Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Oil demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

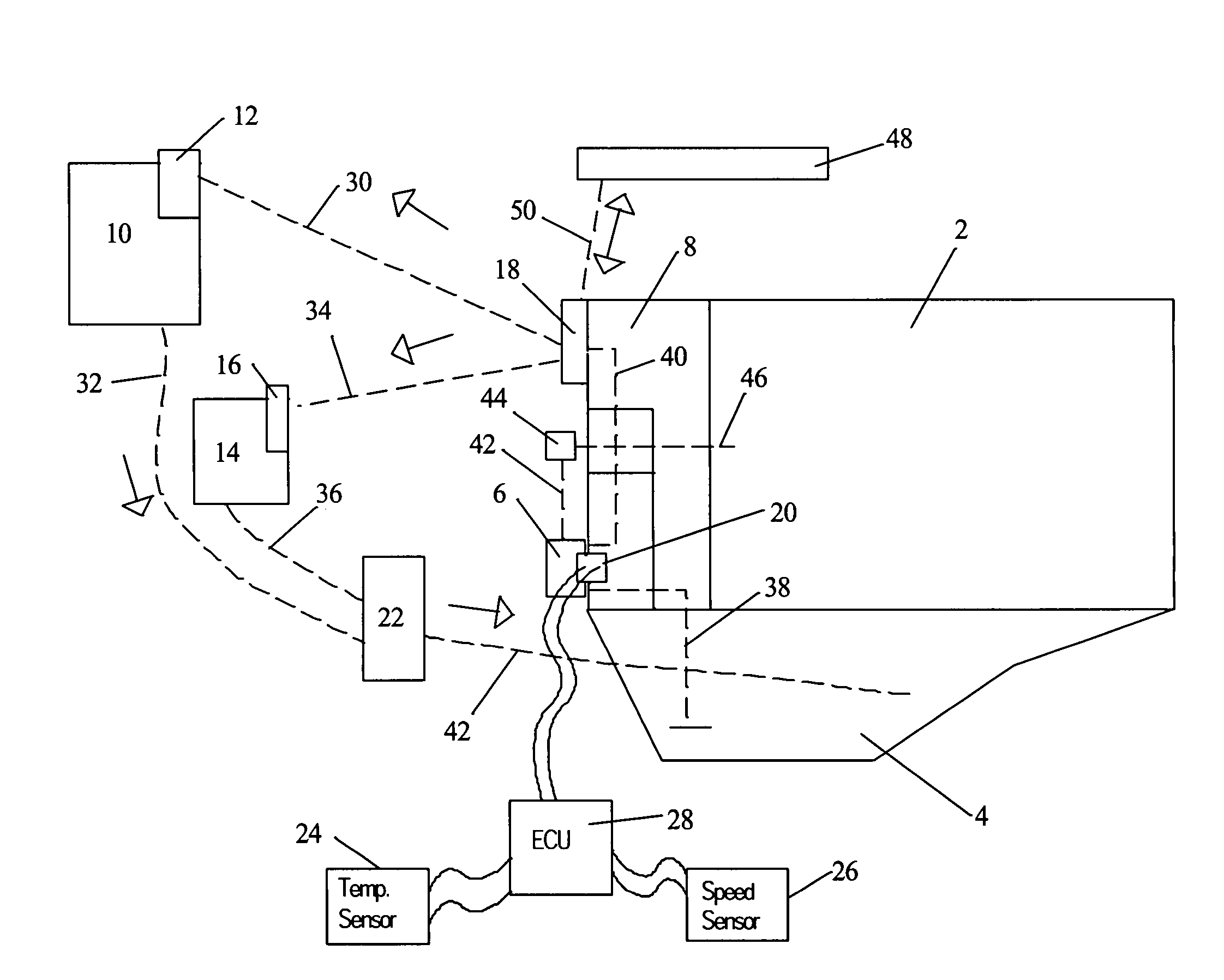

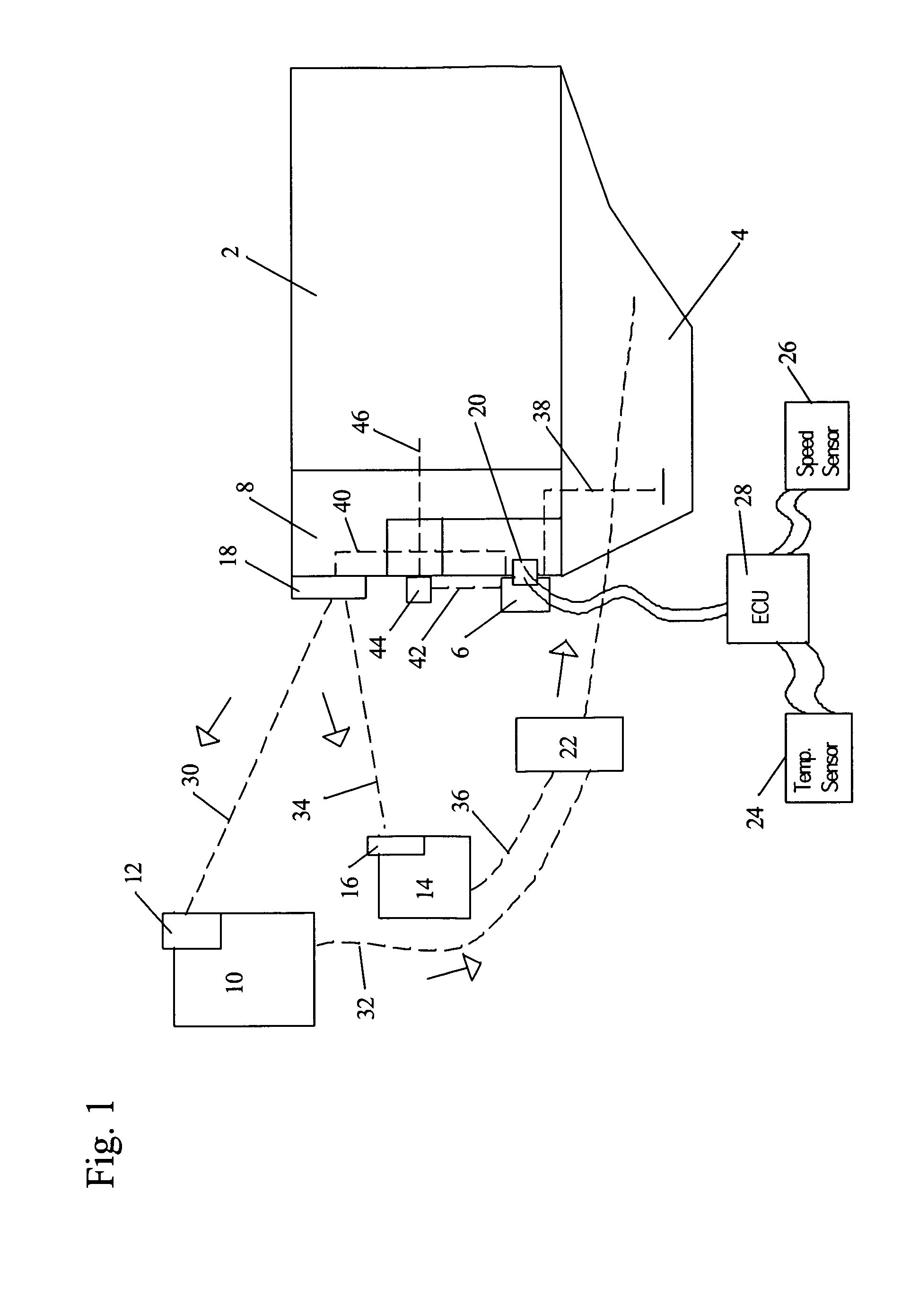

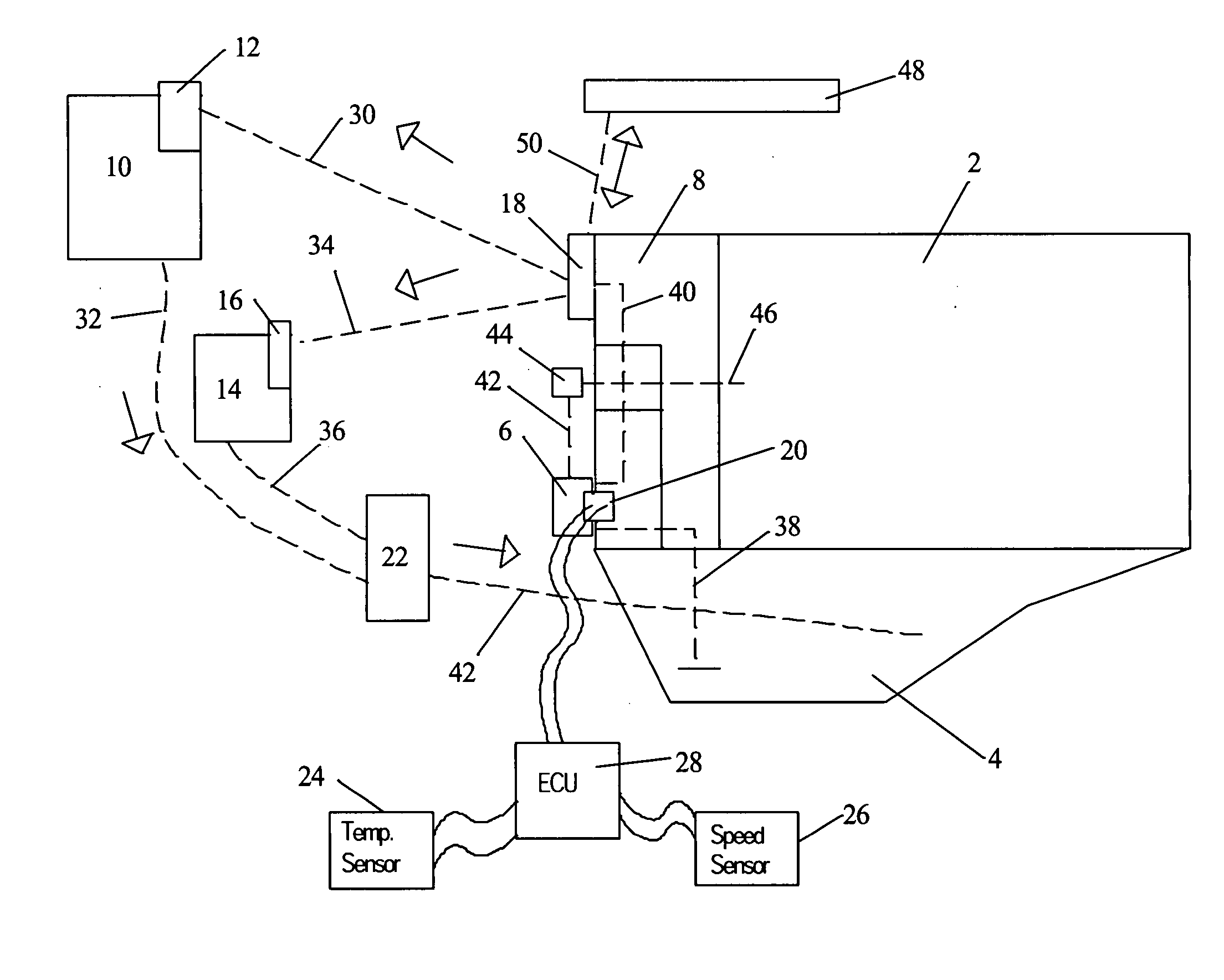

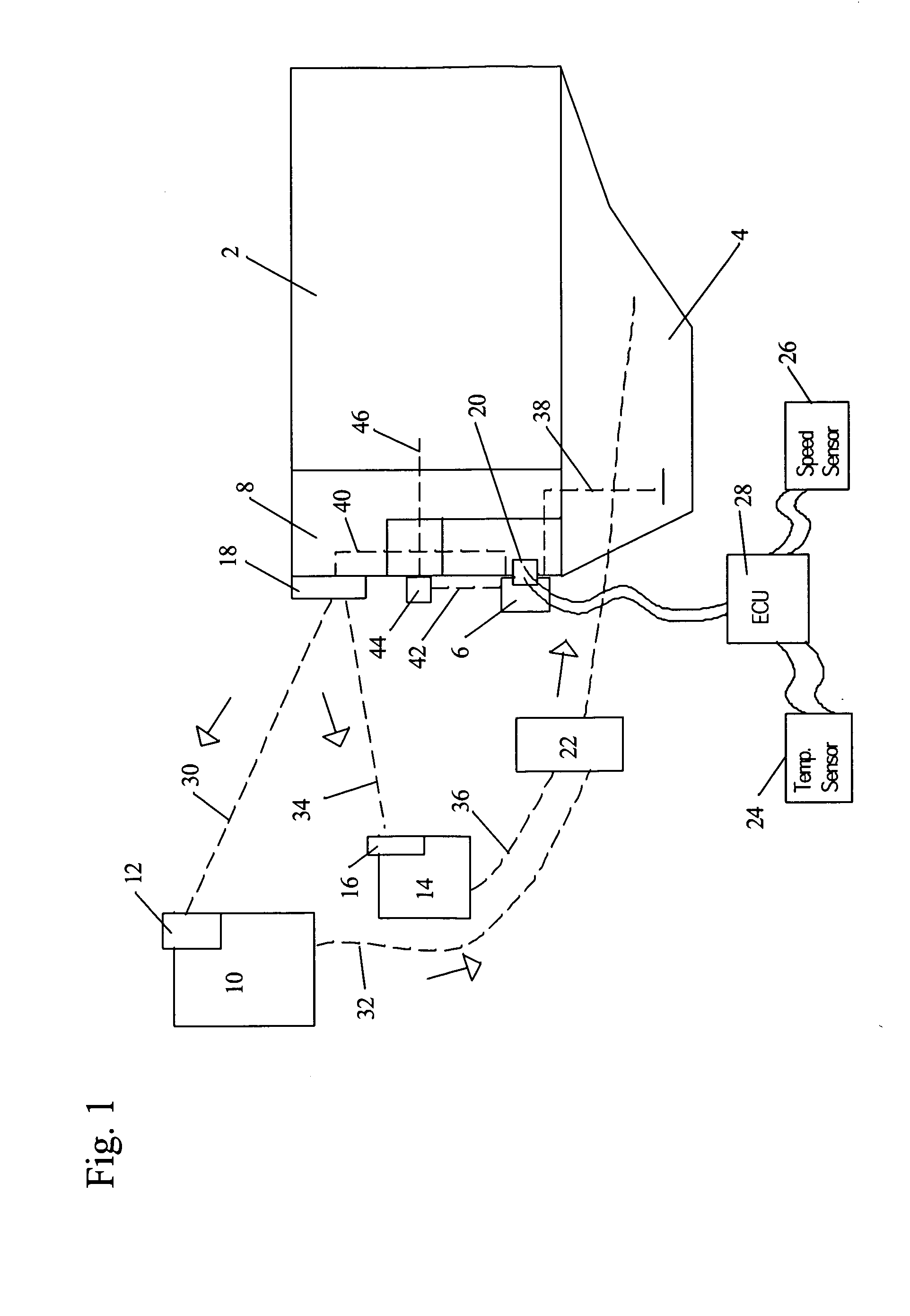

System and method of providing hydraulic pressure for mechanical work from an engine lubricating system

Owner:BORGWARNER INC

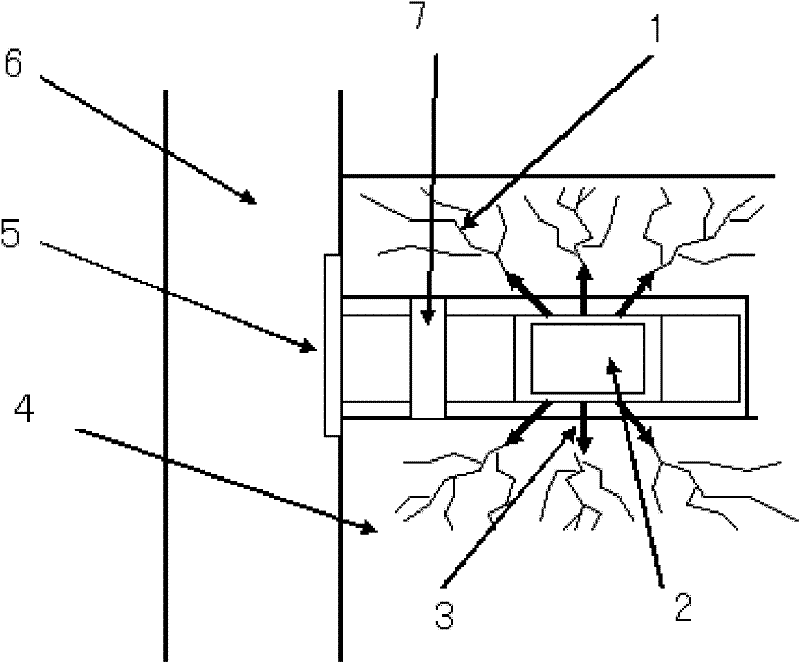

Blasting and fracturing stimulation method for low-permeability oil and gas layers in oil production wells

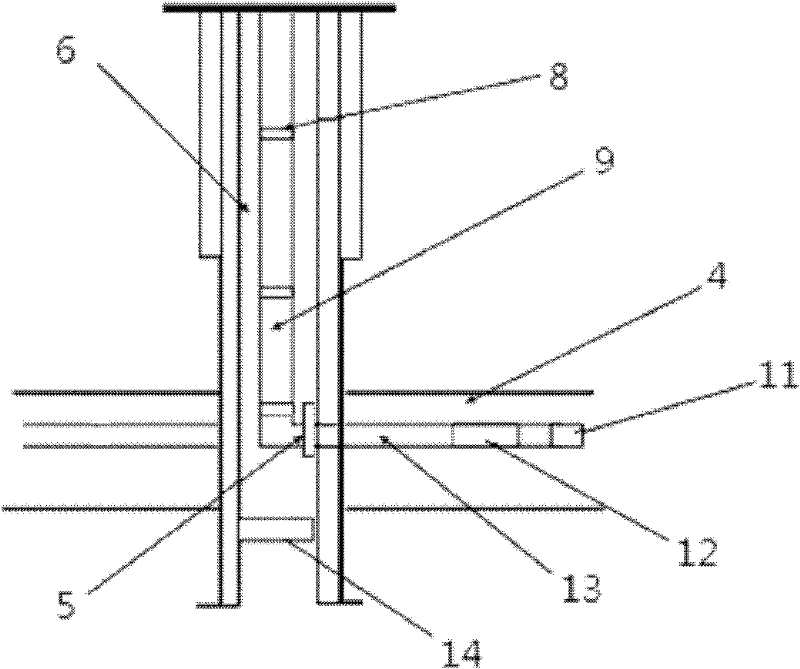

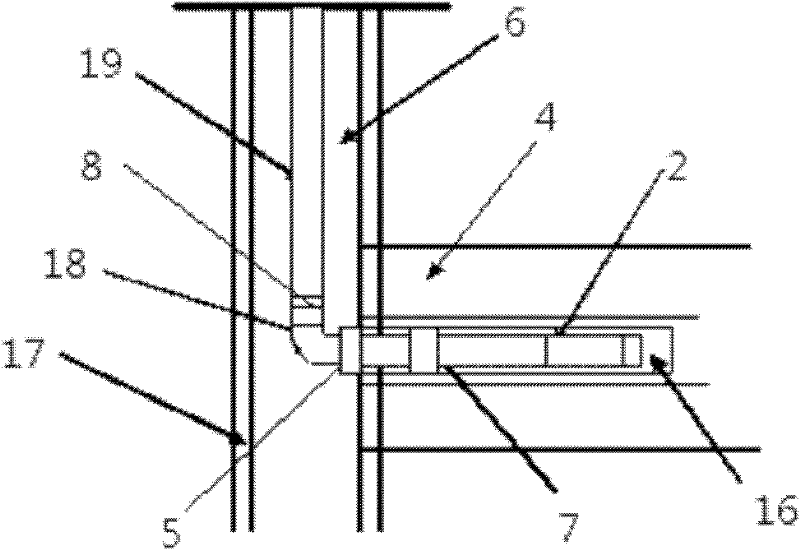

InactiveCN102296945AReduce material costsIncrease drilling speedFluid removalPorosityHorizontal wells

The invention discloses a method for blasting and fracturing production stimulation of low-permeability oil and gas layers in oil production wells. The specific steps are as follows: firstly, open a window and sidetrack a small wellbore in a vertical well that has been drilled, the drilling direction is horizontal, and the window is opened for sidetracking. Select low-permeability oil and gas reservoirs; secondly, use soft tubing to transport multiple groups of explosive columns to the horizontal slimhole section to complete the blasting; thirdly, carry out oil and gas production after screen oil testing for production. The invention can solve the technical problem of greatly increasing the porosity and permeability of low-permeability oil and gas layers.

