Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1974results about How to "High synthesis efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

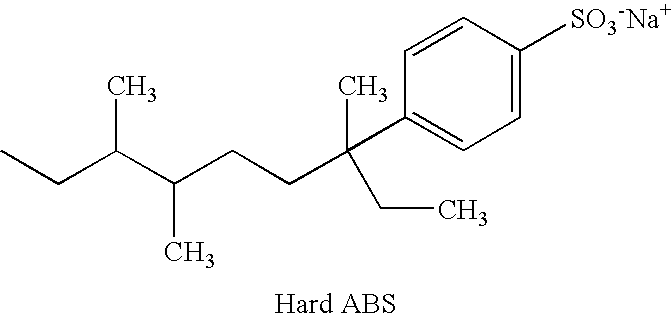

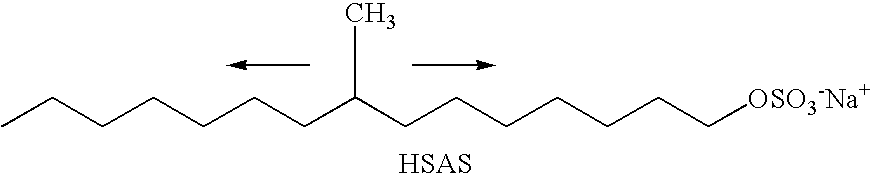

Specific Branched Aldehydes, Alcohols, Surfactants, and Consumer Products Based Thereon

ActiveUS20100137649A1Promote degradationImprove solubilityOxygen-containing compound preparationPreparation by oxo-reaction and reductionHydrogenAlcohol

A process for preparing a detergent alcohol mixture comprising the steps of providing one or more poly-branched poly-olefins, wherein the poly-branched poly-olefins must contain one non-branched terminal olefin and one or more additional branched olefins in the molecule; hydroformylating said poly-branched poly-olefins to produce a poly-branched olefin containing aldehyde product with one or more olefins or mixture thereof; reducing the aldehyde product of step (b) in the presence of hydrogen and a hydrogenation catalyst to form a poly-branched detergent alcohol mixture; and removing said poly-branched alcohol mixture from said catalyst and branched aldehydes, alcohols and surfactants produced from the products of this process.

