Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

339results about "Multiple component coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

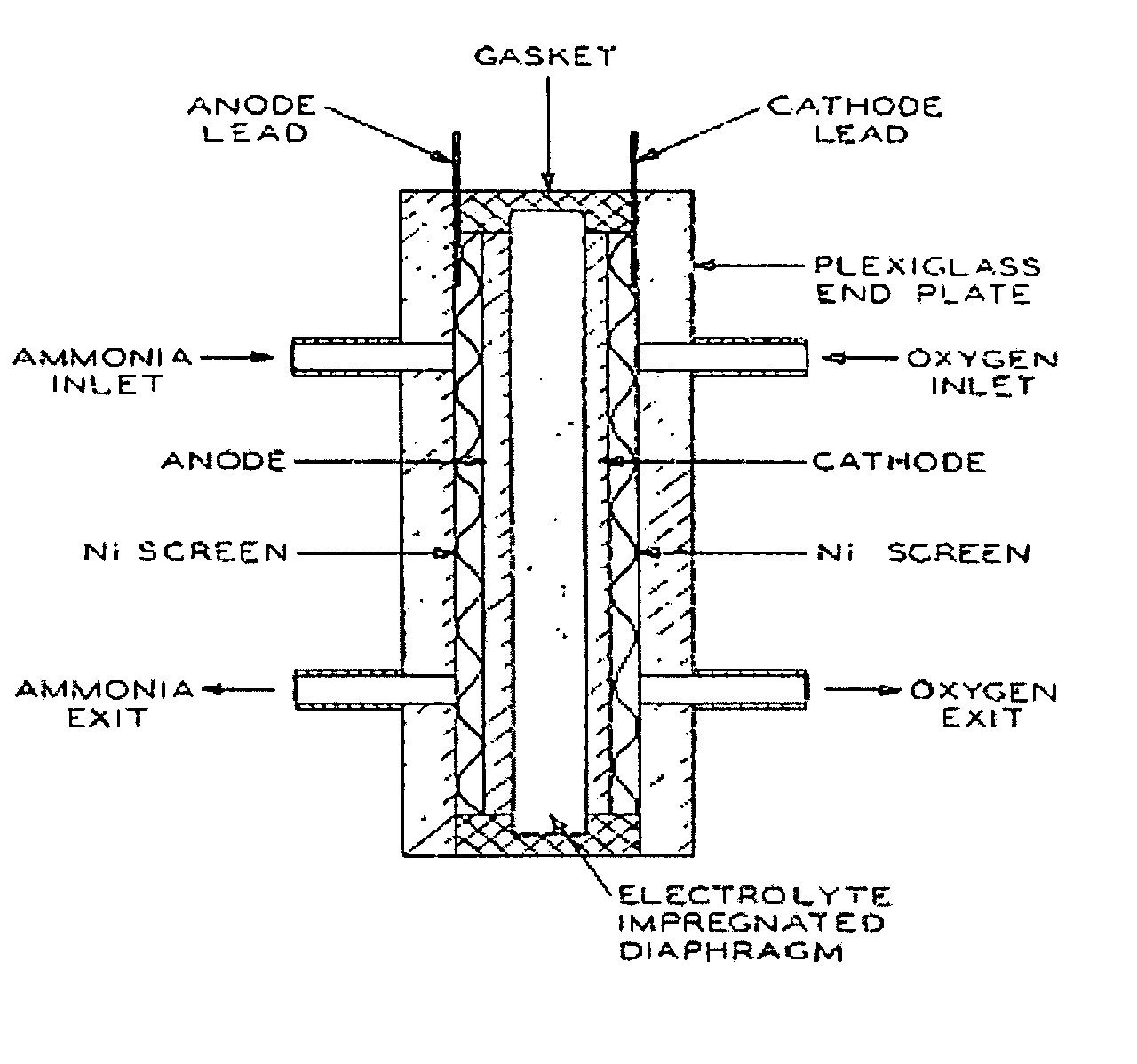

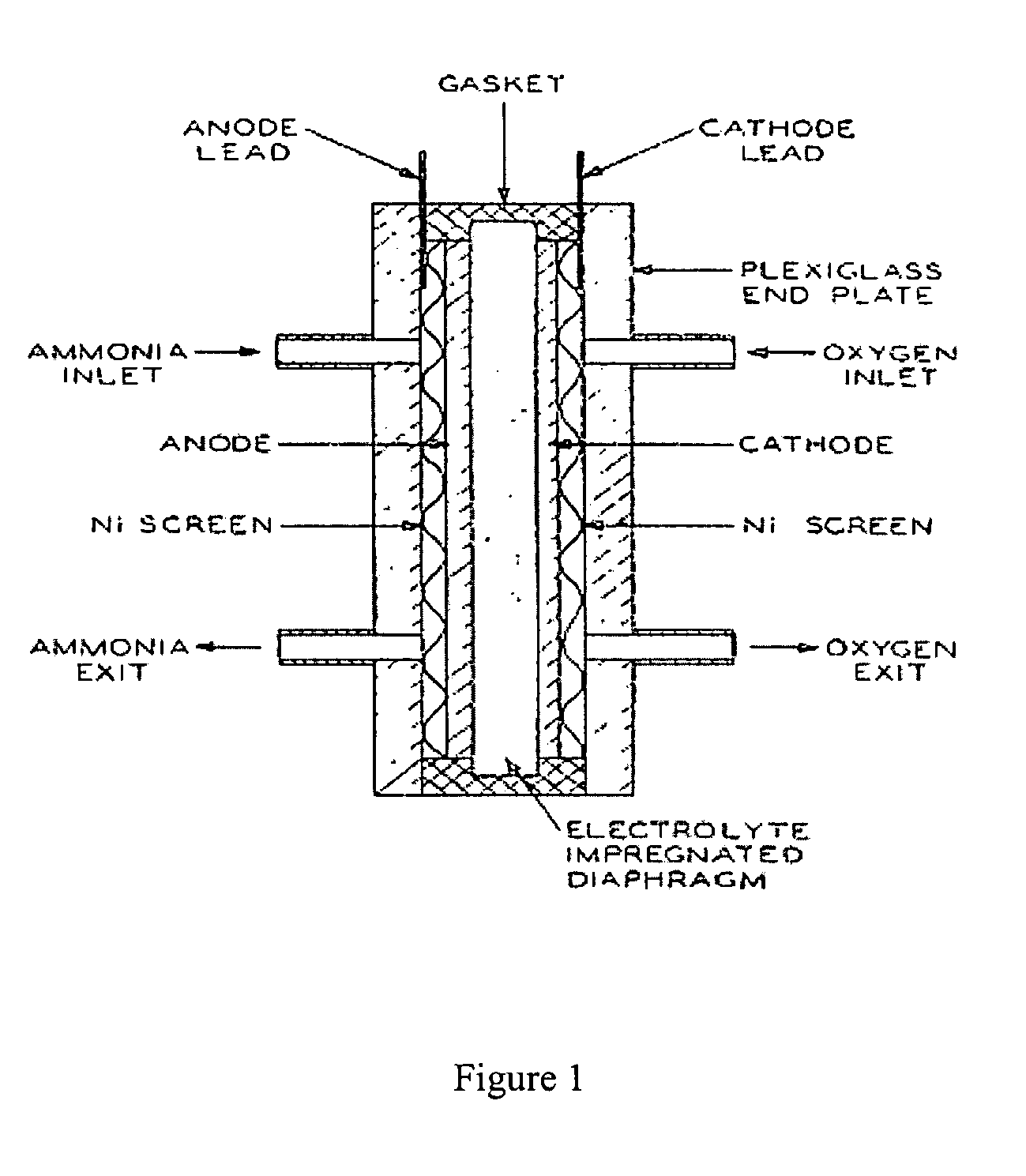

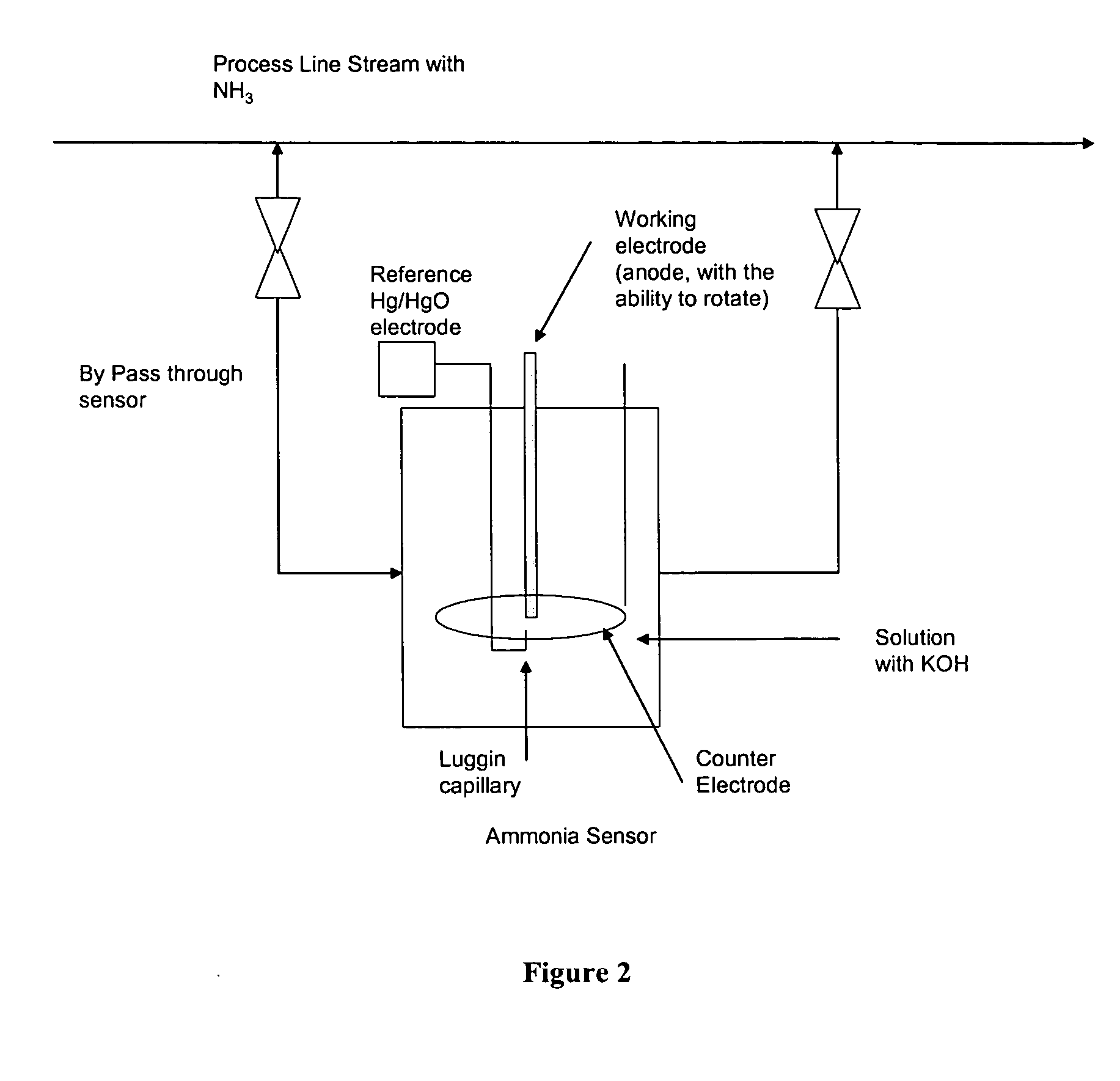

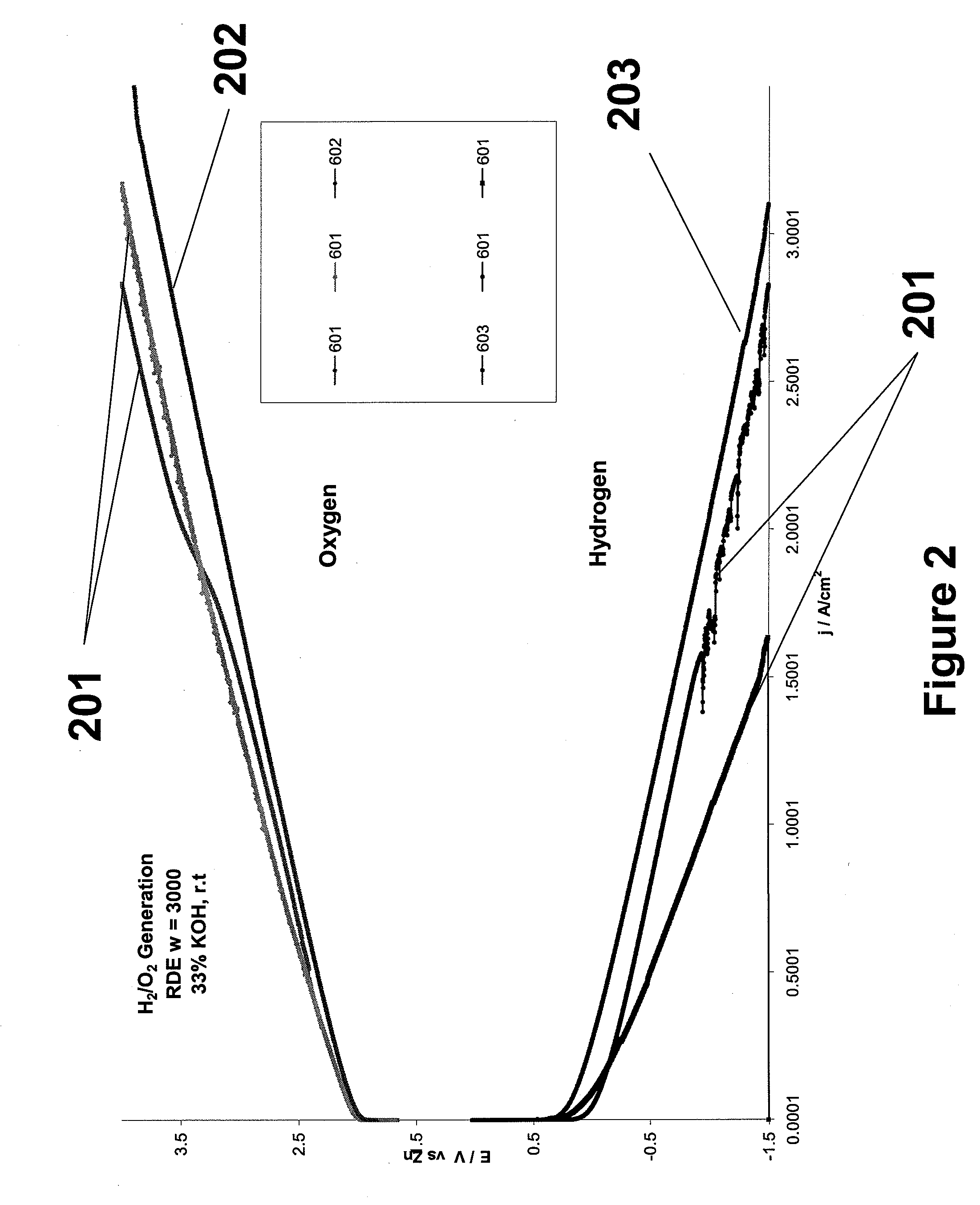

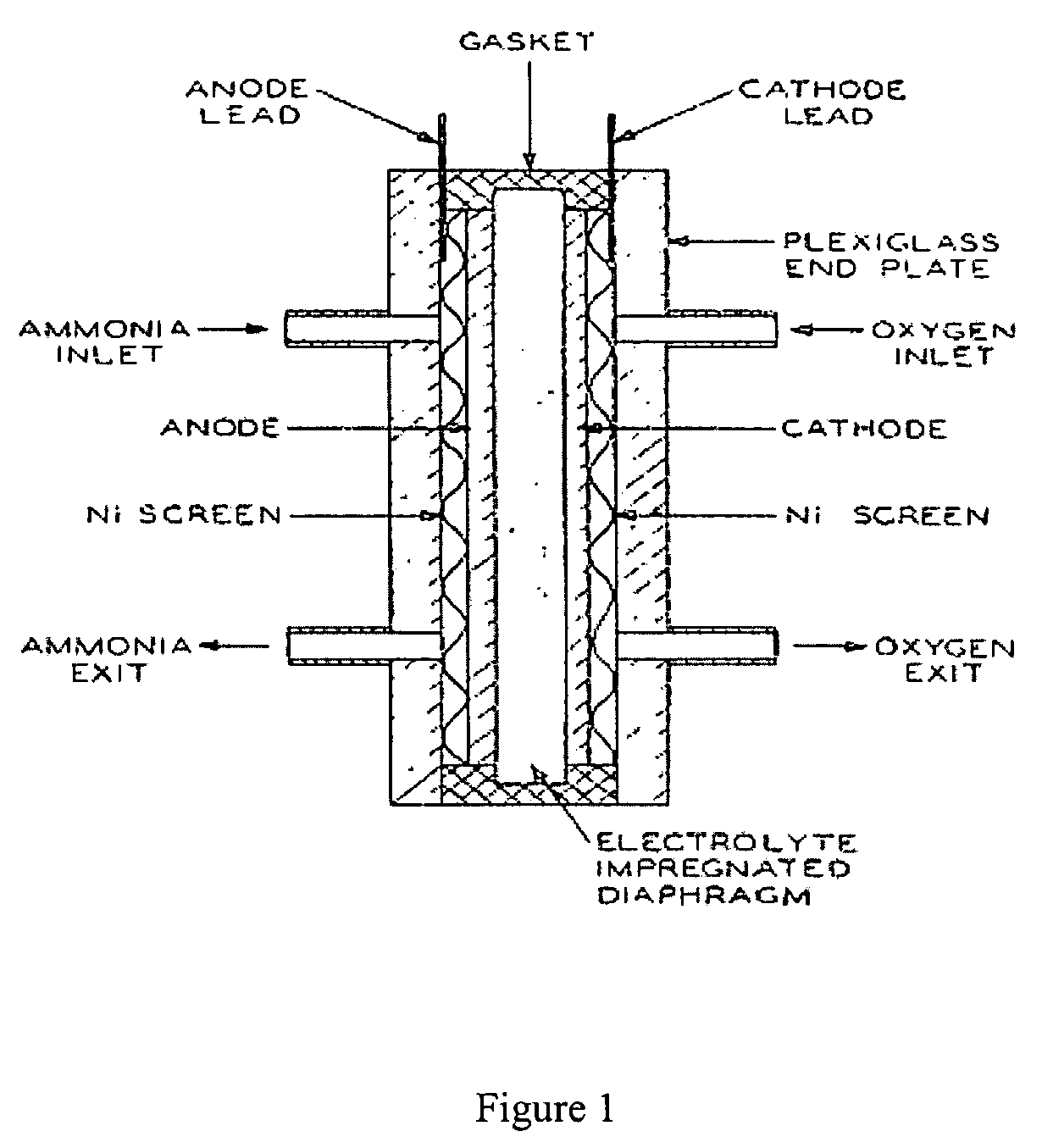

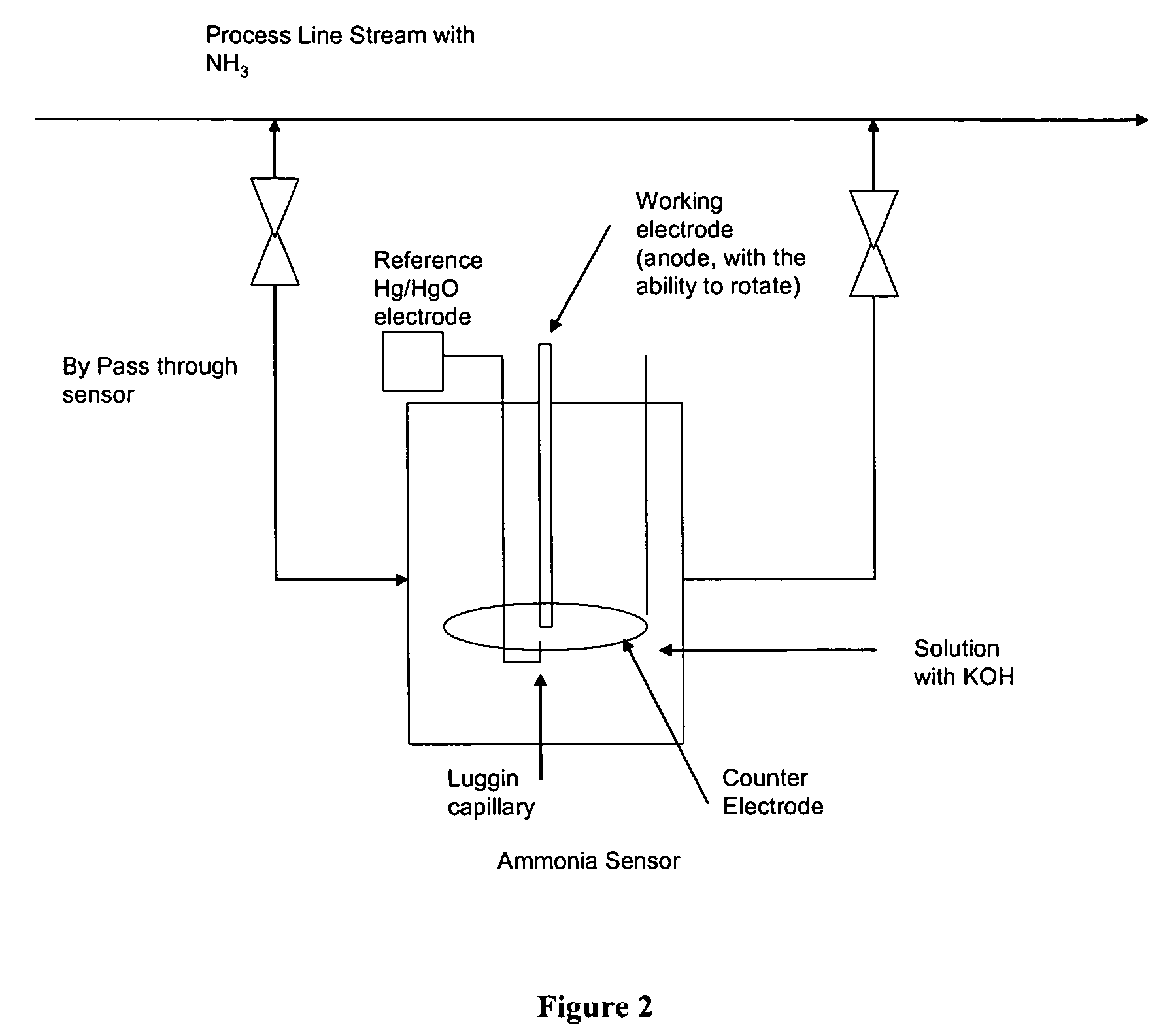

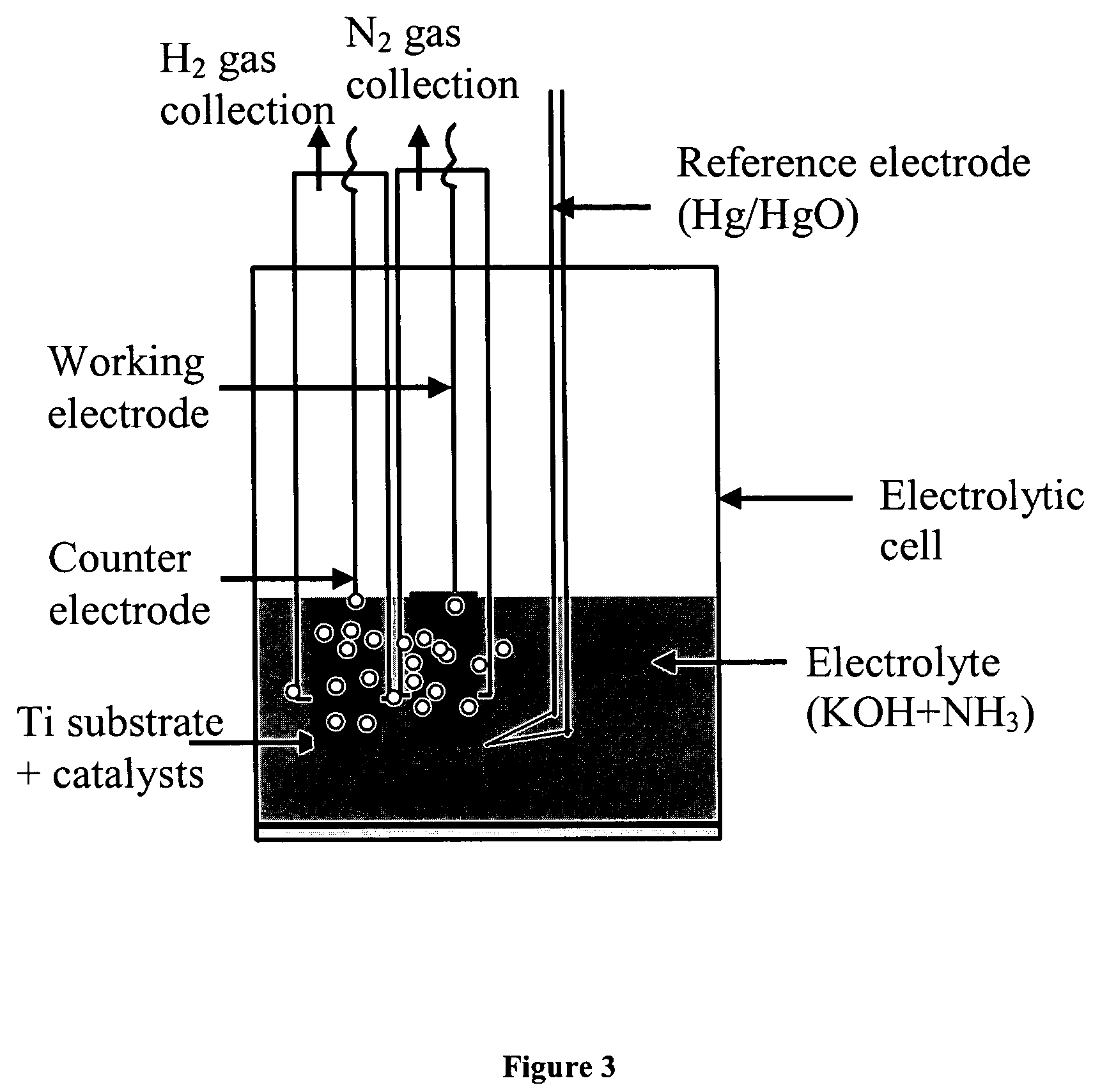

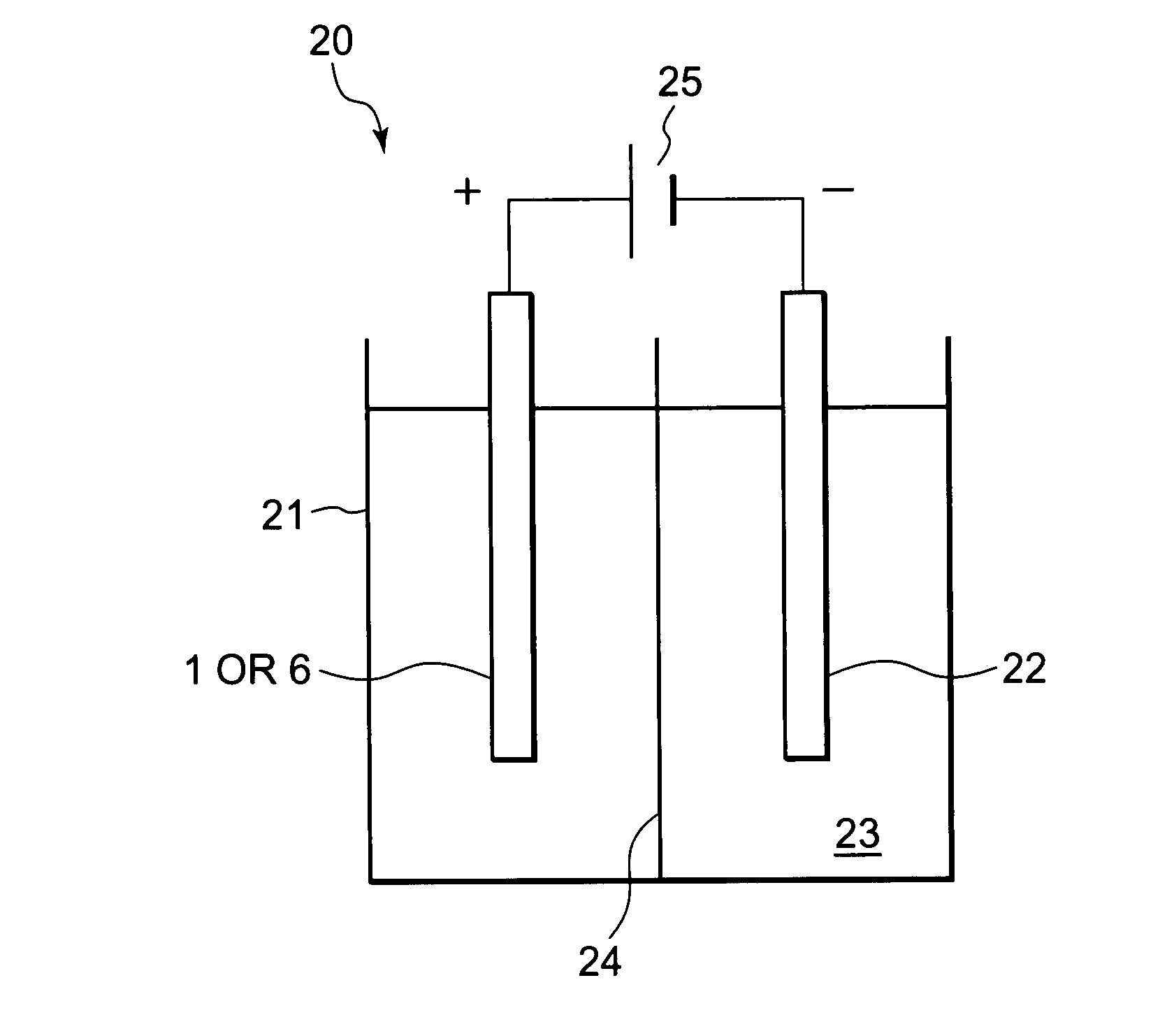

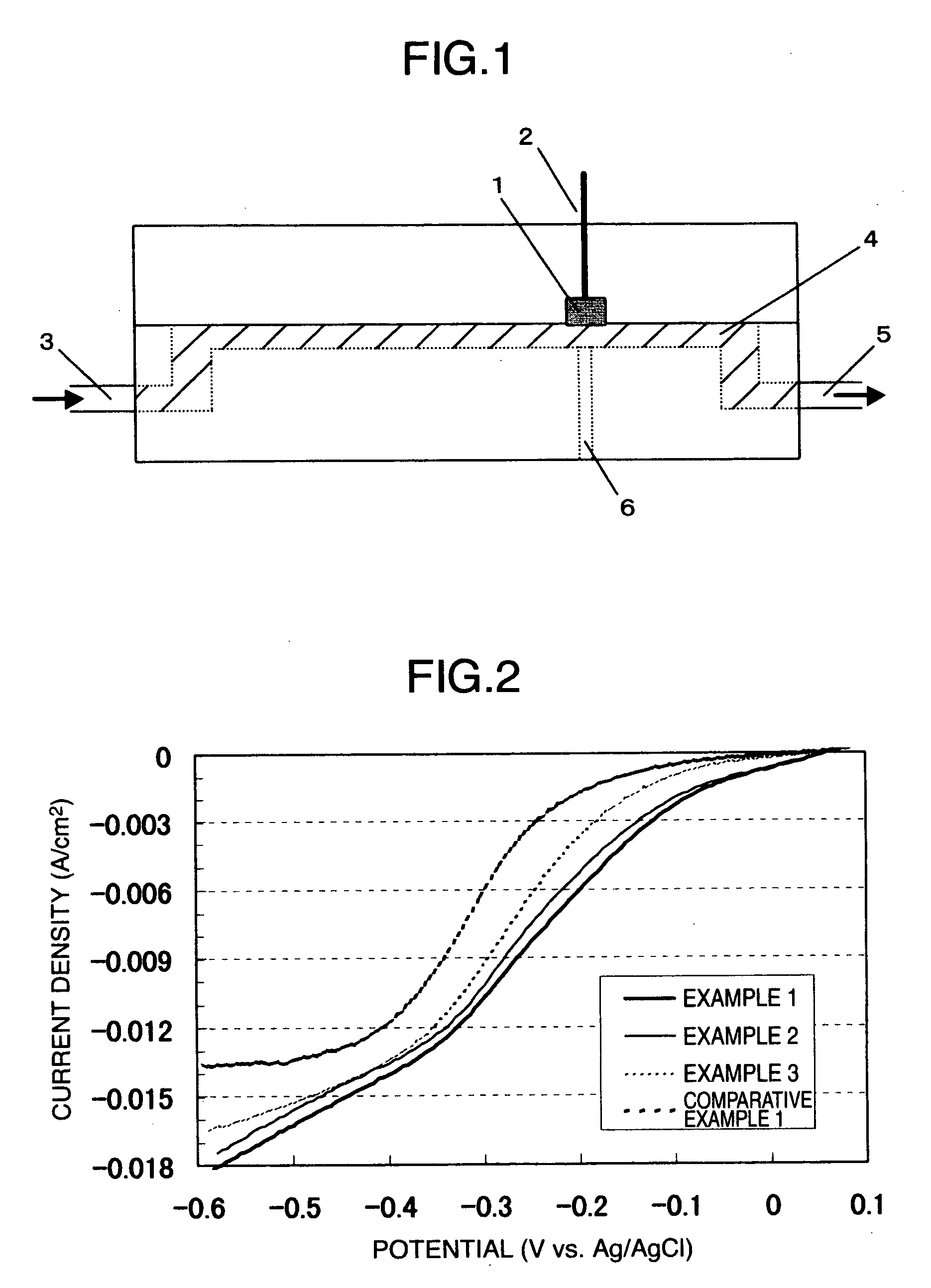

Electro-catalysts for the oxidation of ammonia in alkaline media

InactiveUS20050211569A1From normal temperature solutionsLiquid separation by electricityChemistryIridium

