Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about "Gas pressure measurement discharge tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

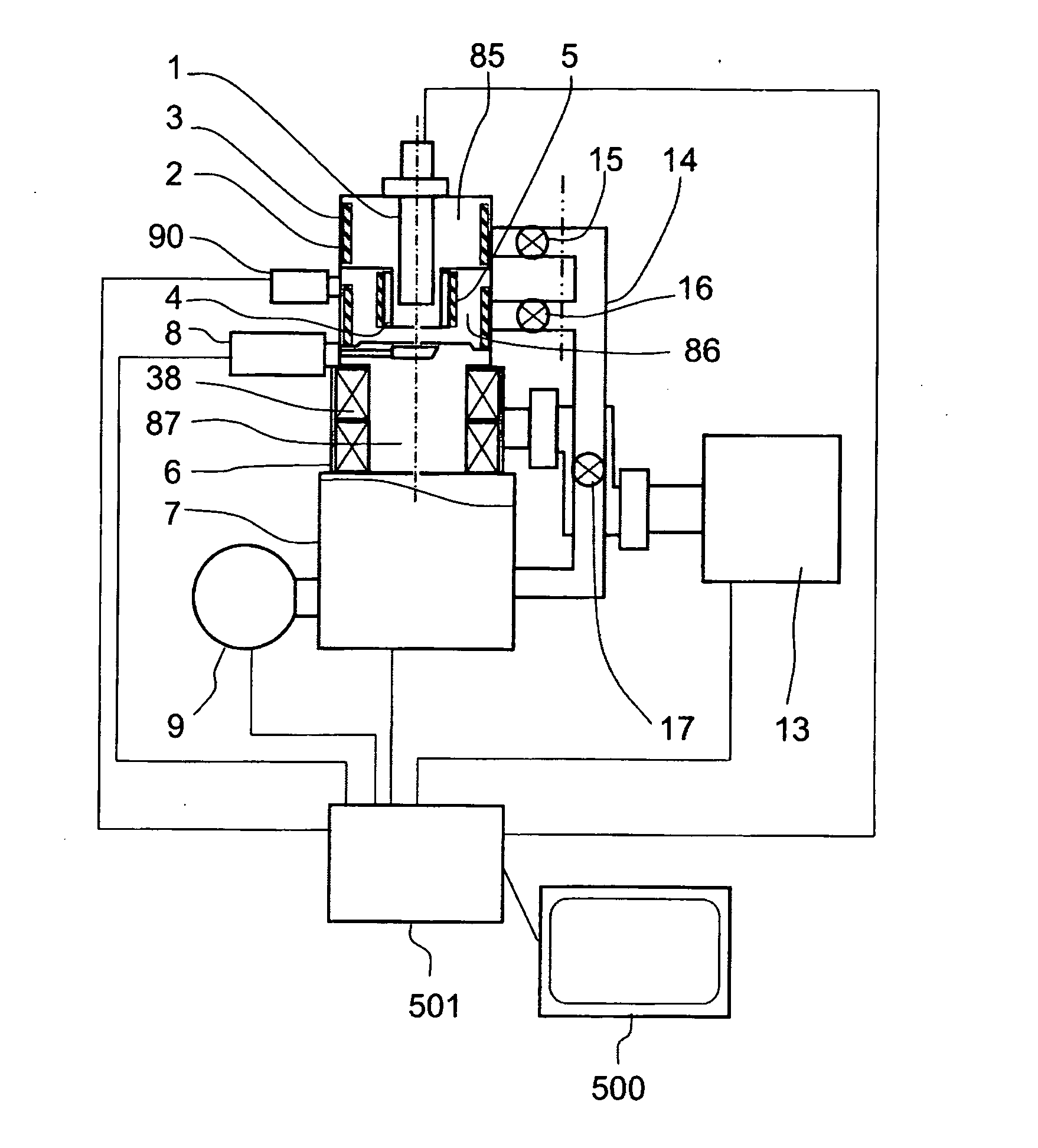

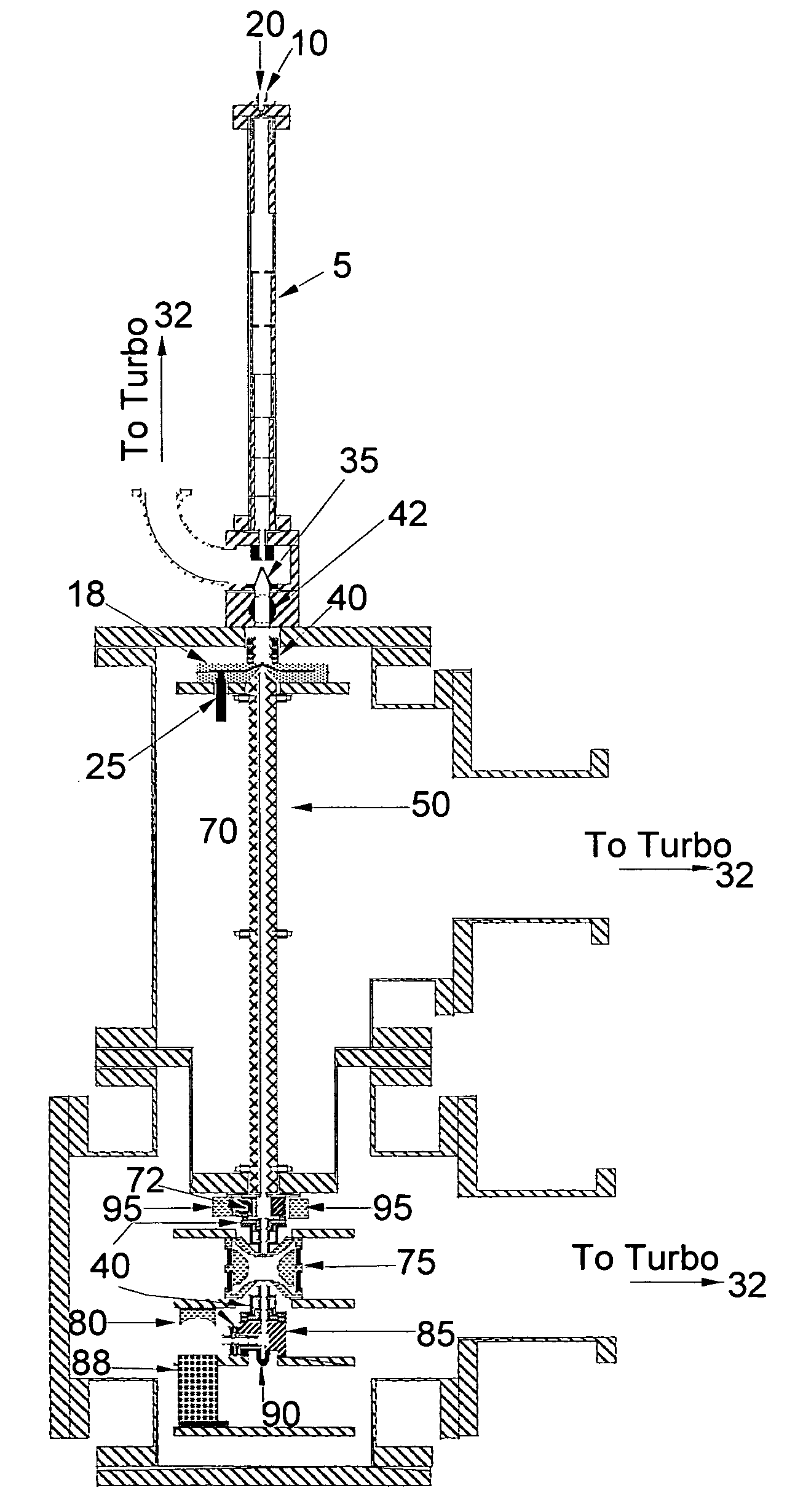

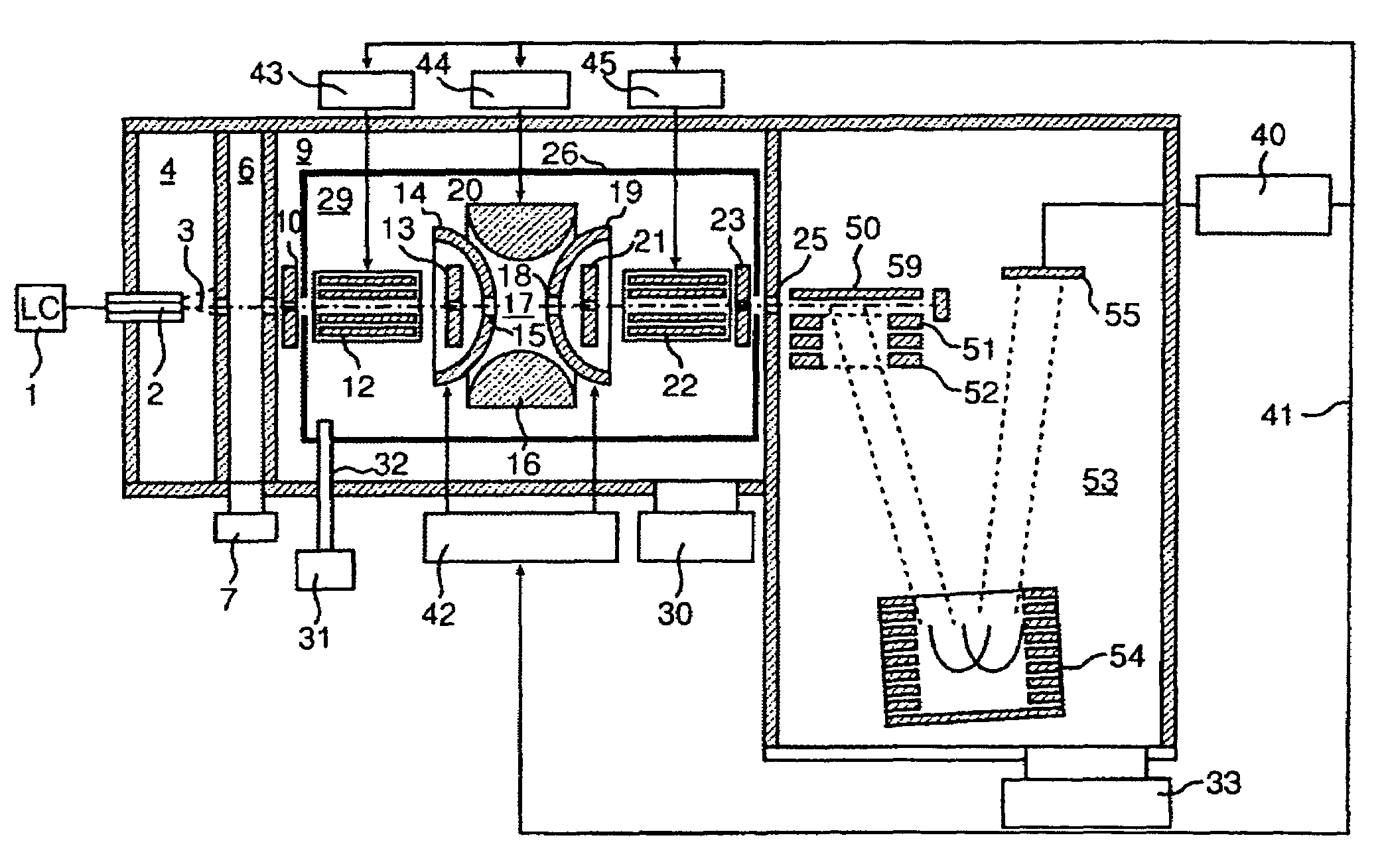

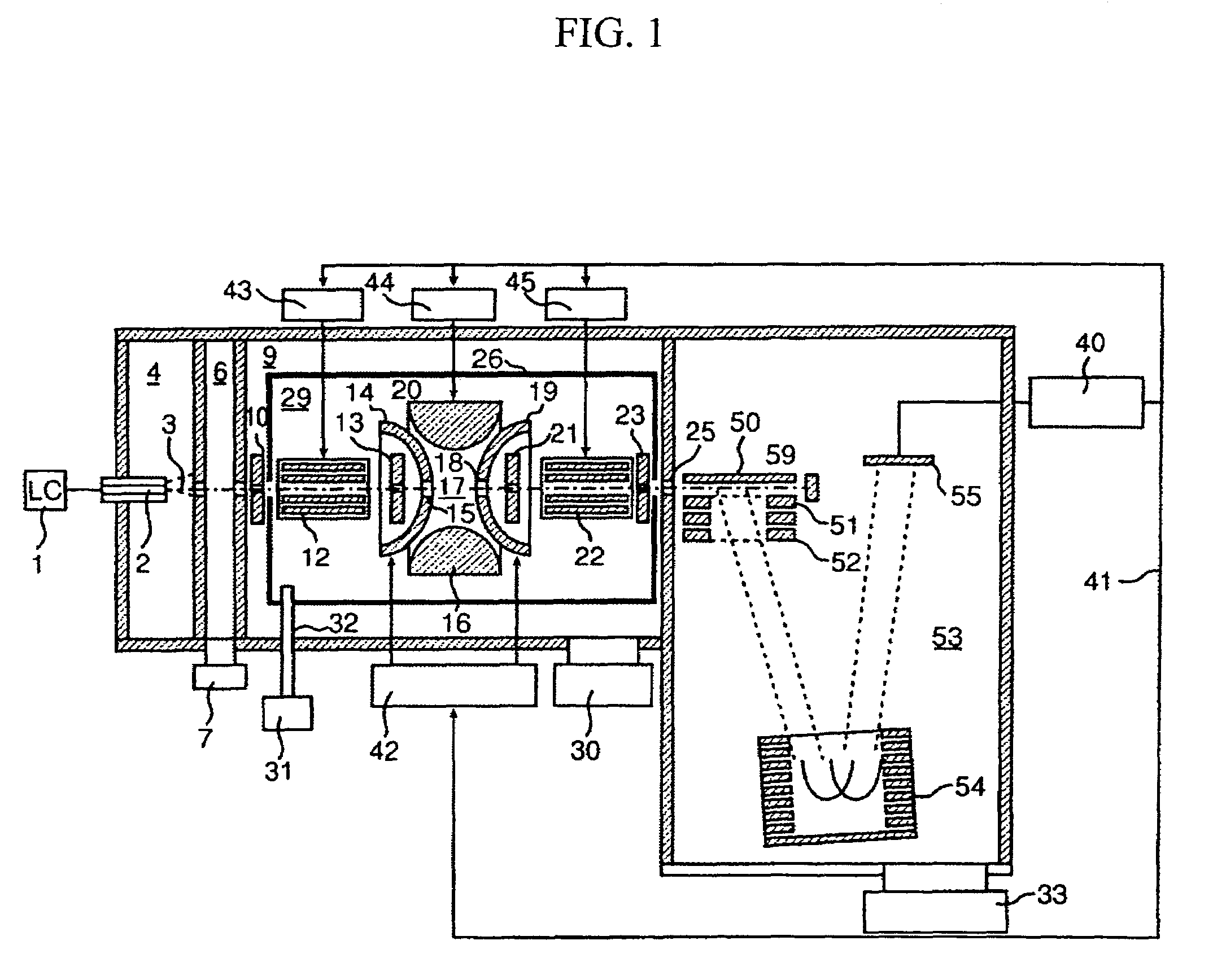

Charged particle beam apparatus

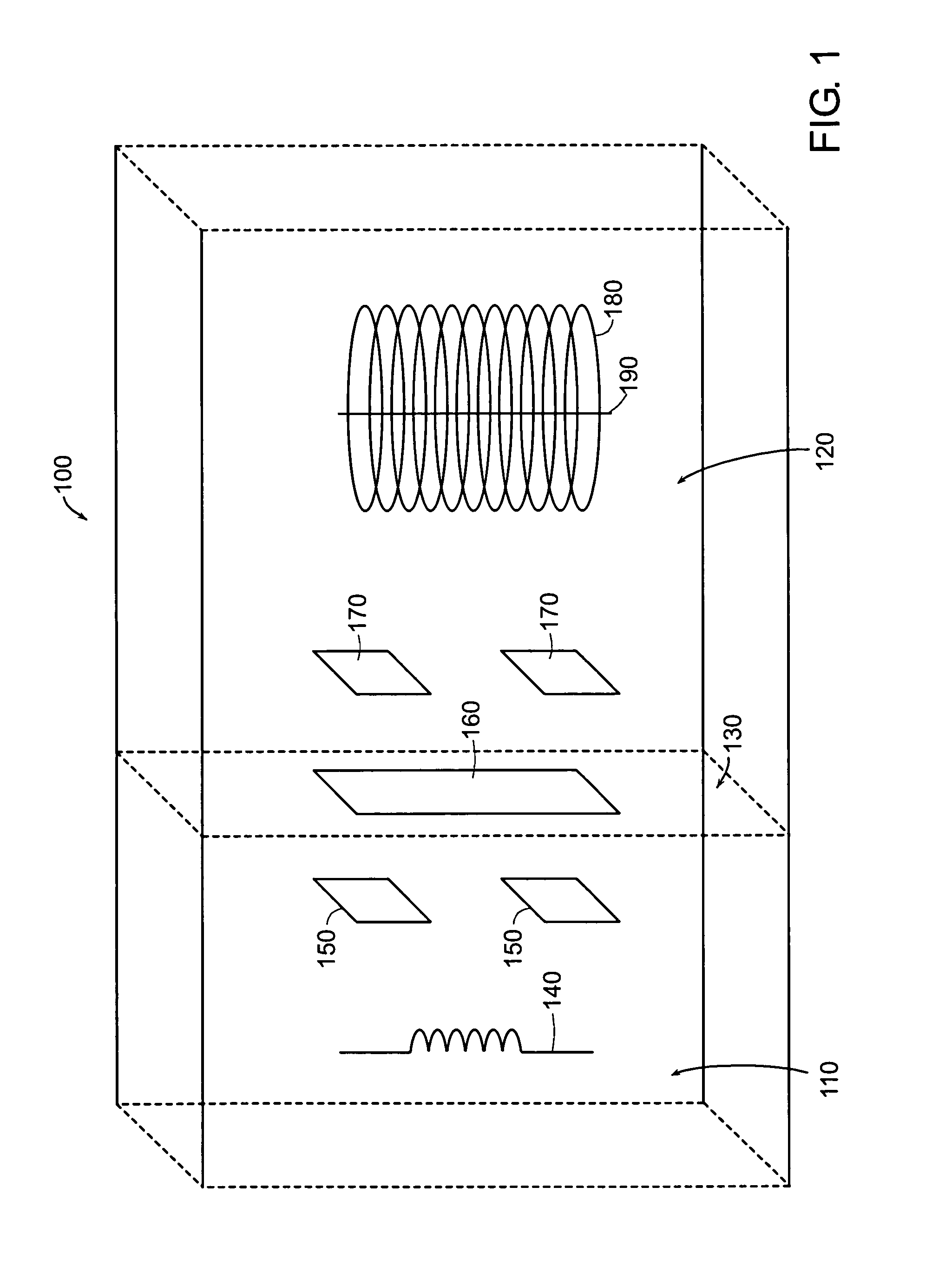

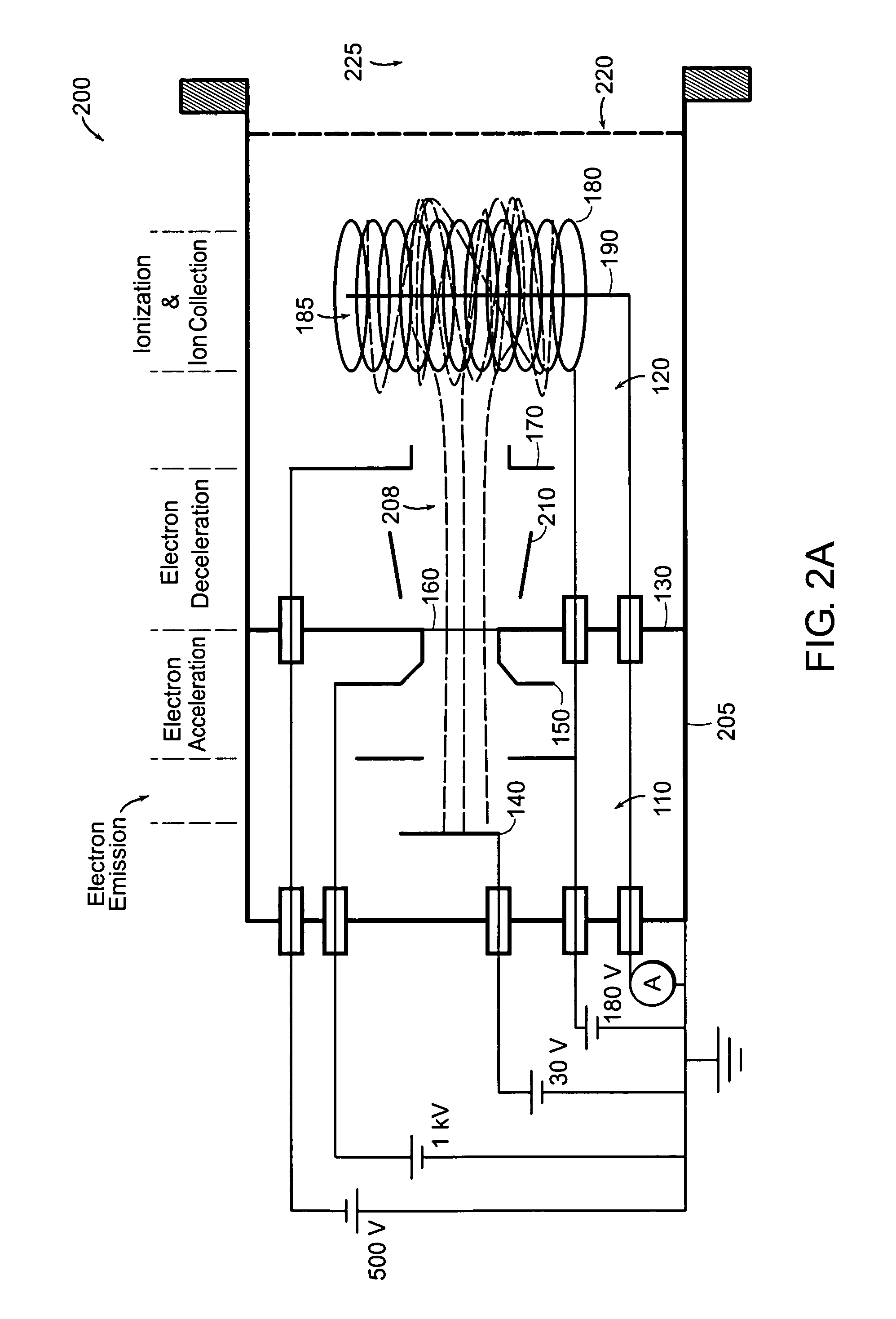

InactiveUS20060231773A1Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsGetterFree space

A small-sized charged particle beam apparatus capable of maintaining high vacuum even during emission of an electron beam is provided. A nonevaporative getter pump is placed upstream of differential pumping of an electron optical system of the charged particle beam apparatus, and a minimum number of ion pumps are placed downstream, so that both the pumps are used in combination. Further, by mounting a detachable coil on an electron gun part, the inside of a column can be maintained under high vacuum with a degree of vacuum in the order of 10−8 Pa.

Owner:HITACHI HIGH-TECH CORP

Charged particle beam apparatus

InactiveUS7582885B2Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsRemoving coilGetter

