Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

448results about How to "Guaranteed dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nubby low-density gel heat-insulation composite material

The invention discloses a low-density aerogel composite material and block-shaped low-density gel insulating composite material through packing the low-density aerogel composite material, which comprises the following steps: utilizing high-polymerization degree polyacrylic acid as porous nanometer silica reinforced frame to make the silica gel and composite material with certain elasticity and contractility; inhibiting crack during gel preparing course and hyper-critical drying course effectively; adopting packing slurry with alumina, titania, carborundum, hollow glass microball or ferroferric oxide and soluble silicate, organosilicon resin or silica gel to pack the surface of large block of silica aerogel; sintering the packed aerogel composite material at 650-700 deg. c; using the material under 1000 deg. c at most.

Owner:NANJING UNIV OF TECH

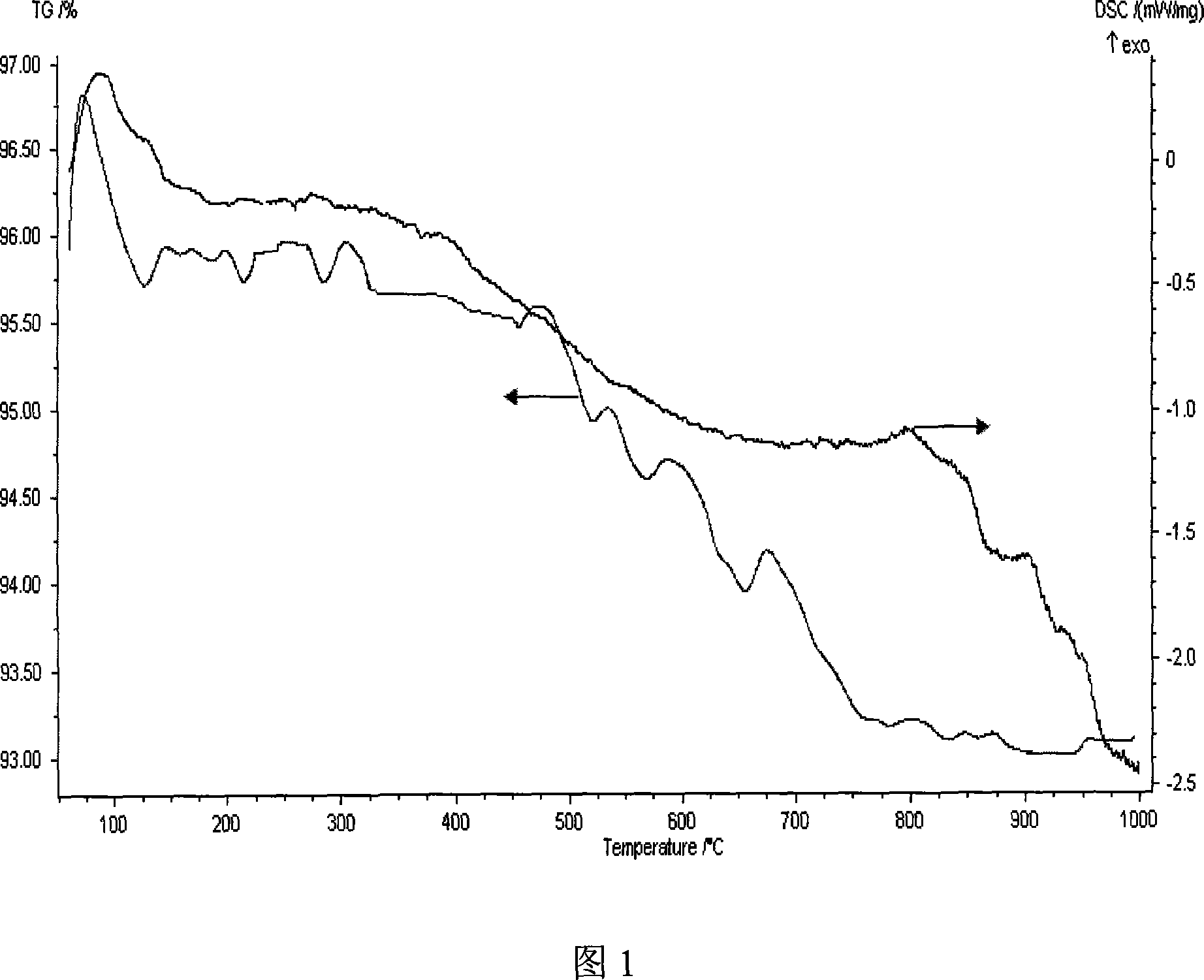

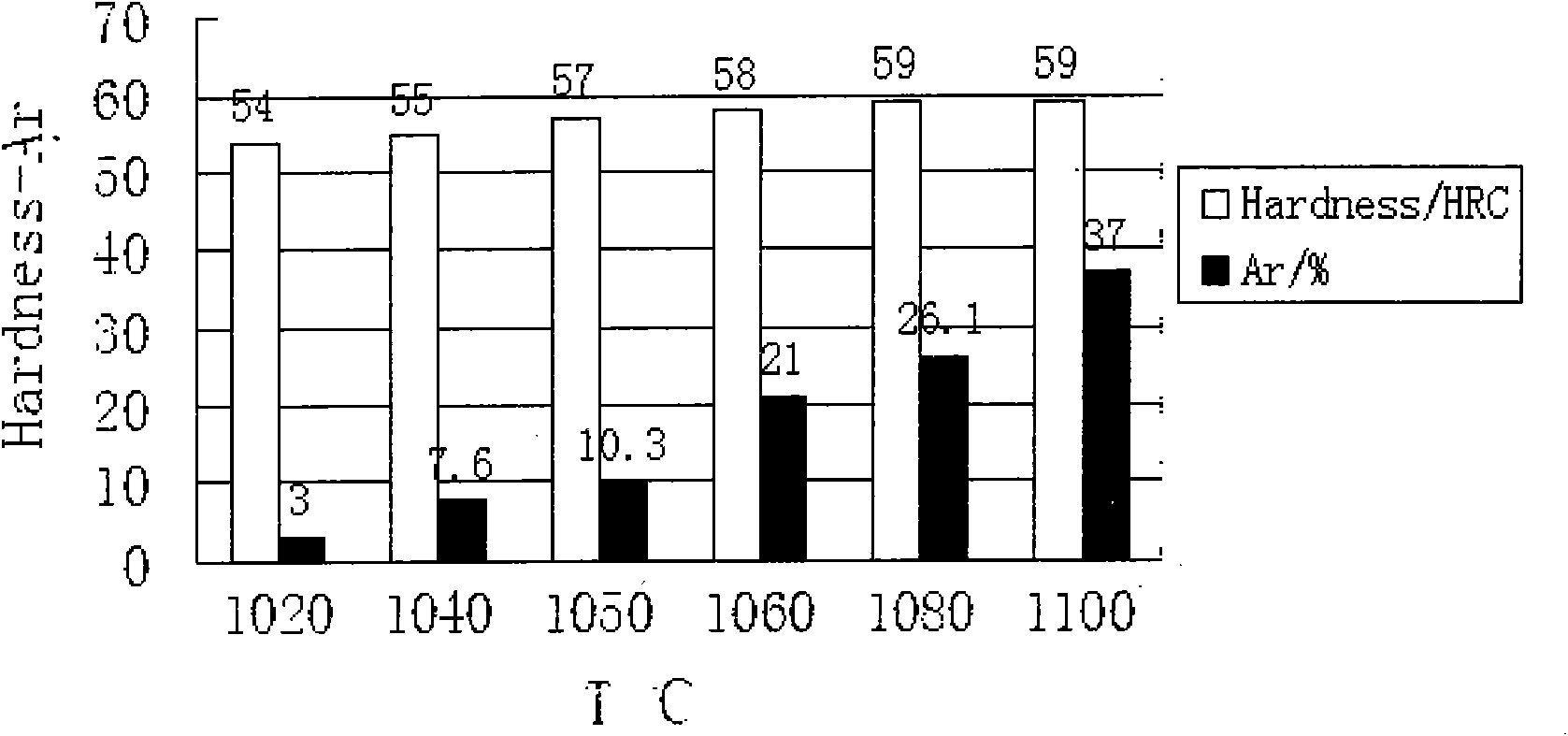

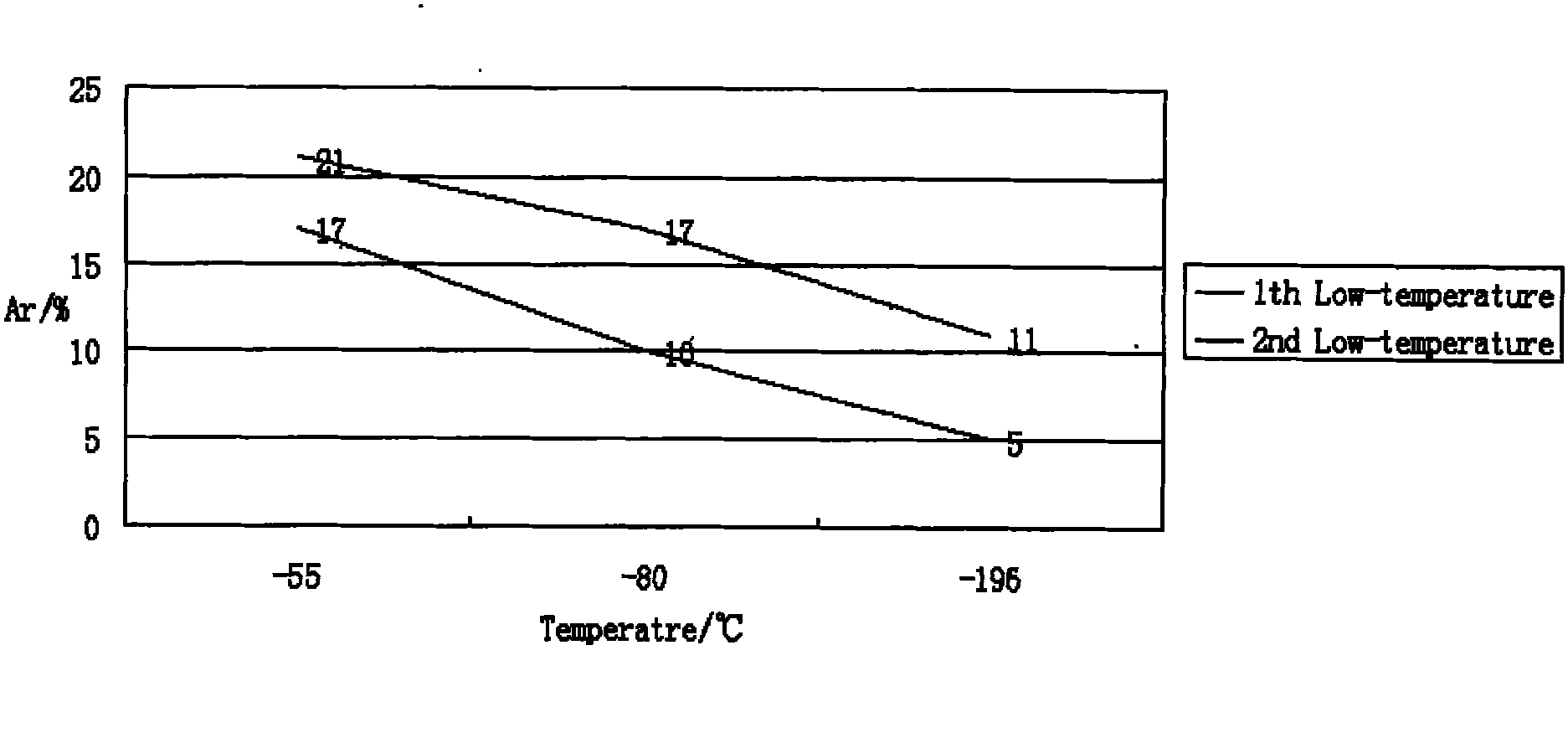

Thermal treatment technology of high-nitrogen stainless bearing steel

InactiveCN101935752AControl contentGuaranteed dimensional stabilityHeat treatment process controlCold treatmentRoom temperature

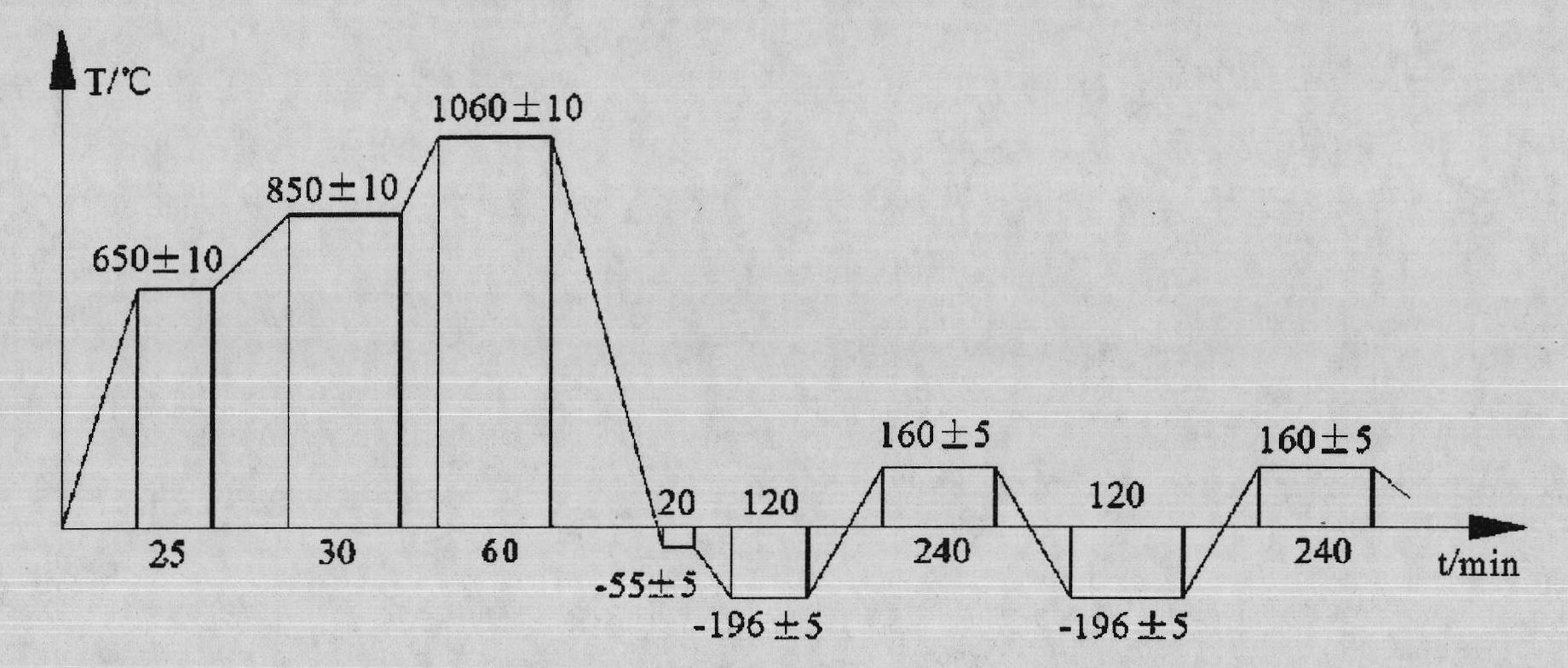

The invention discloses a thermal treatment technology of high-nitrogen stainless bearing steel, comprising the following steps of: primarily preheating at a temperature of 650+ / -10 DEG C and preserving the temperature for 25-35 min; secondarily preheating at a temperature of 850+ / -10 DEG C and preserving the temperature for 20-45 min; quenching at a temperature of 1060+ / -10 DEG C and preserving the temperature for 50-60 min; cooling to the room temperature after the quenching and performing cold treatment in half an hour at a temperature of -196+ / -5 DEG C for 2-3 h for twice; and warming to the room temperature after the cold treatment and performing tempering immediately at a temperature of 160+ / -5 DEG C for 4-4.5 h for twice. The best thermal treatment technology of 40Crl5Mo2VN high-nitrogen stainless bearing steel of the invention, which is finally determined on the basis of numerous experiments, not only effectively controls the content of the remained austenite to guarantee the size stability problem of the 40Crl5Mo2VN steel workpiece, but also solves the deformation problem and crack problem of the thermal treatment.

Owner:LUOYANG LYC BEARING

Self-mounting-reference equal-common-normal-line gear involute template

ActiveCN108061651AEasy to processEasy to testMachine gearing/transmission testingShape deviationInvolute

The invention belongs to the field of precise gear testing technology, and discloses a self-mounting-reference equal-common-normal-line gear involute template. The self-mounting-reference equal-common-normal-line involute template comprises a left tooth surface, a right tooth surface, an upper reference cylindrical surface, a lower reference cylindrical surface, an upper end surface, a lower end surface and a reference hole. The gear involute template satisfies a basic requirement for a grade-1 precise gear involute template in a gear involute template national standard. Furthermore the involutes of the left special-shaped tooth surface and the right special-shaped tooth surface of the template have a common normal line and a unified expanded basic circle arc. The self-mounting-reference equal-common-normal-line gear involute template facilitates subsequent ultra-precise processing and testing of the gear involute template. Furthermore, the self-mounting-reference is used for processing and measuring and is furthermore used as a magnitude transmission reference in use of the gear involute template. The measurement results of the structure tooth profile shape deviation ffalpha and atoth profile inclination deviation offset fHalpha are not closely related with the processing error and the mounting deviation error of a measuring core shaft in a use process, thereby ensuring highconvenience in use and high dimension stability in magnitude transmission.

