Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Good deacidification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

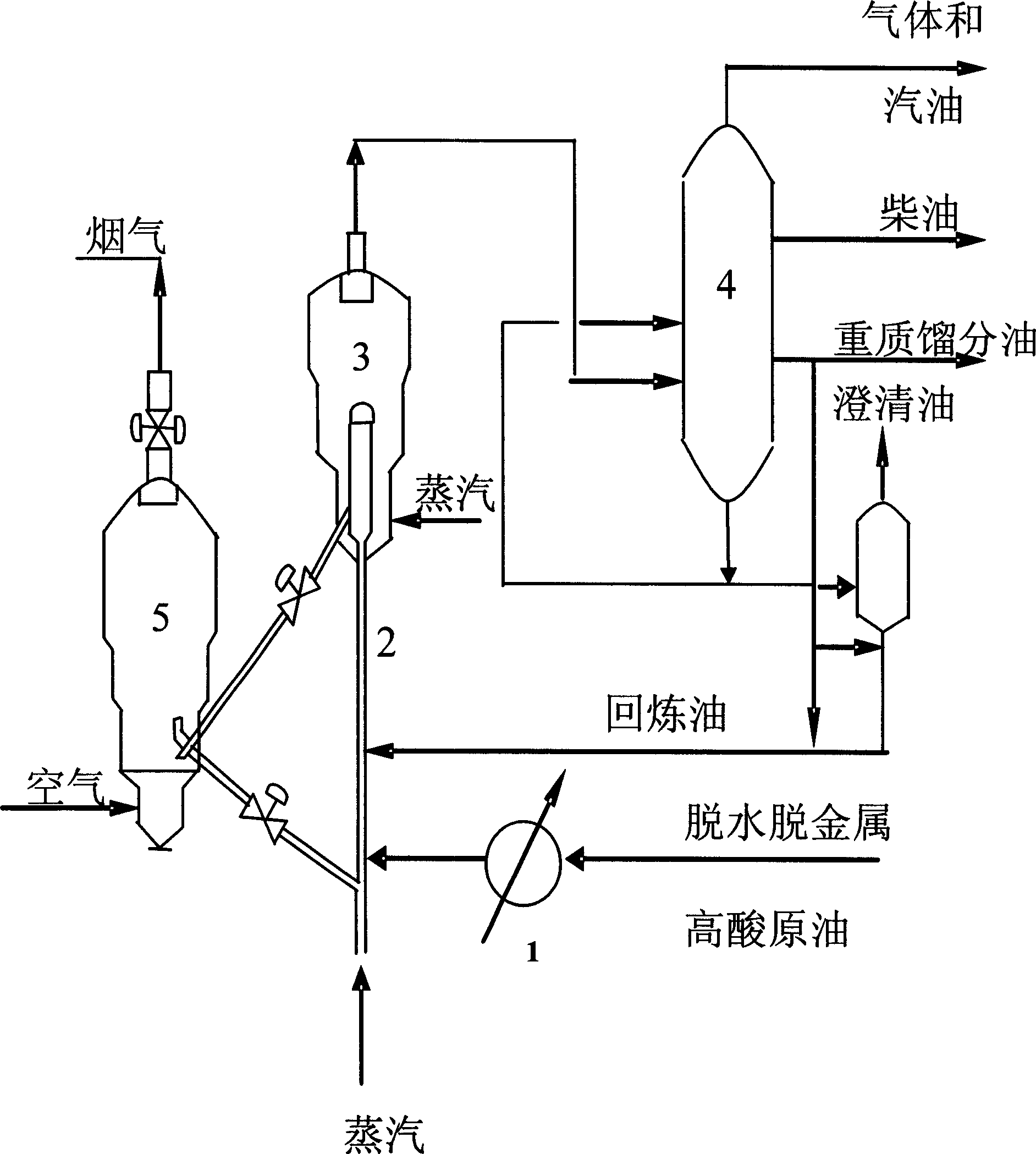

Method for processing crude oil with high acid value

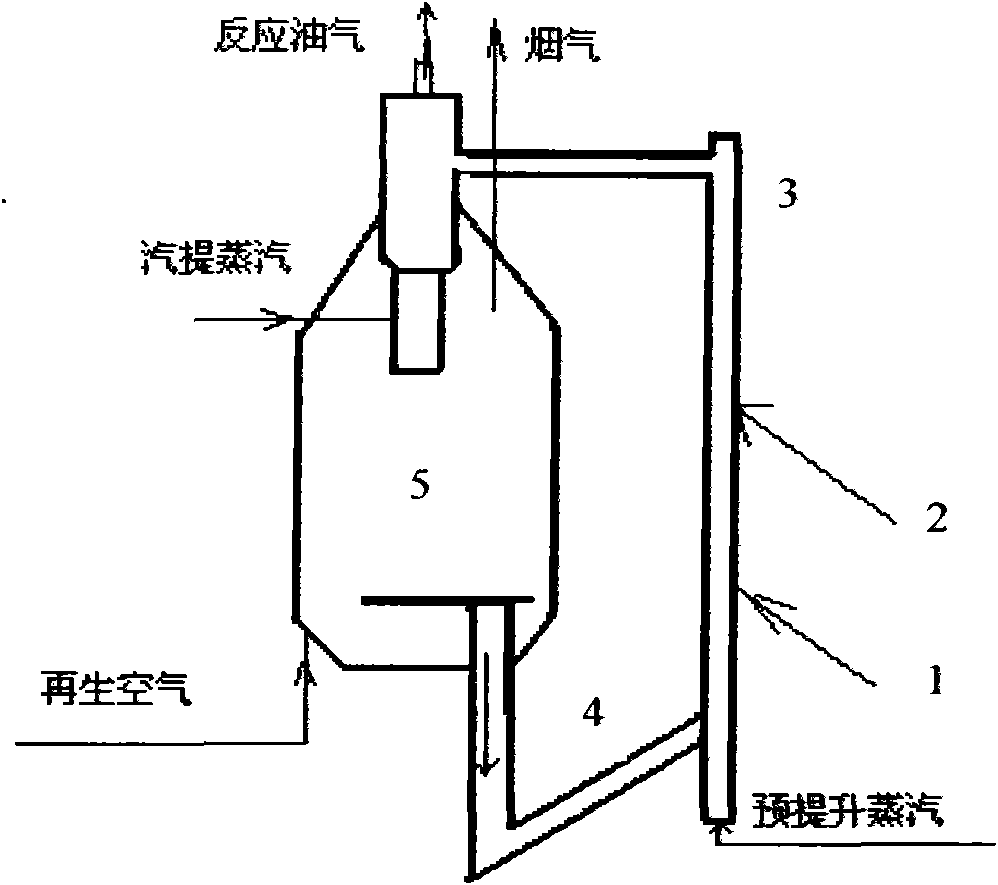

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

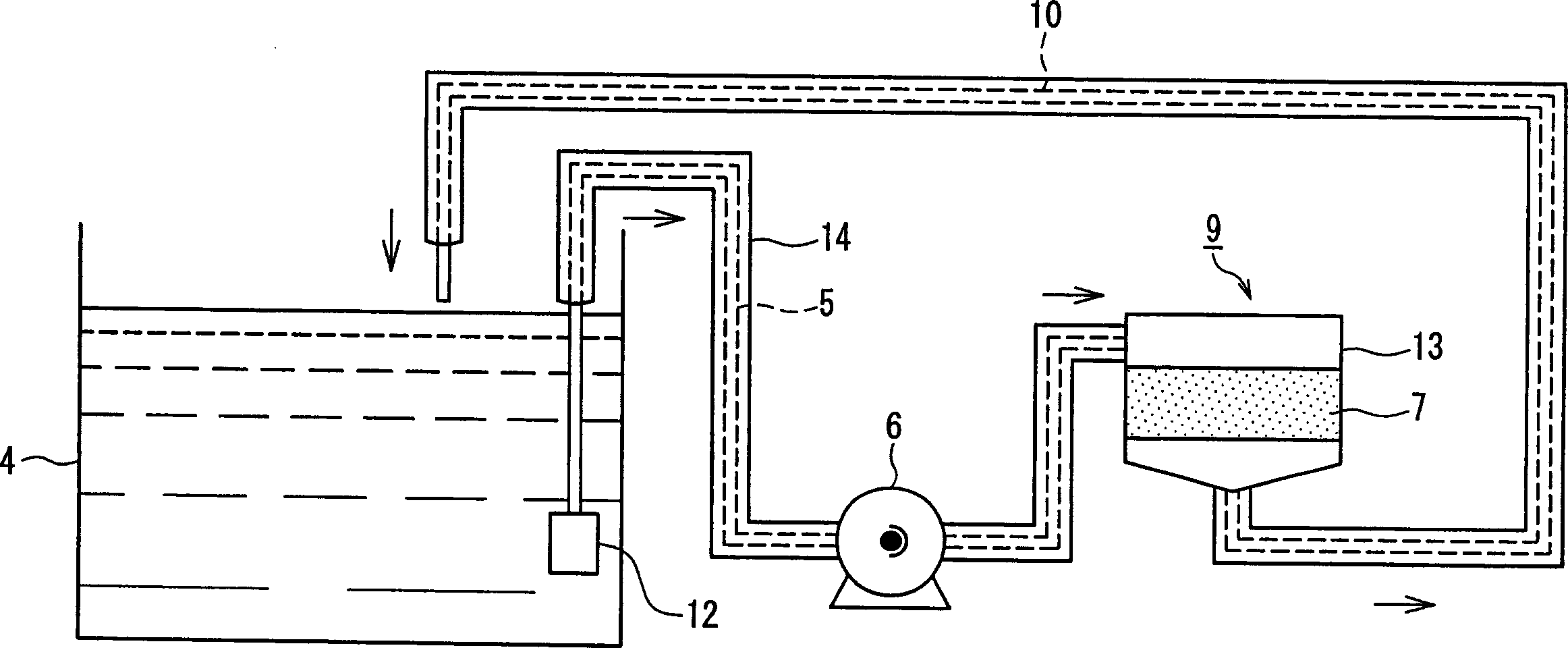

Paper deacidification agent, and paper deacidification system and method thereof

The invention belongs to the technical field of paper deacidification, and specifically relates to a paper deacidification agent, and a paper deacidification system and a paper deacidification method thereof. The paper deacidification agent comprises nanometer oxide particles, a silane coupling agent and n-perfluorooctane liquid, wherein the nanometer oxide particles are suspended in the n-perfluorooctane liquid after coated by the silane coupling agent, and the nanometer oxide particles can also be replaced by nanometer magnesium hydroxide particles. The paper deacidification system comprises a deacidification liquid storage tank, a centrifugation pump, a deacidification device and a circulation device which are in successive connection, wherein the outlet of the circulation device is respectively connected with the inlet of the deacidification liquid storage tank and the inlet of the deacidification device; a circulation loop is formed between the deacidification device and the circulation device; and the deacidification device is also connected with the deacidification liquid storage tank via a deacidification liquid recovery device. The paper deacidification method comprises the following steps: putting a literature into the deacidification device, then pumping the paper deacidification agent into the deacidification device, shaking the literature, subjecting deacidification liquid to circulation, pumping the deacidification liquid back, and carrying out condensation recovery. According to the invention, safety and effectiveness are obtained; and the paper deacidification agent has the advantages of easy recovery, good effects and low cost.

