Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about "Gas filling substance selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

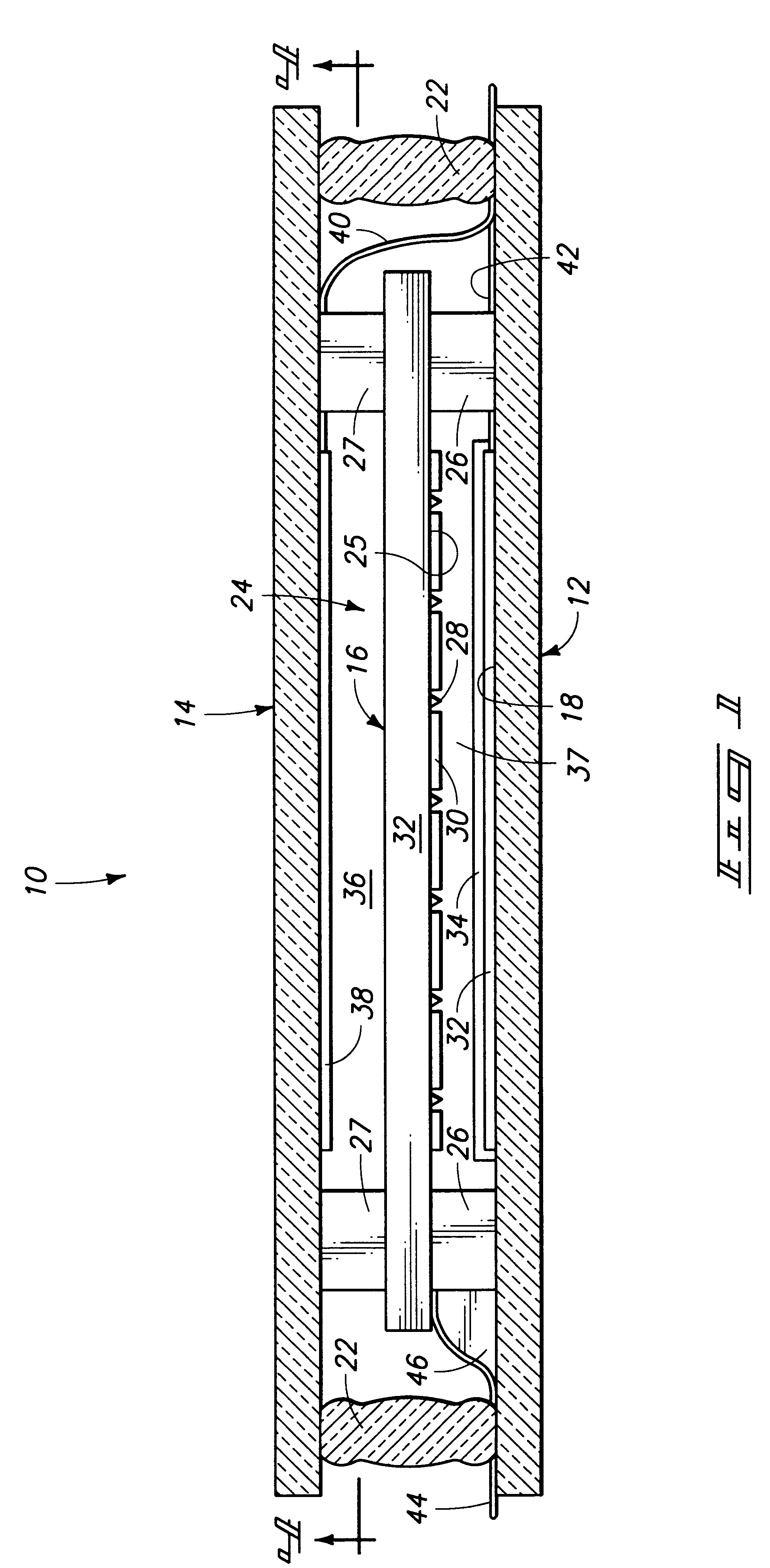

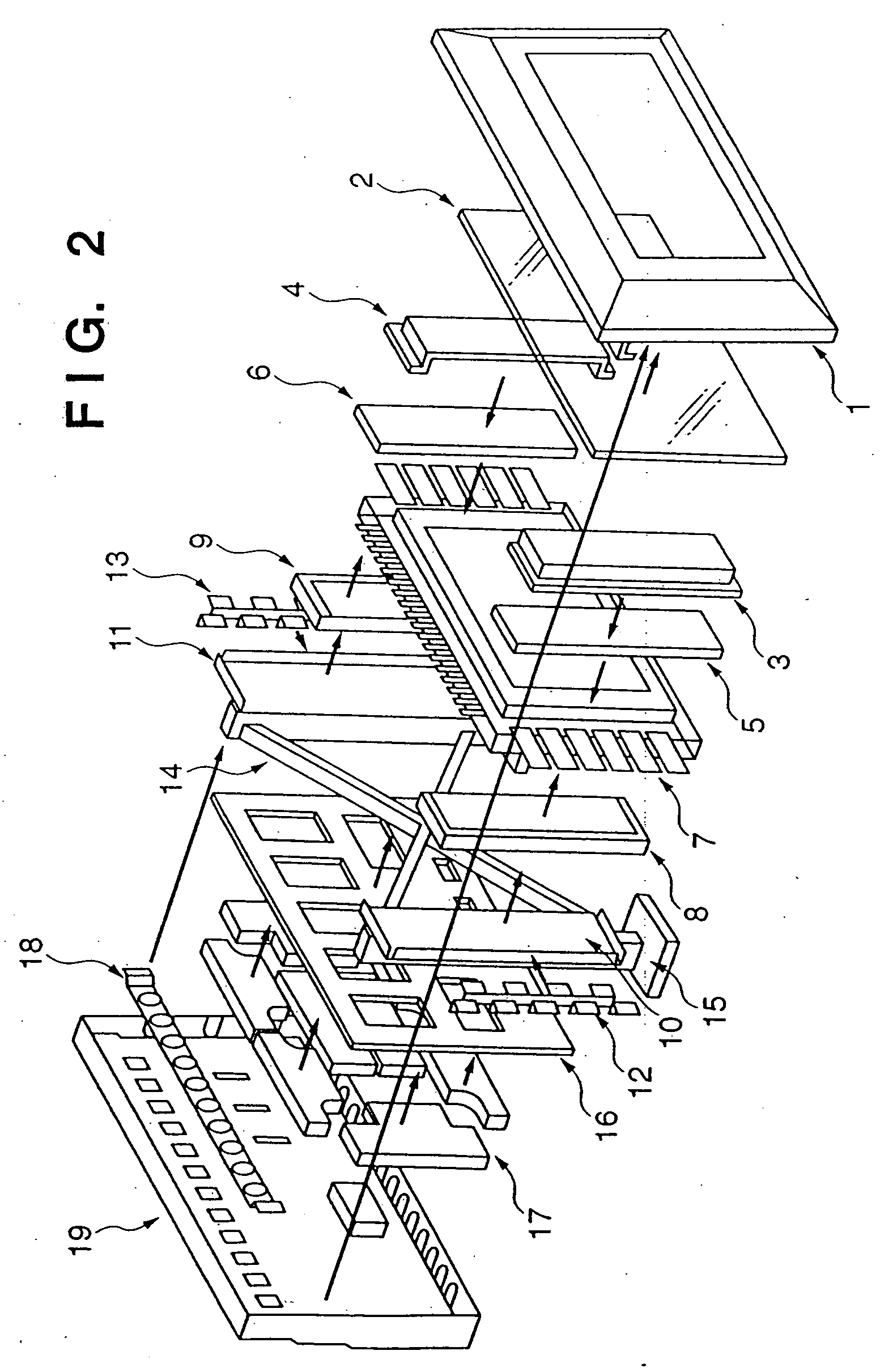

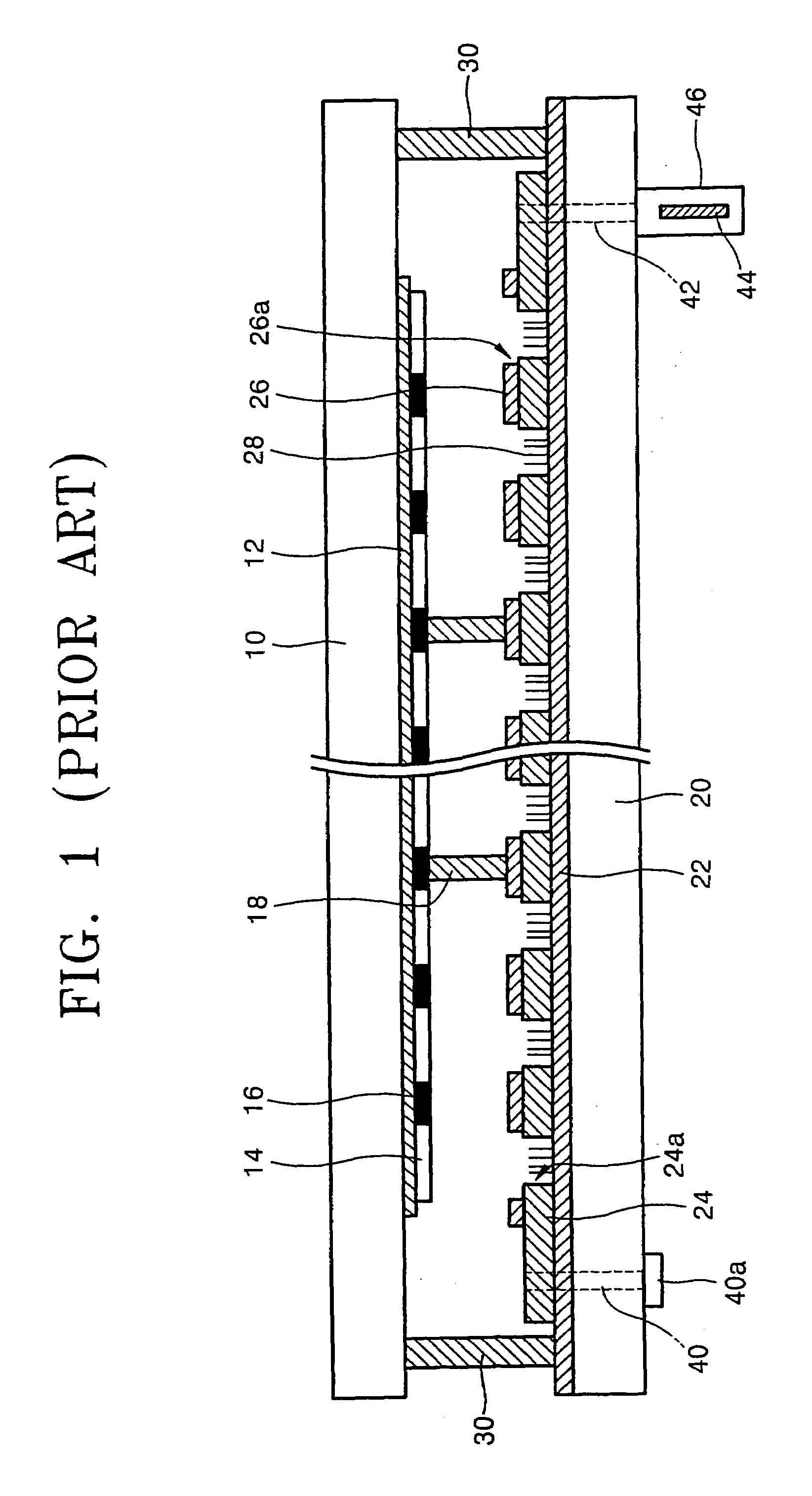

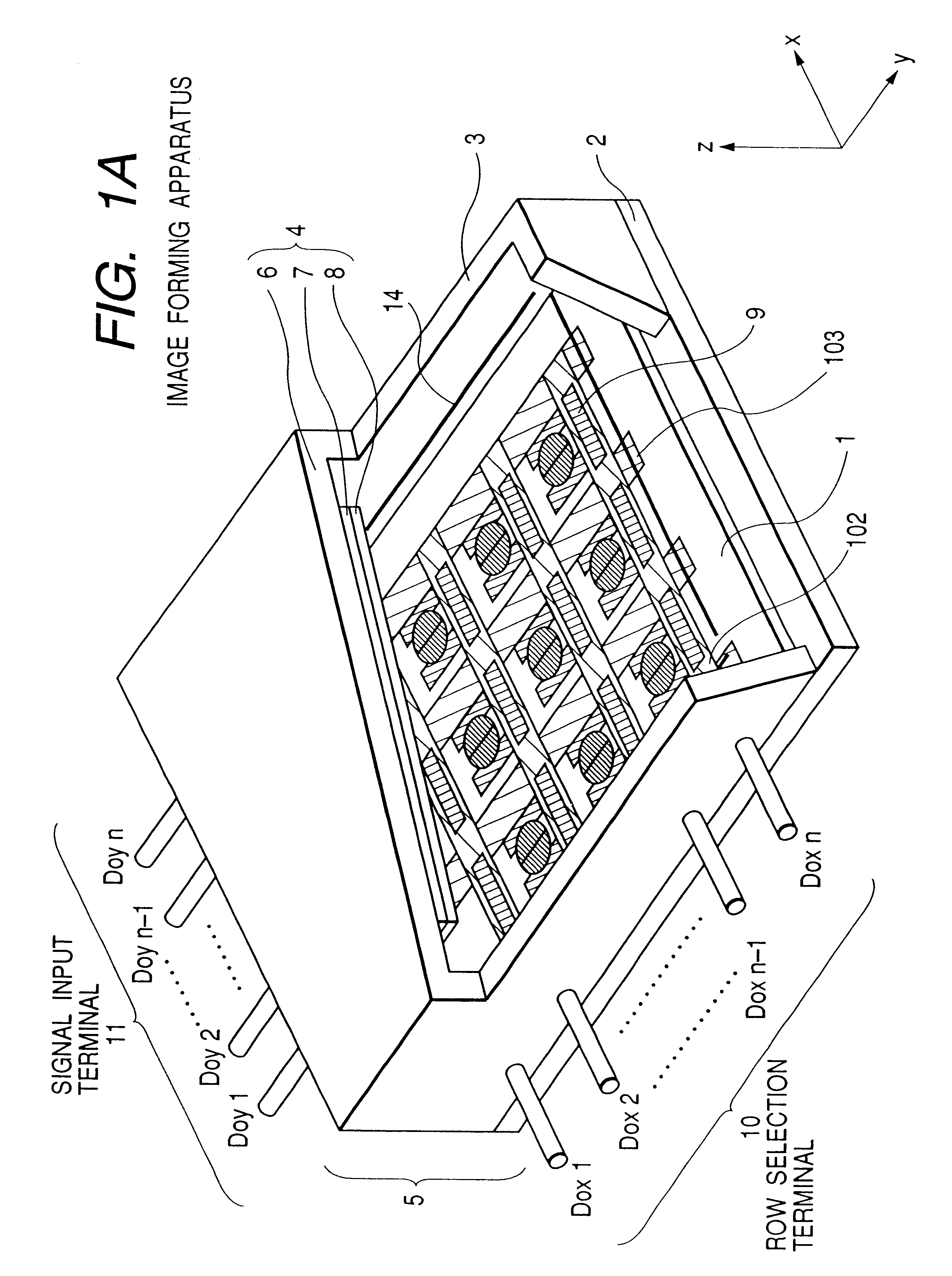

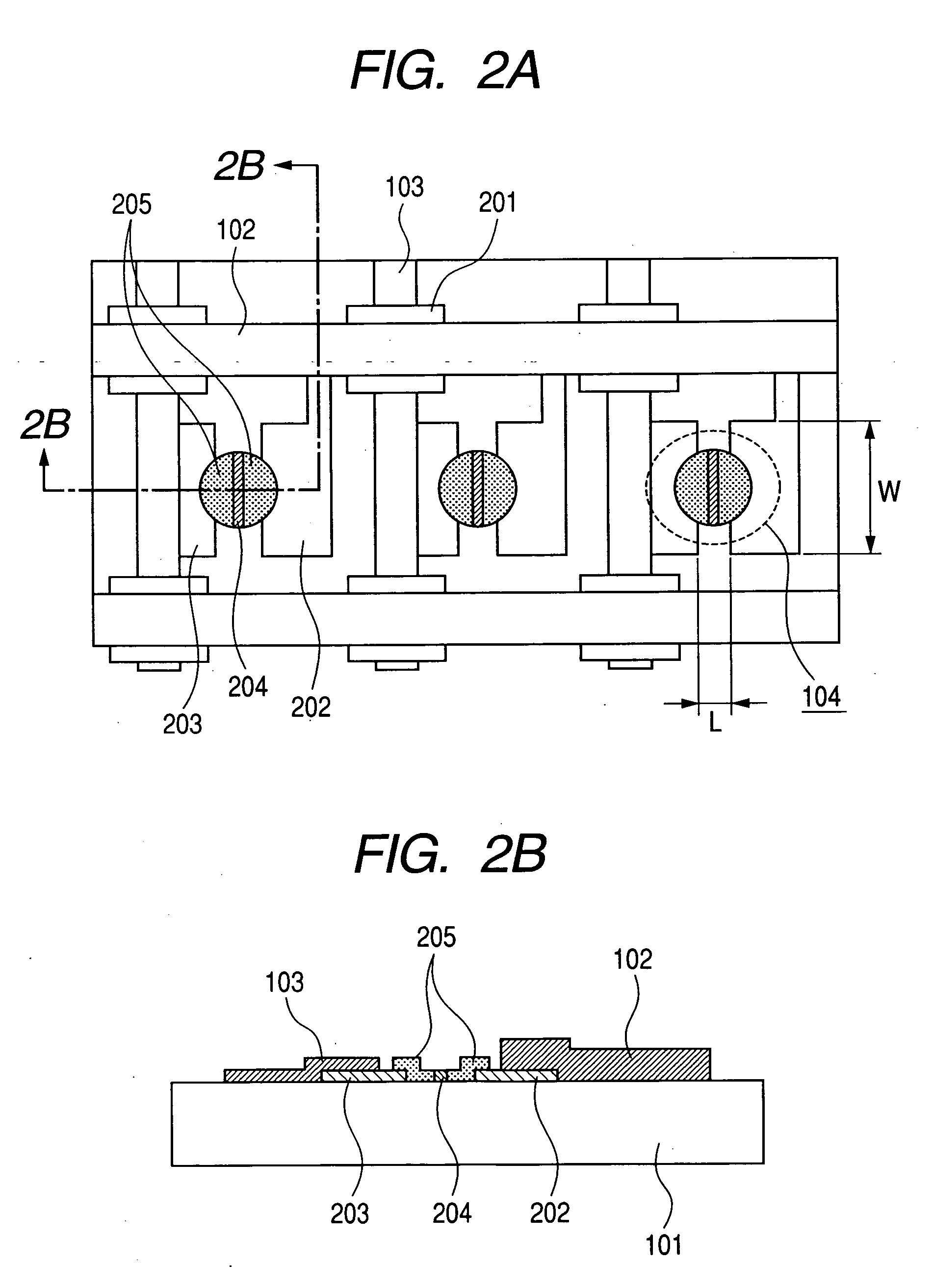

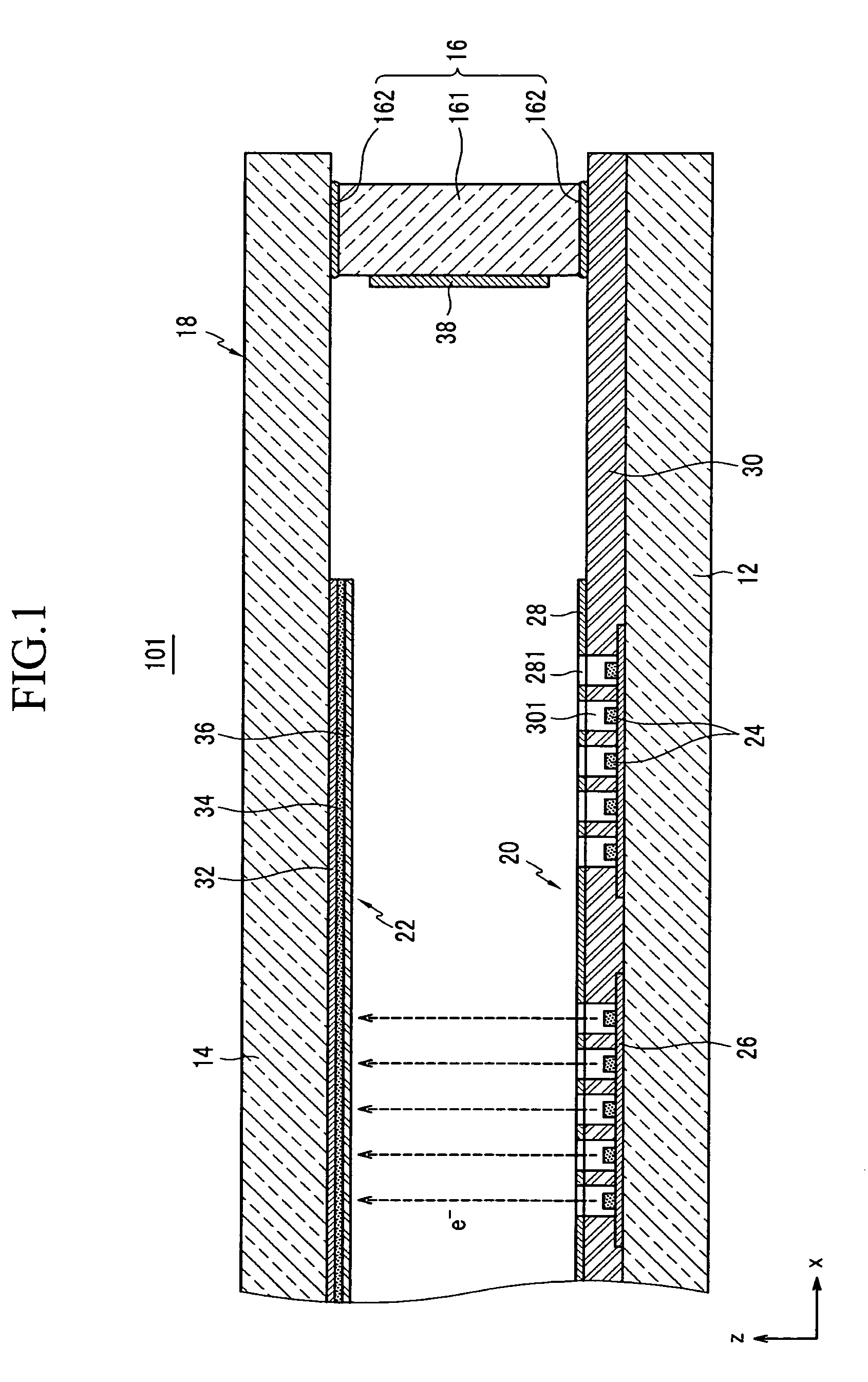

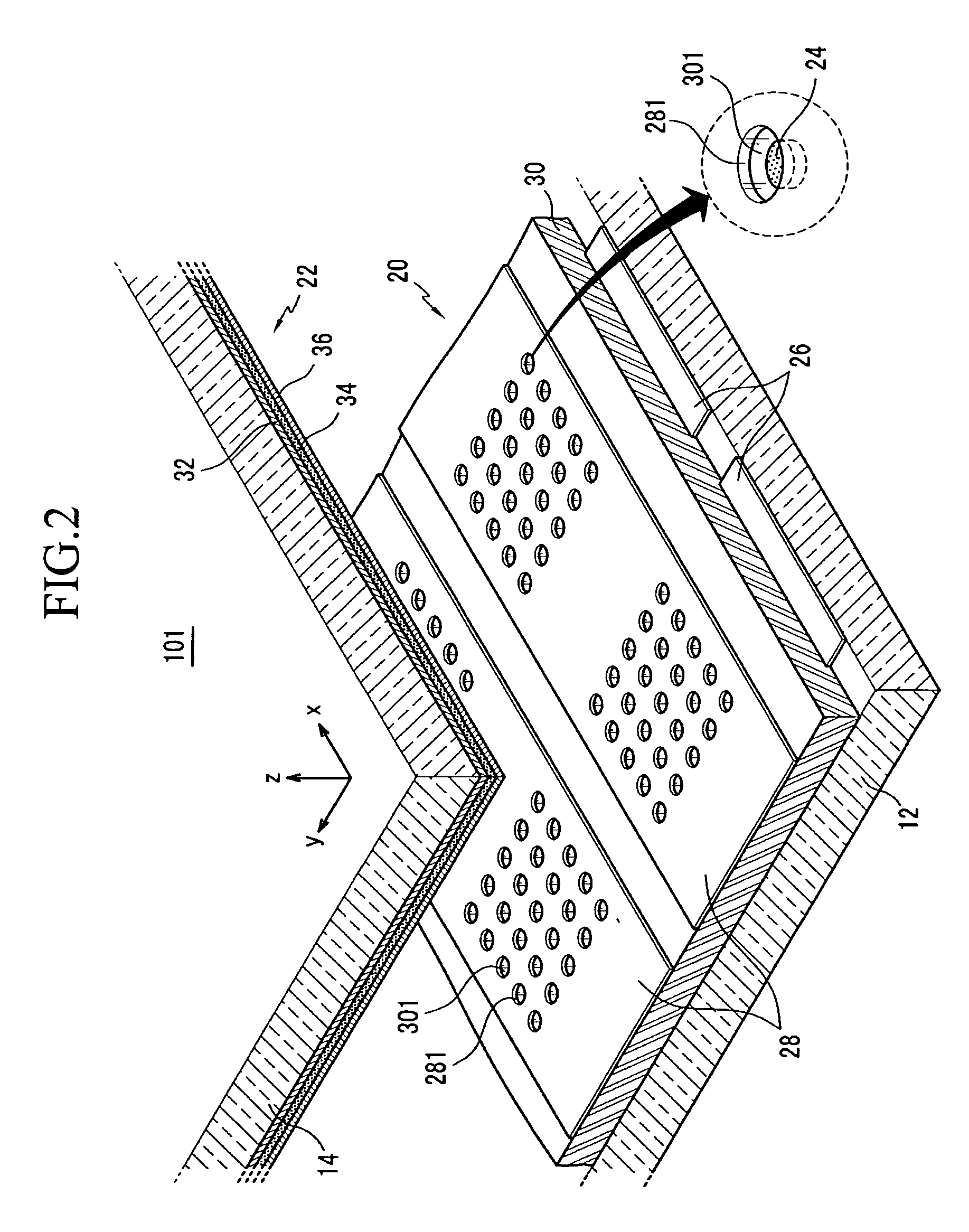

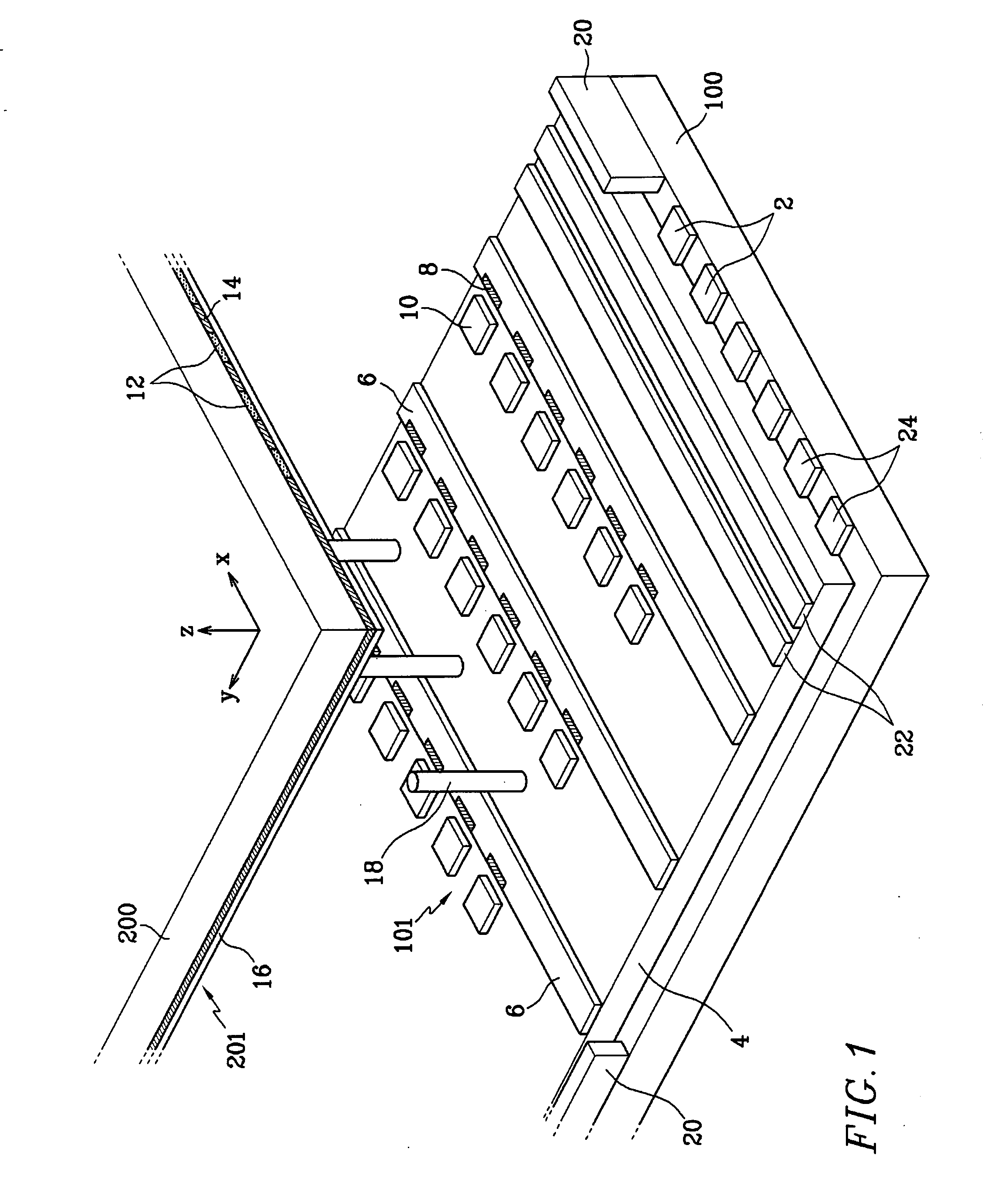

Image formation apparatus

InactiveUS6879096B1High display-quality configurationSatisfies requirementTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

