Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Improve field emission performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

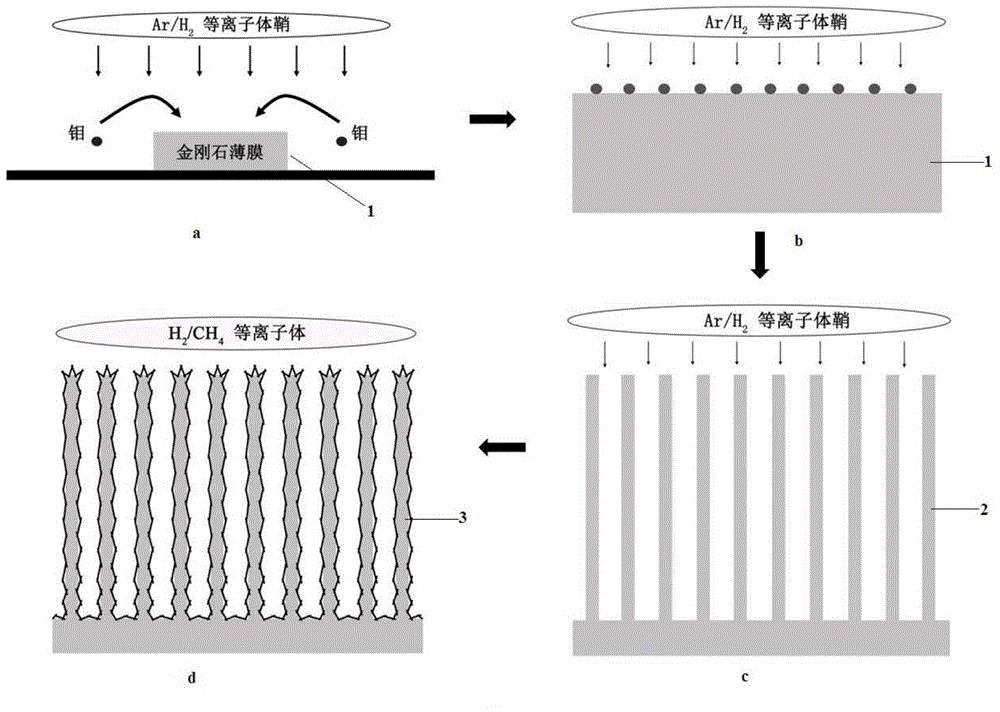

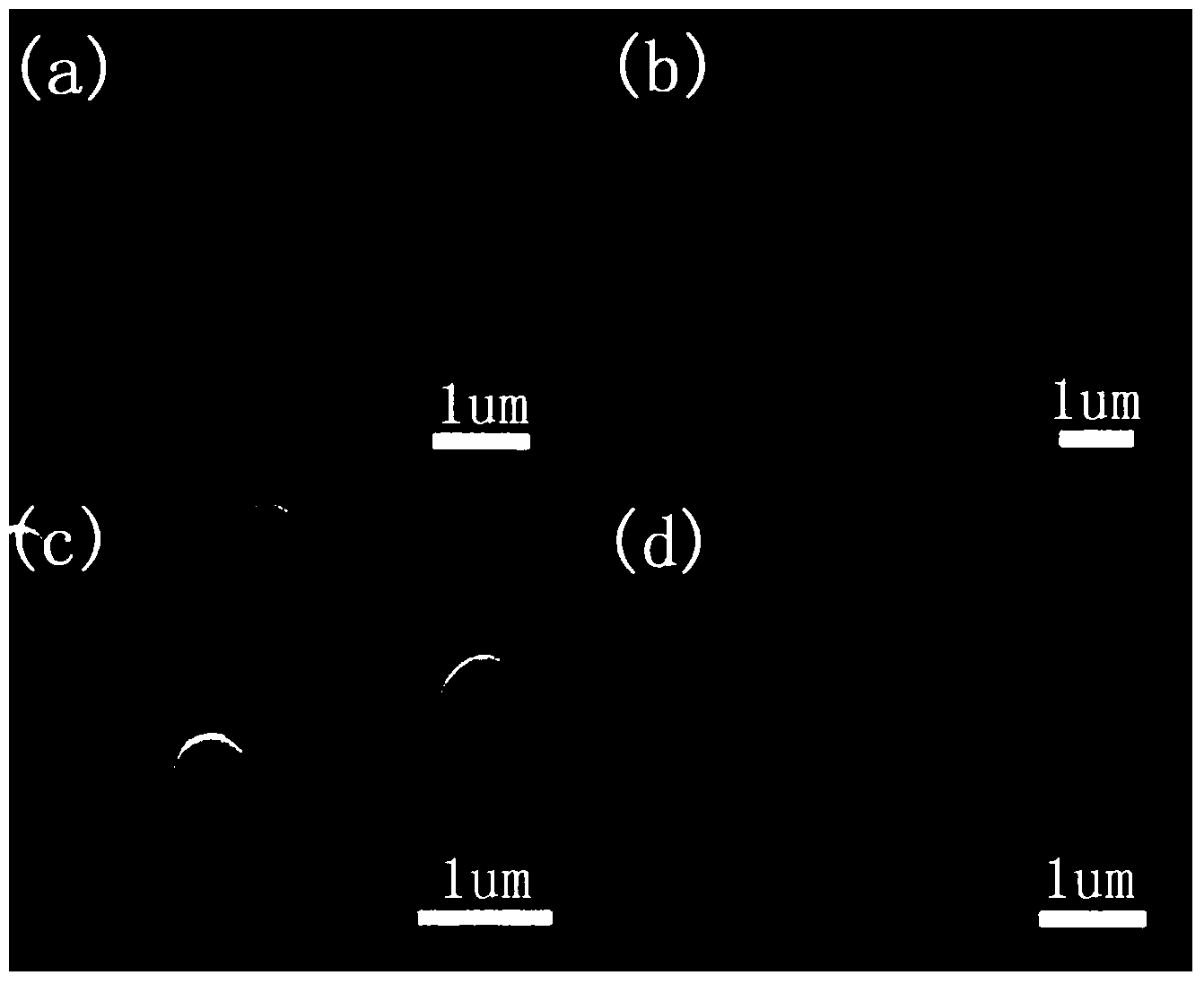

Carbon nano-fibre/carbon nano-tube heterogeneous nano-array for field electronic emitter and manufacturing technology thereof

InactiveCN101508421AEasy to operateImprove field emission performanceIndividual molecule manipulationImage/pattern display tubesFiberManufacturing technology

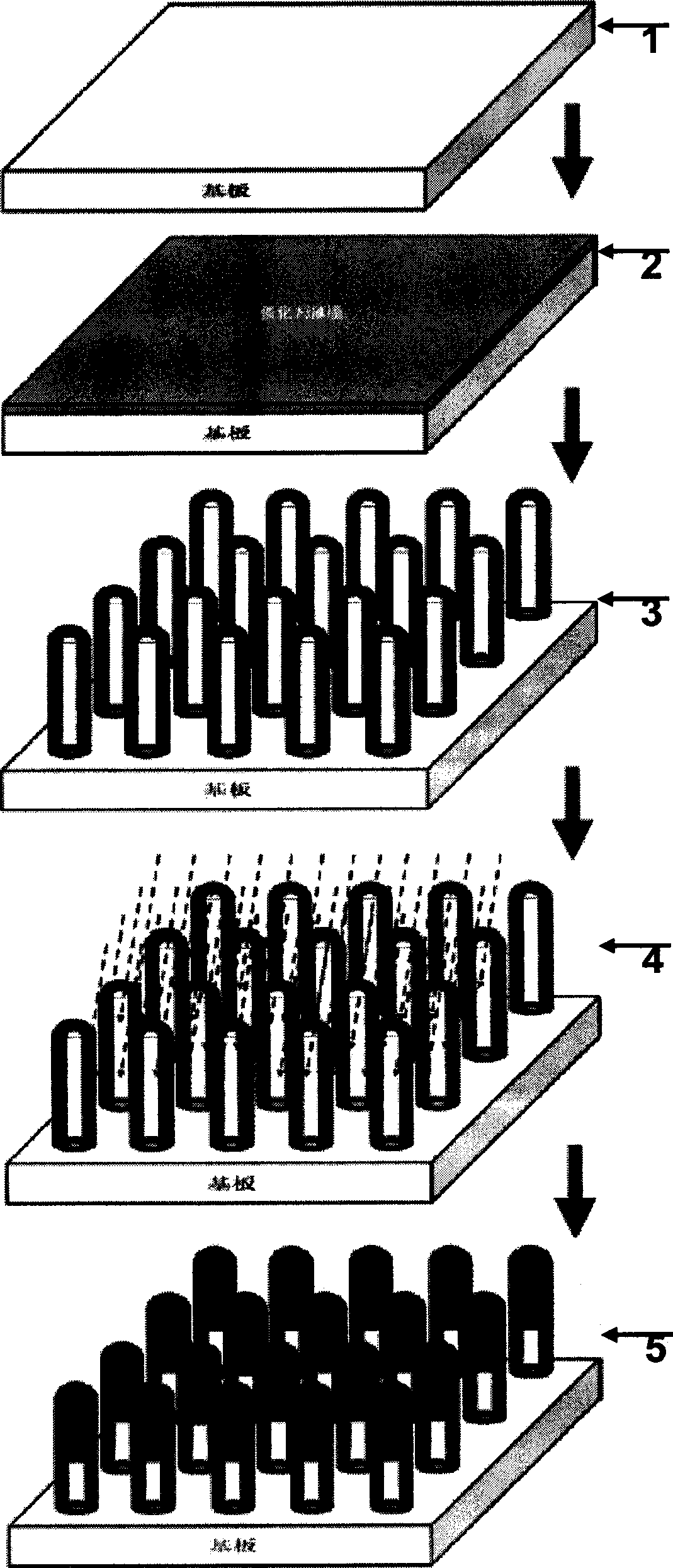

The invention discloses a carbon nano fiber / carbon nanotube heterogenous nano array capable of being used for a field electronic emitter and a preparation method thereof. The preparation method mainly comprises the following steps: (1) taking a silicon single-crystal chip or a glass sheet or a ceramic chip, and the like as a substrate; (2) utilizing magnetic filtration vacuum vapor arc plasma deposition technology or magnetron sputtering technology to deposit a catalyst film on the substrate; (3) performing high-temperature heat treatment on the catalyst film in an ammonia gas reaction chamber; (4) introducing working mixture taking hydrogen as carrier gas and acetylene as reaction gas at high temperature, and synthesizing a directional carbon nanotube array on the substrate subjected to heat treatment; (5) adopting an energy-carrying ion beam or a plasma to process the carbon nanotube, and forming the carbon nano fiber / carbon nanotube heterogenous nano array; and (6) using the carbon nano fiber / carbon nanotube heterogenous nano array to process the field electronic emitter.

Owner:BEIJING NORMAL UNIVERSITY

New method for synthesizing patterned single-crystal tungsten oxide nanowire arrays with catalyst localization technology

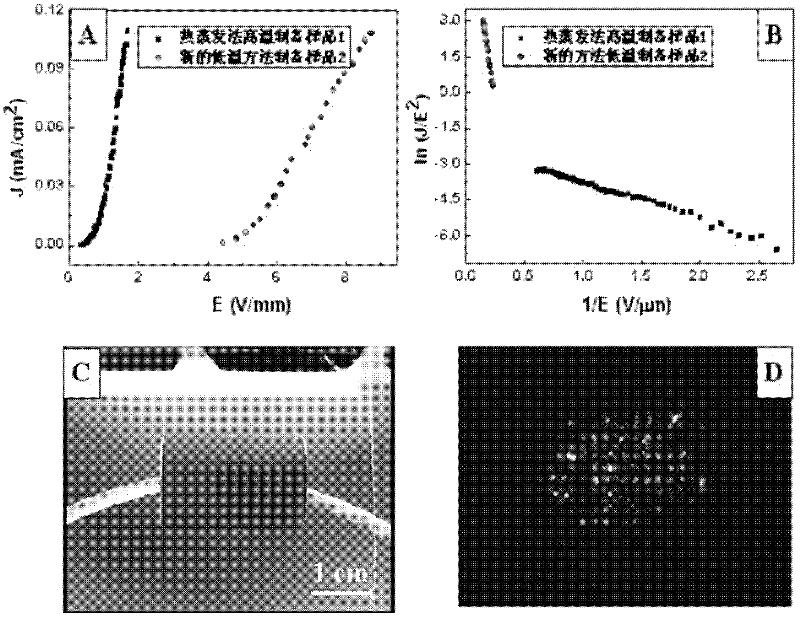

ActiveCN102358938AHigh Field Emission UniformityLow Field Emission UniformityChemical vapor deposition coatingSource materialReaction temperature

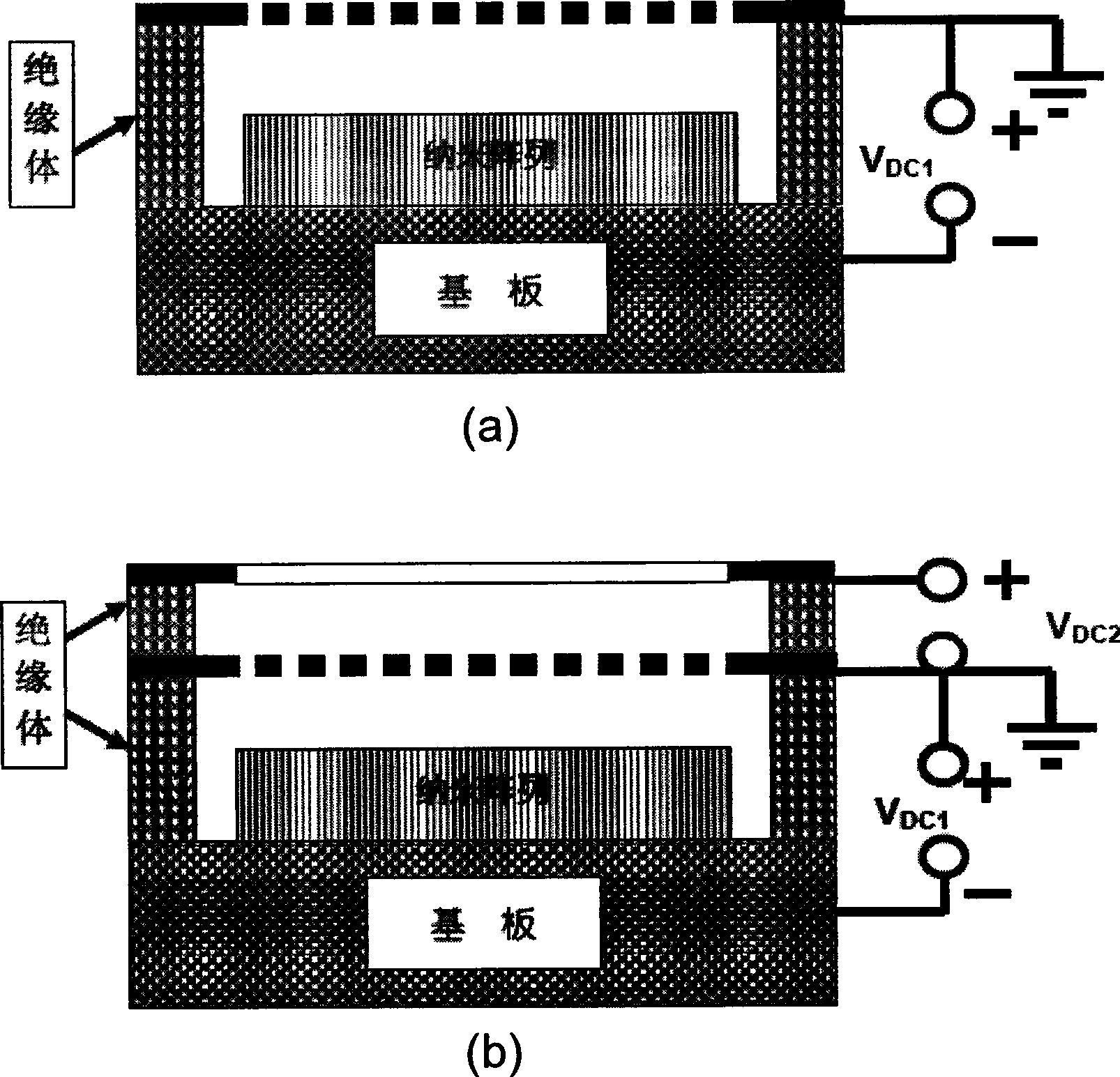

The invention discloses a new method for synthesizing patterned single-crystal tungsten oxide nanowire arrays with a catalyst localization technology. Employing a tungsten film as a source material and a metal nanoparticle film as a catalyst, the method comprises: (a) catalyst film localization synthesis: realizing film patterning through fixation of a ceramic template and a substrate material together or application of the exposure technology in a micromachining process, then enabling localization growth of the catalyst nanoparticle film in a vacuum plating instrument; (b) chemical vapor deposition: in a reaction gas atmosphere and at a temperature of 400-800DEG C, placing a W film into a CVD device for growth of 1-8h, then opening a fixation device or removing a photoresist, thus finally obtaining patterned tungsten oxide nanowire arrays. The preparation method of the invention not only can prepare patterned tungsten oxide nanowire arrays of different growth density, but also has the advantages of low reaction temperature (lower than 500DEG C) and suitability for the growth of low-melting point substrates.