Owner:HITACHI HIGH-TECH CORP

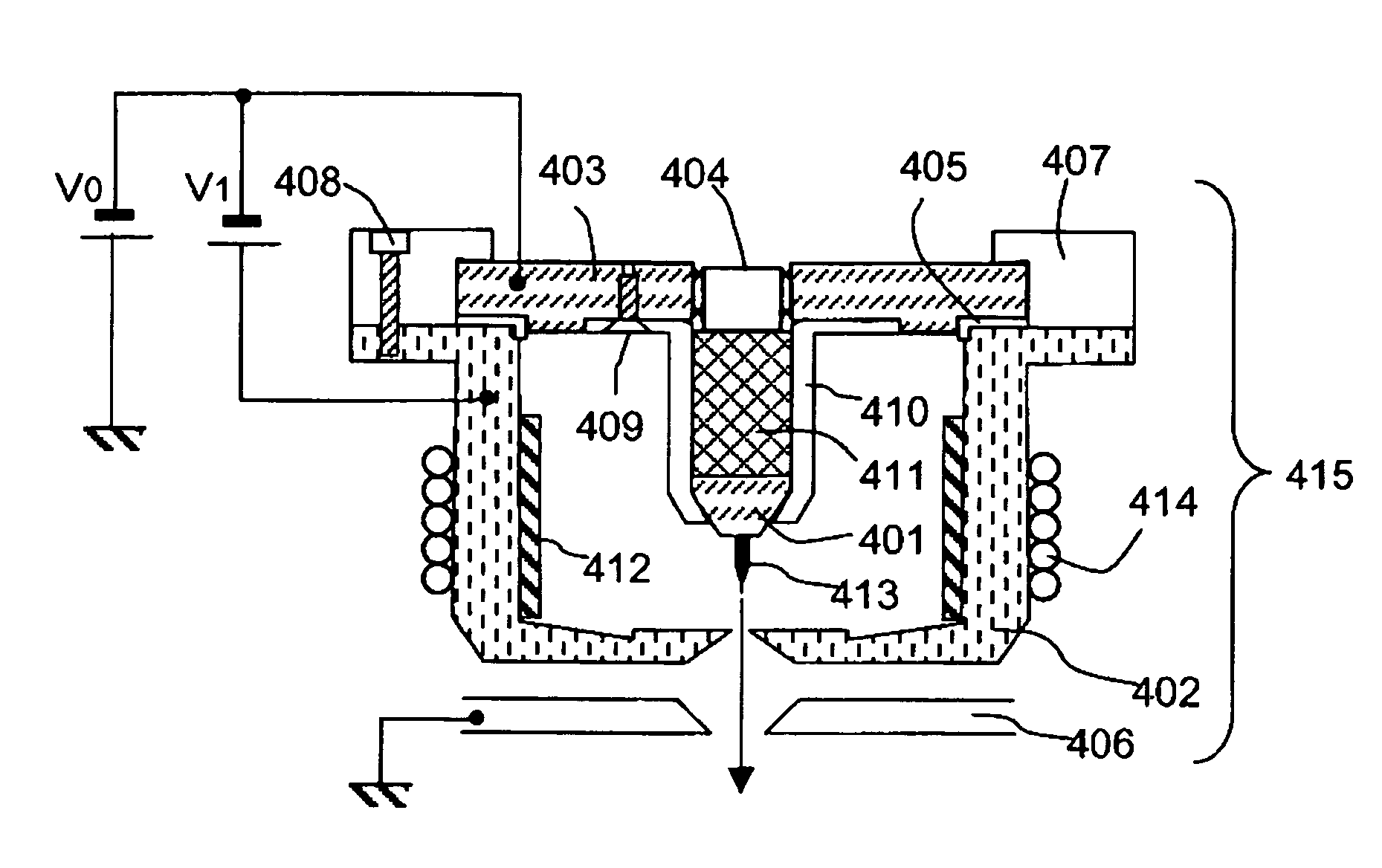

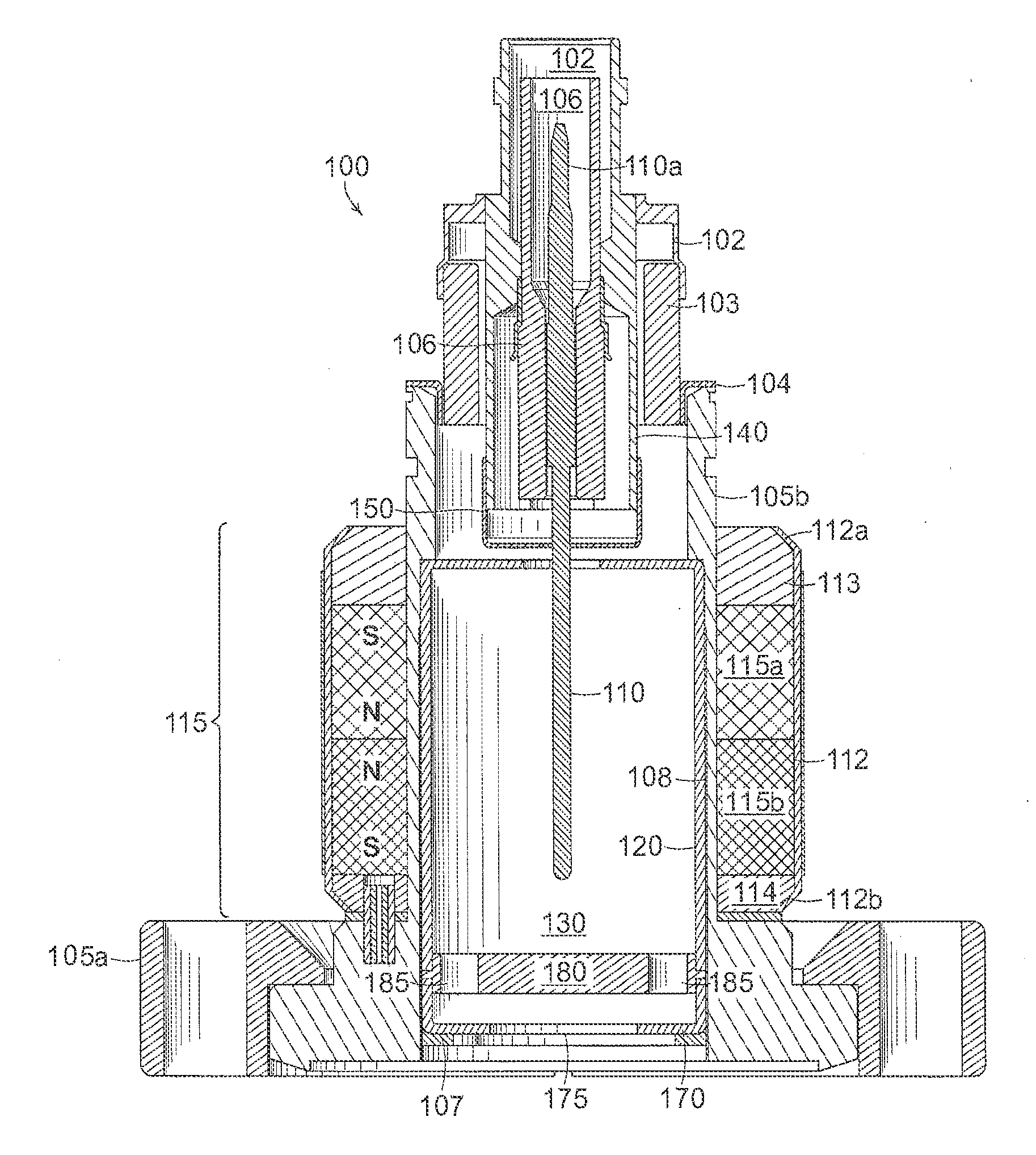

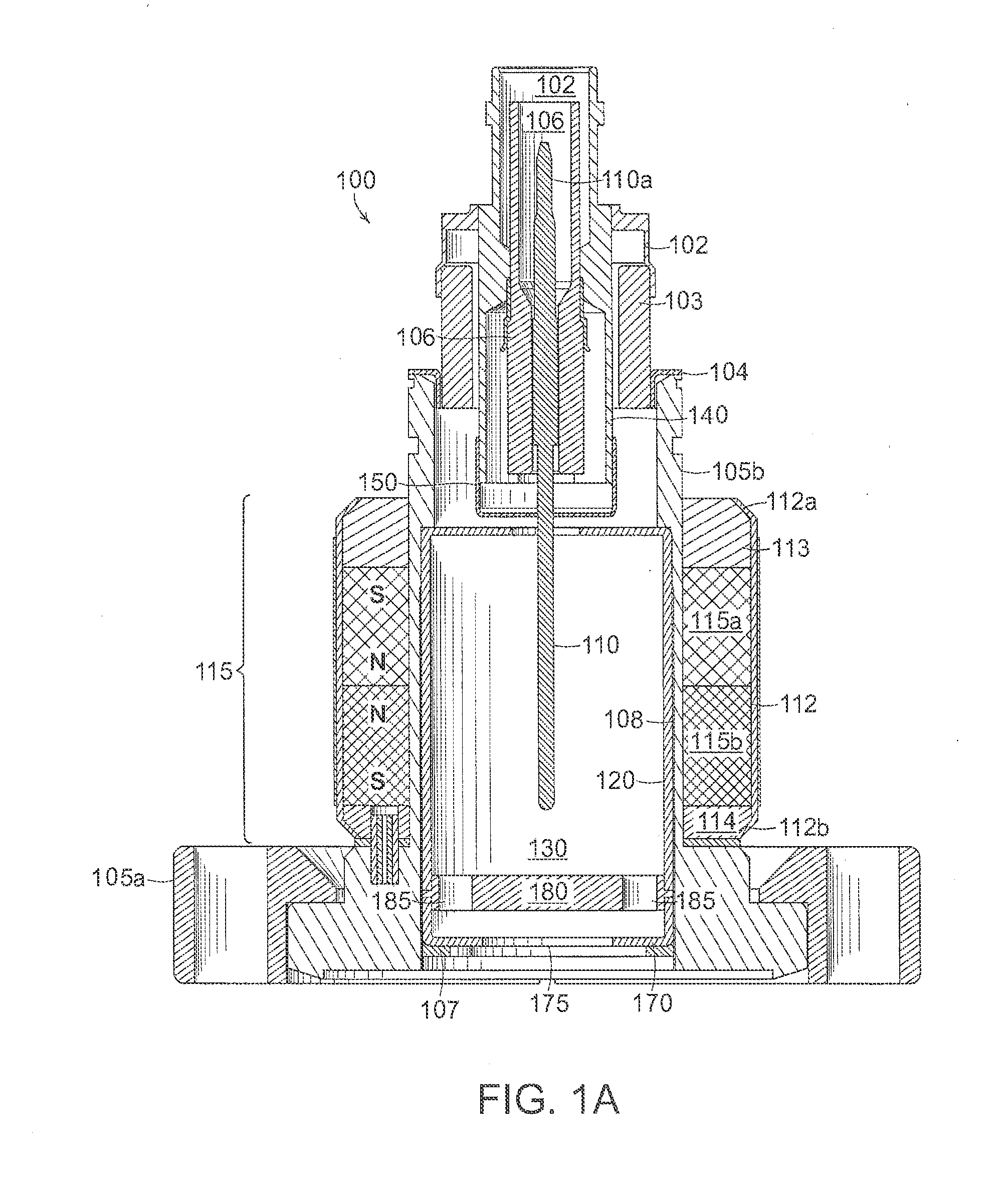

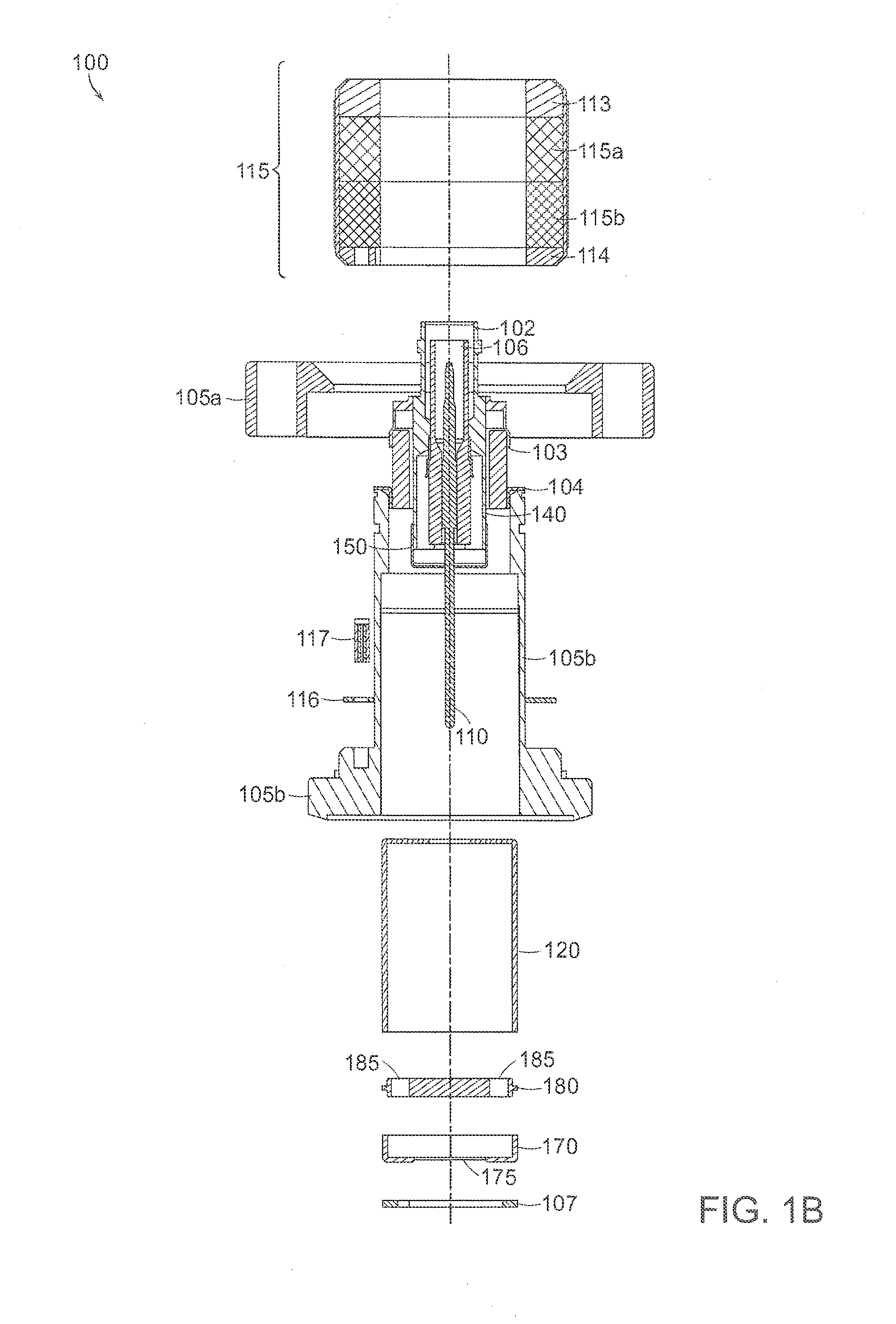

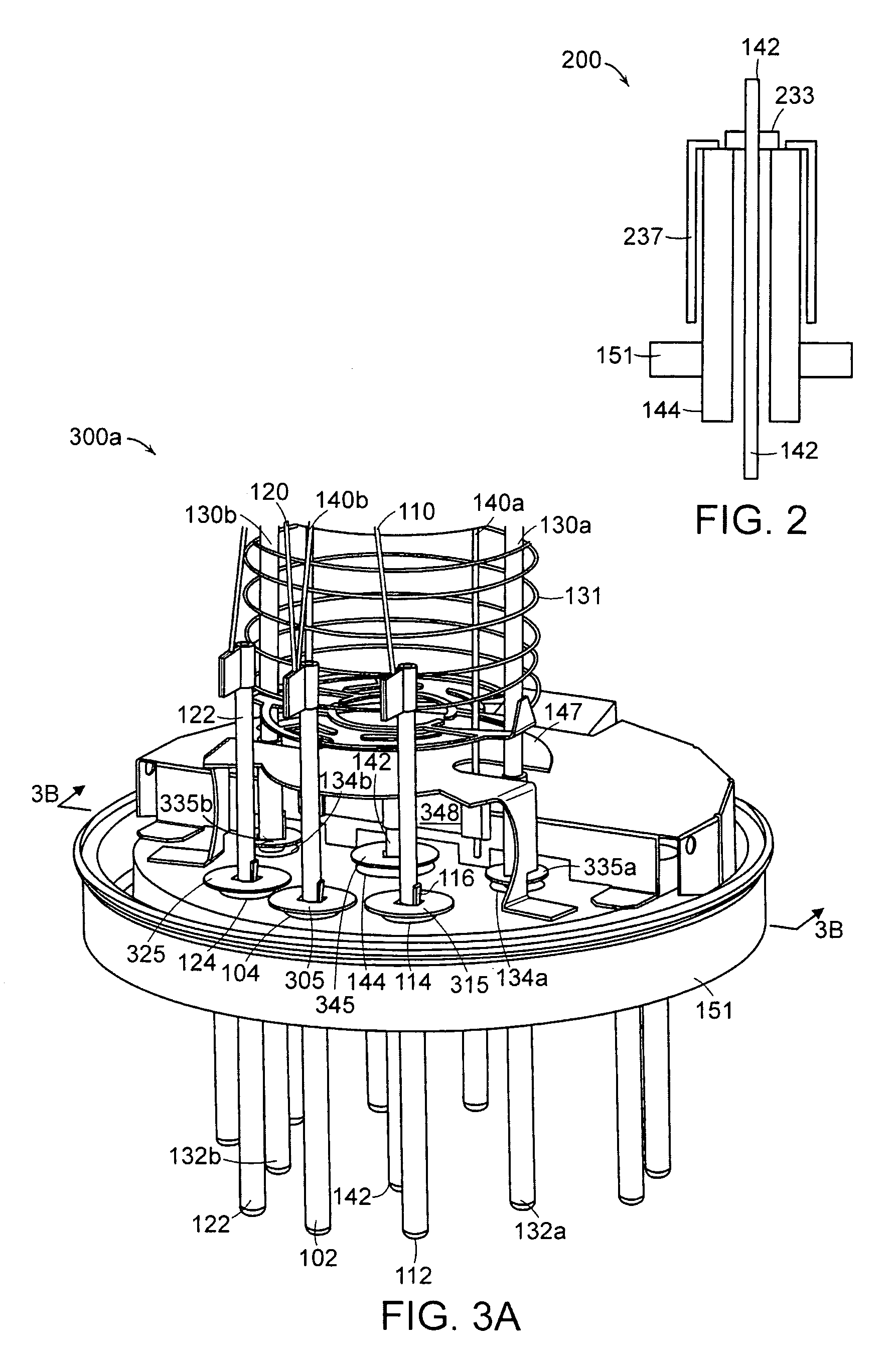

Ultra high mass range mass spectrometer systems

InactiveUS6972408B1Reduce kinetic energyPermit deliveryCombination devicesLaser detailsIon trap mass spectrometryMass analyzer

Applicant's present invention comprises mass spectrometer systems that operate in a mass range from 1 to 1016 DA. The mass spectrometer system comprising an inlet system comprising an aerodynamic lens system, a reverse jet being a gas flux generated in an annulus moving in a reverse direction and a multipole ion guide; a digital ion trap; and a thermal vaporization / ionization detector system. Applicant's present invention further comprises a quadrupole mass spectrometer system comprising an inlet system having a quadrupole mass filter and a thermal vaporization / ionization detector system. Applicant's present invention further comprises an inlet system for use with a mass spectrometer system, a method for slowing energetic particles using an inlet system. Applicant's present invention also comprises a detector device and a method for detecting high mass charged particles.

Owner:UT BATTELLE LLC

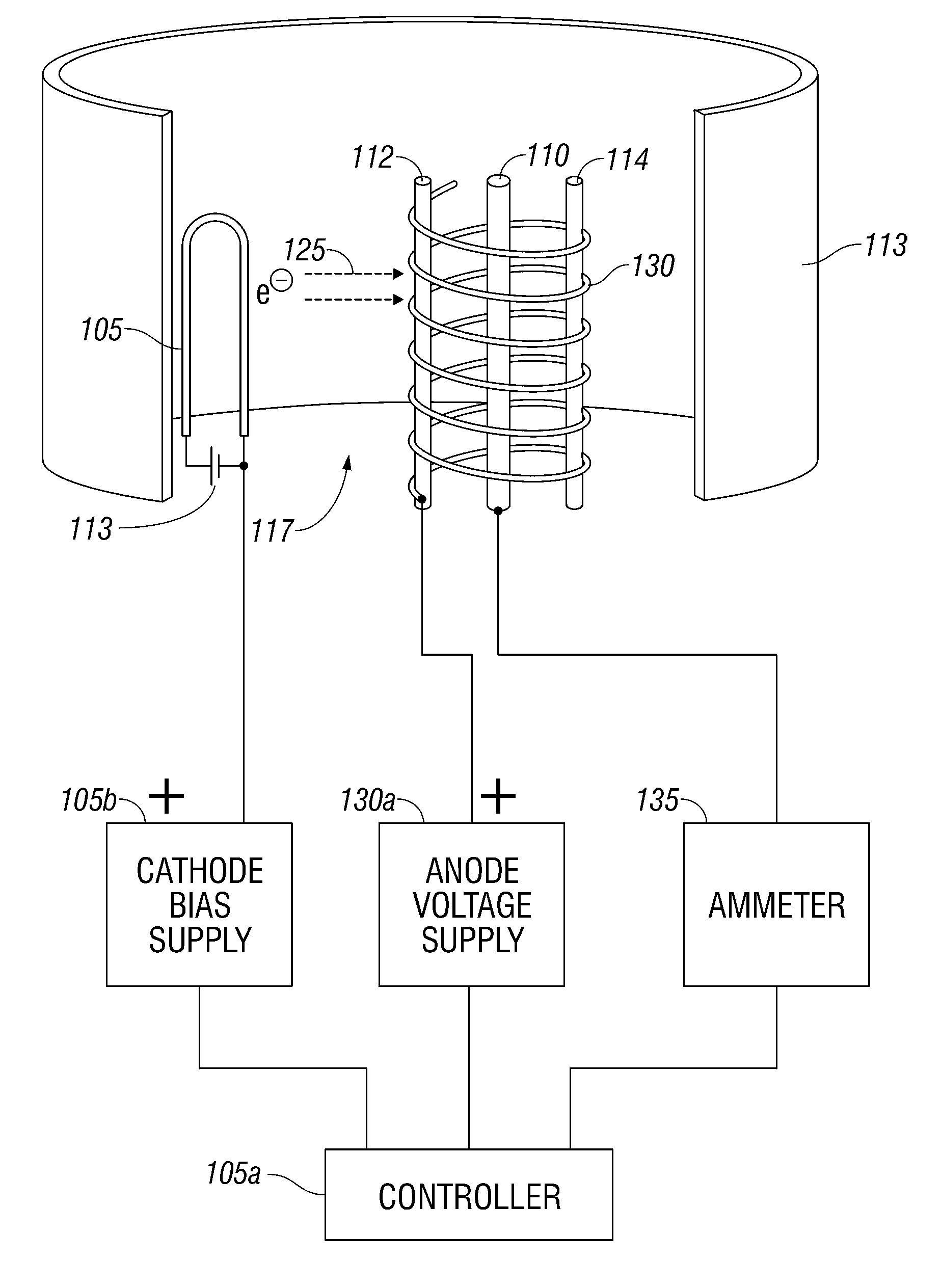

Cold cathode ionization vacuum gauge, vacuum processing apparatus including same and discharge starting auxiliary electrode

InactiveUS20100259273A1Avoid simple structuresShort timeVacuum gauge using ionisation effectsGas pressure measurement discharge tubesCarbon nanotubeCold cathode