Owner:NAT LIBRARY OF CHINA

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

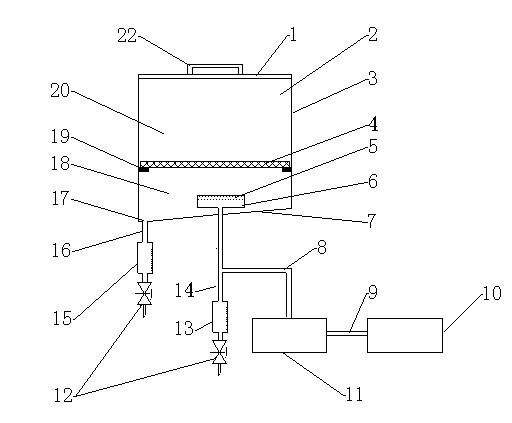

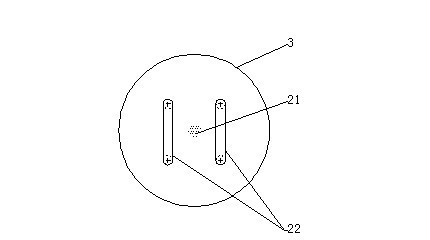

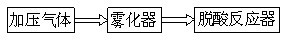

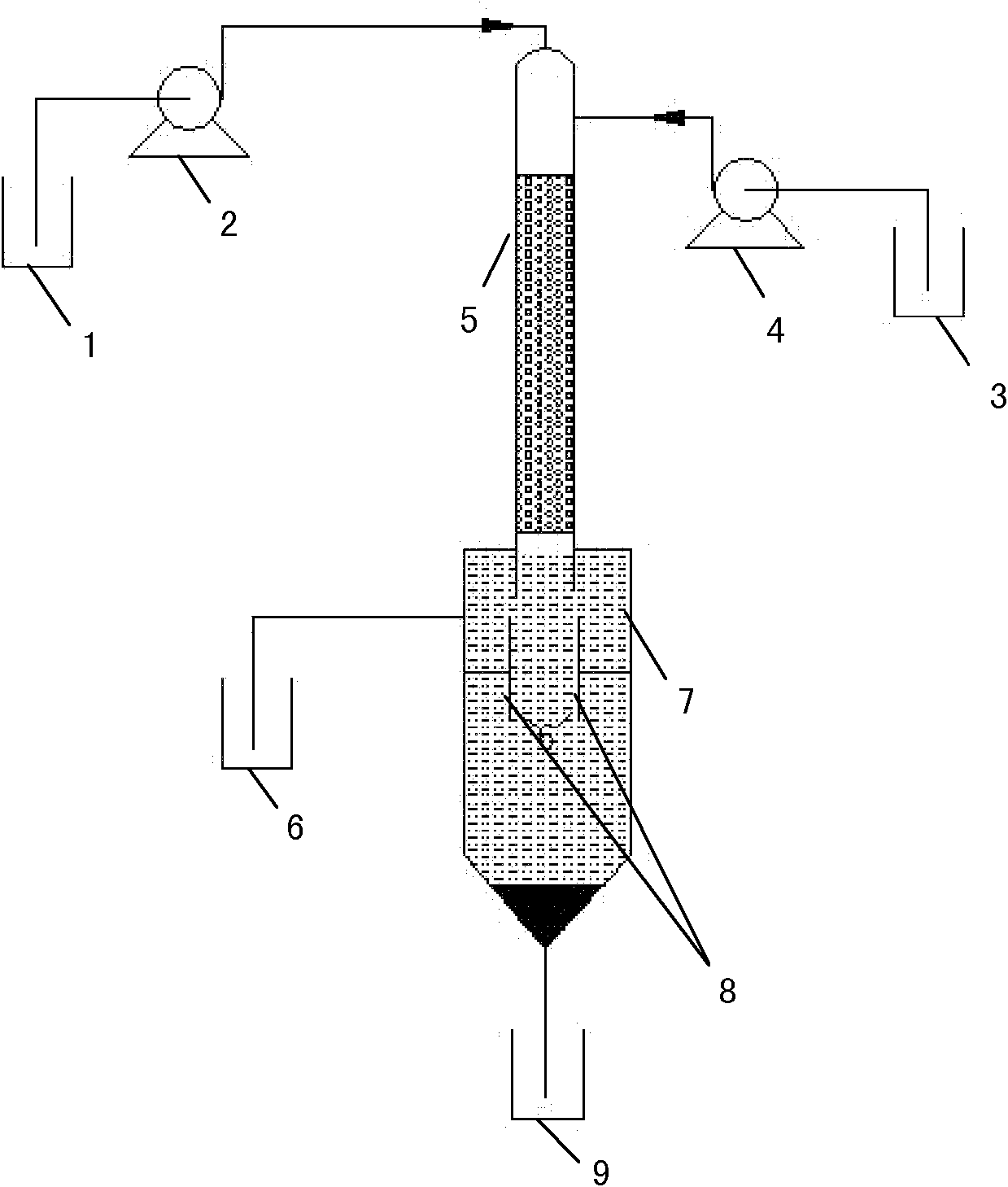

Pressurizing, atomizing and deacidifying device and method for pressurizing, atomizing and deacidifying by using same

ActiveCN102242529AShorten the timeHigh active ingredientOld paper after-treatmentPhysical chemistryAir pump

The invention discloses a pressurizing, atomizing and deacidifying device and a method for pressurizing, atomizing and deacidifying by using same. The device comprises an air pump, an atomizer, a deacidifying reactor, a liquid collector and a distributor; the device is low in manufacturing cost, convenient to use and wash and good in de-acidifying effect, and is suitable for any paper deacidifying agent solution, particularly suitable for deacidification of paper by using an organic deacidifying agent solution and a natural deacidifying agent solution; and the deacidified paper does not deform and is not sticky, ink handwriting is not affected, and the time for air-drying the deacidified paper in a shady place is short. The method comprises the steps of adding a deacidifying agent in the atomizer, introducing the atomized deacidifying agent steam into the deacidifying reactor, and deacidifying the acidified paper; and the pH value of the de-acidified paper is raised, therefore, the purpose of deacidifying is achieved. In the invention, pressurizing and atomizing technologies are used in the paper deacidification, and the operation is convenient and pollution-free.

Owner:GUANGDONG UNIV OF TECH +1

Method for removing ginkgolic acid from ginkgo leaf extract by extraction method

InactiveCN1470487ASave raw materialsSimple and fast operationOrganic compounds purification/separation/stabilisationSolid solvent extractionAlcoholOrganic solvent

The present invention discloses a method for removing ginkgolic acid from ginkgo leaf extract by orgnaic solvent extraction process, and said process mainly includes: extracting and drying. In which the refining procedure includes: adding methyl alcohol or ethyl alcohol to pulverized ginkgo leaf extract, stirring, dissolving, standing still, filtering, reduced pressure concentrating and drying; and its extracting procedure includes: stirring the pulverzed ginkgo leaf extract with ethyl alcohol or acetone, dissolving and placing said material into extract, adding paraffins material, uniformly mixing them, standing still and demixing, removing upper layer, repeatedly operating lower layer for several times, drying.

Owner:YANGTZE RIVER PHARM GRP CO LTD

Method for refining rape-seed raw oil

The invention provides a method for refining rape-seed raw oil and relates to the technical field of grain and oil processing. The method for refining the rape-seed raw oil comprises the steps of carrying out degumming, carrying out deacidifying, carrying out decoloring, carrying out deodorizing and carrying out subsequent processing. The method for refining the rape-seed raw oil, provided by the invention, the deacidifying effect of the deacidifying step is good, and the whole process effect is good.

Owner:成都市新津迎先粮油有限公司

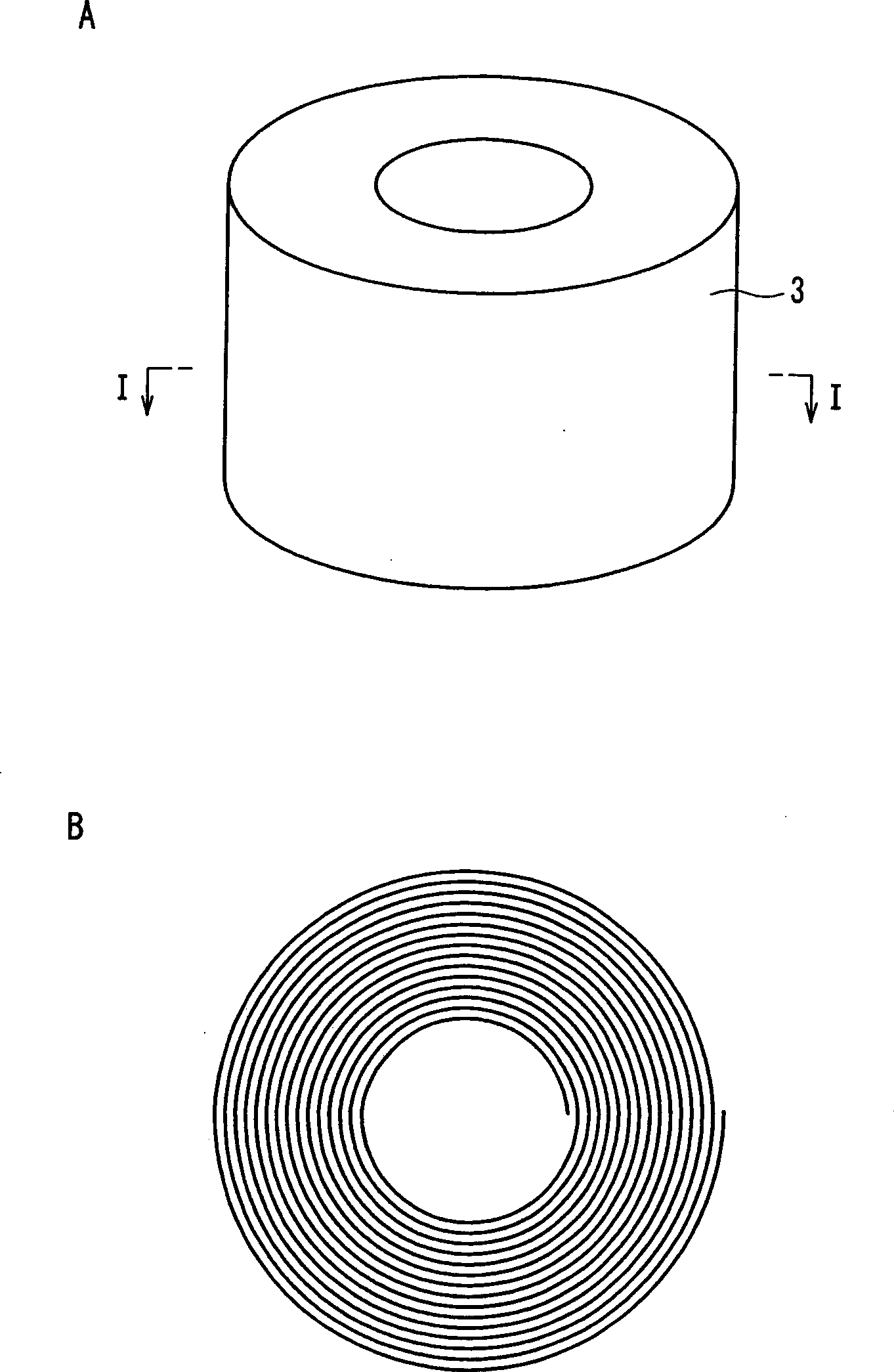

Regeneration processor of used edible oil and filter and regeneration processor using the filter

InactiveCN1891805AGood deacidification effectGood decolorization effectFatty oils/acids recovery from wasteFatty substance recoveryPotassium hydroxideSilicon oxide

The reproduction filter of the used edible oil is obtained by processing the mixture of a treating agent A (powder obtained by supporting a basic compound of such as magnesium oxide, calcium oxide, magnesium hydroxide, potassium hydroxide to silicon oxide) which can adsorb free fatty acid selectively or can convert it to a compound which is hardly melted in oil and a treatment agent B (powder of the silicon oxide, active carbon and activated clay) which can adsorb colored matter selectively to be a replenishing filter or a paper-blended rolled filter. The regeneration apparatus consists of a sucking tube for taking out the used oil in a fryer oil tub; a reproduction apparatus consisting of the reproduction processing filter and a container for housing the reproduction processing filter; aliquid-feeding pump or a suction pump; and a return tube for returning reproduced oil to the fryer oil tub.

Owner:PANASONIC CORP +1

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technical method of deacidifying vegetable fat

InactiveCN102839049AReduce contentEasy to separateFatty-oils/fats refiningUltrasonic technologyDehydration

The invention relates to a technical method of deacidifying fat, in particular to a technical method of deacidifying vegetable fat with ultrasonic waves introduced to a deacidification procedure. The technical method comprises the steps that plant crude oil is heated to a certain temperature; then aqueous alkali with a certain concentration is added to the plant crude oil; the ultrasonic waves are introduced to accelerate reaction and deacidification simultaneously; an obvious oil-soap separating state is presented; and after centrifugal separation, washing, heating, stirring, dehydration and cooling, the deacidified fat is obtained. The traditional alkali refining and deacidification technology is improved by the technical method; the ultrasonic technology is introduced to the deacidification procedure; the deacidification time is shortened, and the deacidification effect is improved effectively through the improvement; during the course of the deacidification, the oil-soap separation phase is good, and the separation interface is obvious, thereby facilitating separation; in addition, the technical method has the advantages of convenience in use, simplicity in operation, low cost, low investment and the like, and is applicable to large and medium-sized fat processing enterprises.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