Owner:PROCTER & GAMBLE CO

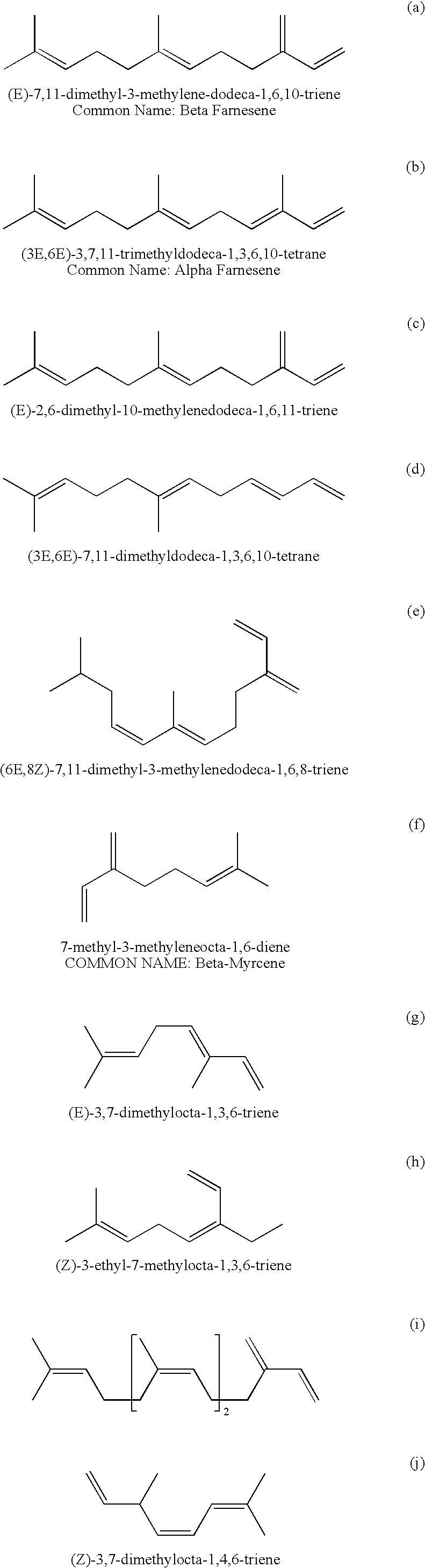

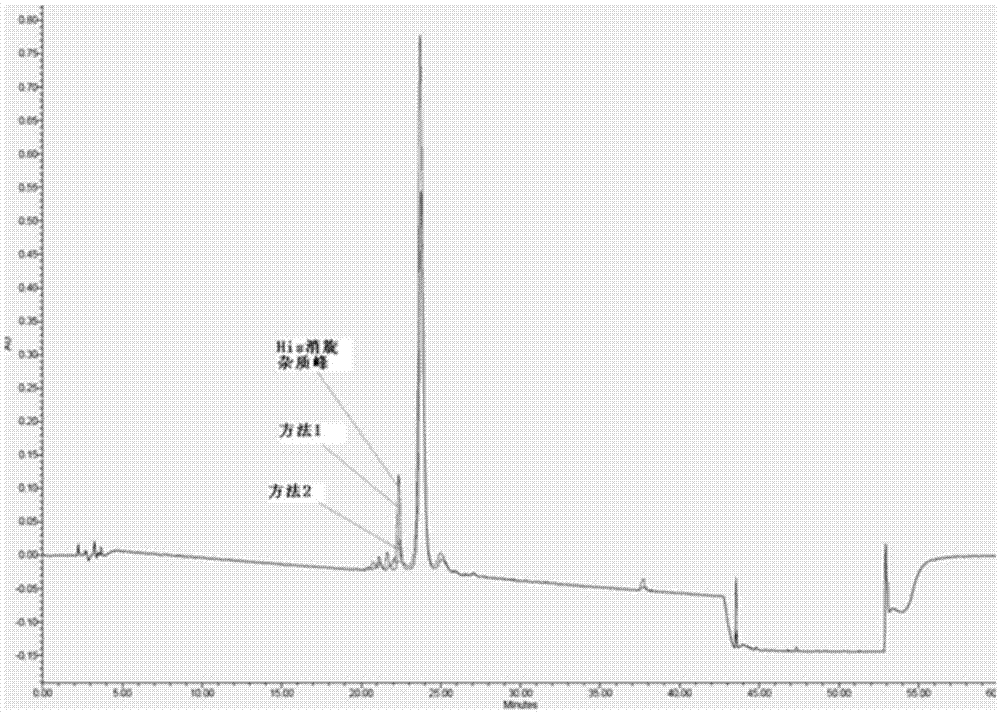

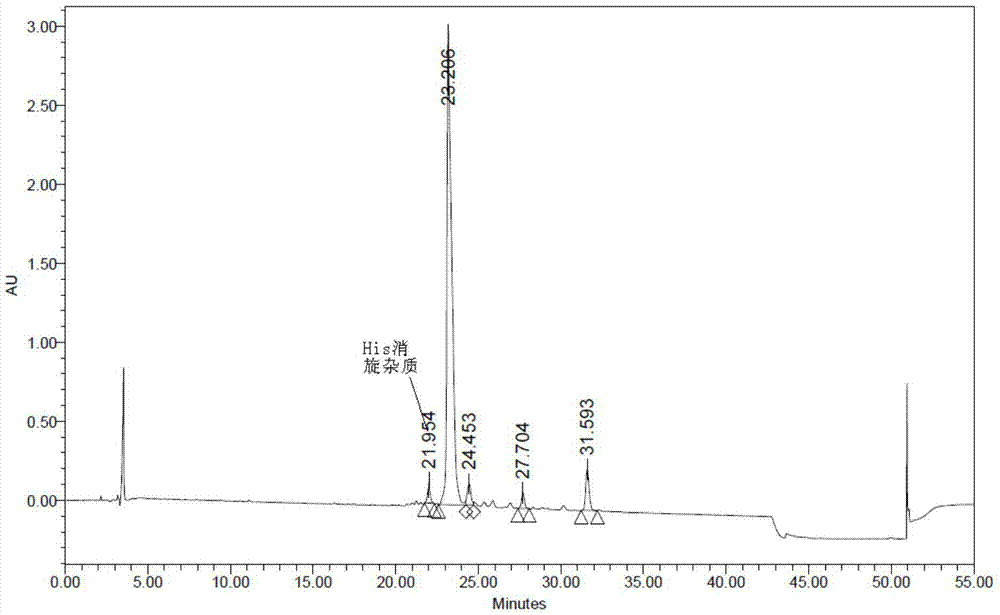

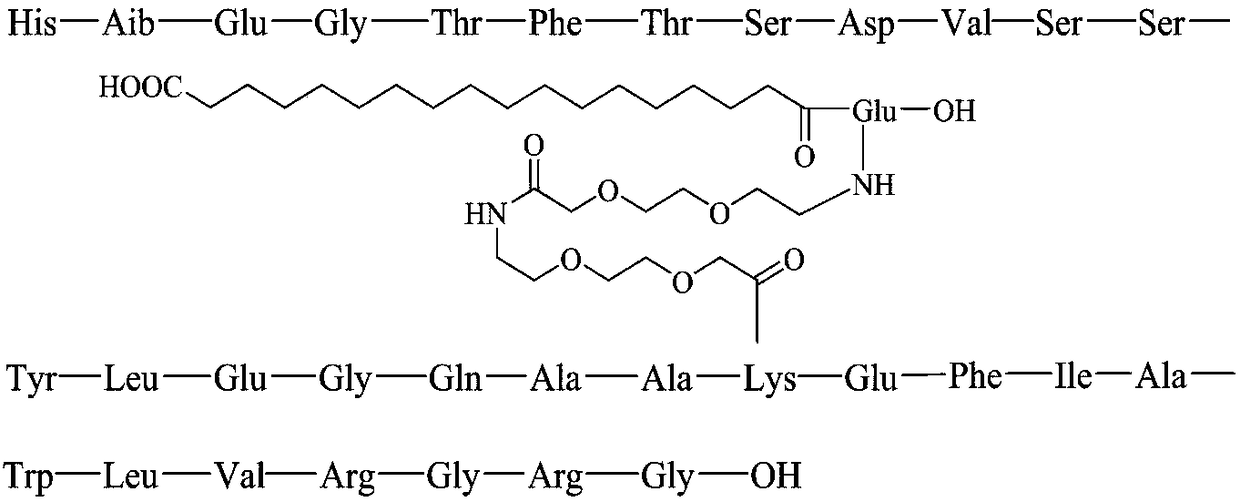

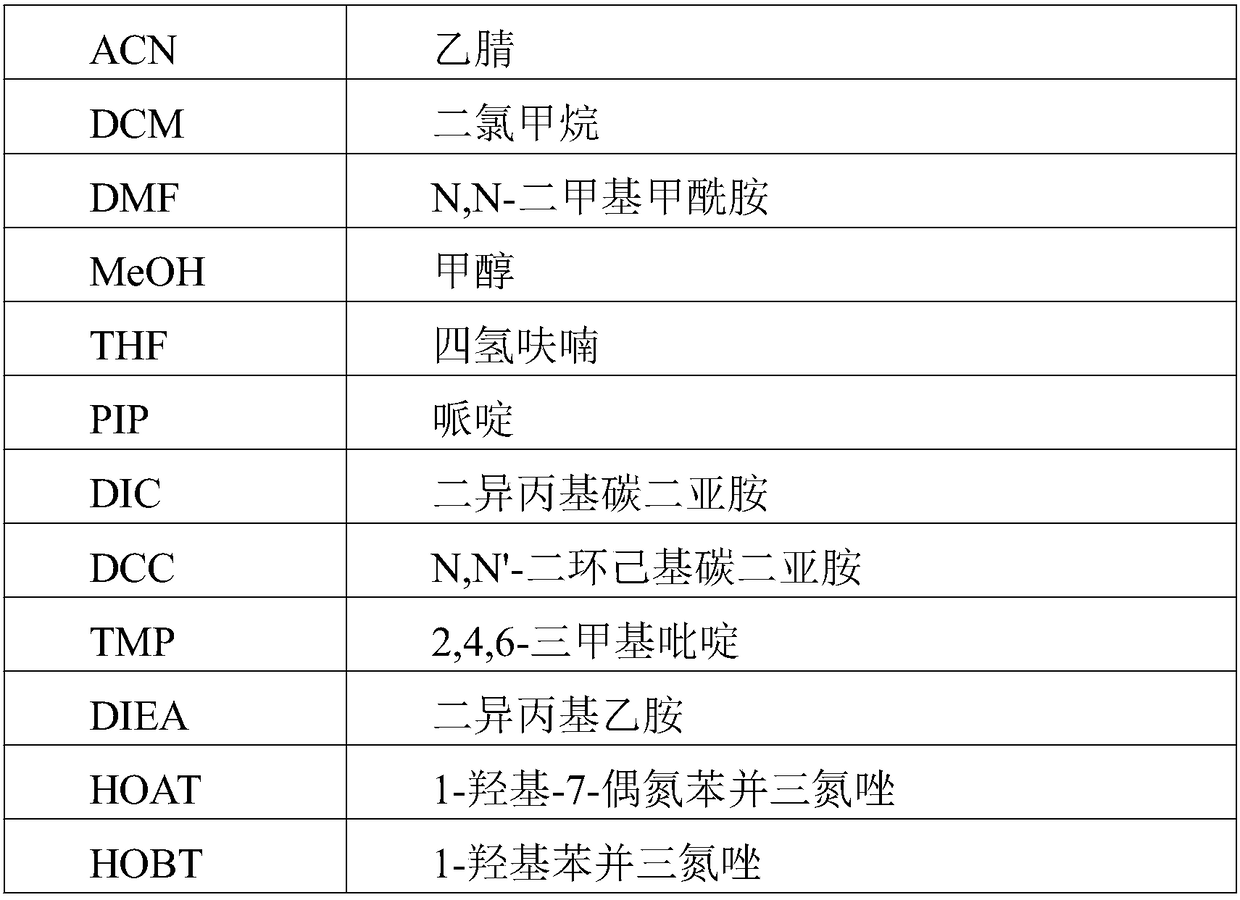

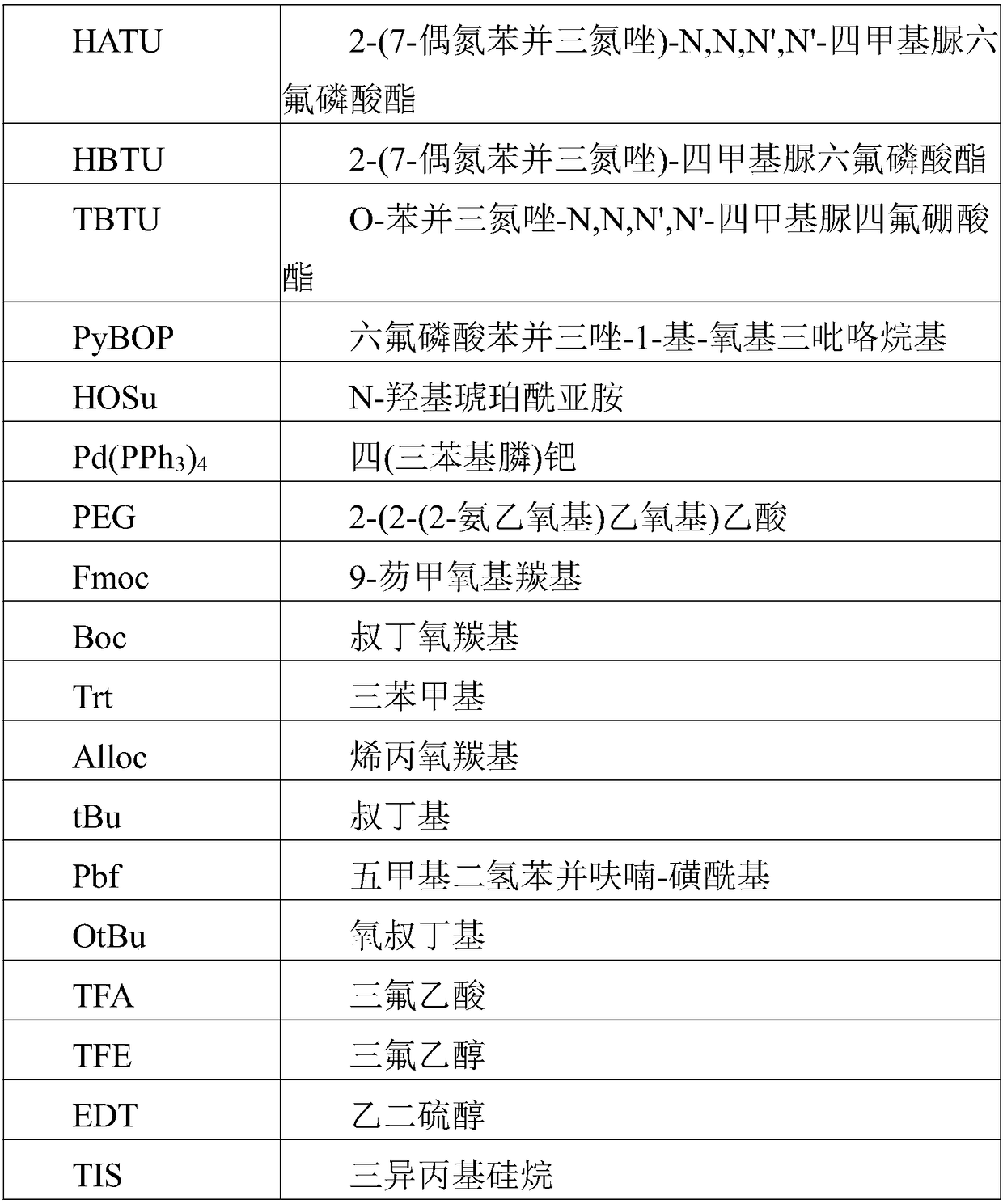

Method for preparing semaglutide

InactiveCN106928343AEasy to operateNo side effectsPeptide-nucleic acidsPeptide preparation methodsSide reactionSemaglutide

The invention relates to the field of polypeptides, in particular to a method for preparing semaglutide. The method has the advantages that Fmoc-Lys (Alloc)-OH protection amino acid is used as a raw material, de-protection is carried out by the aid of selected Pd (PPh3) 4, accordingly, operation procedures are simple, only 1-2 times of simple elimination reaction operation are required, each elimination reaction operation is carried out for 10-30 min, side reaction is prevented, the operation procedures are safe, and enlarged production can be facilitated; Boc-His (Boc)-OH. DCHA and Boc-His (Trt)-OH are used as raw materials in the procedures, and accordingly His racemization risks can be reduced to the greatest extent; special fragments are coupled, and accordingly the synthesis efficiency can be improved.

Owner:HYBIO PHARMA

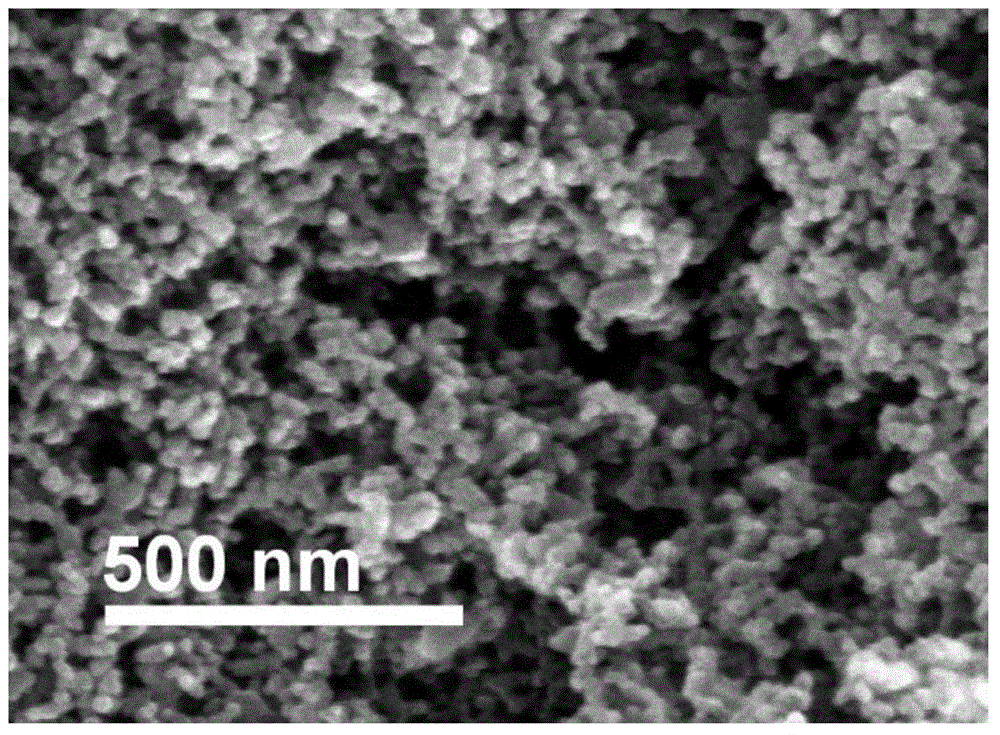

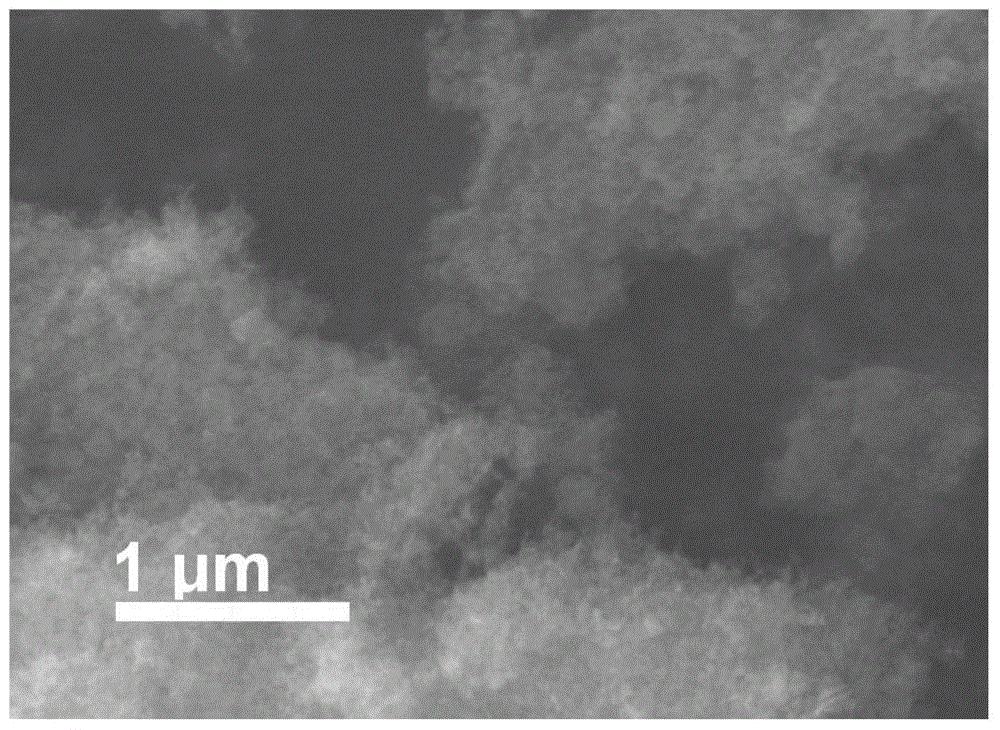

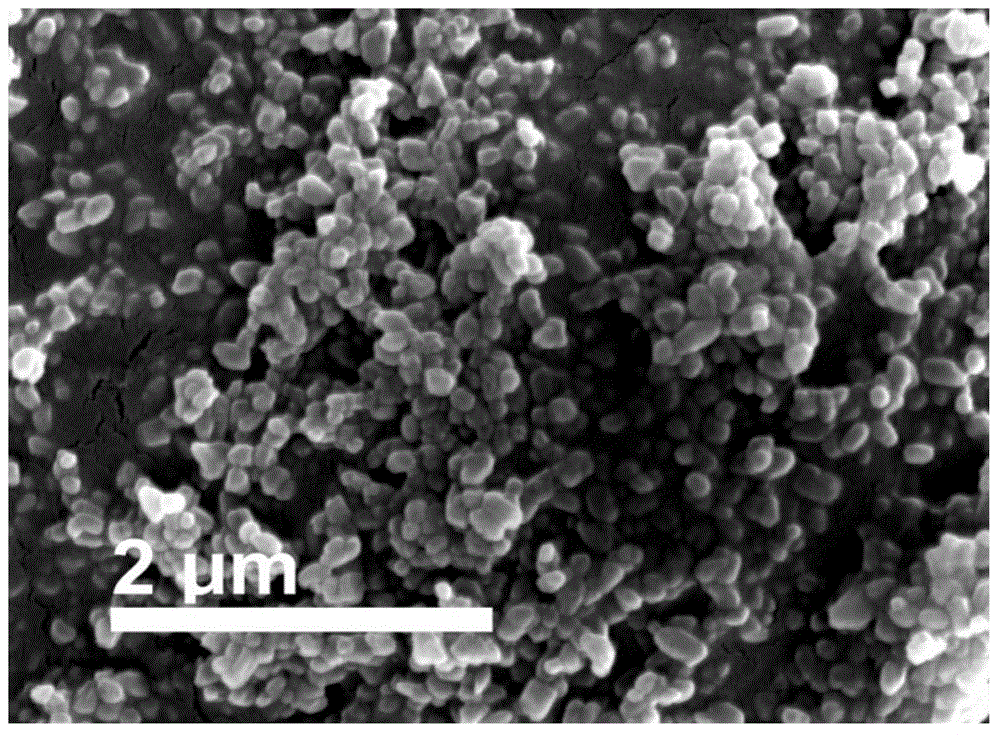

Preparation method and application of porous nano metal organic framework material

