Modulation method for silicon-based GaN crystal structure with optimal field emission performance

A technology of crystal structure and modulation method, which is applied in the field of crystal structure modulation for optimizing the field emission performance of GaN thin films, can solve the problems of few reports on the field emission performance of GaN film cathodes, and achieve improved field emission performance, broad economic benefits, and savings in research and development. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

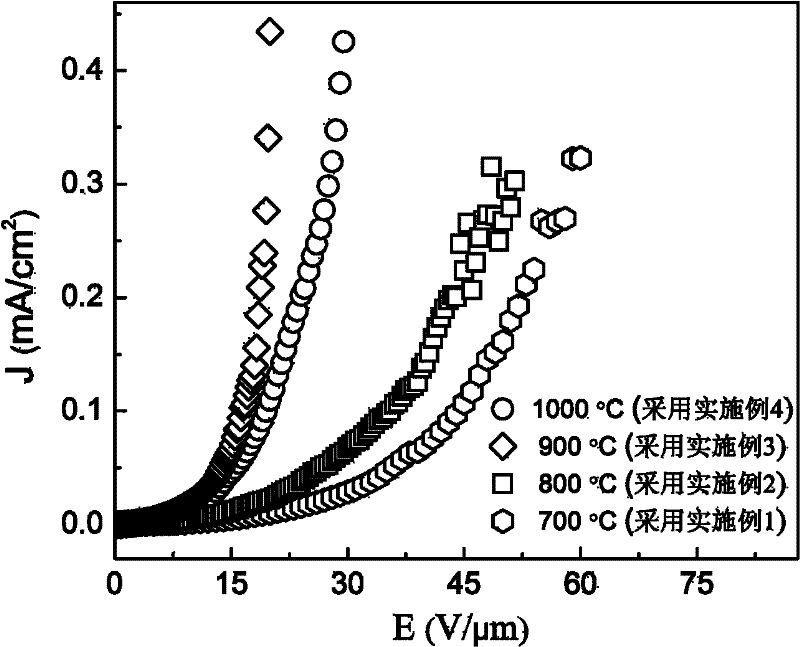

[0025] Using polished n-type (100) silicon as the substrate, gallium nitride powder with a purity of 99.99% was sintered at 560°C for 120 minutes to make a gallium nitride target, and the substrate and target were placed in the cavity of the laser pulse deposition system. The target base distance is 65mm, and the deposition chamber is pumped to about 5×10 -4 Pa, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, set the pulse laser frequency to 10Hz, pulse energy to 350mJ / pulse, heat the substrate to 700°C to obtain low crystallinity by deposition Hexagonal GaN thin films.

Embodiment 2

[0027] Using polished n-type (100) silicon as the substrate, gallium nitride powder with a purity of 99.99% was sintered at 560°C for 120 minutes to make a gallium nitride target, and the substrate and target were placed in the cavity of the laser pulse deposition system. The target base distance is 65mm, and the deposition chamber is pumped to about 5×10 -4 Pa, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, set the pulse laser frequency to 10Hz, pulse energy to 350mJ / pulse, and heat the substrate to 800°C to obtain lower crystallization degree of hexagonal multi-orientation gallium nitride thin film.

Embodiment 3

[0029] Using polished n-type (100) silicon as the substrate, gallium nitride powder with a purity of 99.99% was sintered at 560°C for 120 minutes to make a gallium nitride target, and the substrate and target were placed in the cavity of the laser pulse deposition system. The target base distance is 65mm, and the deposition chamber is pumped to about 5×10 -4 Pa, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, set the pulse laser frequency to 10Hz, pulse energy to 350mJ / pulse, heat the substrate to 900°C to obtain higher crystallization Hexagonal gallium nitride thin film with a preferred orientation along the (002) crystal plane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com