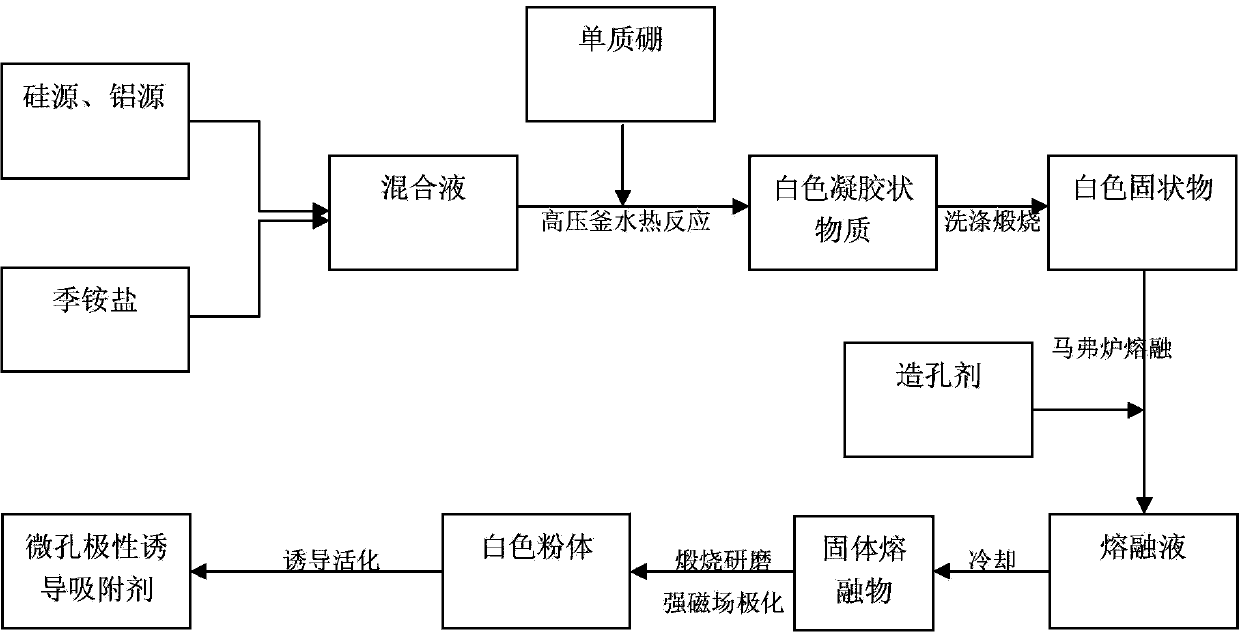

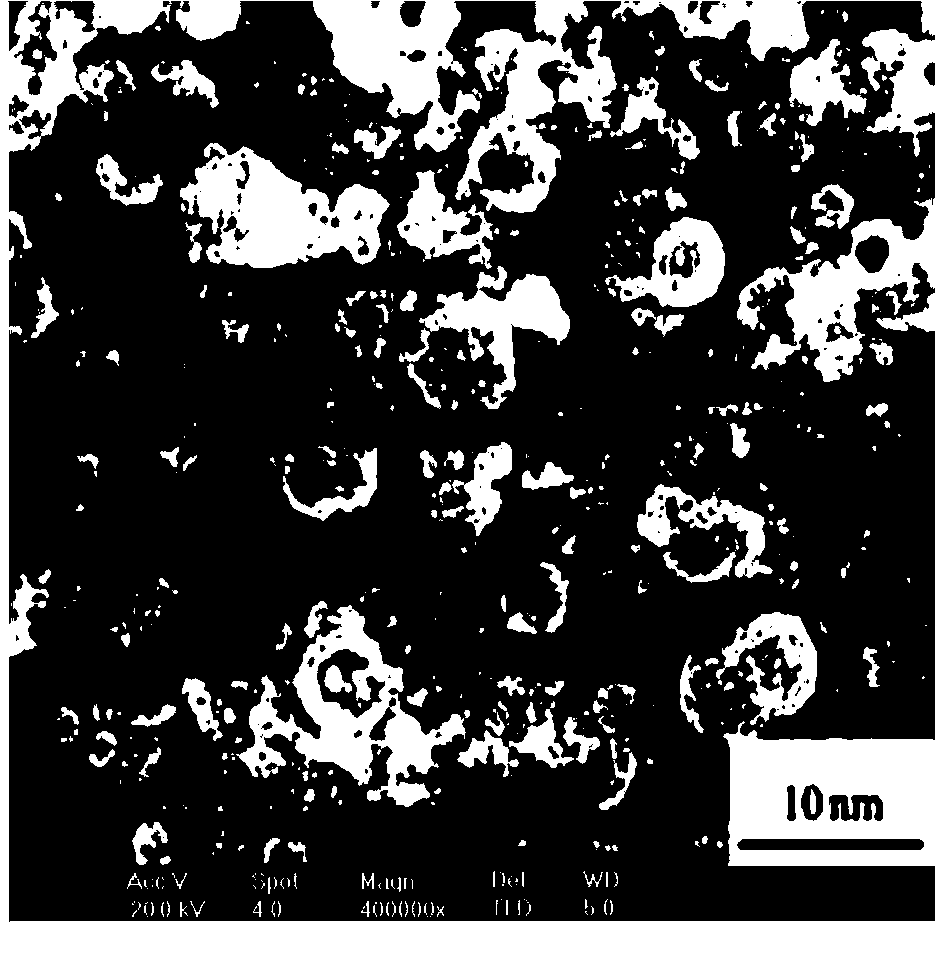

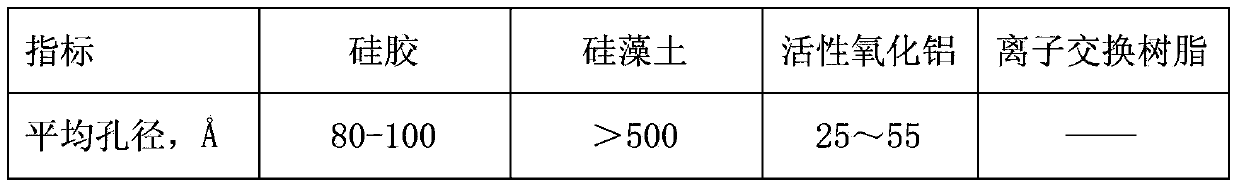

Micro-pore polarity induction absorbent for regeneration treatment on electric power oil and preparation method of micro-pore polarity induction absorbent

ActiveCN103432983AImprove molecular activityGood deacidification effectOther chemical processesHydrocarbon oils refiningChemistrySorbent

The invention discloses a micro-pore polarity induction absorbent for regeneration treatment on electric power oil and a preparation method of the micro-pore polarity induction absorbent. The absorbent comprises the following components: Si, Al and B, wherein the mole ratio of Si to Al to B is (5-14):(8-20):1; the molecule aperture of the absorbent is 8 Angstrom-10 Angstrom; the specific surface area of the molecular aperture of the absorbent is 530m<2> / g to 650m<2> / g; and the absorbent has a micropore molecular structure. The preparation method comprises the following steps: dissolving quaternary ammonium salt into distilled water or an ethanol solution according to a ratio, adding a silicon source and an aluminum source according to a ratio, stirring in water bath, further adding elementary-substance boron, moving the solution into a high-pressure reaction kettle, carrying out hydrothermal reaction so as to obtain a white gel substance, washing the white gel substance and subsequently calcining, heating and melting the obtained white solid substance, adding a pore-making agent, after the molten liquid is cooled to be the room temperature, calcining and putting into a strong-magnetic field environment to be polarized, and finally carrying out induction and activation so as to obtain the absorbent. The absorbent has a micropore aperture and is large in specific surface area and high in molecular polarity and activity, and the absorption capacity and the absorption velocity on polar molecular compounds of degraded oil are greatly improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Paper deacidification agent and using method thereof

ActiveCN103321100AEasy to useGood deacidification effectOld paper after-treatmentChemistryAqueous solution

The invention discloses a paper deacidification agent and a using method thereof. The paper deacidification agent is prepared by dissolving 4-8g of tris (hydroxymethyl) aminomethane in each liter of ethanol water solution with the volume fraction of 50-98 percent. The using method comprises the following steps: directly contacting paper and the paper deacidification agent for 0.3-2 hours for deacidification at the temperature of 25 to 60 DEG C, wherein the amount of the paper deacidification agent is 1-10 times that of the mass of the paper; and drying the deacidified paper, and finishing the deacidification process. The provided paper deacidification agent is mild in nature, the paper structure is prevented from being damaged, the chroma of the paper does not have obvious change after deacidification treatment, and the paper is preserved for a long time.

Owner:GUANGDONG UNIV OF TECH

Application of PMS (potassium methyl silicate) water solution in deacidification and reinforcement of paper

InactiveCN104032623ALittle change in appearanceGood deacidification effectOld paper after-treatmentCelluloseFiber

The invention discloses application of a PMS (potassium methyl silicate) water solution to deacidification and reinforcement of paper. According to the application, a deacidification and reinforcement method comprises the following steps: soaking the paper in a deacidification agent; treating, hanging and airing to complete the deacidification and the reinforcement, wherein the deacidification agent is any one of the PMS water solution and an alcohol water mixing solution. The paper is treated by using a PMS paper deacidification agent, so that the deacidification effect is obvious, and the mechanical property of the paper is well improved. By improving different solvent ratios and concentration ratios, the acid property and the mechanical property of the paper are improved to different extents. Meanwhile, the paper is obvious in hydrophobic performance. According to the characteristics, the water absorption of paper cellulose can be reduced, so that the damage to swelling, degradation and hydrogen-bonding of fibers caused by water is alleviated. The microbiological corrosion degree of the paper is greatly reduced.

Owner:RENMIN UNIVERSITY OF CHINA

Method for processing highly acidic crude oil

ActiveCN101580732ALess corrosiveLow cracking reaction depthCatalytic crackingPre treatmentHigh activity

The invention relates to a method for processing highly acidic crude oil, in particular to a method for removing petroleum acid in the highly acidic crude oil by utilizing a fluidized catalytic cracking technology. The method adopts a lifting pipe two-stage feeding technology and comprises the following steps: pretreating and preheating the highly acidic crude oil to be injected in the middle of the lifting pipe as the second-stage feeding of the catalytic cracking lifting pipe; enabling the second-stage feeding to mix and contact with reaction products from an upstream first stage and a catalyst parched with partial coke; and achieving the aim of deacidifying the mixture by a catalytic reaction, a cracking reaction and a decarboxylation reaction so as to avoid the corrosion of sequent processing equipment and accord with the acidity requirement of the product. Compared with a CN1827744A method, the highly acidic crude oil enters a second stage of the lifting pipe and contacts with thepartial parched catalyst from the first stage to have a slow cracking reaction so as to benefit the generation of medium distillate oil and avoid generating a great amount of dry gas and coke causedby an intense reaction generated by the contact of the highly acidic crude oil and the high-temperature high-activity catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

