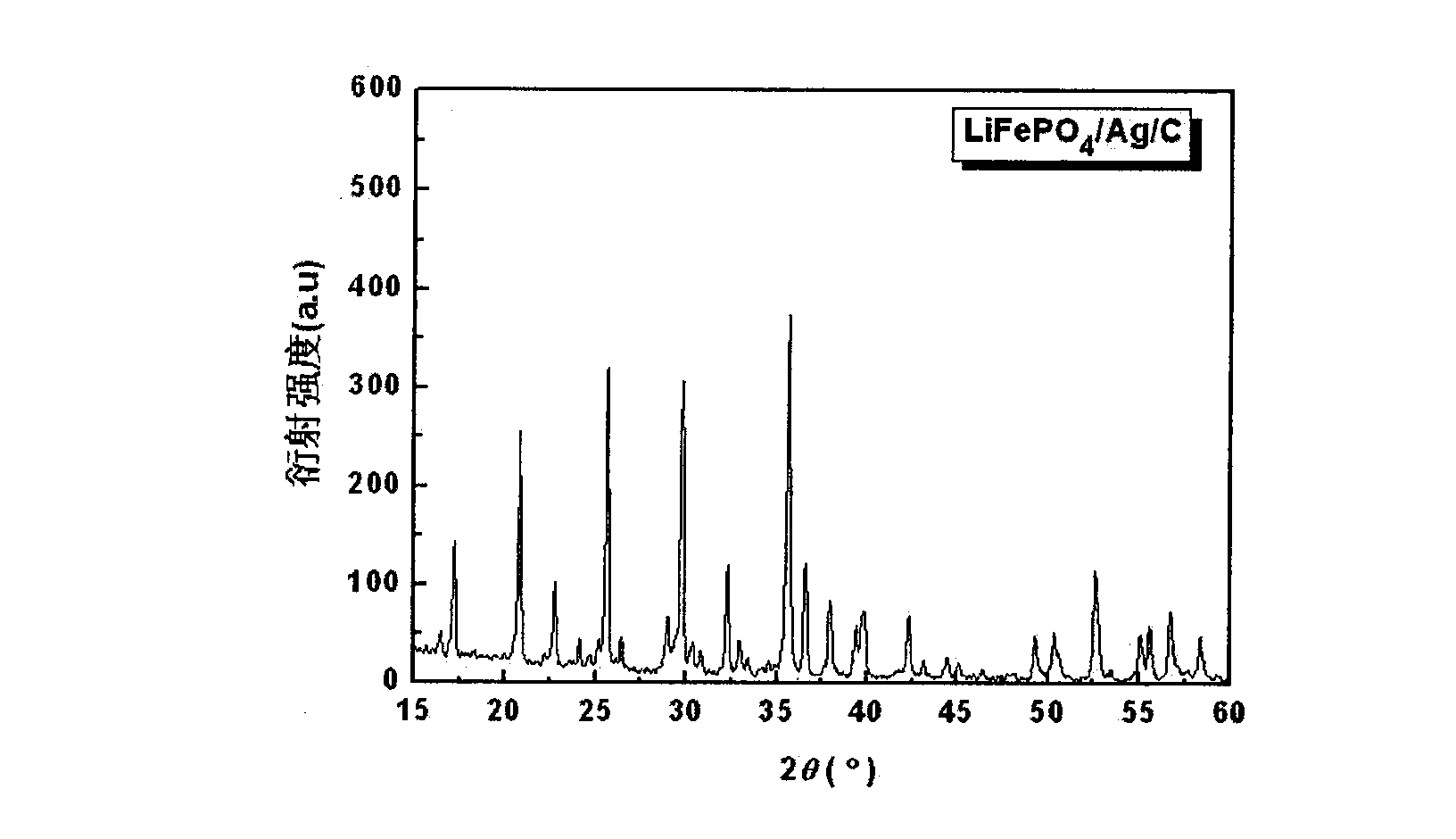

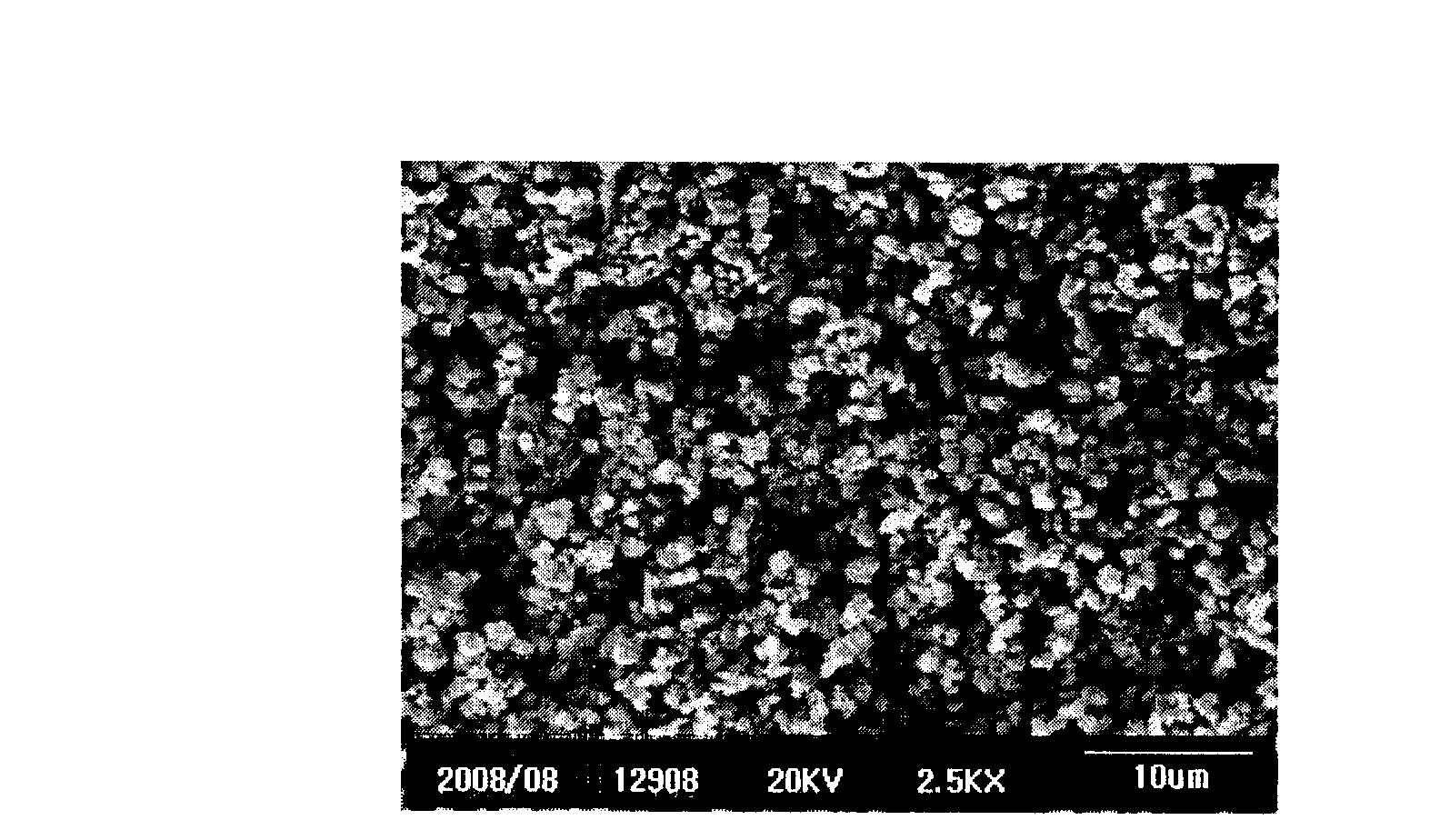

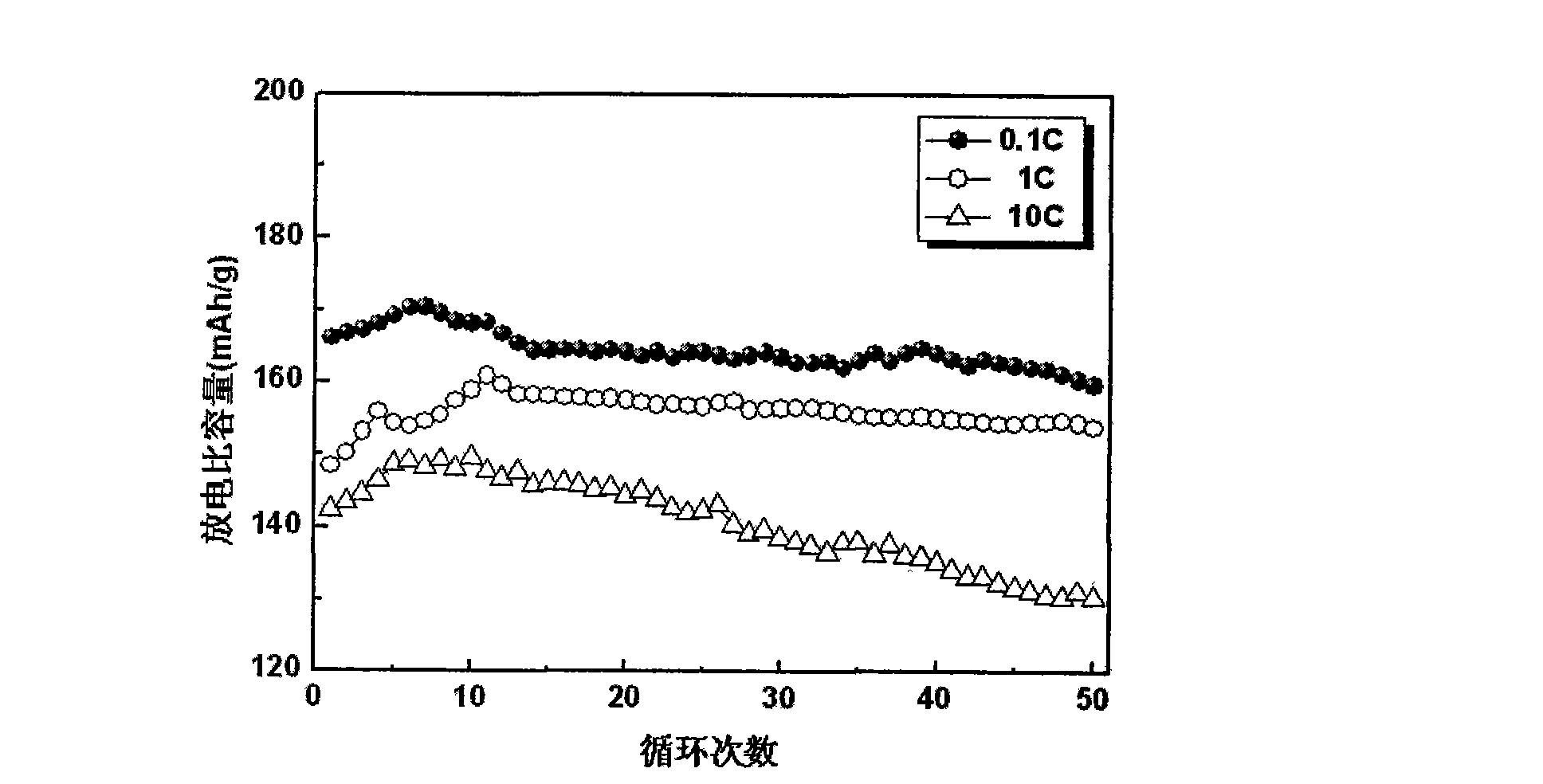

Method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material

A technology of carbon-coated lithium iron phosphate and positive electrode material, which is applied in electrode manufacturing, battery electrodes, circuits, etc. to achieve uniform particle size distribution, improved utilization, and improved electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Mix lithium hydroxide, diammonium hydrogen phosphate and silver oxide at a Li:P:Ag molar ratio of 1:1:0.00005, dissolve in distilled water, add 1g of citric acid and 1mL of ethylene glycol, and heat at 55°C Stirring under conditions to make a sol;

[0039] In the second step, in the first step sol, add glucose whose molar weight is 1 times the molar weight of the silver salt, react for 5 minutes, add ferrous oxalate equal to the molar number of the lithium salt and an equimolar amount based on pure carbon Acetylene black (Li:Fe:C=1:1:1, molar ratio), mixed evenly, vacuum-dried at 65°C for 12 hours, ball milled for 0.5 hour, and the ball-milled mixture powder was pressed into a square shape to obtain Precursors for the synthesis of lithium iron phosphate;