ActiveCN104892518AIncrease surface areaLarge hole volumeMaterial nanotechnologyOther chemical processesSulfurMetal-organic framework

The invention aims to provide a preparation method and application of a porous nano metal organic framework material, and is characterized in that the preparation method comprises the steps: adding a metal ion, an organic ligand, a surfactant and a nanocrystalline guide agent or a reagent forming the nanocrystalline guide agent into a growth medium, forming a framework structure through chemical complexation, crystallizing, filtering, washing, drying, and finally obtaining the porous nano metal organic framework material. The addition amount of the surfactant is 0-30% of the molar concentration of the metal ion; the metal ion is one or more of Cu<II>, Al<III>, Mg<II>, Fe<III>, Ni<II>, Co<II> and Zn<II>; the organic ligand has at least one atom independently selected from oxygen, sulfur and nitrogen and can be subjected to coordinated complexation to the metal ion through the atom. The method not only can effectively suppress the size of MOFs materials, but also easily improves size homogeneity and synthetic efficiency of the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method and device for shooting panorama and electronic device

ActiveCN103176347AEasy to operateImprove experienceTelevision system detailsColor television detailsComputer graphics (images)Computer vision

The invention provides a method and device for shooting a panorama and an electronic device. The method includes the following steps: rotating a shooting device in a first direction, and simultaneously detecting rotating angles of the shooting device; recording the rotating angles of the shooting device in the first direction and controlling the shooting device to shoot a plurality of first images whenever the rotating angles exceed a preset threshold; and when the shooting device finishes rotating in the first direction, splicing the plurality of shot first images according to the recorded rotating angles in the first direction so as to generate the panorama in the first direction. According to the embodiment of the method, panorama combination is conducted on a plurality of images by recording the rotating angles through the shooting device, a precise panorama can be obtained without a complex combining algorithm, combining efficiency of the panorama is improved, and a scene image of different rotating angles can be shot through a single shooting device. The cost is low, operation is simple and easy to conduct, and user experience is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Self-adaptation camouflage design method based on background

InactiveCN104318570AHigh synthesis efficiencyQuality assuranceImage analysisTexturing/coloringCluster algorithmSelf adaptive

The invention discloses a self-adaptation camouflage design method based on a background. According to the method, on the basis of a texture synthesis algorithm based on pixels, a whole camouflage image is synthesized pixel by pixel; in the synthesis process, a self coding algorithm is adopted to extract a texture primitive containing background sample complete texture features, and a neighborhood of the pixels to be synthesized is determined; by means of the neighboring correlation principle and a helix supplement search mechanism, a neighborhood matched with a target pixel neighborhood is searched for in a background sample; similarity matching is carried out through a pixel and texture similarity matching rule, pixels in the neighborhoods which are most similar in the sample are selected to serve as synthesis pixels, pixels of a target image are synthesized according to the sequence of scanning lines, and after synthesis, color quantization is carried out on the image by means of the clustering algorithm to generate a final camouflage image. By means of the method, similar camouflage images can be synthesized quickly according to the background, and the application aim of quickly camouflaging a target in a self-adaptation mode can be achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for preparing TS-1 molecular sieve

ActiveCN101134575ASynthesis speedHigh synthesis efficiencyCrystalline aluminosilicate zeolitesMolecular-sieve compoundsMolecular sieveTitanium

The TS-1 molecular sieve preparing process features that surfactant is added into the mother liquid for synthesizing the molecular sieve, so that most of the silicon source and titanium source after hydrolysis agglomerate into solid grains. After the solid grains are filtered out and crystallized, the filtrate containing small amount of residual silicon source and titanium source is used as the alkali source for hydrolyzing the newly added silicon source and titanium source for synthesizing the next batch of molecular sieve. The process has greatly reduced environmental pollution, lowered preparation cost and raised synthesizing efficiency and benefit.

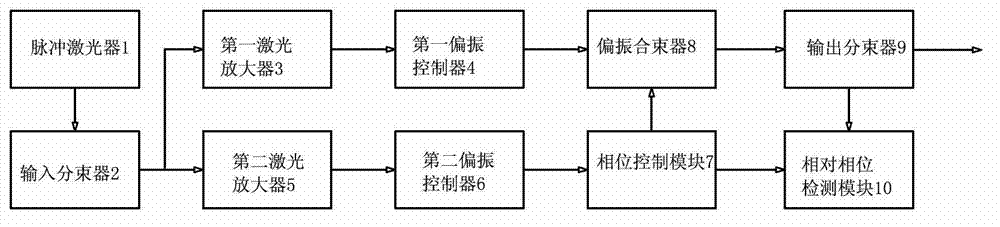

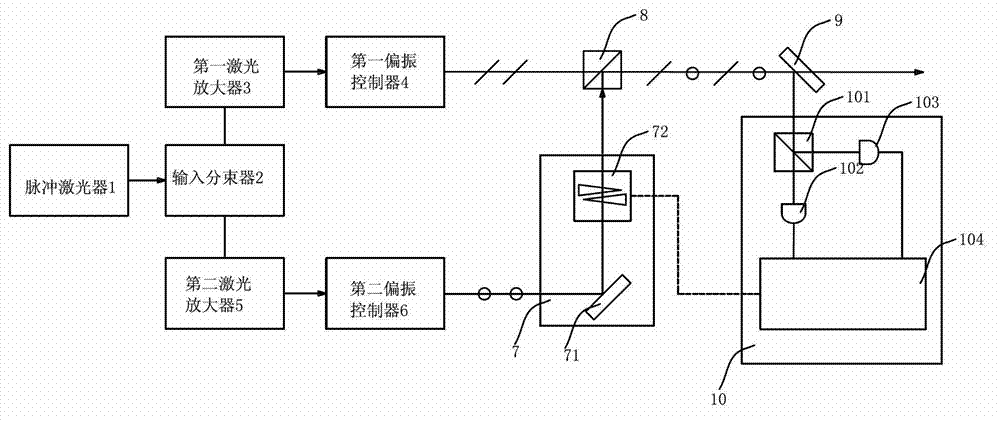

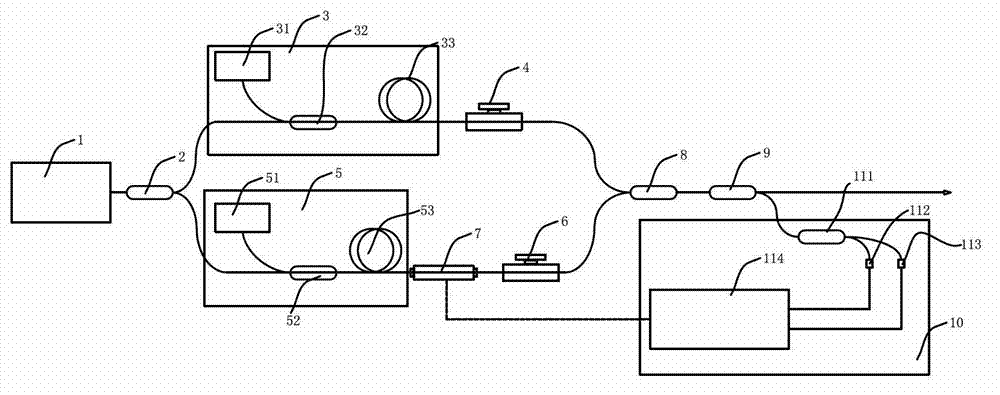

Polarization beam-combination device for pulsed laser

InactiveCN103033944AAchieve coaxial synthesisHigh synthesis efficiencyLaser detailsCoupling light guidesBeam splitterOptoelectronics

The invention discloses a polarization beam-combination device for a pulsed laser. The polarization beam-combination device comprises the pulsed laser, an input beam splitter, n laser amplifiers and n-1 polarization coherent beam-combination units. The pulsed laser outputs a beam of seed light. The input beam splitter divides the seed light into n sub-seed light beams. The n laser amplifiers respectively carry out power amplification to the n sub-seed light beams. The n-1 polarization coherent beam-combination units carry out pairwise polarization in-phase beam-combination for n-1 times to n laser beams output by the n laser amplifiers. N is a natural number which is bigger than or equal to two. An output end of the polarization beam-combination device is connected with an output beam splitter. A hard light output end of the output beam splitter is used as an output end of the polarization coherent beam-combination units. Light output from a low light output end of the output beam splitter shoots into a relative phase detection module of a drive phase control module, and the relative phase detection module enables phase positions of two laser beams to be consistent. Through adoption of a polarization detection method, the polarization beam-combination device detects the relative phase positions of the two laser beams, and is capable of achieving coaxial combination of a plurality of coherent light beams, high in combined efficiency and good in beam quality.

Owner:广东华快光子科技有限公司

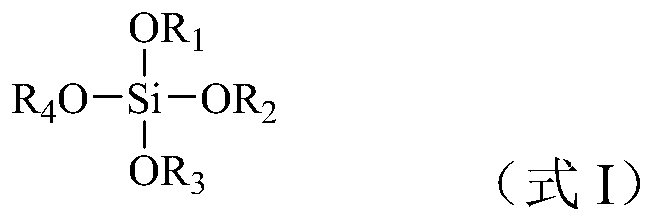

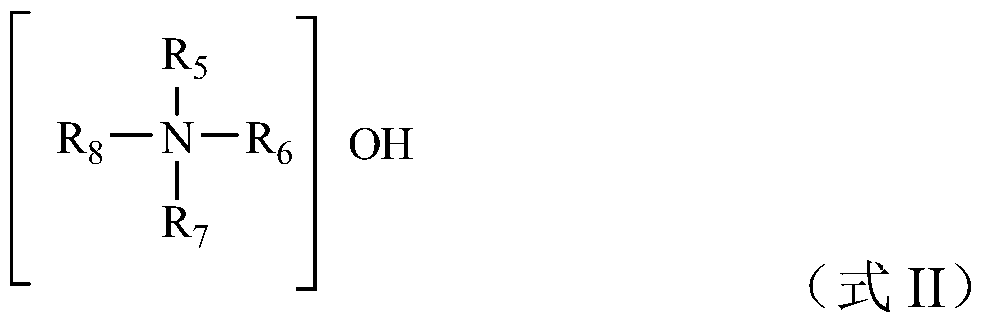

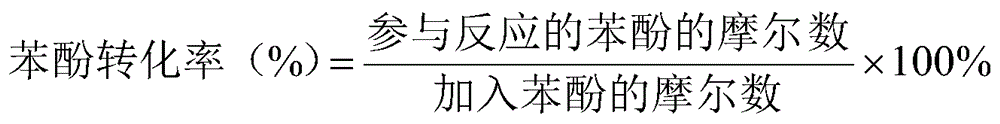

Tin-silicon molecular sieve and synthetic method and application thereof, and phenol hydroxylation method

ActiveCN105271294AHigh crystallinityReduce dosageOrganic chemistryMolecular sieve catalystsMolecular sieveCatalytic oxidation

The invention provides a method for synthesizing a tin-silicon molecular sieve. The method comprises: (1) hydrolyzing an organic silicon source, a tin source and an alkali source template agent to obtain a mixture A and carrying out first crystallization on the obtained mixture A; and (2) mixing the material obtained by first crystallization with an inorganic silicon source to obtain a mixture B and carrying out second crystallization on the obtained mixture B. The invention provides the tin-silicon molecular sieve synthesized through the method and an application of the molecular sieve. The invention provides a phenol hydroxylation method. By taking the inorganic silicon source which is relatively low in price as a part of, or even, a main silicon source, the use level of organosilicone esters is reduced, and the synthetic benefit is improved to a great extent. Moreover, the synthesized tin-silicon molecular sieve is high in relative crystallinity, high in catalytic oxidation activity and high in selectivity, and shows the characteristics of being high in catalytic oxidation activity and high in selectivity on hydroquinone in a probe reaction, i.e. a phenol hydroxylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