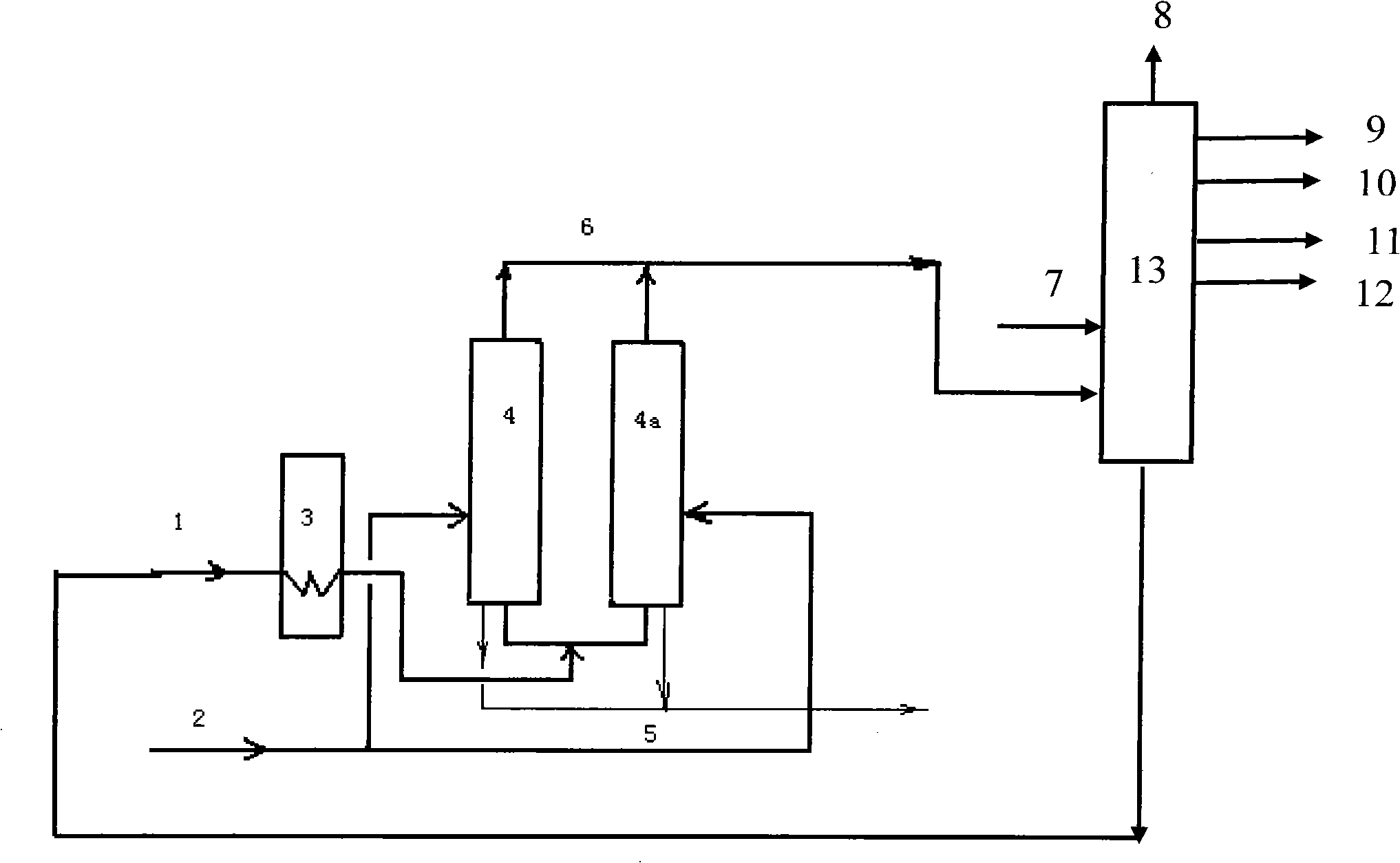

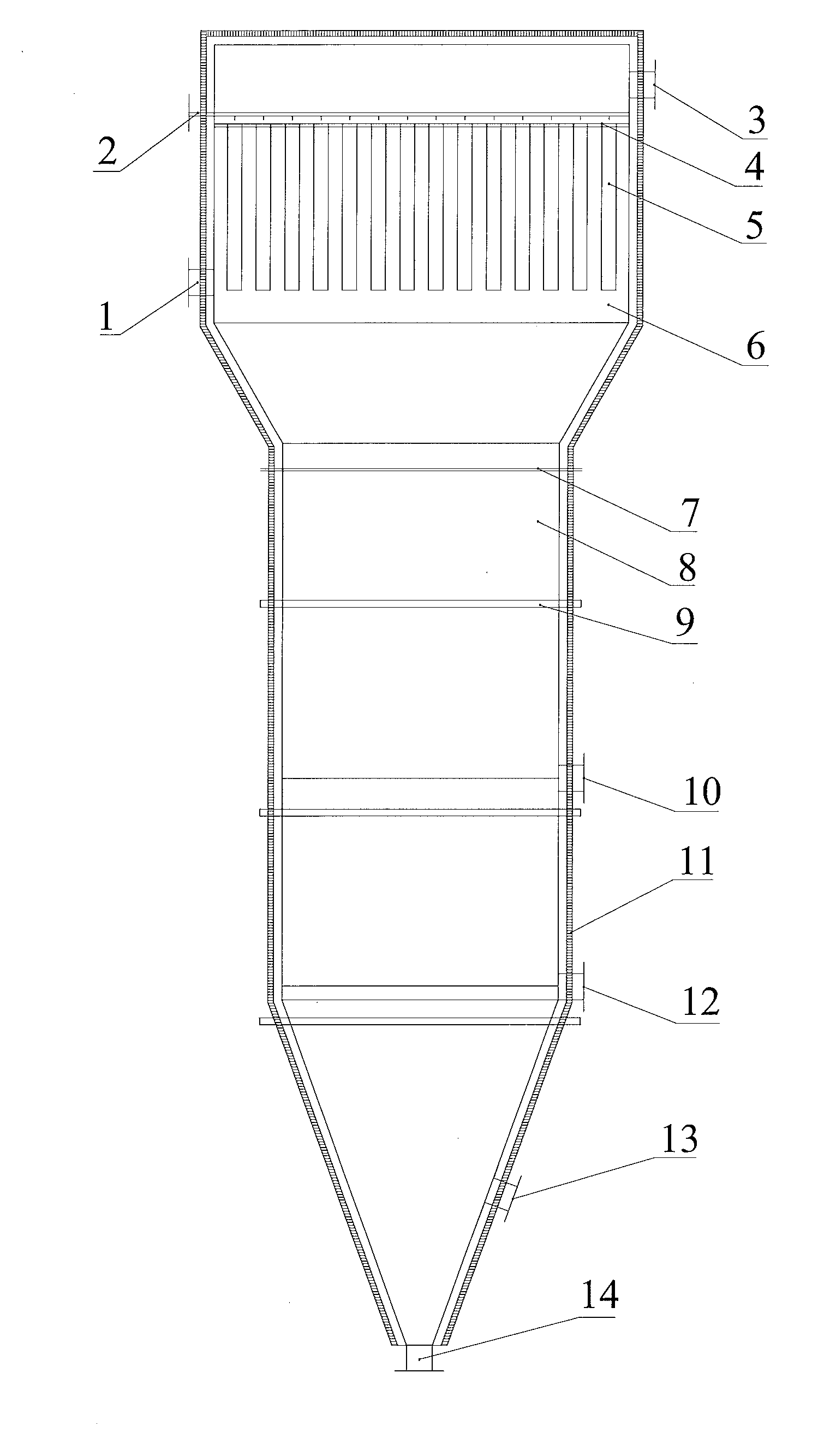

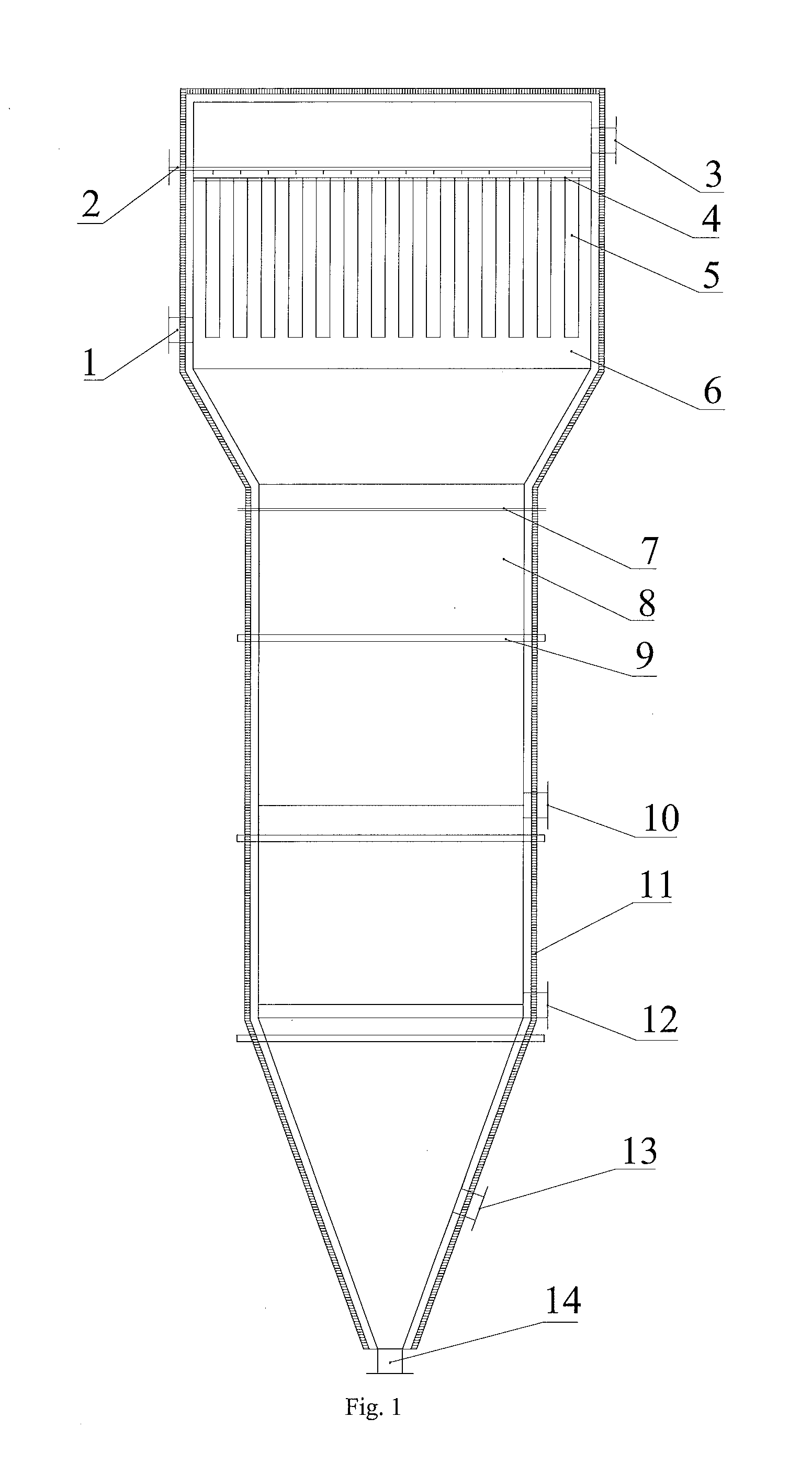

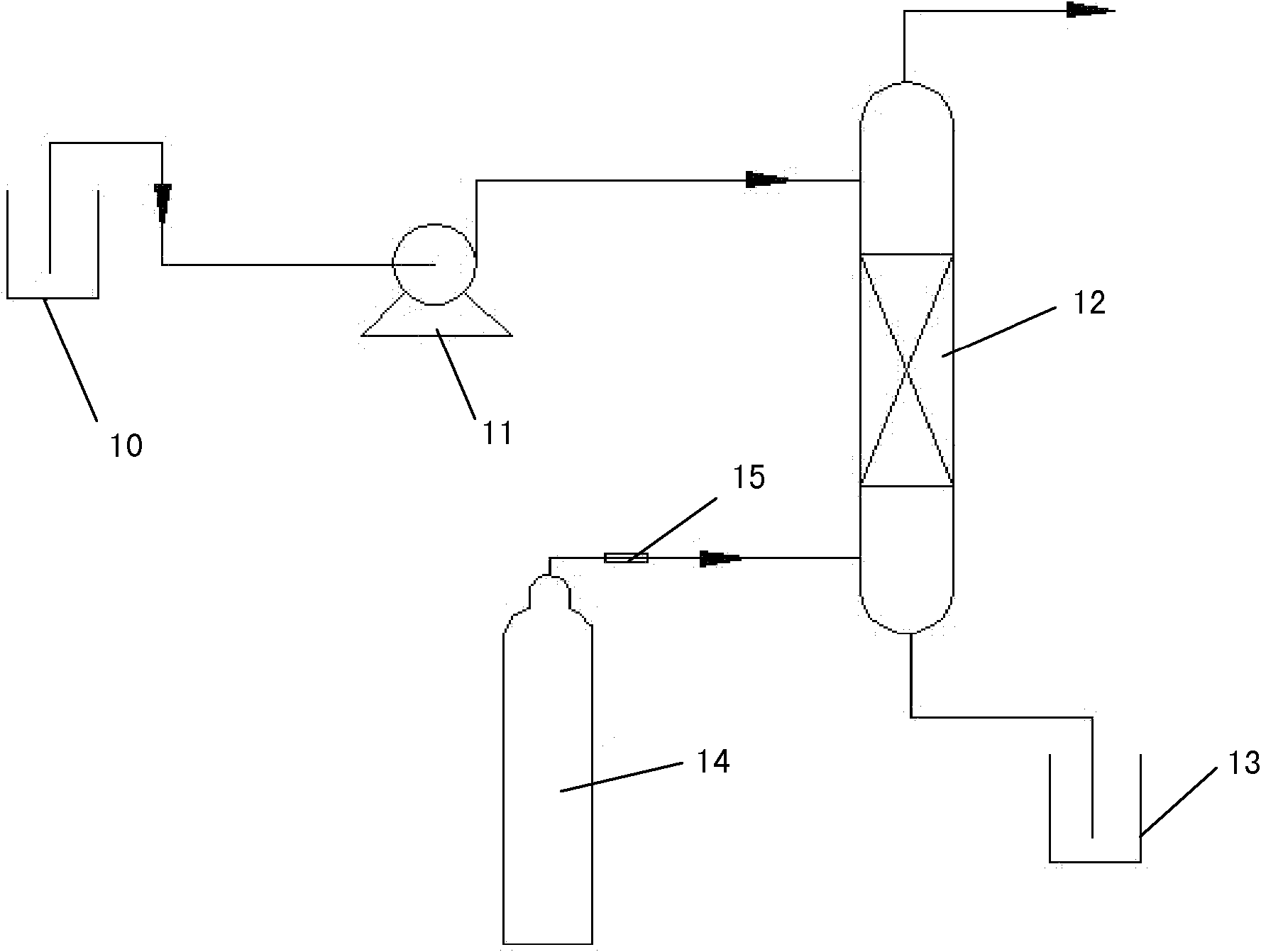

Deacidification process and apparatus thereof

ActiveUS20150044128A1Improve the immunityLarge fluctuationsGas treatmentSilicaProcess engineeringAtmosphere

A deacidification apparatus and a deacidification process using the apparatus are disclosed. The deacidification apparatus includes a deacidification furnace, of which a furnace upper section, a furnace middle section and a furnace lower section are provided in upper, middle and lower portions respectively, wherein a gas-solid mixture inlet (1), a exhaust outlet (3) and a filtered air port (2) are provided on the furnace upper section, a product outlet (13) is provided on the furnace lower section, the upper portion of the deacidification is mounted with a filter (5) to which the gas-solid mixture inlet (1), the exhaust outlet (2) and the filtered air port (3) are connected, the filtered air port (2) is connected with a gas pulse device and a vacuum device by a three-way connecting device, and the exhaust outlet (3) is connected with atmosphere or connected with the vacuum device.

