Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Improved thermal dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

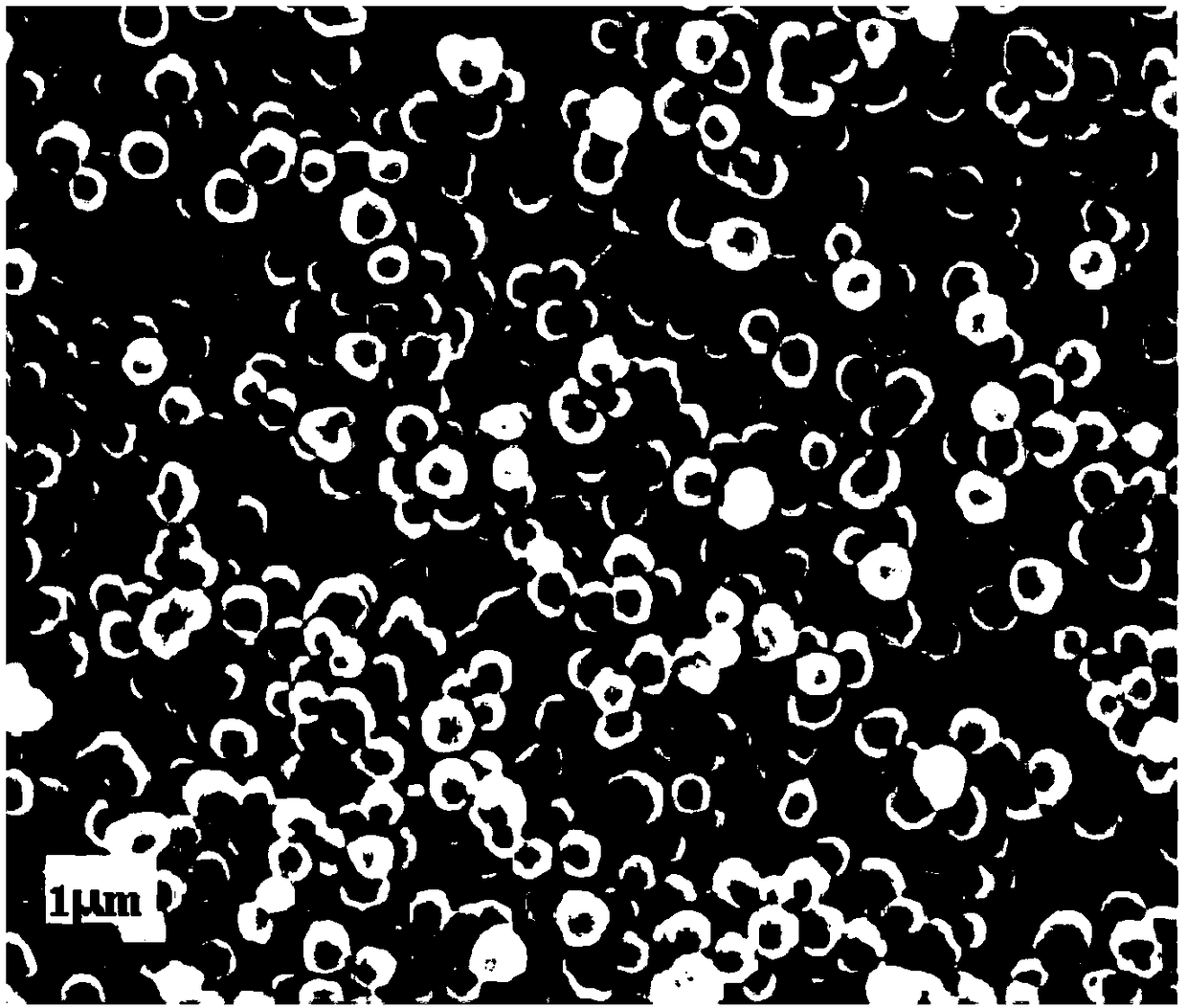

Composite nanofiber lithium battery diaphragm and making method thereof

ActiveCN103824988AHigh strengthImproved thermal dimensional stabilityCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryAramid

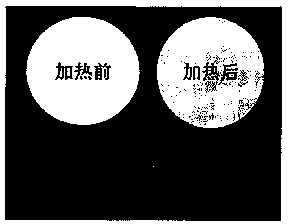

The invention relates to a composite nanofiber lithium battery diaphragm and a making method thereof. The composite nanofiber lithium battery diaphragm is obtained by compounding at least one layer of an aramid 1313 nanofiber film containing nanoparticles with at least one layer of a low-melting-point polymer nanofiber film containing nanoparticles, and nanofibers in the fiber films containing nanoparticles are mutually interlaced and are bonded and connected with each other at interlaced points. The aperture range and the pore closing temperature of the surface layer of the fibers in the composite nanofiber lithium battery diaphragm are 100-400nm and 130-170DEG C respectively, the fiber film does not shrink after the pore closure, the heat shrinkage is less than 2% after the fiber film is heated at 250DEG C for 1h, and the tensile strength is 100-1000MPa, so the composite nanofiber lithium battery diaphragm has the characteristics of heat closing effect, good heat dimension stability and high strength. The making method has the advantages of simple process and low cost, and the obtained composite nanofiber lithium battery diaphragm has a wide application prospect in energy storage fields of supercapacitors, sodium ion batteries and the like.

Owner:DONGHUA UNIV

Composite diaphragm, preparation method thereof and lithium ion battery

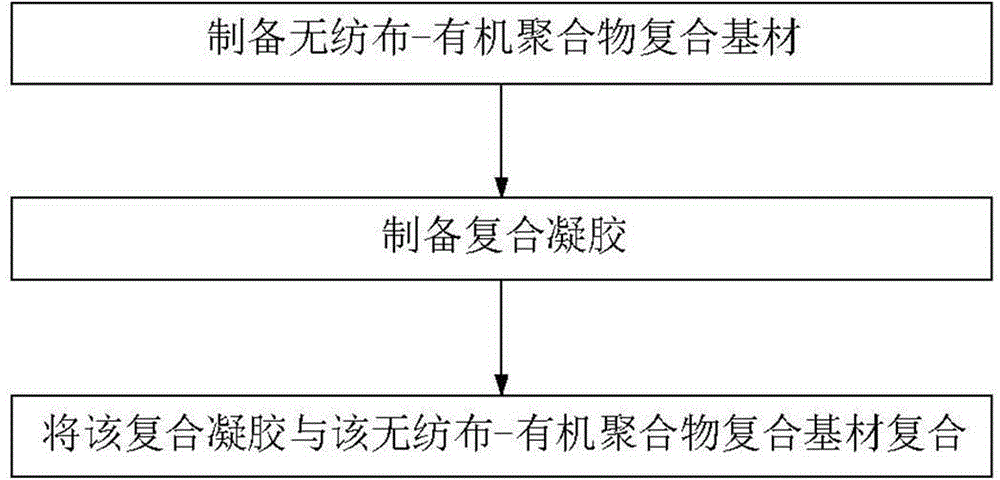

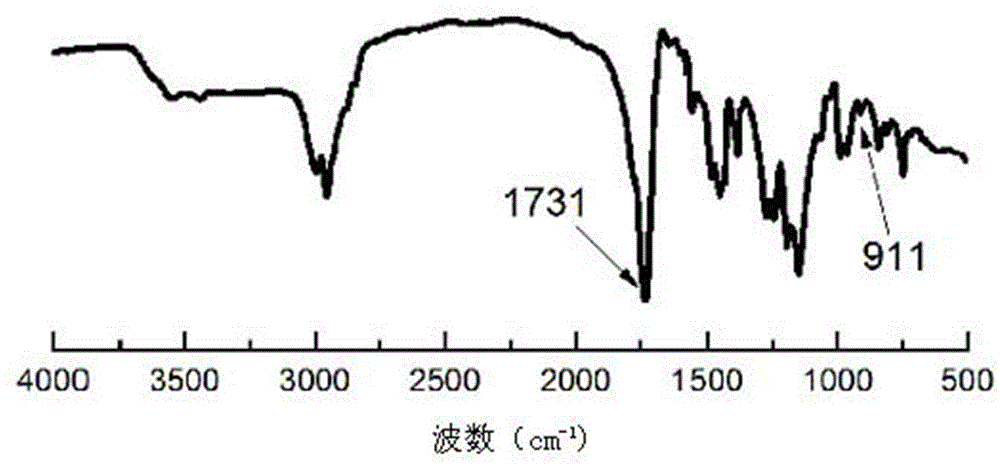

ActiveCN104088155AGood thermal dimensional stabilityImprove safety and charge and discharge performanceFibre typesSecondary cellsMethyl methacrylateSilane coupling

The invention relates to a composite diaphragm. The composite diaphragm comprises a non-woven fabric-organic polymer composite base material, and a composite gel compounded with the non-woven fabric-organic polymer composite base material, wherein the non-woven fabric-organic polymer composite base material comprises a non-woven fabric and a cross-linked polymer, and the cross-linked polymer is formed by copolymerization of a polymer monomer containing alkenyl and alkoxy silane containing alkenyl in the presence of a catalyst and a cross-linking agent; the composite gel comprises a gel polymer and inorganic modified nano powder, and the inorganic modified nano-powder comprises a polymer formed by copolymerization of methyl methacrylate and a silane coupling agent containing C=C groups, and further comprises a nano-sol connected with the alkoxy silane by virtue of condensation reaction. The invention also relates to a preparation method of the composite diaphragm and a lithium ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

