Crude oil deacidification apparatus and method

A deacidification method and crude oil technology, which are applied in the petroleum industry, refined hydrocarbon oil, and multi-stage series-connected refining process treatment, etc., can solve the problems of insufficient reaction between crude oil and deacidification agent, emulsification phenomenon, serious problems, etc. Emulsification phenomenon, good deacidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

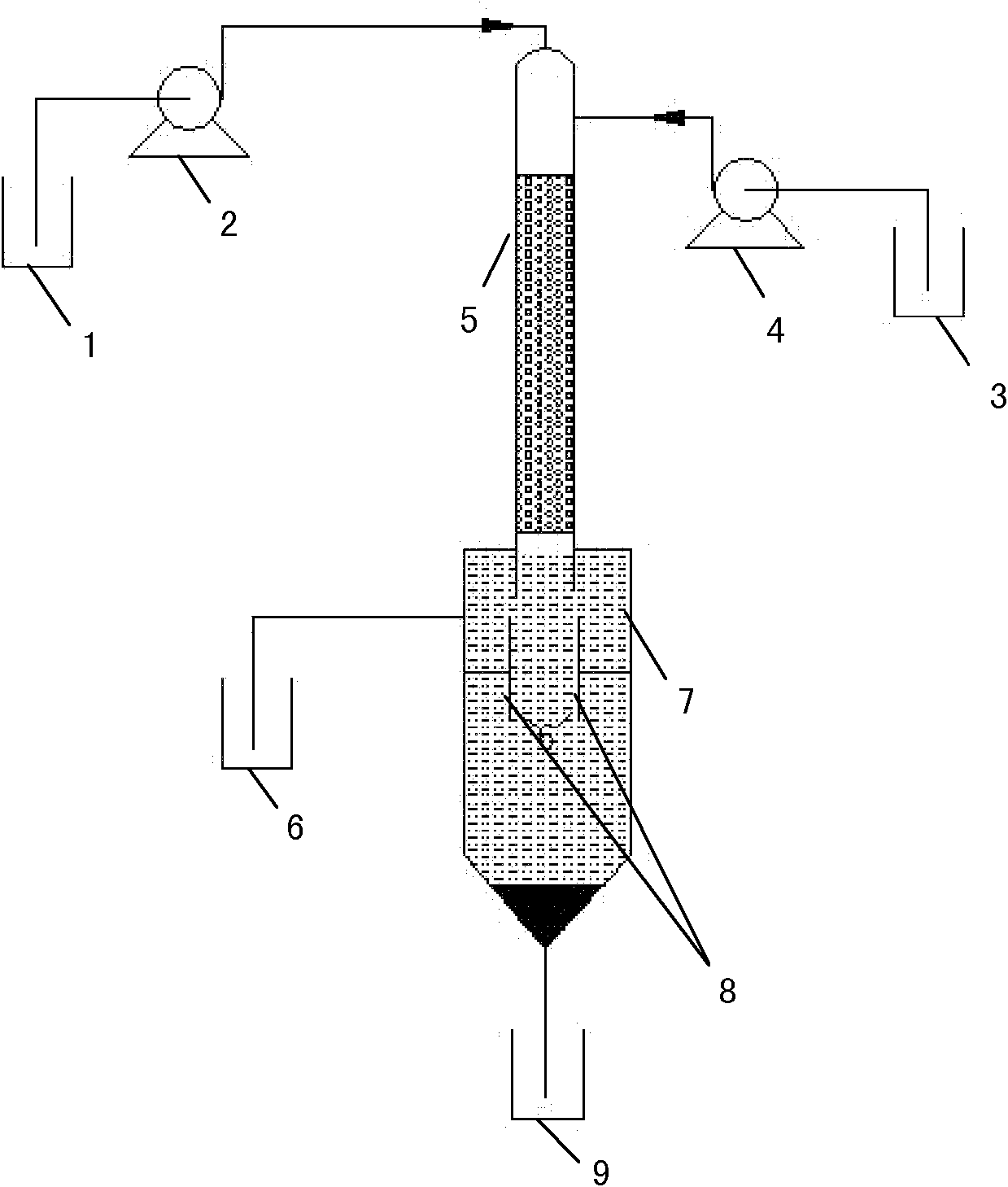

[0021] figure 1 An experimental crude oil deacidification device is shown, which mainly includes: deacidification agent tank 1, deacidification agent transfer pump 2, crude oil tank 3, crude oil transfer pump 4, packed tower 5, crude oil tank after deacidification 6. Sedimentation and separation device 7, electrode plate 8 and alkali slag tank 9.

[0022] As the name implies, the deacidification agent tank 1 and the crude oil tank 3 are respectively used to accommodate the deacidification agent and crude oil to be treated, while the deacidified crude oil tank 6 and the alkali residue tank 9 are respectively used to accommodate the deacidified crude oil and alkali scum. The deacidification agent transfer pump 2 is connected to the deacidification agent tank 1 to transfer the deacidification agent, and the crude oil transfer pump 4 is connected to the crude oil tank 3 to transfer crude oil to be treated.

[0023] The packed tower 5 is connected to the deacidifying agent transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com