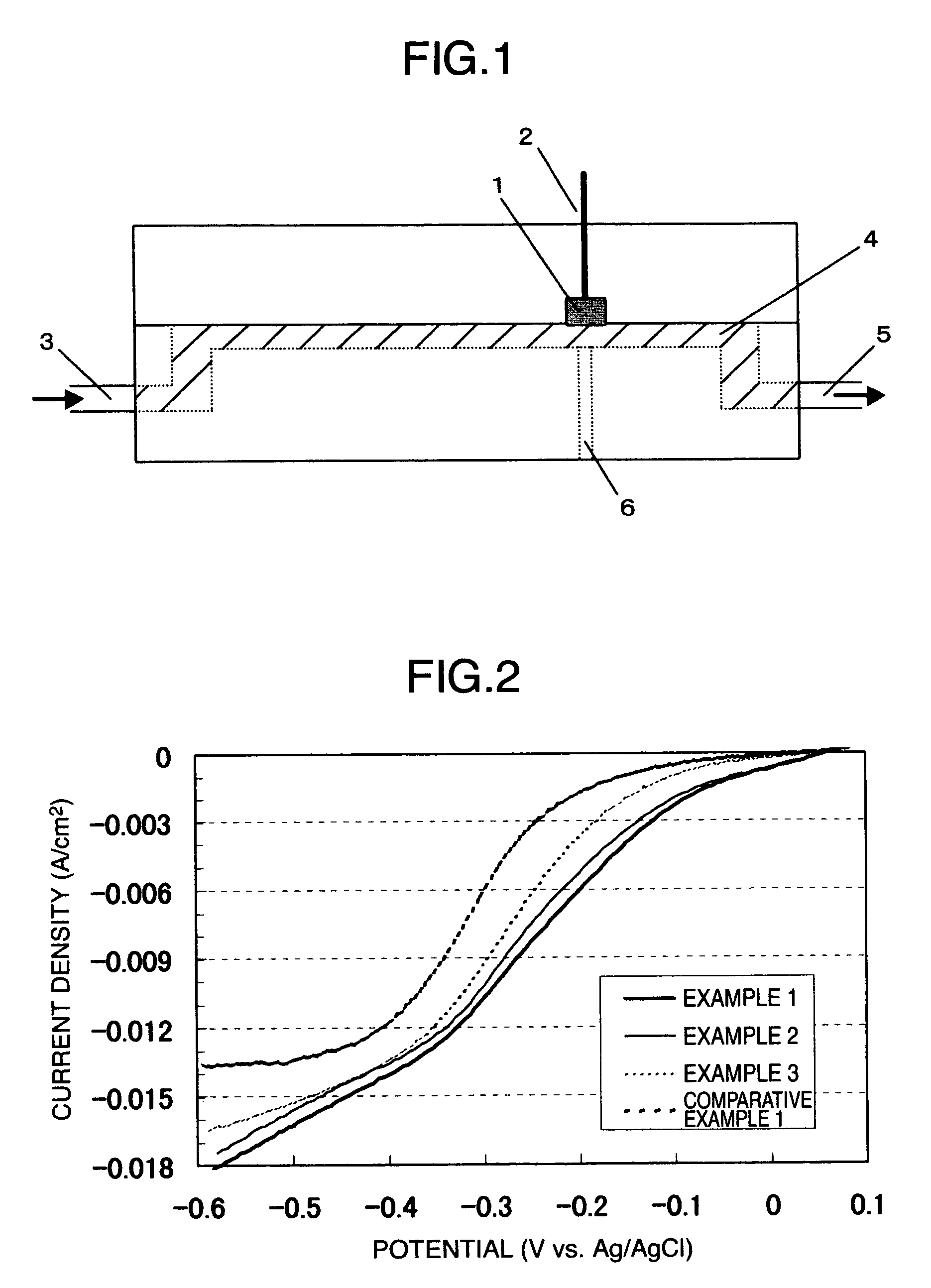

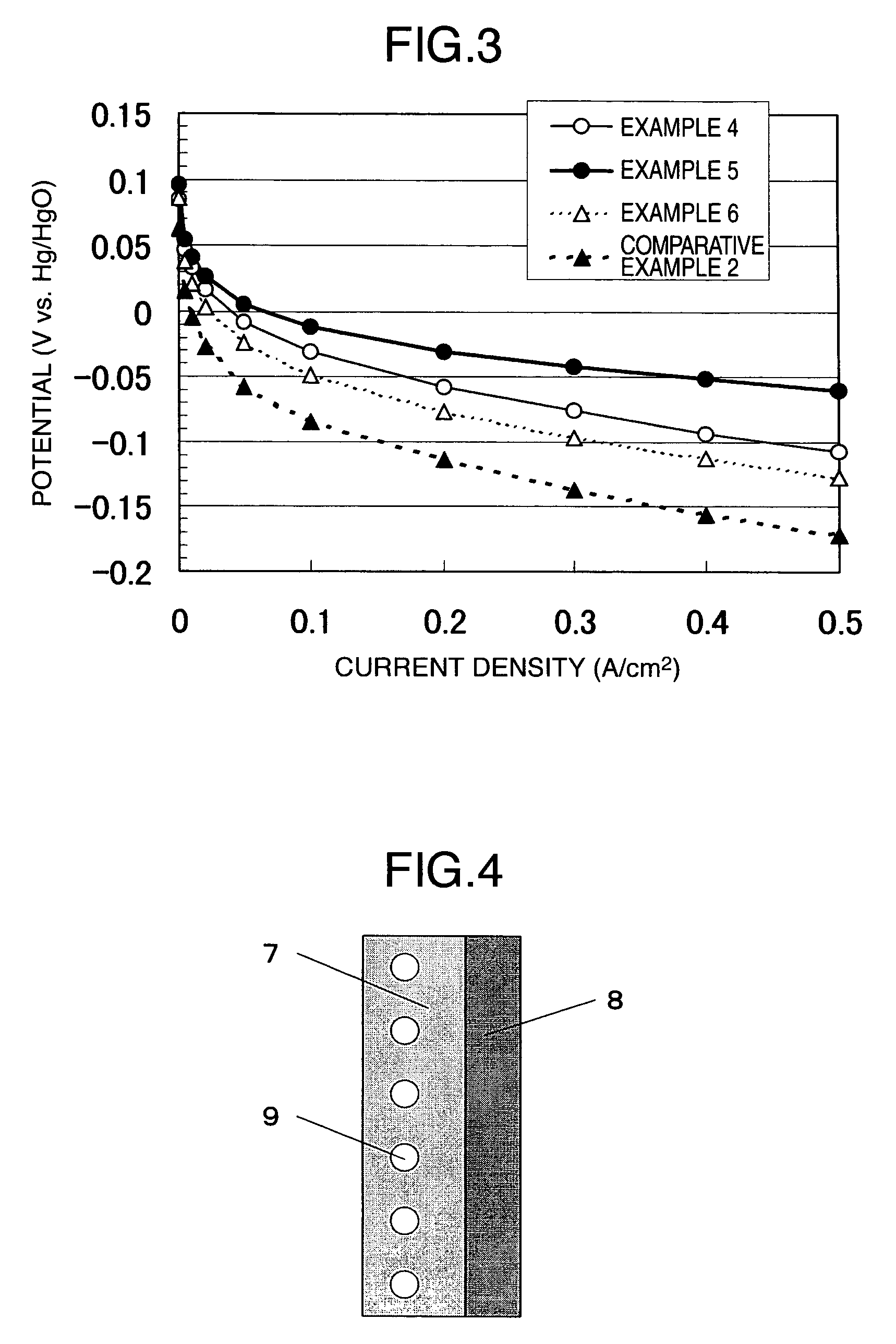

An electro-catalyst for the oxidation of ammonia in alkaline media; the electrocatalyst being a noble metal co-deposited on a support with one or more other metals that are active to ammonia oxidation. In some embodiments, the support is platinum, gold, tantalum, or iridium. In some embodiments, the support has a layer of Raney metal deposited thereon prior to the deposition of the catalyst. Also provided are electrodes having the electro-catalyst deposited thereon, ammonia electrolytic cells, ammonia fuel cells, ammonia sensors, and a method for removing ammonia contaminants from a contaminated effluent.

Owner:OHIO UNIV

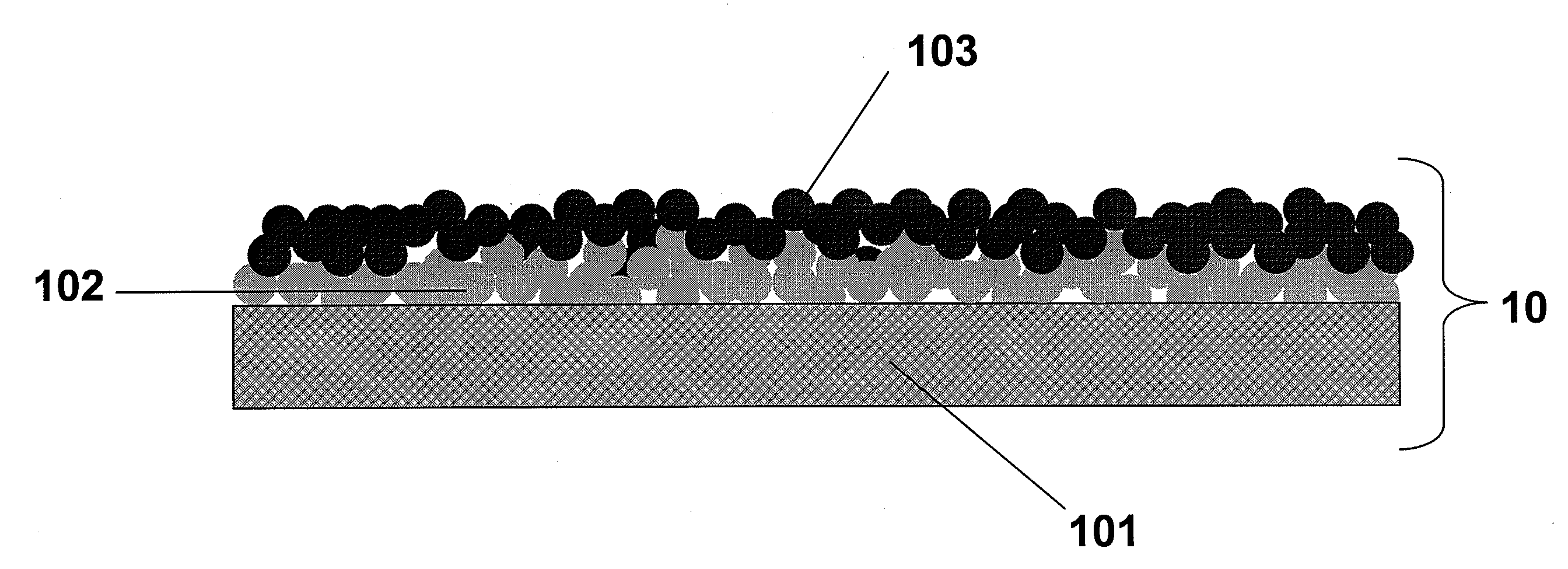

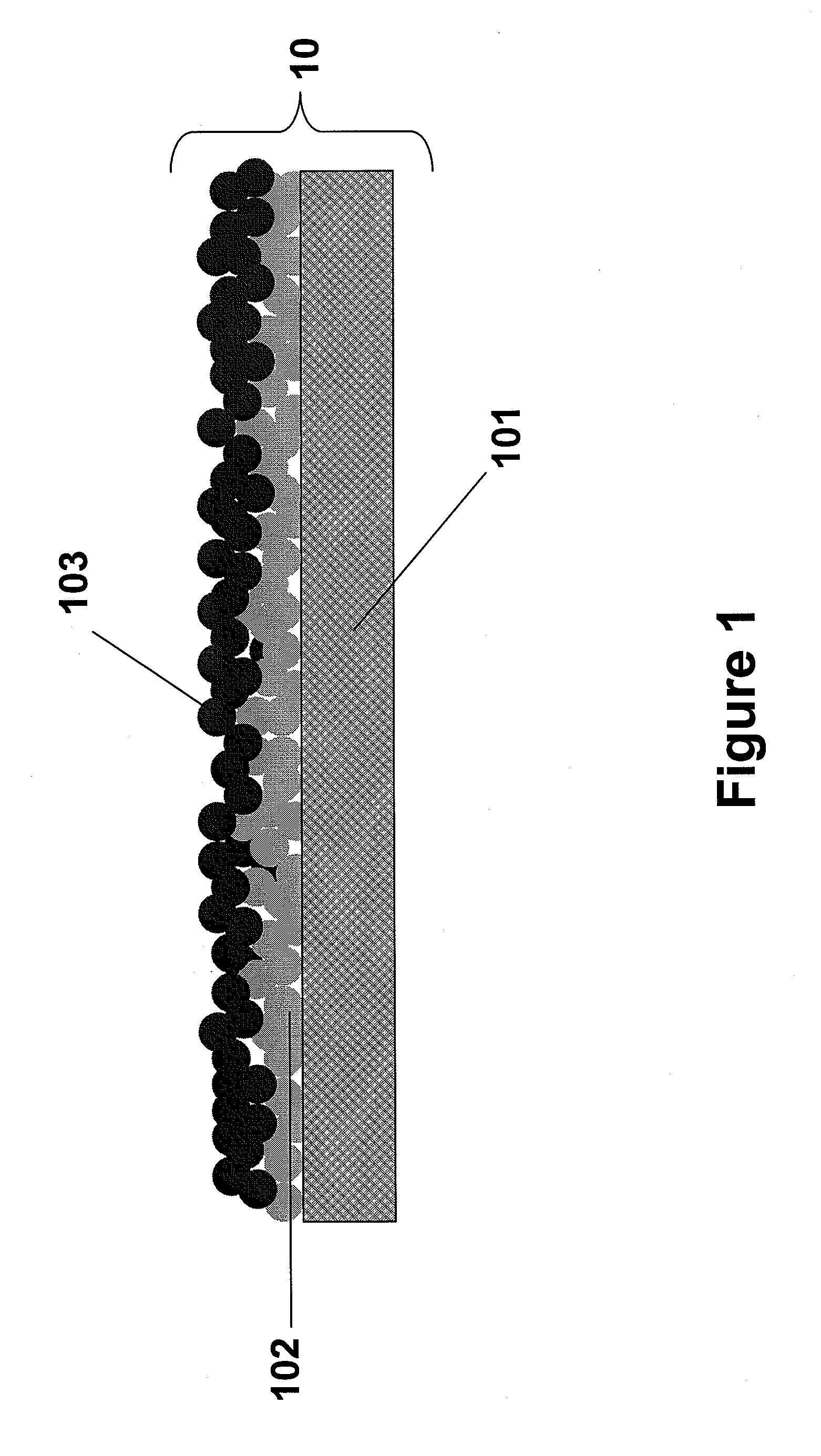

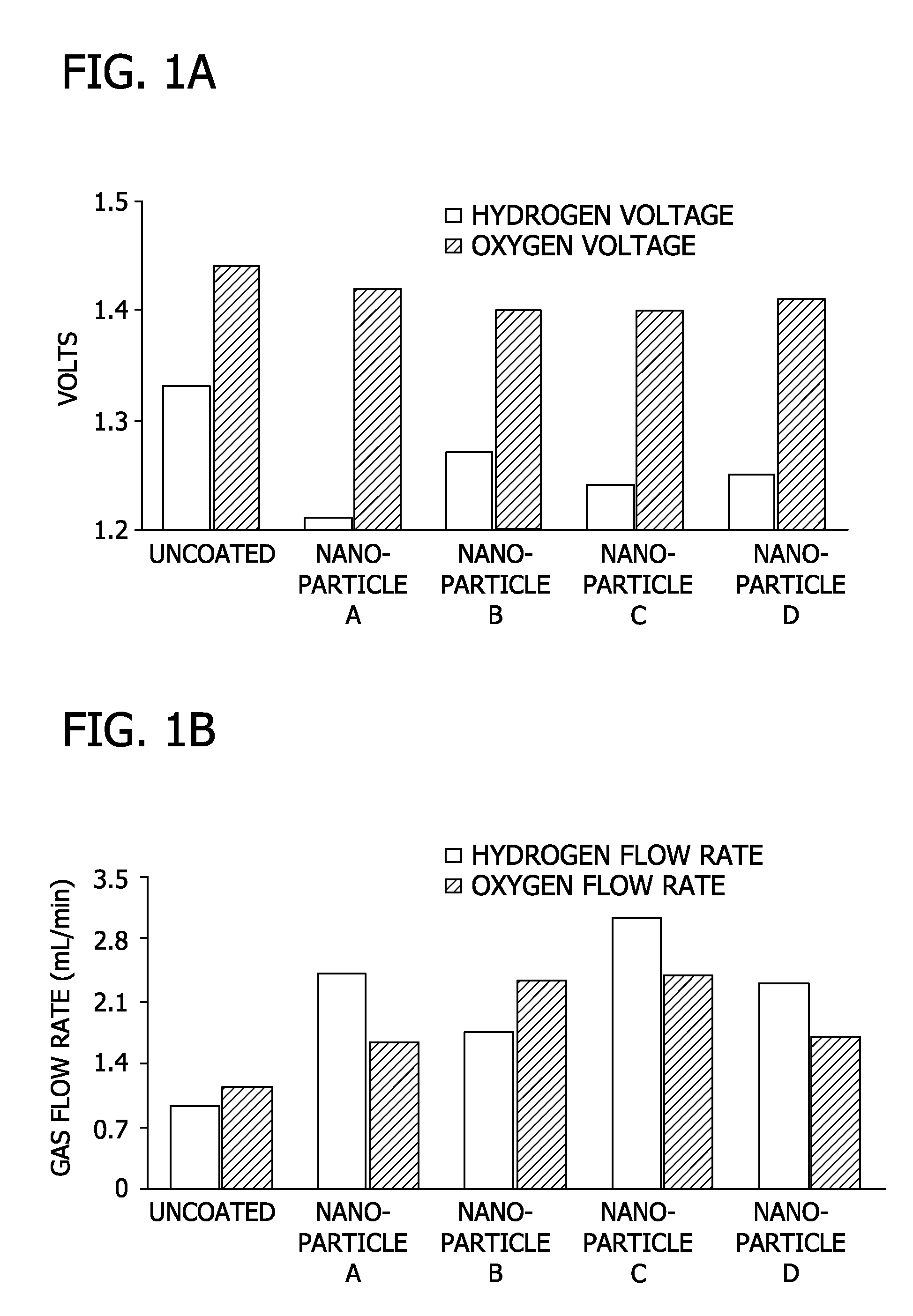

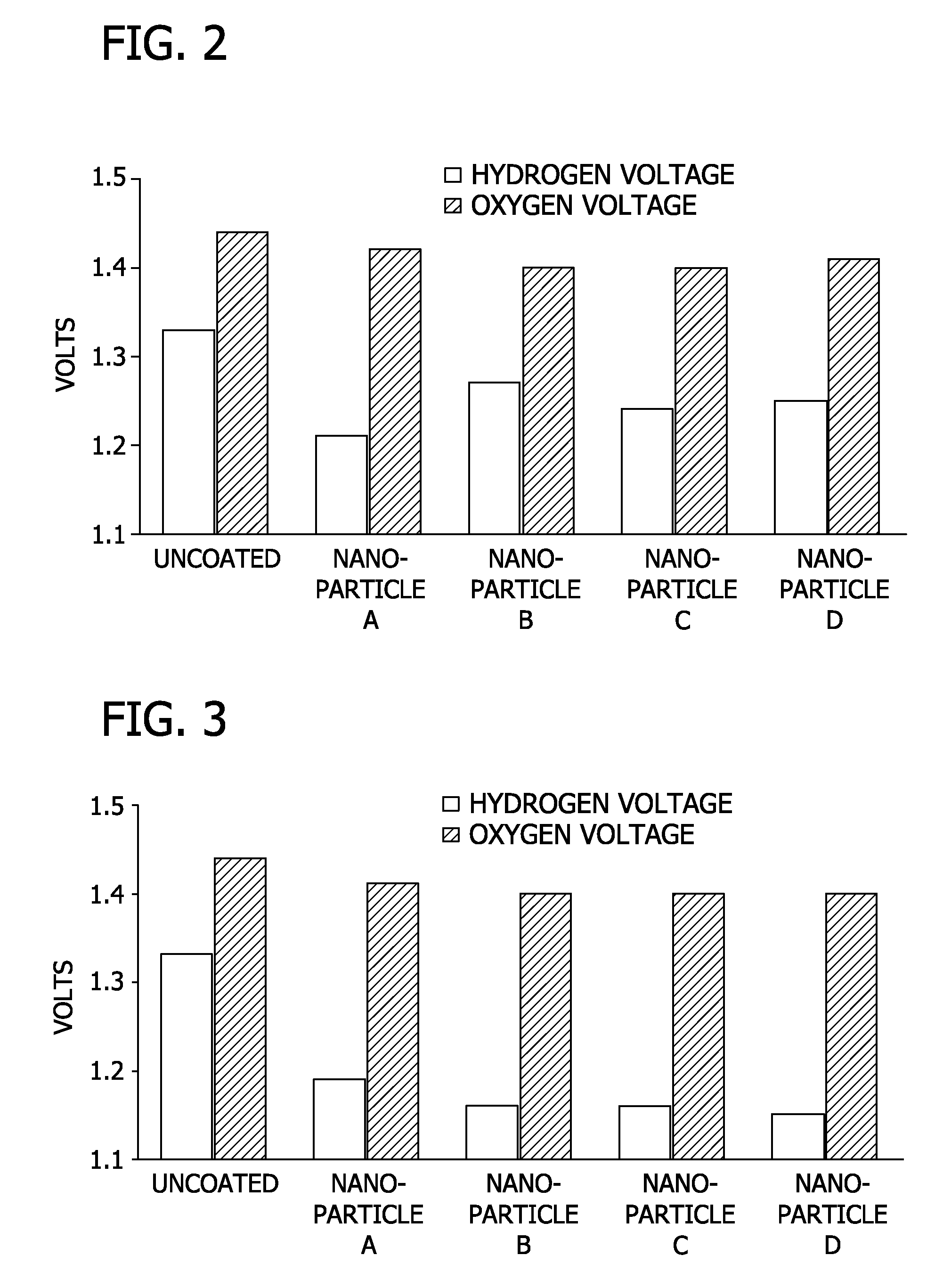

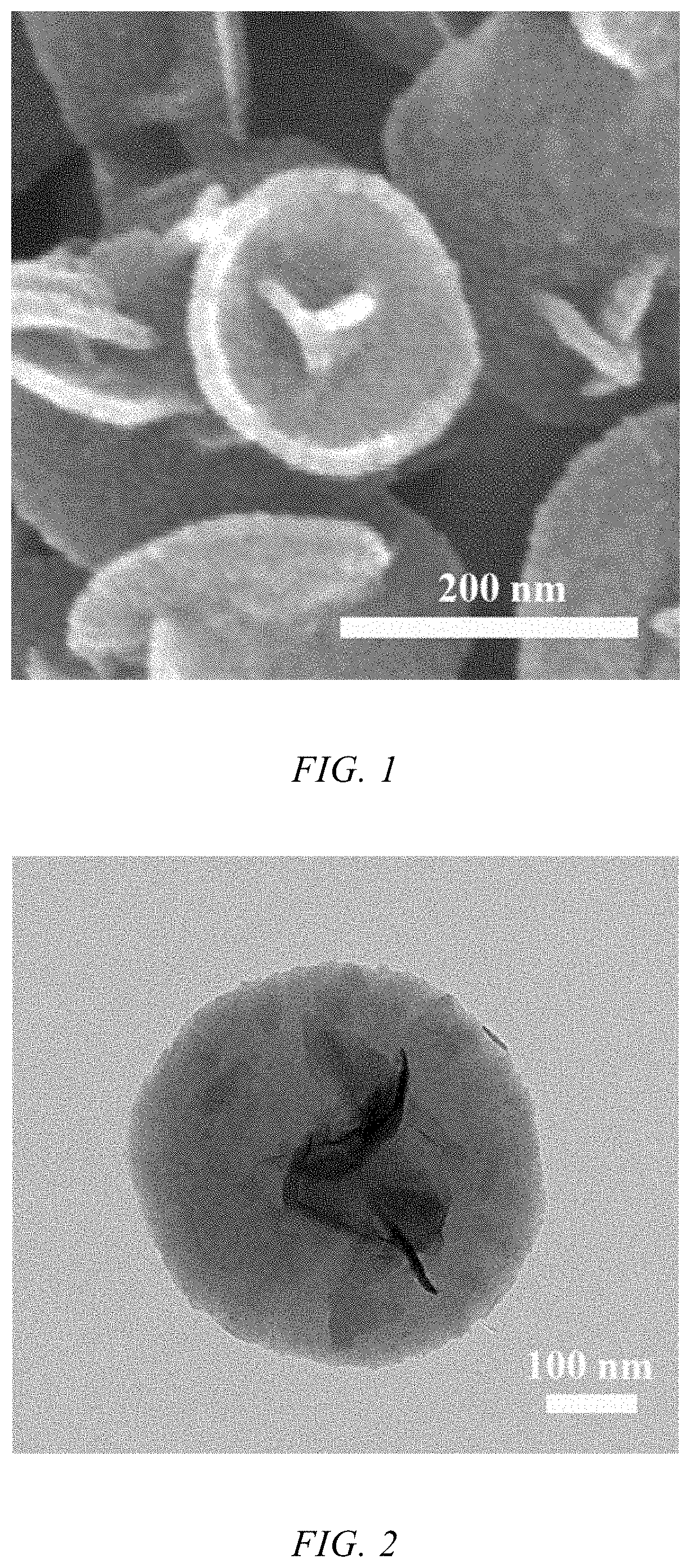

Nanoparticle coated electrode and method of manufacture

InactiveUS20090092887A1Increase surface areaFirmly connectedMachining electrodesMultiple component coatingsElectrolysisFuel cells

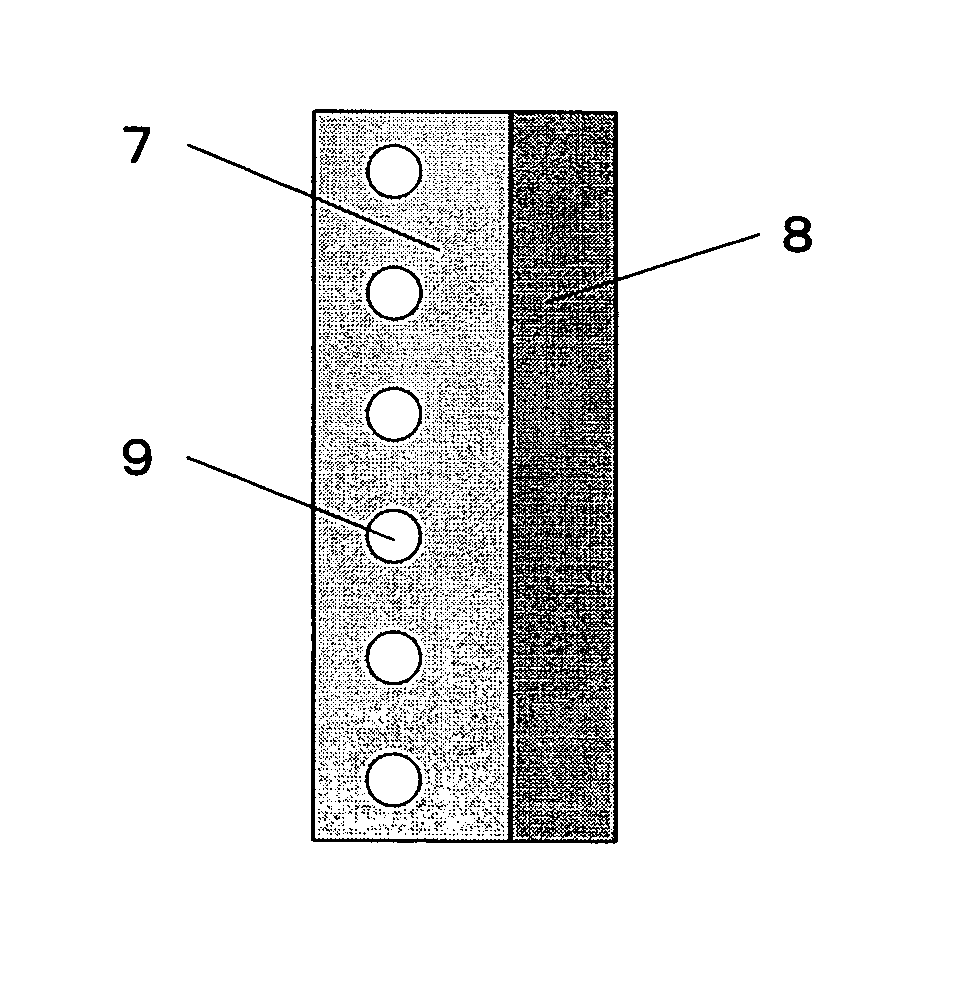

An electrode comprising a primary and secondary metal nanoparticle coating on a metallic substrate is prepared by dispersing nanoparticles in a solvent and layering them onto the substrate, followed by heating. The enhanced surface area of the electrode due to the catalytic nanoparticles is dramatically enhanced, allowing for increased reaction efficiency. The electrode can be used in one of many different applications; for example, as an electrode in an electrolysis device to generate hydrogen and oxygen, or a fuel cell.

