Electric field activated sintering method of solid electrolyte material

A technology of electric field activation sintering and solid electrolyte, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of high sintering temperature, low lithium ion conductivity, long sintering time, etc., and achieve low sintering temperature, lithium High ionic conductivity and the effect of improving synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

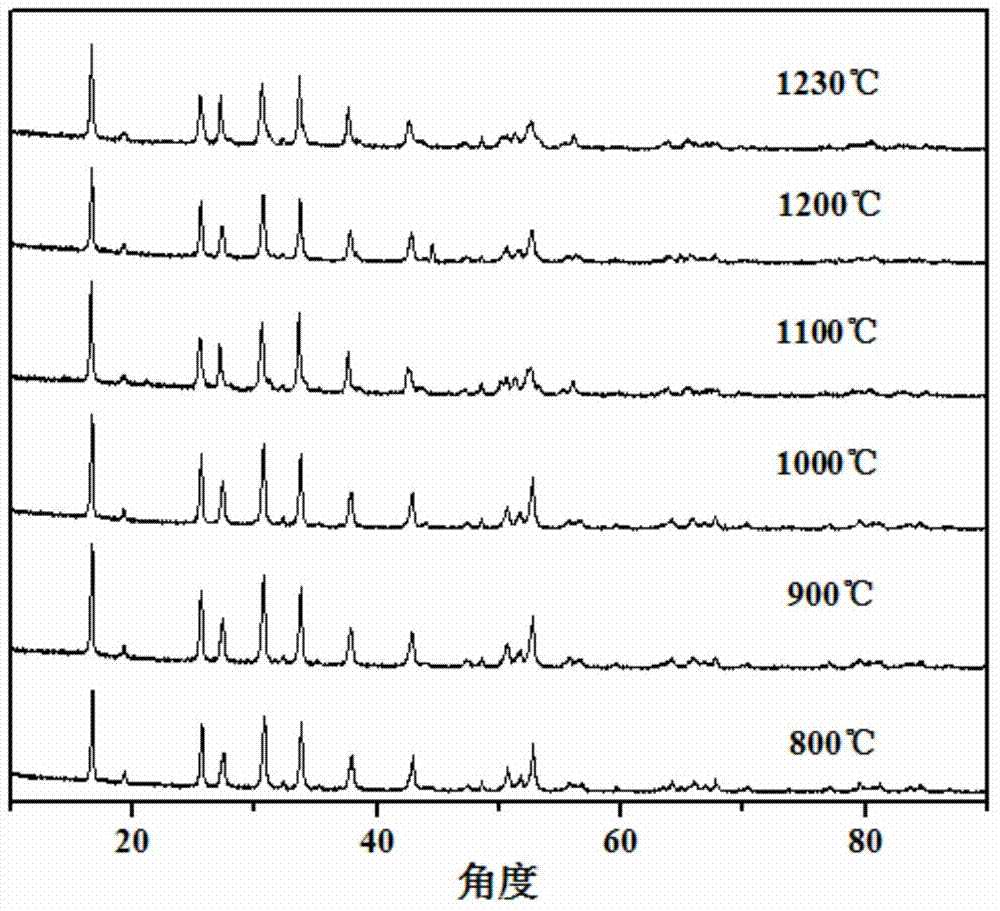

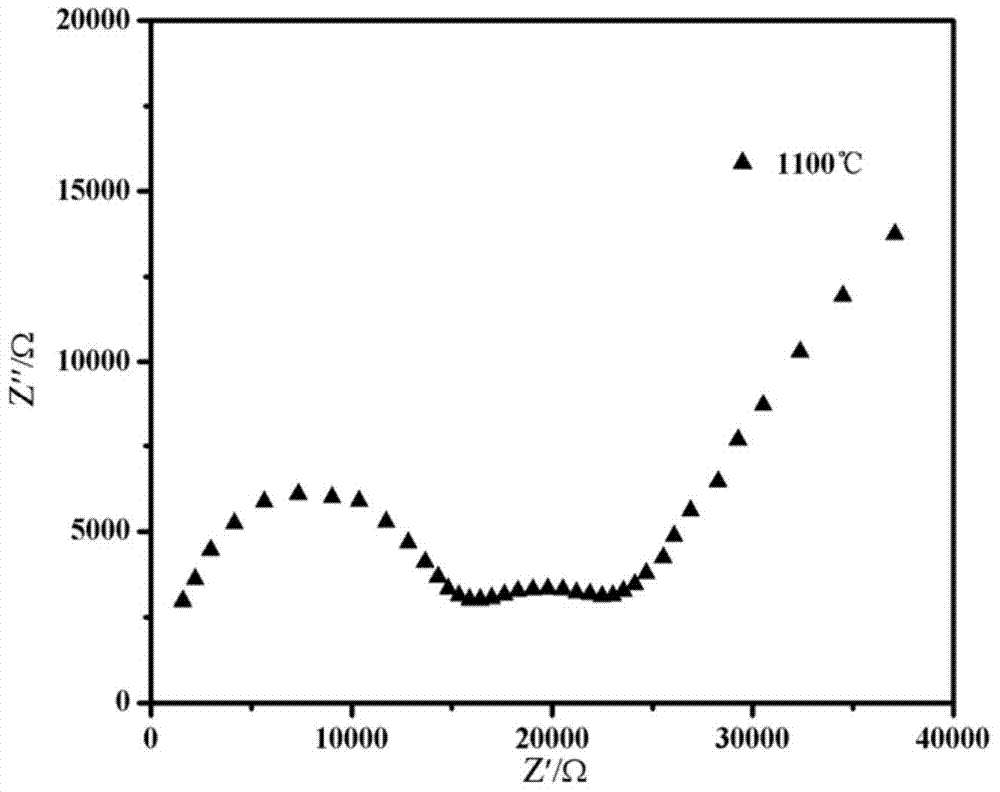

[0031] Use lithium oxide Li 2 O, lanthanum oxide La 2 o 3 , Zirconia ZrO 2 The powder is used as the raw material powder, and the lanthanum oxide (La 2 o 3 ) was roasted at a constant temperature of 900°C. According to the mass fraction is 9.2%, 60.4% and 30.4% respectively weigh and synthesize 5g required raw material powder lithium oxide (Li 2 O, 99.9%) 0.46g, lanthanum oxide (La 2 o 3 ,99.99%) 3.02g, zirconia (ZrO 2 ,99.9%) 1.52g. Put the above three kinds of powder into a ball mill jar made of zirconia for ball milling, and use zirconia balls as the ball milling medium, use isopropanol as the solvent, and the mass ratio of isopropanol to powder is 3:1, and the milling speed is 100 Ball milling for 36 hours under