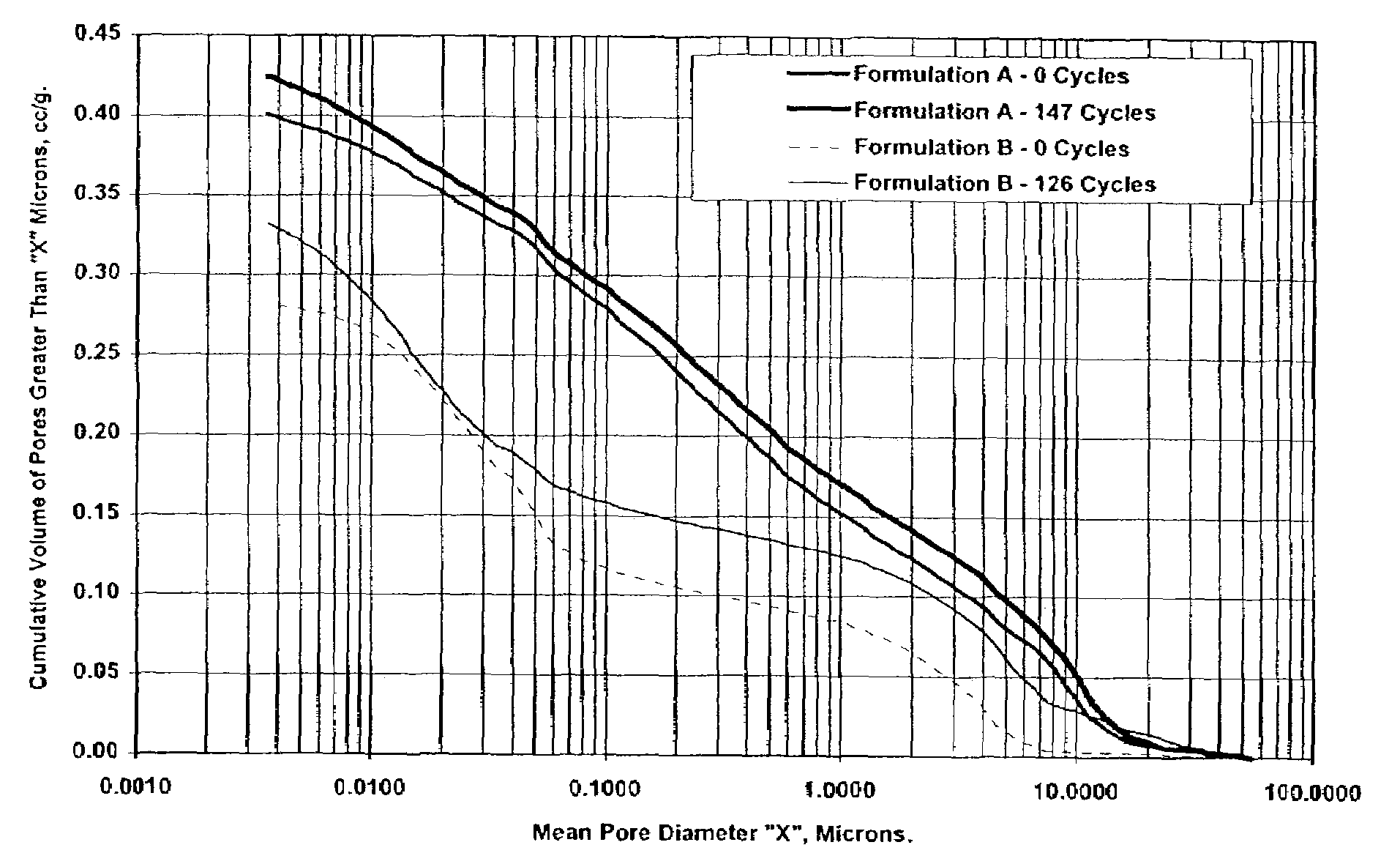

Fiber Cement Building Materials With Low Density Additives

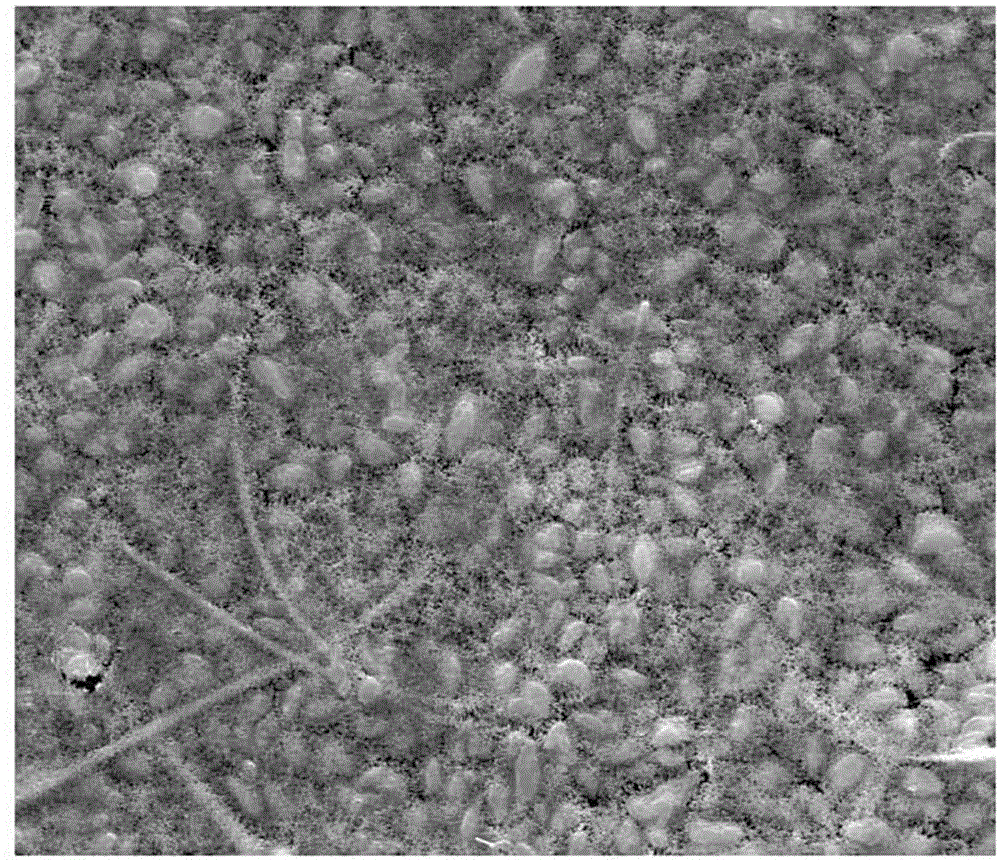

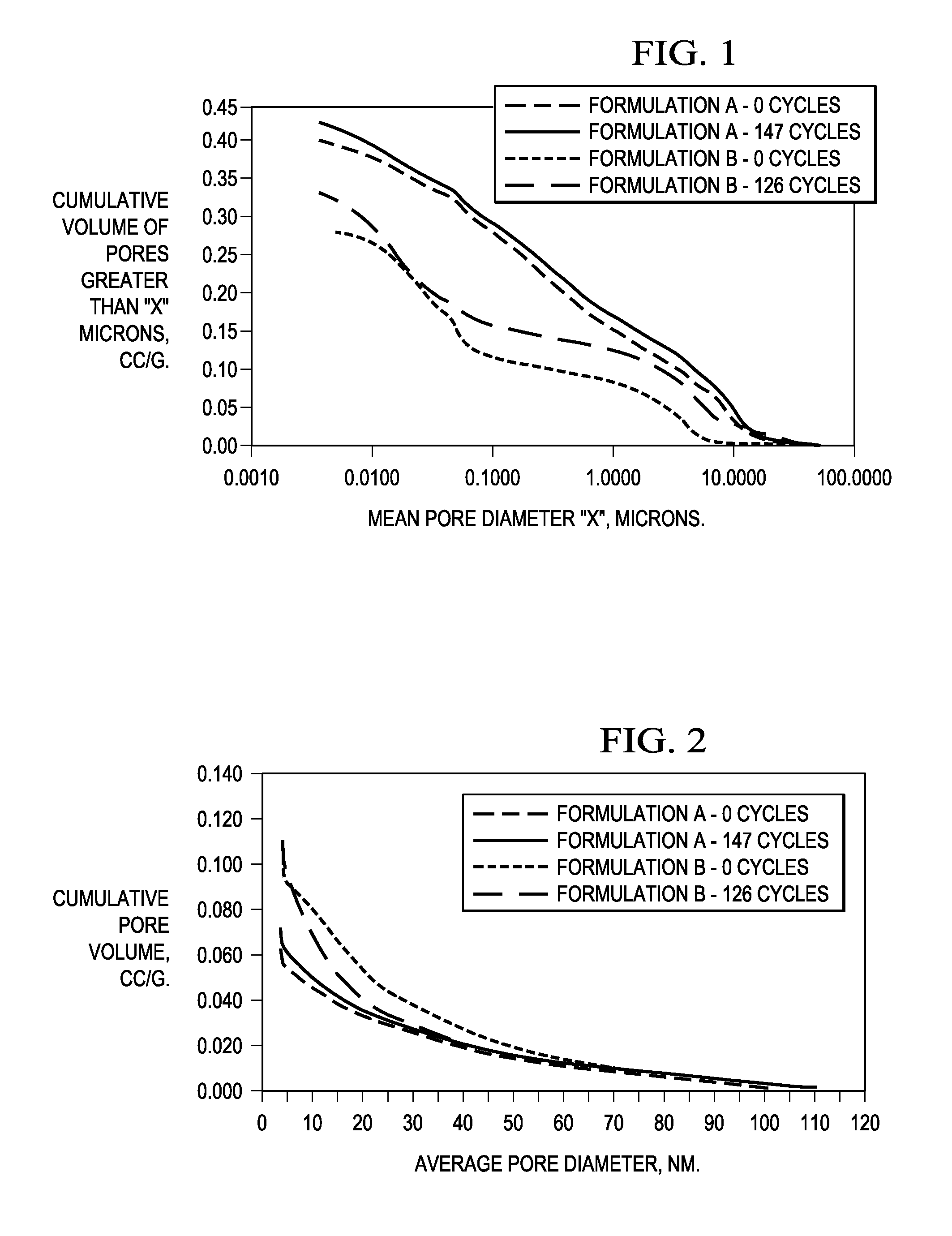

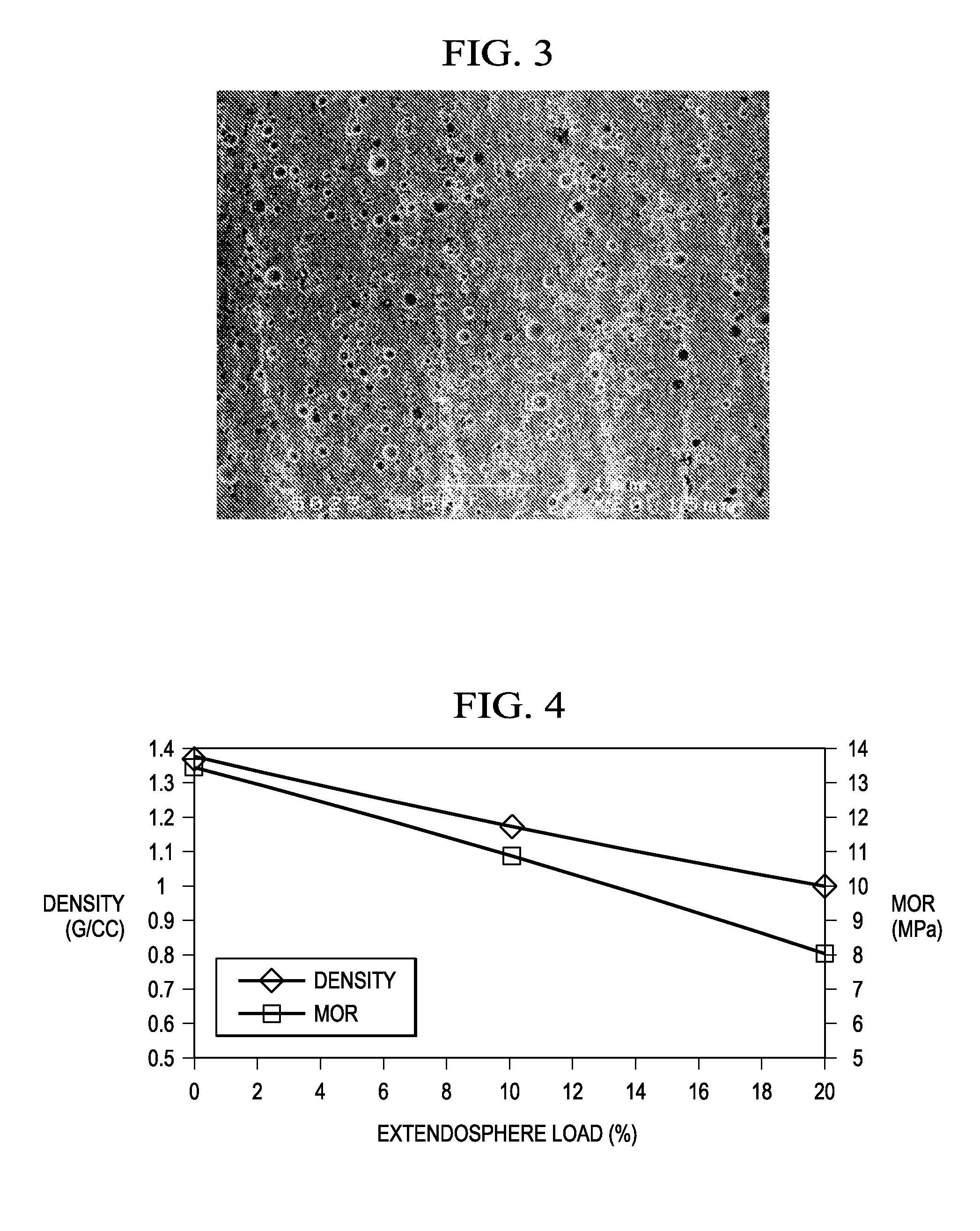

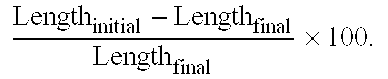

InactiveUS20080203365A1Low densityImprove workabilityConstruction materialSolid waste managementFreeze thawingMicrosphere

This invention relates to a formulation with the addition of low density additives of volcanic ash, hollow ceramic microspheres or a combination of microspheres and volcanic ash or other low density additives into cementitious cellulose fiber reinforced building materials. This formulation is advantageously lightweight or low density compared as compared to current fiber cement products without the increased moisture expansion and freeze-thaw degradation usually associated with the addition of lightweight inorganic materials to fiber cement mixes. The low density additives also give the material improved thermal dimensional stability.

Owner:JAMES HARDIE TECH LTD

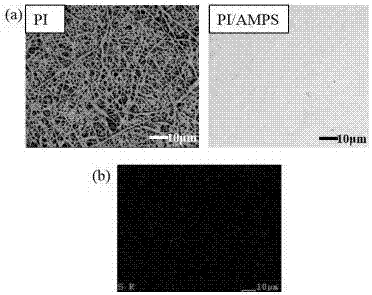

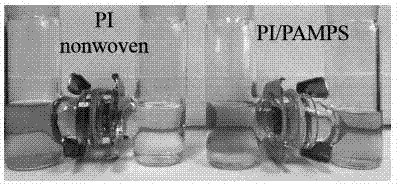

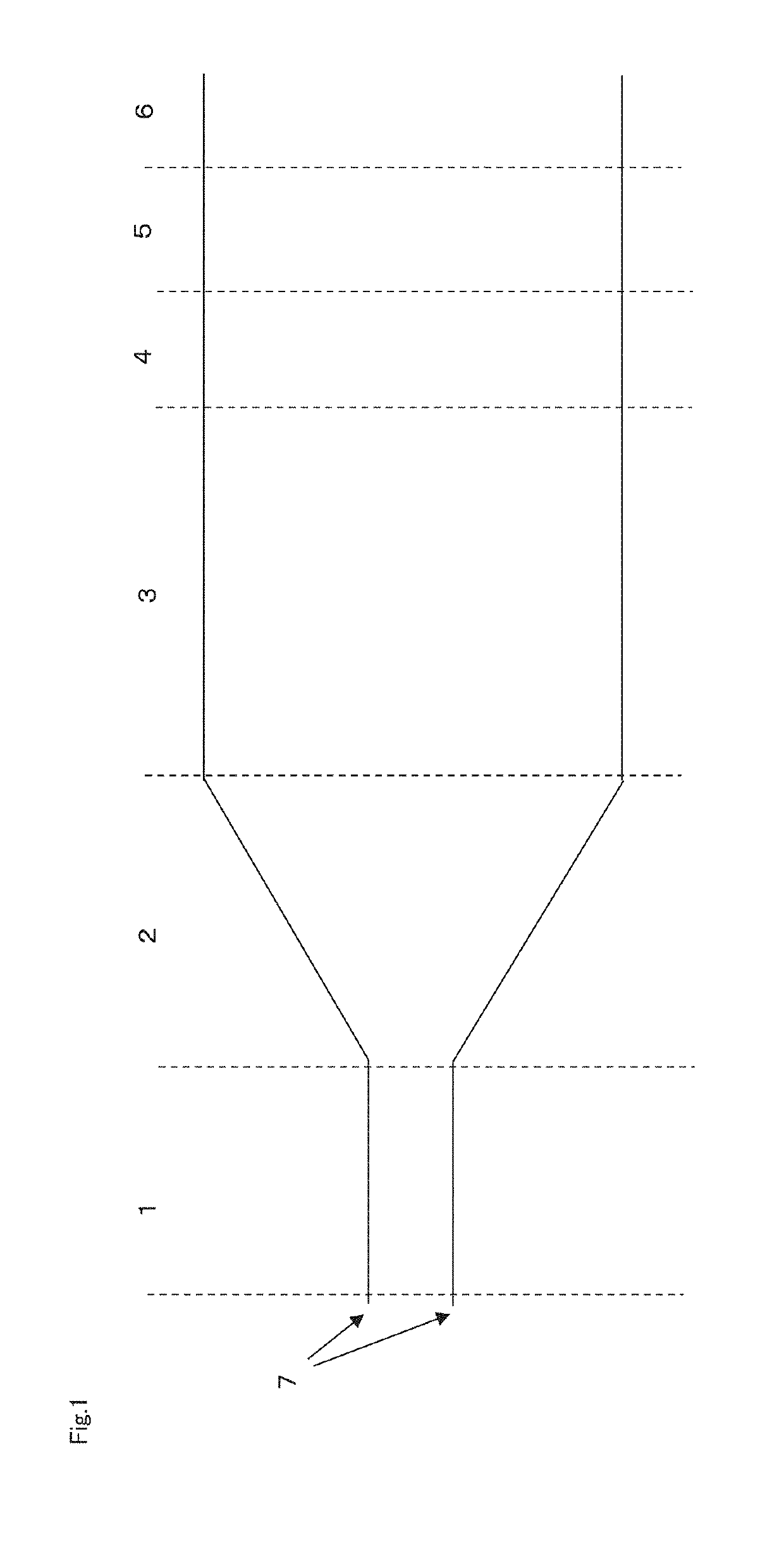

Preparation method for polyimide with cross-linked structure and application of polyimide nanofiber membrane in lithium battery diaphragm

InactiveCN103474600ASolve the lack of mechanical propertiesReduce thicknessMaterial nanotechnologySecondary cellsPolymer sciencePolyolefin

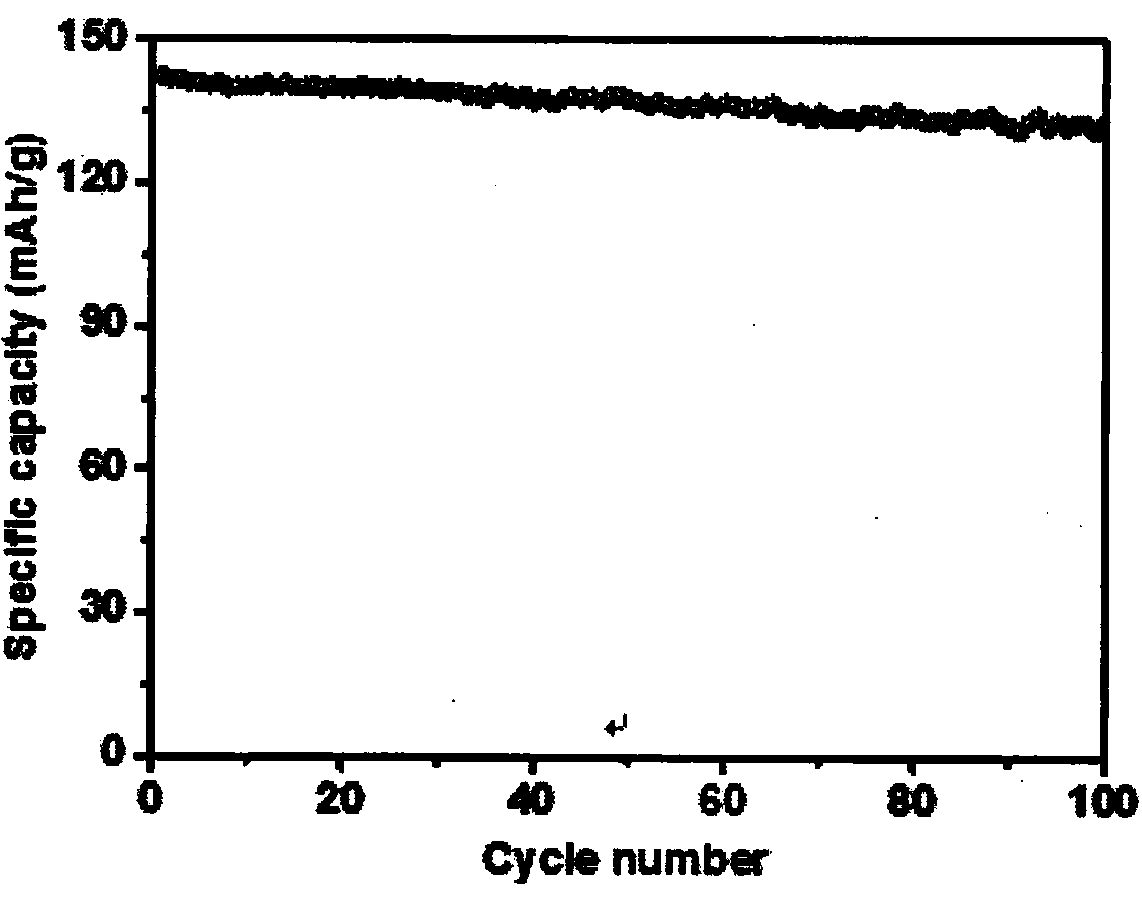

The invention provides a preparation method for a polyimide nanofiber membrane with a cross-linked structure and application of the polyimide nanofiber membrane in a lithium battery diaphragm, belonging to the field of high polymer materials. The preparation method comprises the following steps: subjecting a polyamide acid solution to electrostatic spinning to prepare a polyamide acid nanofiber membrane; etching the polyamide acid nanofiber membrane in an aqueous ammonia solution with a pH value of 8 to 10 for 60 s to form the cross-linked structure; and carrying out washing, drying and imidization at a temperature of 300 DEG C so as to prepare the polyimide nanofiber membrane. The lithium ion battery diaphragm provided by the invention has high mechanical properties, heat stability, high porosity and excellent electrochemical performance. The battery diaphragm has the cross-linked structure and high mechanical properties, thereby overcoming the problems of low strength and an over-open pore structure of a nonwoven polyimide nanofiber membrane. Meanwhile, the diaphragm has porosity of about 80% and can resist a high temperature of 300 DEG C without any deformation, thereby overcoming the disadvantages of low porosity and poor temperature resistance of a polyolefin microporous diaphragm. In particular, the diaphragm provided in the invention has specific capacity substantially better than that of the traditional polyolefin microporous diaphragm under the conditions of high-rate rapid charging and discharging.