Owner:SUN YAT SEN UNIV

SiC flexible field emission cathode material

ActiveCN103311068AImprove flexibilityExcellent Field Emission PerformanceCold cathode manufacturePyrolysisAtmosphere

A method of preparing SiC flexible field emission cathode material includes the steps: 1, holding organic precursor polysilazane at 260 DEG C for 30 min for thermal crosslinking and solidification, and crushing by ball milling; 2, making a flexible substrate out of carbon cloth, soaking the substrate in 0.05mol / LCo(NO3)2 ethanol solution for ultrasonic treatment for 10s, and naturally air-drying the substrate for use; 3, placing the crushed powder and the soaked carbon cloth substrate at the top and bottom of a graphite crucible; 4, placing the graphite crucible in an atmosphere sintering furnace, and heating to 1500-1550 DEG C under the protection of nitrogen-argon mixed atmosphere for high temperature pyrolysis; 5, allowing for furnace cooling till room temperature so that a flexible SiC quasi-oriented nano array with the carbon cloth substrate is prepared; and 6, using the SiC quasi-oriented nano array structure as the field emission cathode for field emission performance detection and analysis. The prepared SiC field emission cathode material is well flexible and excellent in field emission performance, and is expected to be applied to the fields of flexible displays, small-sized X-ray tubes and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Array nanotube, mfg. method and use thereof

InactiveCN1401560ARegular arrayUniform structureSemiconductor/solid-state device manufacturingNitrogen and non-metal compoundsField emission deviceDisplay device

A carbon nitride nanotube array used for field emission device can be directly grown on the substrate. Its diameter is 20-200 nm. Its length is 1-100 microns. Its N content is 0.5-9%. Its initial emissino field is 1.5-5 V / micron.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing molybdenum disulfide film for field emission device

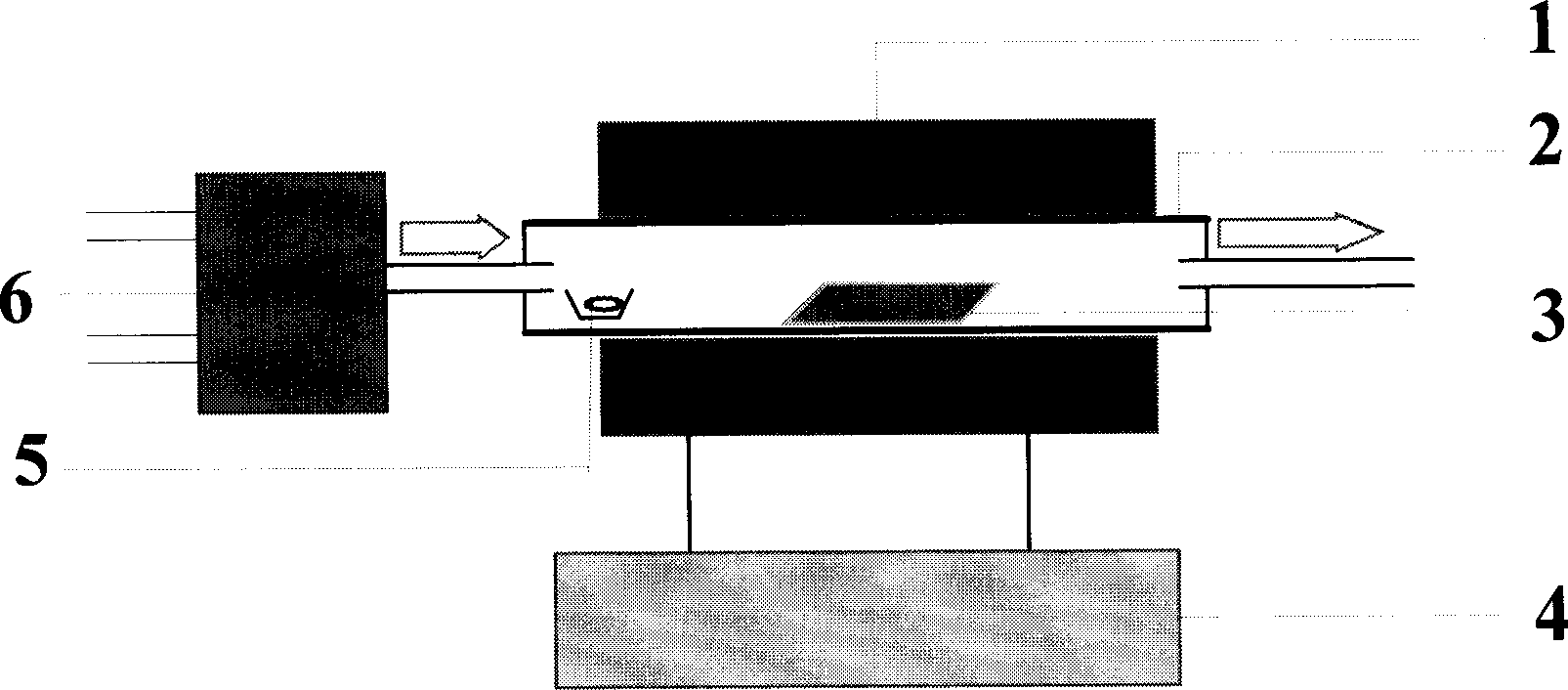

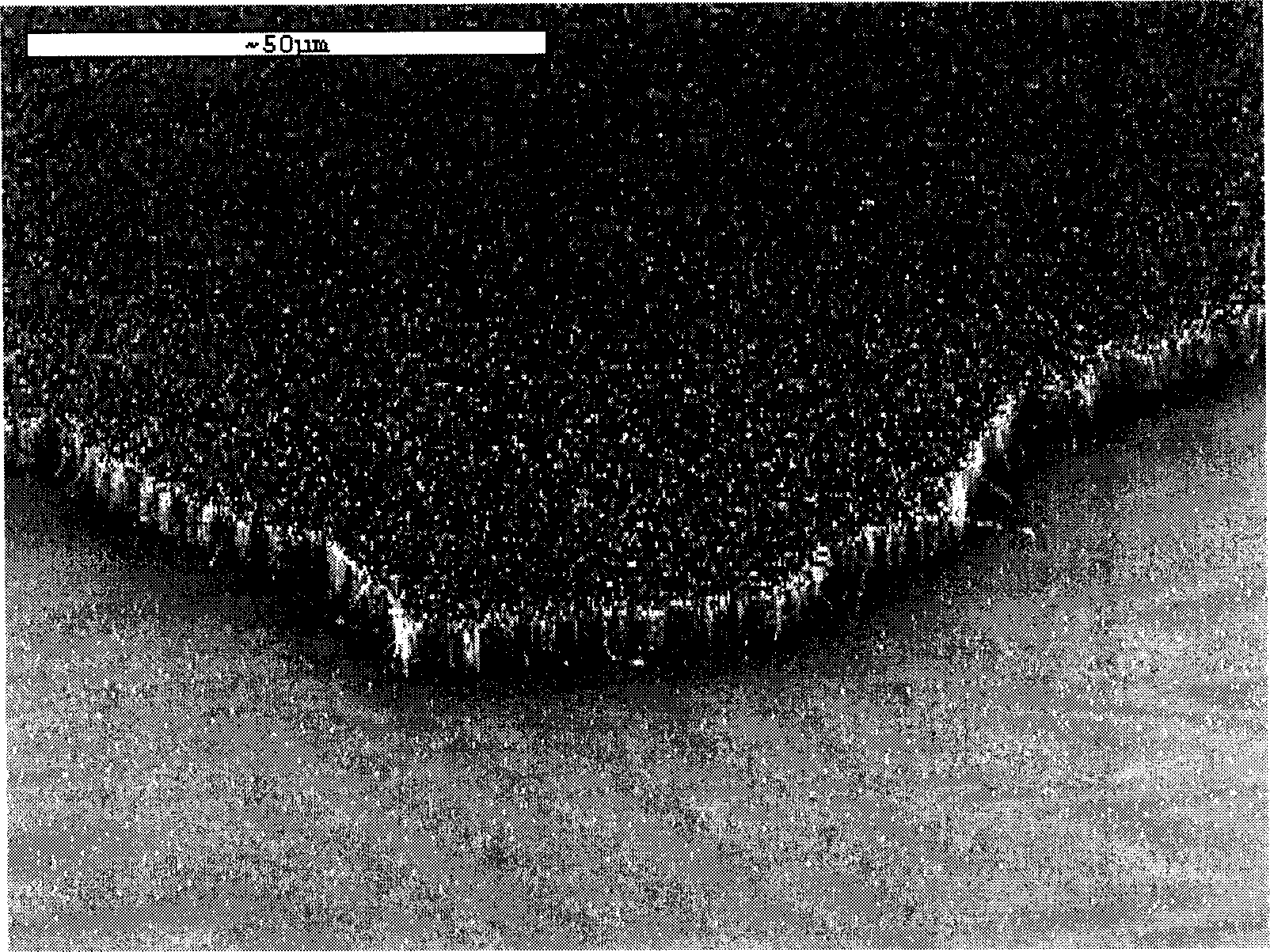

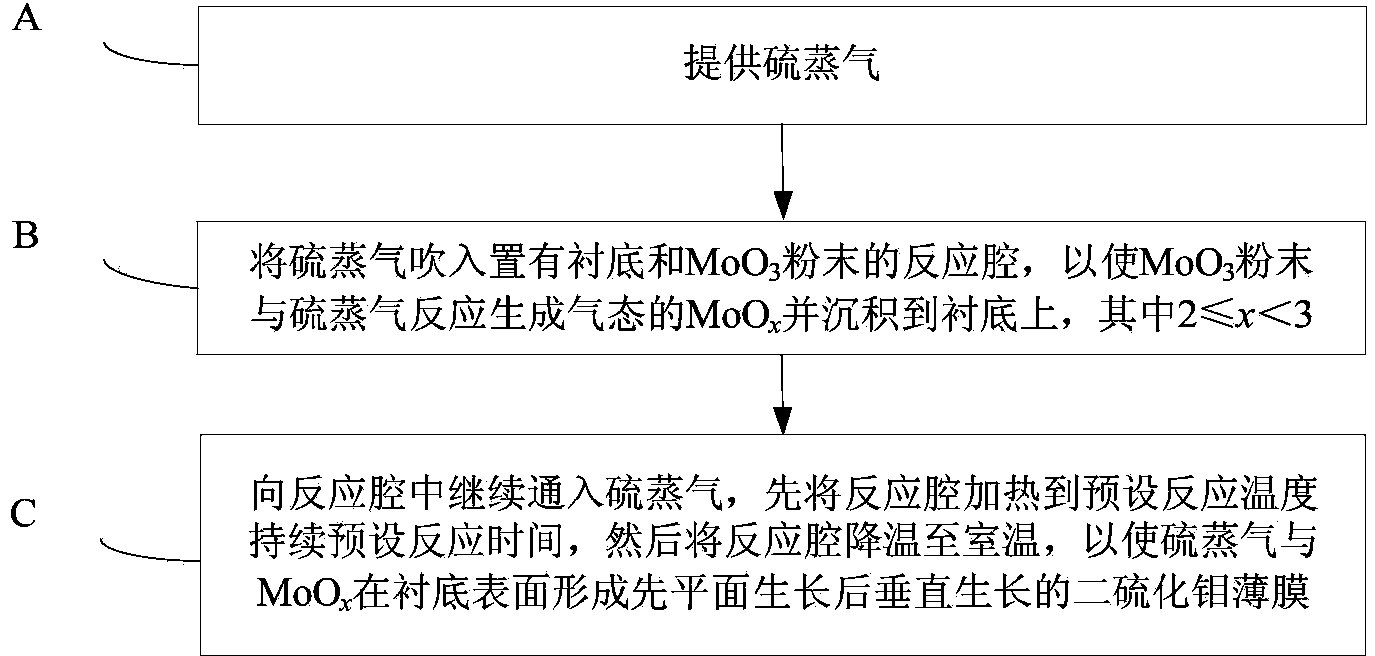

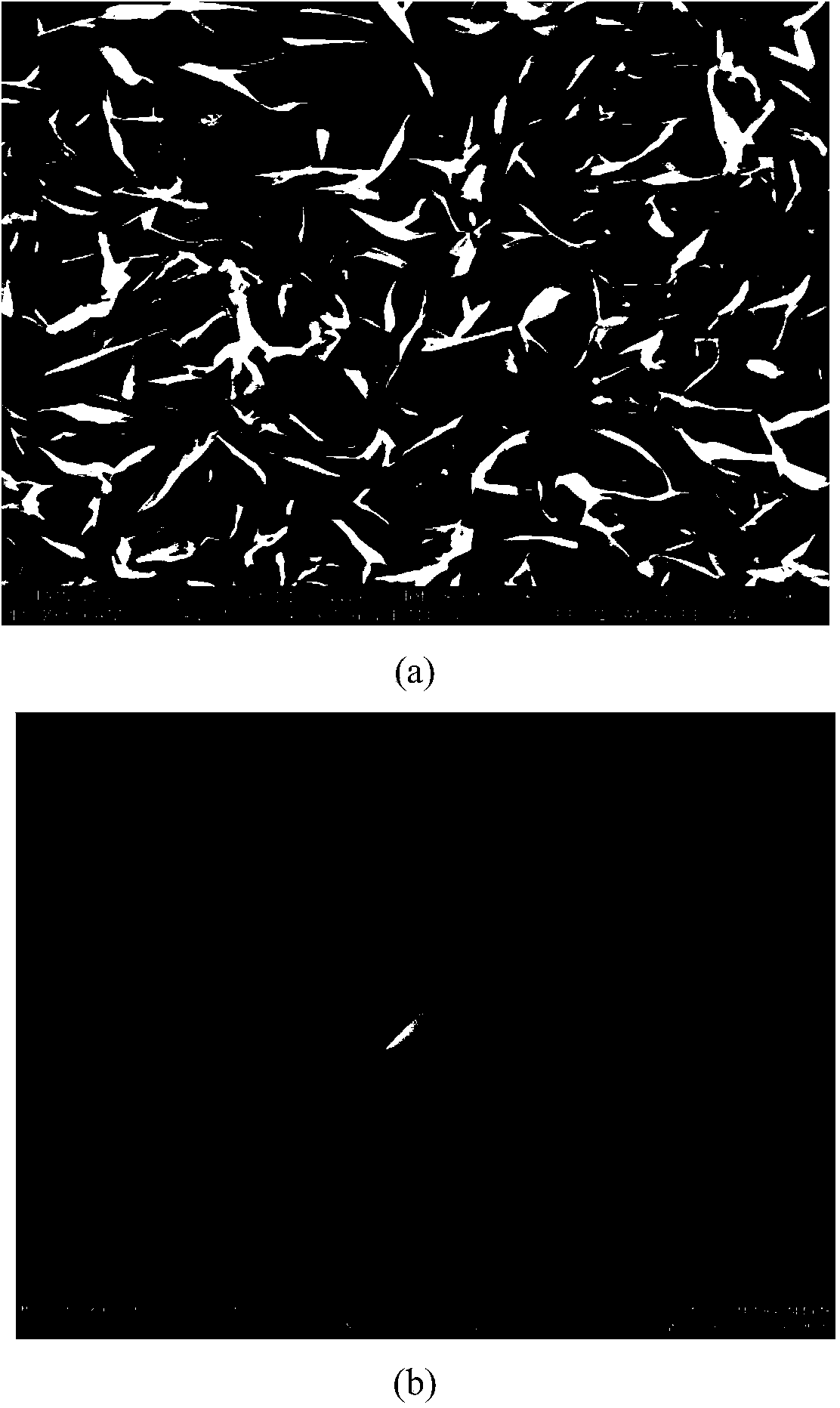

InactiveCN103924213ALarge specific surface areaRich space geometric edgeElectric discharge tubesDischarge tube/lamp detailsReaction timingChemistry

The invention discloses a method for preparing a molybdenum disulfide film for a field emission device. The method comprises the following steps: providing sulfur vapor; blowing the sulfur vapor into a reaction cavity with a substrate and MoO3 powder, so that the MoO3 powder reacts with the sulfur vapor to generate gaseous MoOx and deposit on the substrate, wherein x is smaller than 3 and greater than or equal to 2; continuing to introduce the sulfur vapor into the reaction cavity; and firstly heating the reaction cavity to the preset reaction temperature to last for preset reaction time, and then cooling the reaction cavity to room temperature and lasting for second reaction time, so that the molybdenum disulfide film which firstly grows in a plane and then vertically grows is formed by the sulfur vapor and MoOx on the surface of the substrate. The preparation method of the molybdenum disulfide film disclosed by the invention is simple and feasible, and the obtained MoS2 film is good in field emission properties.

Owner:TSINGHUA UNIV

Method for preparing titanium dioxide nano tip array film for field emission

InactiveCN102995091ASimplify the manufacturing processThe experimental equipment is simpleSurface reaction electrolytic coatingNanotechnologyTitaniumField intensity

The invention provides a method for preparing a titanium dioxide nano tip array film for field emission, mainly comprising the following steps of: firstly, performing primary anodic oxidation on a swing-cleaned titanium sheet, and then removing the titanium dioxide nano-tube film attached to the titanium sheet through ultrasound; and next, loading the titanium sheet into the electrode again and performing secondary anodic oxidation, and then taking out the titanium sheet for cleaning through swinging to finally obtain the titanium dioxide nano tip array film. The method provided by the invention realizes the preparation of the titanium dioxide nano tip array film suitable for field emission. Compared with the traditional microelectronic field emission tip array, the method provided by the invention is simple, and preparation parameters are easy to control; and the tip of the array is sharp, which is advantageous for gaining field emission. Furthermore, the titanium dioxide nano tip array film annealed at high temperature previously has lower opening and threshold field intensity; and particularly, the sample annealed at 450 DEG C has the minimum opening and threshold field intensity and is obviously improved in field emission performance.