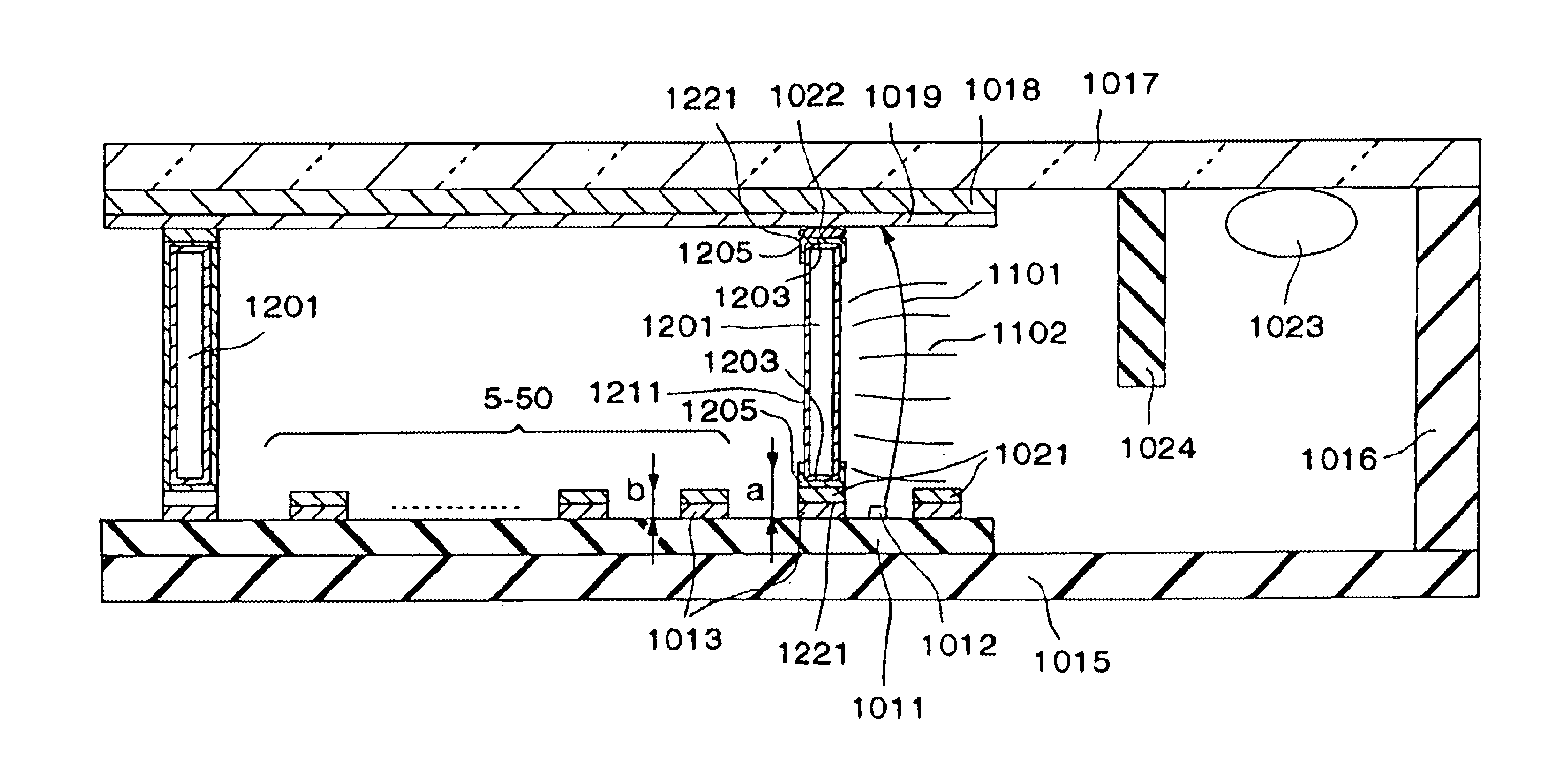

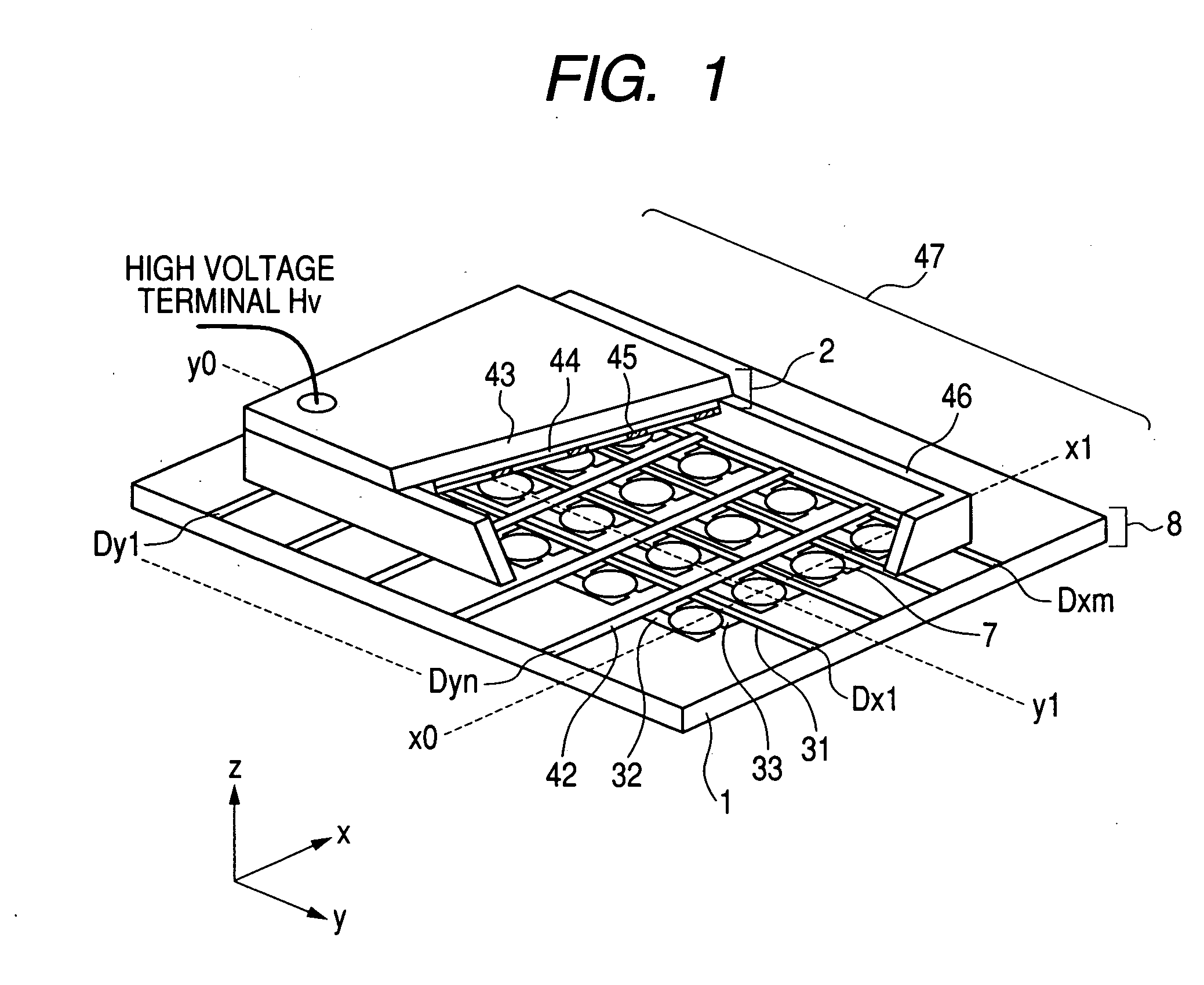

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

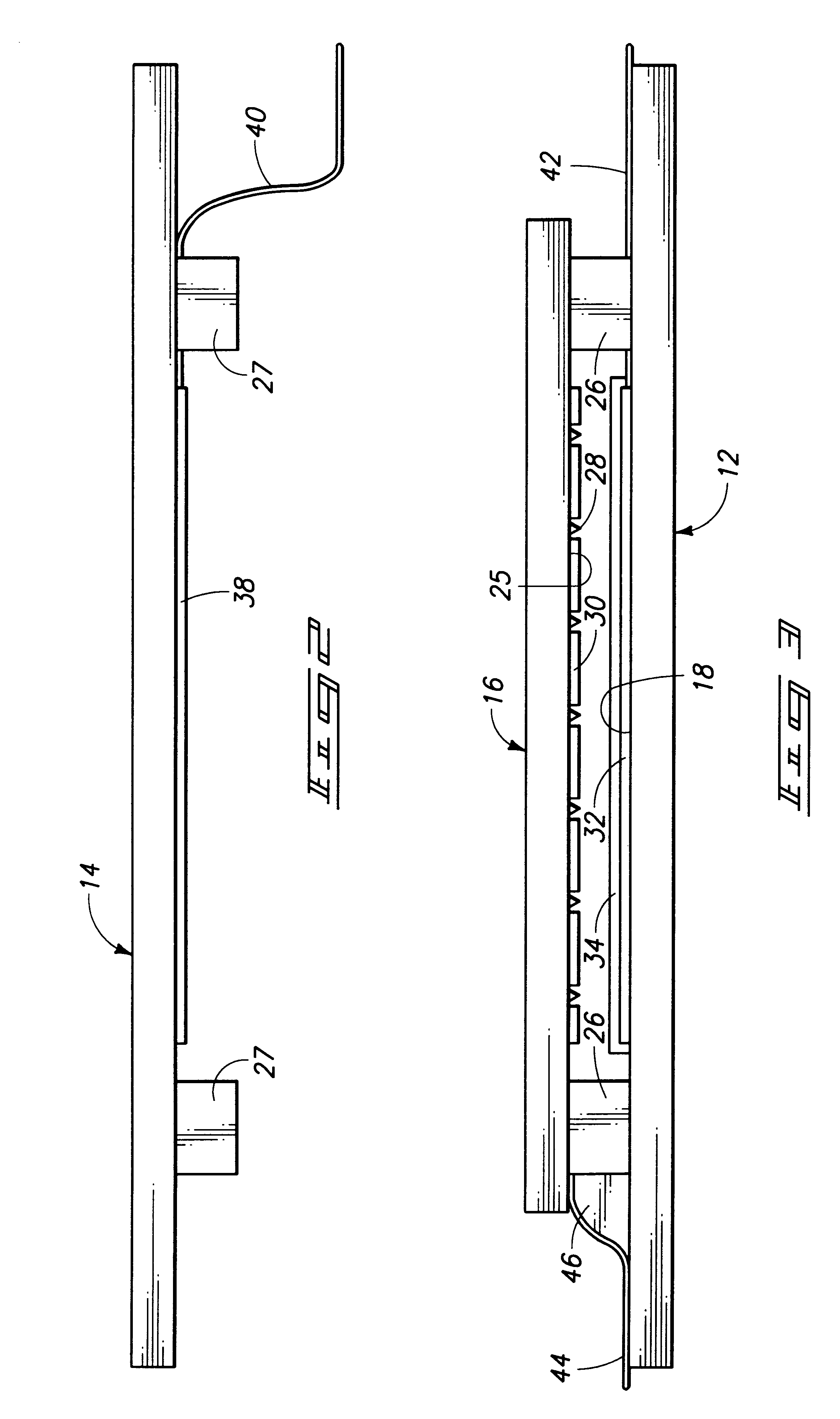

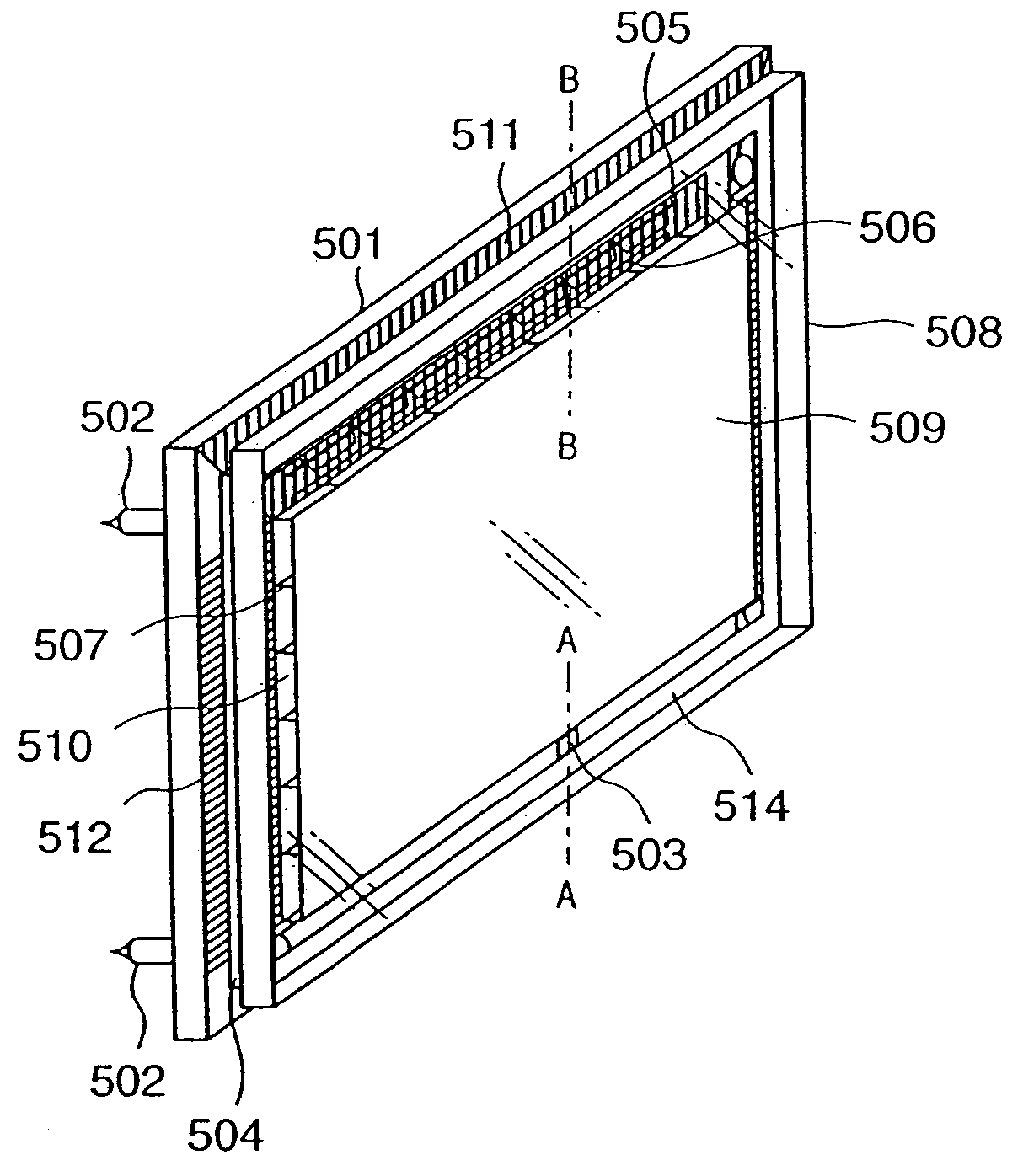

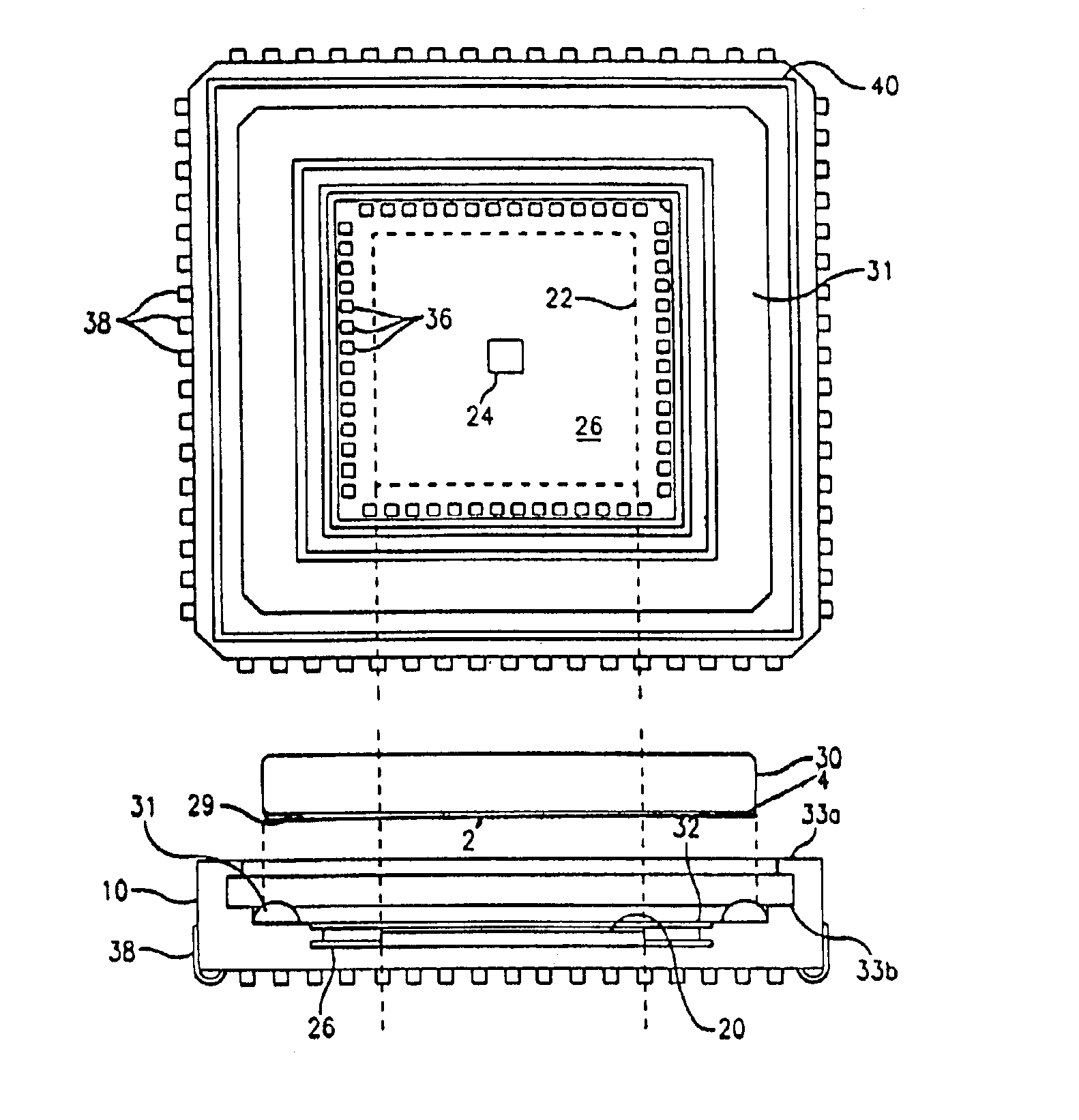

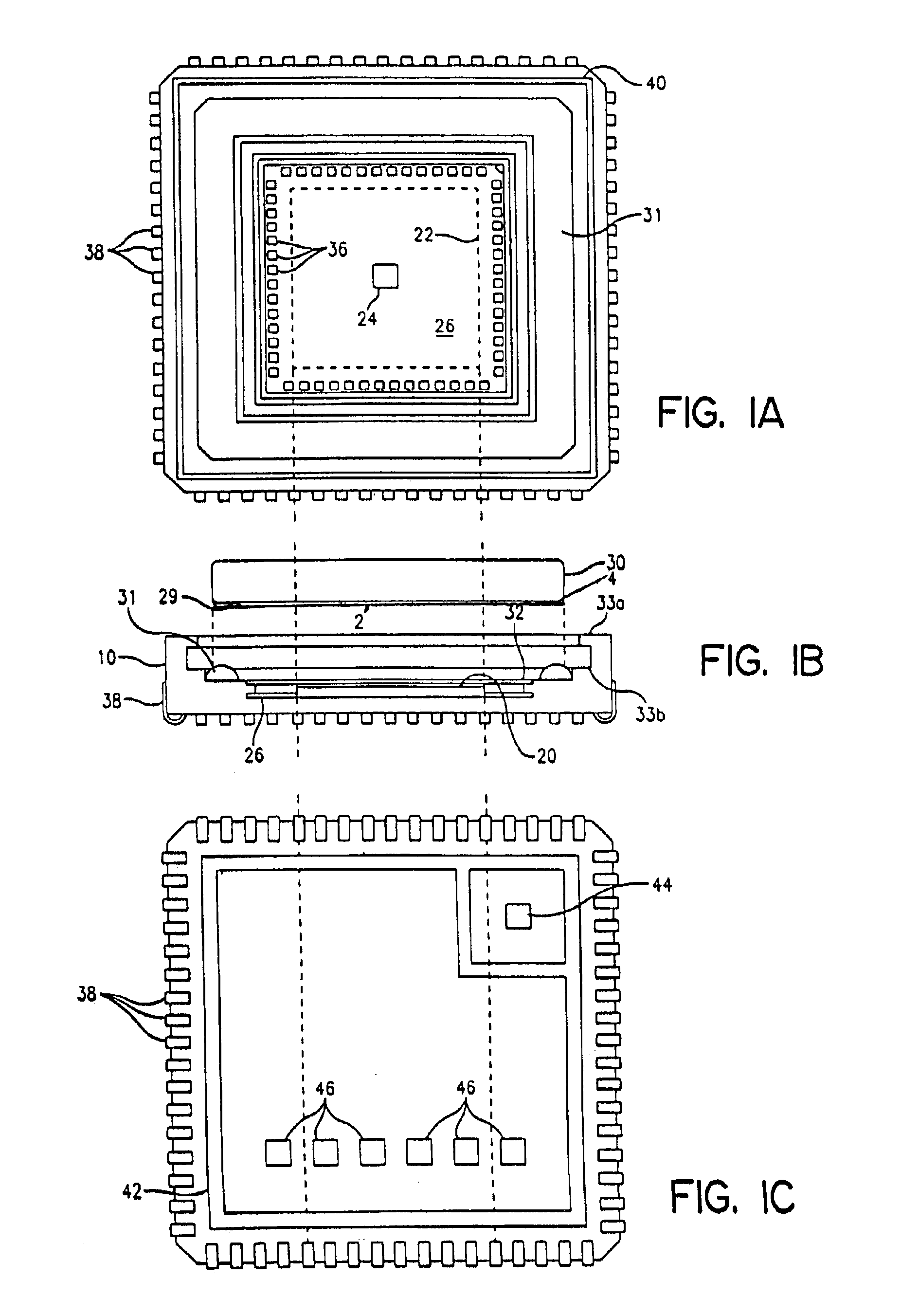

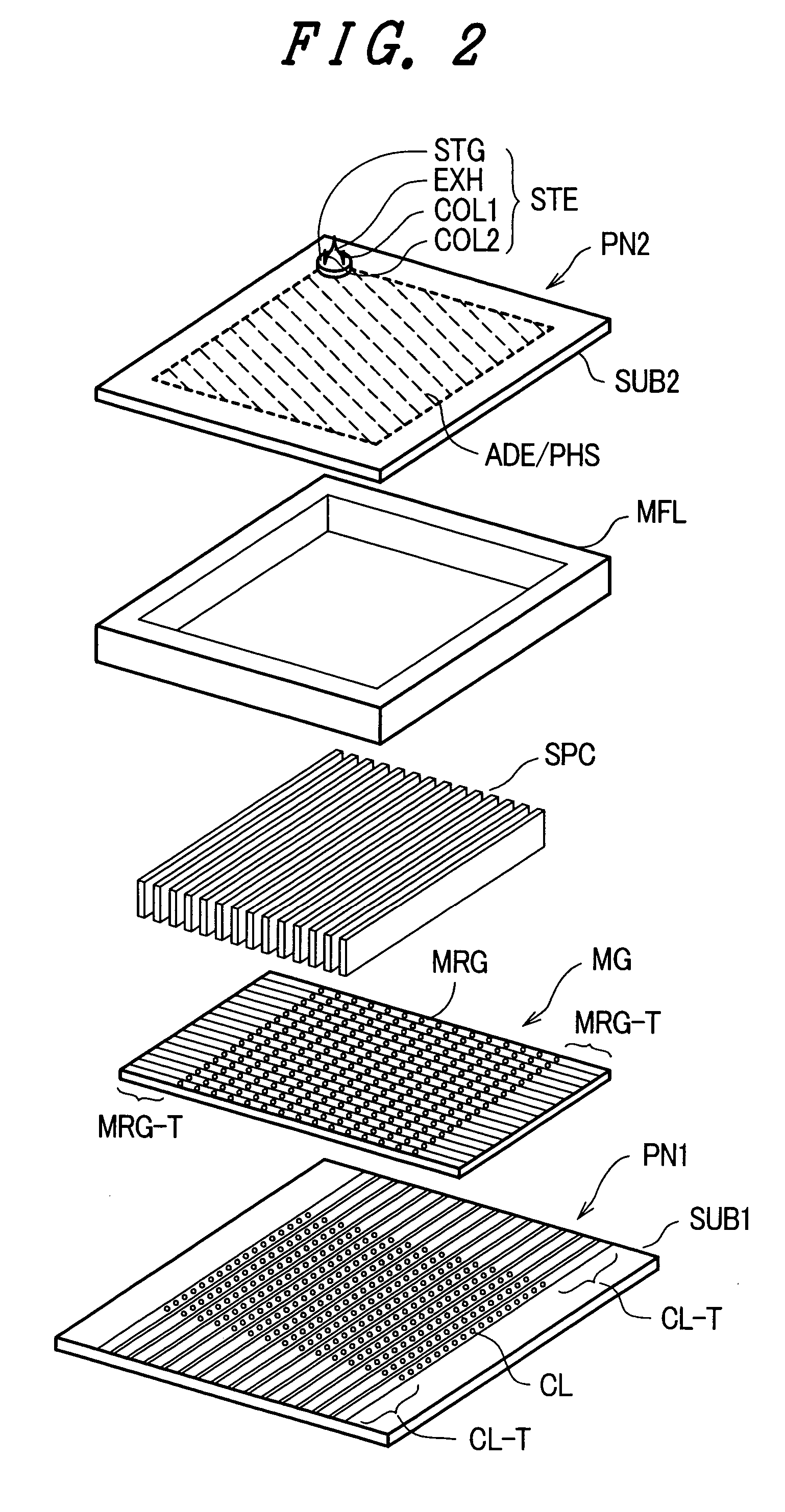

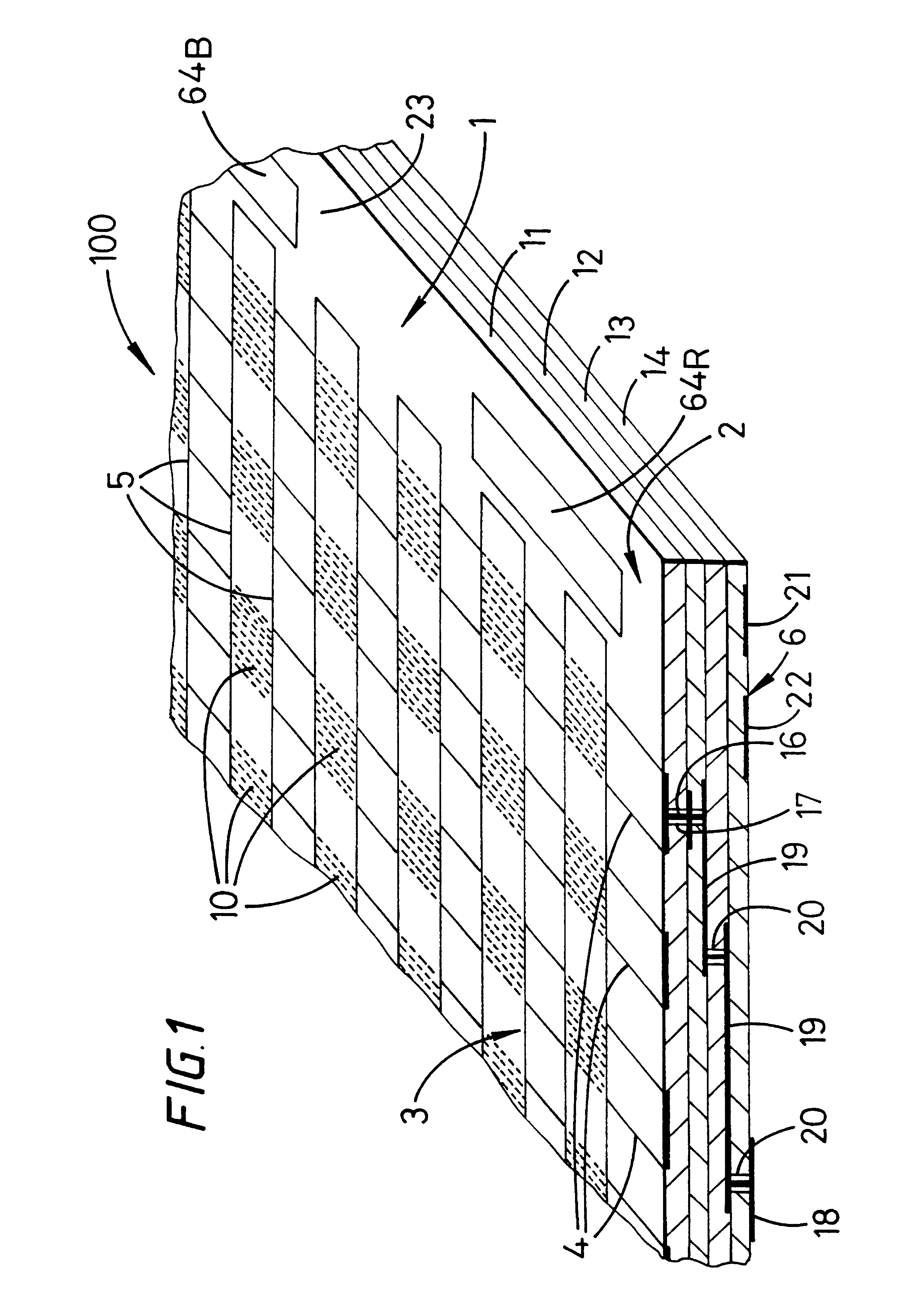

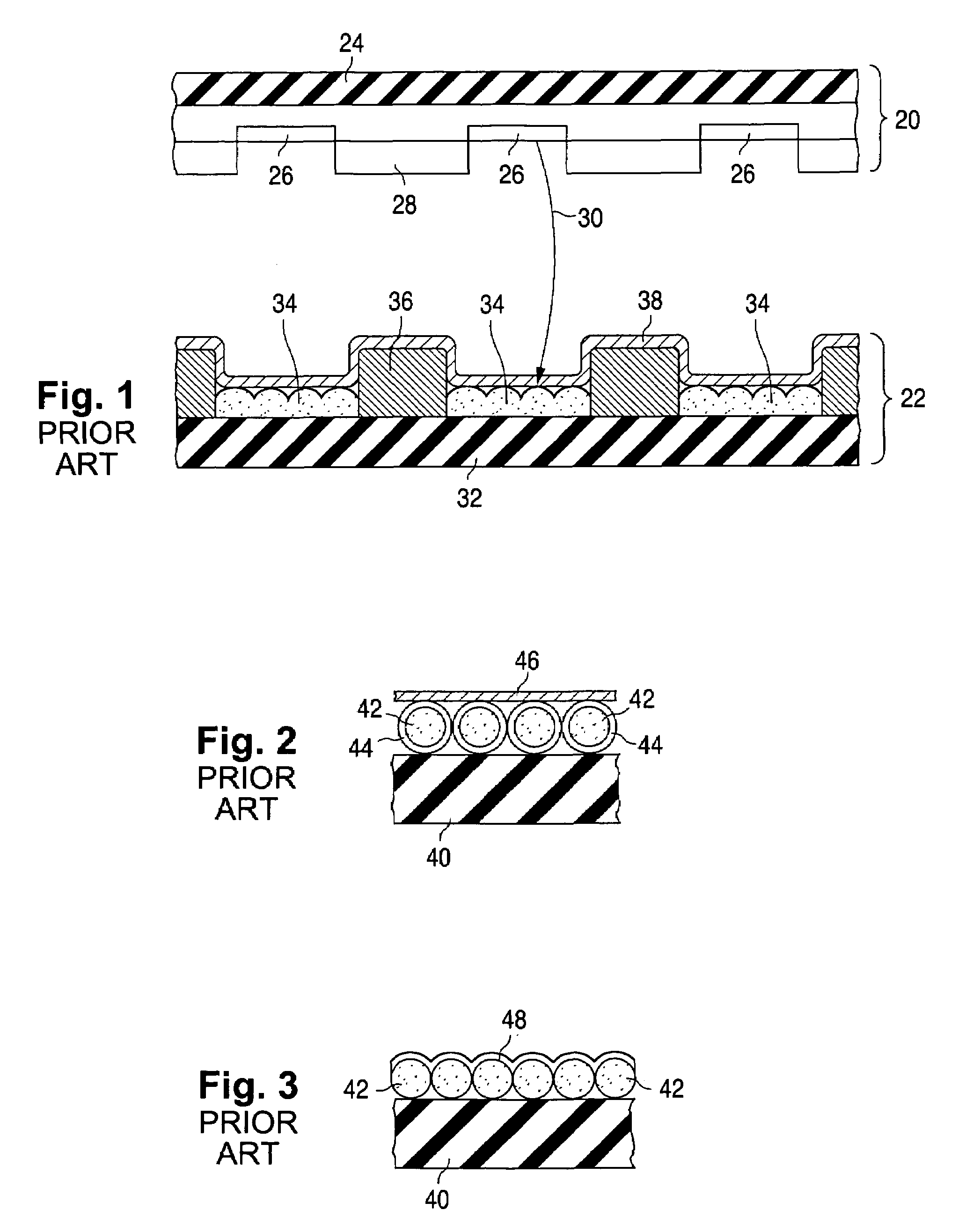

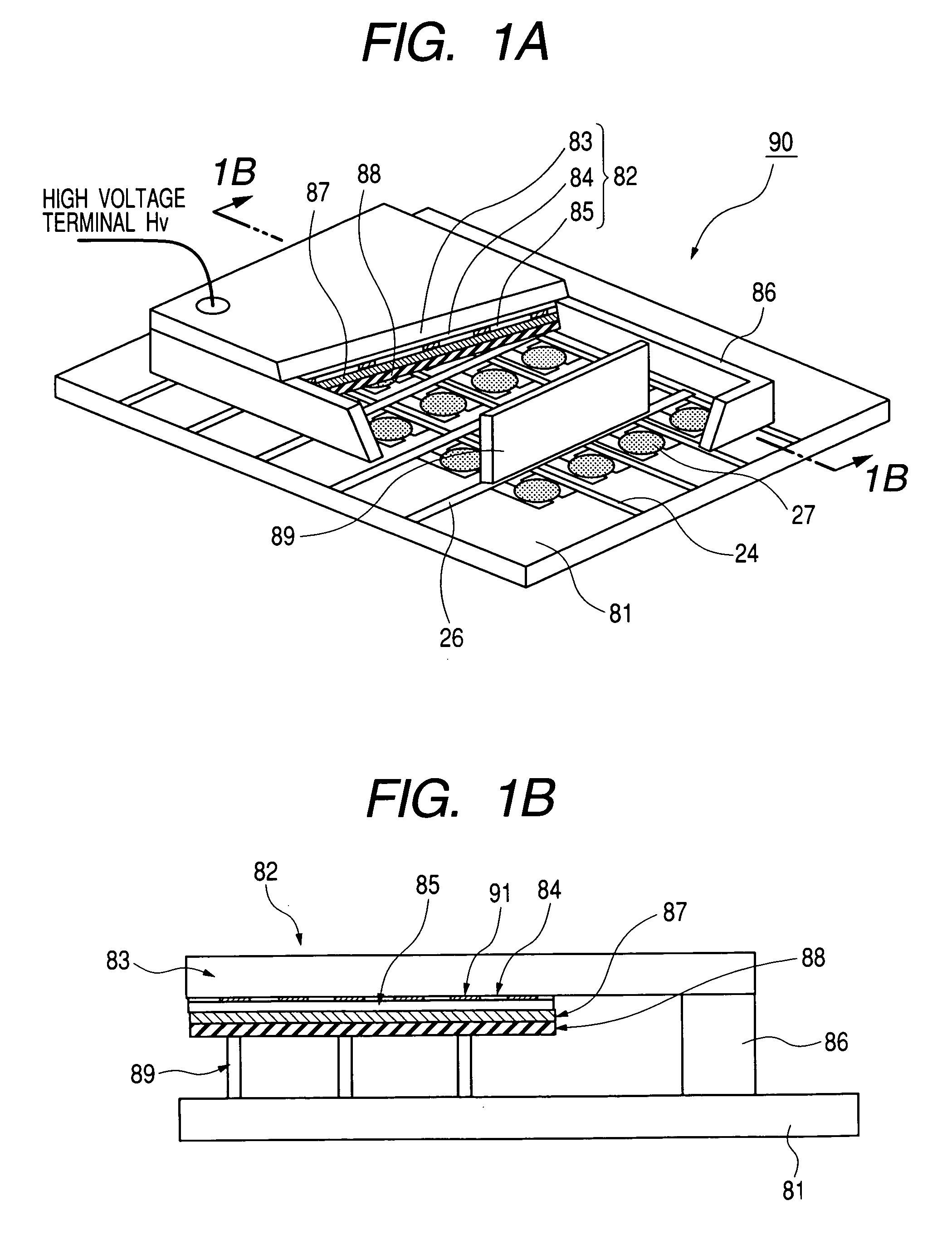

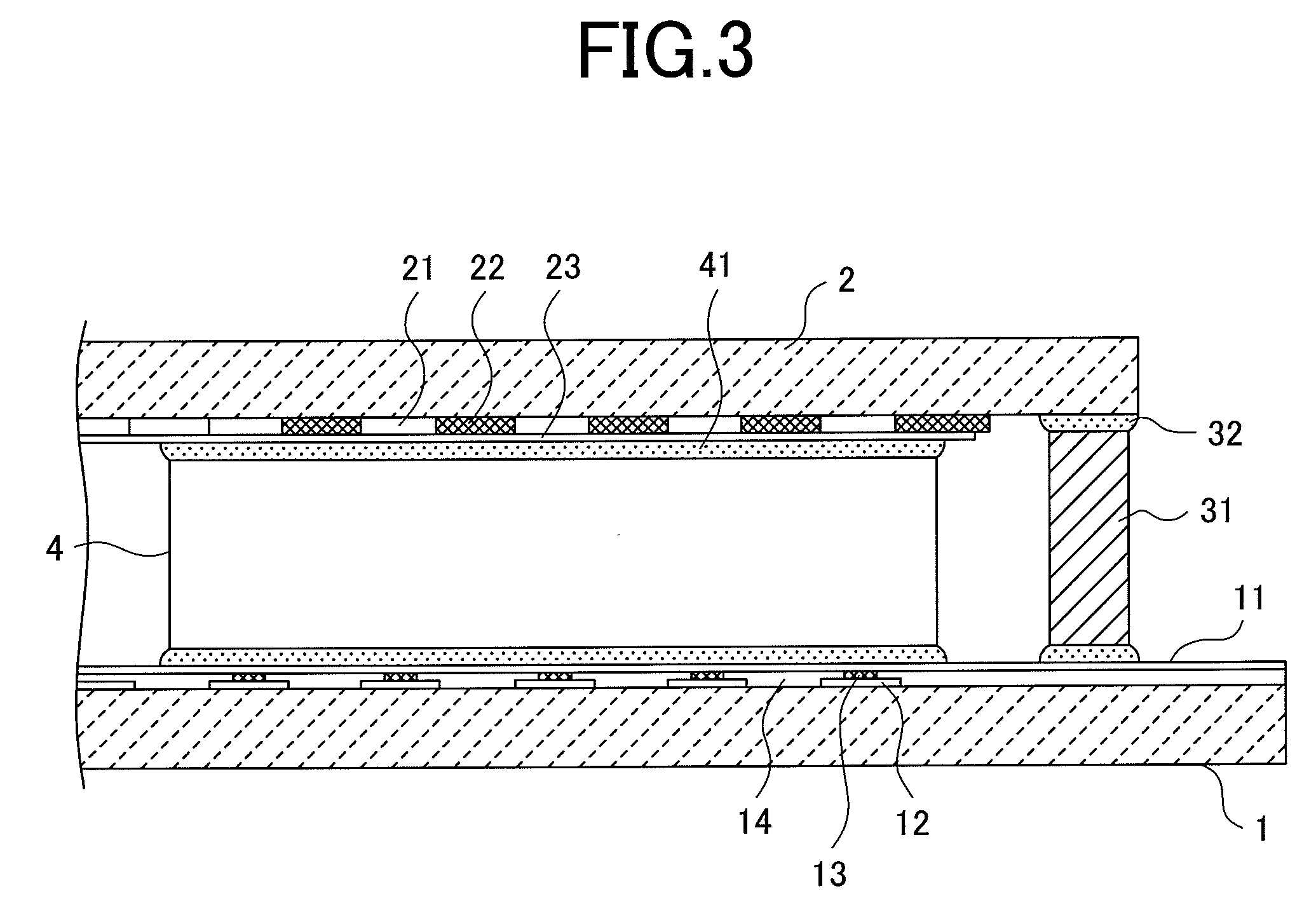

Field emission display

InactiveUS6172456B1Reduce in quantityIncrease in costGas filling substance selectionDischarge tube luminescnet screensField emission displayDisplay device