Owner:BEIJING UNIV OF CHEM TECH

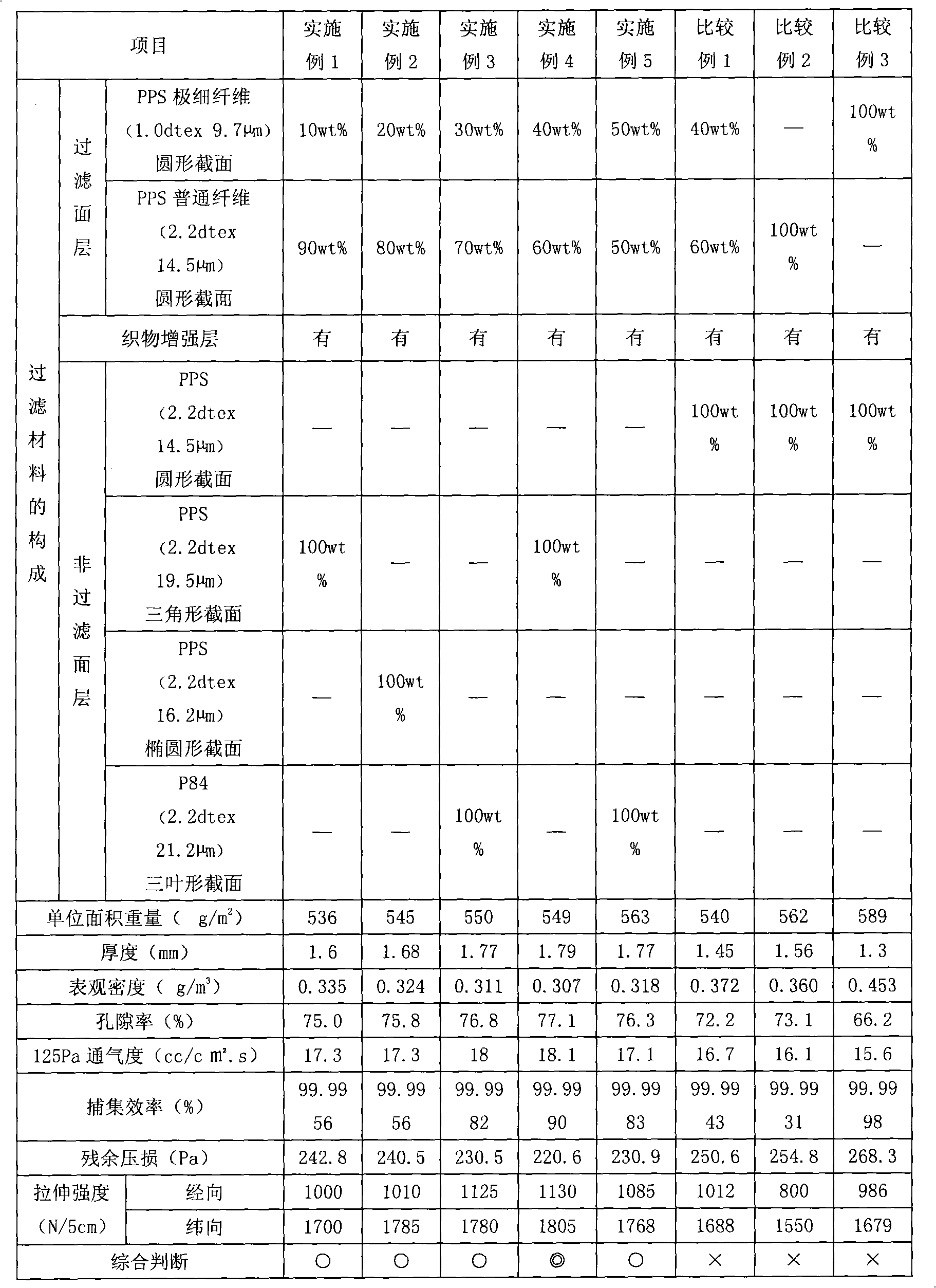

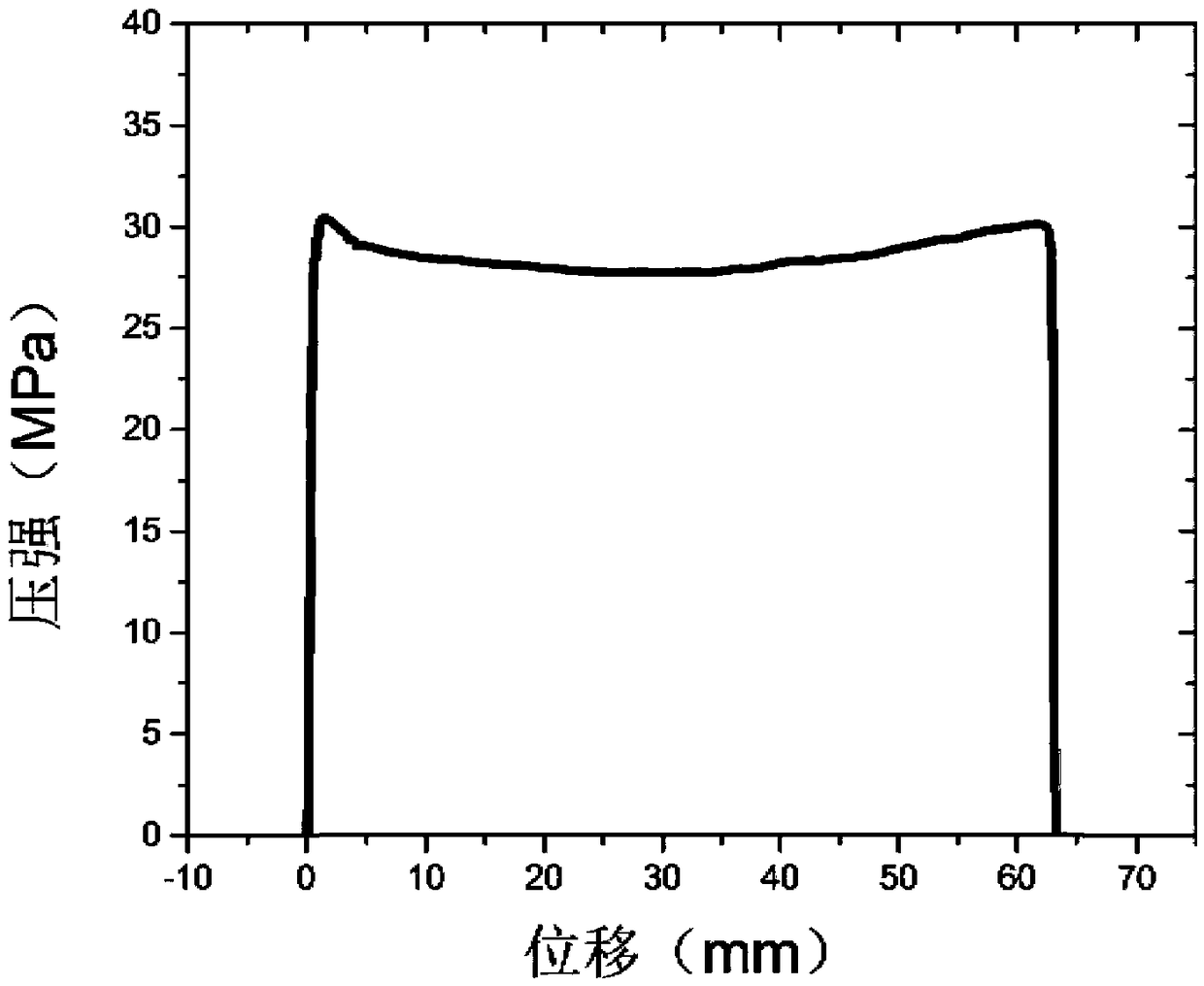

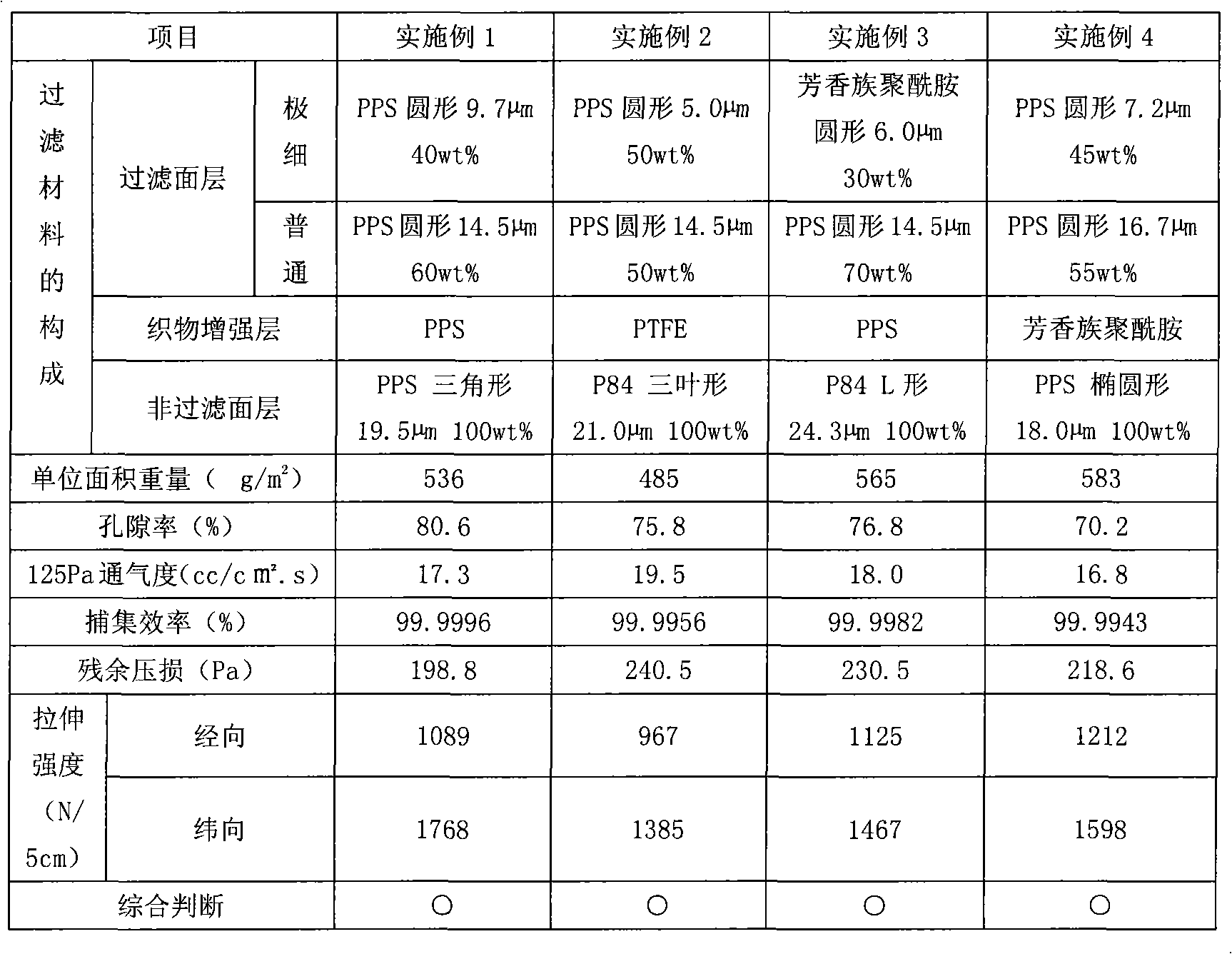

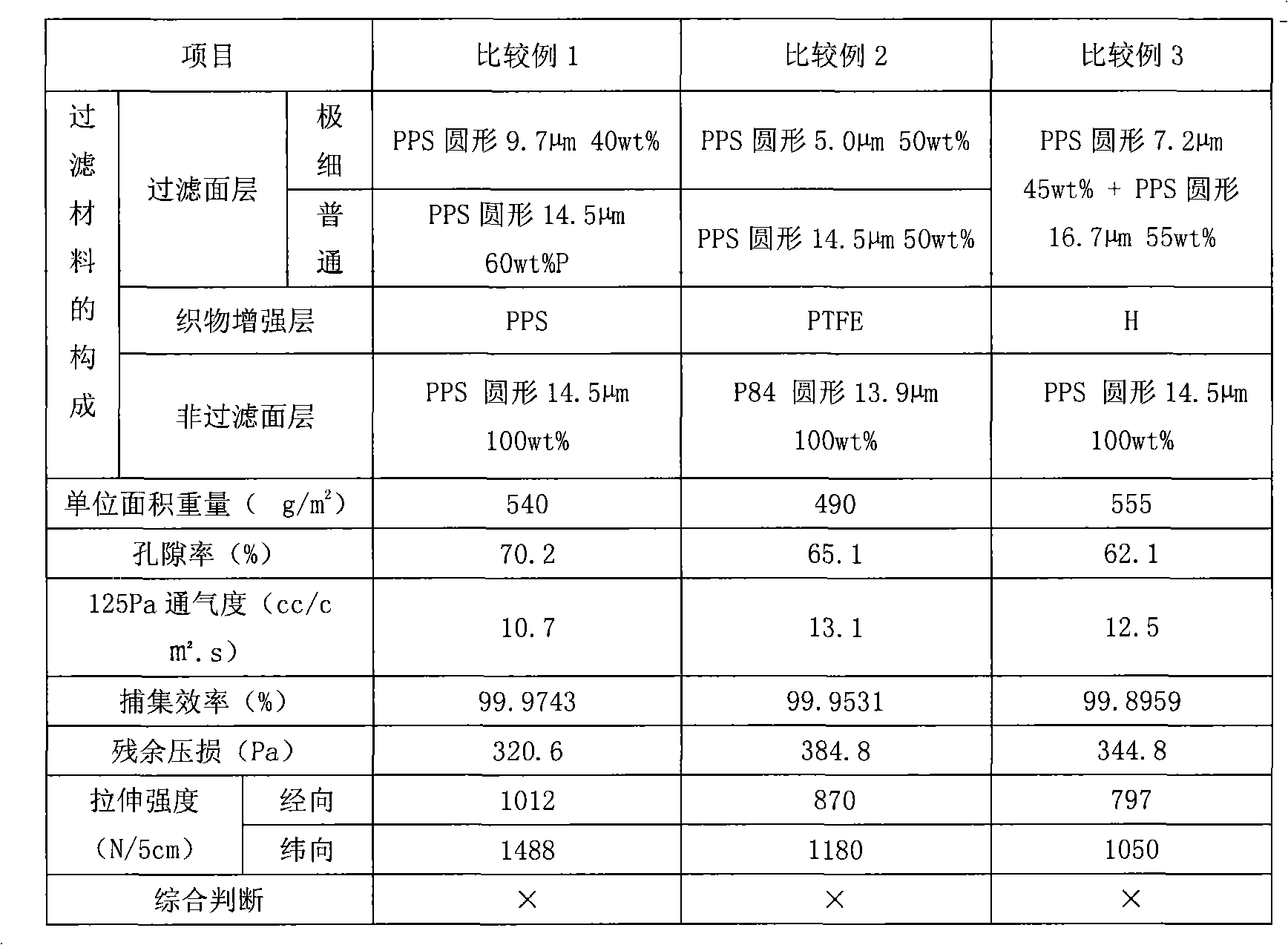

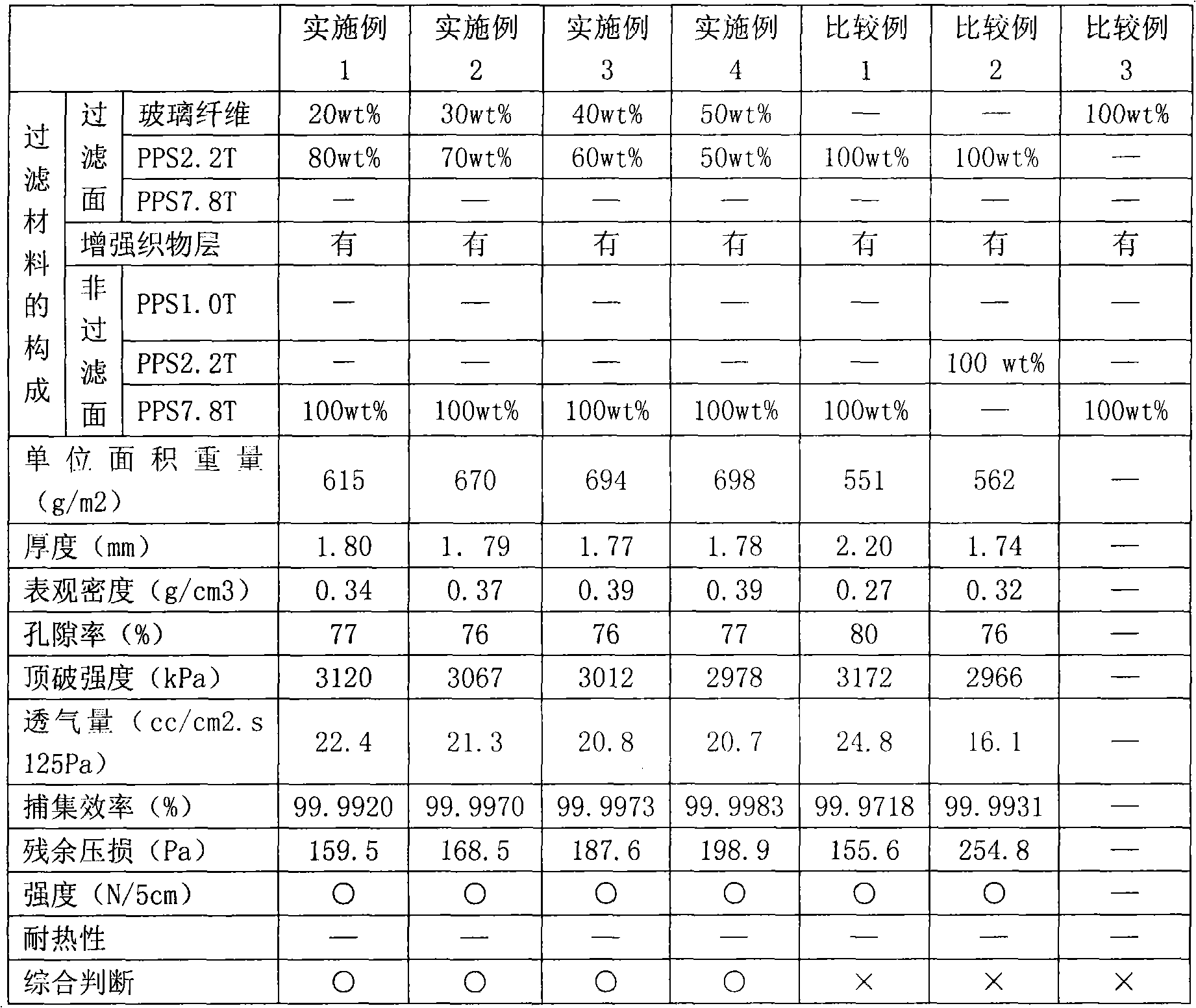

Filter medium

InactiveCN1767882AGood dust collection efficiencyLess rise in pressure lossHuman health protectionFiltration separationFinenessFilter material

