Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about "Cathode-ray/electron-beam tube leading-in arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

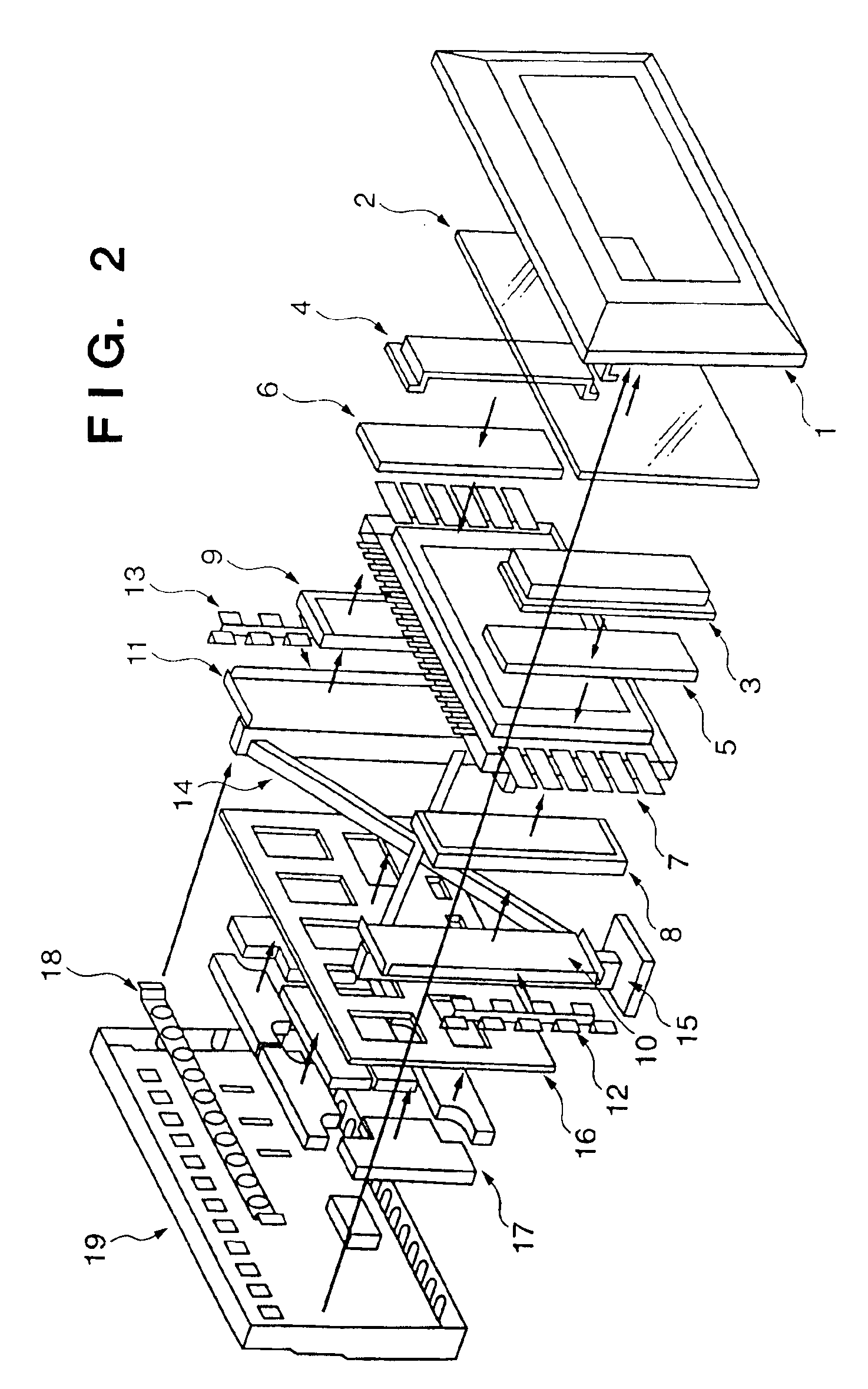