Owner:PEKING UNIV

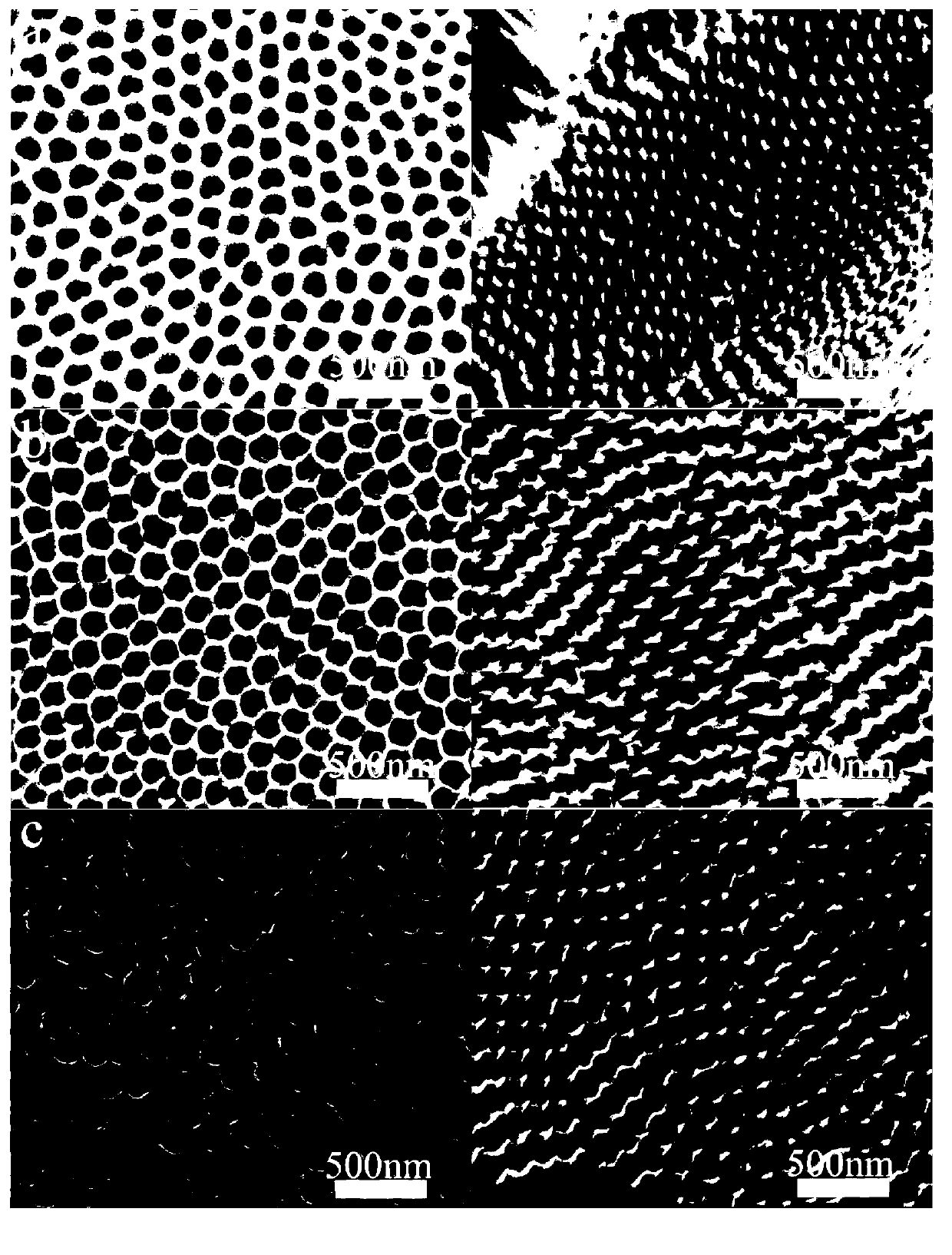

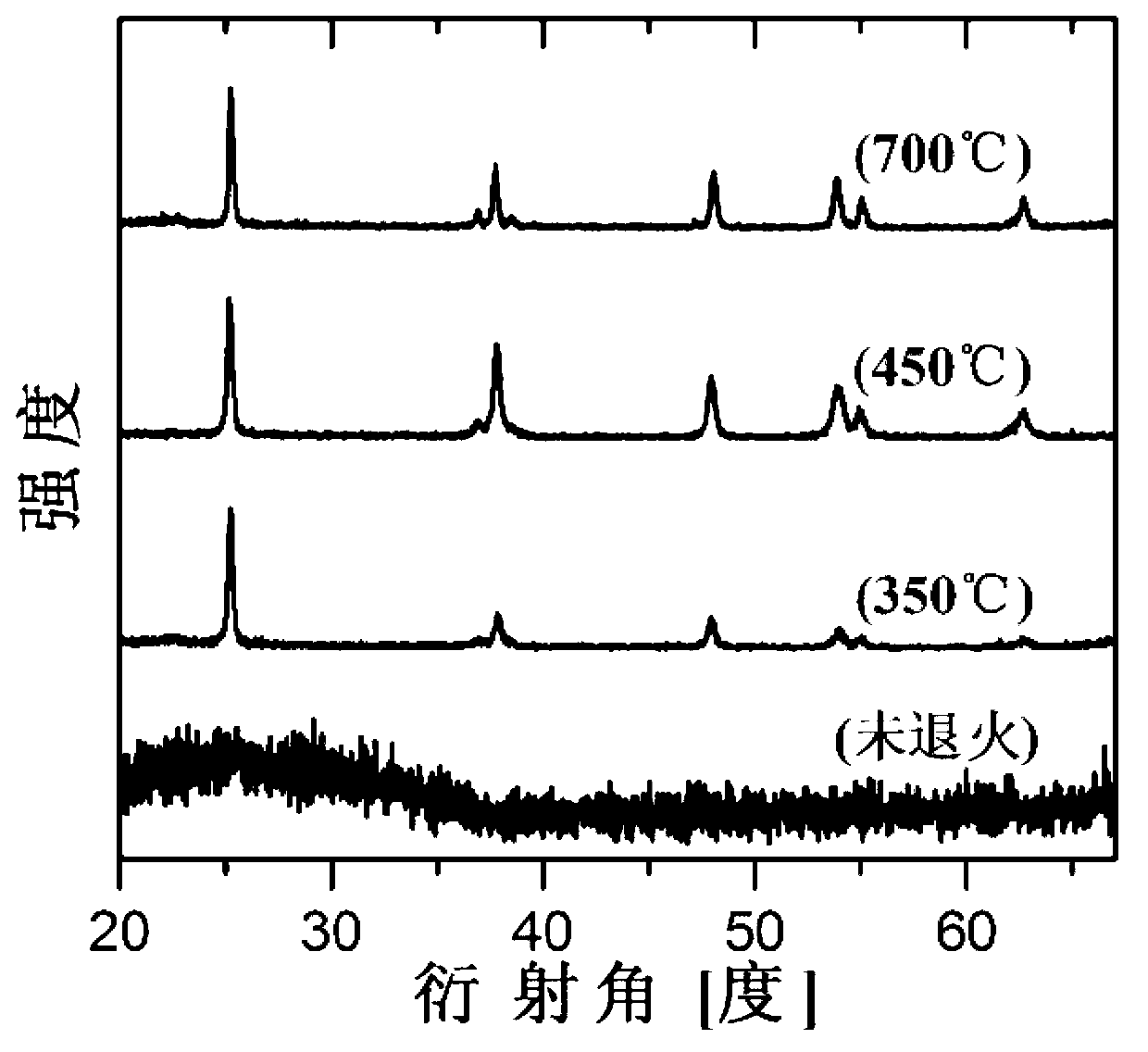

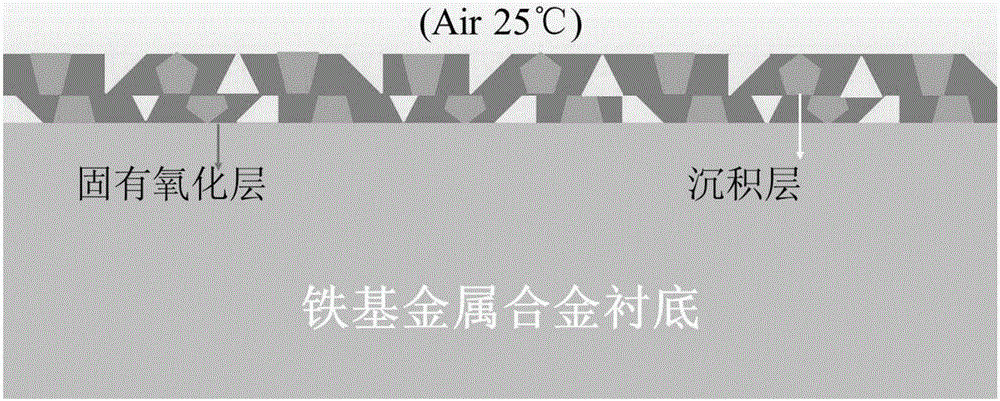

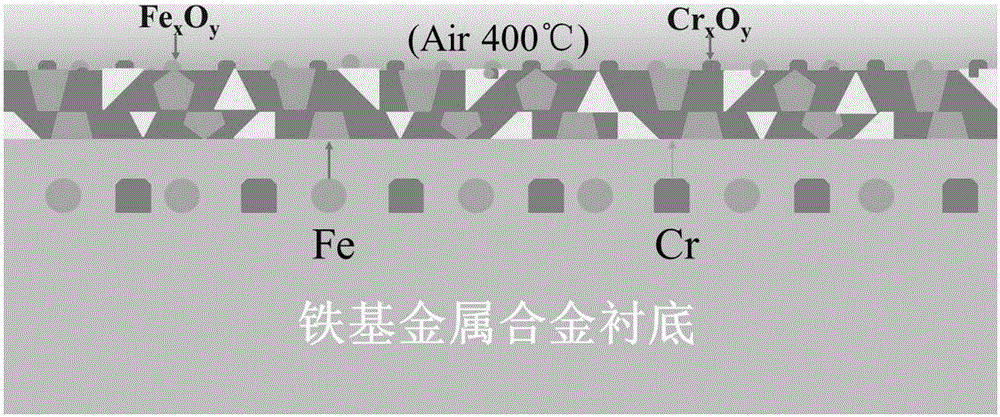

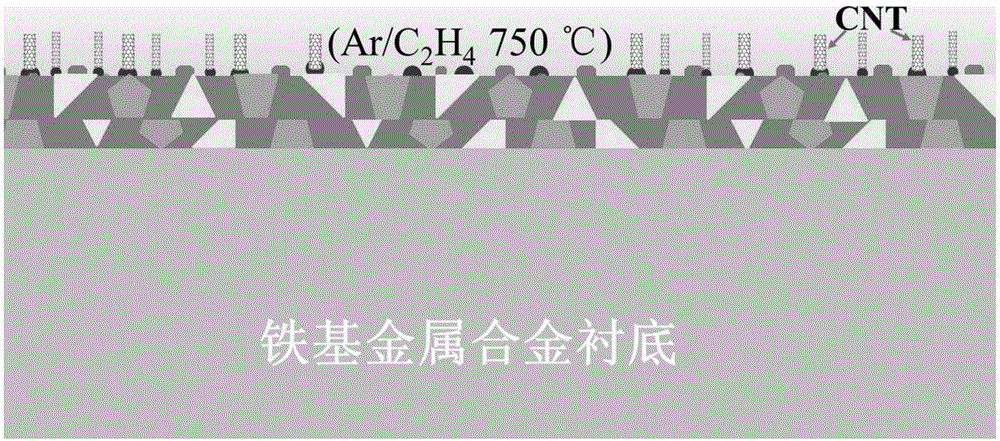

Preparation method for carbon nanotube array cathode on Fe-based metal alloy substrate

ActiveCN105070619AInhibited DiffusionEvenly distributedCold cathode manufactureField electron emissionCarbon nanotube

The invention provides a preparation method for a carbon nanotube array cathode on a Fe-based metal alloy substrate. According to the method, the contents of iron and chromium elements in a sedimentary deposit of the surface layer of the Fe-based metal alloy are regulated and controlled, chromium oxide and iron catalyst particles are obtained via oxidation and reduction, wherein the chromium oxide is arranged between the substrate and the iron catalyst particles in a stable manner so that the iron catalyst particles cannot react with the substrate, large-scale diffusion of the iron catalyst particles can be suppressed, and high-density and uniformly-distributed nanometer iron catalyst particles are obtained; and crack and nucleation of acetylene are performed via the catalysis of the iron nanometer particles so that the carbon nanotube array cathode is formed. The carbon nanotube array cathode reacts with the Fe-based alloy substrate in the processing process of vacuum high-temperature annealing, the carbon nanotube and the substrate are organically combined so that the transfer of electrons and heat between the carbon nanotube and the substrate can be effectively enhanced, and the performance of the field emission of the carbon nanotube array cathode is comprehensively improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