A filter material containing polyphenylene sulfide fiber satisfies the following characteristics (1) and (2), thereby providing a filter material with excellent dust collection efficiency and high mechanical strength and a composition thereof The bag filter, (1) contains at least 2 layers of fiber mesh, the fiber mesh on the air inflow side contains 50wt% or more heat-resistant fibers with a fiber diameter of less than or equal to 15 μm, and the fiber on the air discharge side The net contains 50wt% or more of heat-resistant fibers with a fiber diameter greater than or equal to 20 μm; (2) contains a fiber net, which contains polyphenylene sulfide short fibers with a fineness in the range of 1 to 3 decitex and a fineness in the range of Short fibers of fluorine-based fibers in the range of 2 to 4 dtex.

Owner:TORAY IND INC

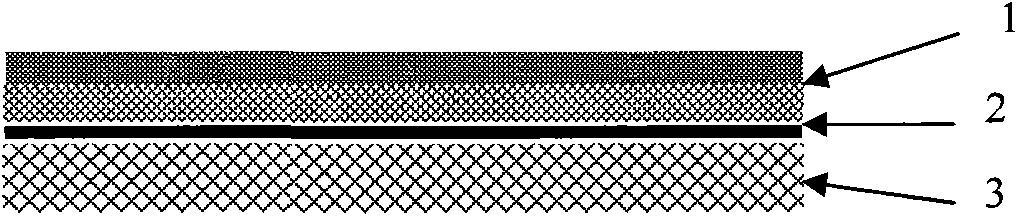

Filtering material and application thereof

InactiveCN102335533AAvoid damageExtended service lifeDispersed particle filtrationLayered productsFiberSurface layer

The invention discloses a filtering material and its application. The filtering material comprises a three-layer structure of a filtering surface layer, a non-filtering surface layer, and an intermediate fabric enhancement layer, wherein, the filtering surface layer is a fibrous mesh comprising 10-90 wt% of heat resistant fibers with the average diameter of below 10 mum and 10-90 wt% of heat resistant fibers with the average diameter of 10-20 mum, the non-filtering surface layer is a fibrous mesh comprising deformed section heat resistant fibers with the average diameter of 10-200 mum, and the intermediate fabric enhancement layer is a fibrous mesh comprising heat resistant fibers. The filtering material disclosed herein has good filtering performance, high mechanical strength, little loss of pressure, and long cycle time, and can improve the service life of the filtering material.

Owner:TORAY IND INC

Fiber cement building materials with low density additives

InactiveUS7658794B2Low densityImprove workabilityConstruction materialSolid waste managementFreeze thawingMicrosphere

This invention relates to a formulation with the addition of low density additives of volcanic ash, hollow ceramic microspheres or a combination of microspheres and volcanic ash or other low density additives into cementitious cellulose fiber reinforced building materials. This formulation is advantageously lightweight or low density compared as compared to current fiber cement products without the increased moisture expansion and freeze-thaw degradation usually associated with the addition of lightweight inorganic materials to fiber cement mixes. The low density additives also give the material improved thermal dimensional stability.

Owner:JAMES HARDIE TECH LTD

SiO2-PS nuclear shell structure ceramic coating diaphragm and preparation method and application thereof

ActiveCN108735953AImprove bindingGood dispersionCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinSilanes

The invention relates to the technical field of the lithium ion battery diaphragm production, and specifically relates to a SiO2-PS nuclear shell structure ceramic diaphragm coating. A preparation method of the SiO2-PS nuclear shell structure ceramic diaphragm coating comprises the following steps: after modifying the monodispersed nanometer SiO2-particle in-situ grafted gamma-methacryloyloxy trimethoxy silane (MPS) prepared through the St-ber method, coating the monodispersed nanometer modified SiO2 particles by adopting the polyvinyl pyrrolidone ethanol solution and styrene-azodiisobutyronitrile mixed solution, thereby forming the nuclear shell structure with stable combination effect, and preparing the SiO2-PS nuclear shell structure ceramic diaphragm coating slurry; the nuclear shell SiO2-PS composite particle with good dispersibility can be uniformly dispersed in the coating slurry system and cannot produce excessive agglutination, and can form the coating not hindering the polyolefin porous diaphragm gap after being coated on the polyolefin porous diaphragm, and has good combining effect with the polyolefin porous diaphragm, and the membrane has good mechanical performance onthe whole; the diaphragm has stable membrane form under high-temperature state, the SiO2 of the nuclear layer is free from ceramic powder falling and blocking diaphragm duct under the coating of theglass-state polymer when the heat shrinkage phenomenon of the diaphragm caused by the high temperature is effectively blocked, and the security of the lithium ion battery is improved.

Owner:安徽美芯新材料有限公司

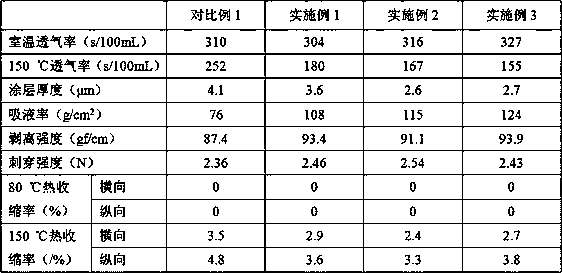

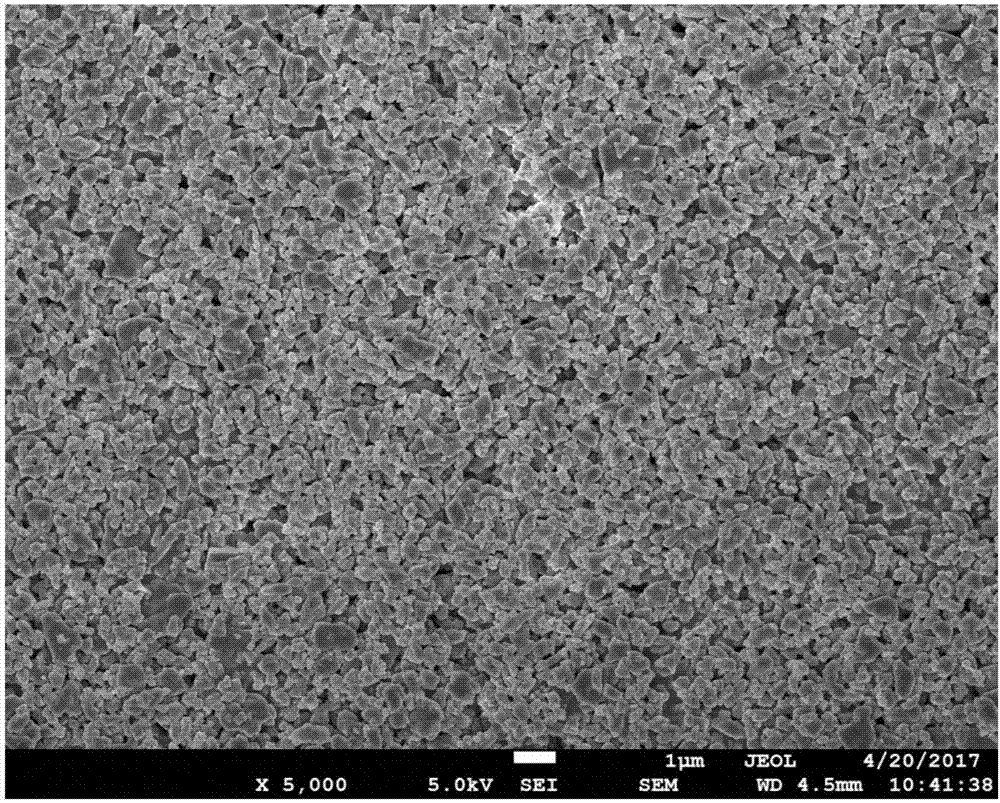

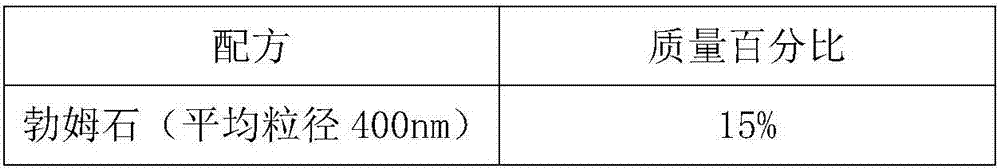

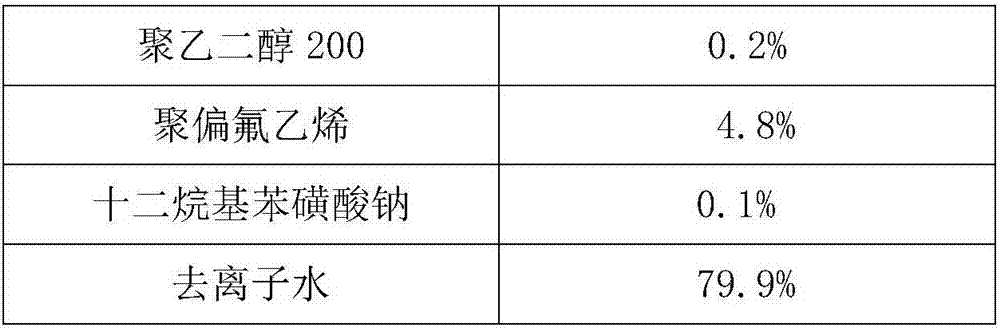

Waterborne ceramic slurry for lithium ion battery and preparation method of composite separator from waterborne ceramic slurry

InactiveCN107403898ASlurry stabilizationNot easy to settleCell component detailsCeramic compositeHeat resistance

The invention provides waterborne ceramic slurry for a lithium ion battery and a preparation method of a composite separator from the waterborne ceramic slurry. The waterborne ceramic slurry is prepared from inorganic powder, an adhesive, a dispersant, an aid and deionized water. The invention further provides a preparation method of the waterborne ceramic composite separator. Compared with oily ceramic coated lithium ion battery separators, the composite separator has good wettability, heat resistance and adhesion performance, a coating contains inorganic powder with uniform particle sizes, the safety performance of the battery is effectively improved, and the composite separator cannot cause pollution to the environment and has a good application prospect.

