Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

536 results about "Chloride salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloride (salts) Chlorides, sulfates, salinity, and dissolved minerals are all forms of “salts” that can harm fish and plant life at high concentrations. For example, the salt applied to roads, parking lots, and sidewalks during our icy winters contains chloride, a water pollutant.

Concentrated aqueous bromine solutions and their preparation

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

Biocidal applications of concentrated aqueous bromine chloride solutions

Methods for disinfecting surfaces and for sanitizing bodies of water using a single-feed, bromine-based biocide are described. These methods use concentrated liquid biocide compositions comprising biocidally active bromine as the biocide. Also described is a process of producing the concentrated liquid biocide composition: mixed together are (a) bromine chloride and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the composition is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine in the composition is greater than 0.93. Use of bromine chloride as the source of the active bromine in the process is advantageous because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

Low Sodium Salt Composition

The present invention relates to a low sodium salt composition and the methods used to make it. In particular, the invention relates to the combined processing of sodium and potassium chloride to produce a low sodium salt composition. The low sodium salt composition includes sodium chloride and a modified chloride salt composition. The modified chloride salt composition includes a homogenous amalgamation of chloride salts, food grade acidulant, and carrier.

Owner:S & P INGREDIENT DEV

Method for recycling ammonia from low concentration ammonium chloride wastewater

The invention discloses a method for recovering ammonia from low-concentration ammonium chloride wastewater, which comprises the following steps that: an alkaline substance is added into the low-concentration ammonium chloride wastewater to prepare mixed slurry containing ammonia water and chloride salt; the mixed slurry is subjected to the separation and concentration of the ammonia water in an ammonia water distillation concentration tower to obtain ammonia vapor and a drained waste liquid; the ammonia vapor is conveyed to an ammonia water cooler for cooling treatment, and the ammonia water obtained by the cooling treatment is stored for standby; and the drained waste liquid is subjected to solid-liquid separation to obtain solid-phase residue and a waste liquid containing the chloride salt. The method evaporates the ammonia in the low-concentration ammonium chloride wastewater and concentrates the ammonia to an industrial grade concentration, and has the advantages of broad source of auxiliary materials, low cost, completely sealed technical process, and low energy consumption; and drained substances meet the requirement of no pollution and no nuisance.

Owner:包头市西骏环保科技有限公司

Environment-friendly dust fall agent for coal mine

InactiveCN103450855ACohesion effect is goodQuick dustOther chemical processesActive agentSurface-active agents

The invention relates to the field of dust fall agents, in particular to an environment-friendly dust fall agent for a coal mine. The environment-friendly dust fall agent enables water mist on the surfaces of dust particles to quickly wet and permeate the insides of the dust particles, dust particle coagulation is quickened, dust particle sedimentation is quickened, and the dust fall agent is biodegradable. The environment-friendly dust fall agent for the coal mine comprises the following raw materials, by mass ratio, 60-100 parts of surface active agents, 5-30 parts of biodegradable high-molecular polymers, 20-60 parts of solvents, 6-20 parts of antifreezing agents and 0.5-4 parts of metal corrosion inhibitors. The dust fall agent is a concentrated solution, the ratio can reach 1: 1000 to 1: 5000, quick dust fall can be achieved, chloride salt is not contained, the agent is biodegradable after being sprayed, and therefore secondary environment pollution is avoided.