Owner:杨瑞召 +1

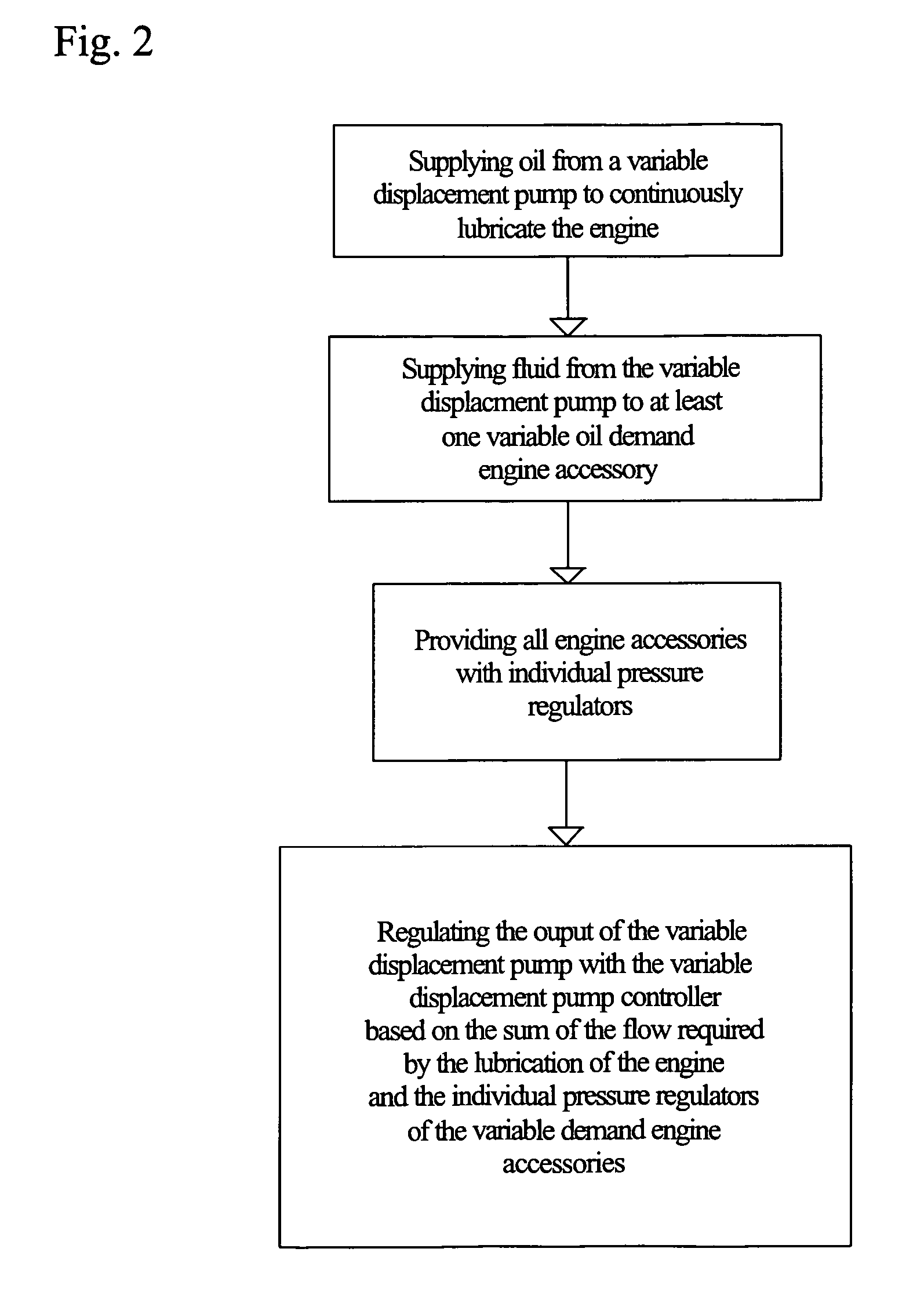

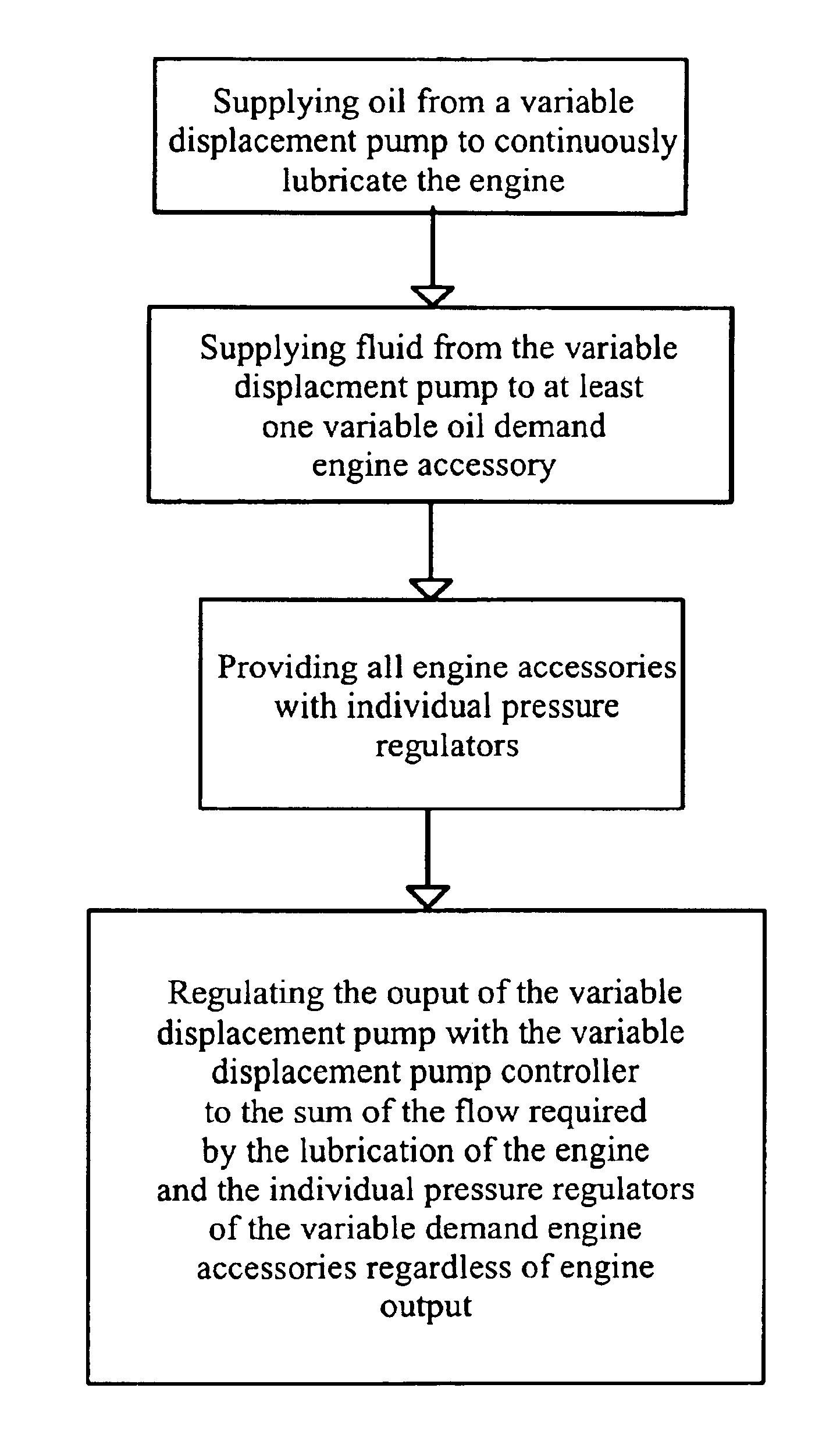

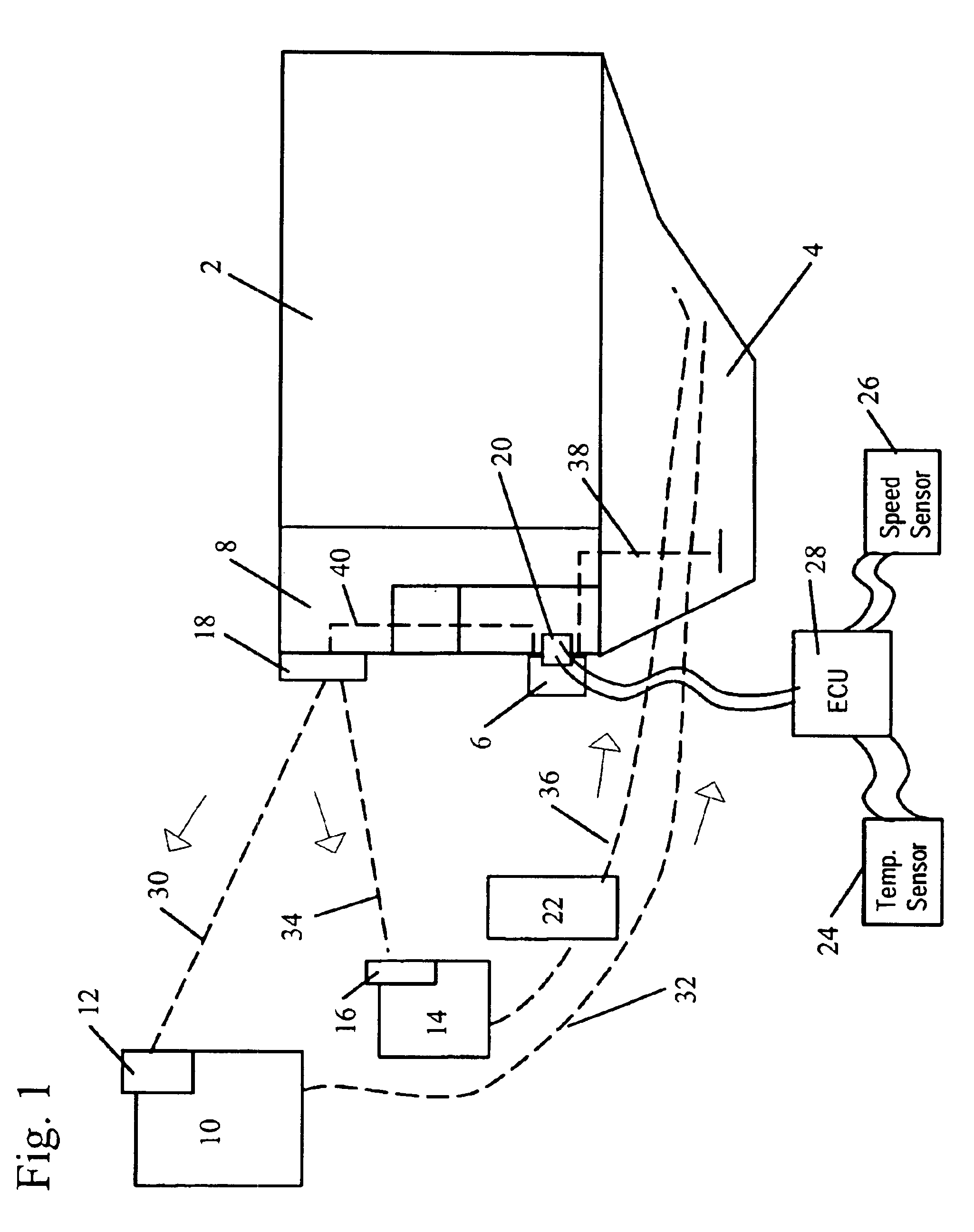

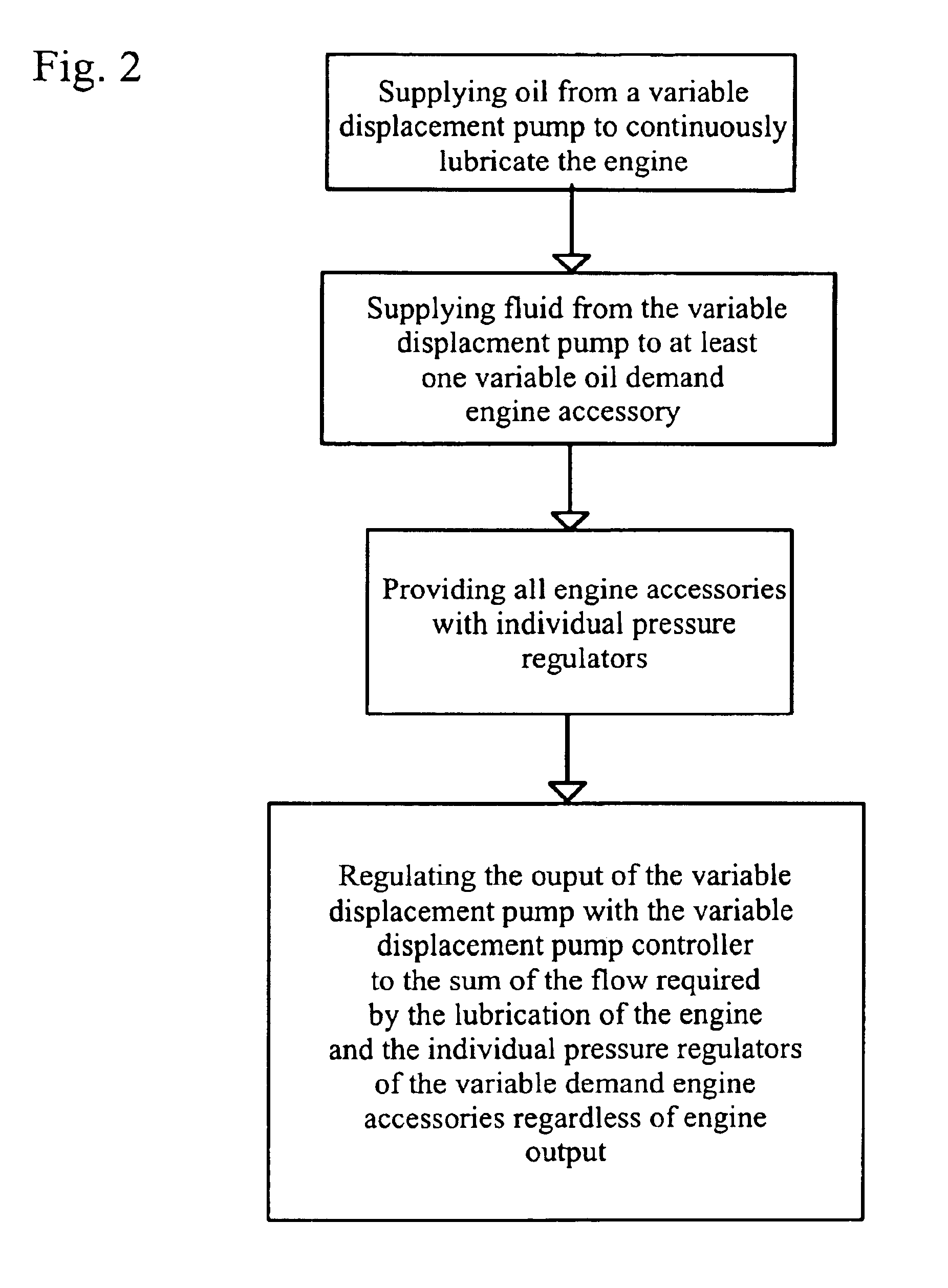

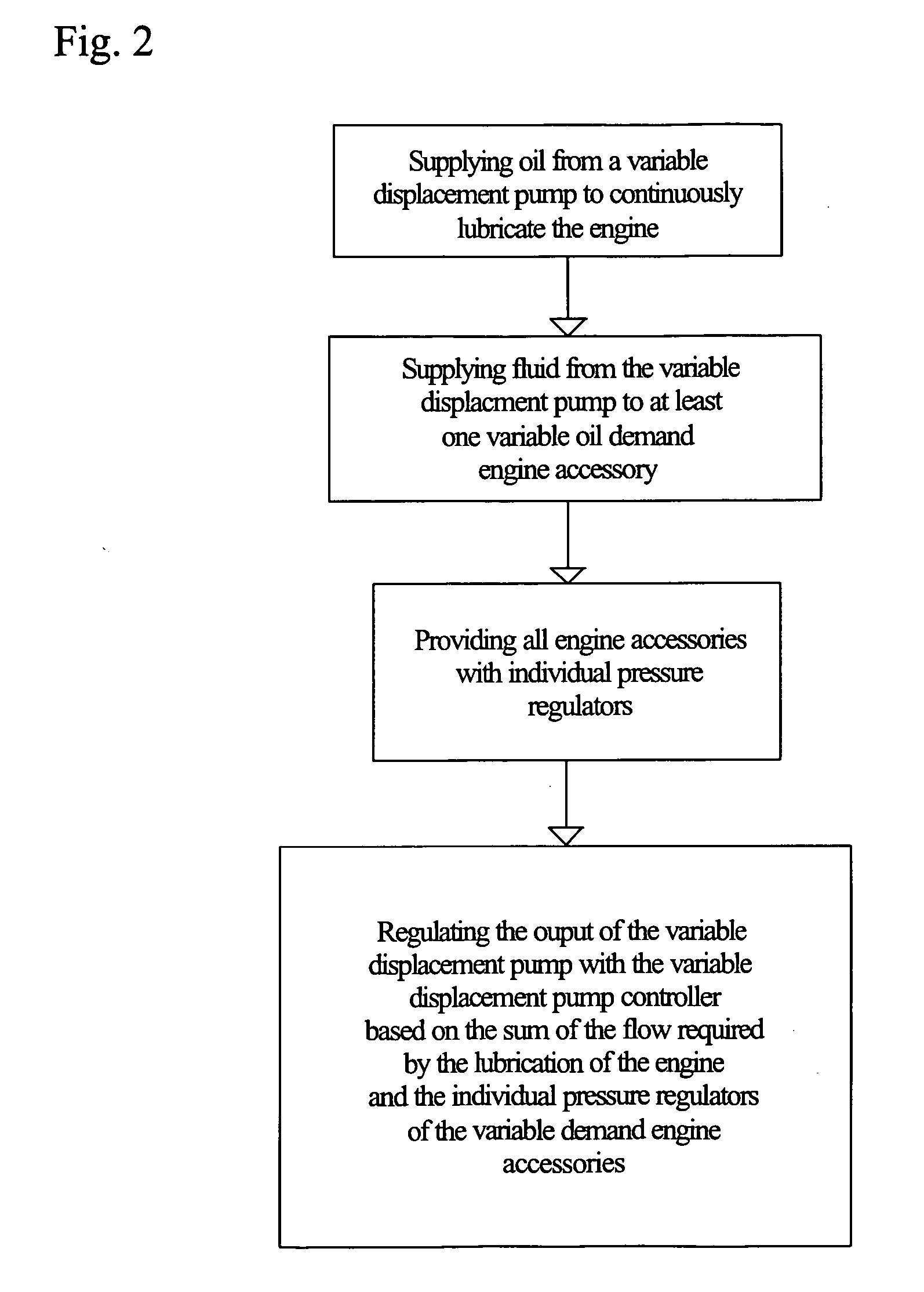

Method of providing hydraulic pressure for mechanical work from an engine lubricating system

InactiveUS6889634B1Lubrication of auxillariesCoolant flow controlInternal combustion engineLubrication

A method of providing hydraulic pressure for mechanical work from an engine lubricating system in an internal combustion engine by supplying oil to an engine lubrication gallery for lubricating the engine and at least one variable oil demand accessory. Each of the variable oil demand accessories have individual pressure regulators. The output of the variable displacement pump is regulated to the sum of fluid flow required by the engine lubricating system and the demand for fluid generated by the individual pressure regulators on each of the engine accessories, regardless of the engine output.

Owner:BORGWARNER INC

Waste oil anticipate regenerated energy device and processing method

InactiveCN101812320AAlleviate shortagesAlleviate needsThermal non-catalytic crackingHydrocarbon distillationFractionating columnFractionation

The invention discloses a waste oil anticipate regenerated energy device and a processing method. Calculated according to the oil exploitation amount in 2000, oil resources of China tend to be exhausted until 2020. The annual growth for oil demand of China is 5.77 percent, while the annual growth for national oil production is 1.67 percent, thus the contradiction between supply and demand is increasingly remarkable and the full utilization of waste oil is the current problem to be solved urgently. The device comprises a distillation part and a cracking part connected with the distillation part. The distillation part comprises a distillation tower (1) which is connected with an oil-water separator (2); the oil-water separator is connected with a fractionation catalytic converter (5) which is connected with a condensation water tank (4); and the condensation water tank is connected with a semi-finished product oil tank (7); and the fractionation catalytic converter is connected with a clean oil tank (8). The invention is applied to the field of water oil anticipate regeneration.

Owner:李宝东 +1

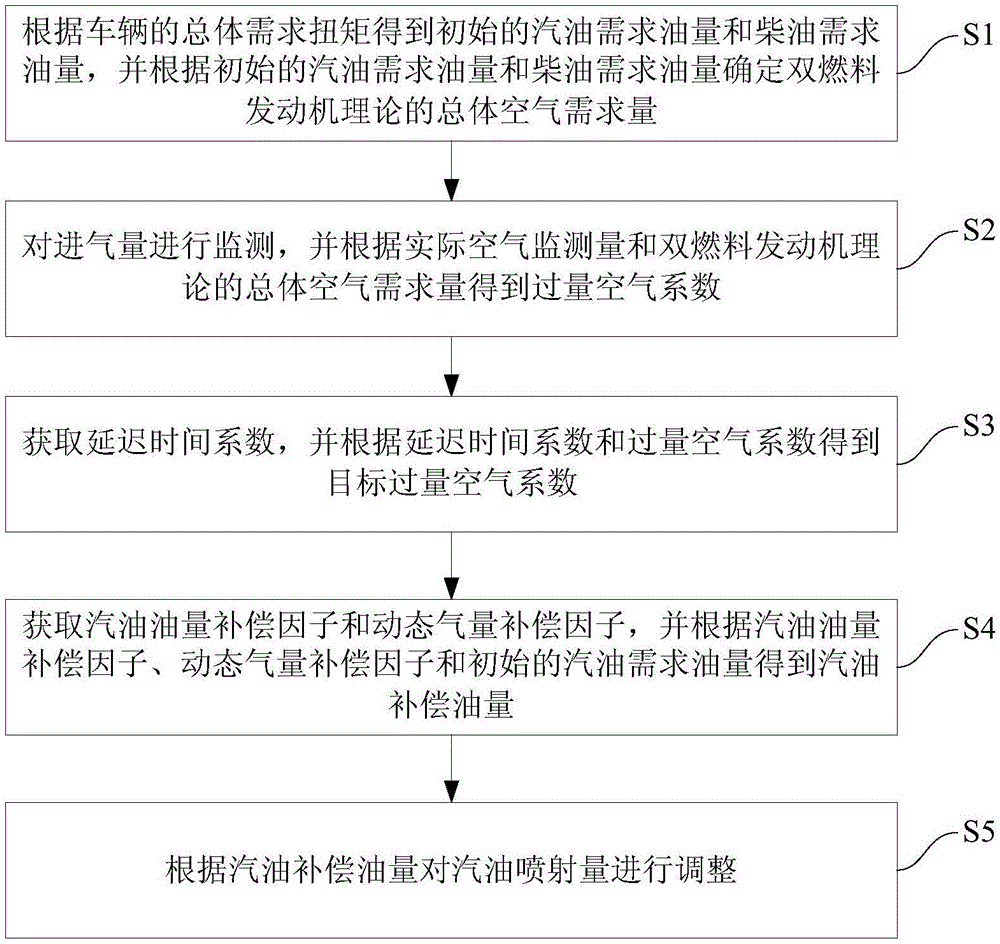

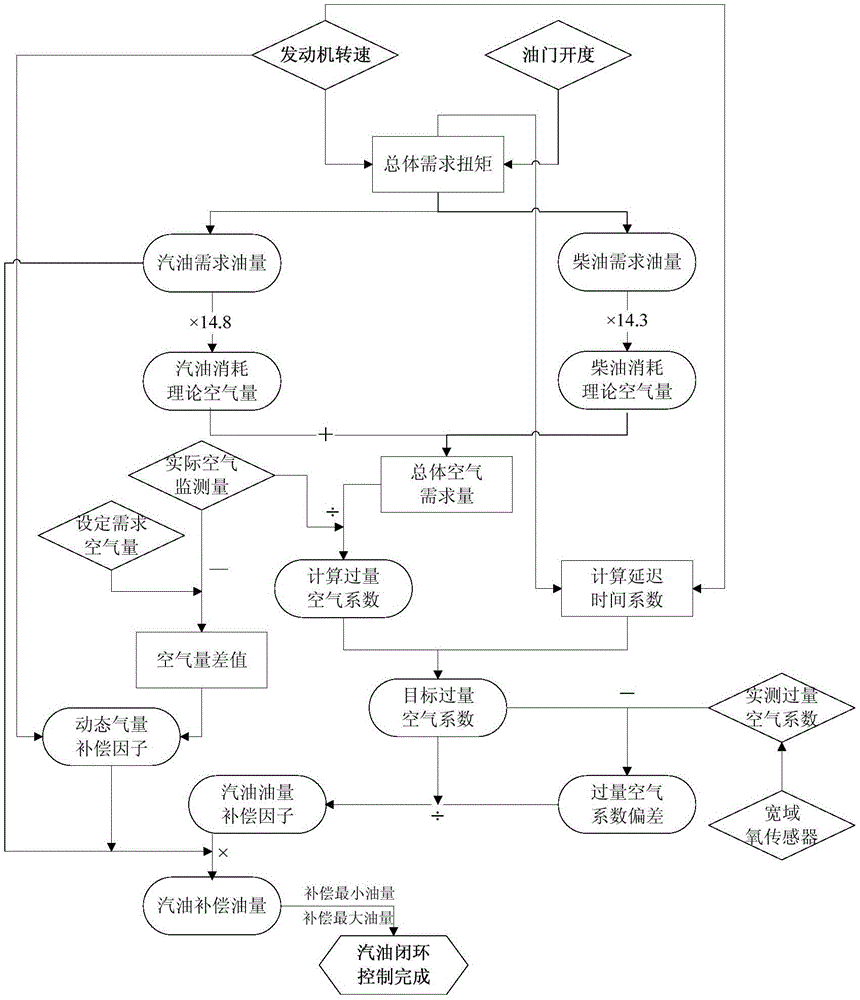

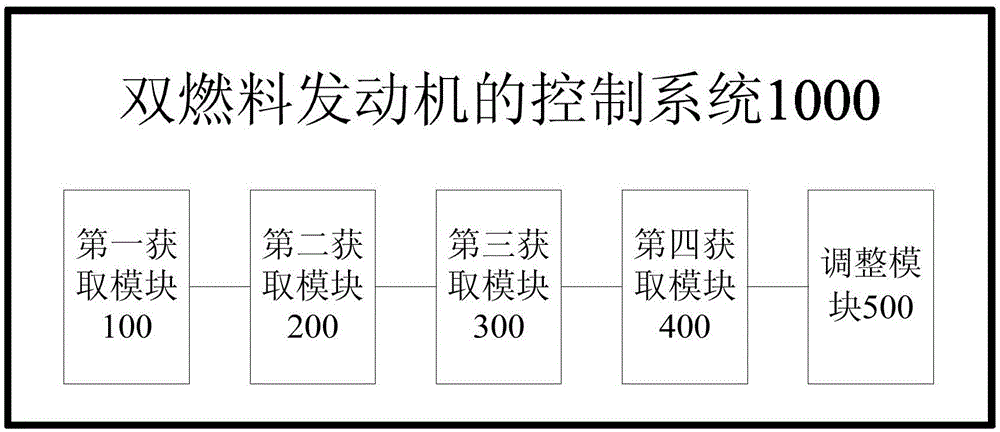

Dual-fuel engine control method and system, and vehicle with control system

ActiveCN106401759APromote combustionImprove featuresElectrical controlMachines/enginesCombustionAir monitoring

The invention provides a dual-fuel engine control method and system, and a vehicle with the control system. The control method includes: acquiring the initial gasoline demand amount and the initial diesel oil demand amount according to a total demand amount torque, and determining the theoretical total air demand amount of a dual-fuel engine according to the initial gasoline demand amount and the initial diesel oil demand amount; monitoring the air inflow amount, and acquiring an excess air coefficient according to the actual air monitoring amount and the theoretical total air demand amount of the dual-fuel engine; acquiring a delay time coefficient, and acquiring a target excess air coefficient according to the delay time coefficient and the excess air coefficient; acquiring a gasoline amount compensation factor and a dynamic air amount compensation factor, and acquiring the gasoline compensation amount according to the gasoline amount compensation factor, the dynamic air amount compensation factor, and the initial gasoline demand amount; and adjusting the gasoline injection amount according to the gasoline compensation amount. The method can allow the dual-fuel engine to accurately acquire the fuel oil mixing ratio required by combustion, and thereby allowing the dual-fuel engine to possess excellent combustion and emission performance.