Owner:VONTRON MEMBRANE TECH CO LTD

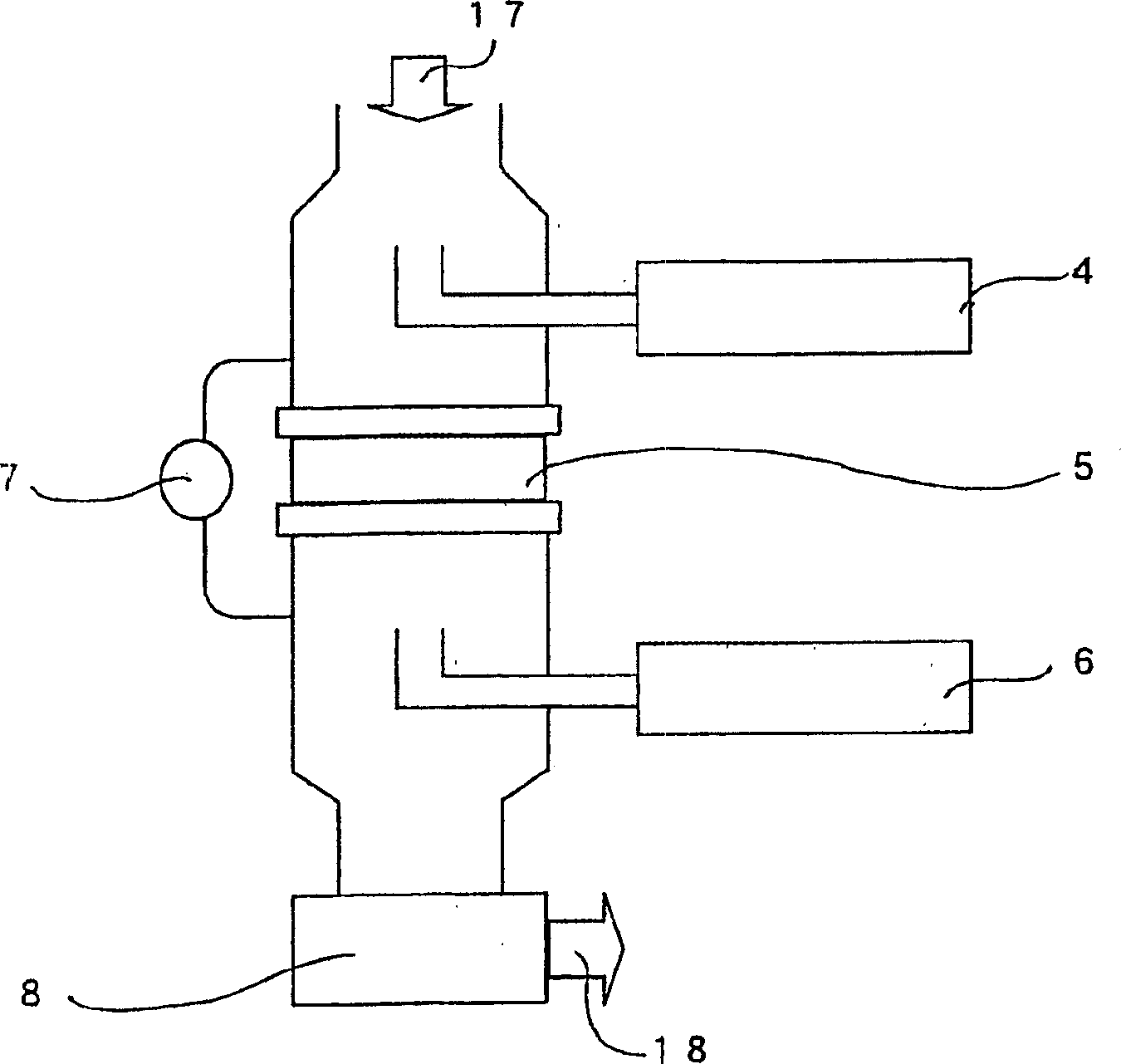

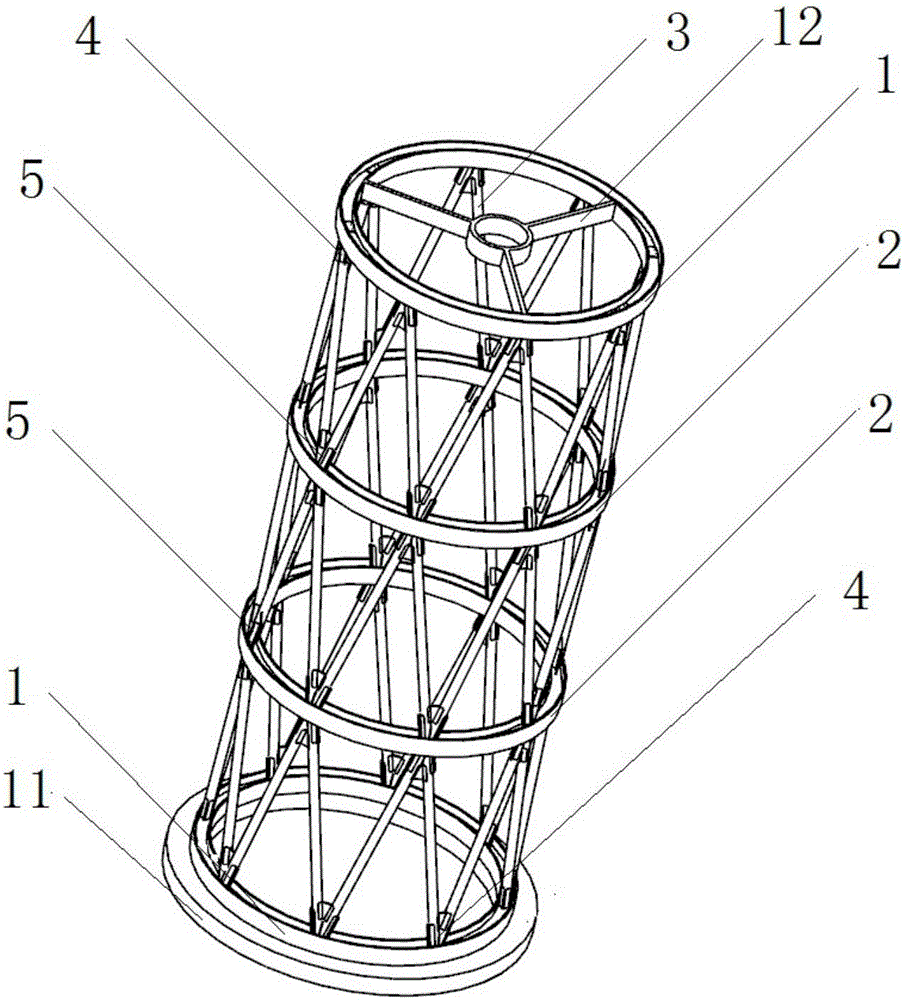

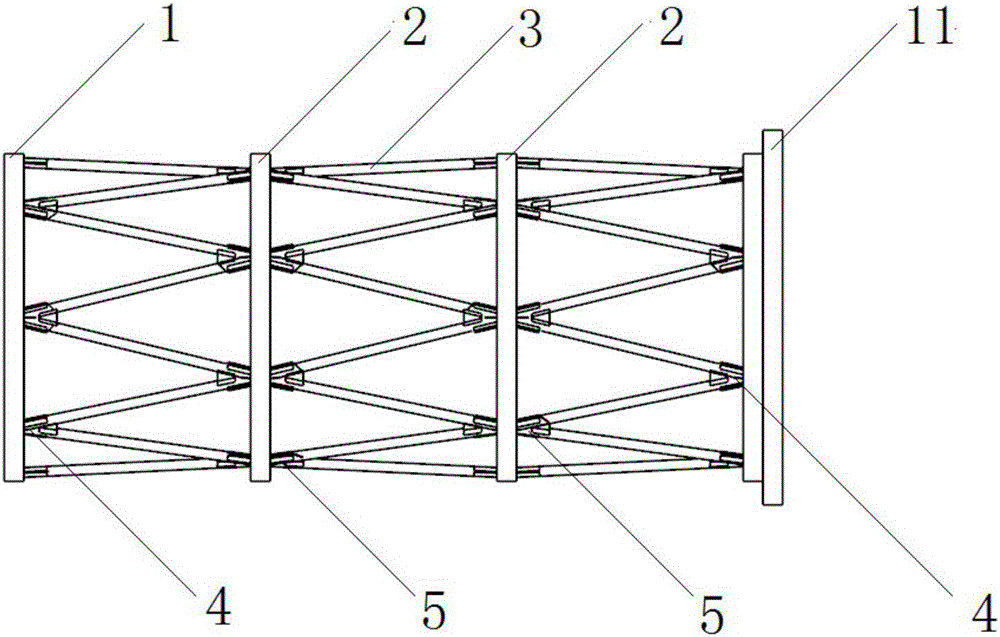

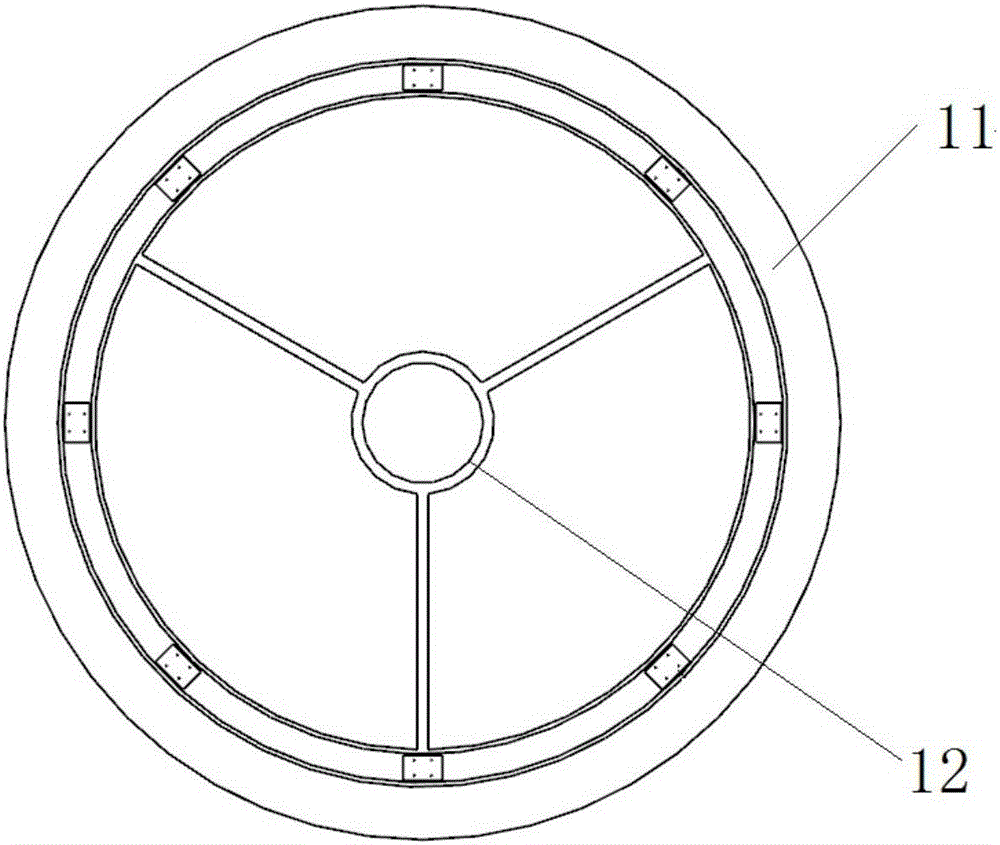

Space optical remote sensor and supporting device for same

InactiveCN106287151AIncrease stiffnessHigh strengthRod connectionsStands/trestlesEngineeringStructural stability

The present invention discloses discloses a supporting device for a space optical remote sensor. The supporting device comprises two external frames disposed oppositely, and an internal frame disposed between the two external frames. The internal frame is connected to the two external frames by means of a plurality of truss rods, respectively. The external frames are connected to the plurality of truss rods by means of a plurality of external joint assemblies. The internal frame is connected to the plurality of truss rods by means of a plurality of internal joint assemblies. By means of the split frames and the truss rods and using the joint assemblies for connection, the rigidity and strength of the supporting device are effectively improved with good structural stability, thereby meeting the requirements of large aperture and long focal length. The present invention also discloses a space optical remote sensor comprising the supporting device.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

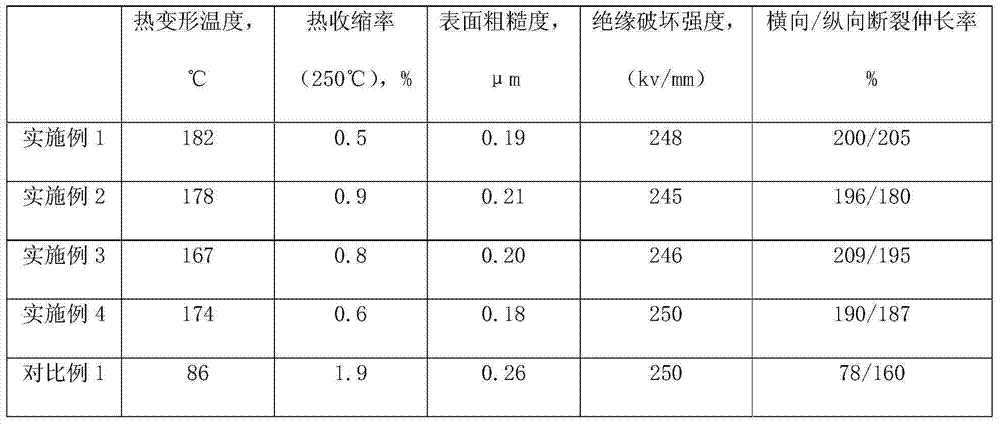

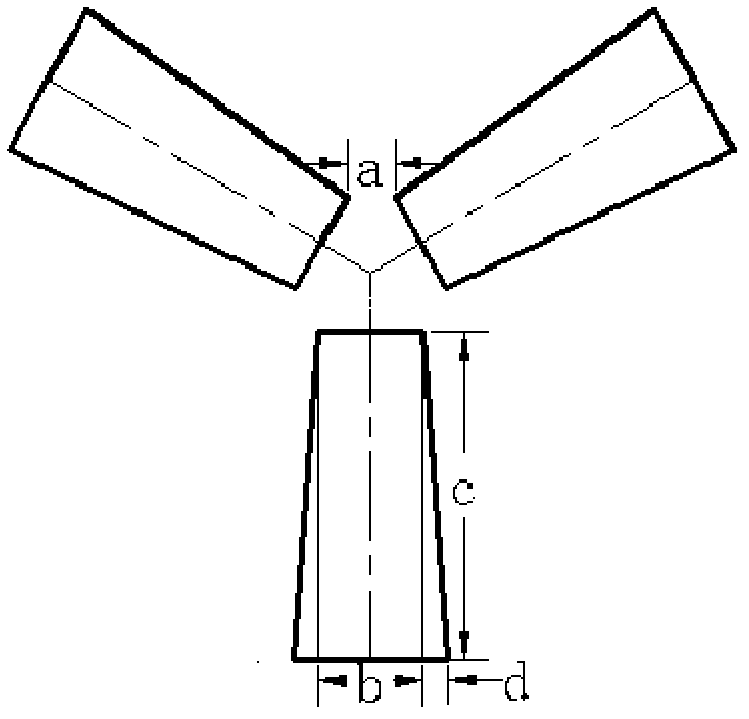

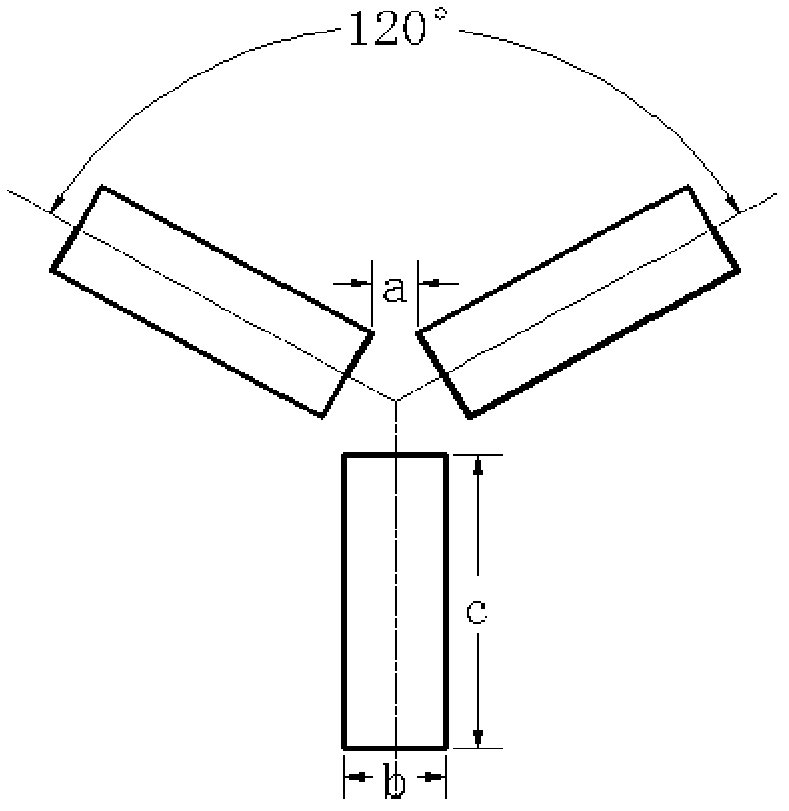

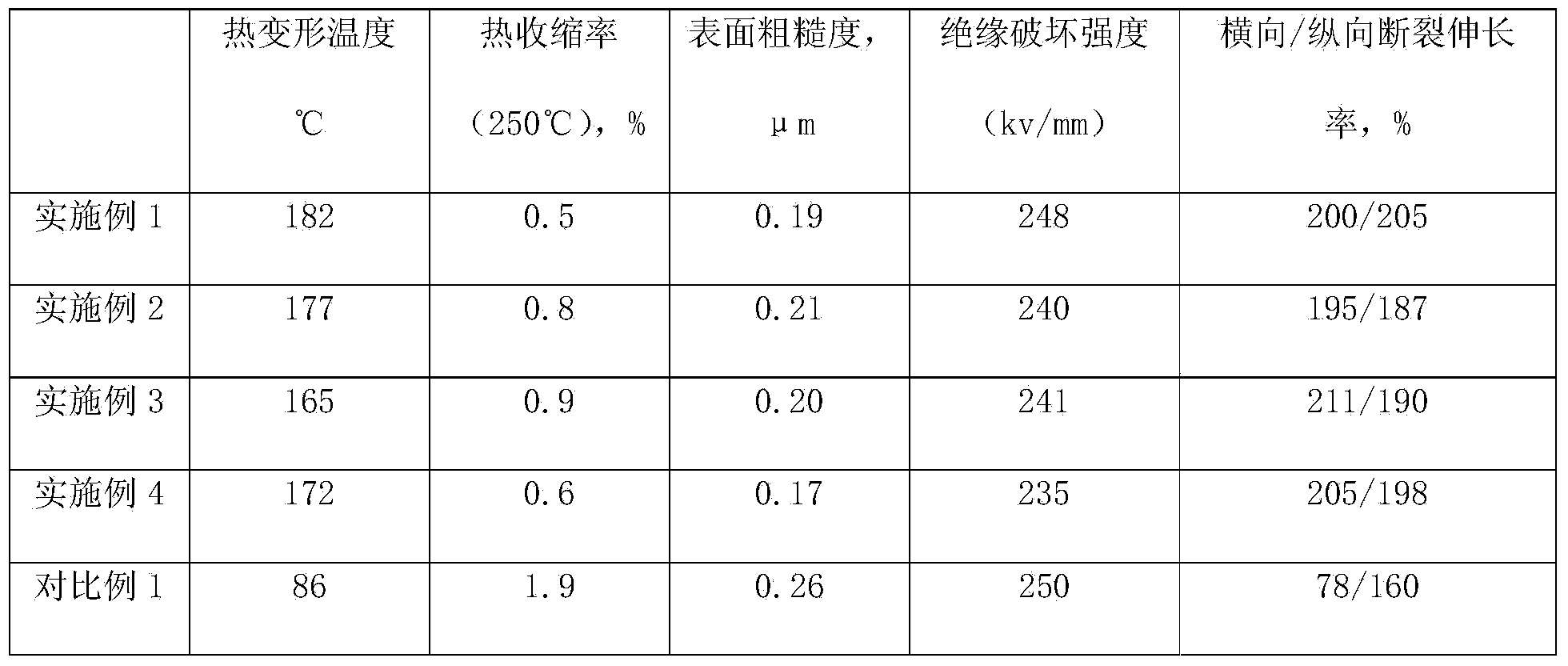

Preparation method of biaxially oriented polyphenylene sulfide composite film

The invention relates to the technical field of extraordinary film preparation, and especially relates to a preparation method of a biaxially oriented polyphenylene sulfide composite film with good toughness and excellent heat resistance. The preparation method comprises the steps of master batch preparation, sheet casting and stretching film formation. The biaxially oriented polyphenylene sulfide composite film prepared by adopting a technical scheme in the invention has the advantages of excellent heat resistance, excellent dimensional stability, excellent heat formability and excellent toughness, can be applied the fields of electric insulation materials or forming materials of motors, transformers and insulation cables, the field of circuit substrate materials, and the field of loudspeaker vibration plates for mobile phones.

