Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

275 results about "Shrinkage cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

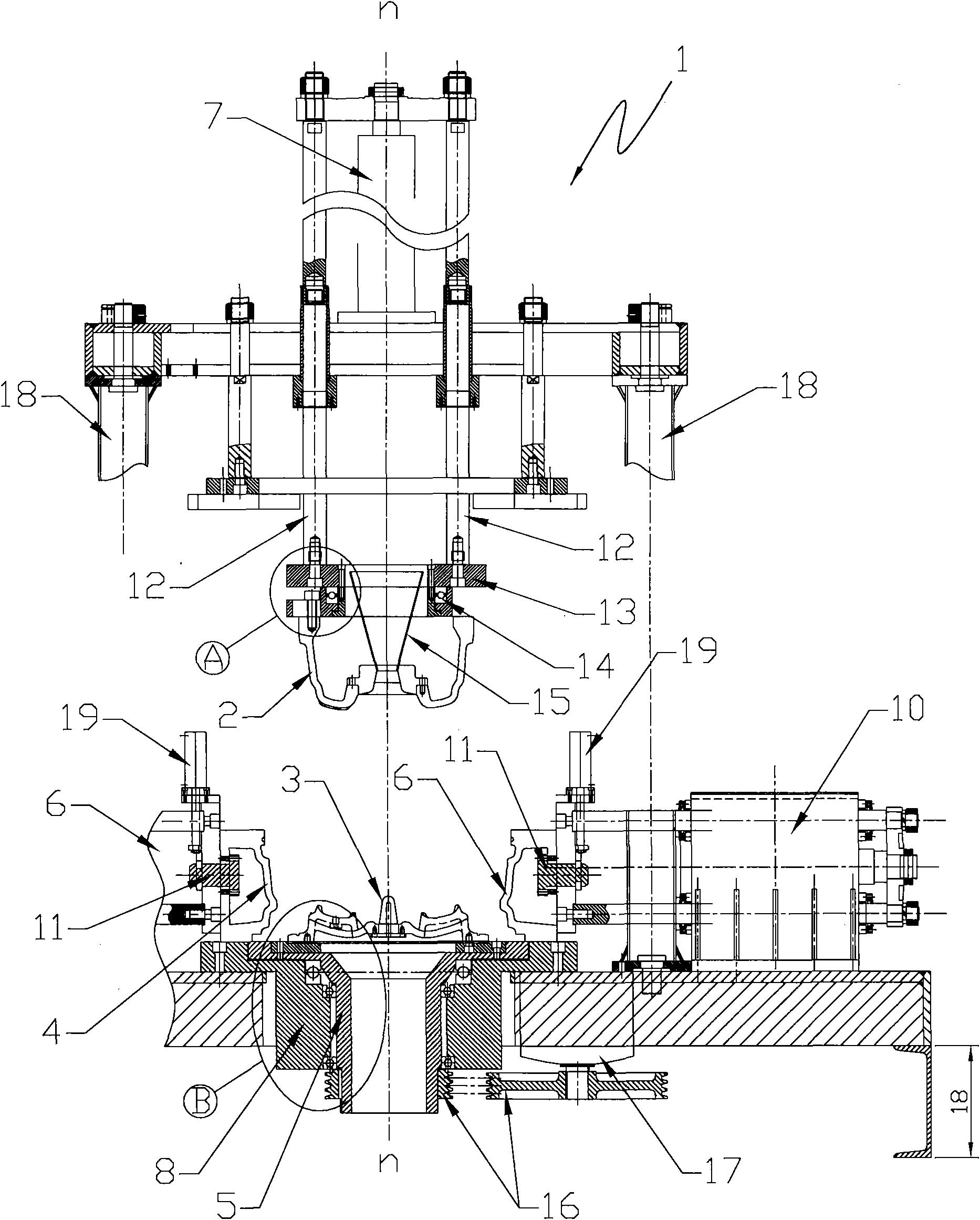

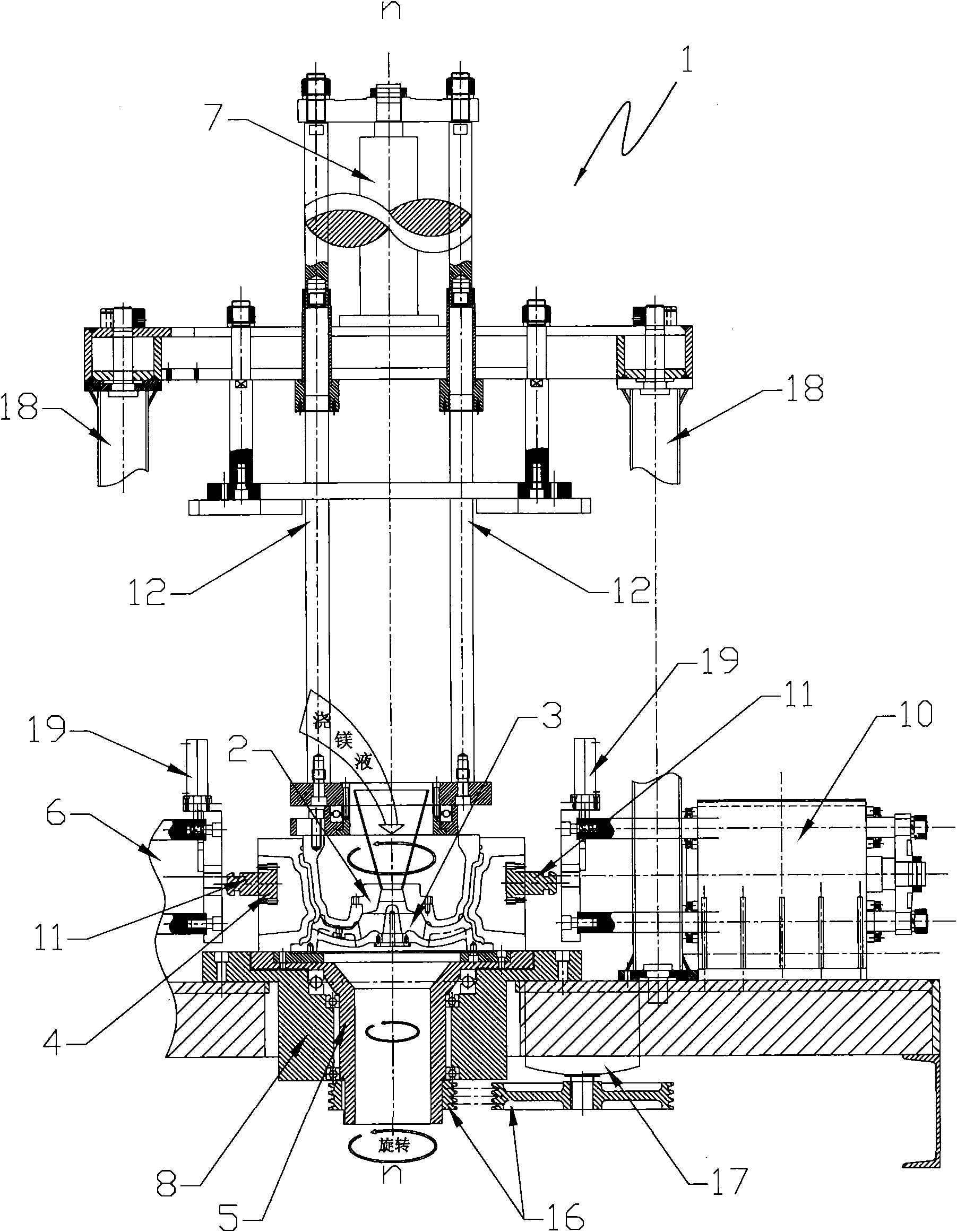

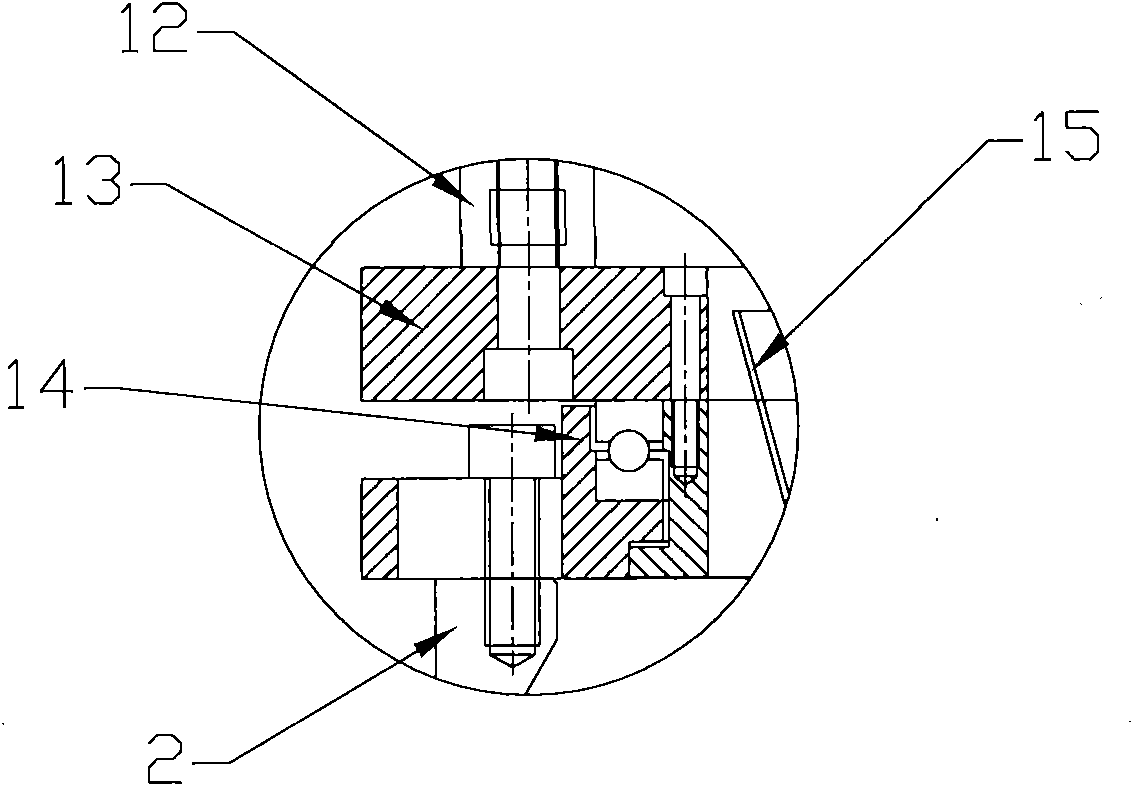

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

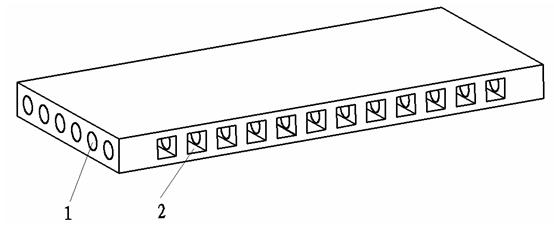

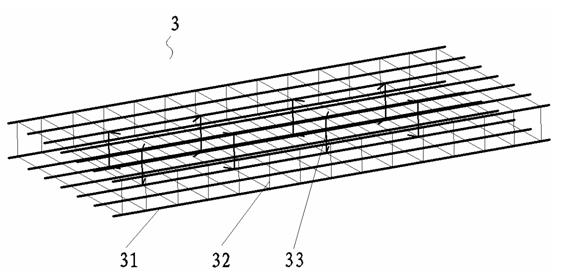

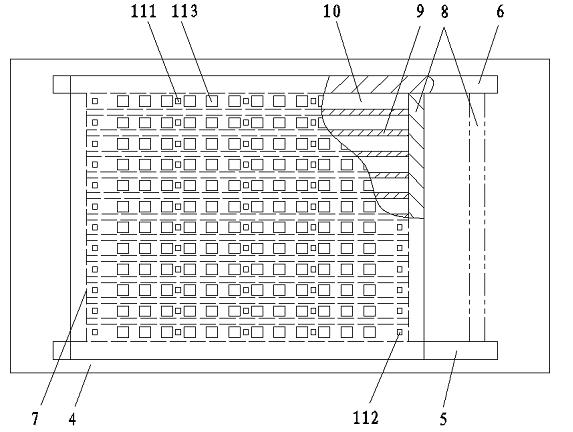

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

Ultra-high performance concrete with micro-expansion and compensation shrinkage and preparation method thereof

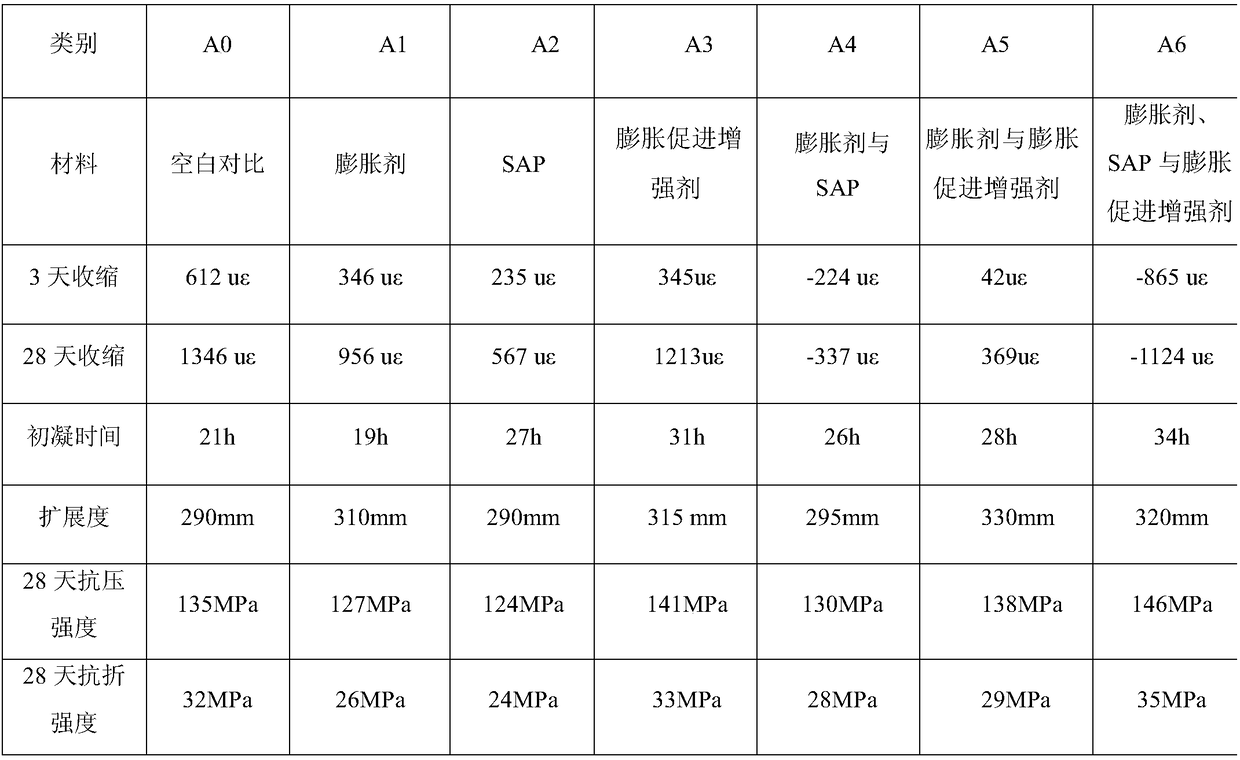

The invention belongs to the field of building materials, and especially relates to ultra-high performance concrete with micro-expansion and compensation shrinkage and a preparation method thereof. Raw materials include, by weight, the following components: 1 part of cement, 0.05-0.2 part of fly ash, 0.2-0.5 part of silica fume, 0.1-0.25 part of mineral powder, 0.05-0.2 part of quartz powder, 0.9-1.2 parts of quartz sand, 0.04-0.2 part of an expanding agent, 0.01-0.03 part of a water reducing agent, and 0.01-0.03 part of an expansion promotion reinforcing agent. A mixing amount of super absorbent resin is 0.4%-0.8% of a cementing material; a volume mixing amount of steel fiber is 1%-3% of a total volume of the concrete; the water-to-binder ratio is 0.16-0.22; and the compressive strength is 100-160 MPa. The ultra-high performance concrete with the micro-expansion and the compensation shrinkage has the characteristics of micro-expansion, high strength, high toughness, excellent workingperformance, and the like, and solves the problem that the expanding agent is difficult to produce effective expansion in the ultra-high performance concrete with a low water-to-binder ratio, and so,the risk of early shrinkage cracking of the ultra-high performance concrete is reduced, and the ultra-high performance concrete can maintain the micro-expansion for a long time.

Owner:HUNAN UNIV

Reinforced concrete containing antimicrobial-enhanced fibers

InactiveUS6162845AReduce sensitivityReduce odorBiocideAntifouling/underwater paintsShrinkage crackingFlexural strength

A fiber-reinforced concrete-like material product includes a plurality of fibers containing an effective amount of at least one antimicrobial agent to inhibit organisms and protect the concrete from biological attack. Preferably, the antimicrobial agents are added to the fibers prior to the fibers being dispersed in the concrete. Such a concrete product containing antimicrobial-enhanced fibers simultaneously inhibits organisms from biological attack, reduces plastic shrinkage cracking of the concrete and improve post-peak flexural strength of the concrete.