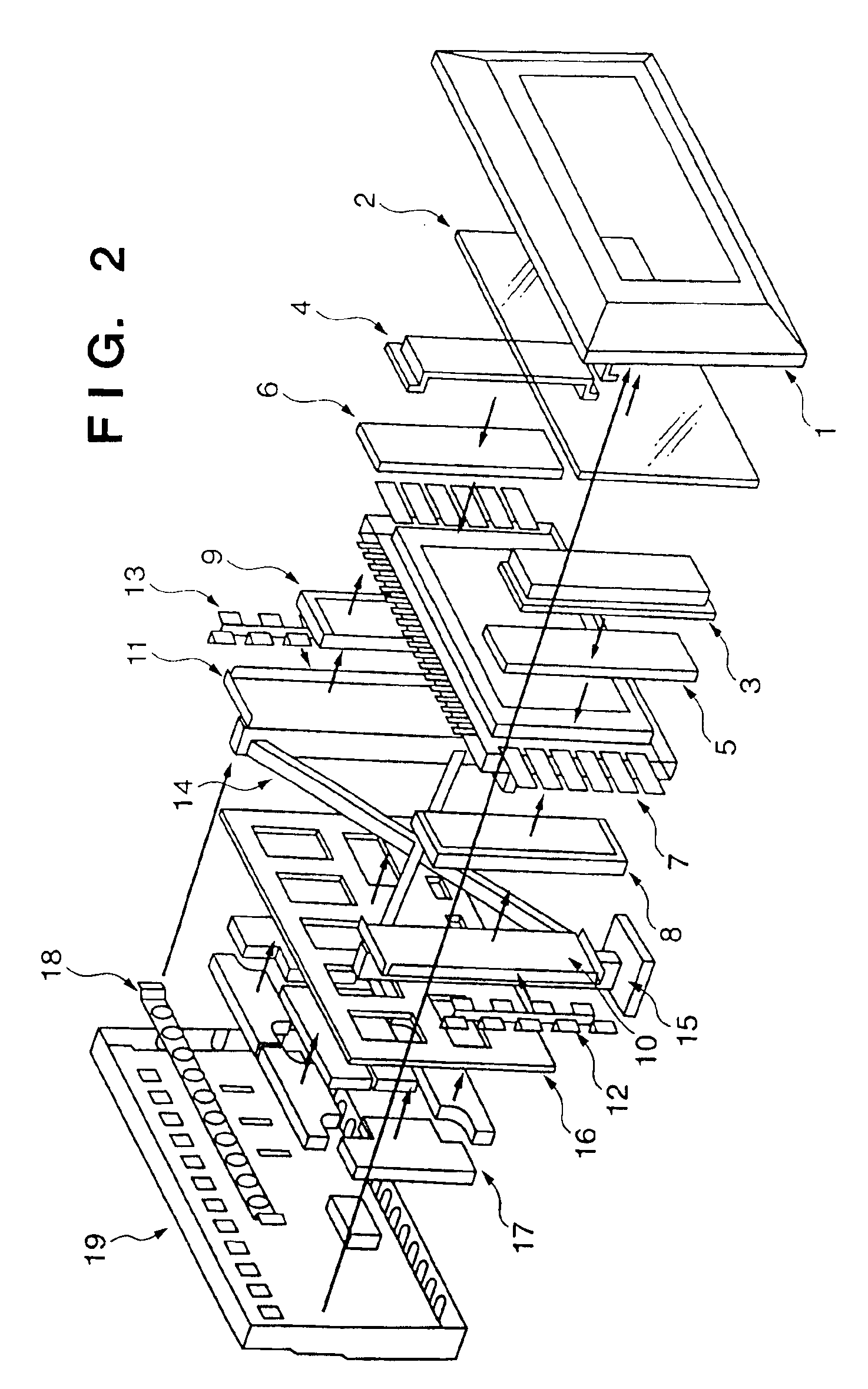

A flat-panel field emission display comprises a luminescent faceplate, a rigid backplate, and an interposed or sandwiched emitter or cathode plate. A positioning spacer or connector ridge is formed on the rear surface of the faceplate to space the cathode plate a fixed distance behind the faceplate. A peripheral seal is formed between the faceplate and the backplate. The faceplate, backplate, and peripheral seal define an evacuated internal space which contains the cathode plate. The backplate is spaced behind the cathode plate to create a rearward vacuum space in which a getter is located.