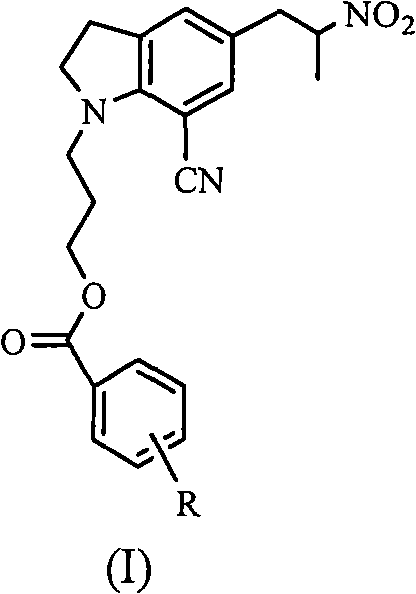

Indoline compound for preparing silodosin and preparation method thereof

The invention provides an indoline compound of 1-(3-substituted benzoyl alkoxypropyl)-5-(2-nitrylpropyl)-7-cyanophoric indoline and a preparation method thereof. The indoline compound can be used as an intermediate compound and is used for synthesizing silodosin. The indoline compound uses substituted phenylformic acid as a raw material, is prepared by multiple-step reaction, has high yield and is easy to industrially produce.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

Method for preparing Semaglutide through solid and liquid combination

ActiveCN108059666AReduce generationAvoid it happening againPeptide preparation methodsBulk chemical productionDipeptideSide chain

The invention relates to a method for preparing Semaglutide through solid and liquid combination, and solves the technical problems that in the process for synthesizing long-sequence polypeptide by the existing technology, the synthesis period is long; the purification difficulty is high; the yield is low. The method for preparing Semaglutide through solid and liquid combination provided by the invention is characterized in that firstly, Lys and resin are condensed in an Alloc-Lys(Fmoc)-OH form by adopting a solid phase synthesis method; Fmoc protecting groups on epsilon-NH2 are removed; sidechain connection is performed; cracking is performed to obtain Alloc-Lys(PEG-PEG-gamma-Glu(OtBu)-Monobutyl octadecanate)-OH; meanwhile, 10 dipeptide or tripeptide or tetrapeptide fragments are simultaneously synthesized by a liquid phase synthesis method; then, the condensation reaction of the synthesized peptide fragments and single amino acid is performed by using the resin as a carrier; the 15-step solid phase condensation reaction is reduced in the process; the generation of lacked peptide impurities is reduced; the product purity and the yield are improved; meanwhile, the generation of the impurities of [+Gly]-Semaglutide and [+Ala]-Semaglutide is effectively avoided; the purification difficulty is greatly reduced. The method is widely applied to the technical field of polypeptide medicine preparation.

Owner:润辉生物技术(威海)有限公司

Text transformation model training method and apparatus, and text transformation method and apparatus

ActiveCN107680580AAutomate trainingIncrease flexibilitySemantic analysisCharacter and pattern recognitionSemantic vectorHidden layer

The invention discloses a text transformation model training method and apparatus, and a text transformation method and apparatus. One specific embodiment of the text transformation model training method includes the steps: successively inputting the characters in the input character sequence corresponding to the input text into the neural network corresponding to a text transformation model to begenerated, wherein the neural network corresponding to the text transformation model includes an encoder and a decoder; for each character in the input character sequence, based on the state of the hidden layer in the decoder after decoding of the input last character, using the encoder to code to obtain an intermediate meaning vector of the character, and using the decoder to interpret the intermediate semantic vector to obtain the prediction result of the character; and according to the difference between the prediction result of the input character sequence and the mark result corresponding to the input text, adjusting the parameters of the neural network. The text transformation model obtained through the text transformation model training method can realize combined prediction of text regularization and polyphones, thus reducing the resource maintenance cost.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

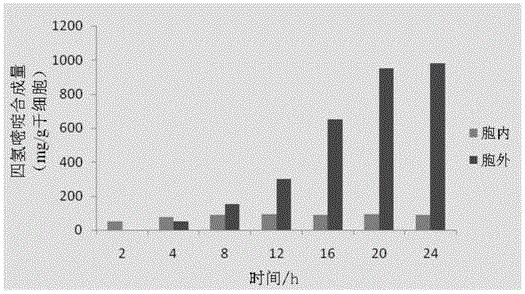

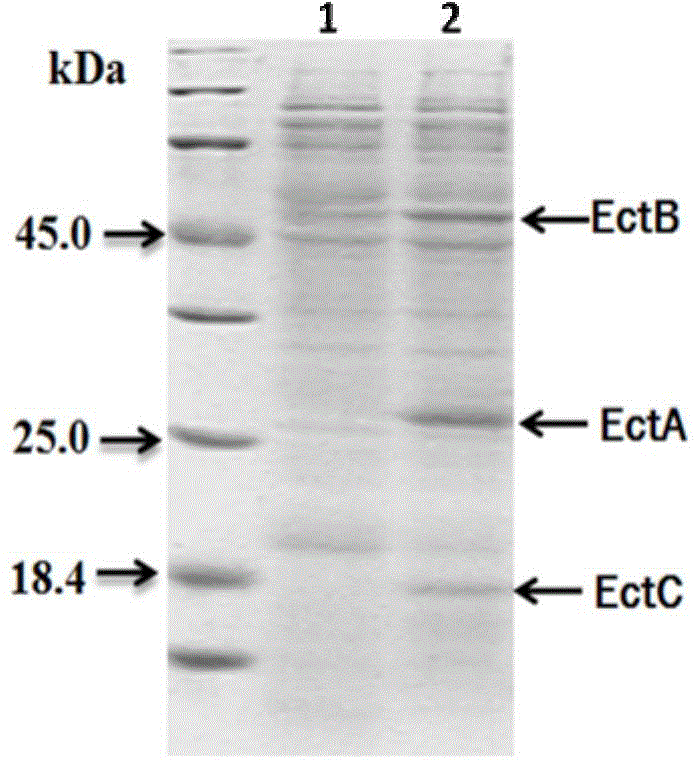

Escherichia coli engineering bacterium for high-yield tetrahydropyrimidine and applications of escherichia coli engineering bacterium

ActiveCN104560844AHigh synthesis efficiencyFacilitate downstream purification and separationBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention provides a recombinant escherichia coli for high-yield tetrahydropyrimidine and a method for preparing tetrahydropyrimidine by using the recombinant escherichia coli. The recombinant escherichia coli provided by the invention is prepared by importing Halomonas elongate EctABC containing recombinant plasmids into escherichia coli. The recombinant escherichia coli disclosed by the invention realizes the soluble expression of three key enzymes synthesized by tetrahydropyrimidine under the adjustment and control of an arabinose promoter. Thalli subjected to induced expression implements the efficient secretory expression of tetrahydropyrimidine by taking sodium aspartate as a precursor through a bioconversion method. Thalli per gram can synthesize 1.1 grams of tetrahydropyrimidine, and more than 90% of tetrahydropyrimidine is secreted to extracellular receptors. The method for preparing tetrahydropyrimidine by using the recombinant escherichia coli provided by the invention facilitates the downstream purification and separation of products, and has great significance on the industrial production and large-scale application of tetrahydropyrimidine.

Owner:南京众惠生物材料科技有限公司

Method for preparing silver-carried silica microsphere functional materials

InactiveCN102764617ANo pollution in the processEasy to operateMicroballoon preparationMicrocapsule preparationSilica particleEtching

The invention discloses a method for preparing silver-carried silica microsphere functional materials. Monodisperse uniform spherical composite metallic silver-carried silica functional particles are prepared by chemical etching and metal salt pyrolysis methods, the particles are formed by uniformly loading nanometer metallic silver with the grain diameter of 5-50nm on the monodisperse multihole silica particles used as inner cores, so that the original silica particles have the special properties of nanometer silver particles. The particle obtained by the method has high purity and good monodispersity, the size of a product can be controlled by reaction conditions, and the method has wide application prospects. The method for preparing the silver-carried silica microsphere functional materials disclosed by the invention has a simple process and is environment-friendly, raw materials and equipment are cheap and are easy to obtain, and the cost is low. The synthesis time is short, the efficient is high, and the method has great industrial production prospects.

Owner:SHAANXI UNIV OF SCI & TECH

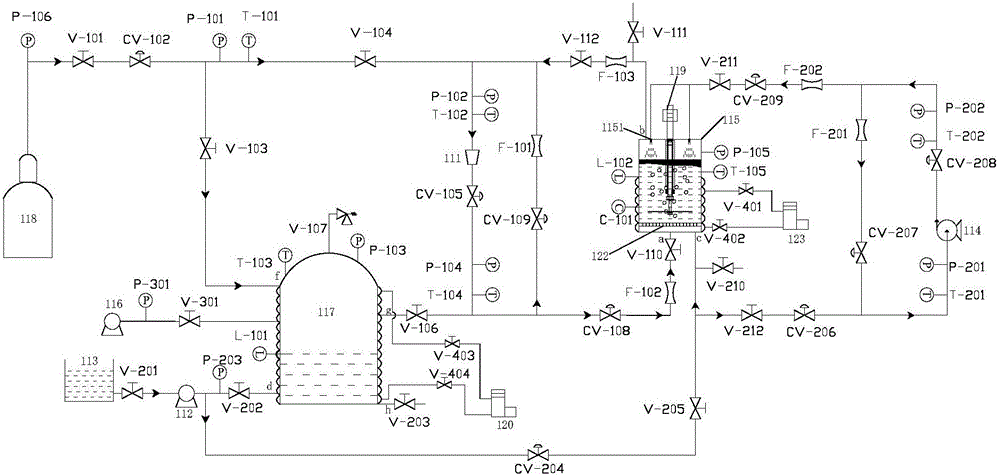

Rapid synthesis device for natural gas hydrate

InactiveCN106010698AHigh synthesis efficiencyPromote the process of industrializationGaseous fuelsGas cylinderControl system

The invention provides a rapid synthesis device for natural gas hydrate. The rapid synthesis device comprises a gas supply pipeline, a liquid supply pipeline, a stirring device and a data acquisition control system. The gas supply pipeline is used for conveying gas in a gas cylinder into a reaction kettle and is communicated with a gas inlet a in the bottom of the reaction kettle through an outlet of the gas cylinder via a pipeline. The liquid supply pipeline is used for conveying water in a water tank into the reaction kettle and is communicated with a liquid phase inlet c of the reaction kettle through an outlet of the water tank via a pipeline, and a plunger pump is arranged on the communicating pipeline. The stirring device is formed by installing a stirrer in the reaction kettle, propeller blades are adopted for a stirring and smashing paddle of the stirrer, and a smashing tooth cone is installed below the blades. By means of the rapid synthesis device for natural gas hydrate, the synthesis efficiency of natural gas hydrate can be improved, and thus the industrialization process of natural gas hydrate is promoted.

Owner:SOUTHWEST PETROLEUM UNIV

Process for solid-phase microwave synthesis of polypeptide

InactiveCN1699404AIncrease reaction rateLower activation energyPeptide preparation methodsBulk chemical productionCombinatorial chemistrySolvent

Disclosed is a process for solid-phase microwave synthesis of polypeptide comprising, (1) preparing amino acid and resin compound, (2) removing amino protecting group through microwave radiation, (3) condensating amino acid through microwave radiation, (4) replacing amino acids, repeating step (2) and (3) to synthesize the needed polypeptides, (5) preparing the polypeptides crude product.