Owner:常州钟恒新材料股份有限公司

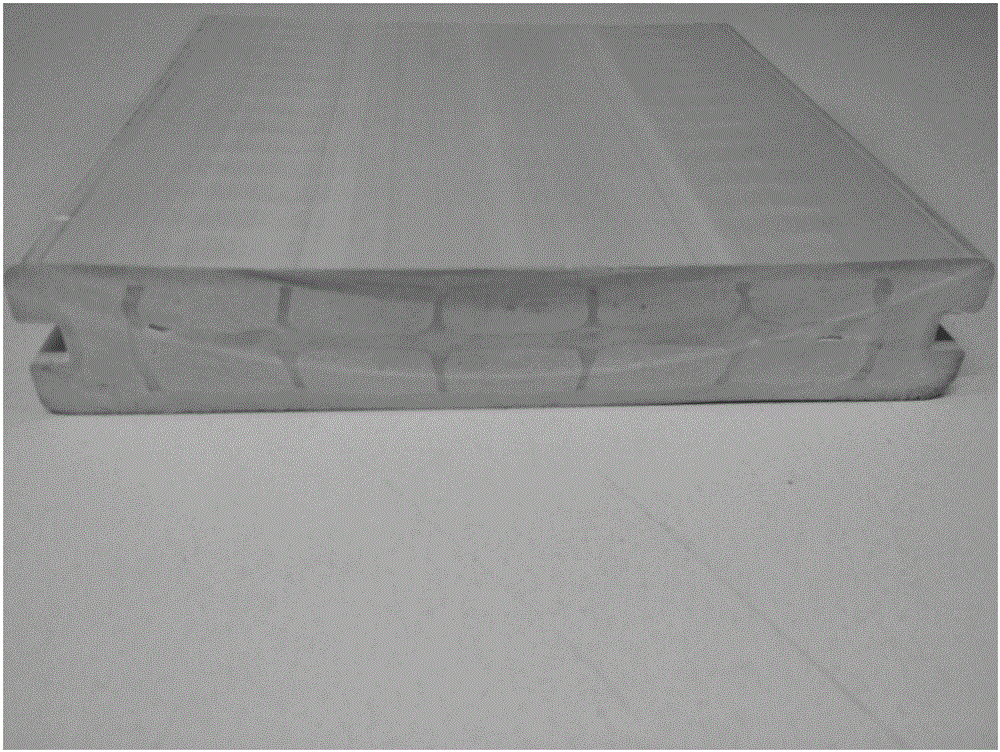

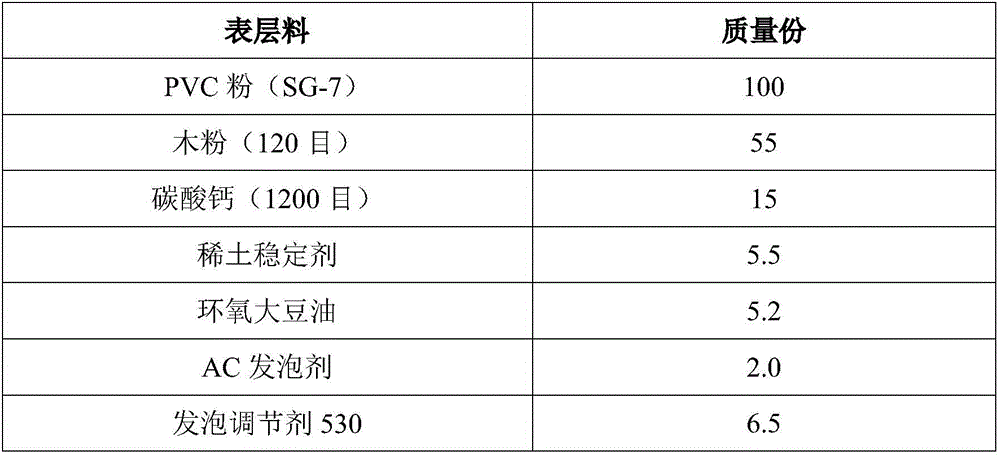

Fiber internally-reinforced wood plastic product with high impact resistance, high folding resistance and high size stability and preparation method thereof

ActiveCN106003950AImprove impact resistanceImprove bending resistanceSynthetic resin layered productsWood layered productsFiberPolymer resin

The invention discloses a fiber internally-reinforced wood plastic product with high impact resistance, high folding resistance and high size stability and a preparation method thereof. The product is formed through co-extrusion of a core layer and a surface layer; the core layer is composed of core layer polymer resin, fibers, plasticizer, a lubricating agent, antioxygen, core layer stabilizer and an interface modifying agent; the surface layer is composed of surface layer polymer resin, wood flour, surface layer stabilizer, calcium carbonate, a foaming agent, a foaming conditioning agent and plasticization stabilizer. The preparation method includes the steps that 1, surface layer raw materials are mixed to be uniform; 2, melt extrusion granulation is conducted, and surface layer particle materials are obtained; 3, the dried core layer resin is uniformly mixed with other core layer raw materials; 4, melt extrusion granulation is conducted, and core layer particle materials are obtained; 5, the surface layer particle materials and the core layer particle materials are subjected to co-extrusion, and the fiber internally-reinforced wood plastic product is obtained; or, the uniformly mixed surface layer particle materials and core layer particle materials are subjected to co-extrusion, and the fiber internally-reinforced wood plastic product is obtained. The wood plastic product has good impact resistance and bending resistance and is good in heated size stability.

Owner:GUANGDONG KINGFA TECH CO LTD

High-temperature-resistant polymer modified ceramic diaphragm and application thereof

ActiveCN108666511AImprove thermal stabilityImproved thermal dimensional stabilityCell component detailsSecondary cells servicing/maintenancePolymer modifiedMetallurgy

The invention discloses a high-temperature-resistant polymer modified ceramic diaphragm and an application thereof. The high-temperature-resistant polymer modified ceramic diaphragm comprises a porousbase membrane, and at least one surface of the porous base membrane is coated with a ceramic layer; and a high-temperature-resistant polymer layer is arranged on the surface and in the interior of pores of the ceramic layer, in the interior of pores of the porous base membrane, and on the surface not coated with the ceramic layer in an in-situ polymerization manner. The high-temperature-resistantpolymer modified ceramic diaphragm has relatively high thermal stability. Through the in-situ polymerization method of pyrrole, the thiophene and the aniline monomer, a high-temperature-resistant polymer protection layer is formed on the surface and in the interior of pores of the ceramic layer, on the surface of the porous base membrane, and in the pores in an in-situ coating manner, so that theceramic layer, the polymer layer and the base membrane form an organic integrated body; therefore, the thermal size stability of the modified ceramic diaphragm is improved, and the modified ceramic diaphragm does not contract at a high temperature of 200 DEG C; and in addition, relatively high mechanical performance is still kept, positive and negative electrode contact can be effectively obstructed, and the safety performance of the battery can be guaranteed.

Owner:XIAMEN UNIV

Heat-resistant synthetic fiber sheet

InactiveCN1522326ASolve the above-mentioned problems that haveImprove heat resistancePrinted circuit aspectsReinforcing agents additionPolymer sciencePolymer chemistry

Owner:TEIJIN LTD

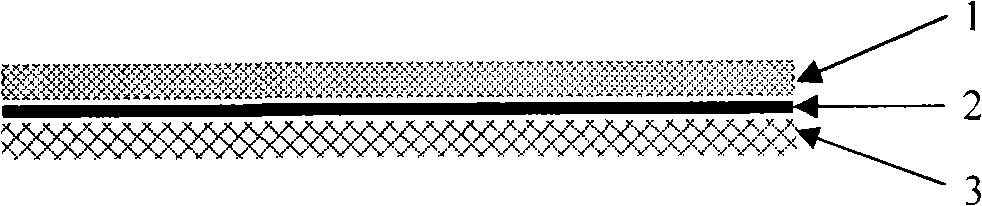

Polyimide film with ultralow dielectric loss

ActiveCN109648970AExcellent dielectric lossImprove bondingSynthetic resin layered productsCopper foilDielectric loss factor

The invention provides a polyimide film with ultralow dielectric loss and a preparation method thereof, the polyimide film is capable of being directly adhered to a copper foil, the polyimide film comprises a core layer and a surface layer, or the polyimide film comprises two surface layers and a core layer which is sandwiched between the two surface layers, the dielectric loss factor of the polyimide film at 10GHz test frequency is 0.0030-0.0060, and the dielectric constant is less than 3.0.

Owner:RAYITEK HI TECH FILM CO LTD

Filter material and purpose thereof

InactiveCN102380259AAvoid damageExtended service lifeDispersed particle filtrationLayered productsFiberFilter material

The invention discloses a filter material and a purpose thereof. The filter material consists of three layers of structures, namely, a filtering surface layer, a non-filtering surface layer and an intermediate fabric enhancing layer. The filtering surface layer is a fiber web that consists of 20-80wt% heat resistance fibers of which the diameter is less than or equal to 10mum and 20-80wt% heat resistance fibers of which the diameter is more than 10mum and less than or equal to 20mum in a layering manner, wherein the fibers of which the diameter is less than or equal to 10mum is used as an upper layer; the non-filtering surface layer is a fiber web which consists of heat resistance fibers with special-shaped sections, the diameter of which is 10-200mum; and the intermediate fabric enhancing layer consists of heat resistance fibers. The filter material has the effects that the filtering performance is good, the mechanical strength is high, the loss of pressure is less, and the cycle time is long, and has the advanatage that the service life of the filter material can be prolonged.

Owner:TORAY IND INC

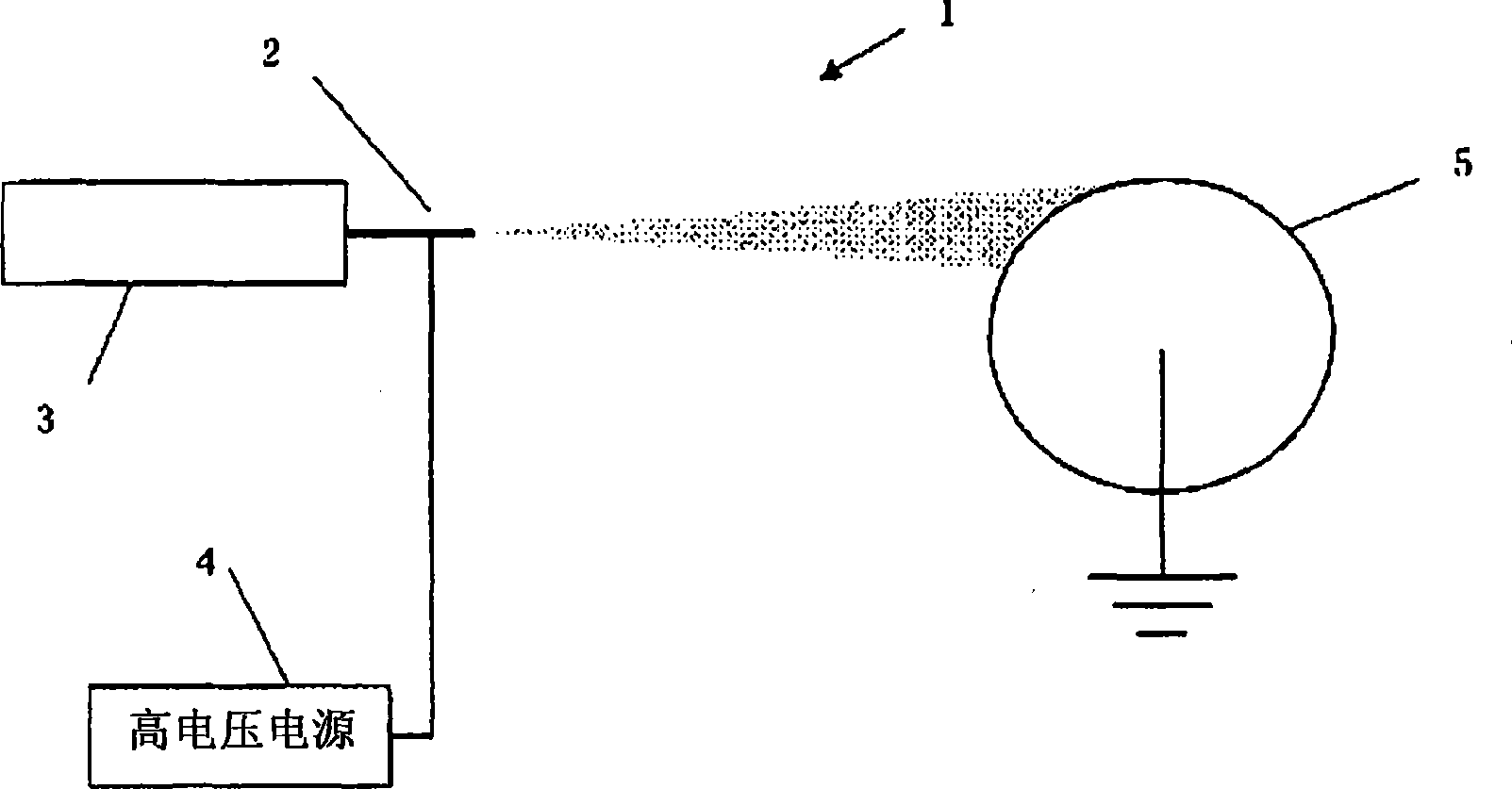

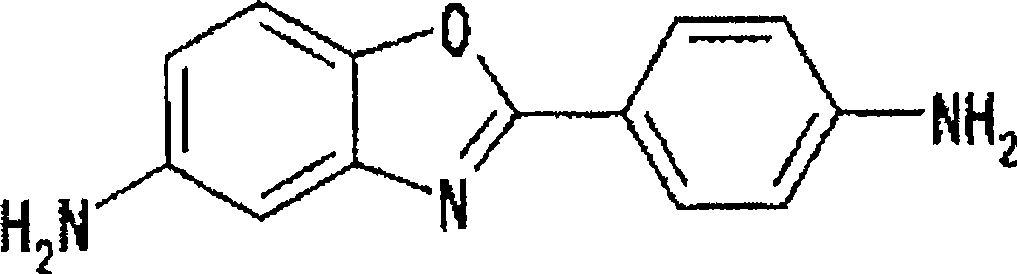

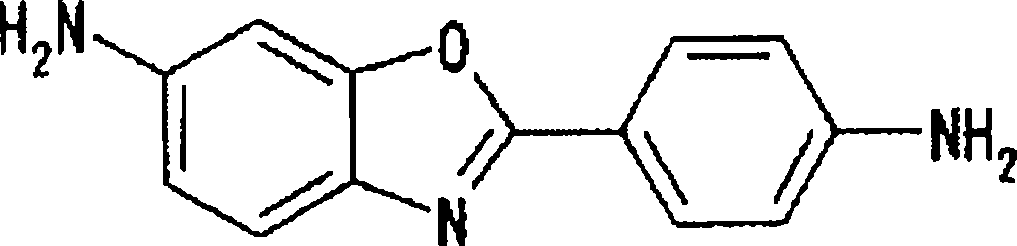

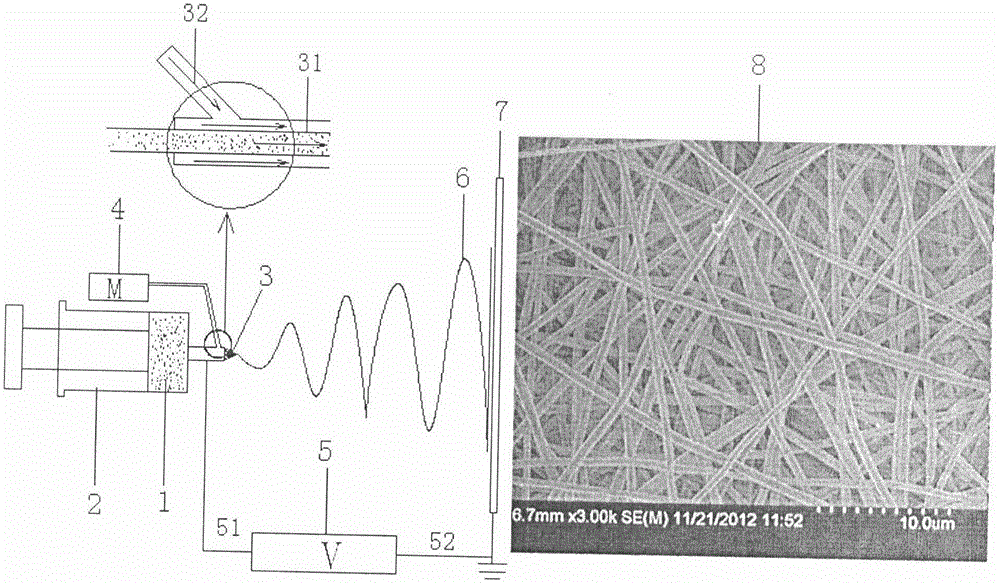

Polyimide nonwoven fabric and process for production thereof

InactiveCN101473080AIncrease surface areaImprove filtering effectFilament/thread formingMonocomponent synthetic polymer artificial filamentPolymer scienceHeat resistance

The invention provides a nonwoven fabric which exhibits excellent heat resistance, mechanical strength and dimensional stability under heat even in applications accompanied with the exposure to high temperature and has an extremely large surface area and high filter performance. The fabric is made of polyimide fibers which are prepared from a raw material comprising as the essential components an aromatic tetracarboxylic acid and antissu non tisse de peo aromatic diamine having a benzoxazole structure through polycondensation and have fiber diameters of 0.001 to 1[mu]m. This fabric can be produced by a process which comprises the step of forming a polyimide precursor nonwoven fabric by charge-spinning a polyamic acid prepared from a raw material comprising as the essential components an aromatic tetracarboxylic acid and an aromatic diamine having a benzoxazole structure through polycondensation and the step of subjecting the polyimide precursor fibers constituting the obtained precursor nonwoven fabric to imidation.