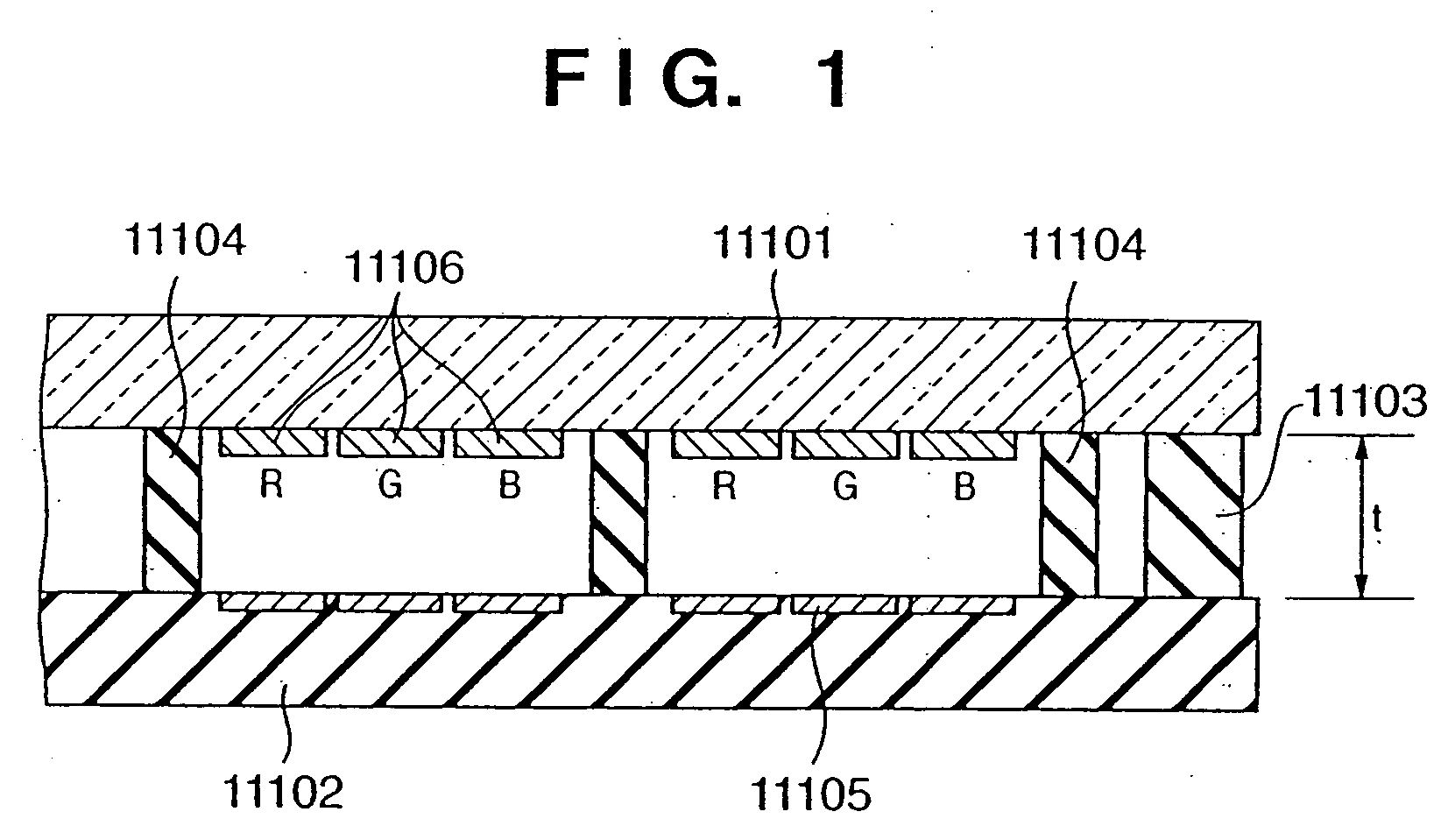

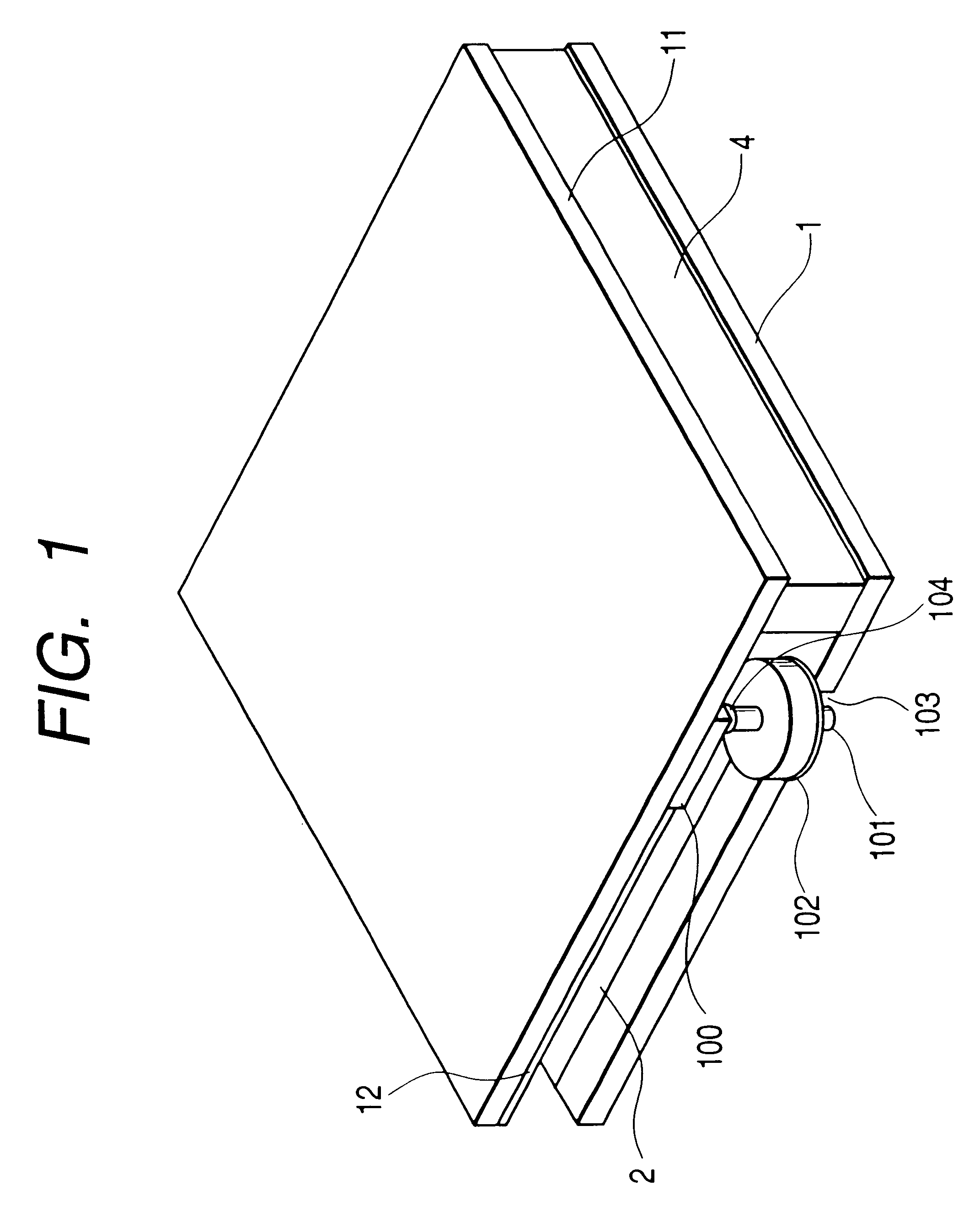

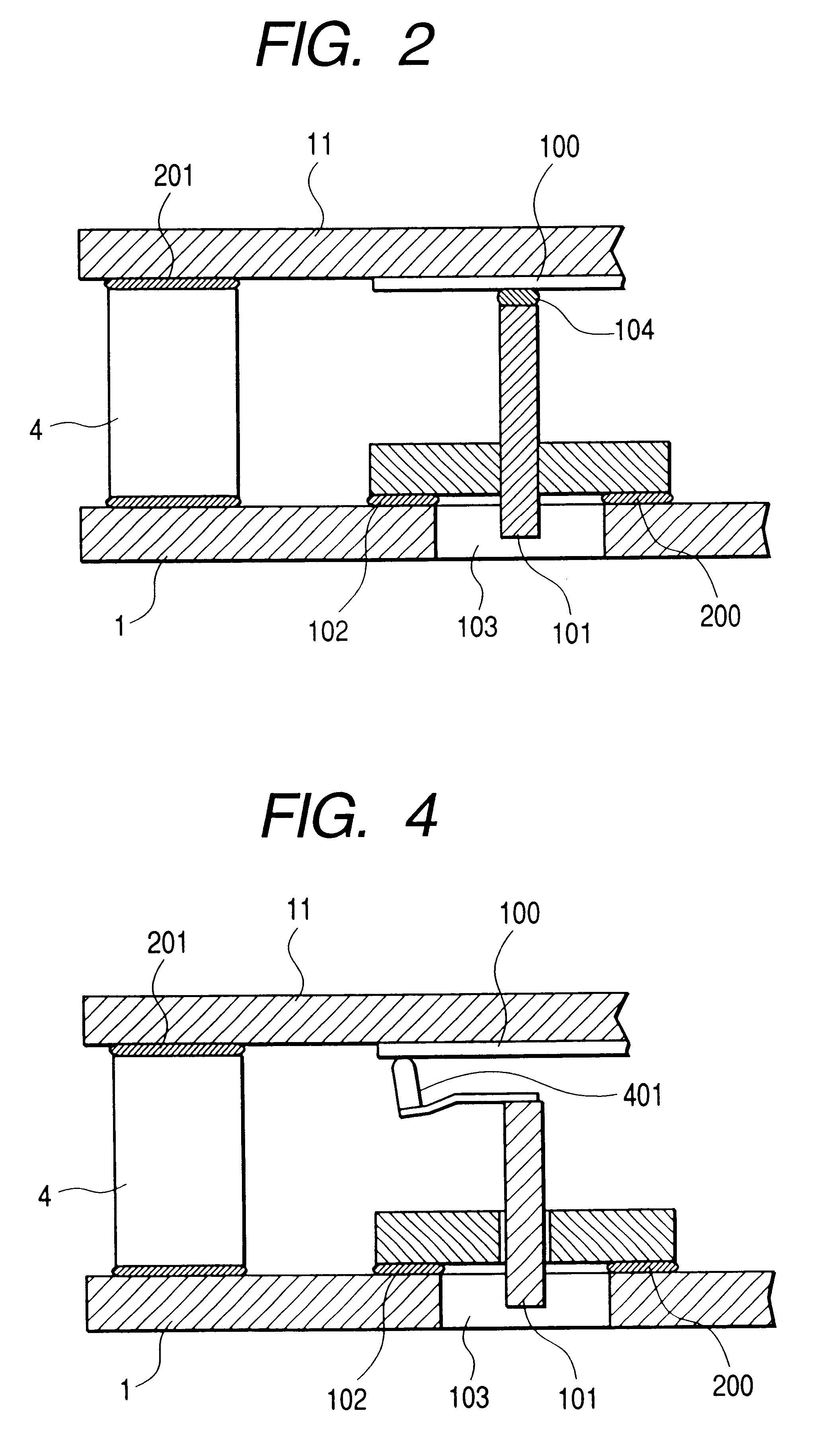

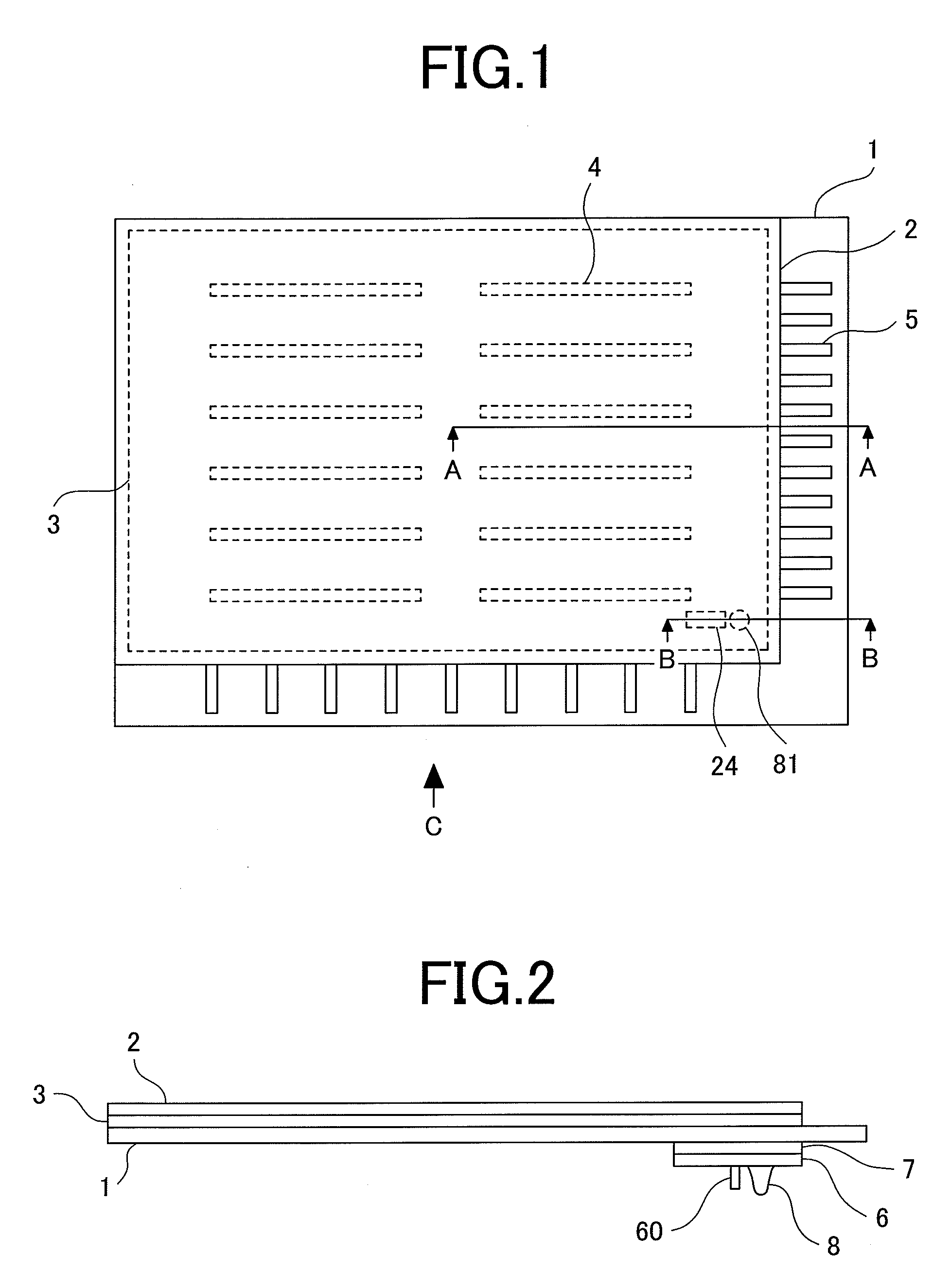

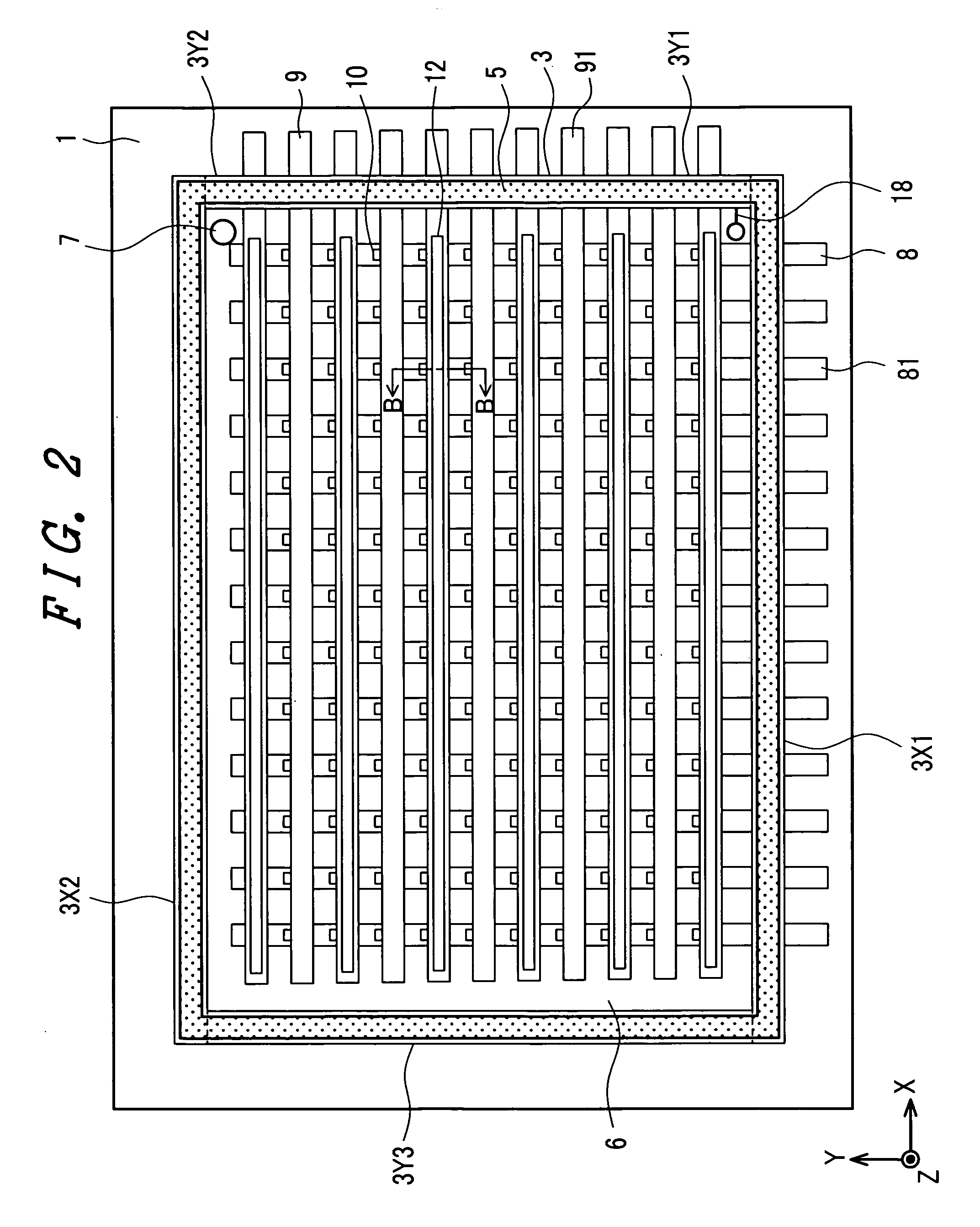