Owner:GUANGZHOU GBS HIGH TECH & IND

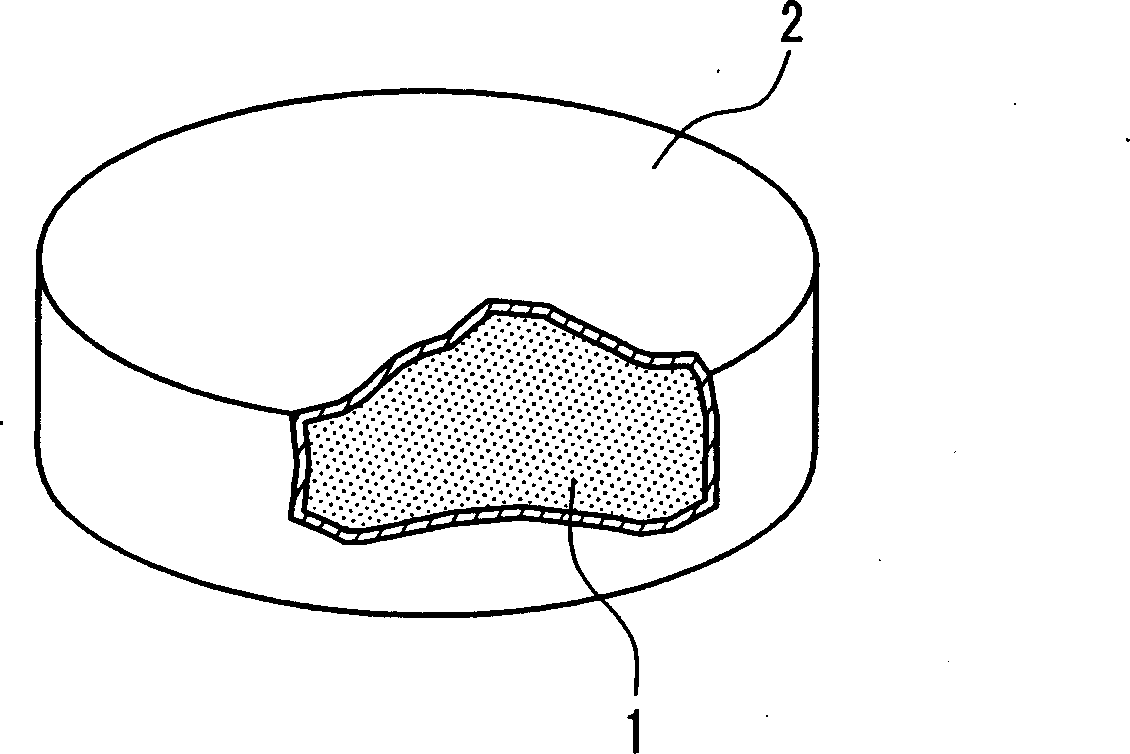

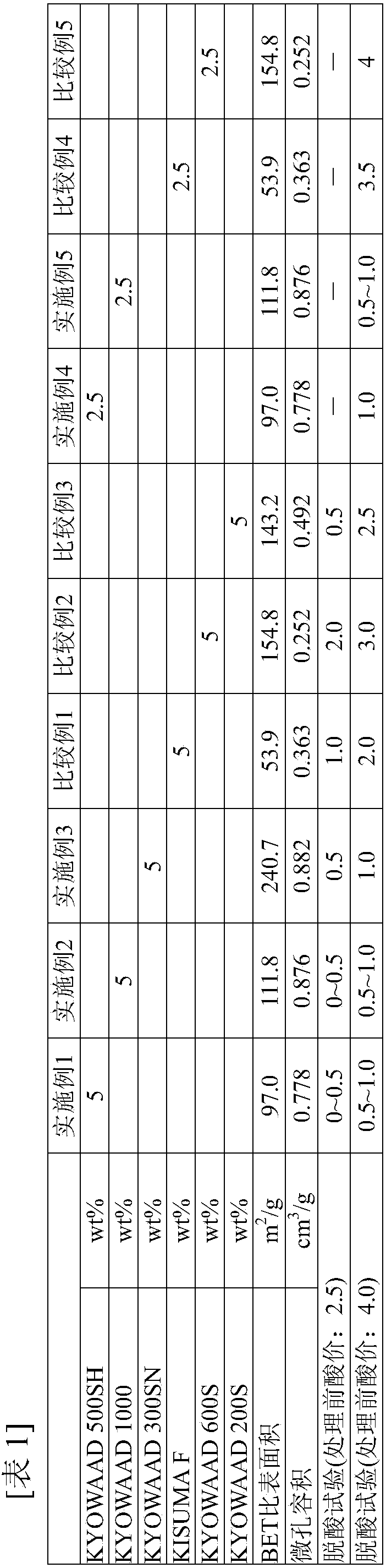

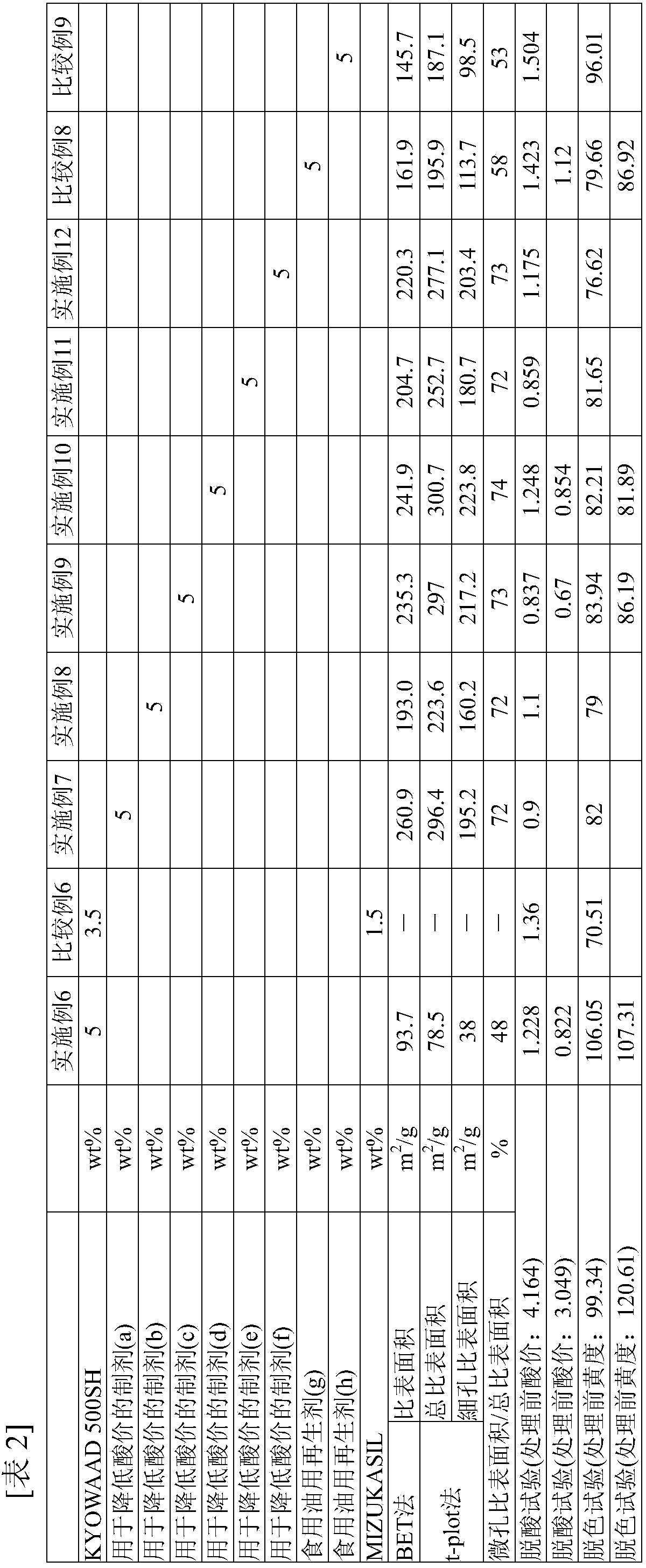

Deoxidizing agent for edible oils, and method for regeneration of used edible oil using same

InactiveCN102959067AGood deacidification effectFatty oils/acids recovery from wasteMagnesium carbonatesEdible oilCarbonate

The purpose of the present invention is to provide: a deoxidizing agent for edible oils, which has excellent deoxidizing capability; and a method for regenerating a used edible oil using the deoxidizing agent. The present invention relates to a deoxidizing agent for edible oils, which comprises particles of magnesium hydroxide containing a carbonate group or a burned product of the particles, wherein the magnesium hydroxide containing a carbonate group is represented by formula (1) and each of the particles has a specific surface area of 80-400 m2 / g as measured by a BET method. Mg(OH)2-x(CO3)0.5xmH2O (1) In the formula, x and m fulfill the following requirements: 0.02 <= x <= 0.7; and 0 <= m <= 1.

Owner:KYOWA CHEM IND

Method for preparing gingko extract with low acid number by ultrasonic extraction

InactiveCN102091103AShorten the production cycleSimple and fast operationNervous disorderMetabolism disorderGinkgo bilobaHigh pressure

The invention relates to a method for preparing a gingko extract with a low acid number by ultrasonic extraction, comprising the following processing steps: (1) baking ginkgo leaves, crushing to obtain ginkgo leaf powder; (2) mixing the ginkgo leaf powder with an ethanol solution, performing ultrasonic extraction to obtain an extracted solution; (3) concentrating the extracted solution by pressure reduction to obtain a concentrated solution; adding a precipitant to the concentrated solution, regulating the pH value of the concentrated solution to 5-10; filtering by suction or centrifuging to obtain a clear solution; (4) enriching the clear solution by macroporous resin columns so that the gingko extract component in the clear solution are enriched on the resin; eluting the macroporous resin columns with an eluent; collecting the solution passing through the columns, namely the liquid eluted by the eluent; and (5) concentrating the solution passing through the columns by pressure reduction, then drying by high-pressure spray to obtain the gingko extract. The method provided by the invention is simple and convenient in operation and has a short production cycle, low production cost and good deacidification effect.

Owner:江苏九久环境科技有限公司

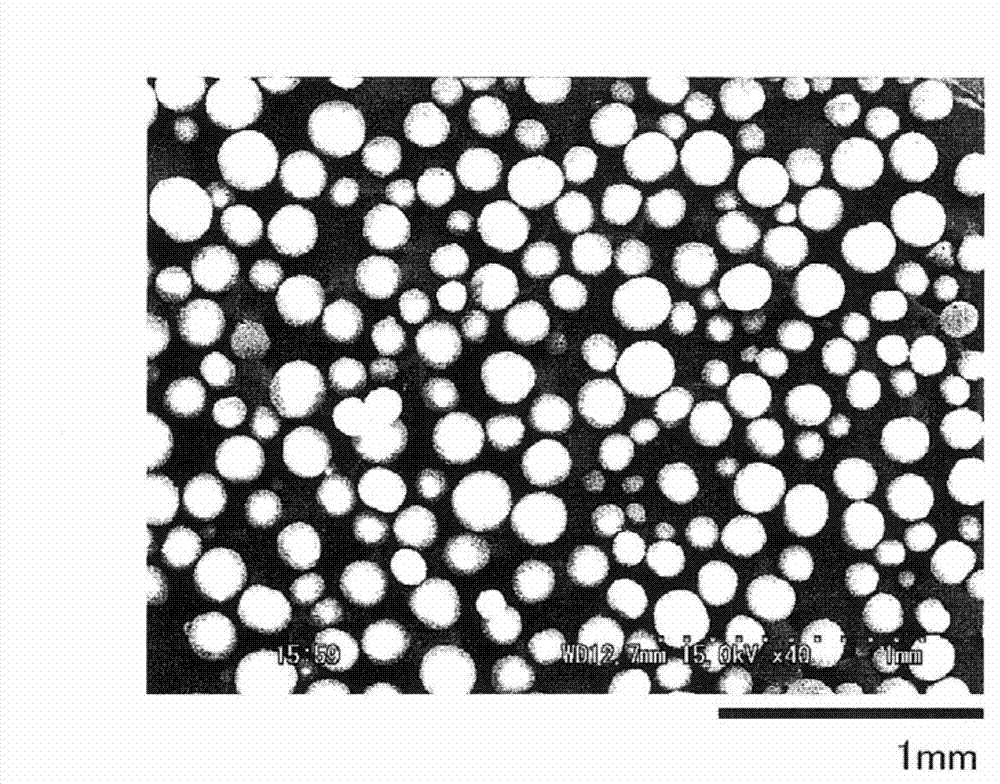

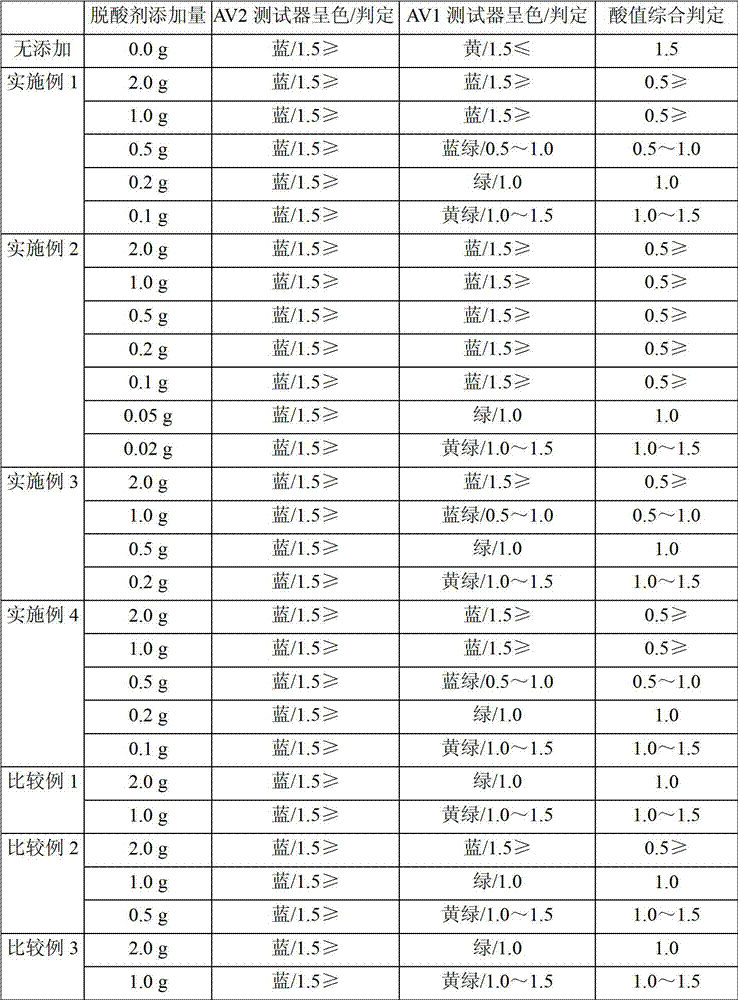

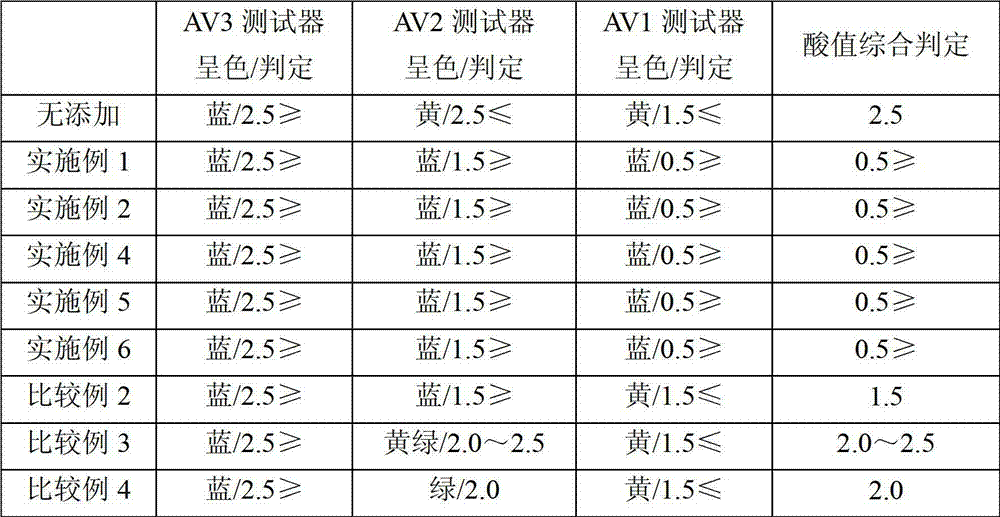

Agent for reducing acid value of used cooking oil and method for regenerating used cooking oil using same

InactiveUS20190055492A1Good deacidification effectHigher deacidification effect and decoloration effectFatty oils/acids recovery from wasteFatty-oils/fats refiningAcid valueCooking oil

An agent for reduction of the acid value of used cooking oil that exerts the effects required for a regeneration agent for used cooking oil, and a regeneration treatment method for used cooking oil using it are provided. The agent is an agent for reduction of the acid value of used cooking oil containing a hydrotalcite-related compound as an effective component, wherein the agent has a decoloration capacity that reduces the acid value by 70% or more. The agent also has a deacidification capacity that reduces yellowness due to deterioration by 15%. The hydrotalcite-related compound is a hydrotalcite-related compound calcined at 150 to 400° C. The hydrotalcite-related compound is a hydrotalcite-related compound granulated to have an average particle size of 50 to 200 μm.