The present invention provides a cold cathode ionization vacuum gauge that can trigger discharge in a short time even in the case of use over a long period of time without needing a complicated apparatus. It has the structure in which a rod-like anode is located in an internal part of a measuring element container (cathode) having a discharge space with one end thereof which is sealed, and a discharge starting auxiliary electrode is mounted on this anode. The discharge starting auxiliary electrode triggers the discharge in a short time by the formation of a carbon nanotube layer on a discharge starting auxiliary electrode plate.

Owner:CANON ANELVA CORP

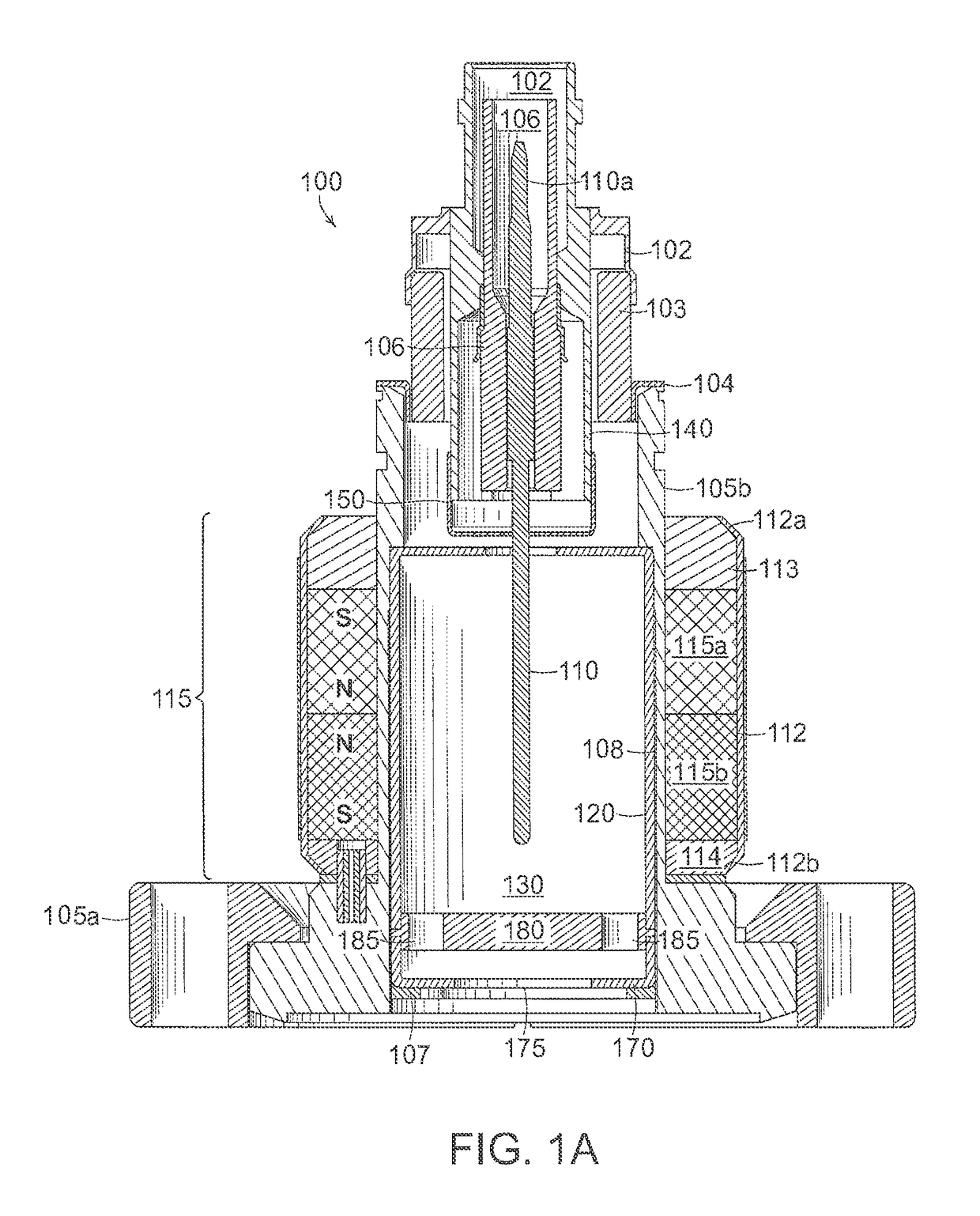

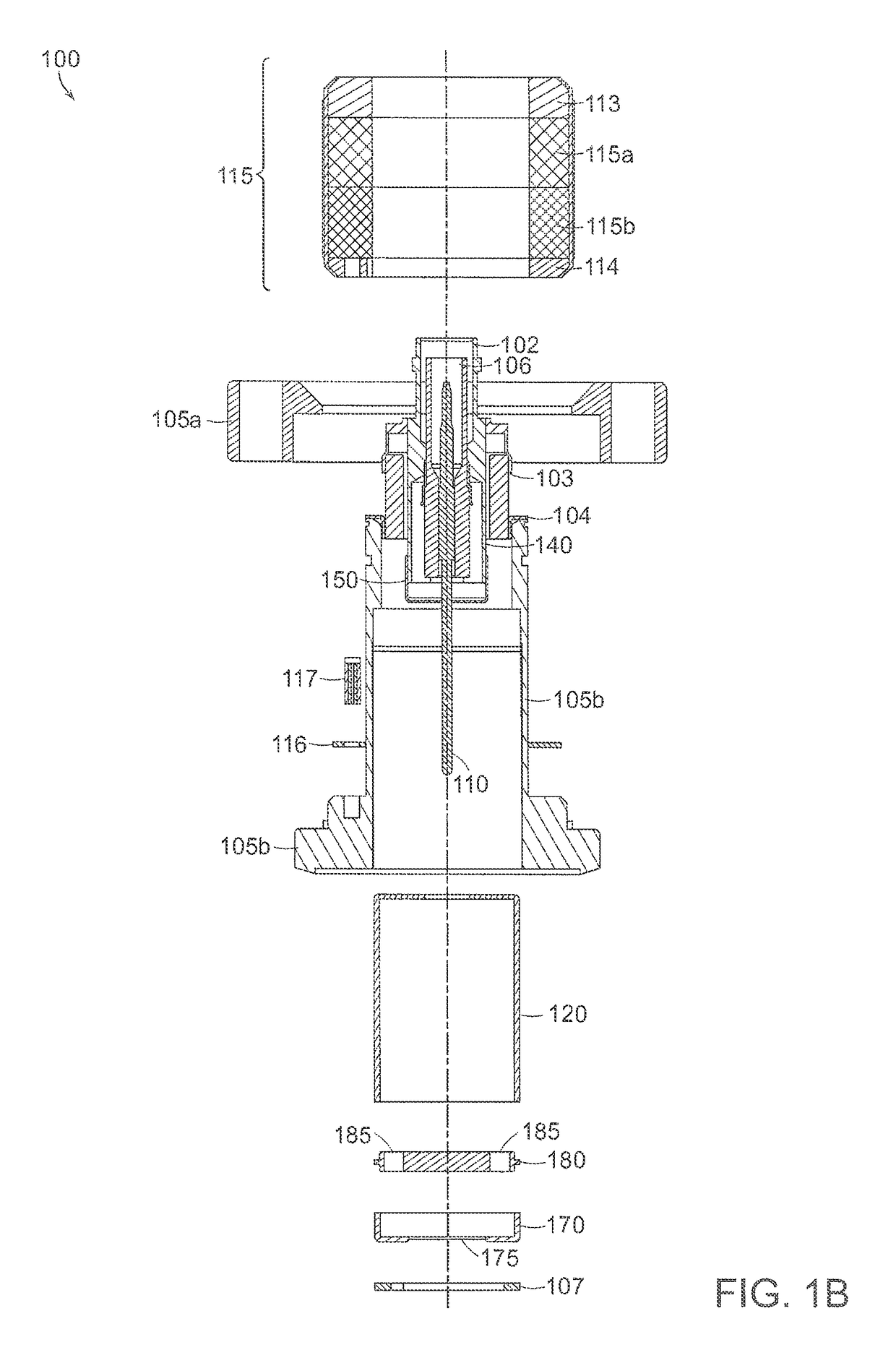

Cold cathode ionization vacuum gauge

ActiveUS20150091579A1Long-term stabilityStart fastVacuum gauge using ionisation effectsManufacture of electrical instrumentsCold cathodeIonization

A cold cathode ionization vacuum gauge includes an extended anode electrode and a cathode electrode surrounding the anode electrode along its length and forming a discharge space between the anode electrode and the cathode electrode. The vacuum gauge further includes an electrically conductive guard ring electrode interposed between the cathode electrode and the anode electrode about a base of the anode electrode to collect leakage electrical current, and a discharge starter device disposed over and electrically connected with the guard ring electrode, the starter device having a plurality of tips directed toward the anode and forming a gap between the tips and the anode.