Owner:MICRON TECH INC

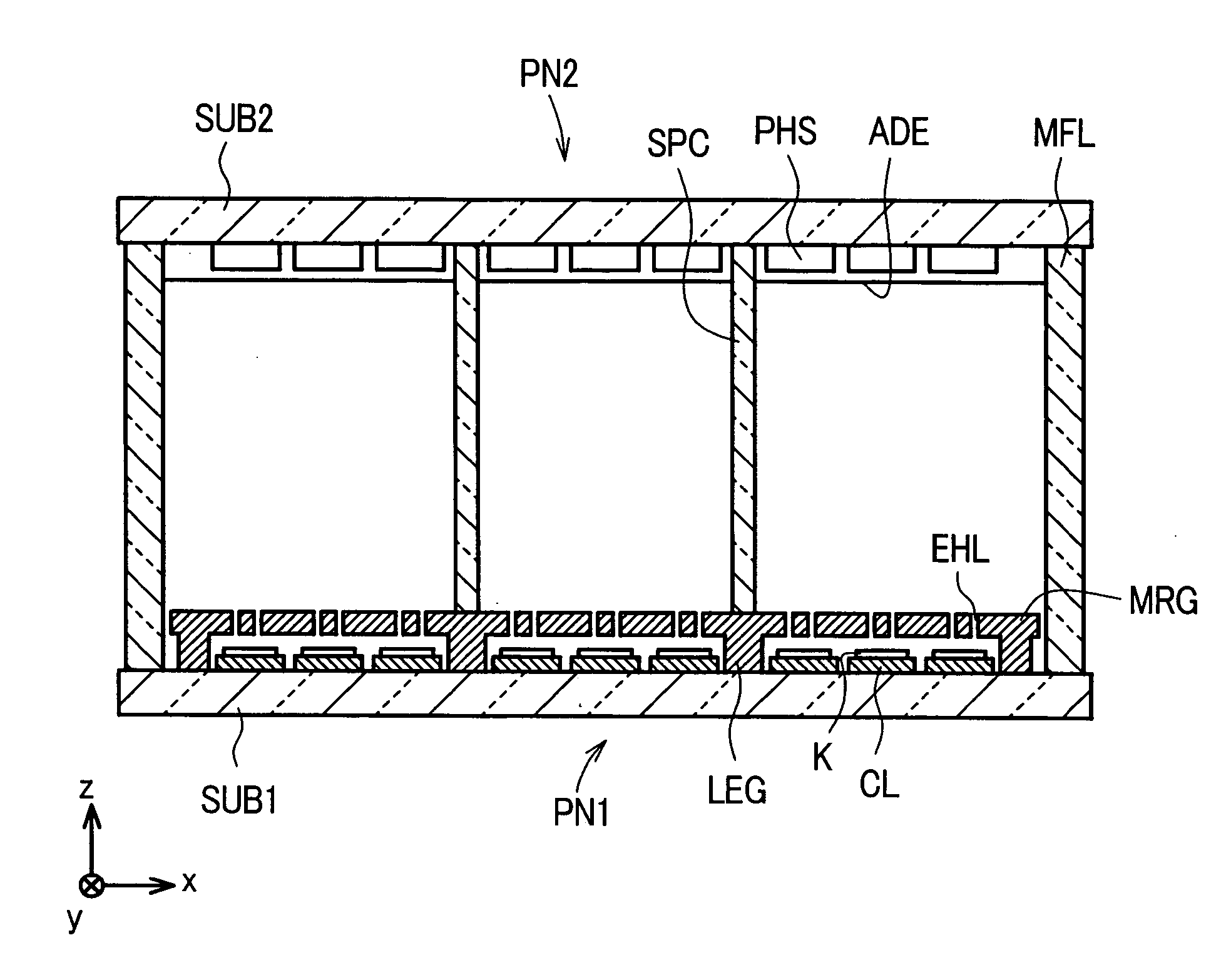

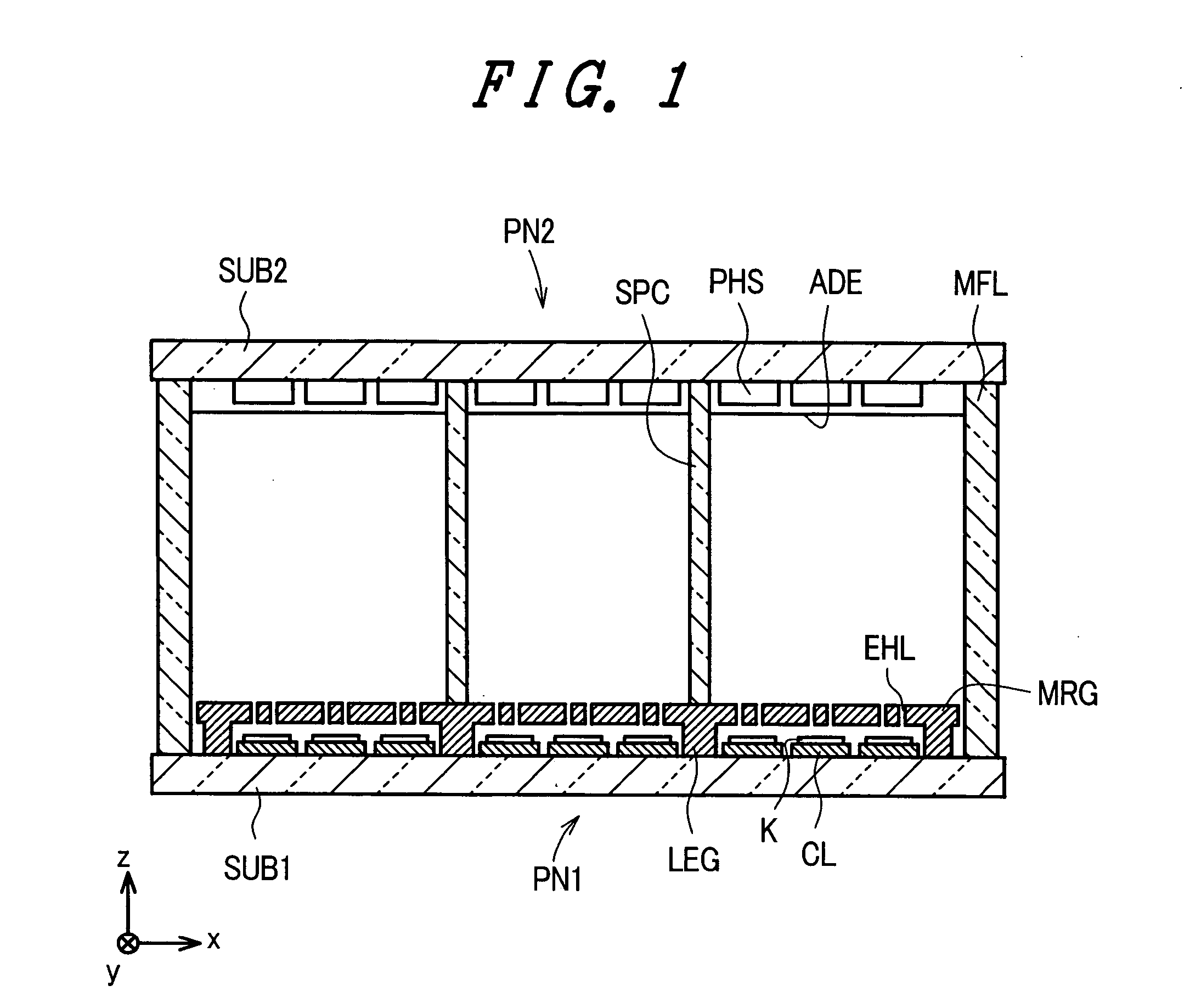

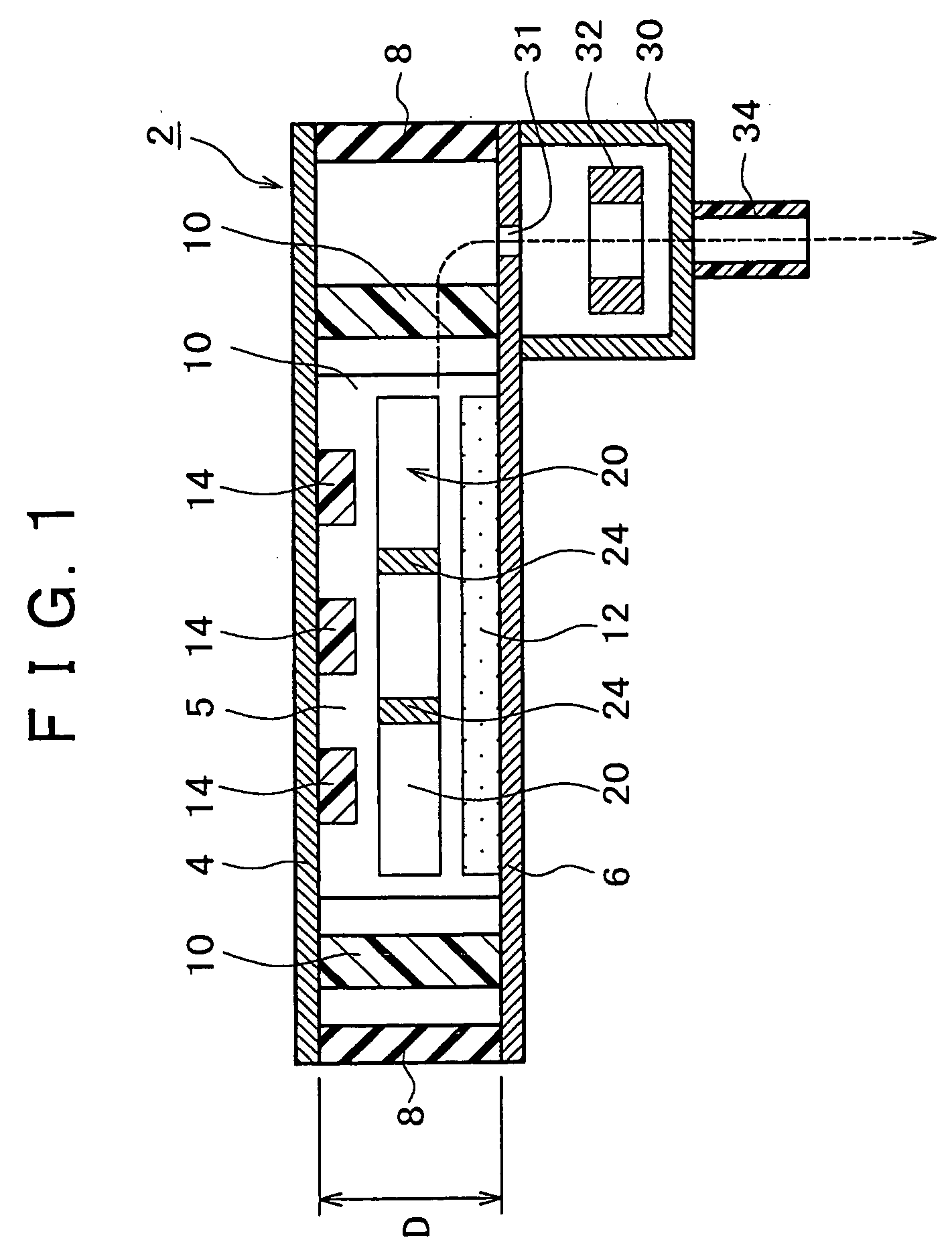

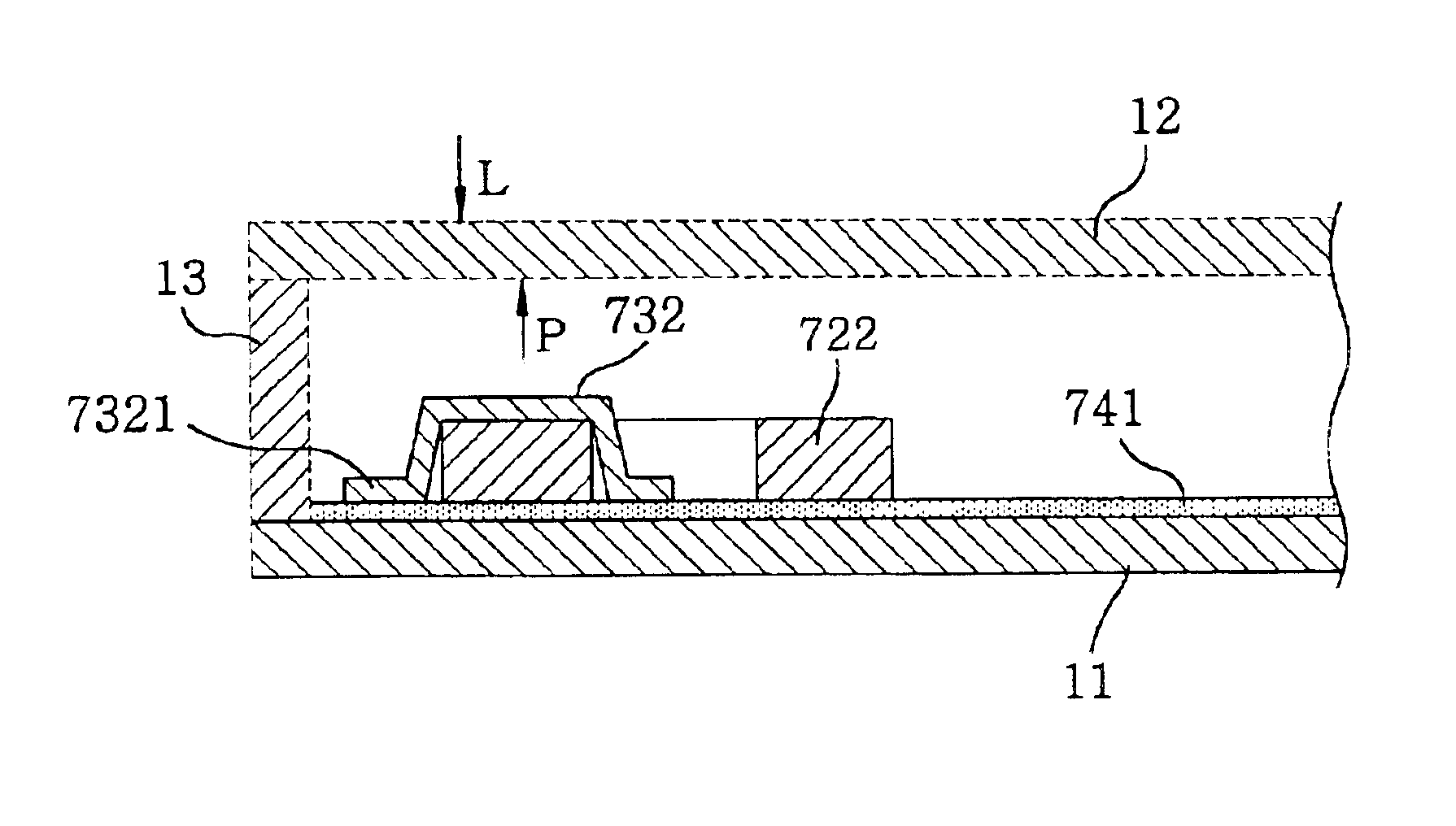

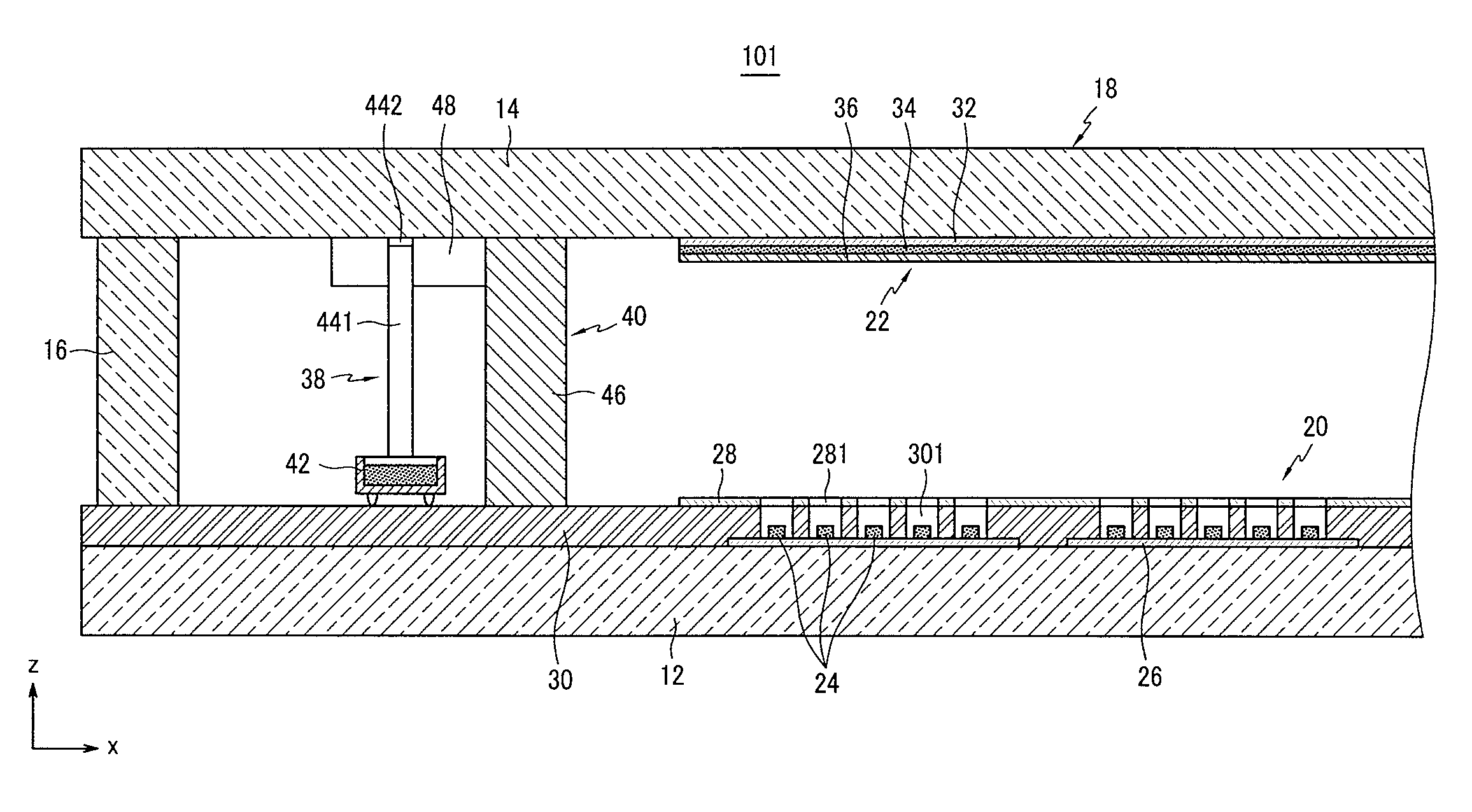

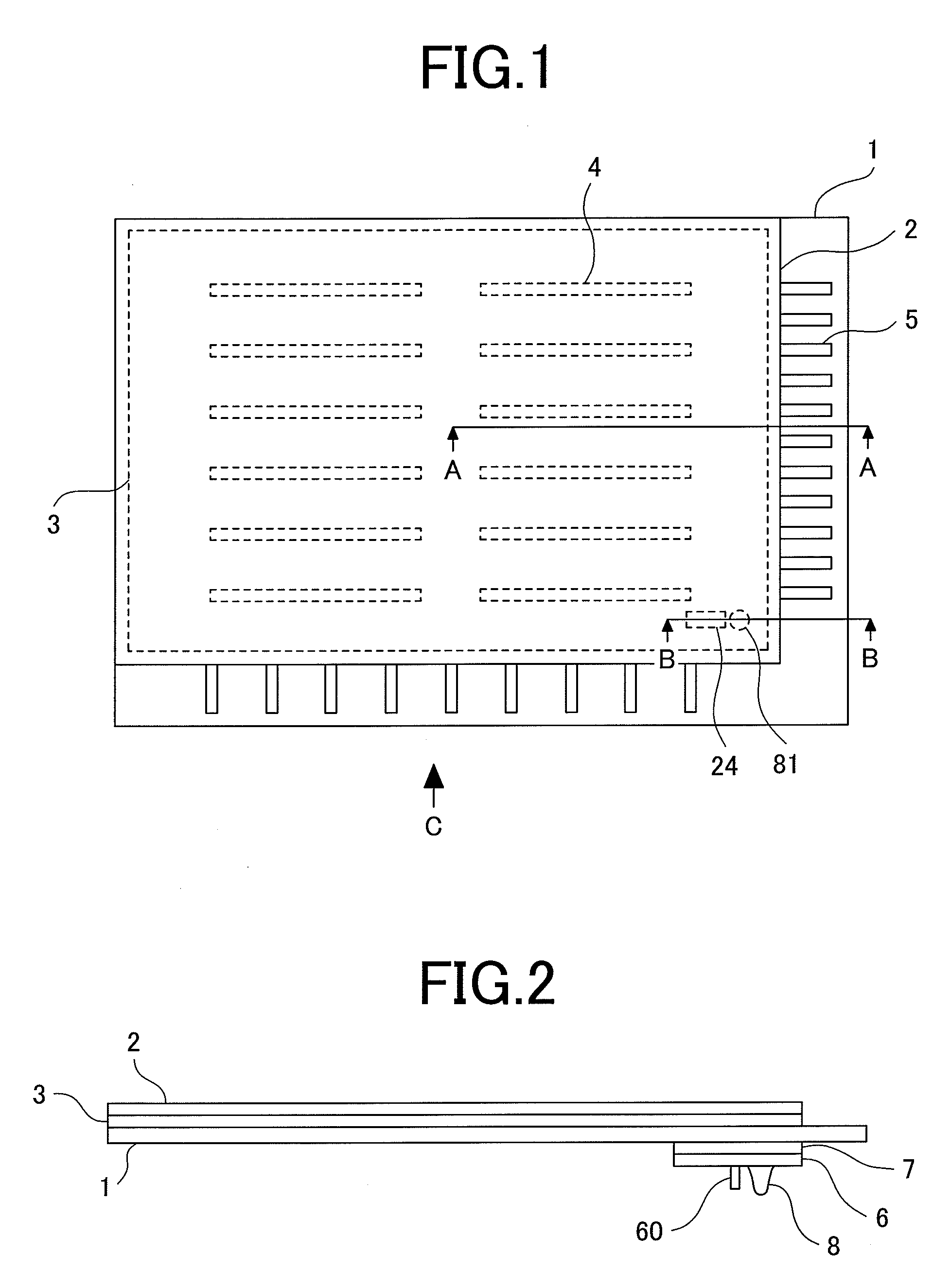

Image formation apparatus

InactiveUS20050082963A1Configuration highFulfil requirementsTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

Unitary vacuum tube incorporating high voltage isolation

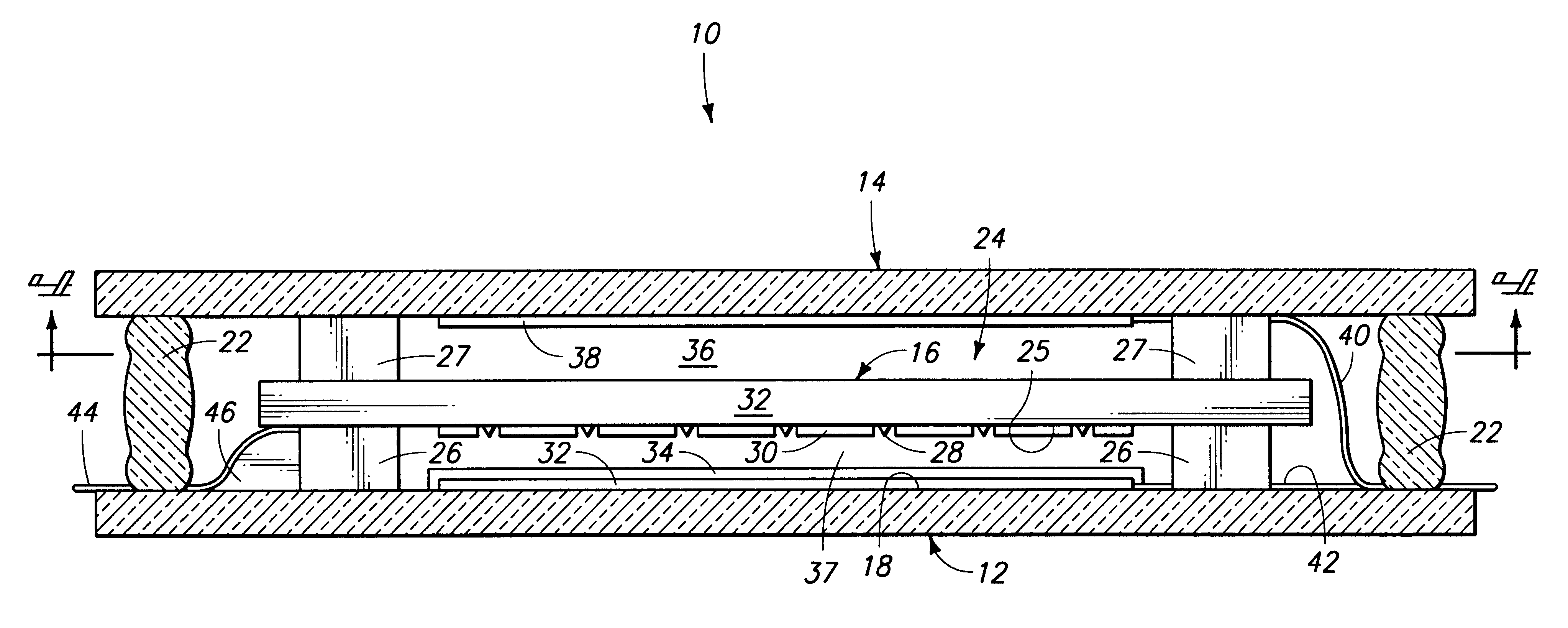

InactiveUS6837766B2Improve isolationLinear distance increasesGas filling substance selectionCathode-ray/electron-beam tube vessels/containersGreen tapeHigh pressure

A housing for microelectronic devices requiring an internal vacuum for operation, e.g., an image detector, is formed by tape casting and incorporates leads between interior and exterior of the housing where the leads are disposed on a facing surface of green tape layers. Adjacent green tape layers having corresponding apertures therein are stacked on a first closure member to form a resulting cavity and increased electrical isolation or channel sub-structures are achievable by forming adjacent layers with aperture dimension which vary non-monotonically. After assembly of the device within the cavity, a second closure member is sealed against an open face of the package in a vacuum environment to produce a vacuum sealed device.

Owner:EOTECH LLC

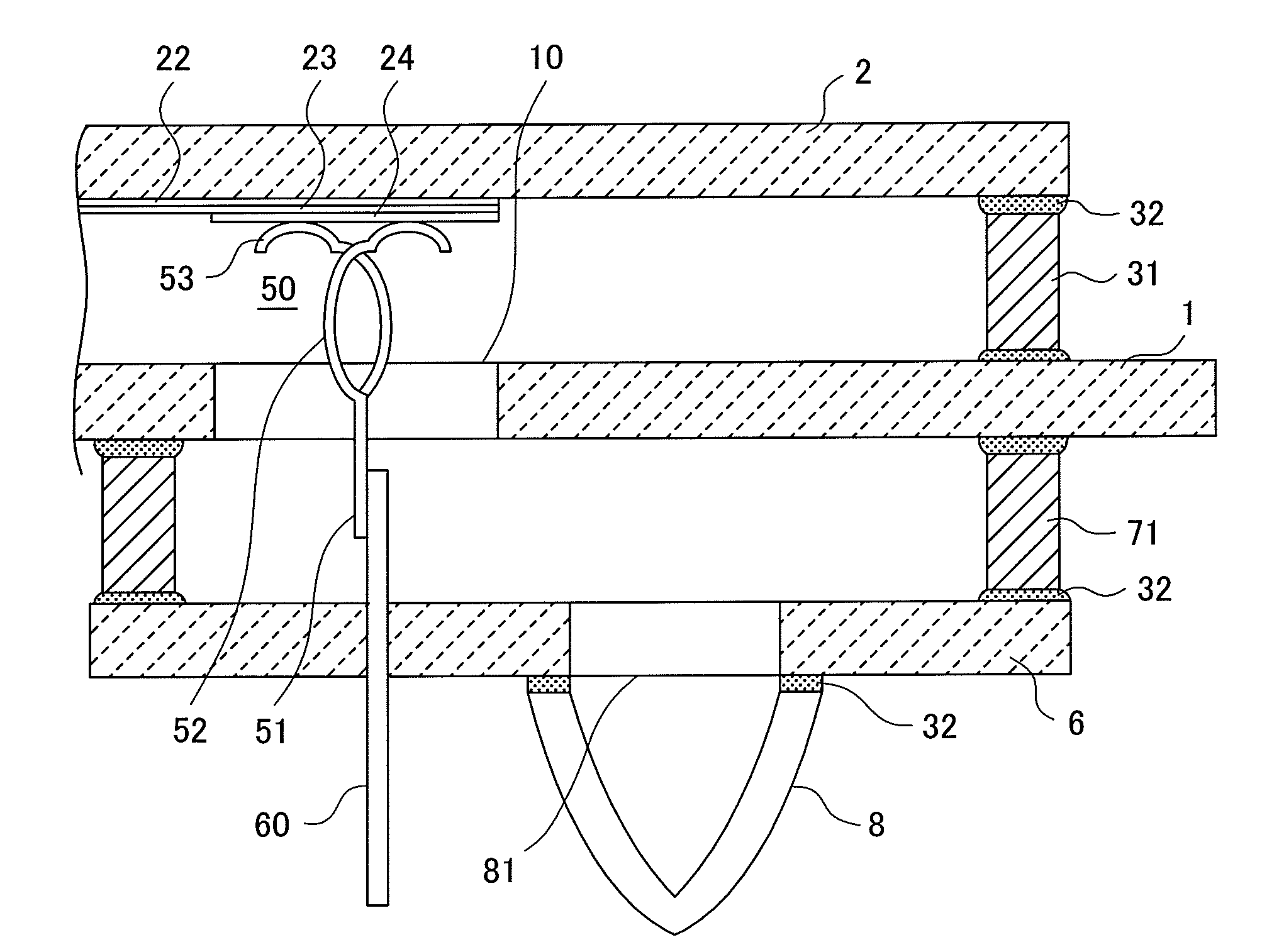

Image display device

InactiveUS20050206299A1High dielectric strengthSimple structureGas filling substance selectionGas-filled discharge tubesDisplay deviceExhaust pipe

In a corner portion outside a display region of a face substrate which constitutes a face panel of a display device, an opening is formed. In the opening, a stem glass structural body, which is configured by integrally forming an exhaust pipe on a center portion of a stem glass and by forming conductive leads in a peripheral portion thereof in an embedded manner, is fixed by welding using curing by heating. The exhaust pipe is evacuated and, thereafter, tipped off, thus realizing vacuum sealing of the inside thereof. A lead line is connected to a distal end of one conductive lead by welding and another end of the lead line is electrically connected with one end portion of the anode formed on an inner surface of the face substrate using a conductive adhesive agent. Further, a getter is mounted and fixed to another conductive lead line by welding.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Treatment method of a getter material and encapsulation method of such getter material

ActiveUS20110079425A1Effective protectionGas filling substance selectionSemiconductor/solid-state device detailsNitrogenOxygen

A treatment method for a getter material, comprising at least one oxidation and / or nitriding step of getter material conducted under dry atmosphere of dioxygen and / or dinitrogen at pressure greater than approximately 10−2 mbar and at a temperature between approximately 50° C. and 120° C. and over a period between approximately 1 minute and 10 minutes, forming a protective layer composed of oxide and / or nitride of getter material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

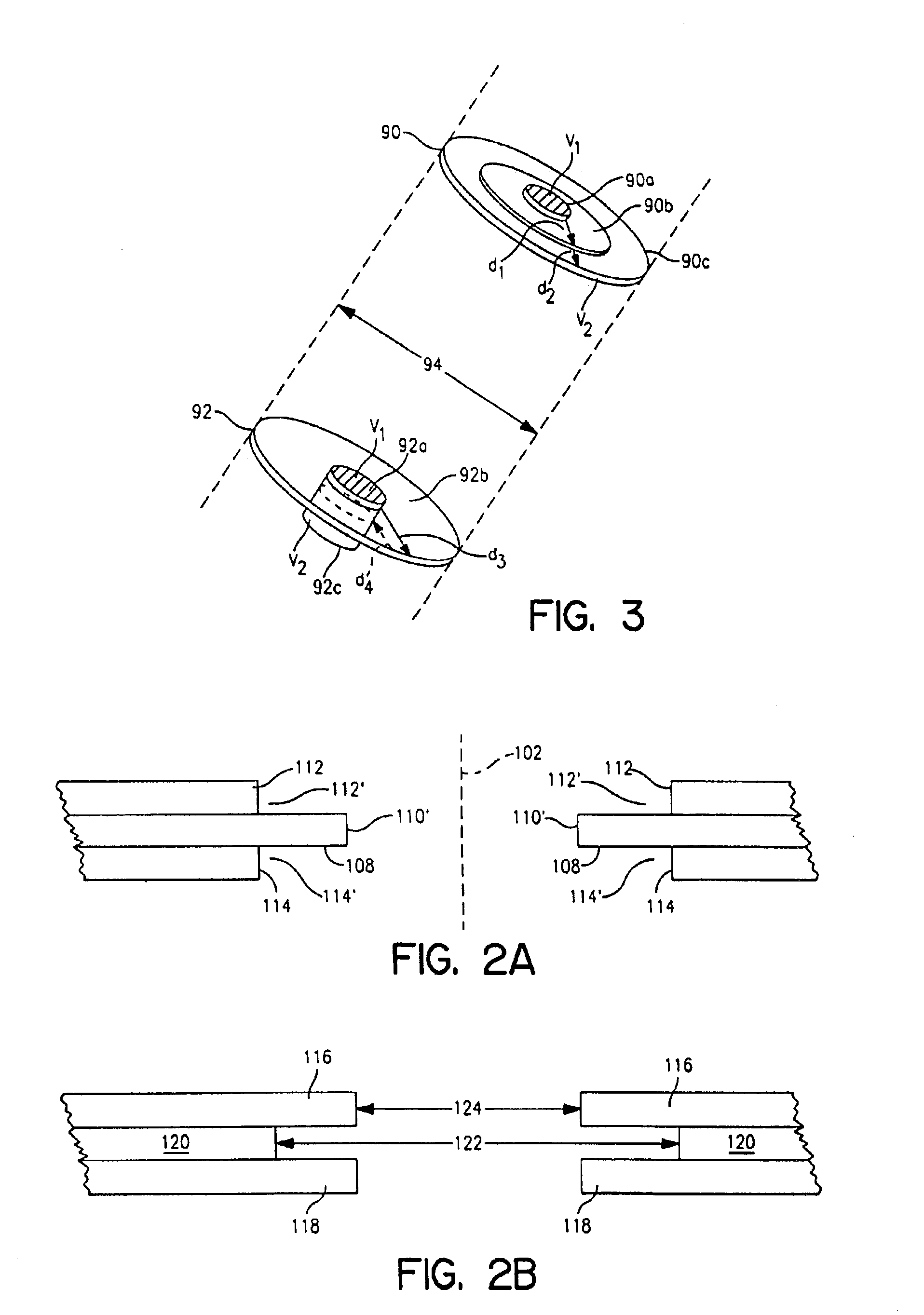

Light-emitting and electron-emitting devices having getter regions

InactiveUS7315115B1Improve performanceEasy to manufactureTube/lamp screens manufactureGetteringLight emitting deviceElectron

A light-emitting device contains getter material (58) typically distributed in a relatively uniform manner across the device's active light-emitting portion. An electron-emitting device similarly contains getter material (112, 110 / 112, 128, 132, and 142) typically distributed relatively uniformly across the active electron-emitting portion of the device.