Owner:金齿传动科技(大连)有限公司

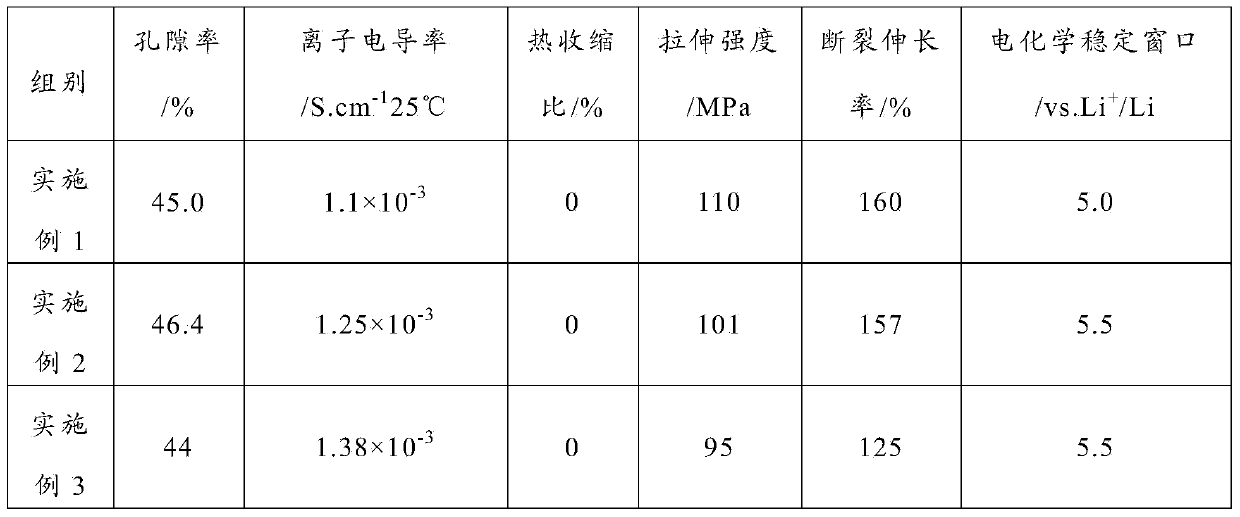

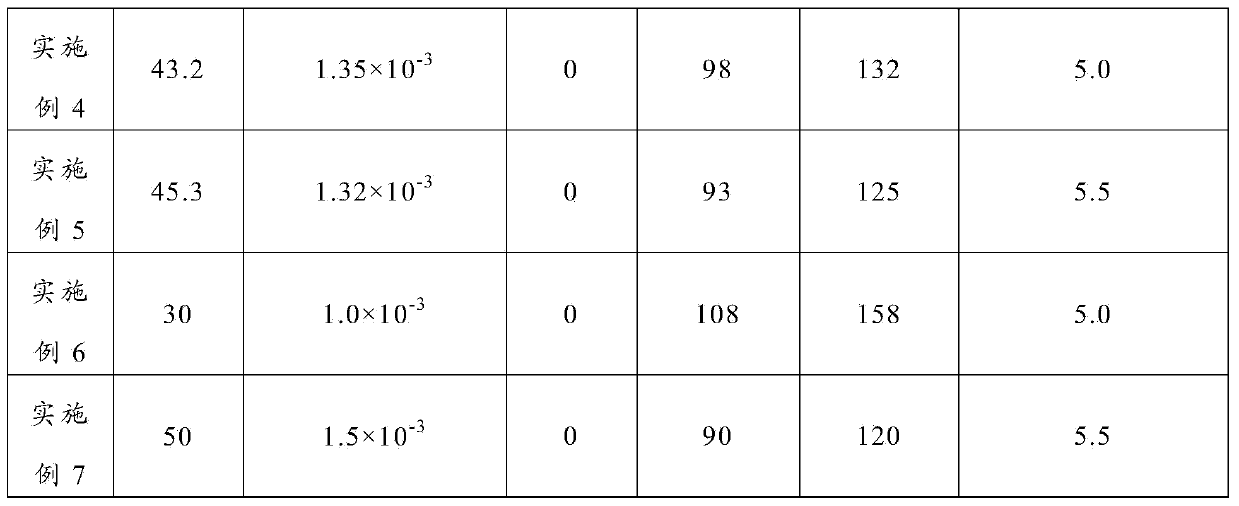

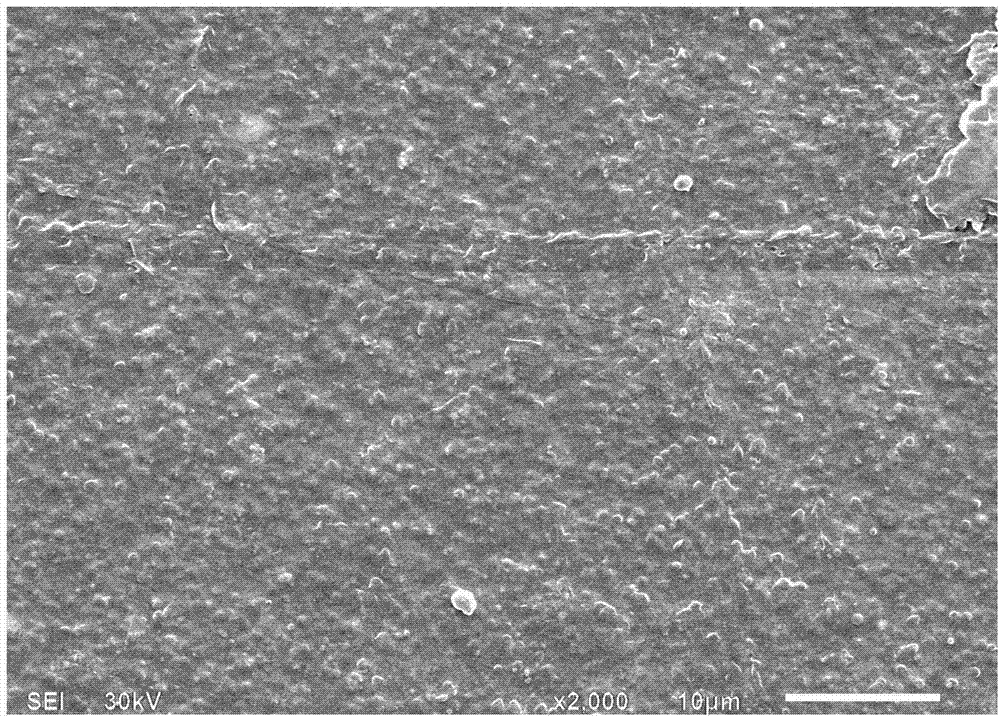

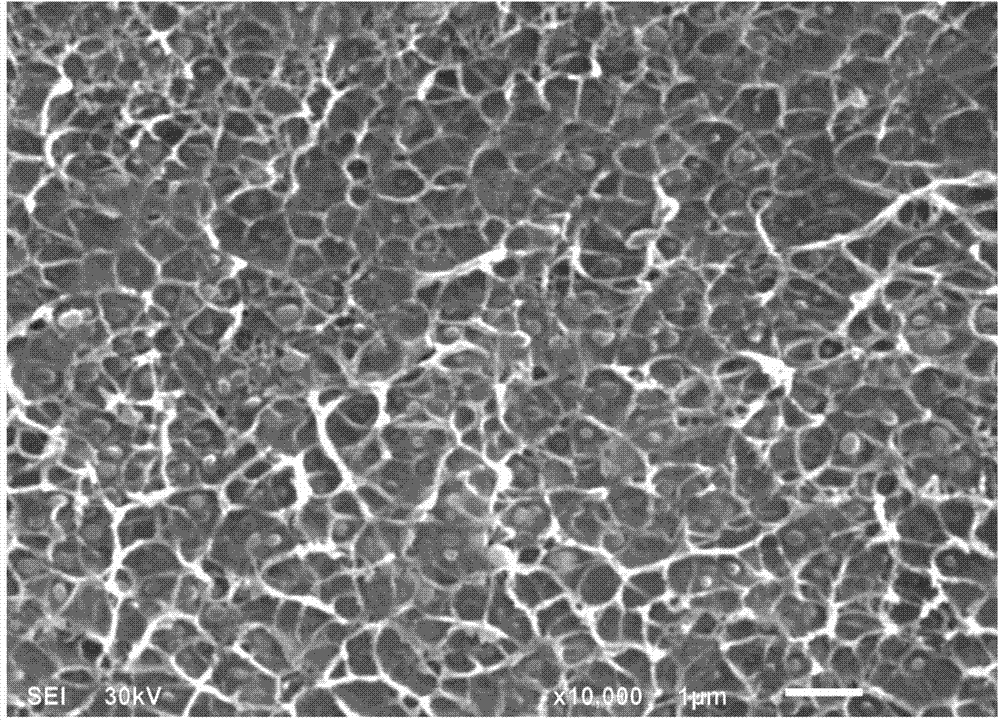

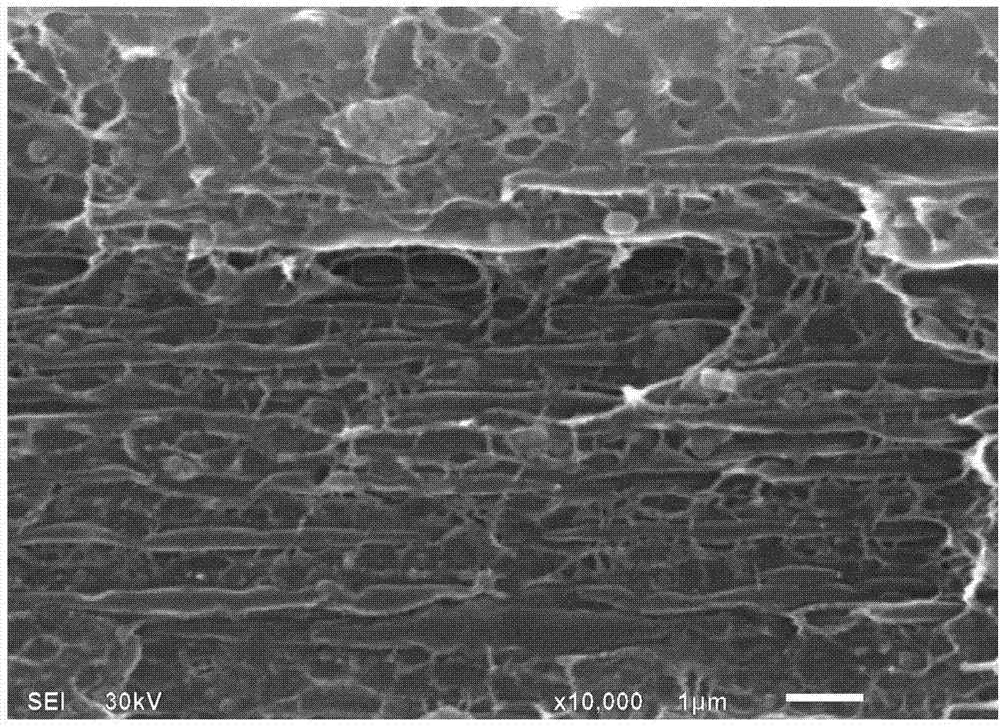

Membrane and preparation method thereof

InactiveCN103618058AHigh porosityImprove electrochemical performanceCell component detailsPlasticizerHeat resistance

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

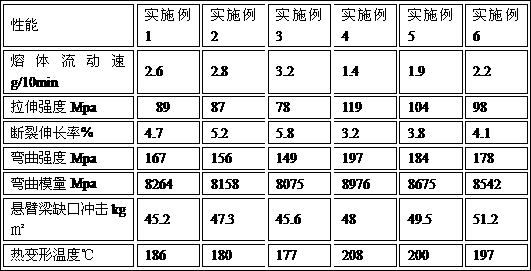

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Preparation method of polyvinylidene fluoride-based thin film

The invention relates to a preparation method of a polyvinylidene fluoride (PVDF)-based thin film. According to the thin film forming process, through an extrusion casting and drawing method, PVDF, polymethyl methacrylate (PMMA), a rubber elastomer, titanium dioxide as well as other auxiliaries and fillers are mixed according to a certain ratio and are melted and extruded at certain temperature, and then the PVDF-based thin film is formed under guiding and stretching effects of casting traction equipment. The PVDF-based thin film prepared by the invention is uniform and easily controllable in thickness, good in barrier property as well as excellent in mechanical property and environmental aging resistance, and is easy to realize industrialization; the PVDF-based thin film, through modification treatment, is significantly improved in surface caking property and guarantees good adhesion with a solar cell packaging material; the thin film brings high convenience for assembly of a solar cell backboard film and is compact in structure; and the thin film has good application prospect in solar cell industry.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

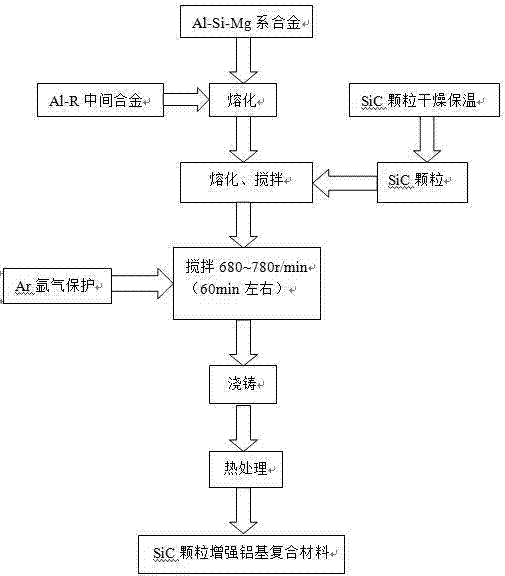

Preparation method for SiC particle reinforced aluminum-based composite material

InactiveCN103484707AGood physical propertiesImprove mechanical propertiesThermal insulationMetal mold

The invention provides a preparation method for SiC particle reinforced aluminum-based composite material. The preparation method comprises the steps as follows: step 1, the Al-Si-Mg alloy is placed into a homemade dry pot resistance furnace, after the Al-Si-Mg alloy is completely melted, 1-17 parts of intermediate alloy Al-R by weight, which is prepared in advance, is added into the melt, wherein the intermediate alloy is prepared in advance through a surface modification technology; step 2, the melt is stirred to enable rare-earth elements to be uniformly distributed into the melt; step 3, SiC is added into the melt; step 4, the melt is poured into a metal mould for formation; step 5, quenching is performed in water with the temperature of 50-60 DEG C; step 6, quenching is performed in water with the temperature of 70-80 DEG C; step 7, air cooling is performed after aging thermal insulation is performed for 6.5-7.5 h at the temperature of 165-175 DEG C. The thermal shock performance of the aluminum-based composite material can be greatly enhanced, the dimensional stability of the material is maintained when the material is used in temperature varying places, the service life of the material is prolonged, and the material has a broad market prospect when being applied to parts requiring weight reduction and excellent abrasion resistance.

Owner:TONGJI UNIV

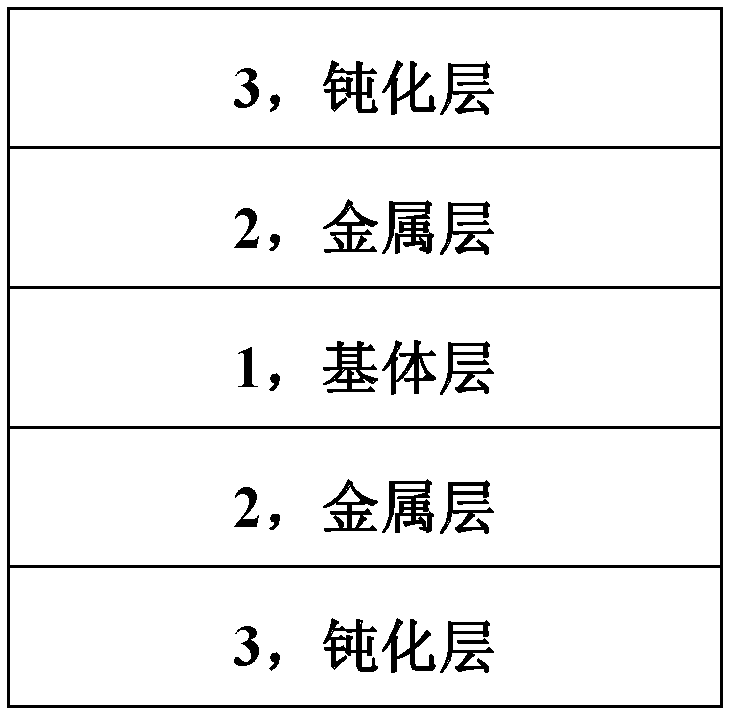

Soft board base material without glue and preparation method thereof

ActiveCN103167731AHigh composite strengthImprove reliabilityPrinted circuit manufactureCircuit susbtrate materialsHeat resistanceHigh intensity

A functional soft board base material without glue is composed of a metal layer, a basal layer and a metal passivation layer which are superimposed. The manufacturing method includes that (1), polyimide is used to make a basal body, and surface treatment is performed for two faces (or one face) of the basal body; (2), a physical vapor deposition (PVD) method is adopted to deposit and form a metal membrane layer on a product improve (PI) face of a treated face; and (3), passivation treatment is performed for the metal membrane layer. The soft board base material without the glue has high-strength tensile performance, excellent chemical resistance, heat resistance, dimensional stability, peel strength, compactness, uniform consistency, and mechanical machining performance, is strong in shielding function, and can be used for manufacturing printed circuit boards (PCB), flexible printed circuits (FPC), soft and hard combination plate, special function (shielding function) material and the like, the PVD method is adopted to deposit the metal layer, the thickness of the metal layer is enabled to be adjustable, achievement of superfine precision circuit is enabled to be possible, and the soft board base material without glue is low in cost, environment-friendly, good in bending performance and easy for technical processing.

Owner:英德宏庆电子有限公司

Method for manufacturing copper base alloy bearing bush wear-resisting layer

The invention discloses a method for manufacturing a copper base alloy bearing bush wear-resisting layer and relates to a bead weld method. The method for manufacturing the copper base alloy bearing bush wear-resisting layer aims at solving the problems that an existing bearing bush coating is low in combining strength, poor in coating performance and short in service life. The method includes the first step of polishing, the second step of cleaning, the third step of tin coating, the fourth step of bead weld of babbit metal on the surface of a bearing bush by a CMT welding machine and the fifth step of turning or scraping. The method is used for improving the combining strength of the wear-resisting coating and a copper base bearing bush base body, optimizing a coating organization, prolonging service life, improving the machining precision of the bearing bush and manufacturing the copper base alloy bearing bush wear-resisting layer.

