Preparation method of network-like carbon-loaded iron-based compound material and application of network-like carbon-loaded iron-based compound material in lithium-sulfur battery

A lithium-sulfur battery and network-like technology, applied in the field of electrochemistry, can solve the problems of inhibition of the shuttling effect of difficult polysulfide compounds, lack of in-depth research on catalysis, and reduce the use of noble metal catalysts, so as to inhibit the shuttling effect and increase the effect of sulfur fixation , The synthetic method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

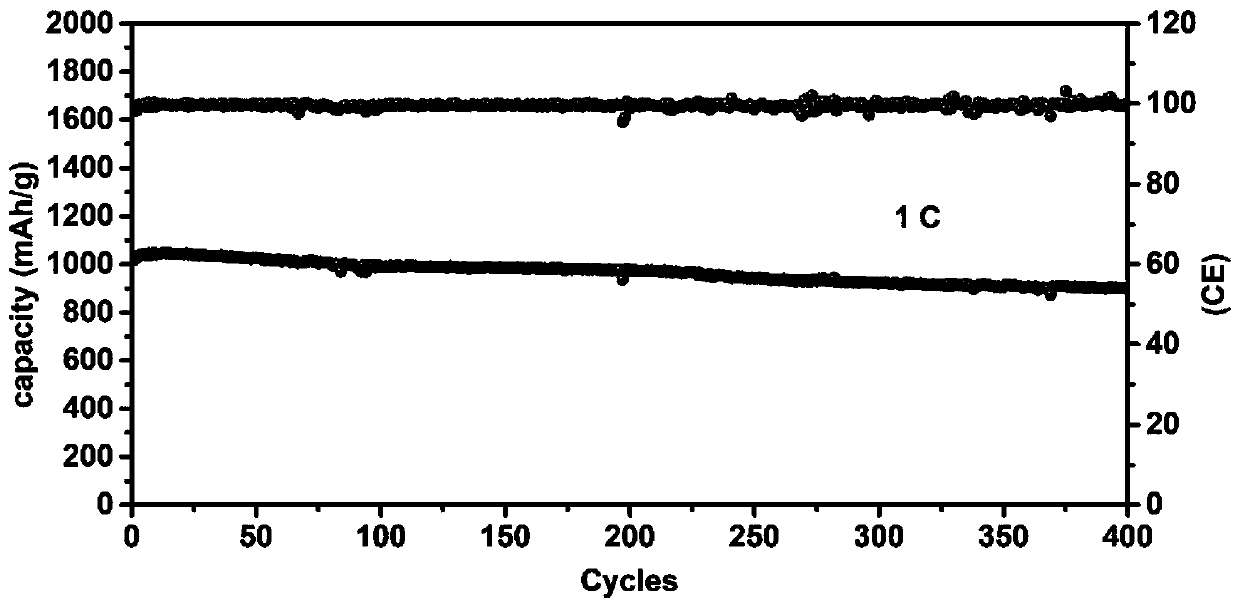

[0030] At room temperature, 1.0050 g of ferric nitrate nonahydrate and 10 mL of GO (5 mg / mL) were added to 40 mL of deionized water, sonicated for 2 hours and stirred for 12 hours. 1.0052 g of glucose was added and stirring was continued for 8 hours at room temperature. The resulting homogeneous mixture was transferred into a hydrothermal kettle and kept at 180°C for 10 hours. After the reaction kettle was lowered to room temperature, it was suction-filtered, washed three times with deionized water, and dried at 60°C. The dried product was thoroughly ground and mixed with 10 times the mass of melamine, and then kept at 900°C for 1 hour under the protection of argon with a heating rate of 5°C / min. When the temperature drops to room temperature, mix the resulting material and binder (PVDF) at a ratio of 9:1, add NMP and stir at room temperature for 12 hours to form a uniform slurry, which is coated on a commercial PP separator with a thickness of 10 microns and heated at 80°C D...

Embodiment example 2

[0036] At room temperature, 1.5 g of ferric nitrate nonahydrate and 20 mL of GO (5 mg / mL) were added to 40 mL of deionized water, sonicated for 1 hour and stirred for 8 hours. 2 g of glucose were added and stirring was continued for 12 hours at room temperature. The resulting homogeneous mixture was transferred into a hydrothermal kettle and kept at 160°C for 10 hours. After the reaction kettle was lowered to room temperature, it was suction-filtered, washed three times with deionized water, and dried at 60°C. The dried product was thoroughly ground and mixed with 8 times the mass of melamine, and then kept at 800°C for 4 hours under the protection of argon with a heating rate of 5°C / min. When the temperature drops to room temperature, mix the resulting material and binder (PVDF) at a ratio of 9:1, add NMP and stir at room temperature for 12 hours to form a uniform slurry, which is coated on a commercial PP separator with a thickness of 10 microns and heated at 80°C Dry for 1...

Embodiment example 3

[0042] At room temperature, 0.5 g of ferric nitrate nonahydrate and 15 mL of GO (5 mg / mL) were added to 40 mL of deionized water, sonicated for 3 hours and stirred for 10 hours. 0.5 g of glucose was added and stirring was continued for 10 hours at room temperature. The resulting homogeneous mixture was transferred into a hydrothermal kettle and kept at 170°C for 13 hours. After the reaction kettle was lowered to room temperature, it was suction-filtered, washed three times with deionized water, and dried at 60°C. The dried product was thoroughly ground and mixed with 6 times the mass of melamine, and then kept at 1000°C for 2 hours under the protection of argon with a heating rate of 5°C / min. When the temperature drops to room temperature, mix the resulting material and binder (PVDF) at a ratio of 9:1, add NMP and stir at room temperature for 12 hours to form a uniform slurry, which is coated on a commercial PP separator with a thickness of 10 microns and heated at 80°C Dry f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com