Owner:PROPEX OPERATING

Methods of minimizing concrete cracking and shrinkage

InactiveUS20090078161A1Reducing plastic shrinkage crackingSolid waste managementShrinkage crackingConstruction aggregate

A method of reducing plastic shrinkage cracking in concrete compositions that includes a) combining 3-40 volume percent cement, 5-50 volume percent fine aggregate, 5-50 volume percent coarse aggregate, and 10-22 volume percent water to form a concrete mixture; b) during or after (a), adding 1.5-40 volume percent of prepuff particles to the concrete mixture to form a concrete composition; c) placing the concrete composition in a form; and d) allowing the concrete to set and harden to form a hardened concrete article substantially free of plastic shrinkage cracking. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The concrete composition has a density of from about 40 to about 135 lb. / ft3.

Owner:NOVA CHEM INC

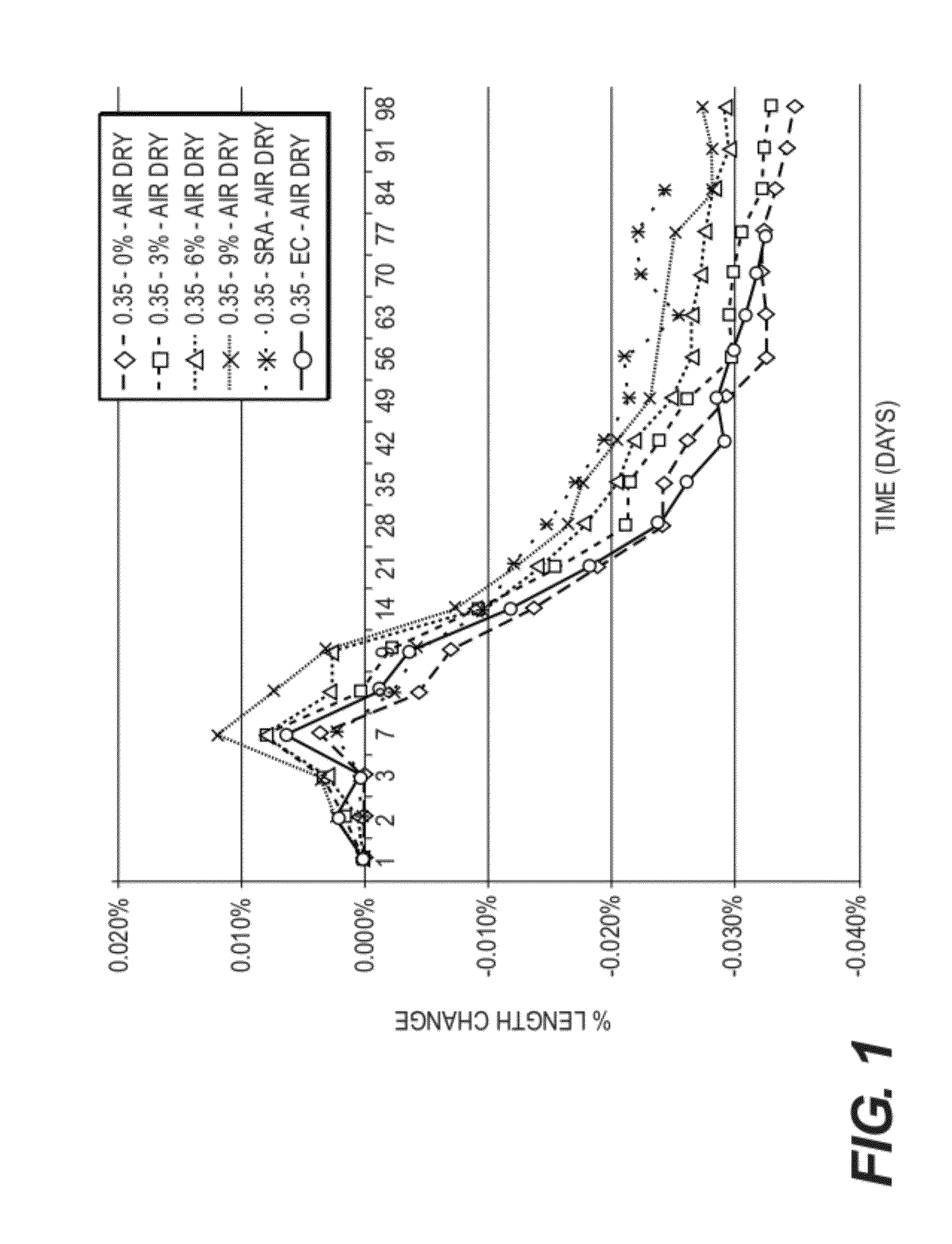

Admixtures for Shrink Crack Reduction of Portland Cement-Based Mortars and Concretes

Portland Cement-based concretes and mortars exhibit significant reduction in shrinkage cracking when combined with Magnesium Oxide (MgO), Shrinkage Reduction Admixtures (SRA) and Super Absorbent Polymers (SAP). However, MgO is a solid that reacts with water, SRA is a liquid, and SAP if not added properly could pull water out of the system and thus increase shrinkage. Unique admixture blends used as supplementary cementing materials that do not significantly affect concrete or cement strength properties of Portland cement itself address such issues. Proper ratios of MgO, SRA and / or SAP perform better against crack reduction when compared to commonly used Expansive Cements (EC).

Owner:PREMIER MAGNESIA

Waterproof mortar with leakage self-repair function and method for preparing waterproof mortar

ActiveCN106082893ASolve the problem of cracking and leakageSolve the number one problemCalcium hydroxideShrinkage cracking

The invention discloses waterproof mortar with a leakage self-repair function and a method for preparing the waterproof mortar. The waterproof mortar comprises, by weight, 10-40% of silicate cement, 5-20% of sulphoaluminate cement, 5-15% of polymers with high water absorption, 3-10% of silicon dioxide powder, 1-3% of dispersing agents, 1-3% of water reducing agents, 5-10% of water-soluble polymers, 3-5% of calcium hydroxide, 10-30% of quartz sand and the balance fillers. The waterproof mortar and the method have the advantages that the problem of leakage due to shrinkage cracking of concrete (mortar) can be solved by the aid of water self-repair processes; the waterproof mortar is convenient and easy to construct; the waterproof mortar can be self-repaired after cracking, and accordingly the problem of trouble of leaking stopping construction on air faces after leakage occurs can be solved; the waterproof mortar can be intelligently self-repaired, a self-repair idea for the waterproof mortar is a combination of stiffness and flexibility, accordingly the waterproof mortar can be used even in dry and wet alternate environments, and effects of the waterproof mortar still can be realized under repeated cracking conditions; the curing time of the waterproof mortar can be controlled, and the waterproof mortar can be used under leaking stopping conditions.