Owner:KYOWA CHEM IND

Preparation method of concentrated clarified pineapple juice

ActiveCN105249088ASolve the problem prone to precipitationIncrease the juice yieldFood thermal treatmentFood membrane processColor changesPINEAPPLE JUICE

The invention discloses a preparation method of concentrated clarified pineapple juice. The preparation method comprises the following steps: crushing and pulping washed and peeled pineapples; heating and gelatinizing pineapple pulp; carrying out enzymolysis and enzyme deactivation, and squeezing to obtain juice and filtering to obtain pineapple juice; clarifying the pineapple juice, and centrifuging to obtain separated liquid; carrying out de-coloring and de-acidifying treatment on the separated liquid to obtain clarified pineapple juice; concentrating the clarified pineapple juice in vacuum and at a low temperature; and sterilely filling to prepare the concentrated clarified pineapple juice. With the adoption of the preparation method of the concentrated clarified pineapple juice, provided by the invention, the squeezing rate of the pineapples is further improved through a compound enzymolysis optimization technology, so that the common level in the industry is improved to be more than or more than 80% from 70% and is improved by 14.3%; an optimal multi-section resin de-coloring and de-acidifying technology is utilized so that the de-acidifying effect of pineapple pulp reaches 92.18%, the color changing index is reduced by 75.86% and the light transmittance reaches 98.36%; and the de-acidifying effect and the light transmittance are effectively improved and the color changing index is remarkably reduced.

Owner:INST OF PROCESSING & DESIGN OF AROPROD OF HAINAN ACADEMY OF AGRI SCI

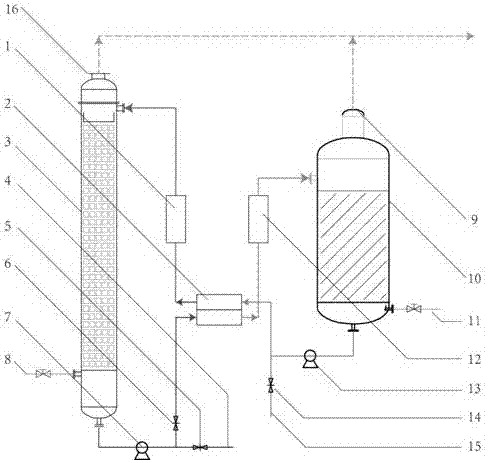

Method and device for physically deacidifying and deodorizing grease with high acid value and thermal instability

PendingCN106854492ASuitable for small batch refiningCost controlFatty-oils/fats refiningThermal instabilityAcid value

The invention discloses a method and device for physically deacidifying and deodorizing grease with high acid value and thermal instability. A deacidifying process of the grease is separated from a deodorizing process of the grease; deacidifying is realized by adopting higher temperature and shorter time; deodorizing is realized by adopting lower temperature and longer time; the deacidifying process and the deodorizing process are alternately carried out by adopting an nternal circulation mode until an acid value of the grease meets standards. A heater connected with a cold oil outlet of a heat exchanger is arranged on a feeding pipeline of a deacidifying tower of the device; a discharging pipeline of the deacidifying tower is connected with a hot oil inlet of the heat exchanger through a circulating valve; a heat dissipator connected with a hot oil outlet of the heat exchanger is arranged on a feeding pipeline of a deodorizing tank; a discharging pipeline of the deodorizing tank is connected with a cold oil inlet of the heat exchanger. According to the method and the device, disclosed by the invention, the content of isomerized fatty acid of the thermally-instable grease can be controlled to be less than or equal to 0.3g / 100g or below. The method and the device have the advantages of good refining effect, low energy consumption and production cost and capability of realizing small-batch production; the method and the device are particularly suitable for physically refining small-variety grease with the high acid value and the thermal instability.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

Agent for reducing acid value of used cooking oil and method for regenerating used cooking oil using same

InactiveCN108473912AGood deacidification effectGood decolorization effectFatty oils/acids recovery from wasteFatty-oils/fats refiningAcid valueHydrotalcite

Problem: To provide an agent which is for reducing the acid value of used cooking oil, which has the required effect as an agent for regenerating used cooking oil, and a method for regenerating used cooking oil using the agent. Solution: The agent for reducing the acid value of used cooking oil contains, as an active ingredient, a hydrotalcite compound, and has a deacidification capability to reduce the acid value by 70% or more. Furthermore, the agent has a deacidification capability to reduce yellowness caused by degradation by 15%. The hydrotalcite compound has been subjected to a sinteringtreatment at 150-400 DEG C. The hydrotalcite compound is in the form of particles having an average particle size of 50-200 [mu]m.

Owner:KYOWA CHEM IND

Oil Molecular Distiller

InactiveCN102295991AReduce the cost of building a factoryOil temperature dropFatty-oils/fats refiningOil and greaseDistillation

The invention discloses an oil molecular distiller, which belongs to an oil physical refining deacidification equipment. It solves the defects of the traditional oil physical refining deacidification method in the prior art, such as high cost, inconvenient equipment installation, unsatisfactory deacidification effect and waste of energy. It mainly includes an oil chamber and a heat transfer oil chamber. The oil chamber is provided with a chamber A and a chamber B. The crude oil inlet is located at the upper part of the chamber A, and the finished oil outlet is located at the lower part of the chamber B. The heat transfer oil chamber is provided with There are heat transfer oil inlet and heat transfer oil outlet. The invention is mainly used in the oil physical refining deacidification process.

Owner:连云港通元机械有限公司

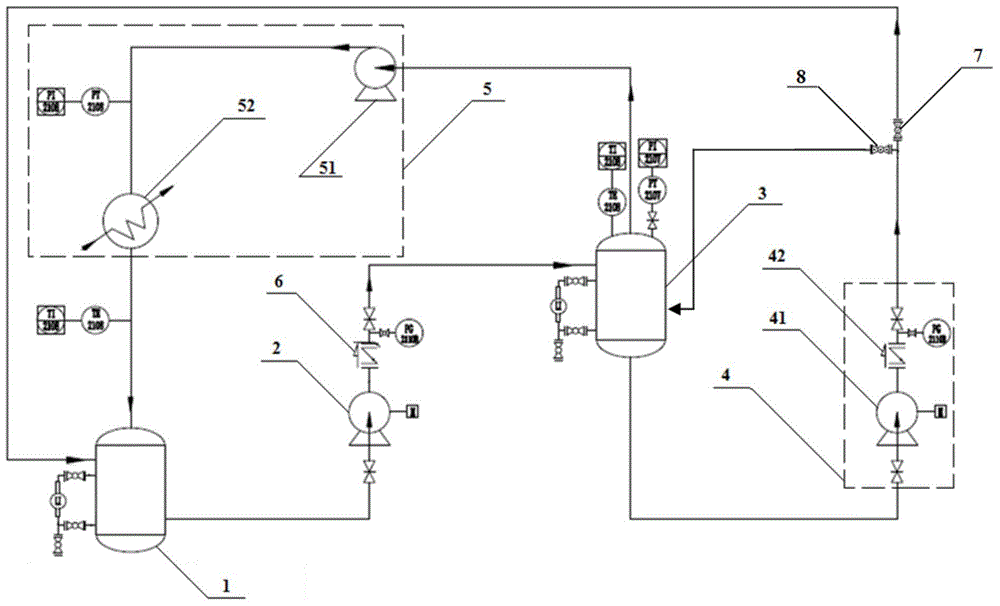

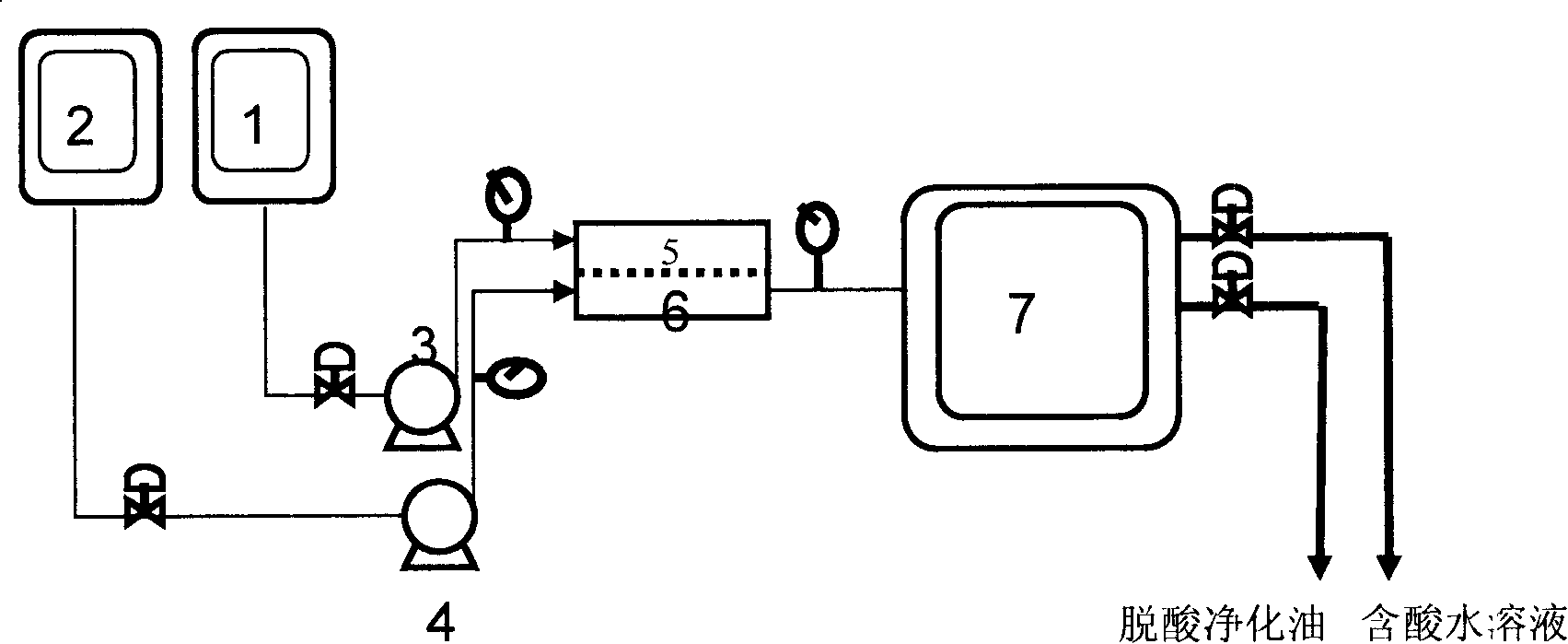

Crude oil deacidification apparatus and method

InactiveCN102925208AGood deacidification effectGood emulsificationTreatment with plural serial refining stagesHydrocarbon oils refiningChemical reactorTower

The present invention provides a crude oil deacidification apparatus, which comprises: a deacidification agent tank for accommodating a deacidification agent and a crude oil tank for accommodating crude oil requiring a treatment; an after-deacidification crude oil tank for accommodating the deacidified crude oil and an alkali residue tank for accommodating alkali residue; a deacidification agent transmission pump connected with the deacidification agent tank and a crude oil transmission pump connected with the crude oil tank; a filler tower, wherein a filler is arranged inside the filler tower, and a deacidification agent and crude oil are respectively conveyed to the filler tower through the deacidification agent transmission pump and the crude oil transmission pump, and are subjected to a reaction in the filler tower; and a sedimentation separation device, wherein the sedimentation separation device is connected with the filler tower and receives a deacidification agent and crude oil mixed liquid from the filler tower after the reaction. The present invention further provides a crude oil deacidification method. According to the present invention, the filler tower is adopted as a chemical reactor in the crude oil deacidification apparatus, such that the crude oil and the deacidification agent can be subjected to a complete reaction so as to achieve a good deacidification effect; and with the filler tower, emulsification phenomenon can be significantly improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for removing petroleum acid in hydrocarbon oil by using membrane dispersion extractor

InactiveCN101200653ASmall amount of lye entrainmentLow lye entrainmentRefining by dialysisSolventChemistry

The present invention relates to a method of removing petroleum acid from hydrocarbon oil by a membrane dispersion extraction device. A continuous phase of the hydrocarbon oil is heated up to 10 DEG C to 150 DEG C; deacidification solvent dispersed phase is heated up to 10 DEG C to 90 DEG C; the cubage ratio of the continuous phase and the dispersed phase is 50 to 2 ®U 1; the pressure difference of the dispersed phase and the continuous phase is 0.05MPa to 0.4MPa; the flow velocity of the dispersed phase deacidification solvent is 0.5 to 5L / <2> per hour; membrane aperture is 0.01 to 60 microns; the dispersed phase deacidification solvent is dispersed into continuous phase oil through membrane micropores; clean oil after the deacidification is obtained after sedimentation and separation. The deacidification solvent is 1 percent to 15 percent of ammonia, 20 percent to 70 percent of alcohol or 0.02 percent to 5 percent of petroleum acid or 0.004 percent to 1 percent of demulsifier and the water with the rest quantity. The contacting time of the oil and the solvent is short; mass transfer efficiency is high; the disposal capability is large; the extraction course is not emulsified easily; the hydrocarbon oil contains little alkali liquid; the device operation is convenient.