Owner:CANON KK +1

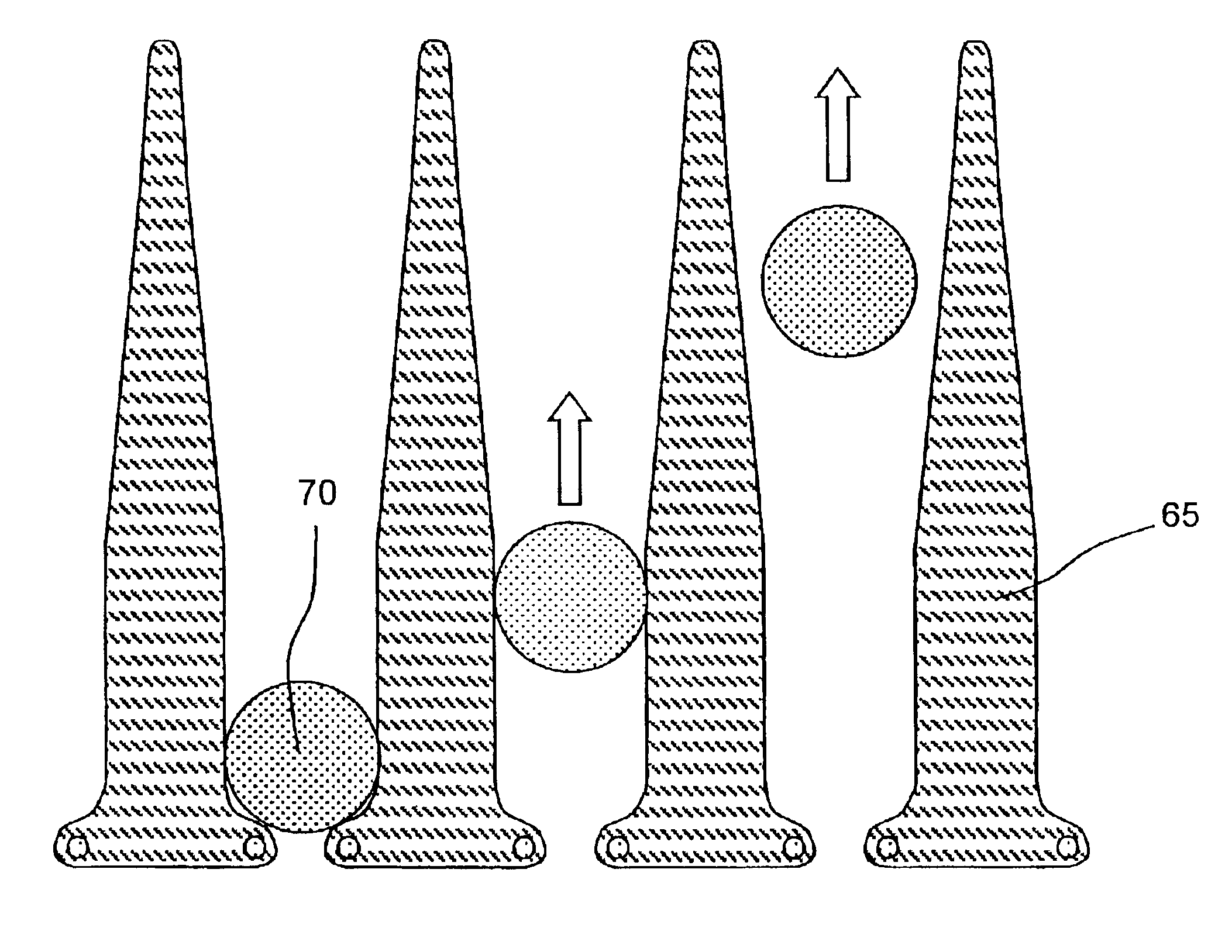

Micro vacuum pump for maintaining high degree of vacuum and apparatus including the same

InactiveUS6236156B1Gas filling substance selectionDischarge tube luminescnet screensNoble gasEngineering

The present invention provides a micro vacuum pump capable of enhancing the performance of exhausting rare gases as well as active gases thereby to ensure quality, good repeatability and stable getter action of the micro vacuum pump over a long time. The invention also provides an apparatus assembling the micro vacuum pump. The micro vacuum pump capable of maintaining a high degree of vacuum includes a first conductive substrate having many protrusions and mounting a second conductive substrate disposed with a predetermined interval provided with respect to the first conductive substrate so that it faces the protrusions. A gate electrode is disposed in the vicinity of the apexes of the protrusions on the first conductive substrate via an insulator layer, and is positioned to face the second conductive substrate. Relative to the first conductive substrate, a negative potential is supplied to the second conductive substrate, and, a same negative potential difference is also applied to the gate electrode relative to the cones.

Owner:NEC CORP

Image forming apparatus

InactiveUS20060087220A1Reduce lossesSmall distribution of luminanceGas filling substance selectionDischarge tube luminescnet screensImage formationImaging equipment

An image forming apparatus in which a first substrate provided with an electron-emitting device and an image displaying member which electrons emitted from the electron-emitting device irradiate are arranged to be opposed is provided with a deflecting means deflecting the electrons emitted from the electron-emitting device and a trapping unit trapping an inert gas ionized by the electrons. Thereby, the damages of the electron-emitting device by the inert gas are prevented, and the life of an image display apparatus is aimed to be elongated.

Owner:CANON KK

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

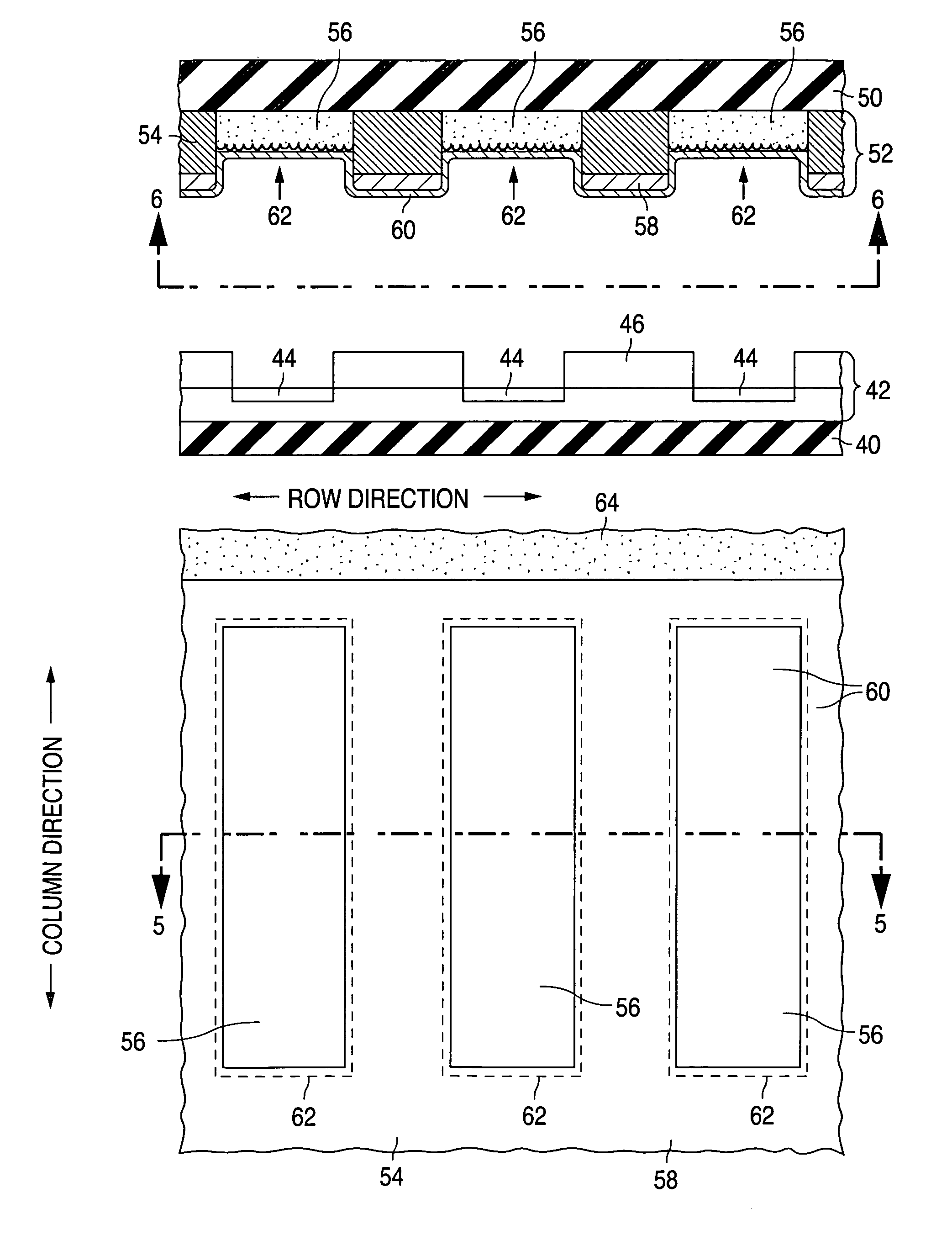

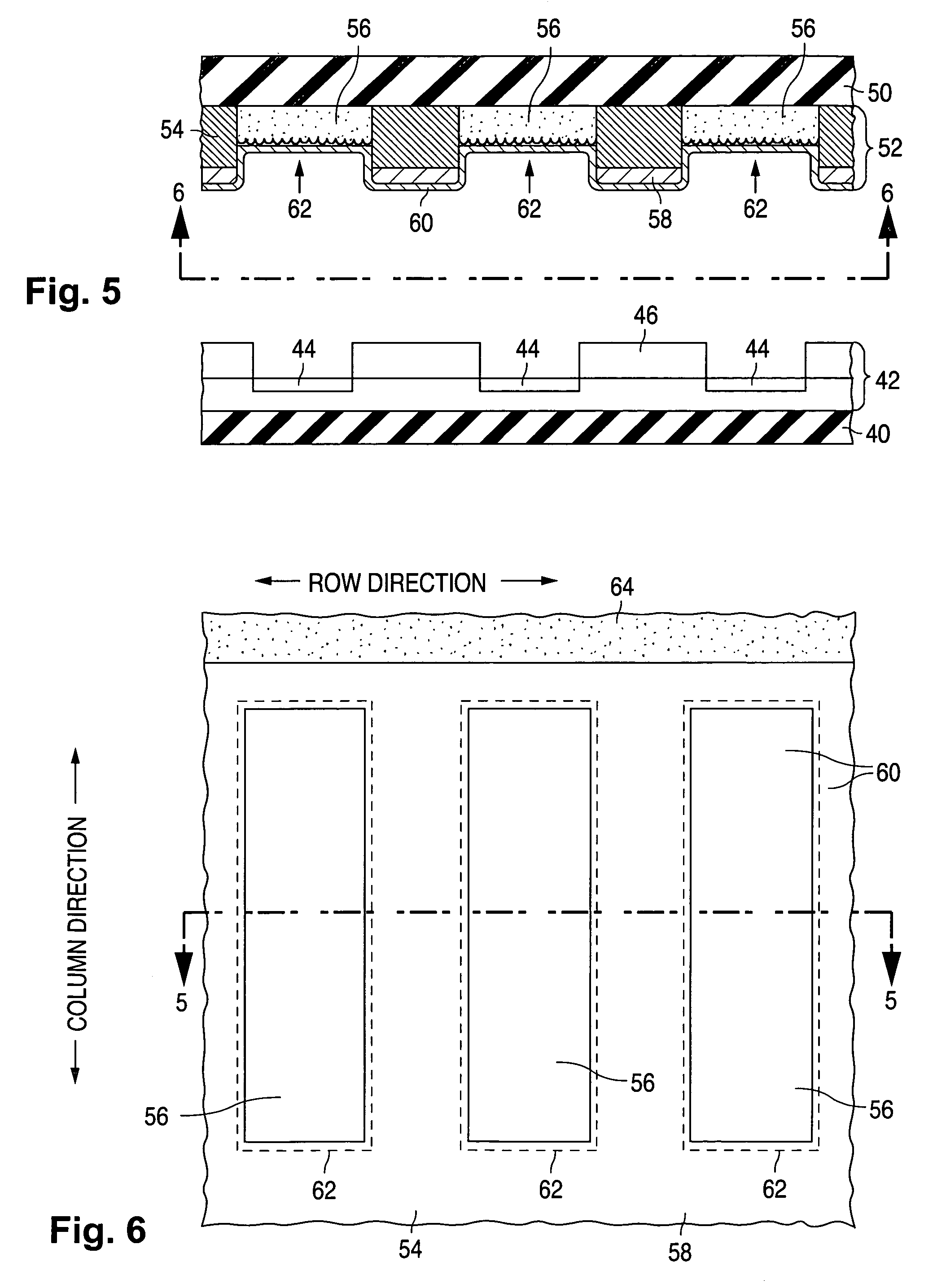

Field emission display manufacturing method having integrated getter arrangement

InactiveUS7131883B2Efficient removalGas filling substance selectionDischarge tube luminescnet screensField emission displayElectron

A field emission display (FED) and a manufacturing method thereof are provided. The FED includes a getter portion isolated outwardly from an active display region. This getter portion includes a non-evaporable getter layer for absorbing gas and an electron emission source for activating the getter layer. Accordingly, by activating the non-evaporable getter, the gas generated in the display is easily absorbed, and the FED is maintained in a high vacuum state.

Owner:SAMSUNG SDI CO LTD

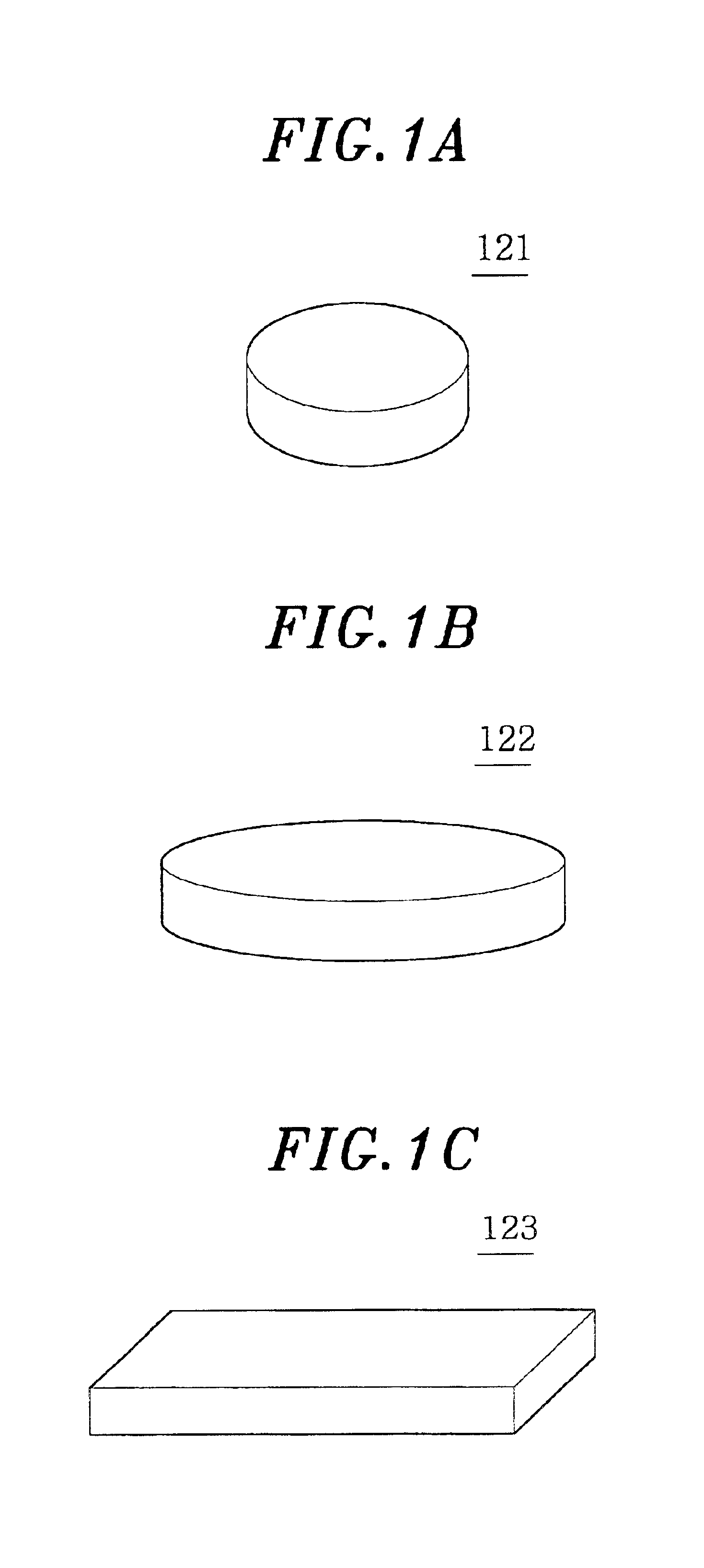

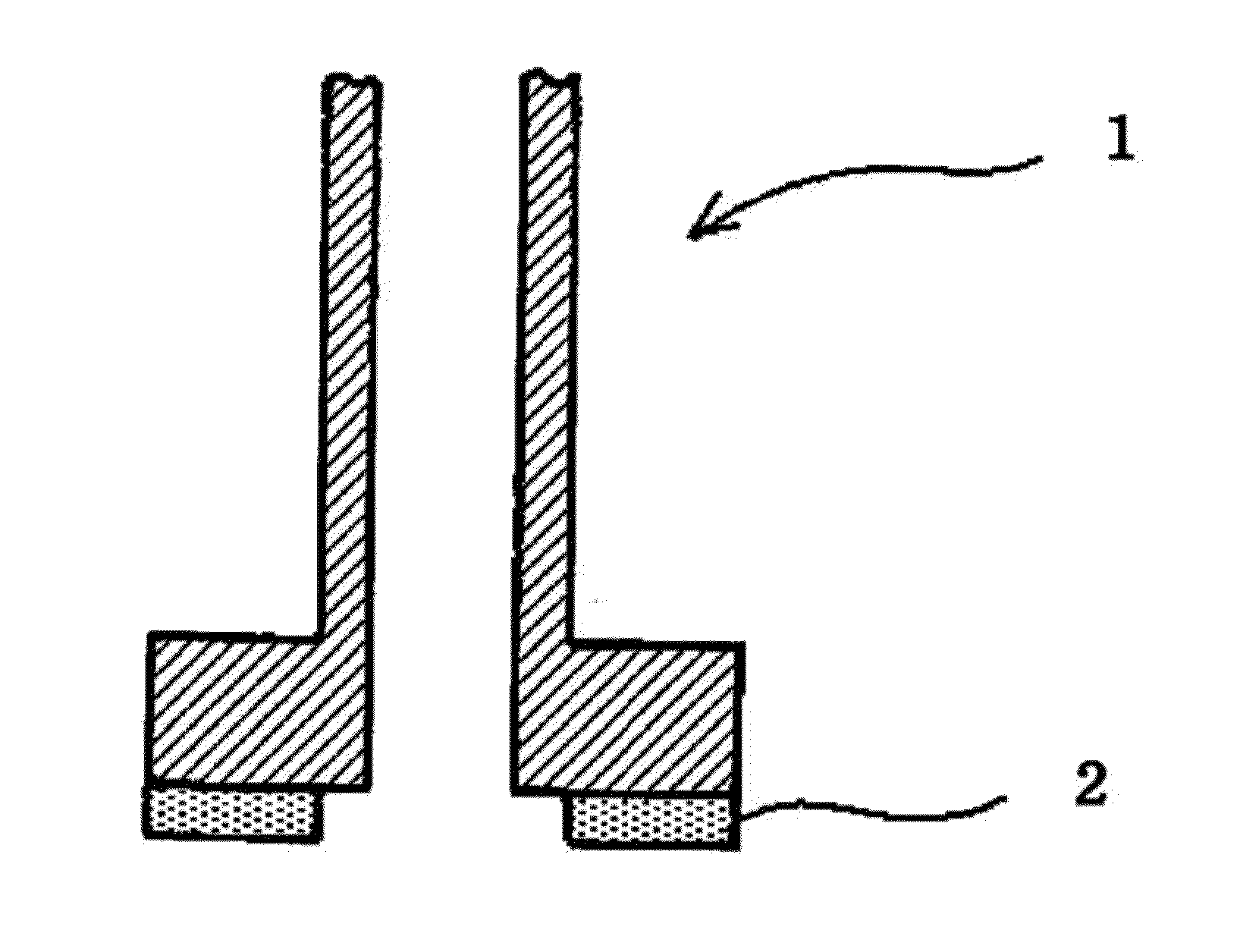

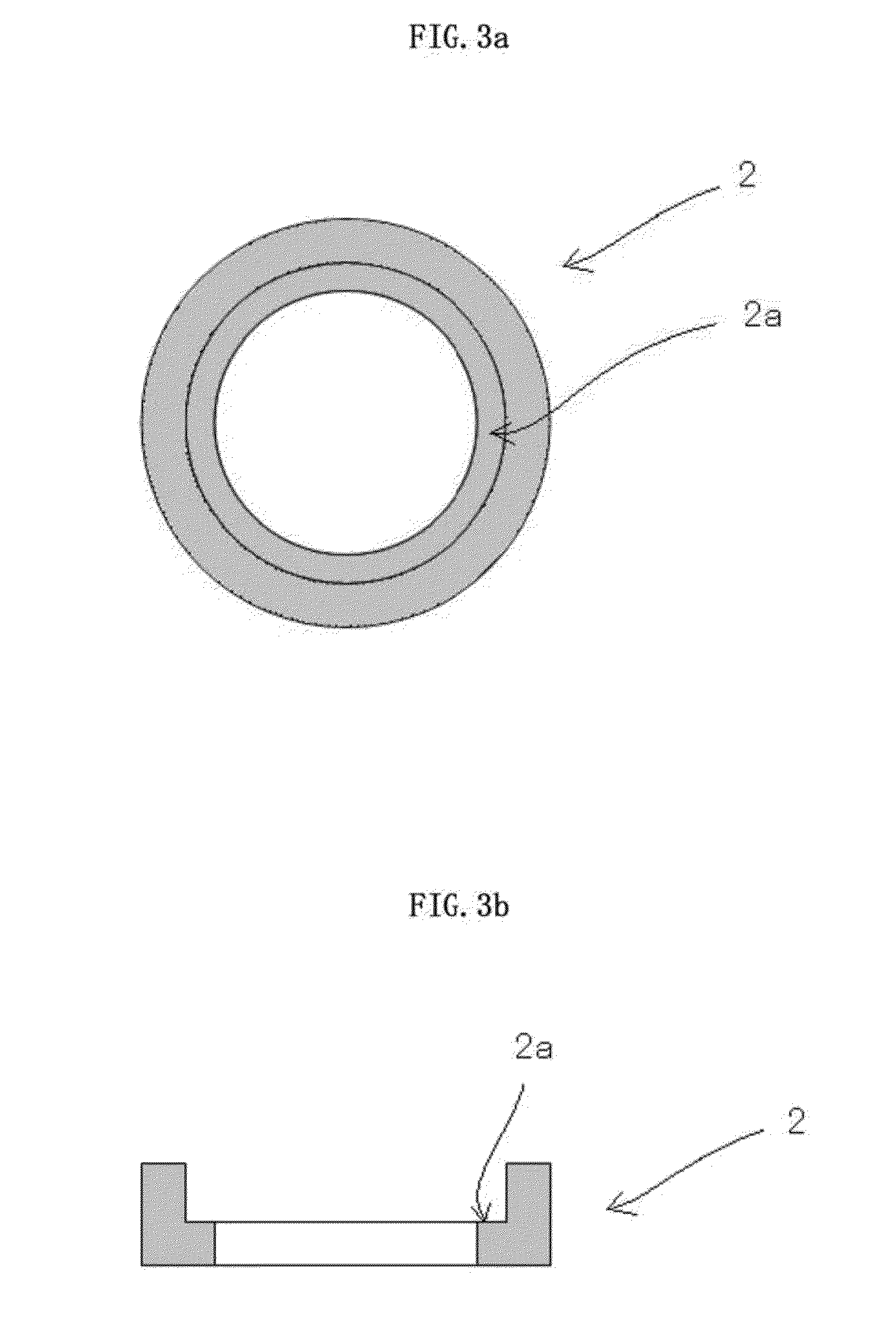

Non-evaporation type getter, display unit and production method for them

InactiveUS20040169469A1Complex shapeHigh mechanical strengthGas filling substance selectionCathode-ray/electron-beam tube vessels/containersPorosityEvaporation

Disclosed are a non-evaporation type getter excellent in gettering effect, capable of maintaining the inside of a gas-tight container in a display apparatus, particularly a flat panel display apparatus or the like, in a high vacuum condition, easy to mount and less liable to contaminate the inside of the gas-tight container, a display apparatus including the getter, and methods of manufacturing the same. The non-evaporation type getter (20) includes a molded body including at least one element selected from the group consisting of Ti, Zr, Al, V, and Fe as a principal constituent thereof, the molded body formed by powder injection molding. The molded body is composed of a porous body having a porosity of 10 to 30%.