Owner:TAIYUAN RONGYUAN TECH CO LTD

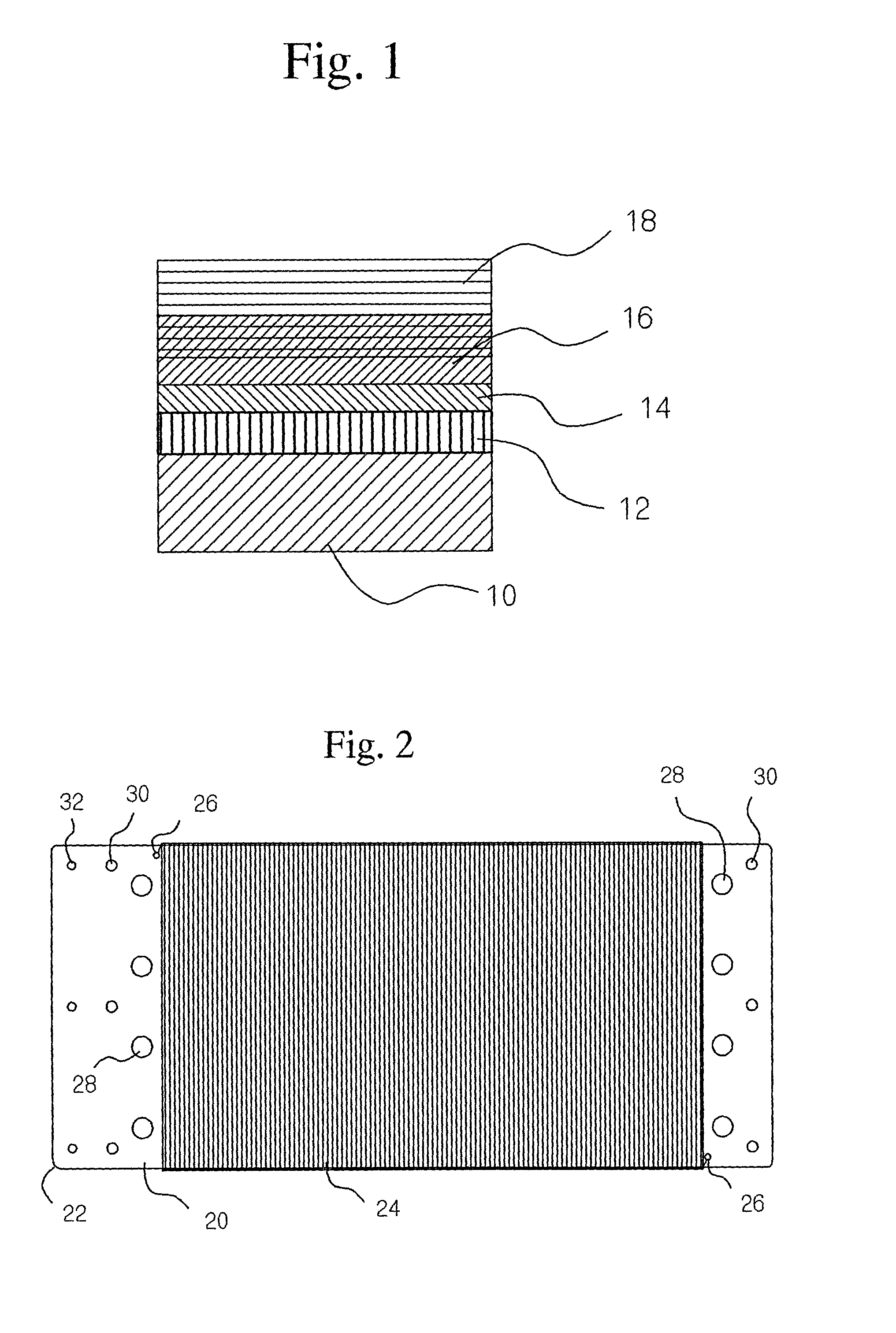

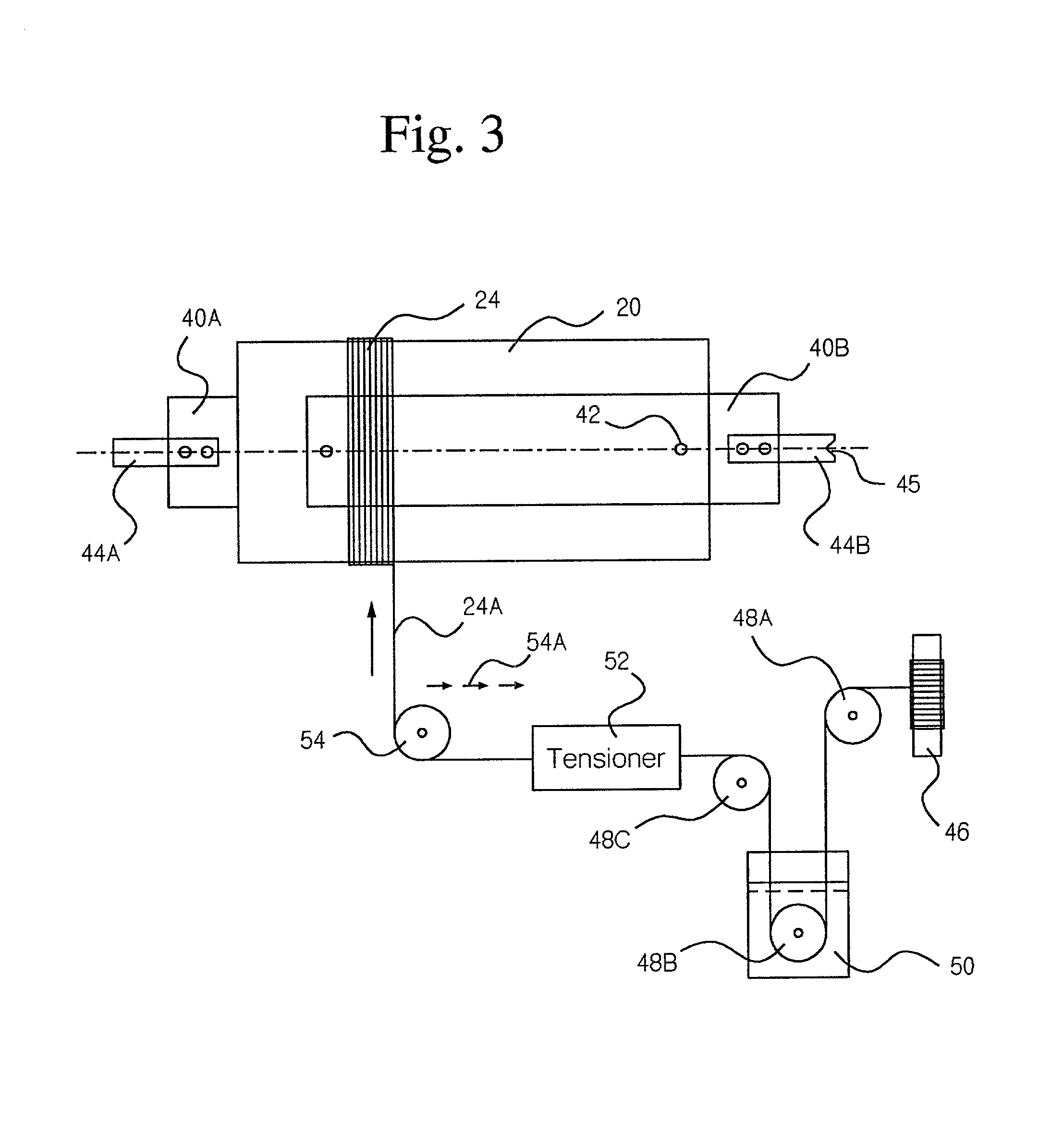

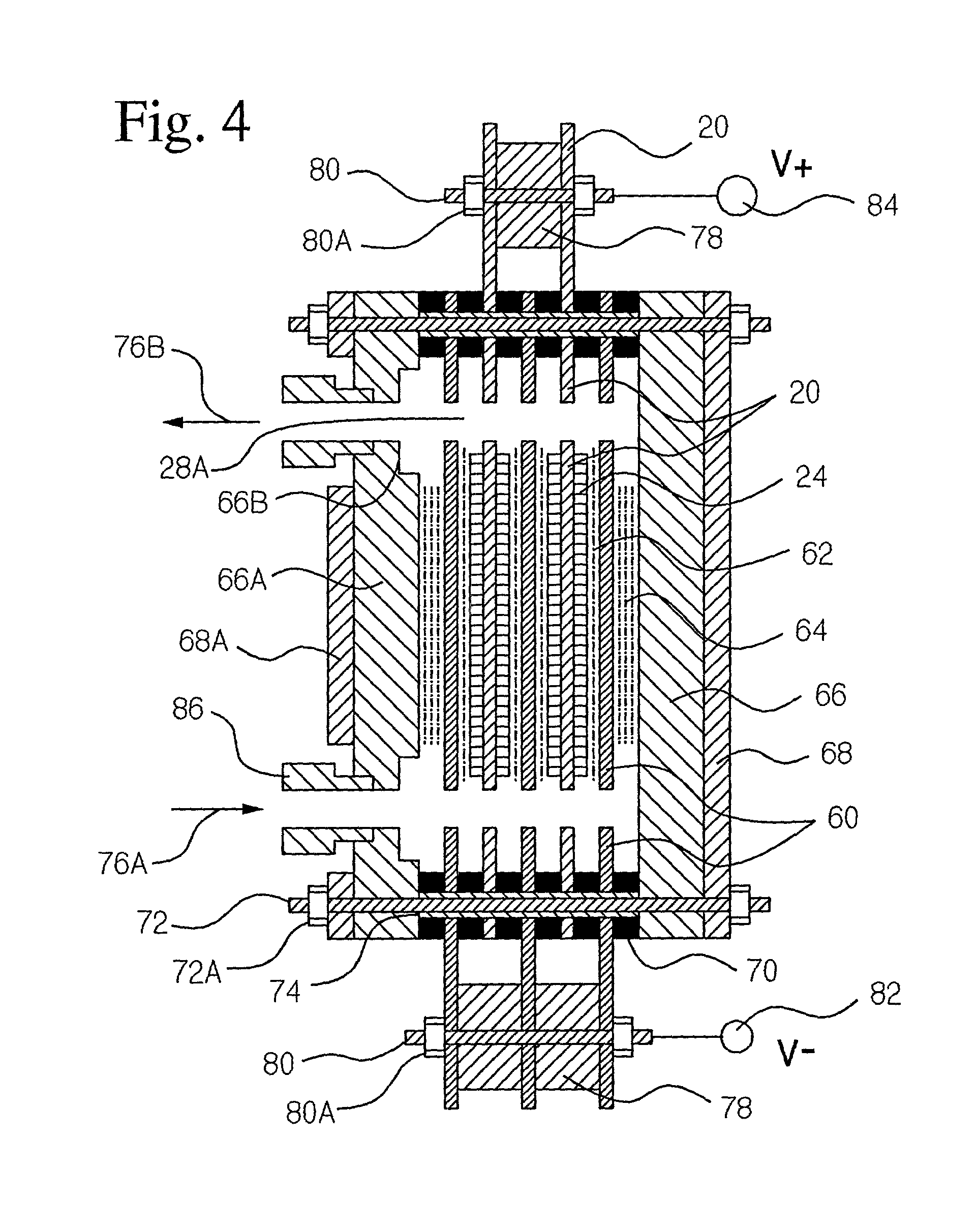

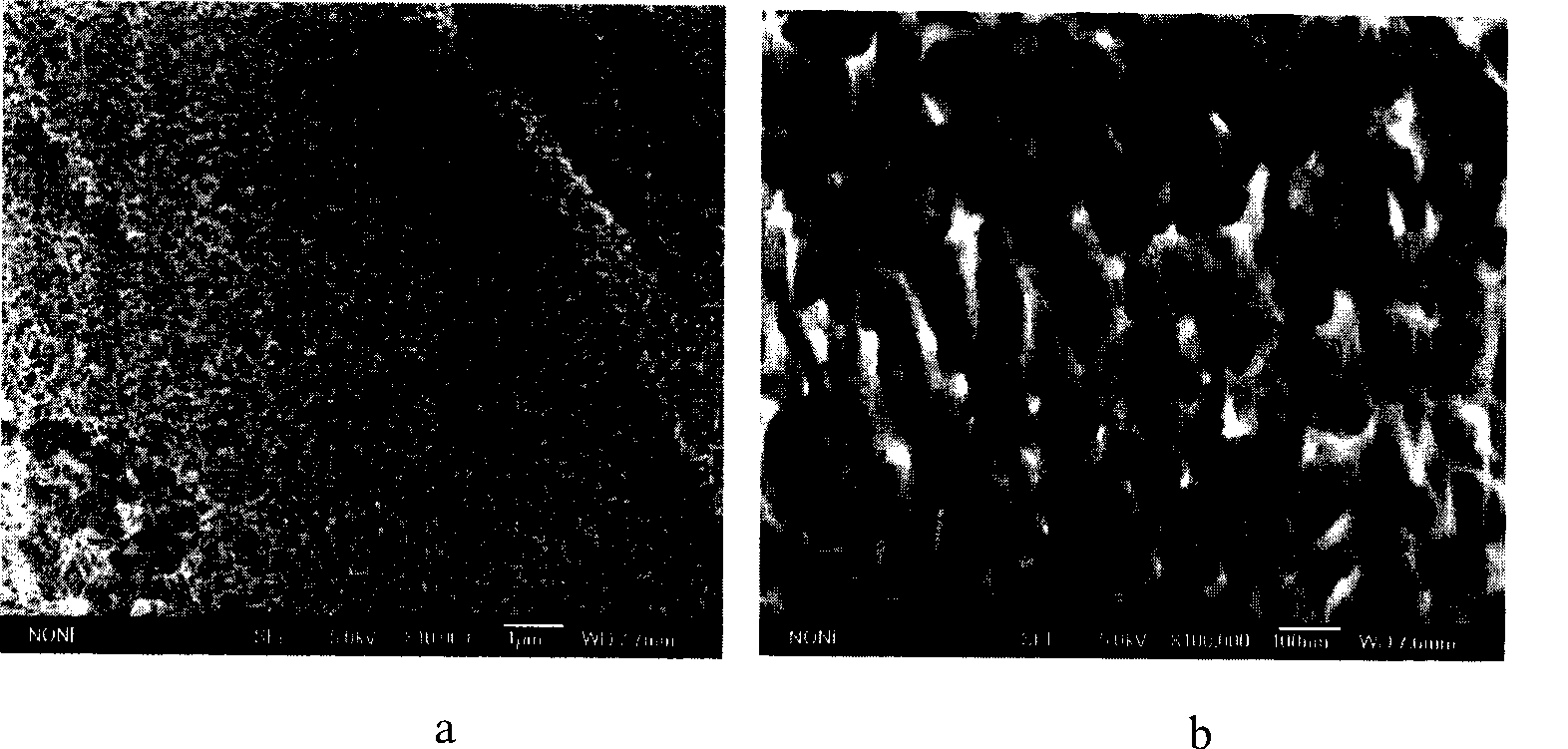

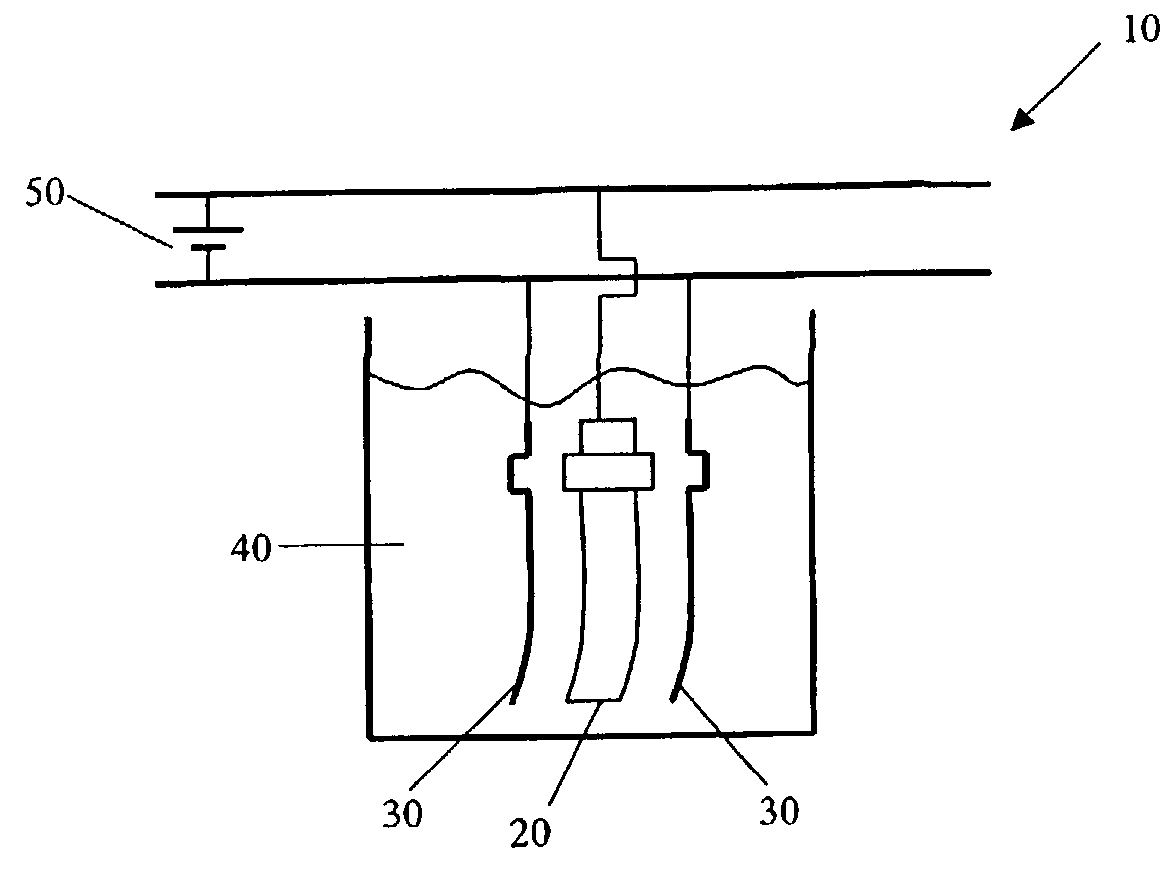

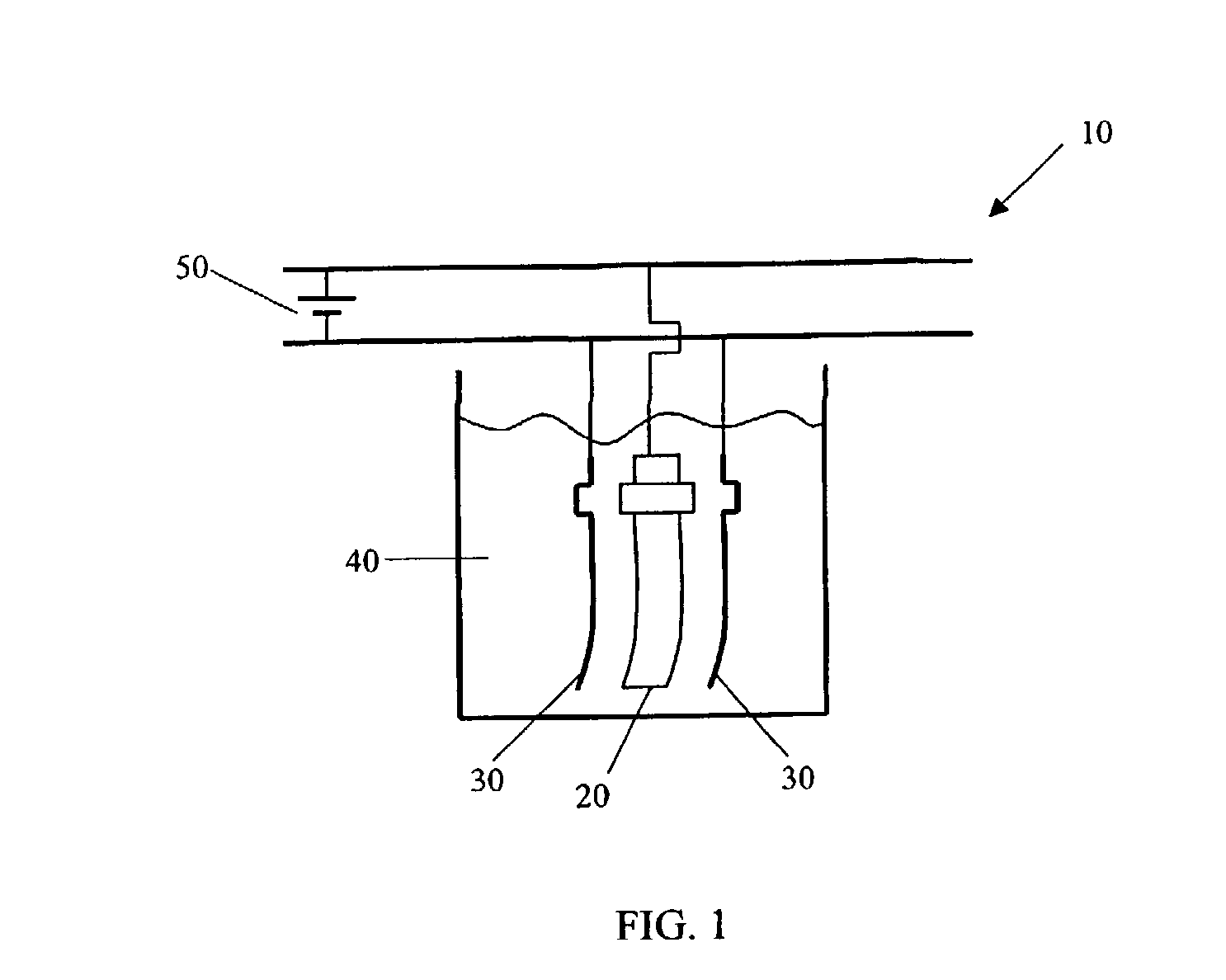

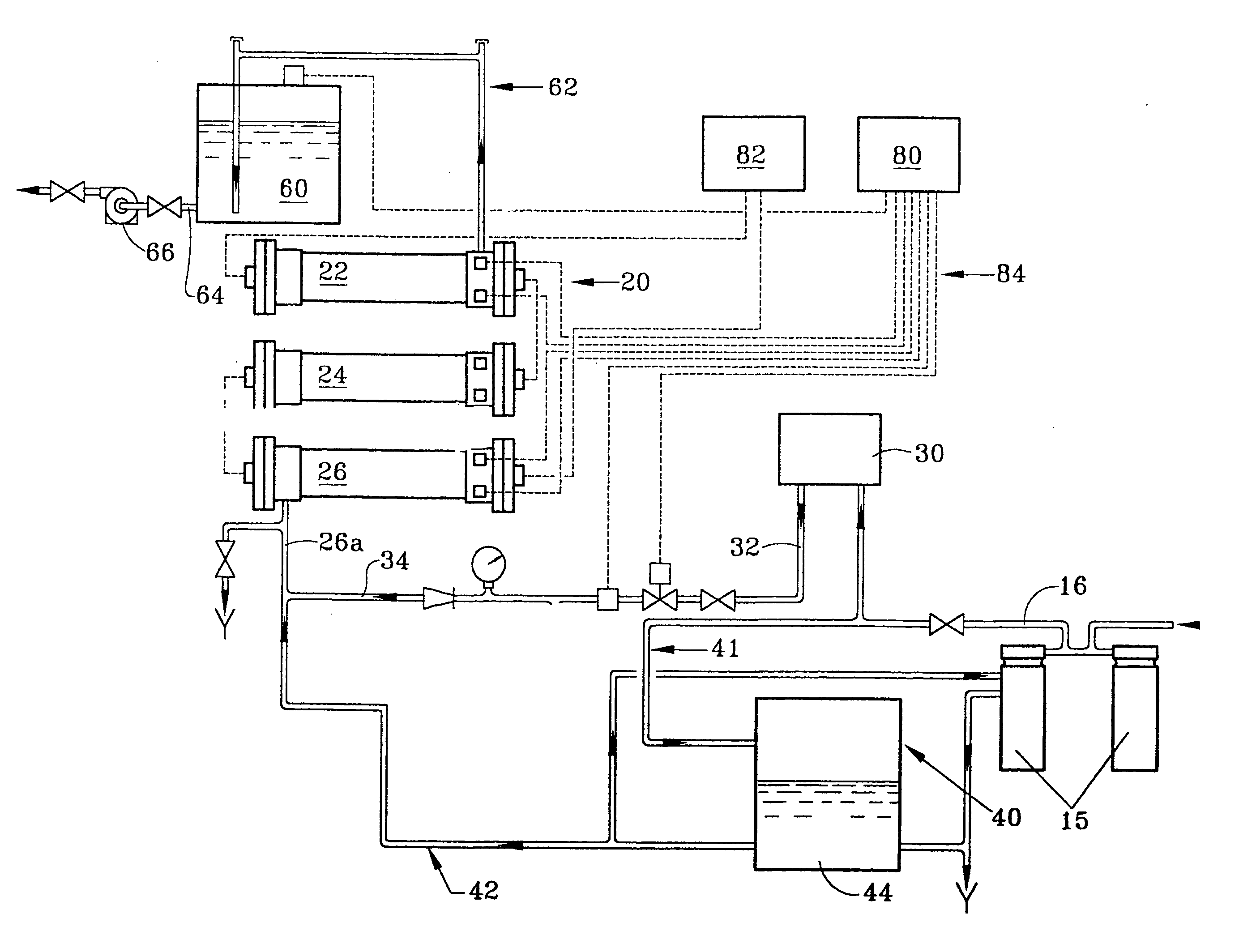

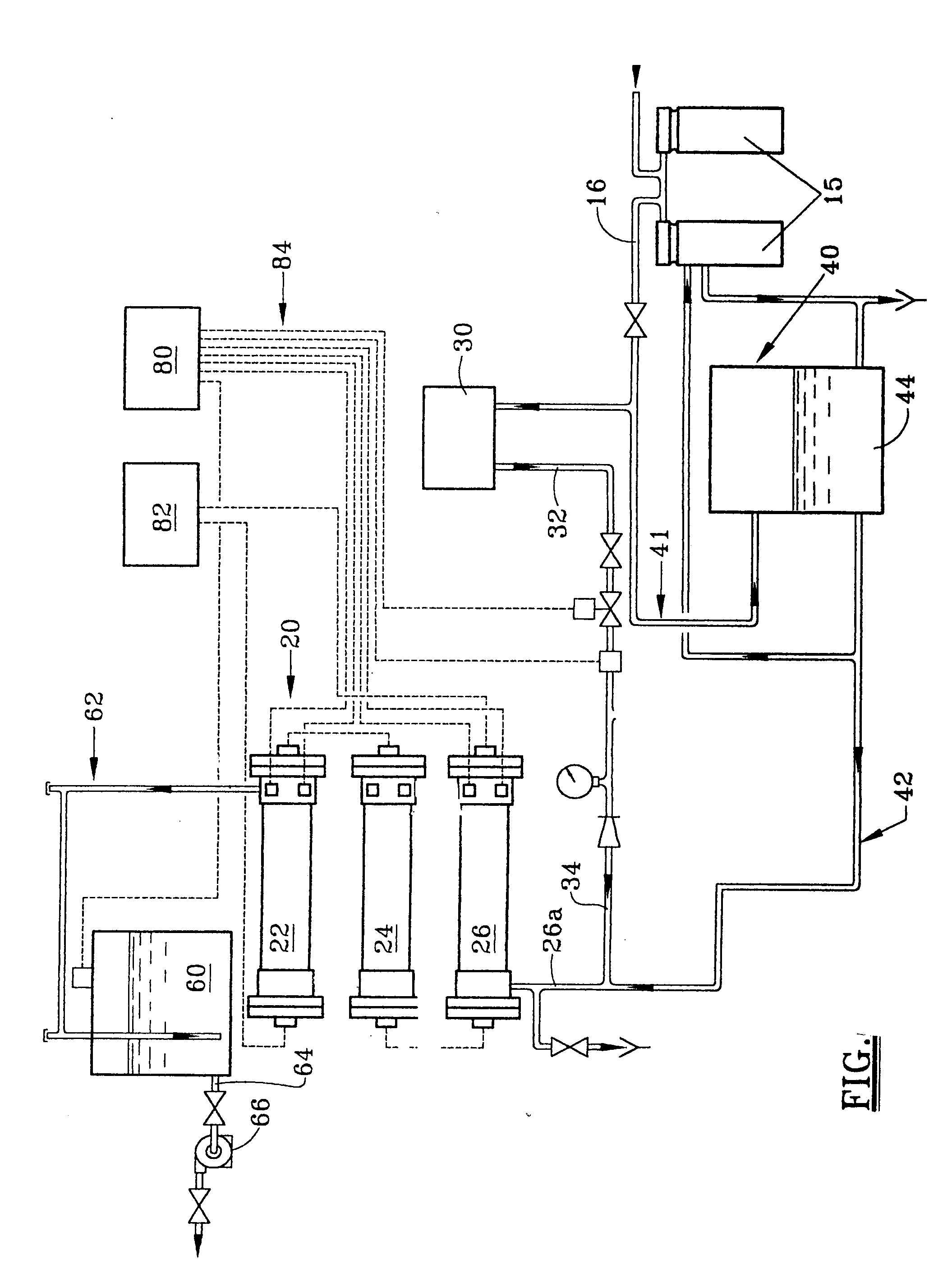

Electrode and electrochemical cell for water purification

An electrode with large active surface area is made by winding a Ti-fiber tow around a rectangular Ti-plate, and an electrocatalytic coating of three layers is applied. A precoat comprising a mixture of iridium dioxide and tantalum pentoxide is applied first, using a solution of the corresponding chloride salts in hydrochloric acid with some nitric acid added to inhibit corrosion of the metal. A sealing coat is then applied, comprising tin dioxide doped with antimony, in order to improve adhesion of the final oxide coat to the precoat. The third and final coat comprises particles of titanium dioxide doped with niobium in the +4 oxidation cemented with titanium dioxide that is doped with antimony. Anodes of this description are preferably assembled together with corrosion resistant cathodes in an alternating sequence, with a plastic coated fiber glass mesh placed between the anodes and cathodes to prevent short circuiting. When a sufficiently large voltage is applied across the cell, organic substances dissolved in the electrolyte will be oxidized.

