Biaxially oriented polyester film for molded part

A molding part, biaxial orientation technology, applied in the direction of synthetic resin layered products, ion implantation plating, coating, etc., can solve the problems of insufficient stress, poor peelability, residual protective film, etc., and achieve the change of film appearance Small size and excellent thermal dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

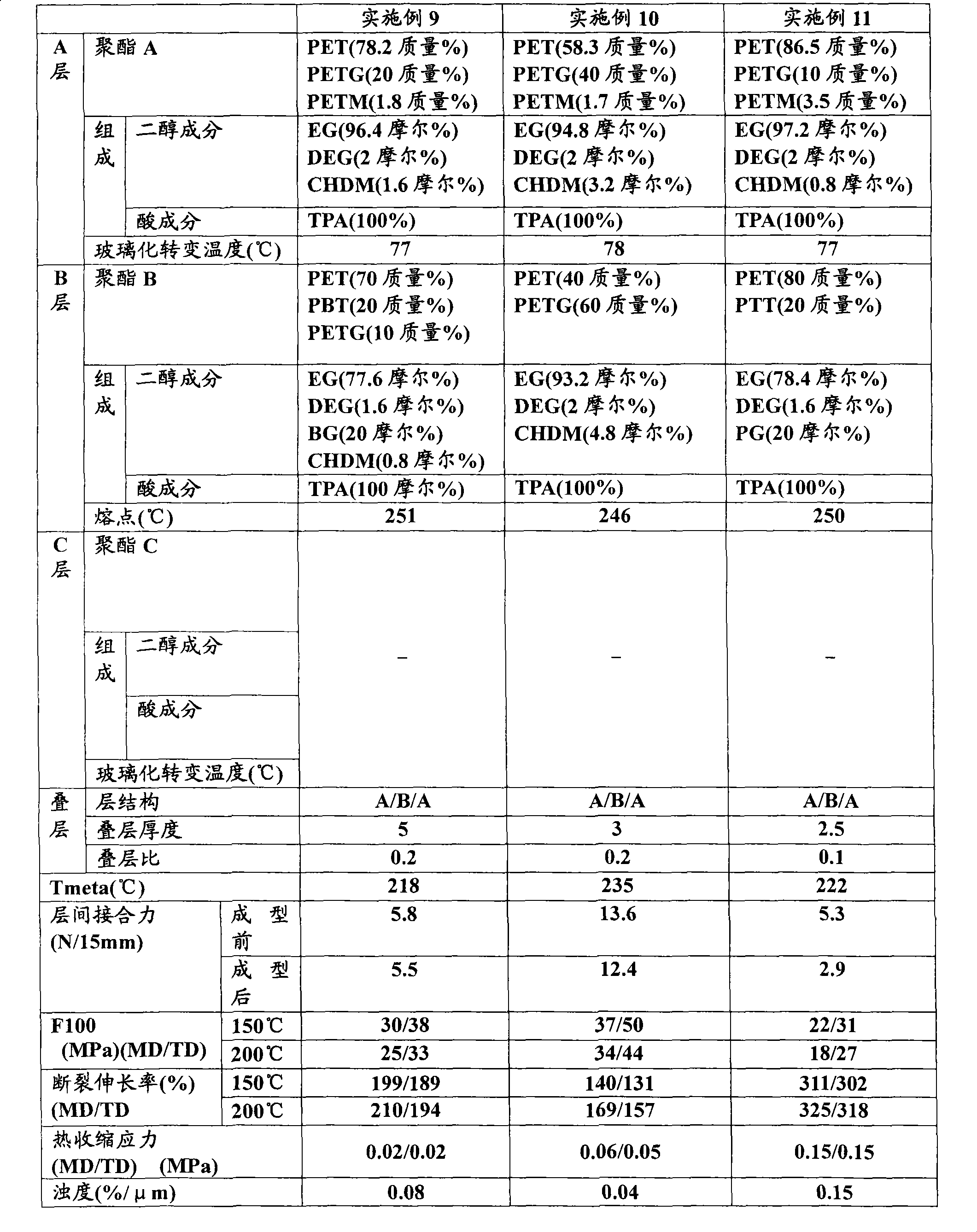

Examples

Embodiment 1

[0168] A 3-layer laminated film of A layer / B layer / A layer is produced. As the polyester A constituting the layer A, PET, PBT, PETG, and PETM were mixed and used in a mass ratio of 34:25:40:1. As the polyester B constituting the B layer, PET, PBT, PETG, and PETM were mixed and used in a ratio of 34.8:25:40:0.2.

[0169] Each mixed polyester resin was dried in a vacuum dryer at 180°C for 4 hours to fully remove moisture, and then supplied to a single-screw extruder, melted at 280°C, and passed through a filter and a gear pump in a separate path. , remove foreign matter, make the extrusion amount uniform, and then laminate in the feeding module set on the upper part of the T-die according to the method of A layer / B layer / A layer (refer to the table for the thickness of the layer), and then pass the T The mold spit is formed into flakes on a cooling drum whose temperature is controlled at 25°C. At this time, static electricity was applied using a wire electrode having a diamete...

Embodiment 2

[0173] A 3-layer laminated film of A layer / B layer / A layer is produced. As the polyester A constituting the layer A, PET, PETG, and PETM were mixed and used at a mass ratio of 33.4:65:1.6. As the polyester B constituting the B layer, PET, PBT, and PETG were mixed and used at a mass ratio of 45:20:35.

[0174] Except having set the heat-processing temperature at 240 degreeC, it carried out similarly to Example 1, and obtained the biaxially-oriented polyester film with a film thickness of 25 micrometers.

[0175]The obtained biaxially oriented polyester film was excellent in moldability and interlayer adhesion after molding, and also excellent in appearance after metal vapor deposition under the condition of item (10), showing that it can be used as a biaxially oriented polyester film for molded parts. Excellent properties of ester film. In addition, the properties of the protective film evaluated under the condition of item (11) were also good, excellent in moldability, and t...

Embodiment 3

[0177] A two-layer laminated film of layer A / layer B is produced. As the polyester A constituting the layer A, PET, PETG, and PETM were mixed and used at a mass ratio of 37:60:3. As the polyester B constituting the B layer, PET, PBT, and PETG were mixed and used in a mass ratio of 50:15:35.

[0178] Except having set the heat treatment temperature at 238° C., it was carried out in the same manner as in Example 1 to obtain a biaxially oriented polyester film with a film thickness of 25 μm.

[0179] The obtained biaxially oriented polyester film was excellent in moldability and interlayer adhesion after molding. However, since the turbidity was slightly high, the appearance after vapor-depositing the metal under the condition of item (10) looked somewhat cloudy.

[0180] In addition, since the F100 at 150°C is slightly high, the thermoformability as a protective film is affected to some extent, and the glossiness of the molded article after molding is slightly lowered, but a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com