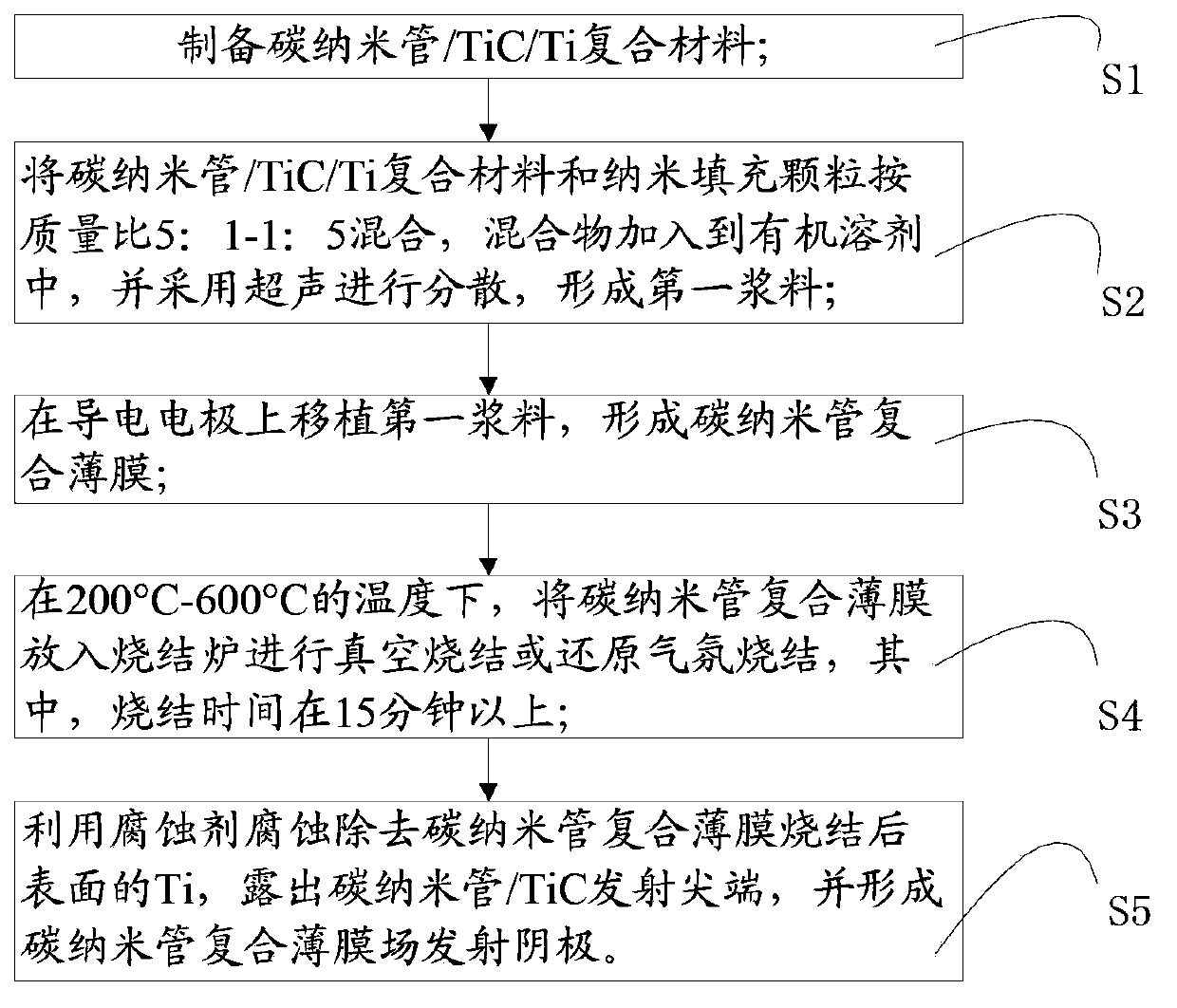

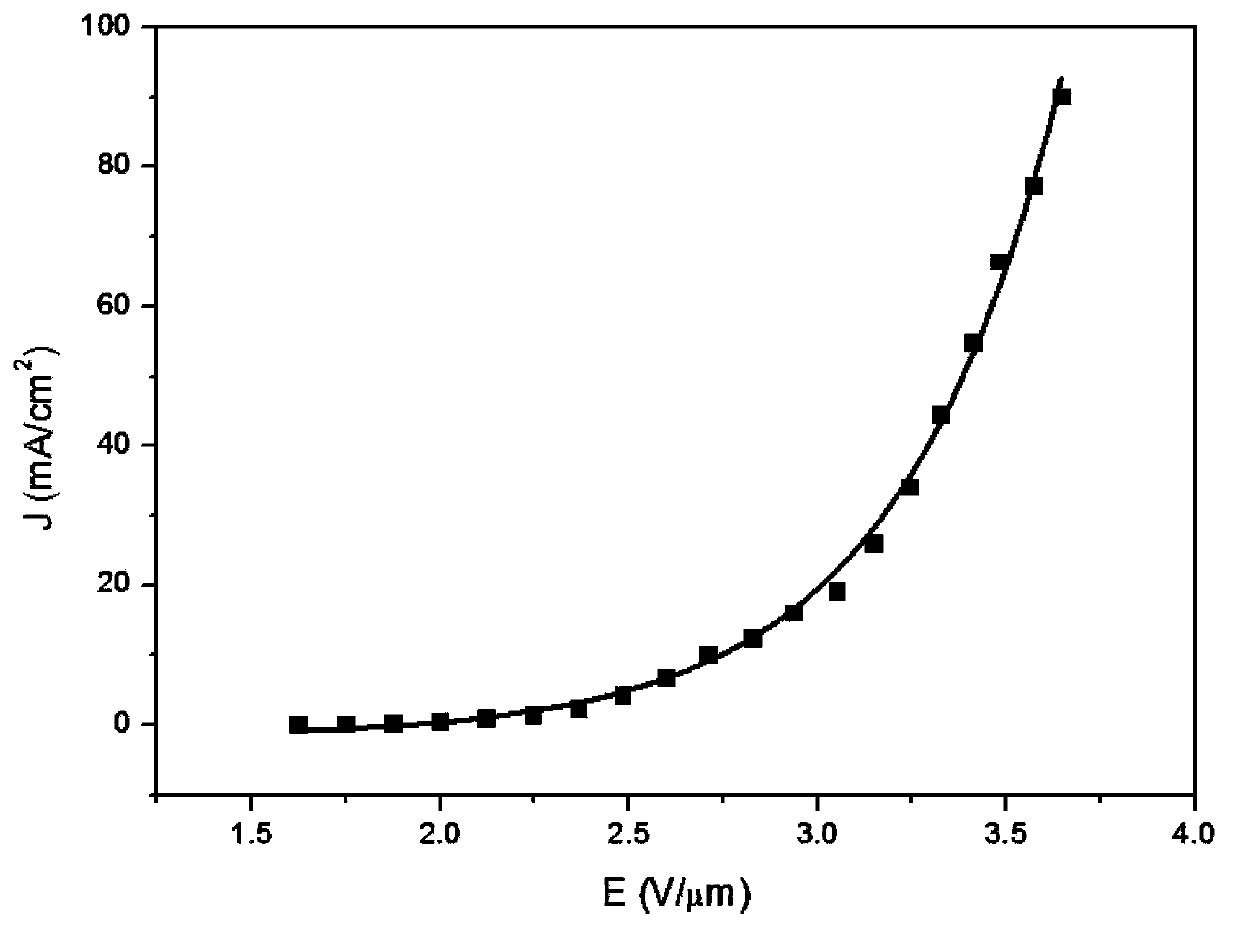

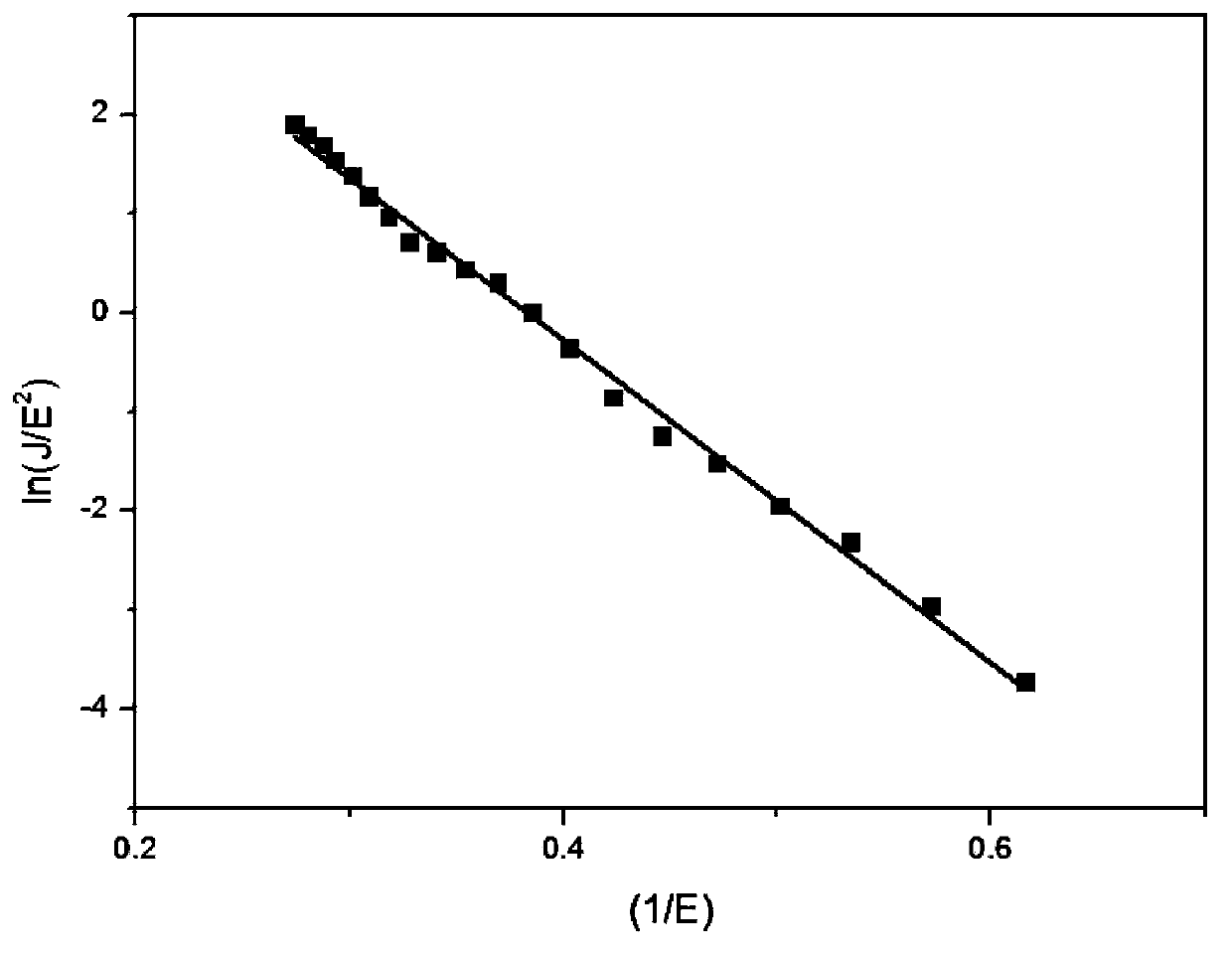

Carbon nanotube composite thin film field emission cathode preparation method

ActiveCN103871802AOvercoming the Schottky BarrierIncrease contact areaMaterial nanotechnologyCold cathode manufactureComposite filmSilver electrode

The invention provides a carbon nanotube composite thin film field emission cathode preparation method. The carbon nanotube composite thin film field emission cathode preparation method includes the following steps that: S1, nanotube / TiC / Ti composite materials are prepared; S2, the nanotube / TiC / Ti composite materials and nano filling particles are mixed according to at the mass ratio of 5:1 to 1:5, and the mixture is added to an organic solvent, and ultrasound is adopted to perform dispersion, and a first slurry can be formed; S3, the first slurry is transplanted on a silver electrode, and a nanotube composite film can be formed; S4, the nanotube composite film is put into a sintering furnace so as to be subjected to vacuum sintering or reducing atmosphere sintering for more than 15 minutes under temperature from 200 DEG C to 600 DEG C; S5, Ti on the surface of the sintered carbon nanotube composite film is corroded and removed through using a corrodent, and a carbon nanotube / TiC emission tip is exposed, and a carbon nanotube composite thin film field emission cathode can be formed. With the carbon nanotube composite thin film field emission cathode prepared by the invention adopted, adhesion and electrical contact between the emitter and the base of a carbon nanotube can be improved, and field emission performance can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

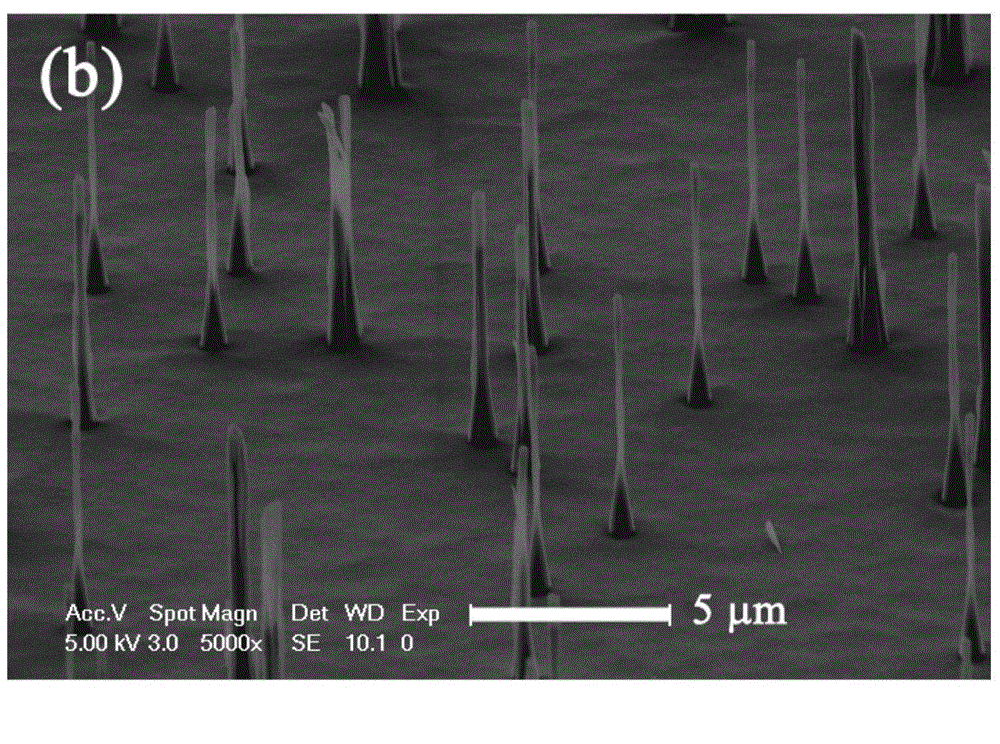

Diamond nano needle array composite material and preparation method and application thereof

ActiveCN104553124AImprove thermal conductivityImprove stabilityMaterial nanotechnologyLaminationHeat conductingGraphene

The invention provides a diamond nano needle array composite material and a preparation method and an application thereof. The diamond nano needle array composite material provided by the invention comprises a substrate layer and a diamond nano needle array which is formed on the surface of the substrate layer, wherein a three-dimensional graphene layer grows on the surface of a diamond nano needle in the diamond nano needle array. The preparation method of the diamond nano needle array composite material, disclosed by the invention, comprises the following steps: depositing a diamond film layer on the surface of a base body; etching the diamond film layer into a diamond nano needle array; and enabling the three-dimensional graphene layer to grow on the surface of the diamond nano needle array. The diamond nano needle array composite material disclosed by the invention is excellent in heat-conducting property, high in property field emission property and stability, simple in preparation process, and good in condition controllability, and can be applied to gas sensors, biosensors and electrochemical fields.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

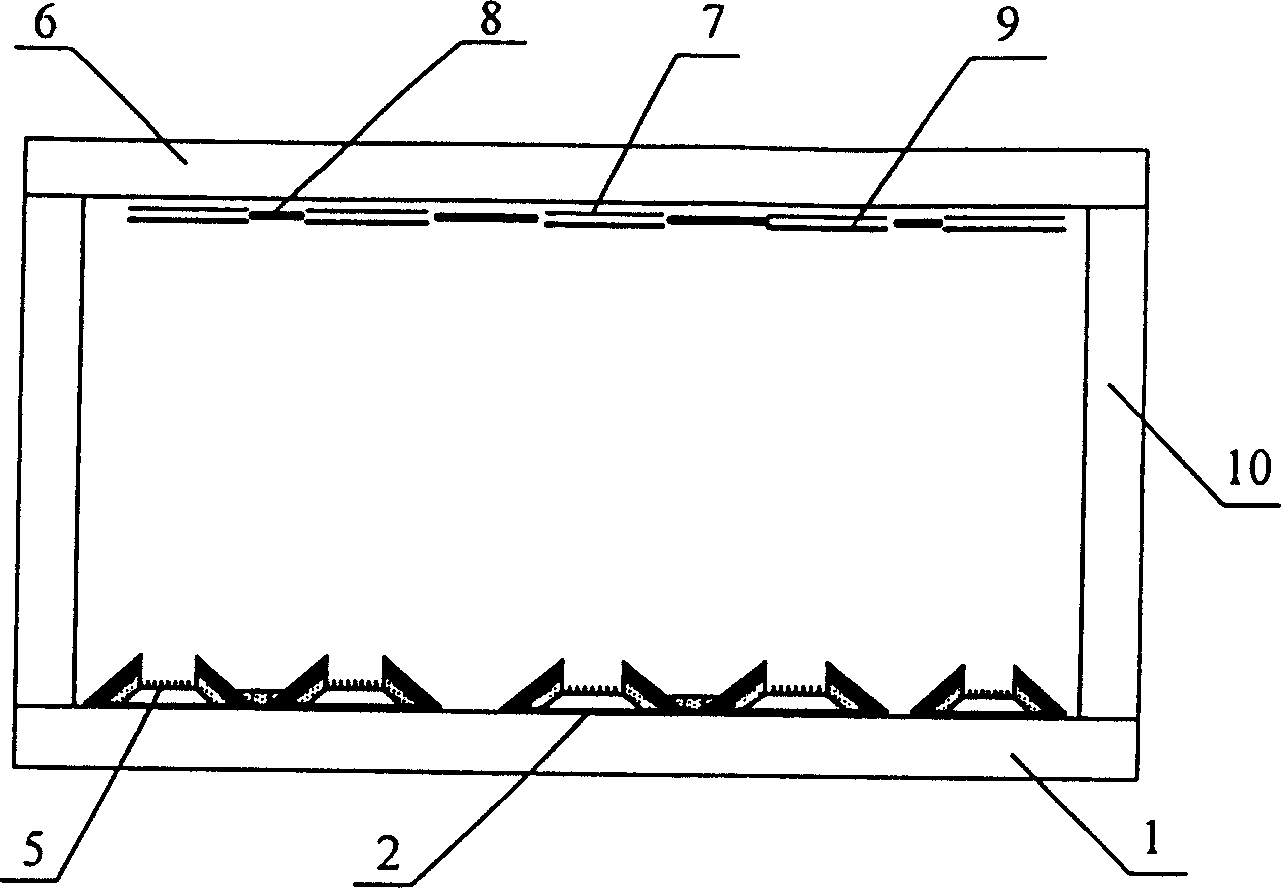

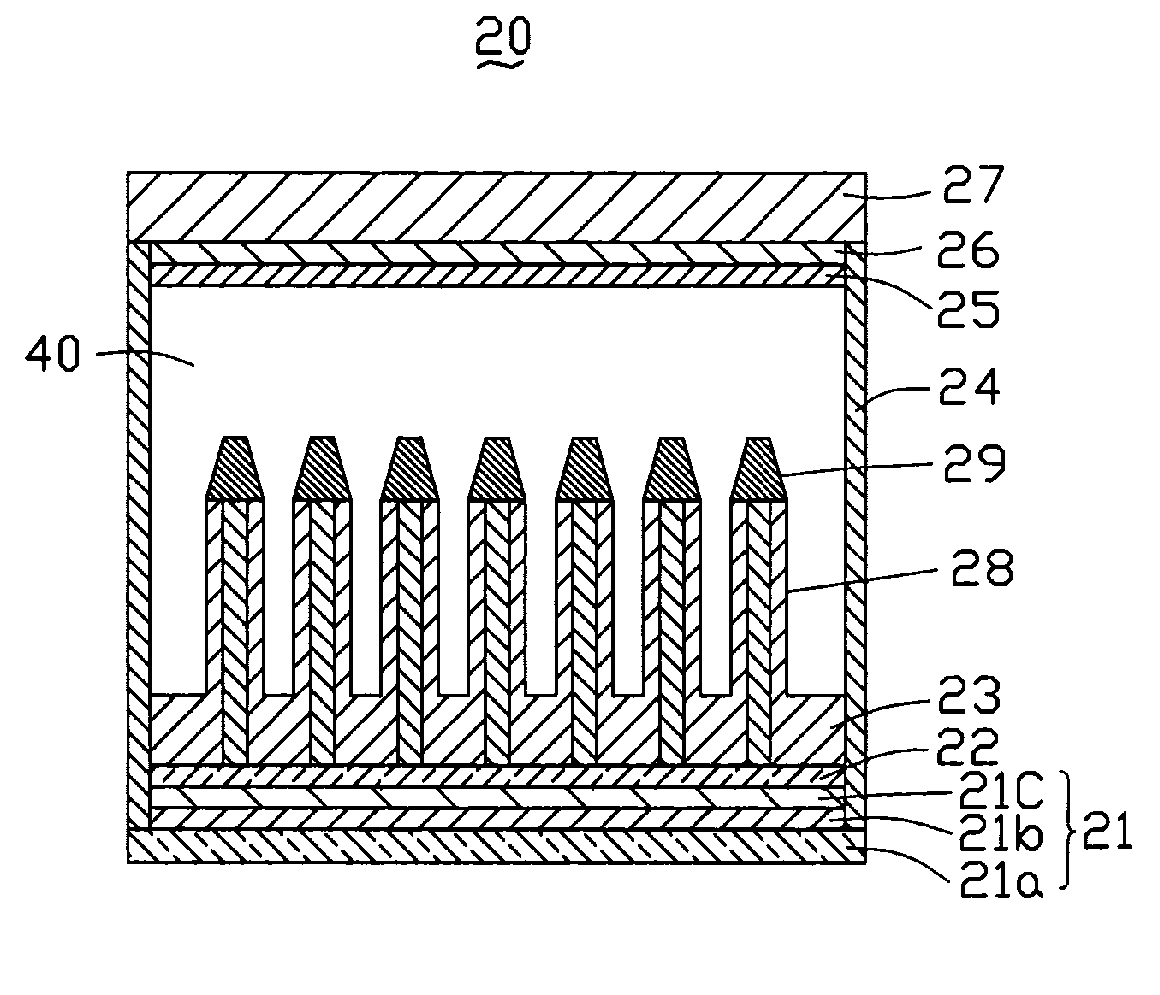

Tripolar field emission display of bridge grating structure and process for preparing same

InactiveCN1667789AIncreased ability to emit electronsImproved Field Emission PerformanceControl electrodesImage/pattern display tubesGratingThree stage

This invention relates to a three-stage field emission display of a carbon nm tube cathode with a bridge-grating structure and a manufacturing method, among which the display includes a sealing vacuum cavity made up of a cathode panel, an anode panel and a glass surrounding frame, the printed carbon nm tube cathode and a bridge-grating control grid for controlling the electronic emission of the tube are set on the cathode panel, a photo-etched SnIn oxide film layer and a phosphor powder layer are on the film layer on the anode panel, which increases the capability of emitting electrons of carbon nm tubes and improves the field emission performance of display devices.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Low-cost low-pollution gallium nitride nano-wire preparation generation method

ActiveCN102936006AImprove field emission performanceMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsSemiconductor materialsInorganic compound

The invention relates to a low-cost low-pollution gallium nitride (GaN) nano-wire preparation generation method, and belongs to the field of inorganic compound semiconductor materials. The method provided by the invention comprises the steps that: (1) GaN powder is subjected to gum-doping, grinding, tabletting, and calcining, such that a GaN target is prepared; (2) a washed and bake-dried silicon wafer is deposited for 30-60s by using a SBC-12 small ion sputtering instrument, such that a substrate with a gold film with a thickness of 10-30nm on the surface is obtained; and (3) a plasma-assisted hot-wire chemical vapor deposition method is utilized, wherein an atmospheric pressure is 1500Pa-2500Pa, a substrate temperature is 800-1000 DEG C, a bias current is 100mA-180mA, a flow rate of fed nitrogen is 10-50cm<3> / min, a flow rate of fed hydrogen is 10-50cm<3> / min, and a deposition time is 5-30min. With the method provided by the invention, solid and linear gallium nitride nano-wires can be obtained. The product is straight, neat, ordered, uniform, and linear. Chemical and physical properties of the nano-wires are stable. The preparation process is short, and product growth is fast. Product diameter reaches 40-150nm, and an average single wire length is 10-15mum.

