Preparation method of lithium-sulfur battery cathode material based on phosphorus-doped graphene supported nickel phosphide material

A phosphorus-doped graphene, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor activity of reactive materials, short cycle life of positive electrodes, etc., and achieve the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

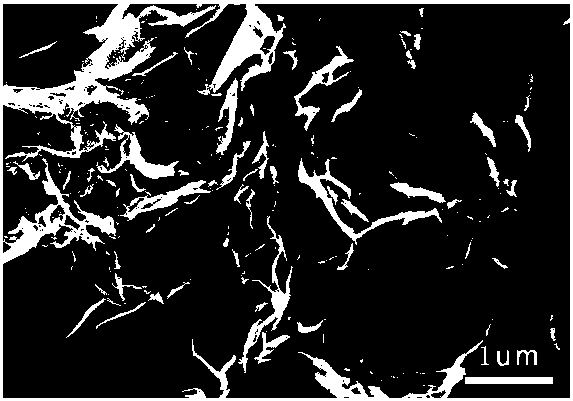

Image

Examples

Embodiment 1

[0023] (1) Take 10 mL of 0.2 mg / mL graphene oxide, add 1 mg of cetyltrimethylammonium bromide to it, and stir magnetically to obtain a graphene oxide dispersion.

[0024] (2) Add 10 mmol of nickel sulfate and 10 mmol of sodium hydroxide to 5 mL of distilled water, and magnetically stir to obtain a salt solution.

[0025] (3) Under vigorous stirring, slowly add the salt solution in step (2) to the graphene oxide dispersion in step (1), and continue to stir for 5 minutes, and then transfer to the reactor, in an oven at 140°C After reacting for 6 hours, the product obtained after the reaction is obtained by filtration and freeze-dried to obtain a graphene composite material supporting the nickel precursor.

[0026] (4) The nickel precursor-loaded graphene composite material obtained in step (3) is mixed with potassium hypophosphite in a mass ratio of 1:1, and the phosphating 1 is calcined in an argon atmosphere tube furnace at a temperature of 250°C. After hours, phosphorus-doped graph...

Embodiment 2

[0033] (1) Take 1000 mL of 10 mg / mL graphene oxide, add 200 mg of Triton X100 to it, and stir magnetically to obtain a graphene oxide dispersion.

[0034] (2) Add 1000 mmol of nickel hypophosphite and 1000 mmol of urea to 50 mL of distilled water, and magnetically stir to obtain a salt solution.

[0035] (3) Under vigorous stirring, slowly add the salt solution in step (2) to the graphene oxide dispersion in step (1), and continue to stir for 100 minutes, and then transfer to the reactor, in an oven at 250°C After reacting for 24 hours, the product obtained after the reaction is filtered and freeze-dried to obtain a graphene composite material supporting the nickel precursor.

[0036] (4) The nickel precursor-loaded graphene composite material obtained in step (3) is mixed with yellow phosphorus in a mass ratio of 1:50, and phosphating is calcined in a helium atmosphere tube furnace at a temperature of 800°C for 12 hours , To obtain phosphorus-doped graphene supported nickel phosphi...

Embodiment 3

[0039] (1) Take 20 mL of 5 mg / mL graphene oxide, add 150 mg of polyvinyl alcohol to it, and stir magnetically to obtain a graphene oxide dispersion.

[0040] (2) Add 800 mmol of nickel acetate and 40 mmol of ammonia to 30 mL of distilled water, and magnetically stir to obtain a salt solution.

[0041] (3) Under vigorous stirring, slowly add the salt solution in step (2) to the graphene oxide dispersion in step (1), and continue stirring for 80 minutes, then transfer to the reactor, and place it in an oven at 200°C. After reacting for 12 hours, the product obtained after the reaction is filtered and freeze-dried to obtain the graphene composite material supporting the nickel precursor.

[0042] (4) The nickel precursor-loaded graphene composite material obtained in step (3) is mixed with sodium hypophosphite in a mass ratio of 1:10, and phosphating is calcined at a temperature of 500°C in a nitrogen atmosphere tube furnace for 9 hours , To obtain phosphorus-doped graphene supported n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com