Owner:WERES OLEH

Production method for direct growth of one-dimensional nano cuprous oxide array on metallic copper substrate

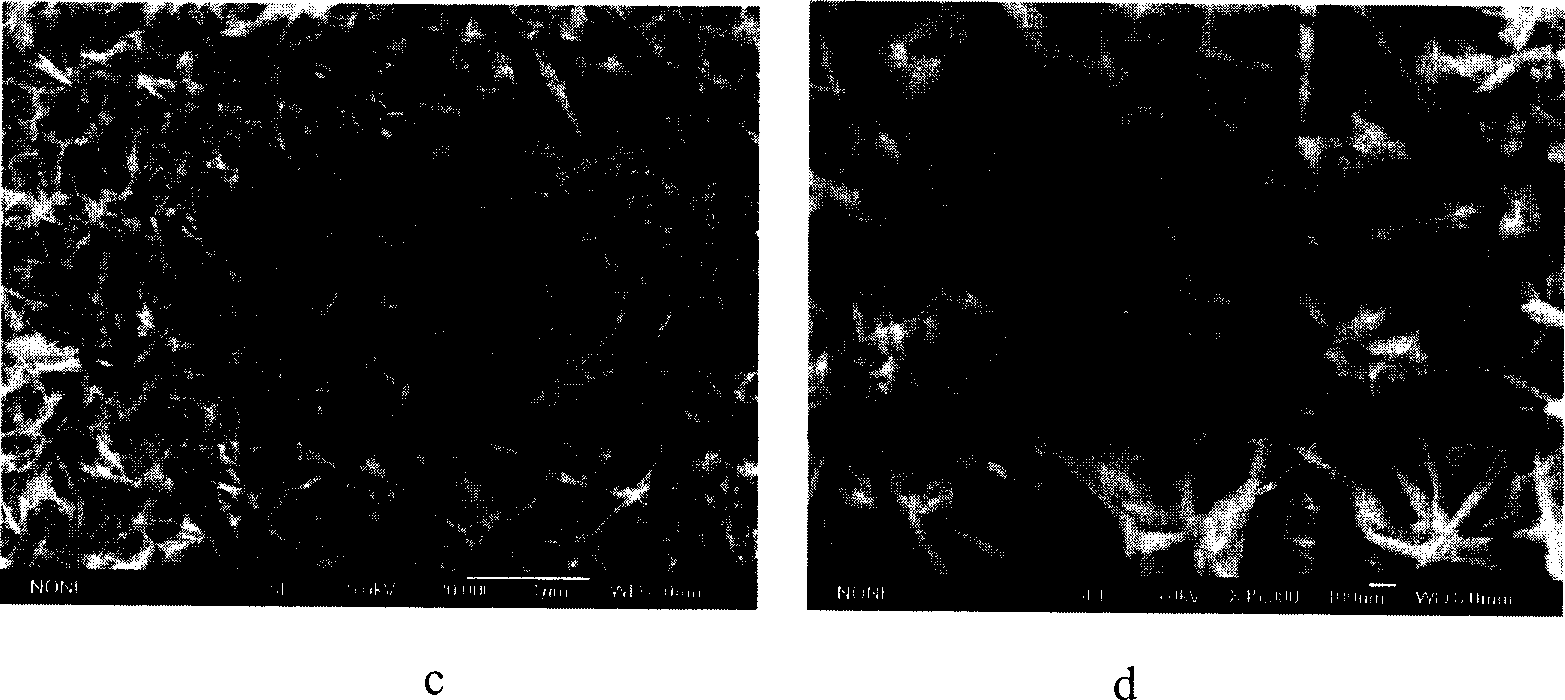

InactiveCN101429680AImprove field emission performanceHigh visible light photocatalytic performanceAnodisationPolycrystalline material growthElectrolysisChloride salt

In chloride media, copper anodic dissolution is a mature process for producing cuprous oxide (Cu2O); and based on the preparation process, the invention provides a method for directly growing a one-dimensional nanometer Cu2O array on an anode metal copper substrate through adding a surface active agent to an anode slot, and controlling the concentration of electrolyte chloride salt in the anode slot, the concentration of alkali in a cathode slot, electric quantity of electrolysis and electrolysis temperature. The array has controllable appearance, and consists of a nanometer belt, a nanometer plate and a nanometer line, wherein the top end of the one-dimensional array can be acicular, circular, and the like. The one-dimensional nanometer Cu2O array directly growing on the copper substrate has excellent effect of field emission performance and visible light catalysis, and has wide application prospect in technical fields of vacuum microelectronic devices, panel display, advanced oxidation and other aspects.