Owner:SONY CORP

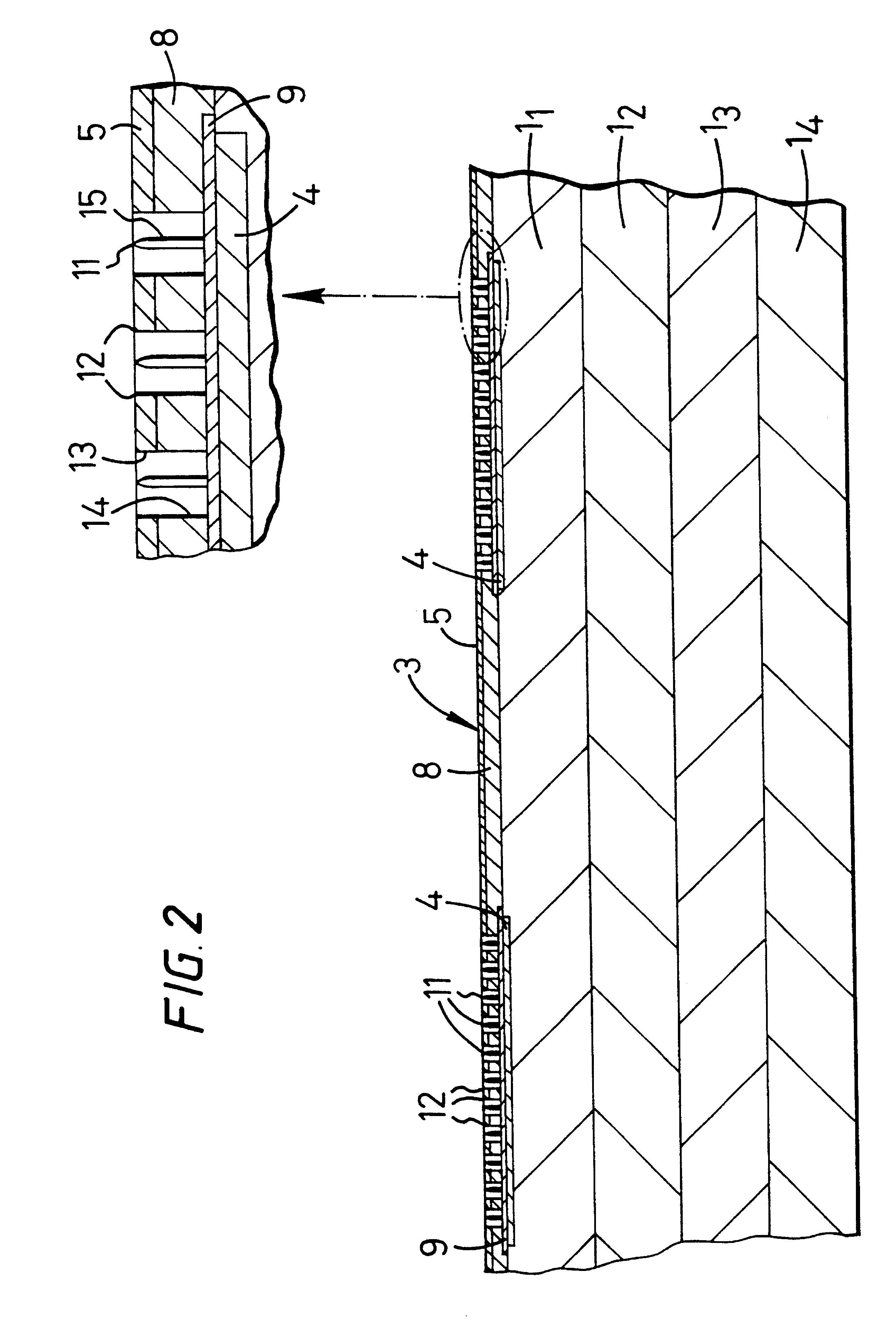

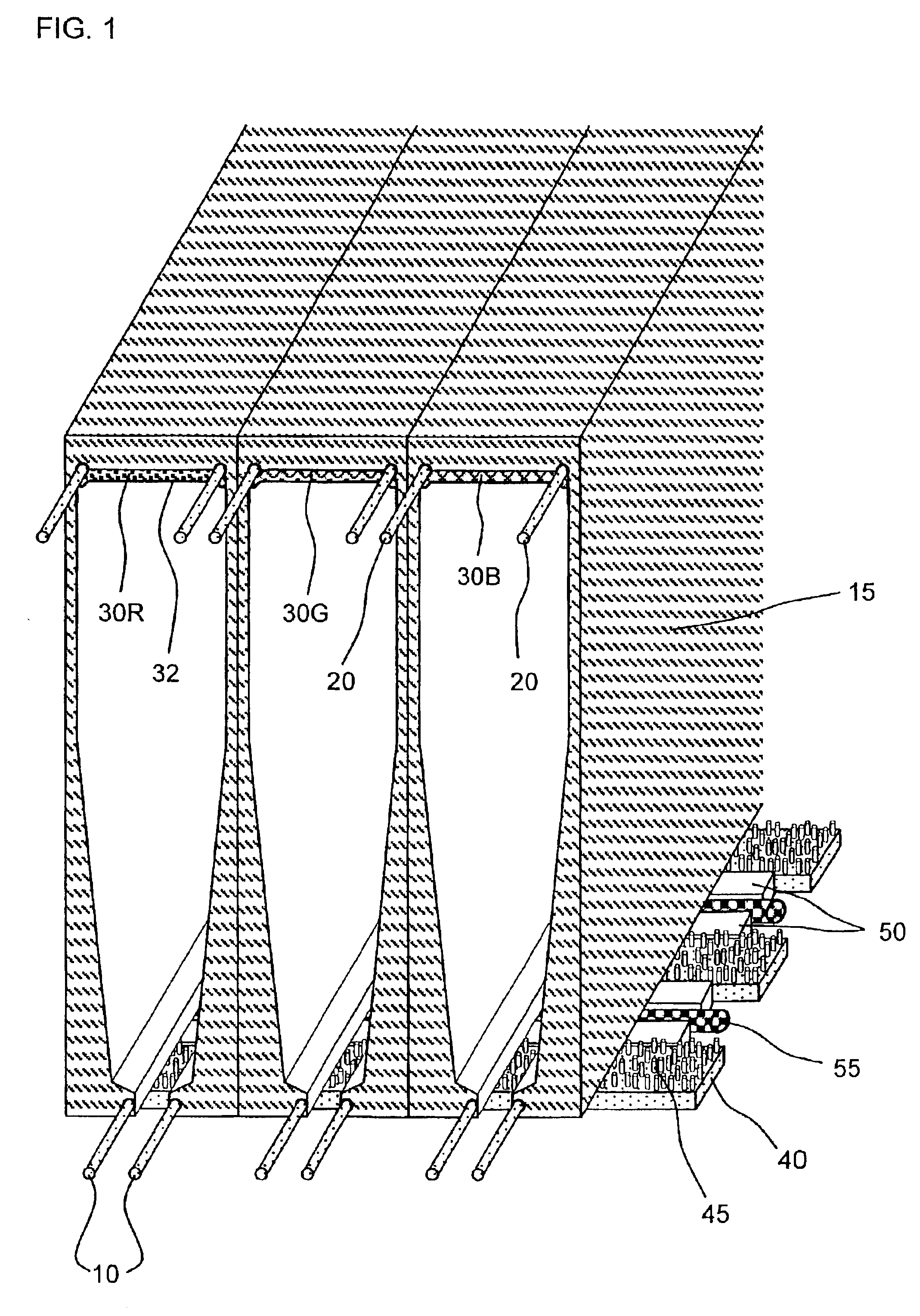

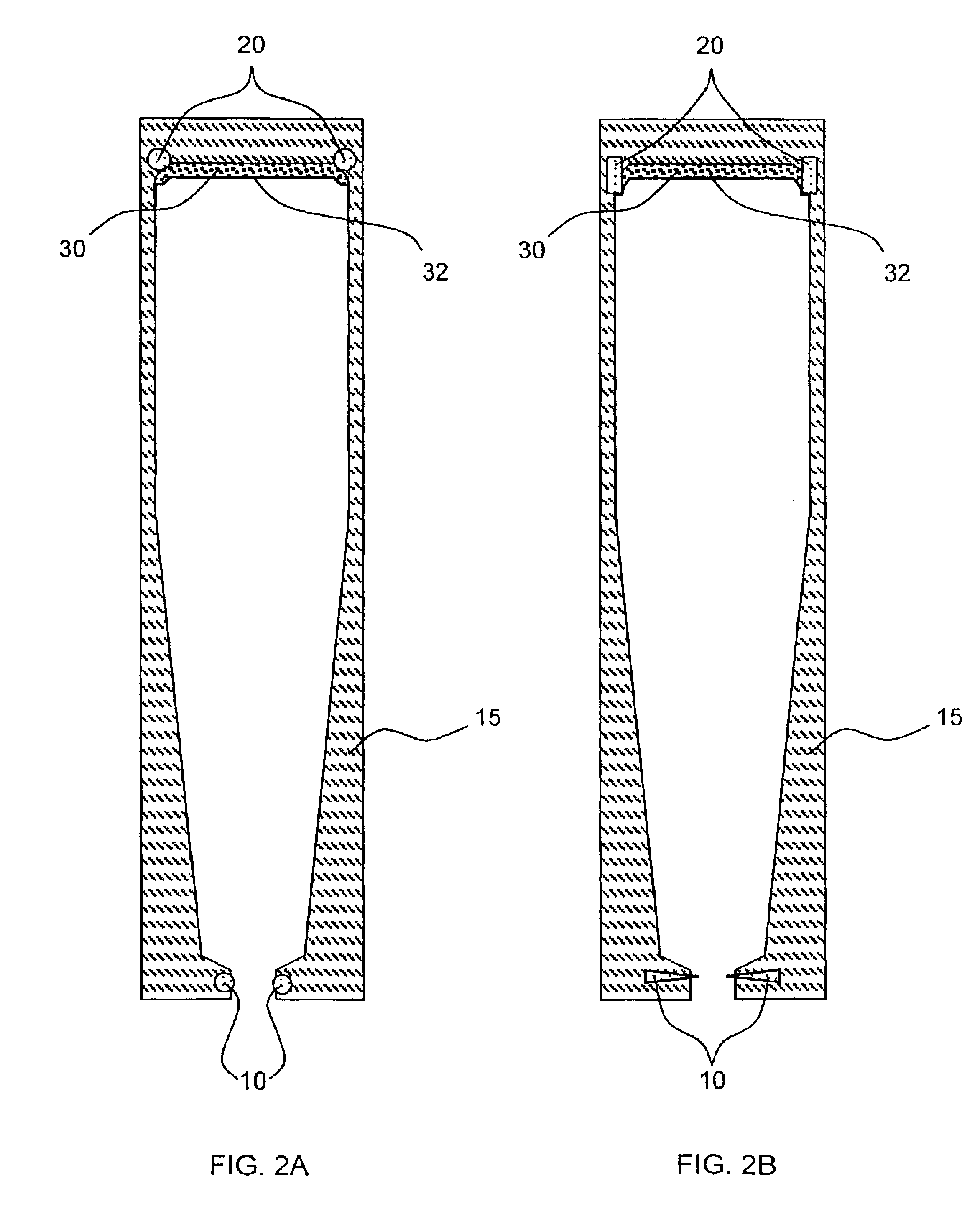

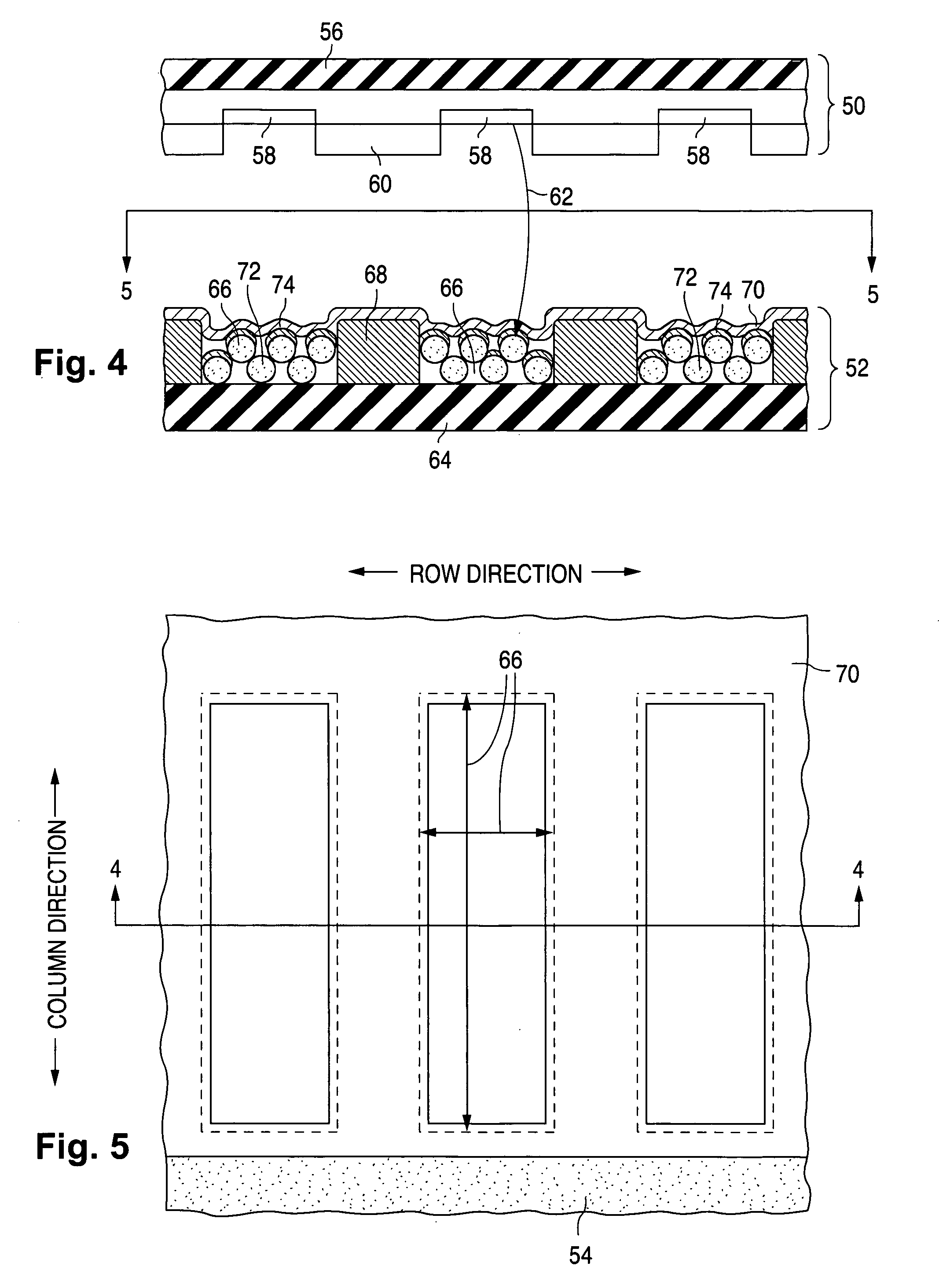

Fiber-based field emission display

InactiveUS6917156B2Increase vacuumGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFiberPhosphor

The invention relates to a field emission display constructed using an array of fibers and an orthogonal array of emitter electrodes. Each fiber in the fiber array contains an extraction electrode, spacer, a high voltage electrode and a phosphor layer. The array of emitter electrodes consists of carbon nanotube emitters attached to conductive electrodes. The emitter electrodes are separated using non-conductive fibers. A getter material in the form of a wire is placed within the array of emitter electrodes to maintain a high vacuum within the display.

Owner:MOORE CHAD BYRON

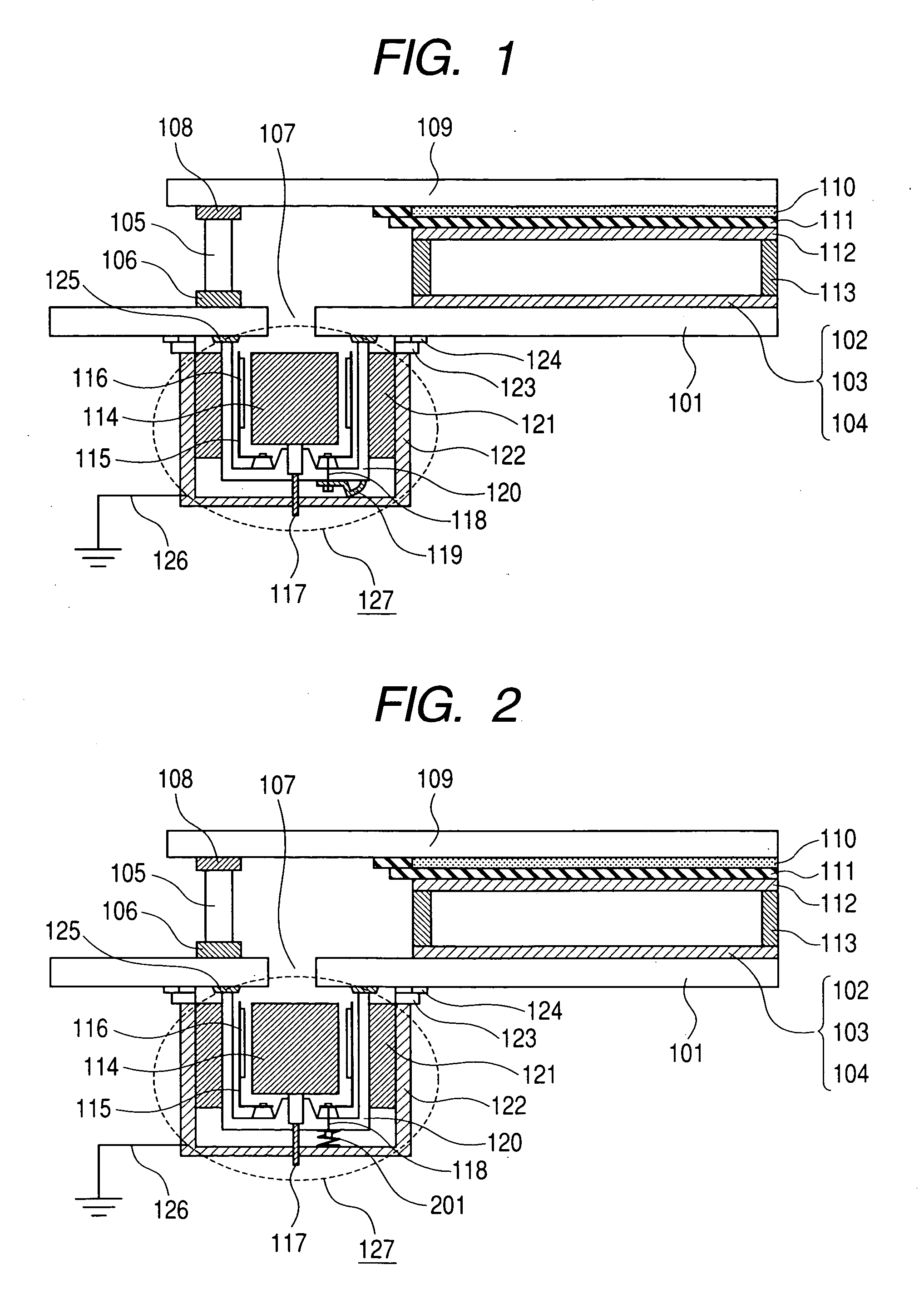

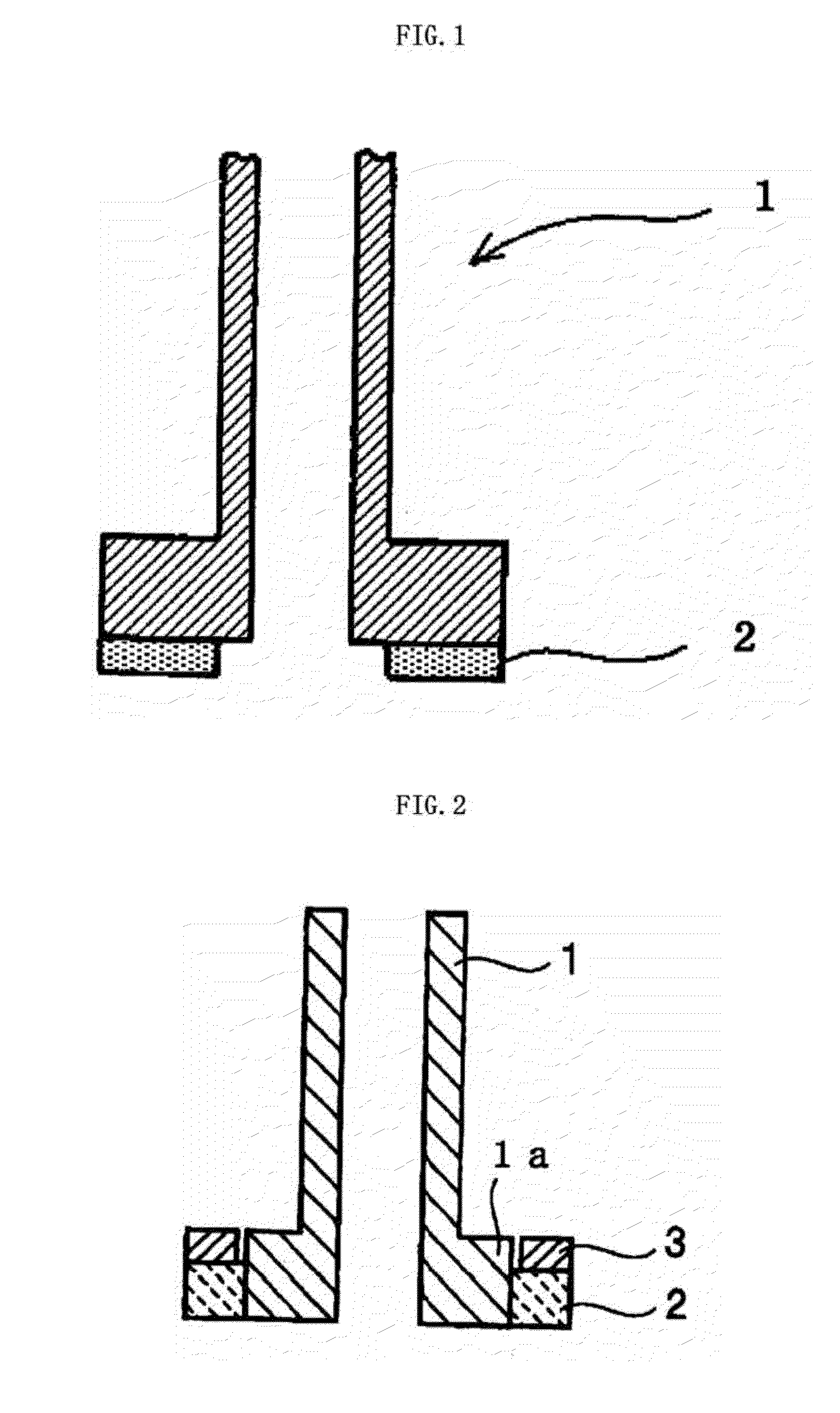

Electron tube with a ring-less getter

InactiveUS6838822B2Reduced space required for installationSimple handlingGetteringGas filling substance selectionEngineeringElectron

In a method for manufacturing an electron tube including a front substrate and a back substrate, a wiring and an electrode are formed on the front substrate and / or the back substrate. A component is mounted on the front substrate and / or the back substrate. A ring-less getter is mounted on at least one of the front substrate, the back substrate and the component. A vessel is assembled and sealed so that the front substrate faces the back substrate. A light is irradiated on the ring-less getter from outside of the sealed vessel, thereby activating the ring-less getter.

Owner:FUTABA CORPORATION

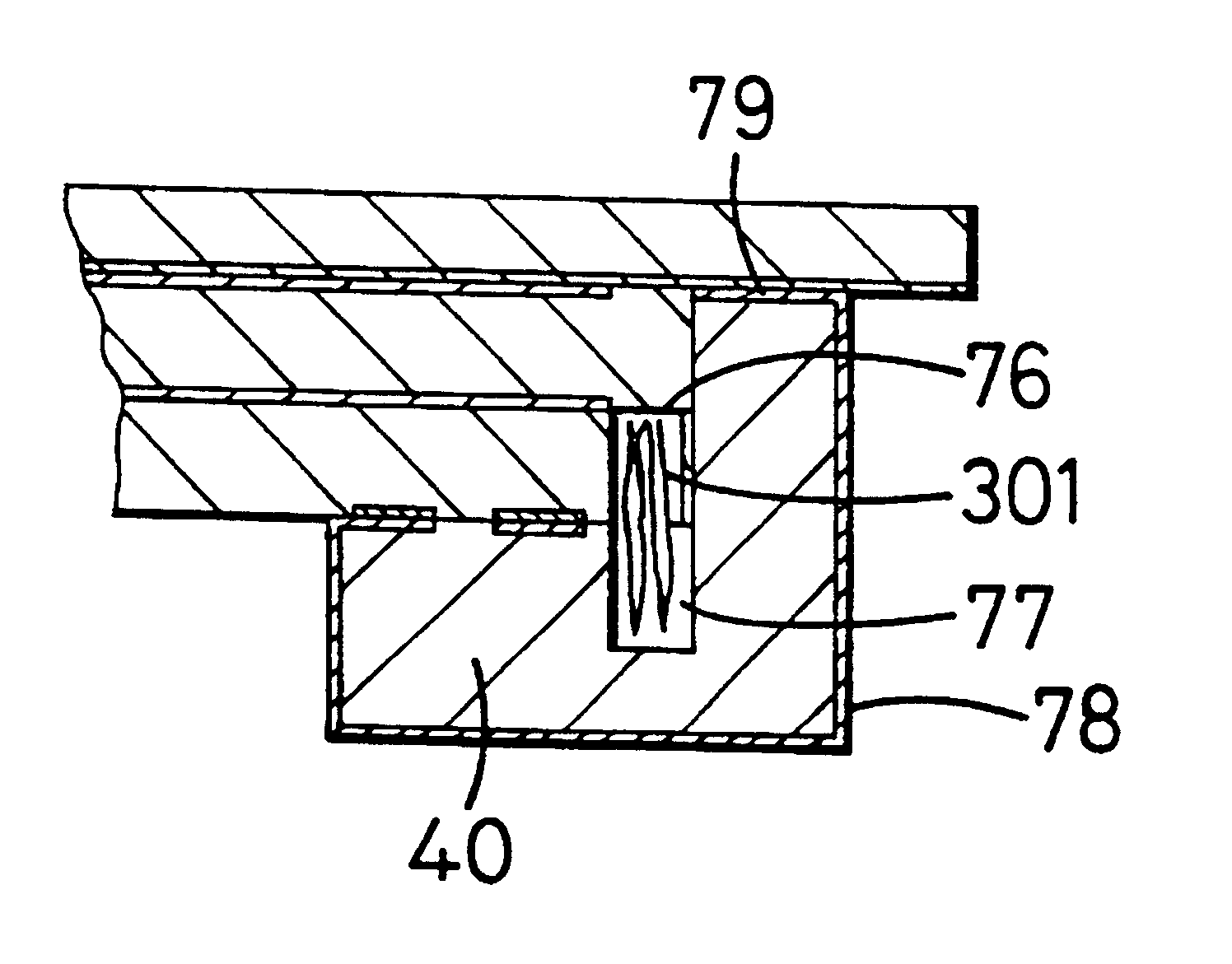

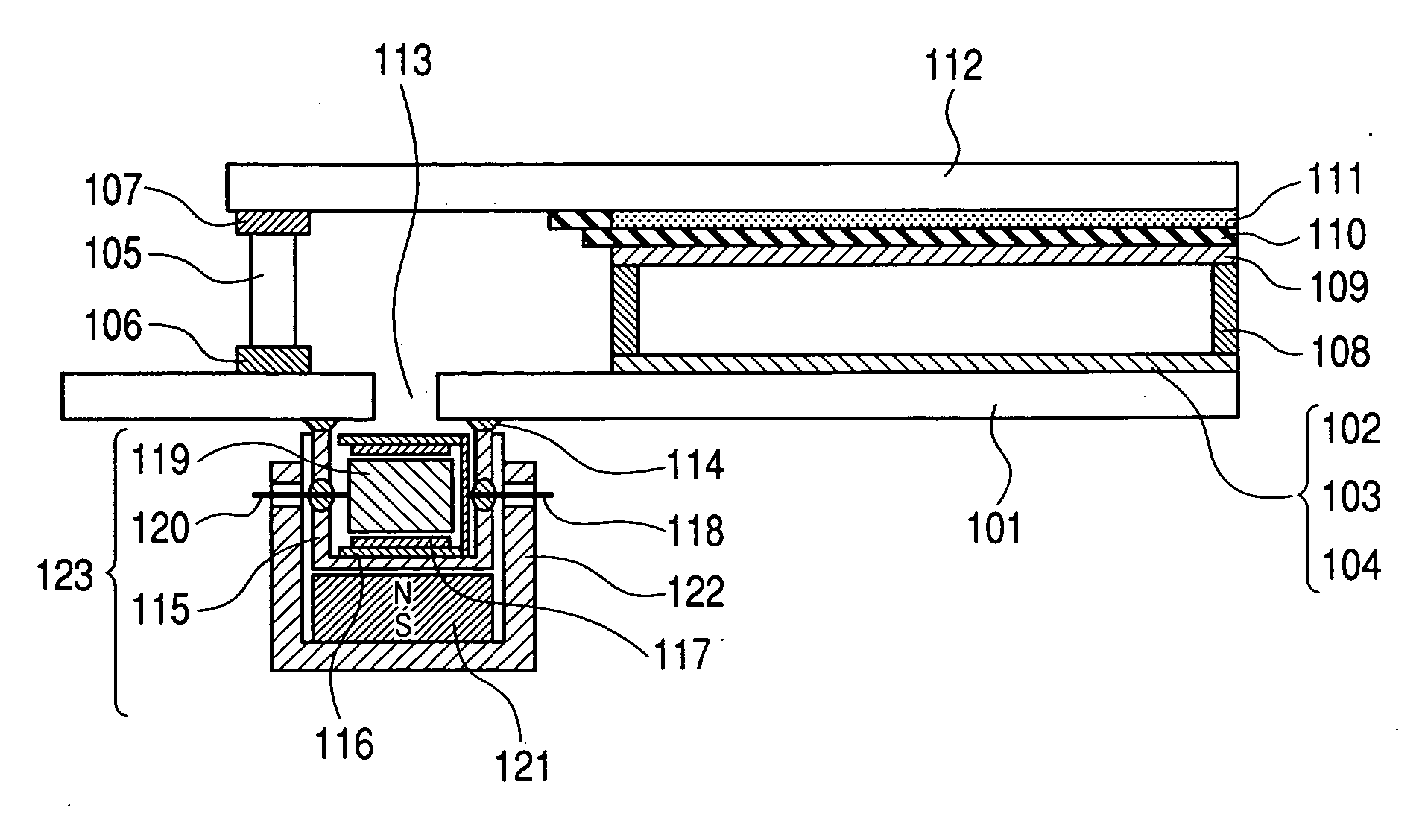

Image display apparatus

InactiveUS20060043871A1Reduce leakageHigh display gradeGas filling substance selectionPump componentsElectron sourceVacuum chamber

An image display apparatus is provided with a vacuum chamber consisting of an electron source substrate and an image display substrate, and an ion pump which is attached to an electron-emitting substrate or the image display substrate and exhausts air from the vacuum chamber by the action of a magnet, wherein the magnet is attached and fixed to the substrate to which the ion pump has been attached. Thereby, the image display apparatus prevents the magnet from applying an excessive force to the ion pump by its weight, and acquires a stable structure without causing a vacuum leak.

Owner:CANON KK

Tablet and exhaust pipe integrated with tablet

InactiveUS20120128904A1Increase productivityDegree of improvementGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFilling ratioBismuth

A tablet comprises a bismuth-based glass and a refractory filler, wherein: (1) the bismuth-based glass comprises, as a glass composition, in terms of mass %, 70 to 90% of Bi2O3, 2 to 12% of B2O3, 0 to 5% of Al2O3, 1 to 15% of ZnO, 0 to 10% of BaO, and 0 to 8% of CuO+Fe2O3; (2) the tablet comprises 1 to 25 vol % of alumina as the refractory filler; and (3) the filling ratio of the tablet is 71% or more.