Owner:ZHEJIANG UNIV OF TECH +1

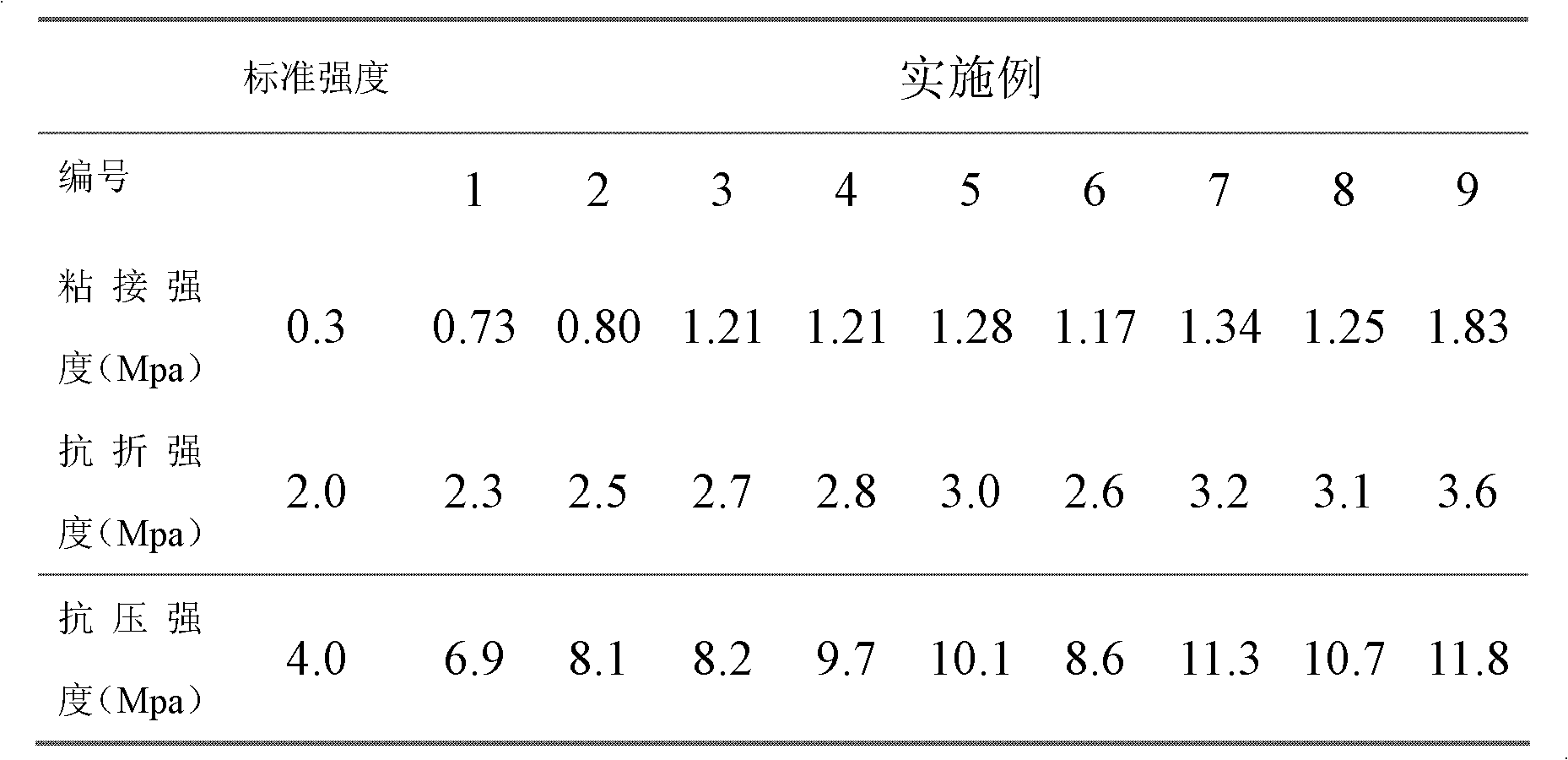

Ternary cementitious system stucco finish, and application method thereof

The invention belongs to the technical field of building material, and more specifically relates to a ternary cementitious system stucco finish, and an application method thereof. The ternary cementitious system stucco finish is composed of white Portland cement, sulphate aluminium cement, gypsum, superfine slag powder, zeolite powder, latex powder, cellulose ether, an air entraining agent, an antifoaming agent, a water repellent, a thixotropic agent, an inorganic pigment, an quartz sand. The ternary cementitious system stucco finish possesses excellent physical mechanical properties; setting time and operable time are controllable; development of early strength is rapid; strength is high; bonding strength with matrix is high; no shrinkage cracking is caused; durability is excellent; no crystalline bloom is caused; stain resistance is excellent; and decorative effect is excellent. The ternary cementitious system stucco finish is suitable for decoration engineering of building internal and external walls and building thermal-insulation decorative integrated systems; relatively mechanical strength is achieved in a relatively short term; construction efficiency is increased; performance of long-term application is excellent; and engineering quality is ensured.

Owner:TONGJI UNIV

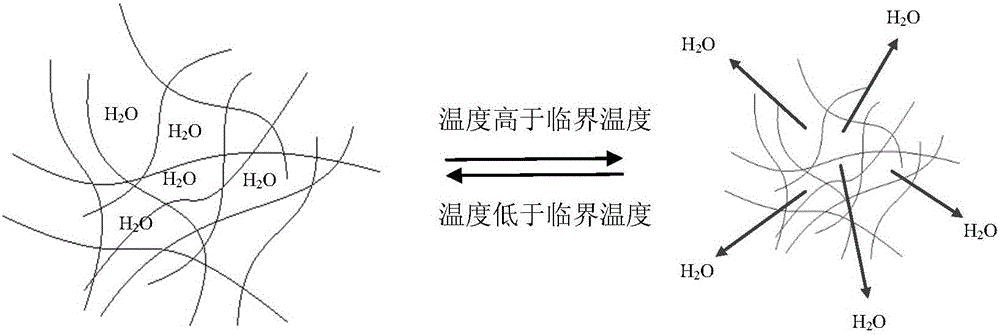

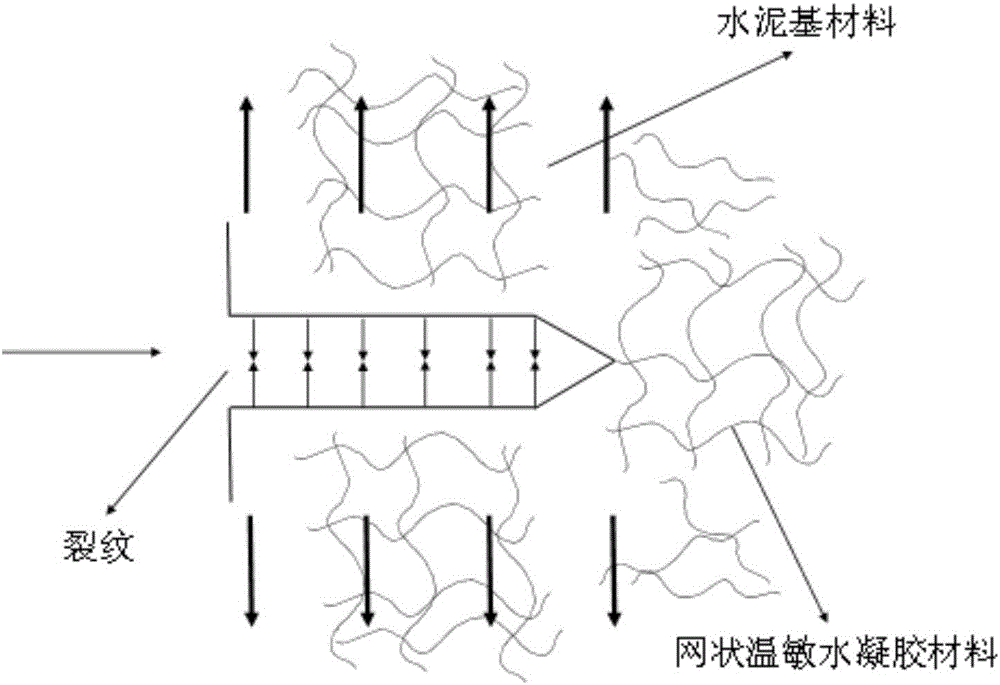

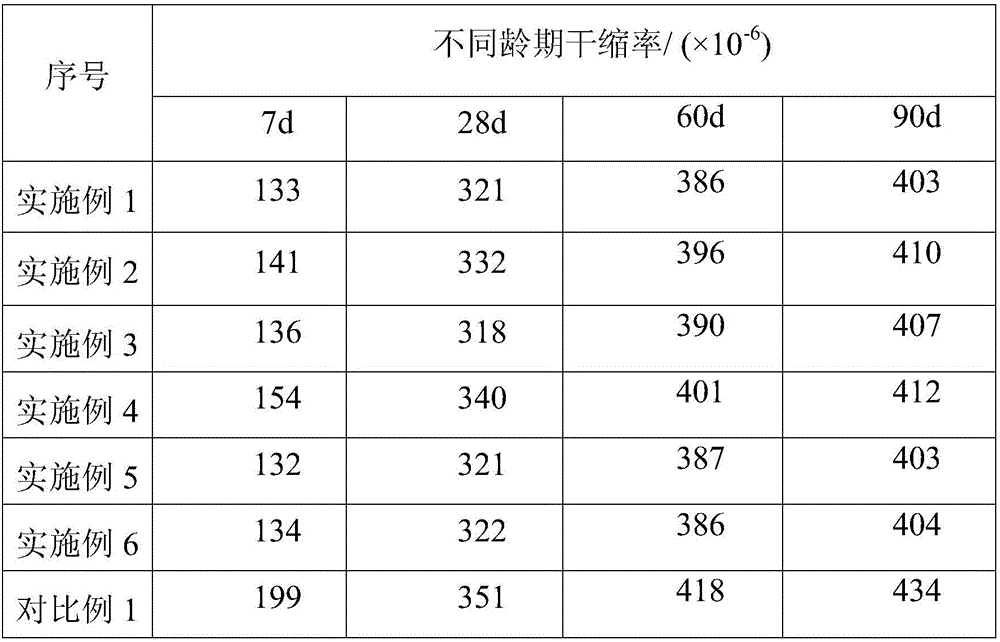

Application of temperature-sensitive hydrogel in improvement of anti-dry-shrinkage cracking property of concrete

The invention provides application of temperature-sensitive hydrogel in improvement of the anti-dry-shrinkage cracking property of concrete. The concrete is prepared from the temperature-sensitive hydrogel, cement, aggregates and water. A preparation method of the concrete comprises the steps that firstly, the temperature-sensitive hydrogel is prepared; secondly, the aggregates and the water are blended to be uniform; lastly, the temperature-sensitive hydrogel and the water are added, the materials are blended to be uniform, and then the concrete can be prepared. The adopted homemade temperature-sensitive hydrogel is lightly-crosslinked macromolecules which can be polymerized to form a film after releasing water, no hole can be reserved in the cement concrete, and other properties of the cement concrete are not affected while the anti-cracking property of the concrete is improved. The initial volume water content of the concrete is increased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the water storage capacity of the concrete is enhanced by mixing the temperature-sensitive hydrogel; the water absorption rate of the concrete is decreased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the connectivity of capillary pores in the concrete is reduced by mixing the temperature-sensitive hydrogel.