Owner:BRICOLEUR PARTNERS LP

Electrode and electrochemical cell for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

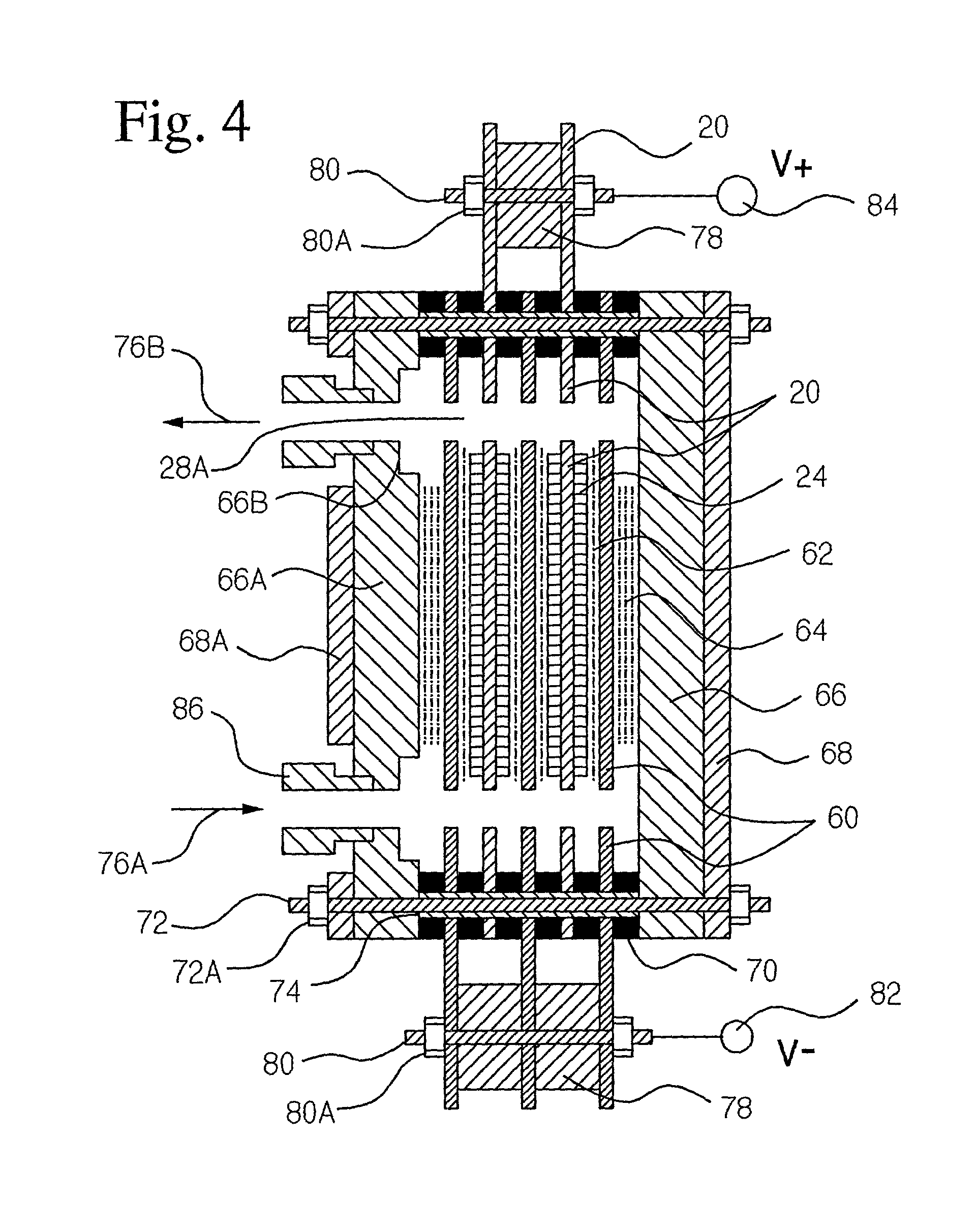

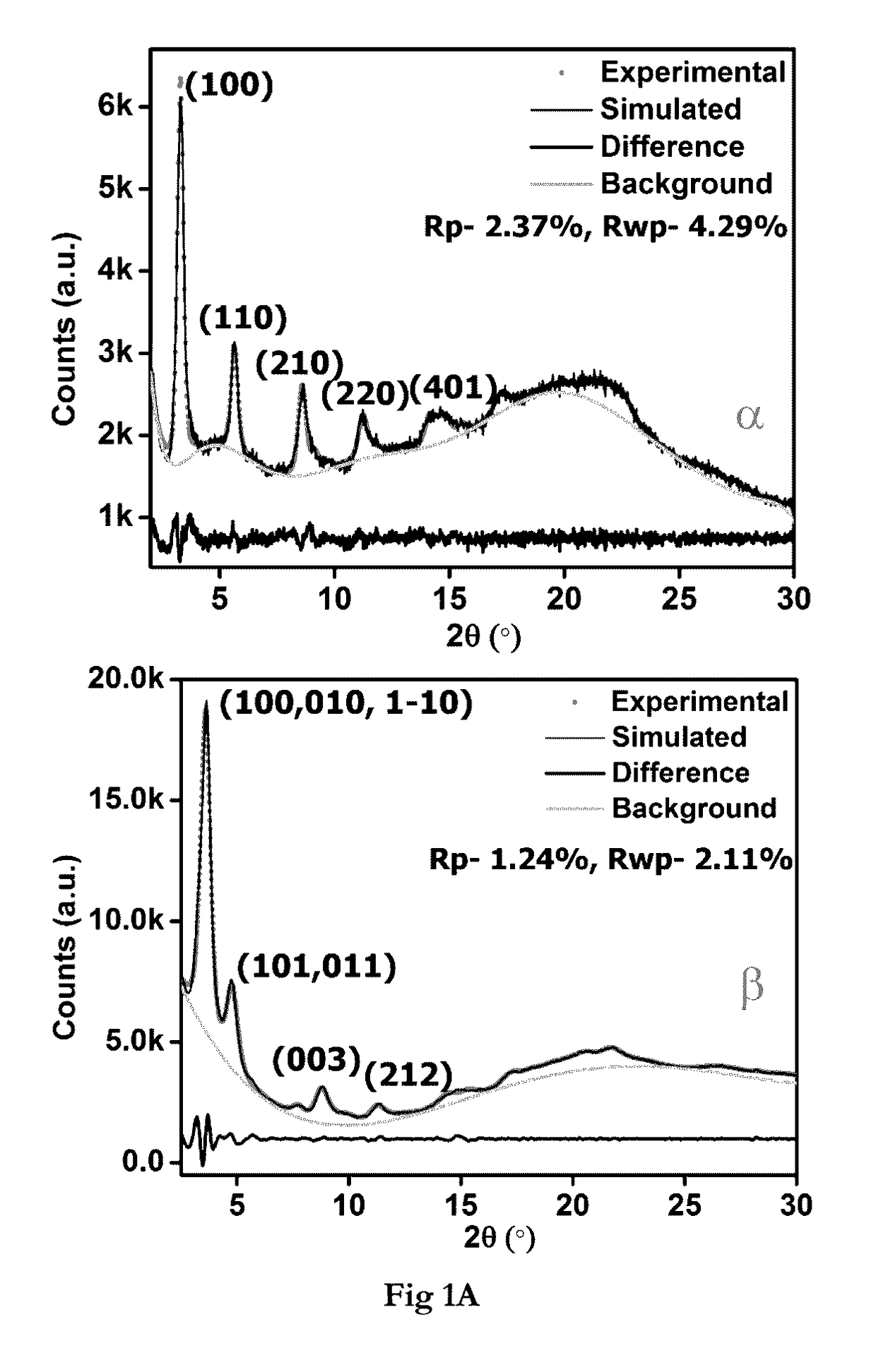

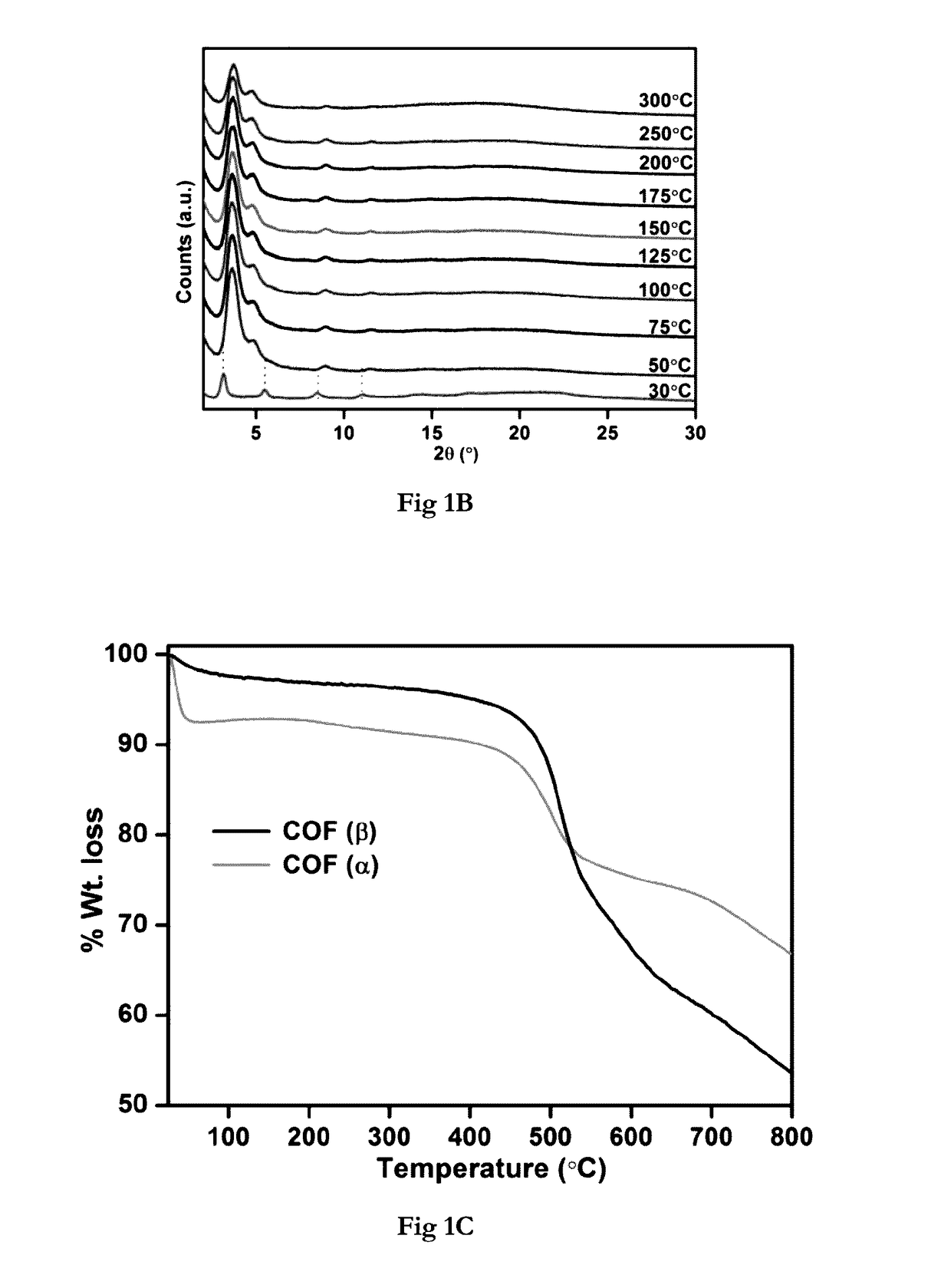

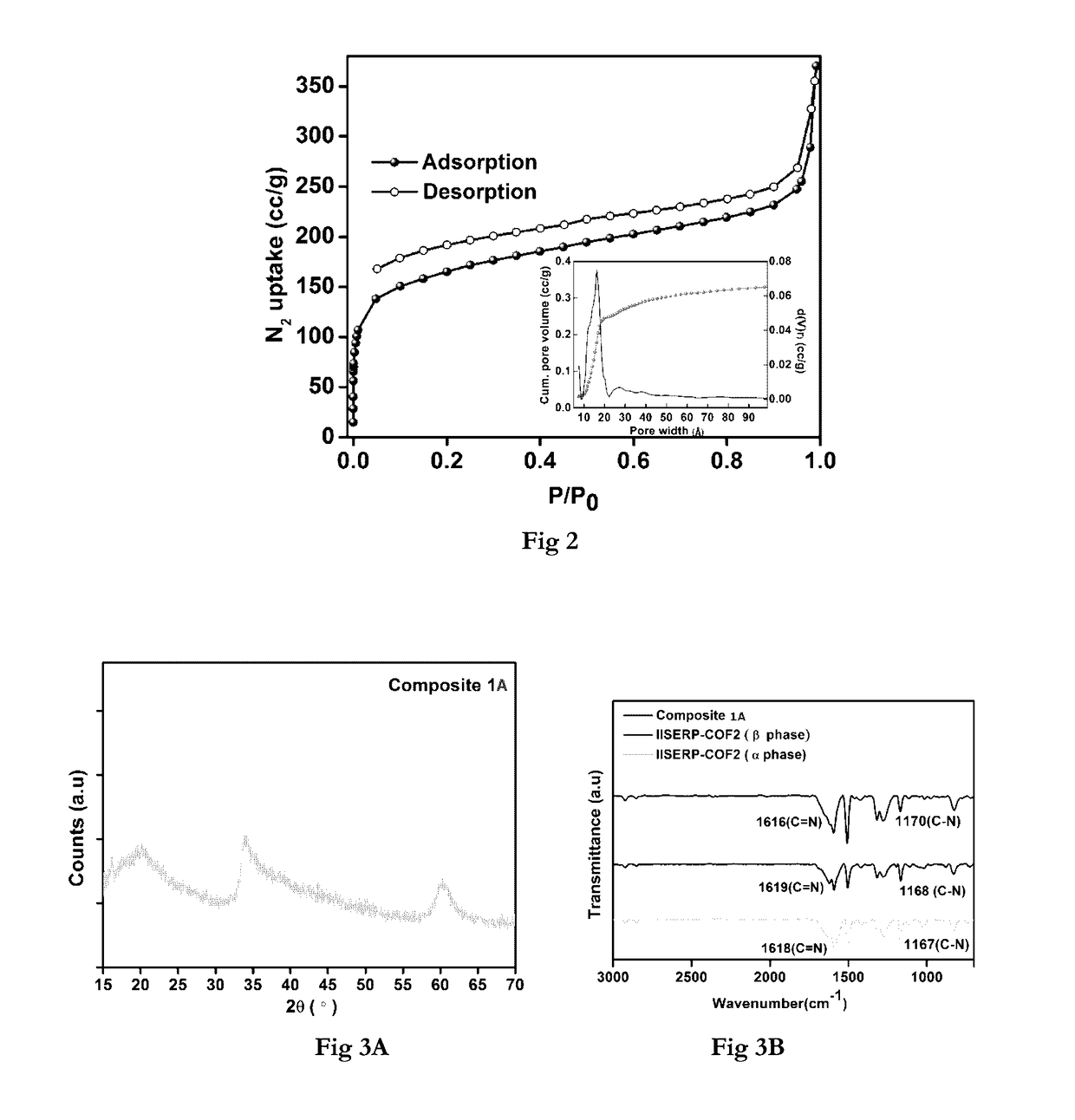

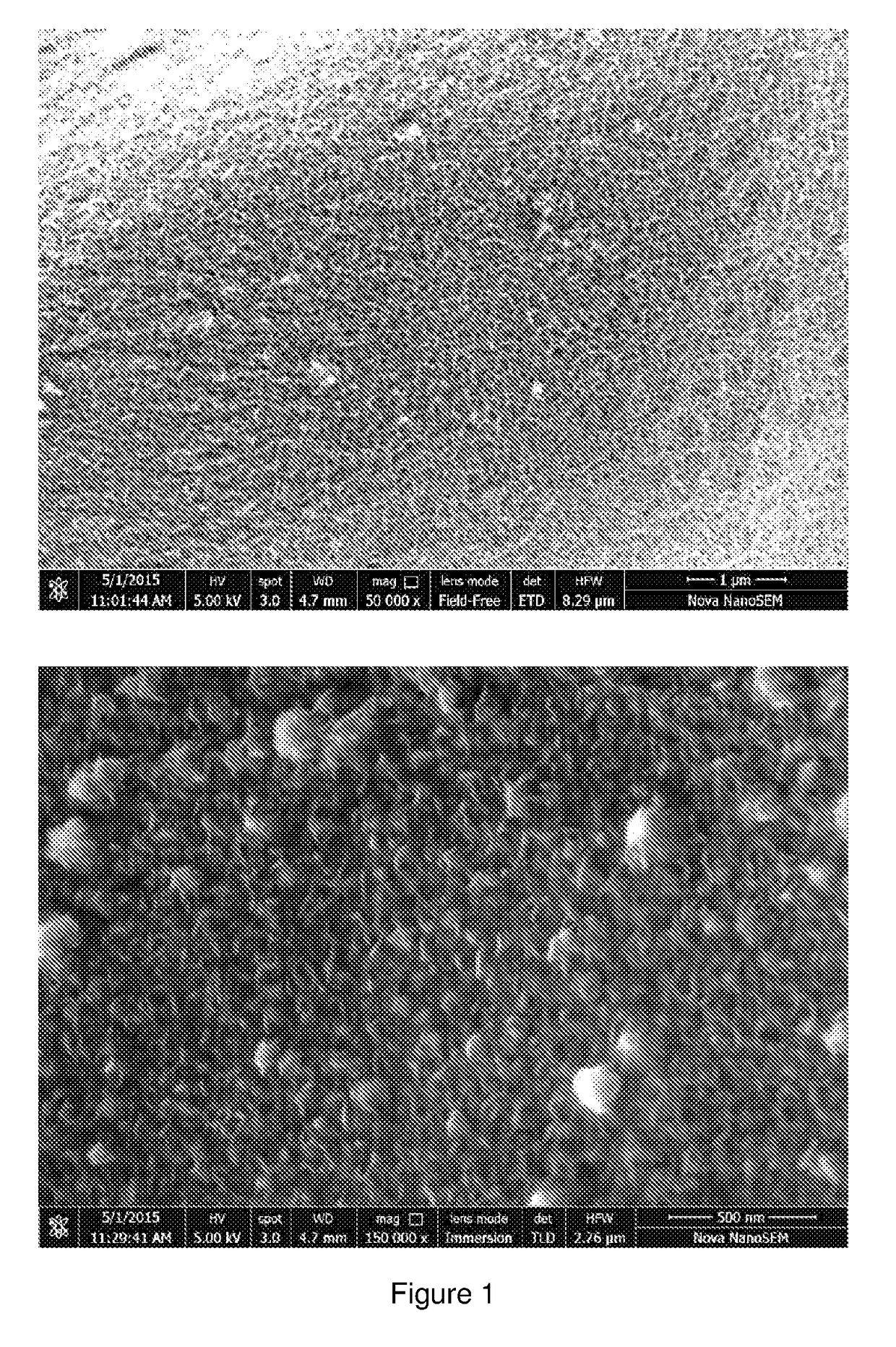

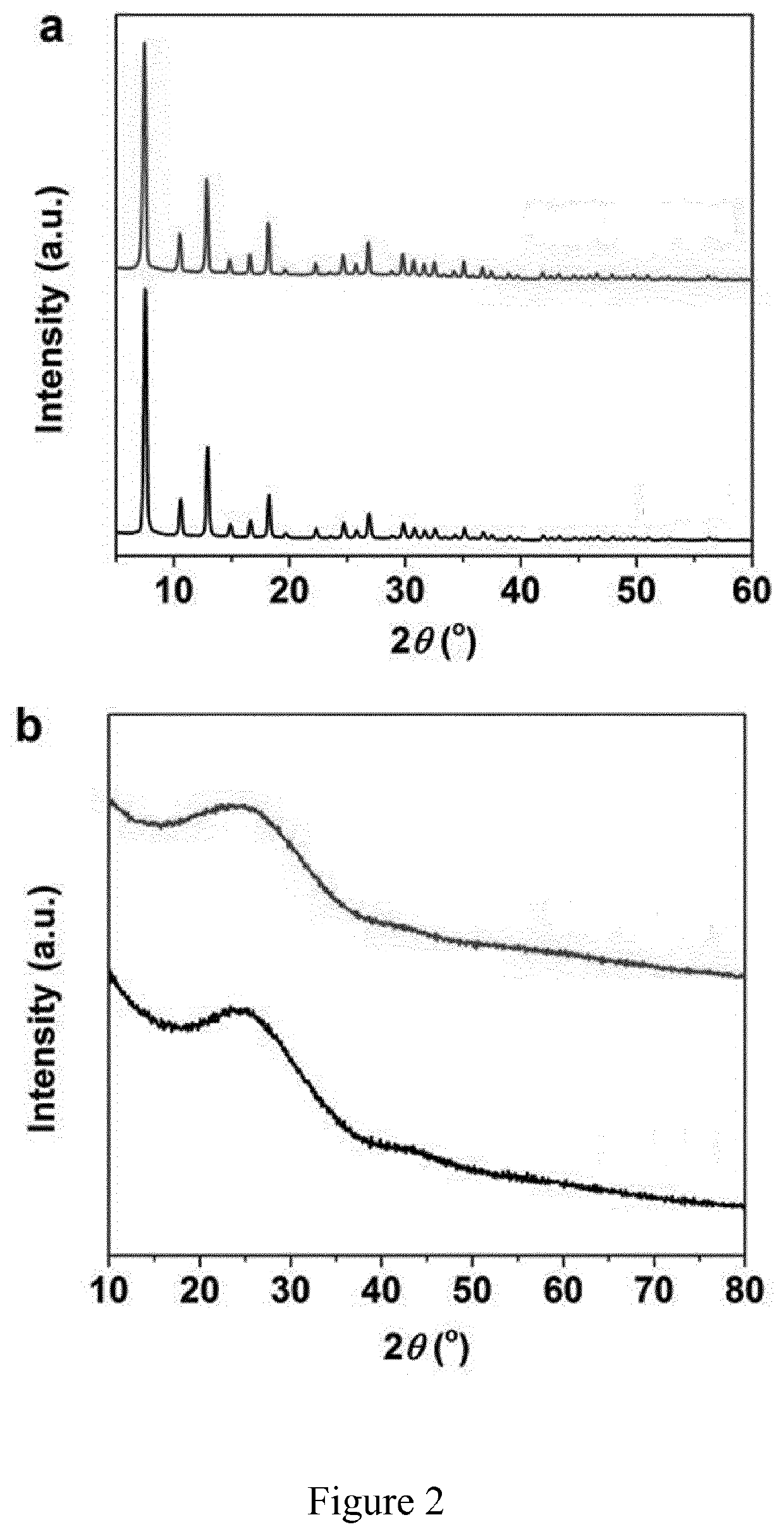

Covalent organic frameworks as porous supports for non-noble metal based water splitting electrocatalysts

ActiveUS20170130349A1Smooth connectionImprove performanceMultiple component coatingsElectrode with substrate and coatingMetal-organic frameworkManganese

The present invention discloses porous covalent organic frameworks (COF) supported noble metal-free nanoparticles which are useful as electrocatalysts for a water splitting system, and to the process for preparation of such electrocatalysts. The covalent organic frameworks (COF) supported noble metal-free nanoparticles have general formula (I):COF_AxBy(M)n (Formula I)wherein COF is selected from a Tris (4-formylphenyl)amine terephthaldehyde polymer or a benzimidazole-phloroglucinol polymer;‘A’ and ‘B’ each independently represent a transition metal selected from the group consisting of Ni, Co, Fe, Mn, Zn, and mixtures thereof; or ‘A’ and ‘B’ together represent a transition metal selected from the group consisting of Ni, Co, Fe, Mn, Zn, and mixtures thereof;‘M’ represents hydroxide or a nitride ion;‘x’ and ‘y’ represent the weight % of the metal loadings; or a ratio of x:y is between 0:1 and 1:0; and‘n’ is an integer 1 or 2 or 3.

Owner:INDIAN INST OF SCI EUDCATION & RES

Electrode

The present invention relates to a process for manufacturing an electrode comprising depositing on an electrode substrate a binder dispersion comprising a precursor of a conductive or semiconductive oxide, forming a conductive or semiconductive oxide coating from the precursor on the electrode substrate, depositing an electroconductive titanium oxide and electrode particles on the conductive or semiconductive oxide coating, adhering the electroconductive titanium oxide and the electrode particles to the formed conductive or semiconductive oxide coating. The invention also relates to an electrode obtainable by the process, and the use thereof in an electrolytic cell.

Owner:AKZO NOBEL NV

Electro-catalysts for the oxidation of ammonia in alkaline media

An electro-catalyst for the oxidation of ammonia in alkaline media; the electrocatalyst being a noble metal co-deposited on a support with one or more other metals that are active to ammonia oxidation. In some embodiments, the support is platinum, gold, tantalum, or iridium. In some embodiments, the support has a layer of Raney metal deposited thereon prior to the deposition of the catalyst. Also provided are electrodes having the electro-catalyst deposited thereon, ammonia electrolytic cells, ammonia fuel cells, ammonia sensors, and a method for removing ammonia contaminants from a contaminated effluent.