Owner:GREAT WALL MOTOR CO LTD

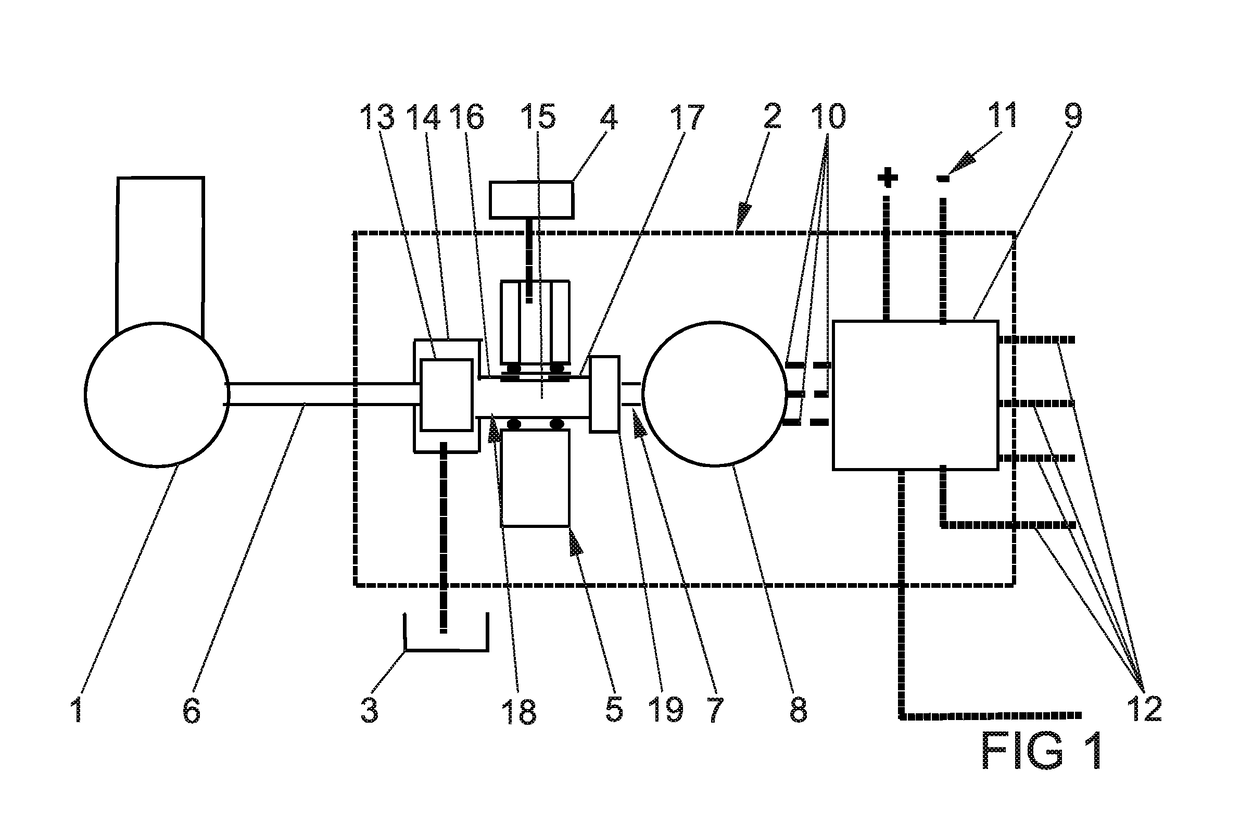

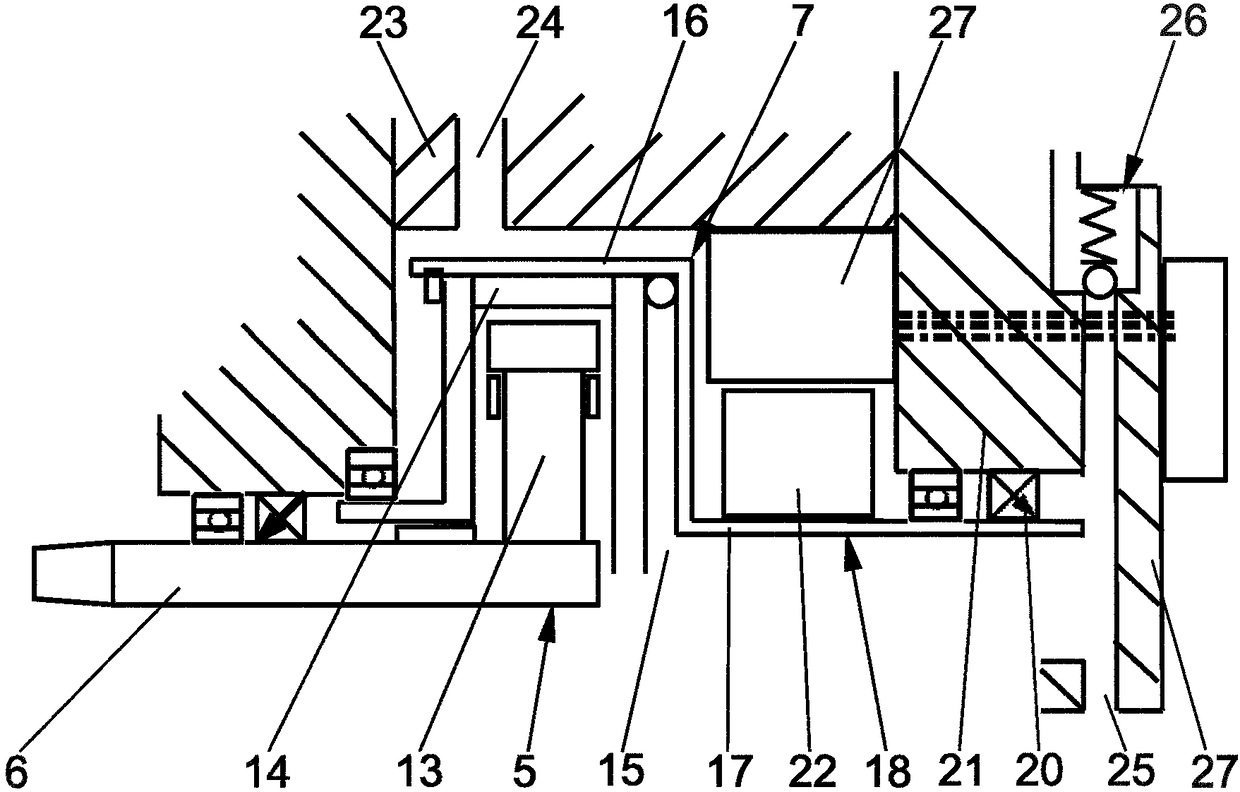

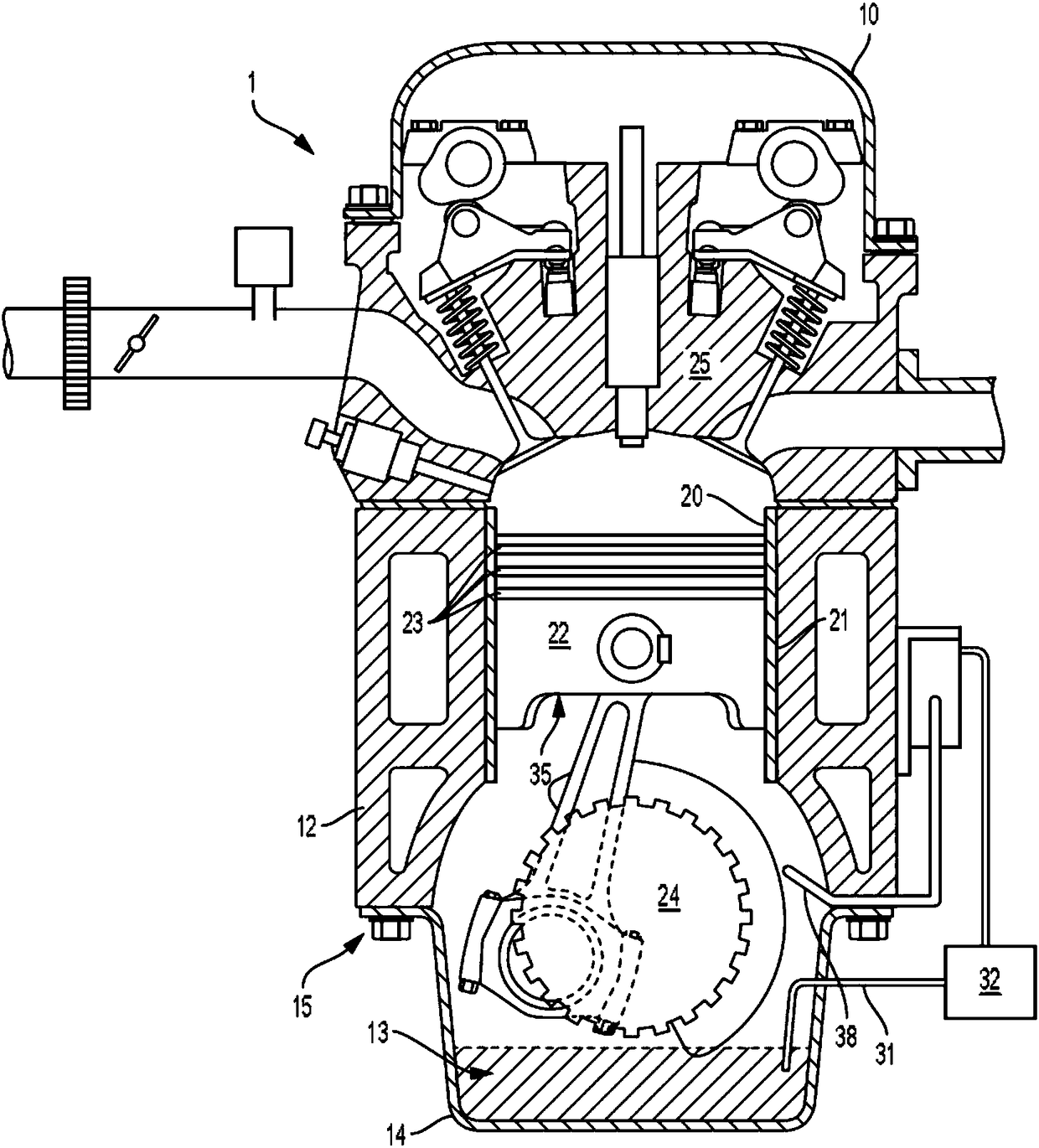

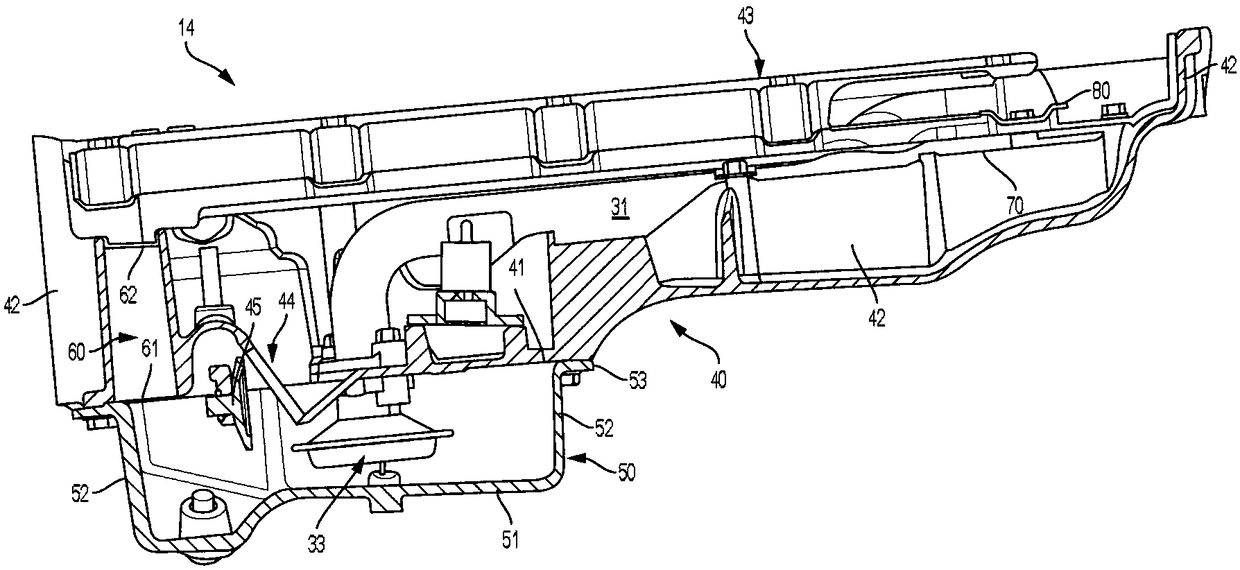

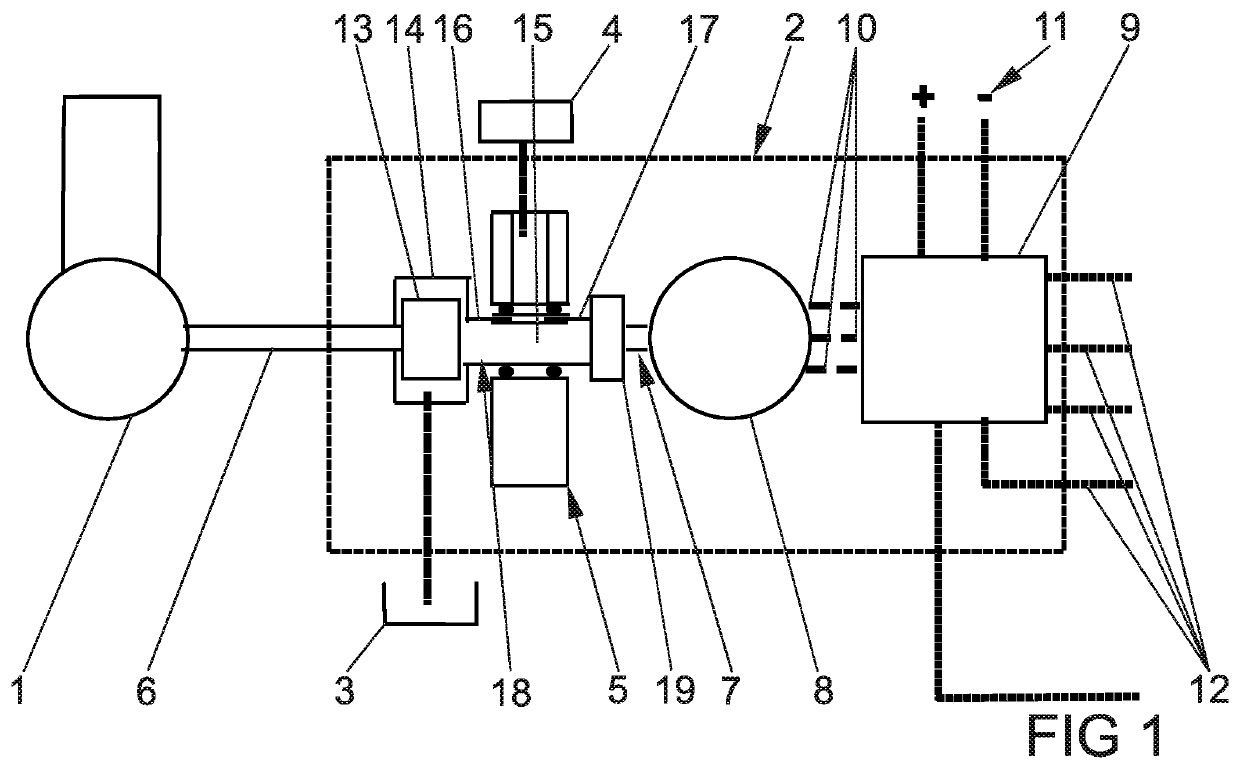

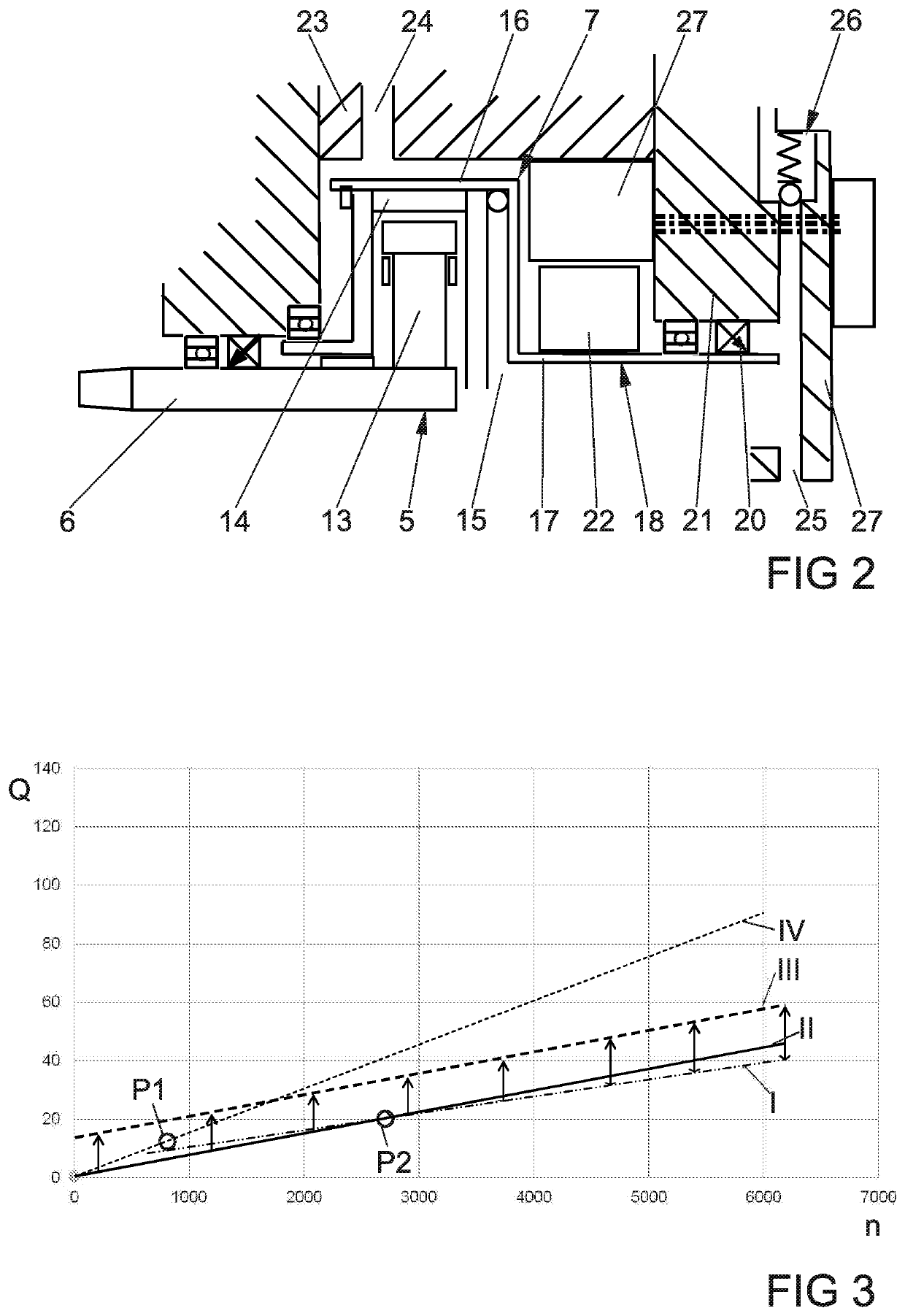

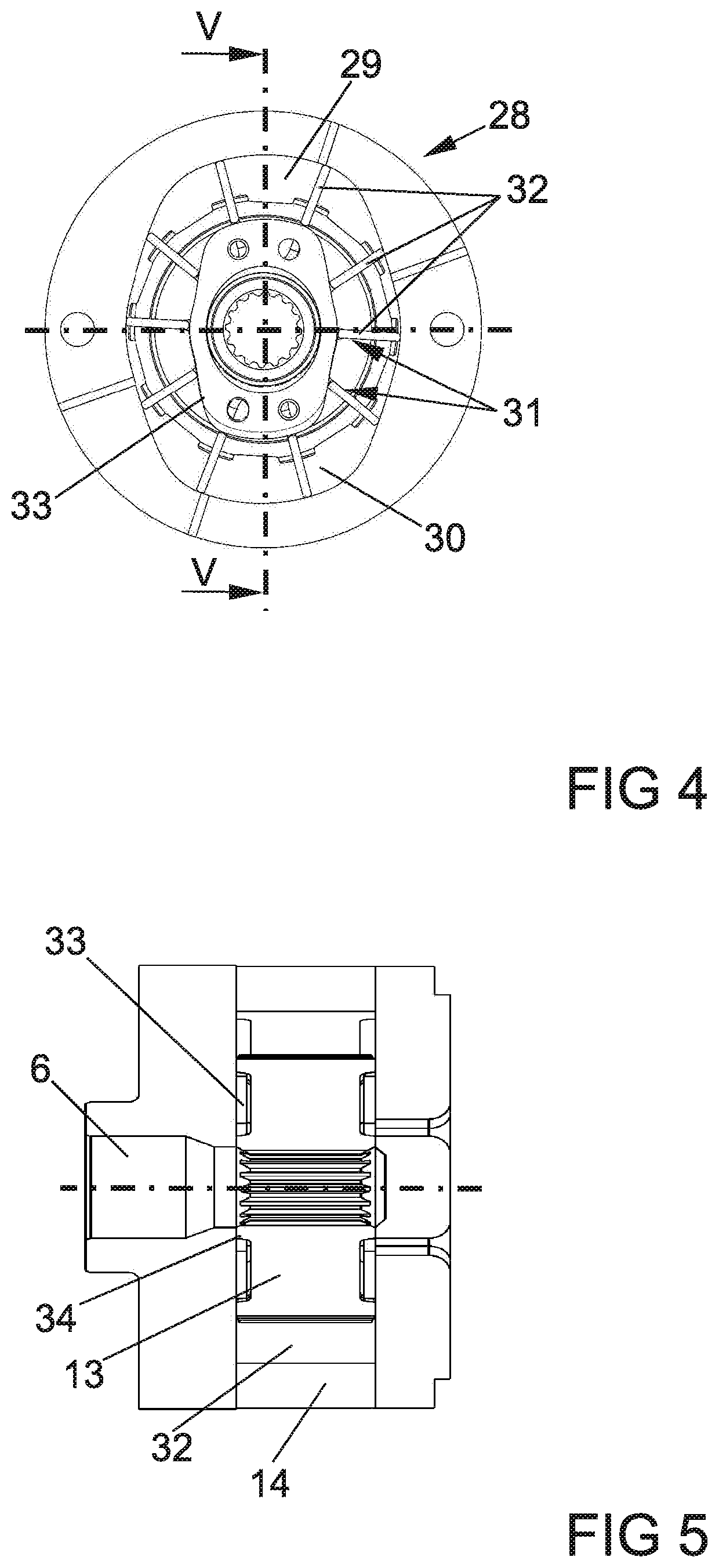

Delivery device for a motor vehicle

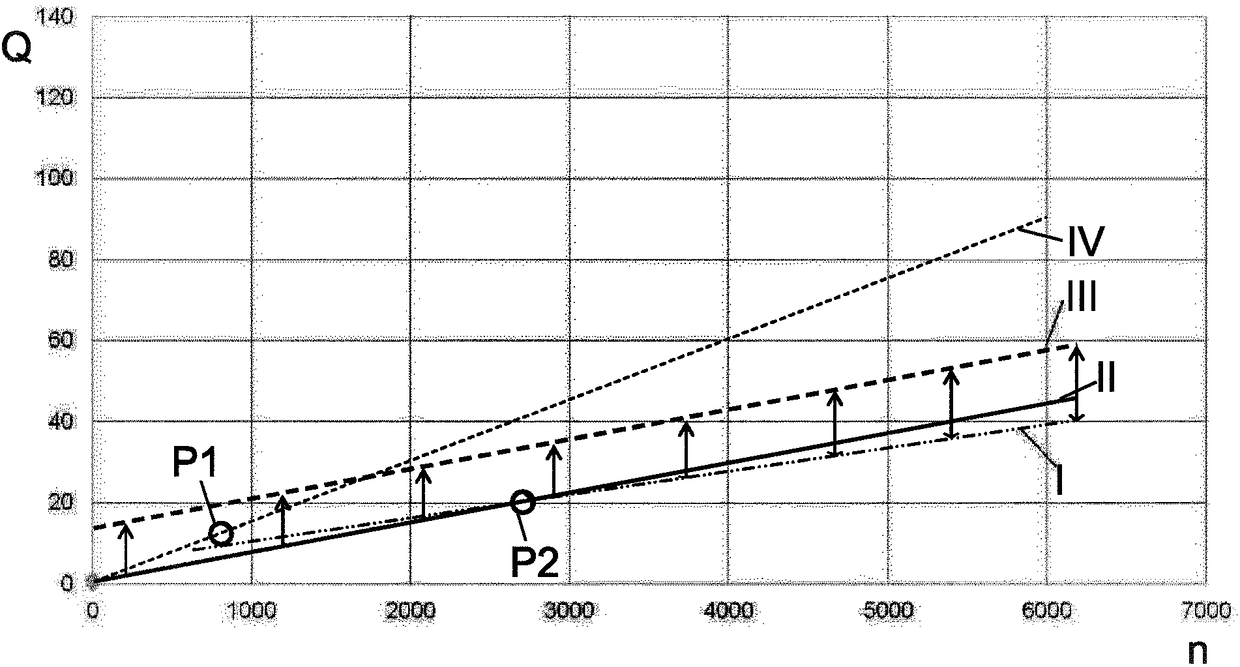

ActiveUS20180371966A1Easy constructionSmall diameterGear lubrication/coolingRotary piston pumpsElectricityMobile vehicle

