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Metamorphite machine-made sand concrete capable of inhibiting alkali activity of metamorphite aggregate and preparation method thereof

The invention relates to a metamorphite machine-made sand concrete capable of inhibiting alkali activity of metamorphite aggregate, which comprises 100 parts of cement, 10-60 parts of fly ash, 0.05-0.8 part of lithium compound, 0.1-2.0 parts of silane, 0.5-4 parts of water reducing agent, 0.005-0.07 part of air entraining agent, 190-480 parts of fine aggregate, 200-480 parts of coarse aggregate and 30-80 parts of water. The preparation method comprises the following steps: after mixing the cement and silane, adding the coarse aggregate, fine aggregate, fly ash, lithium compound and air entraining agent, continuing the dry mixing, dissolving the water reducing agent in water to obtain a water solution, adding the water solution, and continuing stirring to obtain the metamorphite machine-made sand concrete. By using the metamorphite machine-made sand and metamorphite gravel as aggregate, the invention fully utilizes the environmental resources, greatly lowers the manufacturing cost of concrete engineering, and reduces the environmental load; and the prepared concrete product has obvious inhibiting effect on alkali-aggregate reaction of the metamorphite concrete with alkali activity.

Owner:TONGJI UNIV

Seed crystal type early strength agent and preparation method thereof

The invention discloses a seed crystal type early strength agent and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a dispersing agent with waterto obtain a suspension, and then adding pre-hydrated cement particles into the suspension to obtain slurry; and grinding the slurry to obtain a suspension which is the seed crystal type early strengthagent. The seed crystal type early strength agent provided by the invention has effects of early strength and water reduction, and does not contain components which may accelerate steel bar corrosionand alkali aggregate reaction and damage the later strength of concrete. The preparation method provided by the invention has the advantages of simple process, easiness in obtaining of required raw materials, low equipment requirement, low cost, capability of facilitating large-scale popularization and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Composite cement expanding agent and preparation method thereof

The invention relates to a composite cement expanding agent and a preparation method thereof. The composite cement expanding agent comprises 5-50mass% of quicklime, 20-50mass% of anhydrite, 5-40mass% of an aluminum-containing clinker, 5-20mass% of a metakaolin clinker, 2-15mass% of quartz powder and 0.1-1mass% of an organic additive. The expanding agent utilizes different aluminate mineral clinkers to adjust the expansion rate and increase the effective expansion; and the expanding agent also utilizes the organic additive to improve the expanding performance in a cement plasticity phase and well compensate the contraction in the cement hydration plasticity phase and the contraction after the later-stage hardening of cement. The alkali content of the expanding agent is lower than 0.5%, so the alkali aggregate reaction can be effectively avoided; and when the doping amount is 8%, results of detection according to JC476-2001 standard of the expanding agent show that the restrained expansion rate under the maintenance in air for 21d is greater than the standard, and especially the plastic phase expansion rate is 0.02-0.15%.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com