Owner:MKS INSTR INC

Ionisation vacuum gauge

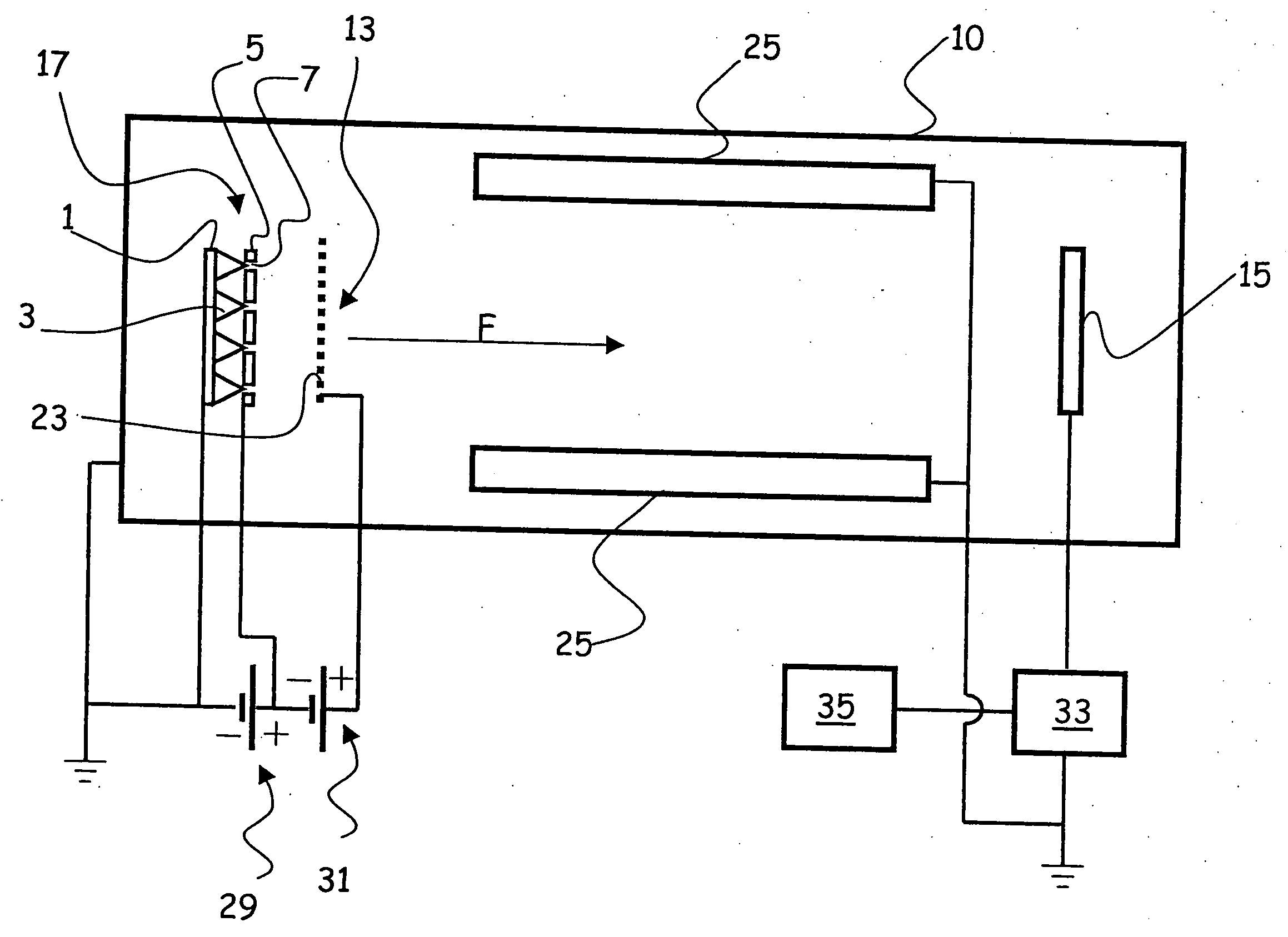

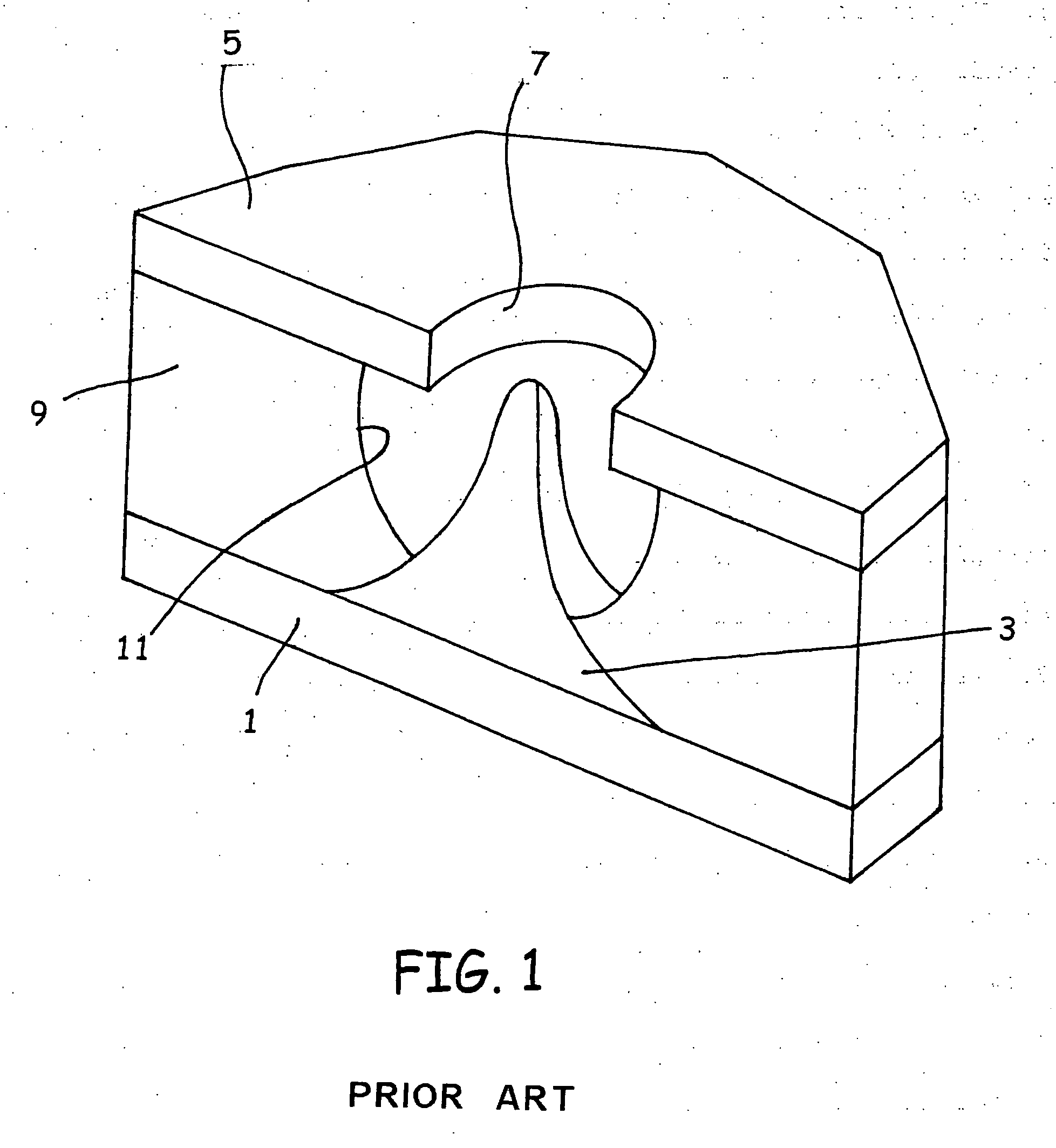

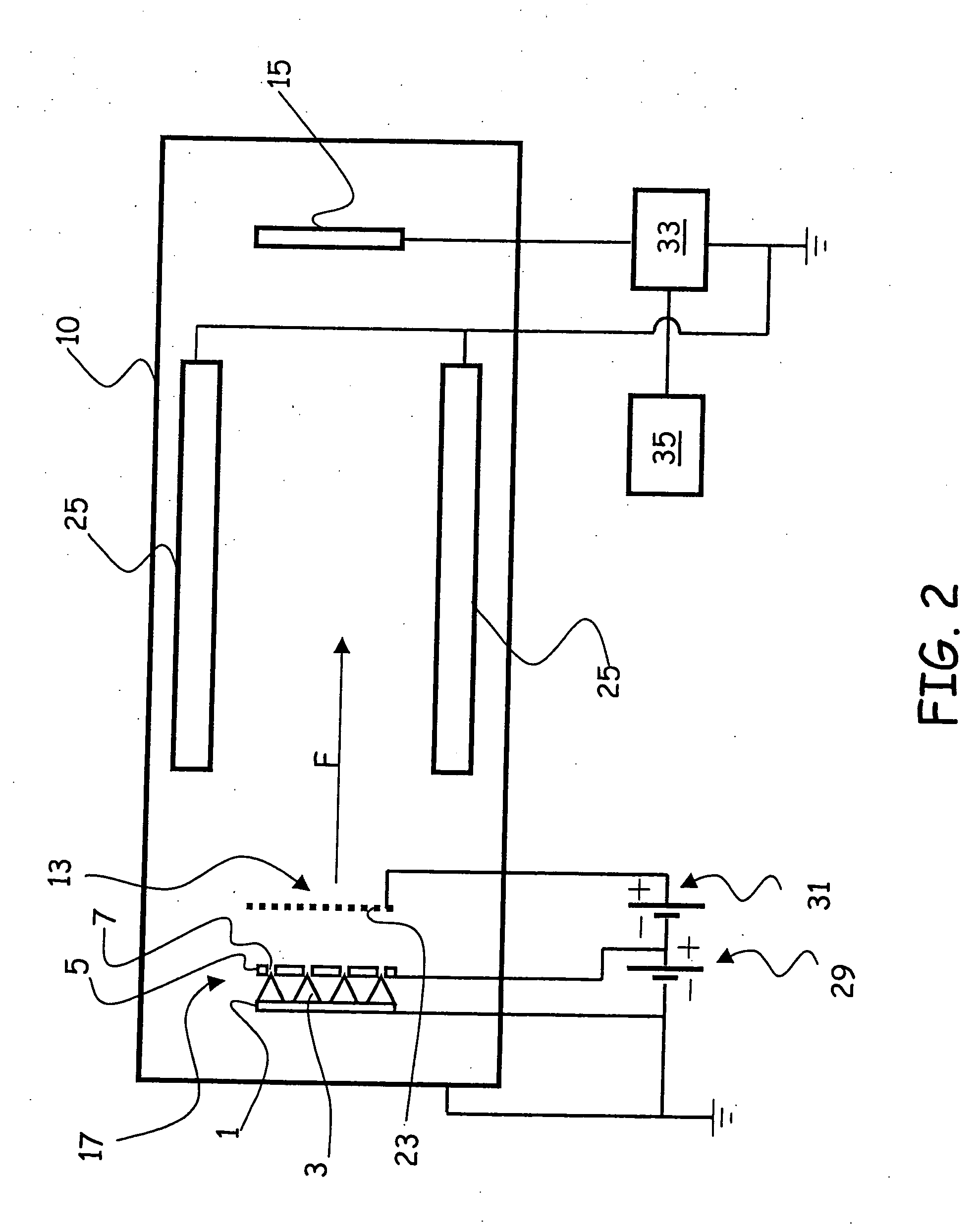

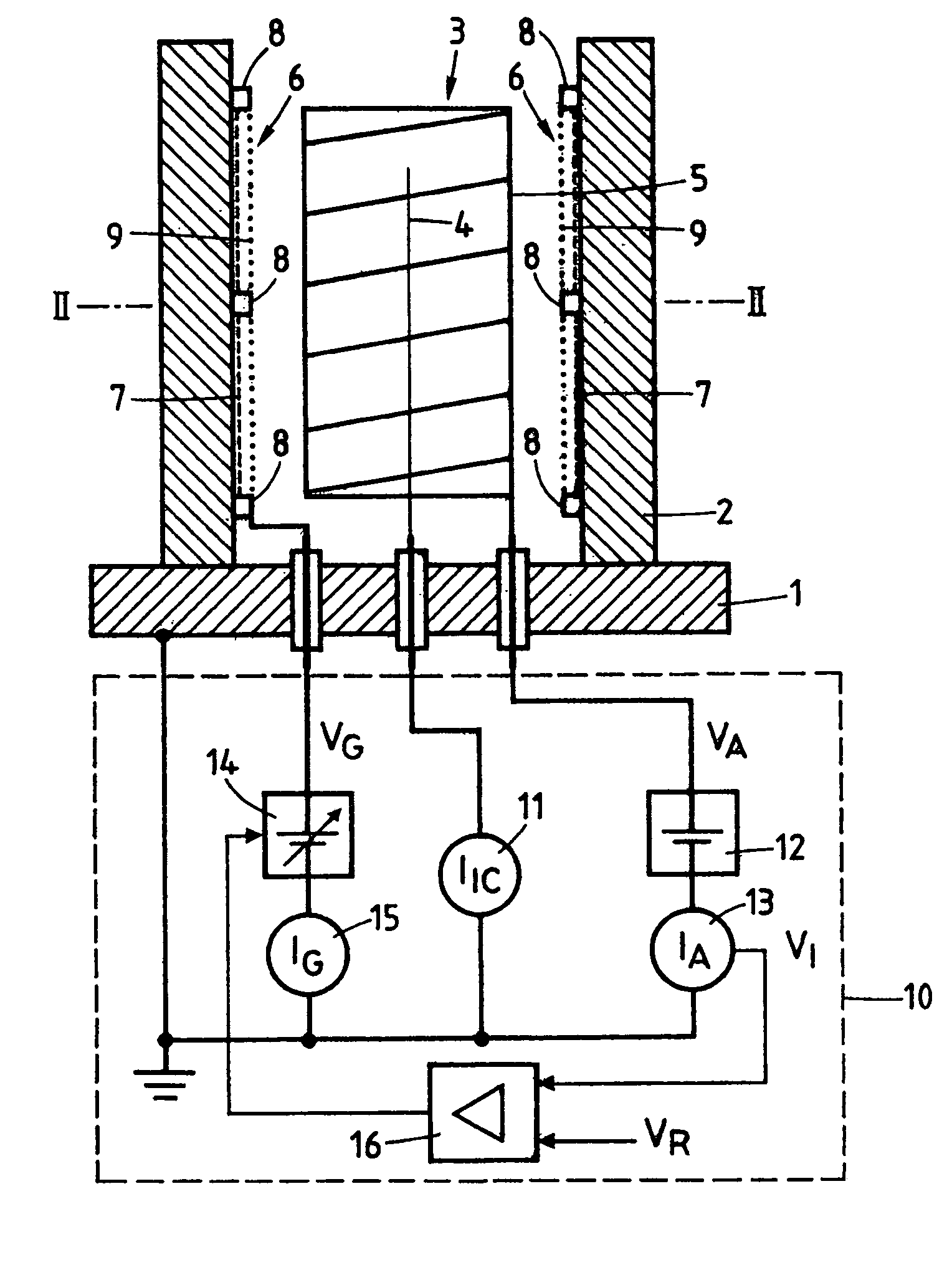

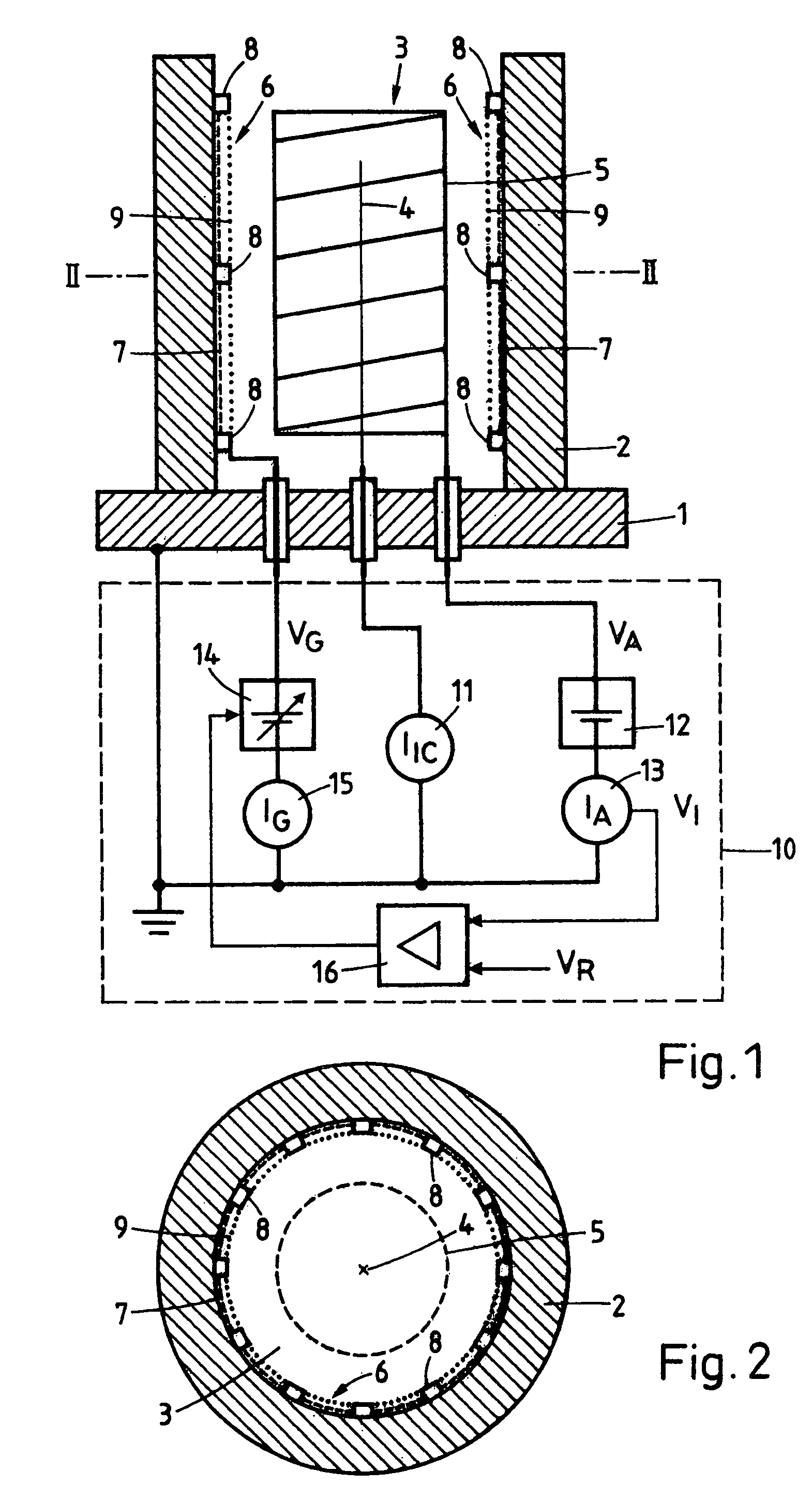

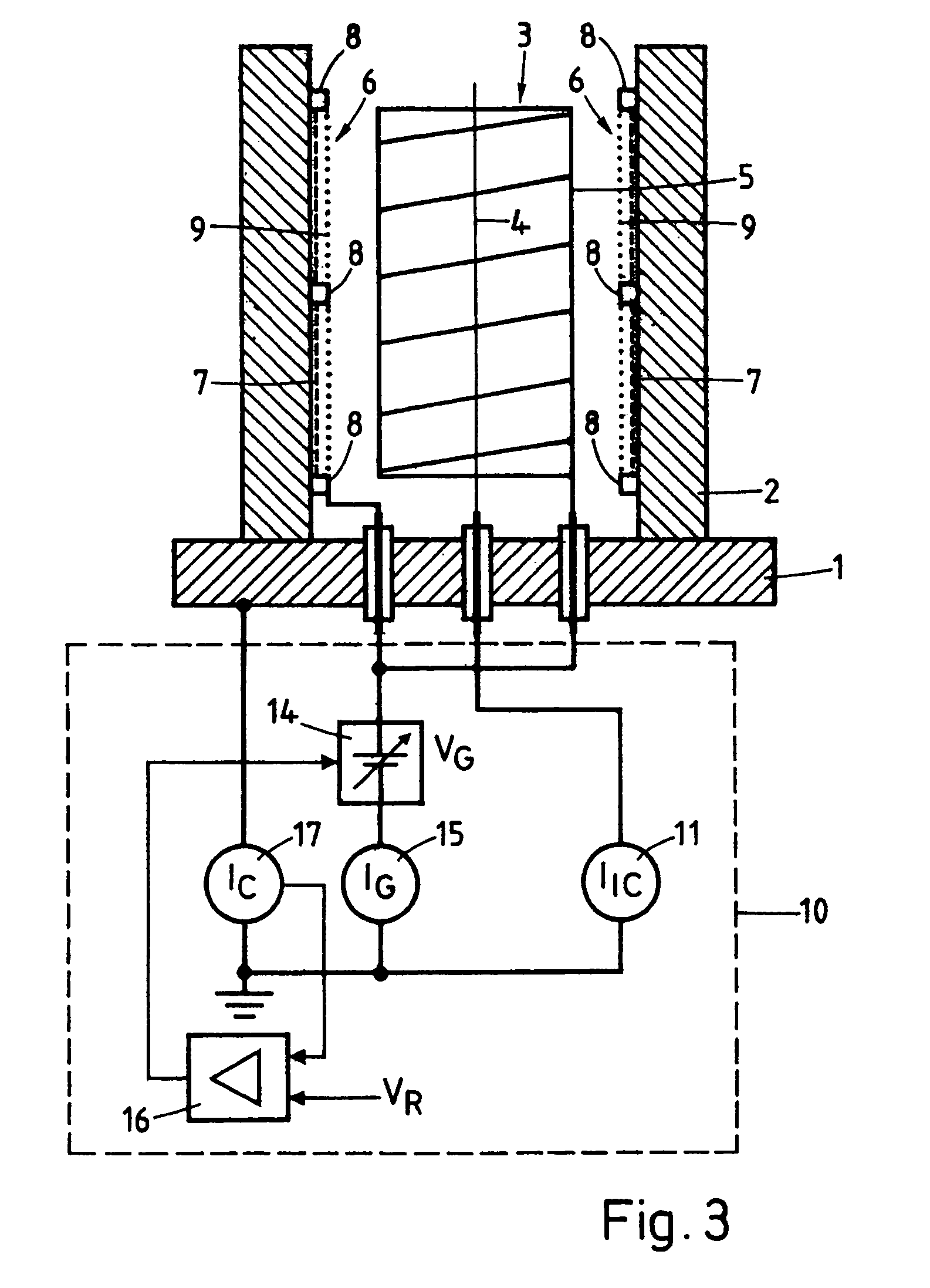

InactiveUS20050030044A1Improve performanceImprove directionalityVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansGalvanometerVacuum pump

The present invention relates to an ionisation vacuum gauge for measuring the residual pressure of a gaseous material remaining in a container (10), more particularly after operation of a vacuum pump. The gauge comprises an electron-emitting cathode (17), a grid (13) for accelerating the electrons emitted by the cathode and a plate (15) collecting the ions and / or the ionised positive molecules of the gas, wherein said plate is placed outside said grid. Measuring the plate current by a galvanometer allows determining the value of the residual pressure inside the container.

Owner:AGILENT TECH INC

Open channel solid phase extraction systems and methods

The invention provides, inter alia, methods of extracting an analyte from a solution comprising the steps of: passing a solution containing an analyte through an extraction channel having a solid phase extraction surface, whereby analyte adsorbs to the extraction surface of said extraction channel; and eluting the analyte by passing a desorption solution through the channel, wherein the method includes a step wherein a multiple-pass solution is passed through at least some substantial portion of the extraction channel at least twice. Non-limiting examples multiple-pass solutions include a solution containing an analyte, a wash solution and / or a desorption solution.

Owner:PHYNEXUS

Ionization vacuum gauge

InactiveUS20090096460A1Vacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansElectron sourceUltimate tensile strength

An ionization vacuum gauge which has at least three electrodes of a grid (2), an electron source (3) and an ion collector (1) in a vacuum vessel (4) connected in communication with a vacuum apparatus, oscillates electrons emitted from the electron source (3) within and outside of the grid (2), ionizes gas molecules flying into the grid (2) by the oscillated electrons, supplements the ionized ions by the ion collector (1) to convert into a current signal, and measures a gas molecular density (pressure) in the vacuum apparatus according to the obtained current intensity, wherein the ion collector (1) is provided with heating means for heating the ion collector.

Owner:MIRAPRO

Micro vacuum pump for maintaining high degree of vacuum and apparatus including the same

InactiveUS6236156B1Gas filling substance selectionDischarge tube luminescnet screensNoble gasEngineering