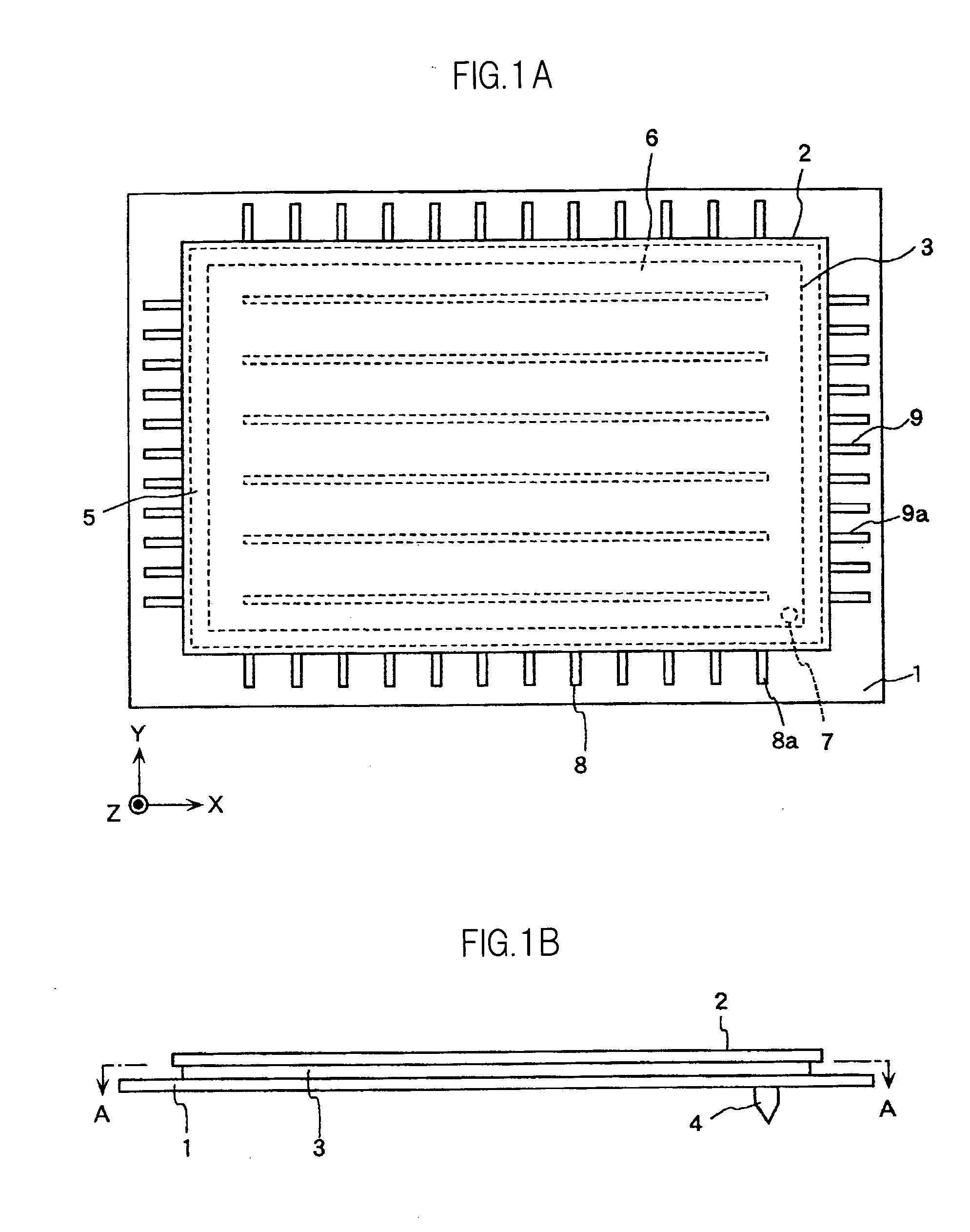

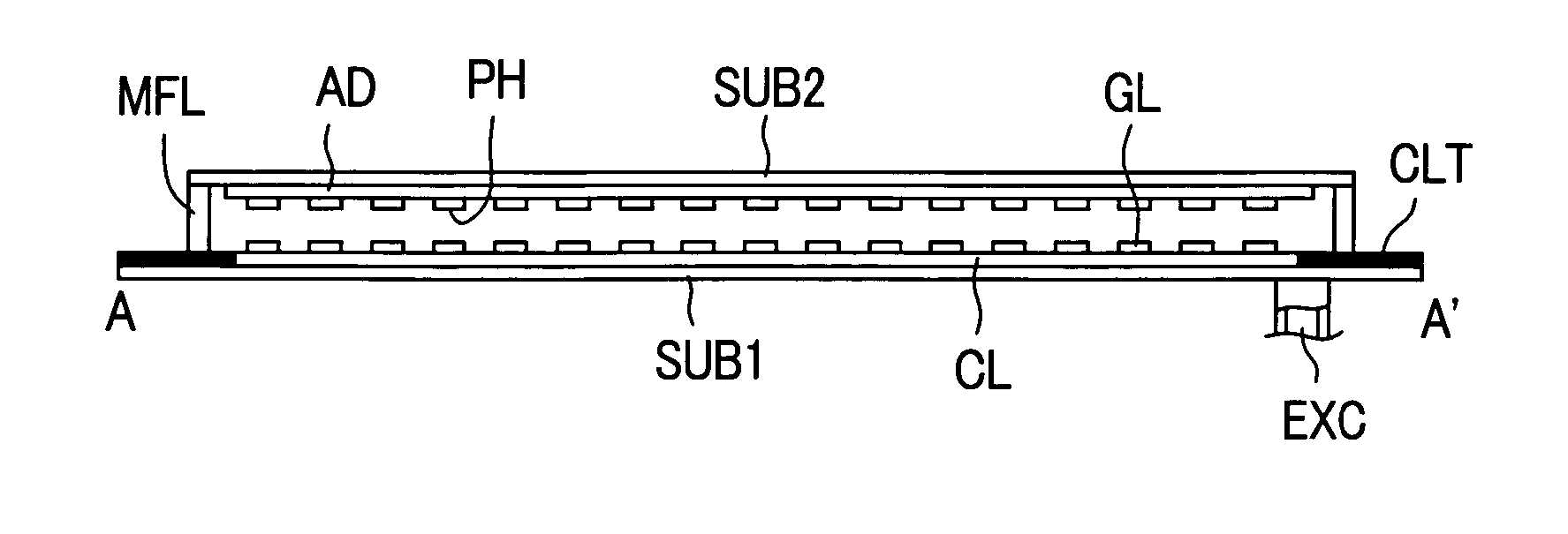

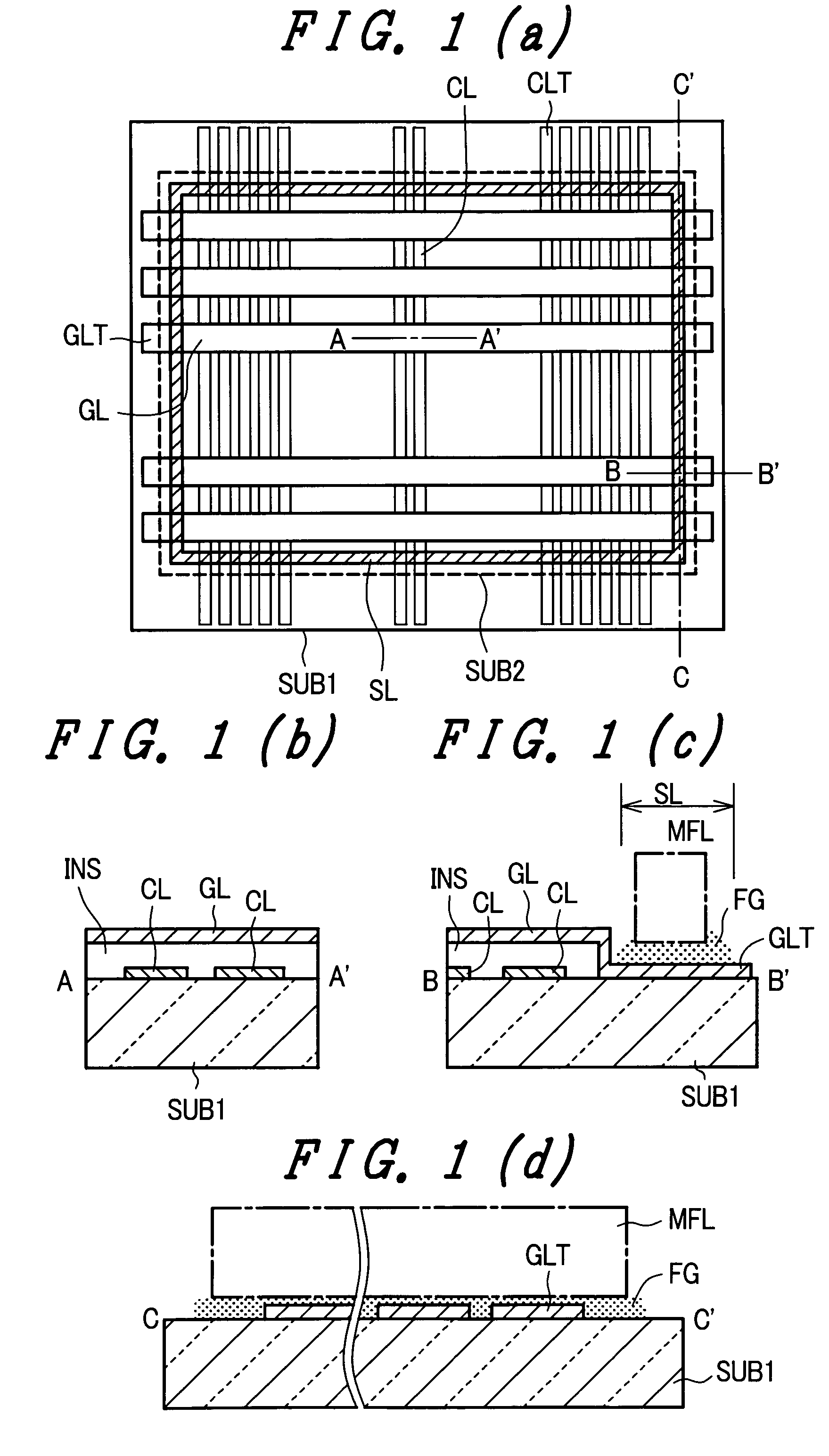

Image formation apparatus

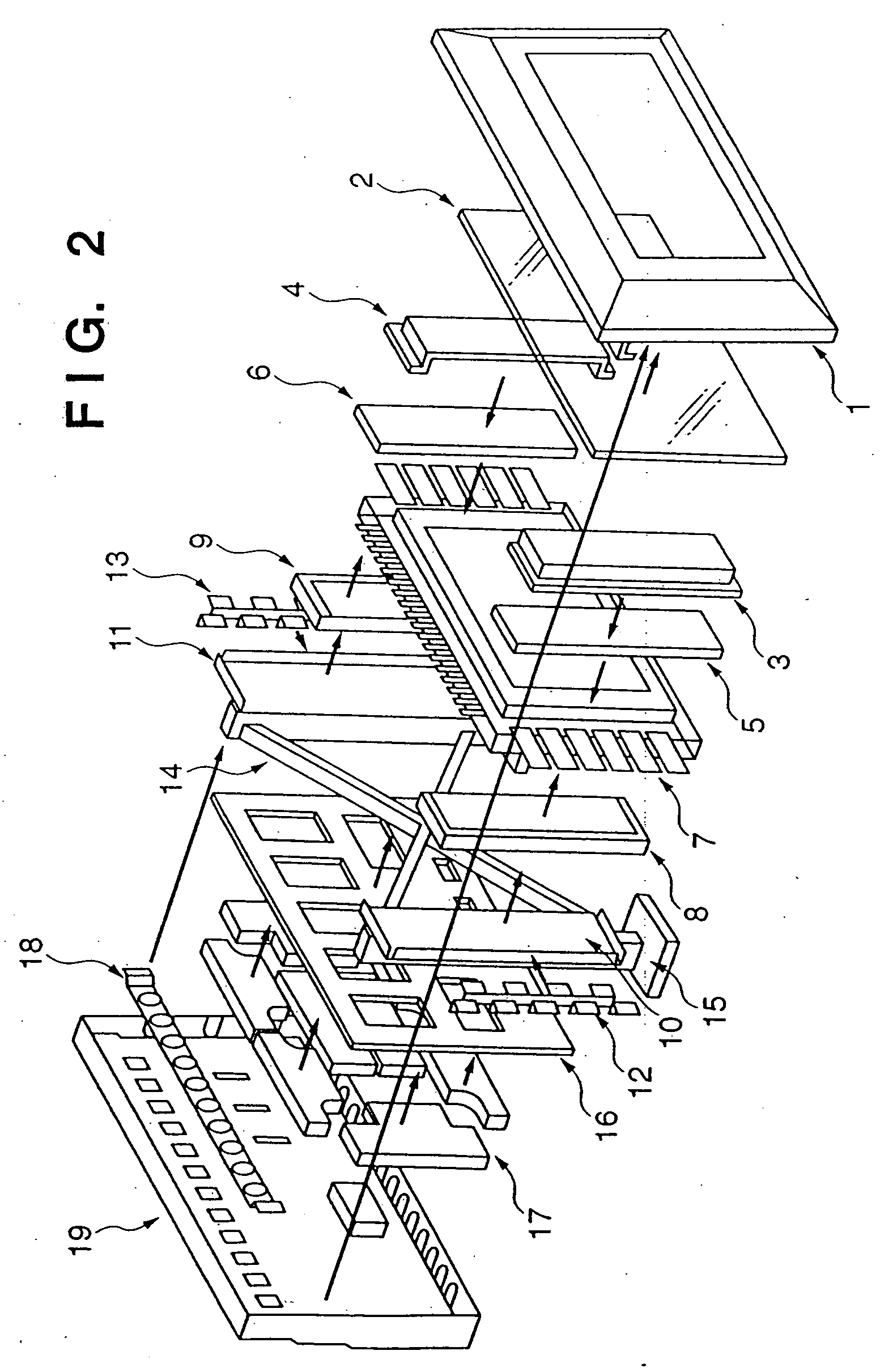

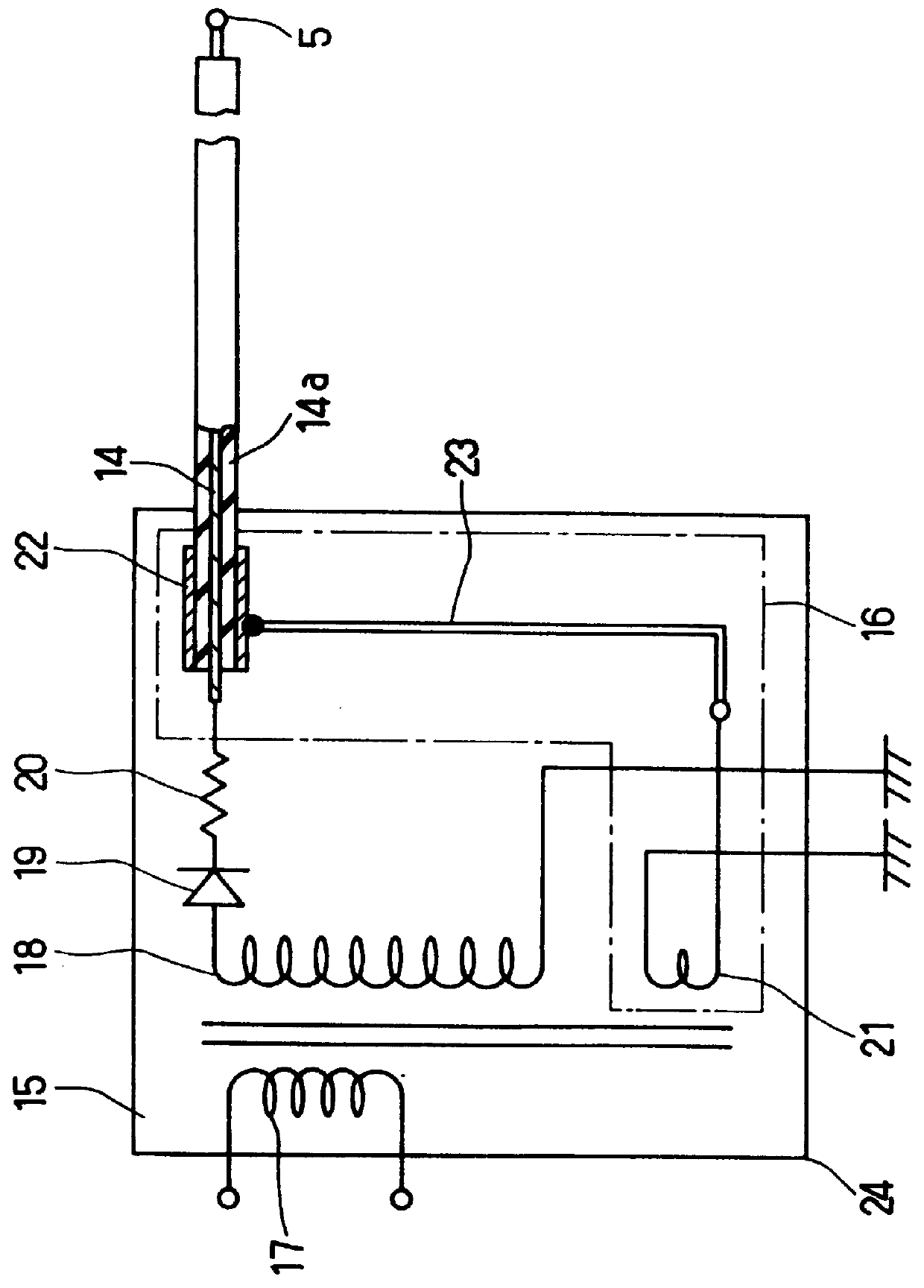