Owner:BEIJING UNIV OF TECH

Preparation technology for copper/graphite core-shell structure

InactiveCN104707997ALarge specific surface areaHigh mechanical strengthVacuum evaporation coatingSputtering coatingField emission deviceSputtering

The invention discloses a preparation technology for a copper / graphite core-shell structure. According to the technical scheme, RF-PECVD equipment is adopted, a copper film prepared through DPS-III type ultrahigh vacuum facing-target magnetron sputtering is used as a copper source, and a copper / graphite core-shell structure (GS / CC) material is successfully prepared. The preparation technology has the advantages that the copper / graphite core-shell structure material is prepared through direct-current magnetron sputtering and radio frequency plasma enhanced chemical vapor deposition methods. The field emission performance of the material can be effectively improved as Cu particles are introduced, the field emission performance of grapheme can be effectively improved by modulating the morphology of the grapheme, and therefore the material has potential application in a field emission device. By using complementary advantages of graphite and copper, the copper / graphite core-shell structure (GS / CC) material is prepared, while cost is reduced, the field emission performance of the core-shell structure material is promoted substantially, and the material has potential application in the fields of the information technology, biomedical science, sensors and the like.

Owner:QINGDAO SHENGLI BOILER

Method for improving field emission performance of carbon nano tube film

InactiveCN101615544AGood adhesionReduce contact resistanceNanostructure manufactureCold cathode manufactureCarbon nanotubeNanometre

A method for improving field emission performance of a carbon nano tube film in the technical field of nano materials comprises the following steps: plating a metal thin film on a plane substrate; depositing the carbon nano tube film on the metal film; carrying out ultrasound nano welding on the metal film and the carbon nano tube film, thus obtaining the carbon nano tube film with improved field emission performance. The method of the invention forms excellent mechanical and electric contact between the carbon nano tube film and the metal film, thus obtaining a field emission component with low starting electric field, large emission current density and good current stability.

Owner:SHANGHAI JIAO TONG UNIV

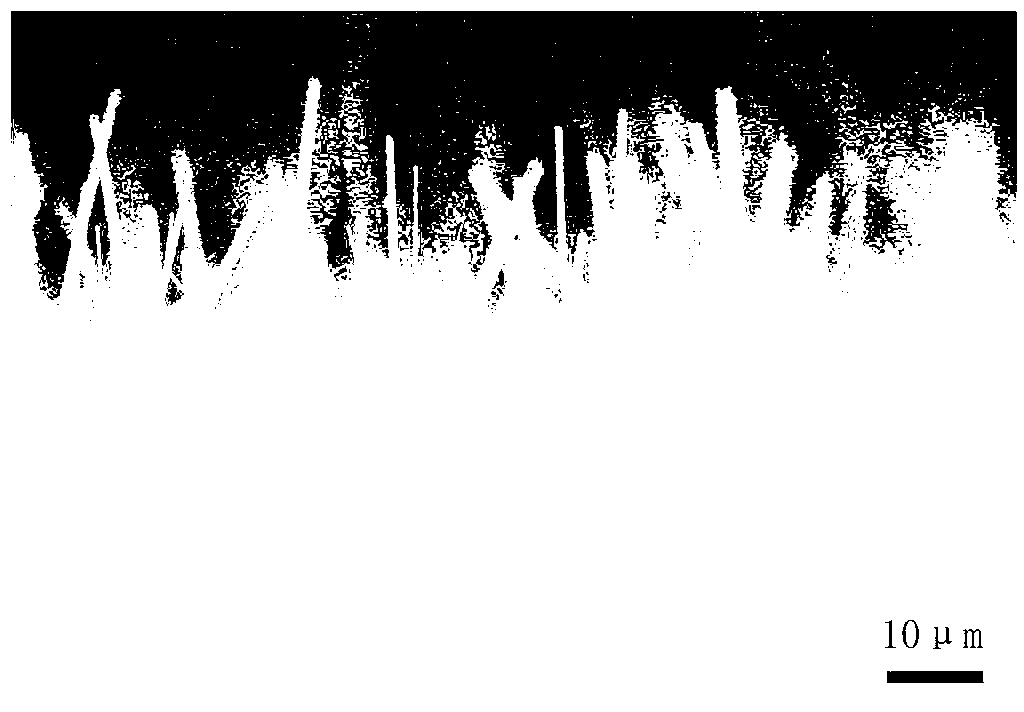

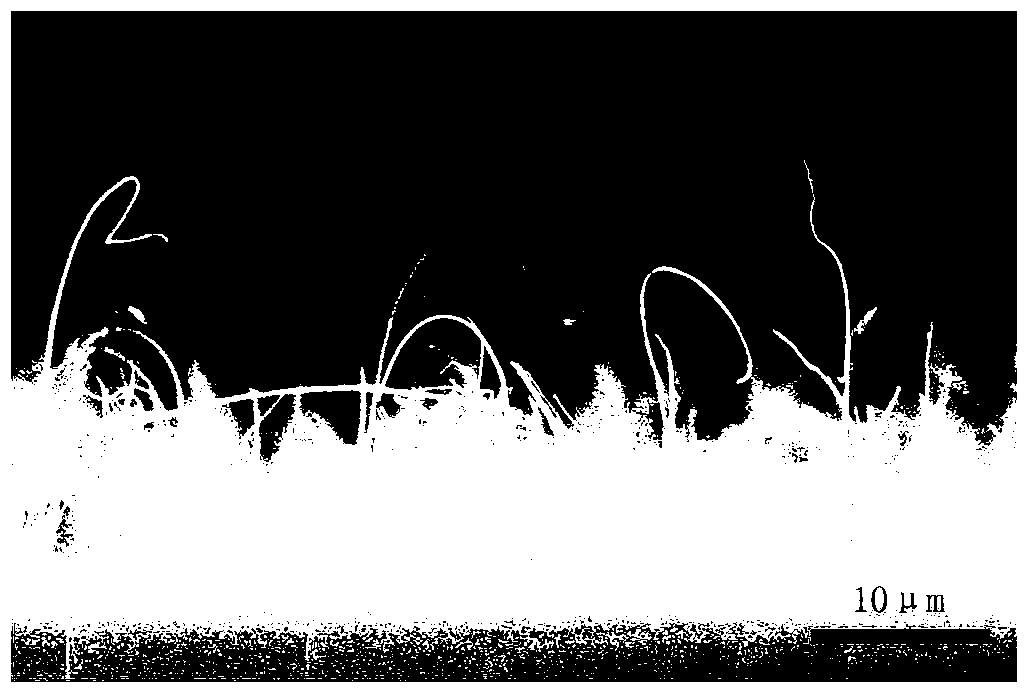

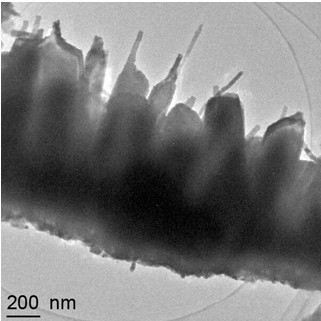

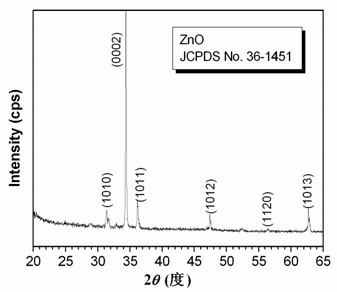

Preparation method of injector-shaped ZnO nanostructural array for field emission

InactiveCN102061498AGuaranteed adhesion strengthFor controlled growthPolycrystalline material growthLiquid-phase epitaxial-layer growthNano structuringNanopillar

The invention relates to a preparation method of an injector-shaped ZnO nano-structural array for field emission, which is a two-step synthesis method based on an aqueous solution system. The method comprises the following steps: firstly, adopting a electrochemical deposition method to directly grow a ZnO nano-column array on a conductive glass substrate; and secondly, adopting the aqueous solution chemical growing method to perform epitaxial growth of nano-needles on the original end surfaces of the ZnO nano-columns. The injector-shaped ZnO nano-structural array is prepared by the two-step synthesis method, thus the adhesive strength of the ZnO nano-structural array on the conductive substrate can be ensured, the electrical conductivity can be increased, the controllable growth of the pointed nanostructure, which is beneficial for electron emission can be realized and the field emission performance of the array structure can be improved.