rpm. The ball-milled powder was put into a vacuum drying oven and dried at 80° C. for 6 hours. Weigh 1.5g of the dried powder and put it into a graphite mold, keep the pressure at 0MPa when the temperature is <800°C, and keep it warm for 5 minutes; then ...

Embodiment 2

[0033] Use lithium oxide Li 2 O, lanthanum oxide La 2 o 3 , Zirconia ZrO 2 The powder is used as the raw material powder, and the lanthanum oxide (La 2 o 3 ) was roasted at a constant temperature of 900°C. According to the mass fraction of 10.1%, 59.8% and 30.1%, respectively weigh and synthesize 5g of the required raw material powder lithium oxide (Li 2 O, 99.9%) 0.505g, lanthanum oxide (La 2 o 3 ,99.99%) 2.99g, zirconia (ZrO 2 ,99.9%) 1.505g. Put the above three kinds of powder into a ball mill jar made of zirconia for ball milling, and use zirconia balls as the ball milling medium, use isopropanol as the solvent, and the mass ratio of isopropanol to powder is 3:1, and the milling speed is 200 Ball milling for 24 hours at rpm. The ball-milled powder was put into a vacuum drying oven and dried at 80° C. for 6 hours. Weigh 1.5g of the dried powder and put it into a graphite mold, keep the pressure at 0MPa when the temperature is <800°C, and keep it warm for 4 minute...