Owner:OHIO UNIV

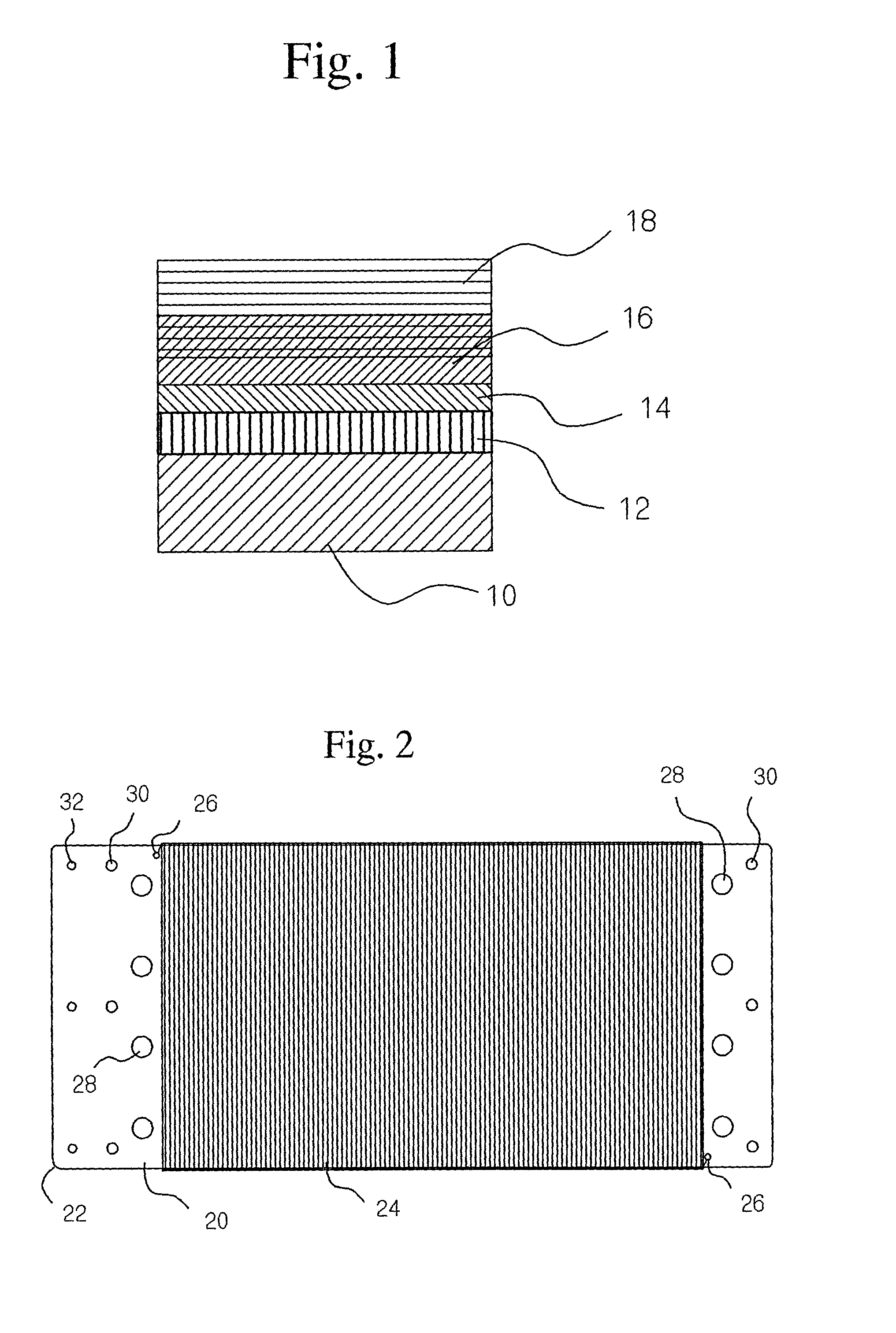

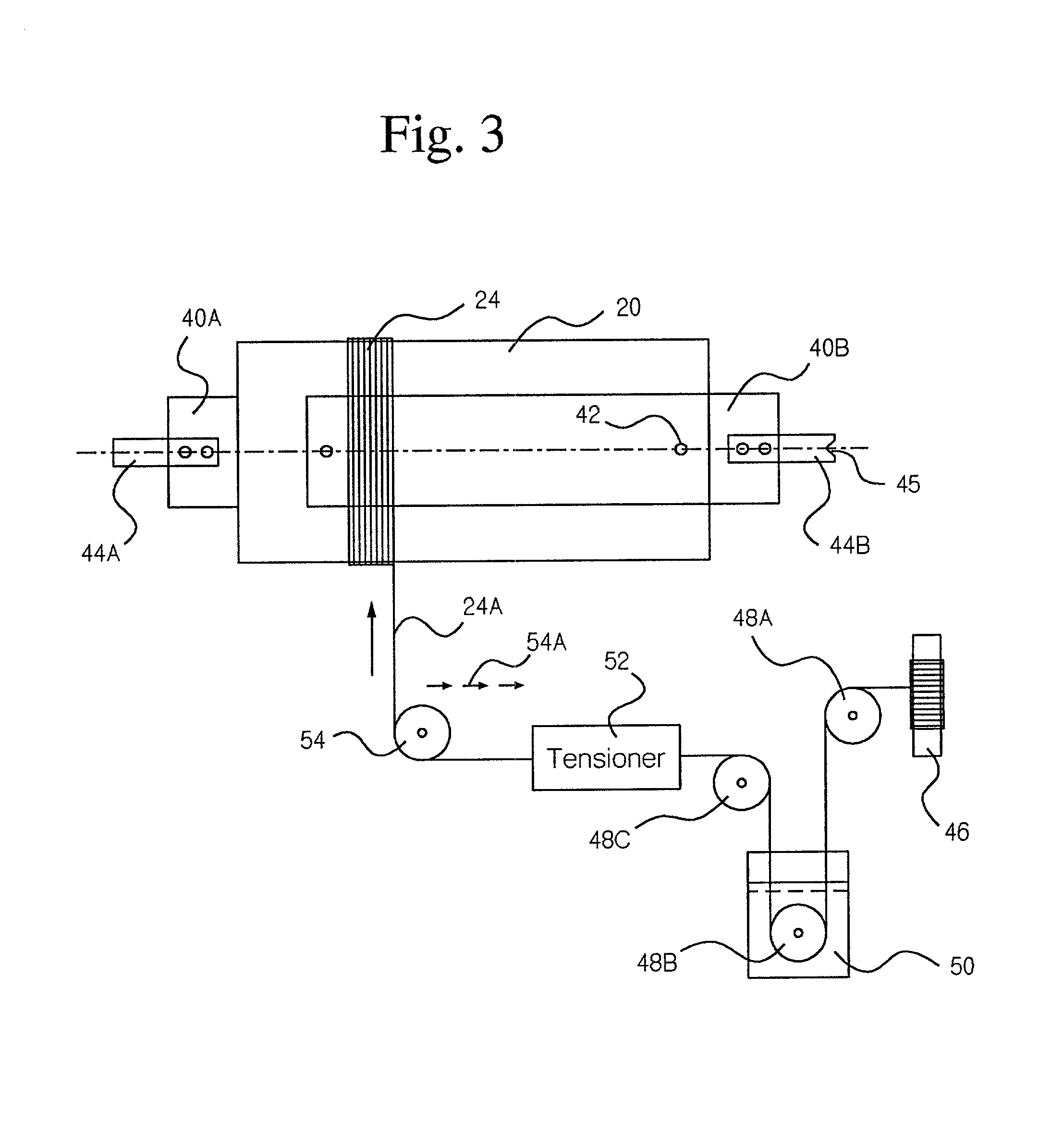

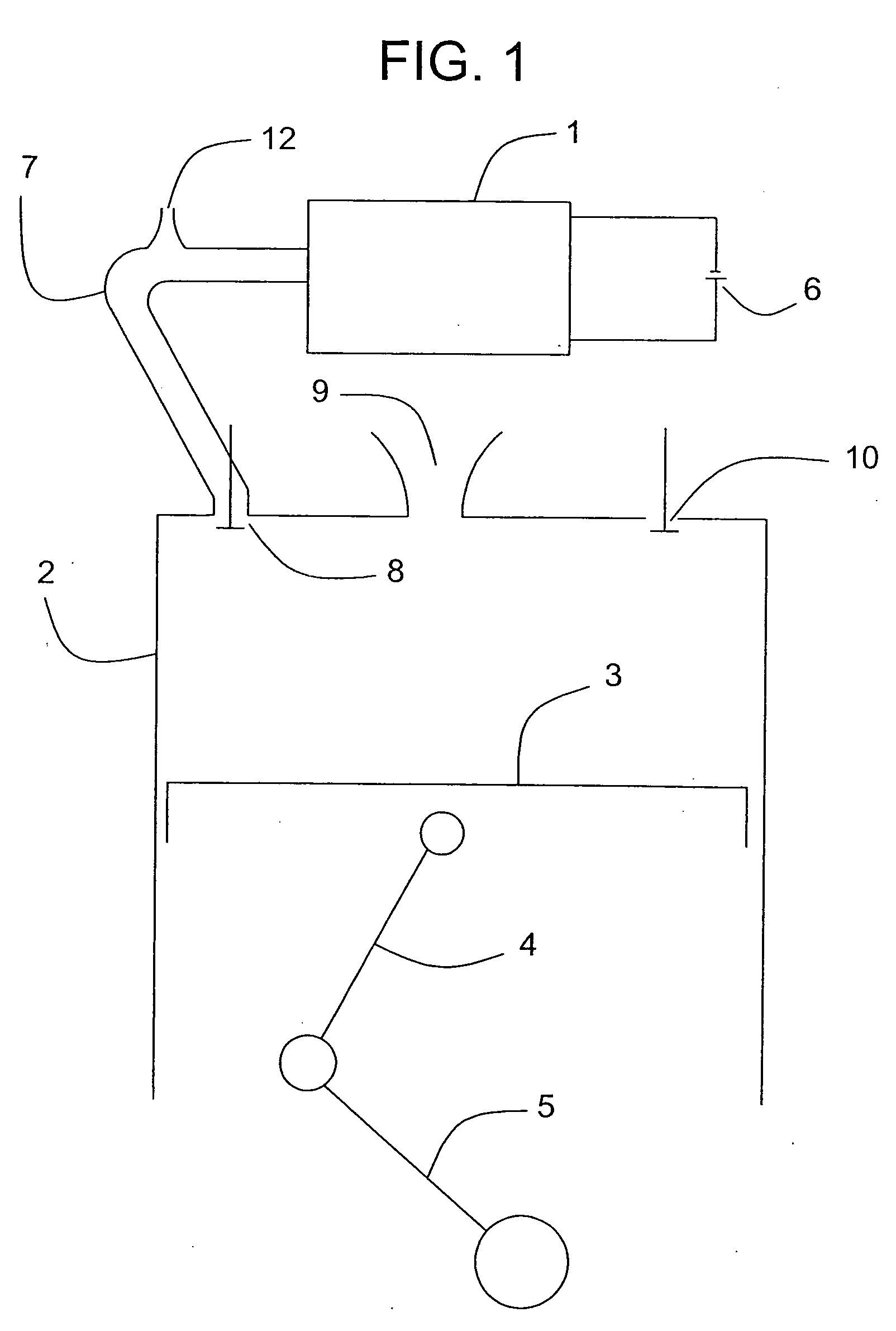

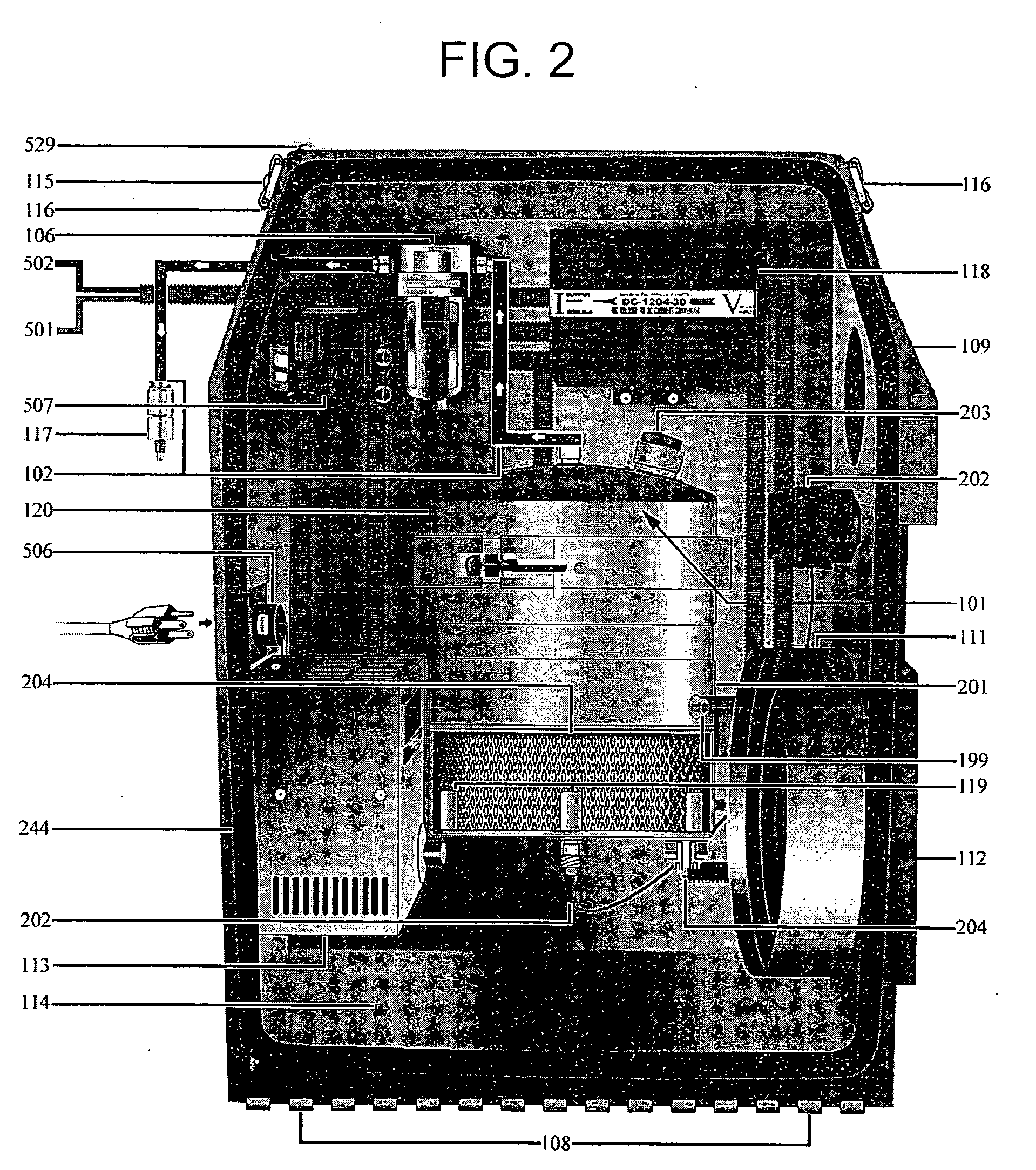

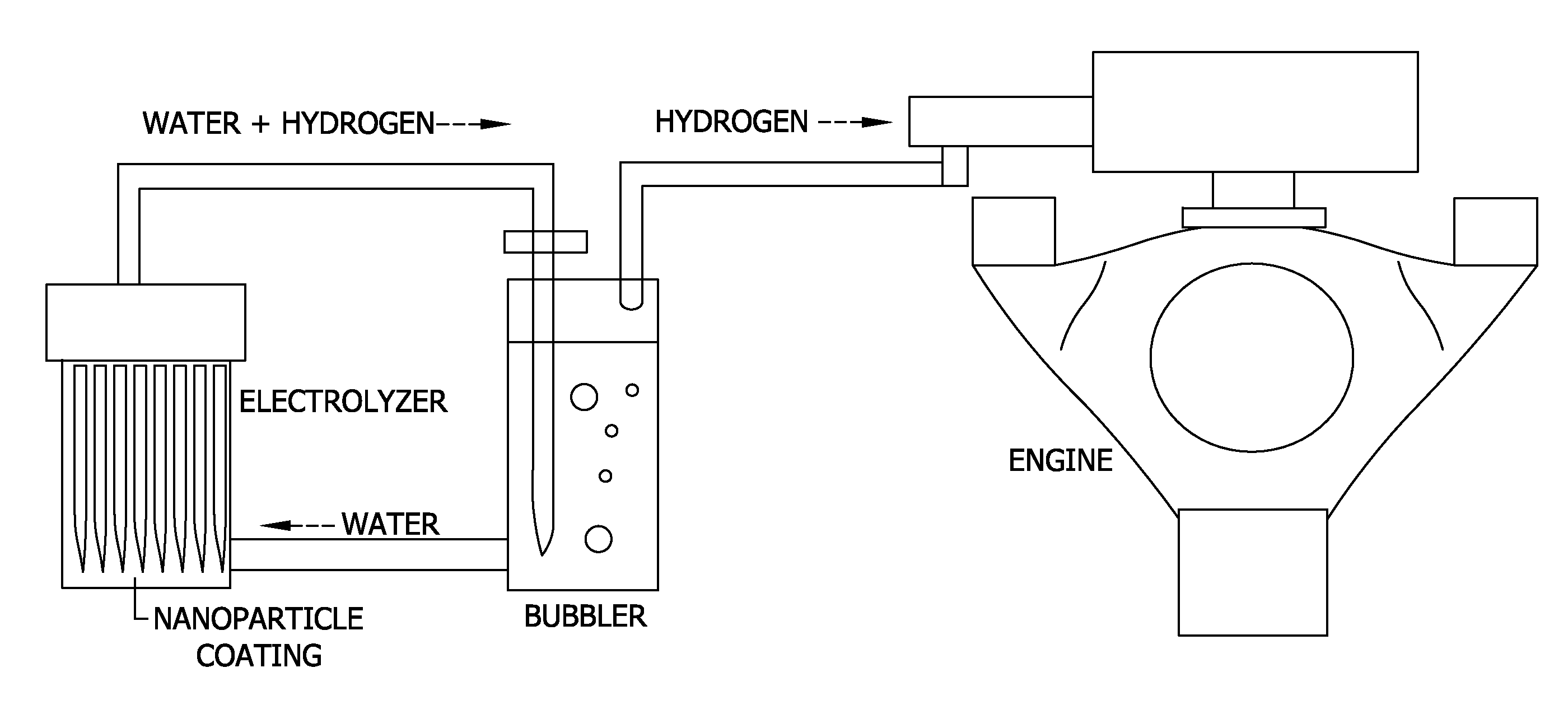

Internal combustion apparatus and method utilizing electrolysis cell

InactiveUS20070080071A1Less indirect maintenanceReduce corrosionCellsNon-fuel substance addition to fuelCombustionElectrolysis

The present disclosure relates generally to the production of hydrogen and oxygen within an electrolysis cell having a coated anode such that these gases can be added to the fuel source (fossil fuel and / or alternative fuels) of a combustion engine system as a supplement for said fuel source(s) for increased performance.