Owner:SOUTHEAST UNIV

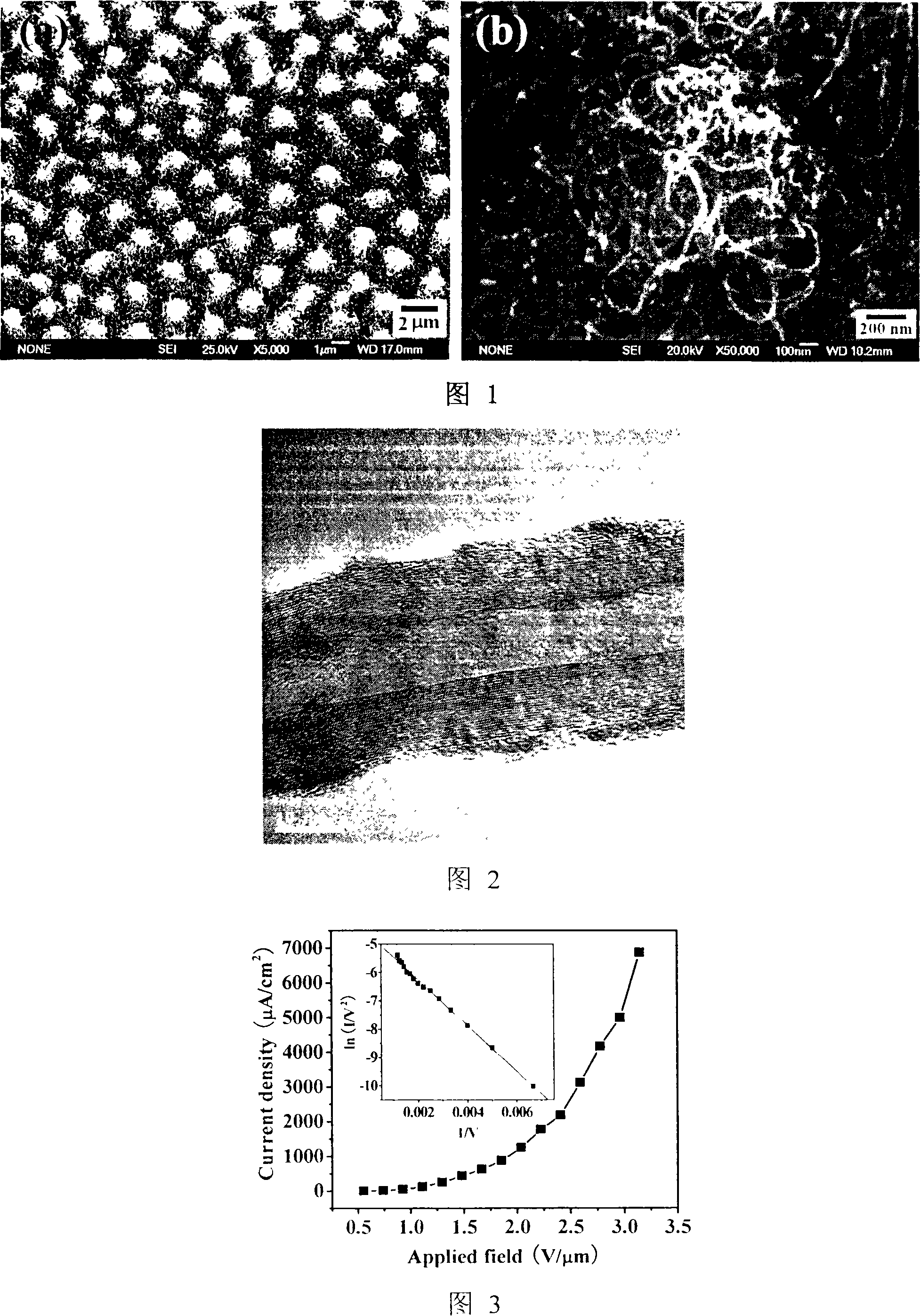

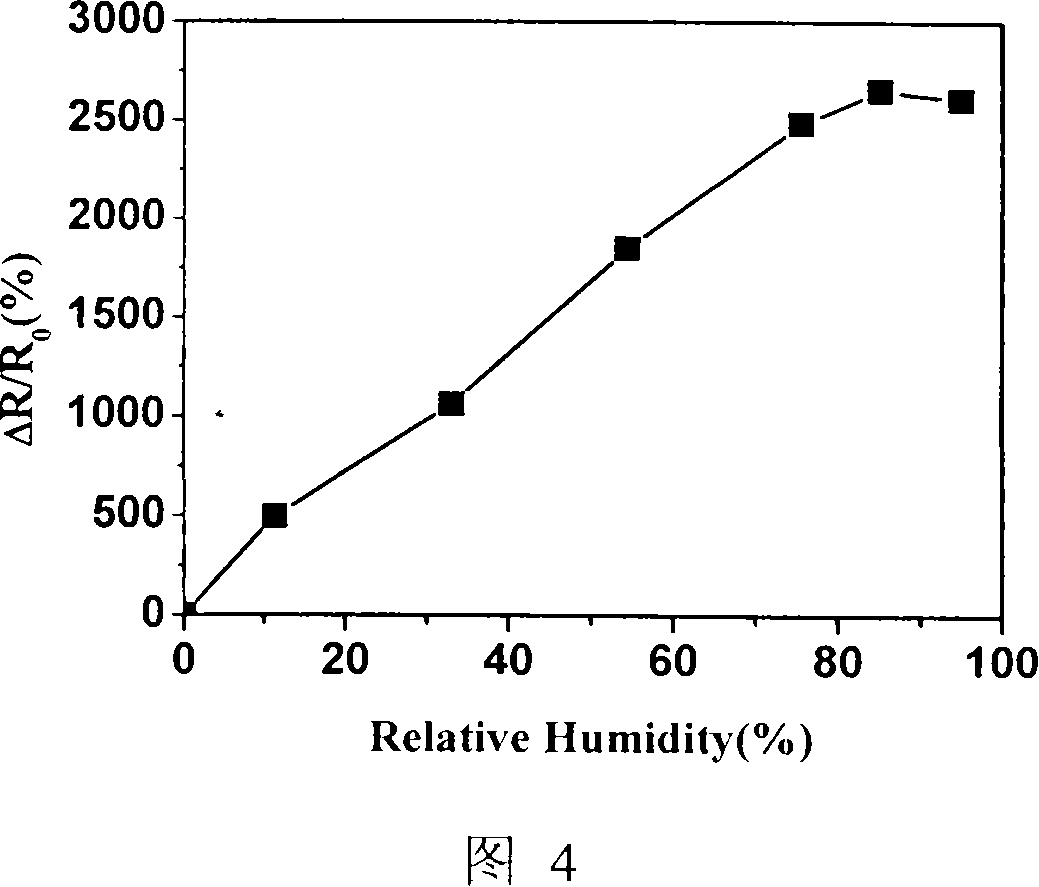

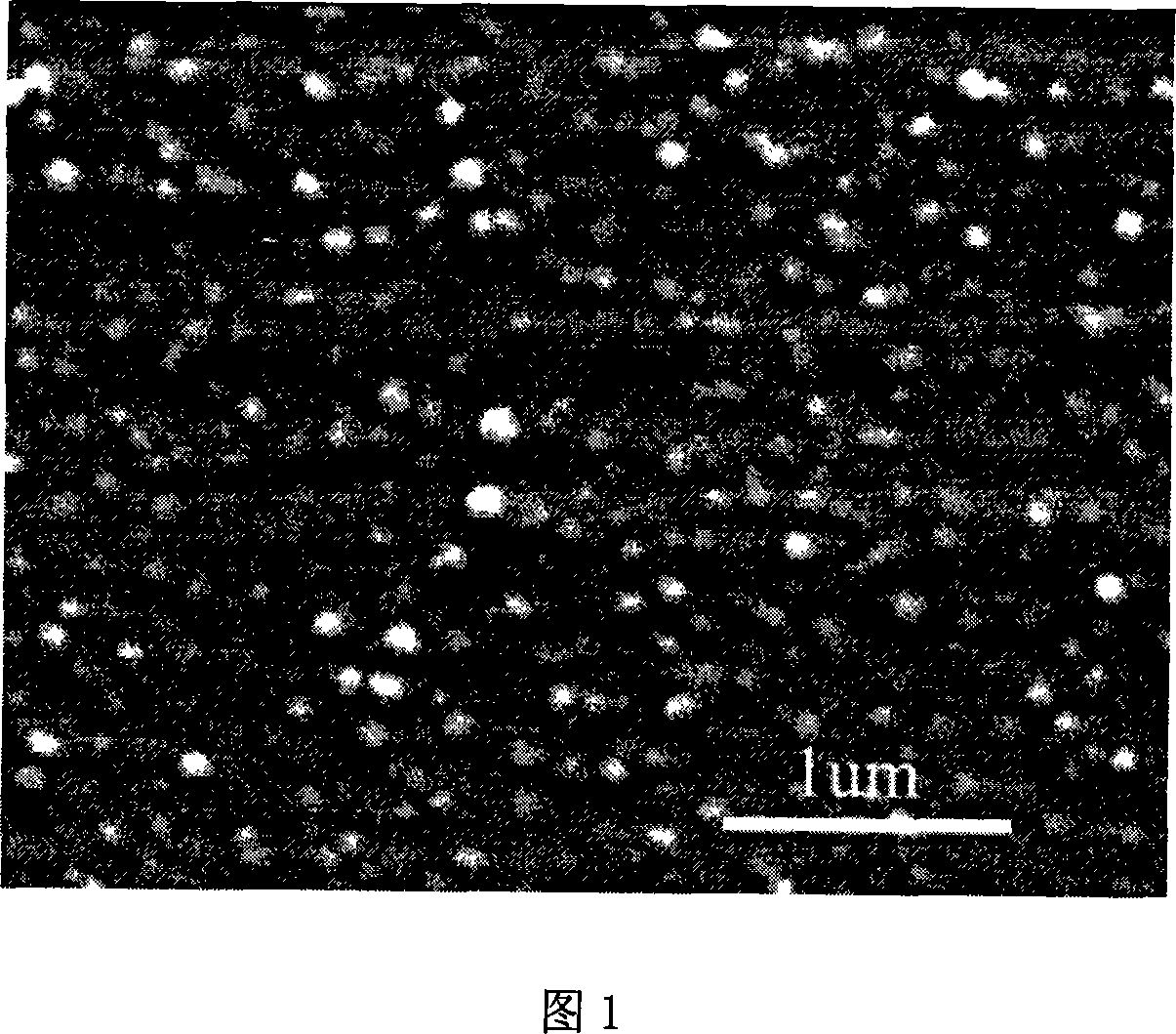

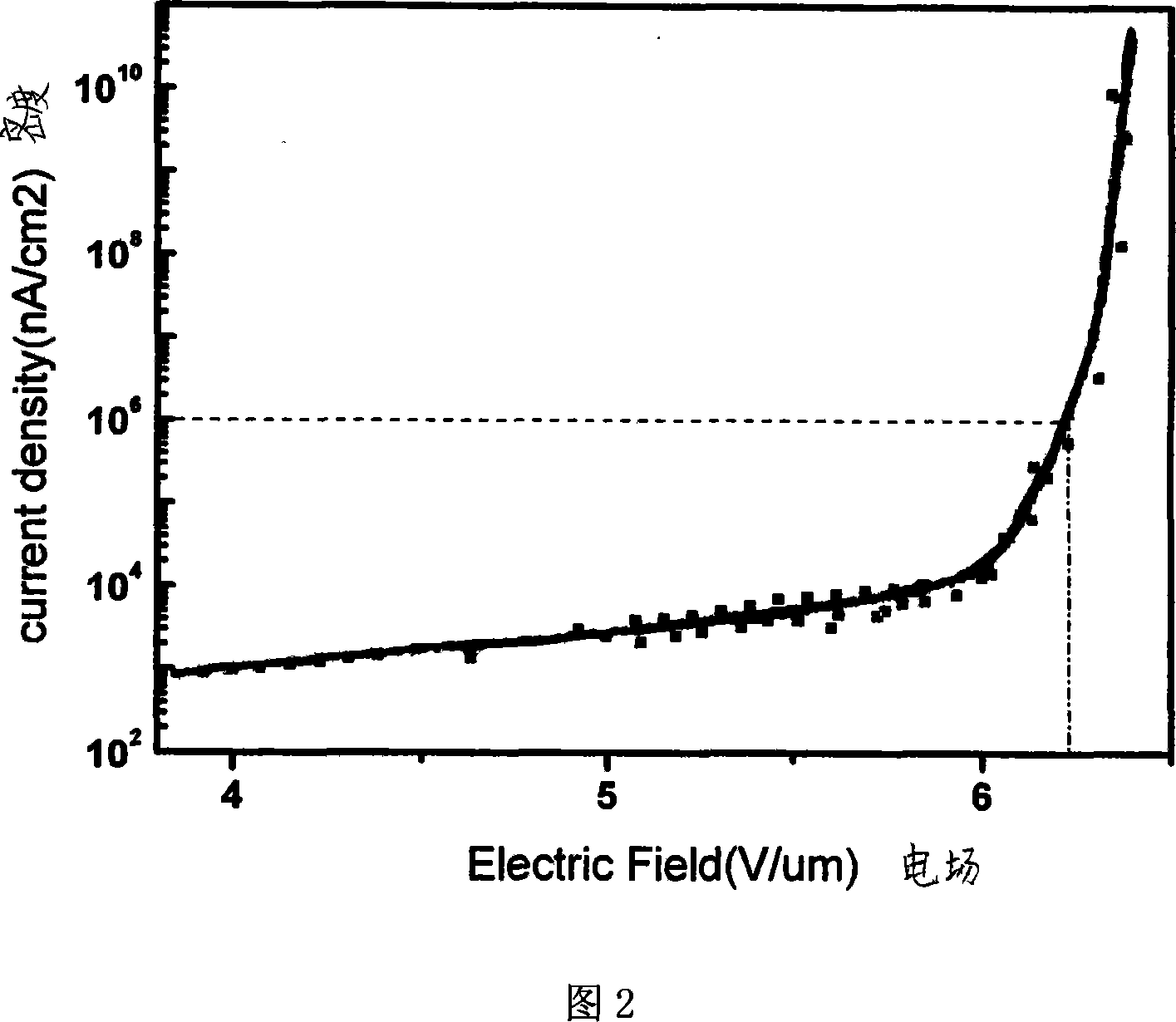

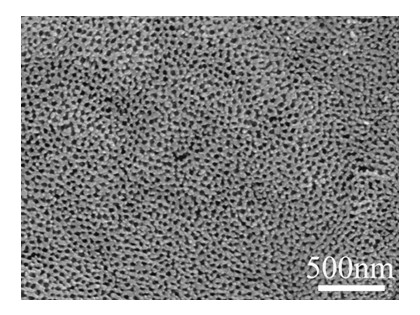

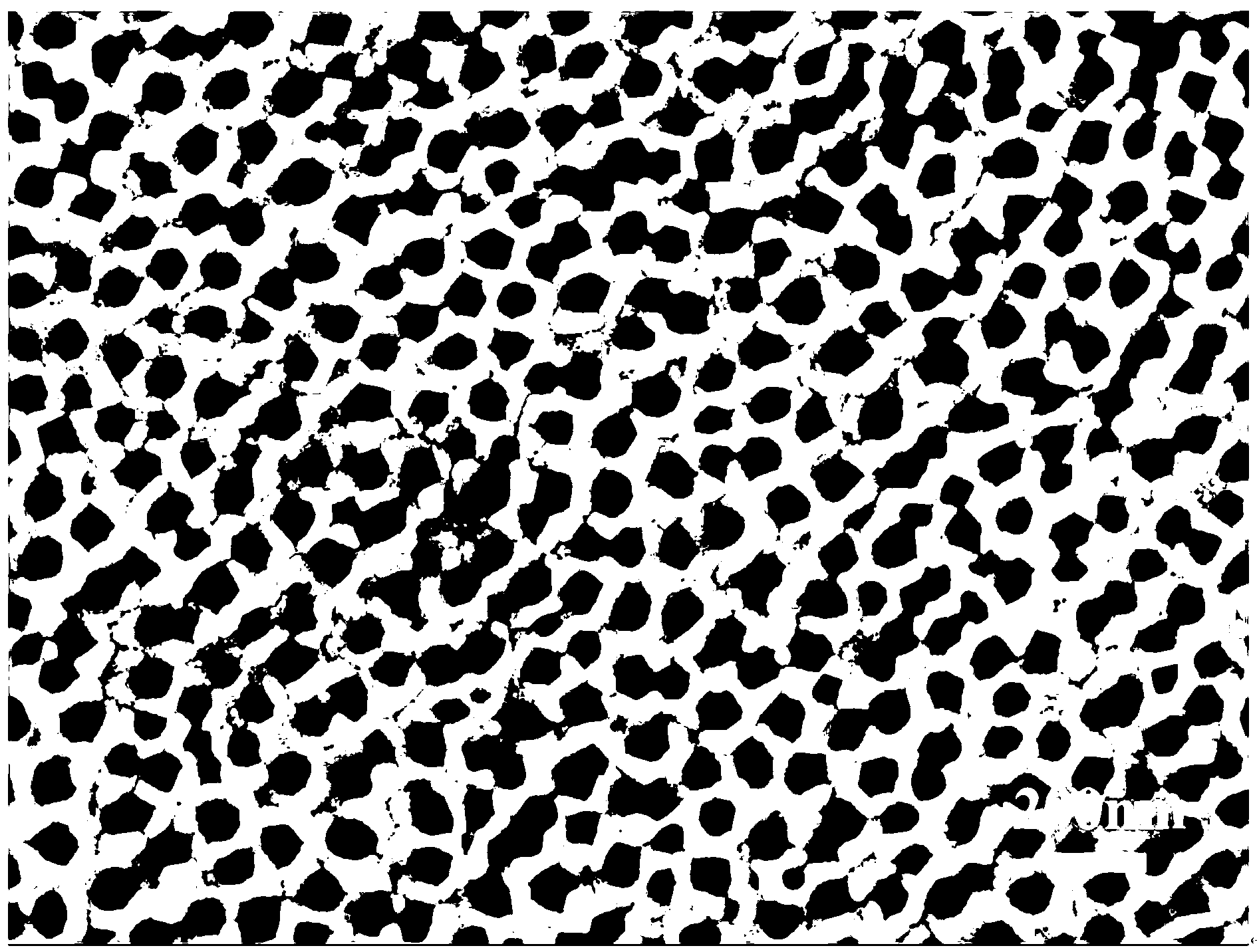

Carbon nanometer tube/silicon honeycomb array preparing method

InactiveCN101148247AImprove field emission performanceIncrease the sensing areaNanostructure manufactureSolid-state devicesCarbon nanotubeShielding gas

The process of preparing carbon nanotube / silicon nest array includes the following steps: setting P-type monocrystalline silicon chip inside a autoclave, and filling solution of 8.00-22.00 mol / l concentration hydrofluoric acid and 0.01-0.50 mol / l ferric nitrate solution to etch at 50-200 deg.c for 10 min to 36 hr to preparing silicon with nanometer pore array as the substrate material; setting the substrate material inside a tubular furnace, heating to 500-1200 deg.c in protective atmosphere, feeding carbon source solution with dissolved organic metal salt along with the carrier gas to in-situ grow carbon nanotube for 1-60 min, and cooling to room temperature under the protection of gas to obtain carbon nanotube / silicon nest array with field emitting and humidity sensing functions. The carbon nanotube / silicon nest array device has the performance as shown, and the preparation process is simple and high in repetition rate.

Owner:ZHENGZHOU UNIV

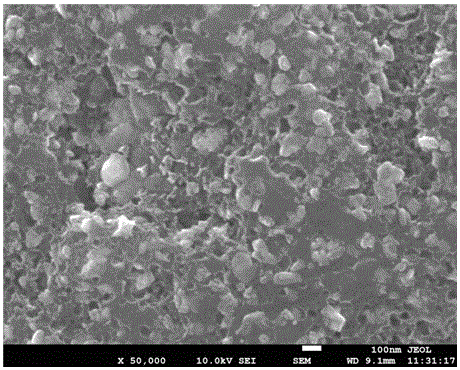

Diamond-like material field electron emission cathode and manufacture method

InactiveCN101060047AImprove field emission performanceCathode ray tubes/electron beam tubesDischarge tube/lamp detailsRadio frequency magnetron sputteringVacuum chamber

The preparation method for field emission electron cathode made of quasi-diamond material comprises: with bluster beam current, depositing the high-density nano pinpoint emitter on substrate for high emission current and low emission threshold; in the high-vacuum chamber, impacting and RF magnetic-controlled sputtering with Ar and He gas to prepare nano particle, orienting the beam to the substrate, and changing the beam strength and deposition time to prepare the high-density emitter. The adjustment method for beam current comprises: adjusting the Ar and He gas in target chamber to 101-102sccm and 1:1-5:1 partial pressure ratio, adjusting the final size constituent of the working flow; adjusting the distance between the sputtering target material and the small hole more than 10cm, and adjusting the nano particle and the final emitter size.

Owner:NANJING UNIV

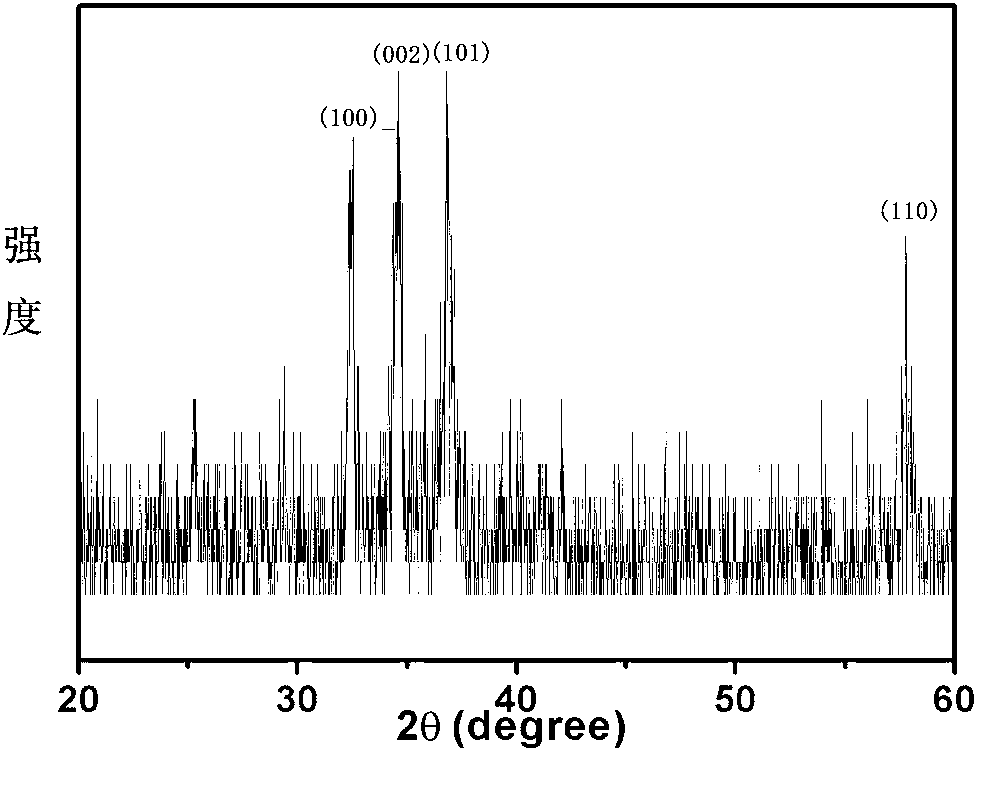

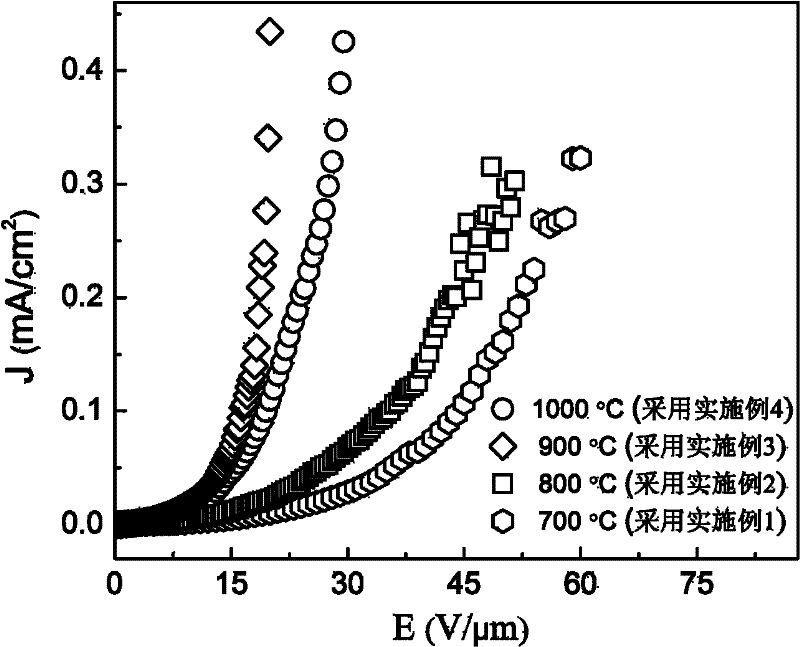

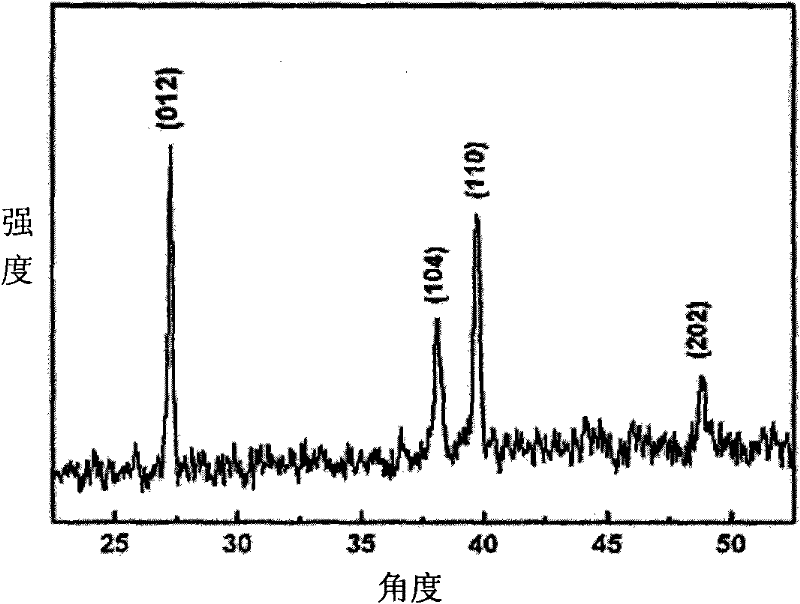

Modulation method for silicon-based GaN crystal structure with optimal field emission performance

InactiveCN102226294AImprove field emission performanceShorten the development cyclePolycrystalline material growthCathode ray tubes/electron beam tubesDeposition temperaturePulse energy

The invention discloses a modulation method for silicon-based GaN crystal structure with optimal field emission performance, belonging to the field of field emission cathodes. The method comprises the following steps: choosing Si as a substrate and a GaN target as a target material; putting the substrate and the target material into a pulsed laser deposition system, adjusting substrate-to-target distance to be 50 to 90 mm, and vacuumizing to obtain a background vacuum of 1*10<-5> to 1*10<-2> Pa; letting in protection gas to adjust an operating air pressure to be 1*10<-2> to 1*10 <1> Pa, and under the condition that pulse frequency is 5 to 15 Hz and pulse energy is 300 to 500 mJ per pulse, changing the temperature of the substrate into 700 to 1000 DEG C and carrying out deposition. According to the invention, the crystal structure of a GaN film is controlled through the controlling of the deposition temperature, thereby obtaining a degree of crystallization and crystallization orientation with optimal field emission performance and effectively improving field emission performance of GaN film type field emission cathodes.