Owner:PETROCHINA CO LTD +1

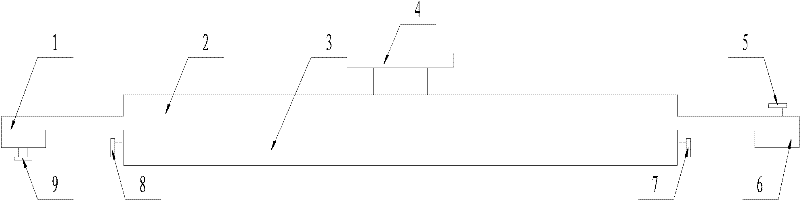

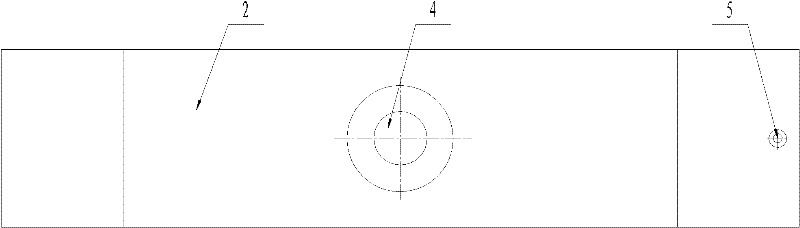

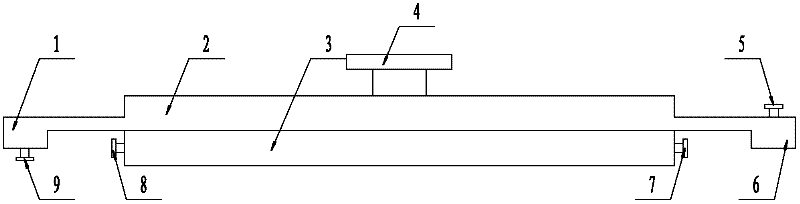

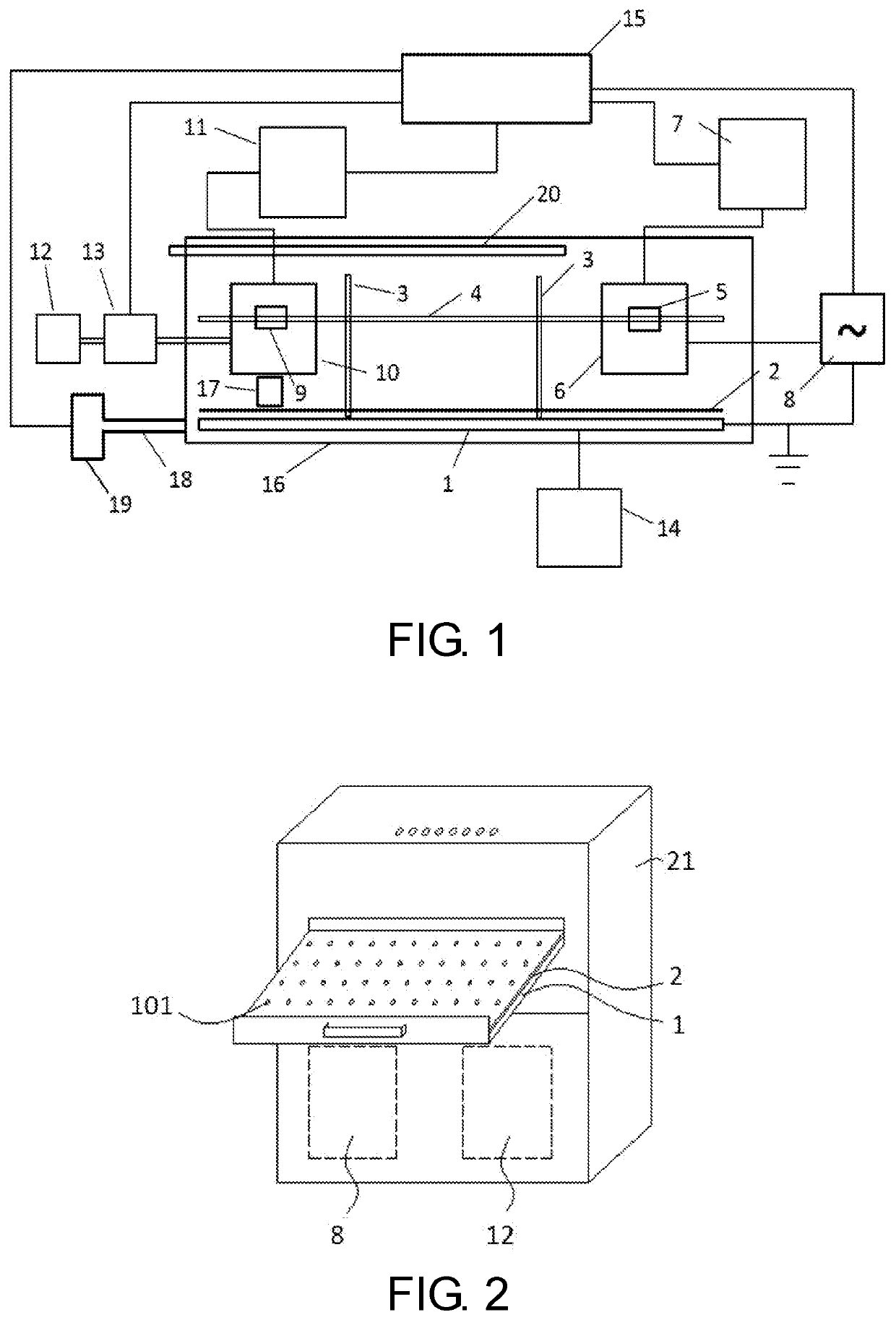

Method and device for protecting paper sheet

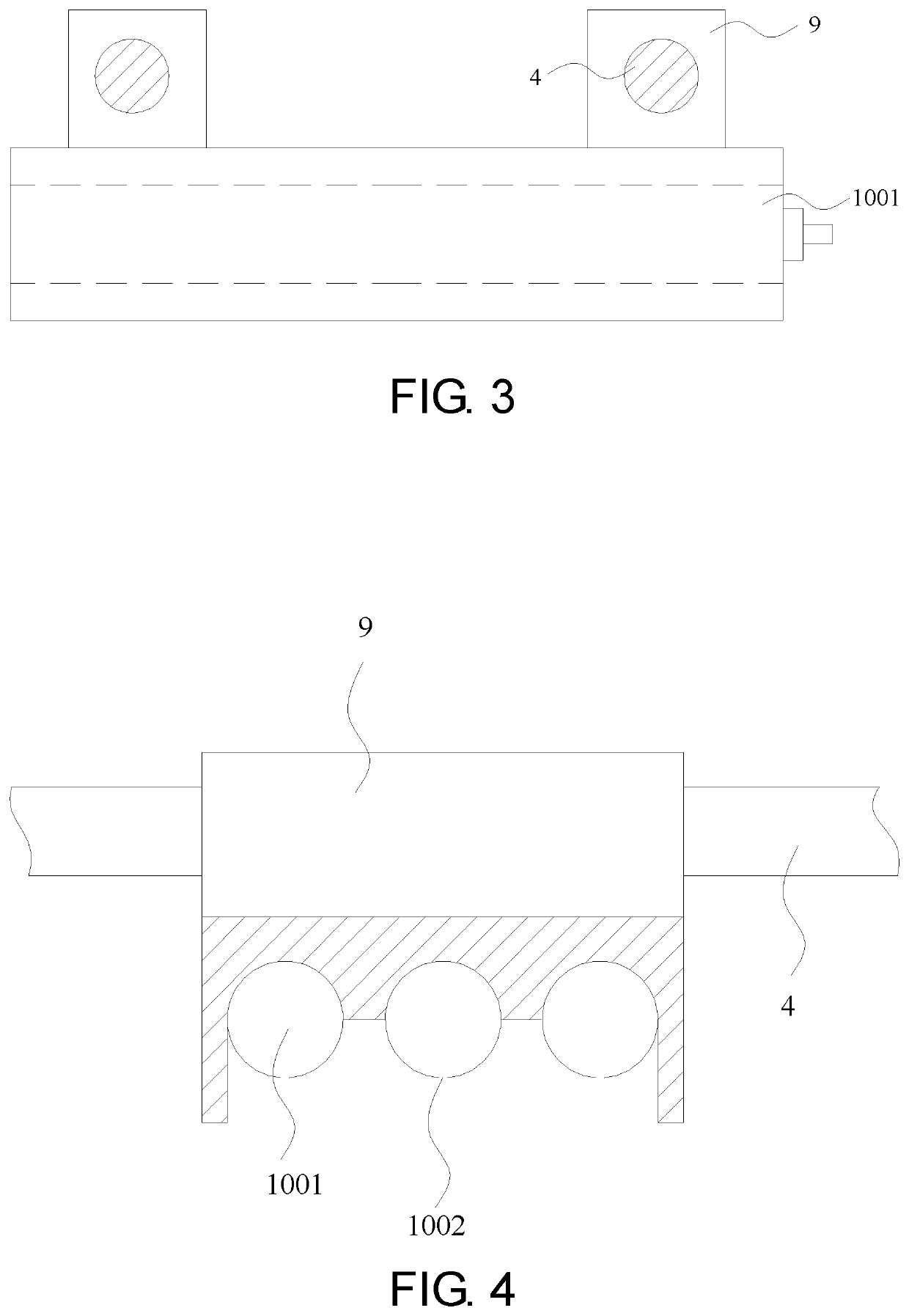

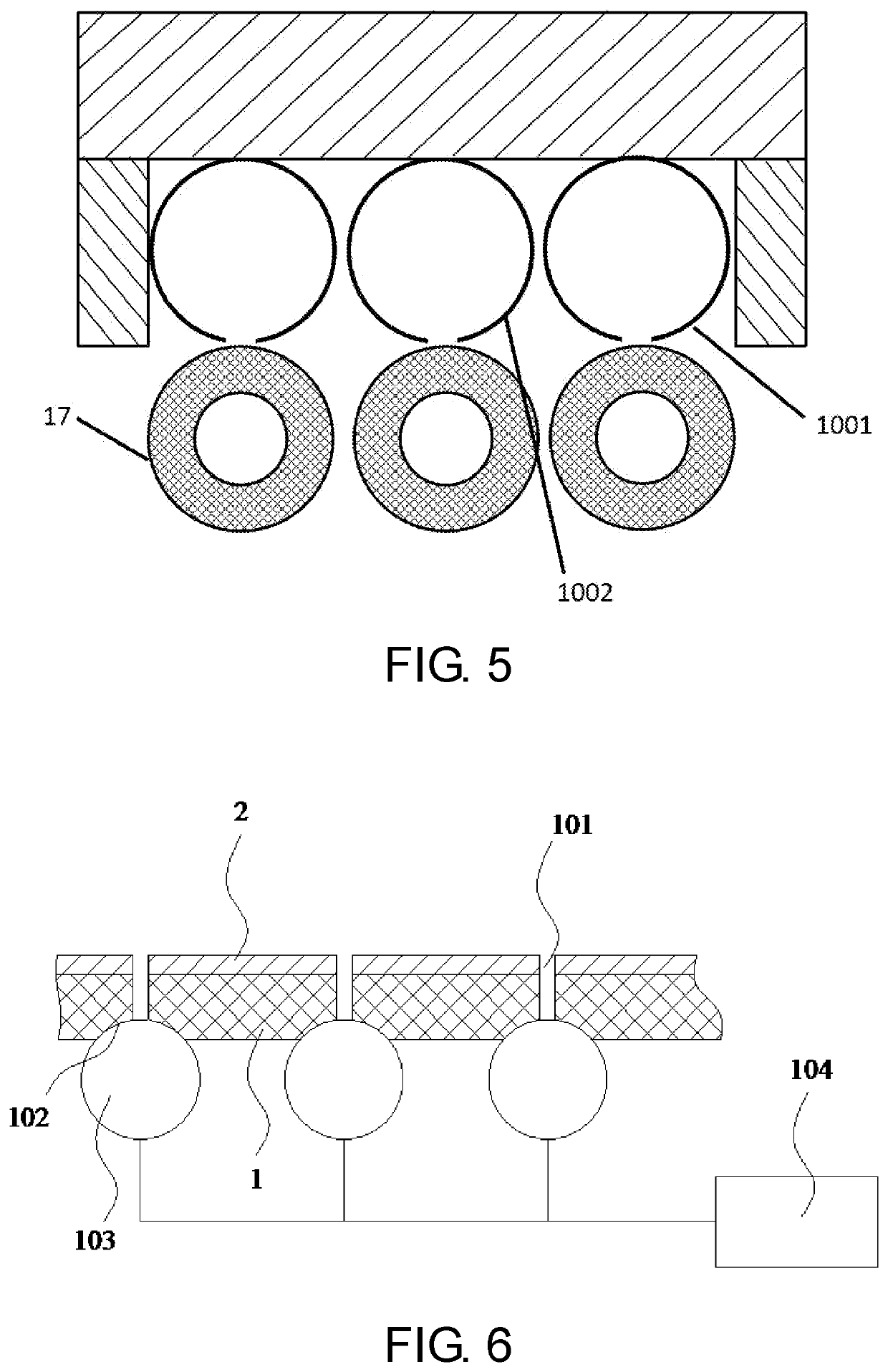

ActiveUS20190390410A1Avoid damageExpand the scope of protectionChemical/biochemical paper treatmentPhysical paper treatmentEngineeringPaper sheet

The present invention relates to a device for protecting paper sheet, including the following. A mist treating system, includes a working cover and a suction port provided on the working cover. A metal base plate is capable of being drawn out from an outlet of the working cover. An inlet and an outlet are provided on the sidewall of the working cover. An insulating layer provided at the top surface of the metal base plate. A sliding rail is provided above the metal base plate. A sprayer is used for applying an atomized deacidification agent to a paper sheet. A discharging electrode is used for discharging to the paper sheet on the insulating layer. The working cover is covered outside of the metal base plate, the insulating layer, the sliding rail, the sprayer, and the discharging electrode. A plasma power supply is used for generating linear plasma.