Owner:GO GREEN FUEL N A

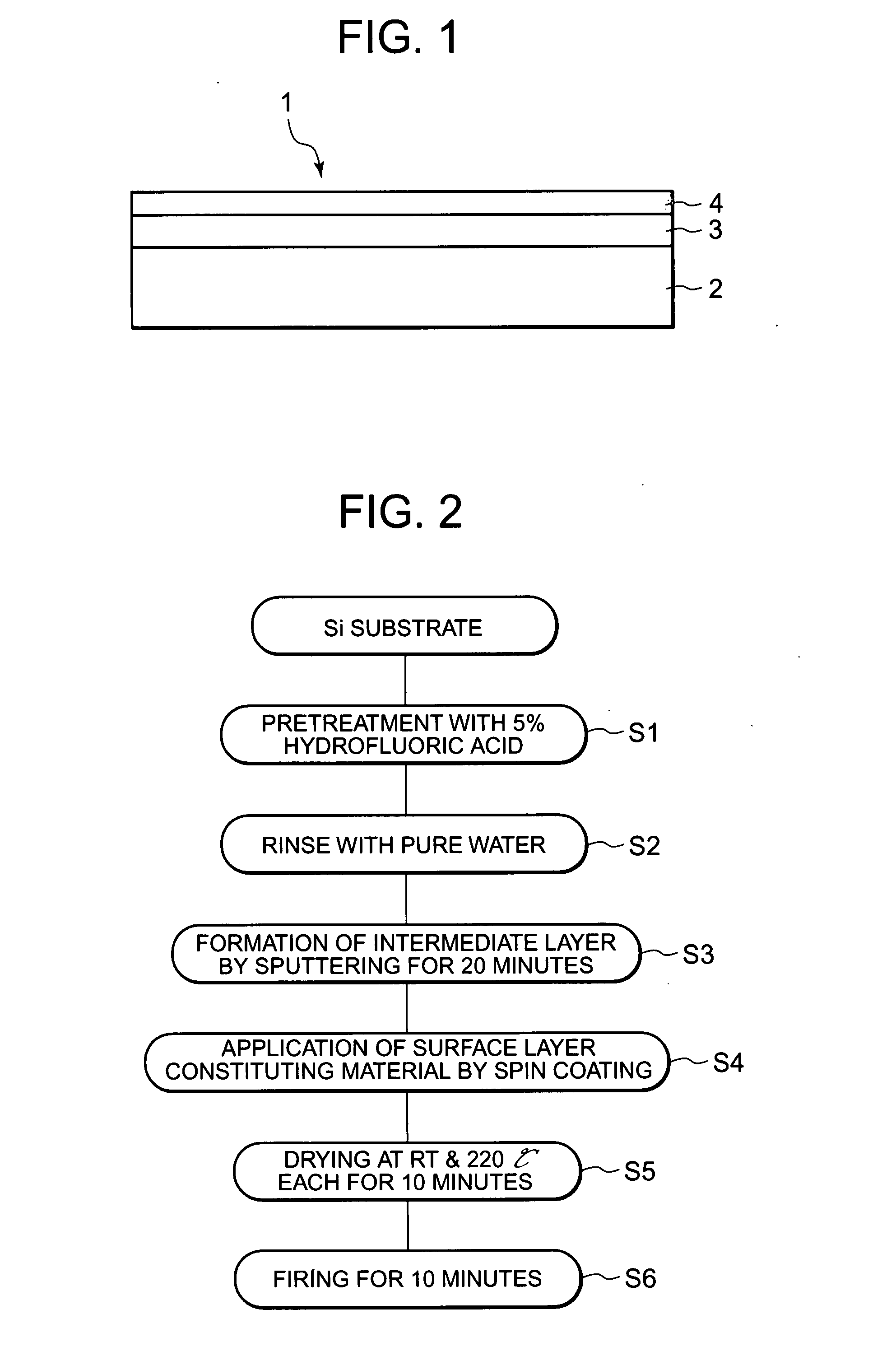

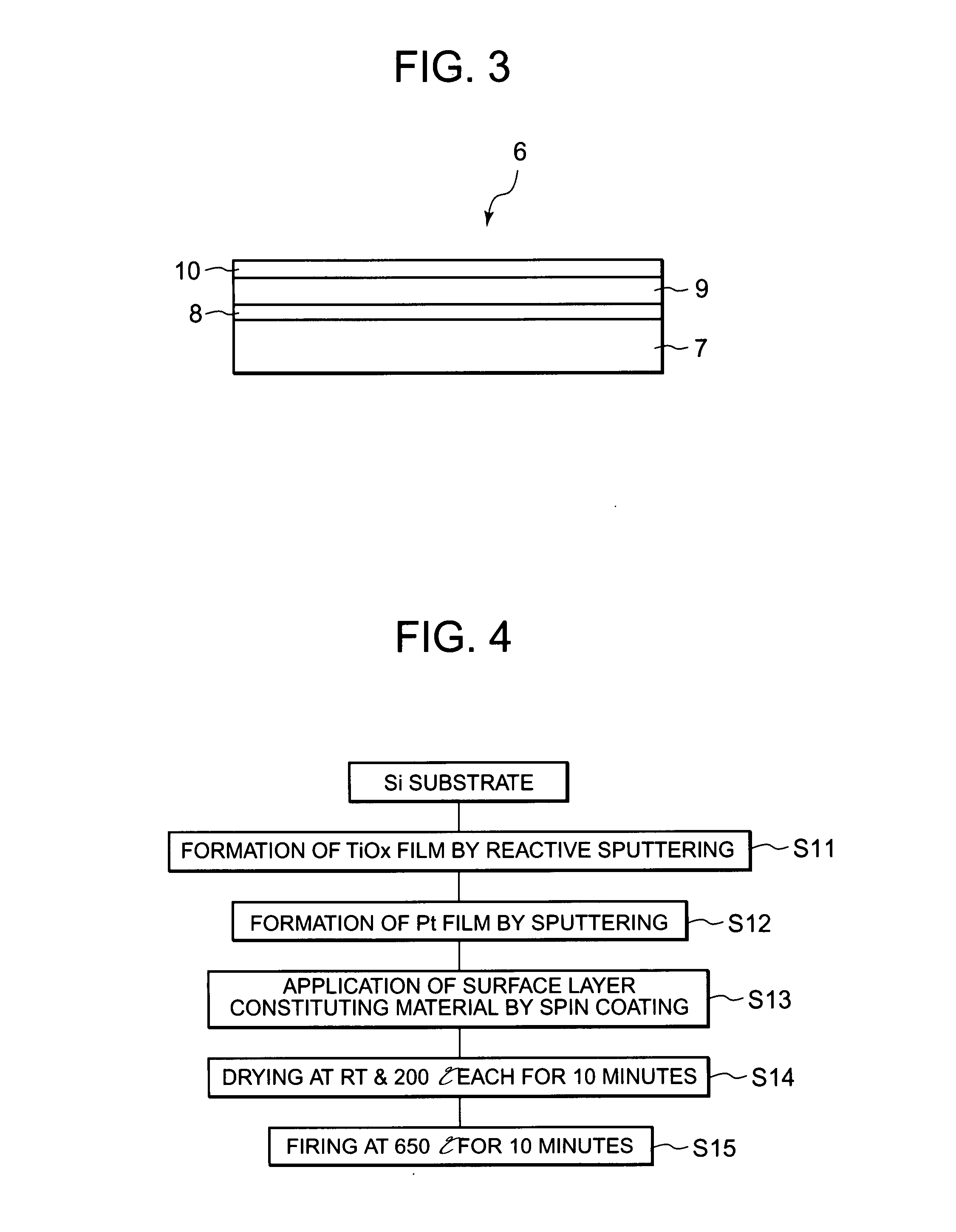

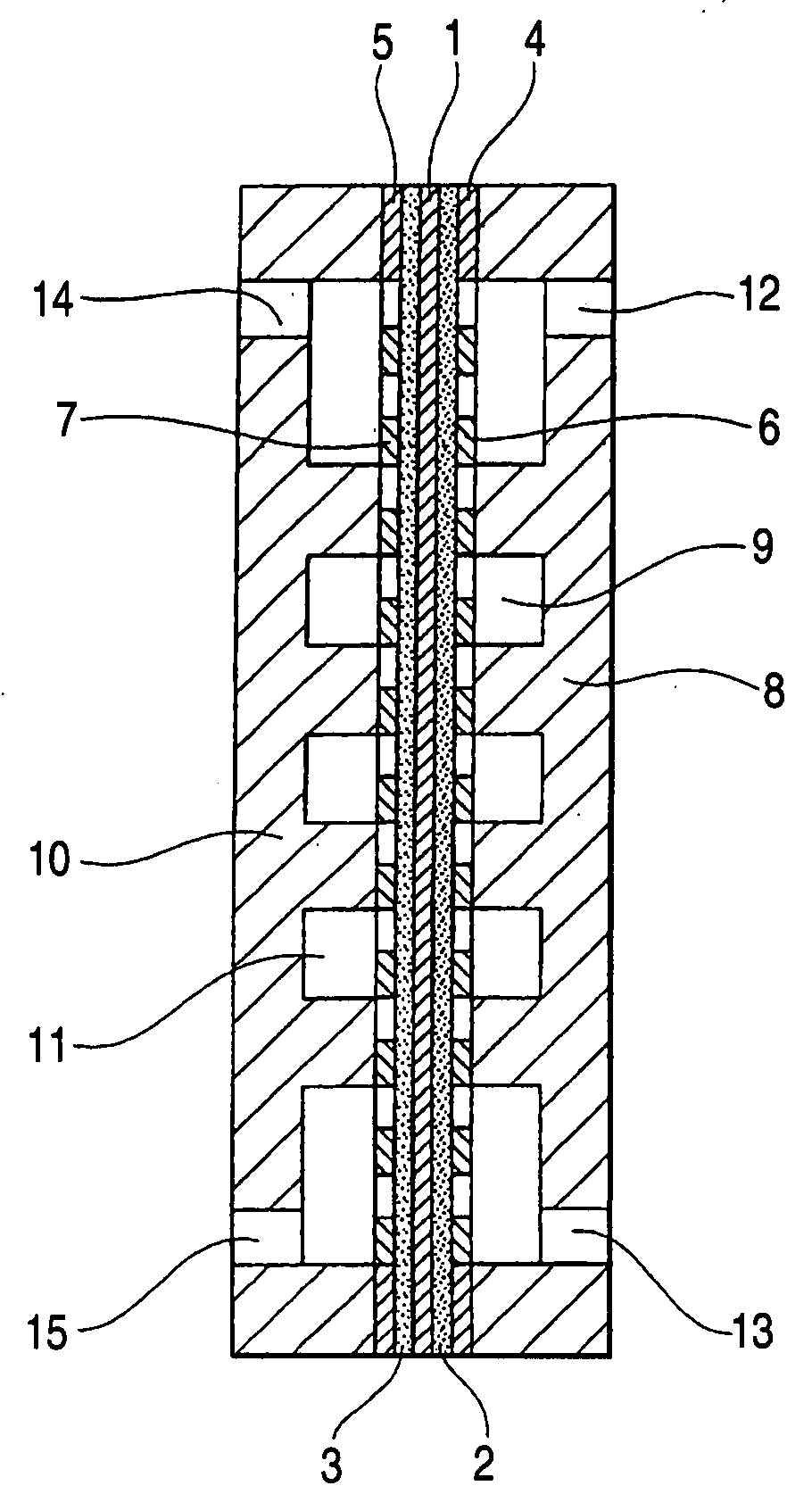

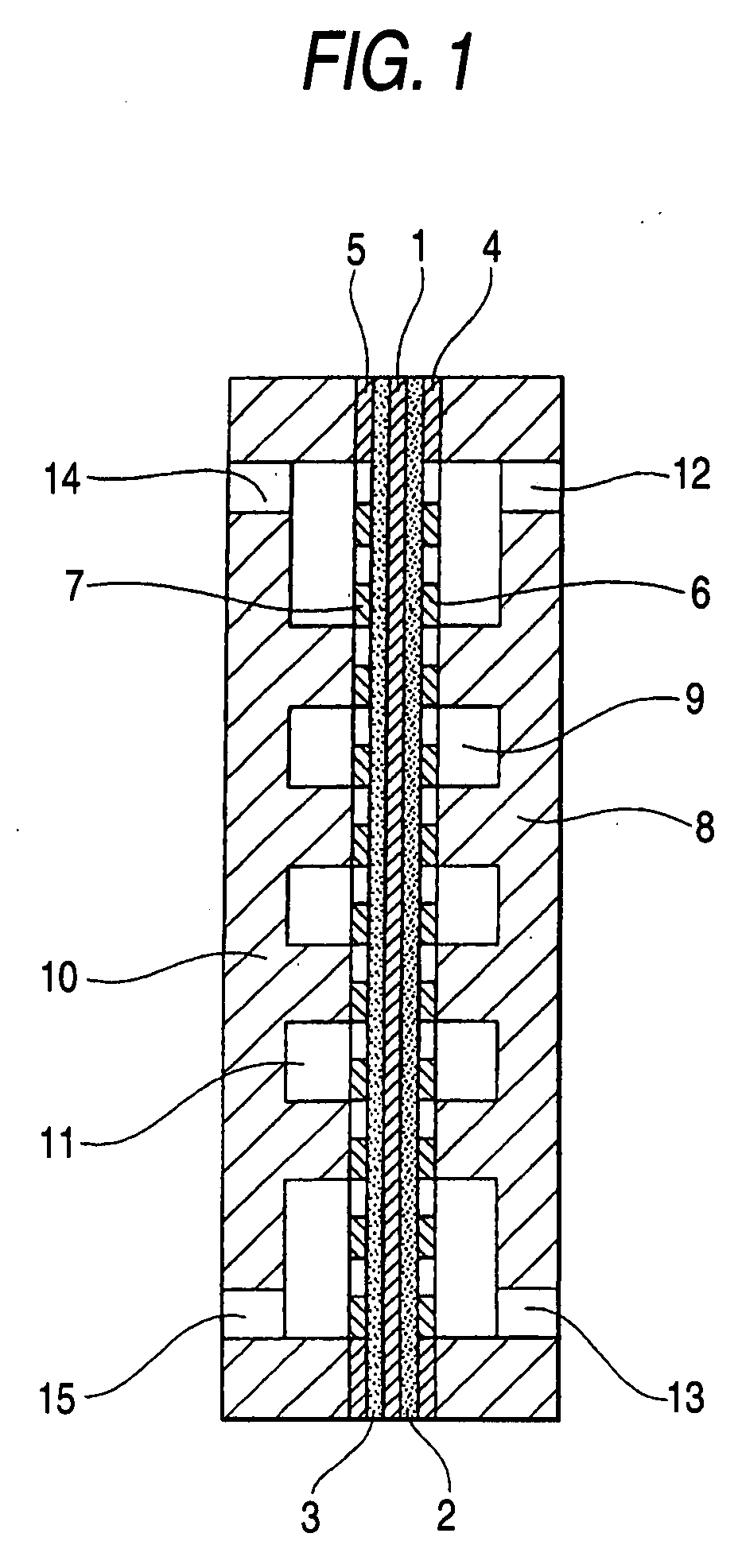

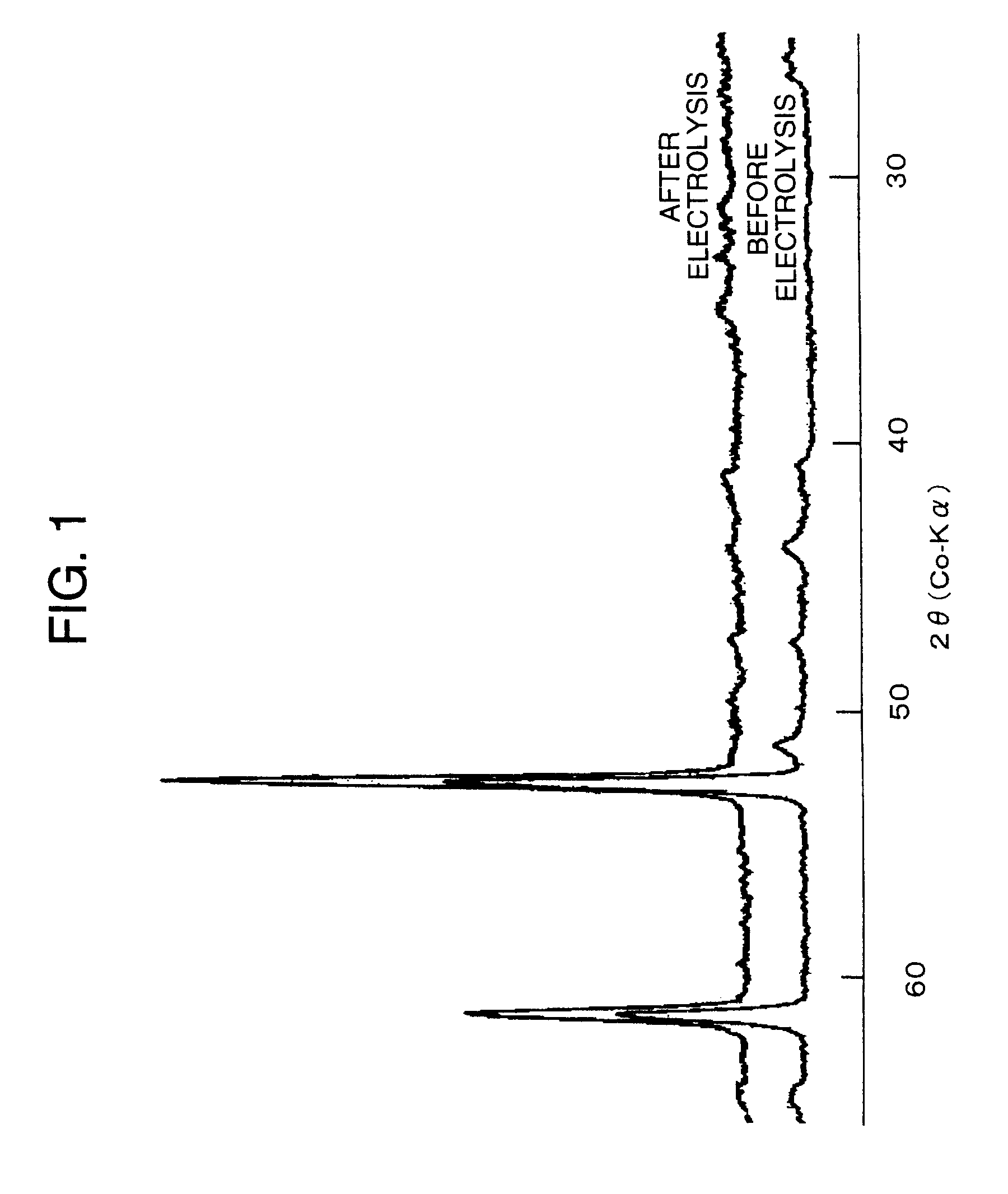

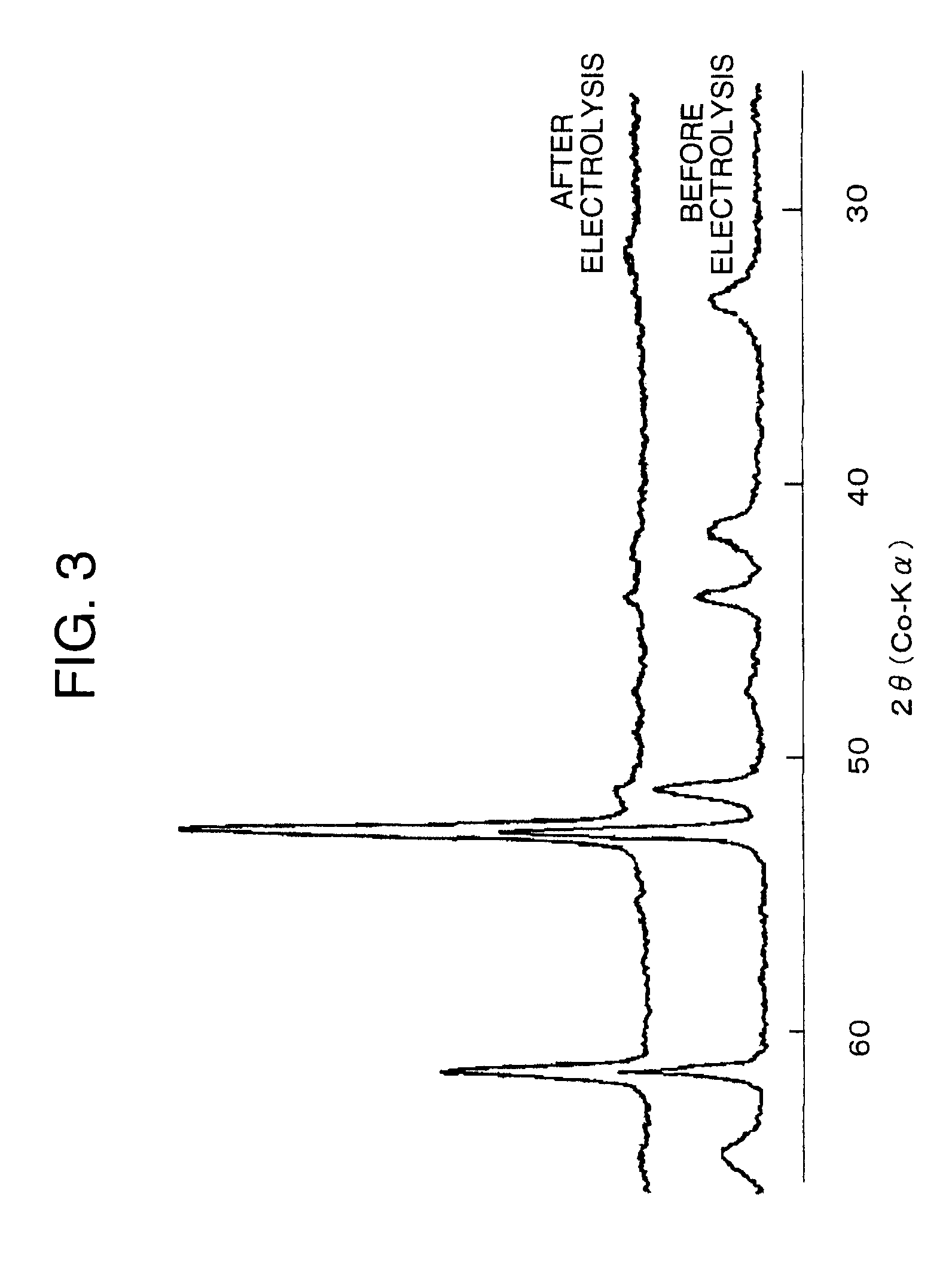

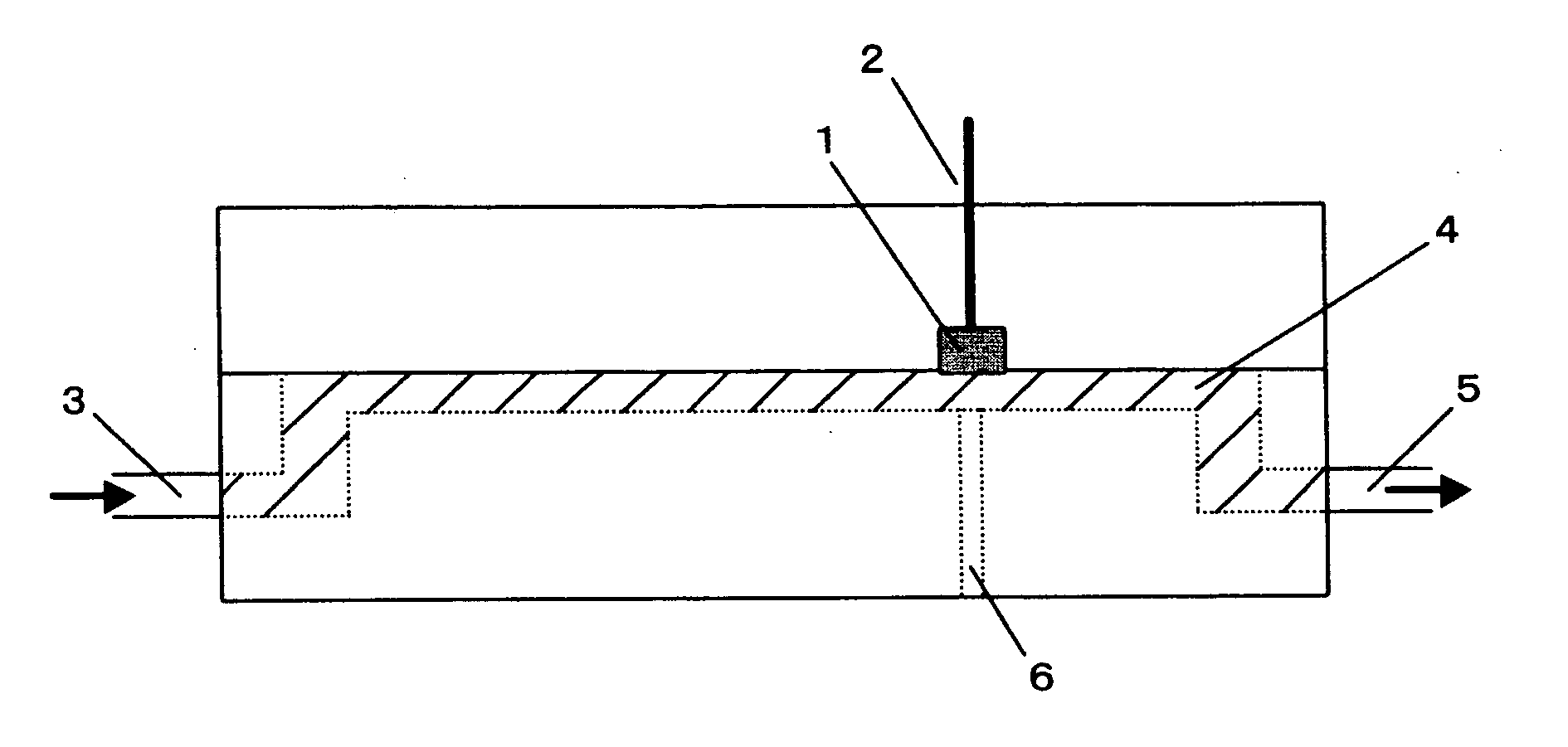

Electrode for electrolysis, electrolytic process using the electrode, and electrolytic apparatus using them

InactiveUS20080060947A1Efficient productionShort lifeMachining electrodesCellsManufacturing technologySurface layer

An object of the present invention is to provide an electrode for electrolysis which is available by an easy fabrication process, can produce ozone water at high efficiency and also can produce hydrogen peroxide and OH radicals having a high oxidizing power by the electrolysis of water at a low current density; an electrolytic process using the electrode; and an electrolytic apparatus using them. The electrode for electrolysis according to the present invention has a substrate and a surface layer formed on the surface thereof, the surface layer being made of anatase type titanium oxide.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Electrode catalyst for electrochemical reaction, process for producing the electrode catalyst and electrode for electrochemical reaction having the electrode catalyst

InactiveUS20070212594A1High catalyst stabilityLong life-timeCellsMultiple component coatingsElectrochemical responseMetal

The present invention provides an electrode catalyst for electrochemical reaction, the electrode catalyst having: a conductive diamond particle having fine pores on a surface thereof; and a carbon-reactive catalyst metal in the fine pores, a process for producing the electrode catalyst, and an electrode.

Owner:DE NORA PERMELEC LTD +1

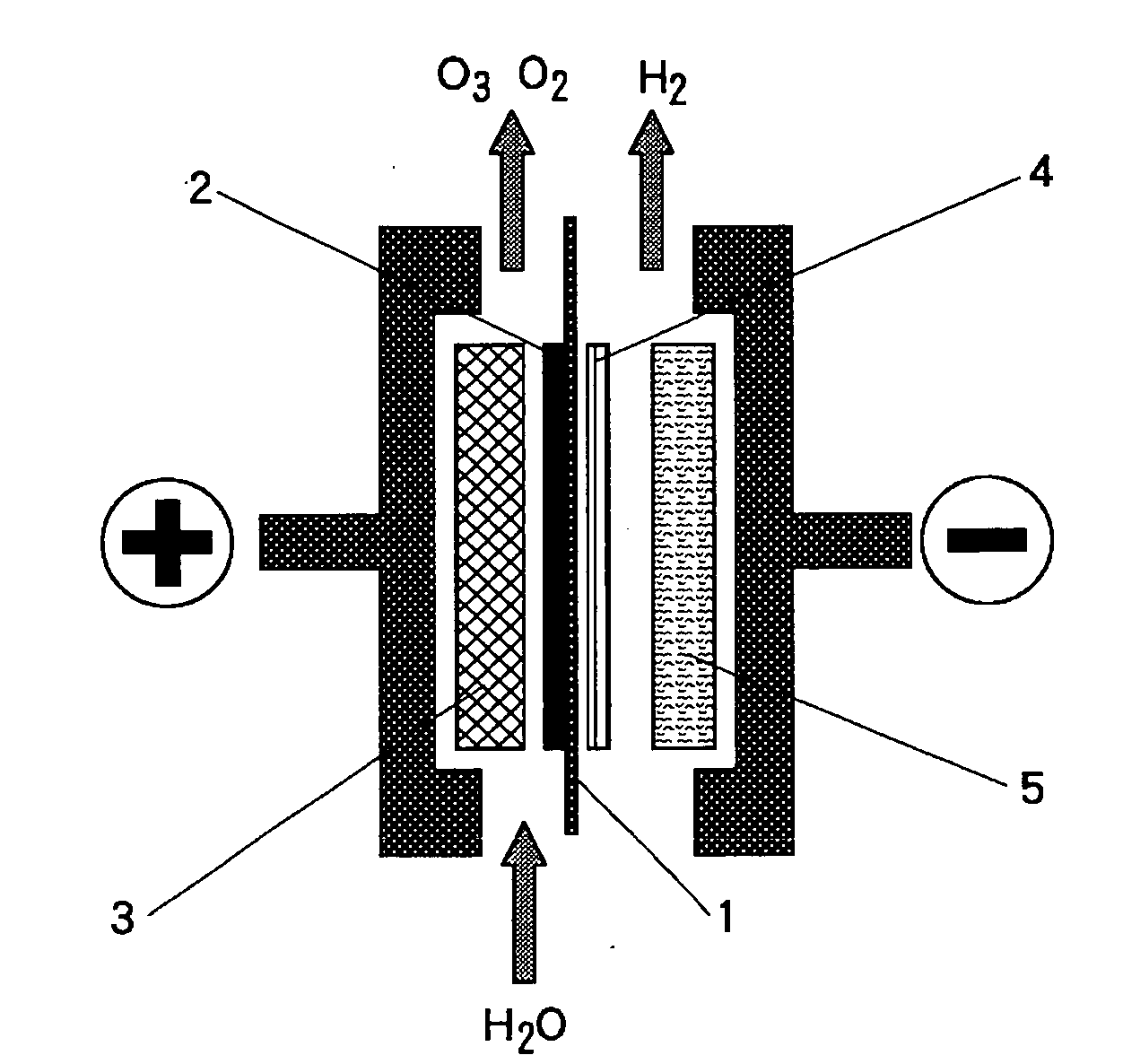

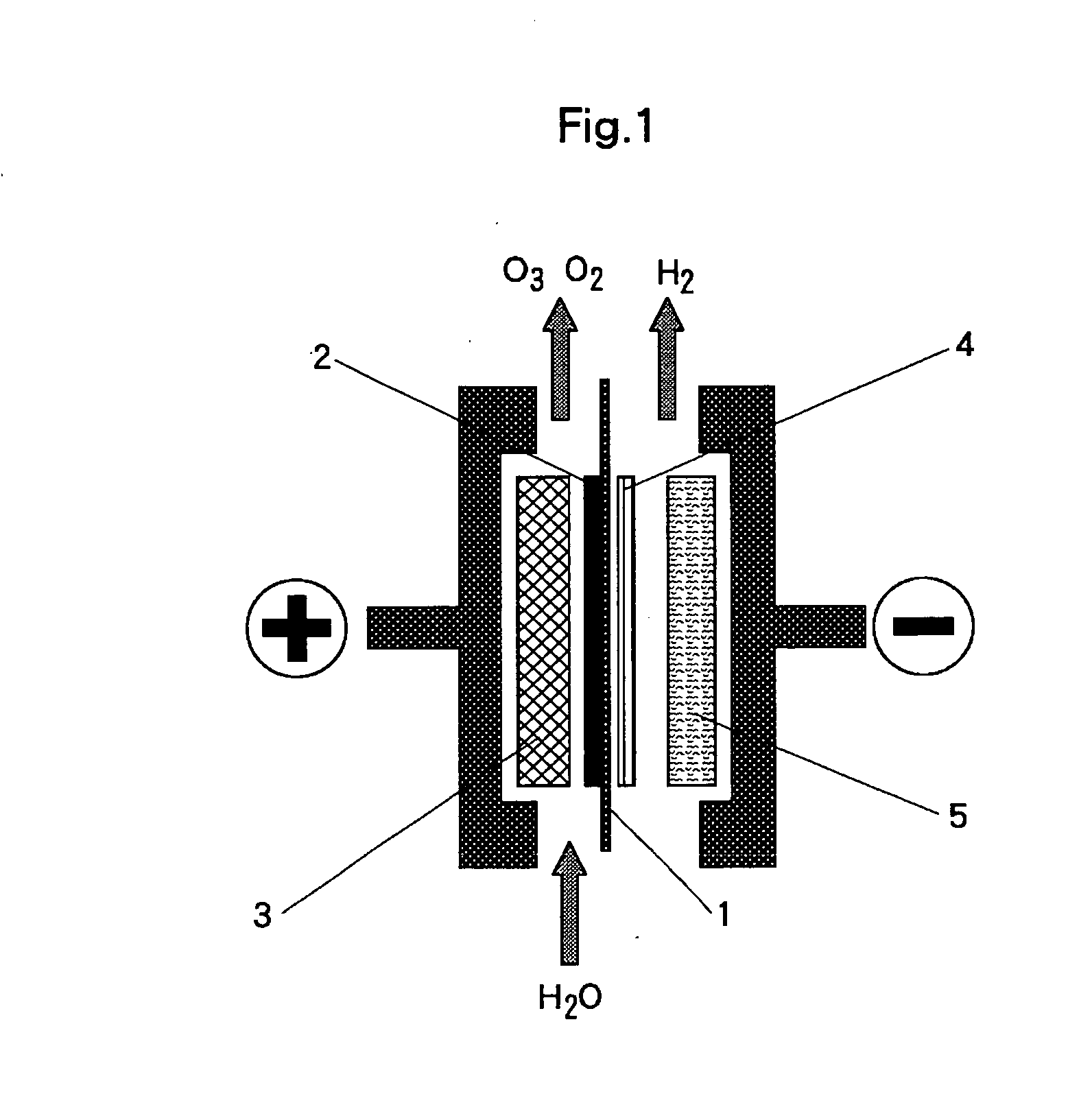

Water electrolysis system

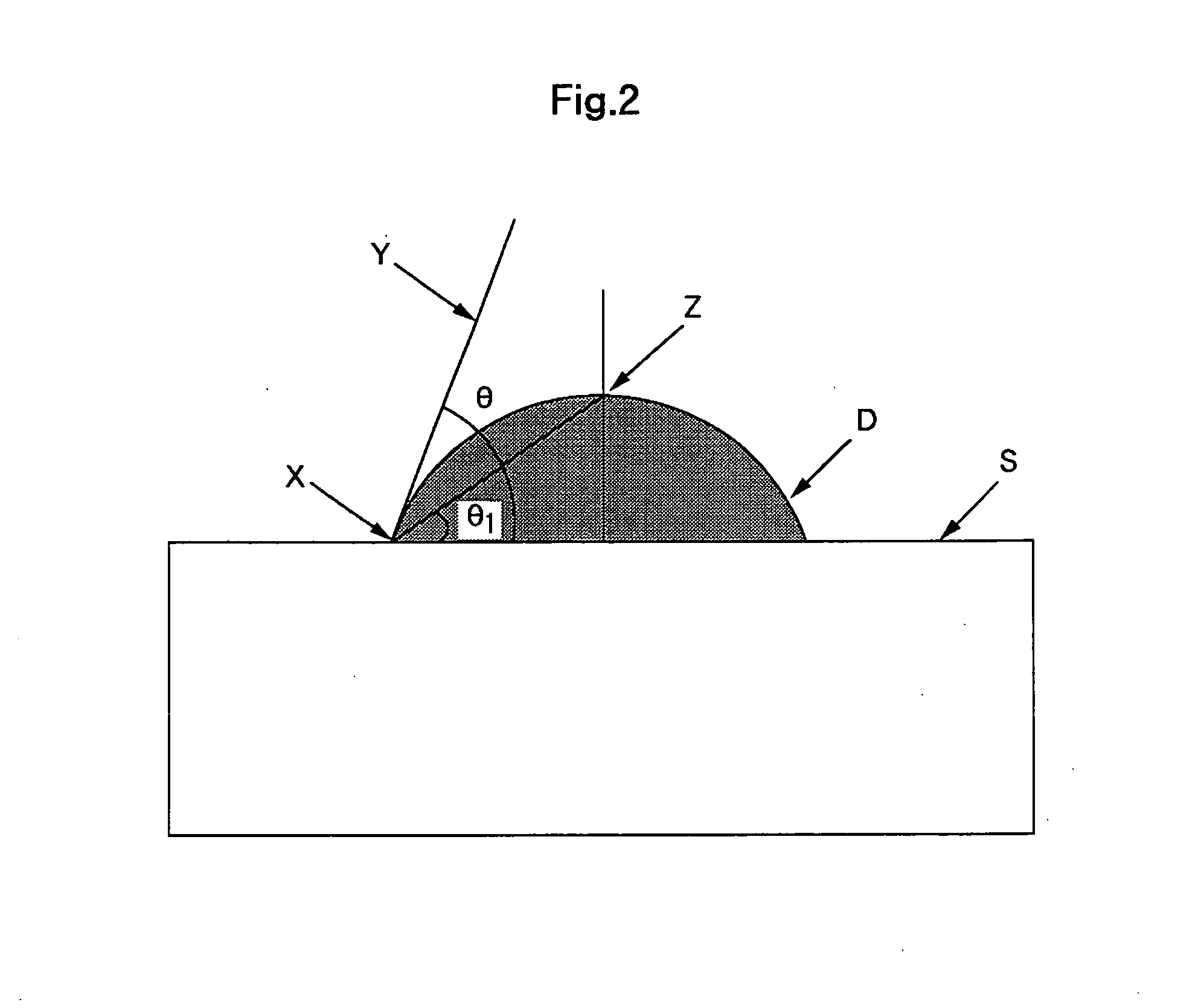

In a water electrolysis system having an anode catalyst layer containing anode catalyst and a cathode catalyst layer containing cathode catalyst tightly attached, respectively, to each surface of a solid polymer electrolyte membrane comprising a cation exchange membrane, wherein at least one catalyst layer of said anode catalyst layer and cathode catalyst layer comprises a porous structure of anode catalyst or cathode catalyst dispersed in fluorine resin containing resin, featuring the surface of the anode catalyst layer or the cathode catalyst layer being hydrophobized and the water contact angle with the surface of the anode catalyst layer or the cathode catalyst layer of said porous structure being 90 degrees or more, whereby the transfer of gas to the counter electrode can be significantly suppressed, gas purity and current efficiency be improved, and safety operation of the electrolysis system be secured, without a major change in configuration of the water electrolysis system.

Owner:CHLORINE ENGINEERS CORP LTD

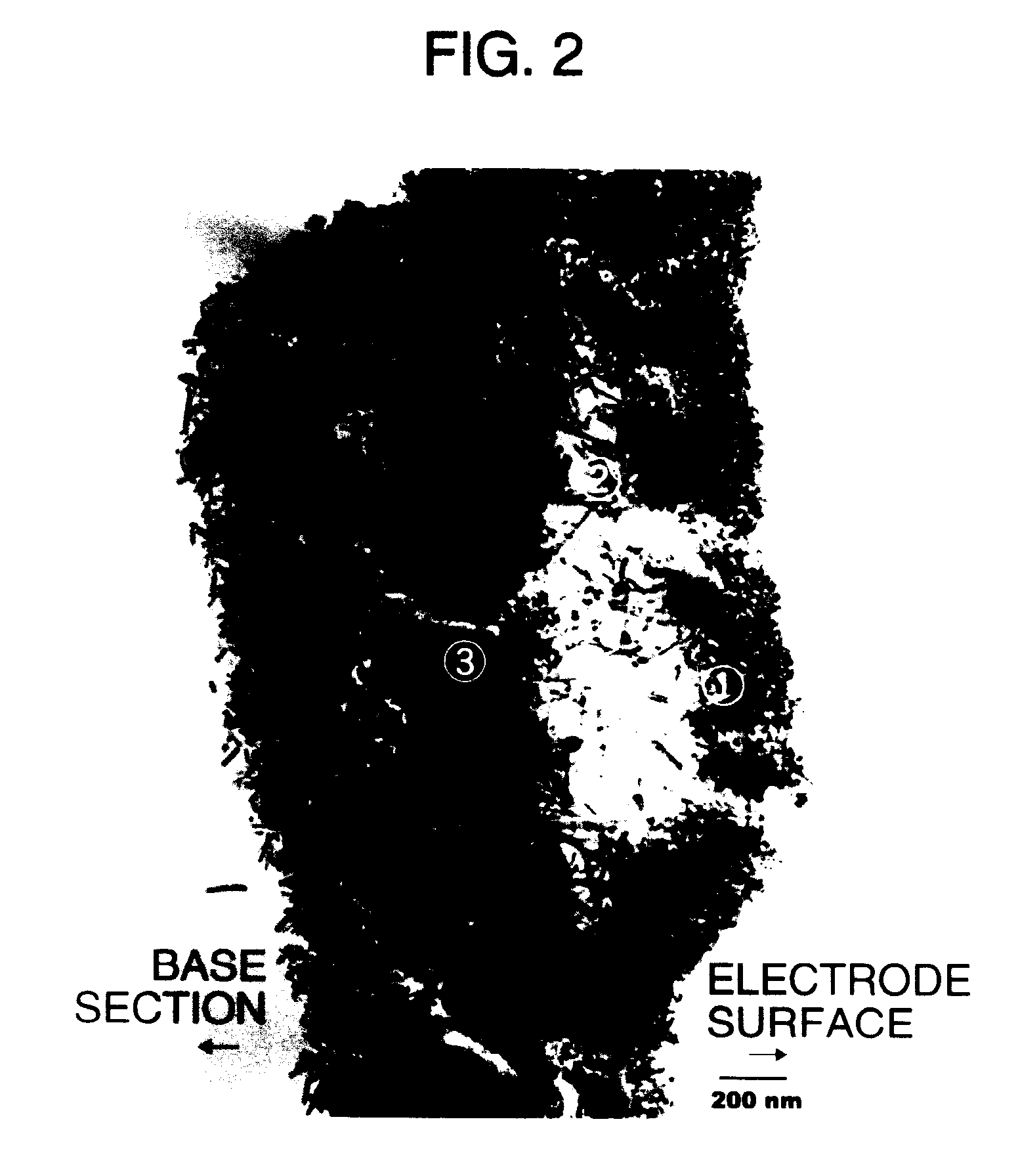

Electrode for electrolysis and process for producing the same

ActiveUS20070029190A1Increased durabilityIncrease surface areaMaterial nanotechnologyPolycrystalline material growthElectrolysisManufacturing technology

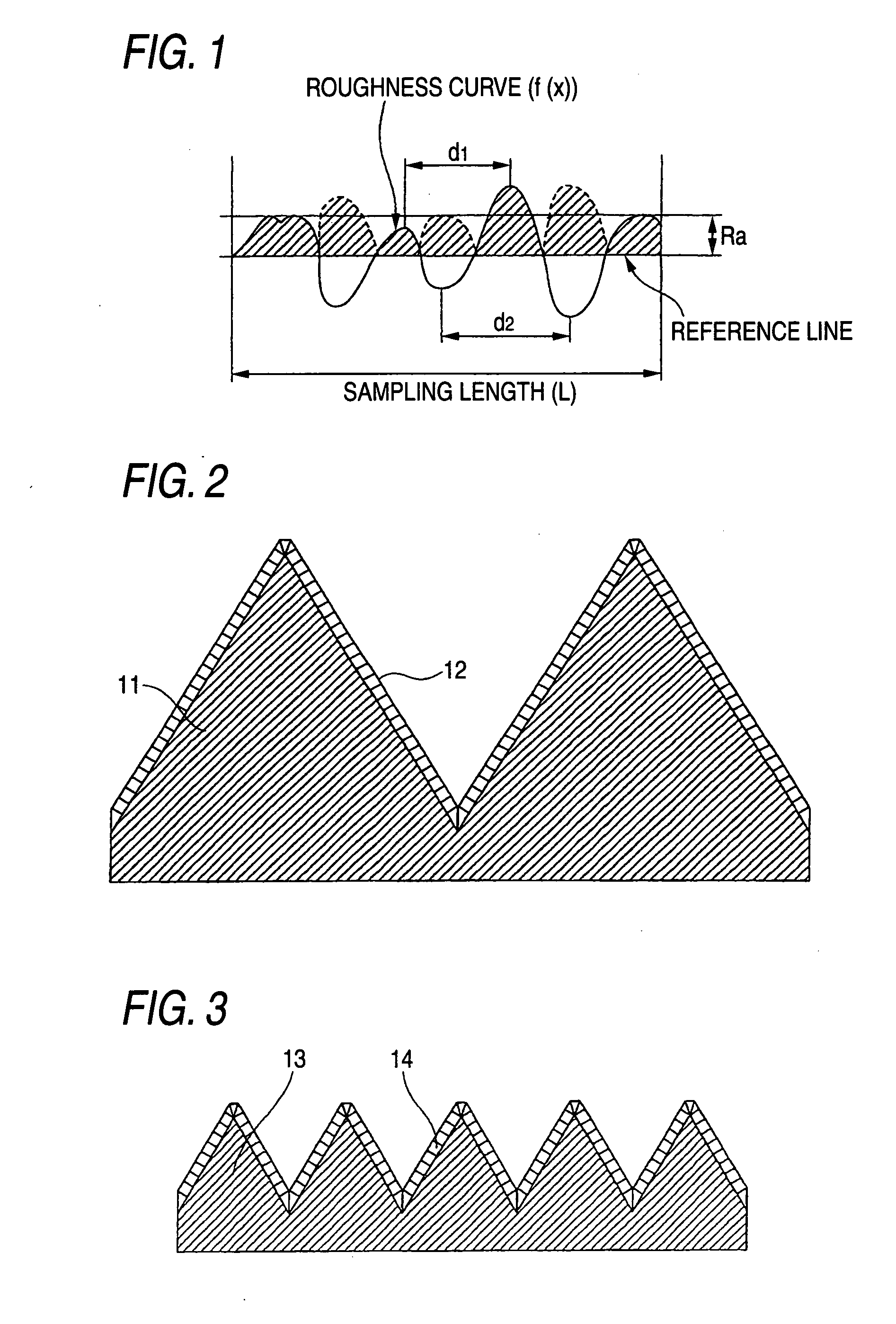

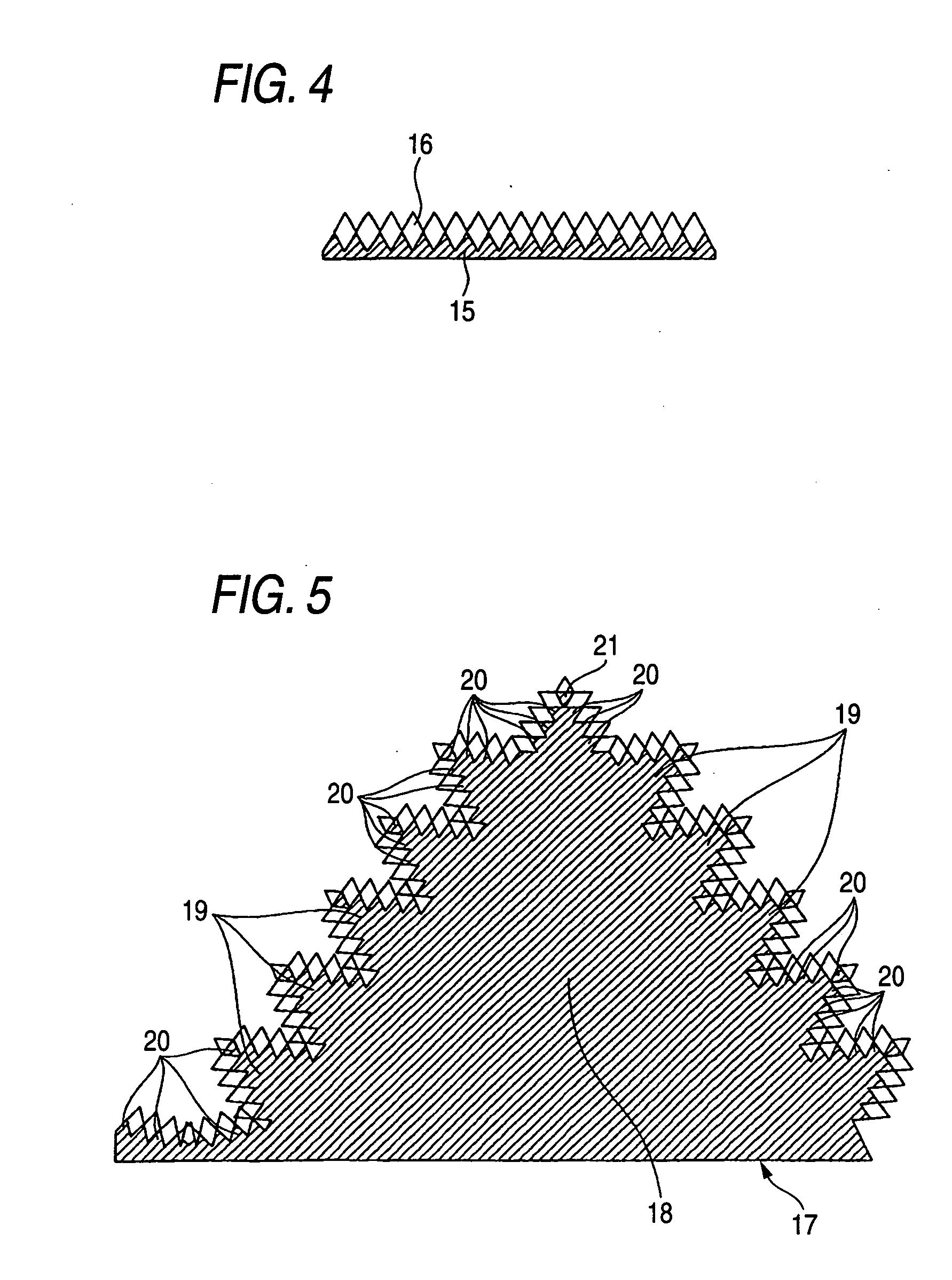

The present invention provides an electrode for electrolysis including: a conductive substrate; and a conductive diamond formed on a surface of the conductive substrate, the conductive substrate having at least one surface shape selected from the group consisting of: (a) a surface shape of a combination of an Ra of 100-1,000-μm and an RSm of 50-10,000 μm; (b) a surface shape of a combination of an Ra of 2.5-100 μm and an RSm of 1.5-800 μm, and (c) a surface shape of a combination of an Ra of 0.01-2 μm and an RSm of 0.005-250 μm, and a process for producing the electrode.

Owner:DE NORA PERMELEC LTD

Electrode catalyst for oxygen reduction and gas diffusion electrode

ActiveUS7566388B2Reduced activityMachining electrodesPhotography auxillary processesParticulatesAlkaline earth metal

An electrode catalyst comprising a conductive carrier, and a mixture containing a particulate noble metal and at least one particulate rare-earth oxide, the mixture being supported on the conductive carrier wherein the particulate rare-earth oxide has an alkaline-earth metal as solid solution therein.

Owner:ASAHI KASEI CHEM CORP

Electrode for use in hydrogen generation

InactiveUS20060231387A1Quality improvementReduce overvoltageCellsMachining electrodesOrganic acidHydrogen

An electrode for use in hydrogen generation comprising a conductive base and a coating layer formed thereon of a composition obtainable by thermally decomposing, in the presence of an organic acid, a mixture comprising at least one type of platinum compound.