Owner:严格集团股份有限公司

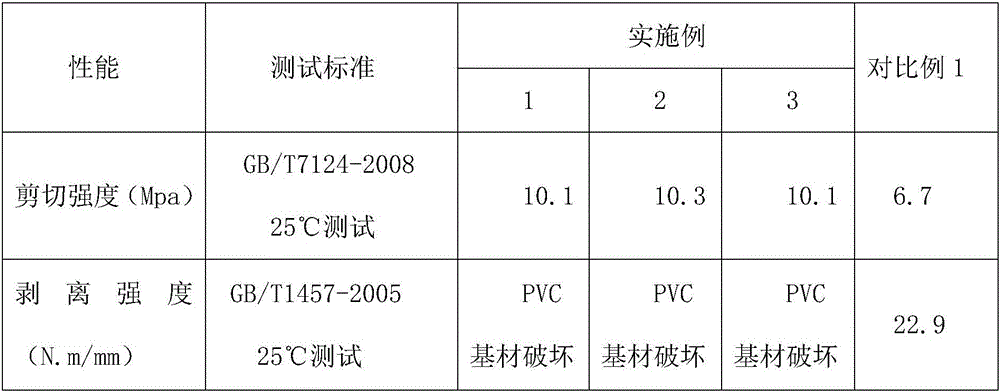

Polyurethane adhesive for compositing two-component PVC plate

ActiveCN105925236AGuaranteed dimensional stabilityHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistancePolyester

The invention discloses a polyurethane adhesive for compositing a two-component PVC plate. The adhesive is composed of a component A and a component B according to the mass ratio of (1-4):1, and the component A is composed of, by weight, 10%-25% of castor oil, 10%-20% of polyether polyol, 1%-5% of coupling agent, 0.5%-2.5% of fumed silica, 30%-60% of filler and 5%-10% of drying agent; the component B is composed of, by weight, 50%-80% of isocyanate, 5%-15% of polyether polyol, 10%-30% of polyester polyol and 1%-4% of chain extender. A preparation method of the polyurethane adhesive for compositing the two-component PVC plate comprises the following steps of preparation of the component A, preparation of the component B and mixing of the component A and the component B. The polyurethane adhesive is used for bonding PVC with a plate. The polyurethane adhesive has the advantages of being free of solvent evaporation, large in initial adhesion, excellent in adhesive force on PVC, high in strength, wide in environmental adaptability, long in storage life, high in stability, environmentally friendly in raw material, capable of obtaining the raw materials conveniently and the like.

Owner:上海都昱新材料科技有限公司

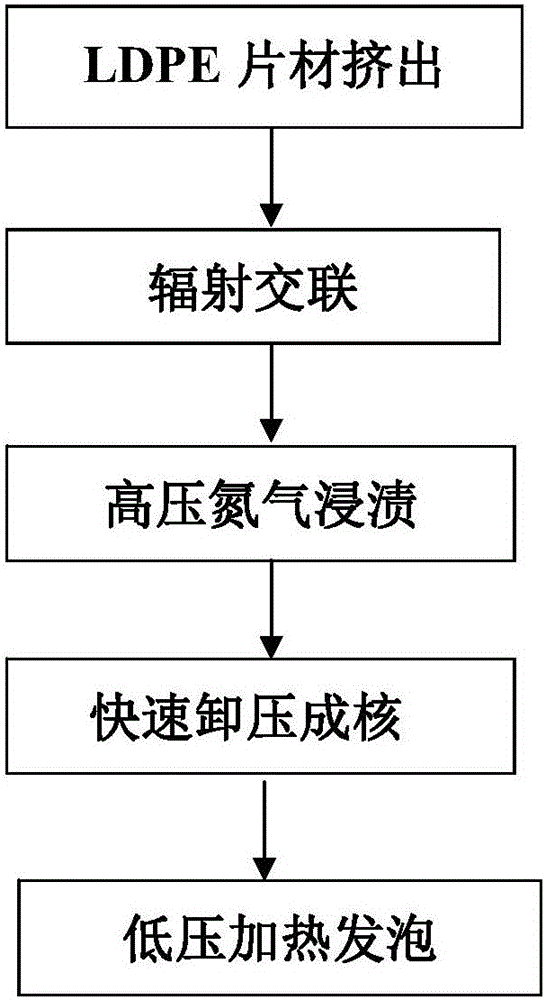

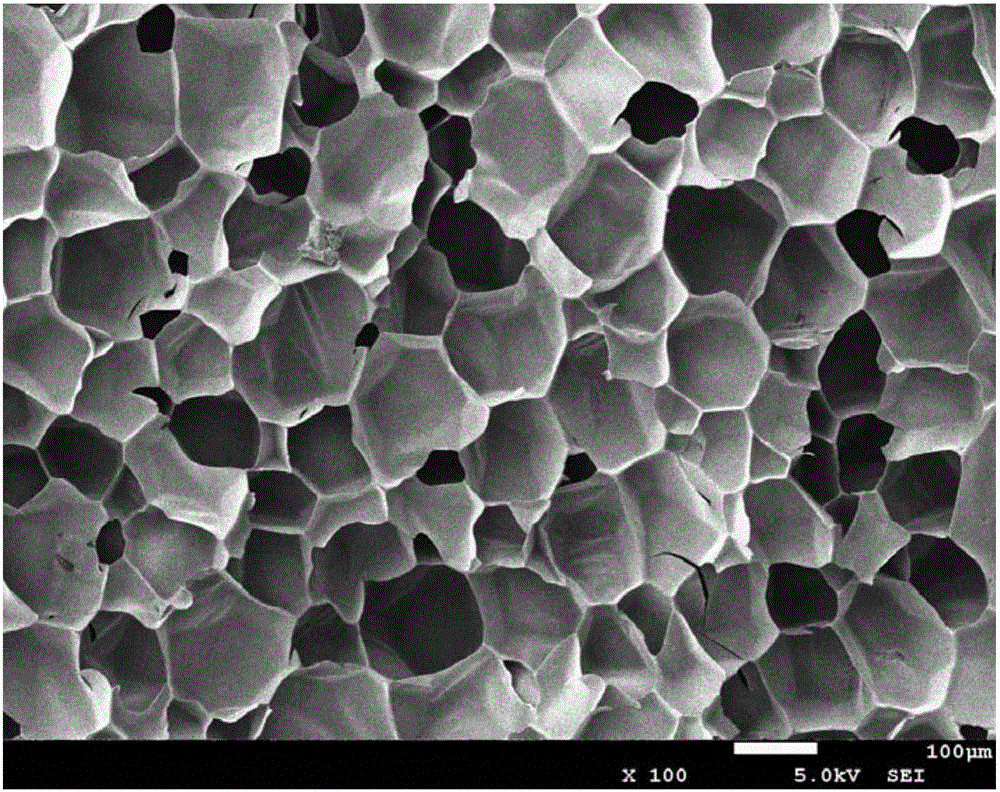

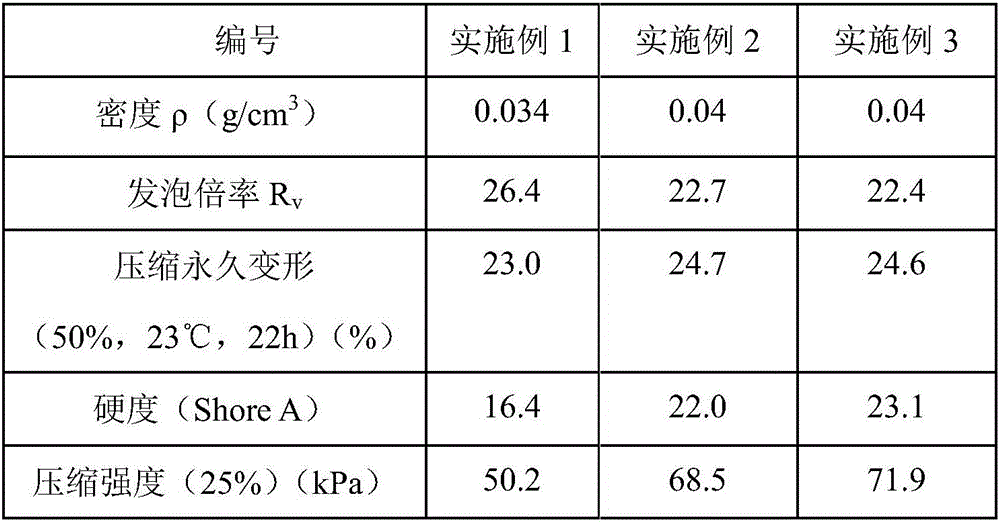

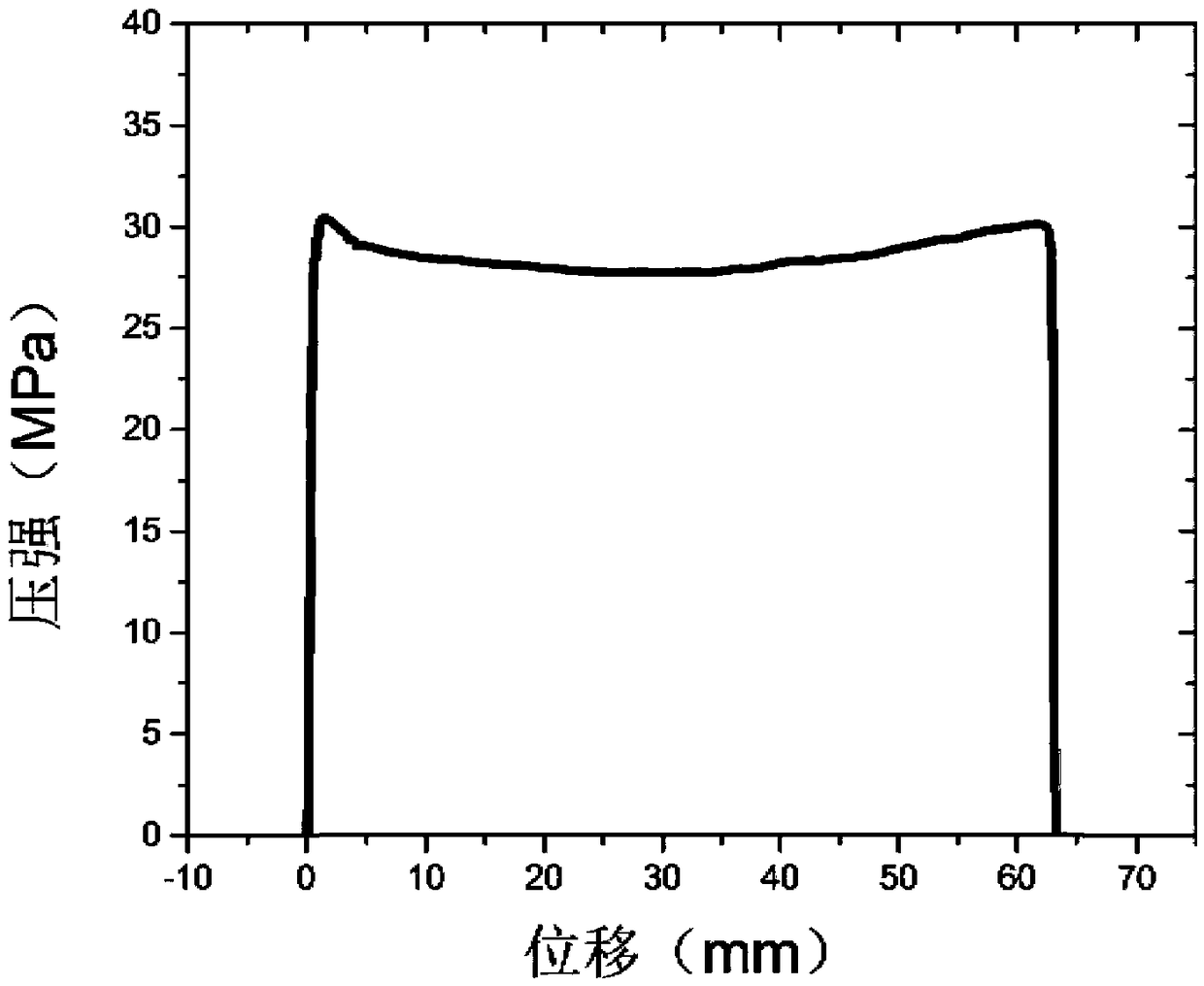

Supercritical fluid foaming polyolefin material and preparing method thereof

ActiveCN106146874AEasy to control the nucleation densityEasy to adjust the degree of expansionPolyolefinPolymer science

The invention provides a supercritical fluid foaming polyolefin material and a preparing method thereof. The supercritical fluid foaming polyolefin material is prepared through the following steps that a polyolefin sheet is prepared, and the melting point of the polyolefin sheet is Tm; radiation crosslinking is carried out on the polyolefin sheet; the crosslinked polyolefin sheet is put into a pressure container for high-pressure nitrogen impregnation, and the impregnation temperature T1 is equal to Tm+(30-120) DEG C; low-temperature heating foaming is carried out, and the foaming temperature T3 is equal to Tm+(20-50) DEG C, and is smaller than T1. By the adoption of the technical scheme, the requirement for material crystallinity is avoided, the time of reaching a dissolution saturation state of gas is greatly shortened, efficiency is improved, and the foaming material which is fine and uniform in bubble, low in density, high in mechanical strength and regular in shape can be obtained.