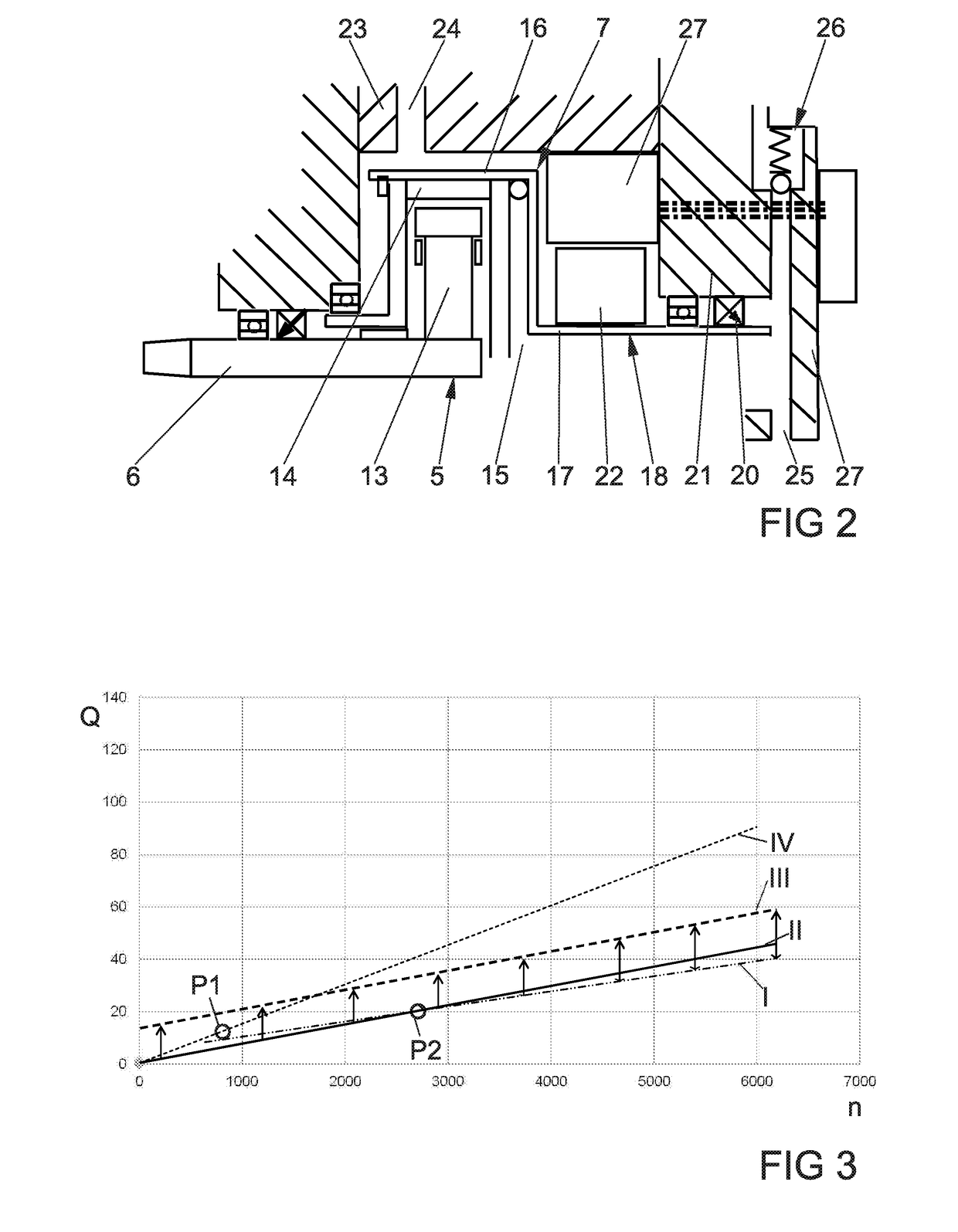

A delivery device for a motor vehicle for delivering oil from an oil sump to a lubricating oil circuit of internal combustion engine has, as an oil pump, a double-stroke vane-type pump with positive guidance of vanes. A direct drive of the vane-type pump by means of the internal combustion engine is configured for an operating point P2. An increased or reduced oil demand is compensated by means of an activatable electric drive. A compact oil pump of very small dimensions may thus be used.

Owner:VITESCO TECH GERMANY GMBH

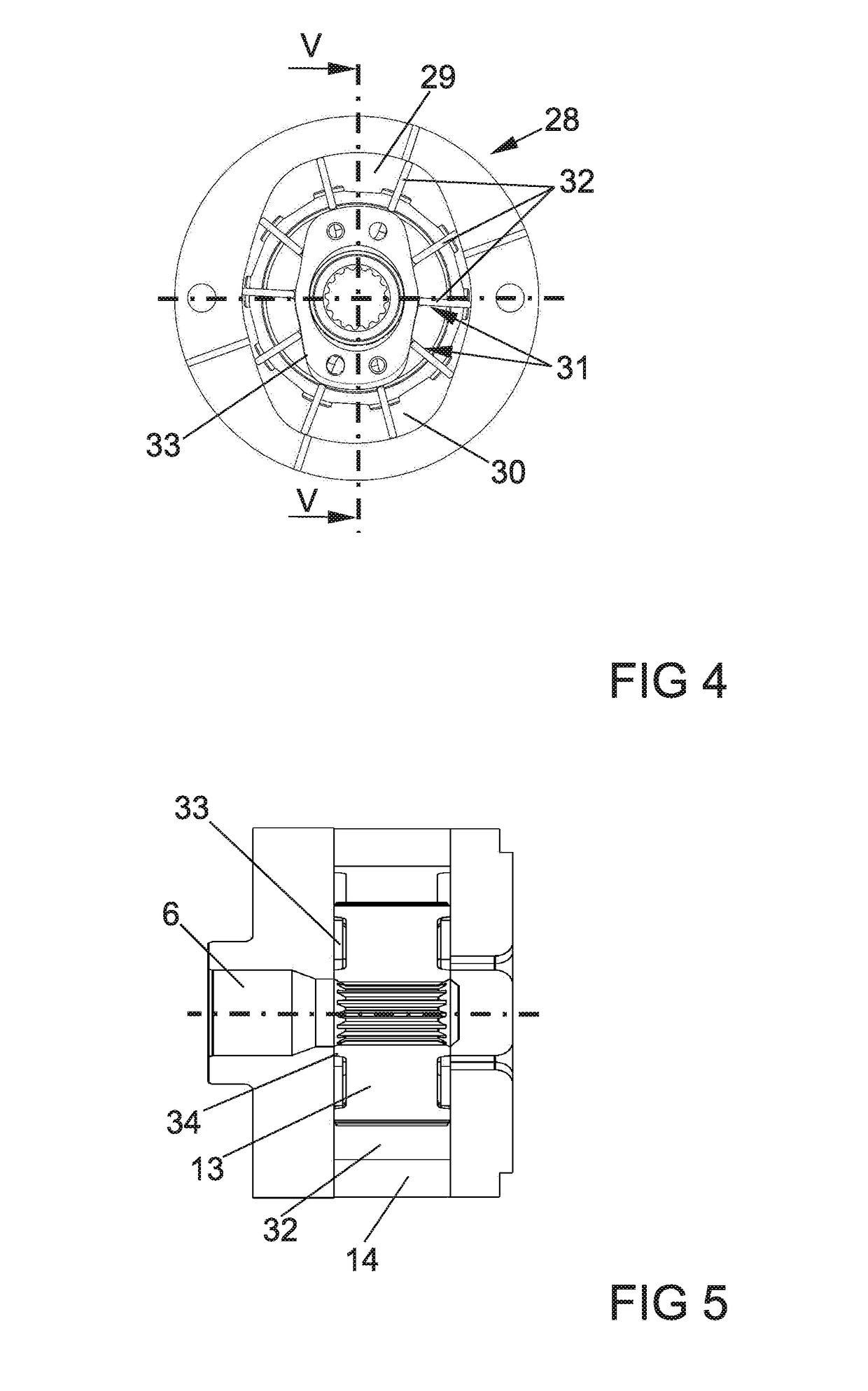

Delivery device for motor vehicle

ActiveCN108138612AReduce delivery powerMeet increased demandGear lubrication/coolingRotary piston pumpsElectricityExternal combustion engine

The invention relates to a delivery device (2) for a motor vehicle for delivering oil from an oil sump (3) to a lubricating oil circuit of an internal combustion engine (1), which delivery device hasas an oil pump (5) a double-stroke vane cell pump (28) having positive guidance of vanes (32). A direct drive (6) of the vane cell pump (28) via the internal combustion engine (1) is designed for a working point P2. An increased or reduced oil demand is compensated for by an electric drive (7) that can be connected. In this way, a compact and very small-dimensioned oil pump (5) can be employed.

Owner:VTESCO TECH GMBH

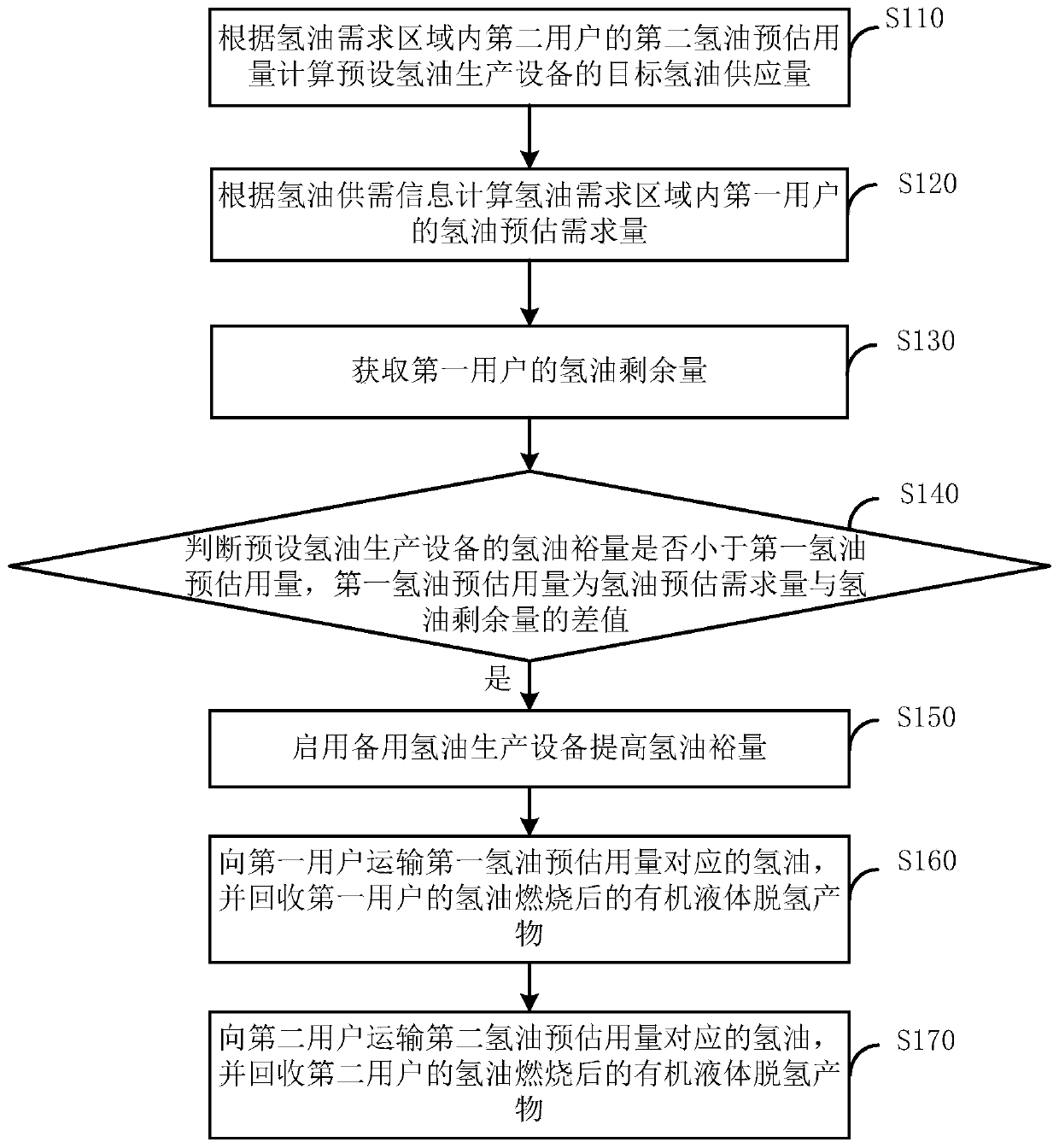

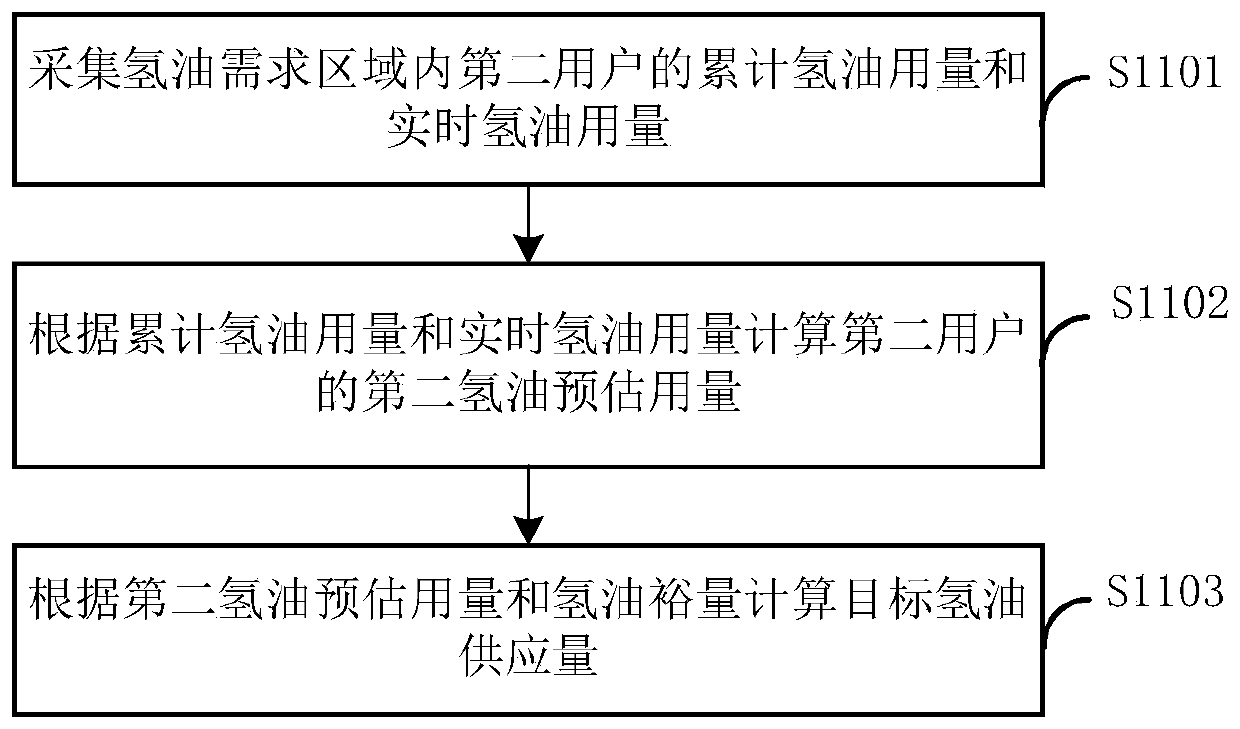

Hydrogen oil production control method

The embodiment of the invention provides a hydrogen oil production control method, and the method comprises the steps: calculating the estimated hydrogen oil demand of a first user in a hydrogen oil demand region according to hydrogen oil supply and demand information, and the hydrogen oil supply and demand information comprising power grid power failure information and power grid load information; obtaining the hydrogen oil surplus of the first user; judging whether the hydrogen oil allowance of preset hydrogen oil production equipment is smaller than a first hydrogen oil estimated amount ornot, wherein the first hydrogen oil estimated dosage being a difference between the hydrogen oil estimated demand amount and the hydrogen oil allowance; if the hydrogen oil allowance is smaller than the first hydrogen oil estimated amount, starting standby hydrogen oil production equipment to increase the hydrogen oil allowance, so that the hydrogen oil allowance is greater than or equal to the first hydrogen oil estimated dosage; and transporting hydrogen oil corresponding to the first hydrogen oil estimated amount to a first user, and recovering crude oil of the first user. According to theembodiment of the invention, the energy consumption is reduced by accurately calculating the hydrogen oil production yield, the hydrogen oil application cost is reduced, and popularization and application of hydrogen oil are facilitated.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Speed adjusting method of hydraulic system transmission mechanism

InactiveCN102954055AMeet the process requirementsHigh movement precisionServomotorsHydraulic motorLogical combination

The invention discloses a speed adjusting method of a hydraulic system transmission mechanism, and the speed adjusting method is characterized by comprising the following steps of installing and determining a hydraulic actuation element, adopting a reversing valve or a logic control unit to control the direction, and adopting a logical combination structure of a cartridge valve and a pilot control valve; adopting a quantitative pump to supply oil, utilizing a flow control valve to change the flow inputting or outputting from the hydraulic actuation element to adjust the speed, and adjusting the speed by changing the displacement of a hydraulic pump or a hydraulic motor; a variable pump is used for supplying the oil in the volume throttling speed adjusting process, utilizing the flow control valve to adjust the flow inputted into or outputted from the hydraulic actuation element, ensuring the oil supply quantity to be equivalent to the oil demand quantity, and determining a circulating form of a loop; and adopting an open circulating way to make the hydraulic pump suck oil from an oil tank, and returning the pressure oil back to the oil tank after releasing the energy through the system. The method has the beneficial effects that different technique requirements of a pressing workpiece can be completely and accurately satisfied, the movement precision of the machine is improved, the abrasion situation is reduced, the service life is prolonged, and the stress of the machine body is assisted.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

System and method of providing hydraulic pressure for mechanical work from an engine lubricating system

The method provides hydraulic pressure for mechanical work from an engine lubricating system in an internal combustion engine by supplying oil to an engine lubrication gallery for lubricating the engine and to at least one variable oil demand accessory. Each of the variable oil demand accessories has an individual pressure regulator. The output of the variable displacement pump is regulated based on the sum of fluid flow required by the engine lubricating system and the engine accessories, regardless of the engine output. The demand for fluid is determined by the individual pressure regulators on each of the engine accessories. In a preferred embodiment, an accumulator stores high-pressure fluid to be used to power the hydraulic accessories.