Owner:TOYOBO CO LTD

Polyester film

ActiveCN1835994AHigh mechanical strengthImprove heat resistanceFlexible coversWrappersPolyesterHeat resistance

Provided is a polyester film which is excellent in heat resistance, chemical resistance, insulating characteristics, dimensional stability at elevated temperatures, and is suitable for use in a variety of fields of application such as those needing a boiling or retort treatment which requires satisfactory levels in toughness, the resistance to pin-holing, the resistance to flexing, the resistance to the breakage of a bag by dropping, impact resistance and the like, those practicing thermal molding or vacuum molding, those of bags for packaging foods containing water or drugs. A polyester film, characterized in that it exhibits an initial modulus of elasticity at least in one direction of 2.5 to 10 GPa, an impact strength of 40 to 10000J / mm, a thermal shrinkage at 150 DEG C at least in one direction of -0.5 to 6 %, a haze of 0.001 to 7 %, and an absolute value of the difference between the thermal shrinkage percentages in the longitudinal direction and in the transverse direction of 1.1 % or less.

Owner:TOYOBO CO LTD

Composite lithium-sulfur battery diaphragm, preparation method thereof and application

InactiveCN107978717AInhibition of the shuttle effectImproved Coulombic efficiency and cycle stabilityCell seperators/membranes/diaphragms/spacersElectro conductivitySolvent

The invention discloses composite lithium-sulfur battery diaphragm, a preparation method thereof and application. The method comprises the steps of impregnating porous substrate membrane into reactionprecursor solution composed of reaction monomers, cross-linking agent, initiator and solvent; and carrying out in situ polymerization and cross-linking reaction under certain condition, thereby acquiring gel electrolyte filled composite lithium-sulfur battery diaphragm with nanoscale pore diameters. According to the lithium-sulfur battery diaphragm, the porous substrate membrane is taken as a framework material, so the good mechanical property and excellent thermal dimension stability are endowed to the diaphragm; the filled gel electrolyte has a great number of lithium conduction functionalgroups, so channels for lithium ions to shuttle are provided, and the problem that the ionic conductivity is relatively low due to reduction of the pore diameters of the diaphragm is avoided; and according to the prepared nanoscale pore diameter composite diaphragm, migration of polysulfide can be inhibited through physical range limitation and chemical absorption effect, so the coulombic efficiency and cycling stability of the lithium-sulfur battery are improved. The composite lithium-sulfur battery diaphragm, the preparation method thereof and the application are simple in technology and high in practicability, are easy to popularize and are beneficial for accelerating industrial application of a lithium-sulfur battery.

Owner:SUN YAT SEN UNIV

Polyester film

ActiveUS20190106534A1Improved thermal dimensional stabilityAdvantageously usableFlat articlesShrinkage rateCarboxylic acid

It is provided that a polyester film excellent in heat resistant dimension stability, impact-resistant strength properties, easy-slipping properties, mechanical properties, transparency, and gas barrier performance, and a film roll obtained by winding up this polyester film. A polyester film includes at least one layer mainly including a polyester resin containing a dicarboxylic acid component including furandicarboxylic acid as a main component and a glycol component including ethylene glycol as a main component; and the polyester film has a plane orientation coefficient ΔP of not less than 0.005 and not more than 0.200, a thickness of not less than 1 μm and not more than 300 μm, a heat shrinkage rate of 3.2% or less in each of the MD direction and the TD direction at 150° C. for 30 minutes, and a layer containing at least one additive.

Owner:TOYO TOYOBO CO LTD +1

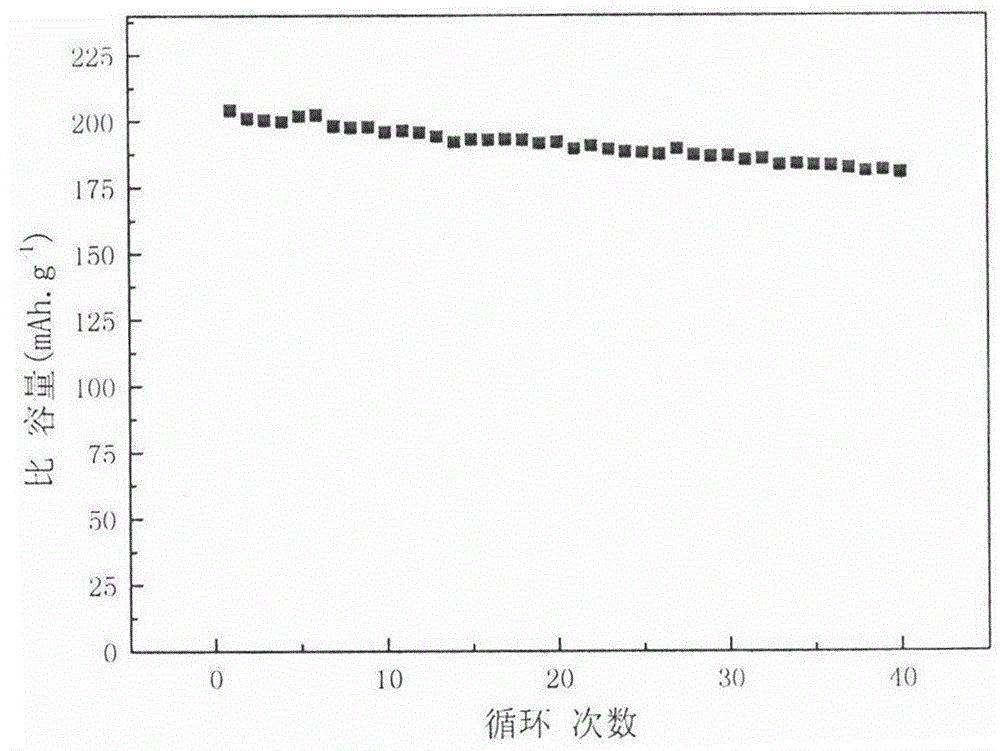

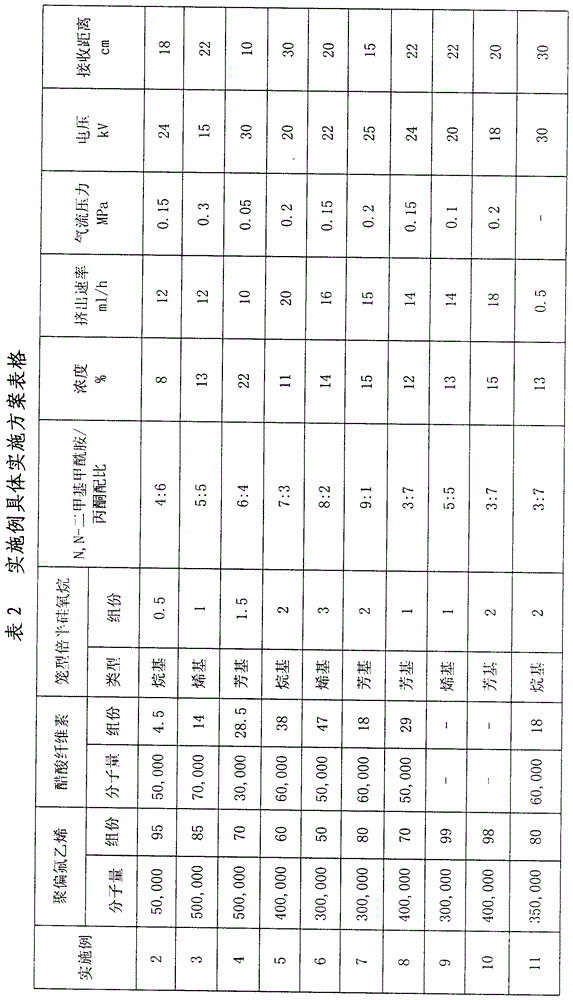

Blend superfine fiber diaphragm for lithium ion battery

InactiveCN104362280AShort processing flowSimple processSecondary cellsCell component detailsFiberCellulose acetate

The invention relates to a blend superfine fiber diaphragm for a lithium ion battery. The blend superfine fiber diaphragm is characterized by comprising polyvinylidene fluoride, cellulose acetate and polyhedral oligomeric silsesquioxane. The polyhedral oligomeric silsesquioxane is one of alkyl silsesquioxane, alkenyl silsesquioxane or aryl silsesquioxane. The blend superfine fiber diaphragm provided by the invention has good hydrophilcity, high strength and excellent thermal size stability; the solution absorbing rate of the blend superfine fiber diaphragm is 300-900 percent, the thermal shrinkage rate of the blend superfine fiber diaphragm is smaller than 5 percent, the specific capacity of a gel polymer lithium ion battery assembled by adopting the blend superfine fiber diaphragm reaches 200-220 mAh.g<-1>, and the lithium intercalation utilization rate of an anode material LiCoO2 can reach above 70 percent.

Owner:TIANJIN POLYTECHNIC UNIV

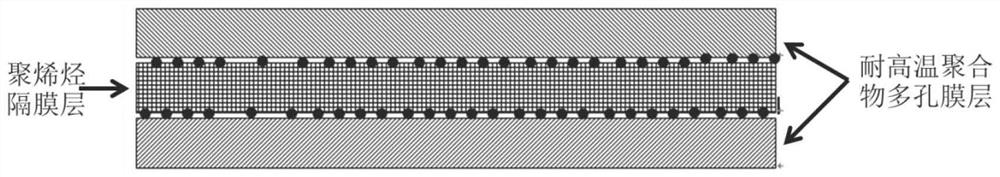

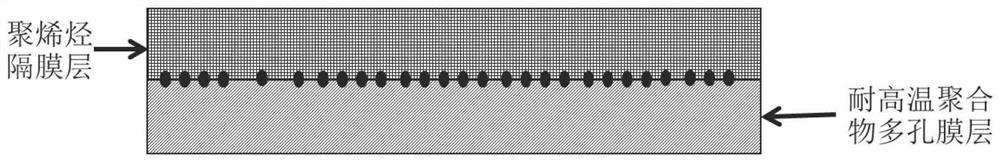

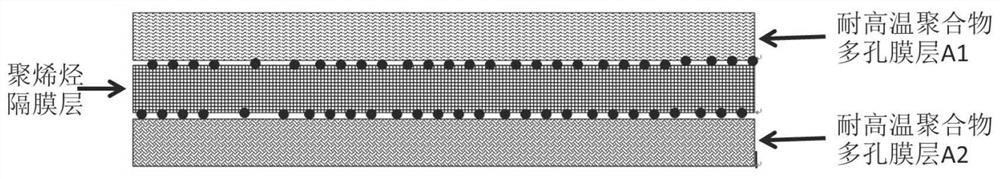

High-temperature-resistant composite diaphragm for lithium ion battery and preparation method thereof

PendingCN111916621AGood effectImproved thermal dimensional stabilitySecondary cellsCell component detailsElectrolytic agentPolyolefin

The invention relates to a high-temperature-resistant multi-layer composite diaphragm for a lithium ion battery and a preparation method thereof. The diaphragm is of an A1 / B / A2 three-layer structure or an A1 / B two-layer structure, wherein A1 and A2 are high-temperature-resistant polymer porous membranes prepared by applying an electrostatic spinning process; the middle layer B is a polyolefin diaphragm, A1 / B / A2 or A1 / B is compounded through a compounding process, and a three-layer or two-layer composite diaphragm is obtained. The lithium battery diaphragm prepared by the invention has the characteristics of lower closed pore temperature of the middle layer and high temperature resistance of the porous diaphragm on the surface layer, the preparation process is simple and feasible, the adhesive force between different diaphragms is strong, the thermal dimensional stability is excellent, and the dimensional stability, the integrity and the electrolyte wettability of the diaphragm under the condition of extremely high temperature of the lithium ion battery can be improved; therefore, the safety of the battery is improved and the application prospect is good.

Owner:BEIJING YUCHENG TECH CO LTD

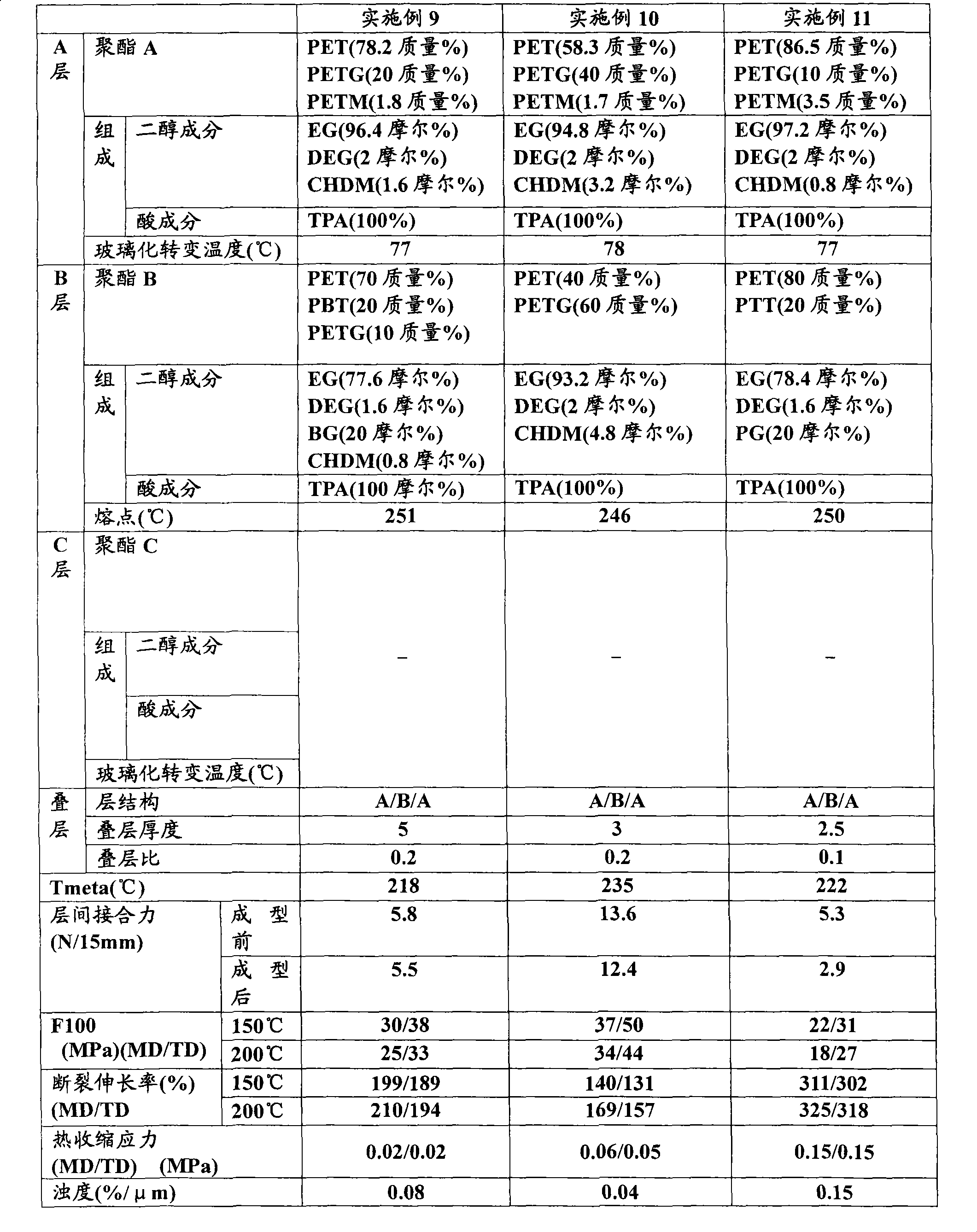

Biaxially oriented polyester film for molded part

ActiveCN101426646ALittle change in appearanceUniform vapor depositionSynthetic resin layered productsVacuum evaporation coatingPolyesterChemical vapor deposition

To provide a biaxially oriented polyester film, particularly a biaxially oriented polyester film for forming members which is useful as a substrate in producing metallic forming members by metal vapor deposition or as a surface protective film in the forming of decorative sheets. [MEANS FOR SOLVING PROBLEMS] A biaxially oriented polyester film for forming members, which is an at least two-ply laminate constituted of a layer (A) made of a polyester (A) and a layer (B) made of a polyester (B) wherein the interlaminar strength between the layers (A) and (B) is 5 N / 15mm or above and the stress values (F100 values) at 100% elongation in the lengthwise and widthwise directions at 200 DEG C and 150 DEG C are 1 to 50 MPa.