Owner:CHANGAN UNIV

Micro-expansion fiber reinforced concrete and preparation method thereof

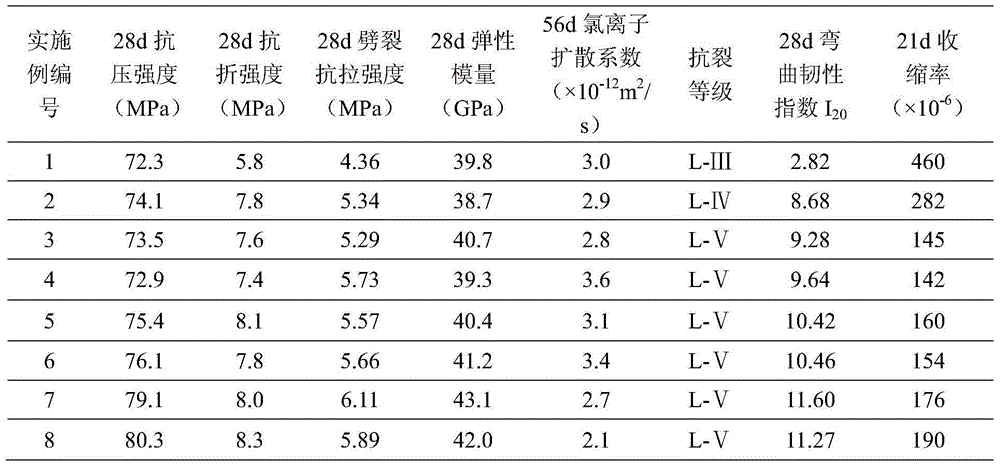

The invention discloses micro-expansion fiber reinforced concrete for a steel-concrete combined beam bridge panel wet joint and a preparation method of the micro-expansion fiber reinforced concrete, and relates to the preparation field of the micro-expansion fiber reinforced concrete. The micro-expansion fiber reinforced concrete comprises gel materials (cement, coal ash, slag powder and an expanding agent), aggregate, reinforcing materials, imitated steel fibers, a water reducer and water, wherein the 28 compressive strength of the micro-expansion fiber reinforced concrete is not lower than 69.0MPa, the 28d breaking strength of the micro-expansion fiber reinforced concrete is not lower than 7.0 MPa, the 28d splitting tensile strength of the micro-expansion fiber reinforced concrete is not lower than 5.0 MPa, the 28d elasticity modulus of the micro-expansion fiber reinforced concrete is not lower than 36.0 GPa, the cracking resistance level of the micro-expansion fiber reinforced concrete reaches L-IV level, the 28d bending toughness index I20 of the micro-expansion fiber reinforced concrete is not lower than 8, the 56d chlorine ion diffusion coefficient of the micro-expansion fiber reinforced concrete is lower than 4.0*10<-12>m<2> / s, the 21d shrinkage percentage of the micro-expansion fiber reinforced concrete is lower than 200*10<-6>. By using the preparation method, the shrinkage cracking of the micro-expansion fiber reinforced concrete can be effectively avoided, so that the reinforced concrete is relatively compact. The micro-expansion fiber reinforced concrete disclosed by the invention is relatively high in strength, relatively low in shrinkage percentage, good in bending toughness and durability, relatively low in cost and conveniently to widely use.

Owner:THE 2ND ENG CO LTD MBEC +1

Light masonry mortar with heat insulation and preservation

InactiveCN101643349AImprove insulation effectAvoid "Cold Bridge" PhenomenonSolid waste managementFiberSlag

The invention discloses a light masonry mortar with heat insulation and preservation, comprising the following components by weight percent: 20 percent to 65 percent of portland cement, 5 percent to 50 percent of fly ashes, 0 percent to 50 percent of furnace bottom slag, 0 percent to 55 percent of slag, 10 percent to 23 percent of vitrified microspheres, 0.1 percent to 1.0 percent of water retention and thickening materials, 0.1 percent to 0.5 percent of lignocellulose and 0.1 percent to 1.0 percent of water reducing agent. The mortar has the dry density of 750 to 1000 kg / m<3>, the thermal conductivity of 0.15 to 0.20 w / m k, the lowest compressive strength of 5 Mpa and the liner shrinkage rate of less than 0.1 percent, satisfies the requirements of heat insulation and preservation of an energy-saving building, has the advantages of favorable heat insulation and preservation performance, favorable water retention, favorable workability, high adhesion strength of a wall body, simple construction, energy saving, environmental protection and the like, completely avoids the occurrence of the phenomenon of cold bridge, and efficiently prevents dry-shrinkage cracking and the phenomenon ofmoisture absorption of the wall surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Low-shrinkage crack self-compacting concrete

The invention discloses low-shrinkage crack self-compacting concrete which is prepared from cement, gravels, sand, a mineral admixture and an anti-shrinkage crack compound additive. By adopting the low-shrinkage crack self-compacting concrete disclosed by the invention, on the basis of overcoming the defects of bleeding, segregation, poor viscosity and great gradual loss of self-compacting concrete, the early shrinkage crack of the self-compacting concrete after hardening is greatly reduced so as to guarantee good durability and volume stability of the self-compacting concrete to satisfy the practical construction application of large-area engineering and the like; and moreover, the cement is saved at least by 40kg / m<3> through proportion optimization on the basis of meeting the requirements of fundamental norms for materials.

Owner:CENT SOUTH UNIV

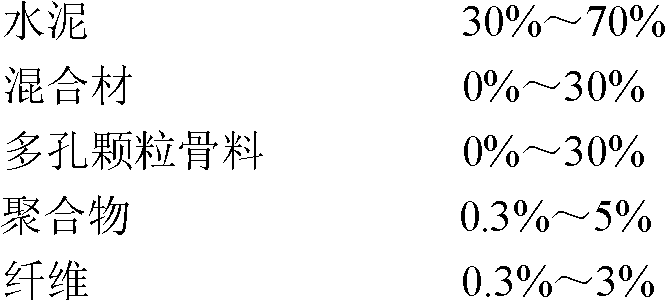

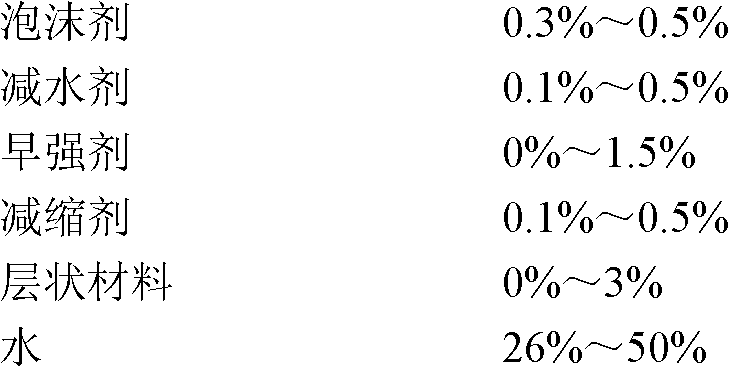

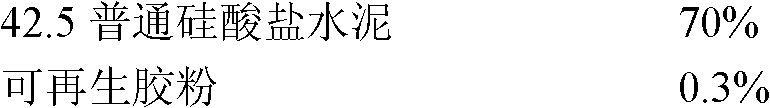

Ultra-low apparent density and high-performance foam concrete material and its preparation method

InactiveCN102424556ALow apparent densityLow thermal conductivityCeramicwareFoam concreteShrinkage cracking

The invention relates to an ultra-low apparent density and high-performance foam concrete material and its preparation method. The material comprises the following components by mass: 30%-70% of cement, 0%-30% of an admixture, 0%-30% of a porous particle aggregate, 0.3%-5% of a polymer, 0.3%-3% of a fiber, 0.3%-0.5% of a foaming agent, 0.1%-0.5% of a water reducing agent, 0%-1.5% of an early strength agent, 0.1%-0.5% of a shrinkage reducing agent, 0%-3% of a layered material, and 26%-50% of water. Compared with ordinary foam concrete, the material prepared in the invention has the technical advantages of ultra-low apparent density, small coefficient of heat conductivity, and no dry shrinkage cracking, etc. And compared with current foam polyphenyl boards for exterior wall external thermalinsulation, the material of the invention has the advantage of non-combustion.