Owner:湖州长园特发科技有限公司

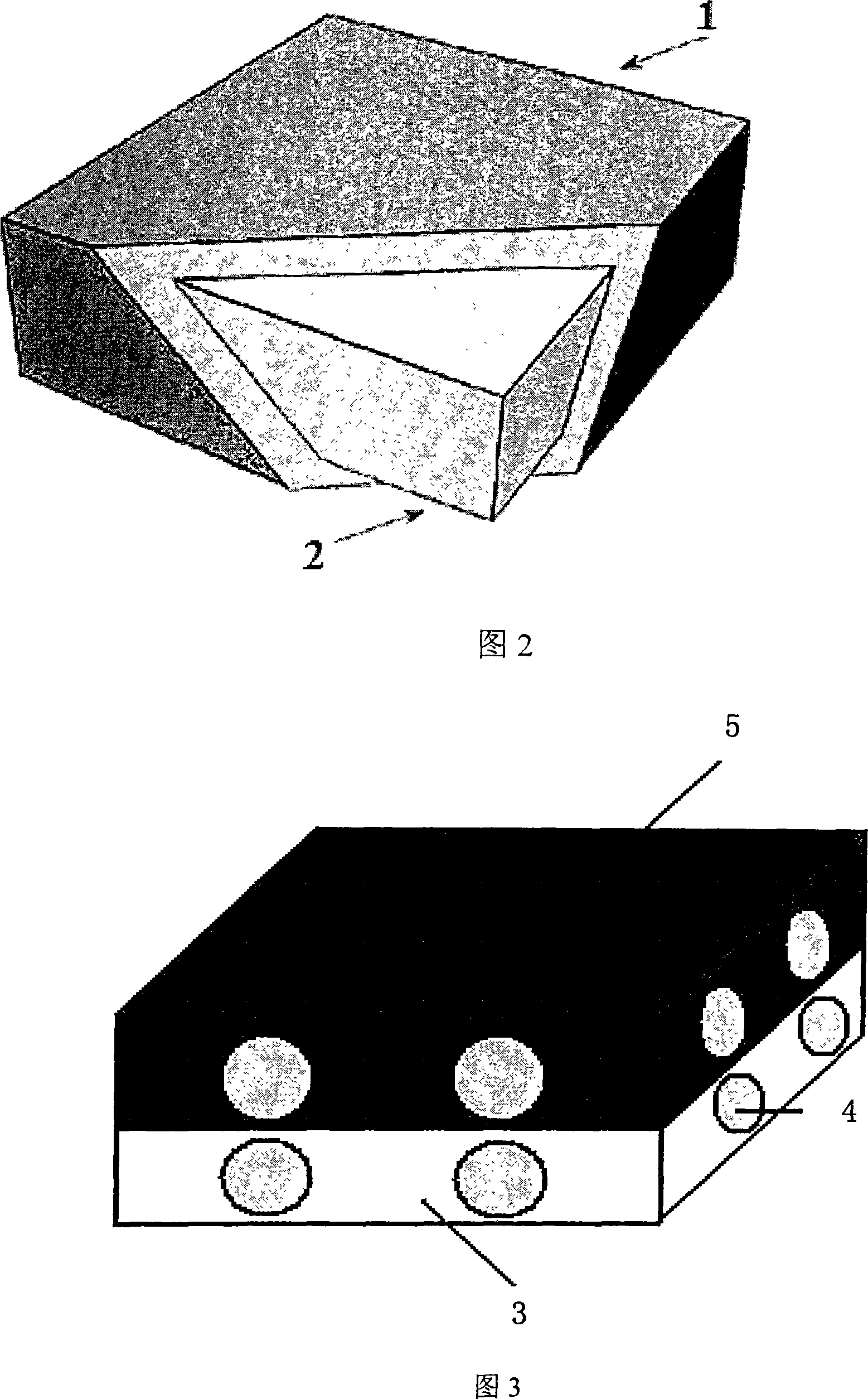

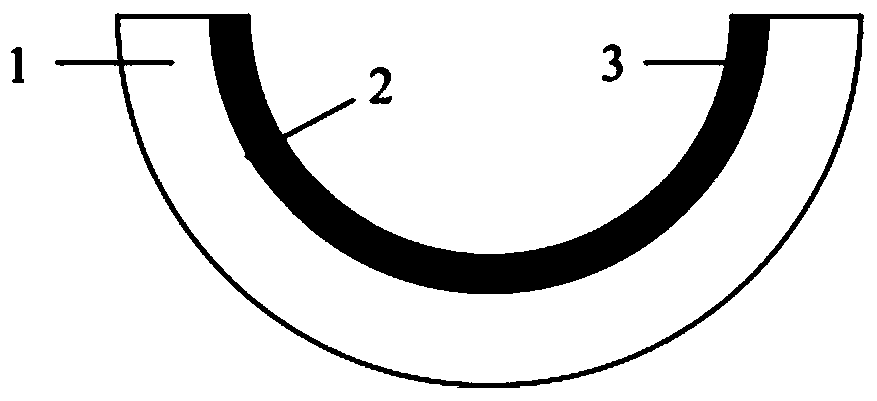

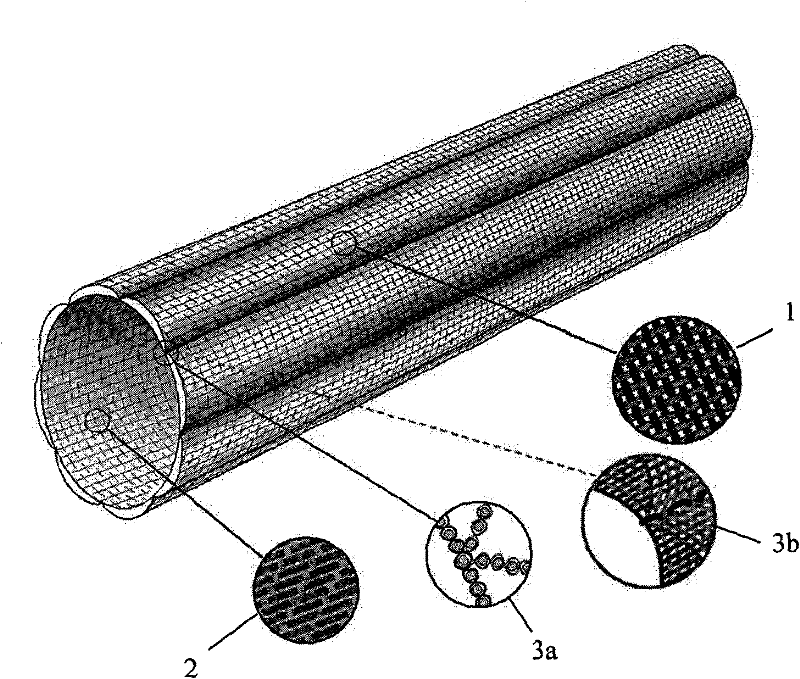

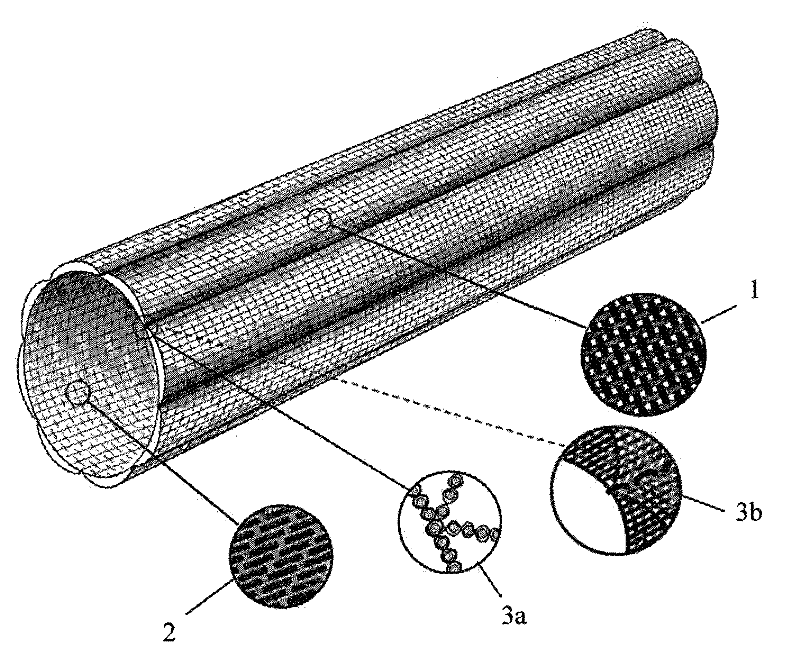

A textile artificial blood vessel with improved radial compliance

The invention relates to a textile artificial blood vessel with a tube wall of a double-layer woven structure, which is composed of an outer fabric tube (1) and an inner fabric tube (2). The outer layer fabric tube (1) is coaxially nested on the inner layer fabric tube (2) and passes through the connection point in the direction of the outer wall of the inner layer fabric tube (2) and the inner layer fabric tube (2) is formed by the binding yarn of the fabric Connection (3a) or sewing connection (3b). The invention can realize the matching with the radial compliance of the host blood vessel of the human body, which is beneficial to the recovery of human body functions and facilitates the development of blood vessel transplantation operations.

Owner:DONGHUA UNIV

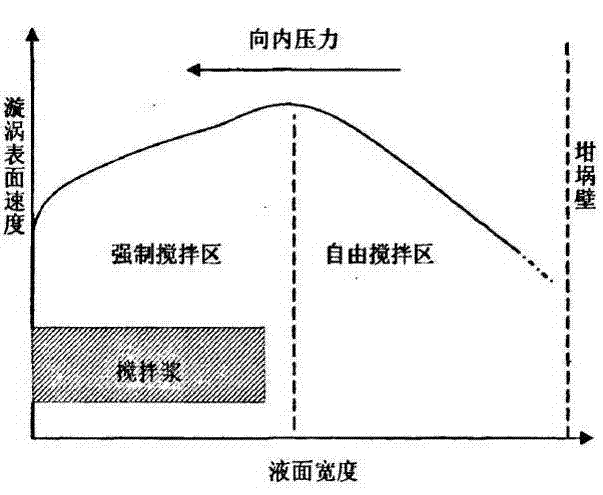

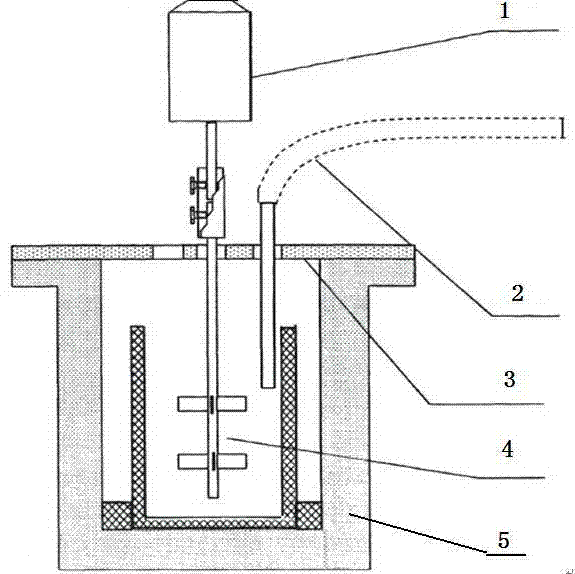

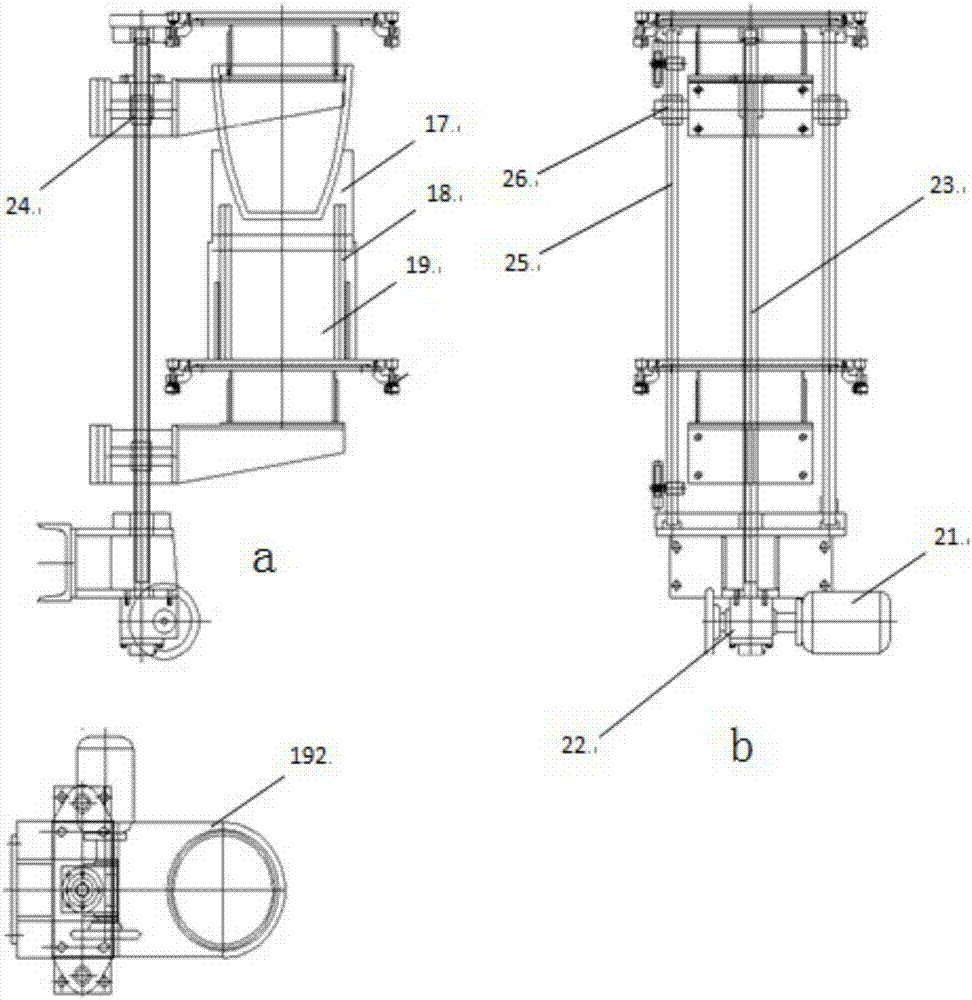

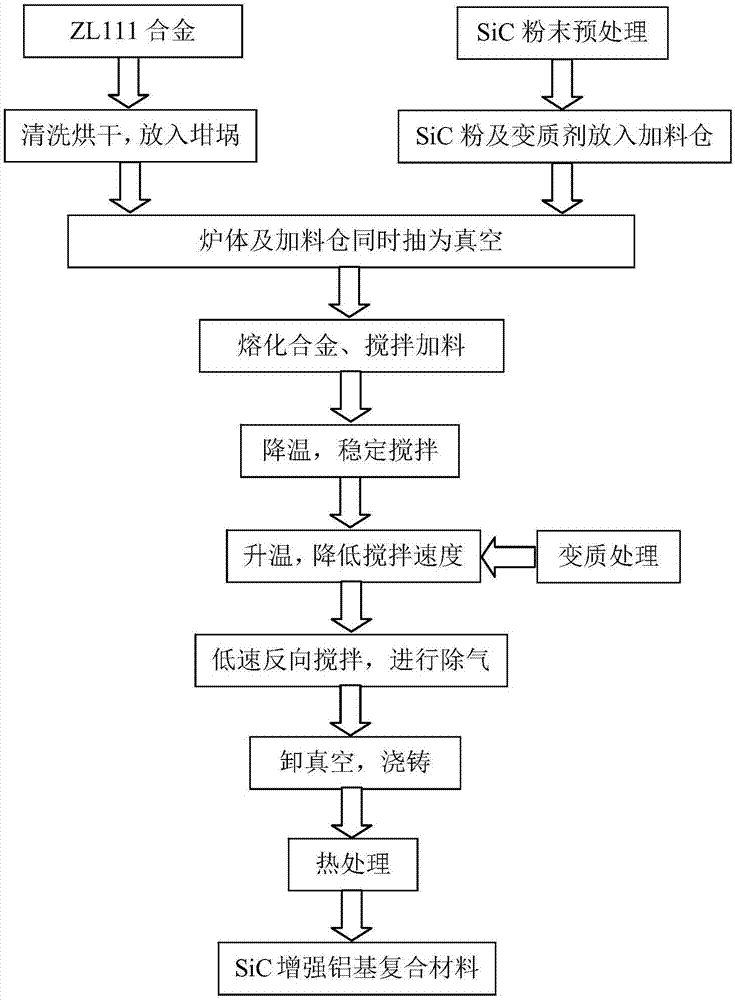

Preparing method for SiC particle enhanced aluminum-base composite material

The invention aims at disclosing a specially-made vacuum smelting furnace and a preparing technology for a SiC particle enhanced aluminum-base composite material. A certain component proportion and a special smelting casting technology are adopted. The vacuum smelting furnace is adopted in the technology, overall closing and vacuum-state charging can be achieved, the inner temperature of melt can be measured in real time, the particles accurately fall into a melt vortex center with a certain speed and are evenly distributed in the melt under powerful stirring, the functions of deoxygenation and degassing can be effectively achieved on the composite material melt, and therefore the composite material uniform in component, low in porosity, high in mechanical performance and excellent in heat-conducting property can be produced through the technology. The crucible lifting type vacuum smelting furnace comprises a crucible composite device and lifting platform system, a stirring device and lifting platform system, a charging device, a vacuum system, a handheld lifting thermocouple, a sealing system and an electric control system.

Owner:SUZHOU WUCHUANG MATERIAL TECH DEV CO LTD

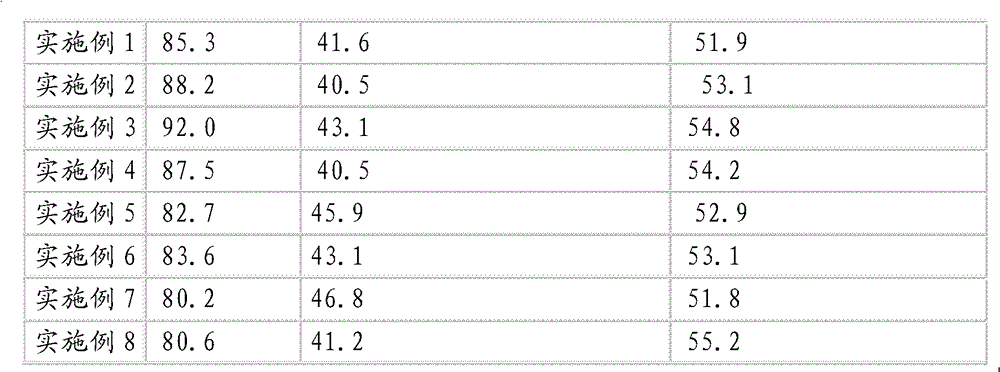

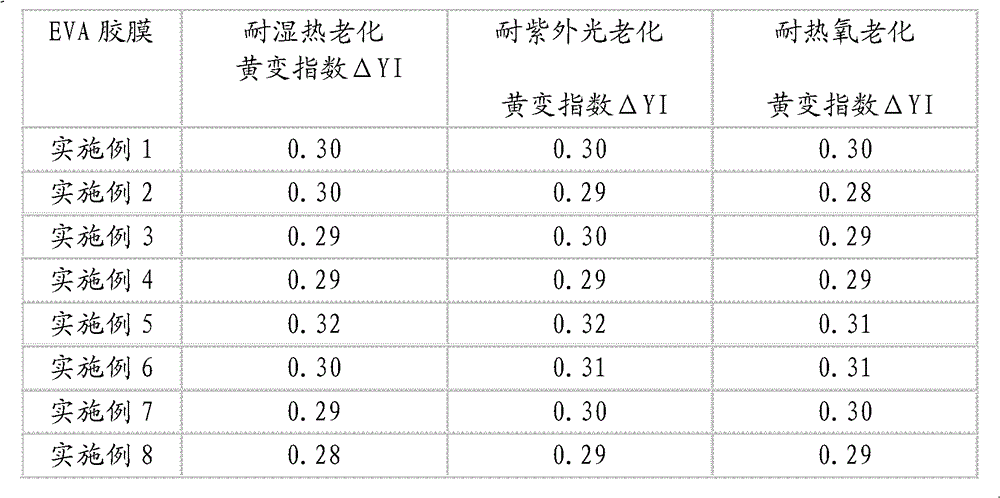

EVA (ethylene vinyl acetate) adhesive film for solar cells

InactiveCN102504715BFast curingIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkHindered amine light stabilizers