Owner:TORAY IND INC

Biaxially oriented polyethylene terephthalate film and method for producing same

ActiveUS20150119548A1Improved thermal dimensional stabilitySmall size changeFlat articlesSemiconductor devicesThermal shrinkagePolyethylene terephthalate glycol

This film provides a polyethylene terephthalate film whereby dimensional variation in various steps can be reduced, particularly when the film is used as a substrate film for a flexible device, and that is suitable as a substrate film having minimal curl and excellent appropriateness for processing. This biaxially oriented polyethylene terephthalate film has a degree of crystallinity (Xc) of 0.35 to 0.50, the intrinsic viscosity (IV) of the resin constituting the film is 0.66-1.0 dl / g, the coefficient of thermal expansion at a temperature of 50-170° C. in each of the machine direction and transverse direction of the film is 0.29 ppm / ° C., and the degree of thermal shrinkage at 180° C. in each of the machine direction and transverse direction of the film is 0.5%-1.0%.

Owner:TORAY IND INC

Polyphenylene sulfide composite fiber and non-woven fabric

ActiveCN104641027AThermally dimensional stableImproved thermal dimensional stabilityWoven fabricsConjugated synthetic polymer artificial filamentsNonwoven fabricInorganic sulfide

Provided are: a composite fiber which comprises a resin containing polyphenylene sulfide as the main component and has excellent thermal adhesion properties while keeping thermal dimensional stability thereof; and a non-woven fabric. A composite fiber mainly composed of a component (A) and a component (B), wherein the component (A) is a resin containing polyphenylene sulfide as the main component and the component (B) is a resin containing polyphenylene sulfide as the main component and having a higher melt flow rate than that of the component (A), and wherein at least a part of the surface of the fiber is formed from the component (B).

Owner:TORAY IND INC

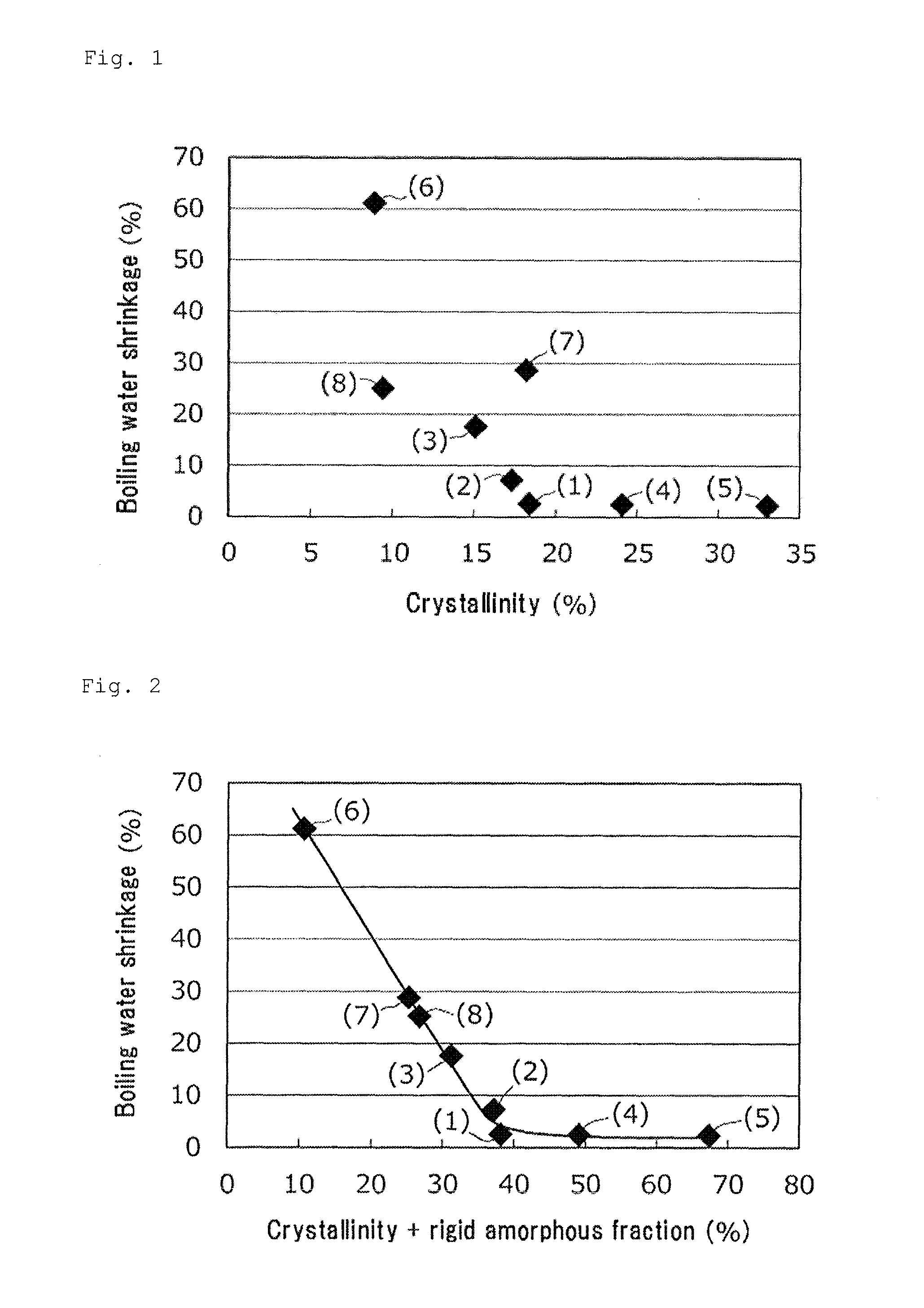

Polyphenylene sulfide fiber and nonwoven fabric

InactiveUS20140187115A1Improve adhesionImproved thermal dimensional stabilityMonocomponent synthetic polymer artificial filamentMelt spinning methodsHeat resistanceSulfide

Provided are a polyphenylene sulfide fiber including a PPS resin as a main component and having both excellent heat resistance and excellent thermal bonding properties, and a nonwoven fabric including the fiber. The polyphenylene sulfide fiber includes polyphenylene sulfide as a main component and having the sum of the crystallinity and the rigid amorphous fraction of 30% to 90%. The crystallinity is preferably not less than 5% and less than 25%. The polyphenylene sulfide fiber is used to form a nonwoven fabric. The nonwoven fabric is preferably produced by consolidation by thermal bonding or mechanical entanglement.

Owner:TORAY IND INC

Filter material and use

The invention discloses a filter material and the application thereof. The filter material has a three-layer structure including a filter layer, a non-filter layer and an intermediate fabric strengthened layer, wherein, the filter layer is a fibre net which consists of 10wt percent to 90wt percent of glass fiber with the average diameter of being smaller than 10microns and 90wt percent to 10wt percent of heat resistant fibre with the average diameter of 10 microns to 20microns, the non-filter layer is a fibre net which consists of heat resistant fibre with the average diameter of 20microns to 200microns, and the intermediate layer is the fibre strengthened layer. The filter material has high dust trapping efficiency; the increase of the pressure loss after the removal of dusts from the surface of the filter material is low, and since that the increase of the dust removal period reduces the damage to the filter material caused by the excessive blowing by compressed air, the service life of the filter material is prolonged and the cost is reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

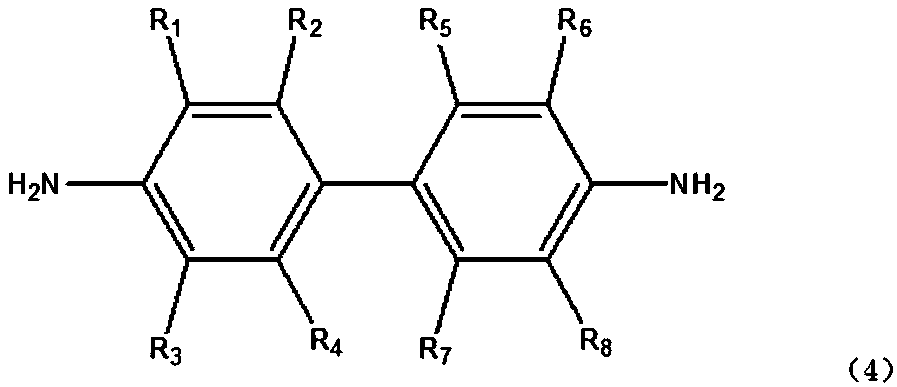

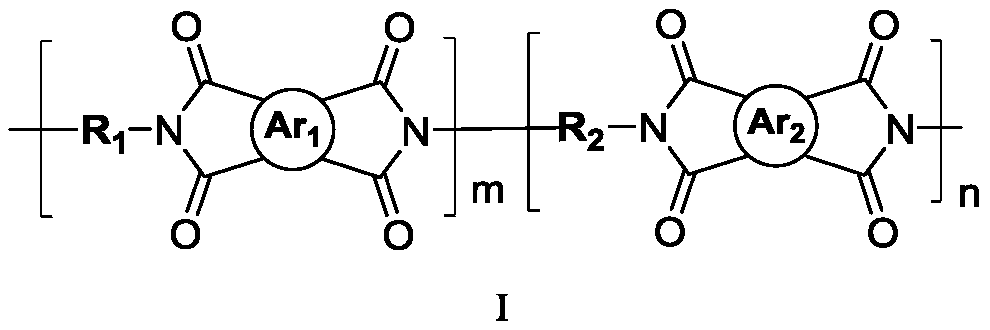

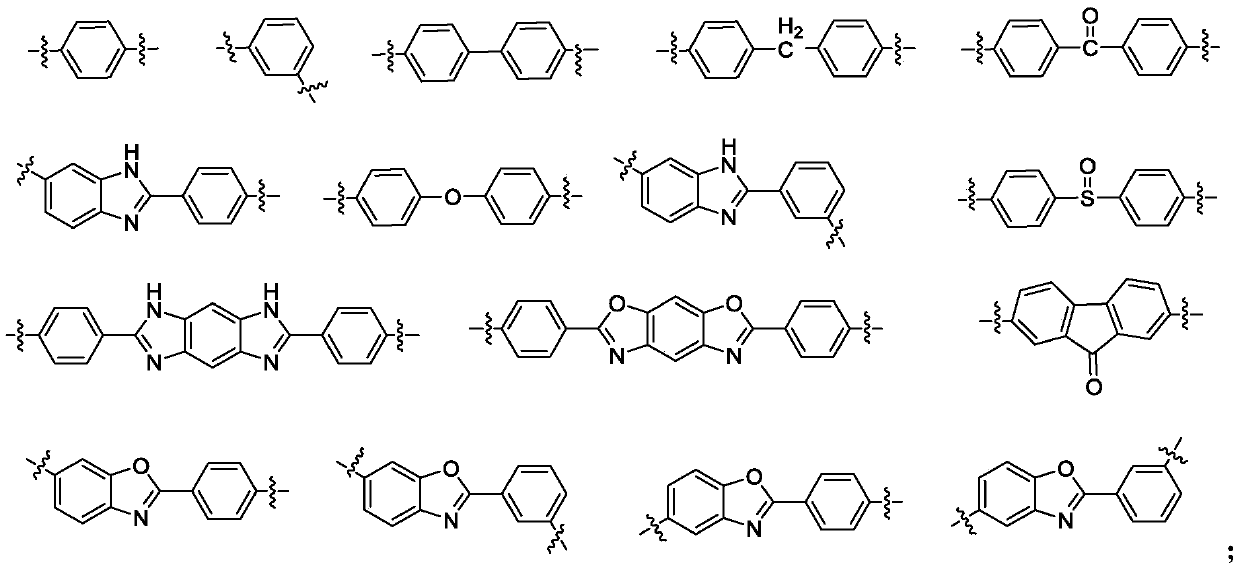

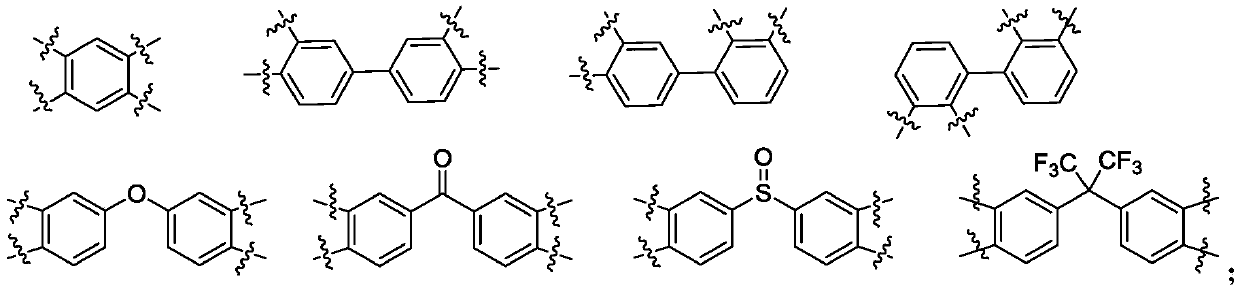

Polyimide with high thermal dimensional stability, preparation method therefor and application of polyimide

ActiveCN110144043AImprove thermal stabilityHigh glass transition temperaturePolymer scienceHeat resistance

The invention discloses polyimide with high thermal dimensional stability, a preparation method therefor and an application of the polyimide. The polyimide disclosed by the invention has a structure represented by a formula I. After a polyimide film is prepared from the polyimide disclosed by the invention, excellent heat resistance, an ultralow thermal expansion coefficient and relatively good mechanical properties and flexibility are shown, and the technical requirements of flexible display industry on development of flexible substrate materials can be met; and the polyimide is applied to production of flexible display devices, and meanwhile, a way of think of designing of a novel monomeric compound is provided for developing high-performance materials.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of polyimide profiled fiber

InactiveCN102277647AIncrease productivitySimple stepsMonocomponent synthetic polymer artificial filamentDry spinning methodsFiberPolyamic acid

The invention relates to a preparation method of polyimide profiled fibers. The method comprises the following steps of: (1) preparing a polyamic acid solution; (2) forming by dry spinning; and (3) performing cyclization on the as-spun fibers. The dry spinning process is adopted to prepare polyimide profiled fibers, which has high production efficiency, simple procedures and strong operability, makes solvent volatilization more convenient and can achieve the effect of controlling the degree of profile of polyimide fibers. The prepared polyimide profiled fibers have good mechanical properties and high specific surface areas, maintain good dimensional stability at a high temperature, and can be widely applied to reinforcing fibers of composite materials, protective clothing against high-level radiation and other severe conditions, filtering materials used in high temperature mining conditions and so on.

Owner:DONGHUA UNIV

Biaxial orientation type polyphenylene sulfide composite membrane

The invention relates to the technical field of preparation of specific membranes, and particularly relates to a biaxial orientation type polyphenylene sulfide composite membrane with good toughness and excellent heat resistance. The composite membrane comprises the following components: membrane-grade polyphenylene resin, an organic elastomer and an inorganic filler, wherein the membrane-grade polyphenylene resin comprises membrane-grade polyphenylene resin for a master batch and membrane-grade polyphenylene resin for casting of a sheet. The biaxial orientation type polyphenylene sulfide composite membrane prepared by adopting the technical scheme provided by the invention has excellent heat resistance, size stability, thermal formability and toughness. The biaxial orientation type polyphenylene sulfide composite membrane disclosed by the invention can be applied to fields of electric insulating materials or forming materials for a motor, a transformer, an insulating cable and the like, a circuit substrate material, a loudspeaker vibrating plate for a mobile phone and the like.

Owner:常州钟恒新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com