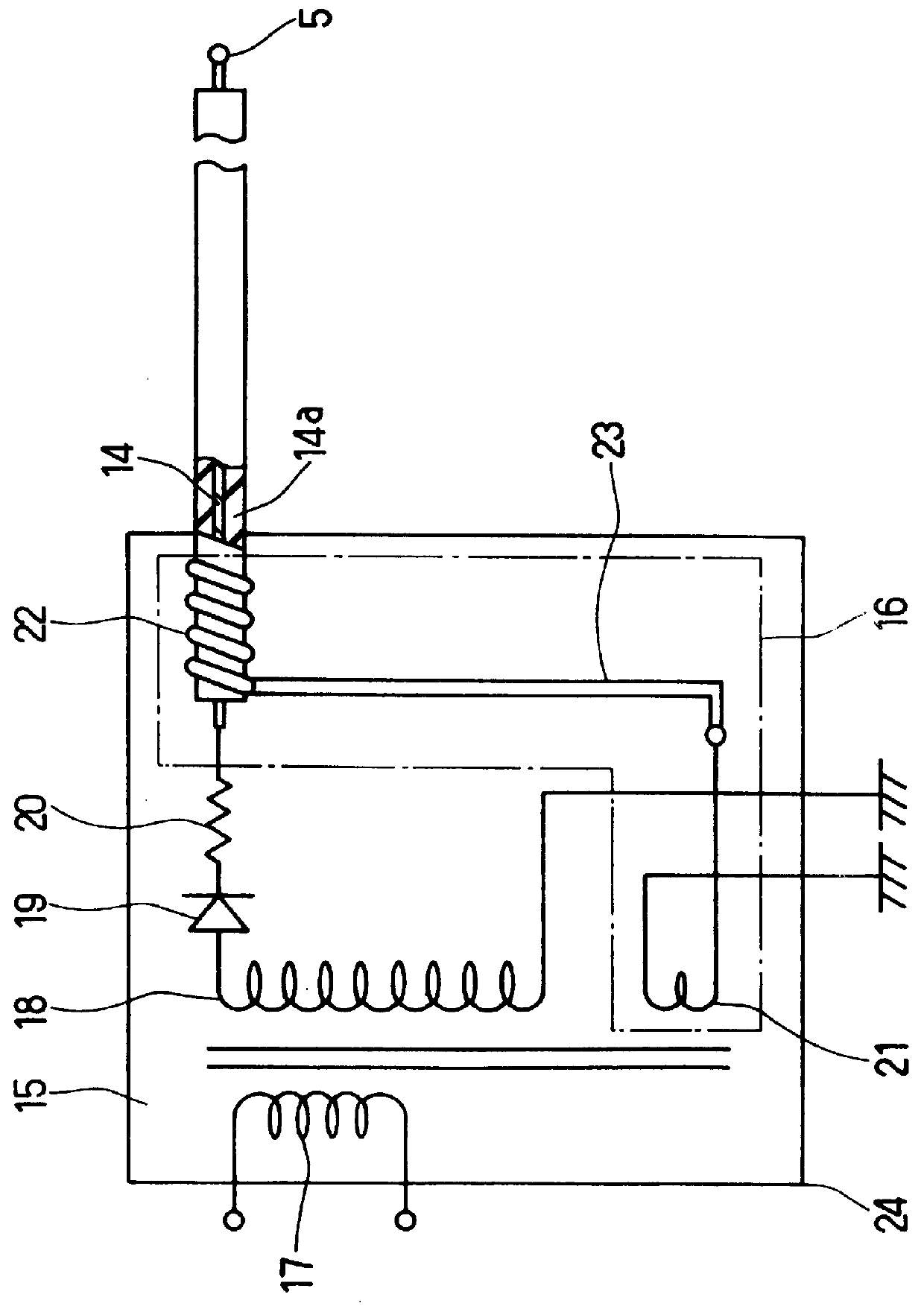

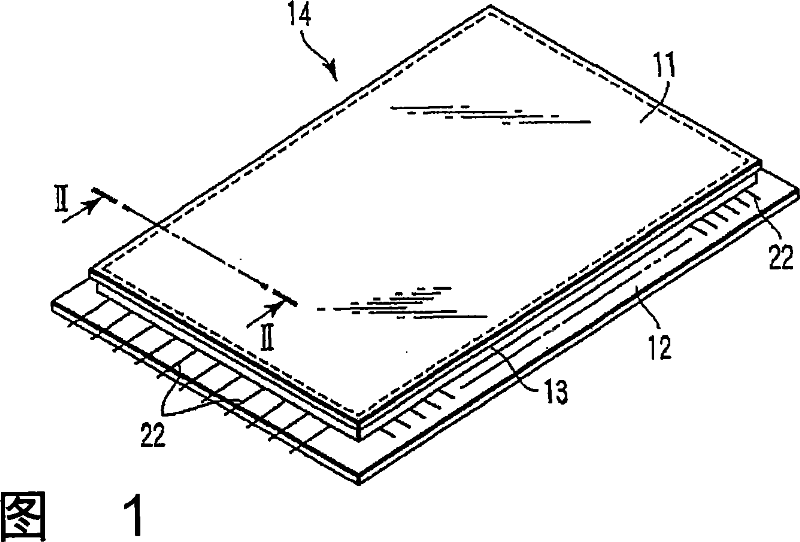

InactiveUS6879096B1High display-quality configurationSatisfies requirementTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