Owner:NINGBO HUAFENG PACKAGE

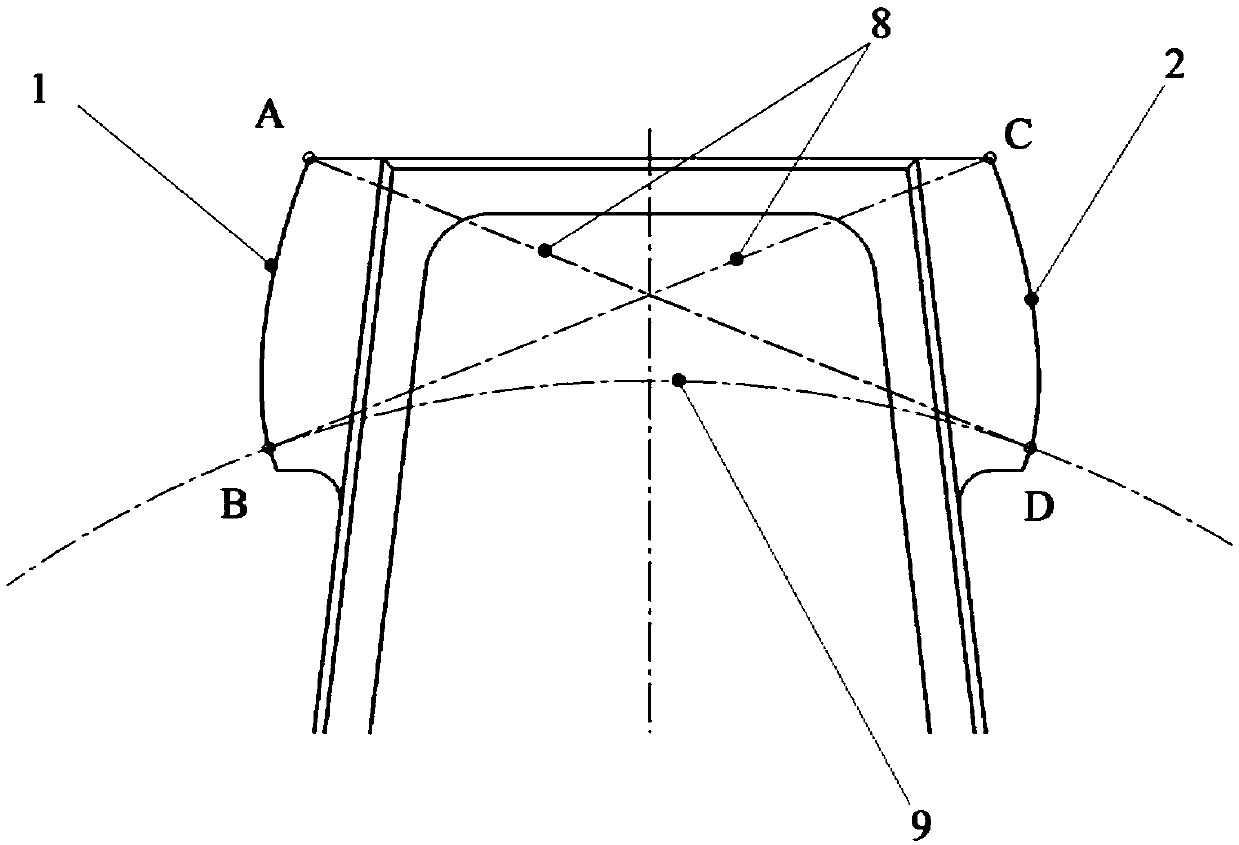

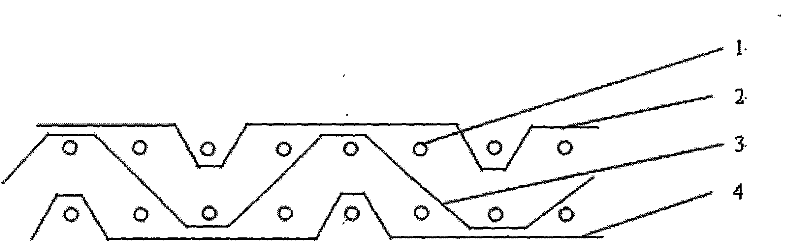

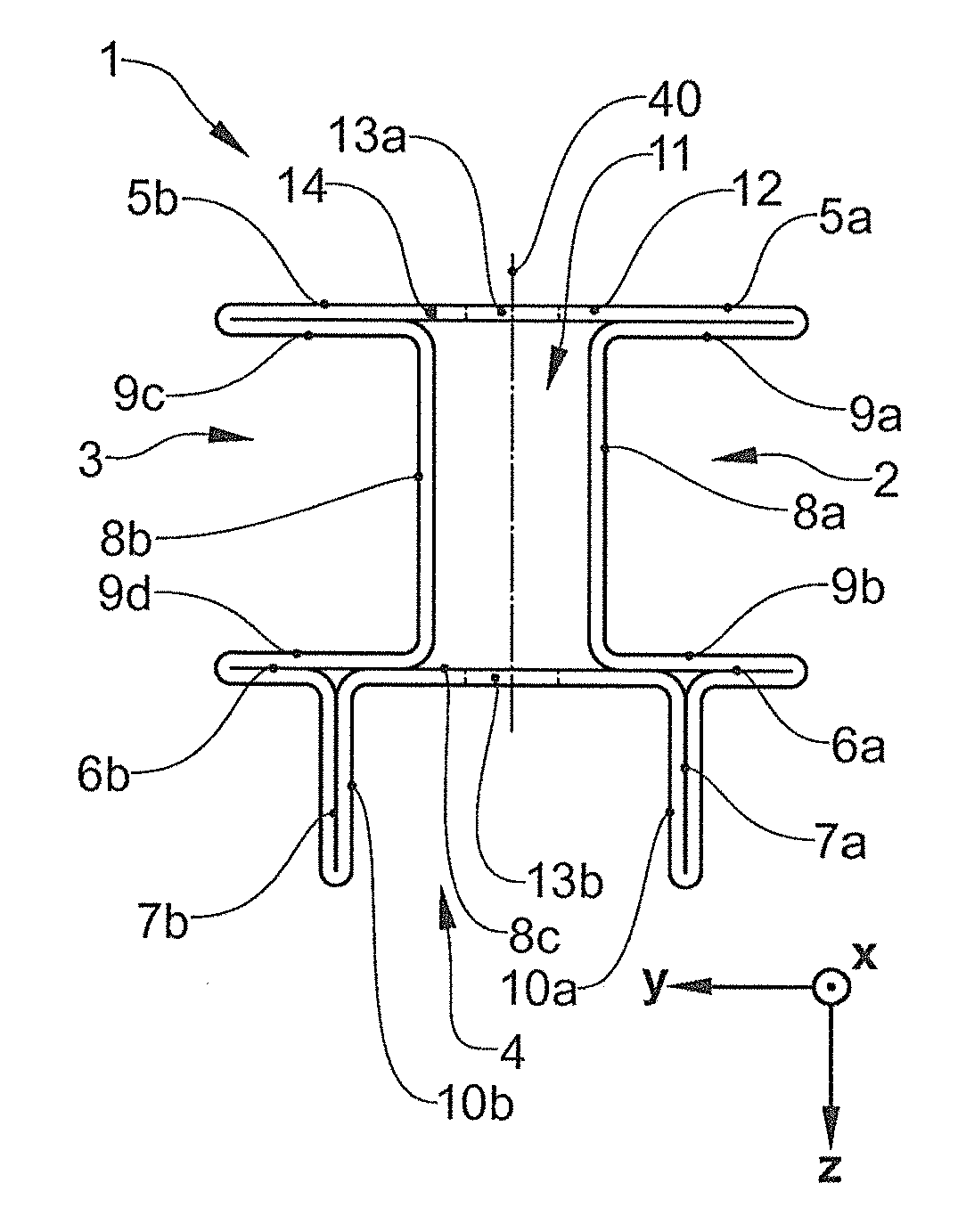

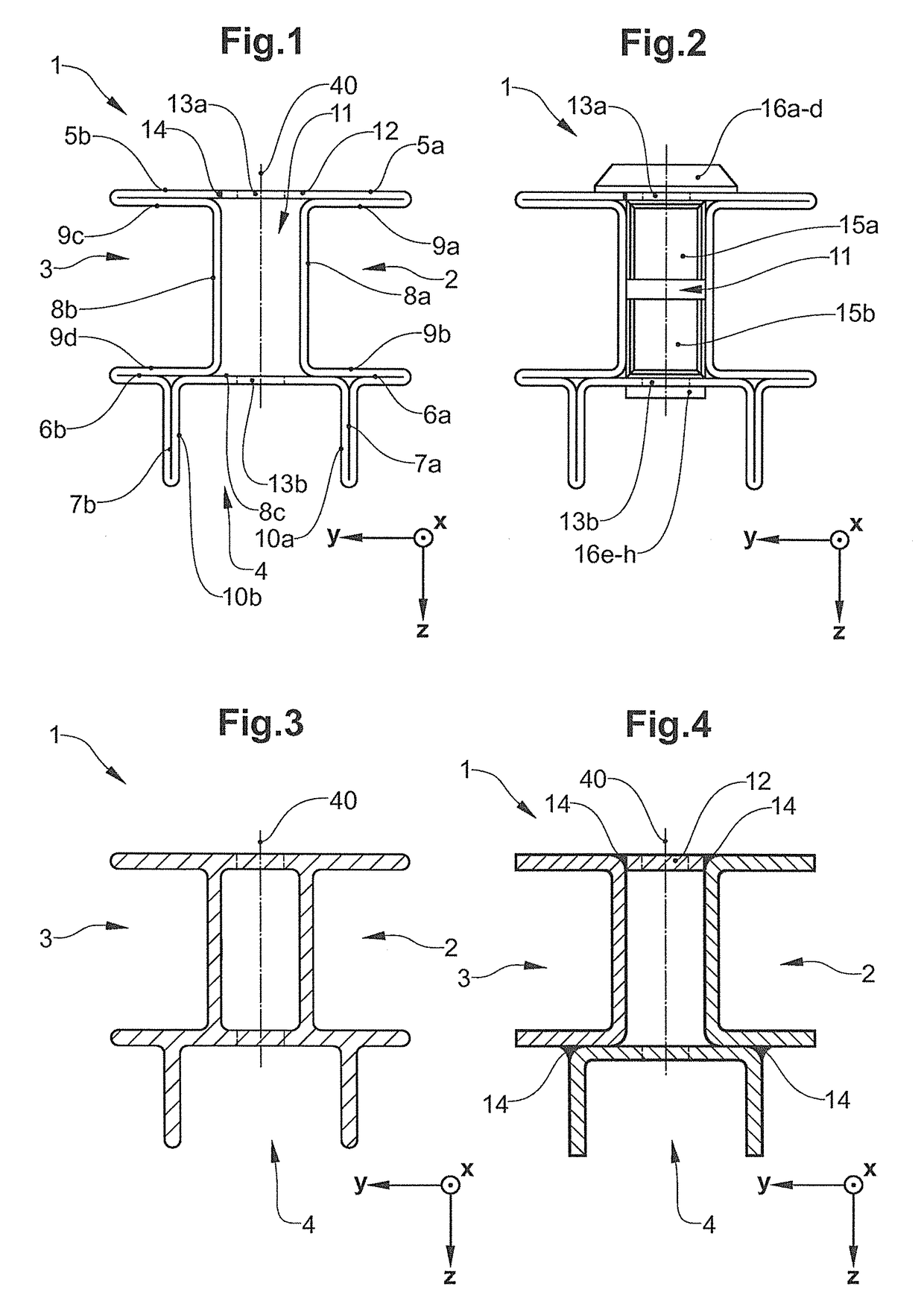

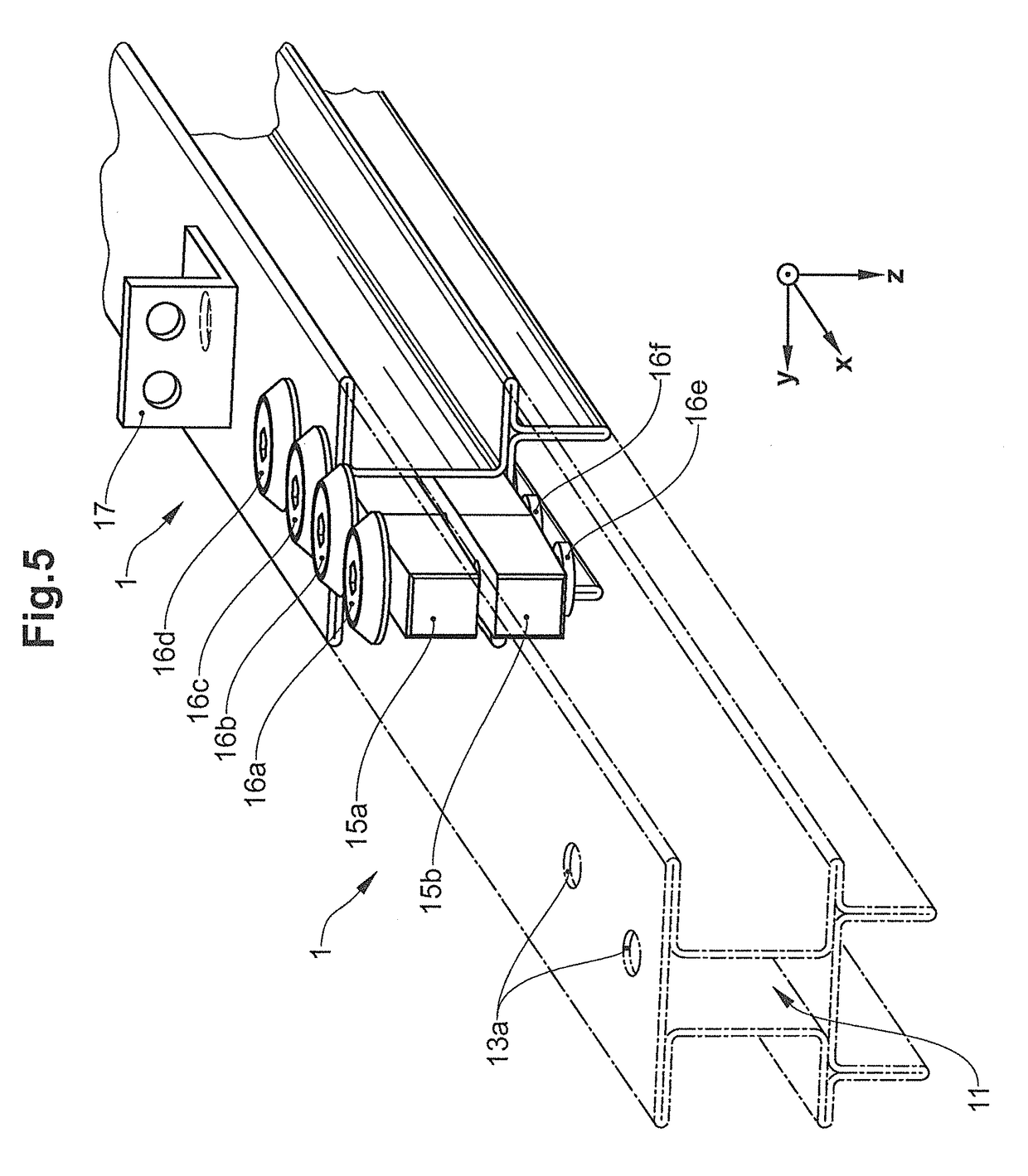

Running rail and method for producing such a running rail

ActiveUS20170275826A1Reliable running characteristicIncreased torsional stiffnessConveyorsMonorailsCarriageDelivery system

A running rail (1) for a conveyor system, the running rail (1) having a cross-sectional profile comprising at least three interconnected profiled portions which comprise a first profiled portion (2), laterally open to the outside, for receiving first rollers (32) of a carriage (30), a second profiled portion (3), laterally open to the outside, for receiving second rollers (33) of a carriage (30), a third profiled portion (4), open in the vertical direction, for receiving third rollers (34) of a carriage (1), wherein the first (2) and the second profiled portion (3) are mirror symmetrical to a vertical central plane (40) of the running rail (1).

Owner:FERAG AG

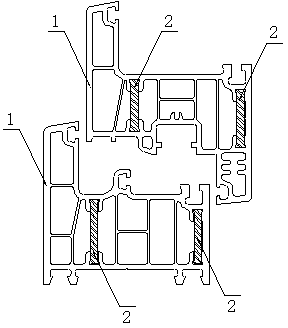

Preparation method for PVC (Polyvinyl Chloride)/modified PBT (Polybutylece Terephthalate) lining material composite section

ActiveCN103075071AMaintain fatigue resistanceSmall creepWindow/door framesWing framesGlass fiberPolymer science

The invention discloses a PVC (Polyvinyl Chloride) / modified PBT (Polybutylece Terephthalate) lining material composite section and a preparation method. The PVC / modified PBT lining material composite section is characterized in that PBT is reinforced and modified, is extruded with a PVC section in a cavity together and is compositely formed to substitute a reinforced section. Compounding with the PVC section can be realized through a co-extrusion process, so that mounting steps of a metal lining are simplified, the effect is improved, and the production cost is greatly reduced. A modified material comprises the following components in parts by weight: 75-84 parts of PBT resin, 15-30 parts of glass fiber reinforcing agent, 0.1-0.3 part of lubricating agent, 1.0-1.4 parts of dispersant, 0.5-1 part of processing flow modifier (AMS), 0.5-0.7 part of anti-aging agent and 1-3 parts of low-temperature modified toughening agent.

Owner:HARBIN ZHONGDA PROFILE TECH

Phenolic resin modified ceramic diaphragm and application thereof

InactiveCN108493389AImprove thermal stabilityGood dimensional stabilityCell component detailsIn situ polymerizationSlurry

The invention discloses a phenolic resin modified ceramic diaphragm and application thereof. The diaphragm comprises porous base film, at least one side of the film is provided with a phenolic resin ceramic layer by spreading a phenolic resin ceramic slurry; at least one surface of the porous base film is coated with the ceramic layer, and the surface of the ceramic layer, the insides of pores, the insides of the pores of the porous base film and the surface which is not coated with the ceramic layer are immersed in a phenolic resin precursor solution to be subjected to the in-situ polymerization to form the phenolic resin layer. Through the mixing coating of the phenolic resin and the ceramic slurry or the in-situ polymerizing of the phenolic resin on the basis of the ceramic diaphragm, aphenolic resin ceramic mixed layer can be formed on the surface of the porous base film, the surface of the porous base film and the insides of the pores are coated with the in-situ coating phenolicresin layer, thereby improving the thermal stability of the diaphragm, the diaphragm does not shrink at 200 DEG C and still maintains strong mechanical strength, the contact of the positive and negative electrodes is effectively blocked, and the safety performance of a battery is ensured.

Owner:XIAMEN UNIV

High-temperature-resistant polymer modified ceramic diaphragm and application thereof

ActiveCN108666511AImprove thermal stabilityImproved thermal dimensional stabilityCell component detailsSecondary cells servicing/maintenancePolymer modifiedMetallurgy

The invention discloses a high-temperature-resistant polymer modified ceramic diaphragm and an application thereof. The high-temperature-resistant polymer modified ceramic diaphragm comprises a porousbase membrane, and at least one surface of the porous base membrane is coated with a ceramic layer; and a high-temperature-resistant polymer layer is arranged on the surface and in the interior of pores of the ceramic layer, in the interior of pores of the porous base membrane, and on the surface not coated with the ceramic layer in an in-situ polymerization manner. The high-temperature-resistantpolymer modified ceramic diaphragm has relatively high thermal stability. Through the in-situ polymerization method of pyrrole, the thiophene and the aniline monomer, a high-temperature-resistant polymer protection layer is formed on the surface and in the interior of pores of the ceramic layer, on the surface of the porous base membrane, and in the pores in an in-situ coating manner, so that theceramic layer, the polymer layer and the base membrane form an organic integrated body; therefore, the thermal size stability of the modified ceramic diaphragm is improved, and the modified ceramic diaphragm does not contract at a high temperature of 200 DEG C; and in addition, relatively high mechanical performance is still kept, positive and negative electrode contact can be effectively obstructed, and the safety performance of the battery can be guaranteed.

Owner:XIAMEN UNIV

High-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy and casting method thereof

InactiveCN105908024AImprove room temperature performanceImprove mechanical propertiesPressure castingGasoline

The invention relates to a high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy and a casting method thereof. The high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is composed of the following components including, by weight, 9%-13% of Si, 0.2%-3% of Mg, 1%-6% of Cu, 1%-4% of Ni, 0.6%-1.0% of Fe, 0.6%-1.0% of Mn, 0.05%-1.2% of Zr, 0.05%-1.2% of V, 1%-25% of TiB2 particles, and the balance Al. After the high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is subjected to pressure casting, the tensile strength is larger than or equal to 235 MPa at the temperature of 300 DEG C, the tensile strength is larger than or equal to 150 MPa at the temperature of 350 DEG C, and the coefficient of linear expansion within the temperature interval of 300 DEG C to 400 DEG C is (14-21)*10<-6> / DEG C; the casting property of the alloy is improved, the high-temperature (300 DEG C and 350 DEG C) tensile strength of the alloy is improved substantially, the coefficient of linear expansion of the alloy is reduced, and the application range of traditional cocrystallized Al-Si alloys is widened; and the high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is particularly applicable to parts such as pistons of gasoline engines and diesel engines with quite high requirements for high temperature mechanical properties and for dimensional stability in the high-temperature working range.