Owner:HUAZHONG NORMAL UNIV

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

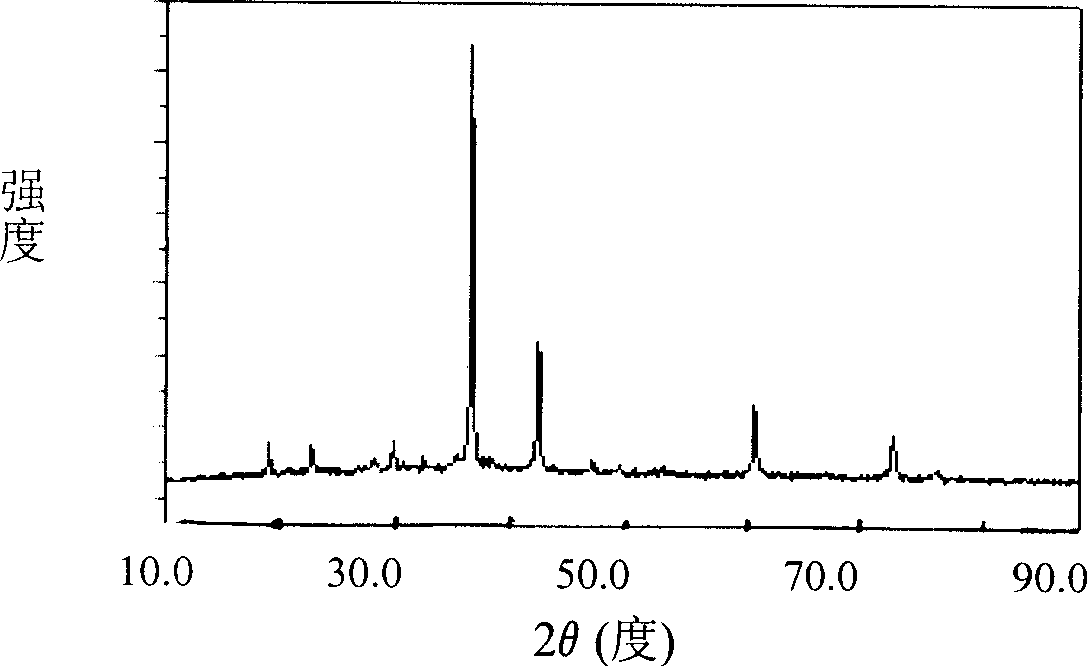

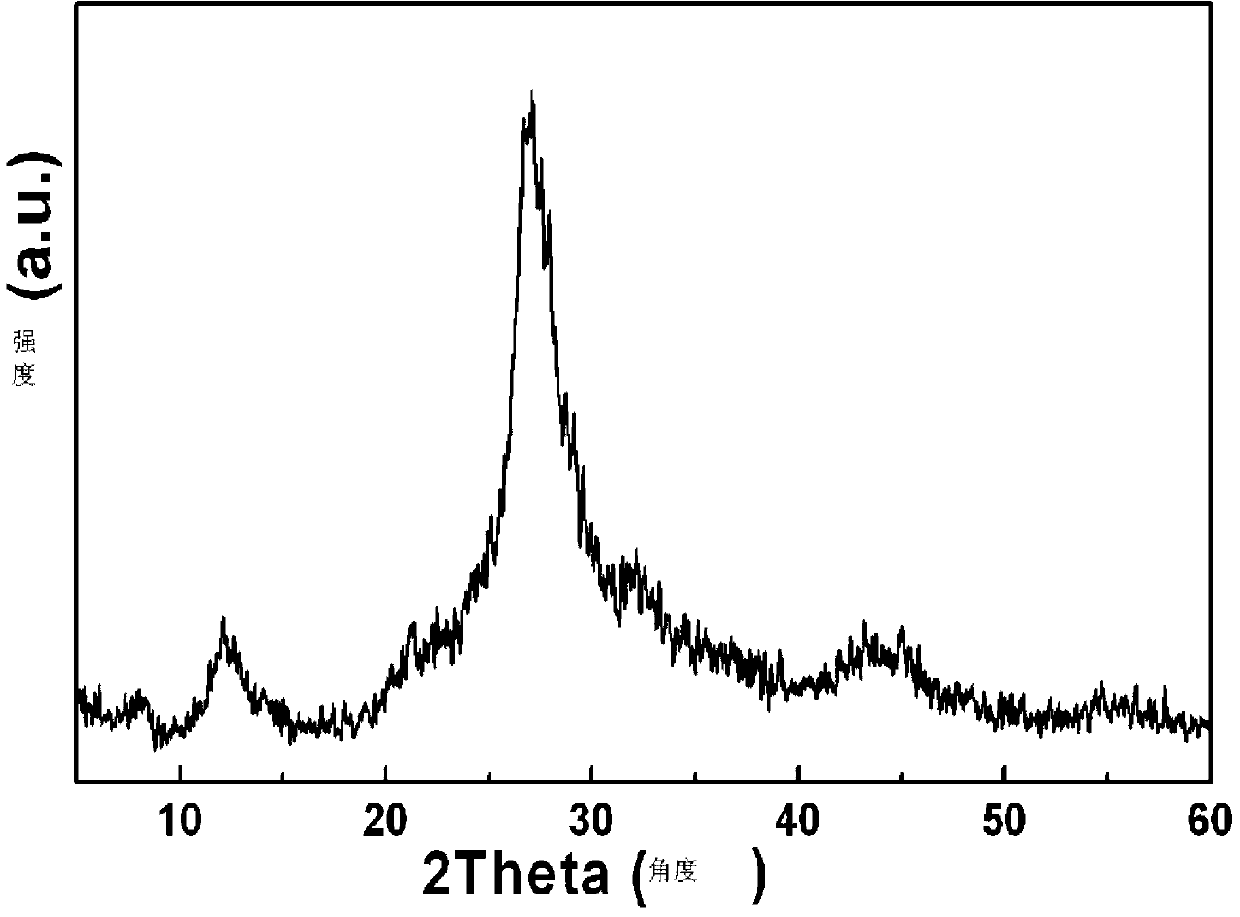

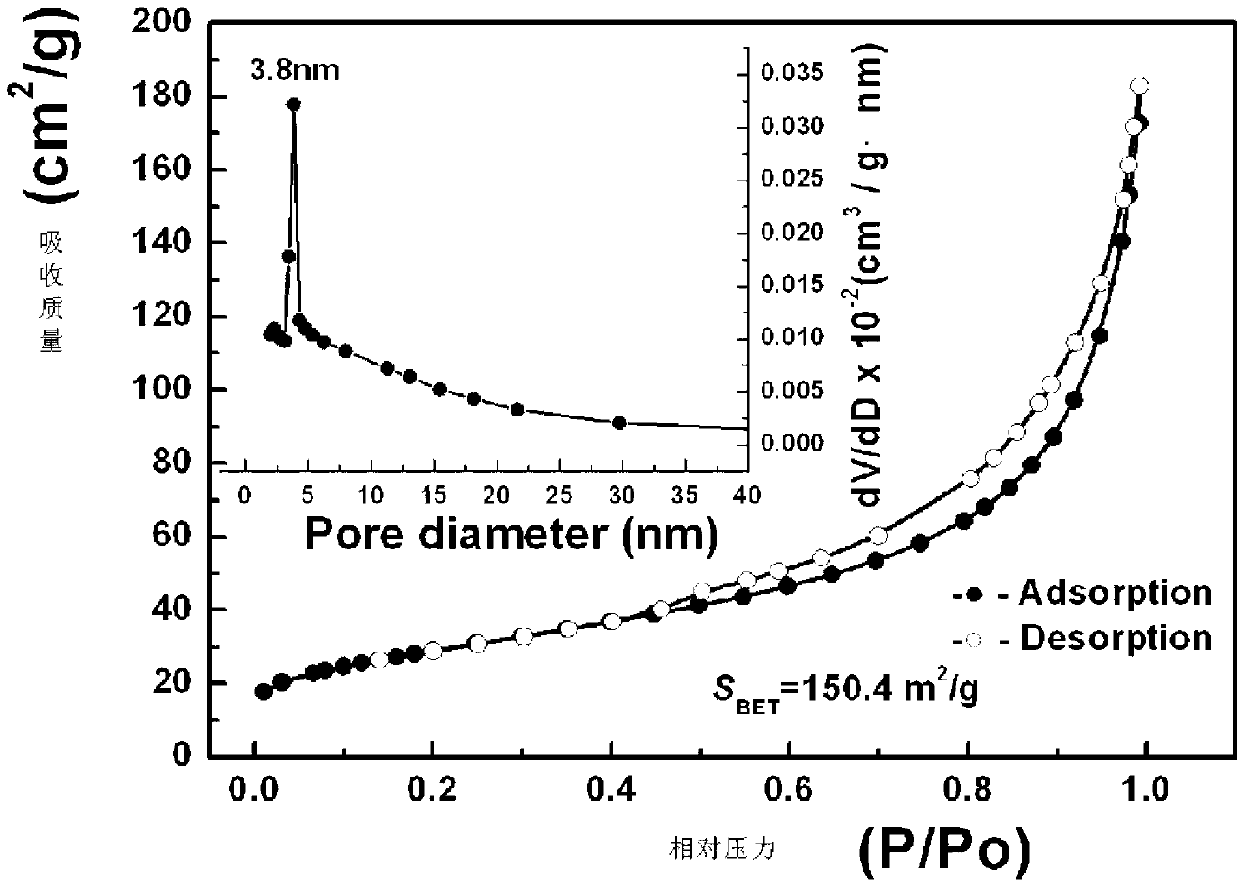

InactiveCN102992282AEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

The invention discloses a mesoporous C3N4 photocatalytic material prepared by using a molten salt method and a preparing method thereof. The method comprises the following steps that water-soluble low-melting-point molten salt is fully mixed with melamine, small molten salt drops are used as a blocked layer under the melting temperature of the molten salt, C3N4 grows in a way of being coated with the small drops, and the molten salt is recycled by water washing after reaction, so as to obtain the C3N4 photocatalytic material. The C3N4 photocatalytic material is in a wormlike mesoporous structure, the mesoporous size is within 3.8+ / -1nm, and the forming mechanism of the mesoporous C3N4 photocatalytic material is that the small molten salt drops are used as the growth blocked layer. When the material is prepared, water-soluble low-melting-point chloride salt is used as the molten salt and is fully mixed with melamine to obtain a mixture, the mixture is subjected to the heat treatment in a muffle furnace for 1-5h under the temperature being 400-680 DEG C to obtain samples, and the samples after the heat treatment are washed by water to recycle the molten salt, so as to obtain the mesoporous C3N4 photocatalytic material. In the whole process, a template is not introduced, and the operation is easy and feasible, so that the large-scale industrial production can be realized easily.

Owner:NANJING UNIV

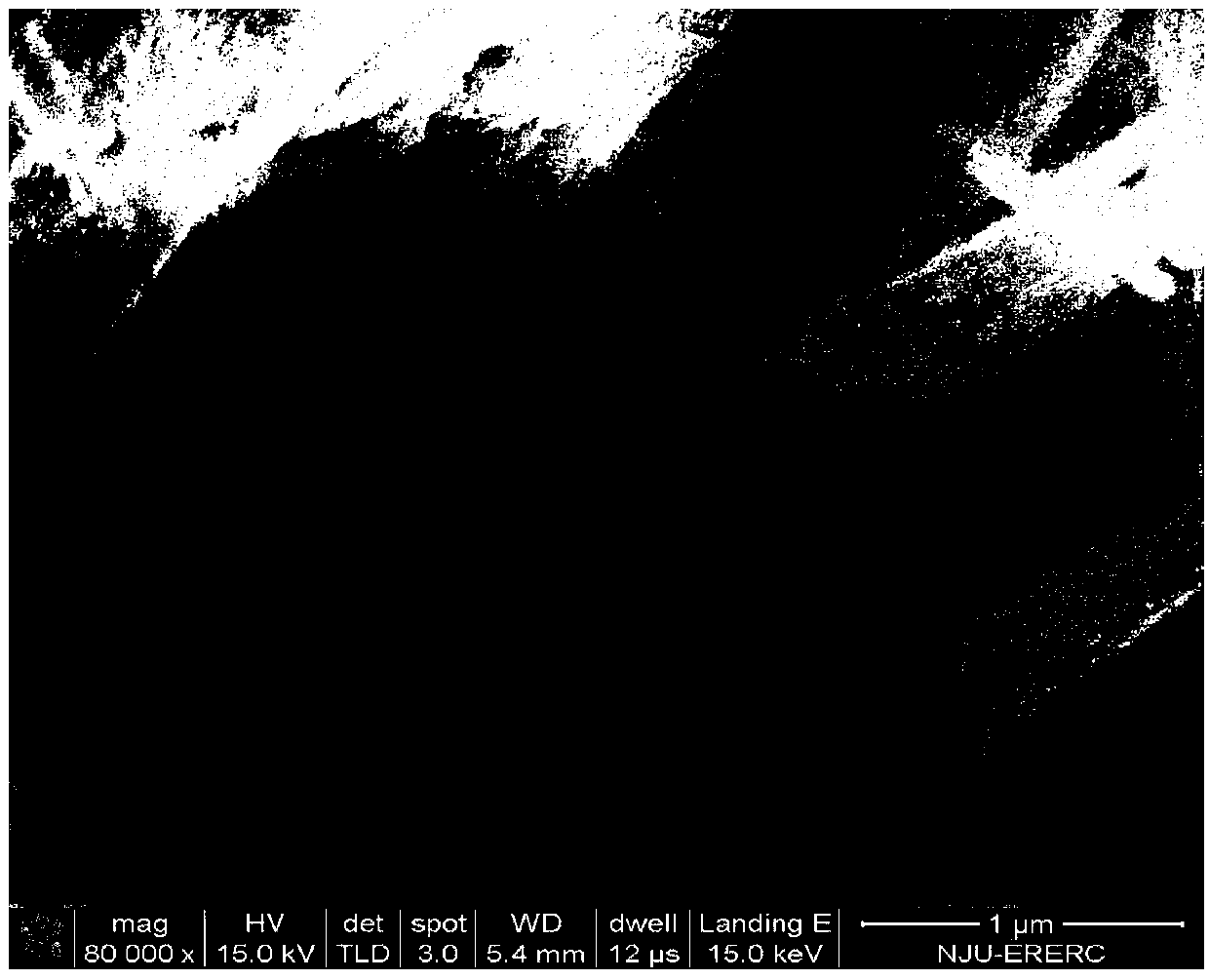

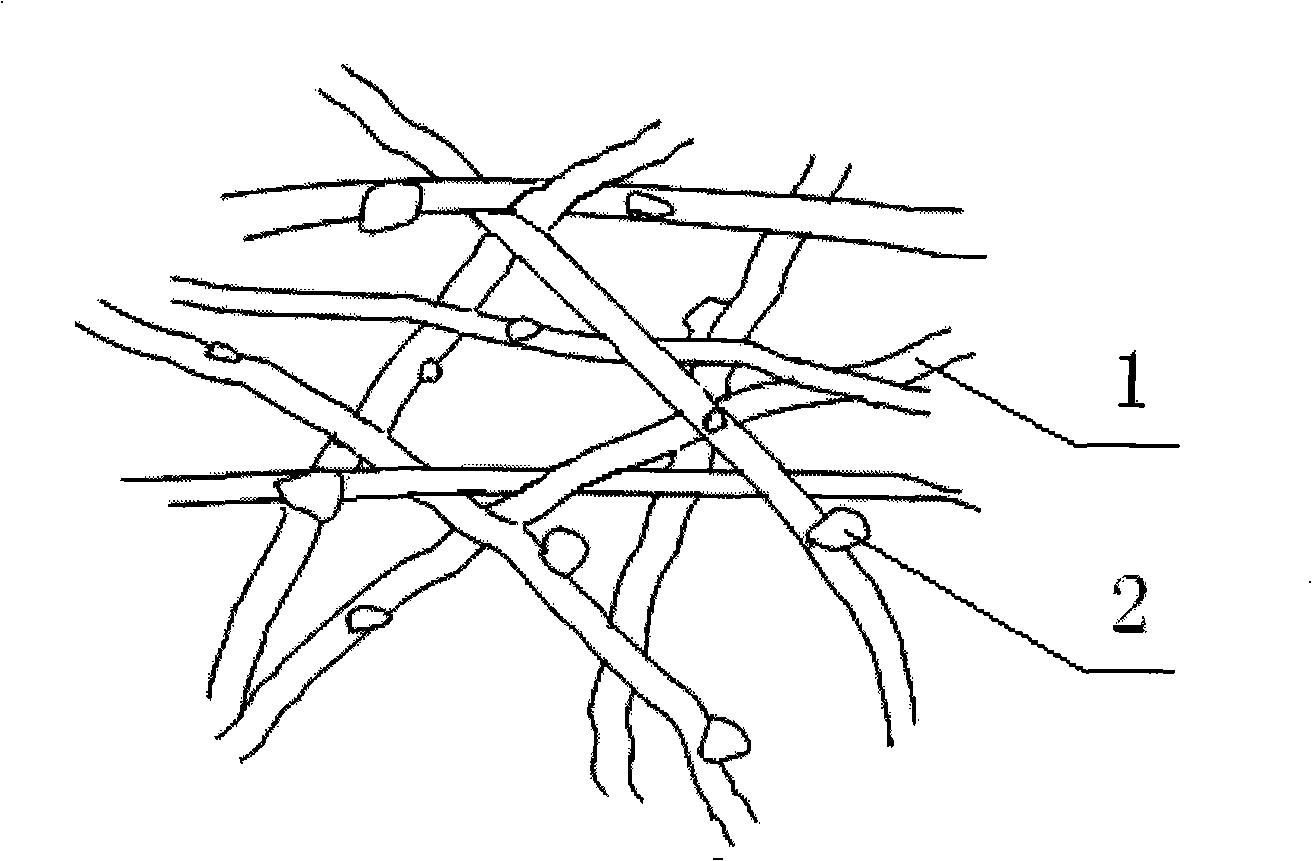

Bacteria cellulose membrane containing silver chloride nano particle and preparation and application thereof

InactiveCN101264335AImprove performanceHigh antibacterial activityAbsorbent padsBandagesNanoreactorChloride salt

The invention provides a bacteria cellulose membrane containing silver chloride nanometer particles, corresponding preparation method and application, which is characterized in that a plurality of silver chloride nanometer particles are adhered to the microfiber surface of the three-dimensional porous reticular structure of the bacteria cellulose membrane, the content of the silver chloride nanometer particle is 0.5 to 21% of the total weight and which particle diameter is 10 to 300nm. The preparation method is base on the principle of using the particular three-dimensional reticular microfibrillar structure and the high oxygen density (ether linkage and hydroxy) to constitute the synthetical effective nanometer reactors by the silver chloride nanometer particles in situ and the product is obtained after repeatedly soaking in the solution of silver salt and chloride salt, rinsing and drying. The bacteria cellulose membrane containing silver chloride nanometer particles has the advantages of excellent antibacterial performance, most simple preparation process, can be used as favorable antiseptic dressing and extracting the silver chloride nanometer particles.

Owner:DONGHUA UNIV

Concentrated aqueous bromine solutions and their preparation and use

InactiveUS6652889B2Improve solubilityMinimize extentBiocideSpecific water treatment objectivesChloride saltNitrogen

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine in the biocidal composition as active bromine capable of providing biocidal activity.