Owner:NIPPON ELECTRIC GLASS CO LTD

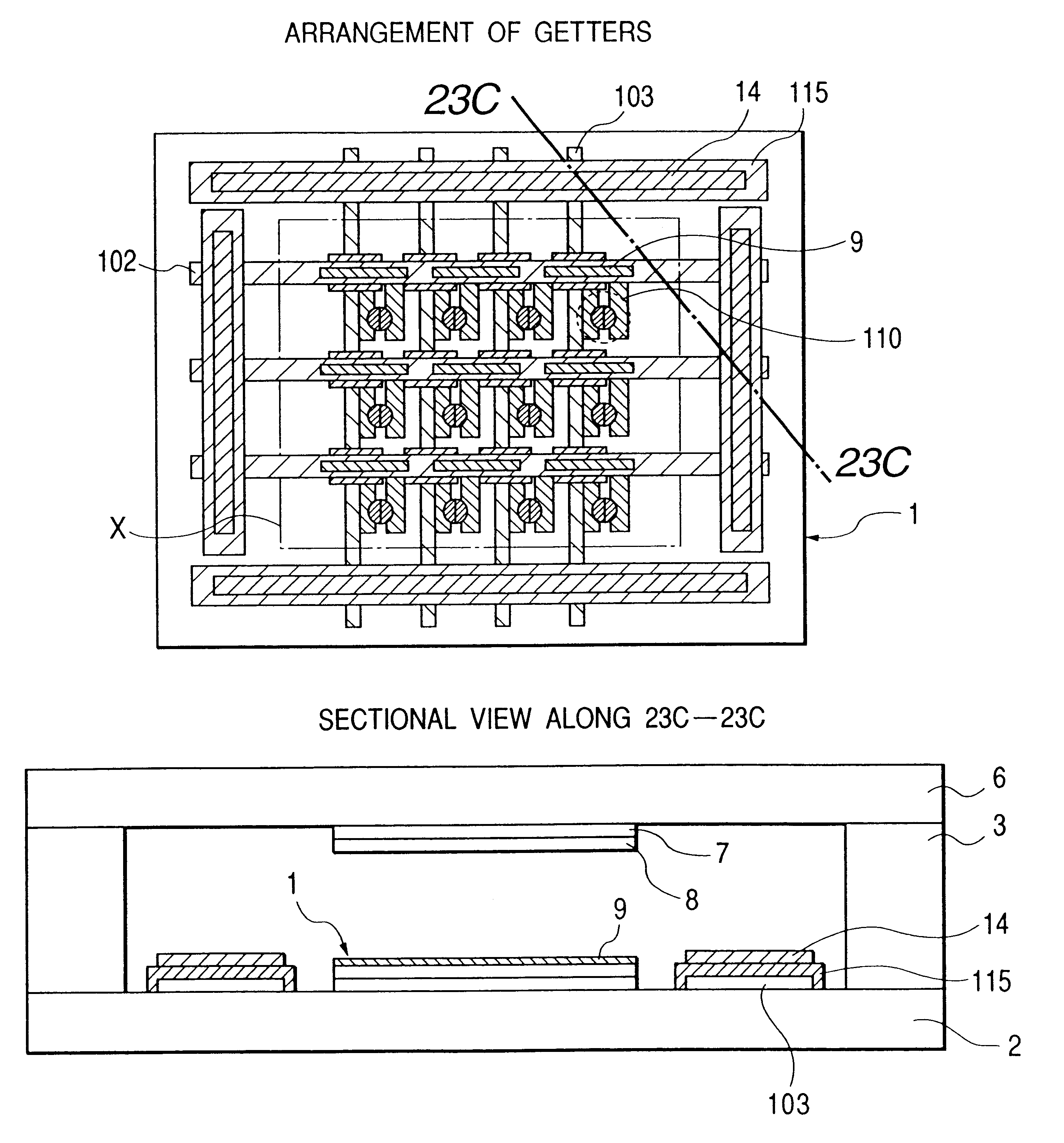

Method for gettering an image display apparatus

InactiveUS6652343B2Little changeLittle unevennessGas filling substance selectionDischarge tube luminescnet screensElectron sourceFluorescence

An image display apparatus is provided with an external housing constituted by members including first and second substrates positioned with a gap therebetween, an electron source positioned on the first substrate in the external housing, and a fluorescent film and an accelerating electrode provided on the second substrate. A first getter is positioned in the image display area in the external housing. A second getter is provided, so that it is insulated from the electron source and the accelerating electrode, which surrounds the first getter.

Owner:CANON KK

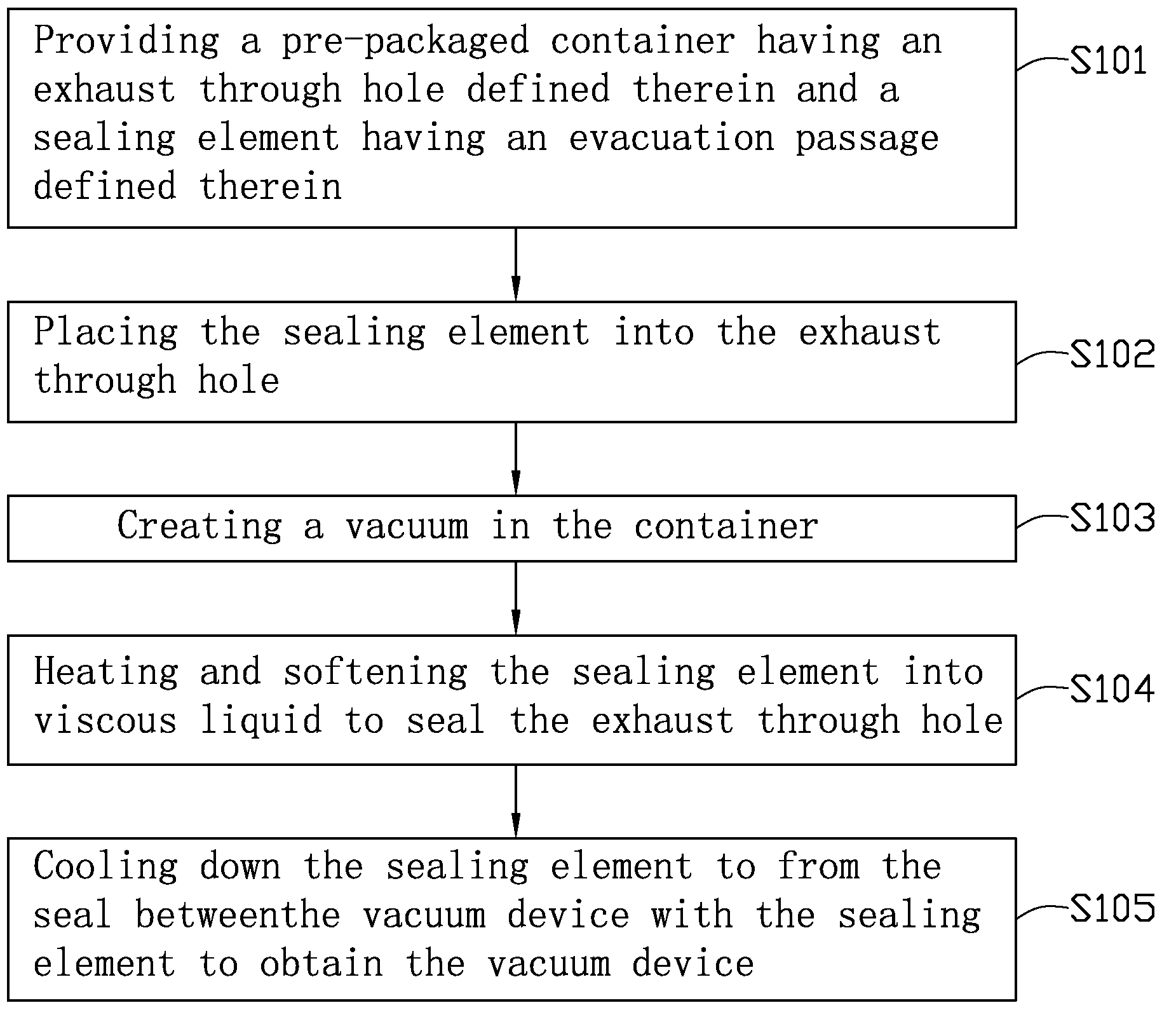

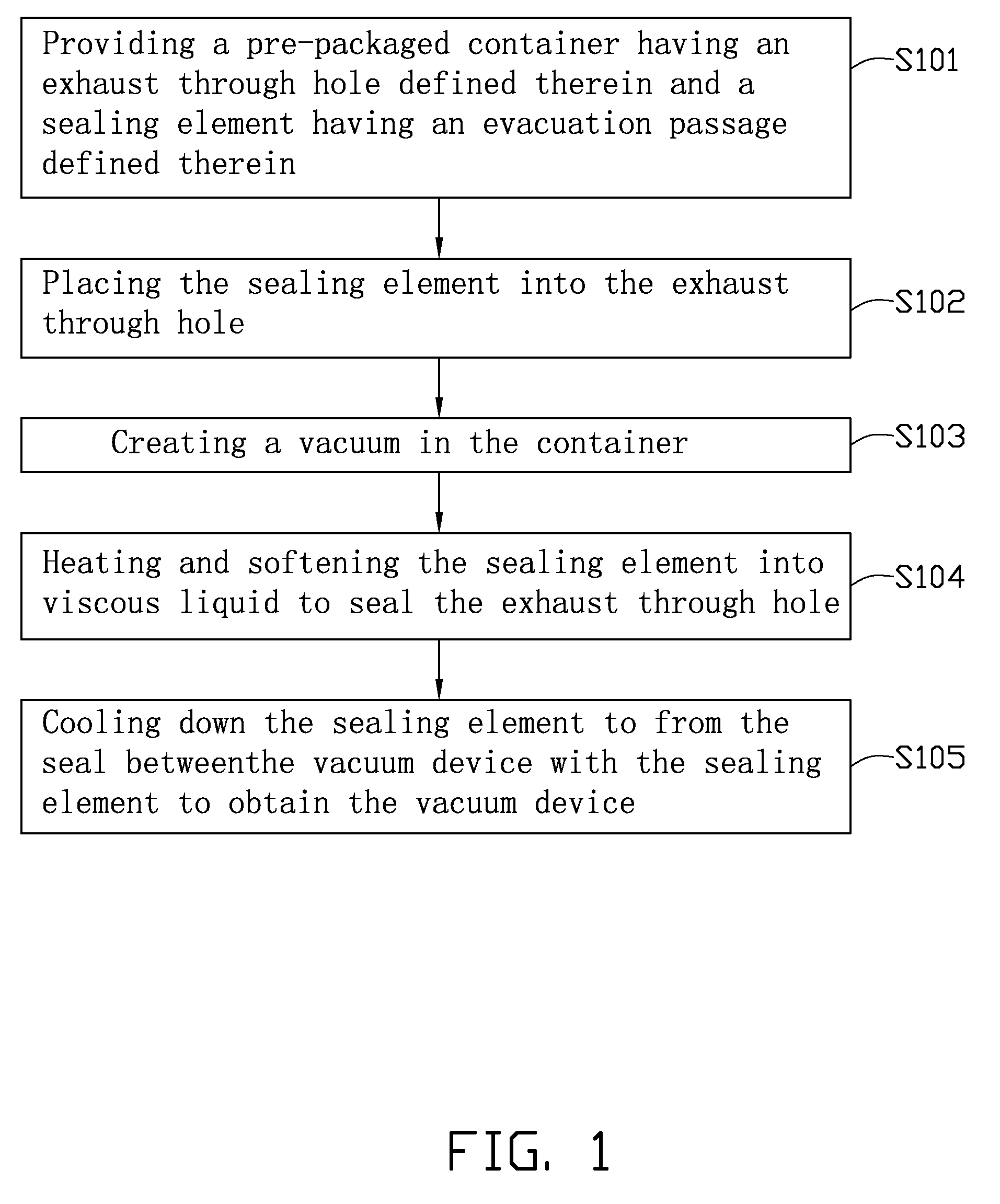

Vacuum device and method for packaging same

A method for packaging the vacuum device includes providing a pre-packaged container having an exhaust through hole defined therein and a sealing element placed into the exhaust through hole, pumping the pre-packaged container to create a vacuum, heating and softening the sealing element to seal the exhaust through hole, and cooling the melted low-melting glass to package the pre-packaged container.

Owner:TSINGHUA UNIV +1

Spiral cold cathode fluorescent lamp

InactiveUS7205712B2Strong enoughLife span of the CCFL is therefore increasedGas filling substance selectionDischarge tube luminescnet screensCelsius DegreePhosphor

A light tube for a cold cathode fluorescent lamp includes a light tube body, anode and cathode disposed in the light tube body and an activated gas absorber. The light tube body contains inert gas, mercury substance and a layer of phosphor coating on its inner surface. The cathode is adapted for electrically connecting to the negative terminal for emitting electrons to excite the mercury substance for conducting the electrons to the anode as an electric circuit, wherein the excited mercury substance emits ultra violet rays causing the phosphor coating to generate visible light. The activated gas absorber is gas absorber made of zirconium-aluminum alloy which can be activated at an activation temperature substantially lower than 900 degrees Celsius, preferably 390 degrees Celsius, to provide stronger oxygenic gas absorption ability while reducing the manufacturing steps and cost.

Owner:TECHN CONSUMER PRODS

Electronic device sealed under vacuum containing a getter and method of operation

InactiveUS7042075B2Gas filling substance selectionSemiconductor/solid-state device detailsEngineeringDielectric layer

An electronic device that is sealed under vacuum includes a substrate, a transistor formed on the substrate, and a dielectric layer covering at least a portion of the transistor. The electronic device further includes a layer of non-evaporable getter material disposed on a portion of the dielectric layer; and a vacuum device disposed on a portion of the substrate. Electrical power pulses activate the non-evaporable getter material.

Owner:SAMSUNG ELECTRONICS CO LTD

Image display apparatus

InactiveUS20060049734A1Reduce brightnessReduce colorGas filling substance selectionDischarge tube luminescnet screensElectron sourceColor shift

It is an object of the present invention to provide an image display apparatus in which the change over time of its electron source characteristics is small, and in which uneven brightness and color shift of an image is almost unnoticeable. To achieve this object, the present invention is directed to an image display apparatus containing an electron source substrate having a plurality of electron-emitting devices arrayed thereon, an image forming substrate arranged so as to face the electron source substrate and having a phosphor film and an anode electrode film, and magnetic field generating means, wherein a component parallel to the electron source substrate of a magnetic flux density of a magnetic field generated by the magnetic field generating means is not greater than 0.01 Tesla at any location of the electron-emitting devices.

Owner:CANON KK +1

Image display apparatus

InactiveUS20060043870A1Reduce magnetic influenceLittle nonuniformity in brightnessGas filling substance selectionElectrode and associated part arrangementsElectron sourceImage formation

An image display apparatus for forming an image in an image displaying region provided with a vacuum chamber having an electron source substrate and an image forming substrate has an ion pump for evacuating the vacuum chamber by an action of a magnet-filed-forming portion through an aperture portion formed in the electron source substrate or an image displaying substrate, wherein the magnet-filed-forming portion is arranged so that a shadow formed by perpendicularly projecting the magnet-filed-forming portion onto the electron source substrate or the image forming substrate can be located outside the image displaying region.

Owner:CANON KK

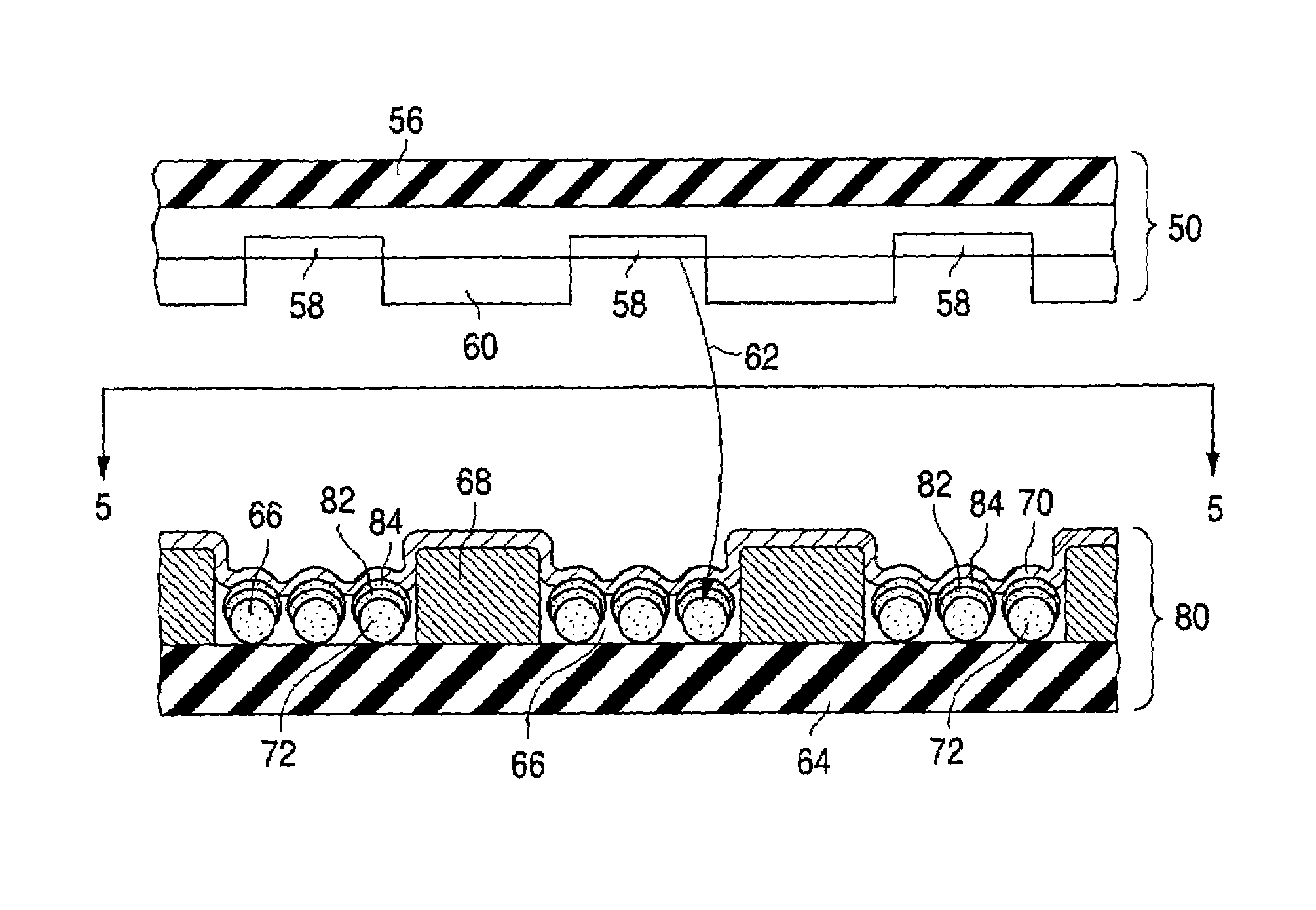

Light-emitting device having light-emissive particles partially coated with intensity-enhancement material

InactiveUS7002289B1Improve performanceExtended service lifeGas filling substance selectionIncadescent screens/filtersDisplay deviceLight emitting device

A light-emitting device (52) suitable for a flat-panel cathode-ray tube display contains a light-emissive region (66) formed over a plate (64). The light-emissive region contains a plurality of light-emissive particles (72). Part of the outer surface of each of a group of the light-emissive particles is conformally covered with a group of intensity-enhancement coatings (82 and 84).

Owner:CANON KK

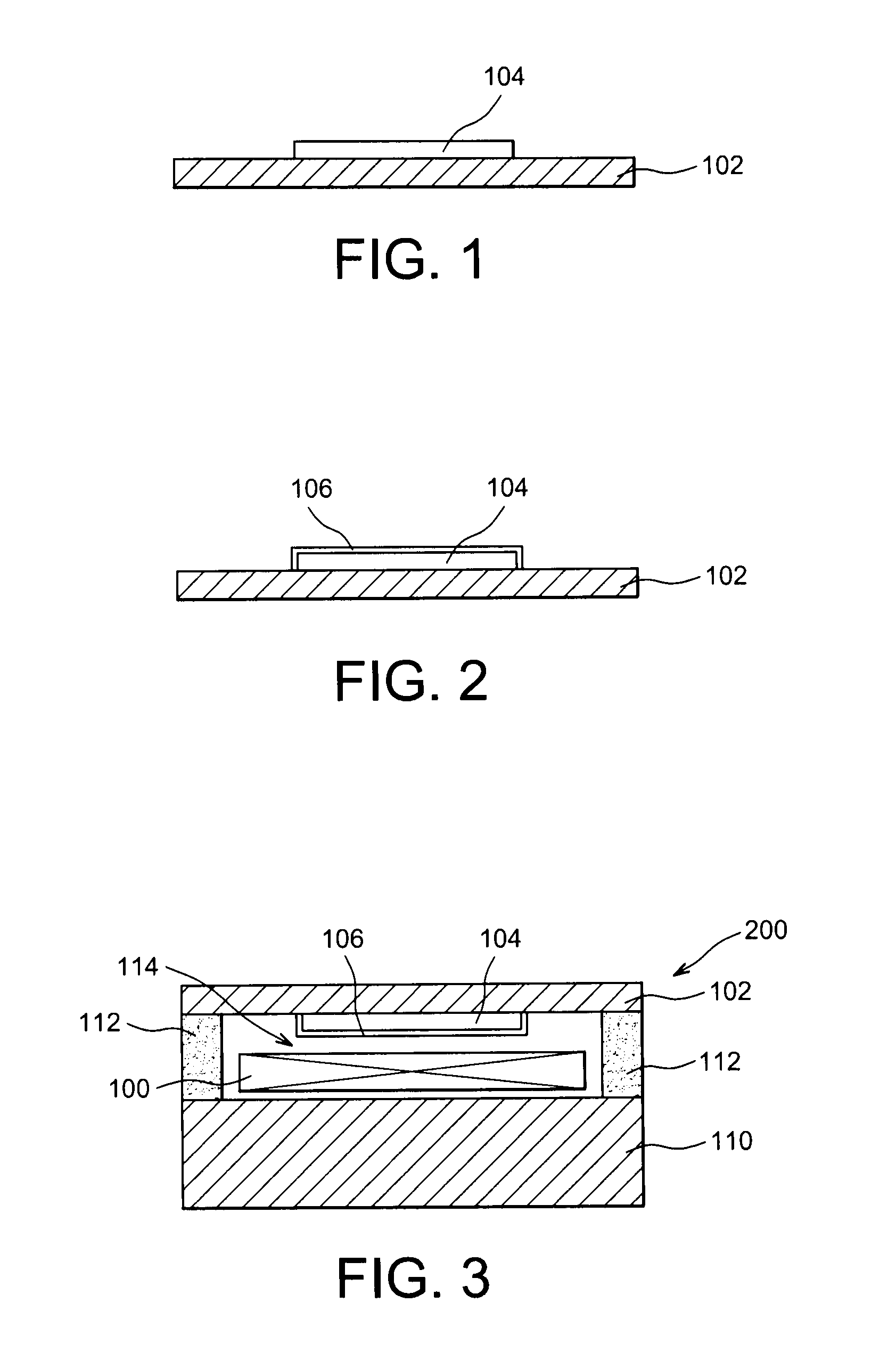

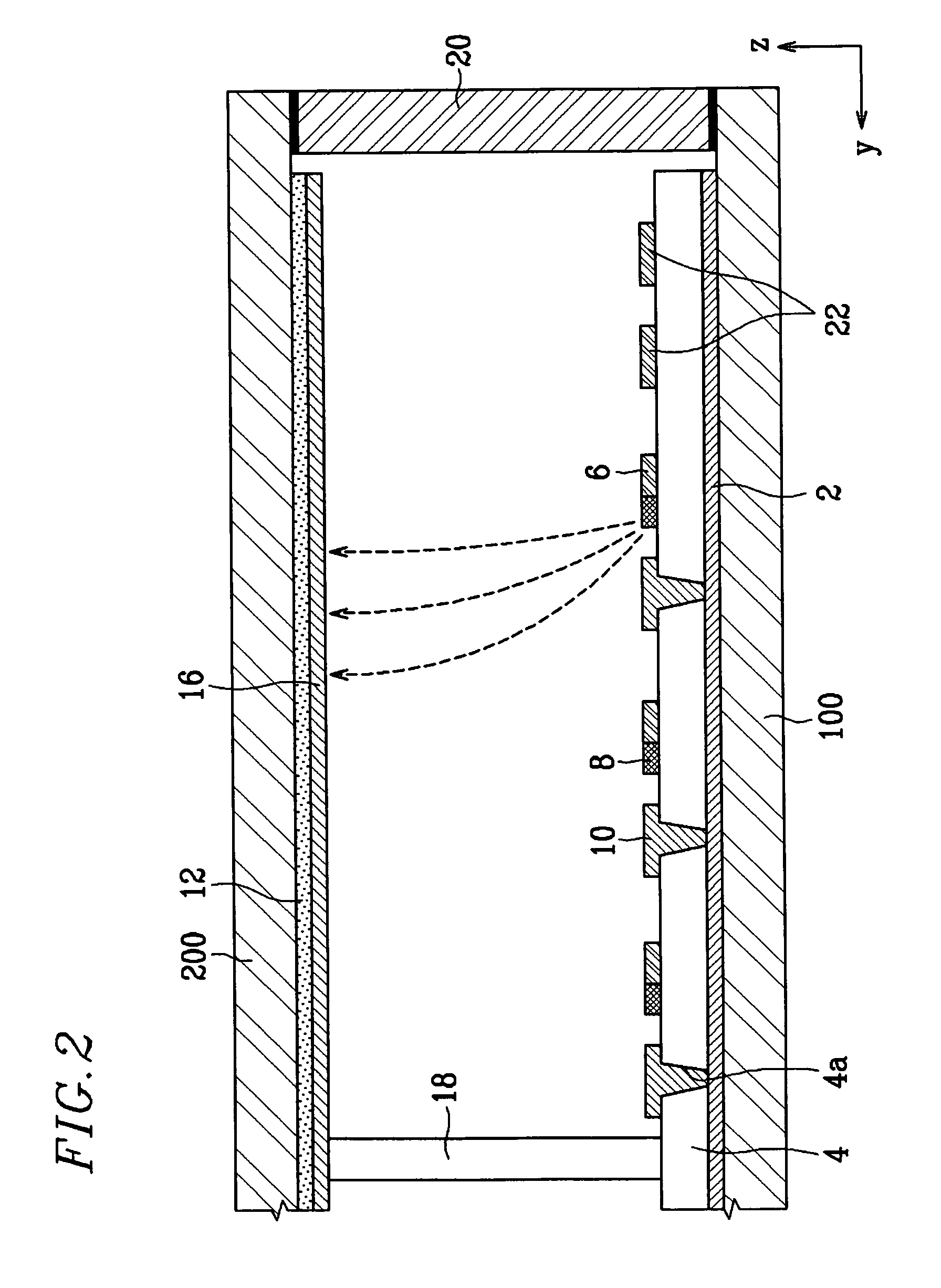

Light emission device and display device using the light emission device as a light source

InactiveUS20080265770A1Gas filling substance selectionDischarge tube luminescnet screensDisplay deviceLight emission

A light emission device having an evaporating getter unit and a display device utilizing the light emission device as a light source. The light emission device includes a vacuum vessel having first and second substrates facing each other and a sealing member, the first and second substrates having an active area and a non-active area, an electron emission unit located on the first substrate at the active area, a light emission unit located on the second substrate at the active area, a getter unit provided between the first and second substrates at the non-active area, and a barrier disposed between the getter unit and the active area. The barrier blocks diffusion of getter material toward the active area during the getter activating process and prevents (or reduces) a slip or a movement of the getter unit.

Owner:SAMSUNG SDI CO LTD

Method for producing an image display apparatus

InactiveUS20020109460A1Little change with timeTime is unevenGas filling substance selectionDischarge tube luminescnet screensElectron sourceFluorescence

An image display apparatus is provided with an external housing constituted by members including first and second substrates positioned with a gap therebetween, an electron source positioned on the first substrate in the external housing, and a fluorescent film and an accelerating electrode provided on the second substrate. A first getter is positioned in the image display area in the external housing. And a second getter is so provided as to be insulated from the electron source and the accelerating electrode and as to surround the first getter.