Owner:TONGJI UNIV

Plastic anti-crack modified fiber of cement-based material and prepn. process

InactiveCN1834050AReduced plastic shrinkage cracking propertiesWorkability is not affectedShrinkage crackingOrganic synthesis

This invention is attributed to the field of materials science and engineering and concretely speaking, relates to a kind of modified fibers for preventing plastic cracking of cement-based materials (such as cement paste, mortar, concrete their composites), which comprises organic synthetic fibers, inorganic fibers or organic-inorganic hybrid fibers and modifiers. The modified fibers in this invention perform significant prevention from plastic shrinkage cracking of cement-based materials from their molding to complete solidification, and over 90% plastic cracking can be reduced by doping with the fibers compared to undoped ones. They also have an effect of reducing 30~50% more plastic cracking than unmodified fibers. This invention can be widely applied in cement-based materials engineering, such as cement-concrete roads, bridge decks, grounds, slope protection, dams, etc, so as promote project quality.

Owner:TONGJI UNIV

Aerated concrete interface agent

The invention discloses an aerated concrete interface agent, and belongs to the technical field of construction materials. The agent comprises, by weight: 20-50% of cellulose ether, 36-73% of a thixotropic thickener, and 5-25% of redispersible latex powder. The agent has the advantages that: with the agent, bonding strength of mortar upon a substrate layer can be improved, construction workability can be improved, surface smoothness can be improved, adhesion with tools during construction can be reduced, water-retention and thickening performances are excellent, mortar operation open time can be prolonged, and problems such as building block falling, adhesion surface shrinkage cracking, and the like can be effectively avoided.

Owner:江苏兆佳建材科技有限公司

Bottom layer brushing gypsum and application thereof

The invention discloses a bottom layer brushing gypsum, which is prepared by mixing the following components in parts by weight: 200-500 parts of building gypsum, 485-785 parts of quartz sand, 3 parts of regulator, 5 parts of inorganic gel, 0.2-0.5 part of retarder and 2 parts of anti-cracking agent, wherein the quartz sand is one or the mixture of more than two of the quartz sands of 30 meshes, 40 meshes and 60 meshes in any proportion, the regulator is hydroxypropyl methyl cellulose, the inorganic gel is sodium bentonite, the retarder is a special retarder for polyphosphate gypsum, and the anti-cracking agent is lignocellulose; and the building gypsum is prepared by desulfurized gypsum according to the following method that the desulfurized gypsum enters a boiling calcinator after being pre-dried at the temperature of 80-90 DEG C, is calcined at the temperature of 120-130 DEG C, then is added into an impact type flour mill to be ground, and is prepared into the building gypsum after being cooled and aged. The invention has strong adhesive force, effectively inhibits the phenomenon of shrinkage cracking in plastering, and has good water resistance.

Owner:上海每天节能环保科技股份有限公司

Straw fiber reinforcement air-entrained concrete and preparation method thereof

ActiveCN103193448ASmall drying shrinkageImprove crack resistanceCeramicwareShrinkage crackingWaste treatment

The invention discloses straw fiber reinforcement air-entrained concrete which comprises a base material, an aluminum powder paste, a straw fiber, an additive and water, wherein the doping amount of the aluminum powder paste accounts for 0.06%-0.09% of the dry weight of the base material; the doping amount of the additive accounts for 0.5%-0.8% of the dry weight of the base material; the doping amount of the straw fiber accounts for 2%-10% of the dry weight of the base material; and the mass ratio of the water and the base material is 0.52-0.60, The invention also discloses a preparation method of the straw fiber reinforcement air-entrained concrete. The straw fiber reinforcement air-entrained concrete disclosed by the invention reduces the shrinkage cracking and production cost of air-entrained concrete and solves the problems of straw resource waste, ceramic waste treatment and environmental pollution to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

Self-leveling mortar doped with low-temperature rice hull ash

The invention belongs to the technical field of building materials, and particularly relates to self-leveling mortar doped with low-temperature rice hull ash. The self-leveling mortar consists of normal Portland cement, high alumina cement, low-temperature rice hull ash, slag powder, fly ash, river sand, a water reducing agent, a defoaming agent, a stabilizing agent and water. The low-temperaturerice hull ash is formed by burning rice hulls at a low temperature of 600 DEG C and grinding, has a huge surface area and super-high pozzolanic activity. According to a product provided by the invention, the problems of high cost, unsmooth hardened surface, shrinkage and crack of the normal self-leveling mortar can be solved, and meanwhile, the problem of treatment of the agricultural rice hulls can also be solved. The product provided by the invention has the characteristics of high fluidity, quickness in condensation and hardening, high early strength, smooth and flat hardened surface, solidness, wear resistance, small shrinkage, no crack and the like, is suitable for construction of a new floor, can also be used for repairing worn, dusting and damaged floor and can be used for self-leveling of various floor base courses.

Owner:TONGJI UNIV

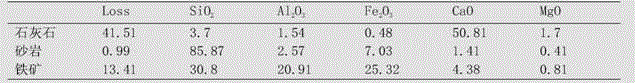

Autogenously-pulverizable low calcium cement, and making method of prefabricated products thereof

ActiveCN105347706ALower firing temperatureReduce production processHigh concentrationShrinkage cracking

The invention relates to an autogenously-pulverizable low calcium cement, and a making method of a prefabricated product thereof. The autogenously-pulverizable low calcium cement is made from limestone, sandstone and iron ore, the CaO content of the prepared autogenously-pulverizable low calcium cement is 40-60%, and the main mineral phase of the autogenously-pulverizable low calcium cement is CS, C3S2, gamma-C2S and a liquid phase. The activity of the cement is excited by using high-concentration CO2 gas in a short period (8h) to make the prefabricated products of the autogenously-pulverizable low calcium cement, and the prefabricated products can be a sheet, a building block, a brick and a tile, and can also be solid or hollow or porous high-strength prefabricated products. The problems of long curing period, high energy consumption and shrinkage cracking of ordinary Portland cement prefabricated products are solved in the invention; and additionally, the autogenously-pulverizable low calcium cement has the advantages of low energy consumption in the baking process, small CO2 discharge amount, high early strength, and slow increase of the later strength, and the product of the autogenously-pulverizable low calcium cement has the advantages of excellent physical and mechanical performances, good durability, fire and corrosion resistance, good decorativeness and processability, environmental protection, energy saving and emission reduction, and very good social, economic and environmental benefits.

Owner:HENAN POLYTECHNIC UNIV

Cement stabilized base material, preparation, application and preparation method of road base

The invention discloses a cement stabilized base material, a preparation, an application and a preparation method of a road base. The cement stabilized basic material comprises the following materials: 1%-3% of basic slag and 1%-3% of cement and base materials, wherein the basic materials comprises 0.5%-8% of desulfurization gypsum and 92%-99.5% of crushed stone in mass percentage of the basic materials. The preparation method of the cement stabilized base material comprises the step of uniformly mixing the components. According to the preparation method of the road base, the road base is prepared from the cement stabilized base material with the conventional preparation process and conditions. The cement stabilized base material has the advantages as follows: the material cost is reduced, the service life of a road structure is prolonged, the economic benefit is increased, the cement setting time is delayed, the strength, the airtightness, the water retention, the water resistance, the shrinkage crack resistance, the freeze-thaw resistance, the moisture damage resistance and sulfate corrosion resistance of the material are improved, novel application of the desulfurization gypsum is exploited, and the environment is protected effectively.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

Method for preparing silica aerogel by supercritical drying with high-pressure liquid medium

InactiveCN101863479ASolve the phenomenon of prone to shrinkage and crackingRaw materials are easy to getSilicaSupercritical dryingLiquid medium

The invention relates to a method for preparing silica aerogel by supercritical drying with a high-pressure liquid medium, which comprises the following steps of: (1) adding silicon tetrachloride and water to perform reaction with stirring under the acidic condition that the pH is between 3 and 5, adjusting the pH to be between 8 and 10 by using ammonia water, adding the water and ethanol to perform hydrolysis and polycondensation reaction to form alcogel; (2) loading the alcogel into a high-pressure reaction kettle, filling the high-pressure liquid medium into the reaction kettle, and slowly raising the temperature to reach supercritical pressure after the reaction kettle is filled with the high-pressure liquid medium; and (3) slowly releasing gas medium while slowly raising the temperature until the pressure in the kettle and external atmosphere are balanced, opening the reaction kettle, taking the sample out and drying the sample. The method has the advantages of readily available raw materials, simple process and low cost, solves the problem of easy shrinkage cracking of the SiO2 aerogel when dry, and can stably improve the reaction speed at the same time.