Owner:NANJING UNIV OF TECH

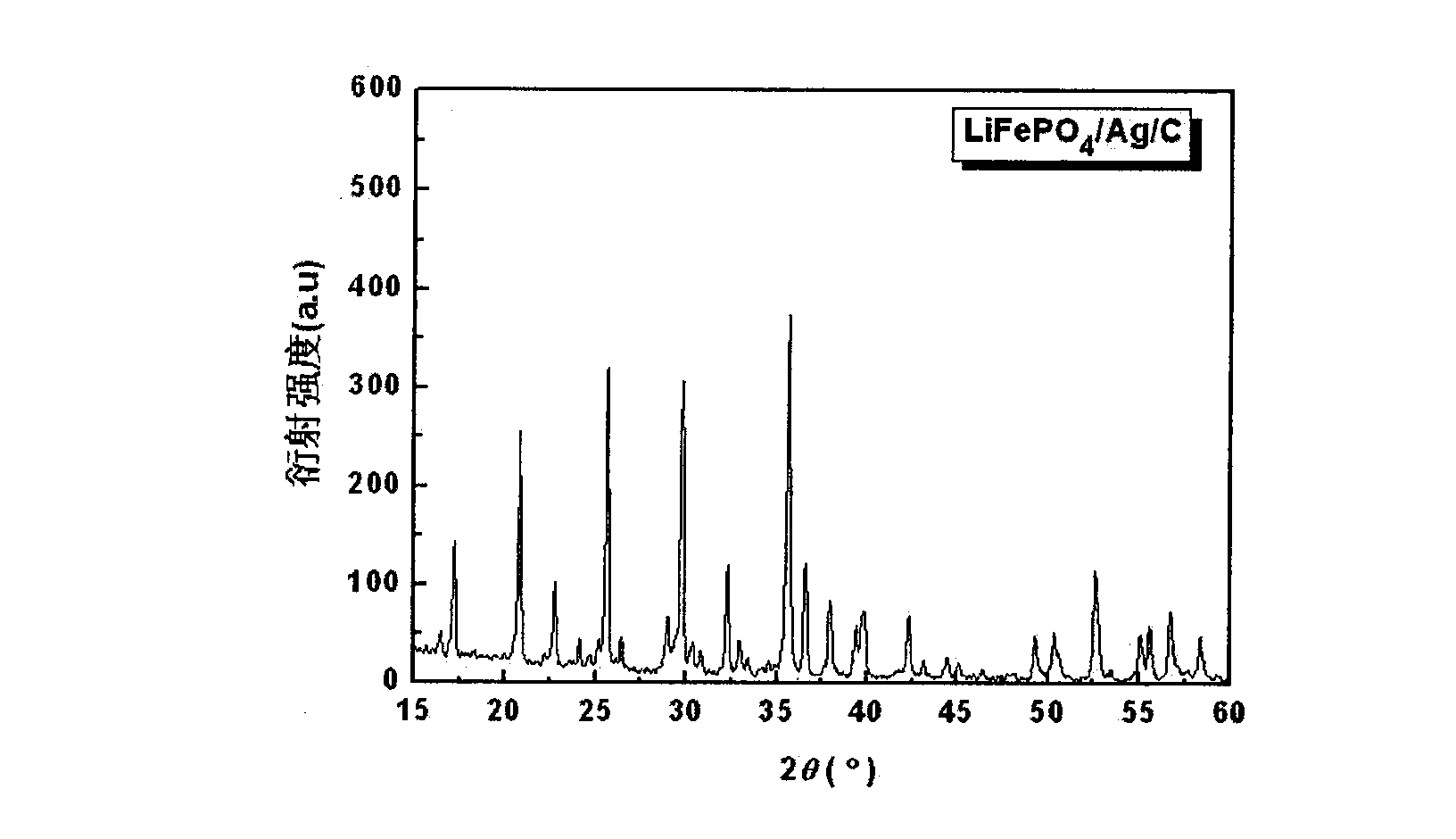

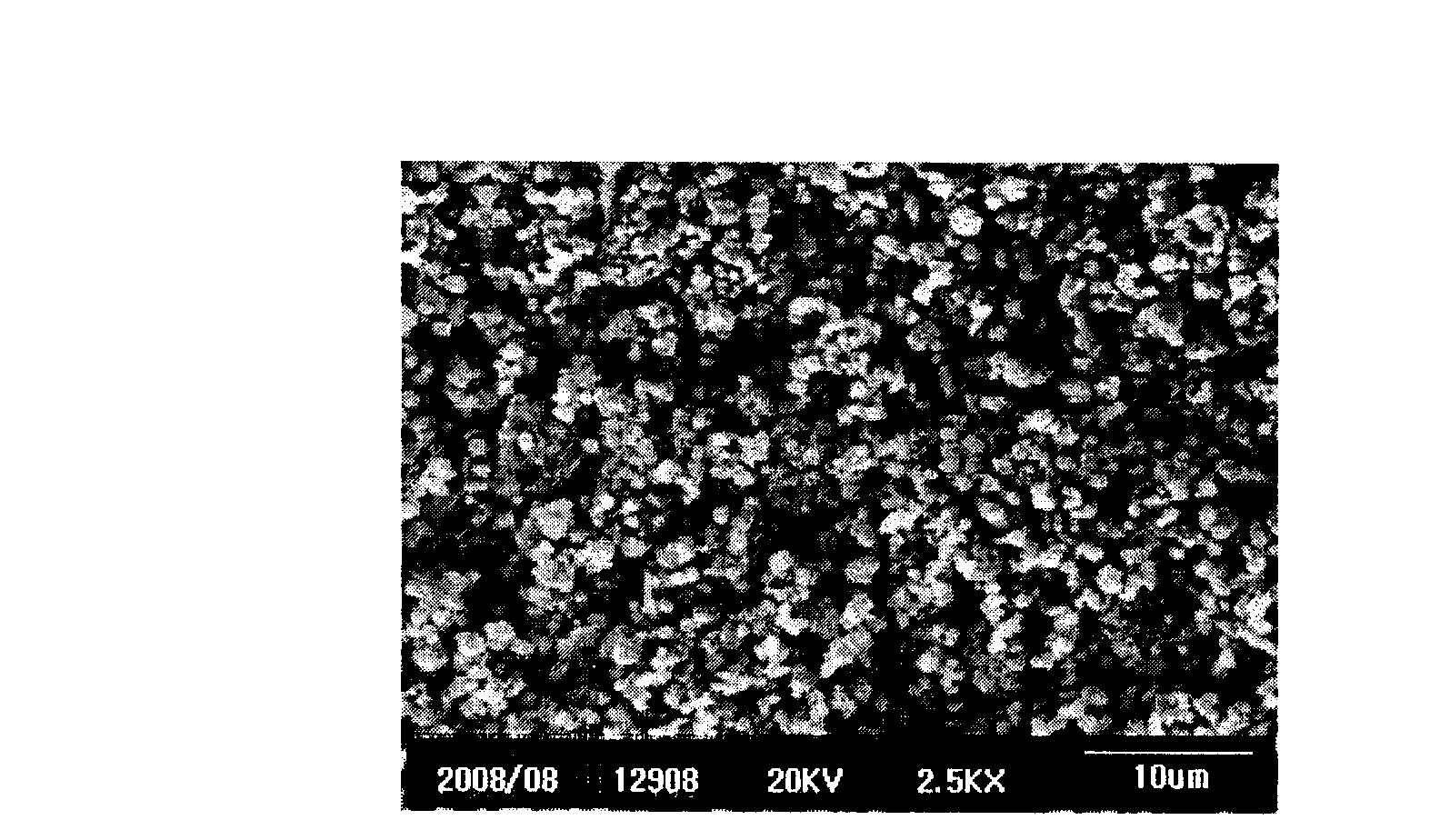

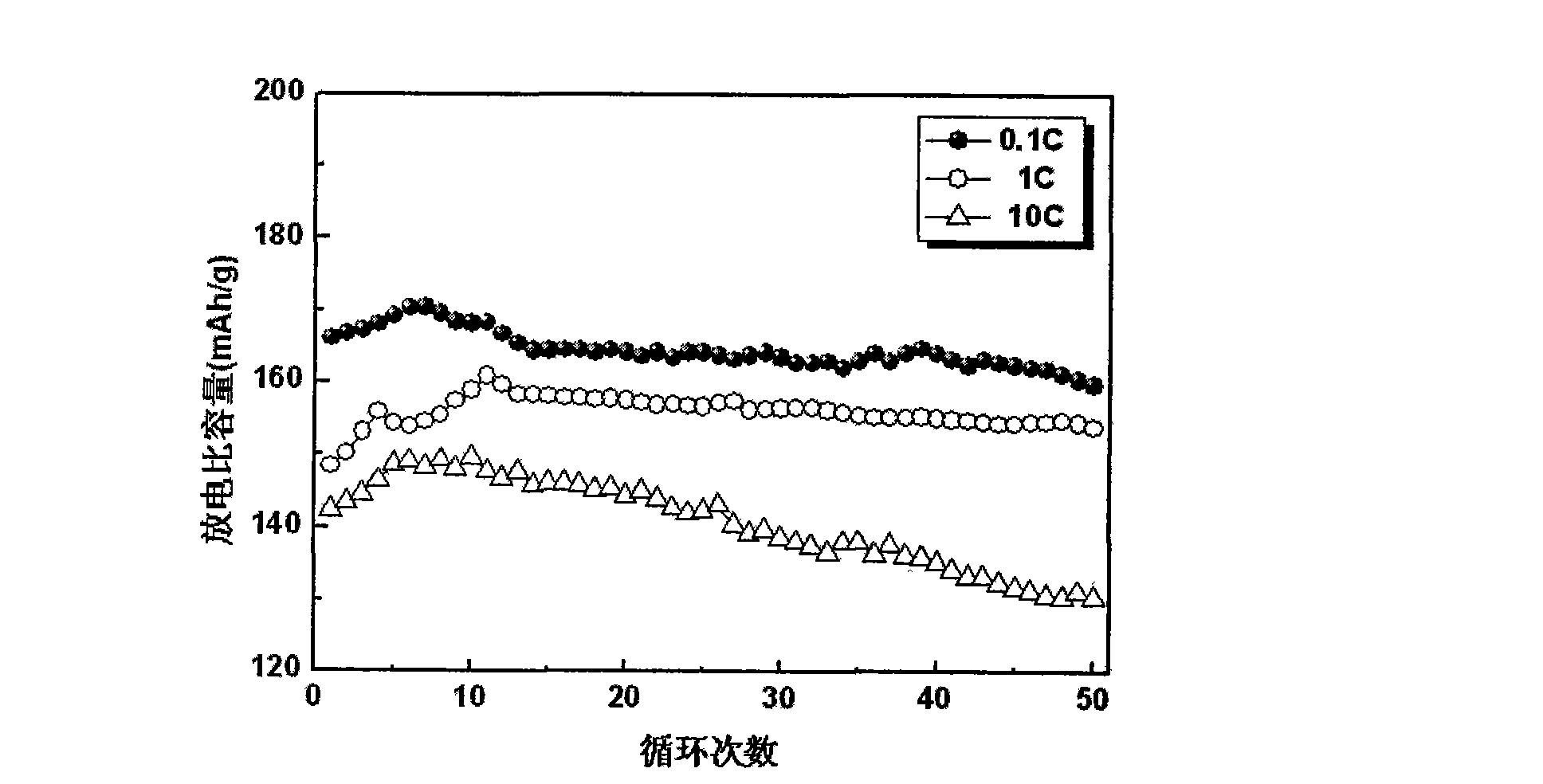

Method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material

The invention discloses a method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material, comprising steps: A. mixing lithium compound, phosphate and silver compound together according to the mole ratio of Li: P: Ag, and dissolving by water; sequentially adding citric acid and glycol, and stirring to prepare collosol; B. adding organic sugar with the molar weight of 1-2 times of that of silver salt into the collosol, adding iron compound with the mole number being the same as that of lithium salt and carbon reducing agent with the equal molar weight based on pure carbon, and evenly mixing, vacuum drying and ball-milling the mixture; then, pressing the mixture powder to be molded after ball-milling, and preparing precursor of synthesized lithium iron phosphate; C. putting the obtained precursor into a vacuum reaction furnace to have reaction under the condition of certain vacuum degree, and ball-milling to obtain the metal-silver-doped carbon-covering lithium iron phosphate LiFePO4 / Ag / C cathode material. The method has the advantages of simple technique, easy amplification, good electric conduction performance, excellent high-rate discharge performance, high specific capacity and electrochemistry efficiency, small particle size distribution range and high tap density.

Owner:广州云通锂电池股份有限公司 +1

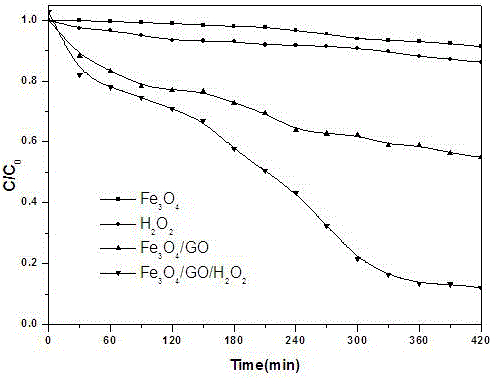

Method for preparing core-shell ferroferric oxide/graphene oxide composite nano-catalyst

InactiveCN105964256AHigh reactivityHigh synthesis efficiencyWater treatment compoundsWater contaminantsNano catalystOxide composite

The invention provides a method for preparing a core-shell ferroferric oxide / graphene oxide composite nano-catalyst. The method comprises the following steps of preparing nanometer ferroferric oxide by utilization of a hydrothermal method, preparing graphene oxide by utilization of a modified Hummers method, preparing the core-shell ferroferric oxide / graphene oxide composite nano-catalyst by utilization of an electrostatic self-assembly method. The catalyst prepared according to the method provided by the invention has the advantages that the adsorptive property is excellent, the stability is good, the catalyst can be cyclically utilized, and an excellent adsorption effect can be achieved during the process of degrading simulated dye rhodamine B.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Poly(ethylene 2,5-furandicarboxylate), and preparation method thereof

InactiveCN102190785AImprove performanceWide variety of sourcesEsterification reactionGlass transition

The invention provides poly(ethylene 2,5-furandicarboxylate), which contains the repeating units shown in formula (I) and has a characteristic viscosity not smaller than 0.2 dL / g. The invention also provides a preparation method for poly(ethylene 2,5-furandicarboxylate) provided by the technical scheme, which comprises the following steps of: carrying out esterification reaction on 2,5-furandicarboxylic acid and ethylene glycol under the action of a tin catalyst to obtain a first intermediate product, wherein the esterification reaction pressure is 0.1-0.4 MPa; and carrying out condensation polymerization reaction on the first intermediate product under the pressure of 10-70 Pa to obtain poly(ethylene 2,5-furandicarboxylate). Experiments show that poly(ethylene 2,5-furandicarboxylate) provided by the invention is dark brown, and has a characteristic viscosity of not smaller than 0.2 dL / g, a glass transition temperature of 60-63 DEG C and a melting point of 210-215 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of milk cow rumen fermentation accelerator

ActiveCN102283321AImprove the fermentation environmentImprove degradation rateAnimal feeding stuffAccessory food factorsBacillus licheniformisBiotechnology

The invention relates to a cow rumen fermentation accelerator, which comprises bacterial broth and complex carbohydrate, wherein the weight ratio of the bacterial broth to the complex carbohydrate is 1:1-2, the bacterial broth comprises 1.0-2.0 * 1010CFU / ml beer yeast, 1.5-2.0 * 1010CFU / ml bacillus subtilis, 1.5-2.0 * 1010CFU / ml bacillus licheniformis, 1.0-2.0 * 109CFU / ml lactic acid bacteria, and 1.0-2.0 * 109CFU / ml aspergillus oryzae. The complex carbohydrate comprises 60-70 percent by weight of lactose, 15-25 percent by weight of fructose, 4-6 percent by weight of fumaric acid, 2-4 percentby weight of malic acid, 4-6 percent by weight of sodium bicarbonate and 1-3 percent by weight of magnesium oxide. Due to the cow rumen fermentation accelerator disclosed by the invention, the activity of cow rumen microorganism can be improved, the degradation of coarse fodder in rumen is promoted, the utilization ratio of nitrogen is improved, the output of MCP is increased, and thus the purpose of promoting the function of cow rumen fermentation is achieved.