Owner:ALBEMARLE CORP

Dust suppressant and soil stabilization composition

InactiveUS7070709B2Low viscosityHigh viscosityOther chemical processesRoads maintainenceChloride saltAdditive ingredient

Disclosed are dust suppressant and aggregate stabilization compositions. In accordance with the subject disclosure, hemicellulose is used as a dust suppressant and / or as a stabilization composition for aggregates such as a road bed or soil field. Other ingredients may be used in a composition in conjunction with hemicellulose. For instance, a lignin compound may be used to enhance dust suppression and / or aggregate stabilization. A surfactant may be used to decrease the viscosity of the composition. A crosslinking agent may be used to enhance the water resistance of the composition. A chloride salt may be added to increase the hygroscopicity of the composition.

Owner:GRAIN PROCESSING CORP

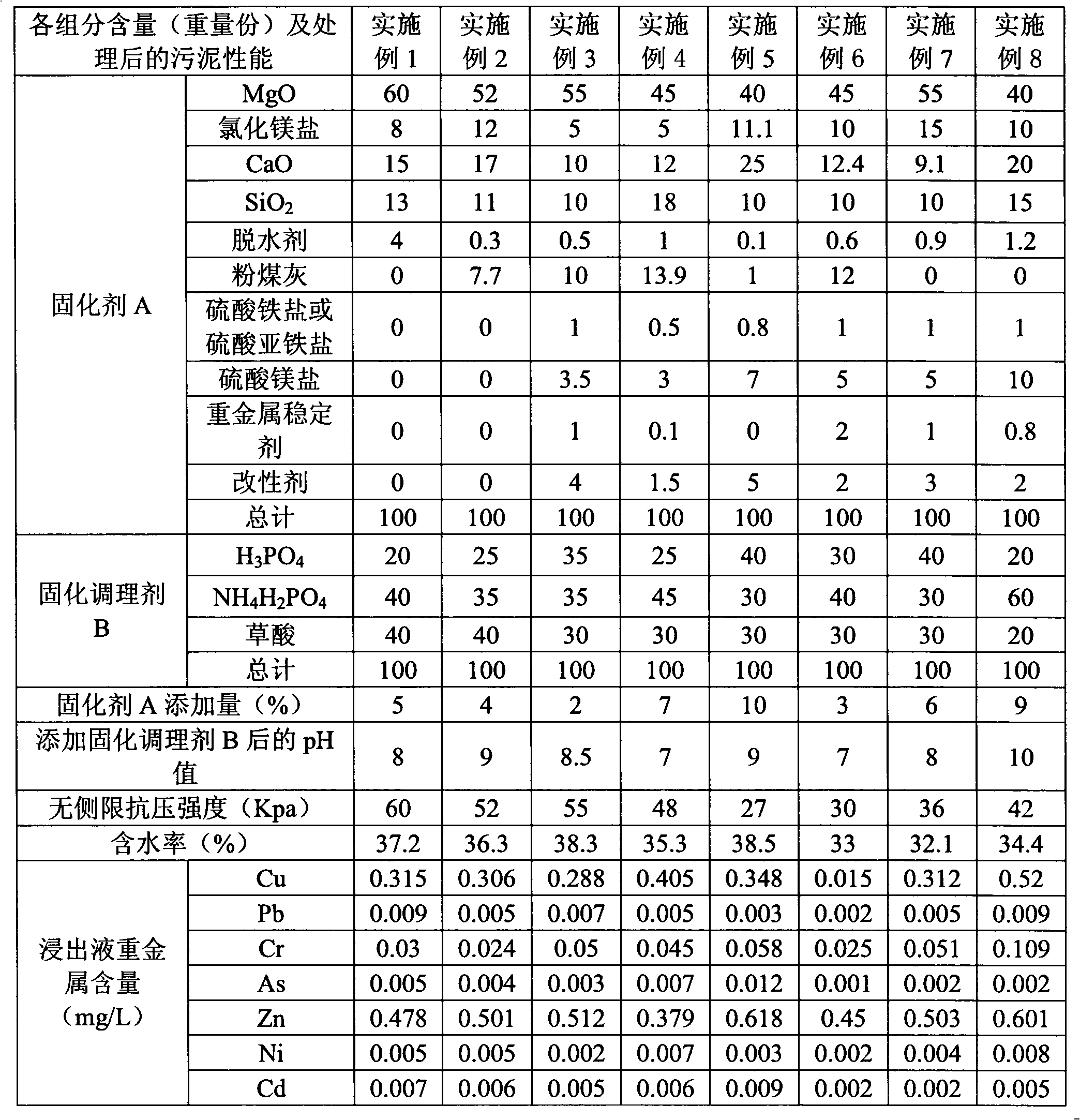

Sludge curing treatment agent and method for treating sludge by use of curing treatment agent

InactiveCN103664126AReduce moisture contentCause secondary pollutionSludge treatment by de-watering/drying/thickeningOXALIC ACID DIHYDRATEChloride salt

The invention provides a novel sludge curing treatment agent. The curing treatment agent comprises a curing agent A and a curing conditioner B, wherein the curing agent A comprises the following components in percentage by weight: 40-60% of MgO, 5-20% of magnesium chloride salt, 10-20% of SiO2, 10-30% of CaO, 0.1-4% of dehydrating agent and 0-20% of fly ash; the curing conditioner B comprises the following components in percentage by weight: 20-40% of H3PO4, 30-50% of NH4H2PO4 and 20-40% of oxalic acid; the curing agent A accounts for 0.5-10% of the total amount of sludge in treatment by mass; and the curing conditioner B accounts for 0-5% of the total amount of sludge in treatment by mass. By adopting the sludge curing treatment agent provided by the invention to treat the sludge with relatively high water content and particularly water content over 80%, the sludge can be cured generally in 1-2 days, the curing time is short, and the water content is reduced to about 30% 7 days later; after the curing, the water content of the sludge is low; and the sludge after the curing treatment can be subjected to landfill on site or applied to roadbed, greening, earthing, ecological restoration and the like, thereby avoiding secondary pollution to environment.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Concentrated aqueous bromine solutions and their preparation

InactiveUS6511682B1Reduced pHRaise the pHBiocideSpecific water treatment objectivesChloride saltBromine

Described is a process of producing a concentrated liquid biocide formulation. Mixed together are (a) bromine chloride or bromine and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the solution is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine from (a) and (b) is greater than 1 when bromine is used and is greater than 0.93 when bromine chloride is used. Use of bromine chloride as the source of the active bromine in the process is preferred because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine in the biocidal composition as active bromine capable of providing biocidal activity.

Owner:ALBEMARLE CORP

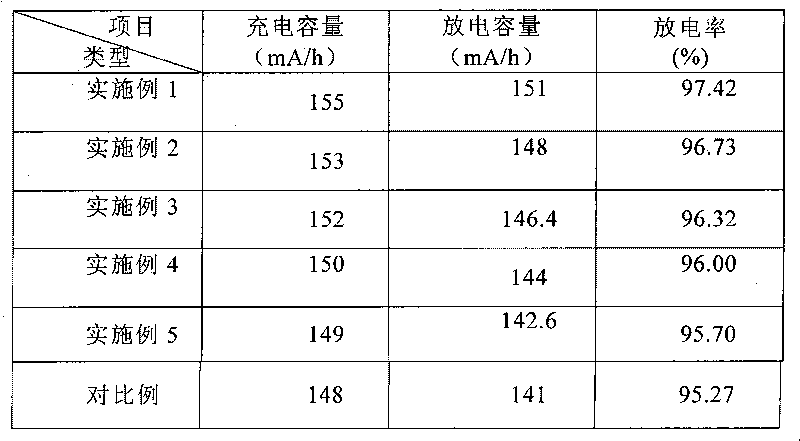

Method for synthesizing iron phosphate with doped metallic elements

InactiveCN101692488AEasy to operateImprove performanceElectrode manufacturing processesPhosphoric acidReaction temperature

The invention relates to a method for synthesizing iron phosphate with doped metallic elements. The method comprises the following steps of: (1) using sulfate, chloride or nitrate of iron as an iron source, mixing any one of substances containing other metal cation elements with the iron source, accurately weighting each material in a mol ratio, and adding distilled water into the materials to prepare a mixed solution, wherein the total mol concentration of the mixed solution is 0.1 to 5 mol / L; (2) using one or a mixture of more than one of ammonium dihydrogen phosphate, ammonium phosphate, ammonium hydrogen phosphate and trisodium phosphate as a phosphorus source, and preparing phosphorus solution of which the mol concentration is 1 to 5 mol / L; (3) using ammonia water as a complexing agent and a neutralizing agent; (4) controlling the reaction temperature to between 20 and 98 DEG C, pumping the mixed solution doped with the doped metallic elements and the phosphorus solution into a reactor respectively, controlling the pH value by the ammonia water, and stirring the mixture to ensure that the mixture is continuously co-precipitated in the reactor to generate the iron phosphate with spherical doped metallic elements; and (5) aging, spin-drying, washing and drying the reaction solution to obtain the iron phosphate with the doped metallic elements. The method has the advantages of simple operation, stable performance, low manufacturing cost, sterility and no pollution.

Owner:HENAN KELONG NEW ENERGY CO LTD

Anti-icing and deicing compositions and method

InactiveUS6641753B1Improve roadway tractionEliminate accumulationOther chemical processesMobile vehicleChloride salt

Disclosed is a deicing / anti-icing composition that includes sugar cane molasses solids and a deicing component, which preferably is a chloride salt. The composition may be applied to surfaces to remove ice or snow therefrom, or to inhibit the accumulation of ice and snow thereon. The sugar can molasses solids may be sprayed onto the salt as the salt is being applied to a road surface from a moving vehicle. Alternately, the sugar cane molasses solid may be applied to body of salt to inhibit ice formation at or near the surface of the body of salt.

Owner:NATURAL ALTERNATIVES

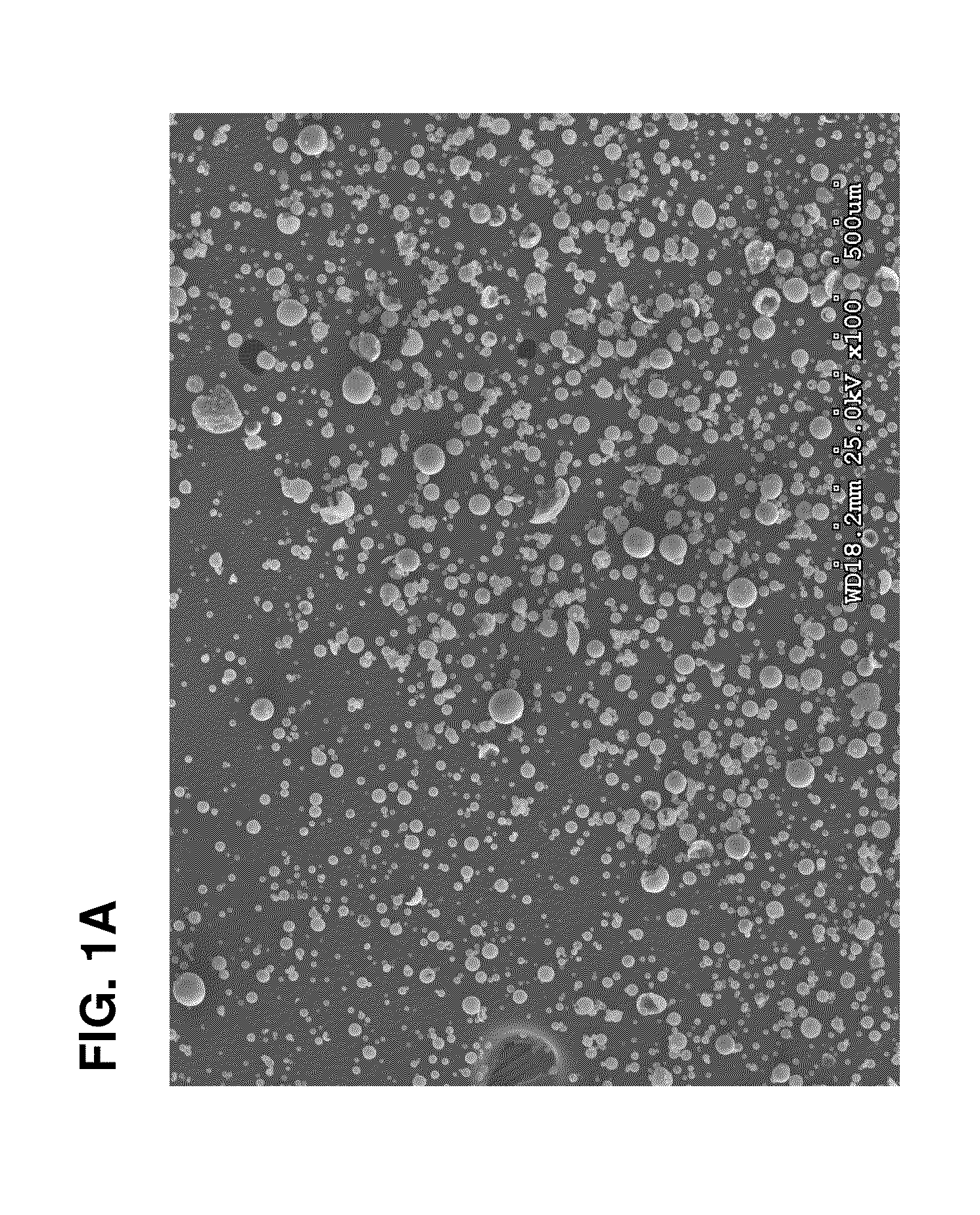

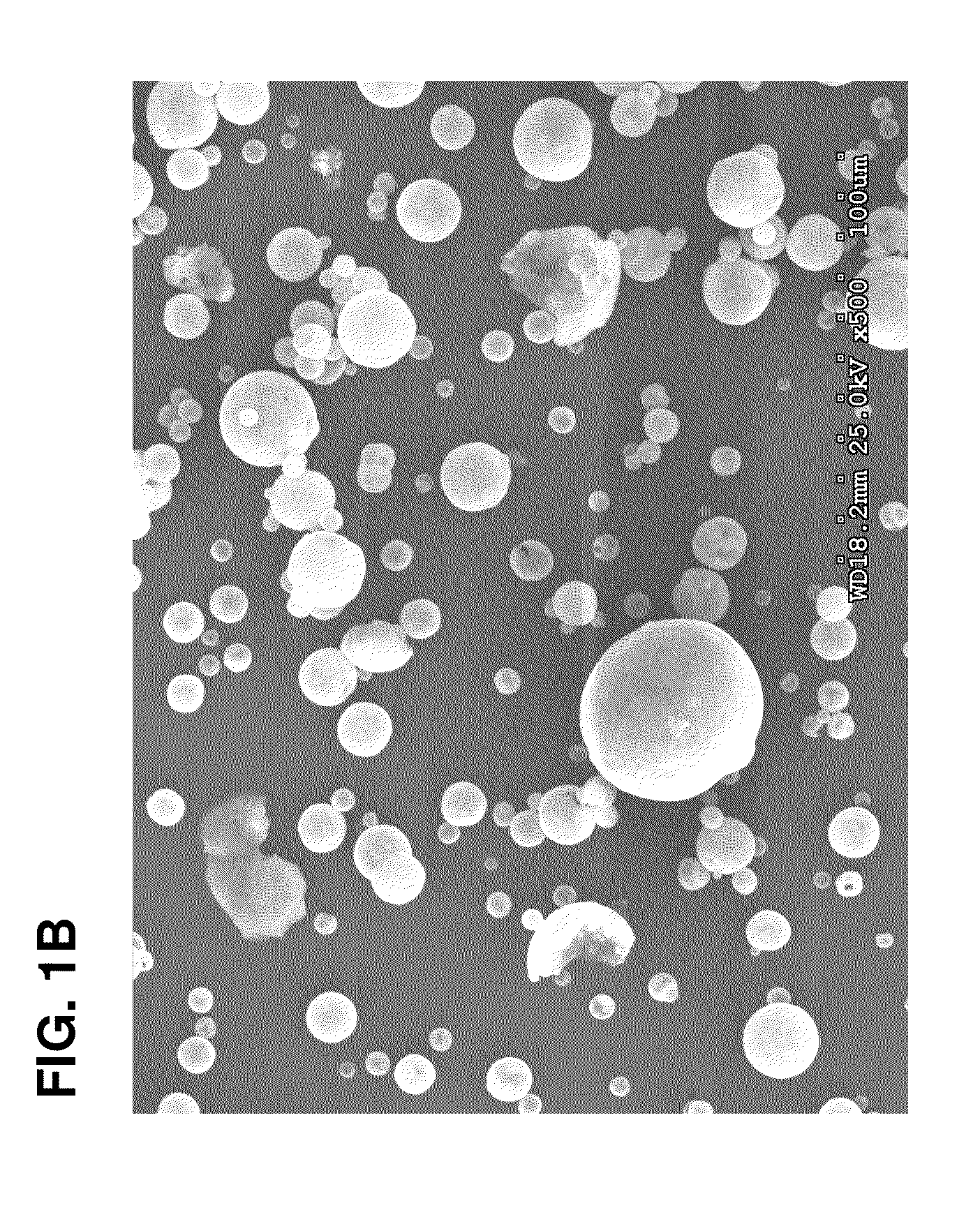

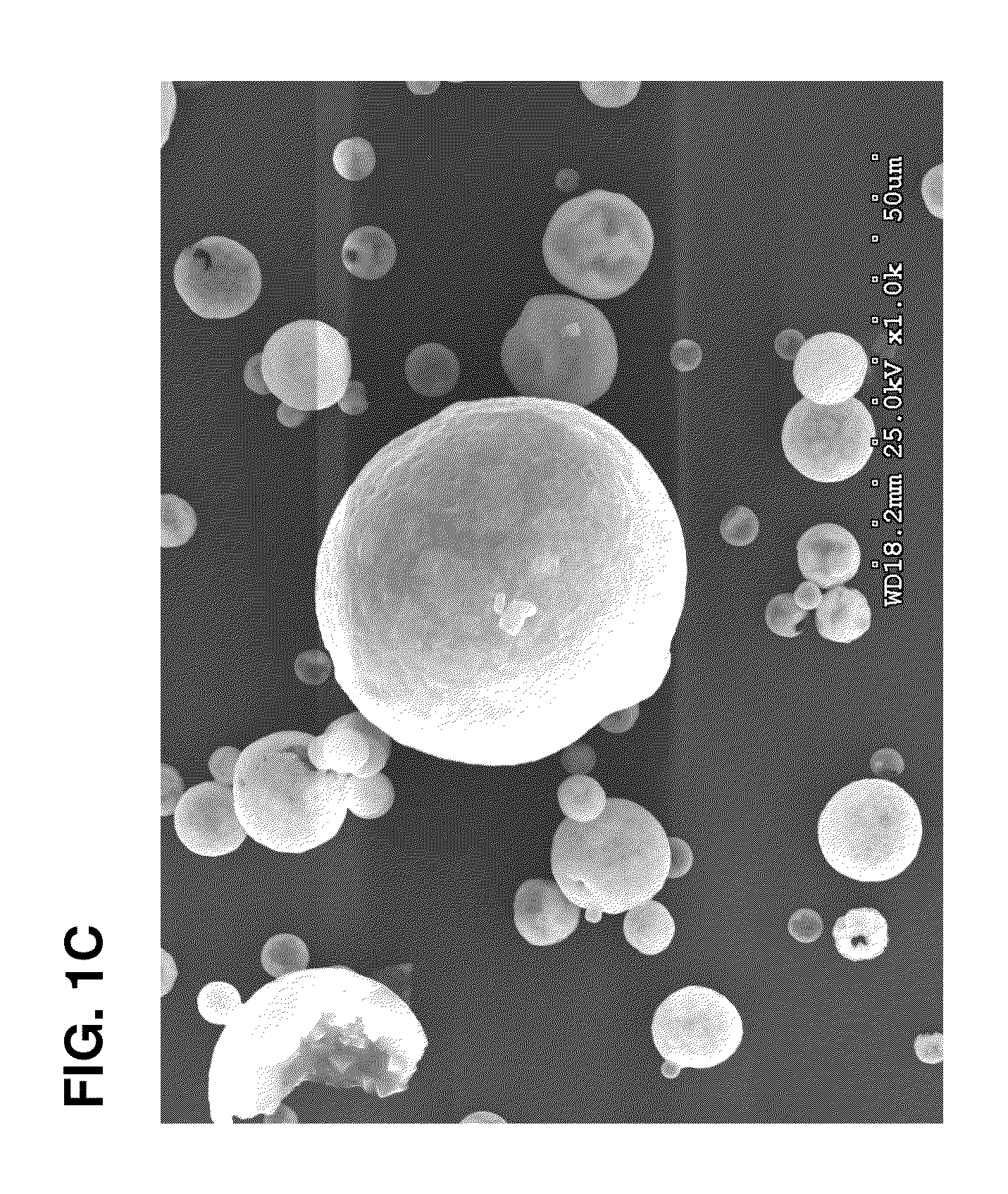

Method for Producing a Low Sodium Salt Composition

The present invention relates to a low sodium salt composition and the method used to make it. More particularly, the invention relates to a two step method of making a salt composition. The first step includes contacting a chloride salt with a modifier to form a chloride salt product, mixing the product with a carrier to form a modified chloride salt solution, and spray drying the modified chloride salt solution. The second step includes contacting the dried modified chloride salt with sodium chloride, and grinding the mixture to form a salt composition. The composition includes a combination of sodium chloride and carrier modified chloride salt.