Embodiment 3

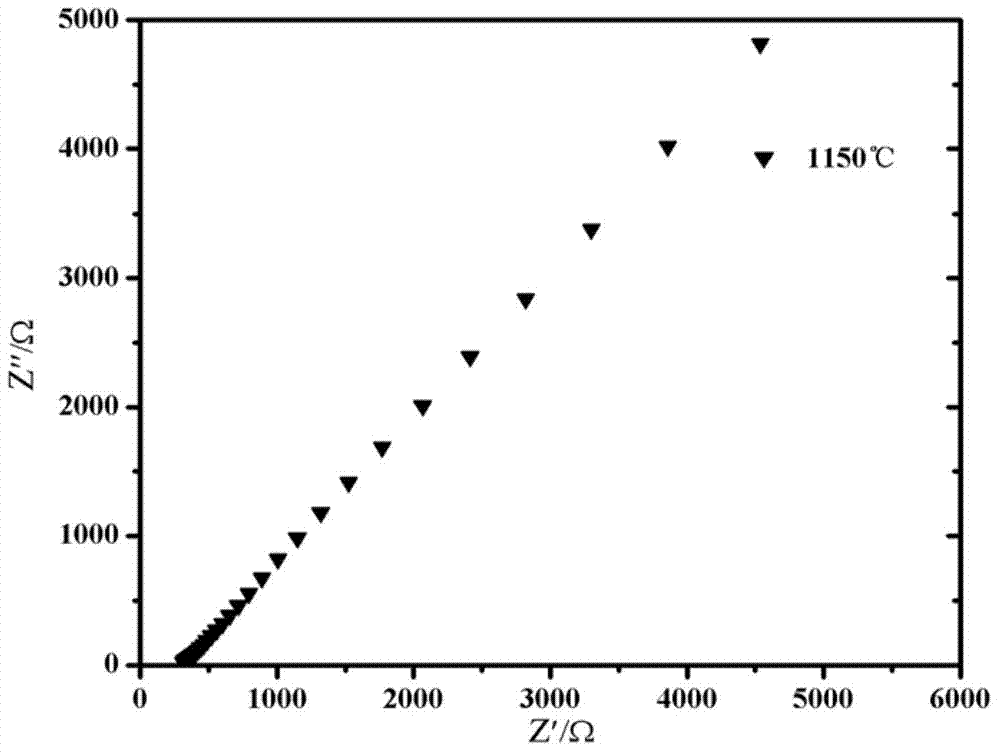

[0035] Use lithium oxide Li 2 O, lanthanum oxide La 2 o 3 , Zirconia ZrO 2 The powder is used as the raw material powder, and the lanthanum oxide (La 2 o 3 ) was roasted at a constant temperature of 900°C. According to the mass fraction is 11.8%, 58.7% and 29.5% respectively weigh and synthesize 10g required raw material powder lithium oxide (Li 2 O,99.9%) 1.18g, lanthanum oxide (La 2 o 3 ,99.99%) 5.87g, zirconia (ZrO 2 ,99.9%) 2.95g. Put the above three kinds of powder into a ball mill jar made of zirconia for ball milling, and use zirconia balls as the ball milling medium, use isopropanol as the solvent, and the mass ratio of isopropanol to powder is 6:1, and the milling speed is 300 Ball milling for 12 hours under rpm. The powder after ball milling was put into a vacuum drying oven, and dried at 80° C. for 8 hours. Weigh 1.5g of the dried powder and put it into a graphite mold, keep the pressure at 0MPa when the temperature is <800°C, and keep it warm for 3 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com