Owner:沈阳爱特杰牧业有限公司

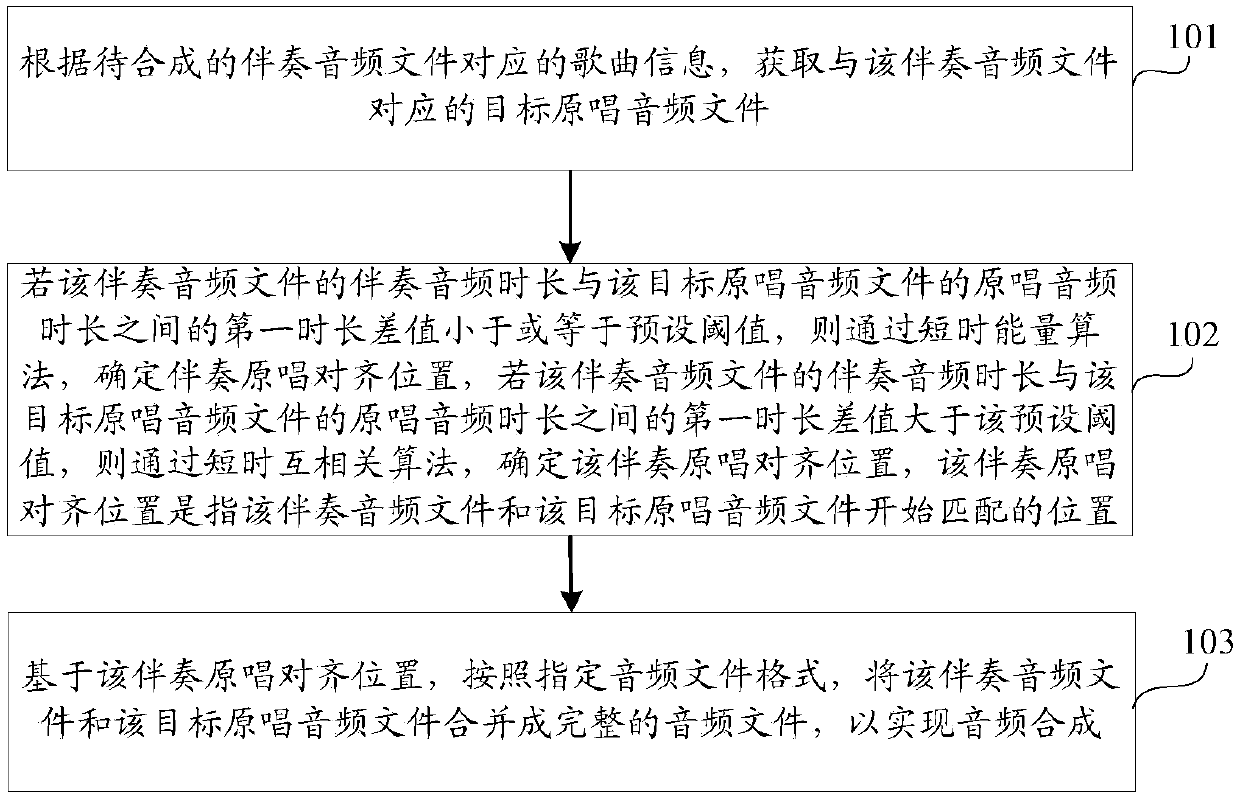

Audio synthesis method and device, and storage medium

ActiveCN107591149AAchieve synthesisSynthesis is automatically implementedElectrophonic musical instrumentsSpeech synthesisComputer hardwareAudio synthesis

The present invention discloses an audio synthesis method and device, and a storage medium, belonging to the multimedia technology field. The method comprises: acquiring a target original audio file corresponding to an accompaniment audio file according to song information corresponding to the accompaniment audio file to be synthesized; if a first duration difference between an accompaniment audioduration of the accompaniment audio file and an original audio duration of the target original audio file is smaller than or equal to a preset threshold, determining an accompaniment original alignment position through a short-time energy algorithm, and if the first duration difference between the accompaniment audio duration of the accompaniment audio file and the original audio duration of thetarget original audio file is larger than the preset threshold, determining an accompaniment original alignment position through the short-time energy algorithm; and based on the accompaniment original alignment position, combining the accompaniment audio file and the target original audio file into a complete audio file according to an assigned audio file format. Therefore, the audio synthesis method and device, and the storage medium can realize audio synthesis and do not need manual operation so as to improve audio synthesis efficiency.

Owner:TENCENT MUSIC ENTERTAINMENT TECH SHENZHEN CO LTD

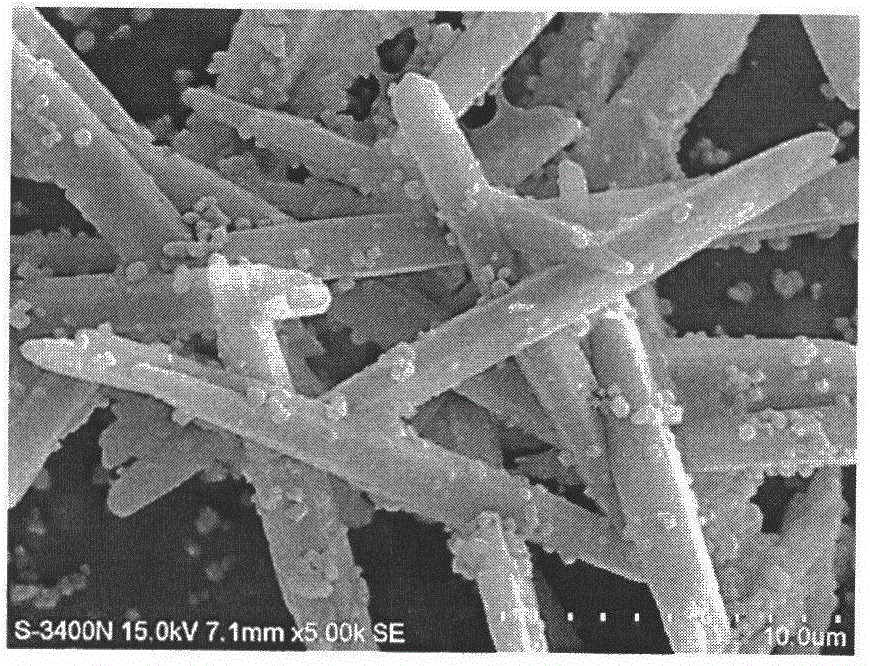

Preparation method for aragonite calcium carbonate whisker with high length-diameter ratio

InactiveCN104790024AEasy to operateLow magnesium to calcium ratioPolycrystalline material growthFrom normal temperature solutionsFiltrationCarbonization

The invention relates to a preparation method for an aragonite calcium carbonate whisker with a high length-diameter ratio. The preparation method comprises the following specific implementation steps: adding a 1.0-8.2 wt% prepared Ca(OH)2 suspension liquid into a carbonation reactor, adding MgCl2 in the aqueous solution form into the reactor, controlling the magnesium-calcium ratio R to be 0.6-2.0 and the carbonization temperature to be 30-85 DEG C, under the action of stirring, mixing CO2 with the flow rate of (5-120)m<3> / (h.m<3> suspension liquid)and N2, introducing the mixture of the CO2 and N2 to a gas distributor at the bottom of the carbonation reactor, and tracking the whole process of carbonation reactor by adopting a digital display pH meter; performing suction filtration and washing on the slurry generated after the carbonization is completed, drying for 5 hours at the temperature of 80 DEG C, and crushing, so as to obtain a calcium carbonate whisker sample. Compared with the existing method for preparing the aragonite calcium carbonate whisker through a carbonation method, the preparation method provided by the invention has the advantages that the calcium carbonate whisker with the high length-diameter ratio is synthesized by adopting the one-step method, the multistage growth is avoided, and the operation is simpler; the co-heating reaction balance phase of magnesium chloride and calcium hydroxide is avoided, the magnesium-calcium ratio in the reaction slurry is low, and the synthesis efficiency is higher.

Owner:GUANGXI UNIV +1

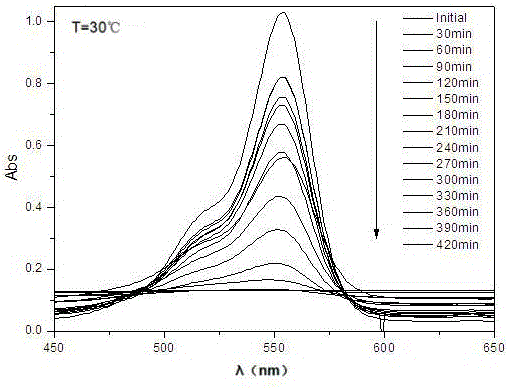

Silicon-based rhodamine derivative, preparation method and applications thereof

InactiveCN104262378AEasy to synthesizeEnables mass productionGroup 4/14 element organic compoundsMicrobiological testing/measurementBio moleculesCombinatorial chemistry

The invention relates to a silicon-based rhodamine derivative, which is represented by a biological structural formula shown in the description. The invention also relates to a preparation method of the silicon-based rhodamine derivative, and applications of the silicon-based rhodamine derivative in preparation of cell dye, biological dye, biological molecule / particle fluorescent marker, and the like. The provided synthesis method of silicon-based rhodamine derivative has the advantages of high yield, simple reaction conditions, convenient operation, capability for massive production, and wide substrate selection range.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Gas hydrate generation accelerant and preparation method thereof

ActiveCN103663451AEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

Image synthesis method, image chip and image equipment

ActiveCN104361556AHigh synthesis efficiencyImage enhancementImage analysisLine segmentImage synthesis

An embodiment of the invention discloses an image synthesis method, an image chip and image equipment. The image synthesis method comprises the following steps of respectively acquiring two coordinates, which correspond to two boundaries of each of a plurality of image layers of an image frame, on a first coordinate axis so as to obtain a plurality of coordinates corresponding to the image layers; dividing the image frame into at least two image segments which are perpendicular to the first coordinate axis by using the coordinates; reading the image segments at different times along the direction of the first coordinate axis according to a scanning sequence; and sequentially performing image synthesis of the image segments according to the time sequence on reading of the image segments so as to generate displaying data. The two boundaries of each of the image layers are perpendicular to the first coordinate axis.