Owner:SHANGHAI JIAO TONG UNIV

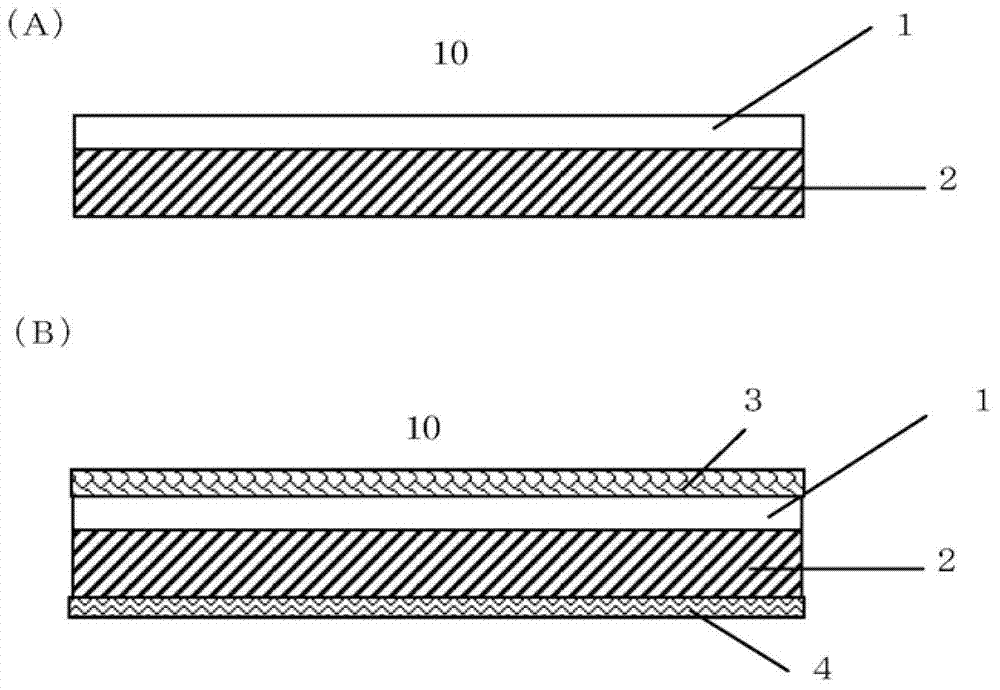

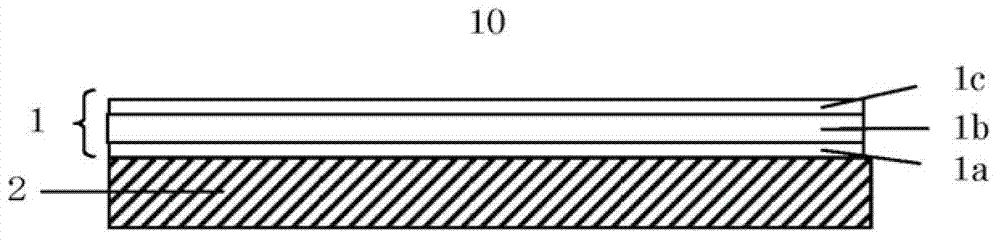

Polyimide laminating body and manufacturing method thereof

InactiveCN103660458AImprove heat resistanceEnsure operabilityFilm/foil adhesivesSynthetic resin layered productsHeat resistanceEngineering

The invention provides a polyimide laminating body and a manufacturing method thereof. According to the invention, polyimide films that are transparent and are good in size stability can be separated from a supporting substrate easily. The polyimide laminating body capable of support substrate is arranged on the back side of the polyimide layer. The transmissivity of the polyimide layer in a predetermined wavelength area is higher than 70 percents. The surfaces of the support substrate in interfaces can be formed by heat-resisting polyimide whose glass transition temperature is higher than 300 DEG C and the surface coarse degree Ra is lower than 100nm. The adhesion strength of the support substrate and the polyimide layer is 1N / m-500N / m and polyimide layer can be separated from the support substrate. Besides, the manufacturing method for the polyimide laminating body utilizes roller-to-roller technique for conveying long strip support substrate and coats resin solution of polyamide acid, so that the substrate can be imided, so that a predetermined polyimide layer can be formed.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

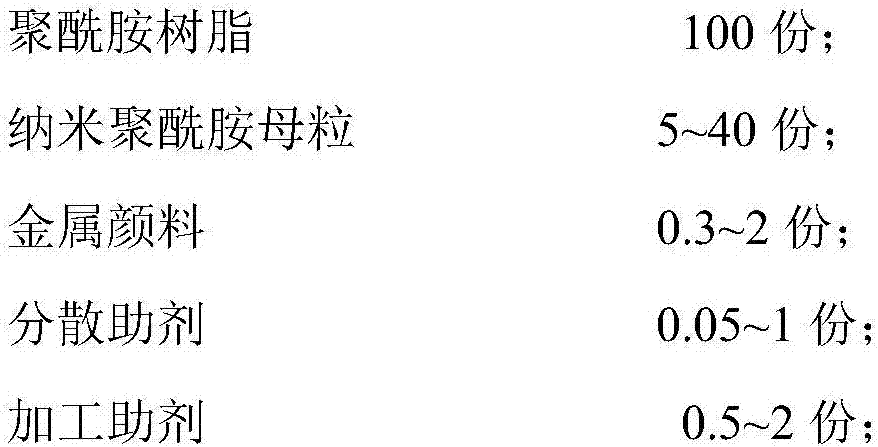

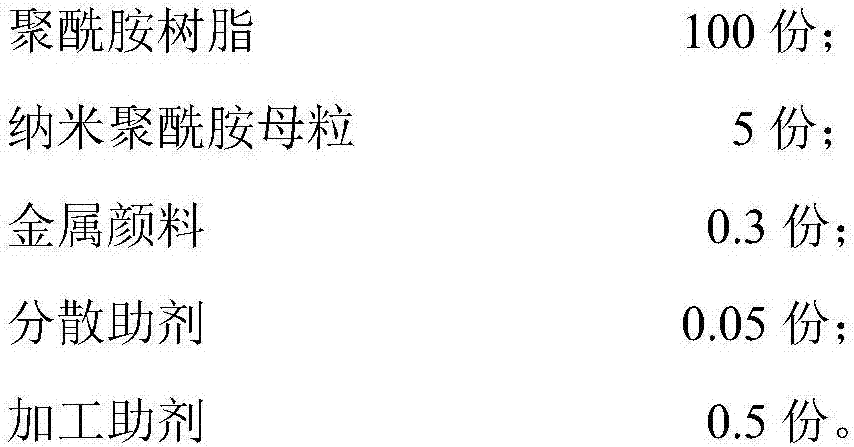

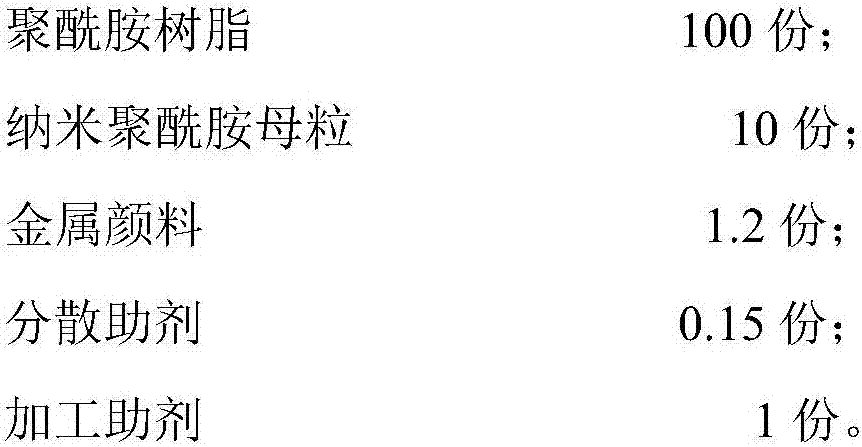

Nanometer polyamide composition with metal luster and preparation method of nanometer polyamide composition

The invention discloses a nano-polyamide composition with metallic luster and a preparation method thereof, which comprises the following raw material components in parts by weight: 100 parts of polyamide resin, 5-40 parts of nano-polyamide masterbatch, and 0.3 parts of metallic pigment ~2 parts, 0.05~1 part of dispersing aid, and 0.5~2 part of processing aid; wherein, the nano-polyamide masterbatch is a self-made product, including nanoparticles and dispersing aid, and the total amount contained in the nano-polyamide composition The weight ratio of nanoparticles to the total dispersion aid is 4:1~52:1. The present invention selects self-made nano polyamide masterbatch as reinforcing material, interacts with core-shell type dispersant, compound with polyamide resin, supplemented with corresponding processing aids, obtains a nano polyamide composition with metallic luster, It has good mechanical properties and surface properties, excellent surface rigidity, scratch resistance, oil resistance and adjustable gloss. It can be used in household appliances, automobiles and other non-spraying materials with metallic luster.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

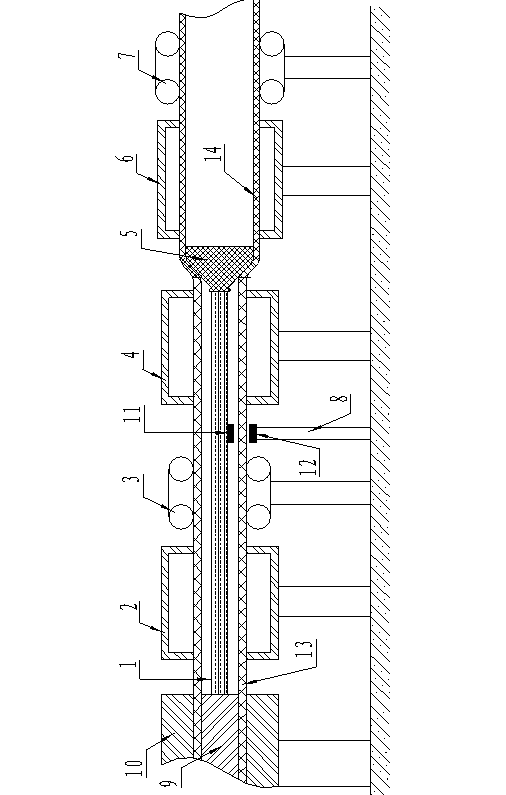

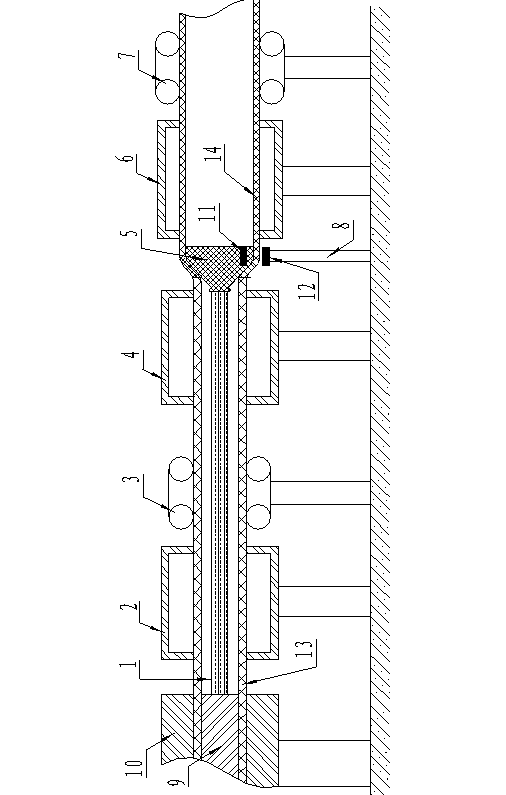

Biaxial orientation plastic tube manufacturing method and apparatus

InactiveCN103171144AUniform radial orientationBi-directional performance improvementTubular articlesDual axisEngineering

The invention relates to a biaxial orientation plastic tube manufacturing method and an apparatus. The manufacturing method is characterized in that a plastic tube raw material is prepared to a plastic tube through a plastic tubing extruder, the plastic tube is heated to a high elastic state, the pipe segment in the high elastic state is performed with axial direction stretching and orientation by a tractor, and then the pipe segment in the high elastic state is performed with radial expansion. An orientation method of the radial expansion is characterized in that a taper expanding head is built in the pipe segment in the high elastic state, the pipe segment in the high elastic state of the taper expanding head can be used for realizing the circumferential orientation, the expanded pipe segment is cooled and sized to obtain the biaxial orientation tube. The manufacturing method and the apparatus can realize the stretching orientation at axial direction and circumferential direction on the plastic tubing, the mechanical properties of the plastic tube are increased, the method is simple, the manufacturing method and the apparatus can be directly used on a plastic tube production line, and are easy to be industrialized.