Owner:ASAHI KASEI KK

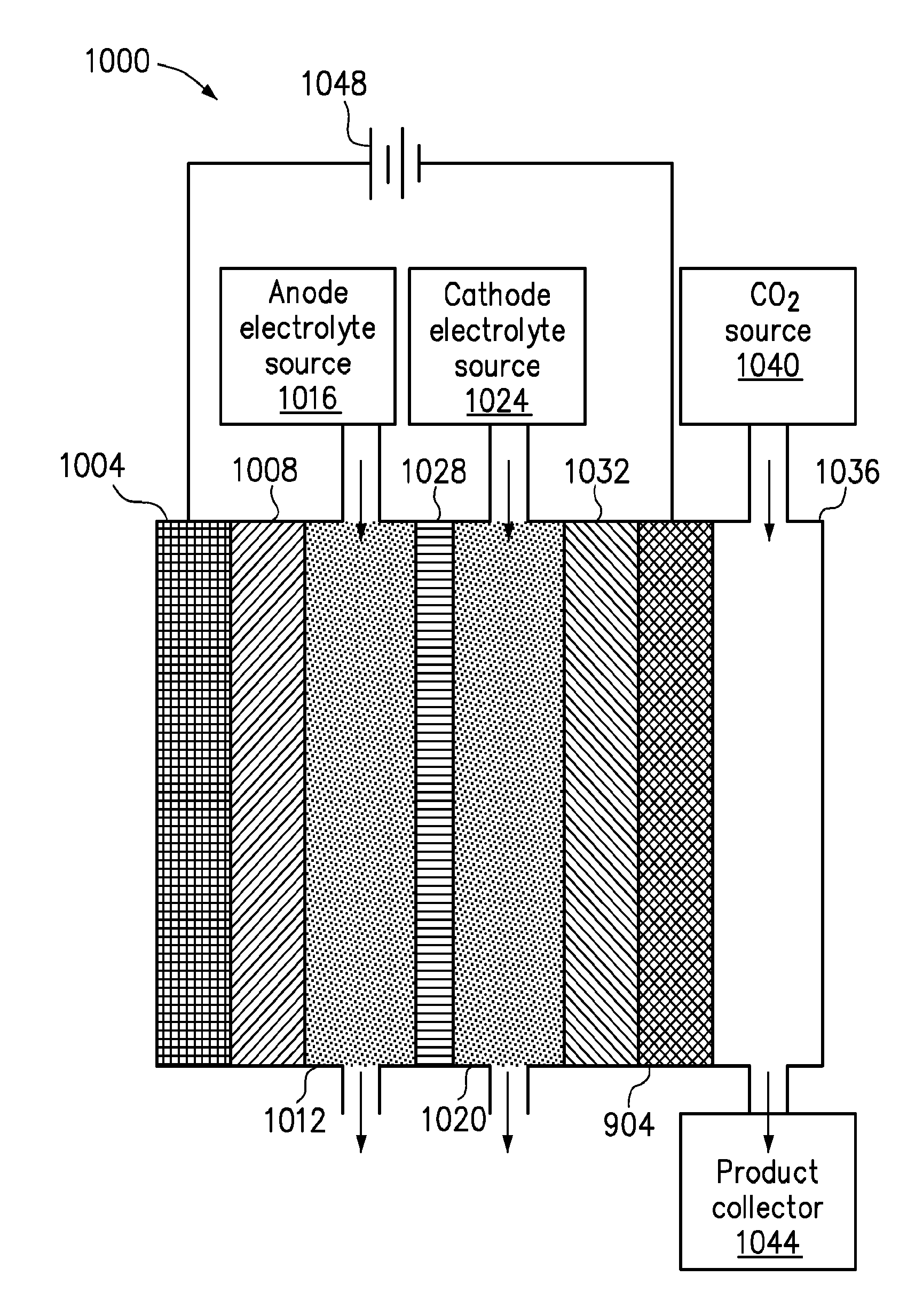

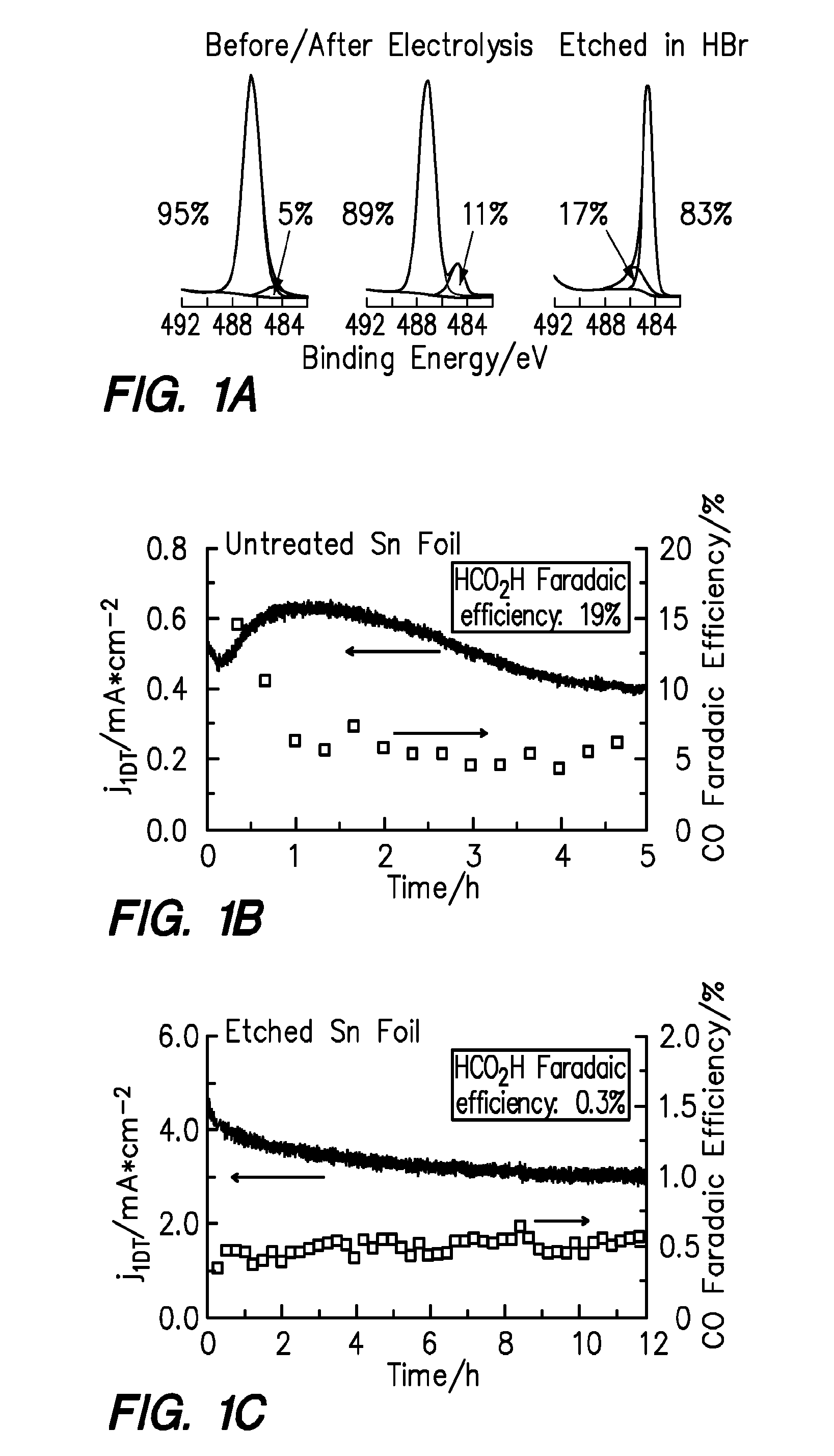

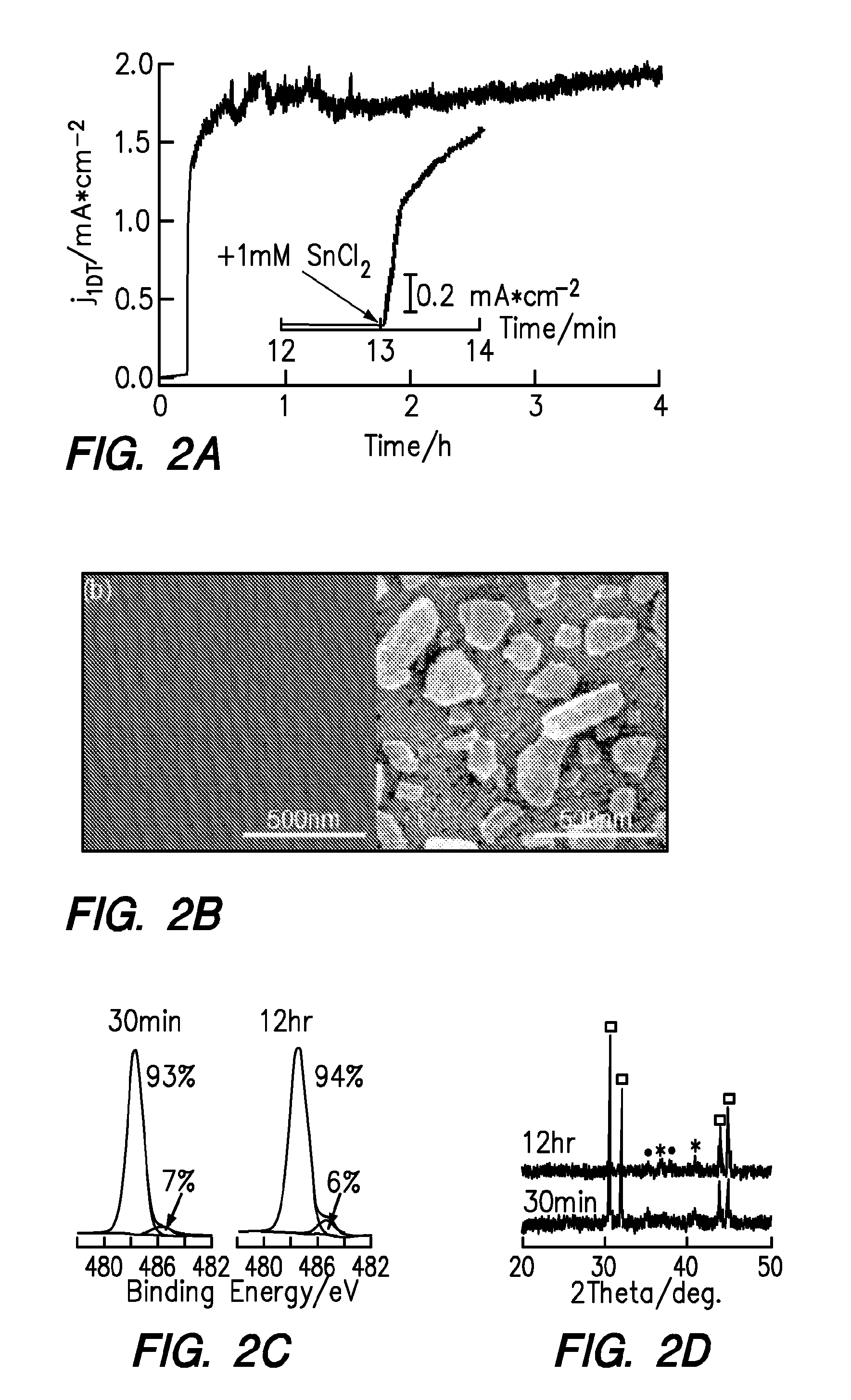

Catalysts for low temperature electrolytic co2 reduction

A method for electrochemically reducing CO2 is provided. A cathode is provided, wherein the cathode comprises a conductive substrate with a catalyst of a metal and a metal oxide based coating on a side of the cathode. An anode is spaced apart from the cathode. An ionic transport is provided between the anode and cathode. The cathode is exposed to CO2 and H2O. The anode is exposed to H2O. A voltage is provided between the cathode and anode.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Nanometer powder catalyst and its preparation method

ActiveUS20110207602A1Improve electrocatalytic activityImprove conductivityCell electrodesMultiple component coatingsTitaniumNon noble metal

A TiO2-containing composite nano-powder catalyst obtained by combining a titanium-based metal ceramic compound in powder form with a mixing solution containing compound(s) of a platinum group metal and / or a non-noble metal, drying the resulting mixture, and then performing oxidative thermal decomposition on the dried mixture. This catalyst also can be used as a support to further support platinum group metal(s) and / or non-noble metal(s) to obtain another composite nano-powder catalyst. A method for preparing a TiO2-containing composite nano-powder catalyst is also disclosed.

Owner:OCEAN UNIV OF CHINA

Electrolytic cell and electrodes for use in electrochemical processes

An electrolytic cell with an anode and cathode for the electrolysis of hydrochloric acid and brine is provided. The anodes and cathodes of the present invention are made of a bulk ceramic or intermetallic material.

Owner:JOVIC VLADIMIR +1

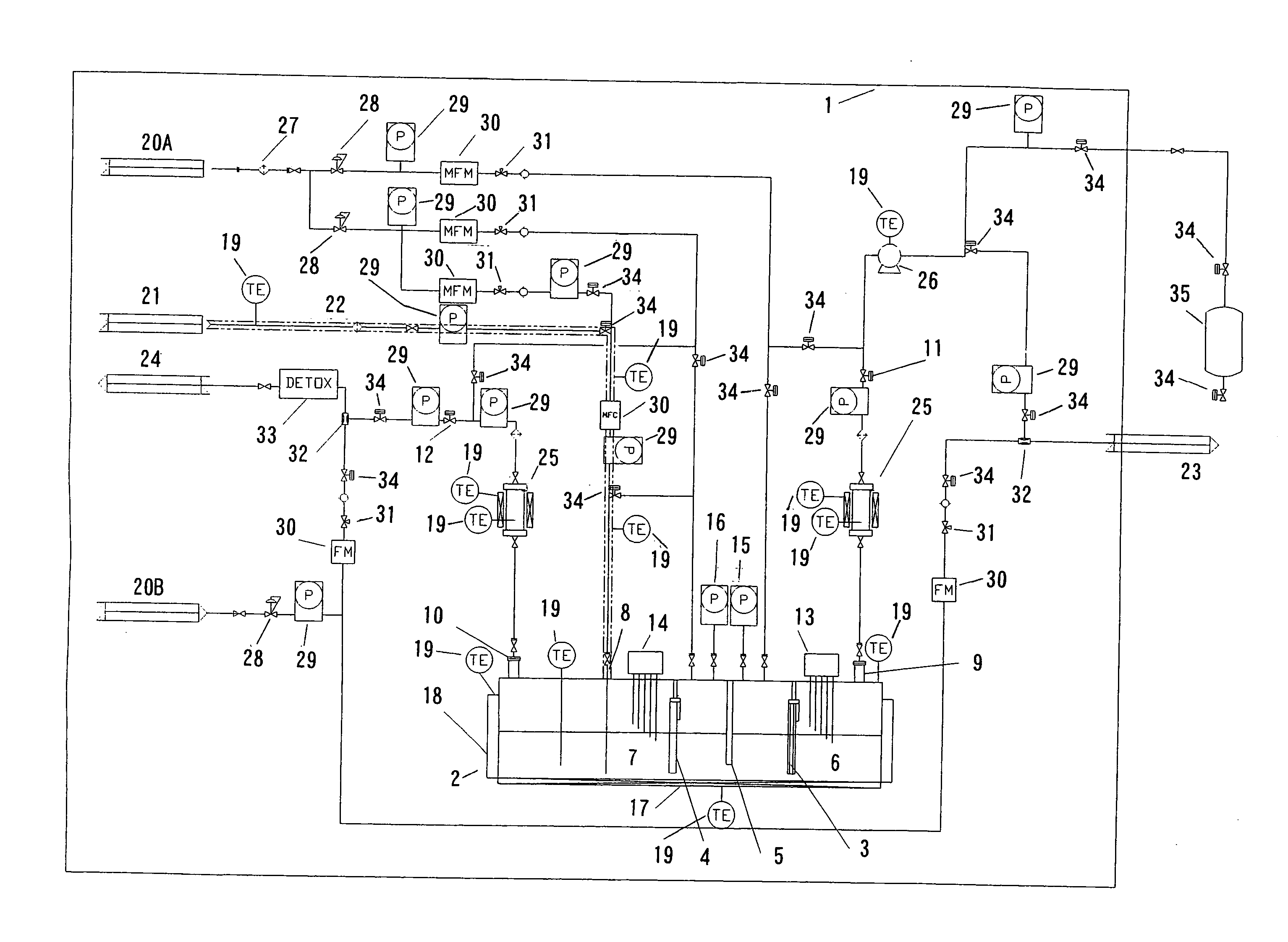

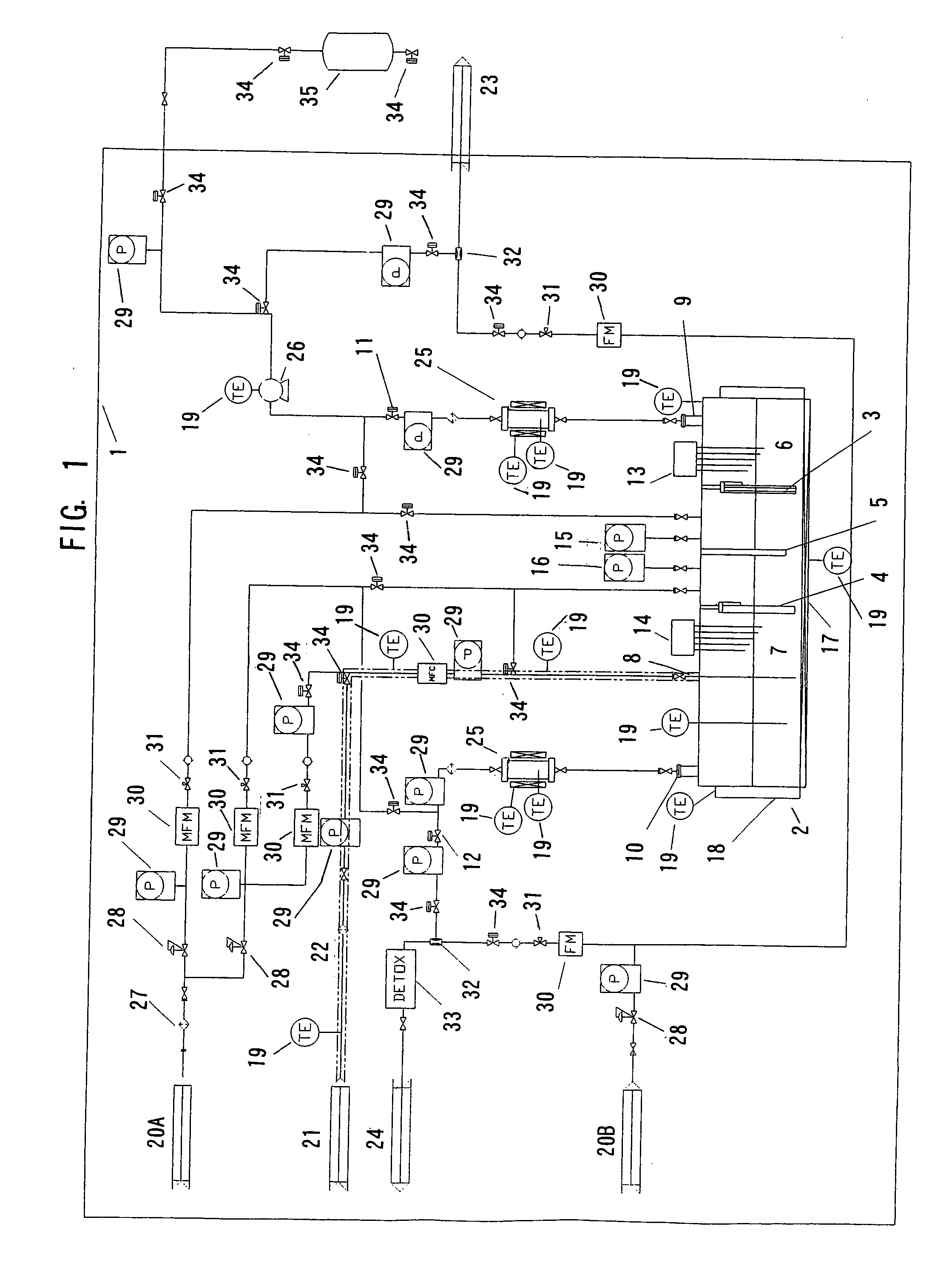

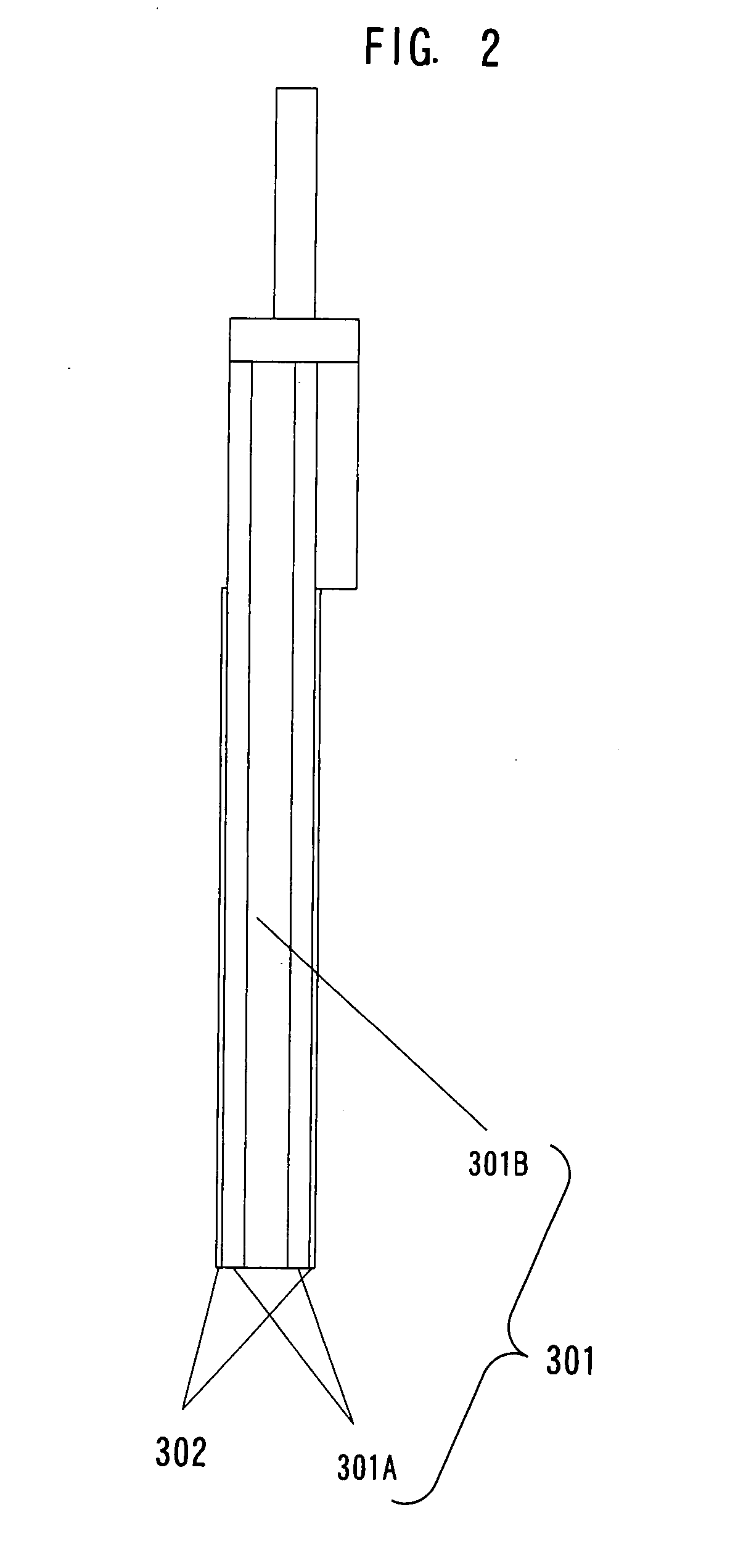

Electrolytic apparatus for producing fluorine or nitrogen trifluoride

InactiveUS20070215460A1Avoid it happening againSuppression amountCellsMachining electric circuitsHigh current densityHydrogen fluoride

It is a task of the present invention to provide an electrolytic apparatus for producing fluorine or nitrogen trifluoride by electrolyzing a hydrogen fluoride-containing molten salt, the electrolytic apparatus being advantageous in that the electrolysis can be performed without the occurrence of the anode effect even at a high current density and without the occurrence of an anodic dissolution. In the present invention, this task has been accomplished by an electrolytic apparatus for producing fluorine or nitrogen trifluoride by electrolyzing a hydrogen fluoride-containing molten salt at an applied current density of from 1 to 1,000 A / dm2, the electrolytic apparatus using a conductive diamond-coated electrode as an anode.

Owner:TOYO TANSO KK

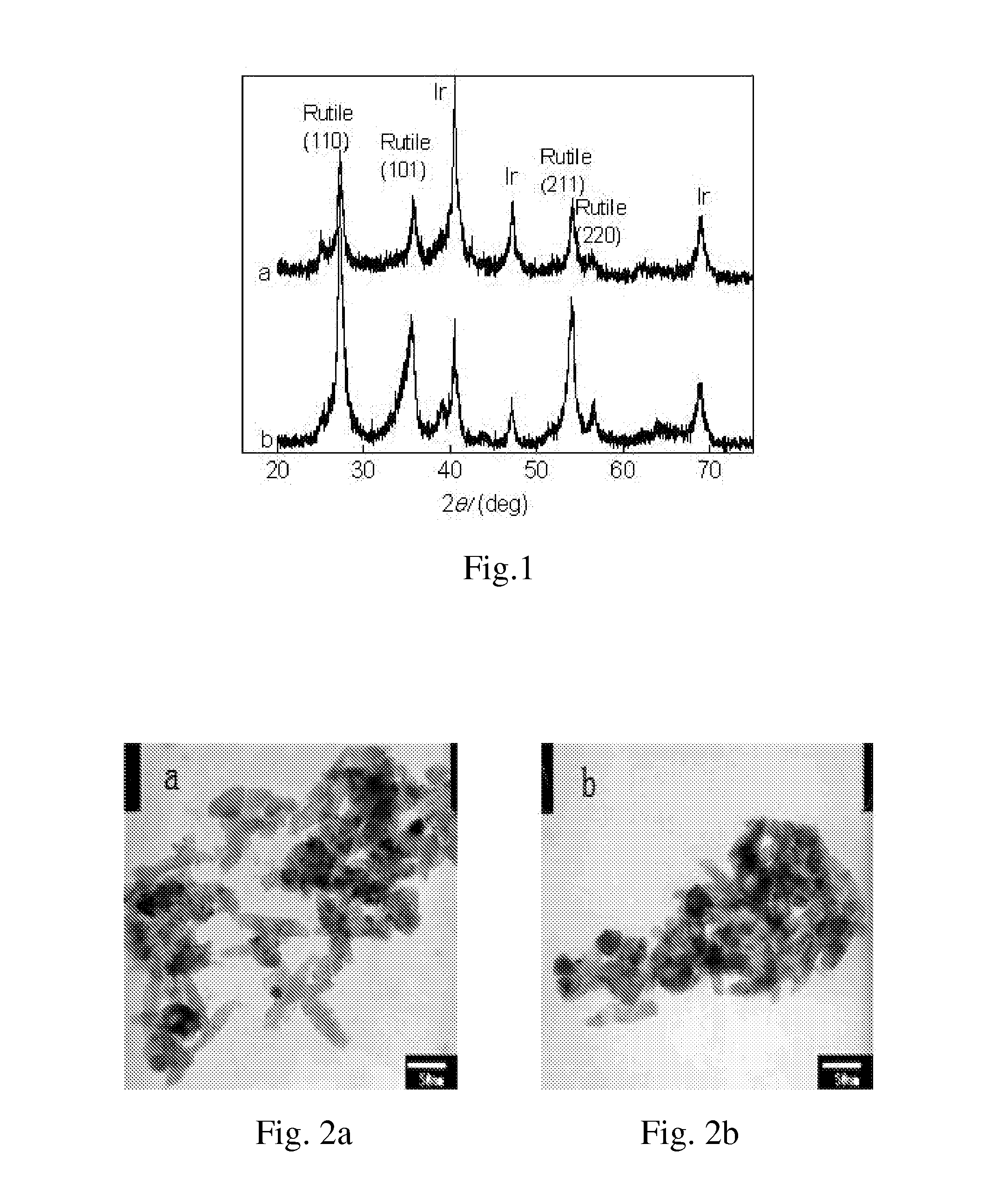

Precious Metal Oxide Catalyst for Water Electrolysis

ActiveUS20070292744A1Low oxygen overvoltageReduce energy consumptionMachining electrodesCellsOvervoltageSolubility

The invention is directed to iridium oxide based catalysts for use as anode catalysts in PEM water electrolysis. The claimed composite catalyst materials comprise iridium oxide (IrO2) and optionally ruthenium oxide (RuO2) in combination with a high surface area inorganic oxide (for example TiO2, Al2O3, ZrO2 and mixtures thereof). The inorganic oxide has a BET surface area in the range of 50 to 400 m2 / g, a water solubility of lower than 0.15 g / l and is present in a quantity of less than 20 wt. % based on the total weight of the catalyst. The claimed catalyst materials are characterised by a low oxygen overvoltage and long lifetime in water electrolysis. The catalysts are used in electrodes, catalyst-coated membranes and membrane-electrode-assemblies for PEM electrolyzers as well as in regenerative fuel cells (RFC), sensors, and other electrochemical devices.

Owner:UMICORE AG & CO KG

Electrode catalyst for oxygen reduction and gas diffusion electrode

ActiveUS20060260955A1Reduced activityMachining electrodesPhotography auxillary processesParticulatesAlkaline earth metal

An electrode catalyst comprising a conductive carrier, and a mixture containing a particulate noble metal and at least one particulate rare-earth oxide, the mixture being supported on the conductive carrier wherein the particulate rare-earth oxide has an alkaline-earth metal as solid solution therein.

Owner:ASAHI KASEI CHEM CORP

Precious metal oxide catalyst for water electrolysis

Owner:UMICORE AG & CO KG

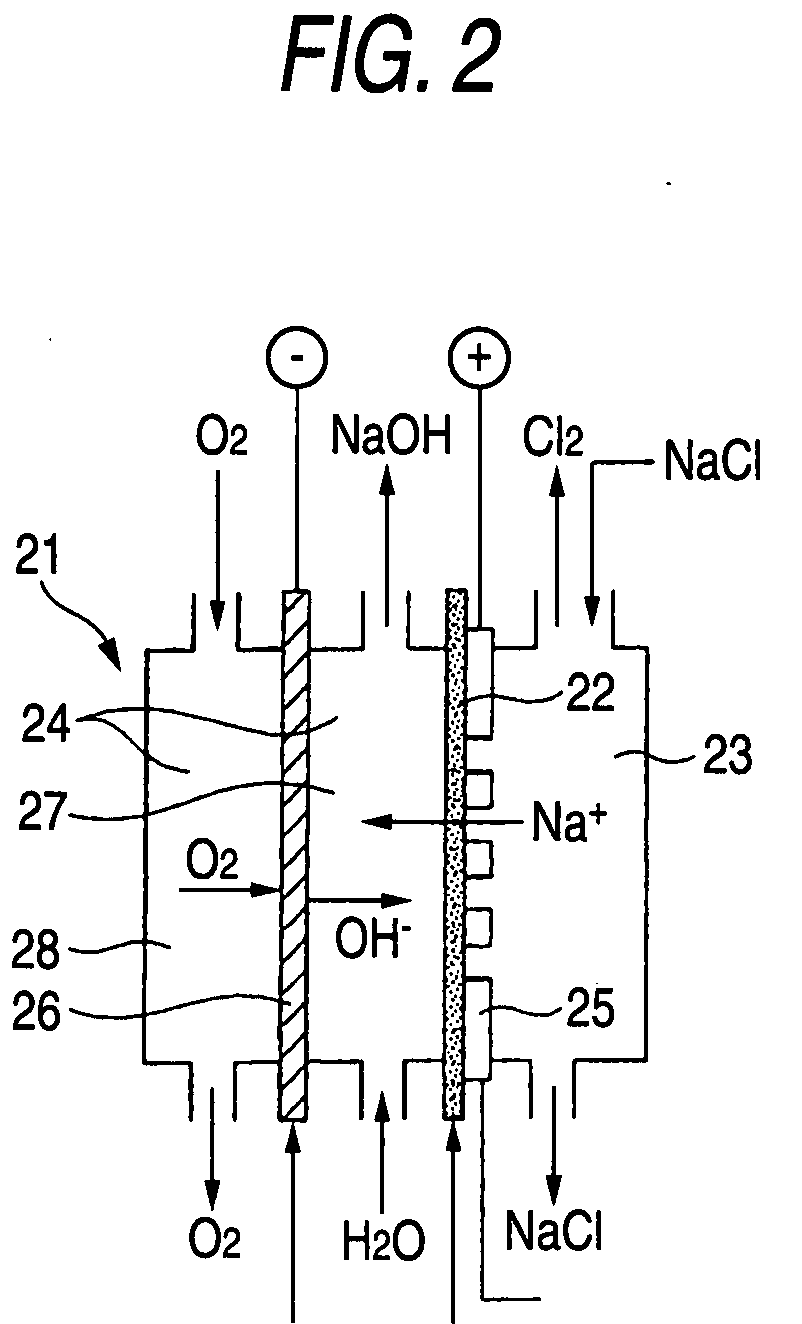

Oxygen evolution electrode

InactiveUS20080116064A1Reduce manufacturing costAlleviate shortagesMachining electrodesMultiple component coatingsElectrolysisOxygen

Disclosed is an oxygen evolution anode for evolving oxygen without chlorine evolution in electrolysis of aqueous solutions of sodium chloride having high performance and durability with decreased amount of the precious metal(s) in the intermediate layer to decrease manufacturing cost and to ease problem of the resources. The oxygen evolution anode comprises an electroconductive substrate, an intermediate layer and an electrocatalyst. The intermediate layer prepared by calcination consists of multiple oxide of the platinum group element(s), Sn and Sb, with the Sn / Sb ratio of 1-40 and with the sum of Sn and Sb of 90 cationic % or less. The electrocatalyst is prepared by anodic deposition and consists of 0.1-3 cationic % of Sn, 0.2-20 cationic % of Mo and / or W and the balance of Mn.