Owner:HUAWEI TECH CO LTD

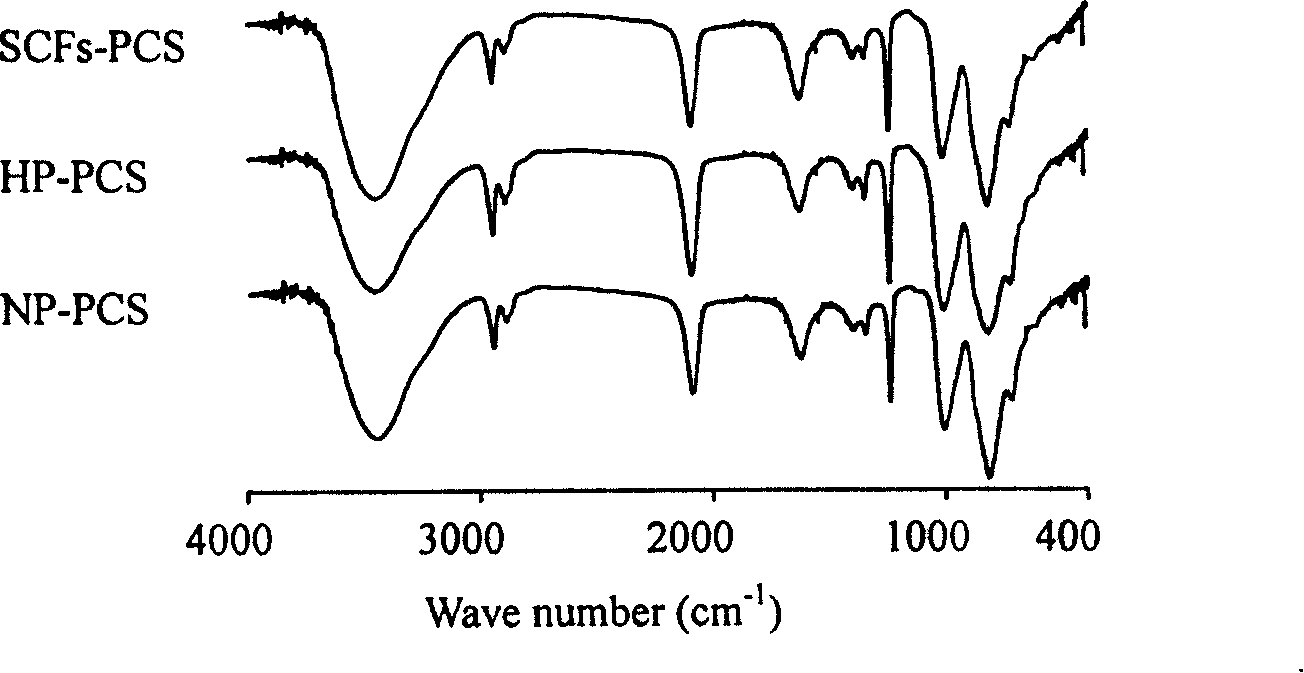

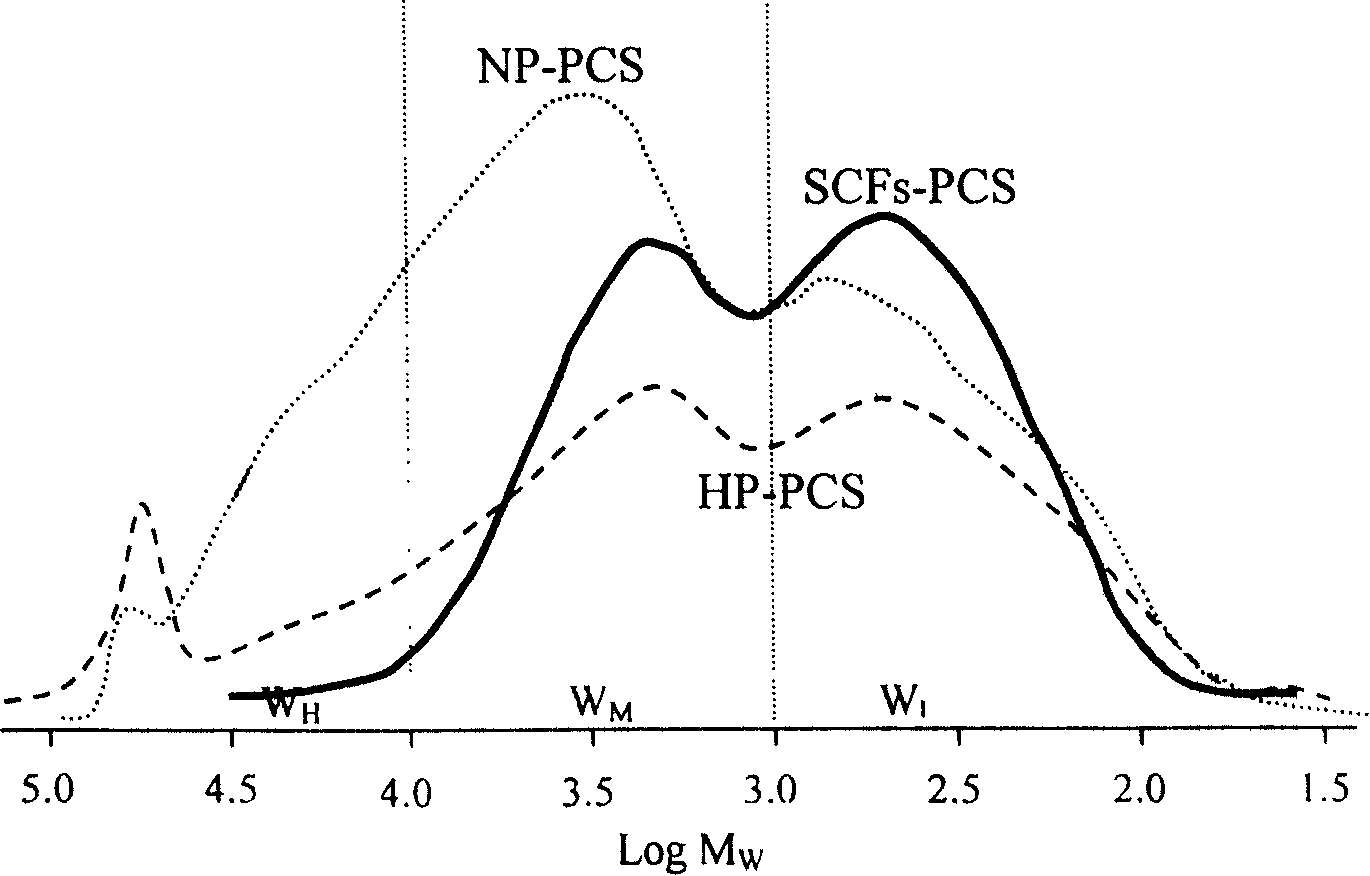

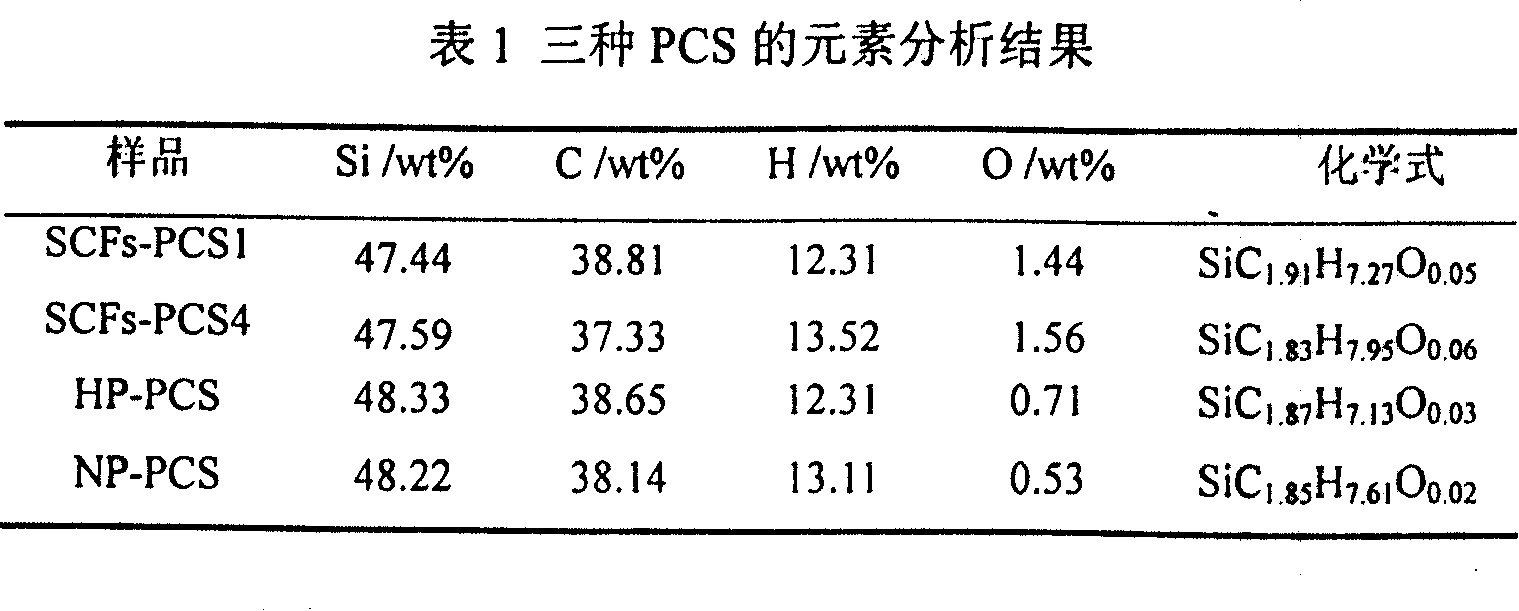

Method for synthesizing supercritical fluid of ceramic precursor polycarbosilane

InactiveCN101240070AImprove heat transfer performanceImprove uniformityBulk chemical productionHigh pressureSuperalloy

The invention discloses a organic silicon compound containing silicon-silicon bond, silicon-carbon bond, silicon-halogen bond and ceramics precursor poly carbon silicon alky synthesized under high pressure and with medium in supercritical fluid status which uses mixture of the aforementioned compound as raw material, uses solvent soluble of poly carbon silicon alky as supercritical fluid medium. Ceramics precursor poly carbon silicon alky with different molecular weight and different softening point can be obtained by controlling reaction condition of synthesis. The inventive method effectively improves uniformity of heat transfer and reaction, with short reaction time, high synthesis efficiency, high synthesis yield. The produced poly carbon silicon has a high molecular weight, high content of bonds of silicon and hydrogen and uniform distribution of molecular weight. The inventive method can be widely used in preparation of SiC fibre, SiC composite, heat resistant alloy with high strength, ceramic binder, SiC membrane, nano-wire, nano-pipe and nano-powder and so on.