Owner:S & P INGREDIENT DEV

Surface coating type reinforced concrete corrosion inhibitor and preparation method thereof

ActiveCN102757197AModerate proportionPrevent and inhibit corrosionWater insolubleSurface-active agents

The invention relates to a surface coating type reinforced concrete corrosion inhibitor. The surface coating type reinforced concrete corrosion inhibitor comprises the components as follows: 15 to 40 wt% of a non-ionic surface active agent with HLB (Hydrophile Lipophile Balance) value more than 10, 5 to 30 wt% of a cosurfactant, 1 to 20 wt% of water insoluble organic inhibitor, and 20 to 50 wt% of water, wherein the cosurfactant is selected from organic alcohol or organic amine. The preparation method comprises the steps of mixing the non-ionic surface active agent, the cosurfactant and the water insoluble organic inhibitor, and agitating along with heating unit the mixture is completely molten, and then agitating along with water adding until the mixed liquid is turned into a clear state from a muddy state, thus obtaining the product. The preparation method provided by the invention is simple; the prepared product can be applied to surface treatment of the constructed concrete structure; and the prepared product has superior infiltration capacity, can effectively prevent the reinforcement surface from being eroded by chloride salt and sulfate, and has no adverse effect to the performance of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

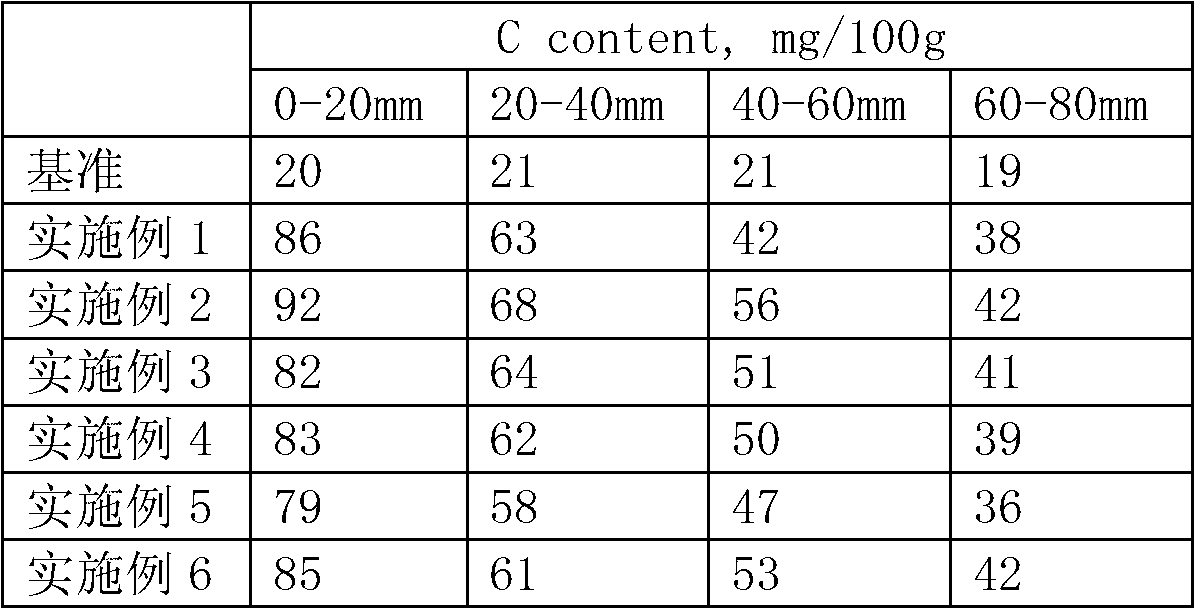

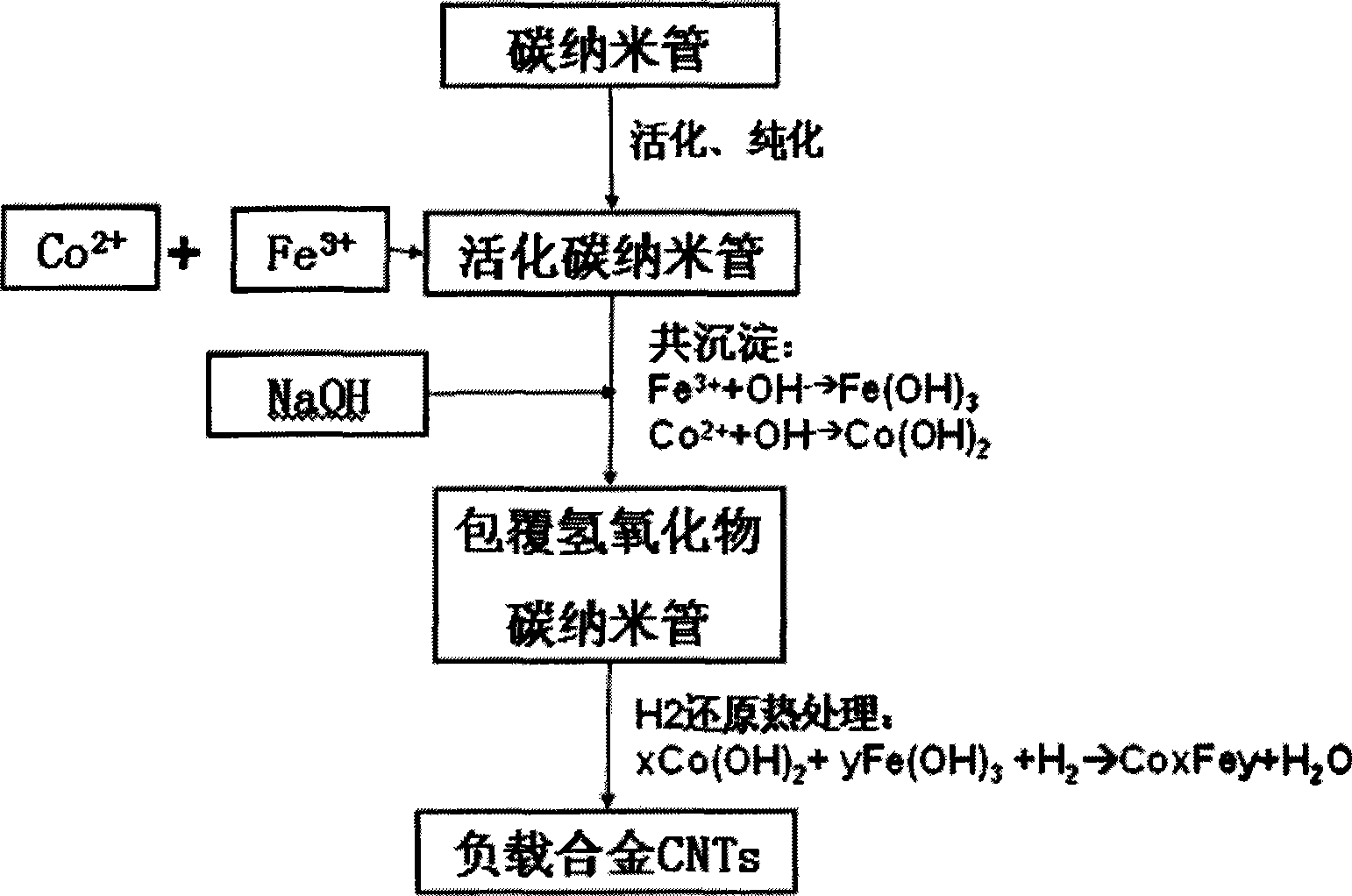

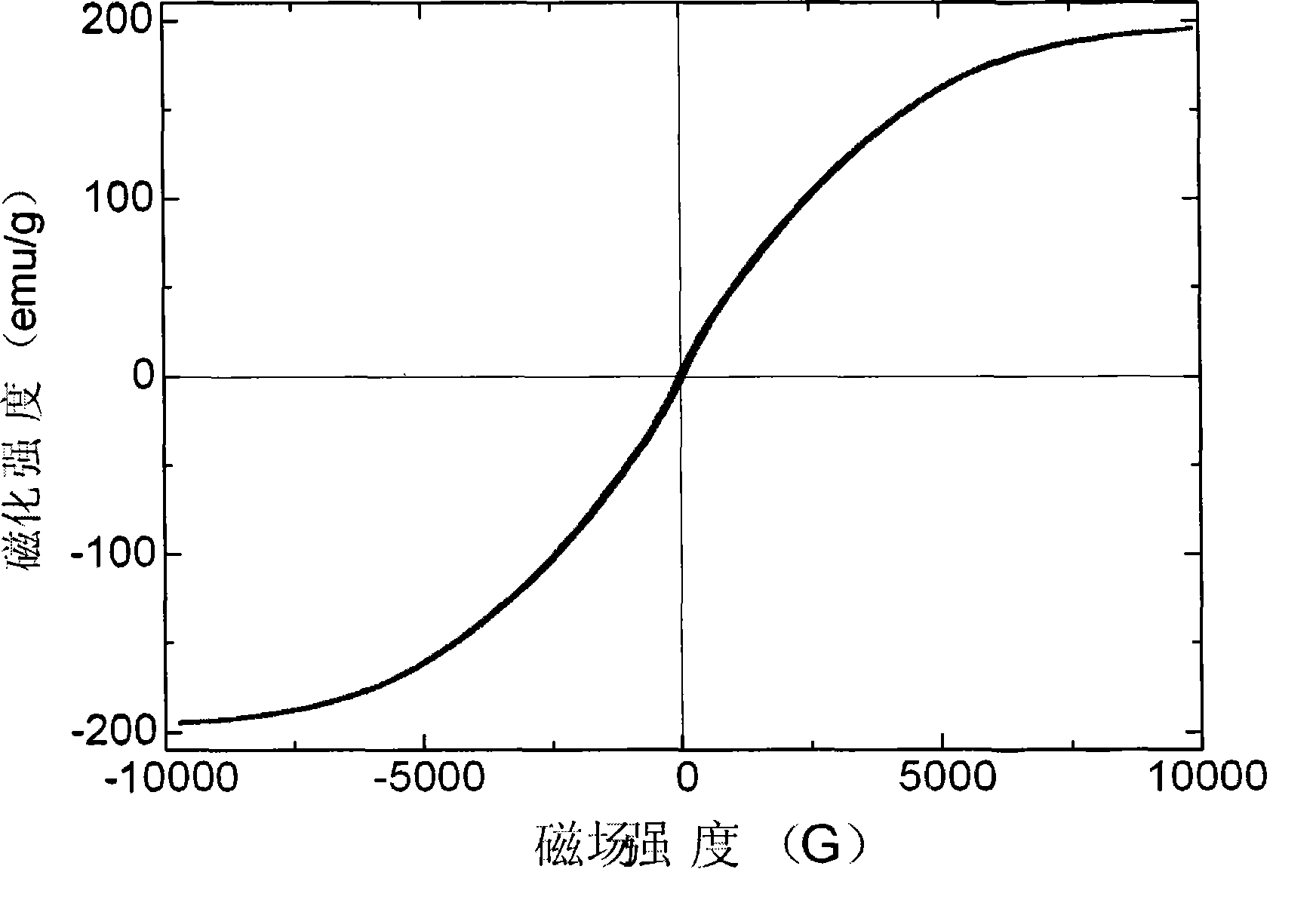

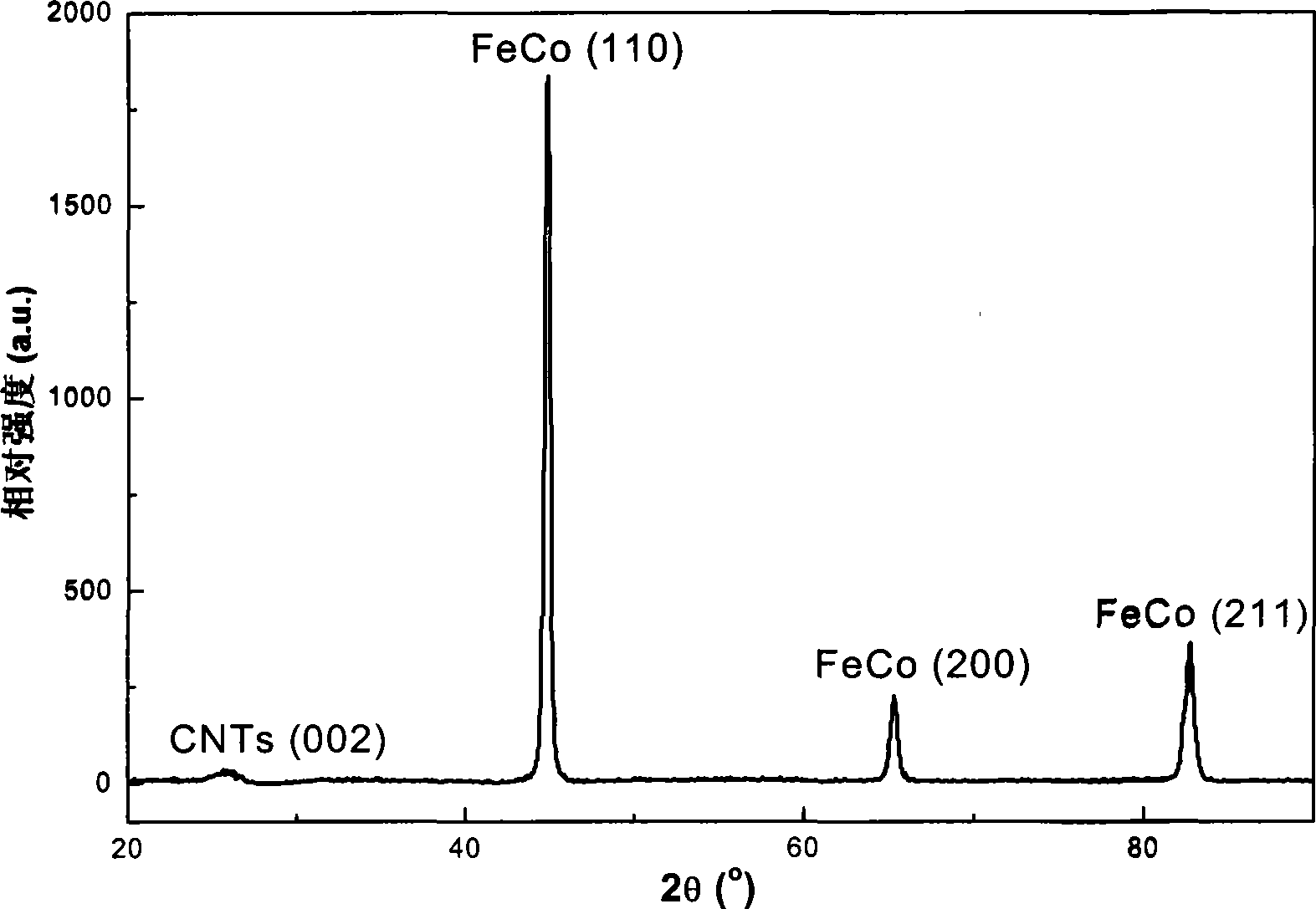

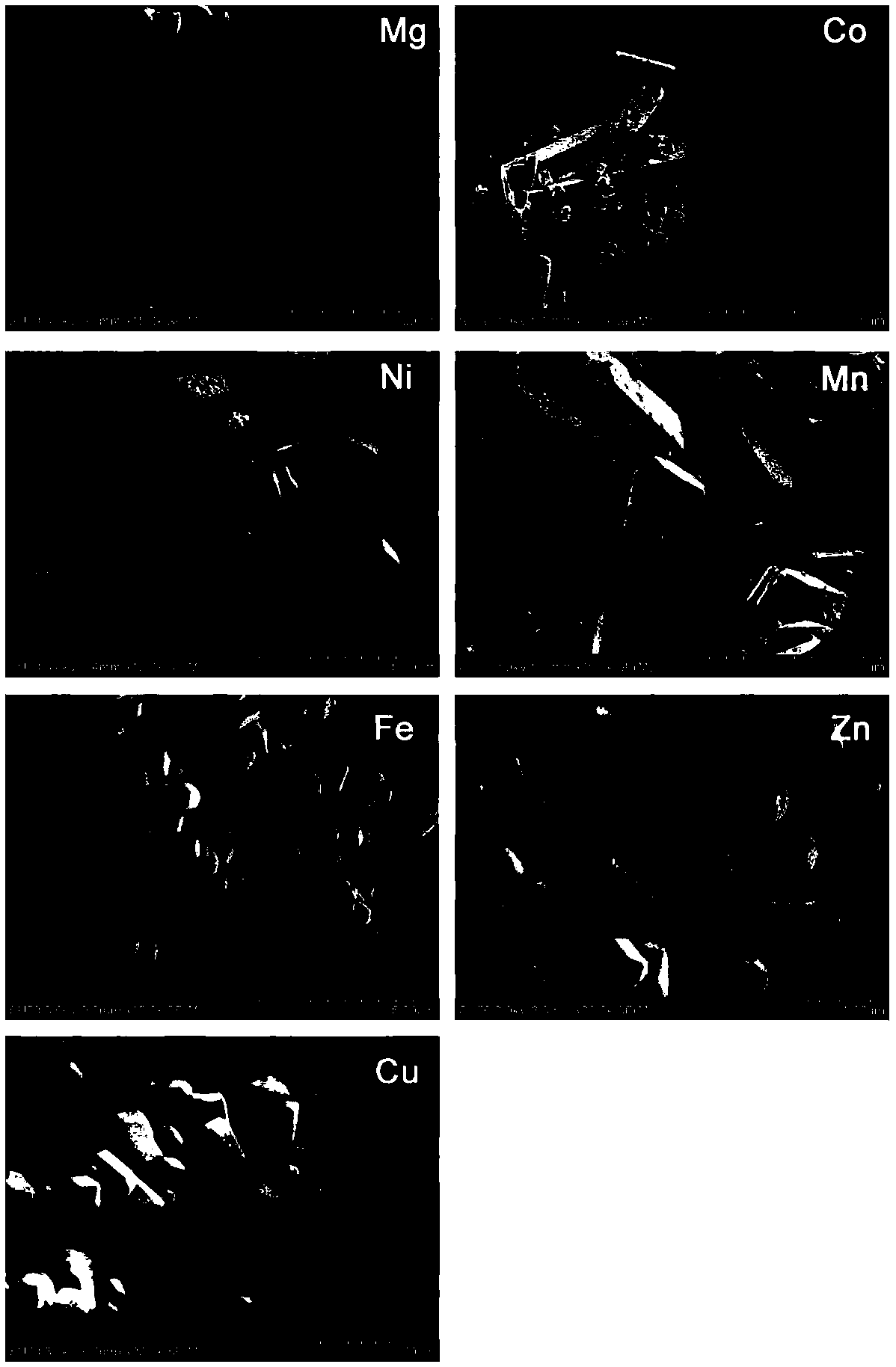

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

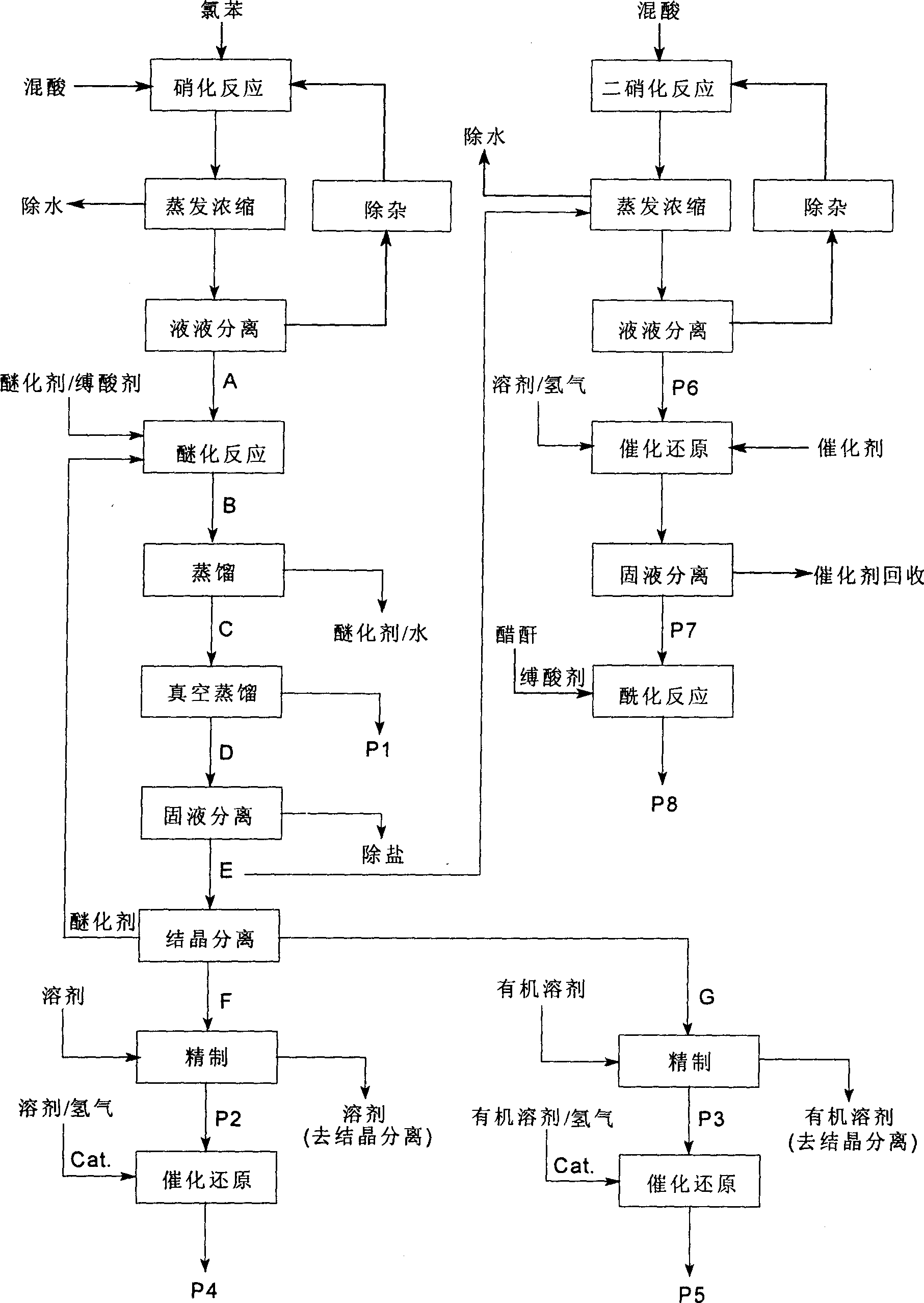

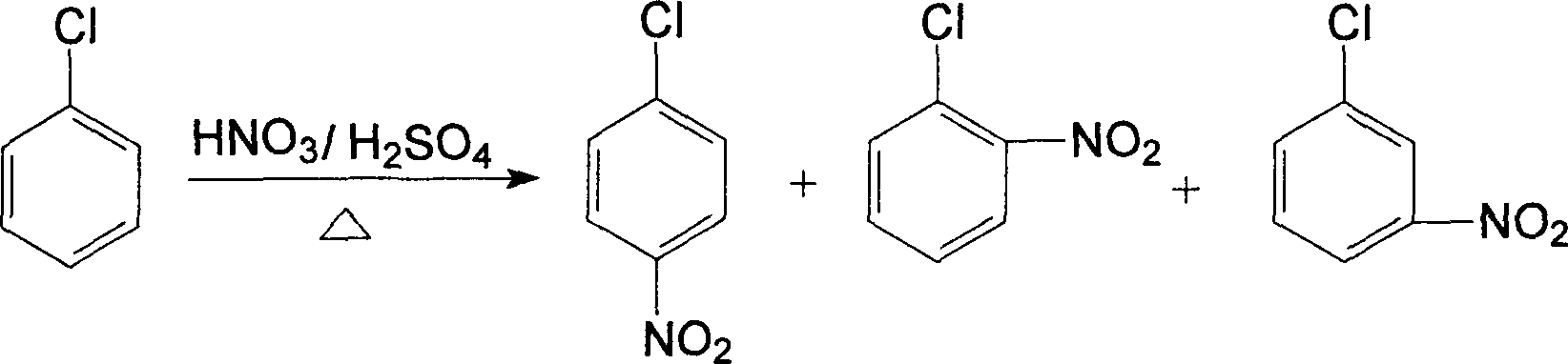

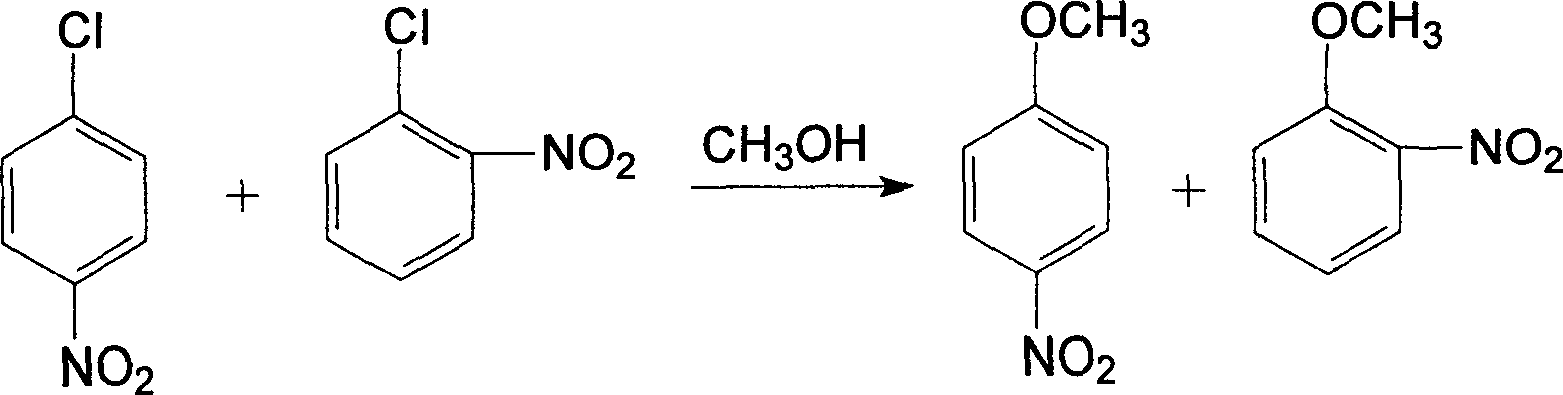

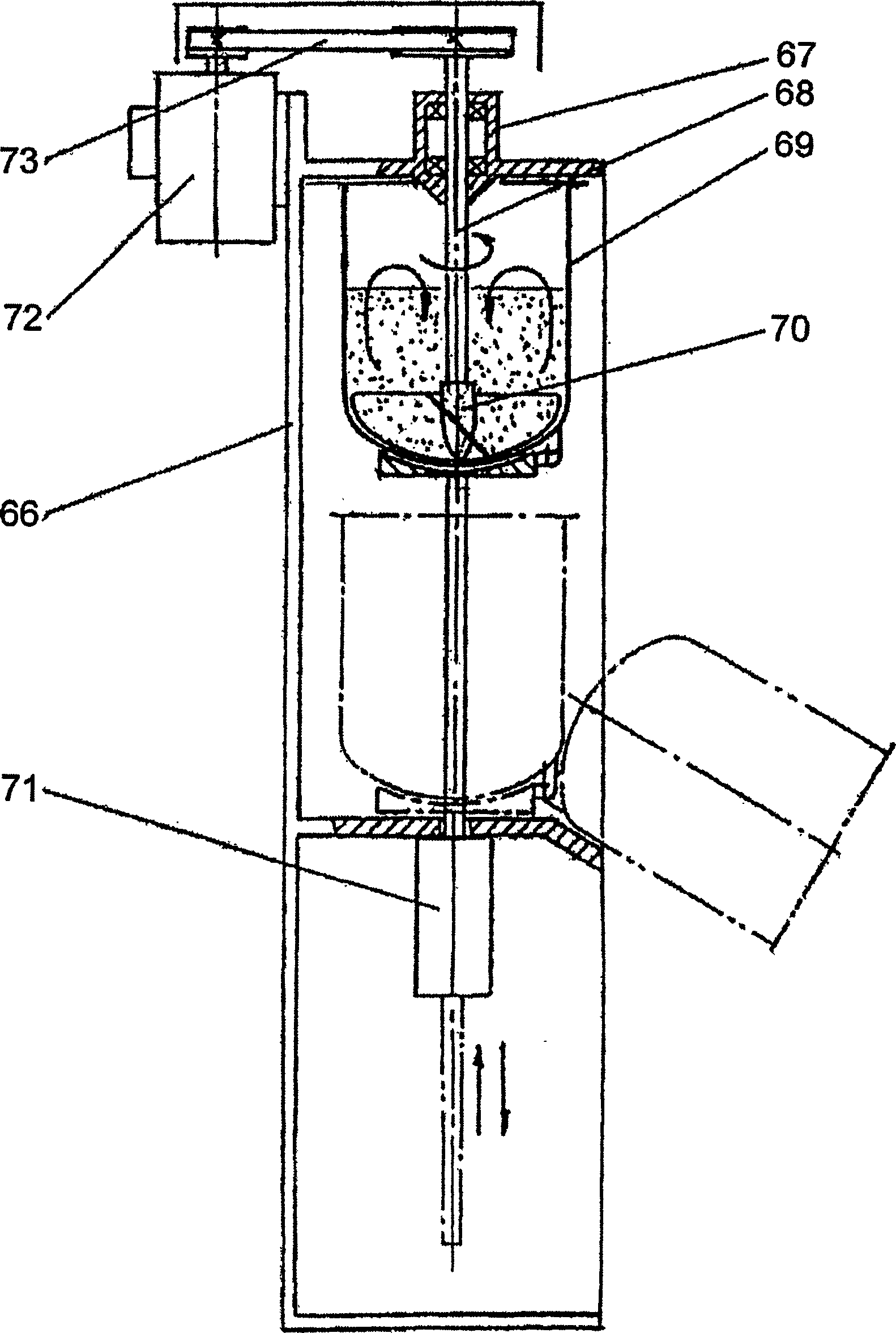

Process of producing nitrobenzether aminobenzether amidobenzether from chlorobenzene

InactiveCN1861562AAvoid conditionsAvoid investment in equipmentOrganic compound preparationCarboxylic acid amides preparationO-nitrochlorobenzeneChloride salt

A process for preparing nitrophenylether, aminophenylether and amidophenylether between chlorobenzene and acid mixture removing water, liquid-liquid separation to obtain organic phase consisting of o-, p- and meta-nitro chlorobenzene compounds, etherifying said mixture, recovering etherifying agent, vacuum distilling, separating and refining meta-nitro chlorobenzene, removing chloride salt generated in etherification, crystallizing separation, recrystallizing p- and o-nitro phenylether compounds, catalytic hydrogenating reaction, nitrifying reaction to obtain 2,4-drinitro phenylether, catalytic hydroreducing reaction to obtain 2,4-diamino phenylether, and aceylating reaction to obtain 2-amino-4-acetylamino phenylether.