Owner:DAIKI ATAKA ENG

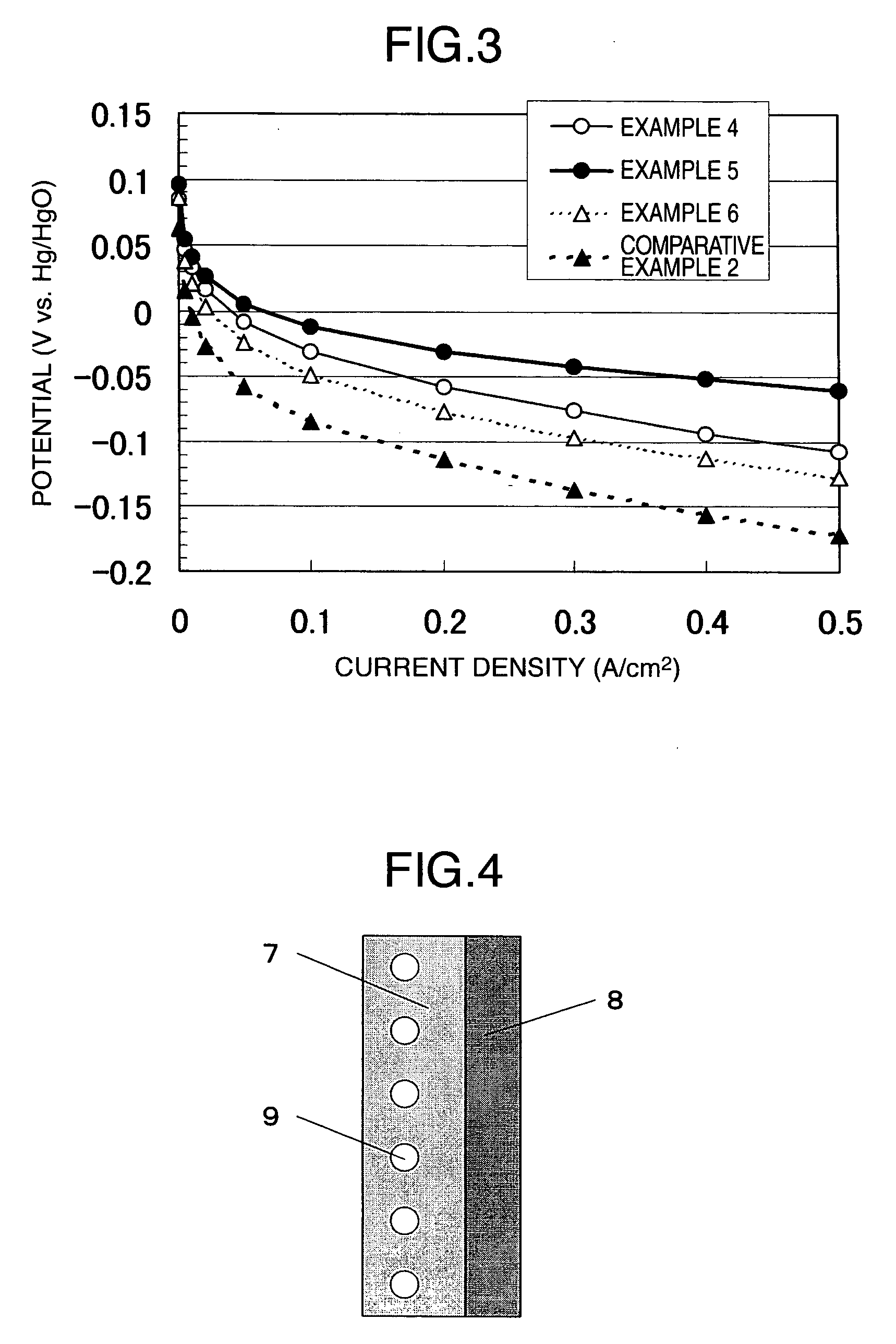

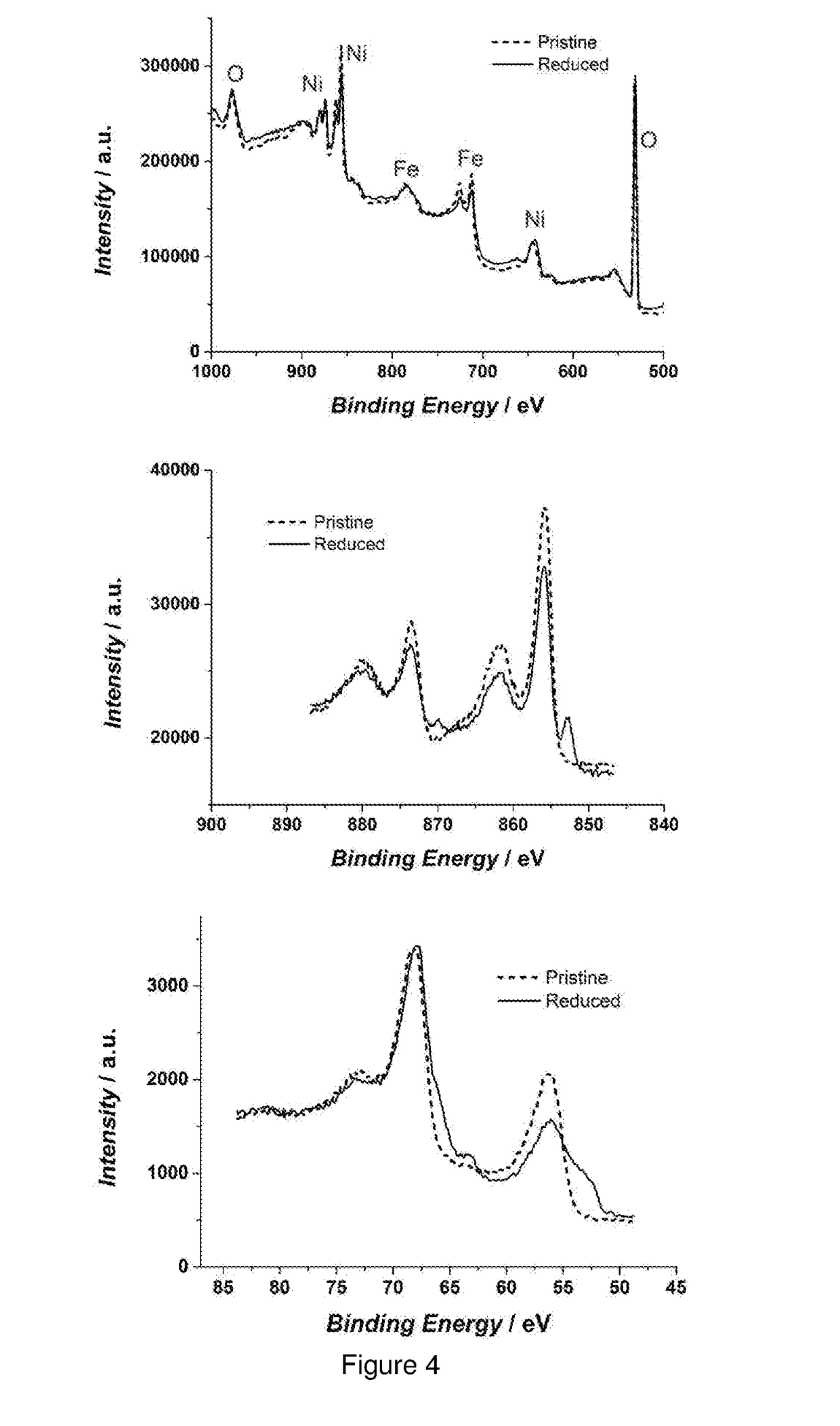

Method for improving catalytic activity

ActiveUS20180345266A1Inexpensive processing techniqueReadily available equipmentMultiple component coatingsCatalyst activation/preparationOxygen vacancyVolumetric Mass Density

The present invention relates to a method for improving the catalytic activity of an oxygen evolution reaction (OER) catalyst comprising a substrate with a catalytic metallic composite coating. The method comprises exposing the metallic composite coating to a reducing agent to thereby increase oxygen vacancy density in the metallic composite coating.

Owner:NEWSOUTH INNOVATIONS PTY LTD

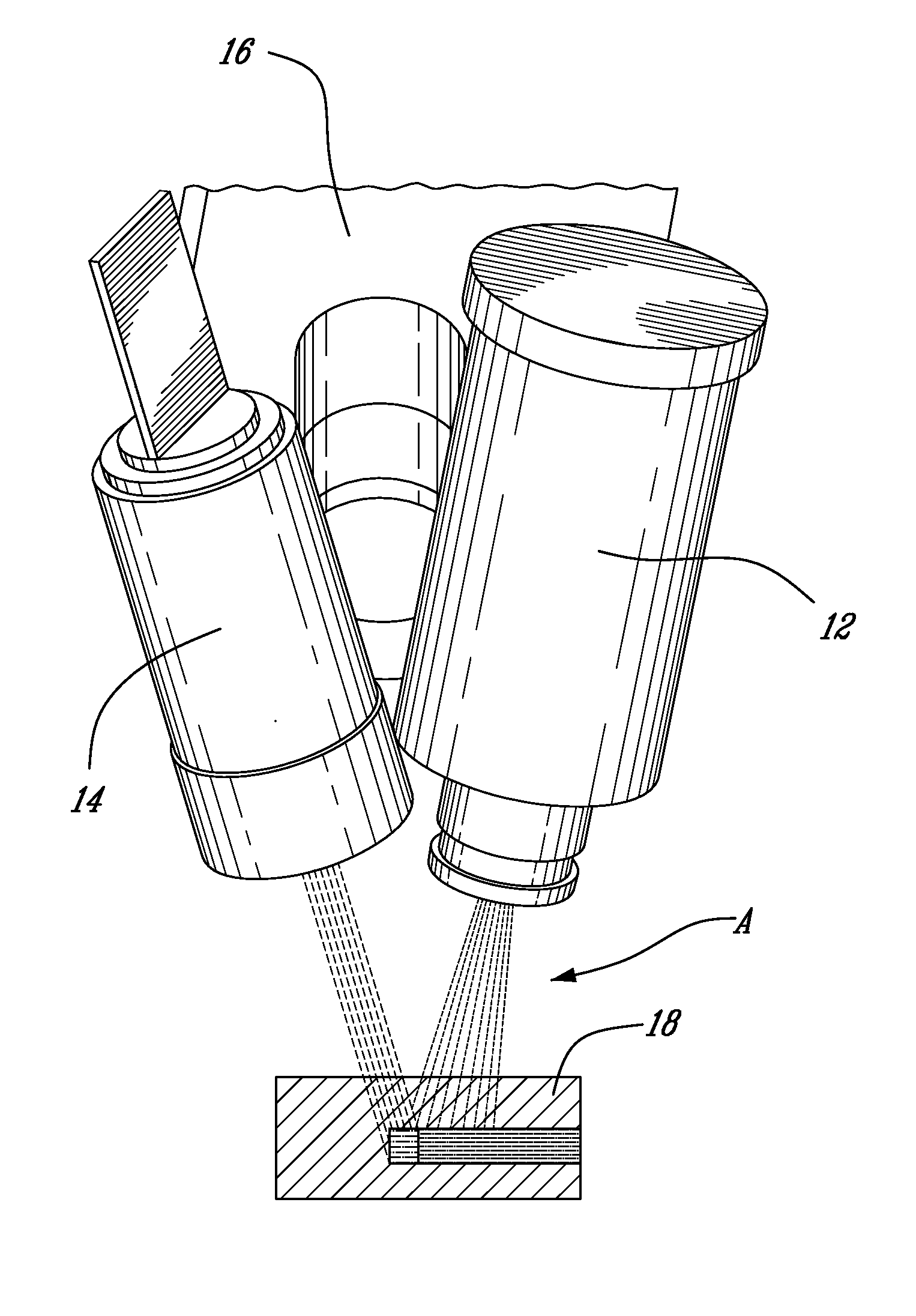

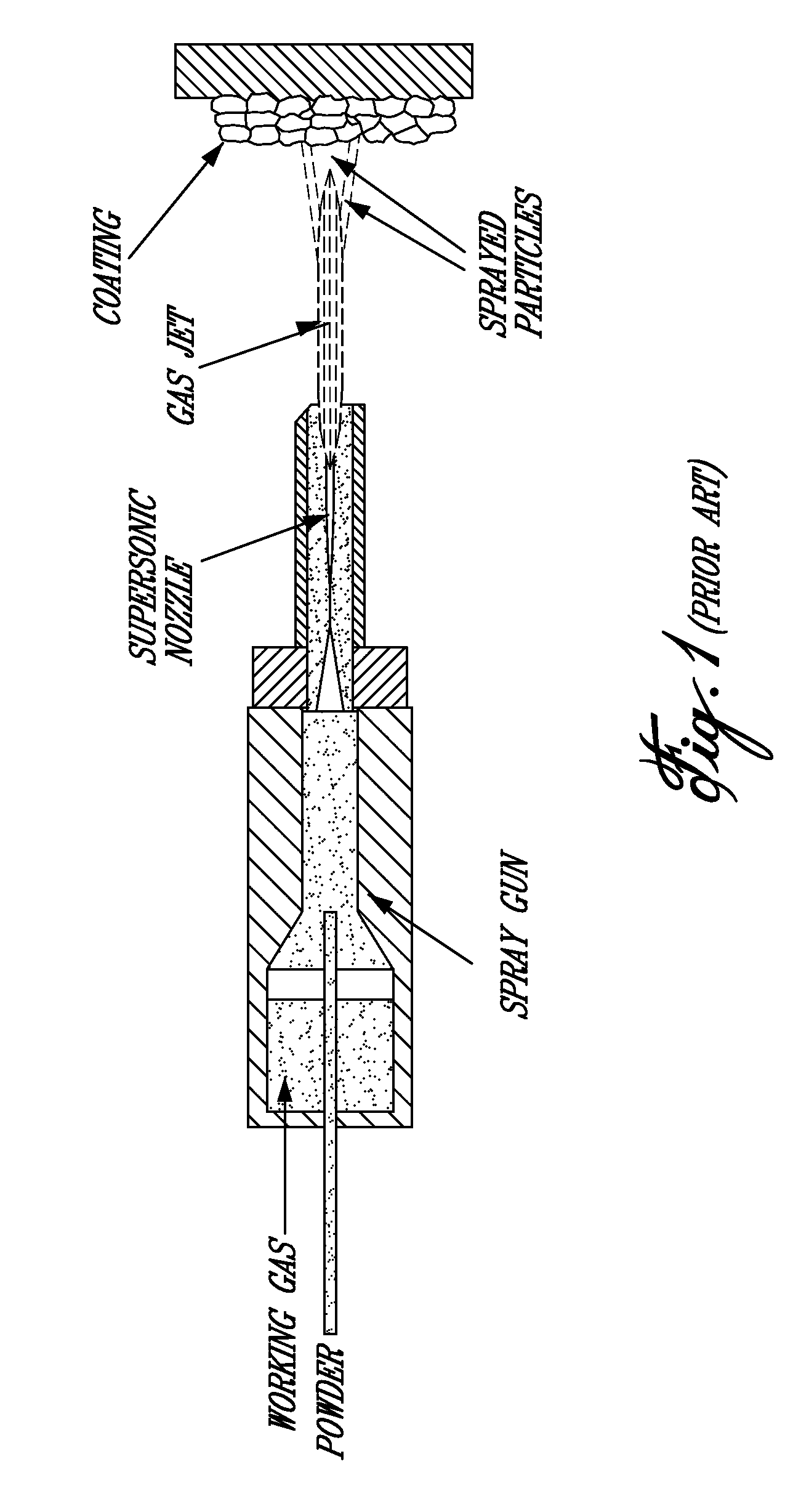

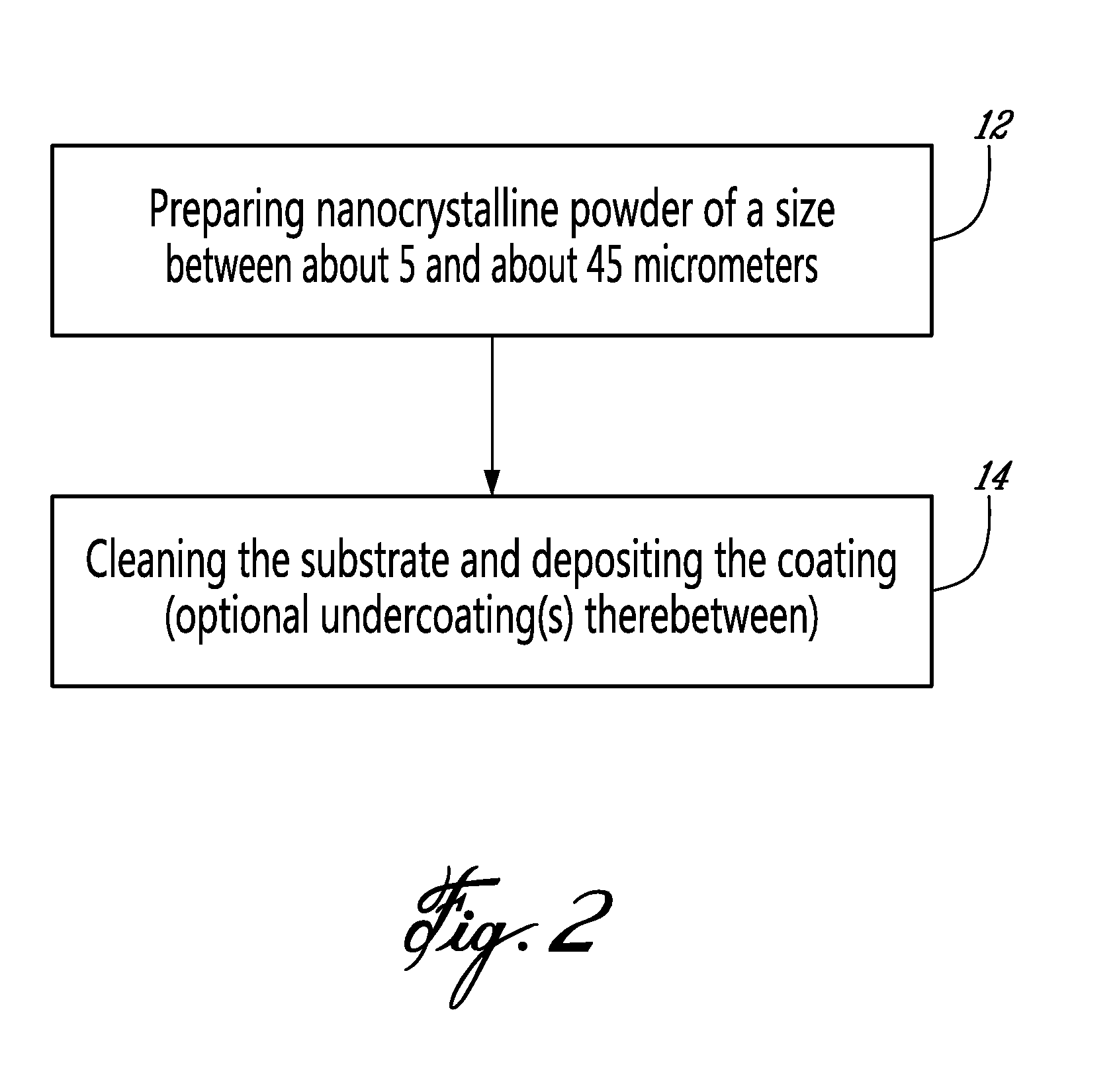

Method and system for producing electrocatalytic coatings and electrodes

A method for producing nanostructured coatings on a substrate, comprising: preparing a nanocrystalline powder of a powder size comprised between 1 and 60 μm; and combining cleaning the surface of the substrate and cold spraying the nanocrystalline powder on the surface of the substrate, and a system for producing nanocrystalline coatings on a substrate, comprising a spray head, a cleaning head and a handling system monitoring the spray head and the cleaning head relative to the substrate to be coated, the spray head being a first cold spray head, the first cold spray head depositing on the substrate at least one nanocrystalline powder, the cleaning head optimizing the surface being coated with the at least one layer of nanocrystalline powder.

Owner:NAT RES COUNCIL OF CANADA +1

Nanoporous materials for reducing the overpotential of creating hydrogen by water electrolysis

Disclosed is an electrolyzer including an electrode including a nanoporous oxide-coated conducting material. Also disclosed is a method of producing a gas through electrolysis by contacting an aqueous solution with an electrode connected to an electrical power source, wherein the electrode includes a nanoporous oxide-coated conducting material.

Owner:WISCONSIN ALUMNI RES FOUND

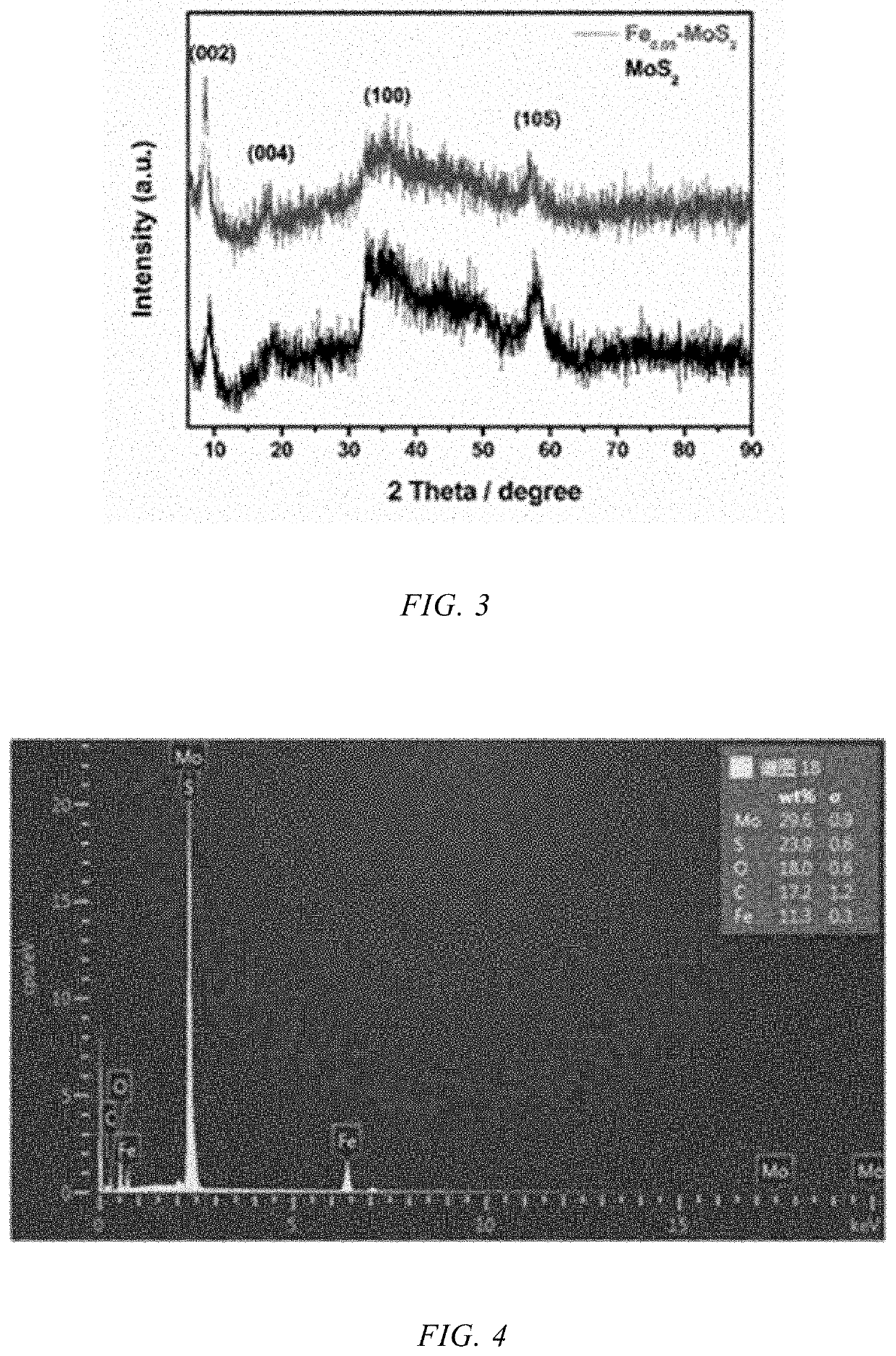

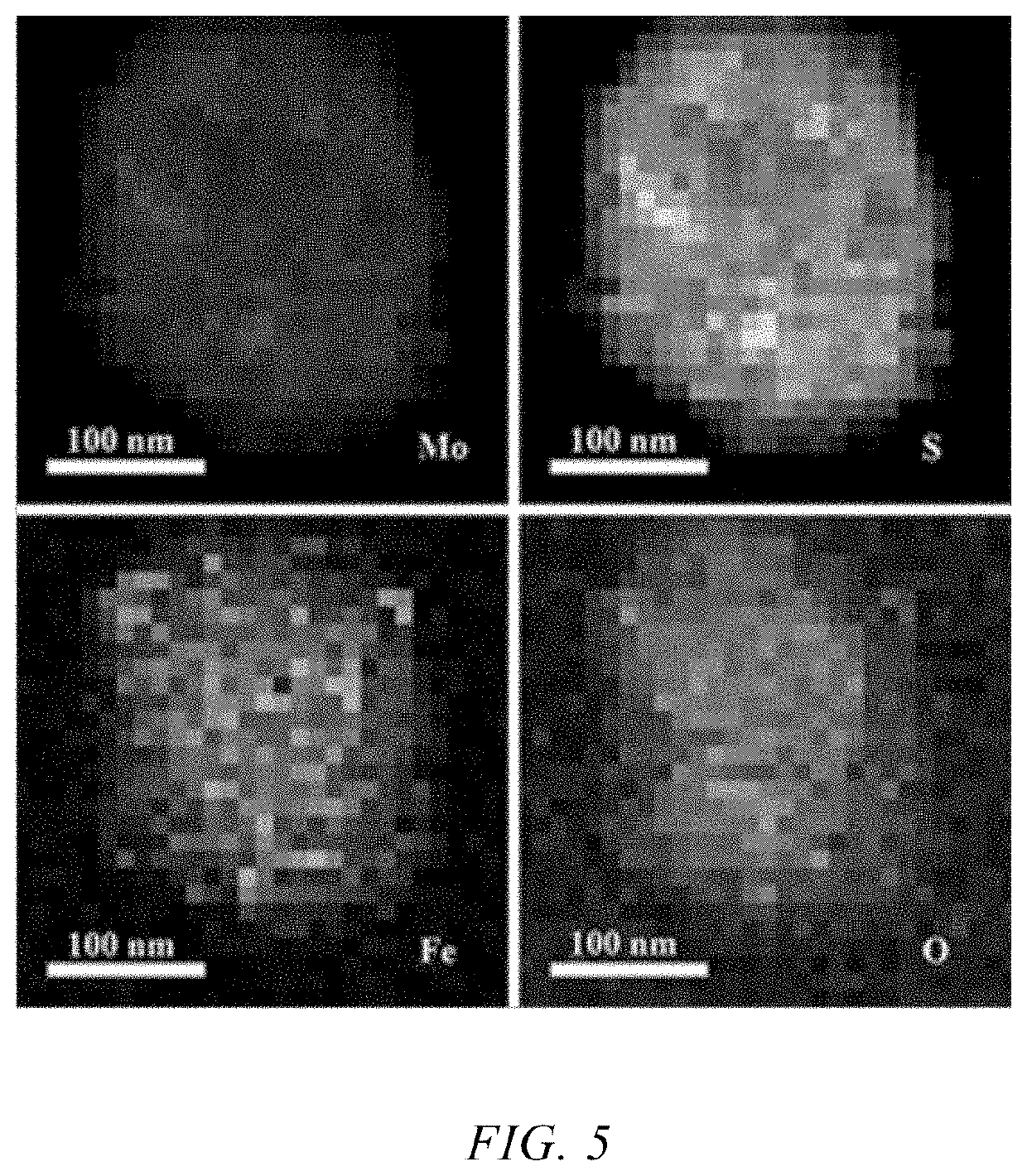

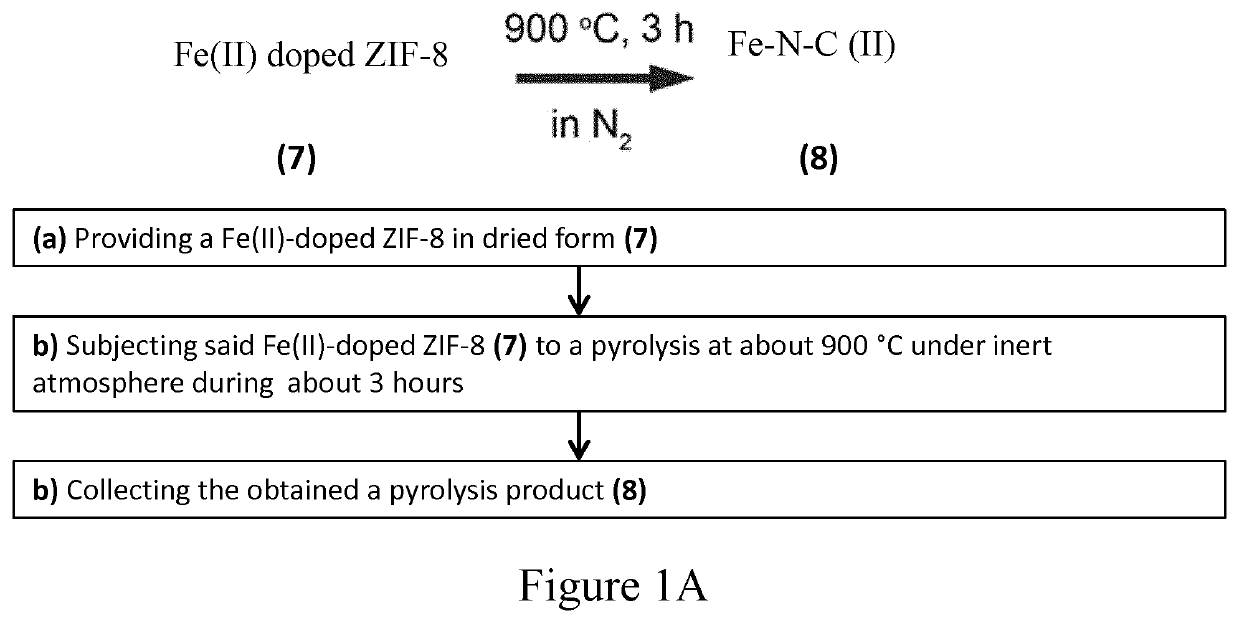

Fe-doped mos2 nano-material, preparation method therefor and use thereof

ActiveUS20210062350A1Surface cleaningEasy to cleanPhysical/chemical process catalystsMultiple component coatingsActive agentEngineering

The invention discloses a method for preparing a Fe-doped MoS2 nano-material, which comprises the following steps: dissolving a ferric salt and ammonium tetrathiomolybdate in DMF and reacting at 180-200° C. for 6-24 hrs to obtain a Fe-doped MoS2 nano-material. The present invention also provides a Fe-doped MoS2 nano-material supported by nickel foam, which includes a nickel foam substrate and the Fe-doped MoS2 nano-material loaded on the nickel foam substrate. Furthermore, the present invention also provides a preparation method and use of the above materials. In the invention, the desired product can be obtained by a one-pot solvothermal reaction, and thus the operation is simple. There is no need to introduce a surfactant for morphological control during the preparation process, and the resulting product has a clean surface and is easy to wash.