Owner:NAT UNIV OF DEFENSE TECH

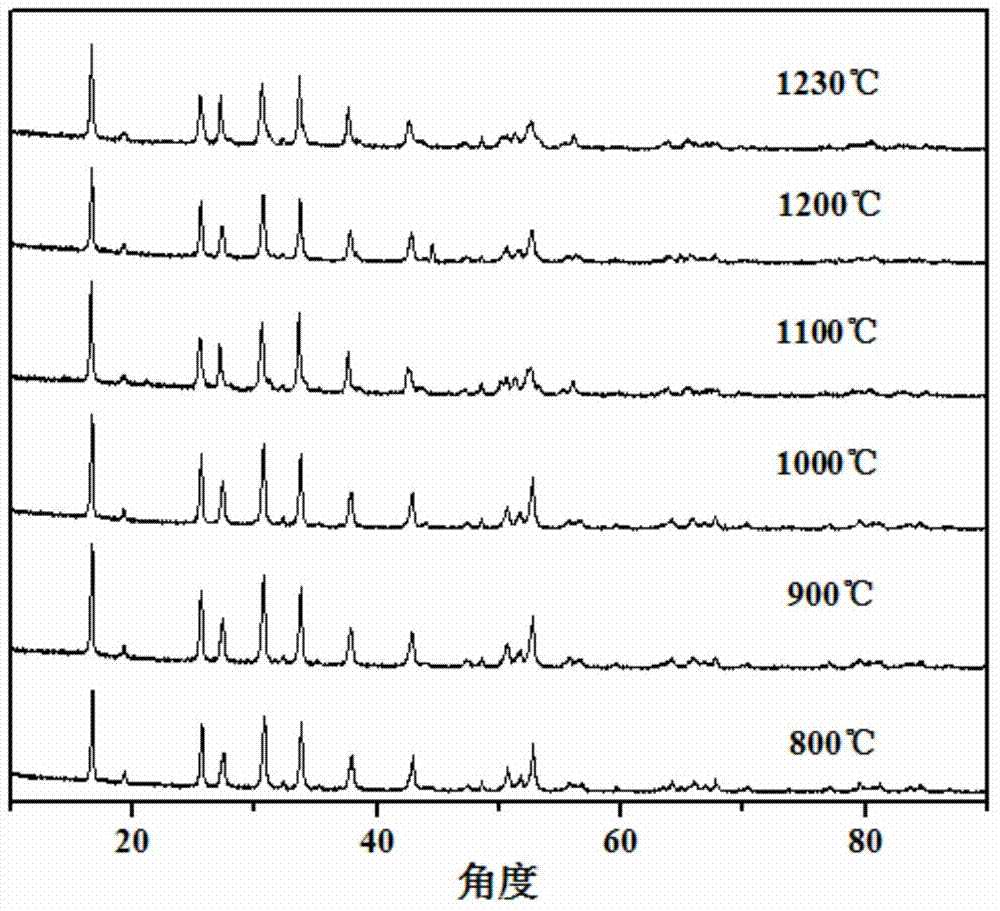

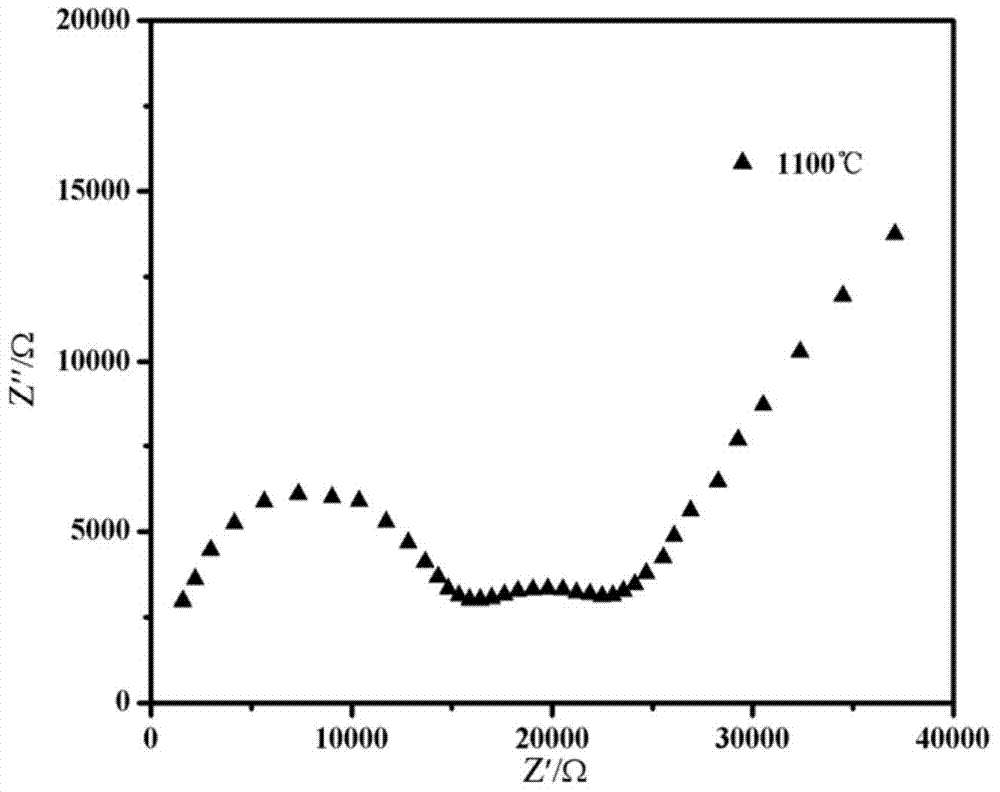

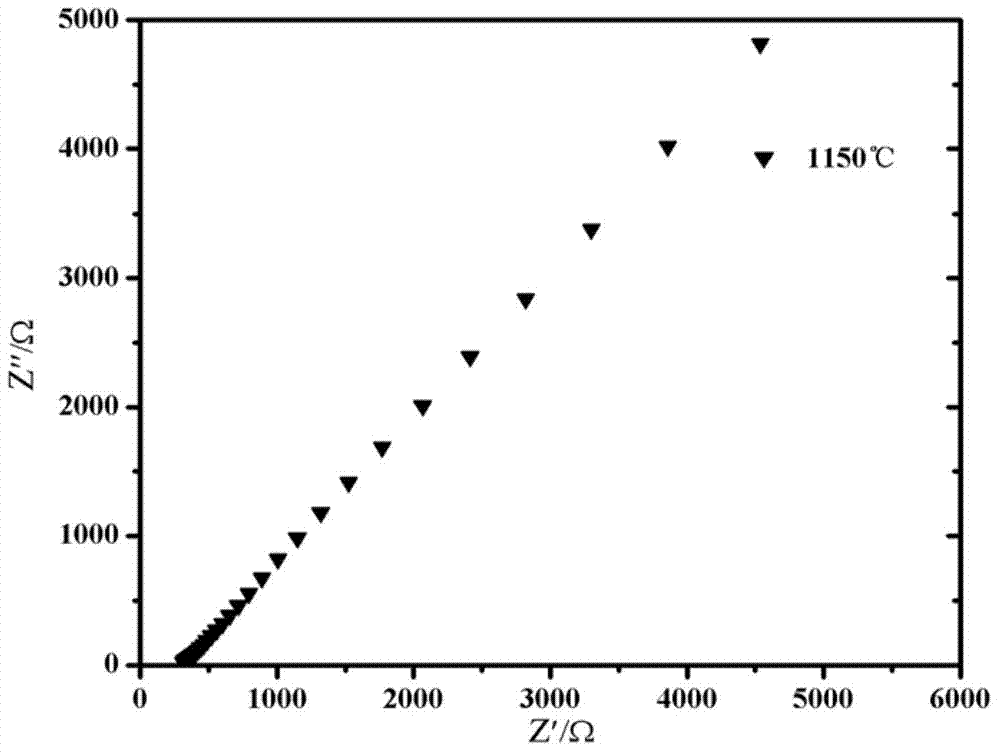

Electric field activated sintering method of solid electrolyte material

The invention provides an electric field activated sintering method of a solid electrolyte material Li7La3Zr2O12 (LLZO). The electric field activated sintering method comprises the following specific steps: ball-milling with a ball and mixing Li2O, La2O3 and ZrO2 powder, the mass percents of which are respectively 9.2-15.5%, 56.2-60.4% and 28.3-30.4%, wherein a zirconium oxide ball is used as a ball-milling medium, isopropanol is used as a solvent, and the ball-milling time is 12-36 hours; carrying out vacuum drying on ball-milling milled powder for 6-12 hours at the temperature of 80 DEG C; and carrying out electric field activated sintering, wherein the temperature is in the range from 800 to 1230 DEG C, the pressure is 0-100 MpaMPa, and a sintered sample has the room-temperature lithium-ion conductivity greater than 6*10<-4S>S / cm. Compared with a conventional solid-phase synthesis method, the electric field activated sintering method has the advantages that the synthesis reaction and the sintering compact process are completed in one step, the synthetic efficiency is improved to a large extent, the preparation technology is simplified, and the LLZO with the high lithium-ion conductivity is obtained.

Owner:WUHAN UNIV OF TECH

A Ti/MCM-22/MCM-41 composite material as well as preparing method and application

InactiveCN101157050AHigh synthesis efficiencyIncrease success rateMolecular sieve catalystsMicrowaveSewage

The invention relates to composite material taking micro / mesoporous composite molecular sieves as carriers and loading semiconductor elements, a preparation method and an application of composite material taken as photocatalyst. In order to overcome the respective limitation of a microporous molecular sieve and a mesoporous molecular sieve, simultaneously through the integration of the adsorption of molecular sieves and the photocatalysis of a semiconductor, the invention provides Ti / MCM-22 / MCM-41 composite material taking the microporous-mesoporous composite molecular sieves as the carriers and loading TiO2, and the invention synthesizes the composite material by adopting the synthesis technology of a microwave-hydrothermal method. The Ti / MCM-22 / MCM-41 composite material can be taken as photocatalyst of the effluent purification. Organic pollutant bisphenol A being difficult to be degraded is removed by adopting 0.1 g / l dosage of the composite material, in order that bisphenol A solution of 1000 ppb degrades to 1 ppb for five hours under the general illumination condition, and can degrade to 1 ppb for one hour under the sun illumination condition.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

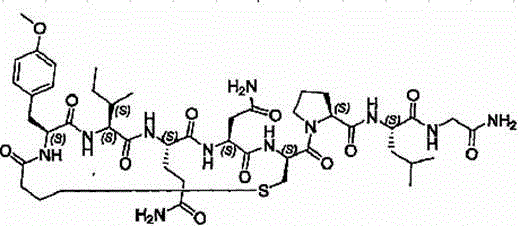

Synthesis process of carbetocin

InactiveCN104592362AHigh purityReduced operating requirementsOxytocins/vasopressinsPeptide preparation methodsSide chainCarbetocin

The invention provides a synthesis process of carbetocin. The synthesis process comprises the following steps: performing a coupling reaction on Fmoc-Gly-OH with Rink Amide-AM Resin obtained in the first step to obtain Fmoc-Gly-Rink Amide-AM Resin; performing deprotection (20% piperidine) with DBLK to obtain H-Gly-Rink Amide-AM RFesin, and orderly completing the coupling of the H-Gly-Rink Amide-AM Resin with Fmoc-Leu-OH, Fmoc-Pro-OH, Fmoc-Cys(Trt)-OH, Fmoc-Asn(Trt)-OH, Fmoc-Gln(Trt)-OH, Fmoc-Ile-OH, Fmoc-Tyr(Me)-OH and tetrachlorobutyric acid until carbetocin linear peptide resin is synthesized; mixing a cracking agent with the carbetocin linear peptide resin obtained in the fourth step to have a cracking reaction, thereby removing the Rink Amide-AM Resin and side chain protecting groups; cyclizing the carbetocin linear crude peptide into a carbetocin crude product, and separating and purifying the carbetocin crude product to obtain the carbetocin. The synthesis process has the advantages that the polymerization side reaction is prevented, the process route is greatly simplified, the production cost is reduced and the synthesis efficiency is improved; in addition, the purity of the finished product is high; in short, the synthesis process is convenient for large-scale production, and meanwhile, advantageous for environmental protection, and has remarkable economic and social benefits.

Owner:苏州天马医药集团天吉生物制药有限公司

Production method of 2-acrylamide-2-methylpropanesulfonic acid

ActiveCN103664709AReduce the length of the synthesis processHigh synthesis efficiencyOrganic chemistryOrganic compound preparationChemistryIsobutylene

The invention discloses a production method of 2-acrylamide-2-methylpropanesulfonic acid. The method comprises the steps of (1) mixing acrylonitrile with a sulfonating agent to form an acrylonitrile solution of the sulfonating agent; (2) enabling the acrylonitrile solution of the sulfonating agent, obtained in the step (1), to be in contact with isobutylene to form a pasty product; (3) filtering the pasty product to obtain a filter cake containing 2-acrylamide-2-methylpropanesulfonic acid; (4) washing the filter cake containing the 2-acrylamide-2-methylpropanesulfonic acid, obtained in the step (3), by using glacial acetic acid, thereby obtaining an AMPS crude product. By adopting the method, the synthesis time of the 2-acrylamide-2-methylpropanesulfonic acid can be effectively reduced, the synthesis efficiency is improved, and the cost is reduced. Moreover, the obtained product is high in yield and purity.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-vitro protein synthesis system, method of enhancing protein synthesis efficiency by using system and kit including system

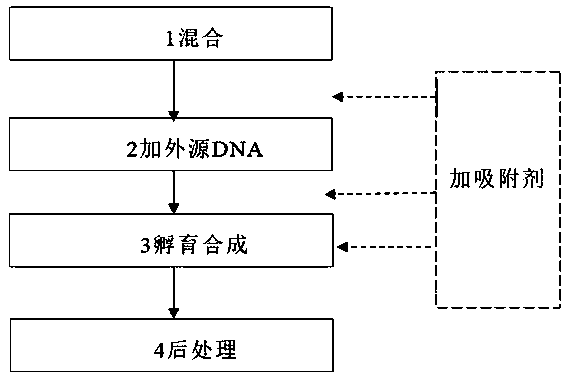

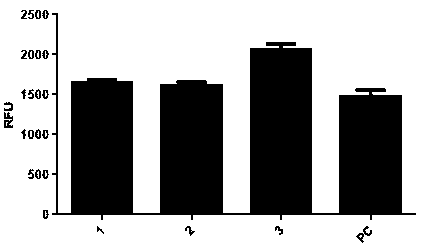

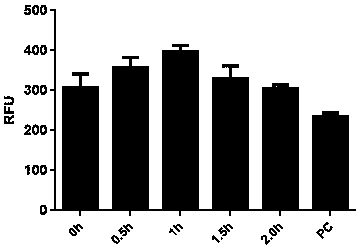

PendingCN110964736AHigh synthesis efficiencyVector-based foreign material introductionForeign proteinCell extraction

The invention provides an in vitro protein synthesis system, a kit and a preparation method. The in vitro protein synthesis system includes: (a) a cell extract; (b) an adsorbent used for enhancing protein synthesis efficiency; (c) amino acids; (d) nothing or NTPs; and (e) exogenous DNA molecules. A method for enhancing in vitro protein synthesis efficiency is provided. The method adopts the synthesis system and includes the following steps: (1) performing mixing; (2) adding the exogenous DNA molecules; (3) performing incubation synthesis; and (4) performing post-processing; and the method alsoincludes a step of adding the adsorbent after the step (1) or (2). In addition, the kit of the in vitro protein synthesis system is also provided. Therefore, the synthesis efficiency of foreign protein can be significantly enhanced.

Owner:KANGMA SHANGHAI BIOTECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com