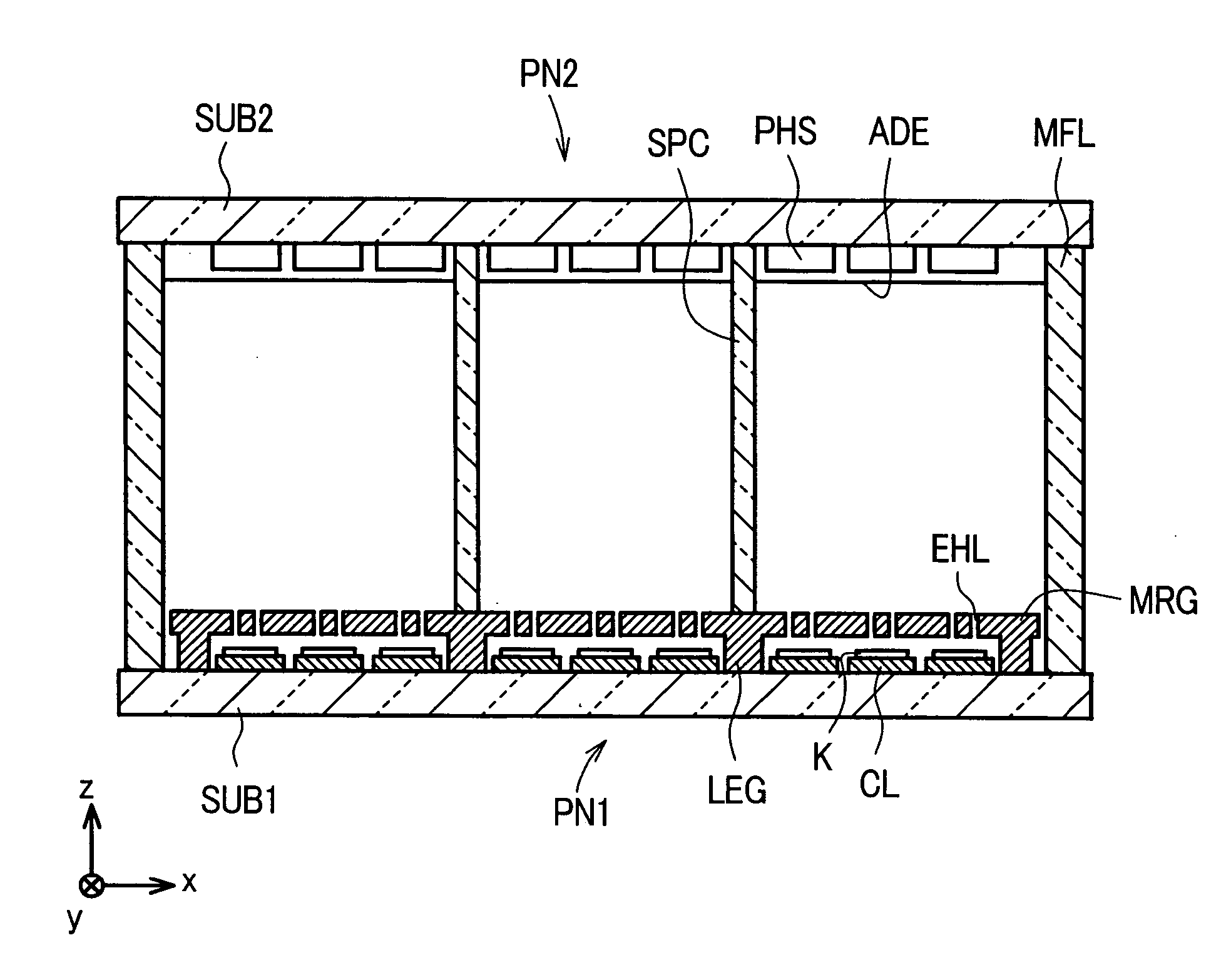

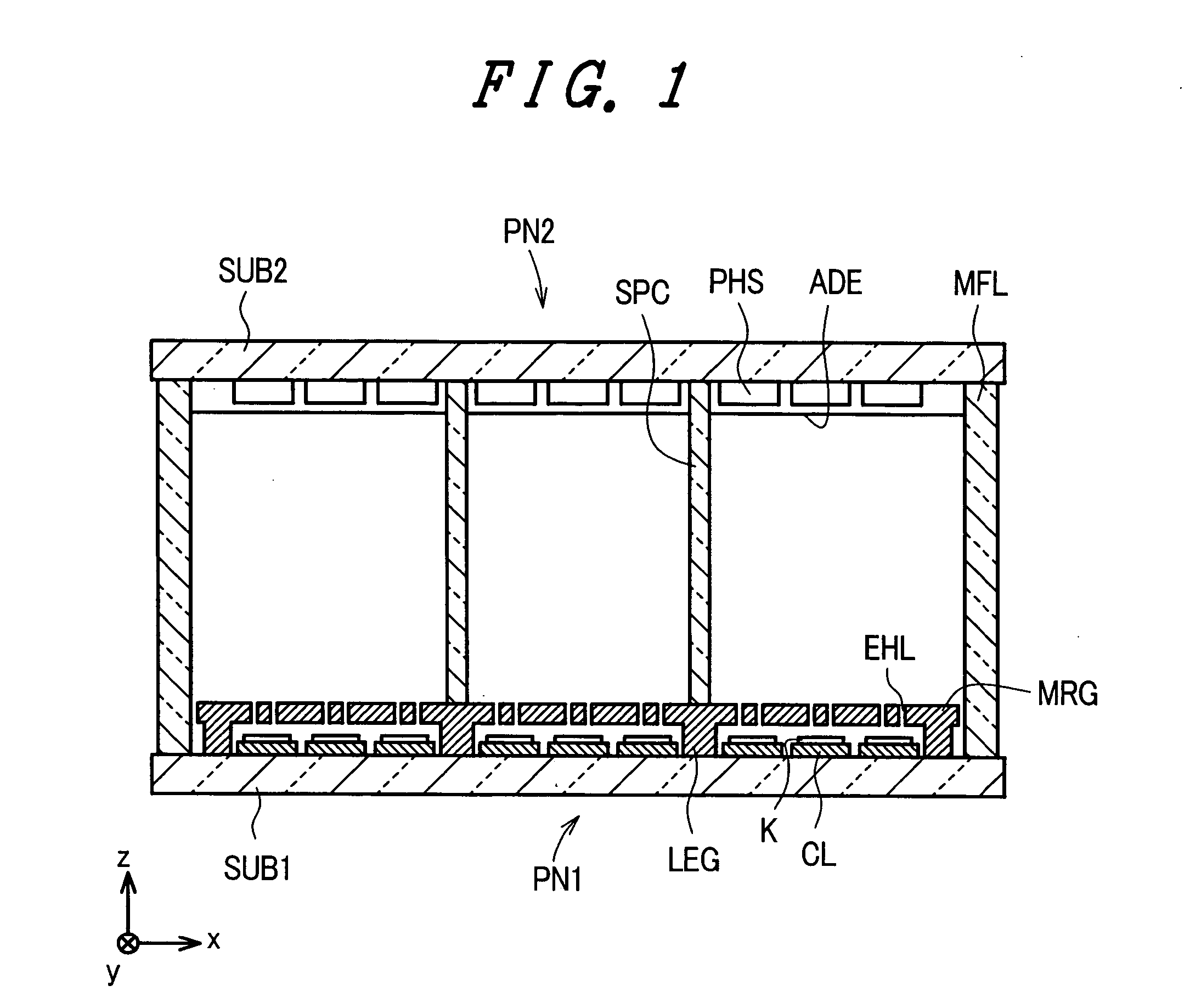

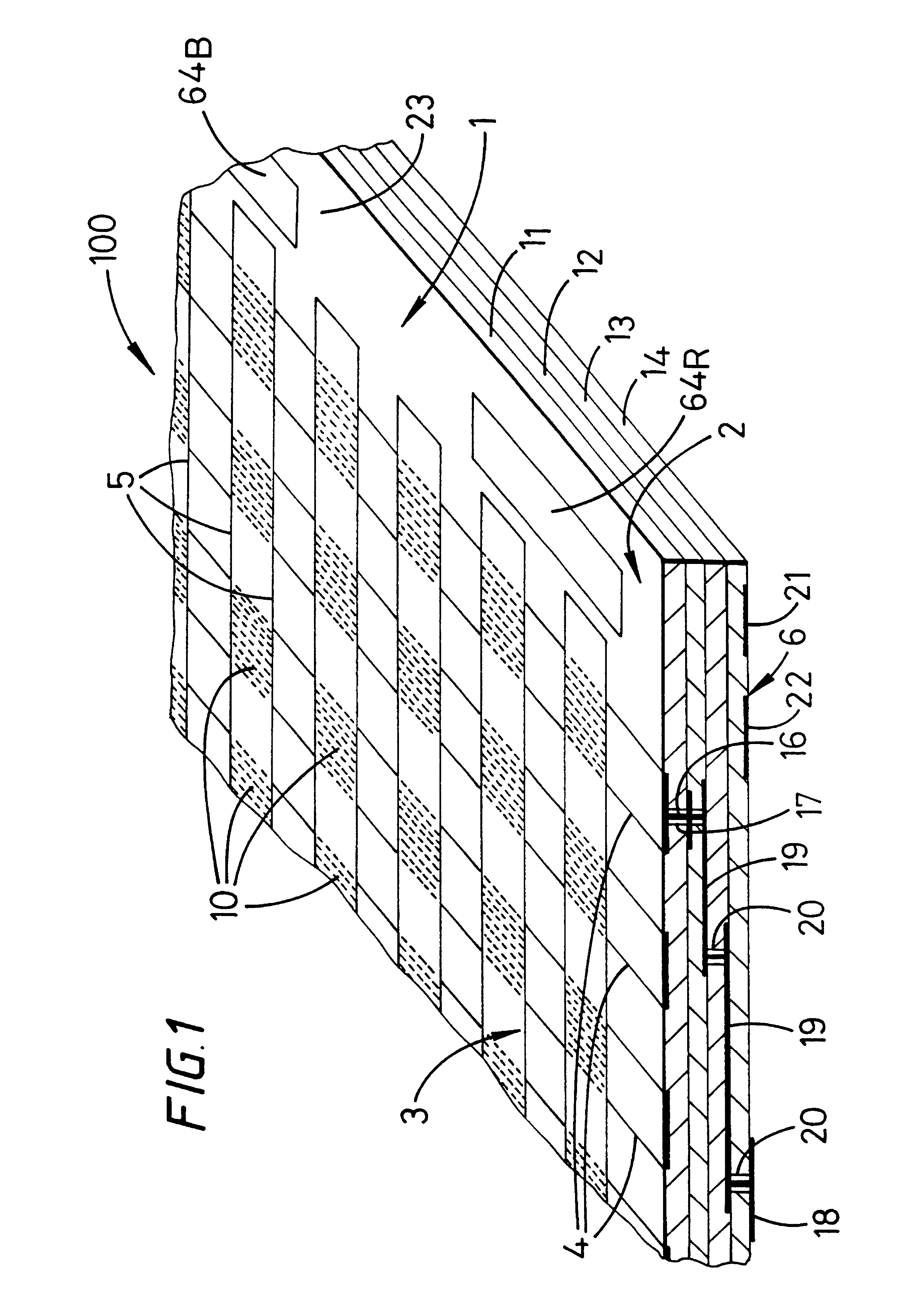