The present invention provides a micro vacuum pump capable of enhancing the performance of exhausting rare gases as well as active gases thereby to ensure quality, good repeatability and stable getter action of the micro vacuum pump over a long time. The invention also provides an apparatus assembling the micro vacuum pump. The micro vacuum pump capable of maintaining a high degree of vacuum includes a first conductive substrate having many protrusions and mounting a second conductive substrate disposed with a predetermined interval provided with respect to the first conductive substrate so that it faces the protrusions. A gate electrode is disposed in the vicinity of the apexes of the protrusions on the first conductive substrate via an insulator layer, and is positioned to face the second conductive substrate. Relative to the first conductive substrate, a negative potential is supplied to the second conductive substrate, and, a same negative potential difference is also applied to the gate electrode relative to the cones.

Owner:NEC CORP

Open channel solid phase extraction systems and methods

InactiveUS20050106585A1Efficient executionMaterial nanotechnologyComponent separationAnalyteDesorption

The invention provides, inter alia, methods of extracting an analyte from a solution comprising the steps of: passing a solution containing an analyte through an extraction channel having a solid phase extraction surface, whereby analyte adsorbs to the extraction surface of said extraction channel; and eluting the analyte by passing a desorption solution through the channel, wherein the method includes a step wherein a multiple-pass solution is passed through at least some substantial portion of the extraction channel at least twice. Non-limiting examples multiple-pass solutions include a solution containing an analyte, a wash solution and / or a desorption solution.

Owner:PHYNEXUS

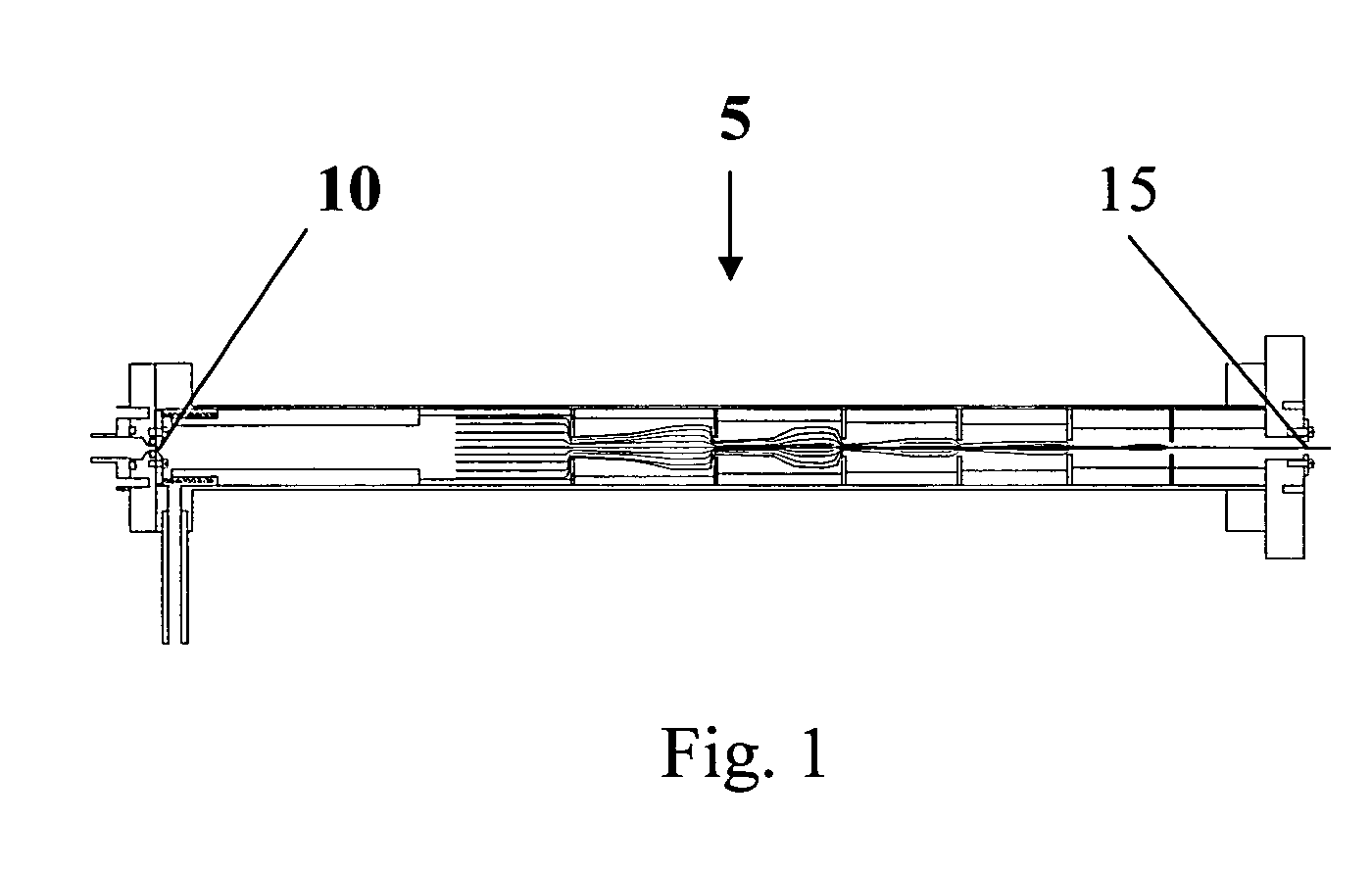

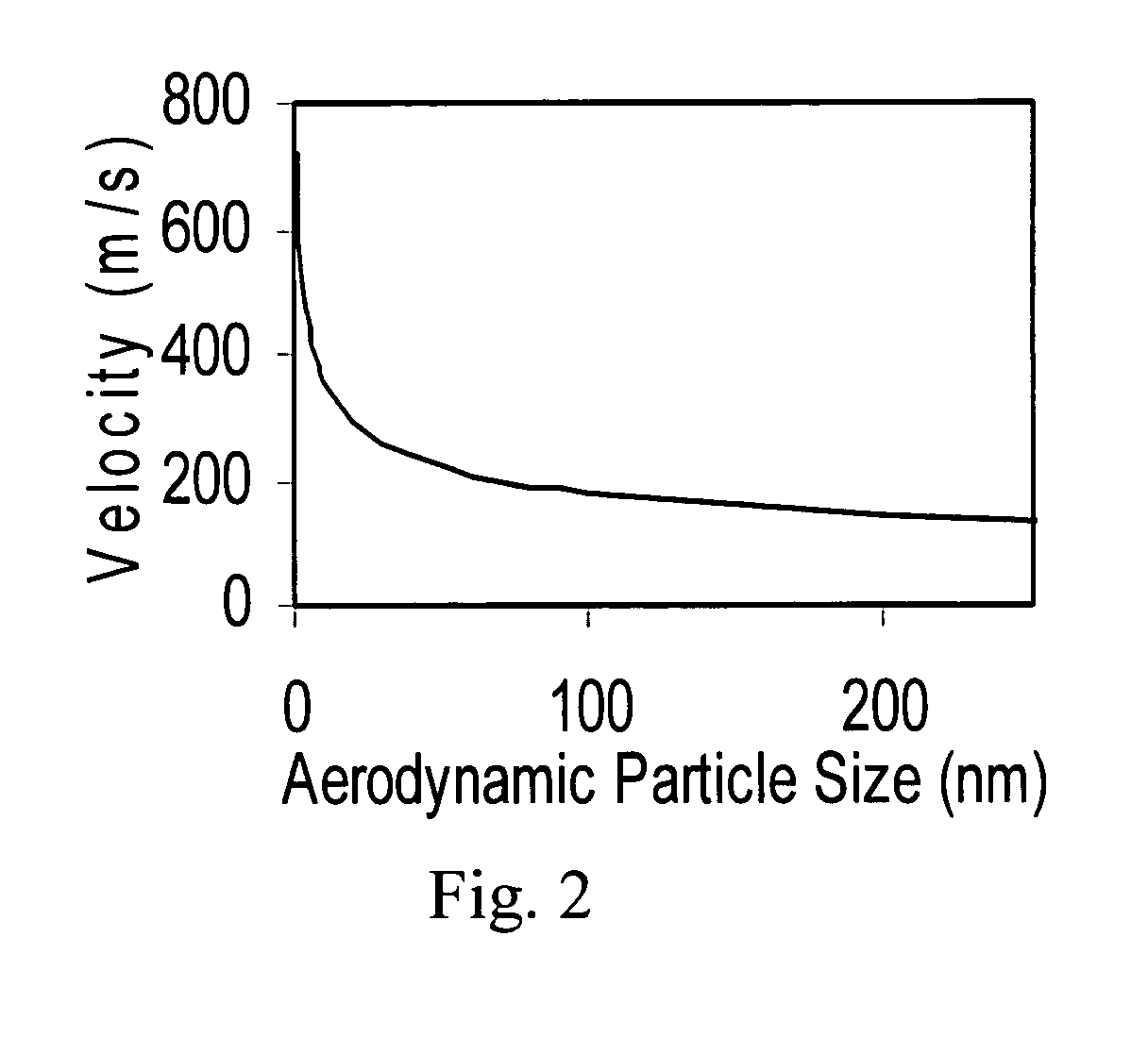

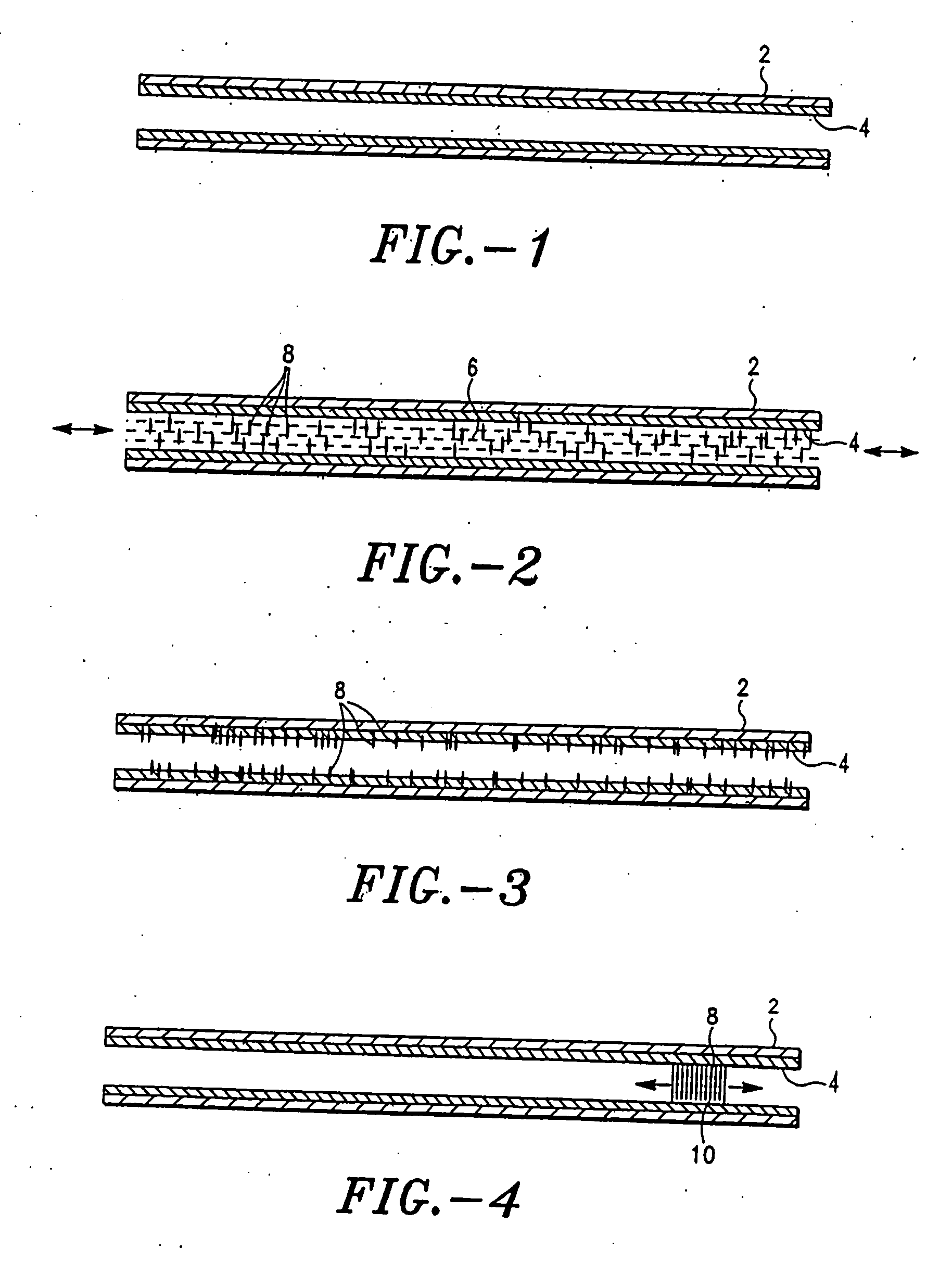

Aerodynamic Lens Particle Separator

ActiveUS20080022853A1Reduce flow rateIncrease concentrationAdditive manufacturing apparatusGas current separationInhalable particlesMicrofabrication

Respirable particles with diameters on the order of 0.05 to 10 microns entrained in an air stream. are concentrated in an aerodynamic lens (FIG. 2) for separation from the air steam. The entire structure is made by microfabrication techniques, such as silicon micro-machining which enables arrays of precisely aligned slit lenses to be made on a silicon chip. At a Reynolds number of 800, a slit 25 microns wide by 1 mm tall will pass a flow of only 0.28 liters per minute, but arrays of lenses (FIG. 4), stacked in parallel banks, multiplies the available flow rate. Placing a skimmer (27) at the exit of each silicon micro-machined lens in the assembly and connecting the skimmer channels in chimneys (55), allows the bulk of the gas flow to be stripped off while allowing the concentrated particle stream to pass into a region of much lower flow rate, thereby producing a highly concentrated aerosol in the low velocity stream.