Owner:SUZHOU UNIV

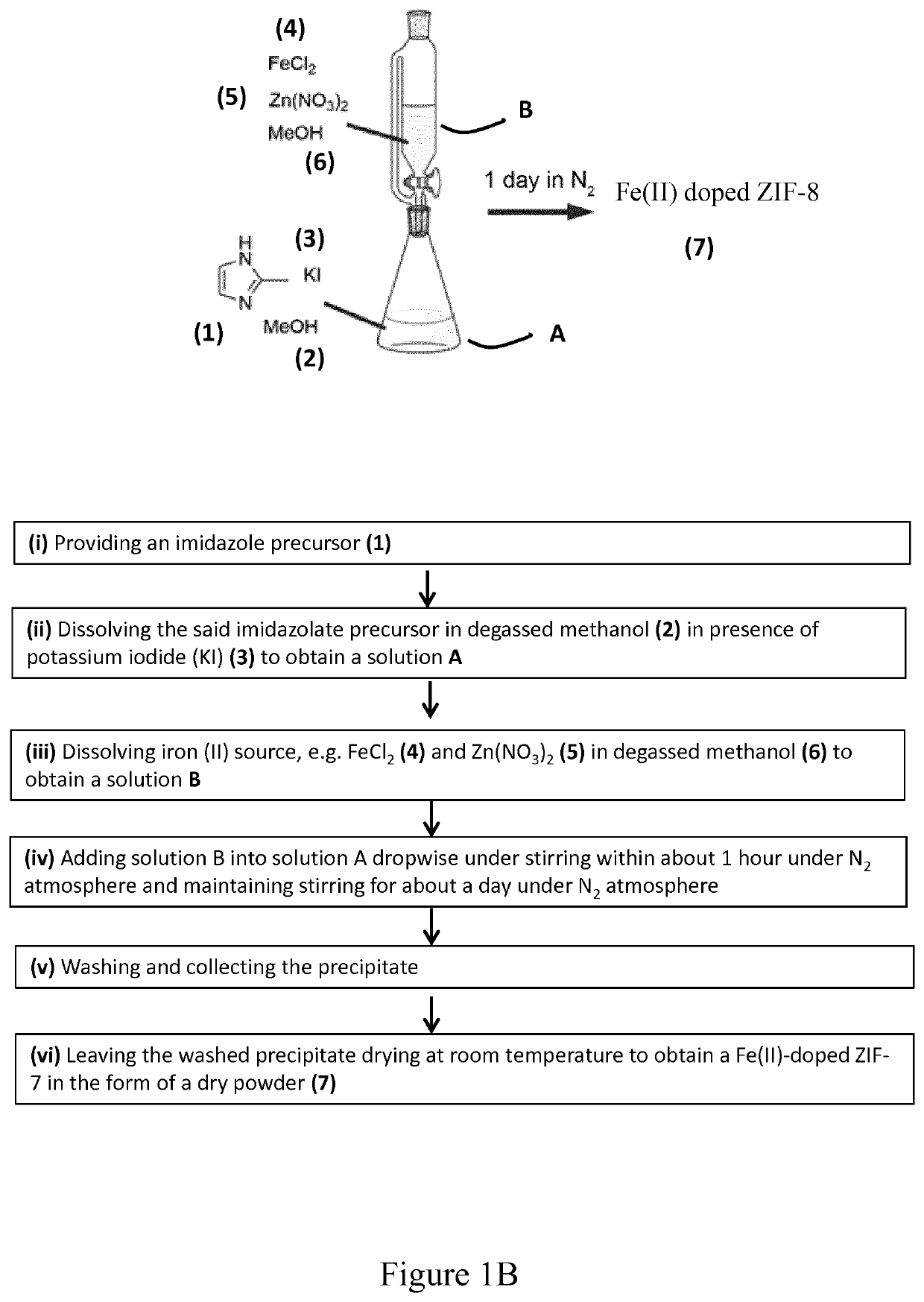

Fe-N-C CATALYST, METHOD OF PREPARATION AND USES THEREOF

PendingUS20210047741A1High catalytic activityHigh selectivityMolecular sieve catalystsMultiple component coatingsPtru catalystPhysical chemistry

The invention relates to single-atom Fe catalysts useful for the electrochemical reduction of carbon dioxide, method of preparation as uses thereof. In particular, the invention relates to a method of preparation of Fe(II) doped Zn-ZIF precursor material and use thereof in the preparation of a catalyst containing Fe single atoms on N doped carbon matrix derived from the pyrolysis of this Fe(II) doped Zn-ZIF precursor material.

Owner:GAZNAT SA

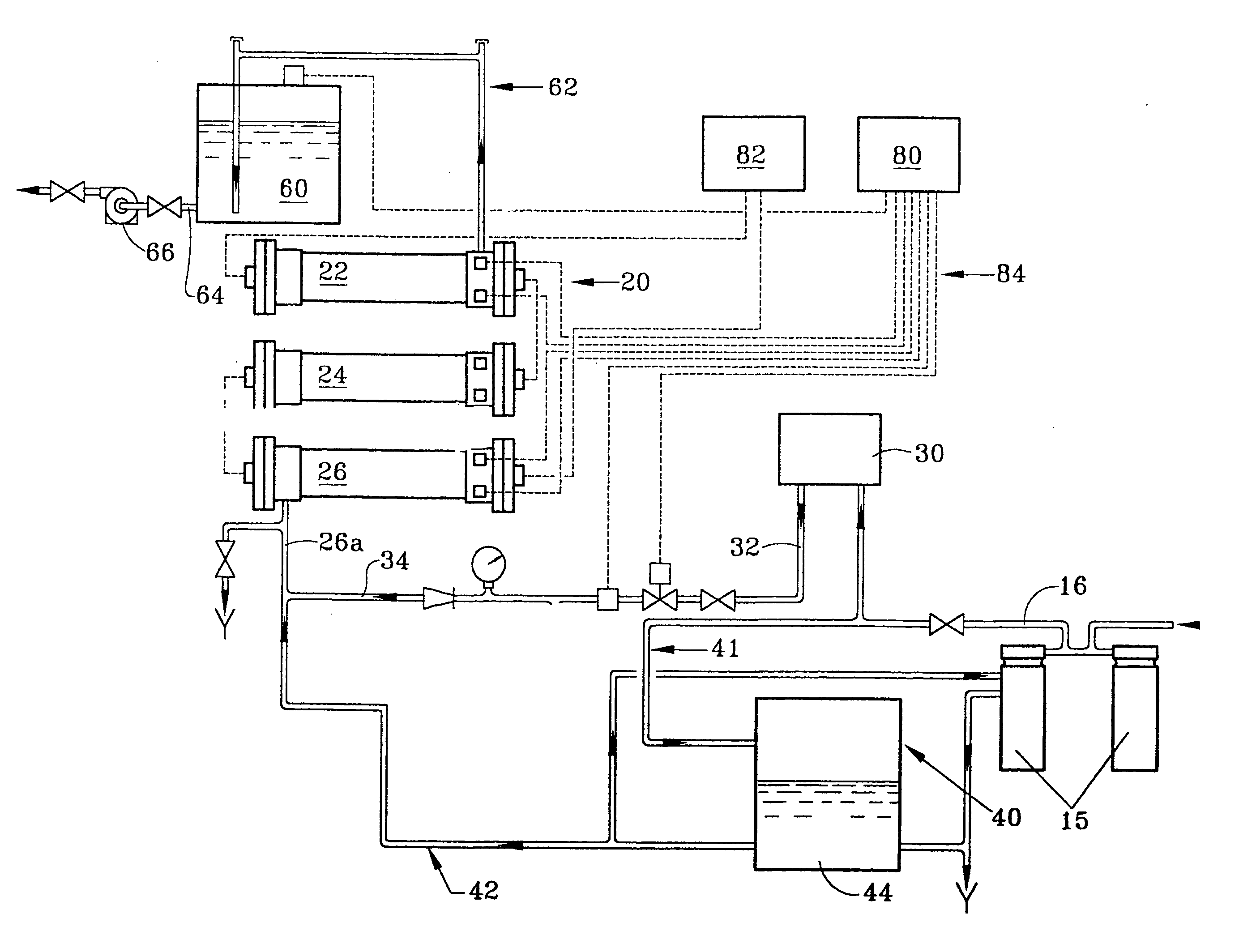

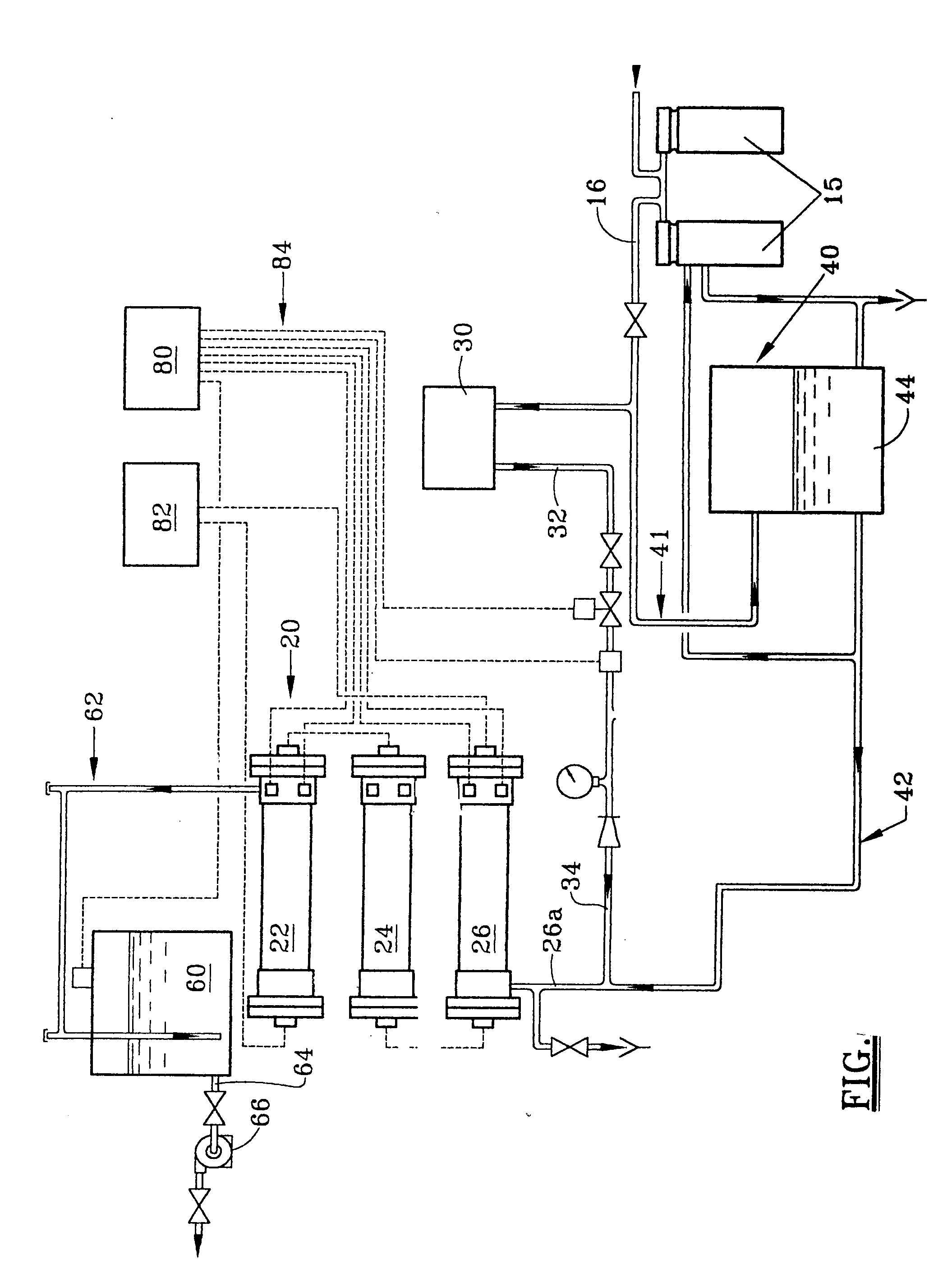

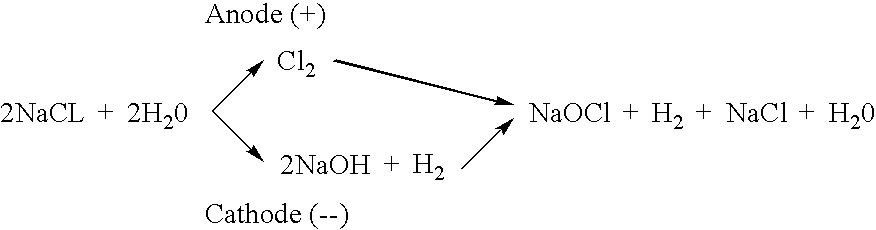

Process for producing hypochlorite

InactiveUS20070007146A1Reduce power consumptionImprove current efficiencyMultiple component coatingsHypochloriteChloride salt

In a process for producing sodium hypochlorite in an electrolytic cell comprises forming an aqueous based chloride solution with a chloride salt; controlling the concentration of chloride within the solution to an amount comprising less than 25 g / L chloride salt; piping the salt solution to the electrolytic cell, the electrolytic cell comprising an anode and a cathode, the cathode comprising a metallic base material, a first coating on the metallic base material and a second non-conductive ceramic coating on the metallic base material. The chloride solution is then in contact with the anodes and cathodes and an electric current is sent throughout the electrolytic cell to produce hypochlorite. During this process the electric current is controlled so that the power consumption is less than 2.5 kWh per pound of hypochlorite produced and the resulting cell efficiency comprises less than 2.5 kg of chloride salt consumed for every 1 kg of hypochlorite generated.

Owner:SEVEN TRENT WATER PURIFICATION INC

Method for making a highly stable diamond film on a subtrate

InactiveUS20080070049A1Increase substrate temperatureMultiple component coatingsWater/sewage treatmentCarbideTitanium

A method of depositing a stable diamond film on a metal substrate includes pretreating a surface of the substrate and depositing a diamond film on the substrate by way of a multi-stage chemical vapor deposition, in which each subsequent stage is performed at progressively higher temperature. The deposited diamond may be doped with boron. The substrate may be titanium, a titanium alloy, iron, an iron alloy, or any other valve metal. The diamond deposition may be a high temperature chemical vapor deposition. The first deposition stage may optionally create a carbide of diamond and substrate, and an optional mixture of diamond and amorphous carbon may be deposited to bond this carbide layer to a subsequently applied layer. The resulting product may be used as an electrode, as a tooth or blade in a cutting tool, or may have many other uses.

Owner:THE HONG KONG UNIV OF SCI & TECH

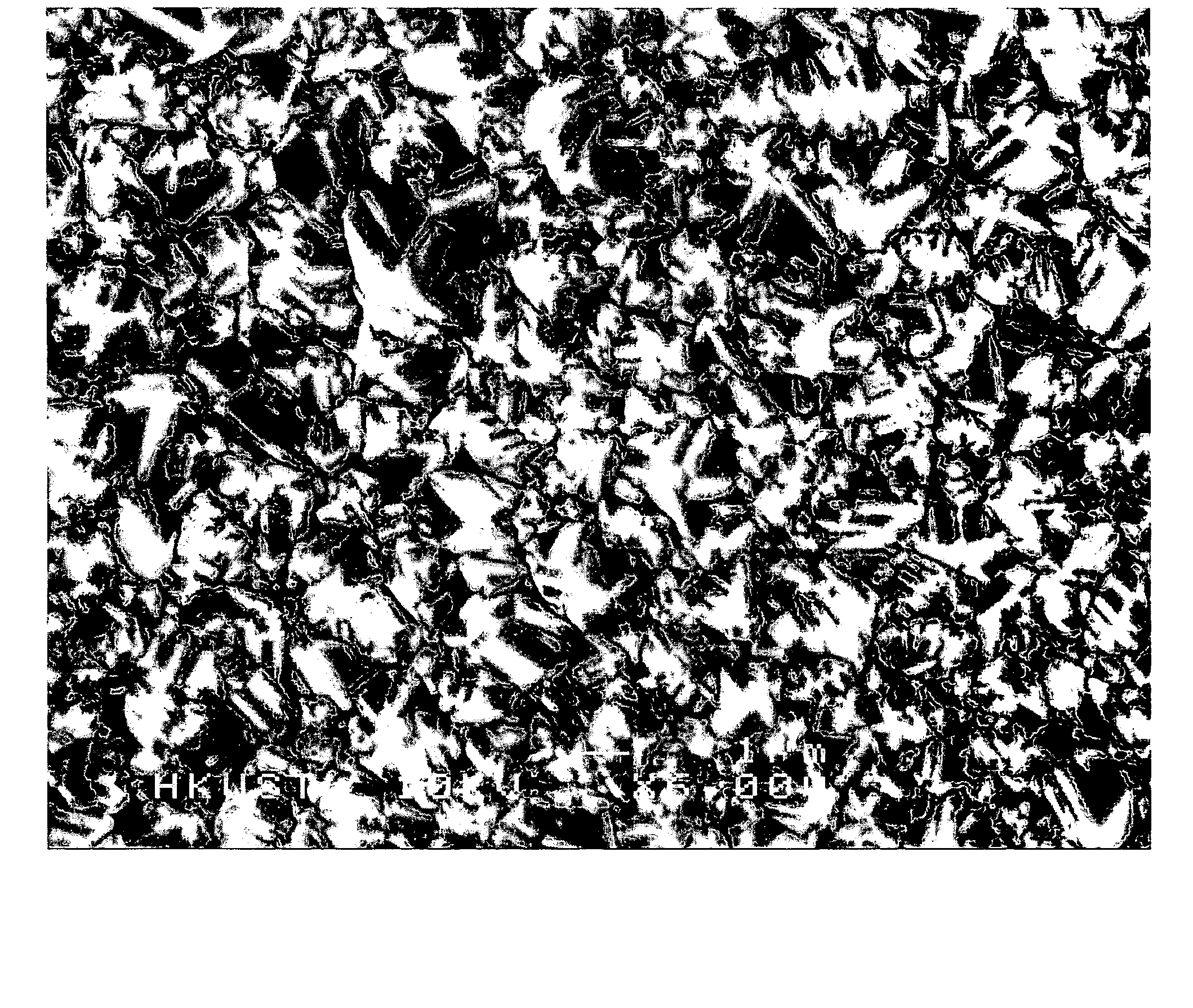

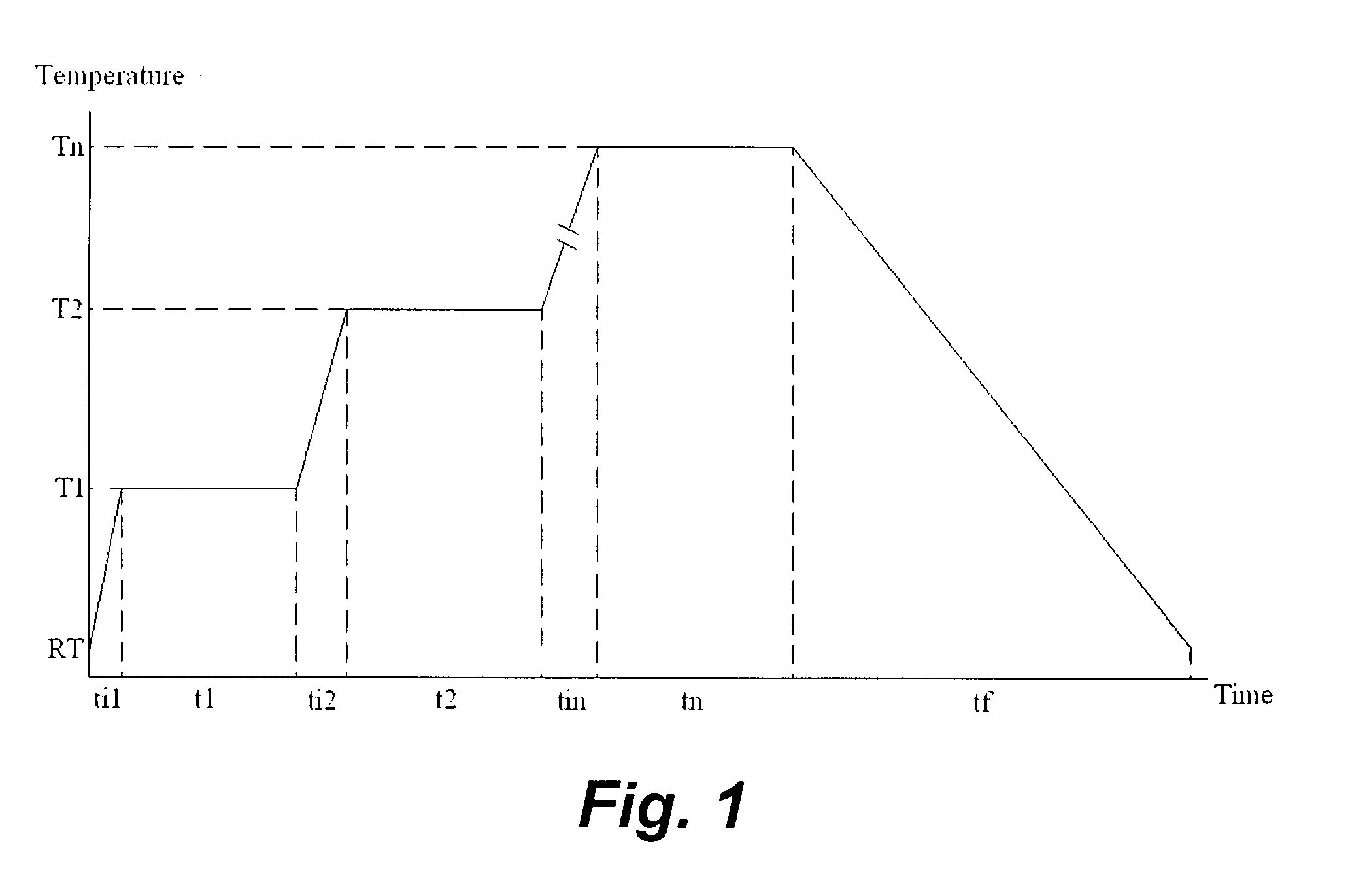

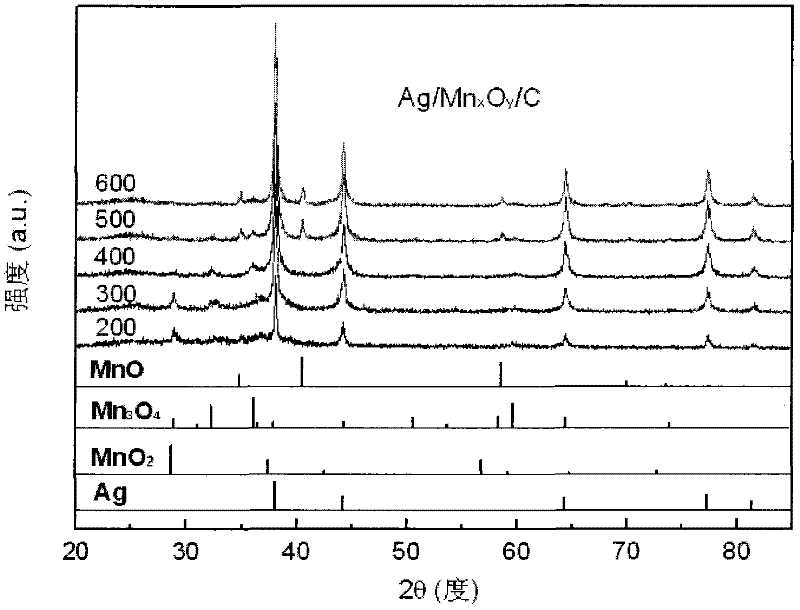

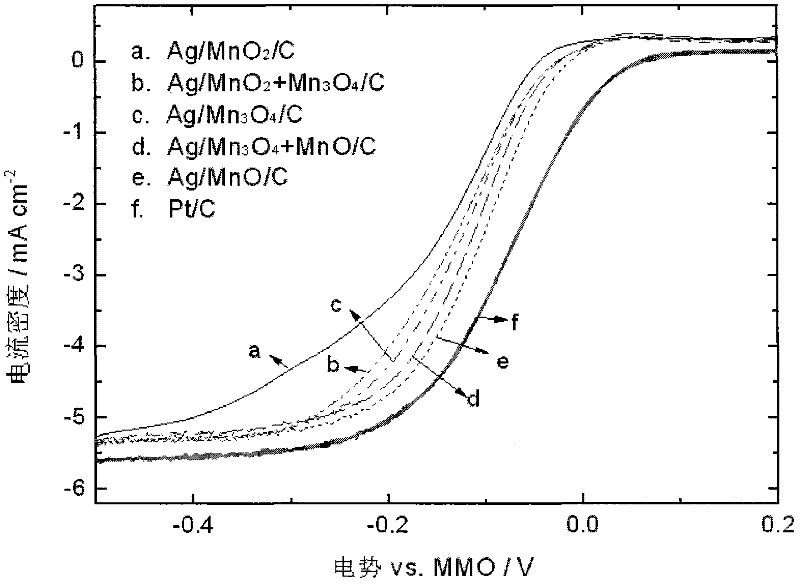

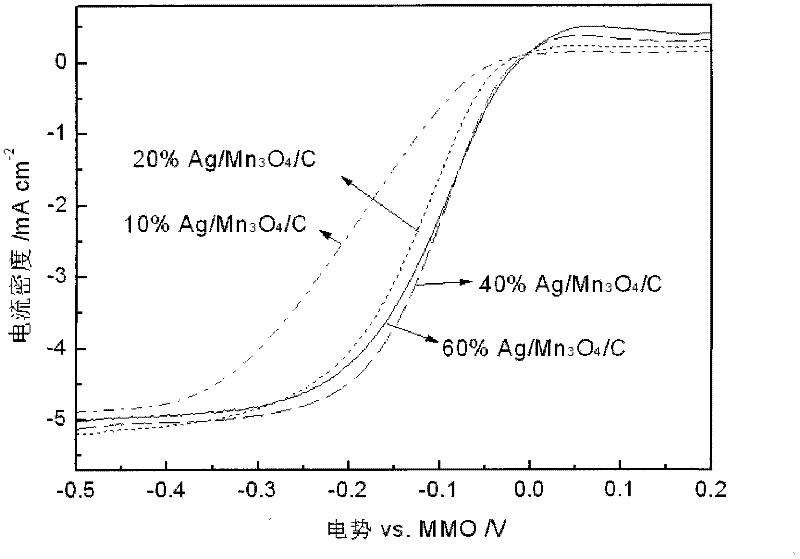

Ag/MnyOx/C catalyst and preparation and application thereof

ActiveCN102476054AHigh catalytic activityImprove stabilityFuel and primary cellsCatalyst carriersEnvironmental resistanceFuel cells

Disclosed is an Ag / MnyOx / C catalyst. MnyOx is any one of Mn3O4 and MnO or is a compound of Mn3O4 and MnO or a compound of Mn3O4 and MnO2, wherein the mass percentage of MnO2 in the compound of Mn3O4 and MnO2 ranges from 0.01% to 99.9%. The Ag / MnyOx / C catalyst is prepared through high-temperature pyrolysis of AgMnO4 by two steps including (1) preparation of a precursor AgMnO4 crystal and (2) preparation of Ag / MnyOx / C catalyst. The catalyst has high ORR (oxygen reduction reaction) catalytic activity on alkaline condition, is high in stability, low in cost, safe, non-toxic and non-pollution, favorable for environmental protection and capable of being produced massively and the like, can be used as oxygen reduction catalyst for metal air fuel cells, alkaline anion-exchange membrane fuel cells and other alkaline conditions, while resources of raw materials of the catalyst are rich and low in cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

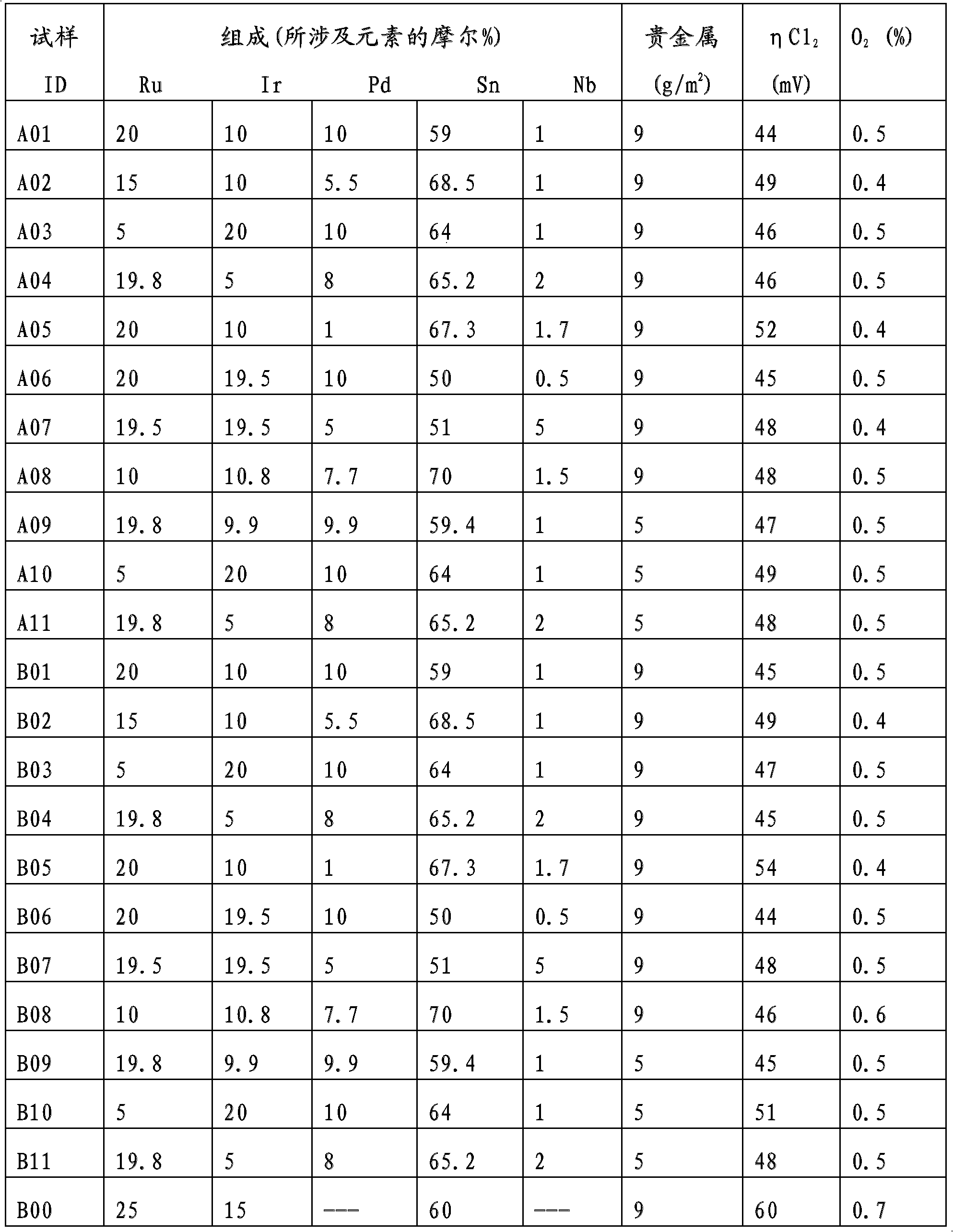

Electrode for electrolysis cell

The invention relates to an electrode formulation comprising a catalytic layer containing tin, ruthenium, iridium, palladium and niobium oxides applied to a titanium or other valve metal substrate. A protective layer based on titanium oxide modified with oxides of other elements such as tantalum, niobium or bismuth may be interposed between the substrate and the catalytic layer. The thus obtained electrode is suitable for use as anode in electrolysis cells for chlorine production.

Owner:IND DE NORA SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com