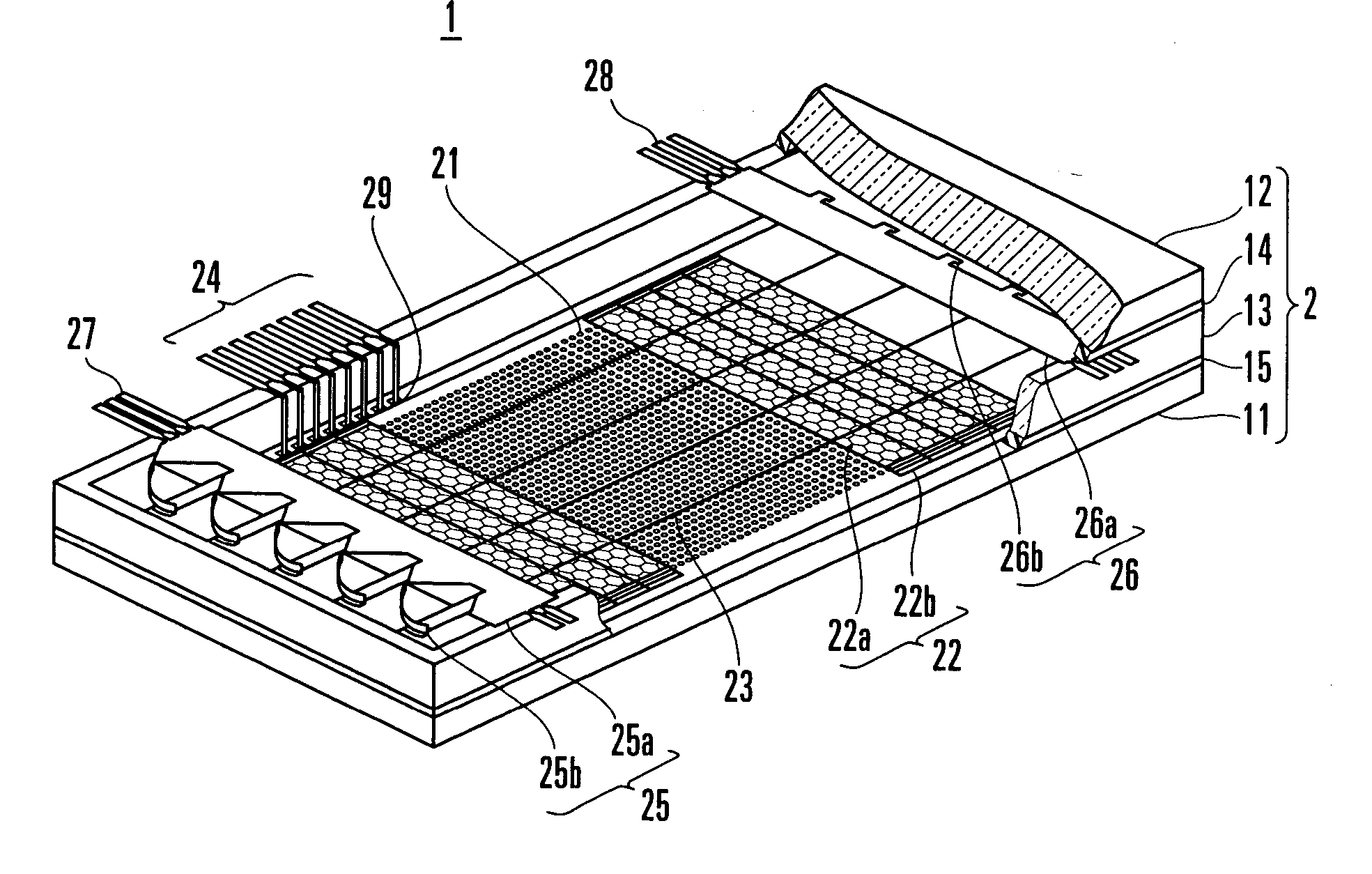

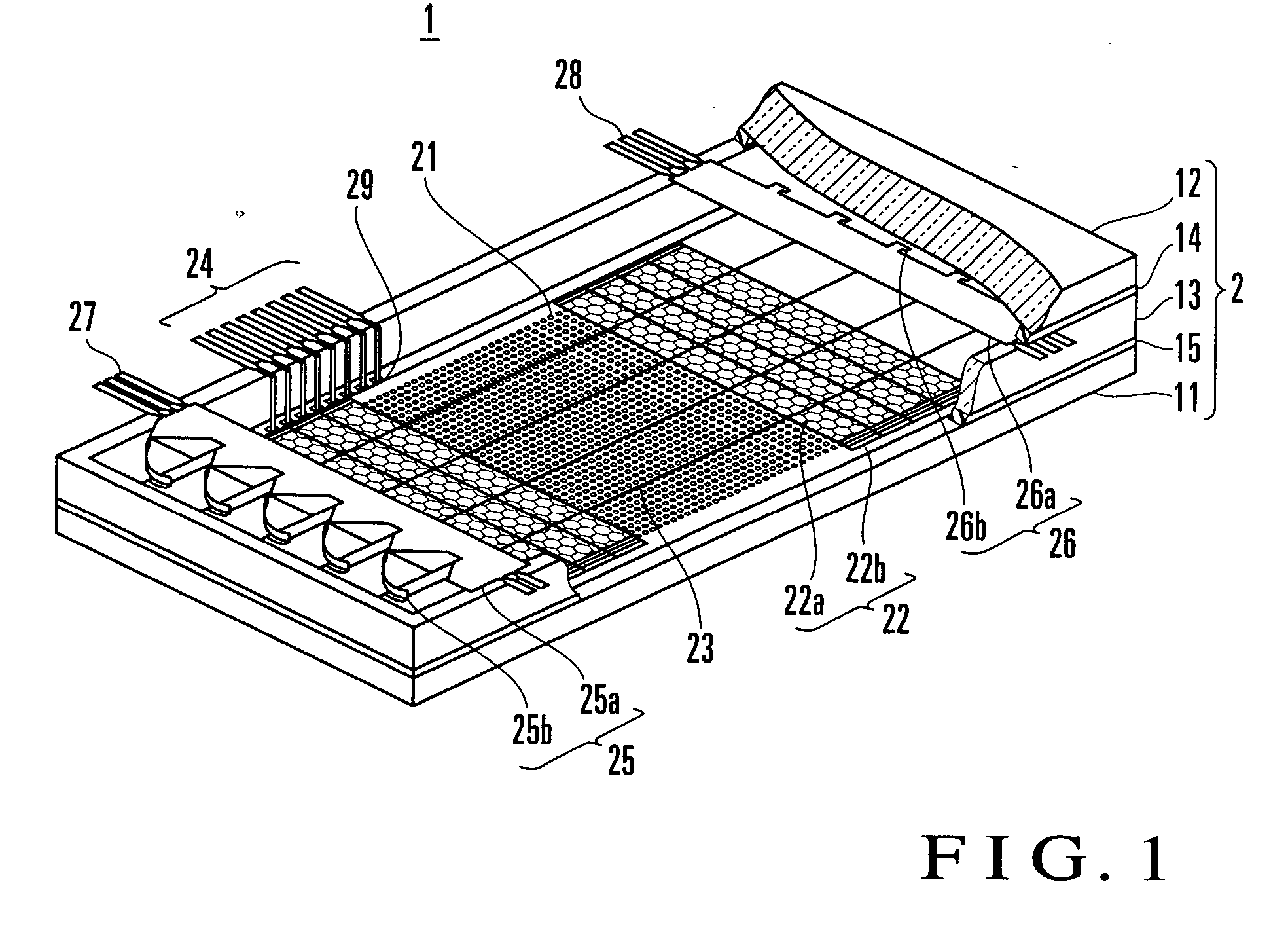

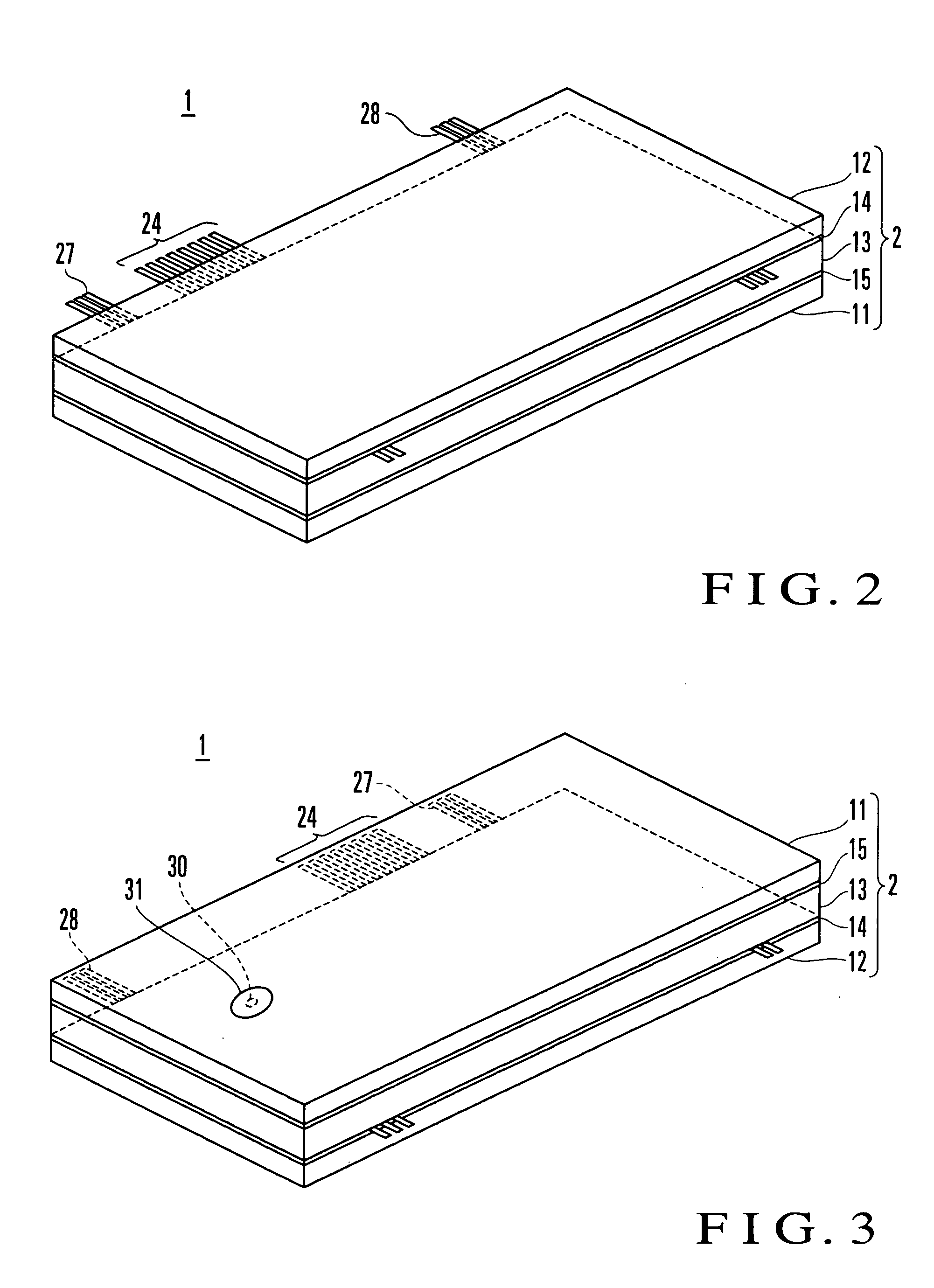