Owner:应城市东诚有机硅有限公司

Self-leveling mortar doped with phosphorus slag powder

The invention belongs to the technical field of building materials, and particularly relates to a self-leveling mortar doped with phosphorus slag powder. The self-leveling mortar doped with phosphorus slag powder comprises ordinary Portland cement, high-aluminum cement, phosphorus slag powder, S105 slag powder, coal ash, river sand, a composite activator, a water reducer, a stabilizer, a defoaming agent and water. By adopting the self-leveling mortar doped with phosphorus slag powder, the problems of high cost, rough hardened surface and shrinkage crack of ordinary self-leveling mortar are solved, and the recycling use ratio of the industrial byproduct phosphorus slag is also improved. The self-leveling mortar doped with phosphorus slag powder has the advantages of good fluidity, fast speed in curing and hardening, low heat of hydration, high early strength, fast speed in improvement of long-term strength, small shrinkage distortion, smooth and level hardened surface, no crack and so on, can be used for not only construction of new ground and but also repairing of worn, dusting or damaged ground, and can be used for self leveling of various floor base levels.

Owner:TONGJI UNIV

Plastic fibers for improved concrete

InactiveUS6844065B2High strengthLayered productsCeramic shaping apparatusShrinkage crackingPolyolefin

Owner:DOW GLOBAL TECH LLC

Centrifugal casting method and device of magnesium alloy hub

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die and a lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

Environment-friendly anti-cracking waterproof agent for concrete and preparation method thereof

ActiveCN112110675AImprove pore structureImprove compactnessSolid waste managementSlagCarboxylic acid

The invention discloses an environment-friendly anti-cracking waterproof agent for concrete and a preparation method thereof. The anti-cracking waterproof agent comprises the following raw materials in percentage by weight: 1%-3% of graphite phase carbon nitride nanosheets, 5%-20% of modified ardealite powder, 10%-30% of ultrafine lithium slag powder, 5%-10% of nano titanium dioxide, 5%-15% of bauxite, 20%-50% of modified bentonite, 5%-15% of a magnesium oxide expanding agent, 1%-5% of zirconium silicone, 5%-15% of an organosilicon water repellent, 0.5%-2% of high alkali resistant water absorbent resin, and 1%-5% of a polycarboxylic acid water reducer. the waterproof agent provided by the invention not only can improve the pore structure of concrete, improve the compactness of concrete andenhance the impermeability of concrete, but also can reduce the risk of shrinkage cracking of concrete by utilizing the micro-expansion characteristic, and improves the crack resistance of concrete under the synergistic action of the waterproof agent and an alkali-aggregate reaction inhibition component; by utilizing the excitation effect of the nano titanium dioxide on the graphite-phase carbonnitride nanosheet, the nano titanium dioxide shows efficient photocatalytic performance under natural light, can effectively degrade harmful components such as nitric oxide in the air, and plays a positive role in purifying the environment.

Owner:重庆源锦锦兴新材料科技有限公司

Self-dense concrete of mixed fiber with fly ash in use for prefabricated acoustic barrier

This invention relates to preparation and application of high-performance and anti-crack self-tight concrete reinforced with fiber and fly ashes. This invention uses fly ashes as a substitute for part of cement, and high-alkali-resistant glass fiber modified polypropylene fiber as the reinforcing materials. Besides, an appropriate quantity of water-reducer is used to improve the processability of the mixture. The obtained self-tight concrete has such advantages as high performance and good anti-crack property. The method for preparing sound barrier from the self-tight concrete is simple and needs no complicated equipments. The obtained sound barrier has better performance when compared with conventional concrete sound barriers, metal-plate sound barriers, and plastic organic glass sound barriers.

Owner:DALIAN UNIV OF TECH

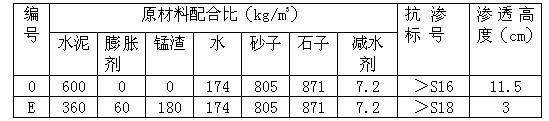

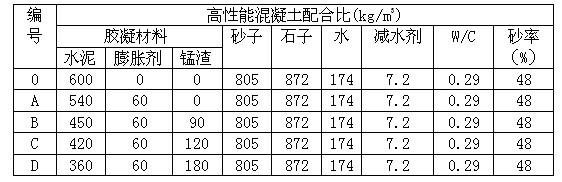

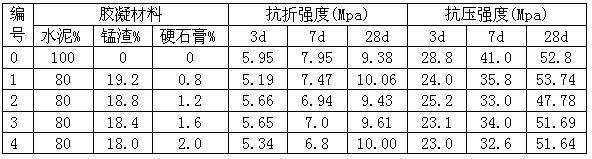

High performance concrete with water quenching manganese slag and preparation method thereof

ActiveCN101844905ALow costGuaranteed dimensional stabilitySolid waste managementShrinkage crackingMining engineering

The invention discloses a high performance concrete with water quenching manganese slag and a preparation method thereof. The high performance concrete is prepared by hydraulic cementing materials, gravel, sand, water and a small amount of surfactant, wherein the hydraulic cementing materials comprise the following components in percentage by weight: 15%-30% of water quenching manganese slag doped with 4%-10% of natural anhydrite, 8%-10% of expanding agent and 60%-77% of cement. In the invention, the manganese slag and the expanding agent are used for preparing the high performance concrete in a double-doped way; firstly, aiming at potential hydraulicity of the manganese slag, high-value comprehensive application is carried out, thereby reducing the hydration heat of the cement, saving the cement consumption in the concrete and lowering the cost of the concrete; the expanding agent is also used for solving the problem of shrinkage cracking of the concrete, thereby ensuring the dimensional stability of the high performance concrete; and meanwhile, a large amount of industrial solid wastes (manganese slag) can be slaked by the invention, thereby strengthening the comprehensive utilization of waste slag and reducing the environmental pollution.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

Preparation method of carbonized steel slag lightweight aggregate and concrete containing carbonized steel slag lightweight aggregate

The invention discloses a preparation method of carbonized steel slag lightweight aggregate and concrete containing the carbonized steel slag lightweight aggregate. The preparation method of the carbonized steel slag lightweight aggregate comprises the following steps: step 1, weighing 40-60 parts by mass of steel slag powder, 30-50 parts by mass of vitrified micro bubbles and 10-30 parts by massof quick lime, putting into a tray, and performing mixing to form uniform mixed powder; step 2, uniformly spraying water drops to the surface of the mixed powder according to a certain water-cement ratio, continuously shaking the oscillation tray, and mixing the powder with water to form small balls, so as to obtain steel slag lightweight aggregate; 3, placing the steel slag lightweight aggregatein a curing chamber with the temperature being 20 + / -1 DEG C and the relative humidity being 55 + / -5% to be cured for 48 h; and step 4, putting the cured steel slag lightweight aggregate into a carbonization box to be carbonized for 24 hours. The invention has the advantages of simple preparation process, light weight and high strength of aggregate, low cost, low-carbon and environment-friendly production and the like. When applied to concrete, the carbonized steel slag lightweight aggregate can provide internal curing, promote hydration of a cementing material and reduce shrinkage cracking ofthe concrete.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