Owner:CANON KK

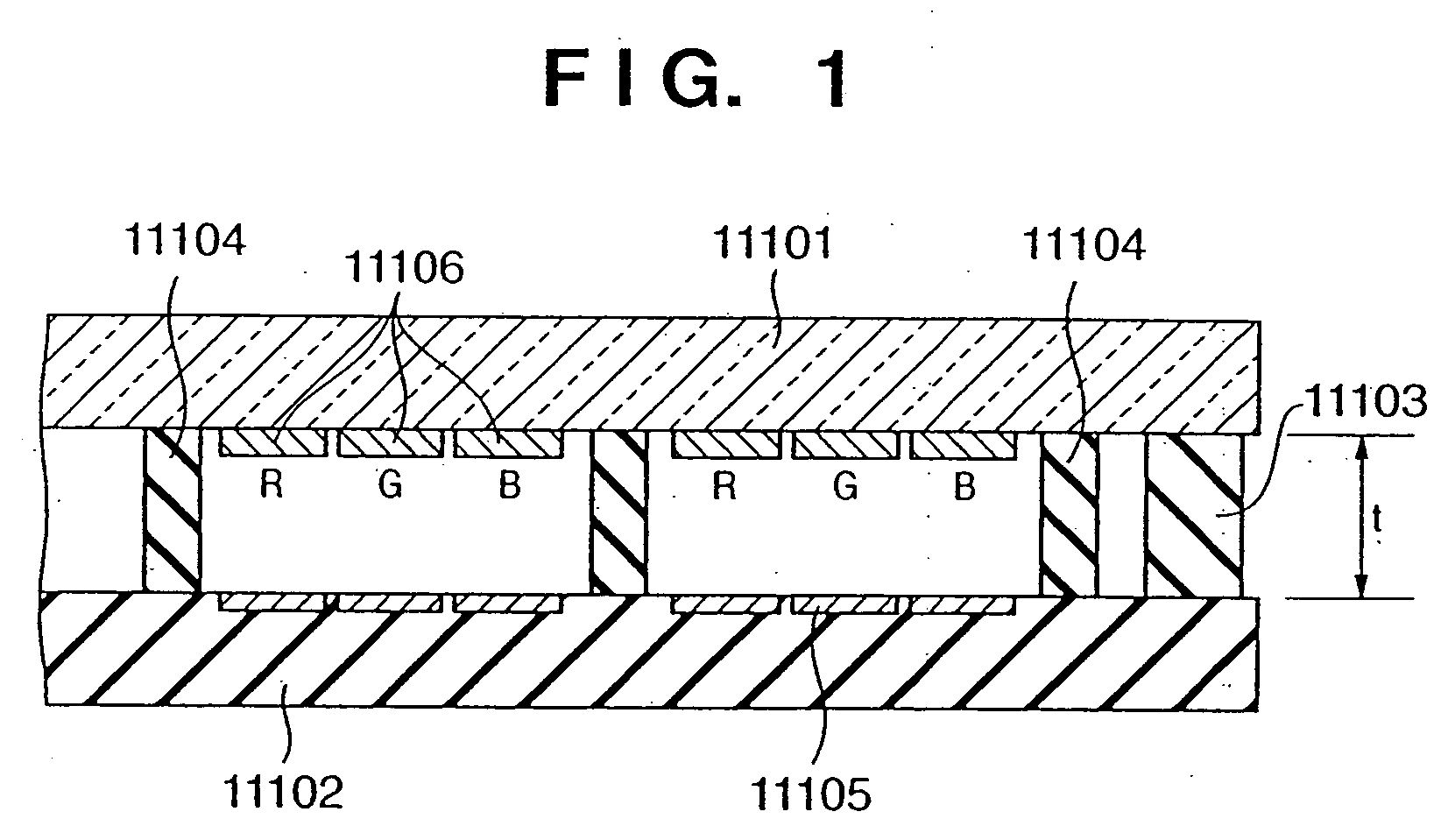

Image display device and method of manufacturing the same

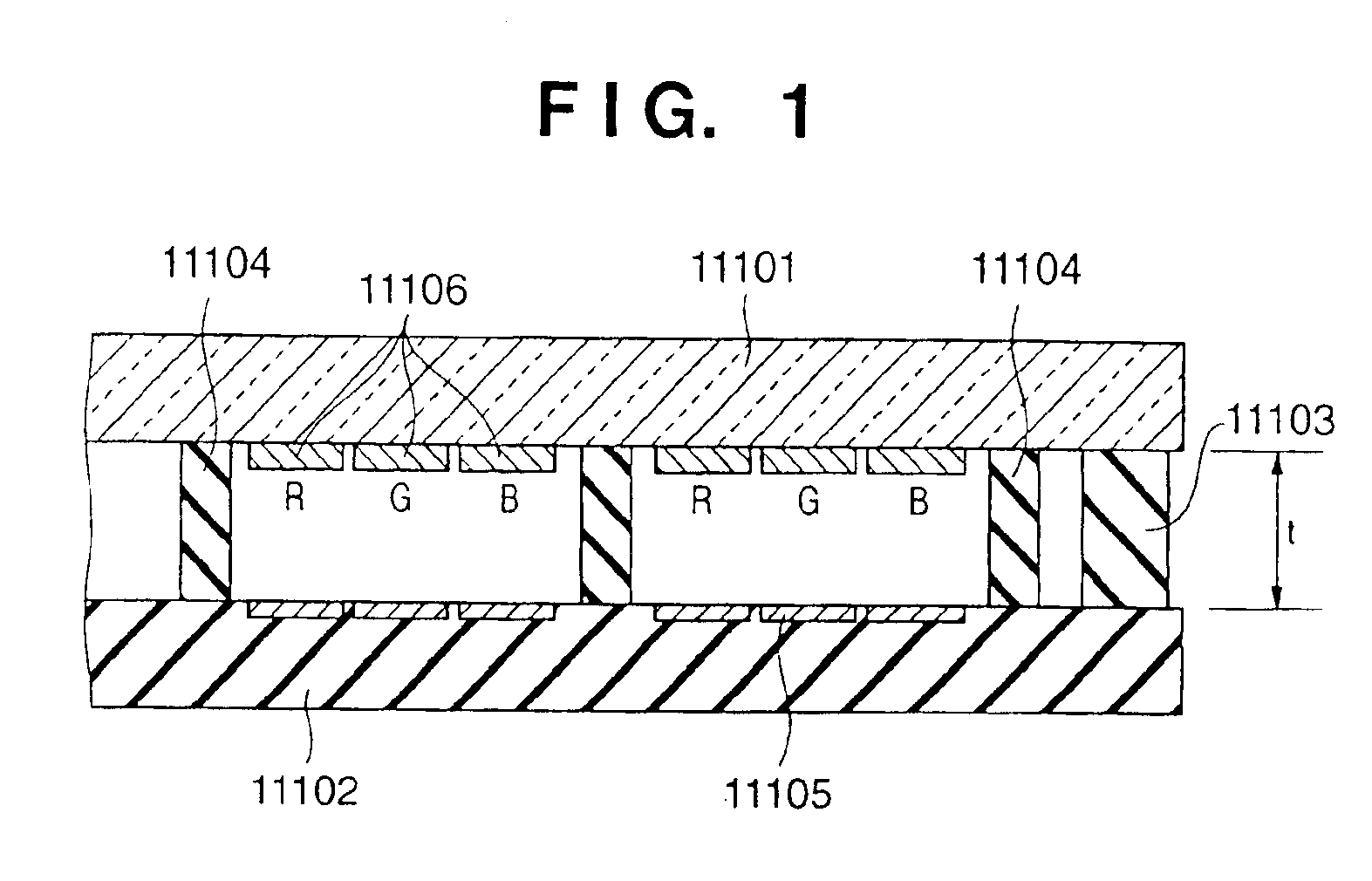

InactiveUS7091662B2Less luminanceLess deteriorationGetteringGas filling substance selectionElectron sourceVacuum level

In an image display device having in an airtight container an electron source and an image display member that receives electrons from the electron source, an evaporating getter and a non-evaporating getter are stacked in the airtight container. This makes it possible to maintain the vacuum level in the airtight container. The image display device thus obtains a prolonged life and a stable display operation.

Owner:CANON KK

Light emission device and display device using the light emission device as a light source

InactiveUS20090001871A1Degree of improvementImprove adsorption efficiencyGas filling substance selectionDischarge tube luminescnet screensPhosphorDisplay device

A light emission device, which can enhance degree of vacuum in a vacuum vessel by increasing an adsorption efficiency of a getter, and a display device using the light emission device for a light source are provided. The light emission device includes a vacuum vessel having first and second substrates facing each other with a predetermined distance therebetween, and a sealing member disposed between the first and second substrates and enclosing an inner space formed between the first and the second substrates. An electron emission unit is located on one side of the first substrate and having a plurality of electron emission regions. A light emission unit is located on one side of the second substrate and having an anode electrode and a phosphor layer. A getter layer is disposed on an inner surface of the sealing member that faces an inner space of the vacuum vessel.

Owner:SAMSUNG SDI CO LTD

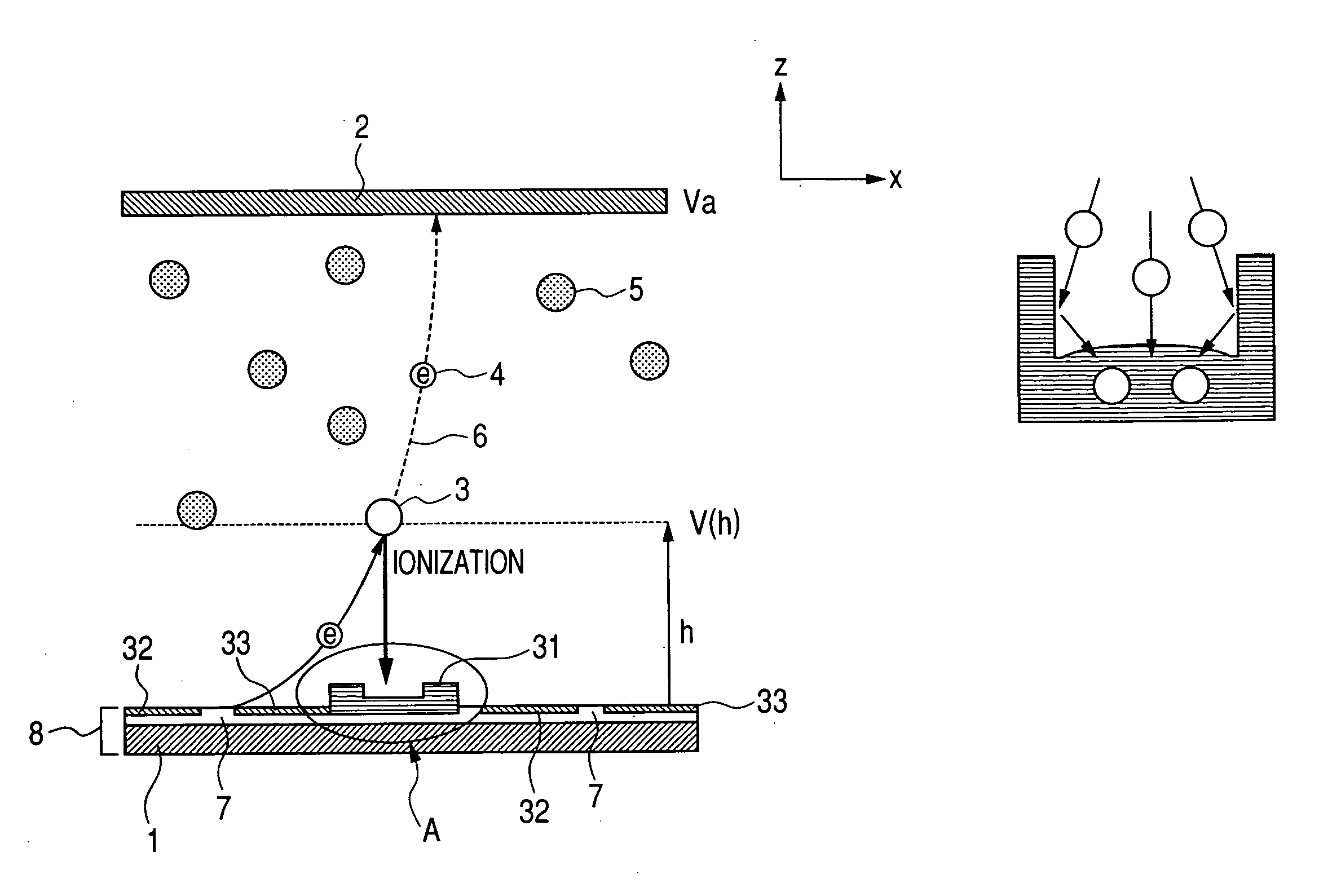

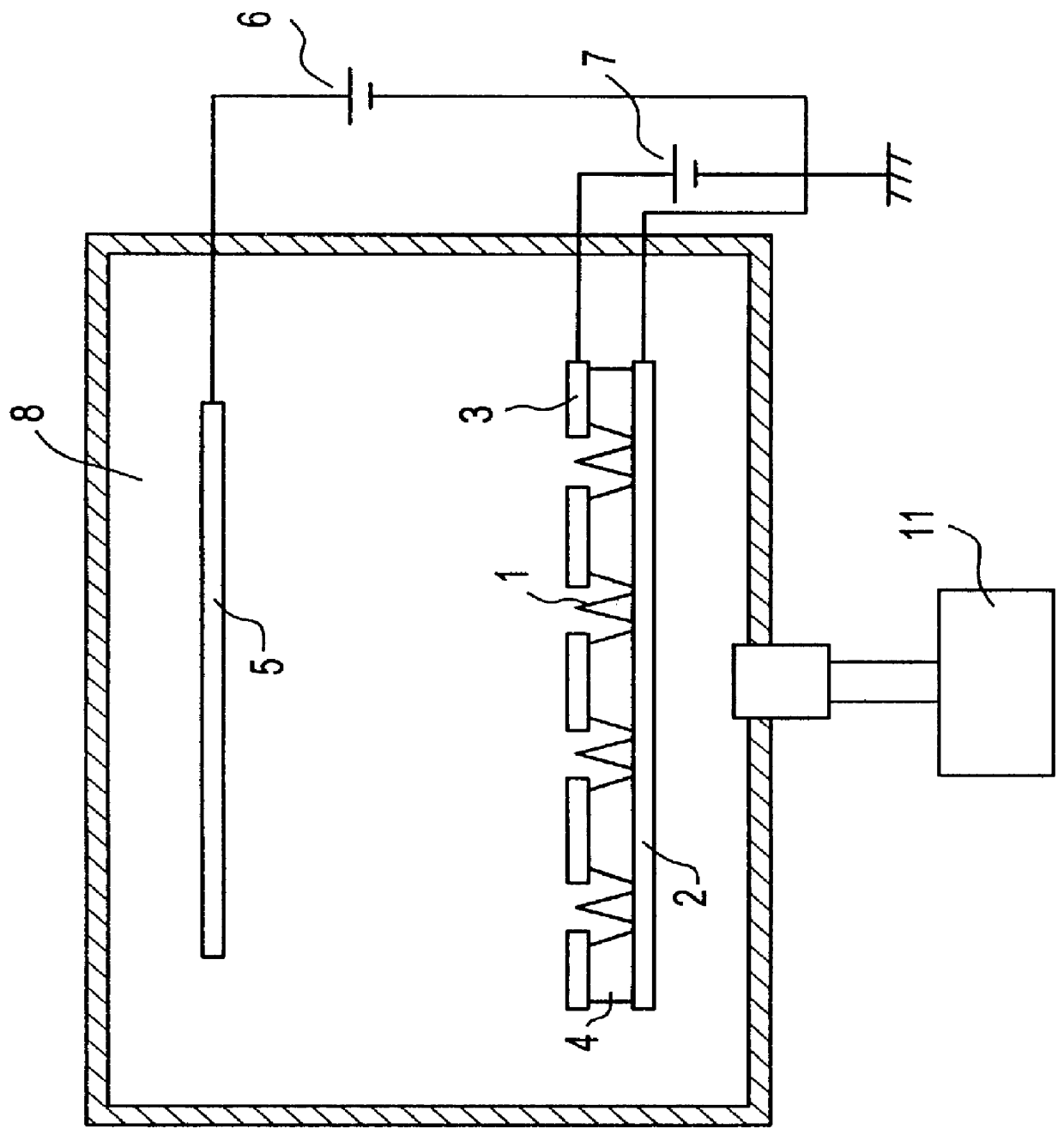

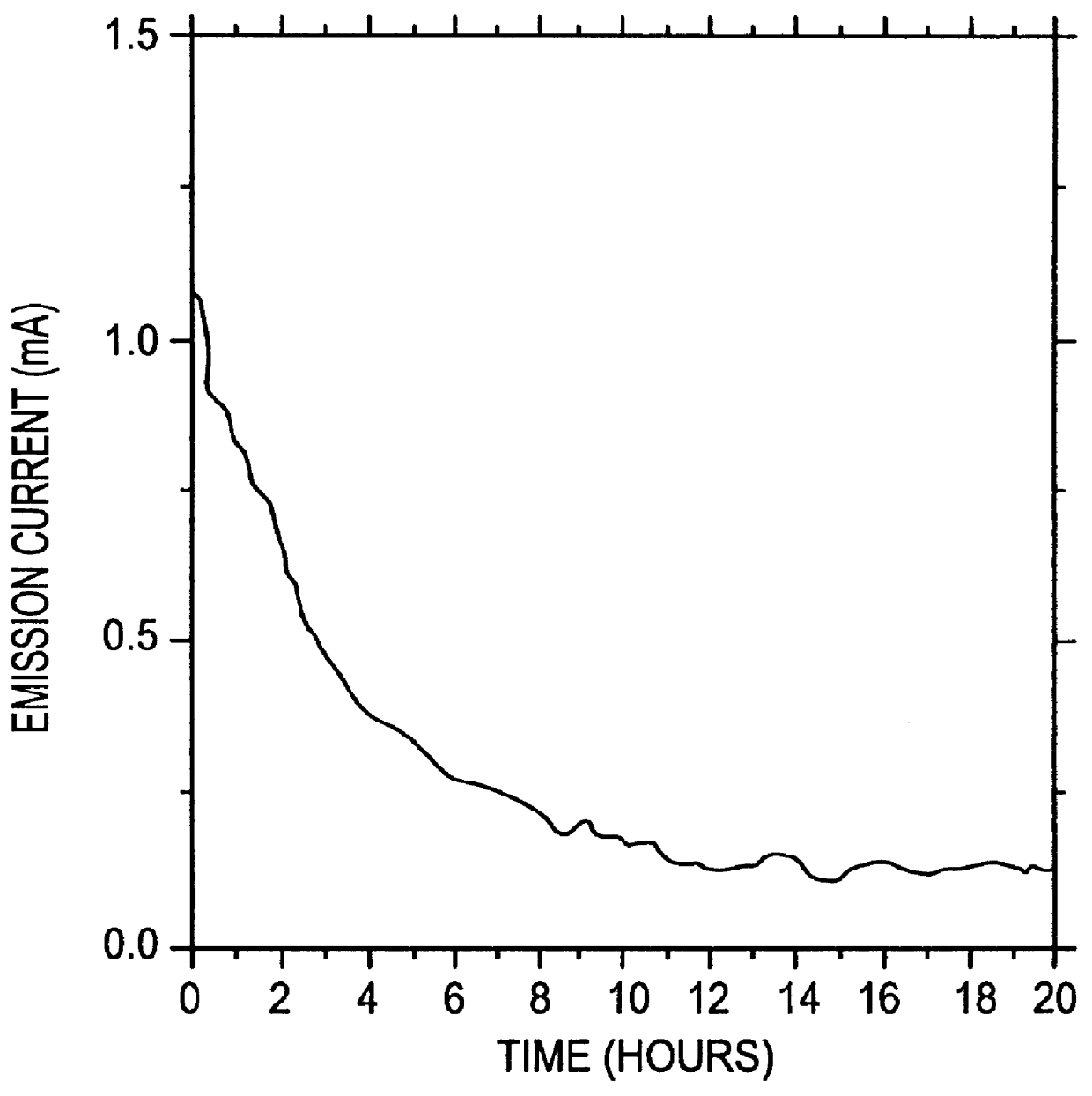

Device having field emission type cold cathode and vacuum tank exhausting method and system in the same

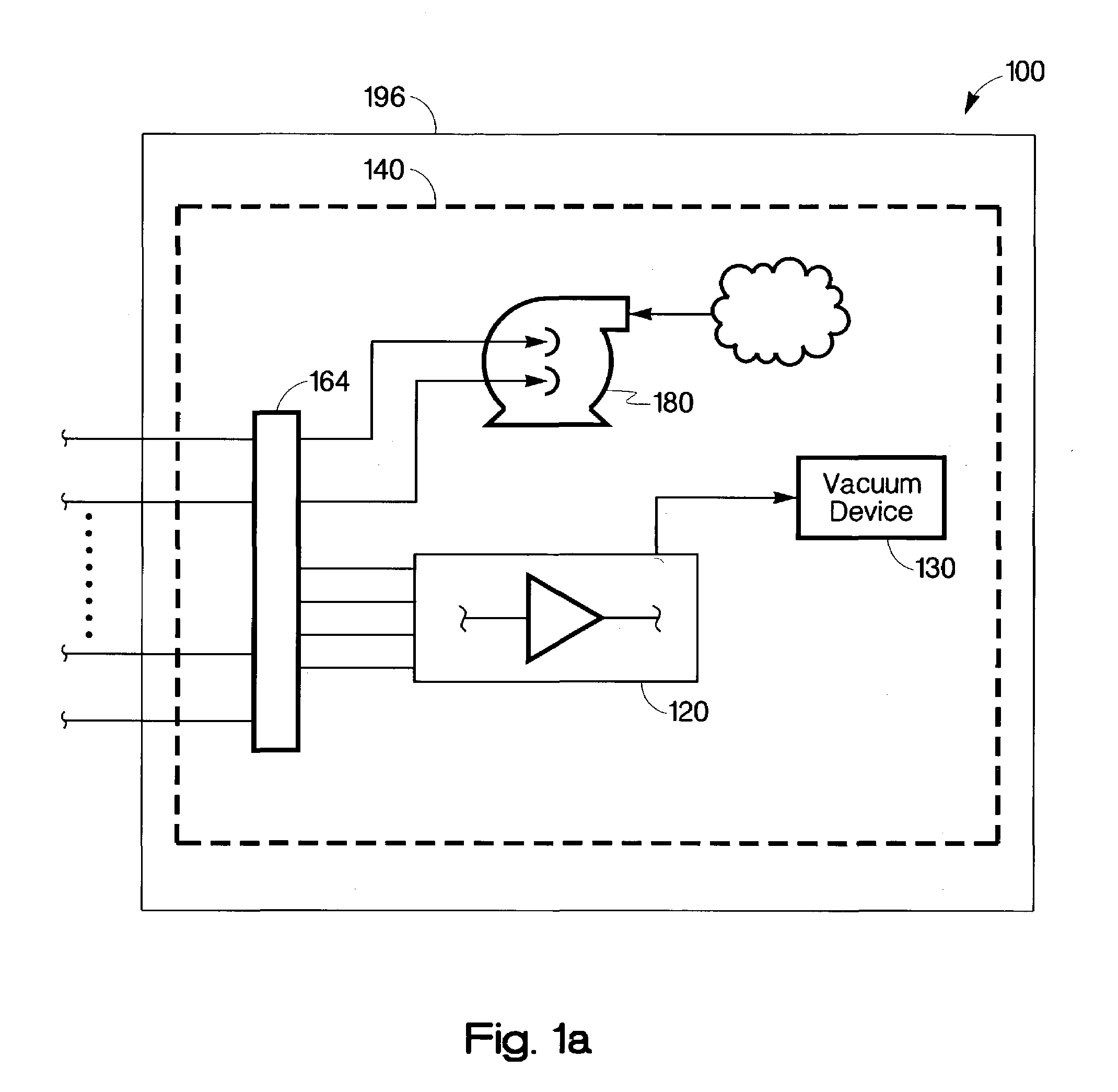

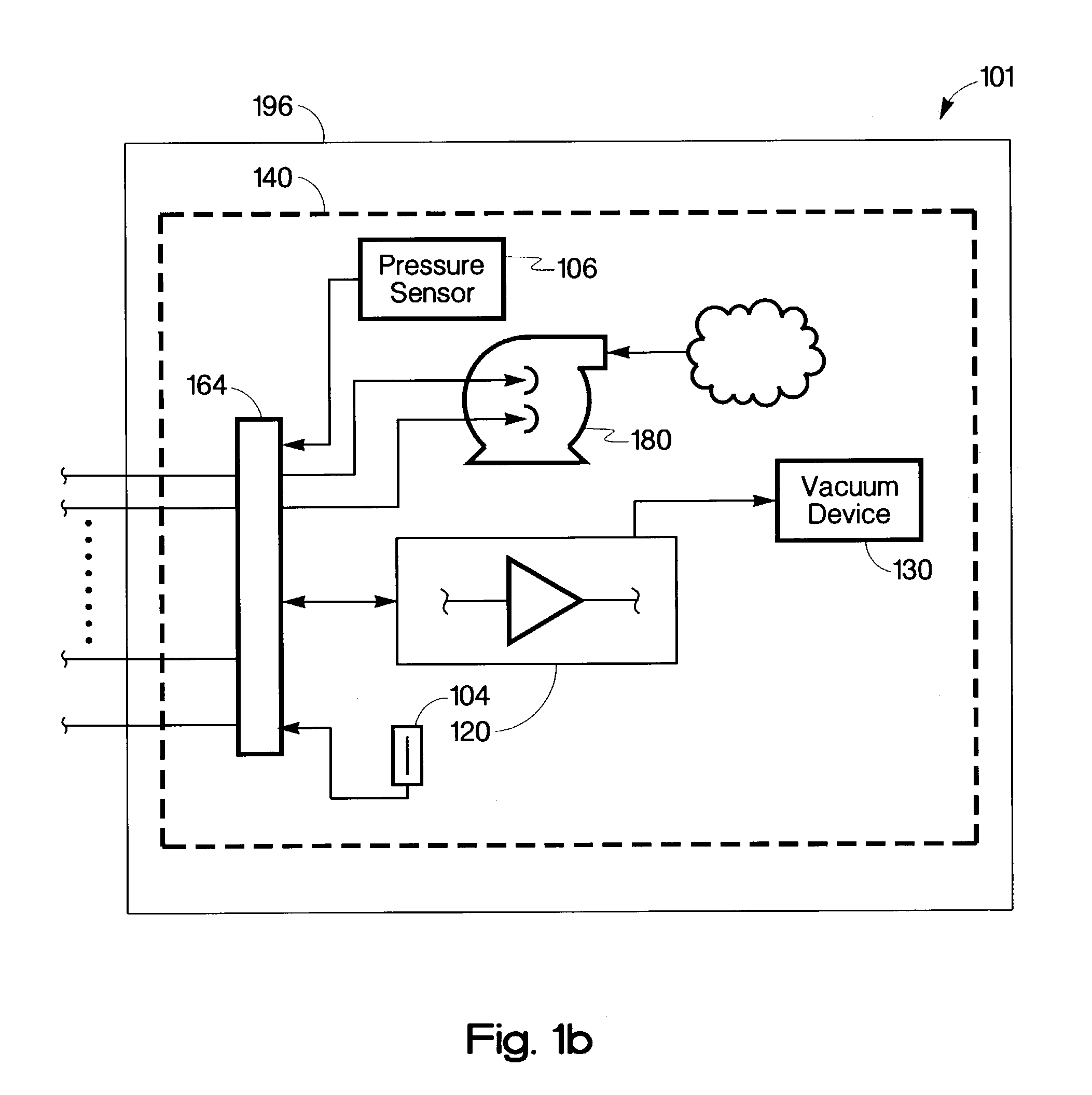

The present invention discloses a field emission type cold cathode incorporated device, which comprises a field emission type cold cathode having a number of electron emitting sections, said sections having sharp projections, and a vacuum tank for placing the field emission type cold cathode in a vacuum environment. In this device, a partial pressure of particular noble gas in residual gas contained in the vacuum tank is set equal to or lower than C / I (C is a constant and I is a maximum emission current value per one of the number of electron emitting sections during driving of the field emission type cold cathode). Also, in order to set a partial pressure of the particular noble gas in the residual gas contained in the vacuum tank equal to C / I (C: constant) or lower, a partial pressure of the particular residual gas in the vacuum tank is monitored by a mass analyzer during vacuum tank exhaustion.

Owner:NEC CORP

Display Device

InactiveUS20080315748A1High voltageImprove reliabilityCathode-ray/electron-beam tube electrical connectionGas filling substance selectionContact pressureAnode voltage

There is disclosed an FED (field emission display) capable of supplying an anode voltage, which is a high voltage, to an anode substrate with high reliability. A high voltage introduction button is sealed to a sealing plate, in which a contact spring is attached to the high voltage introduction button by spot welding. The high voltage introduction button has a flat portion connected to the contact spring, a sealing portion sealed to the glass substrate, and an external terminal to be connected to an external power source. The contact spring contacts an anode terminal of an anode substrate with an appropriate contact pressure, by a spring force from an arm portion of the contact spring. The anode terminal is formed of a conductive film containing metal particles.

Owner:HITACHI LTD

Electron emission device including dummy electrodes

InactiveUS20050140269A1Avoid signal distortionScreen quality is deterioratedGas filling substance selectionDischarge tube luminescnet screensPhosphorElectron

An electron emission device having various functional electrodes in addition to the electrodes serving to emit electrons includes: first and second substrates facing each other, and cathode and gate electrodes arranged on the first substrate within an effective electron emission area and including an insulating layer interposed therebetween. The electron emission regions are electrically connected to the cathode electrodes. At least one dummy electrode is arranged external to the effective electron emission area. At least one anode electrode is arranged on the second substrate. Phosphor layers are arranged on one surface of the anode electrode.

Owner:SAMSUNG SDI CO LTD

Popular searches

Cathode-ray/electron-beam tube leading-in arrangements Picture reproducers using solid-state color display Incadescent body mountings/support Electrode assembly support/mounting/spacing/insulation Lamp details Image/pattern display tubes Cathode-ray tube indicators Mounting/support/spacing/insulation of electrode assemblies Thermionic cathodes Discharge tube solid thermionic cathodes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com