Owner:福建亚通新材料科技股份有限公司

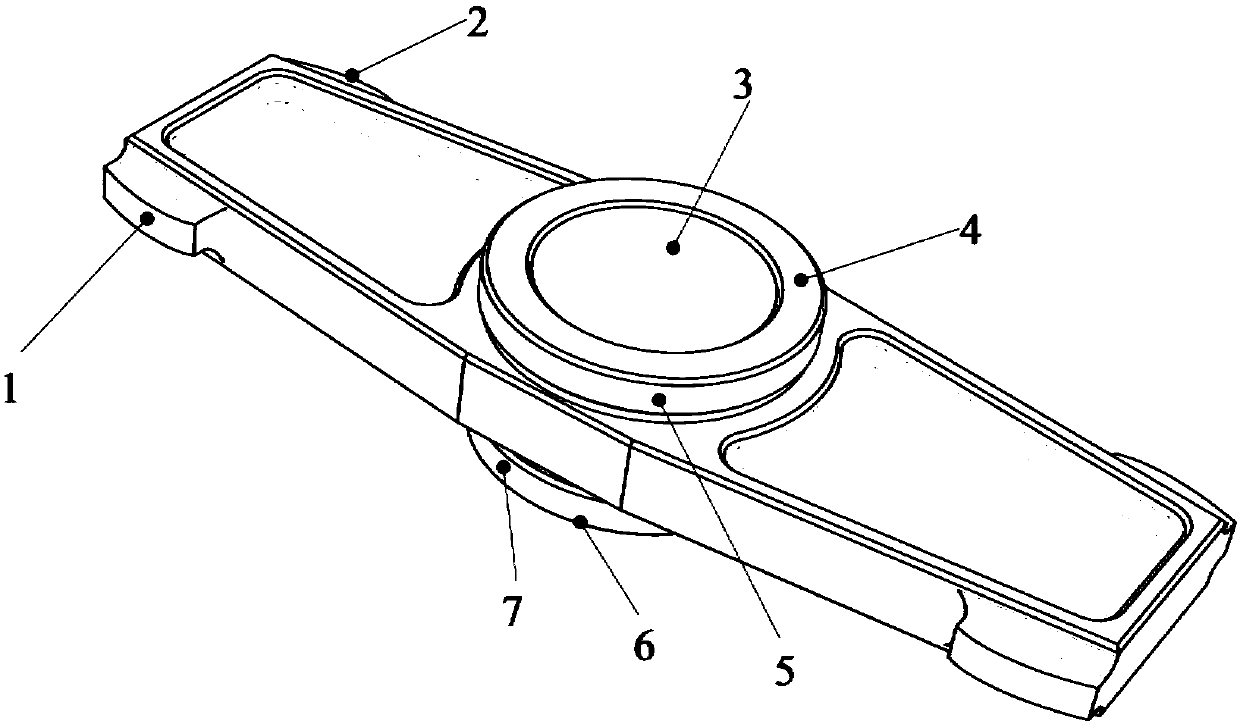

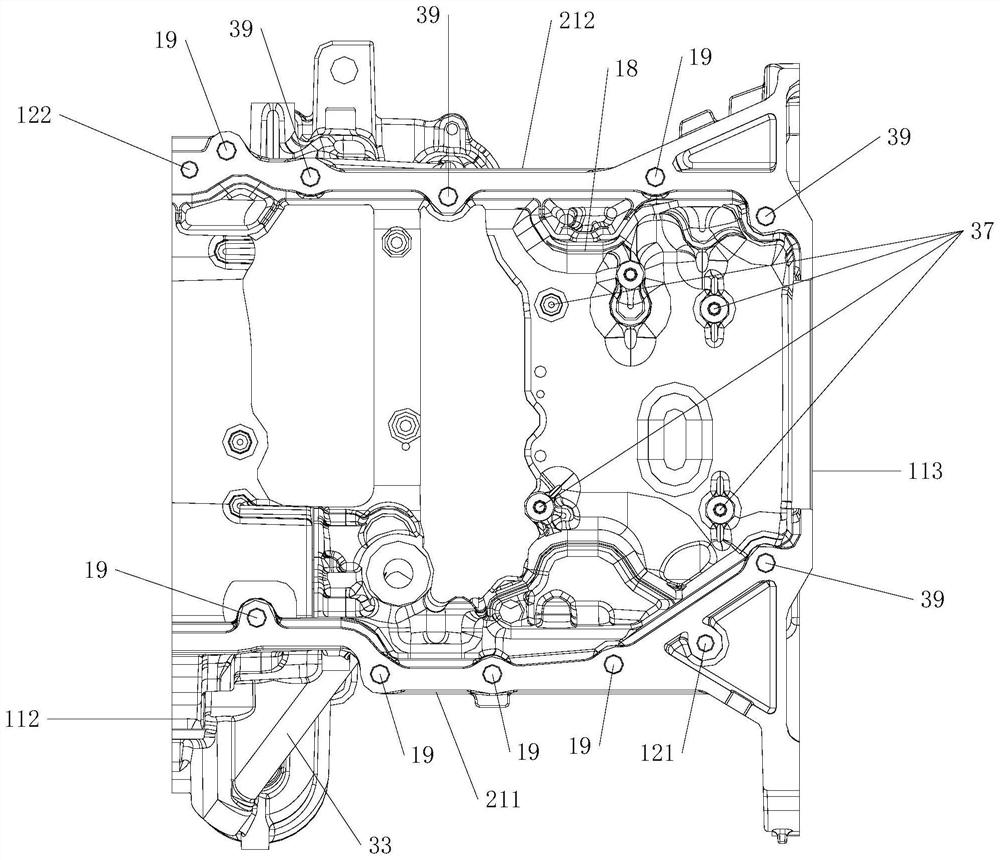

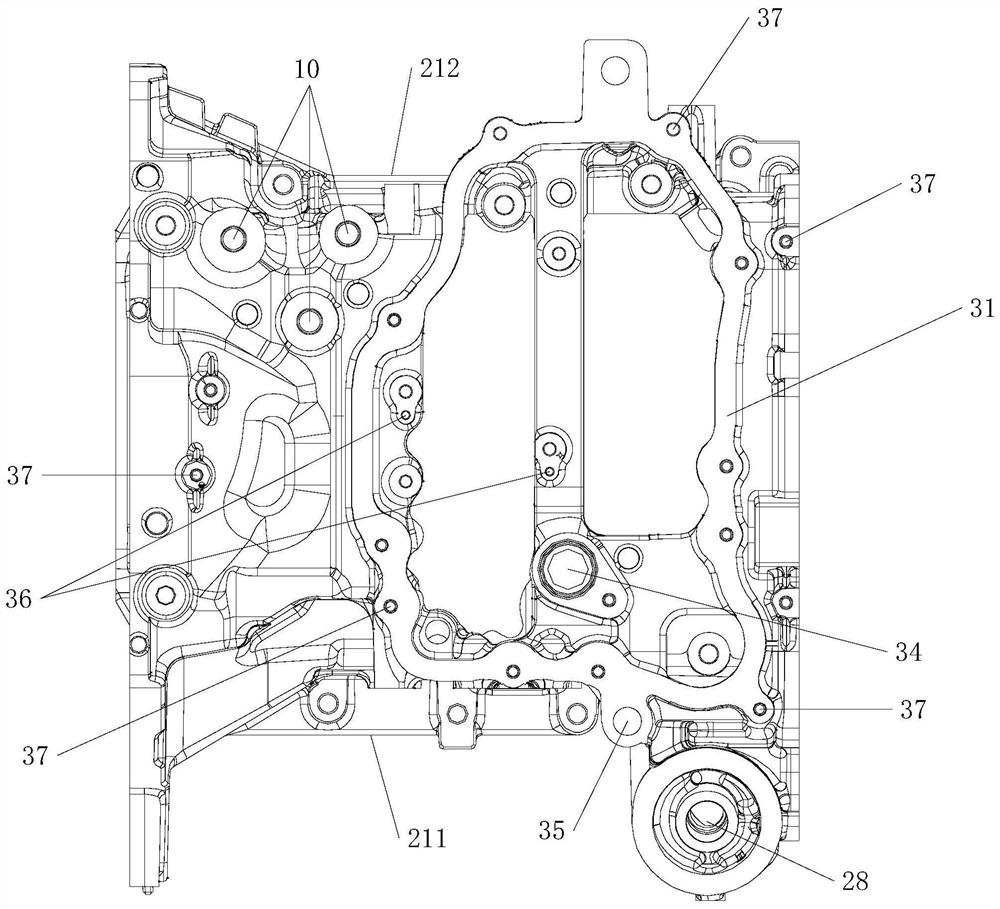

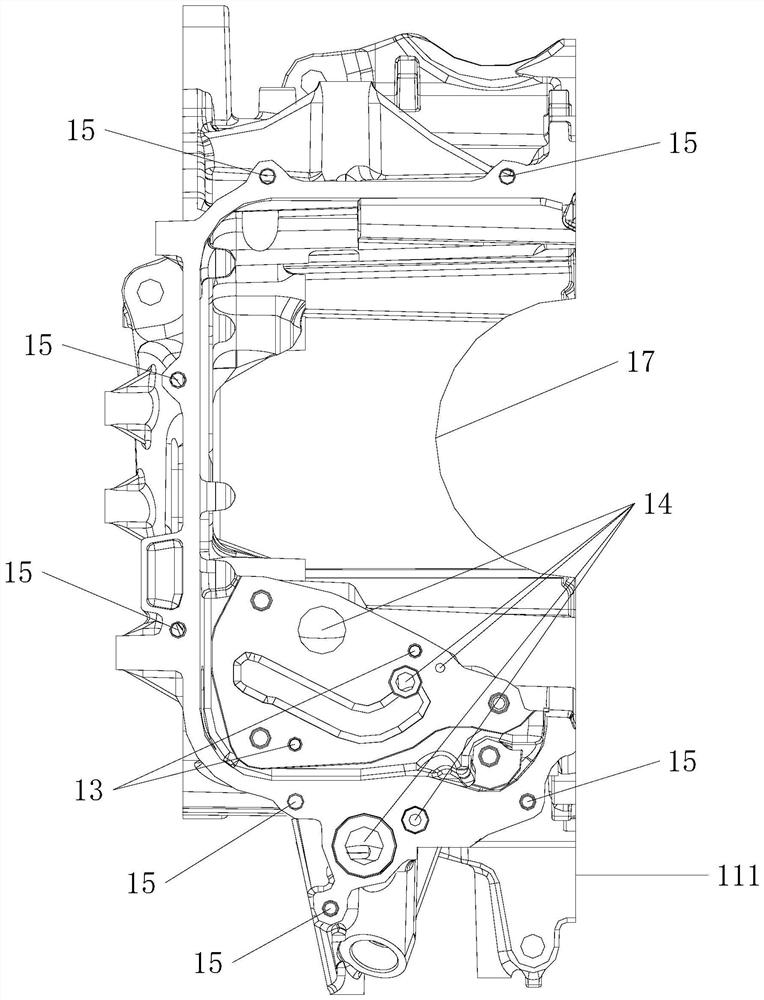

Oil pan and processing method thereof

ActiveCN111660070AAvoid wastingEliminate positioning errorsMachines/enginesEngine lubricationProcess engineeringCylinder block

The invention discloses an oil pan and a processing method thereof. The oil pan processing method comprises a first processing procedure, a second processing procedure and a third processing procedure; the first processing procedure comprises the following steps: clamping a to-be-processed oil pan body onto a first processing center, and utilizing a positioning hole in the oil pan body and the endface of the oil pan body for positioning; milling a cylinder block connecting surface; and drilling and reaming a first reference hole and a second reference hole; the second processing procedure comprises the following steps: clamping the oil pan body after being processed through the first processing procedure onto a second processing center, and utilizing the cylinder block connecting surface,the first reference hole and the second reference hole for positioning; and milling a belt mounting surface; and the third processing procedure comprises the following steps: clamping the oil pan body after being processed through the second processing procedure onto a third processing center, and utilizing the cylinder block connecting surface, the first reference hole and the second reference hole for positioning; milling a lower oil pan mounting surface; and tapping the internal thread of the positioning hole. The oil pan processing method can ensure product size stability and the pace balance among all procedures.

Owner:ZHANJIANG DENI VEHICLE PARTS

Additive manufacturing method for parts with thin wall structure based on SLM process

ActiveCN107876770AReduce manufacturing costGuaranteed successAdditive manufacturing apparatusIncreasing energy efficiencyProcess supportTitanium alloy

The invention relates to an additive manufacturing method for parts with a thin wall structure based on an SLM process, and belongs to the technical field of laser advanced additive manufacturing. According to the additive manufacturing method, the problem that aluminum alloy or titanium alloy thin wall structural components printed by an existing additive manufacturing method are difficult to form, prone to deforming and prone to breaking due to large stress can be solved; the cost of additive manufacturing can be reduced, the success of additive manufacturing of the aluminum alloy thin wallstructural components is ensured, and a practical and reliable process support design method for the additive manufacturing of the aluminum alloy or titanium alloy thin wall structural components is provided.

Owner:BEIJING SATELLITE MFG FACTORY

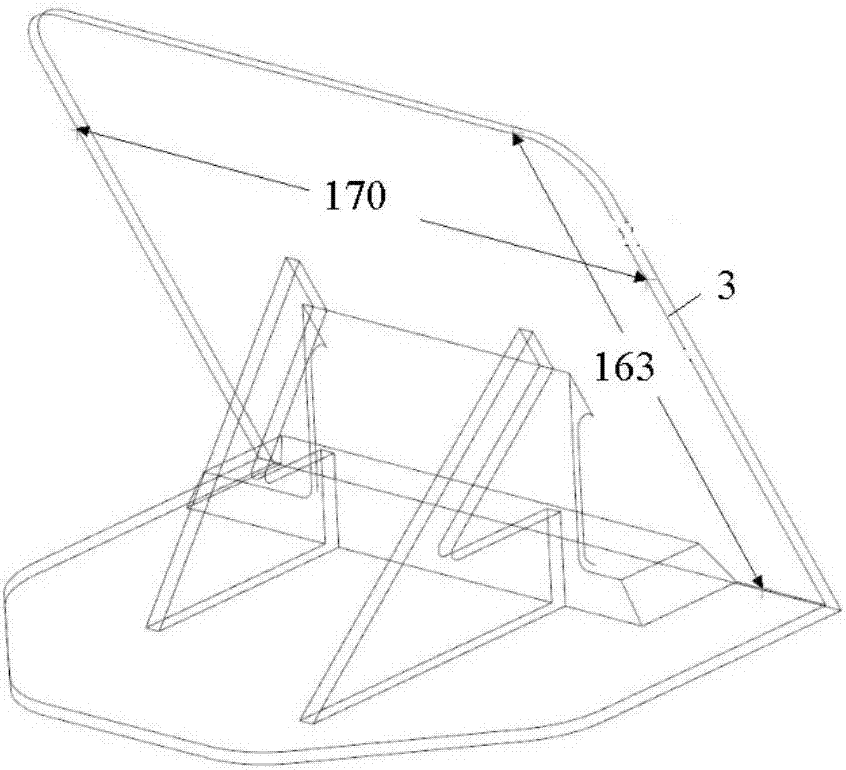

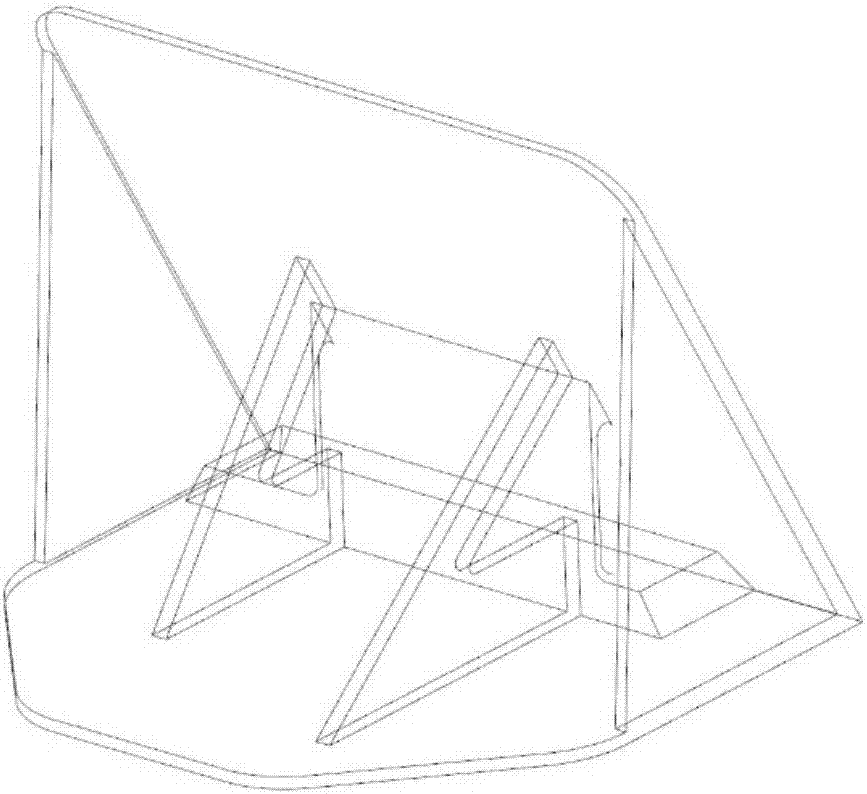

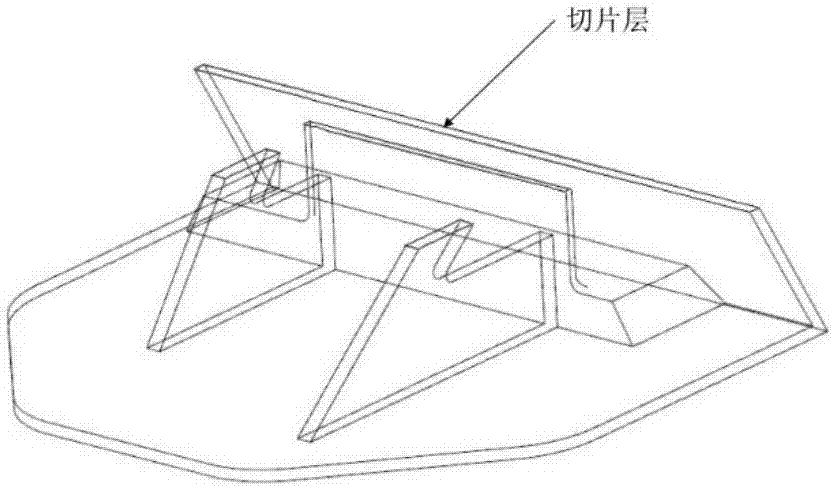

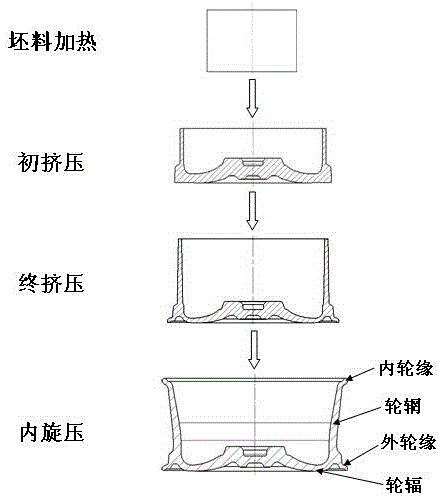

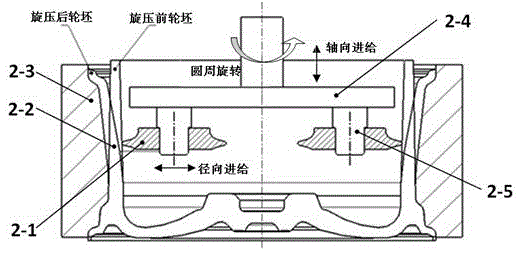

Magnesium alloy wheel forging forming method

InactiveCN105014321AGuaranteed dimensional stabilityShort processWheel manufactureDisc wheelsSpokeMetallurgy

The invention discloses a magnesium alloy wheel forging forming method. The technological process of the magnesium alloy wheel forging forming method can be summarized as ''twice-squeezing and once-rotating''. The magnesium alloy wheel forging forming method is characterized by comprising the steps that (1), heating is conducted, wherein a round magnesium alloy blank is heated to the forging temperature, and the temperature of a die is controlled to be equal to that of the blank; (2), primary squeezing is conducted, wherein primary forming of spokes and a rim is completed in a closed backward squeezing way, but an outer rim is not formed; (3), final squeezing is conducted, wherein the outer rim is finally formed in a closed forward squeezing way, and backward-squeezing final forming of the rim portion are completed at the same time; and (4), inward rotary squeezing for forming is conducted, wherein flaring of the rim and forming of a folded edge of an inner rim are completed through inward rotary squeezing. The magnesium alloy wheel forging forming method has the advantages that the technological process is simple; the streamline is smooth; the production efficiency is high; the utilization rate of materials is high; the defect of cracking can be effectively avoided in the forming process; and the volume production can be achieved easily.

Owner:秦皇岛燕大现代集成制造技术开发有限公司

High elasticity fiber blended spinning method and elastic fabric thereof

InactiveCN107557938AGood hygroscopicityImprove wearing comfortLayered productsWoven fabricsComposite effectPerspiration

The invention discloses a high elasticity fiber blended spinning method and an elastic fabric thereof. The high elasticity fiber is prepared by blending cotton fiber, nylon filament embedded with polyamide fiber, spandex, and worsted fiber, the mass ratio of the four components of cotton fiber, nylon filament embedded with polyamide fiber, spandex, and worsted fiber is 3: 1: 2: 1. The elastic fabric comprises a bottom layer, an interlayer and a face layer, the three layers of materials are fixed by stitching, a lining fabric layer is arranged on the back of the bottom layer, and the fabric layer comprises warp and weft; the interlayer is provided with an elastic layer and a thermal storage layer; high elasticity fiber is arranged in the elastic layer. According to the high elasticity fiberblended spinning method, composite effects and functional complementarities are produced by utilizing four different fiber combinations for the first time, moisture absorption and wear comfort of thefabric are improved, on the basis of ensuring wear resistance and dimensional stability of the fabric, the elasticity of the fabric is improved, and the properties of anti-bacteria, bacteriostasis, anti-ultraviolet, moisture absorption, deodorization and perspiration are added.