Owner:HANGZHOU ZHONGCAI TECH CO LTD

Method for removing free fatty acid in grease by enzyme catalysis

The invention discloses a method for removing free fatty acid in grease by enzyme catalysis, which comprises the following steps of mixing a natural deep-eutectic solvent with crude vegetable oil, adding lipase, stirring for reaction, and after the reaction is finished, performing centrifugal separation to obtain an upper oil phase, namely the crude vegetable oil without the free fatty acid. The multifunctional natural deep-eutectic solvent system constructed by the invention can realize synchronous deacidification and dehydration of lipase catalysis, the acyl acceptor type natural deep-eutectic solvent is a reaction substrate and a reaction medium, and is esterified with free fatty acid as a substrate into glyceride, so that the conversion of the free fatty acid into the glyceride is realized, the raw material loss is reduced, and the grease yield is improved. Quick separation from an oil phase can be achieved, the deacidification process is accelerated, the reaction time can be shortened to be within 3h, the product is easy to separate and purify, and a catalytic reaction system can be recycled in multiple batches.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Compound deacidification agent for frozen Dosidicus gigas

InactiveCN108967829AThe formula is scientific and reasonableImprove securityFood ingredient as antioxidantMeat/fish preservation by coatingSodium bicarbonateSterile water

The invention relates to the field of deacidification agents, and discloses a compound deacidification agent for frozen Dosidicus gigas, containing the following components in parts by weight: 8-16 parts of calcinated shell powder, 5-10 parts of sodium citrate, 5-10 parts of sodium bicarbonate, 3-5 parts of tea polyphenol, 1-3 parts of vitamin E, 1-3 parts of camellia oil, 2-4 parts of lecithin, and 60-80 parts of sterile water. According to the invention, a compound deacidification agent is designed aiming at the characteristics of Dosidicus gigas, and is reasonable and scientific in formulaand good in safety; by adding multiple antioxidants and the deacidification agent, the compound deacidification agent achieves a synergistic effect with unsaturated fatty acid, is better in deacidification effect, has the effects of retaining water and inhibiting browning, does not have acerbity, and is good in taste and suitable for popularization.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Method for extracting free fatty acid in vegetable crude oil

The invention discloses a method for extracting free fatty acid in crude vegetable oil, which comprises the following steps: mixing a polyol eutectic solvent with the crude vegetable oil at 40-90 DEGC, stirring the mixture, carrying out standing treatment to form two phases, and separating the upper oil phase to obtain the crude vegetable oil from which the free fatty acid is removed. The methodhas the advantages of simple process, convenient operation, easy separation and purification of products, good deacidification effect, small loss of neutral oil, low cost, simplicity, greenness, safety and the like.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

Paper deacidification solution based on ionic liquid and using method of paper deacidification solution

InactiveCN109706790AGood deacidification effectImprove wettabilityOld paper after-treatmentStarch solutionIon

The invention discloses a paper deacidification solution based on ionic liquid and a using method of the paper deacidification solution. The paper deacidification solution comprises an ionic liquid type surfactant and quaternary ammonium cationic starch, wherein the ionic liquid surfactant is one selected from AEO-9, MOA-3P and [EMIm]NTf<2>. The using method comprises the following steps: preparing a deacidification wetting solution by using ultrapure water, dissolving quaternary ammonium type cationic starch by using an ethanol-water solution, mixing the deacidification wetting solution and the quaternary ammonium type cationic starch solution according to a certain ration to obtain the stably coexistent paper deacidification solution, soaking paper to be treated into the paper deacidification liquid, and drying the deacidified paper. The paper deacidification solution disclosed by the invention is a homogeneous solution system and is green and environmentally friendly, the deacidifying effect of aged paper is obvious, and the pH value after treatment is distributed in a range of 7.3-8.1, so that a good storage environment is provided for the paper, and the paper deacidification solution is widely suitable for wetting and deacidification wetting treatment of ancient calligraphy and paintings, aged paper and literatures.

Owner:CHINA UNIV OF MINING & TECH

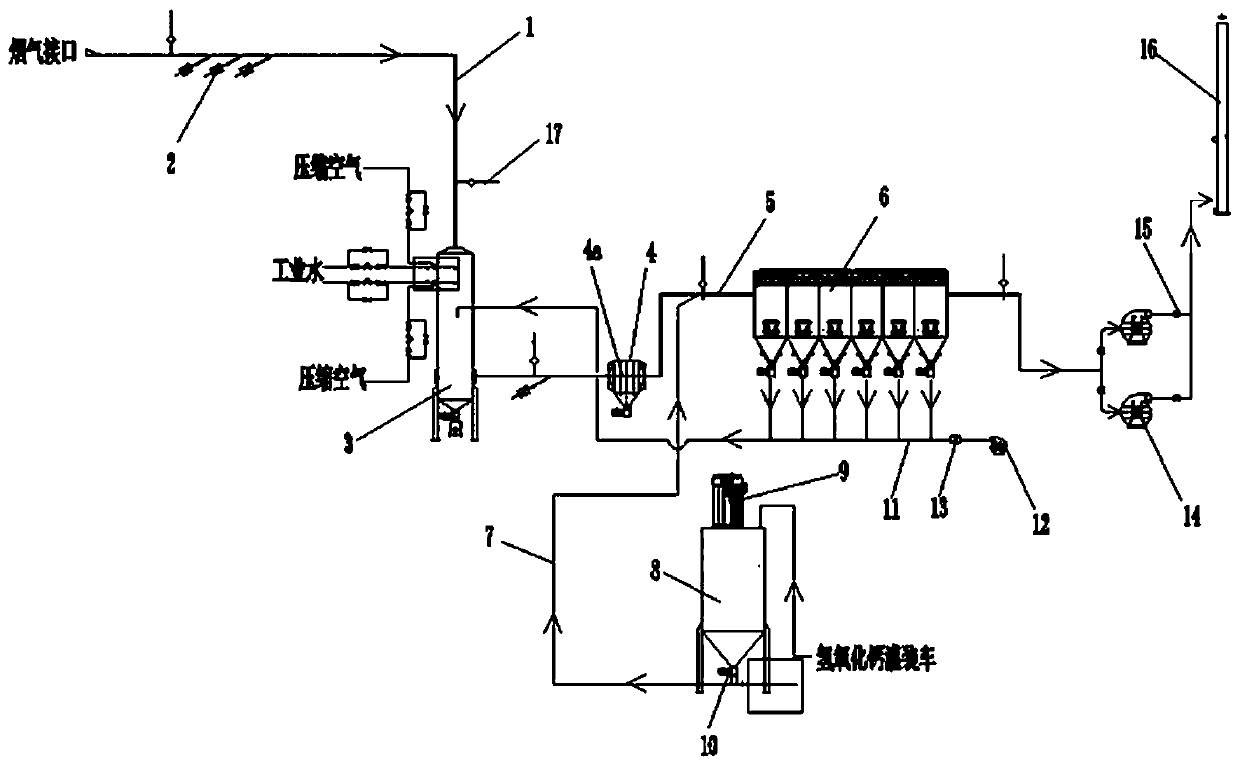

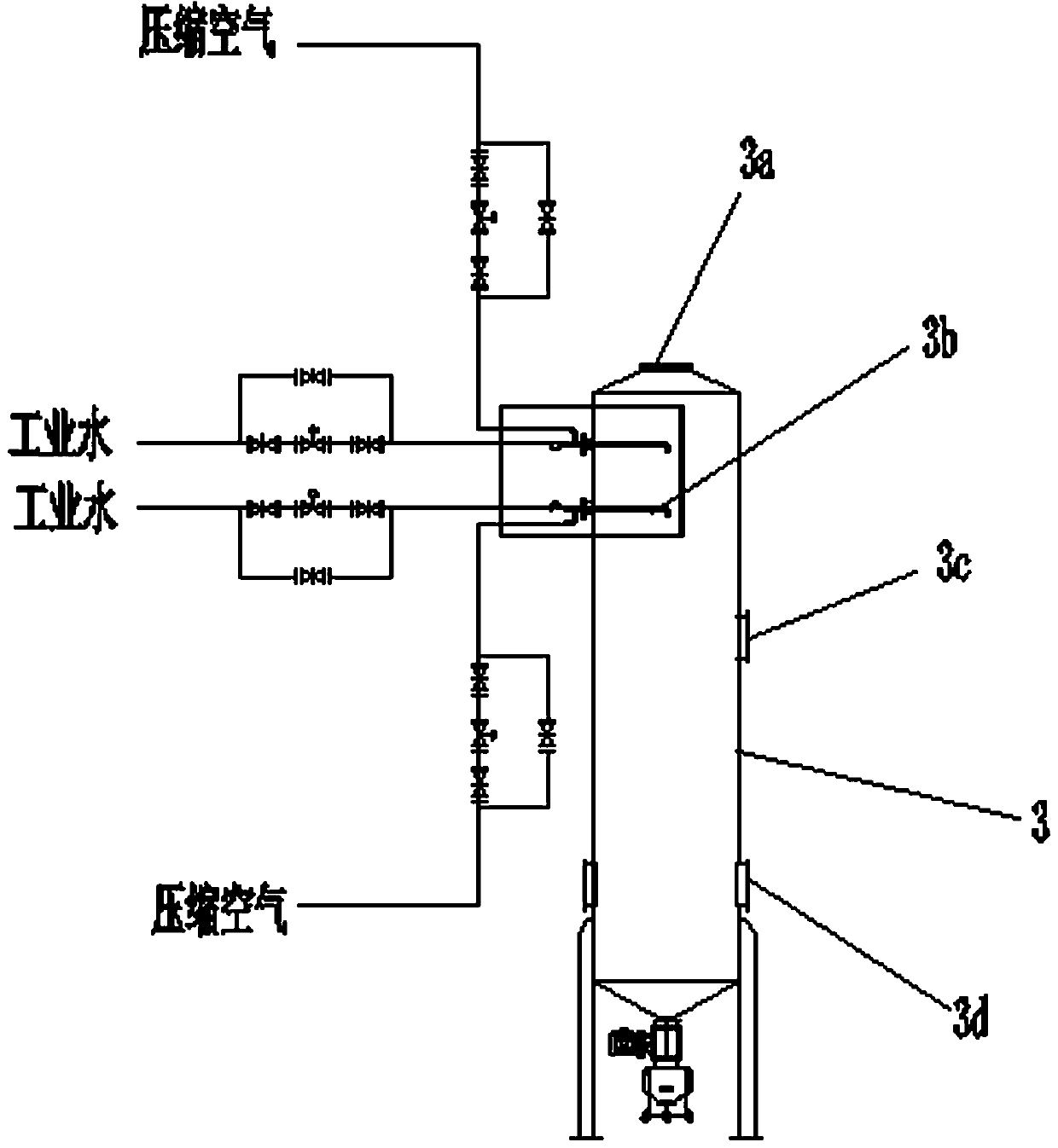

Device and method for dedusting and purifying tail gas of glass melting furnace

PendingCN111408262AAvoid dustPrevent scalingDispersed particle filtrationDirect contact heat exchangersCalcium hydroxideCooling tower

The invention relates to a method for dedusting and purifying tail gas of a glass melting furnace. The method comprises the following steps: flue gas at 450-560 DEG C is introduced into a negative pressure header pipe (1) for cooling; the cooled flue gas at 120-400 DEG C enters a spray cooling tower (3), and the temperature of the flue gas at a gas outlet (3d) is reduced to 75-80 DEG C; then the flue gas enters a mixer (4) and a mixing pipe (5) to be mixed and reacted with calcium hydroxide from a negative pressure branch pipe (7), acidic pollutants and redundant water in the flue gas are absorbed, and the temperature of the flue gas is reduced to 65 DEG C or below; then the flue gas enters a bag-type dust collector (6), incompletely-reacted calcium hydroxide and acid gas in the flue gas continue to be subjected to a secondary reaction, and finally the flue gas is filtered by the bag-type dust collector (6) and introduced into a chimney (16) through a variable-frequency fan (14) to beemptied. The method has the advantages that the tail gas is filtered, reacted and dedusted layer by layer, so that the tail gas is emptied after reaching the standard, the deacidification efficiency is improved, materials are recycled, and the operation cost and the system pressure fluctuation are reduced.

Owner:江苏琥珀环境技术有限公司

Zero-discharge system for desulfurization wastewater

PendingCN109133234AShort processLess process equipmentWater contaminantsWaste water treatment from gaseous effluentsSludgeProcess engineering

The invention discloses a zero-discharge system for desulfurization wastewater. The zero-discharge system comprises a boiler, a dust remover and a desulfurization tower, which are arranged in sequence; a drying tower is arranged between the boiler and the dust remover; and a rotary atomizer is arranged on the tower top of the drying tower. The rotary atomizer rotates at a high speed and wastewatergenerated by the desulfurization tower is sprayed into the drying tower by the rotary atomizer; and an air flow diversion device is arranged in the drying tower, exhaust gas generated by the boiler enters the drying tower through an exhaust gas inlet and forms a downwards rotating air flow under the diversion of the air flow diversion device, and the rotating direction of the air flow is oppositeto the rotating direction of the rotary atomizer. The zero-discharge system for the desulfurization wastewater provided by the invention is used for wastewater treatment, in which the desulfurizationwastewater is directly atomized by the rotary atomizer and instantaneously evaporated by the hot exhaust gas in the drying tower, therefore no sludge is produced and no heating is needed in the process, so that the construction cost and the running cost of the zero-discharge system for the desulfurization wastewater are greatly reduced.

Owner:江苏海澜正和环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com