Owner:BORGWARNER INC

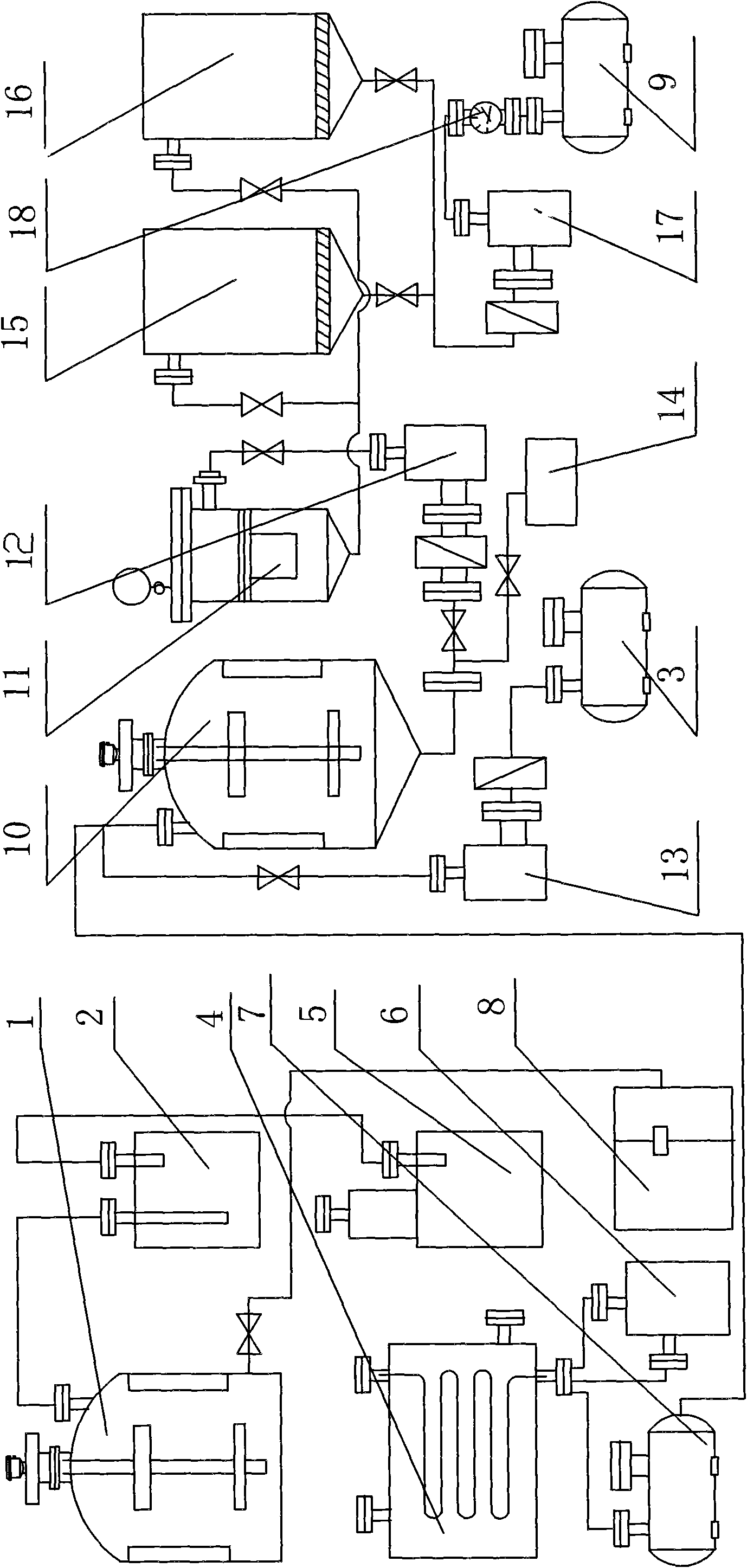

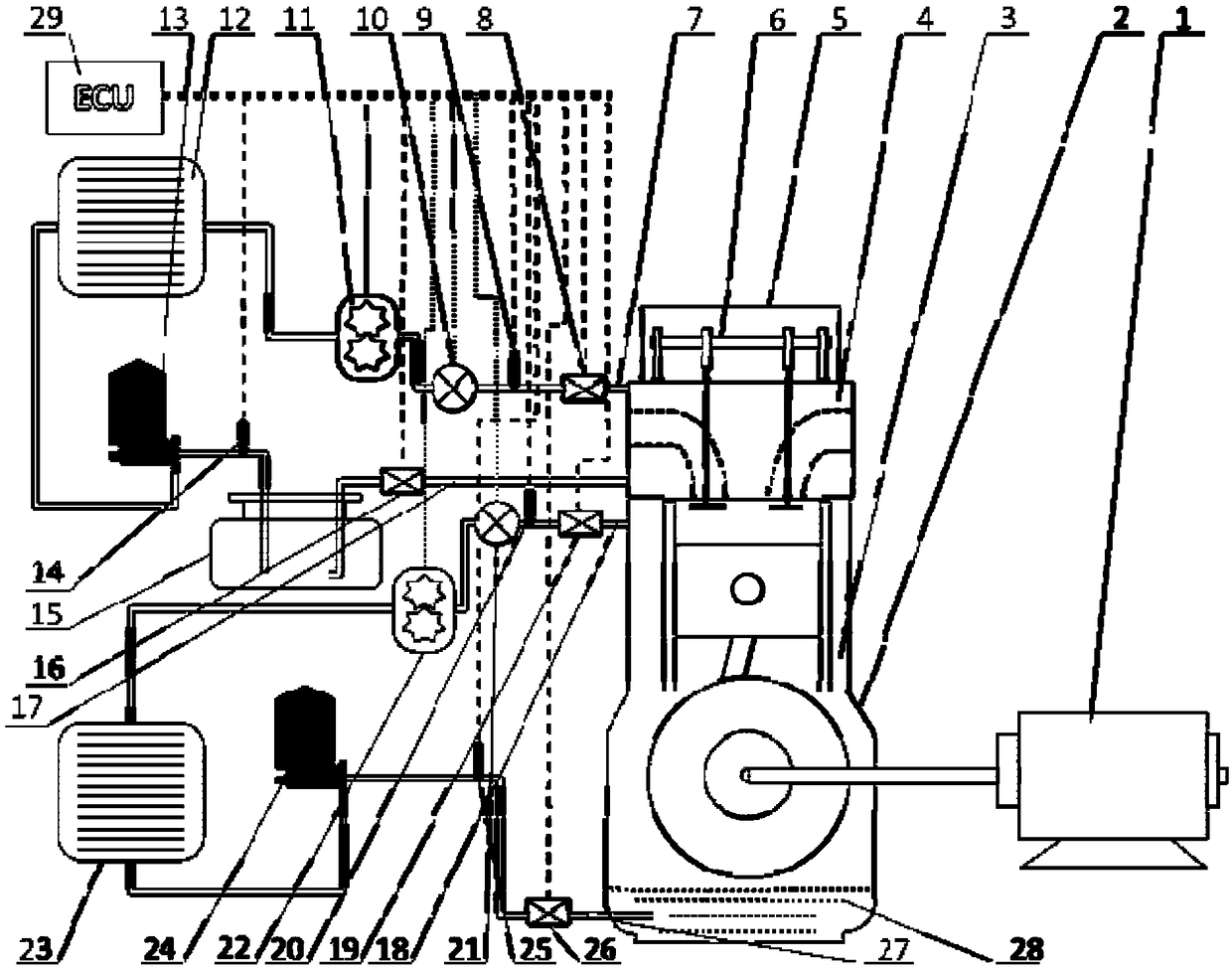

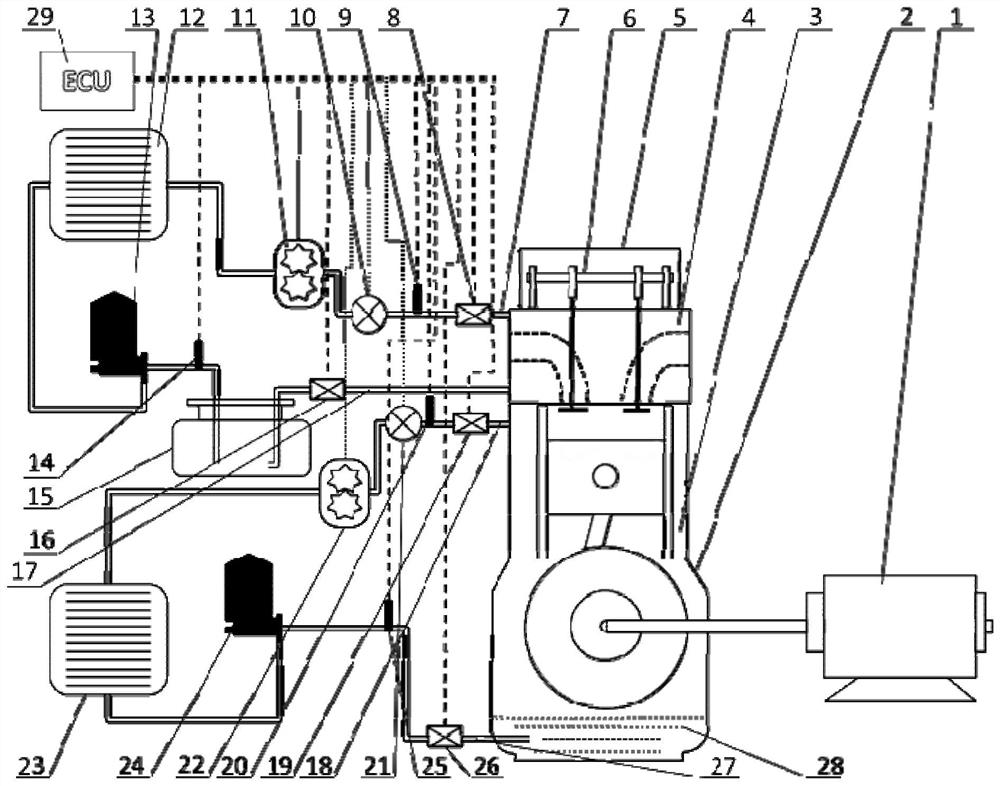

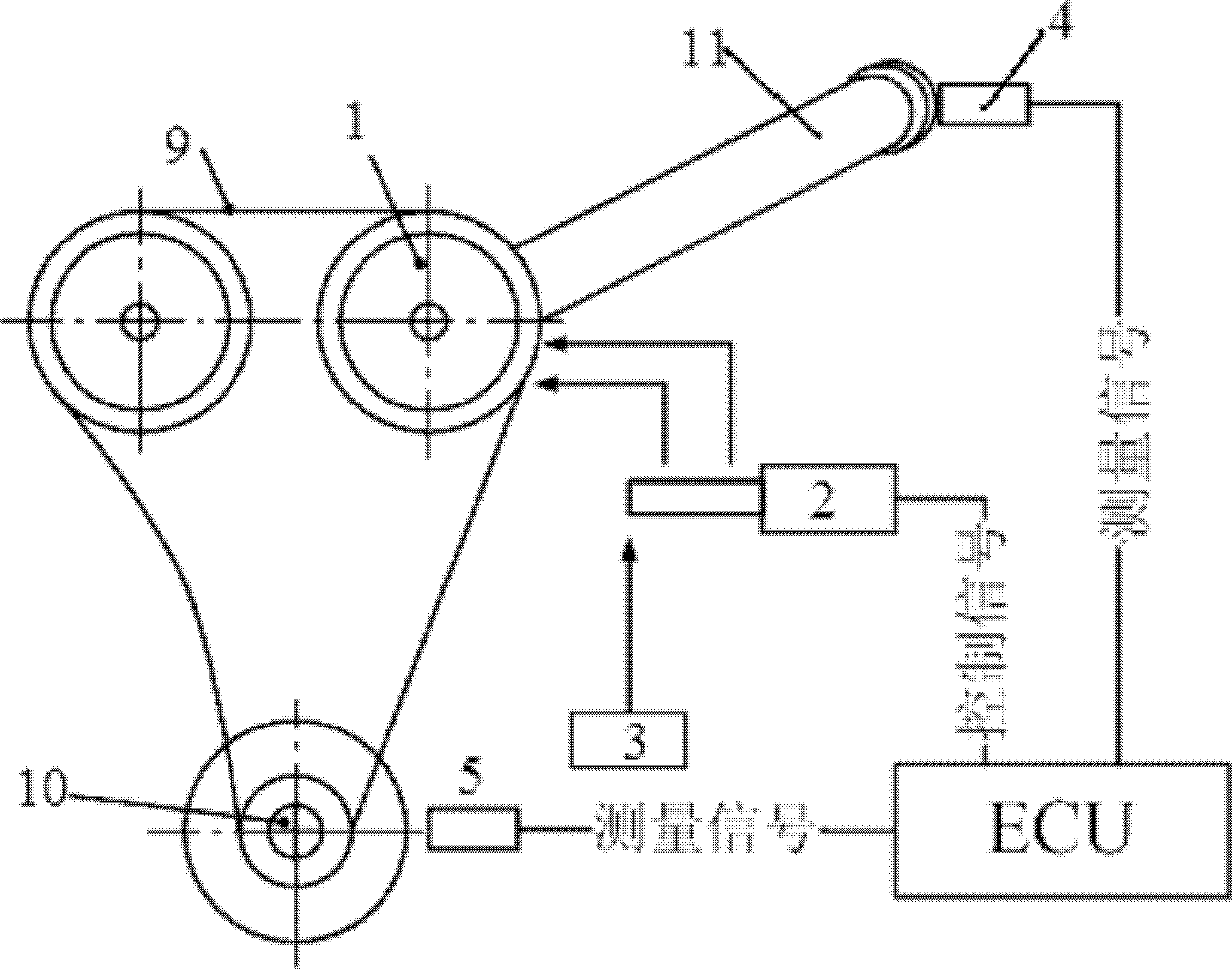

Distributed independent lubricating engine testing device

ActiveCN109184848AIndependent measurementIndependent assessmentMachines/enginesPressure lubrication with lubrication pumpEngine testingDynamometer

The invention provides a distributed independent lubricating engine testing device. The distributed independent lubricating engine testing device comprises a dynamometer, an engine, an ECU, an upper independent lubricating system and a lower independent lubricating system. The dynamometer is connected with the engine. The engine is internally provided with an oil bottom shell, an engine body, a cylinder cover, a gas distribution mechanism and an engine valve cover sequentially from bottom to top. A pipeline at one end of the upper independent lubricating system is connected to the gas distribution mechanism, and a pipeline at the other end of the upper independent lubricating system is connected to the cylinder cover. A pipeline at one end of the lower independent lubricating system is connected to the engine body, and a pipeline at the other end of the lower independent lubricating system is connected to the oil bottom shell. The upper independent lubricating system and the lower independent lubricating system are both in signal connection with the ECU. According to the distributed independent lubricating engine testing device, the upper portion and the lower portion of the engineare separated, and the changes of the lubricating oil demands, the lubricating oil consumption amounts, the part frictional wear states and the lubricating oil quality of the upper portion and the lower portion of the engine along with the working condition and the operation time can be measured and evaluated more accurately and independently.

Owner:CHINA NORTH ENGINE INST TIANJIN

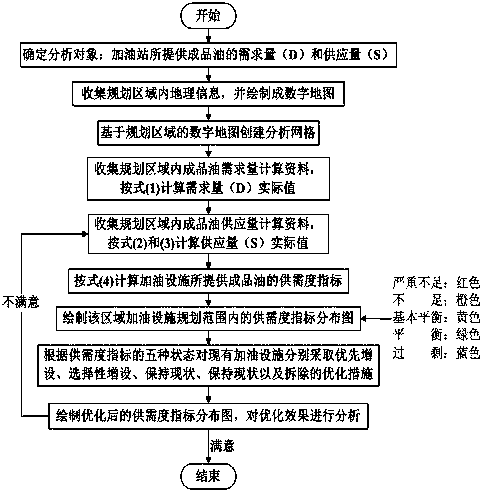

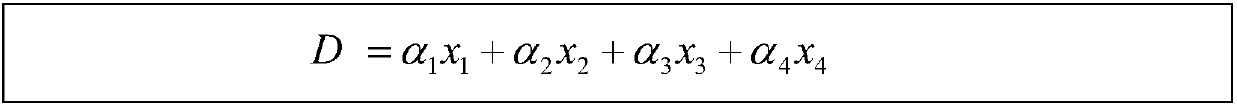

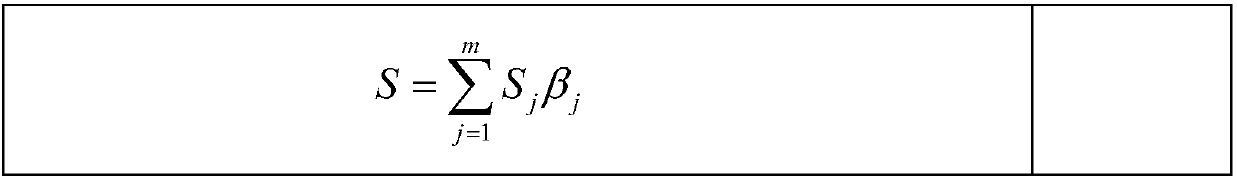

Refueling facility layout optimization method based on refined oil supply and demand indexes

InactiveCN107609766AImprove effectivenessHigh implementabilityResourcesLayout planningUrban infrastructure

The invention discloses a refueling facility layout optimization method based on the refined oil supply and demand indexes. Firstly, the refined oil demand distribution of the refueling facilities ina gas station layout planning area is predicted according to the actual number of cars, buses, passenger cars and freight cars in the area. Secondly, the refined oil supply distribution of the refueling facilities in the area is predicted according to the designed daily supply of refined oil of each refueling facility, the natural distance between the refueling facilities and users and the road condition. Thirdly, the refined oil supply and demand distribution of the area is determined based on the ratio of the refined oil demand distribution to the refined oil supply distribution, and whetherthe refueling facilities are seriously inadequate, inadequate, basically balanced, balanced or surplus is determined. Finally, the layout of the refueling facilities is optimized based on the state of the refueling facilities. The refueling facility layout optimization method is conducive to the precise and differentiated planning and layout of urban infrastructure, and can improve the effectiveness and feasibility of urban and rural planning and further promote the healthy development of cities.

