Catalytic cracking regeneration flue gas sulphur transfer agent and preparation method thereof

A technology of sulfur transfer agent and flue gas regeneration, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of containing toxic and harmful metal vanadium, difficulty in filtering and washing, and small particle size of products, so as to achieve high-efficiency SOx Adsorption and desorption performance, beneficial to environmental protection, and the effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

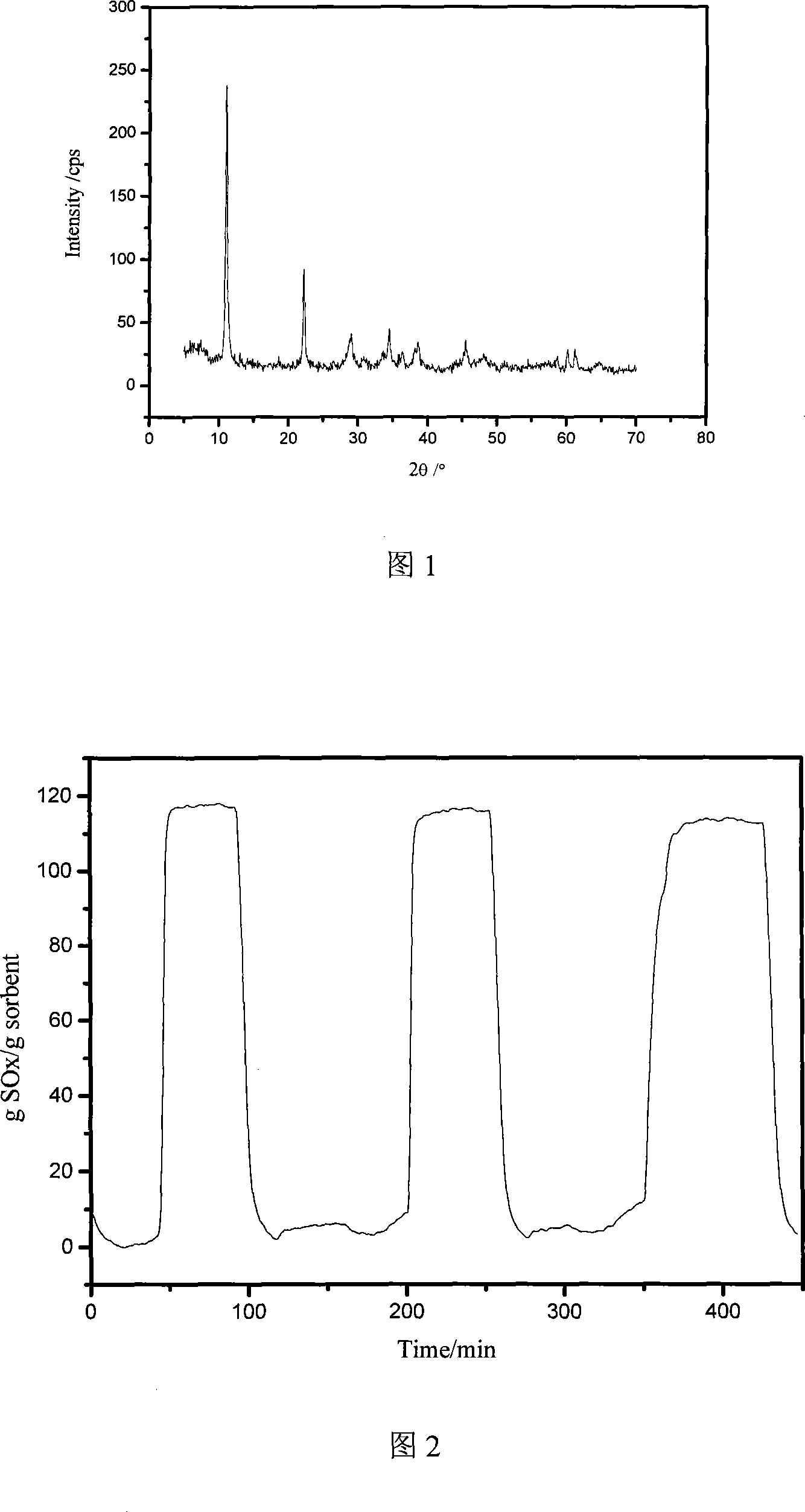

Image

Examples

Embodiment 1

[0025] Add 480.0g of MgO and 320.0g of pseudo-boehmite mixture into 3000g of deionized water at 80°C under stirring conditions, and continue stirring for 60min to obtain slurry A; 64.0g of ZnCl 2 , 144.4gFeCl 3 ·6H 2 O, 176.3 g CeCl 3 ·6H 2 Add O to 1000g of water to obtain slurry B; add slurry B dropwise to slurry A under strong stirring for 1.5 hours; after the dropwise addition, adjust the pH value of the solution to 10 with saturated NaOH solution and continue stirring After 10 hours, slurry C (solid content: 28.8%) was obtained; slurry C was statically crystallized at 80° C. for 24 hours. Then cool, filter with suction, wash until neutral, dry at 80°C for 12 hours, and roast the obtained sample at 850°C for 3 hours to obtain sulfur transfer agent S1.

Embodiment 2

[0027] Add 24.0g of MgO and 16.0g of pseudo-boehmite (above 300 mesh) into 200g of deionized water at 100°C under stirring conditions, and continue stirring for 30min to obtain slurry A; mix 3.6g of ZnCl2, 7.2g of FeCl 3 ·6H 2 O, 8.8g CeCl 3 ·6H 2 O was added to 40g of water to obtain slurry B; under strong stirring, the slurry B was added dropwise to the slurry A, and the dropping time was 0.5h; after the dropwise addition, the pH value of the solution was adjusted to 9 with a saturated NaOH solution, and the stirring was continued for 4h , to obtain slurry C (solid content: 24.3%); slurry C was statically crystallized at 80°C for 24h. Then cool, filter with suction, wash until neutral, dry at 100°C for 10 hours, and roast the obtained sample at 650°C for 6 hours to obtain sulfur transfer agent S2.

Embodiment 3

[0029] Add 24.0g of MgO and 16.0g of pseudo-boehmite (above 300 mesh) into 200g of deionized water at 100°C under stirring conditions, and continue stirring for 30min to obtain slurry A; add 3.6g of ZnCl 2 , 7.2g FeCl 3 ·6H 2 O, 8.8g CeCl 3 ·6H 2 Add O to 70g of water to obtain slurry B; add slurry B dropwise to slurry A under strong stirring for 0.5h; after the dropwise addition, adjust the pH value of the solution to 12 with saturated NaOH solution and continue stirring for 6h , to obtain slurry C (solid content: 20.0%); slurry C was statically crystallized at 150°C for 24h. Then cool, filter with suction, wash until neutral, dry at 100°C for 6h, and roast the obtained sample at 700°C for 5h to obtain sulfur transfer agent S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com