Owner:ENERTECHNIX

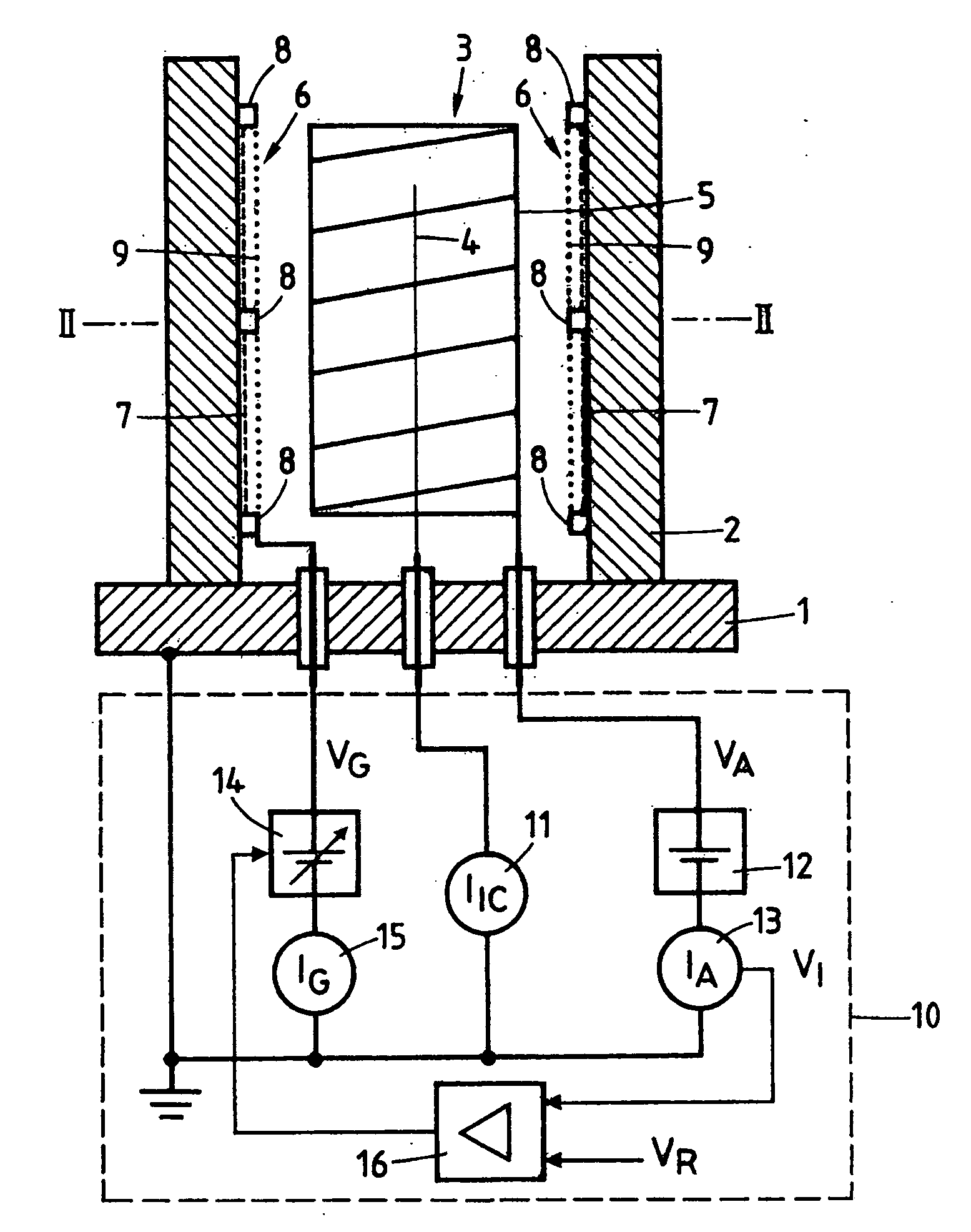

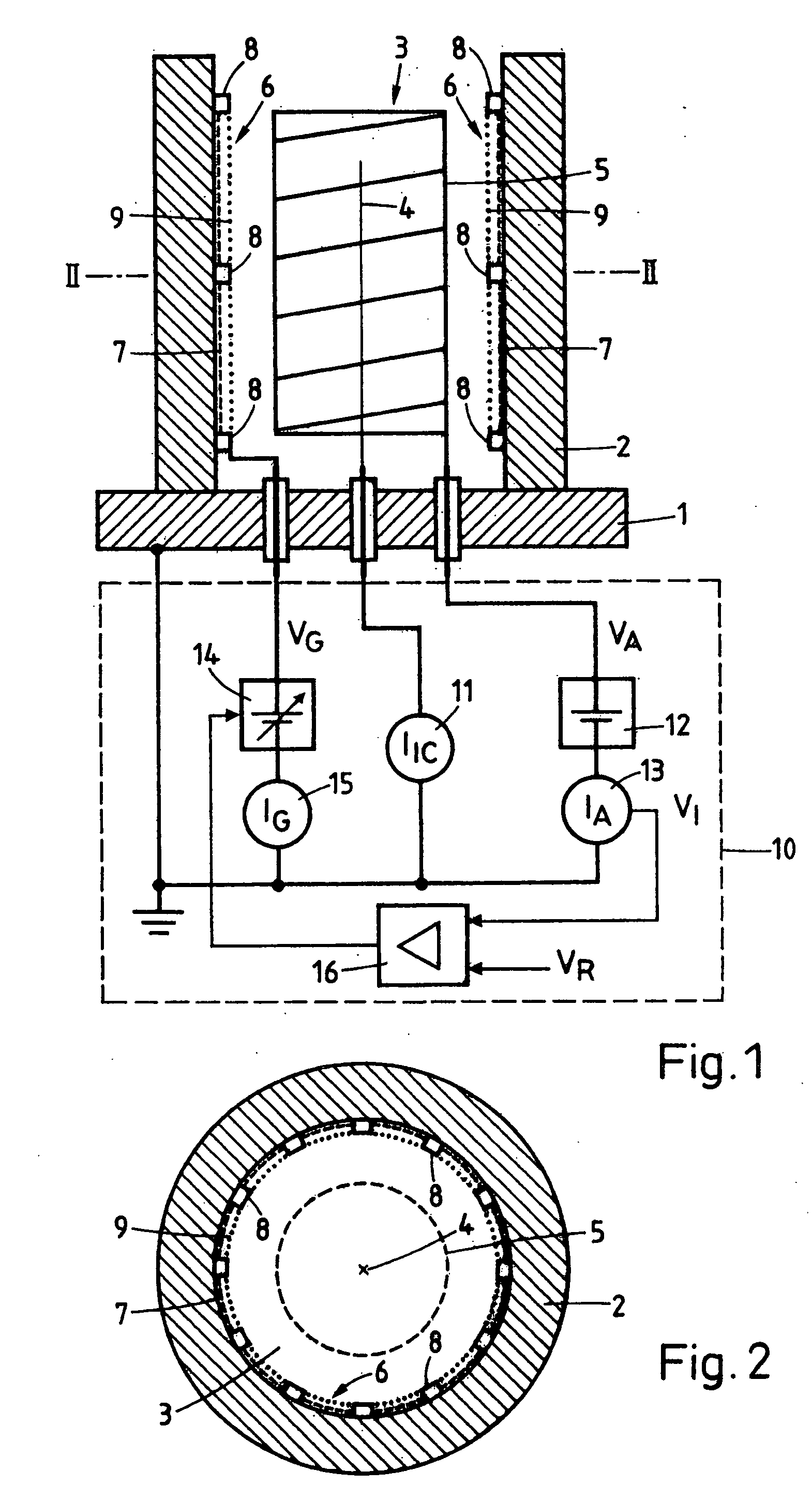

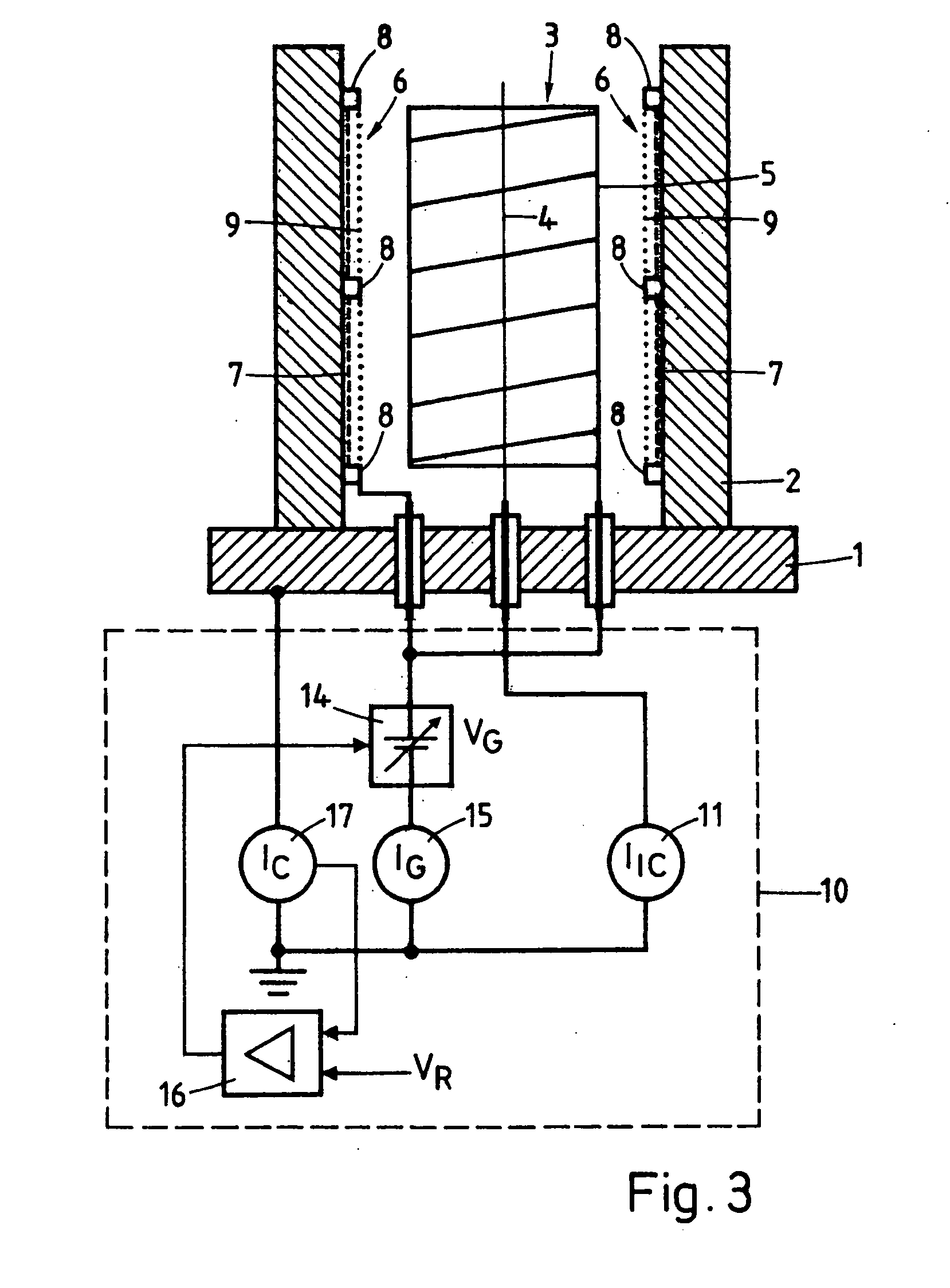

Vacuum measuring gauge

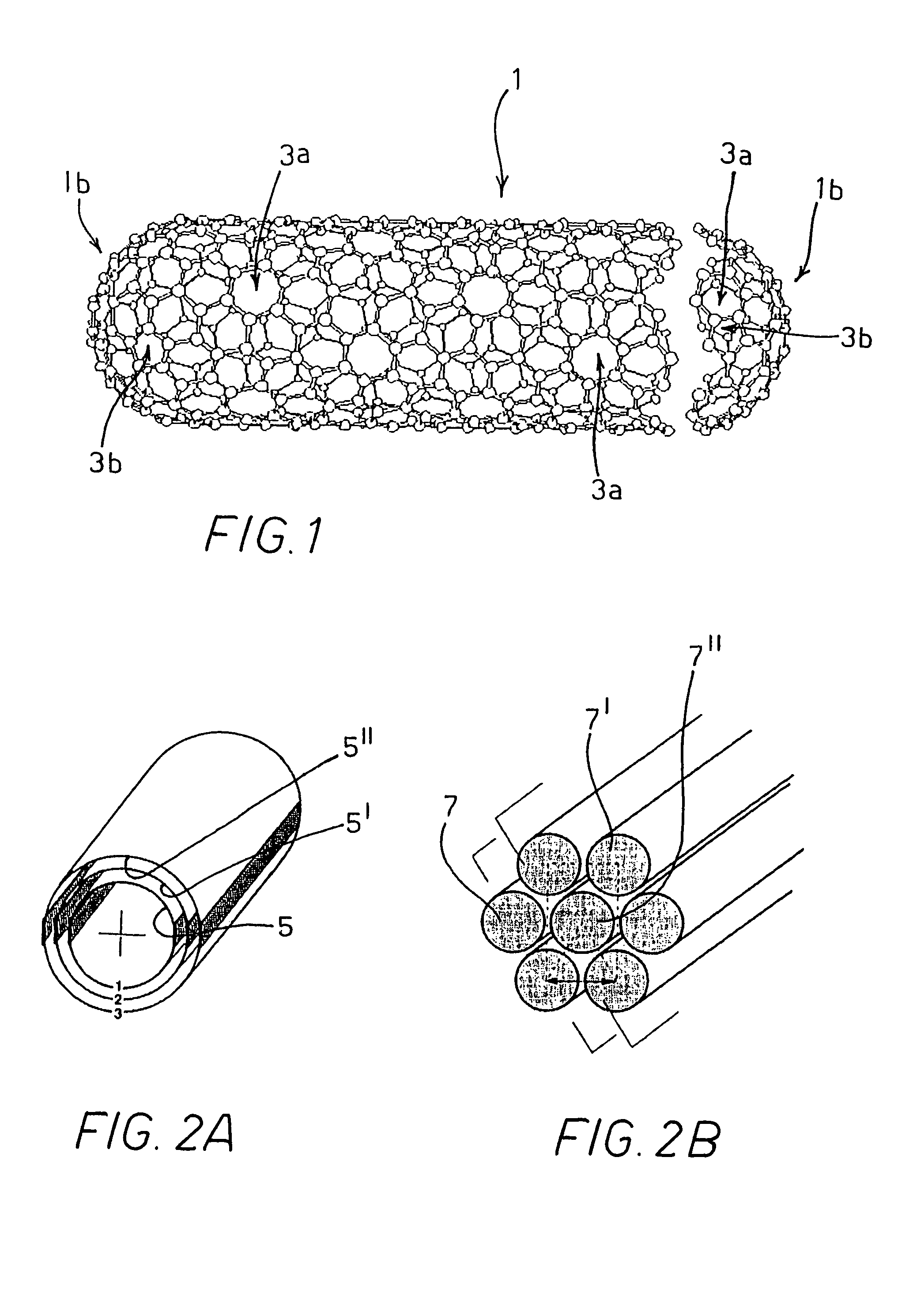

InactiveUS7352187B2Lower requirementWide choiceVacuum tubesVacuum gauge using ionisation effectsSemiconductor materialsDiamond-like carbon

An electron-emitting cathode consists of an electrically conducting emitter layer attached to a side wall which consists of stainless steel and a gate which is fixed at a mall distance inside a concave emitter surface of the emitter layer. The cathode surrounds a reaction area containing a cylindrical grid-like anode and a central ion collector which consists of a straight axial filament. An ion collector current reflecting the density of the gas in the reaction region is measured by a current meter while a gate voltage is kept between the ground voltage of the emitter layer and a higher anode voltage and is regulated in such a way that an anode current is kept constant. The emitter layer may consists of carbon nanotubes, diamond-like carbon, a metal or a mixture of metals or a semiconductor material, e.g., silicon which may be coated, e.g., with carbide or molybdenum. The emitter surface can, however, also be a portion of the inside surface of the side wall roughened by, e.g., chemical etching. The gate may be a grid or it may be made up of patches of metal film covering spacers distributed over the emitter area or a metal film covering an electron permeable layer placed on the emitter surface.