Owner:BEIJING UNIV OF TECH

Method for preparing bunchy bismuth nanostructure material

The invention discloses a method for preparing a bunchy bismuth nanostructure material, which comprises the following steps: performing ultrasonic cleaning of an alumina AAO template in an alcohol solution, performing electrodeposition by multi-potential step, and removing the alumina membrane so as to obtain the bunchy bismuth nanostructure material. The invention has simple preparation and high filling ratio. The invention also discloses the prepared bunchy bismuth nanostructure material which has a unique high-density nano-wire array structure, can receive various heat energy from the environment, and has wide commercial application perspectives.

Owner:EAST CHINA NORMAL UNIVERSITY

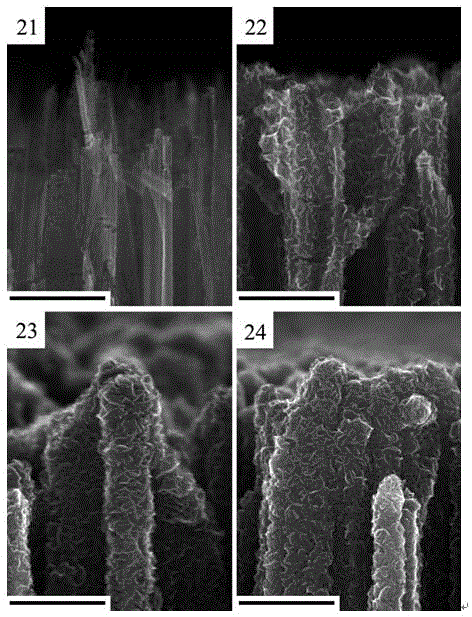

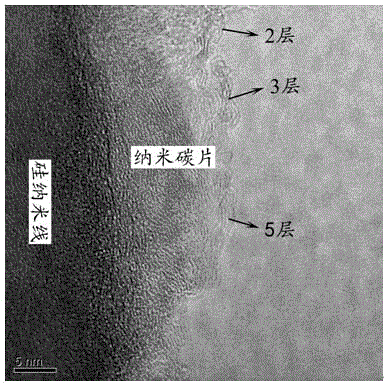

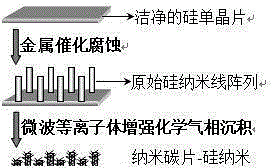

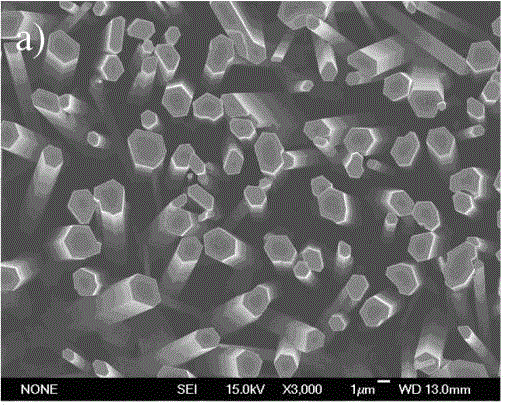

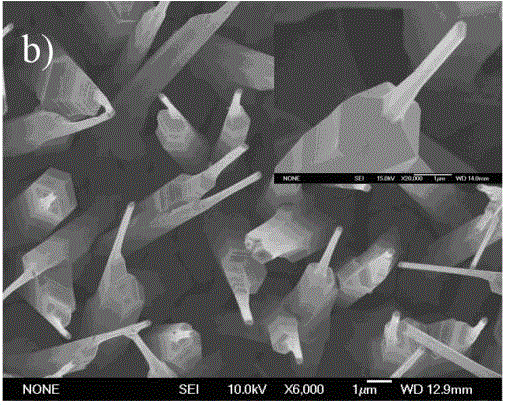

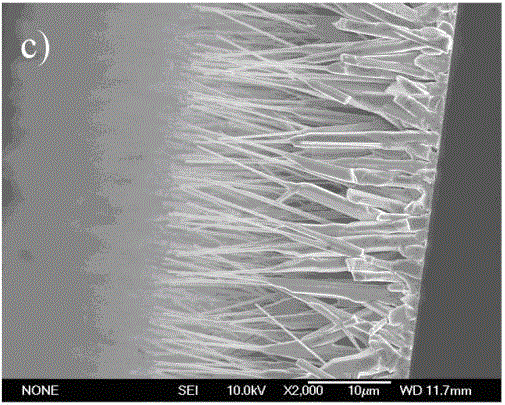

Method for preparing field emission cathode of nano carbon sheet-silicon nanowire composite structure

InactiveCN104882347AGood Field Emission StabilitySimple processMaterial nanotechnologyChemical vapor deposition coatingField emission currentField emission cathode

The invention discloses a method for preparing a field emission cathode of a nano carbon sheet-silicon nanowire composite structure, and belongs to the fields of preparation and application of nano materials. The method mainly includes the following preparation process of using a silicon nanowire array prepared on a clean silicon single crystal wafer by using a metal catalysis and corrosion method as a substrate; growing nano-scale carbon sheets on the substrate by using a microwave plasma enhanced chemical vapor deposition method; and finally using the obtained nano carbon sheet-silicon nanowire composite structure as a cathode assembly field electron emitter. As for the nano carbon sheet-silicon nanowire composite structure prepared by the method, the carbon sheets mostly have a diameter of 60-100nm, with generally 2-5 edge layers, and are distributed densely on the surface of silicon nanowires. As the field emission cathode material, the nano carbon sheet-silicon nanowire composite structure has a lower open field and a larger field emission current density than a single silicon nanowire array, and has a very high application value.

Owner:TIANJIN NORMAL UNIVERSITY

Method for preparing double-layer zinc oxide nanowire array by chemical vapor deposition

InactiveCN103058264AImprove verticalityReduced tip diameterMaterial nanotechnologyZinc oxides/hydroxidesNanowire arrayChemical vapor deposition

The invention relates to a preparation method of a double-layer zinc oxide nanowire array. The method comprises the following steps: by using a silicon wafer coated with a zinc oxide crystal seed layer as a substrate, inducing growth of a ZnO nanowire array by chemical vapor deposition; and spin-coating a ZnO nano crystal seed layer on the top end of the primarily grown ZnO nanowire to carry out gas-phase secondary growth of the ZnO nanowire array, thereby obtaining the double-layer superlong ZnO nanowire array. The method has the advantage of simple preparation process; and the prepared double-layer ZnO nanowire array has the advantages of obviously higher length-to-diameter ratio, small starting electric field, and obviously enhanced field emission properties.

Owner:SHANGHAI UNIV

Growing method and application of semi-metallic titanium dioxide nanotube array film

InactiveCN102162116AReduce the turn-on electric fieldRepeatablePolycrystalline material growthSurface reaction electrolytic coatingElectrolytic agentTio2 nanotube

The invention discloses a growing method and application of a semi-metallic titanium dioxide nanotube array film. The growing method comprises the following steps of: firstly, cleaning a pure titanium sheet, and preparing a polishing solution; chemically polishing the cleaned pure titanium sheet in the polishing solution; putting graphite and the chemically polished pure titanium sheet into an electrolyte at room temperature for oxidizing the pure titanium sheet; putting the oxidized pure titanium sheet into a glycol solution for soaking, and then, putting the pure titanium sheet into a high-temperature resistant reactor; insulating at a certain vacuum degree and temperature under the condition of introducing mixed gas; and then, naturally cooling to the room temperature under the argon atmosphere to obtain the semi-metallic titanium dioxide nanotube array film. The array film is directly used as a field electron emission cold cathode. The growing method disclosed by the invention is convenient for industrialized production, can be used for preparing the semi-metallic titanium dioxide nanotube array film with excellent performance, cheap price and practical values, and has a better application value in the aspect of field electron emission display materials.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method and application of hydrogenated titanium dioxide nanotube array film

InactiveCN103060880AReduce the turn-on electric fieldIncreased emission current densitySurface reaction electrolytic coatingNanotechnologyArgon atmosphereField electron emission

The invention provides a preparation method and an application of a hydrogenated titanium dioxide nanotube array film. The preparation method comprises the following steps: cleaning an industrial titanium sheet, and chemically polishing; oxidizing at room temperature through a constant-voltage direct-current anodizing method; and carrying out heat treatment in a vacuum environment in a hydrogen-containing atmosphere, stopping the let-in of hydrogen, and naturally cooling to room temperature in an argon atmosphere to prepare the hydrogenated titanium dioxide nanotube array film. The hydrogenated titanium dioxide nanotube array film can be directly used as a field electron emission cold cathode. The preparation method enables the hydrogenated titanium dioxide nanotube array film having the characteristics of low turn-on field, large emission current density, good field emission stability, high repeatability and the like and directly used as the field electron emission to be prepared; and the preparation method can be used for the industrial production, enables the cold cathode field emitters having low prices to be prepared, and can be well applied in the field electron emission display cathode material field.

Owner:NORTHWEST NORMAL UNIVERSITY

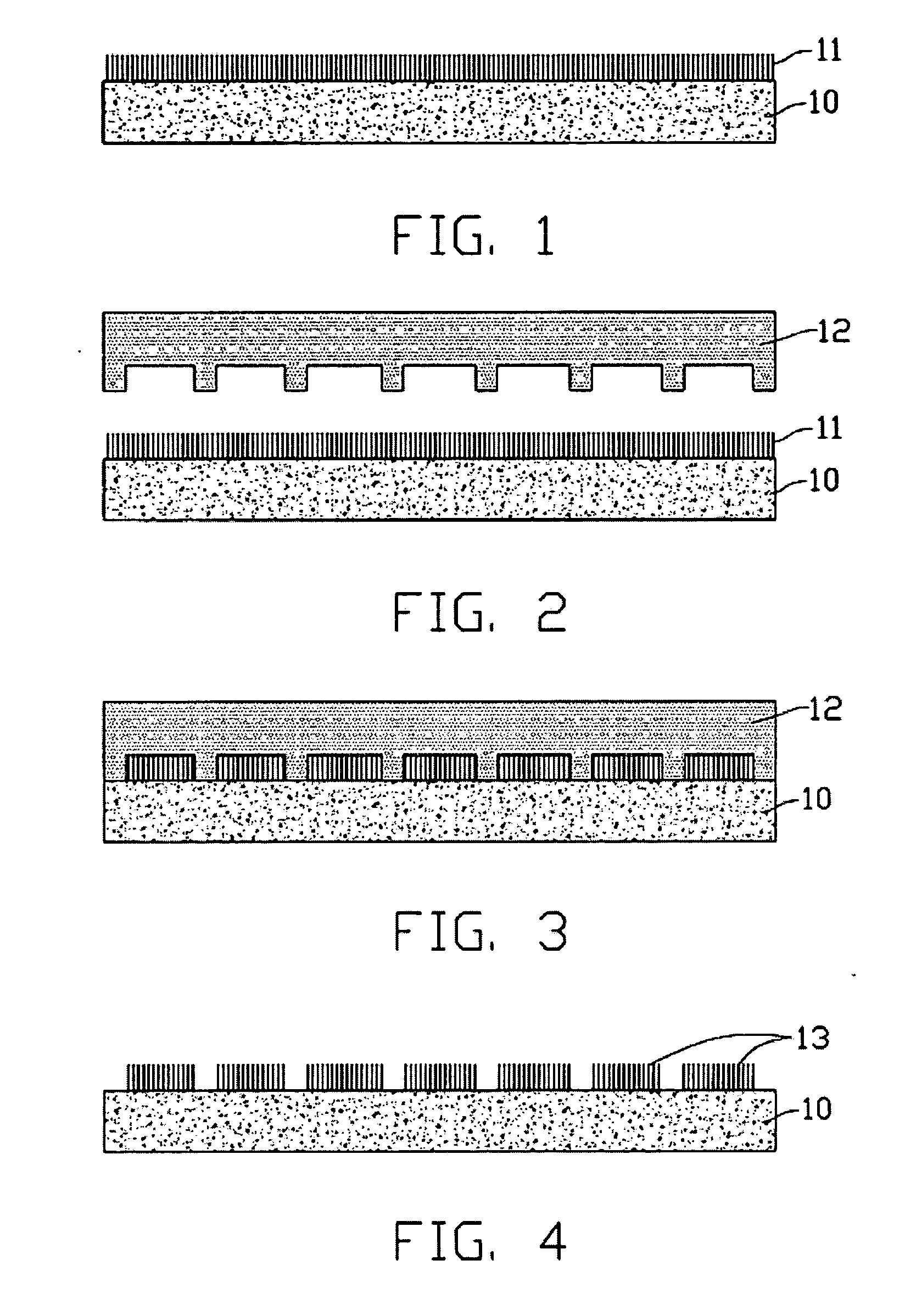

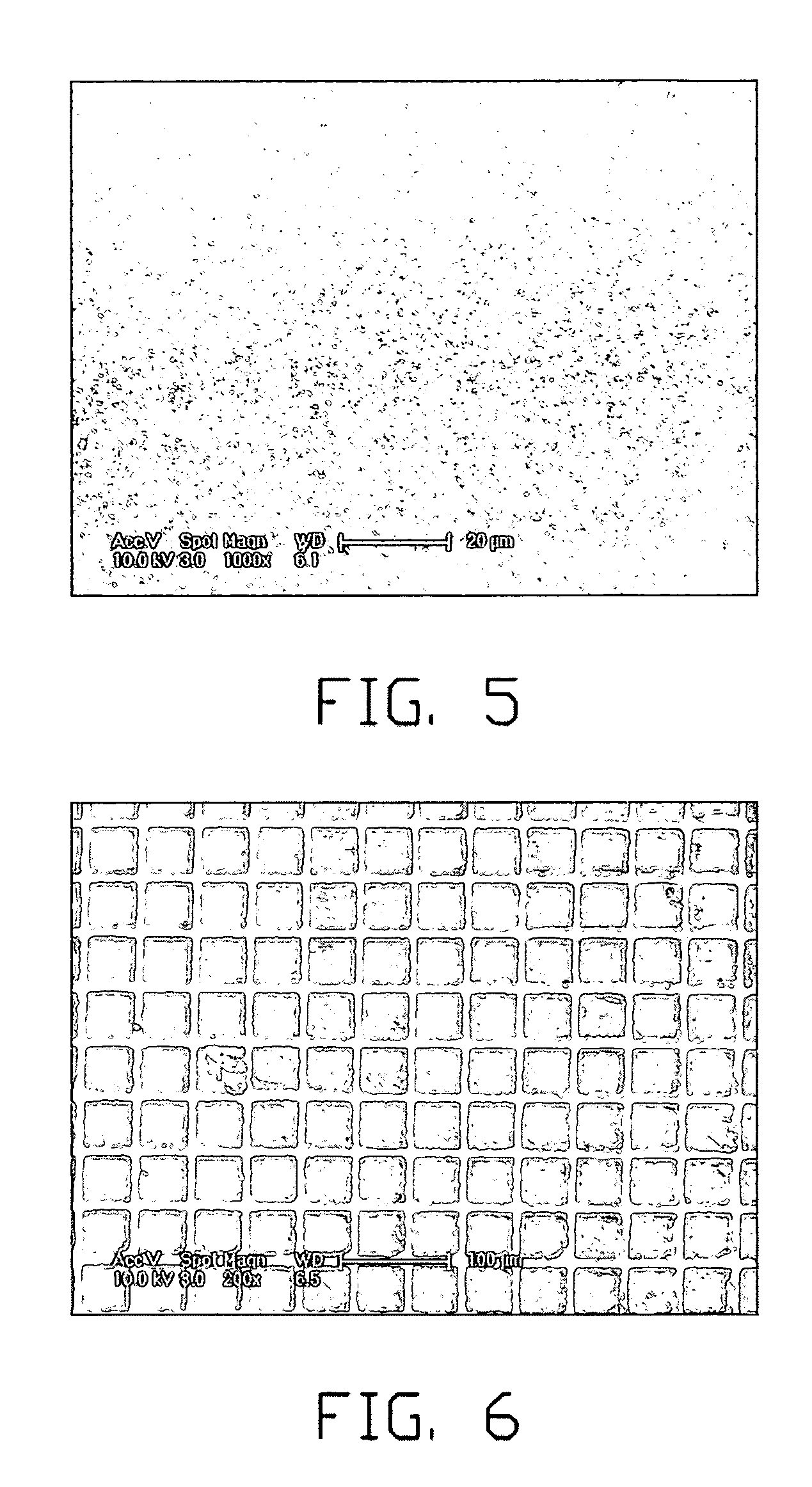

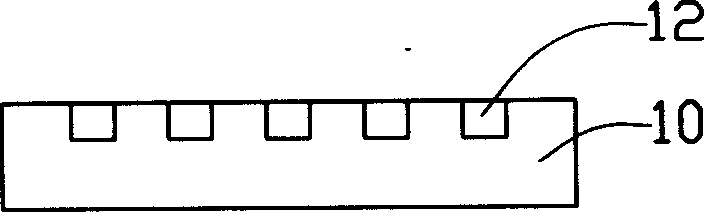

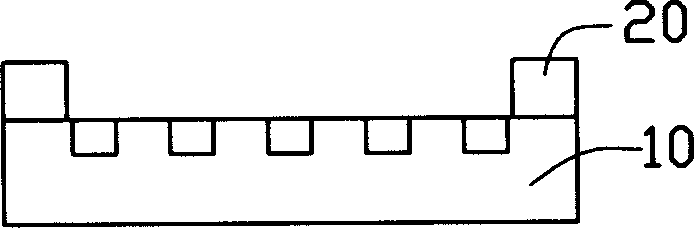

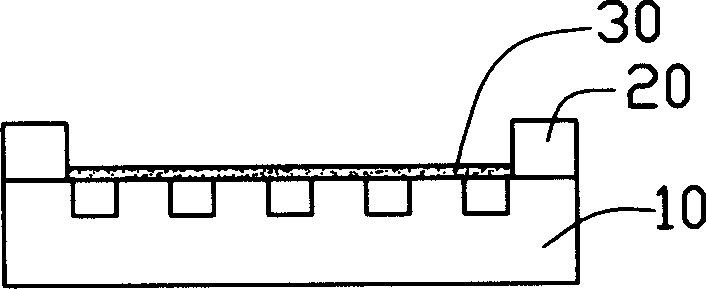

Method for forming a patterned array of carbon nanotubes

ActiveUS20070231493A1Easy to manufactureCost-effectiveMaterial nanotechnologyElectric discharge tubesCarbon nanotubeNanotube array

A method for forming a patterned array of carbon nanotubes (11) includes the steps of: forming an array of carbon nanotubes on a substrate (10); imprinting the array of carbon nanotubes using a molding device (12) with a predetermined pattern; and removing the molding device, thereby leaving a patterned array of carbon nanotubes (13). The method can effectively reduce or even eliminate any shielding effect between adjacent carbon nanotubes, and is simple to implement. The field emission performance of the patterned array of carbon nanotubes is improved.