Owner:JINLING INST OF TECH

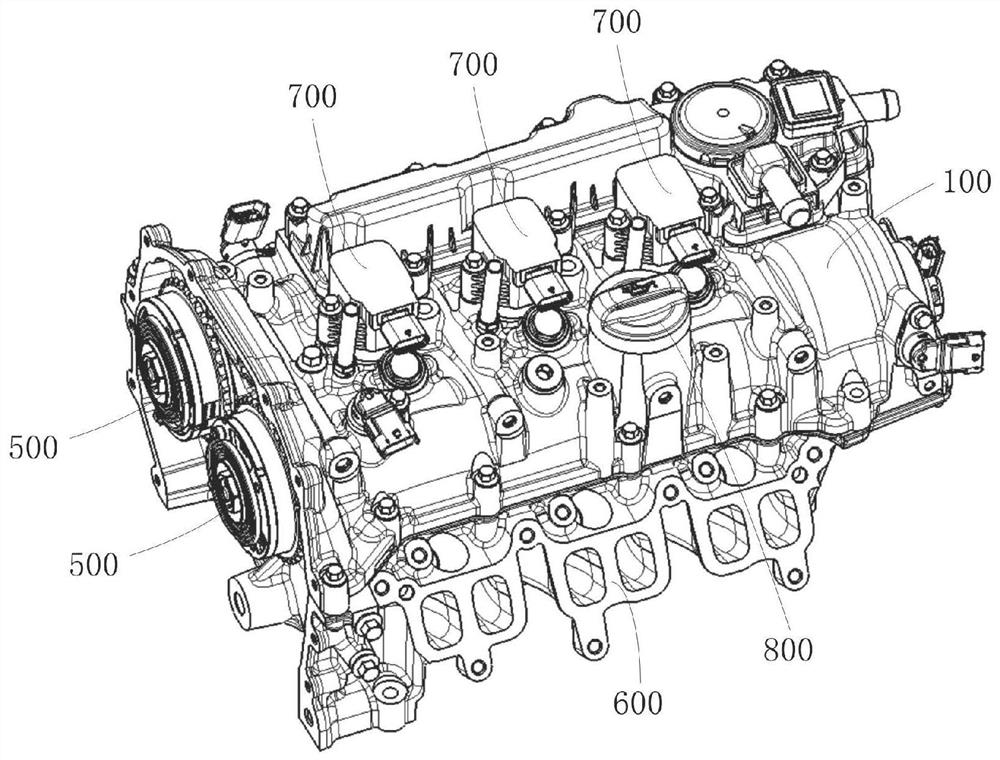

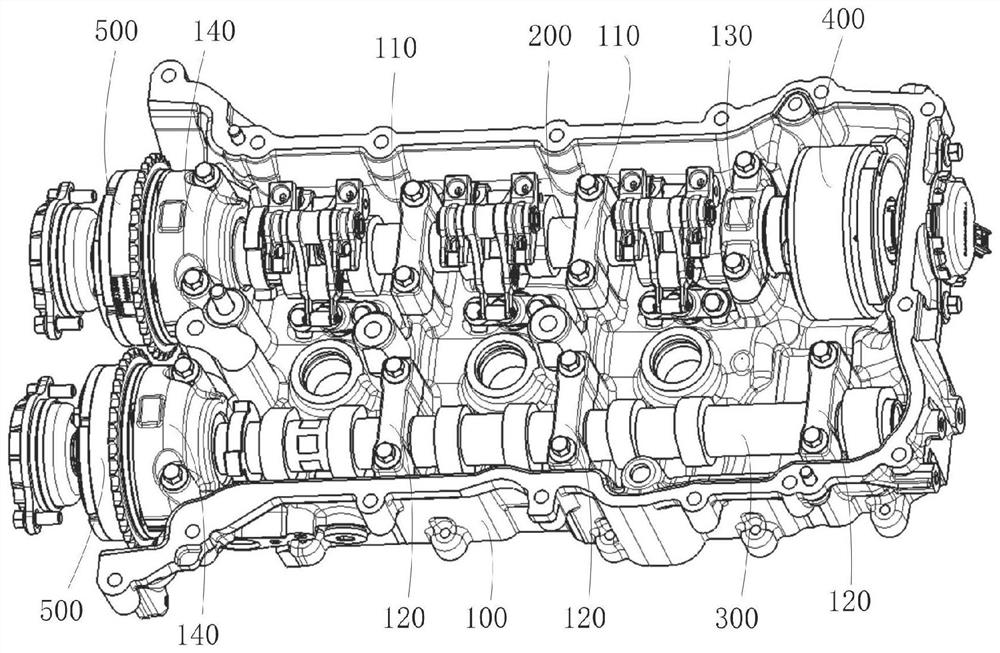

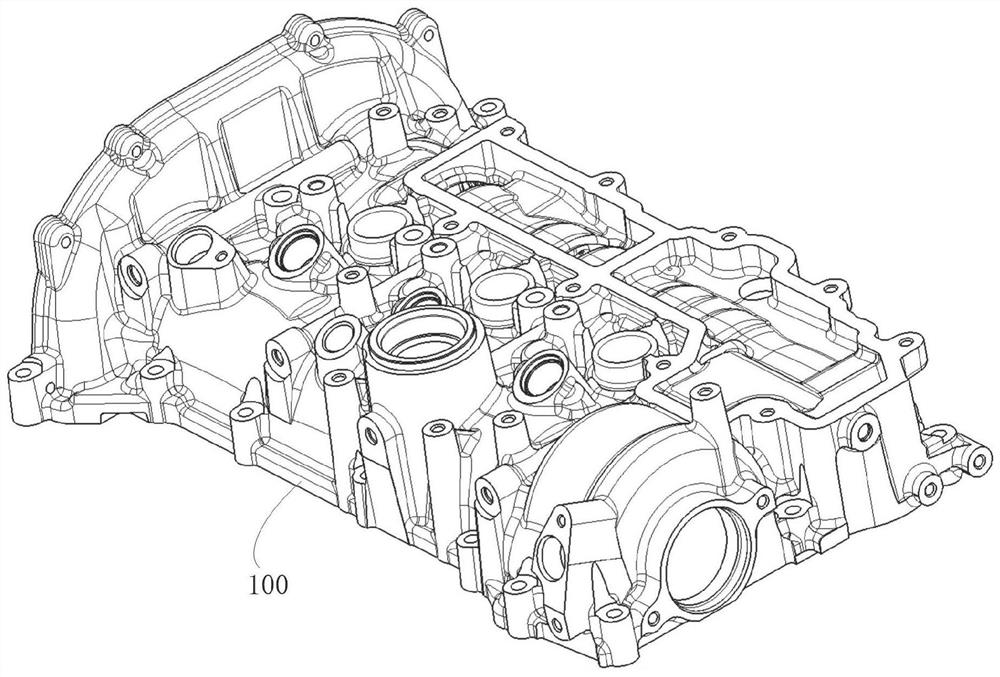

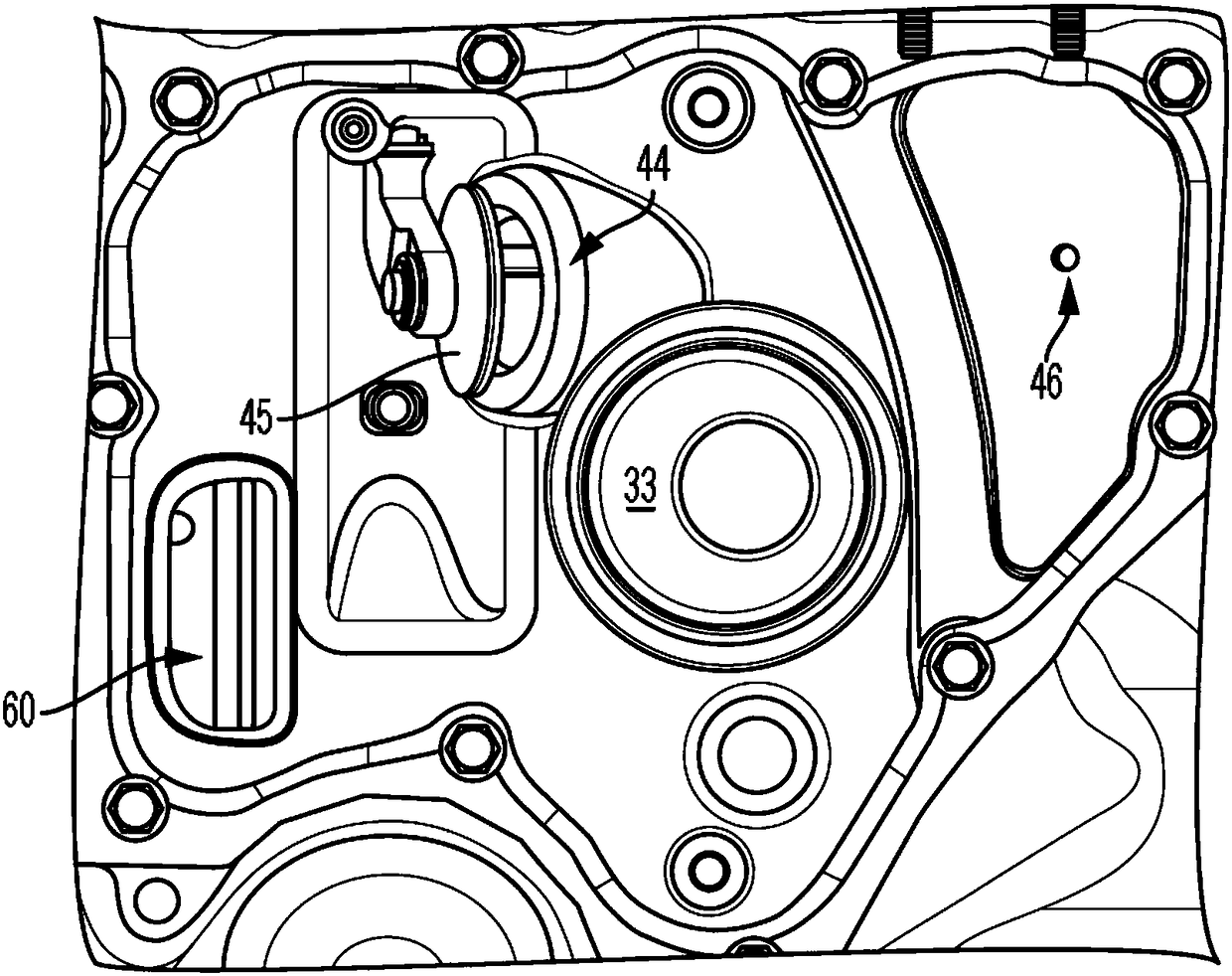

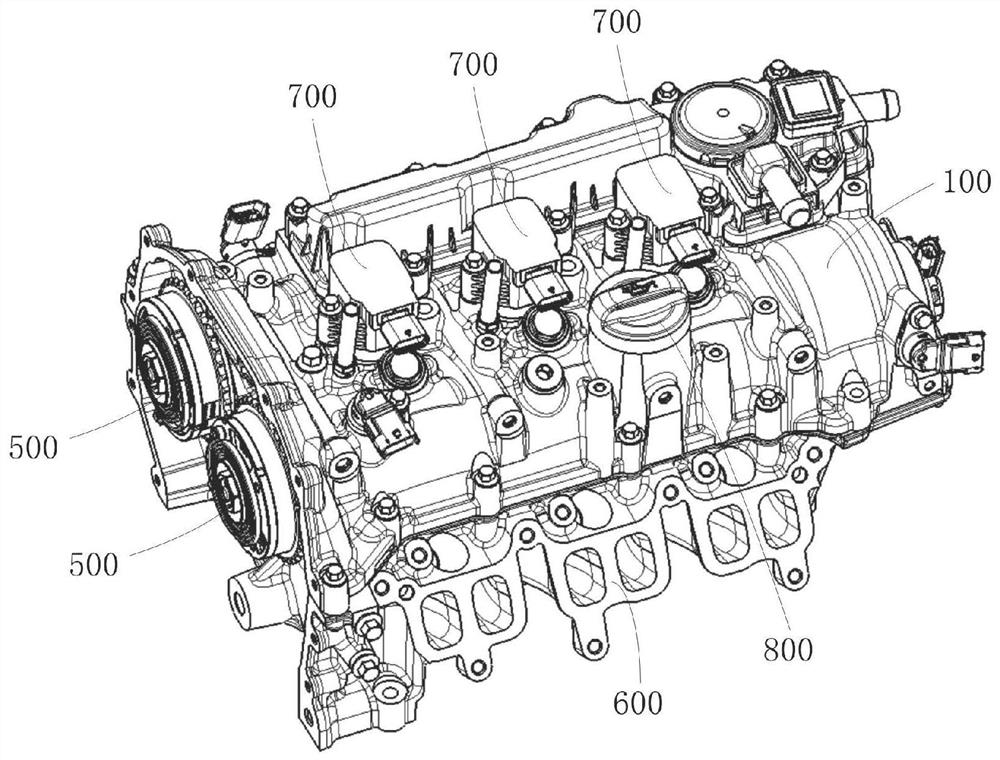

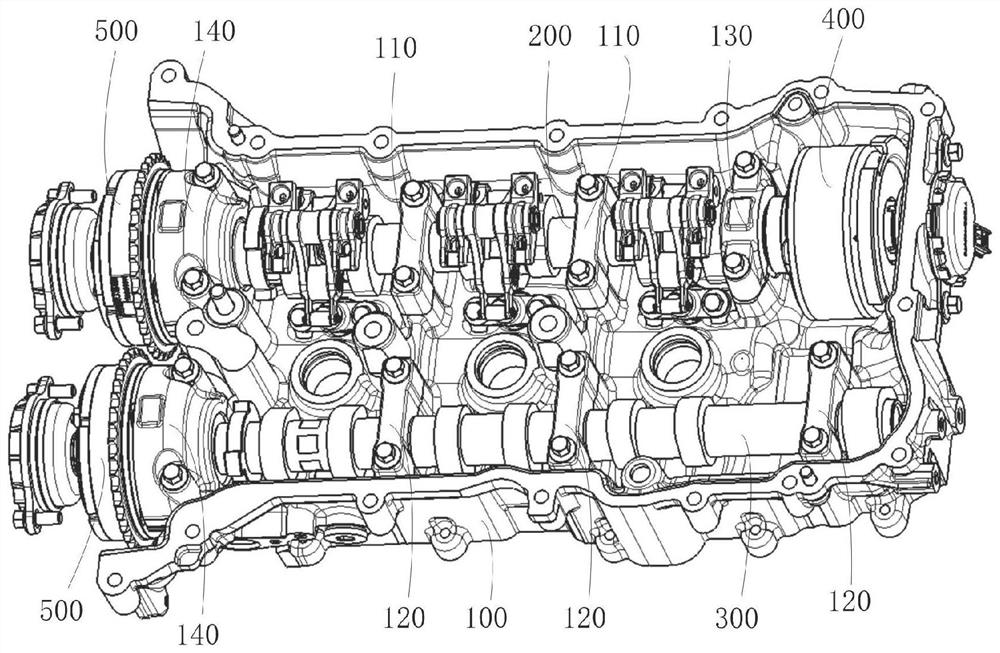

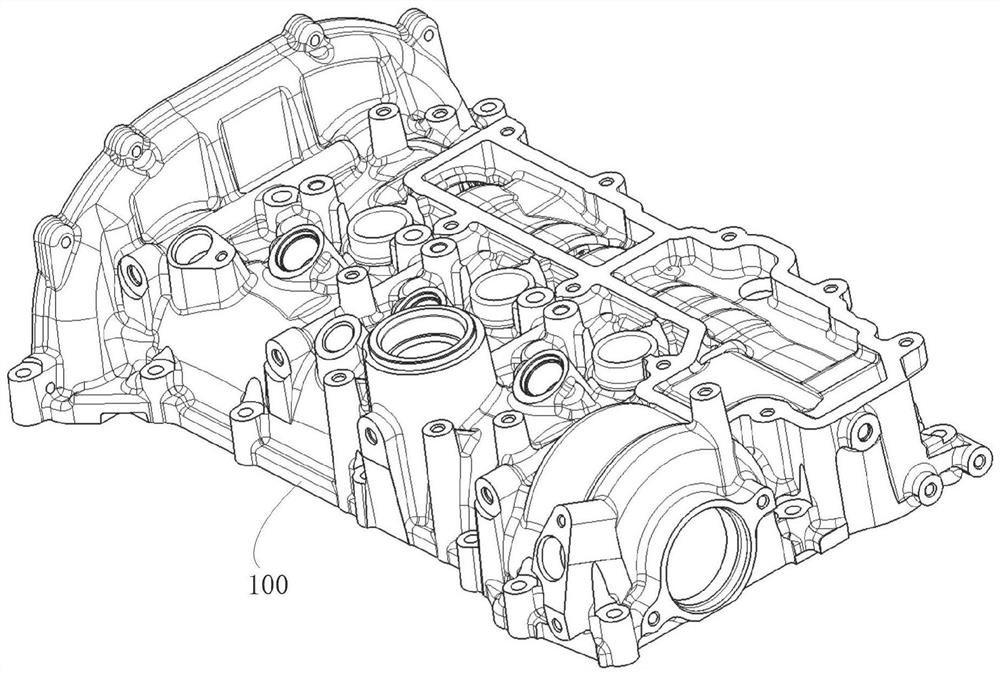

Integrated cylinder head cover and automobile engine

The invention relates to an integrated cylinder head cover and an automobile engine. The integrated cylinder head cover comprises a head cover body, a cam shaft mounting base arranged in the middle ofthe head cover body, an electromagnetic valve mounting base and a variable valve mounting base which are arranged at two ends of the head cover body correspondingly, a first lubricating oil channel structure and a second lubricating oil channel structure. The first lubricating oil channel structure comprises a cam shaft conveying oil channel formed in the middle of the head cover body, a cam shaft lubricating oil channel formed in the cam shaft mounting base and a variable valve lubricating oil channel formed in the variable valve mounting base; both of the cam shaft lubricating oil channel and the variable valve lubricating oil channel communicate with the cam shaft conveying oil channel; and the second lubricating oil channel structure comprises an electromagnetic valve conveying oil channel arranged at the end of the head cover body and an electromagnetic valve lubricating oil channel arranged on the electromagnetic valve mounting base. The integrated cylinder head cover and the automobile engine provided by the invention can solve the problem that in the related technology, after the cylinder head cover is integrated with VVT, VVL and other mechanisms, the engine oil demand isincreased, and consequently the lubricating condition of a cam shaft is deteriorated.

Owner:DONGFENG MOTOR CORP HUBEI

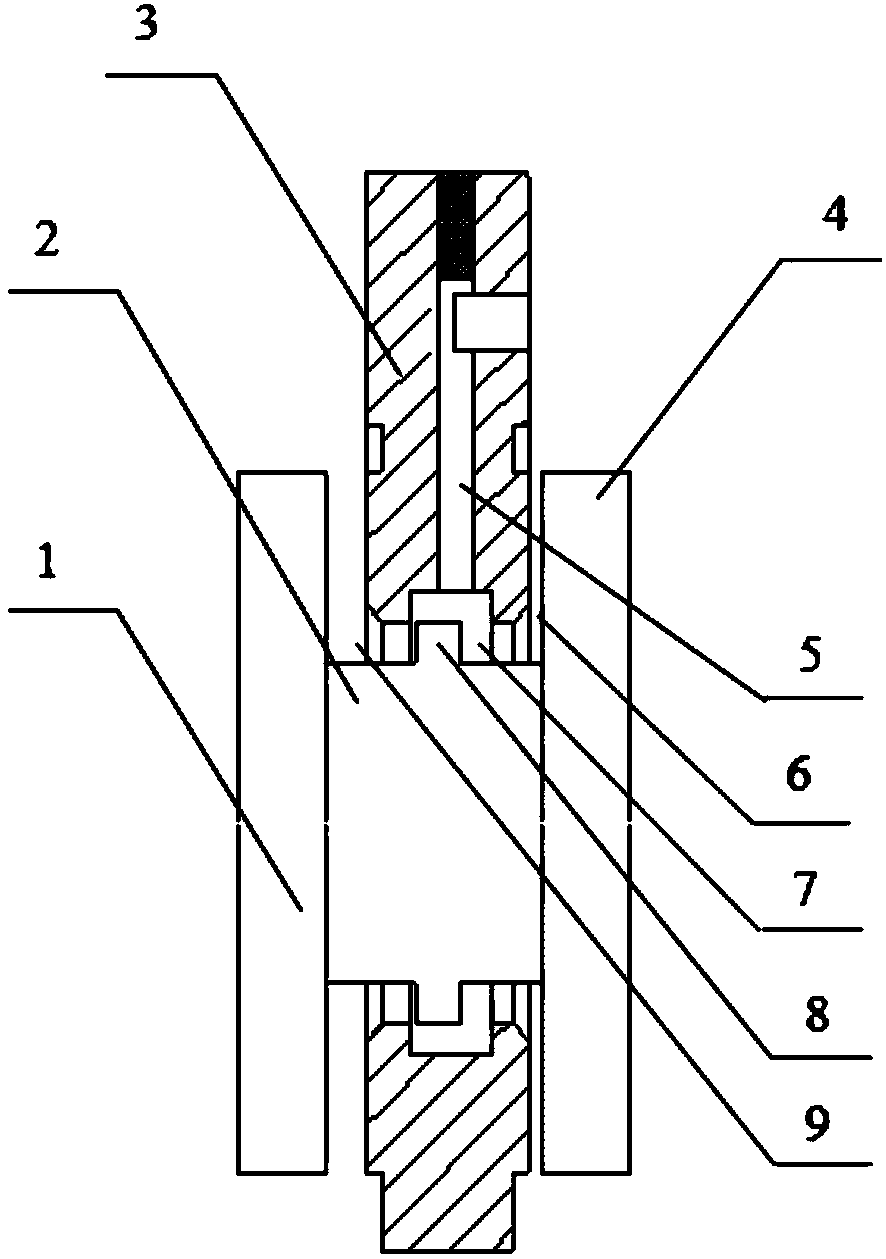

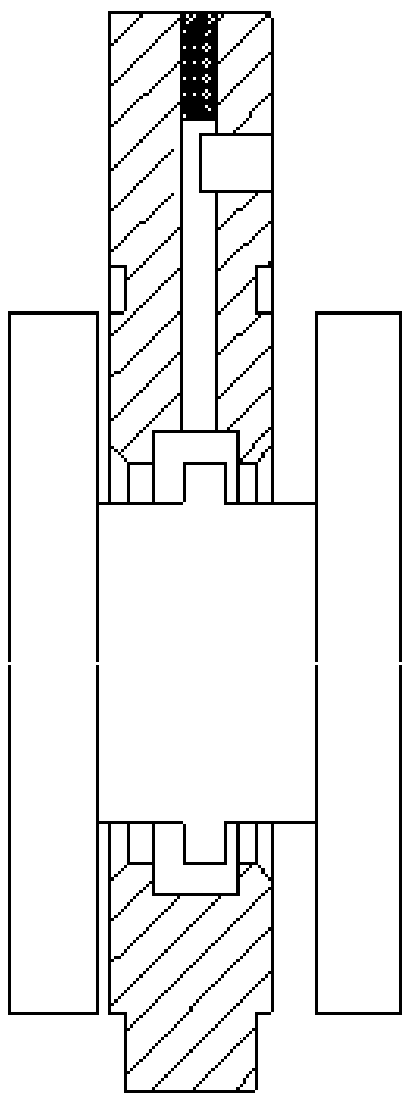

Dynamic oil limiting type trust bearing of turbocharger

ActiveCN106763152ADoes not affect normal bearingReduce demandShaftsBearing componentsTurbochargerThrust bearing

The invention provides a dynamic oil limiting type thrust bearing of a turbocharger. The dynamic oil limiting type thrust bearing comprises a bearing body, a first thrust plate, a spacer sleeve, a thrust bearing plate and a second thrust plate. The first thrust plate and the second thrust plate are fastened to a rotary shaft and fixedly connected through the spacer sleeve which is connected to the middle of the thrust bearing plate fixed to the bearing body in a sleeving mode. A first bearing gap and a second bearing gap are separately formed between the first thrust plate and the thrust bearing plate and between the second thrust plate and the thrust bearing plate. The thrust bearing plate is provided with an oil inlet and a circumferential oil storage and distribution cavity communicating with the oil inlet. The spacer sleeve is provided with an oil limiting ring in the circumferential direction of the outer diameter. The oil limiting ring is located in the oil storage and distribution cavity. The dynamic oil limiting turbocharger has the beneficial effects that under the condition that normal oil supply to a bearing surface is ensured, dynamic bilateral reversing operation is achieved through the oil limiting ring and the oil storage and distribution cavity, the lubricating oil quantity on the non-bearing surface of the thrust bearing is limited, the total lubricating oil demand of the thrust bearing is decreased, and meanwhile, normal bearing of the bearing face of the thrust bearing is not affected.

Owner:CHINA NORTH ENGINE INST TIANJIN

System and method for detecting key parameters of large-power vibration valve

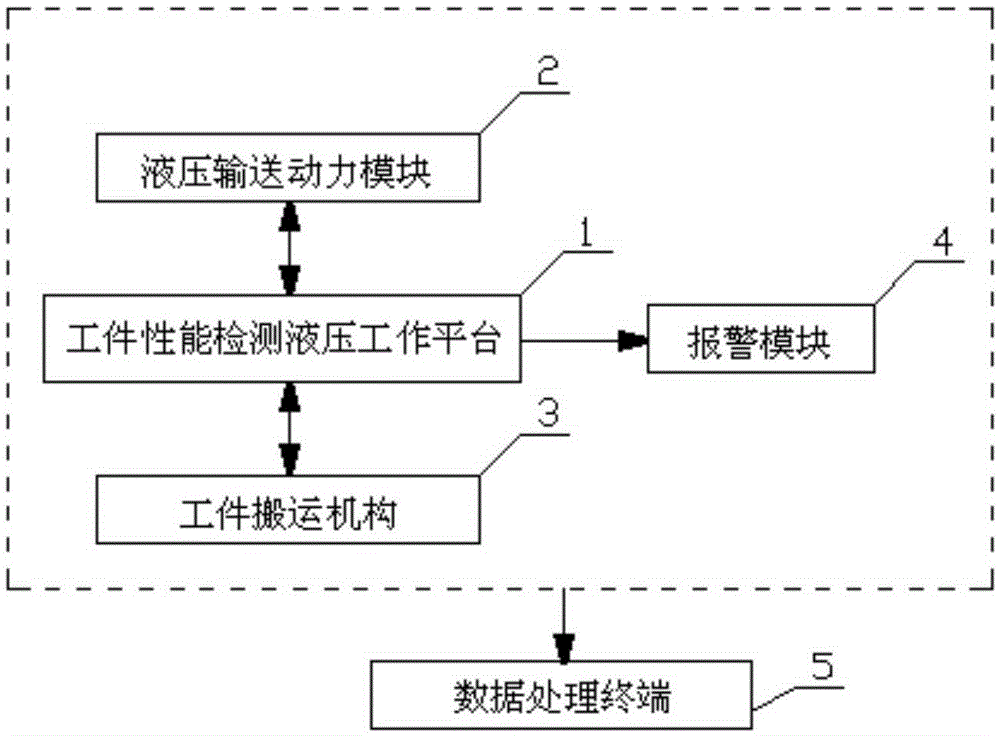

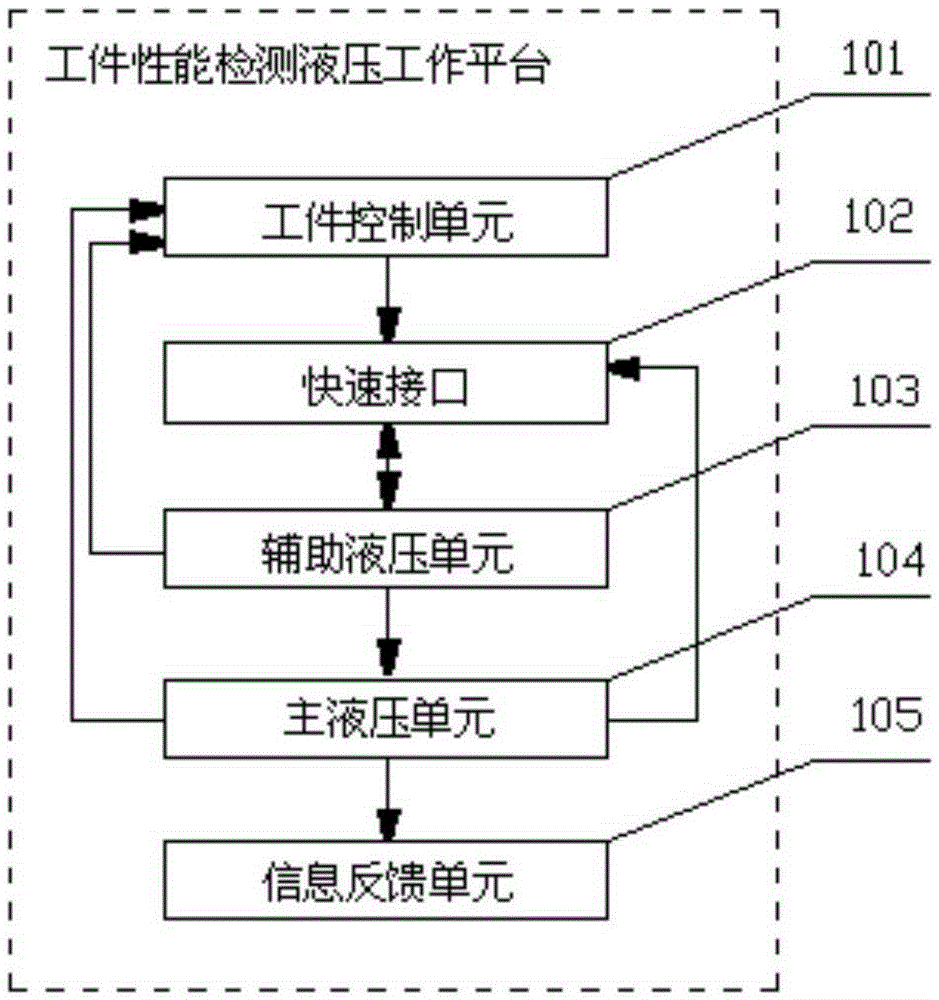

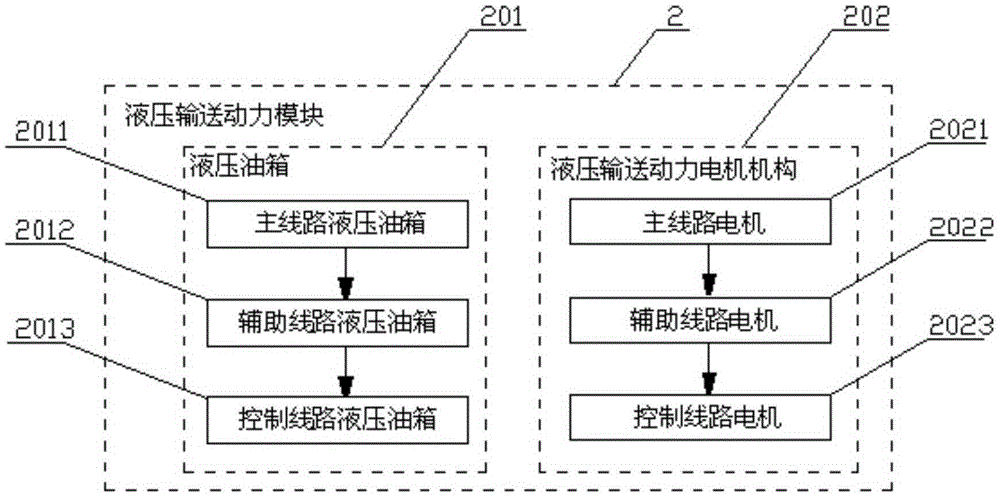

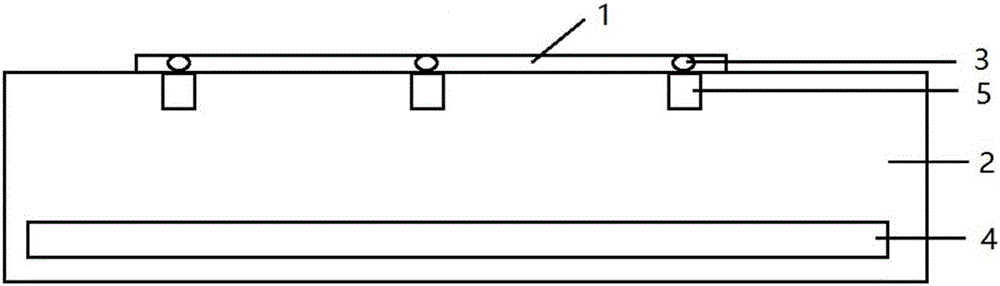

The invention relates to a system and method for detecting key parameters of a large-power vibration valve. The system comprises a hydraulic working platform for work piece performance detection which is used to detect sealing performance and operating performance of a detected work piece, a power transmission module which provides hydraulic oil demanded by an examination and provides power to the hydraulic working platform for the work piece performance detection as well as a work piece carrying mechanism which is used to carry the detected work piece to be examined by the hydraulic working platform for the work piece performance detection. The vibration valve detection system involved in the invention has the advantages that a detection field is saved; labor strength is reduced; working efficiency is increased; a vibration valve is detected intelligently and automatically in a batched manner, so that hydraulic oil consumption is reduced and thus testing cost is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Oil injection tank for workpiece oiling

ActiveCN106040503AMeet oiling needsImprove oiling effectLiquid surface applicatorsSpray nozzlesOil demandFuel tank

The invention discloses an oil injection tank for workpiece oiling. The oil injection tank comprises a tank body, a sprayer device and a conveyor belt, wherein the sprayer device is mounted above the tank body; the conveyor belt is mounted in the tank body and below the tank body; the sprayer device comprises a concentrator and a plurality of spray heads; the spray heads are all connected with the concentrator and are arranged on the inner side of the upper part of the tank body; the concentrator is arranged on the outer side of the upper part of the tank body. The oil injection tank for workpiece oiling has the following beneficial effects: the oiling effect is excellent, the atomization effect is adjustable, the later maintenance is facilitated, the operation is convenient, the oiling demands of different workpieces are met, the labor intensity is low, and the working efficiency is high.