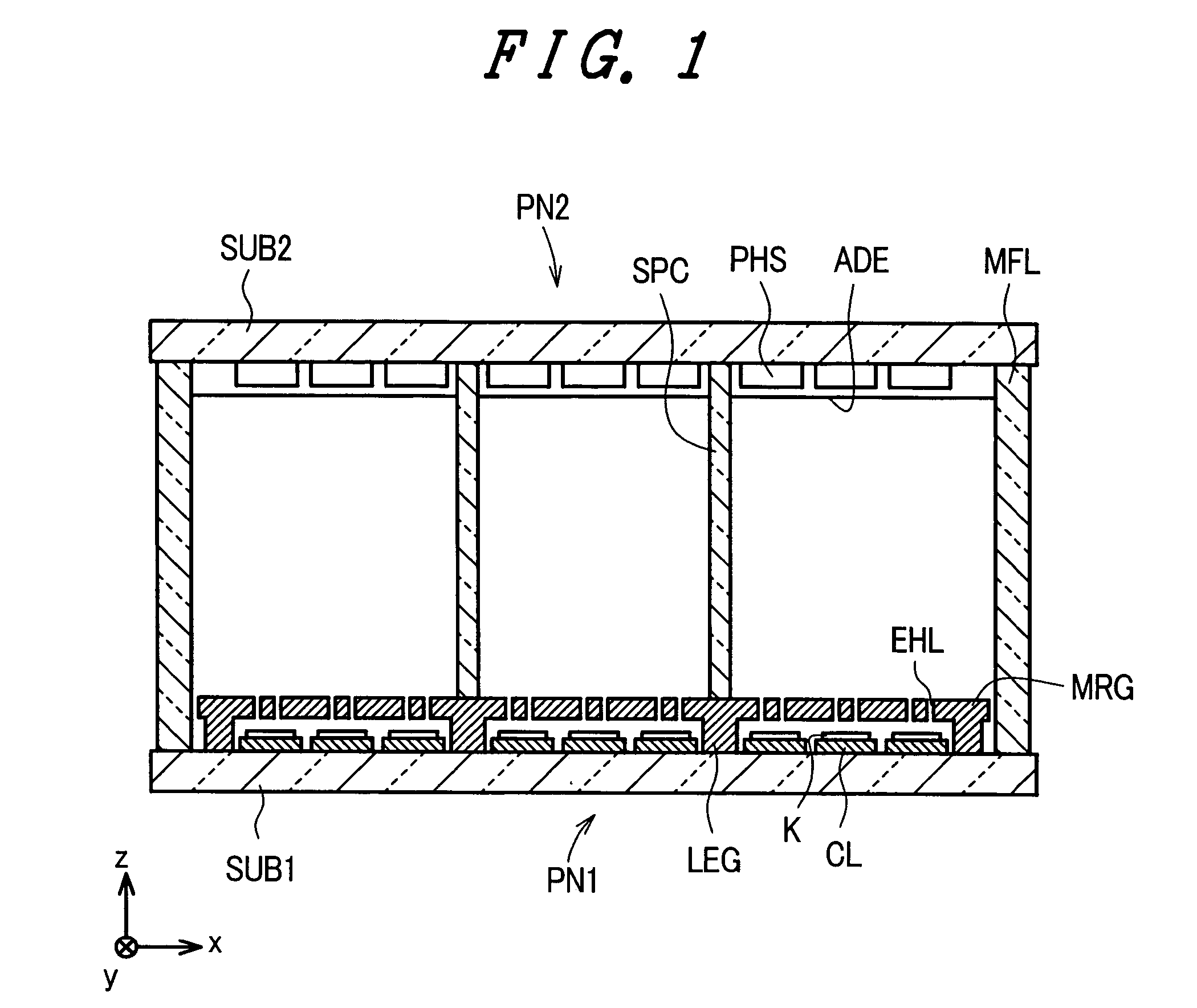

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

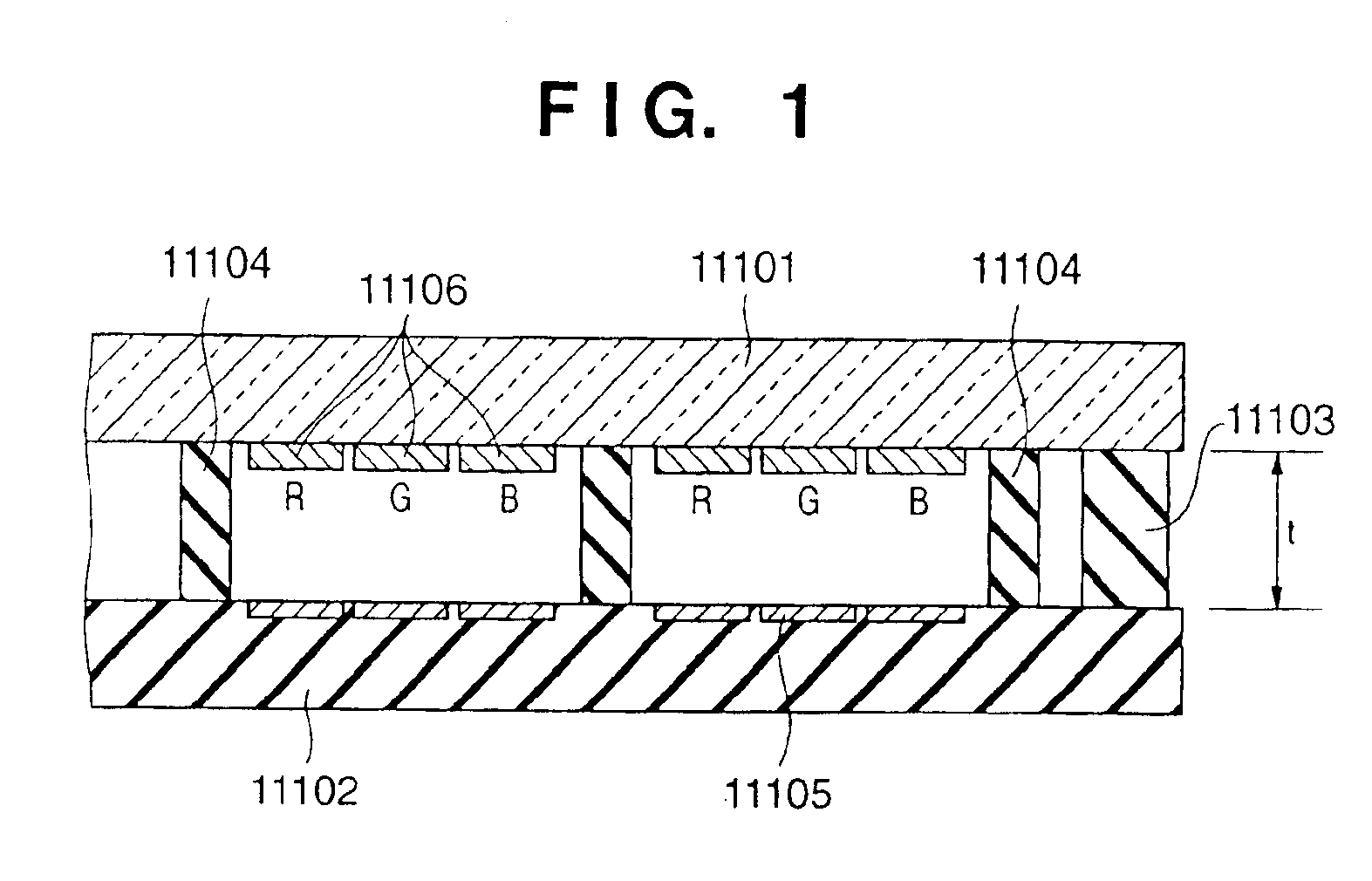