Owner:INFICON GMBH

Ionization vacuum gauge

An ionisation vacuum gauge for measuring the residual pressure of a gaseous material remaining in a container (10), more particularly after operation of a vacuum pump comprises an electron-emitting cathode (31) made by exploiting the nanotube technology, a grid (13; 33; 133; 133′) for accelerating the electrons emitted by the cathode, and a plate (15; 35) collecting the ions and / or the ionised positive molecules of the gas. Measuring the plate current by a galvanometer allows for determining the value of the residual pressure inside the container.

Owner:AGILENT TECH INC

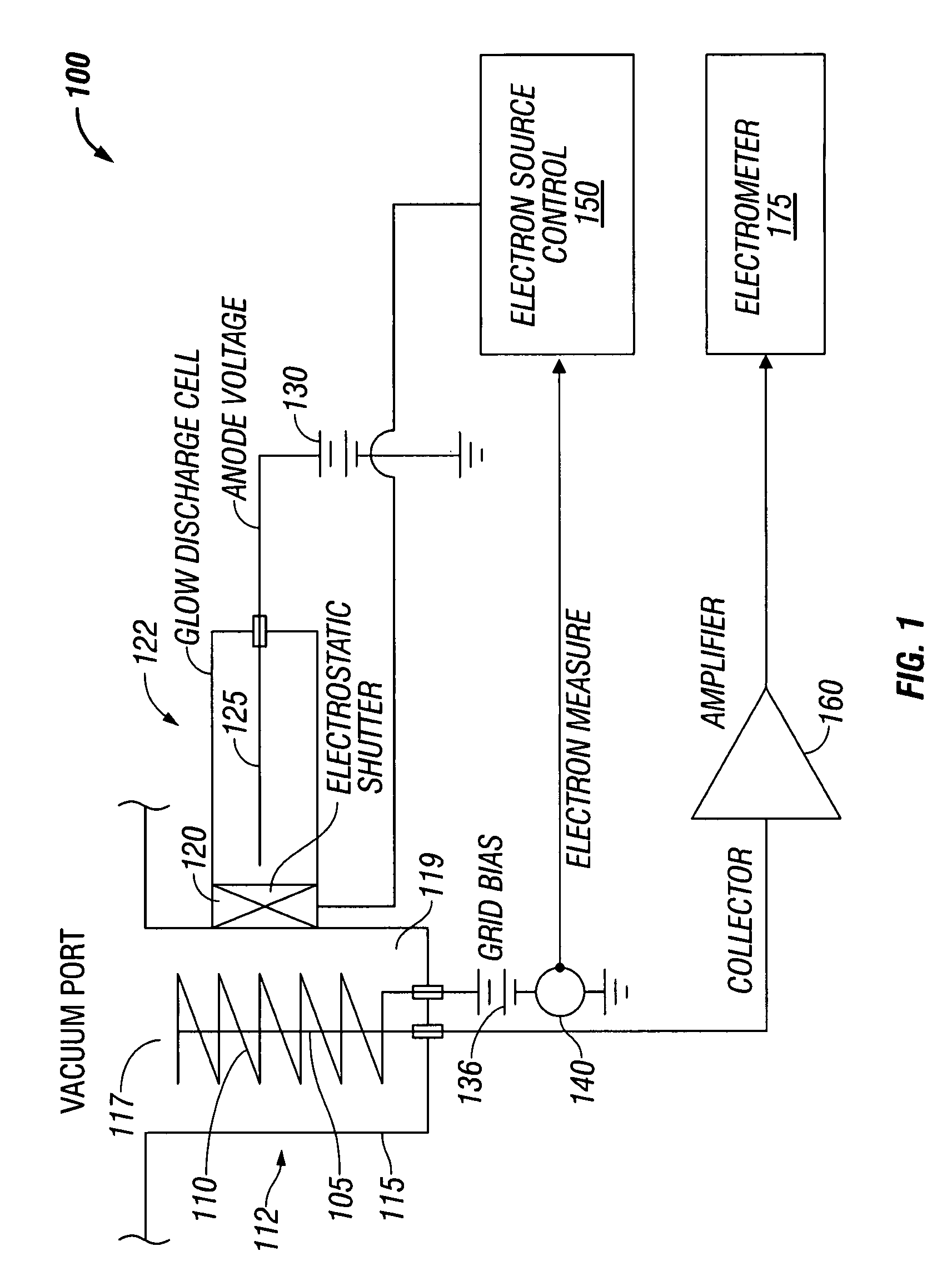

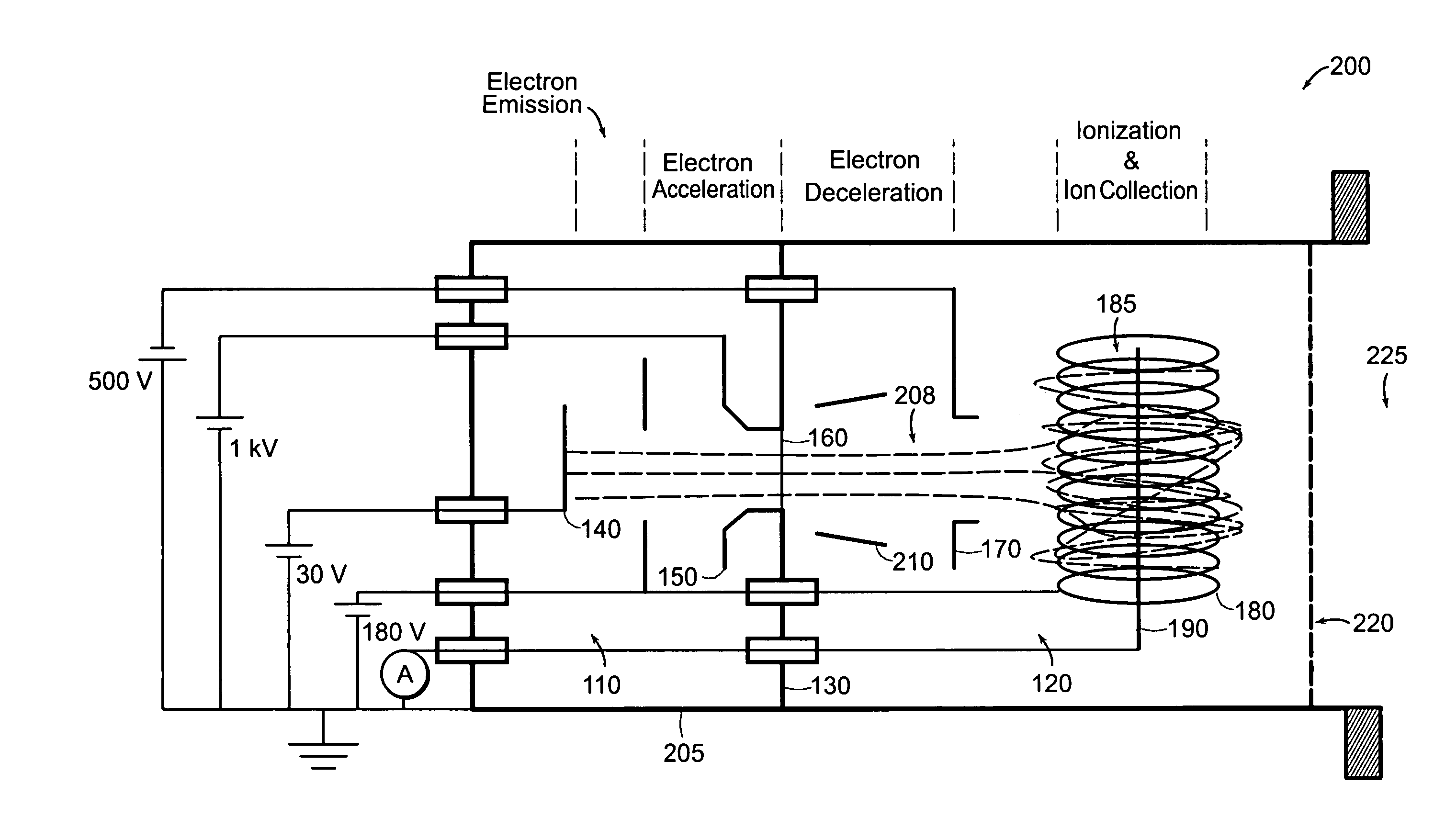

Ionization gauge with a cold electron source

ActiveUS7768267B2Thermometer detailsBeam/ray focussing/reflecting arrangementsElectron sourceIonization

An ionization gauge that eliminates a hot cathode or filament, but maintains a level of precision of gas density measurements approaching that of a hot cathode ionization gauge. The ionization gauge includes a collector electrode disposed in an ionization volume, an electron source without a heated cathode, and an electrostatic shutter that regulates the flow of electrons between the electron source and the ionization volume. The electrostatic shutter controls the flow of electrons based on feedback from an anode defining the ionization volume. The electron source can be a Penning or glow discharge ionization gauge.

Owner:MKS INSTR INC

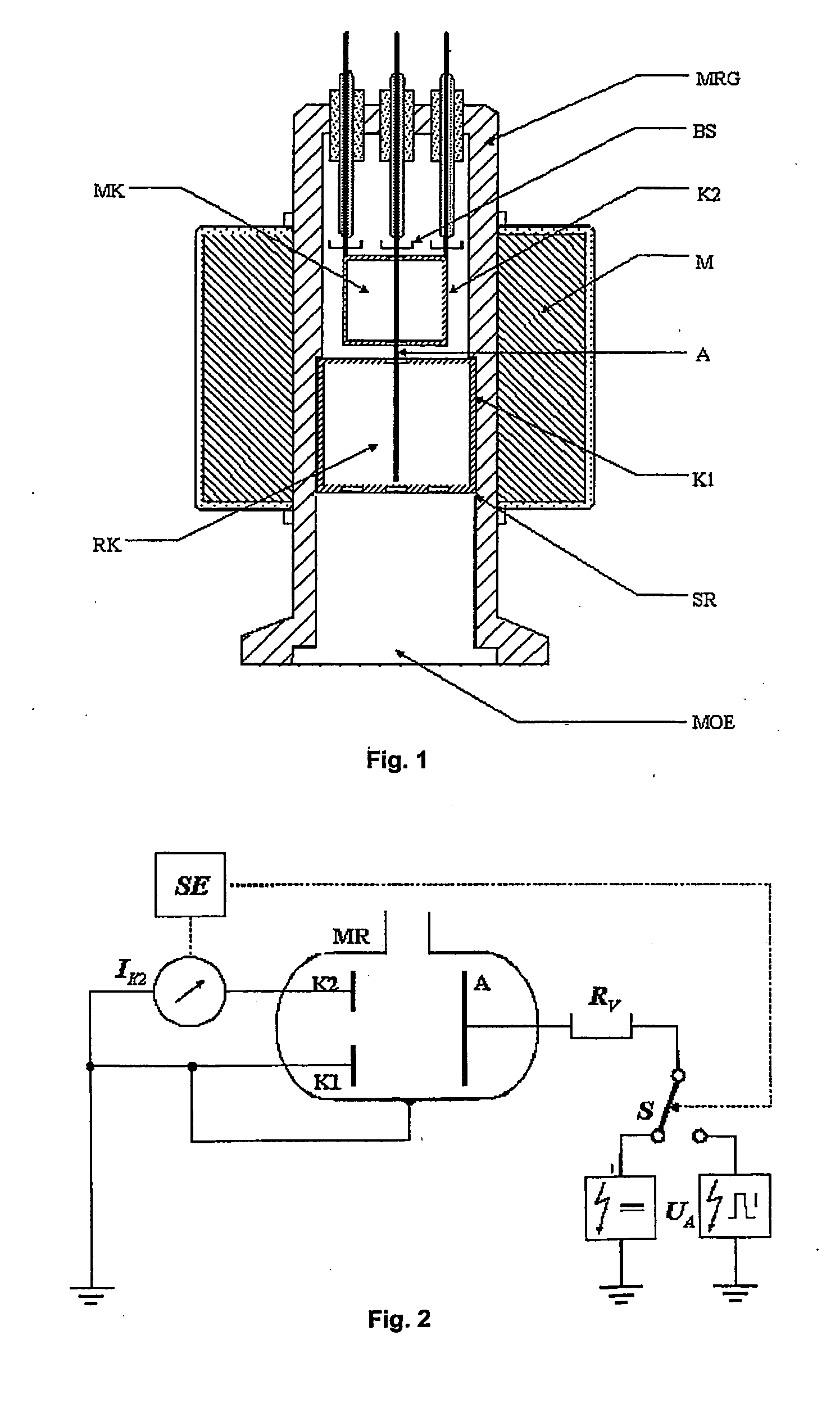

Cold-cathode ionisation manometer having a longer service life due to two separate cathodes

InactiveUS20060012373A1Improved cold cathode measuring tubeSuitable measuring operationVacuum gauge using ionisation effectsGas pressure measurement discharge tubesCold cathodeEngineering

A cold cathode ionization manometer for measuring pressure in vacuum and operating on the inverse magnetron principle. For extending the service life of the manometer it is provided with two independently operating cathodes and a common anode mounted in a measuring tube. The first cathode is mounted at the inlet of the measuing tube and its discharge serves as a gas purification device which prevents the formation of contaminating layers by cracking and polymerizing hydrocarbons and other substances entering the measuring tube thereby protecting the second cathode and extending the overall service life of the manometer.