Owner:浙江安统汽车部件有限公司

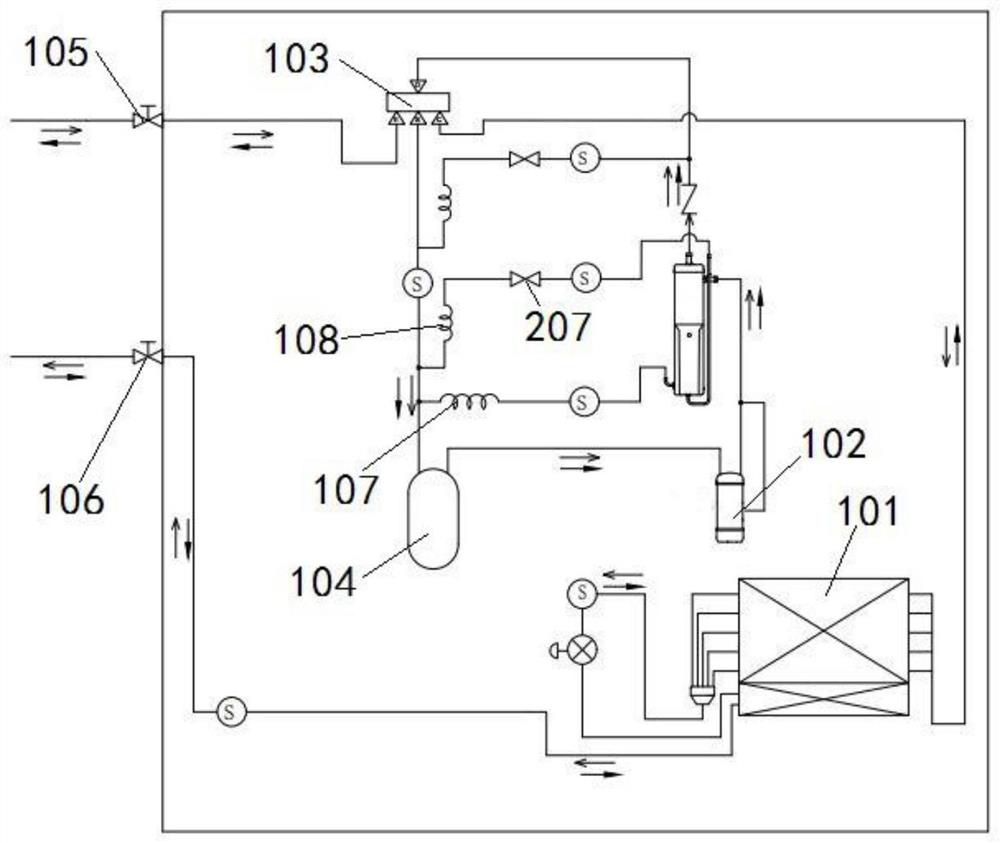

Air conditioner circulation system and circulation method thereof

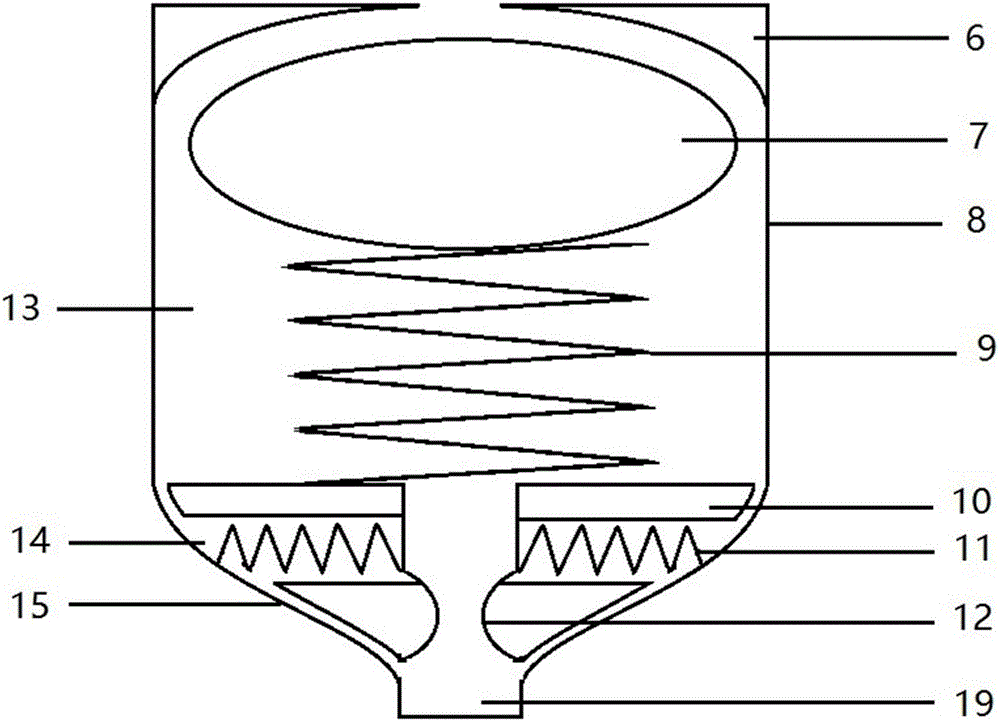

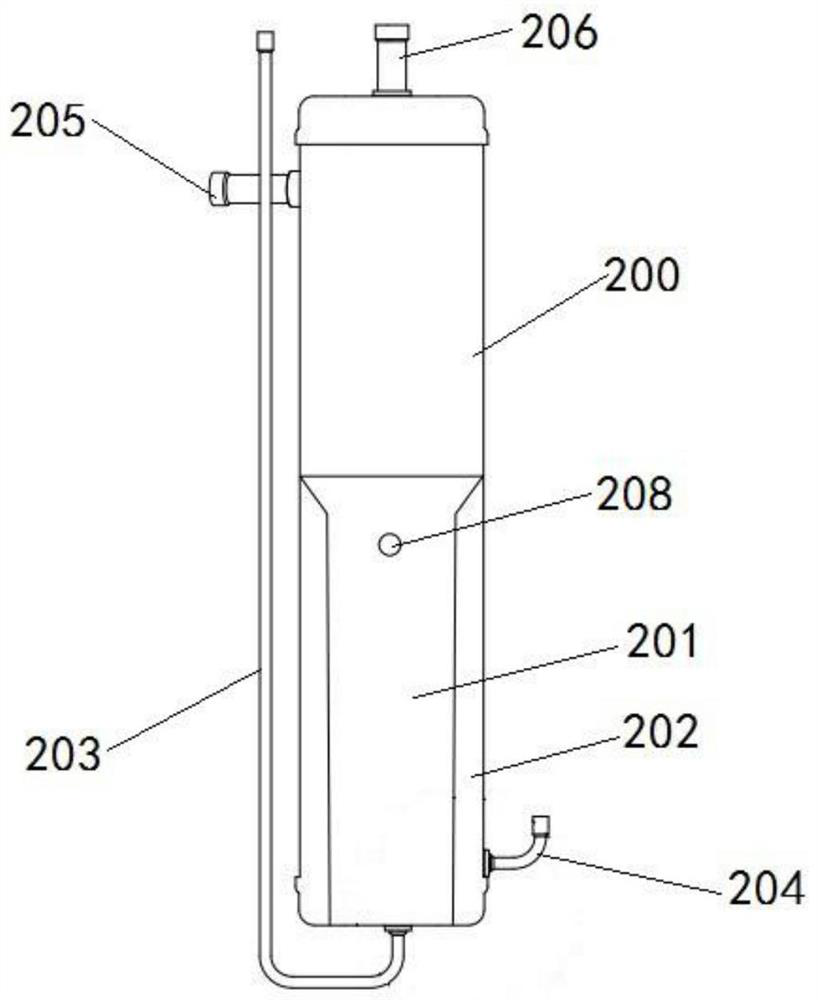

ActiveCN112648754AImprove heat transfer effectReduce oilCompressorCompression machines with reversible cycleOil separationElectromagnetic valve

The invention relates to the technical field of air conditioners, and discloses an air conditioner circulation system and a circulation method thereof. The air conditioner circulation system comprises a compressor, a heat exchanger and an oil separator, an oil storage part and an oil return part are arranged in the oil separator, a first oil return pipe is arranged to communicate with the oil storage part, and a second oil return pipe is arranged to communicate with the oil return part. An oil overflow hole is formed in the upper oil storage limit of the oil storage part, redundant oil flows into the oil return part, when the oil demand is large, an electromagnetic valve of the first oil return pipe is opened, the oil passes through the two pipelines simultaneously, when the oil demand is small, the electromagnetic valve of the first oil return pipe is closed, so that one part of oil is stored in the oil storage part, and the other part of oil flows into the oil return part; and the problems that the compressor needs a large amount of lubricating oil to maintain stable operation, but after the redundant lubricating oil enters the heat exchanger, the heat exchange effect of the heat exchanger is affected are solved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

A Distributed Independent Lubrication Engine Test Device

ActiveCN109184848BAccurate measurementAccurate assessmentMachines/enginesPressure lubrication with lubrication pumpEngine testingThermodynamics

The invention provides a distributed independent lubricating engine testing device. The distributed independent lubricating engine testing device comprises a dynamometer, an engine, an ECU, an upper independent lubricating system and a lower independent lubricating system. The dynamometer is connected with the engine. The engine is internally provided with an oil bottom shell, an engine body, a cylinder cover, a gas distribution mechanism and an engine valve cover sequentially from bottom to top. A pipeline at one end of the upper independent lubricating system is connected to the gas distribution mechanism, and a pipeline at the other end of the upper independent lubricating system is connected to the cylinder cover. A pipeline at one end of the lower independent lubricating system is connected to the engine body, and a pipeline at the other end of the lower independent lubricating system is connected to the oil bottom shell. The upper independent lubricating system and the lower independent lubricating system are both in signal connection with the ECU. According to the distributed independent lubricating engine testing device, the upper portion and the lower portion of the engineare separated, and the changes of the lubricating oil demands, the lubricating oil consumption amounts, the part frictional wear states and the lubricating oil quality of the upper portion and the lower portion of the engine along with the working condition and the operation time can be measured and evaluated more accurately and independently.

Owner:CHINA NORTH ENGINE INST TIANJIN

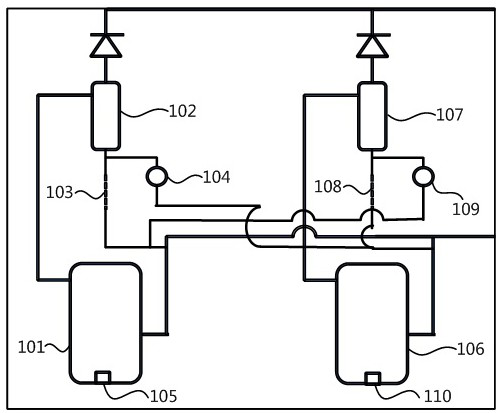

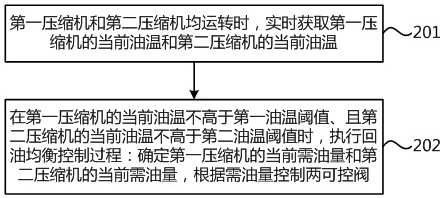

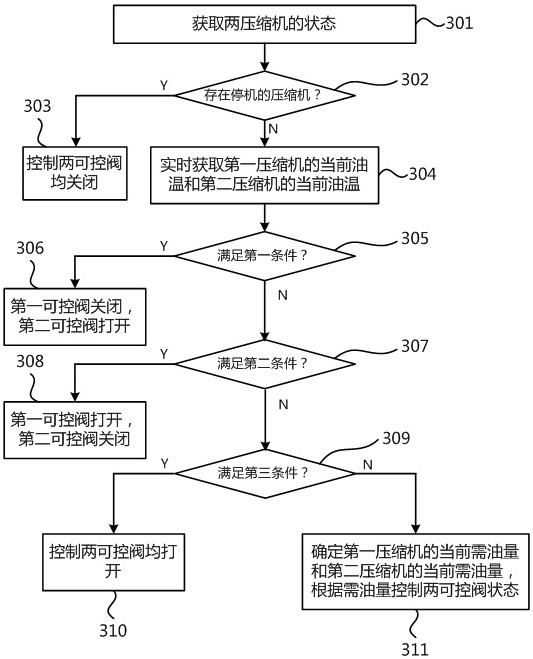

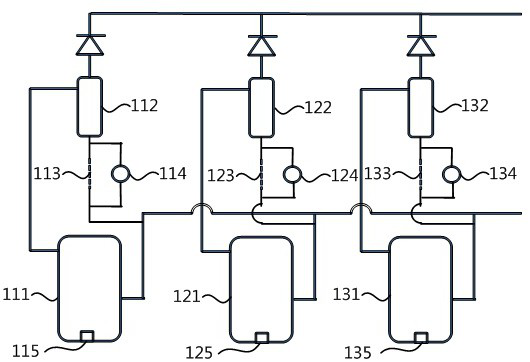

Double-compressor refrigerant circulation system and control method thereof

PendingCN114353360AEasy to operatePrecise oil return balance controlCompressorMechanical apparatusThermodynamicsControl theory

The invention discloses a double-compressor refrigerant circulation system and a control method thereof.The method comprises the steps that when a first compressor and a second compressor both operate, the current oil temperatures of the two compressors are obtained in real time; when the current oil temperatures of the two compressors are not higher than the corresponding oil temperature threshold values, the current oil demand of the first compressor and the current oil demand of the second compressor are determined based on the current oil temperatures and the current operation frequency; and controlling a first controllable valve and a second controllable valve according to the current oil demand of the first compressor and the current oil demand of the second compressor. By applying the invention, the precision of oil return control of the double compressors can be improved, and the operation stability of a refrigerant circulating system is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

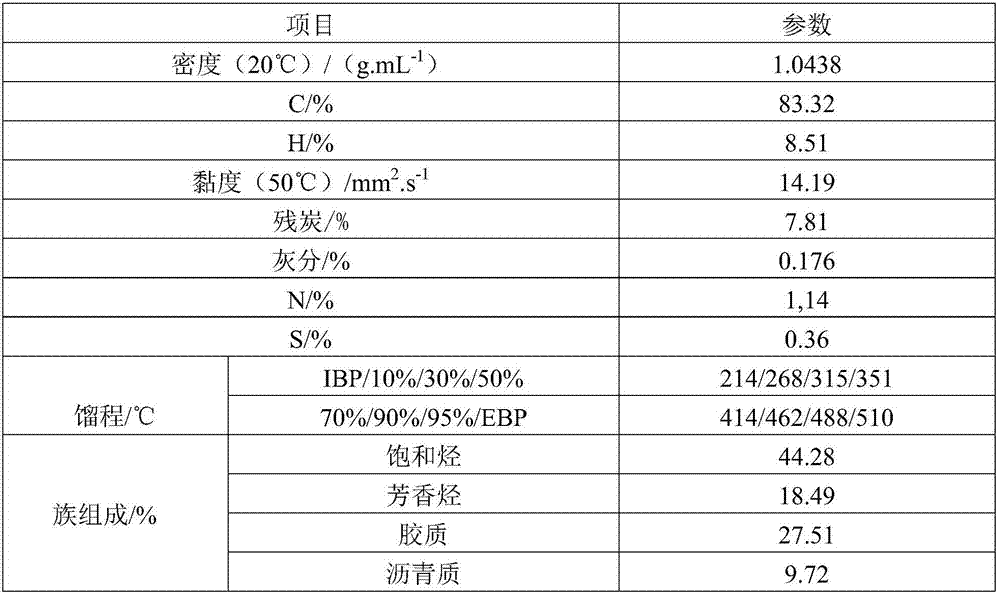

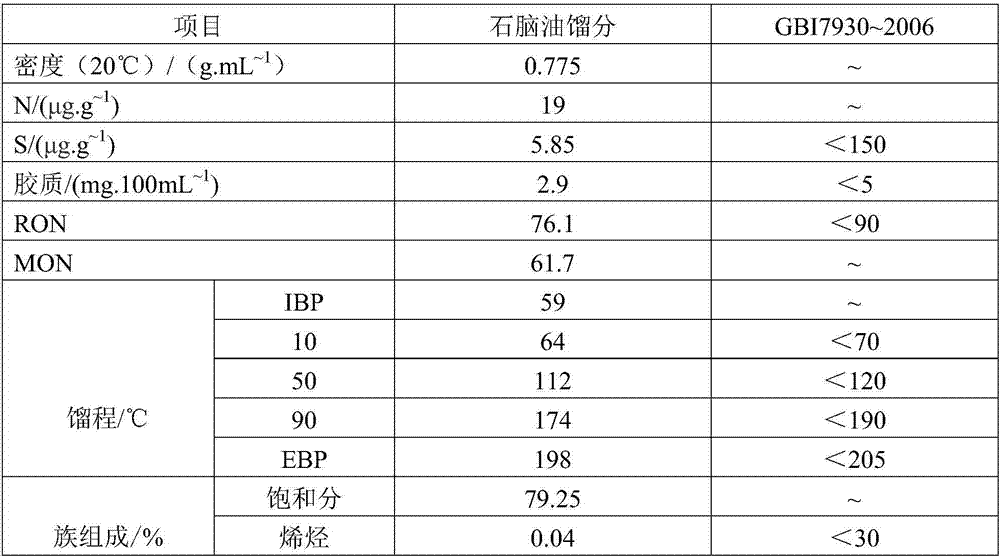

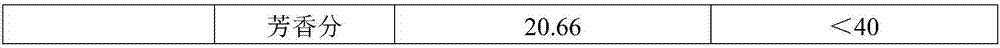

A method for producing high-density jet fuel by hydrogenation of medium and low temperature coal tar

InactiveCN105694970BImprove use valueQuality improvementTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention relates to a method for producing high-density jet fuel by hydrogenation of medium and low temperature coal tar. In the method, firstly, the medium and low temperature coal tar and hydrogen are mixed and heated, and the hydrogenation reaction is carried out successively through the hydrogenation protection catalyst and the hydrogenation refining catalyst. Naphtha, crude jet fuel and tail oil are obtained after product fractionation, and the crude jet fuel is refined with clay to obtain high-density No. 6 jet fuel with good oxidation stability, good emulsification resistance and good insulation. The present invention In view of the characteristics of large amount of cycloalkanes and aromatics in coal tar hydrogenation products, the hydrogenation-clay refining coupling process method is used to process coal tar into naphtha, jet fuel, etc. under specific process parameters and specific catalyst conditions. High value-added products, this method extends the coal tar hydrogenation industry chain, improves the utilization value of coal tar, and also expands the source of military fuel to better meet the oil demand for new weapons and equipment.

Owner:NORTHWEST UNIV

A dynamic oil-limited thrust bearing of a turbocharger

ActiveCN106763152BDoes not affect normal bearingReduce demandShaftsBearing componentsTurbochargerThrust bearing

Owner:CHINA NORTH ENGINE INST TIANJIN

Oil pan having small active volume oil reservoir and methods of using the same

Provided are oil reservoirs and engine oil circulation systems including an upper sump capable of receiving oil from an engine, a lower sump disposed vertically below the upper sump, a valve-controlled orifice (VCO) penetrating the upper sum bottom, an oil chimney capable of receiving oil and communicating oil to the lower sump, and an oil conduit capable of extracting oil from the lower sump. Methods for operating systems include maintaining the VCO in an open position for a draw down duration temporally proximate an engine cold start, subsequently circulating oil between the engine and the oil reservoir, actuating the VCO to a closed position subsequent to the draw down duration for a warmup duration, and actuating the VCO to an open position subsequent to the warmup duration. Methods can further include actuating the VCO to an open position during the warmup duration in response to an increased oil demand event.

Owner:GM GLOBAL TECH OPERATIONS LLC

Delivery device for a motor vehicle

ActiveUS10634235B2Easy constructionSmall diameterGear lubrication/coolingRotary piston pumpsElectric driveInternal combustion engine

A delivery device for a motor vehicle for delivering oil from an oil sump to a lubricating oil circuit of internal combustion engine has, as an oil pump, a double-stroke vane-type pump with positive guidance of vanes. A direct drive of the vane-type pump by means of the internal combustion engine is configured for an operating point P2. An increased or reduced oil demand is compensated by means of an activatable electric drive. A compact oil pump of very small dimensions may thus be used.

Owner:VITESCO TECH GERMANY GMBH

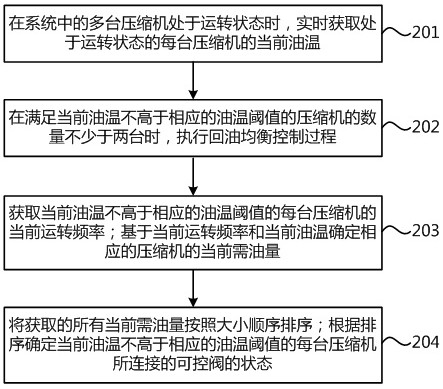

Multi-compressor refrigerant circulation system and control method thereof

PendingCN114484715AEasy to operatePrecise oil return balance controlCompressorMechanical apparatusThermodynamicsControl theory

The invention discloses a multi-compressor refrigerant circulation system and a control method thereof, and the method comprises the steps: when a plurality of compressors in the system are in a running state, obtaining the current oil temperature of each compressor in the running state in real time, and comparing the current oil temperature with a corresponding oil temperature threshold value of the compressor; when the number of the compressors with the current oil temperature not higher than the corresponding oil temperature threshold value is not smaller than two, the current operation frequency of each compressor with the current oil temperature not higher than the corresponding oil temperature threshold value is obtained; determining the current oil demand of the corresponding compressor based on the current operating frequency and the current oil temperature; all the obtained current oil demand quantities are sequenced according to the size sequence; and determining the state of the controllable valve connected with each compressor according to the sequence. By applying the method, the precision of oil return control of the multiple compressors can be improved, and the operation stability of a refrigerant circulating system is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

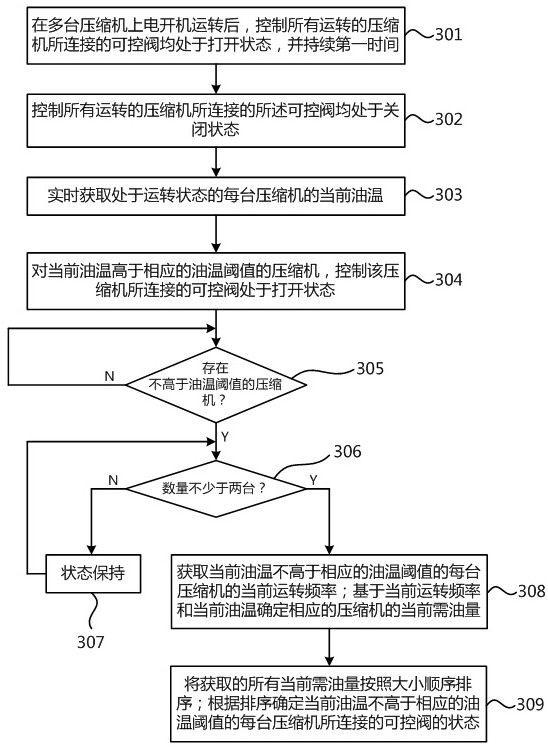

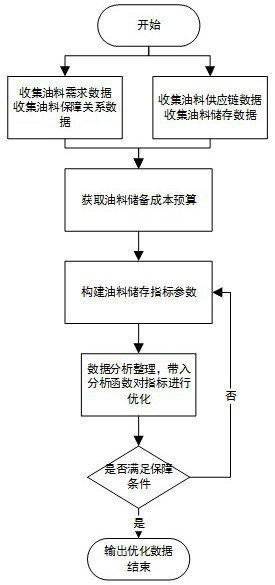

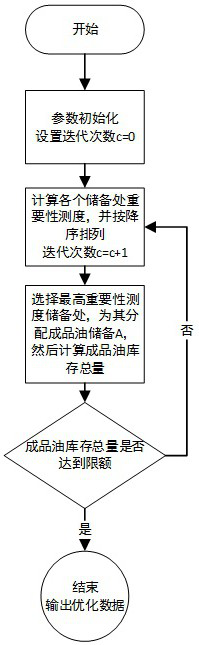

Product oil reserve optimization method based on cost limitation and auxiliary decision-making system

PendingCN111695222AComprehensive assessmentGeometric CADCAD network environmentProcess engineeringNetwork model

The invention discloses a product oil reserve optimization method based on cost limitation and an auxiliary decision-making system. The finished oil reserve auxiliary decision-making system based on cost limitation comprises a finished oil supply chain network module, a finished oil reserve index module, a finished oil reserve optimization module and an auxiliary decision-making module. The methodincludes: firstly, acquiring finished oil supply consumption process elements, and establishing a supply chain network model; then obtaining product oil demand data, calculating corresponding supplychain network reliability by utilizing a reliability evaluation index function, and establishing a reserve optimization model in combination with the obtained product oil reserve cost budget; and finally, based on the supply chain network model, optimizing the reserve optimization model by using a heuristic algorithm to obtain product oil reserve strategy data. The product oil reserve can be comprehensively evaluated.