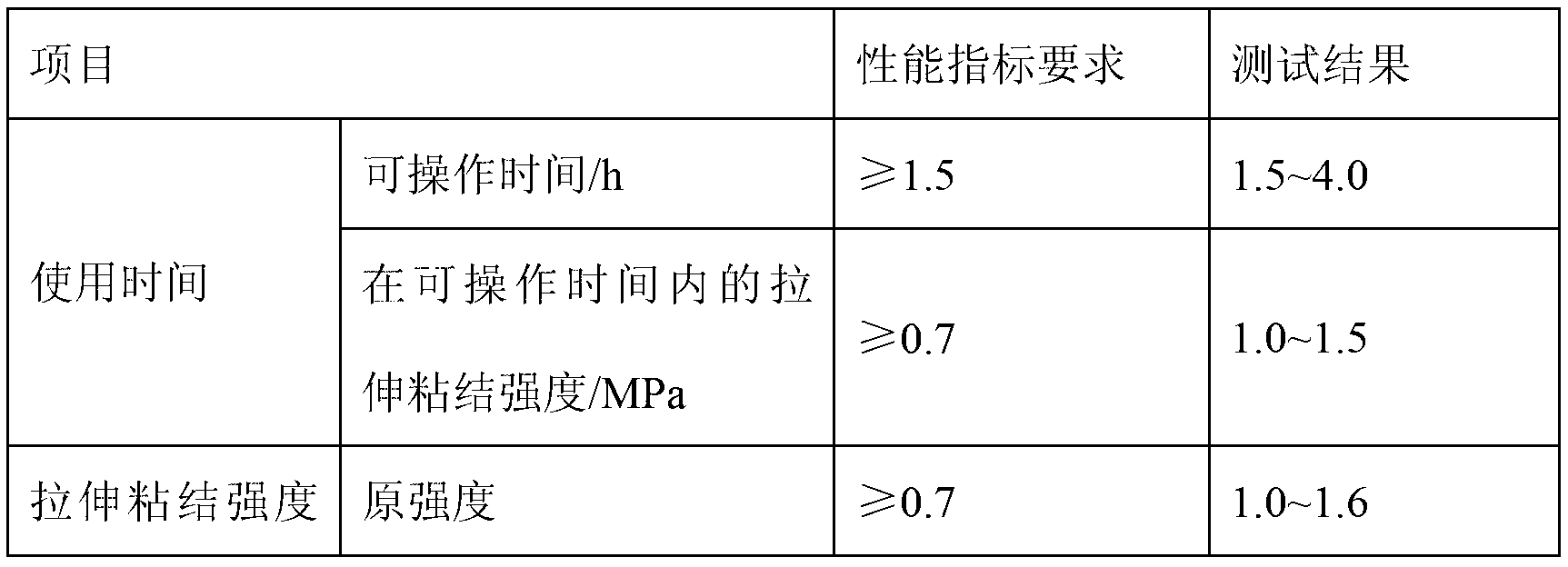

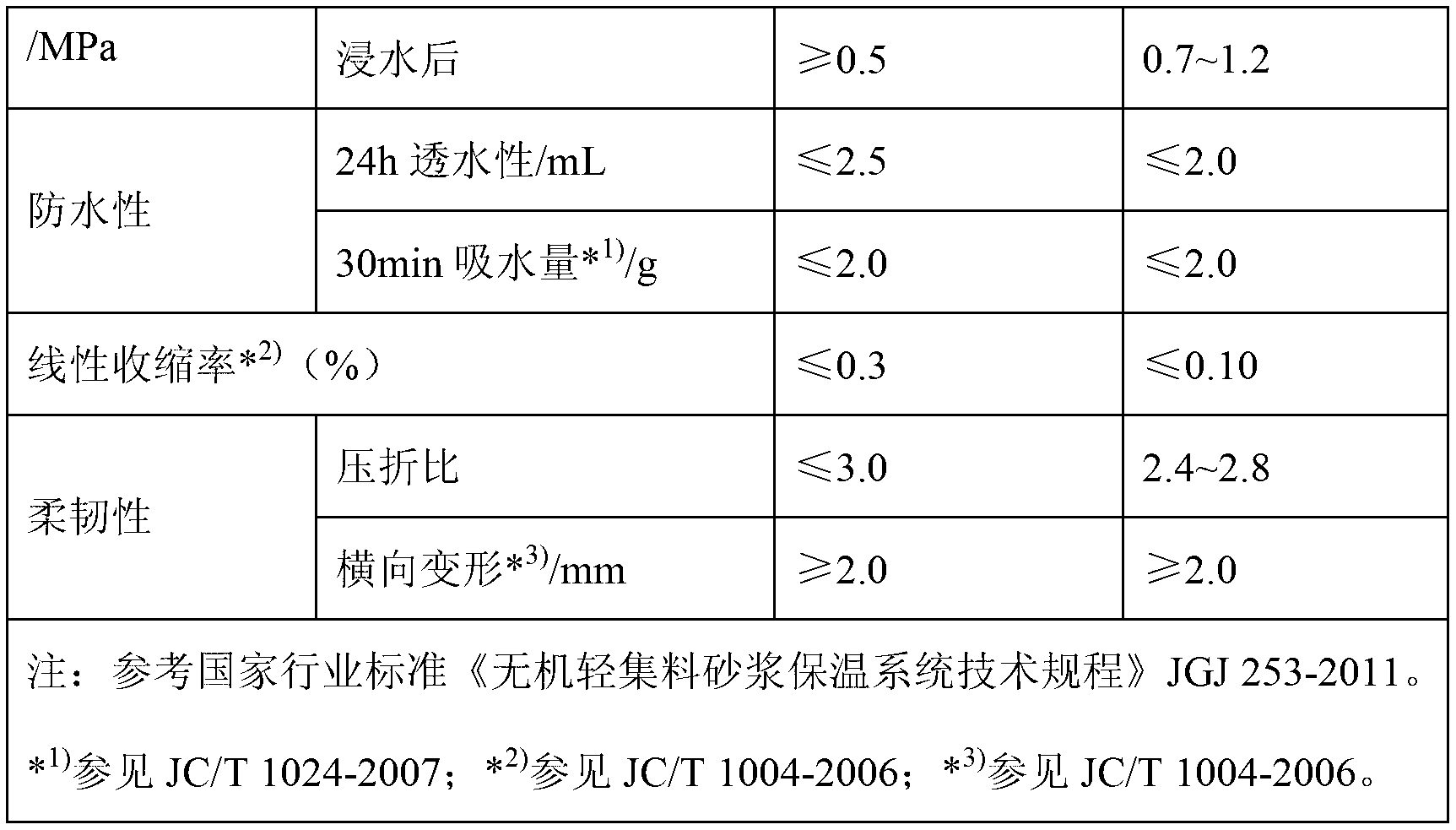

Flexible anti-cracking protective mortar and preparation method thereof

Belonging to the technical field of building materials, the invention relates to a flexible anti-cracking protective mortar and also relates to its preparation method. The flexible anti-cracking protective mortar comprises the following components by weight part: 30-50 of ordinary portland cement, 50-65 of quartz sand, 5-10 of slaked lime, 3-6 of anti-cracking fibers, 1.2-2.5 of redispersible emulsion powder, 0.2-0.5 of cellulose ether, 0.05-0.2 of a plastic expansion agent, and 0.3-0.6 of a water repellent agent. The flexible anti-cracking protective mortar provided in the invention has the characteristics of excellent construction performance, high breaking strength and compressive strength, good flexibility, high bonding tensile strength, good anti-cracking performance, excellent waterproof and hydrophobic effects, etc. When the flexible anti-cracking protective mortar is used for anti-cracking protection of a building wall heat preservation and energy saving system, the drying shrinkage cracking problem caused by various stress can be solved. With good and stable performance, the flexible anti-cracking protective mortar can be used directly by adding water at construction sites. The flexible anti-cracking protective mortar provided in the invention can also be used in plastering anti-cracking protective construction processes of various novel building wall materials so as to play a part in anti-cracking protection and water resistance.

Owner:JIANGSU XIANGYUAN ENVIRONMENTAL PROTECTION BUILDING MATERIALS TECH CO LTD

Gypsum based light energy-saving plate and method for preparing same

ActiveCN107098667AImprove water resistanceSolve the problem of drying shrinkage in the later stageCelluloseShrinkage cracking

The invention discloses a gypsum based light energy-saving plate and a method for preparing the same. The gypsum based light energy-saving plate comprises 40-60 parts of desulfurization gypsum, 10-15 parts of cement, 5-15 parts of vitrified micro-spheres, 10-20 parts of calcite powder and 4-10 parts of functional auxiliaries. The functional auxiliaries comprise 0.2-1 part of retarders, 0.1-5 parts of water reducing agents, 0.001-0.003 part of air entraining agents, 1.5-4 parts of redispersible latex powder, 0.2-0.3 part of cellulose ether and 0.1-0.4 part of defoaming agents. The gypsum based light energy-saving plate and the method have the advantages that the gypsum based light energy-saving plate is relatively high in compactness and comprehensive performance, and the problems of shrinkage cracking, long maintenance periods and the like of existing light partition walls can be effectively solved; the building construction costs can be reduced to a great extent, the construction periods can be shortened, the cost of partition walls can be lowered, and accordingly the gypsum based light energy-saving plate and the method have obvious technical and economical benefits.

Owner:武汉菡美洛建筑材料有限公司

Method for predicting plastic shrinkage cracking of cement mortar material

InactiveCN102183626APredicting trends in early plastic shrinkage crackingMaterial testing goodsShrinkage crackingFiber

The invention relates to a method for predicting plastic shrinkage cracking of a cement mortar material. The method comprises the following step of: substituting four cement-based material composition parameters comprising water cement ratio (Wc), cement sand ratio (Cs), fiber content (Fc) and fiber length (F1), water evaporation speed (Er) and demixing degree (Dd) and restraint degree (Rd) of the cement-based material into the following formula: K = 13.8822 - 14.0949Wc - 2.8247Cs + 0.5293Fc + 0.0022F1 - 17.0650Er + 0.2582Dd + 0.9436Rd, wherein the K is anti-cracking index. When the K value is more than 1.41, the cement-based material test piece is not cracked; when the K value is less than 0.99, the test piece is cracked; and when the K value is between 0.99 and 1.41, the test piece is cracked in certain probability. A multiplex constitutive equation of plastic shrinkage cracking of the mortar is constructed by using the parameters with great influence on the cement-based plastic shrinkage cracking, the tendency of early plastic shrinkage cracking of the cement-based material can be accurately predicted, and the method can be widely applied to early prediction of the plastic shrinkage cracking of the mortar.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com