Waste oil anticipate regenerated energy device and processing method

A renewable energy, equipment and device technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., to achieve the effect of alleviating the contradiction between supply and demand, quick results, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

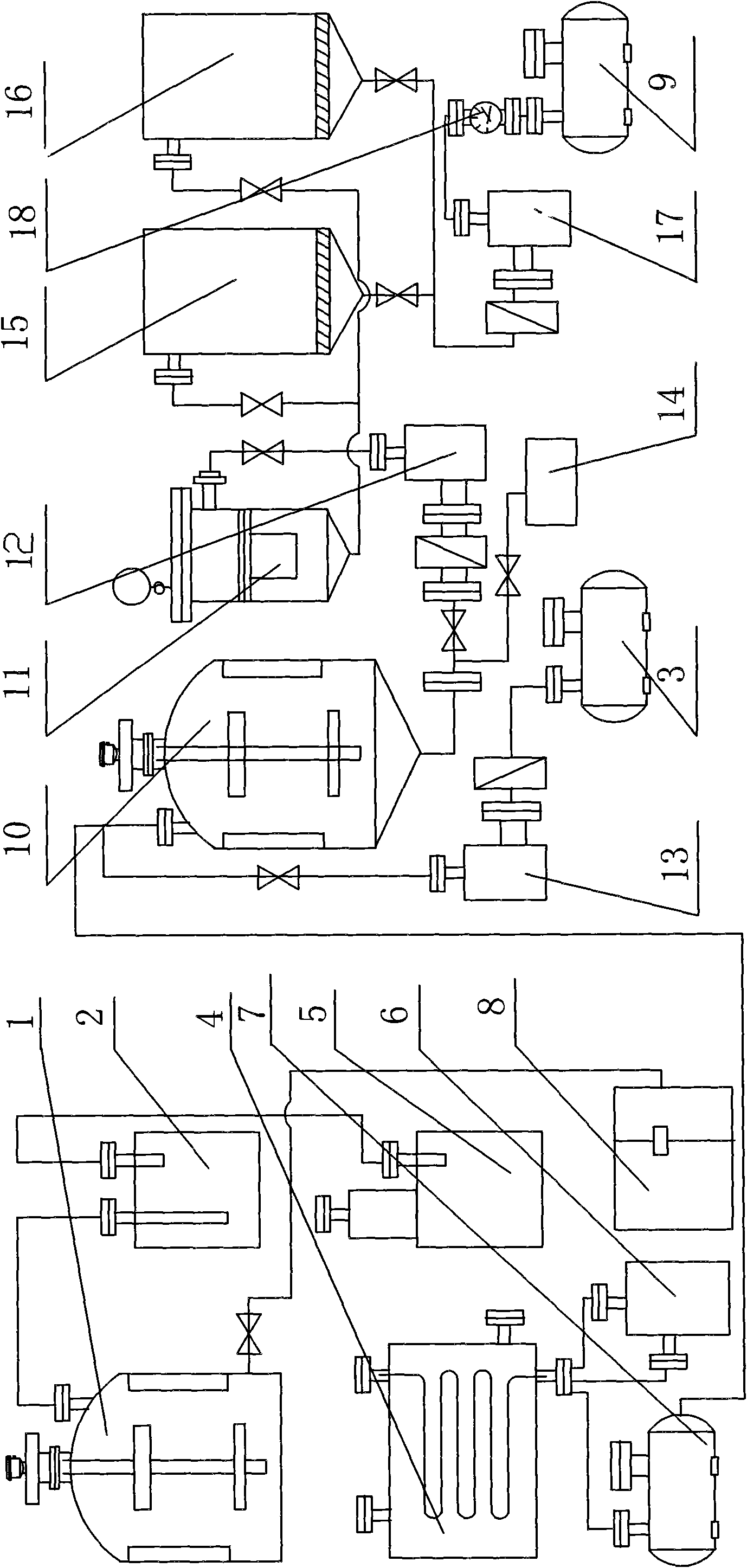

[0015] Waste oil renewable energy equipment, its composition includes: a distillation part, a cracking part connected to the distillation part, the distillation part includes a distillation tower, the distillation tower 1 is connected to the oil-water separator 2, and the oil-water The separator 2 is connected to the fractionation catalytic converter 5, the fractionation catalytic converter 5 is connected to the condensation water tank 4, the condensation water tank 4 is connected to the semi-product oil pump 6, the condensation water tank 4 is connected to the semi-product oil tank 7, and the fractionation catalytic converter 5 connect clear oil tank 8.

[0016] The cracking part comprises that the cracking tank 10 is connected to an oil pump 12, and the oil pump 12 is connected to a pressure filter 11, and the pressure filter 11 is connected to a reaction filter tank 15, and the reaction filter tank 15 is connected to the cracking tank 10, the cracking tank 10 is connected t...

Embodiment 2

[0020] The processing method of using the above-mentioned equipment to regenerate energy from waste oil is to add waste oil to the distillation tower and heat it at 380°C with a far-infrared heat source so that the oil is continuously distilled into a gaseous state. After decompression and dehydration, it enters the split catalysis and enters the condenser. The pipe is cooled to condense the gaseous oil to form oil, and the semi-finished oil is poured into the storage tank through the oil pump. During the production process, the same amount of waste oil is continuously added according to the evaporation amount, and the valve a, valve b, and valve are respectively opened for slag discharge. c. Discharge the residual oil into the waste residue pool, separate the clear oil and enter the semi-finished oil tank;

[0021] The semi-finished oil in the semi-finished oil tank is pumped into the cracking tank and added with 20-40 kilograms of sulfuric acid, and 0.1 kilogram of dispersant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com