Owner:OTTO VONGUERICKE UNIV MAGDEBURG

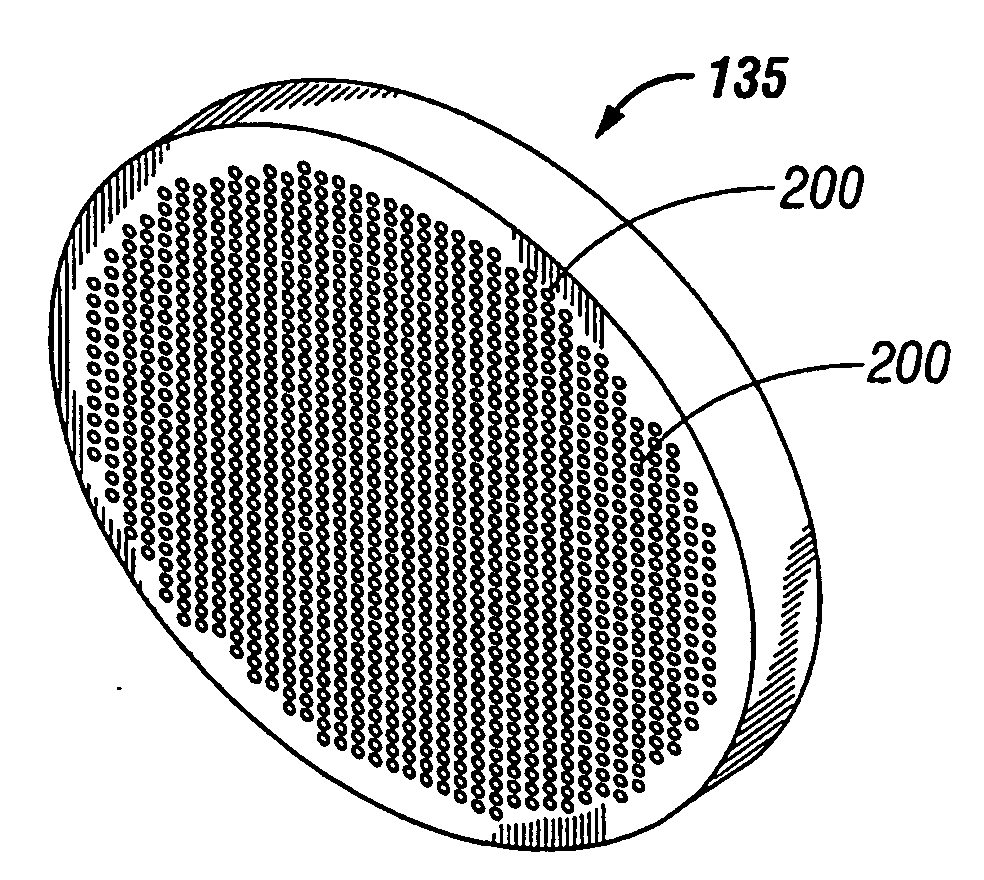

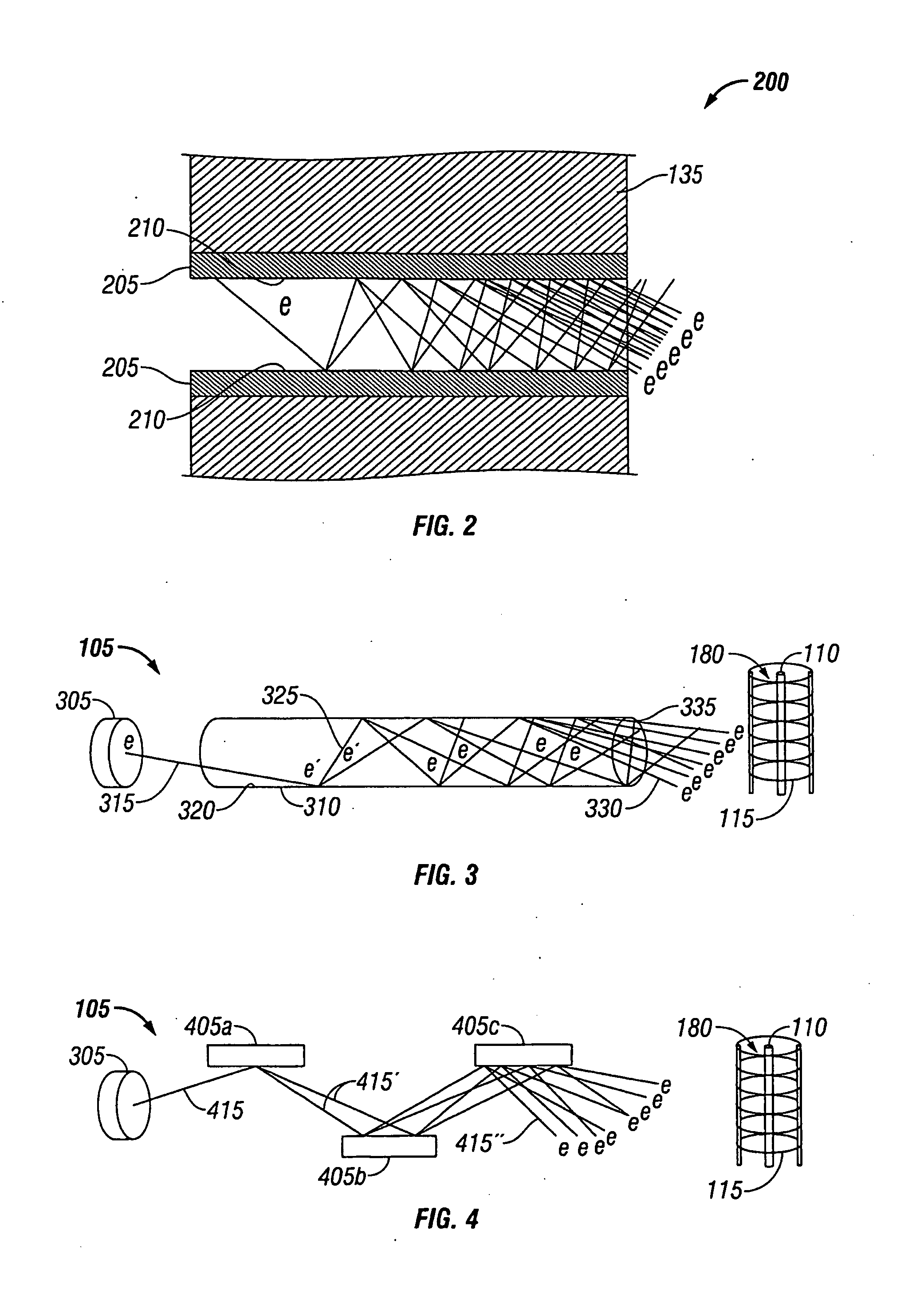

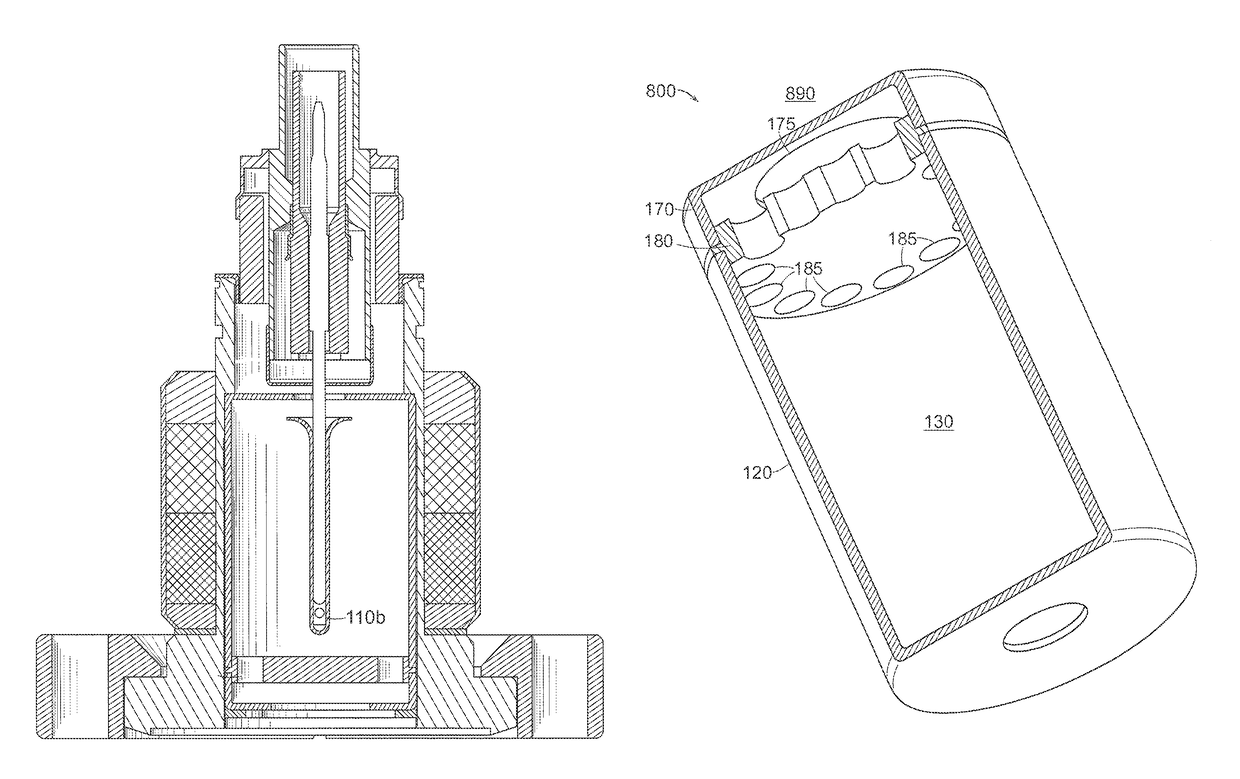

Ionization Gauge Having Electron Multiplier Cold Emission Source

ActiveUS20110234233A1Reduce in quantityReduce stepsVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansElectron multiplierIonization

An ionization gauge includes an electron generator array that includes a microchannel plate that includes an electron generating portion of the microchannel plate comprising a source for generating seed electrons and an electron multiplier portion of the microchannel plate, responsive to the seed electrons generated by the electron generating portion, that multiplies the electrons. The ionization gauge includes an ionization volume in which the electrons impact a gaseous species, and a collector electrode for collecting ions formed by the impact between the electrons and gas species. The collector electrode can be surrounded by the anode, or the ionization gauge can be formed with multiple collector electrodes. The source of electrons can provide for a spontaneous emission of electrons, where the electrons are multiplied in a cascade.

Owner:MKS INSTR INC

Method and apparatus for shielding feedthrough pin insulators in an ionization gauge operating in harsh environments

InactiveUS20080100301A1Easy to operateDamage to materialVacuum gauge using ionisation effectsDischarge tube/lamp detailsEngineeringIonization

Shields for feedthrough pin insulators of a hot cathode ionization gauge are provided to increase the operational lifetime of the ionization gauge in harmful process environments. Various shield materials, designs, and configurations may be employed depending on the gauge design and other factors. In one embodiment, the shields may include apertures through which to insert feedthrough pins and spacers to provide an optimal distance between the shields and the feedthrough pin insulators before the shields are attached to the gauge. The shields may further include tabs used to attach the shields to components of the gauge, such as the gauge's feedthrough pins. Through use of example embodiments of the insulator shields, the life of the ionization gauge is extended by preventing gaseous products from a process in a vacuum chamber or material sputtered from the ionization gauge from depositing on the feedthrough pin insulators and causing electrical leakage from the gauge's electrodes.

Owner:MKS INSTR INC

Vacuum measuring gauge

InactiveUS20060202701A1Increase the areaLower requirementVacuum tubesVacuum gauge using ionisation effectsSemiconductor materialsDiamond-like carbon

An electron-emitting cathode consists of an electrically conducting emitter layer attached to a side wall which consists of stainless steel and a gate which is fixed at a mall distance inside a concave emitter surface of the emitter layer. The cathode surrounds a reaction area containing a cylindrical grid-like anode and a central ion collector which consists of a straight axial filament. An ion collector current reflecting the density of the gas in the reaction region is measured by a current meter while a gate voltage is kept between the ground voltage of the emitter layer and a higher anode voltage and is regulated in such a way that an anode current is kept constant. The emitter layer may consists of carbon nanotubes, diamond-like carbon, a metal or a mixture of metals or a semiconductor material, e.g., silicon which may be coated, e.g., with carbide or molybdenum. The emitter surface can, however, also be a portion of the inside surface of the side wall roughened by, e.g., chemical etching. The gate may be a grid or it may be made up of patches of metal film covering spacers distributed over the emitter area or a metal film covering an electron permeable layer placed on the emitter surface.

Owner:INFICON GMBH

Ionization gauge

ActiveUS20050184735A1Decreased operational lifetimeReduce in quantityVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansResidual gas analyzerElectron source

Owner:MKS INSTR INC

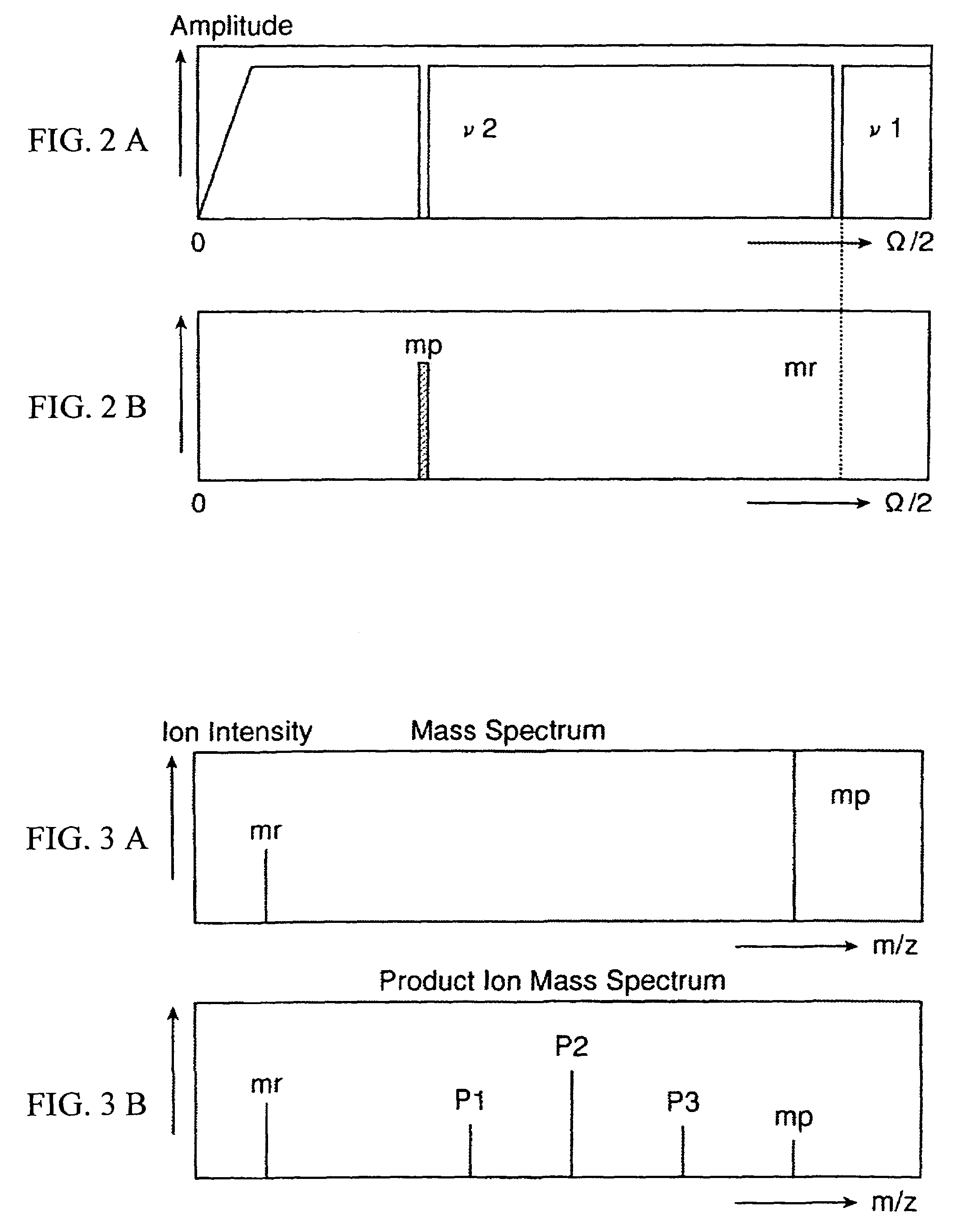

Method for accurate mass determination with ion trap/time-of-flight mass spectrometer

ActiveUS7138624B2Accurate mass determinationImprove accuracyStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryTime-of-flight mass spectrometry

Owner:HITACHI HIGH-TECH CORP

Ionization vacuum device

ActiveUS20090134018A1Easy to separateContamination of materialCellsVacuum gauge using ionisation effectsEngineeringIonization

An ionization vacuum device measures a pressure in a vacuum vessel, and has: an anode provided inside the vacuum vessel; a cathode provided inside the vacuum vessel; a power source for discharge that supplies electric power for discharge between the anode and the cathode; a power source for cathode-heating that supplies power for heating to the cathode, means for forming a magnetic field in a space between the anode and the cathode; control means for controlling so as to heat said cathode by said power source for cathode-heating while discharge of gas inside said vacuum vessel is caused, and so as to maintain the temperature of said cathode within a temperature range where thermonic electrons are not emitted from said cathode.

Owner:MIRAPRO

Ionization gauge with operational parameters and geometry designed for high pressure operation

ActiveUS8648604B2Reduce in quantityReduced service lifeVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansSputteringElectron source

An ionization gauge to measure pressure and to reduce sputtering yields includes at least one electron source that generates electrons. The ionization gauge also includes a collector electrode that collects ions formed by the collisions between the electrons and gas molecules. The ionization gauge also includes an anode. An anode bias voltage relative to a bias voltage of a collector electrode is configured to switch at a predetermined pressure to decrease a yield of sputtering collisions.

Owner:MKS INSTR INC

Ionization gauge

ActiveUS7030619B2Reduce in quantityReduce stepsVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansResidual gas analyzerElectron source

Owner:MKS INSTR INC

Ultrasensitive Ion Detector Using Carbon Nanotubes or Graphene

ActiveUS20150276677A1Spectrometer detectorsMaterial analysis by electric/magnetic meansPower flowCarbon based nanomaterials

An ion detection device has a strip of carbon-based nanomaterial (CNM) film and a chamber enclosing the CNM film. A low bias voltage is applied at the ends of the CNM film strip, and ions present in the chamber are detected by a change in the magnitude of current flowing through the CNM film under the bias. Also provided are methods for fabricating the device, methods for measuring pressure of a gas, and methods for monitoring or quantifying an ionizing radiation using the device.

Owner:NORTHEASTERN UNIV

Method and apparatus for shielding feedthrough pin insulators in an ionization gauge operating in harsh environments

InactiveUS7456634B2Easy to operateDamage to materialVacuum gauge using ionisation effectsDischarge tube/lamp detailsEngineeringIonization

Shields for feedthrough pin insulators of a hot cathode ionization gauge are provided to increase the operational lifetime of the ionization gauge in harmful process environments. Various shield materials, designs, and configurations may be employed depending on the gauge design and other factors. In one embodiment, the shields may include apertures through which to insert feedthrough pins and spacers to provide an optimal distance between the shields and the feedthrough pin insulators before the shields are attached to the gauge. The shields may further include tabs used to attach the shields to components of the gauge, such as the gauge's feedthrough pins. Through use of example embodiments of the insulator shields, the life of the ionization gauge is extended by preventing gaseous products from a process in a vacuum chamber or material sputtered from the ionization gauge from depositing on the feedthrough pin insulators and causing electrical leakage from the gauge's electrodes.

Owner:MKS INSTR INC

Ionisation vacuum gauge

InactiveUS20050028602A1Discharge tube luminescnet screensVacuum gauge using ionisation effectsGalvanometerVacuum pump

An ionisation vacuum gauge for measuring the residual pressure of a gaseous material remaining in a container (10), more particularly after operation of a vacuum pump comprises an electron-emitting cathode (31) made by exploiting the nanotube technology, a grid (13; 33; 133; 133′) for accelerating the electrons emitted by the cathode, and a plate (15; 35) collecting the ions and / or the ionised positive molecules of the gas. Measuring the plate current by a galvanometer allows for determining the value of the residual pressure inside the container.

Owner:AGILENT TECH INC

Cold cathode ionization vacuum gauge

ActiveUS9671302B2Long-term stabilityStart fastVacuum gauge using ionisation effectsElectronic waste recyclingCold cathodeIonization

A cold cathode ionization vacuum gauge includes an extended anode electrode and a cathode electrode surrounding the anode electrode along its length and forming a discharge space between the anode electrode and the cathode electrode. The vacuum gauge further includes an electrically conductive guard ring electrode interposed between the cathode electrode and the anode electrode about a base of the anode electrode to collect leakage electrical current, and a discharge starter device disposed over and electrically connected with the guard ring electrode, the starter device having a plurality of tips directed toward the anode and forming a gap between the tips and the anode.

Owner:MKS INSTR INC

Ionization Gauge With Operational Parameters And Geometry Designed For High Pressure Operation

ActiveUS20110062961A1Reduced service lifeReduce in quantityVacuum gauge using ionisation effectsGas pressure measurement discharge tubesIonizationPhysics

An ionization gauge to measure pressure and to reduce sputtering yields includes at least one electron source that generates electrons. The ionization gauge also includes a collector electrode that collects ions formed by the collisions between the electrons and gas molecules. The ionization gauge also includes an anode. An anode bias voltage relative to a bias voltage of a collector electrode is configured to switch at a predetermined pressure to decrease a yield of sputtering collisions.

Owner:MKS INSTR INC

Quadrupole mass spectrometer and vacuum device using the same

InactiveUS20060226355A1Avoid it happening againRemove background noiseThermometer detailsTime-of-flight spectrometersIon currentIon density

In a quadrupole mass spectrometer which measures partial pressure strength according to a gas type in a vacuum system from ion current intensity, a quadrupole mass spectrometer with a total pressure measurement electrode has a total pressure measurement electrode for examining an ion density disposed in a demarcation space which is comprised of a grid electrode and an ion focusing electrode. And, a vacuum system is provided with only the quadrupole mass spectrometer which measures partial pressure strength according to a gas type in the vacuum system from an ion current intensity and does not have an ionization vacuum gauge other than the quadrupole mass spectrometer.

Owner:VACLAB

Ionization vacuum gauge

InactiveUS7741852B2Vacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansElectron sourceIonization

An ionization vacuum gauge which has at least three electrodes of a grid (2), an electron source (3) and an ion collector (1) in a vacuum vessel (4) connected in communication with a vacuum apparatus, oscillates electrons emitted front the electron source (3) within and outside of the grid (2), ionizes gas molecules flying into the grid (2) by the oscillated electrons, supplements the ionized ions by the ion collector (1) to convert into a current signal, and measures a gas molecular density (pressure) in the vacuum apparatus according to the obtained current intensity, wherein the ion collector (1) is provided with a heating device for heating the ion collector.

Owner:MIRAPRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com