Owner:CHANGZHOU JIASEN CHEM +1

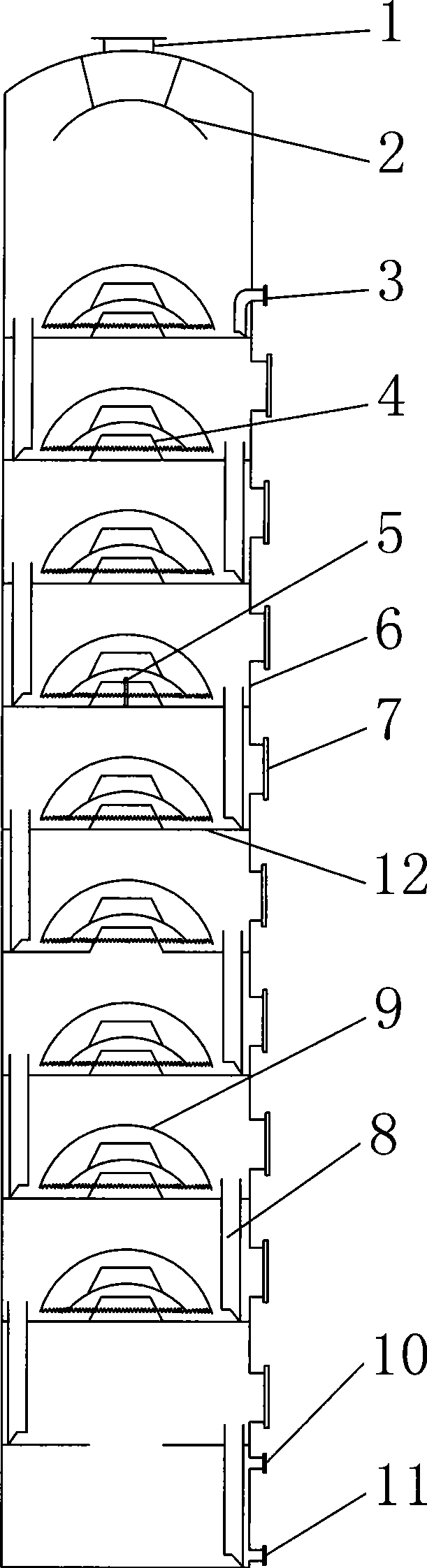

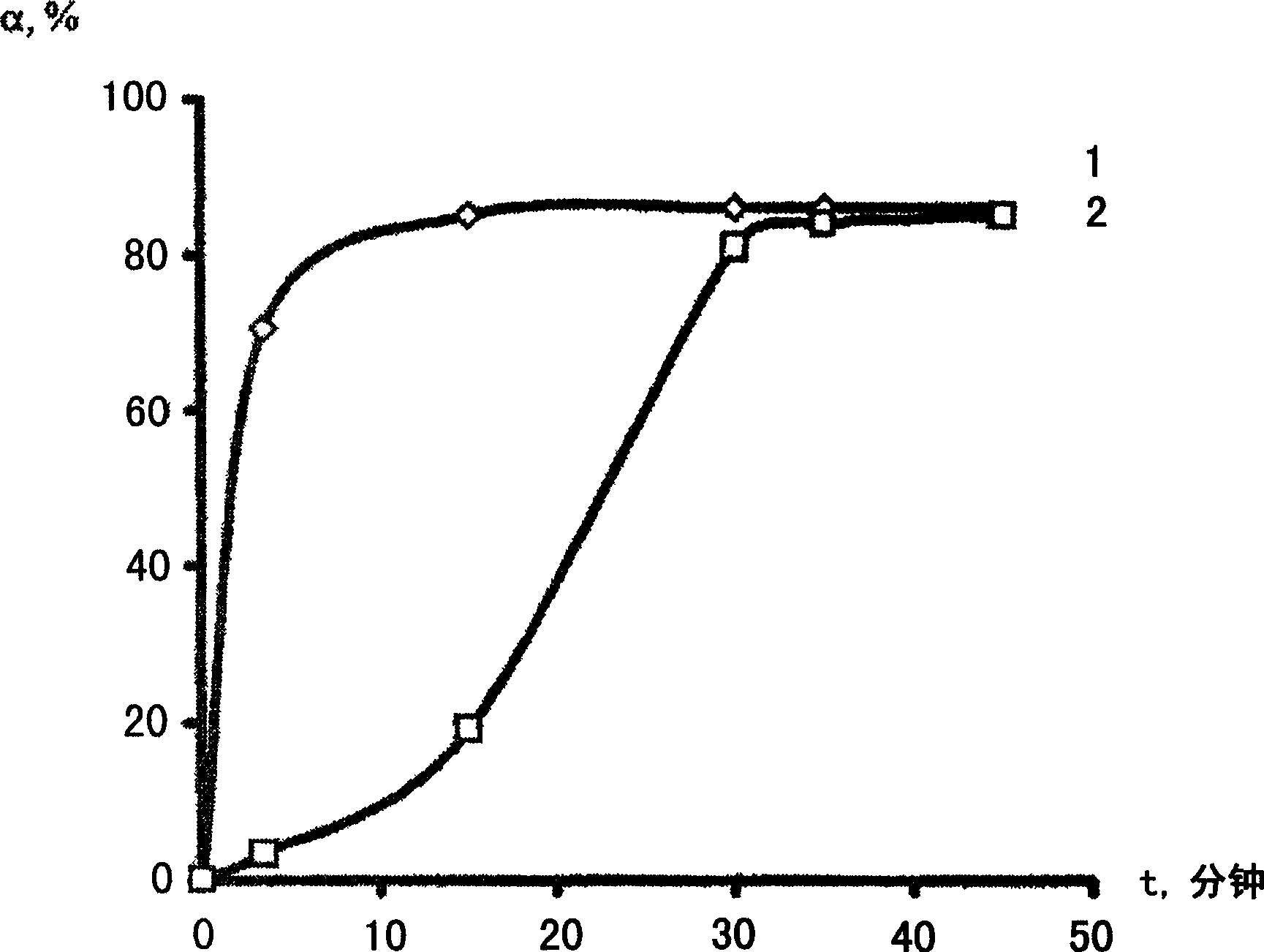

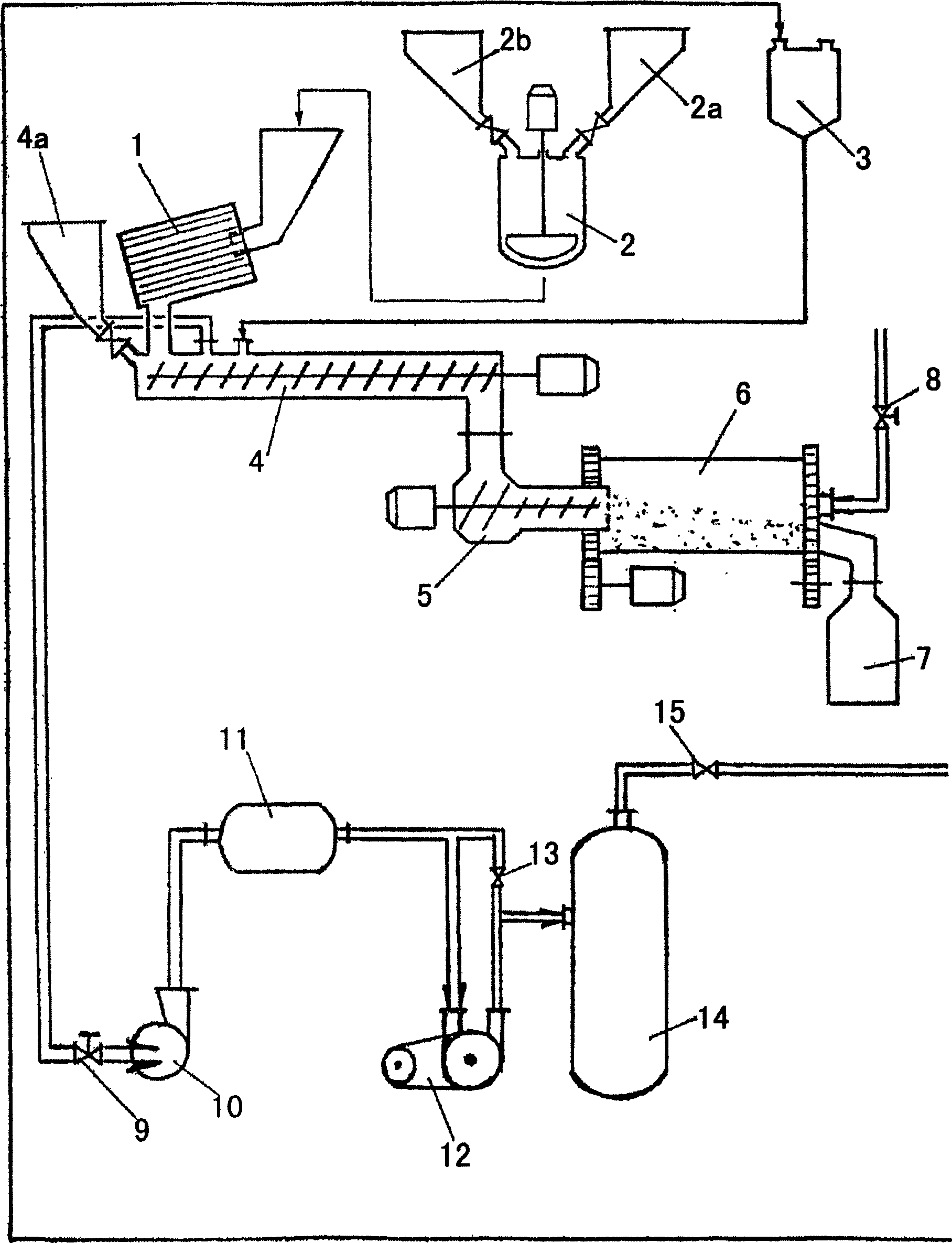

Method for producing granulated sorbents and installation for carrying out the method

The invention relates to a method for producing granulated sorbents, and to an installation for carrying out the method. The aim of the invention is to obtain the chloride form of the double hydroxide of aluminium and lithium as LiCL2AI / OH)3 nH2O (DHAL-CL) in a waste-free solid phase of aluminium hydroxide and lithium salts in a mixer, with subsequent continuous activation of crystalline DHAL-CI in a centrifugal mill activator in order to obtain a defectuous material structure. The product obtained is mixed with chlorinated polyvinyl chloride as a binding agent and with liquid methylene chloride. The granulation is carried out by extruding the paste produced and refining the same in the granulator. The methylene chloride produced is collected by an organic liquid absorbent having a high boiling point. The methylene chloride steam is guided out of the material flow in the carrier gas flow in the manner of an ideal displacement in the counter-current of the contact phases. The methylene chloride recuperation is carried out in two steps according to the thermal method, during the heating of the absorbent used. The inventive method is characterised by essentially reduced environmental impact in relation to prior art, due to the closed material circuits used. The granulated sorbent is especially suitable for the selective extraction of lithium from chloride salt lye of any mineralization, with an extraction degree of 95 %.

Owner:青海盐湖蓝科锂业股份有限公司

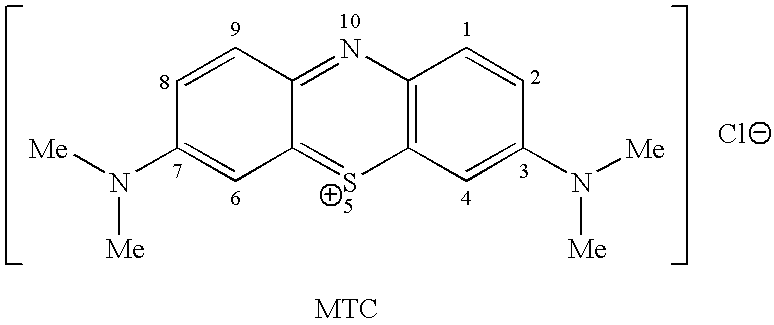

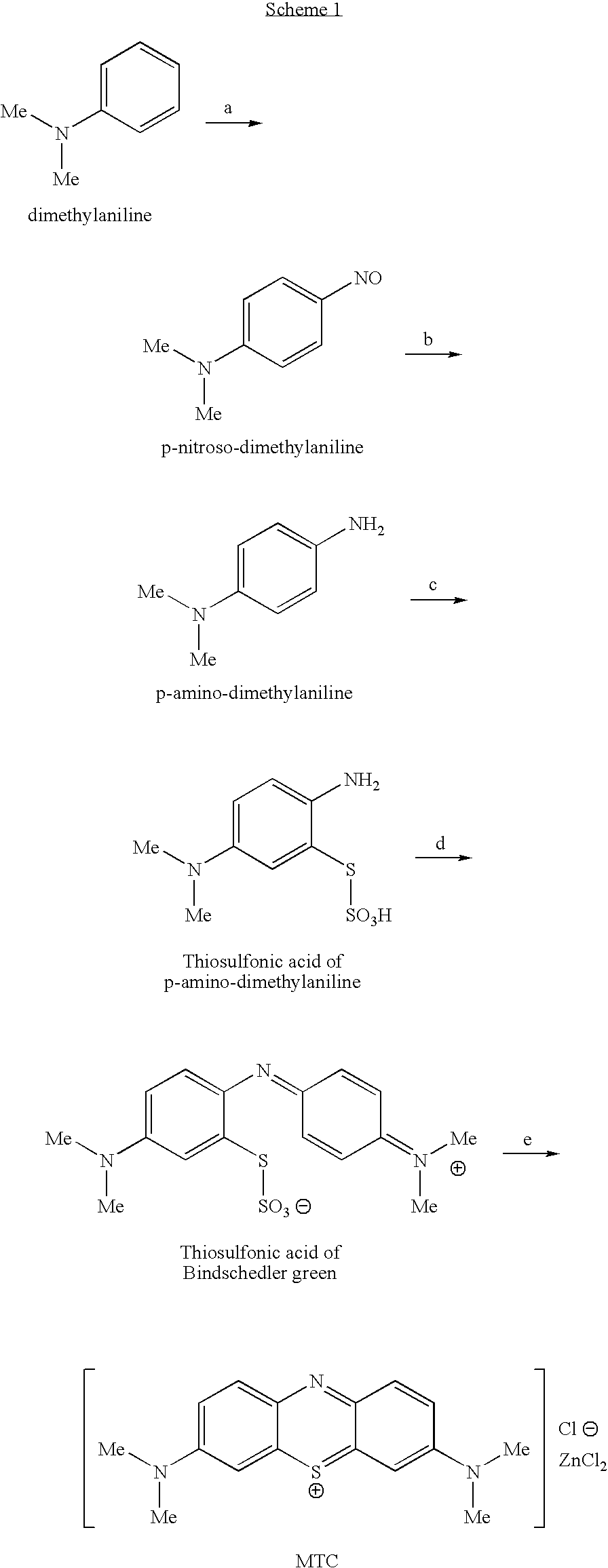

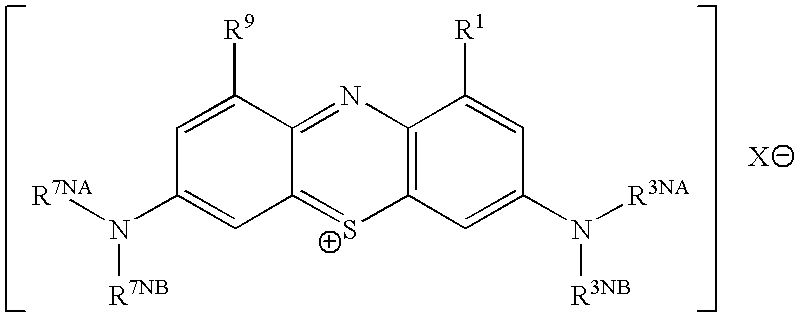

Methods of chemical synthesis and purification of diaminophenothiazinium compounds including methylthioninium chloride (MTC)

This invention pertains generally to the field of chemical synthesis and purification, and more specifically to methods of synthesizing and purifying certain 3,7-diaminophenothiazin-5-ium compounds (referred to herein as “diaminophenothiazinium compounds”) including Methythioninium Chloride (MTC) (also known as Methylene Blue). In one embodiment, the method comprises the steps of, in order: nitrosylation (NOS); nitrosyl reduction (NR); thiosulfonic acid formation (TSAF); oxidative coupling (OC); Cr(VI) reduction (CR); isolation and purification of zwitterionic intermediate (IAPOZI); ring closure (RC); chloride salt formation (CSF); one of: sulphide treatment (ST); dimethyldithiocarbamate treatment (DT); carbonate treatment (CT); ethylenediaminetetraacetic acid treatment (EDTAT); organic extraction (OE); and recrystallisation (RX). The present invention also pertains to the resulting (high purity) compounds, compositions comprising them (e.g., tablets, capsules), and their use in methods of inactivating pathogens, and methods of medical treatment and diagnosis, etc., for example, for tauopathies, Alzheimer's disease (AD), skin cancer, melanoma, viral diseases, bacterial diseases, or protozoal diseases.

Owner:WISTA LAB LTD

Environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, preparation method and use method thereof

ActiveCN103508570AEffective corrosion inhibitionAvoid corrosionScale removal and water softeningPhosphomolybdic acidBenzoic acid

The present invention provides an environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, a preparation method and a use method thereof, and relates to the field of chemistry. The corrosion inhibitor has characteristics of high efficiency, low cost, low toxicity and environmental protection, and is prepared through carrying out mixing stirring dissolving on 5-50% of a benzotriazole substance, 1-10% of benzoic acid and a salt thereof, 1-10% of molybdate, tungstate, phosphomolybdic acid and a salt thereof, and phosphotungstic acid and a salt thereof, 2-20% of an alcohol amine substance, 1-10% of an acid phosphate, 1-10% of a gluconate, 1-10% of an alkaline regulator, 1-10% of an oxygen scavenging agent and the balance of water. According to the present invention, the potassium dichromate or the sodium nitrite with high toxicity, and the non-environmental protection high phosphorus and high zinc can be replaced, and corrosion of calcium chloride salt water on carbon steel and copper can be significantly inhibited when the concentration of the corrosion inhibitor is 0.3-0.5%.

Owner:CHAOYANG GUANGDA CHEM

Electropolishing solution and methods for its use and recovery

InactiveUS20040050715A1Machining working mediaElectrolysis componentsHydrofluoric acidRecovery method

An electrolyte solution containing an alkylene glycol and a chloride salt is useful for electropolishing metal substrates. An electropolishing method using the electrolyte solution is effective for polishing a varied of metals, including titanium and noble metals. The method avoids the handling and disposal challenges associated with previous methods using etching solutions containing hydrofluoric acid. A method of recycling the spent electrolyte solution is also described.

Owner:GENERAL ELECTRIC CO

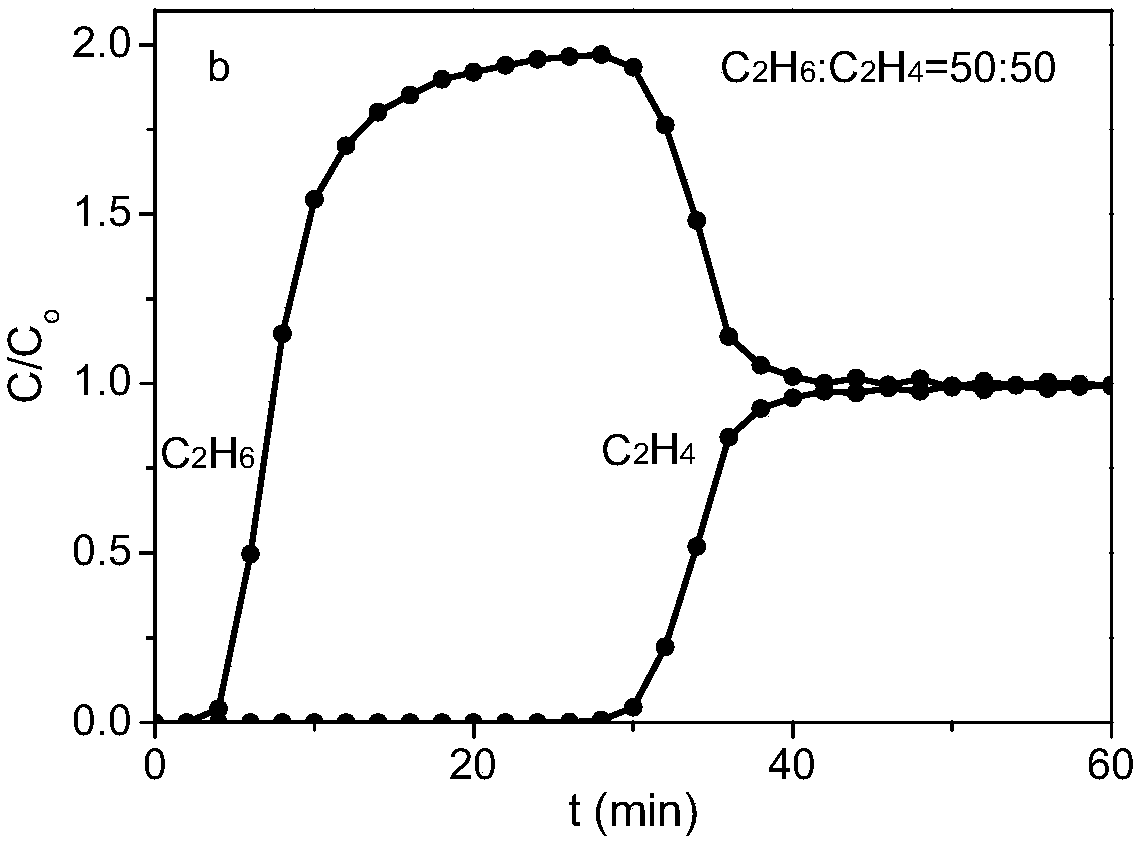

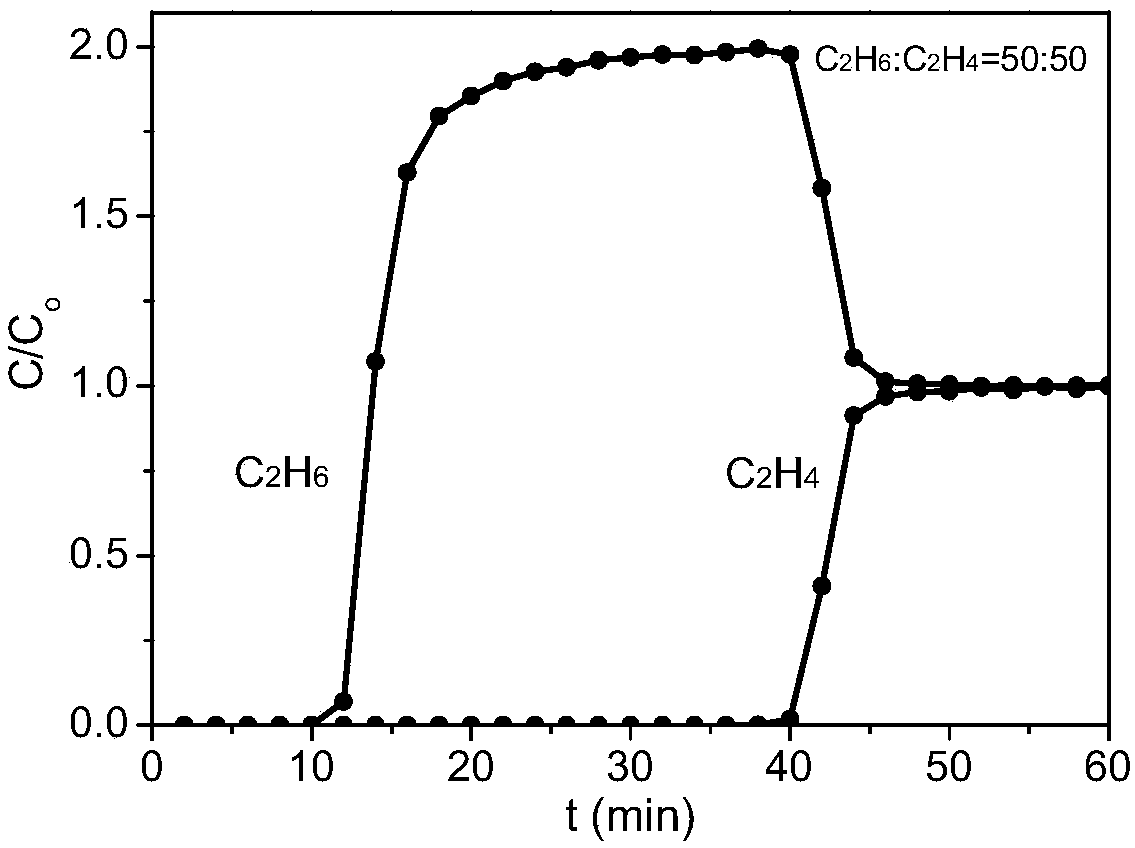

Metal organic frame material for separating ethane and ethylene and separation method of ethylene and ethane

ActiveCN108014752AStable structureImprove performanceOrganic chemistryOrganic compound preparationGallic acid esterAlkaline earth metal

The invention discloses a metal organic frame material for separating ethane and ethylene and a separation method of the ethylene and the ethane .The metal organic frame material has the advantages ofgood stability, high adsorption capacity, good adsorption and separation selectivity, simple preparation method and low preparation cost. The general structural formula of the metal organic frame material is M(C7O5H4).2H2O, wherein M is a metal ion, and the structure of the metal organic frame material is a three-dimensional network structure formed from a transition metal ion or an alkaline earth metal ion and gallic acid through coordinate bonds or intermolecular forces. A preparation method is as follows: (1) an inorganic salt, the gallic acid, an alkali, and deionized water are mixed according to a ratio, stirred and dissolved, and then put into a reaction kettle for hydrothermal reaction; the inorganic salt is a chloride salt, a nitrate salt, an acetate, a carbonate, a sulphate or aperchlorate of the metal ion; and (2) after the end of the hydrothermal reaction, the deionized water and absolute ethanol are in turn used for washing, and vacuum drying is performed. The metal-organic frame material is used as an adsorbent to perform adsorption separation of a mixed gas containing the ethylene and the ethane.