Owner:HON HAI PRECISION IND CO LTD +1

Field emission element

InactiveCN1534708AImprove field emission performanceReduce unevennessElectric discharge tubesNanoinformaticsGas phaseCarbon nanotube

A field emitting element is composed of a cathode, and a carbon nanotube array which is prepared by gas-phase chemical deposition method and has a growth top connected to said cathode and a growth root as the electron emitting end. Its advantages are high electron-emitting uniformity and high emitting performance.

Owner:TSINGHUA UNIV +1

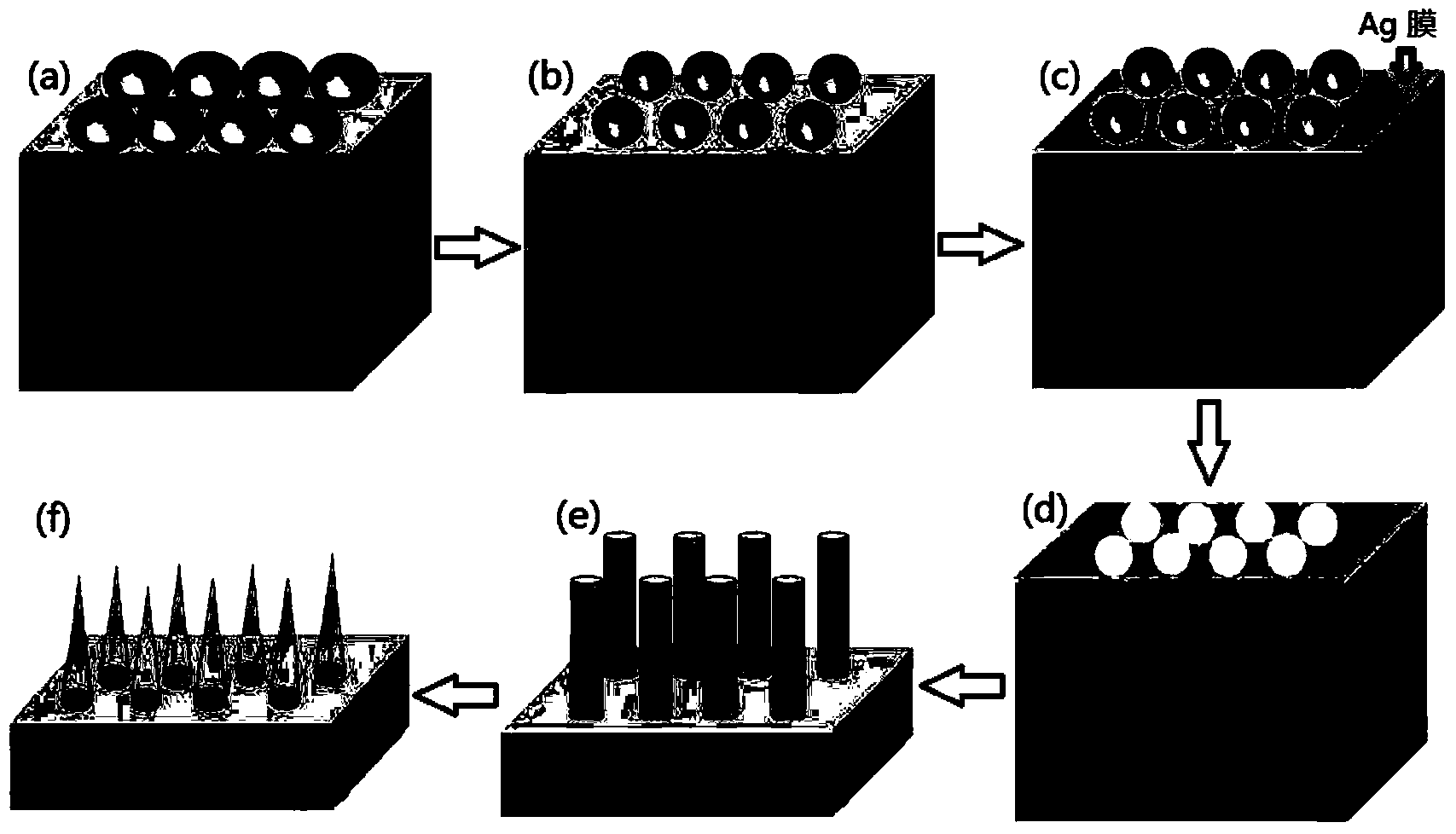

Preparation method of silicon nanowire array with excellent field emission performance and tip structure

The invention discloses a preparation method of a silicon nanowire array with excellent field emission performance and a tip structure, and belongs to the technical field of field emission. The method comprises the following steps: firstly configuring single-layered PS (Polystyrene) spheres densely on a silicon substrate, carrying out reactive ion etching treatment on the PS spheres, adopting an electron beam evaporation method to plate silver, removing the PS spheres, carrying out silver catalytic corrosion to the substrate, and obtaining the silicon nanowire array with larger diameter; adopting a dry-method oxidation treatment to turn the silicon nanowires into the tip structure, further reducing the diameter of the silicon nanowires, and increasing the space between the silicon nanowires. The silicon nanowire array with the tip structure, prepared with the method, is of excellent field emission performance; the threshold voltage of the silicon nanowire array is 1.8 V per microns; the current stability is good; meanwhile, the single crystal performance of the silicon nanowires is good, so that the silicon nanowires can be regularly and densely configured in a large area, and the controllability of the draw ratio is strong. The method is low in cost, high in yield and good in controllability, so as to be applied to production of silicon-substrate field emission electronic devices.

Owner:TSINGHUA UNIV

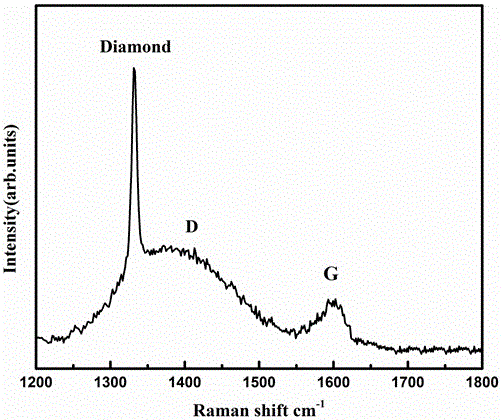

Metal nanoparticle/diamond composite film with excellent field emission performance and preparation method

InactiveCN105970184ASimple methodEasy to operateVacuum evaporation coatingSputtering coatingComposite filmField electron emission

The invention discloses a metal nanoparticle / diamond composite film with excellent field emission performance and a preparation method thereof, and belongs to the technical field of optoelectronic materials. Based on the ion implantation technology, metal ions with the energy ranging from 100 keV to 500 keV and the dosage ranging from 1,016 ions / cm<2> to 1,017 ions / cm<2> are implanted into a diamond thin film, then the thin film is annealed in N2 or Ar or H2 atmosphere, and the metal nanoparticle / diamond composite film can be obtained. The method is simple and easy to operate. Metal nanoparticles and diamonds in the obtained composite film are directly bonded, and stability is good. The composite film obtained through preparation is low in specific resistance, high in Hall mobility rate and excellent in field emission performance, and great scientific significance and engineering value for achieving application of the composite film to the fields such as semiconductor devices and field emission displayers are achieved.

Owner:TAIYUAN UNIV OF TECH

Preparation method and application of nitrogen-doped graphene@SiO2 coaxial nanotube

InactiveCN105810530AAvoid makingAvoid removalMaterial nanotechnologyDischarge tube/lamp detailsDisplay deviceLarge screen

The invention discloses a preparation method and application of a nitrogen-doped graphene@SiO2 coaxial nanotube. The nitrogen-doped graphene@SiO2 coaxial nanotube is prepared by taking melamine and methane as reaction raw materials, Si-SiO2 mixed powder as an auxiliary material and nickel nitrate as a catalyst and carrying out a template-free one-step chemical vapor reaction method in a vacuum atmosphere furnace. The template-free one-step chemical vapor reaction method provided by the invention has the advantages of simple process, low cost and high repeatability, and is easy to control, the tube diameter of the obtained nitrogen-doped graphene@SiO2 coaxial nanotube is 150-250 nanometers, the thickness of a SiO2 cladding layer is 6-8 nanometers, and the nitrogen-doped graphene@SiO2 coaxial nanotube has excellent field emission performance and can have wide application prospect in the fields such as a field emission flat-panel displayer, a vacuum electronic device, a large-screen LCD backlight module and a field emission lighting source.

Owner:QINGDAO UNIV OF SCI & TECH

Symmetrical type carbon nanotube cathode ionization gauge

ActiveCN105070628AExtend the motion pathAvoid interferenceGas pressure measurement discharge tubesCarbon nanotubeHeat sensitive

The invention discloses a symmetrical type carbon nanotube cathode ionization gauge. A carbon nanotube array capable of achieving electron field emission at room temperature is taken as a cathode, interferences of the high-temperature thermionic cathode to a heat sensitive, light sensitive and strong magnetic field system are overcome, and a power consumption demand is reduced based on a field emission mechanism. The carbon nanotube array cathode grows on two faces of a substrate, and symmetrical double-electrode arrangement is adopted; and, on the premise that the complexity of a circuit is not changed, the lengths of electron trajectories are effectively prolonged, and improvement of the sensitivity of an ionization gauge in the kind is facilitated. Furthermore, higher-voltage anodes 5 are added between gate electrodes 4 and collecting electrodes 6, so electrons oscillates between the gate electrodes 4 and the collecting electrodes 6, the electron trajectories are also prolonged, and the sensitivity of the ionization gauge is further improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Method for preparing zinc oxide nano-layer structure on supportless carbon nano-tube film

InactiveCN101560640AImprove field emission characteristicsImprove field emission performanceVacuum evaporation coatingSputtering coatingField emission currentNitrogen

The invention discloses a method for preparing a zinc oxide nano-layer structure on a supportless carbon nano-tube film, which is characterized in that zinc oxide is evenly attached to the supportless carbon nano-tube film to form the zinc oxide nano-layer structure through thermal evaporation by using nitrogen as carrier gas, wherein the zinc oxide nano-layer has a needle-like structure; the length thereof is 1mu m; and the particle size of zinc oxide particles is about 100 nanometers. The method improves the field emission characteristic of a carbon tube, improves the field emission performance and increases the field emission current density with lower turn-on electric field and good emission stability; and compared with the prior art, the method has the advantages of simple manufacturing process, low cost and good repeatability, is particularly suitable for large-area manufacture, and can perform kinking and clipping.

Owner:EAST CHINA NORMAL UNIV

Field emission lighting device

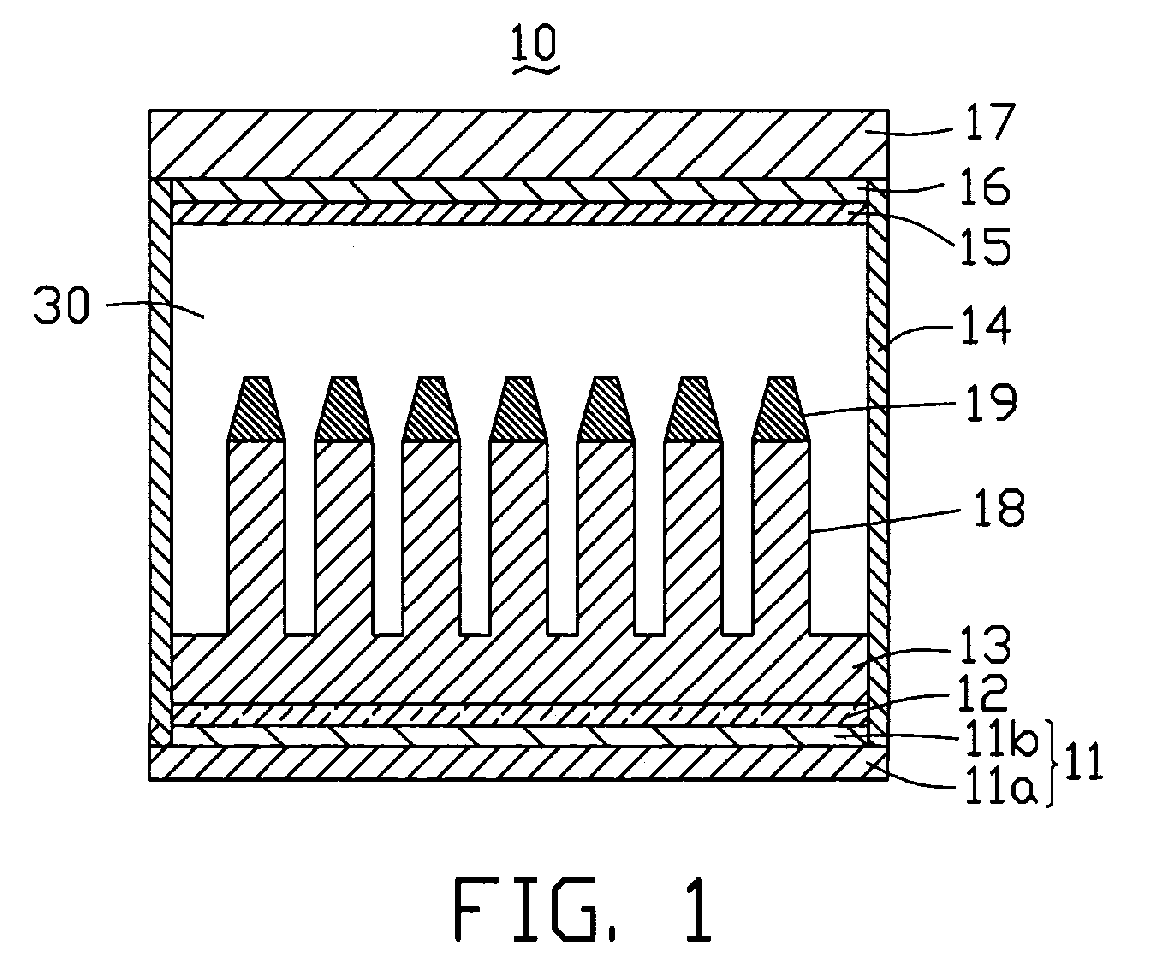

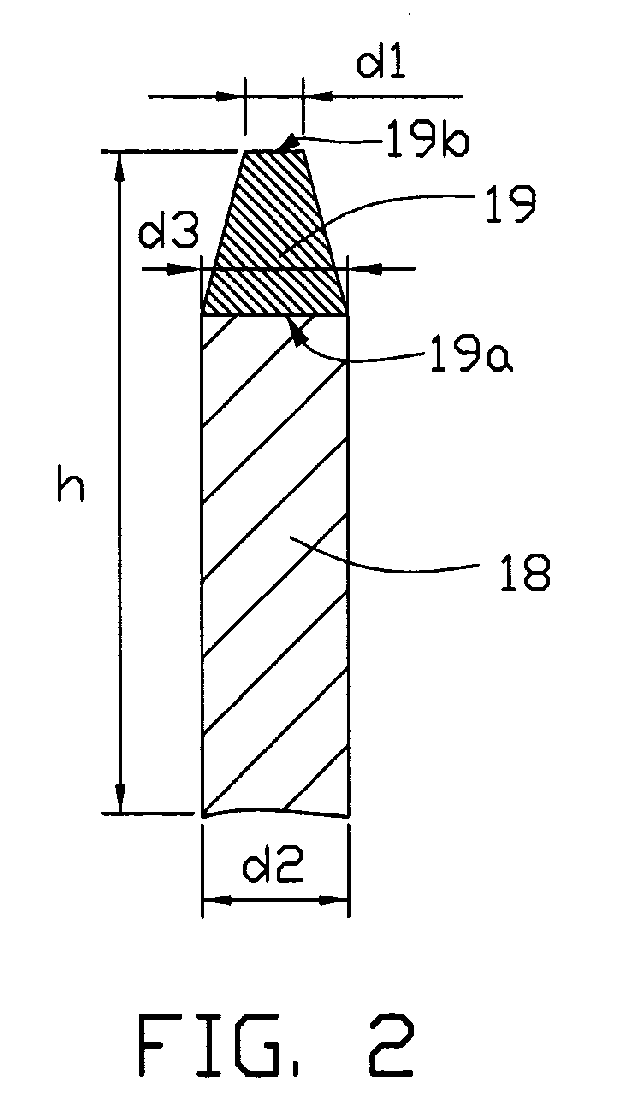

InactiveUS20060197426A1High mechanical strengthImprove field emission performanceDischarge tube luminescnet screensLamp detailsDiamond-like carbonFluorescence

A field emission lighting device is disclosed in the present invention. The field emission lighting device includes a cathode, an isolating layer, a plurality of isolating emitter bases, a plurality of niobium emitter tips each formed on a respective emitter base, a light-permeable anode disposed opposite to the cathode, and a fluorescence layer formed on the anode. The isolating layer is formed on the cathode. The isolating emitter bases extend from the isolating layer. The isolating layer and the isolating emitter bases are comprised of diamond like carbon. The isolating emitter bases each include an electrically conductive connecting portion configured for establishing an electrically conductive connection between the emitter tip and the cathode.

Owner:HON HAI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com