Owner:NANTONG SUZHONG TEXTILE

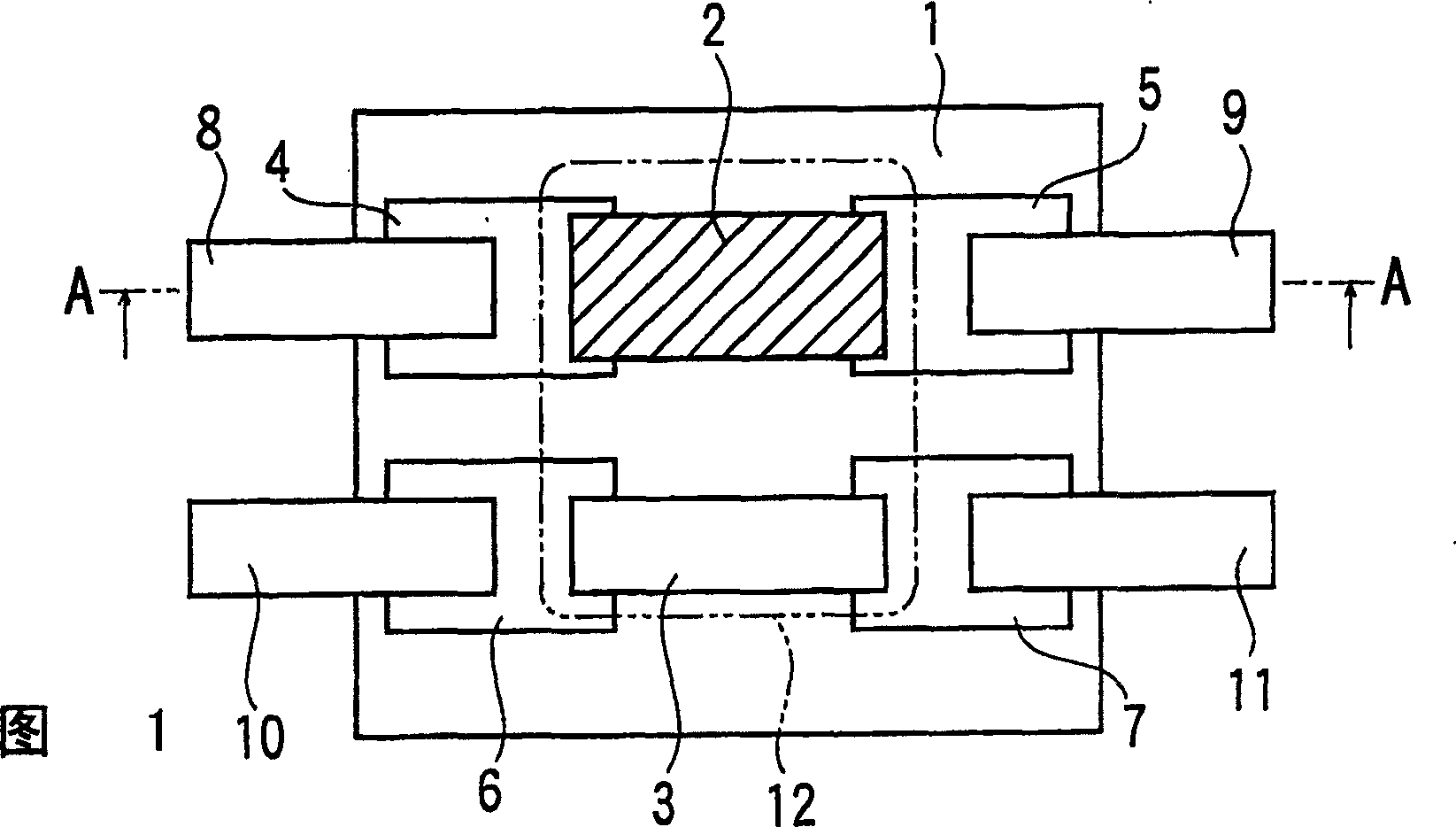

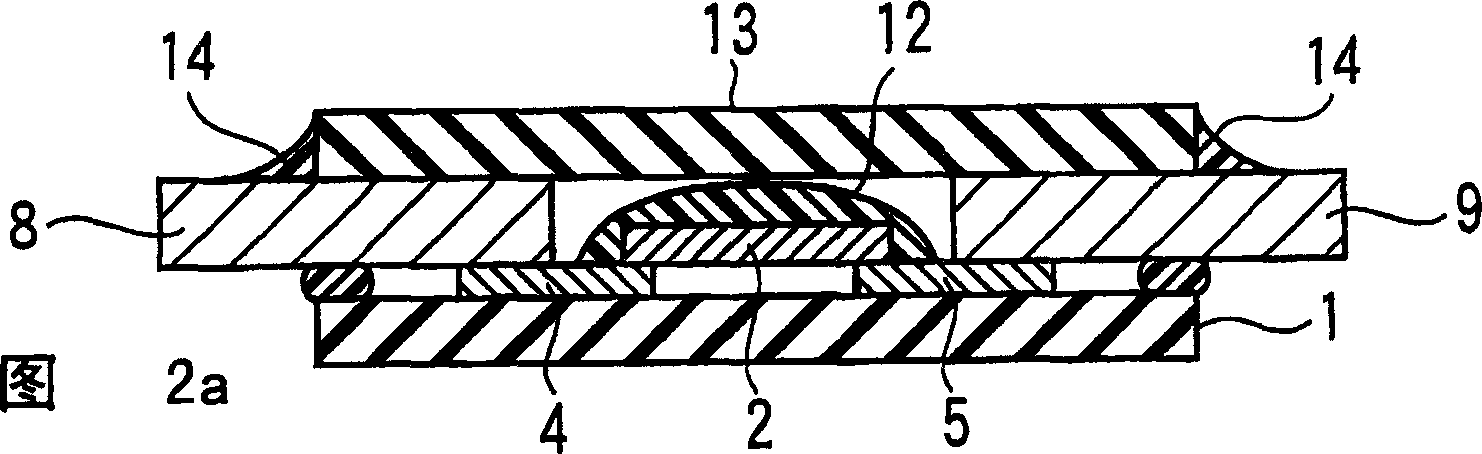

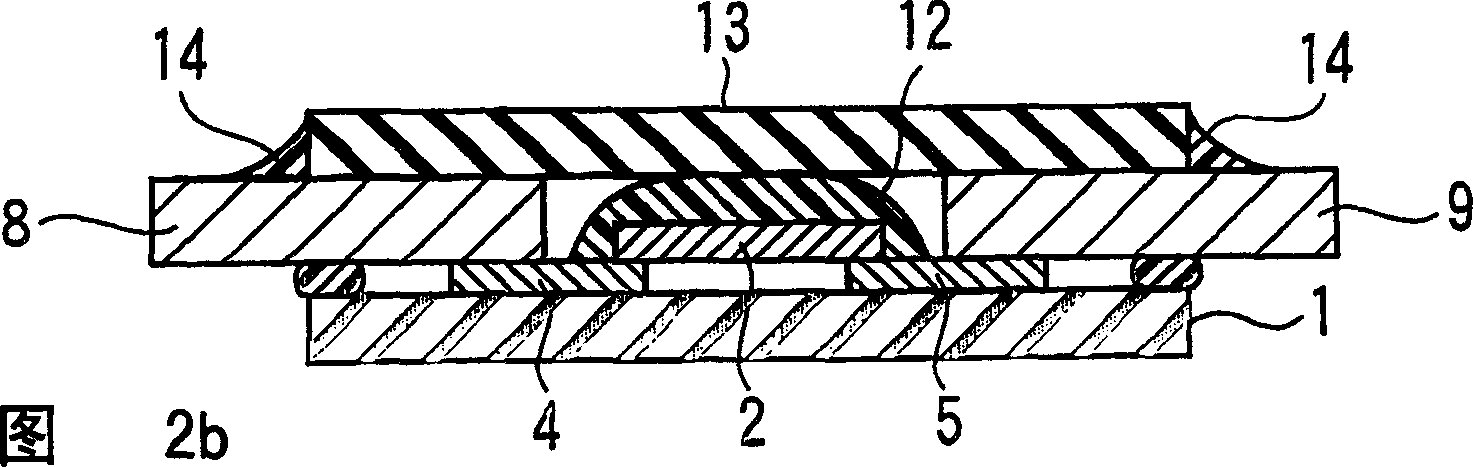

Protective device

InactiveCN1748279ARequired distanceAchieve thinningHeating/cooling contact switchesEmergency protective devicesMetalLow melting point

A protection element for preventing over-current and over-voltage, comprising a base substrate (1), a pair of electrodes (4, 5) formed on the base substrate (1), and a low-melting-point metal element (2) connected between the pair of electrodes (4, 5) to cut off a current running between the electrodes (4, 5) by being fused. An insulation cover plate (13) is positioned and fixed while being kept in contact with the electrodes (4, 5) as spacer members.

Owner:DEXERIALS CORP

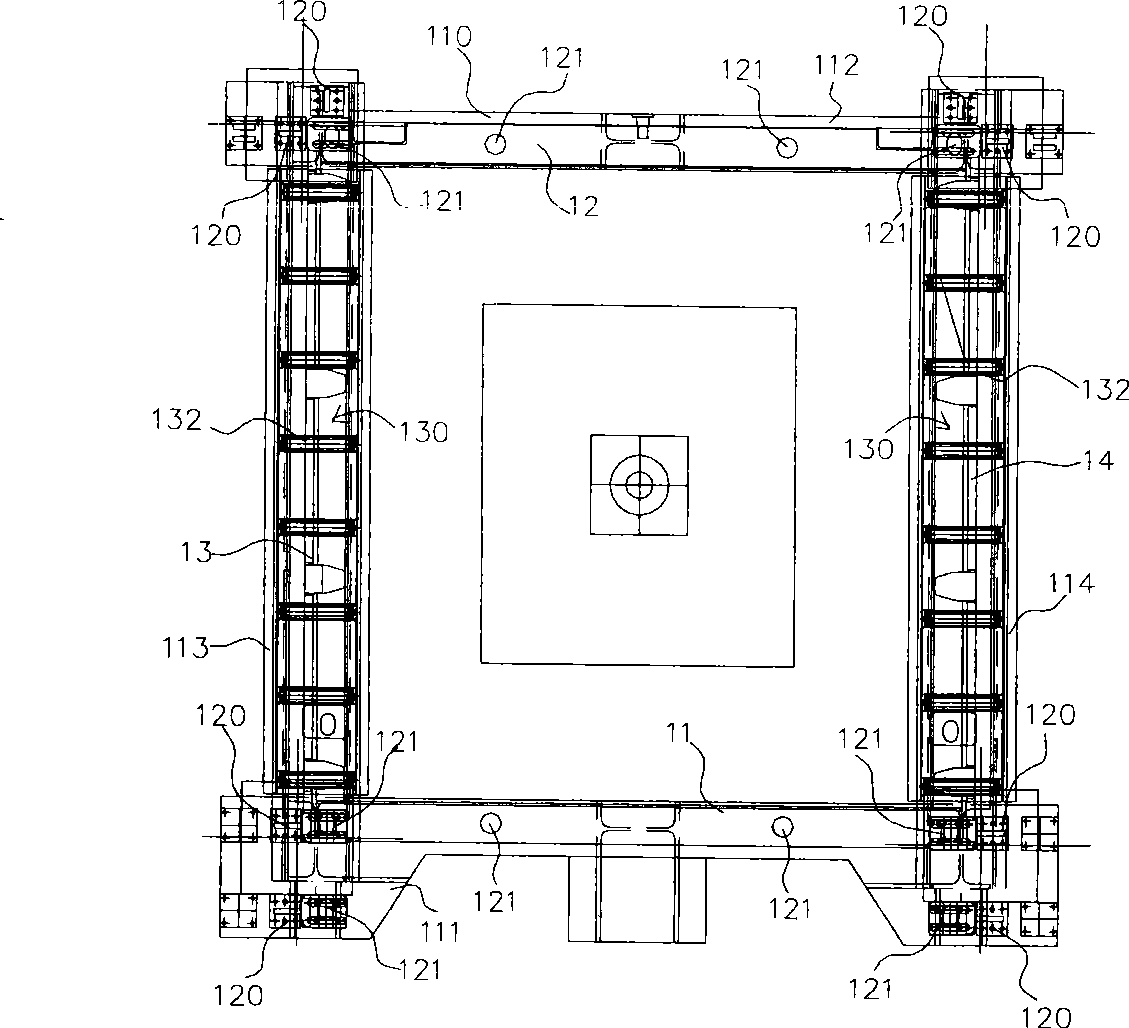

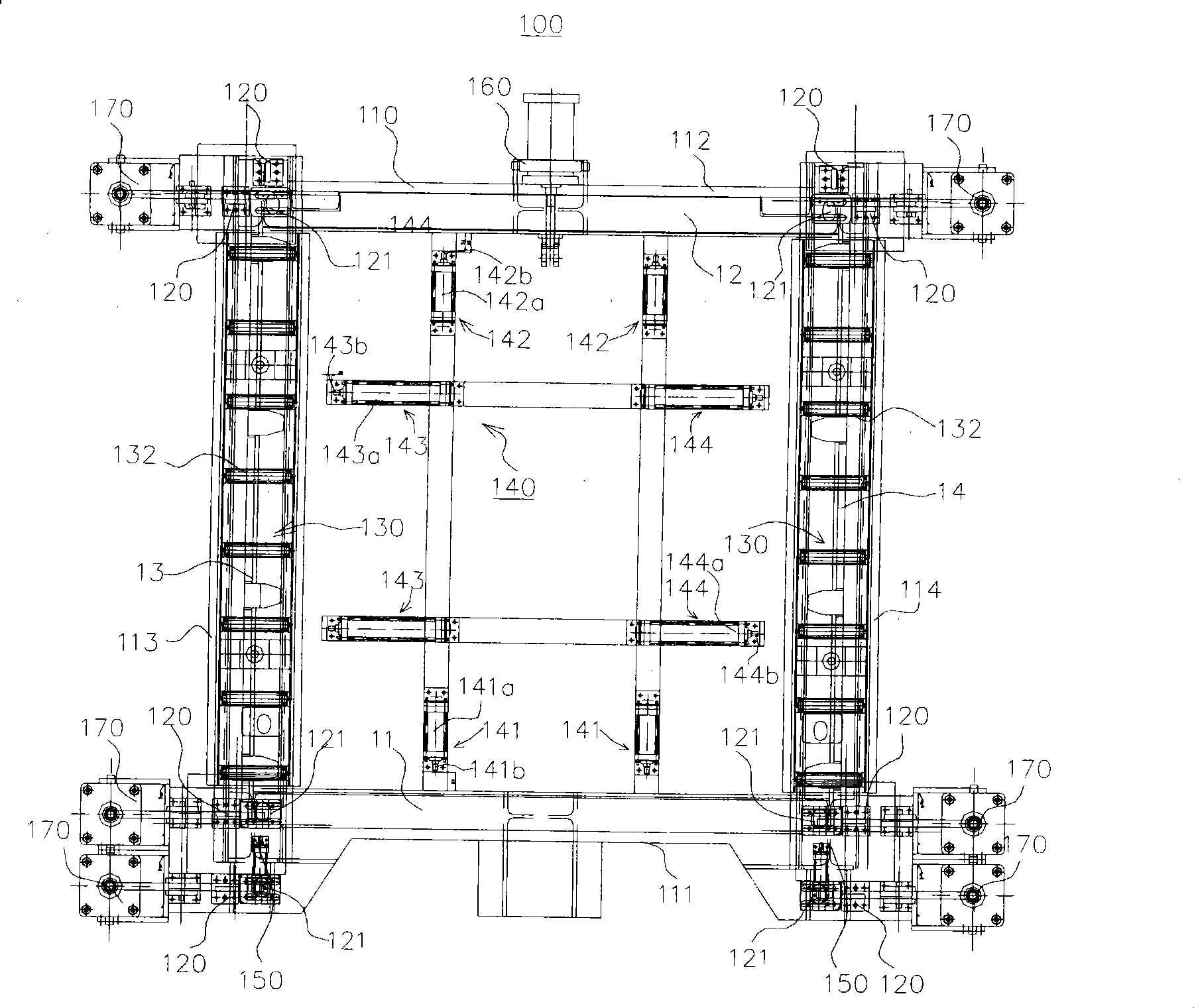

Container after-frame assembling tyre

InactiveCN101396783ASolve the problem of dimensional stabilitySolve the problem that the size of the rear frame cannot be guaranteed to be stableWelding/cutting auxillary devicesAuxillary welding devicesChassisEngineering

The invention provides a container rear frame assembly tyre; the rear frame comprises an upper crossbeam, a lower crossbeam, a left corner column, a right corner column and a corner fittings which is formed by welding the left corner column and the right corner column together; the upper crossbeam, the lower crossbeam, the left corner column and the right corner column are connected with each other; the rear frame assembly tyre comprises an underframe which is used for arranging all parts of the rear frame which comprises two end beams and two side beams, a vertical positioning block which is arranged on the underframe and used for limiting the positions of the upper crossbeam, the lower crossbeam, the left corner column and the right corner column in the vertical direction, and a horizontal positioning block which is arranged on the underframe and used for limiting the positions of the upper crossbeam, the lower crossbeam, the left corner column and the right corner column in the horizontal direction; the rear frame assembly tyre also comprises an internal positioning device which is arranged at the middle part of the underframe; the internal positioning device comprises four groups of push-press devices which are respectively corresponding to the two end beams and the two side beams of the underframe; each group comprises at least a push-press device; each push-press device comprises a mainbody which is fixed on the underframe and a pushing rod which can extend out of the main body facing the corresponding end beam or side beam of the underframe.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

New process method for manufacturing mold capable of ensuring size accuracy of cast blade for large-scale water turbine

ActiveCN101716654AUnique material selectionEasy to implementFoundry mouldsFoundry coresWater turbineCasting mold

The invention relates to a new process method for manufacturing a mold capable of ensuring the size accuracy of a cast blade for a large-scale water turbine. The method is characterized by comprising the following steps of: selecting materials; designing a technical scheme for manufacturing the mold; establishing a three-dimensional model for manufacturing the mold; manufacturing a mold blank; processing the mold; and detecting the mold. The process method of the invention is unique and solves the problem that a distorted-surface blade casting mold has low manufacturing efficiency and that the kind of casting mold manufactured by the traditional manual method cannot achieve the accuracy of a design size. The method solves the deformation problem of the mold per se and ensures the size accuracy of a blade-type mold through the research and application of a new material and a new method in a mold manufacturing process.

Owner:KOCEL EQUIP

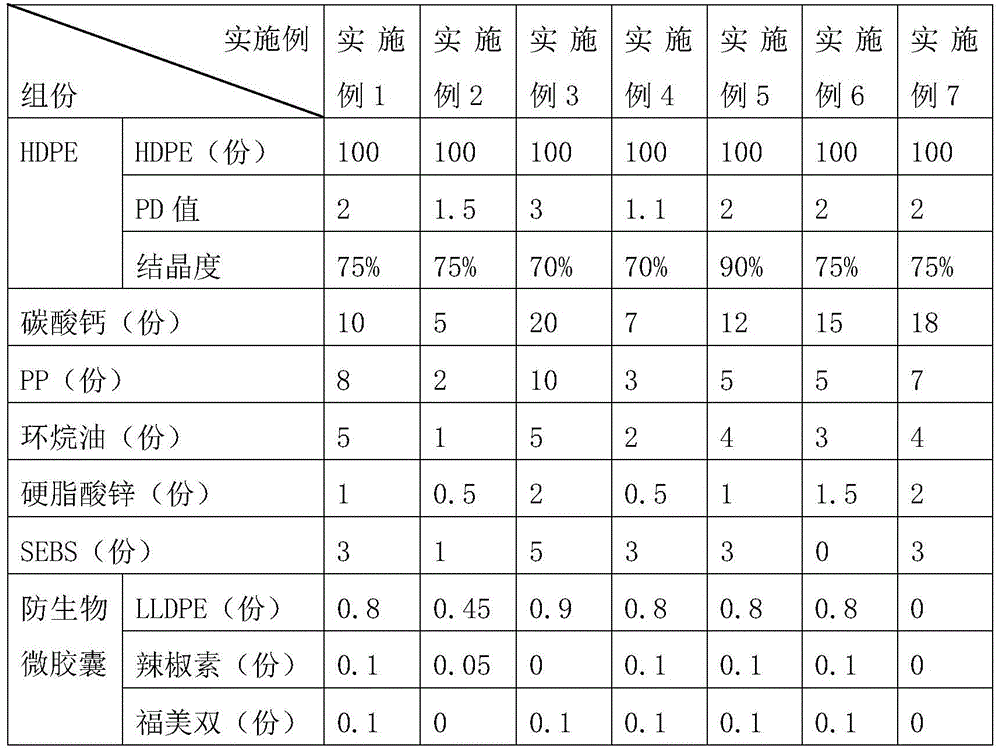

Septic tank special material and preparation method thereof

ActiveCN105542284AImprove processing fluidityImprove toughnessLow-density polyethyleneLinear low-density polyethylene

The invention discloses a septic tank special material with good processing fluidity. The septic tank special material is prepared from the following components in parts by weight: 100 parts of HDPE (high-density polyethylene); 5 to 20 parts of calcium carbonate; 1 to 10 parts of PP (propene polymer); 1 to 5 parts of naphthenic oil; 0.5 to 2 parts of zinc stearate. The invention also discloses a preparation method of the septic tank special material. The preparation method comprises the following steps: S1, mixing the HDPT, the calcium carbonate, the PP, the naphthenic oil, the zinc stearate and the SEBS, softening and fusing; S2, smashing an anti-bio agent and spraying on LLDPE (linear low density polyethylene) flux, and cooling to room temperature, so as to obtain an anti-bio microcapsule; S3, adding the anti-bio capsule obtained in S2 into the fusant of S1, and performing injection molding.

Owner:SHANDONG WENYUAN BUILDING MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com