[0040] The third step is to place the precursor of the second step in a vacuum reaction furnace, react for 36 hours at a vacuum degree of about 1 Pa and 550 ° C, and ball mill to obtain metal silver-doped car...

Embodiment 2

[0043]The first step, lithium hydroxide, lithium acetate and lithium carbonate mixed in equimolar amounts, mixed with equimolar amounts of diammonium hydrogen phosphate, ammonium phosphate, and silver nitrate and silver oxide mixed in equimolar amounts by Li: P: Ag moles Mix at a ratio of 1:1:0.0001, dissolve in deionized water, add 2g of citric acid and 5mL of ethylene glycol, and stir at 60°C to make a sol;

[0044] In the second step, in the first step sol, add glucose whose molar weight is 2 times that of the silver salt molar weight, react for 55 minutes, add ferrous oxalate with a molar number equal to that of the lithium salt and an equimolar amount based on pure carbon The mixture of mixed acetylene black and activated carbon (Li: Fe: C = 1: 1: 1, molar ratio), mixed evenly, vacuum-dried at 125°C for 1 hour, ball milled for 5 hours, and the ball-milled mixture powder was pressed into Block type, made into a precursor for the synthesis of lithium iron phosphate;

[004...

Embodiment 3

[0048] The first step, lithium oxalate and lithium acetate mixed in equimolar amounts, mixed with equimolar amounts of diammonium hydrogen phosphate and ammonium phosphate and silver fluoride and silver oxide mixed in equimolar amounts, by Li: P: Ag molar ratio is 1 : Mix at a ratio of 1:0.0002, dissolve in distilled water, add 5g of citric acid and 10mL of ethylene glycol, and stir at 65°C to make a sol;

[0049] In the second step, in the first step sol, add glucose whose molar weight is 1.2 times of the silver salt molar weight, react for 50 minutes, add ferrous oxalate with the same molar number as the lithium salt molar number and an equivalent molar amount based on pure carbon A mixture of graphite and activated carbon (Li:Fe:C=1:1:1, molar ratio), mixed evenly, vacuum-dried at 120°C for 3 hours, ball milled for 4 hours, and the ball-milled mixture powder was pressed into cubes type, made into a precursor for the synthesis of lithium iron phosphate;

[0050] The third s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com