Composite lithium-sulfur battery diaphragm, preparation method thereof and application

A lithium-sulfur battery, composite technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of unsuitability for large-scale industrial production, poor stability, and high equipment requirements. Achieve the effect of improving cycle stability and Coulomb efficiency, improving Coulomb efficiency and cycle stability, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

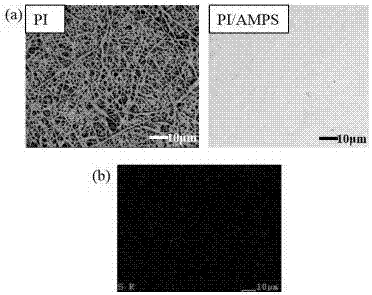

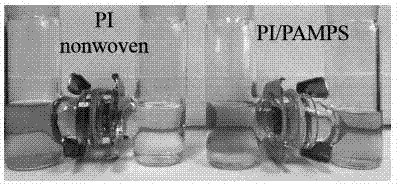

[0045] Example 1 A composite lithium-sulfur battery separator filled with PI non-woven fabric by PAMPS

[0046] 1. Preparation method

[0047] (1) Use 2-acrylamide-2-methylpropanesulfonic acid (AMPS) as the monomer containing acrylic group, N,N-methylenebisacrylamide (MBA) as the crosslinking agent, ammonium persulfate (APS) ) is a thermal initiator; AMPS (7.5g), MBA (3g) and APS (0.02g) are dissolved in 30mL deionized water, mixed to form a reaction precursor solution;

[0048] (2) Immerse the polyimide (PI) non-woven fabric into the prepared reaction precursor solution, take it out after 30 minutes and drain it for 5 minutes, and place it in an oven at 60°C for 6 hours to form a gel electrolyte-filled precursor After the membrane, it was taken out, and repeatedly washed with deionized water to remove the residual reaction solution, and finally dried in a vacuum oven at 40°C to obtain a PI non-woven membrane filled with PAMPS.

[0049] 2. Product nature and characteristics ...

Embodiment 2

[0059] Example 2 A composite lithium-sulfur battery separator filled with PI non-woven fabric by PAMPS

[0060] 1. Preparation method

[0061] (1) 2-acrylamide-2-methylpropanesulfonic acid (AMPS) is used as acryl-containing monomer, N,N-methylenebisacrylamide (MBA) is used as a crosslinking agent, and benzophenone ( BP) is photoinitiator; AMPS (15g), MBA (3g) and BP (0.03g) are dissolved in the N'N-dimethylacetamide of 50mL, mix and form reaction precursor solution;

[0062] (2) Immerse the polyimide (PI) non-woven fabric into the prepared reaction precursor solution, take it out after 1.5 hours and drain it for 6 minutes, and then place it under ultraviolet light to initiate the reaction for 10 minutes to form a gel electrolyte filled front After the body membrane, it was taken out, washed repeatedly with ethanol and deionized water to remove the residual reaction solution, and dried in a vacuum oven at 60°C to obtain a PI non-woven membrane filled with PAMPS.

[0063] 2. P...

Embodiment 3

[0066] Example 3 A composite lithium-sulfur battery separator filled with PI flat porous membrane by PAMPS

[0067] 1. Preparation method

[0068] (1) Use 2-acrylamide-2-methylpropanesulfonic acid (AMPS) as the monomer containing propylene group, polyethylene glycol (PEG) as the cross-linking agent, and azobisisobutyronitrile (ABIN) as the heat Initiator: AMPS (10g), PEG (1.5g) and ABIN (0.015g) were dissolved in 50mL of N'N-dimethylformamide, mixed uniformly to form a reaction precursor solution;

[0069] (2) Immerse the polyimide (PI) flat porous membrane into the prepared reaction precursor solution, take it out after 1 hour and drain it for 4 minutes, and then place it in an oven at 60°C for 8 hours to form a gel electrolyte filled front After the body membrane was removed, it was washed repeatedly with ethanol and deionized water to remove the residual reaction solution, and dried in a vacuum oven at 40°C to obtain a PI diaphragm filled with PAMPS.

[0070] 2. Product n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com