Owner:智强通达科技(北京)有限公司

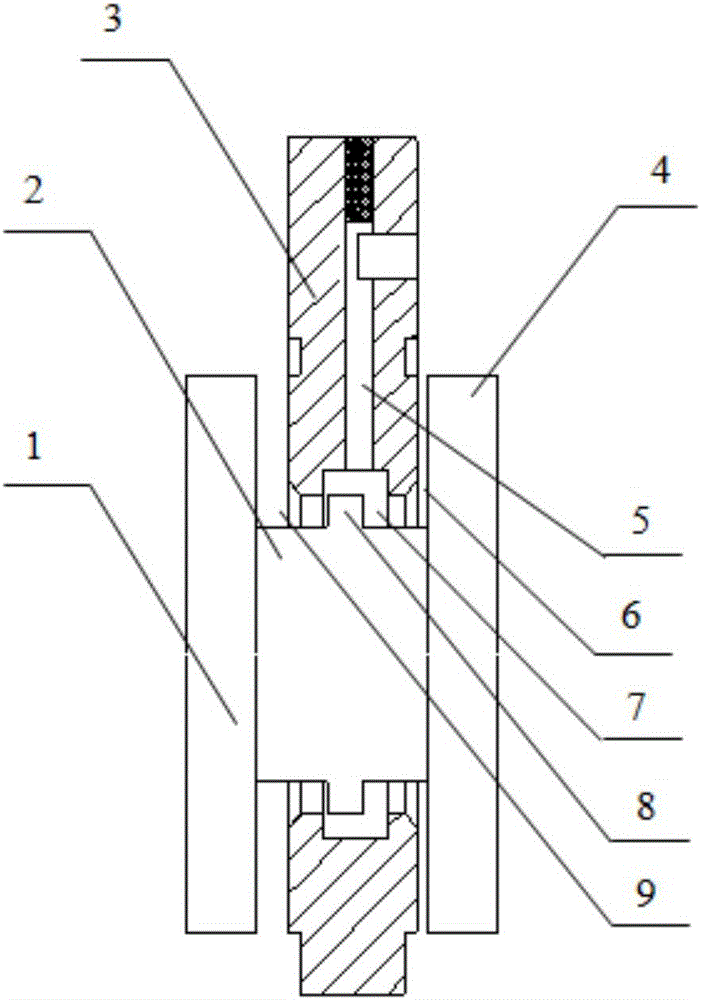

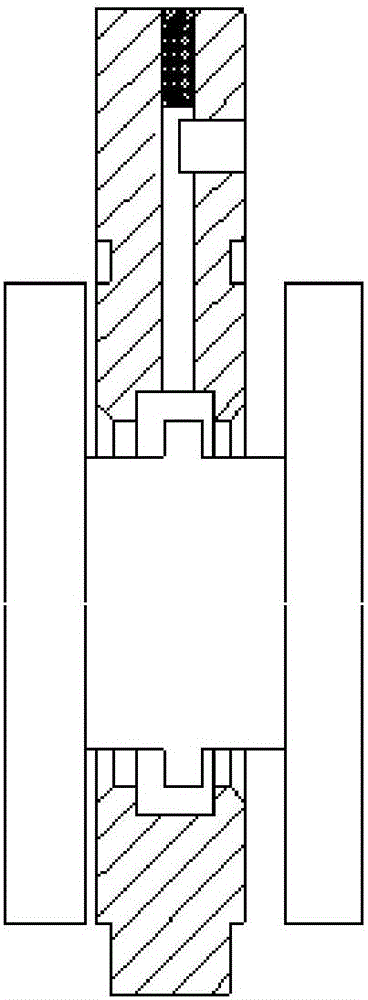

VVT (Variable Valve Timing) control method capable of combining self-learning feed-forward and active anti-interference feedback

ActiveCN102374038BSufficient control precisionEnough responsivenessInternal combustion piston enginesOutput powerVariable valve timingControl signal

The invention discloses a VVT (Variable Valve Timing) control method capable of combining self-learning feed-forward and active anti-interference feedback, which can improve the response speed of a VVT phase control, reduce the energy consumption of a regulating process and increase the adaptability to the operating environment change and the state change of an engine. The control method disclosed by the invention comprises the following steps of: carrying out a feed-forward control, an active anti-interference feedback control and a self-learning correction; regulating a hydraulic oil demand volume of a solenoid valve and a demand current I of a VVT solenoid valve through the feed-forward control; and obtaining a control signal It of a VVT system through the active anti-interference feedback control. The self-learning correction comprises the steps of concluding and calculating a characteristic parameter of the VVT system according to a VVT control quantity (a duty ratio of a PWM (Pulse Width Modulation) wave) and a response characteristic yr of the VVT system during the regulation of the VVT system so as to correct a calculating coefficient in a feed-forward controller model, thereby continuously increasing the calculation accuracy of the feed-forward control, improving the control capability of the feed-forward control, reducing the dependence on the feedback control and effectively improving the response speed and the accuracy of the control of the VVT system.

Owner:TIANJIN UNIV

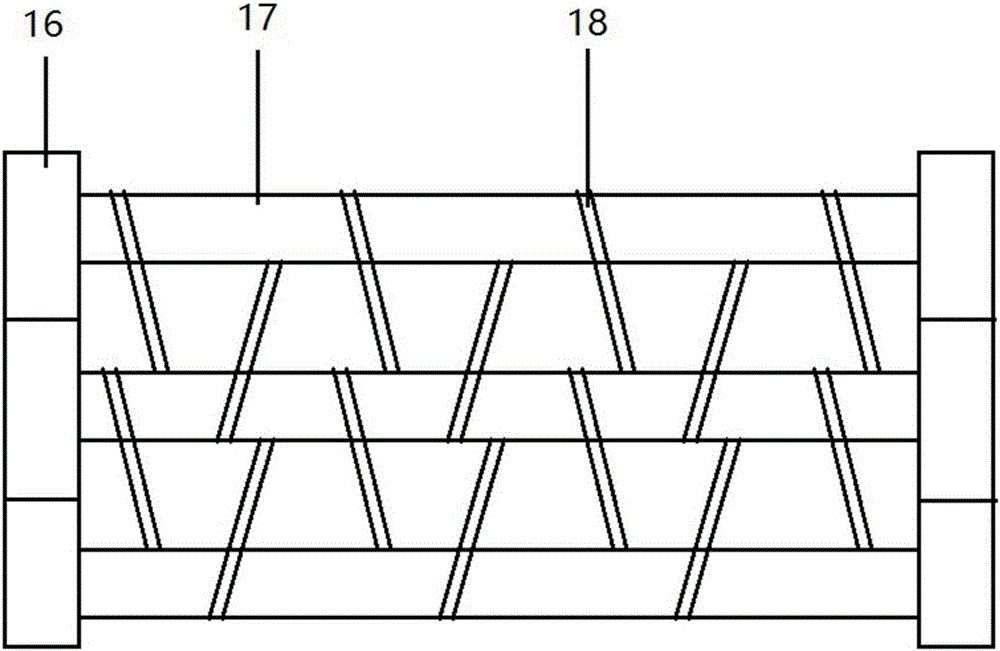

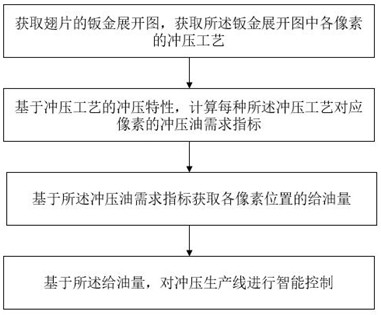

Intelligent control method and system for closed fin stamping production line

ActiveCN114535450AAvoid wastingQuality improvementHeat exchange apparatusTotal factory controlProduction lineOil can

The invention relates to the technical field of stamping, in particular to an intelligent control method and system for a closed fin stamping production line, and the method comprises the steps: obtaining a sheet metal expansion drawing of a fin, and obtaining a stamping process of each pixel in the sheet metal expansion drawing; based on the stamping characteristics of the stamping process, the stamping oil demand index of the pixel corresponding to each stamping process is calculated; based on the stamping oil demand index, the oil supply amount of each pixel position is obtained; and based on the oil feeding amount, the punching production line is intelligently controlled. Waste of stamping oil can be avoided, the stamping effect can be guaranteed, and the quality of stamping parts is improved.

Owner:南通精丰智能设备有限公司

Integrated cylinder head cover and automotive engine

ActiveCN112096537BGuaranteed lubrication effectReduce wearCasingsValve arrangementsSolenoid valveCylinder head

Owner:DONGFENG MOTOR CORP HUBEI

Compressor and air conditioner

PendingCN114087194ASolve the problem of fuel supply delayImprove reliabilityCompressorRotary/oscillating piston pump componentsOil pumpPhysics

The invention discloses a compressor and an air conditioner. An oil circulation structure is arranged in the compressor, the oil circulation structure comprises an oil storage structure and an oil supply path, the compressor further comprises an oil pump, the oil pump is arranged in the compressor, an inlet of the oil pump is communicated with the oil storage structure, and an outlet of the oil pump is communicated with the oil supply path. According to the compressor, the oil pump is arranged in the compressor, so that the distance between an oil supply point and an oil demand point of the compressor is shortened; when the compressor just runs, the whole runner space can be rapidly filled with lubricating oil, and therefore, the problem that oil supply of the compressor is delayed is solved; and moreover, the oil pump is arranged in the compressor, so that the space for installing the external oil pump can be saved, leakage caused by oil way faults can be avoided, and the operation reliability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

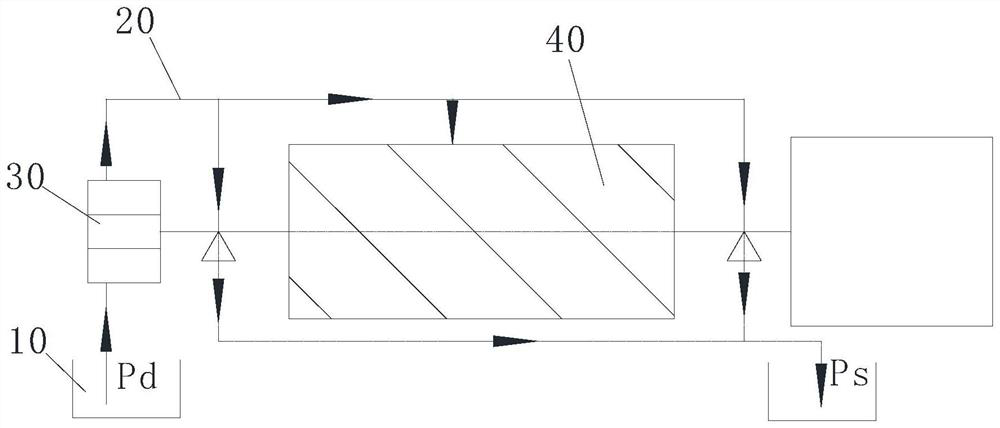

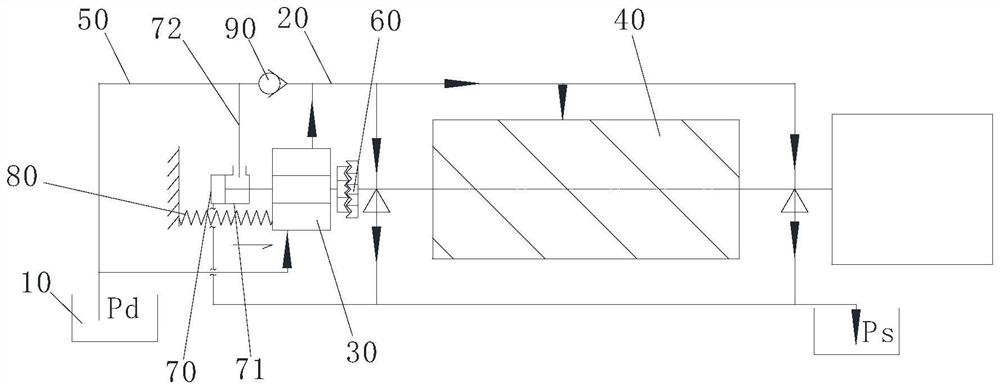

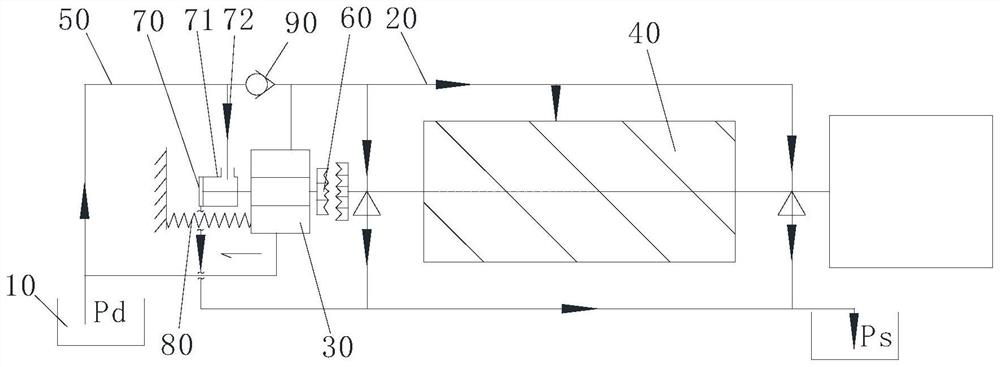

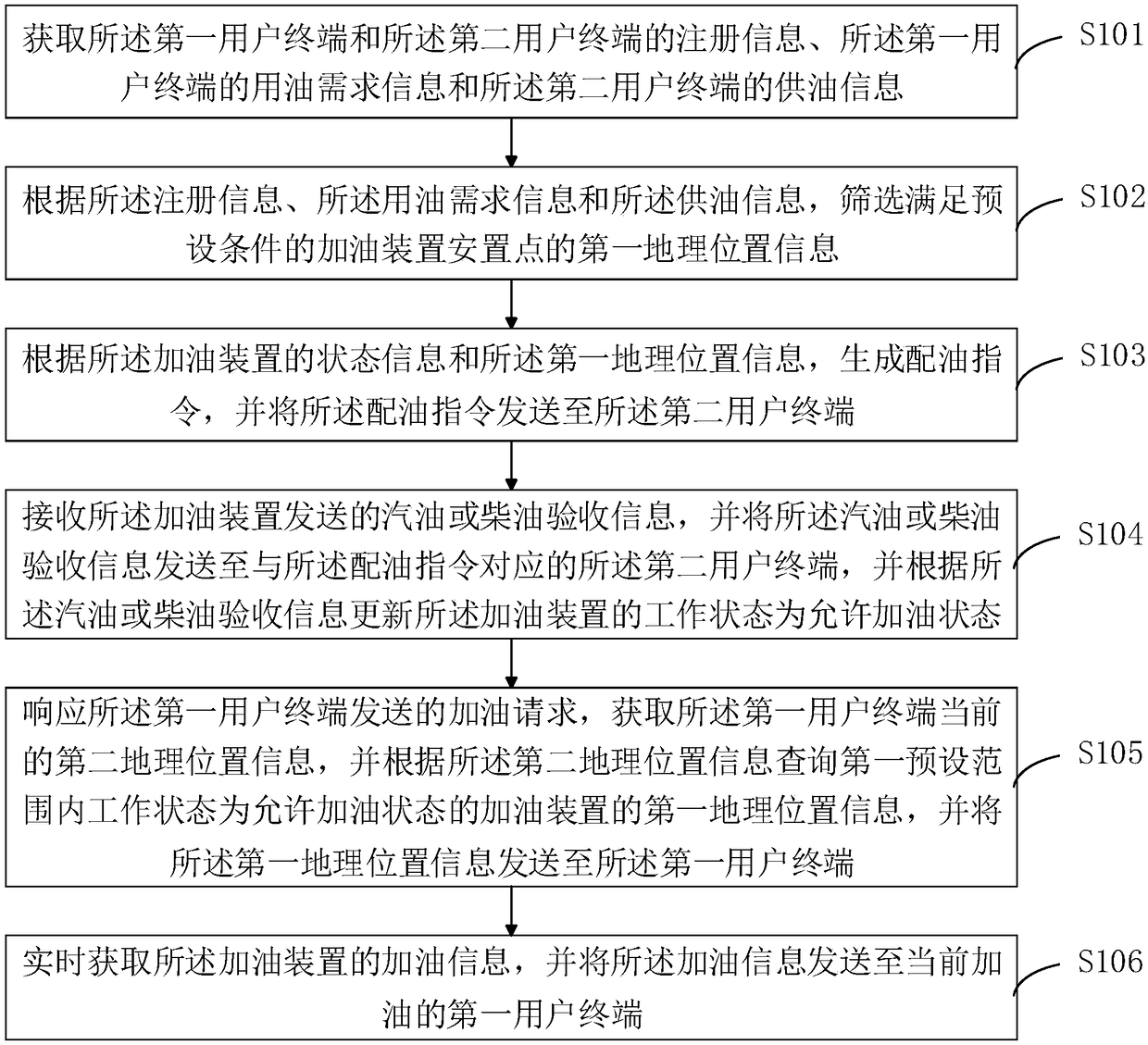

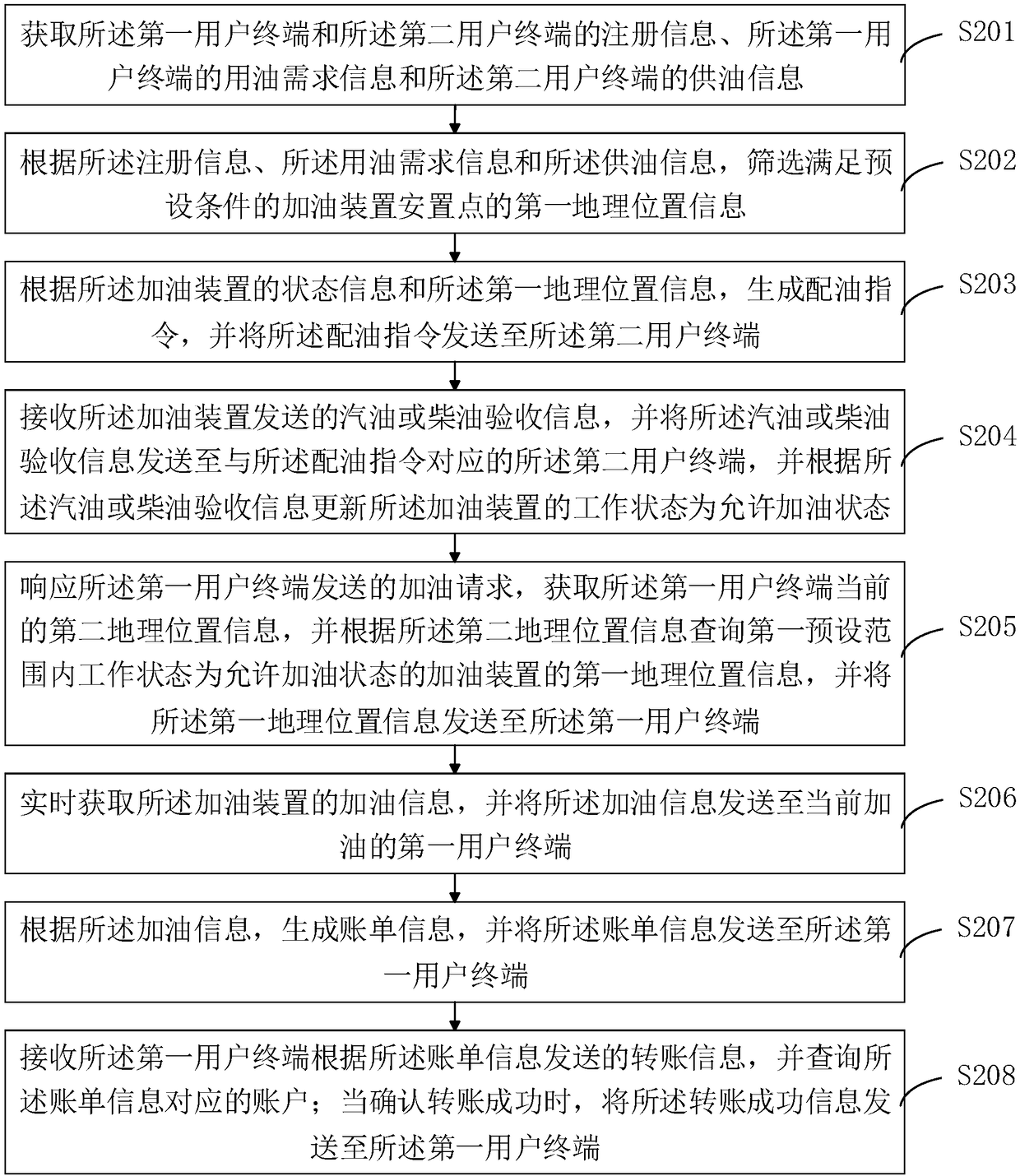

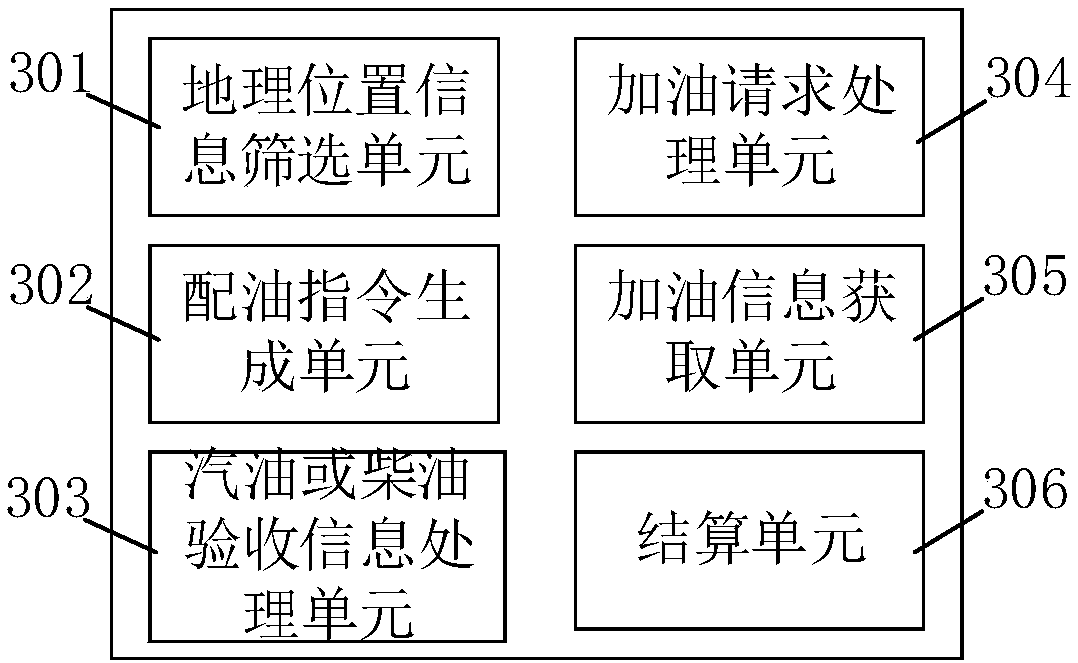

Shared oil filling method, device, server and system based on cloud side

The invention discloses a shared oil filling method, device, server and system based on a cloud side. The method comprises the steps of sifting first geographical location information of an oil filling device placement site which satisfies a preset condition according to registration information, oil demand information and oil supply information; generating and sending an oil distribution instruction to a second user terminal according to the first geographical location information; receiving and transmitting gasoline or diesel acceptance inspection information sent by the oil filling device to the second user terminal; obtaining current second geographical location information of a first user terminal in response to an oil filling request sent by the first user terminal, and querying andsending the first geographical location information of the oil filling device within a first preset range to the first user terminal; obtaining the oil filling information of the oil filling device inreal time, and sending the oil filling information to the current first user terminal needing oil filling. According to the shared oil filling method, device, server and system, the handy intelligentoil filling device can be provided for an oil demander based on the cloud side, the device is simple and convenient to use, and the cost of the oil demander and an oil supplier is greatly reduced.

Owner:韶关市易通车联电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com