Owner:ZHEJIANG UNIV

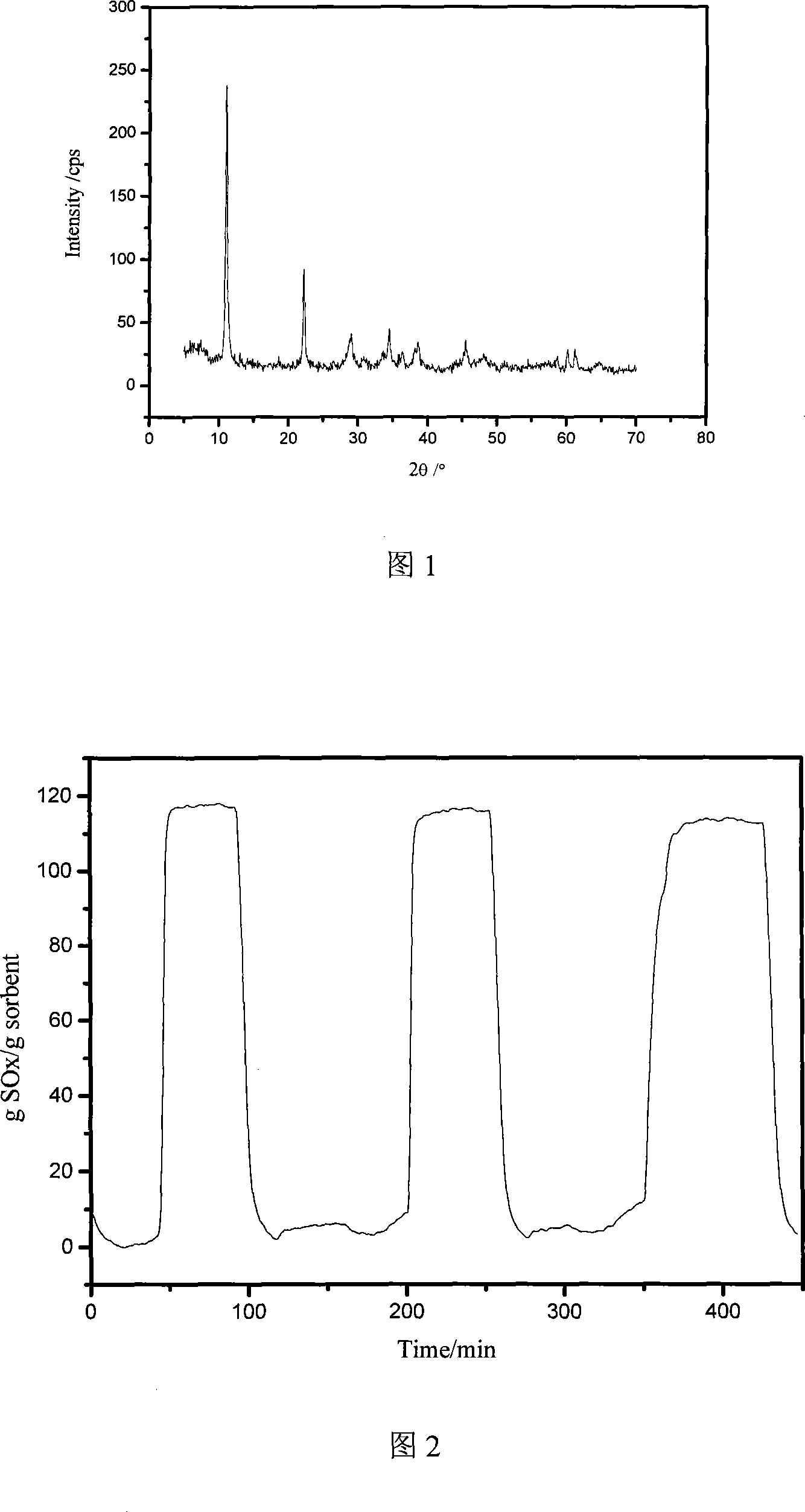

Catalytic cracking regeneration flue gas sulphur transfer agent and preparation method thereof

The invention discloses a catalytic cracking recycling flue gas sulfur transfer agent and a preparation method, and is characterized in that the sulfur transfer agent is obtained by first forming a high built content serosity that takes MgO and pseudo-boehmite as active group component, takes chlorate of zinc, iron, and cerium as oxidation and reduction promoter, and takes sodium hydroxide as general precipitant, and then anion clay is thermally compounded by water with high temperature, finally, the anion clay is filtered, washed, dried, and roasted. The invention has the advantages that: (1) the serosity has high built content and is beneficial to improving compounding efficiency of the anion clay and reducing discharge of waste water; (2) harmful contamination in the waste water can be avoided by adopting the material of the invention to prepare the anion clay, thus being in favor of the environmental protection; (3) the obtained FCC recycling flue gas sulfur transfer agent has highly efficient SO< X > absorbing and desorbing properties.

Owner:EAST CHINA NORMAL UNIVERSITY

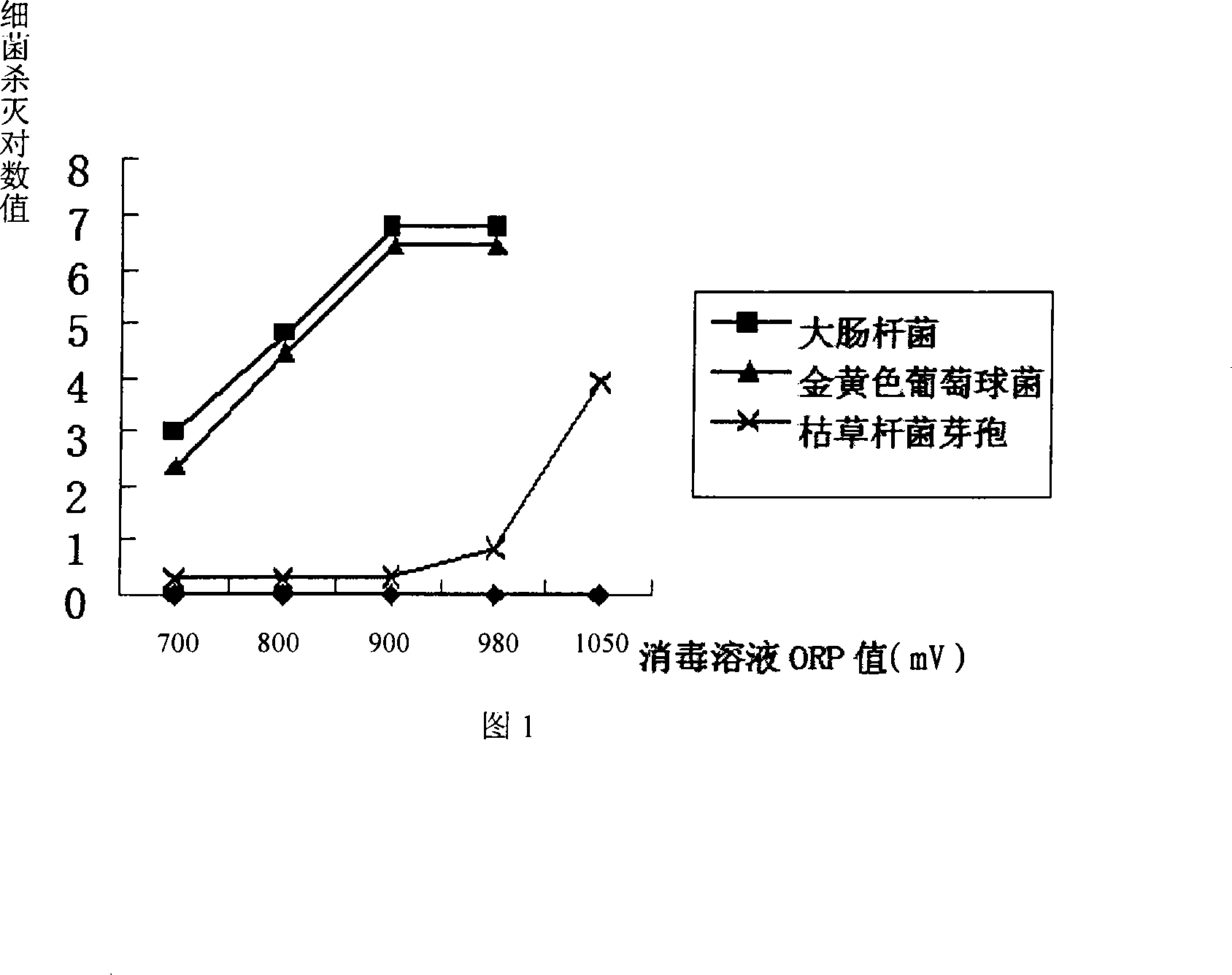

Disinfection effervescence tablet capable of continuously generating high oxidation-reduction potential

InactiveCN101233851AReduce concentrationAvoid disadvantagesBiocideDisinfectantsSide effectIrritation

The invention relates to a disinfectant effervescent tablet which can generate continuously high redox potential. The disinfectant effervescent tablet comprises the following components by weight portions: 4-8 portions of inorganic chloride salt, 8-12 portions of organic acid, 3-5 portions of one or more selected from carbonate, sodium bisulfate and hydroxylamine hydrochloride, 1-2 portions of stabilizing agent and 1-2 portions of corrosion inhibitor. The disinfectant effervescent tablet also comprises 1-2 portions of synergistic agent. An effervescent tablet of 1g / tablet is put in water and completely dissolved in 5-10 minutes to obtain 100ml-1,000ml solution; pH value of the dissolved solution is 3-7; redox potential is 800-1,200mv and concentration of available chlorine is 1000-3,000mg / L. The disinfectant of the invention is put in water; the inorganic chloride salt reacts with the organic acid to generate hypochlorous acid, nascent state chlorine, nascent state oxygen and high redox potential which interact with each other so as to greatly improve the bactericidal function; when in use, the consentration of available chlorine falls below 280ppm, which reduces side effects such as residue and irritation. The disinfectant effervescent tablet is a monobasic solid tablet, overcomes the shortcomings existing in liquid disinfectant and binary packing disinfectant, and improves largely convenience of use.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

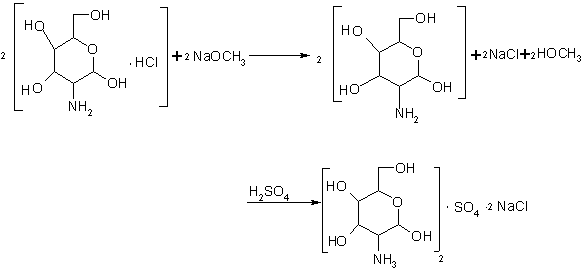

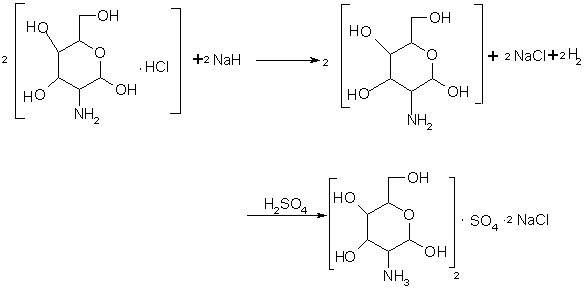

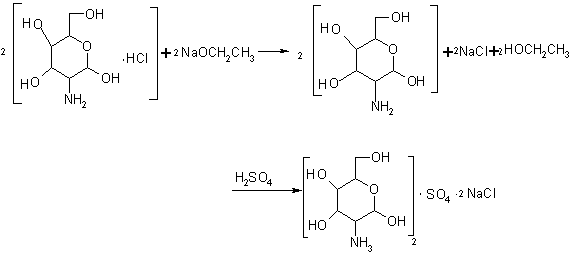

Preparation method of D-glucosamine sulfate sodium chloride salt

ActiveCN102850412AHigh purityNovel methodSugar derivativesSugar derivatives preparationChloride saltNitrogen

The invention discloses a preparation method of D-glucosamine sulfate sodium chloride salt. The preparation method comprises the following steps of: dissolving D-glucosamine hydrochloride in a solvent; adding a sodium-containing alkaline substance into the obtained solution at the temperature of minus 40-100 DEG C, or adding the sodium-containing alkaline substance into the obtained solution under the protection of one or more protective gas(s) of nitrogen, carbon dioxide and inert gases; adding the sodium-containing alkaline substance into the mixed solution at the maintained temperature of minus 40-90 DEG C; adding sulfuric acid into the obtained solution at the temperature of minus 25 to 90 DEG C for salifying; carrying out complexation reaction to obtain a D-glucosamine sulfate sodium chloride salt complex; and filtering and crystallizing to obtain the D-glucosamine sulfate sodium chloride salt solid. The method is novel and unique and simple and reasonable in technology, product quality is good and purity is high, and completely reaches the standard of United States patent (USP) 34 edition pharmacopeia.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

Hot dipping plating assistant agent containing fluoro-carbon surfactant

InactiveCN101555577AGood compatibilityGood workmanshipHot-dipping/immersion processesIodideAmmonium chloride mixture

The invention provides a hot dipping plating assistant agent containing a fluoro-carbon surfactant, which belongs to the technical field of surface plating process of steel materials. A compounded fluoro-carbon surfactant is added in plating assistant agents which take zinc chloride, or zinc chloride and ammonium chloride as the main part, to improve the coating effect of the plating assistant agent and the wetting property of the plating assistant agent which contacts with zinc-based molten metal. The method comprises the steps: nonionic N-propyl, N-ethoxyl perfluorooctylsulfonyl amide and cationic perfluorooctanosulfonyl quaternary iodide are mixed to form a compounded fluoro-carbon surfactant, and then the compounded fluoro-carbon surfactant is blended with water solution which takes zinc chloride, or zinc chloride and ammonium chloride as the main part to form the hot dipping plating assistant agent containing the fluoro-carbon surfactant. The addition level of the compounded fluoro-carbon surfactant in the hot dipping plating assistant agent containing the fluoro-carbon surfactant is 0.1 to 10 g / L, wherein the mass fraction of the perfluorooctanosulfonyl fluoride quaternary iodide accounts for 5 to 90 percent, and the rest are N-propyl and N-ethoxyl perfluorooctylsulfonyl amide. The operation temperature and the plating assistant drying temperature are equal with that during the plating assistant process of the traditional zinc chloride and zinc chloride salt system plating assistant agent. The hot dipping plating assistant agent has the advantages that the preparation operation of the plating assistant agent is simple, the wetting effect of the surface of a steel finished piece in zinc liquid is good after plating, the uniformity of the plating layer can be improved, the plating leakage ratio is reduced, and the use level of the chlorine salt in the plating assistant agent can be also reduced.

Owner:KUNMING UNIV OF SCI & TECH

Process for the production of hcl gas from chloride salts and for the production of carbohydrates

InactiveUS20110178290A1Weak acidImprove hydrophilicityChlorine/hydrogen-chloride purificationPhosphatesChloride saltWater insoluble

A process for the co-production of gaseous HCl and a salt product comprising a cation and an anion, which process comprises the steps of a. providing an aqueous solution comprising protons, chloride anions, and cations and anions of the salt product, b. bringing the solution into contact with a substantially immiscible extractant, the extractant comprising: 1) an oil soluble amine, which amine is substantially water insoluble both in free and in salt form; and 2) a carrier solvent for the amine; whereupon HCl selectively transfers to the extractant to form an HCl-carrying extractant and a chloride depleted aqueous solution containing the salt product; c. separating the HCl-carrying extractant from the chloride-depleted aqueous solution; and d. distilling HCl from the separated HCl-carrying extractant to form gaseous HCl and HCl depleted extractant.

Owner:VIRDIA

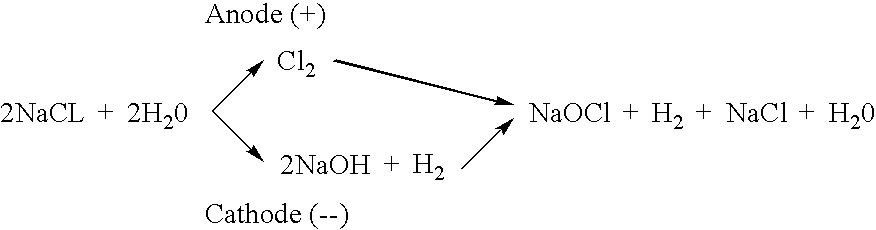

Process for producing hypochlorite

InactiveUS20070007146A1Reduce power consumptionImprove current efficiencyMultiple component coatingsHypochloriteChloride salt

In a process for producing sodium hypochlorite in an electrolytic cell comprises forming an aqueous based chloride solution with a chloride salt; controlling the concentration of chloride within the solution to an amount comprising less than 25 g / L chloride salt; piping the salt solution to the electrolytic cell, the electrolytic cell comprising an anode and a cathode, the cathode comprising a metallic base material, a first coating on the metallic base material and a second non-conductive ceramic coating on the metallic base material. The chloride solution is then in contact with the anodes and cathodes and an electric current is sent throughout the electrolytic cell to produce hypochlorite. During this process the electric current is controlled so that the power consumption is less than 2.5 kWh per pound of hypochlorite produced and the resulting cell efficiency comprises less than 2.5 kg of chloride salt consumed for every 1 kg of hypochlorite generated.

Owner:SEVEN TRENT WATER PURIFICATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com