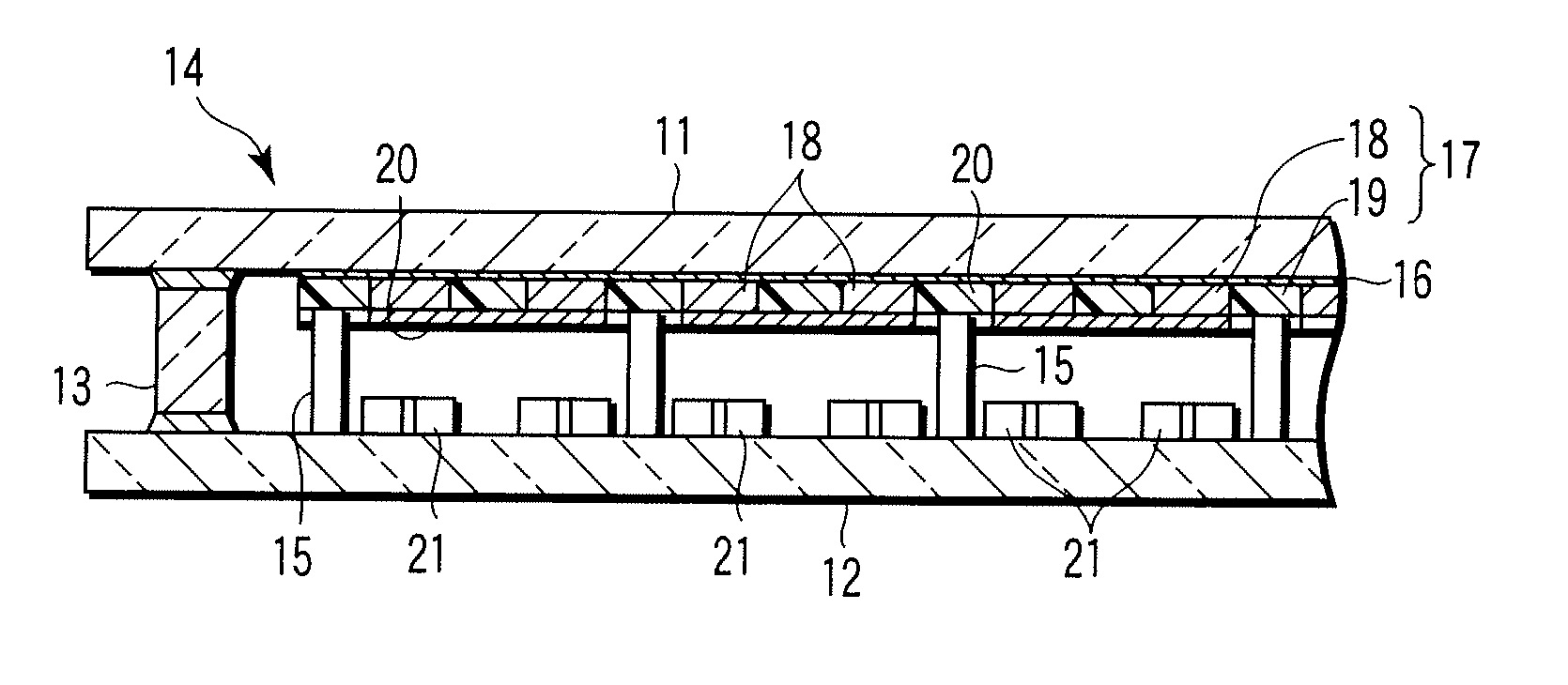

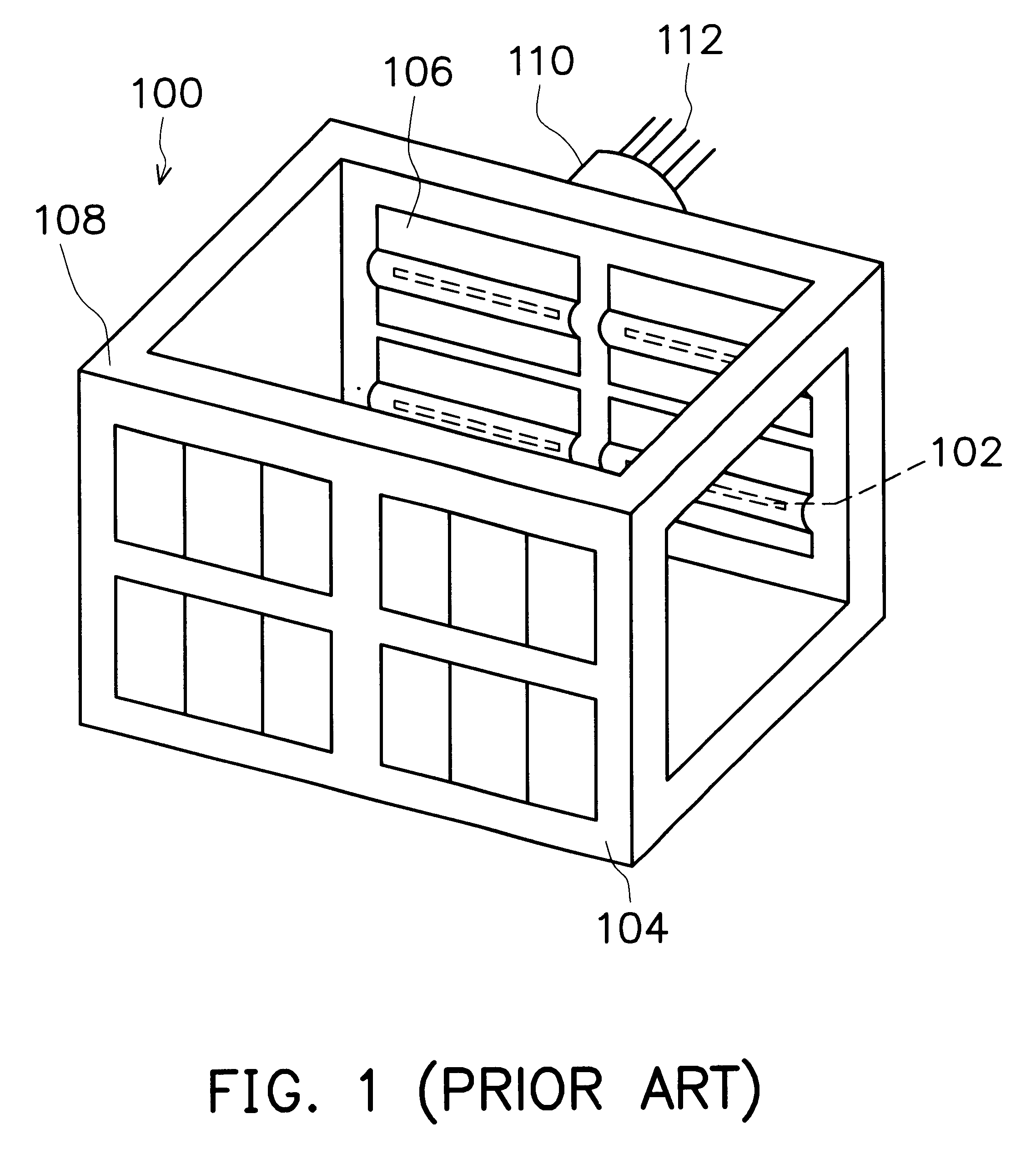

Field emission display

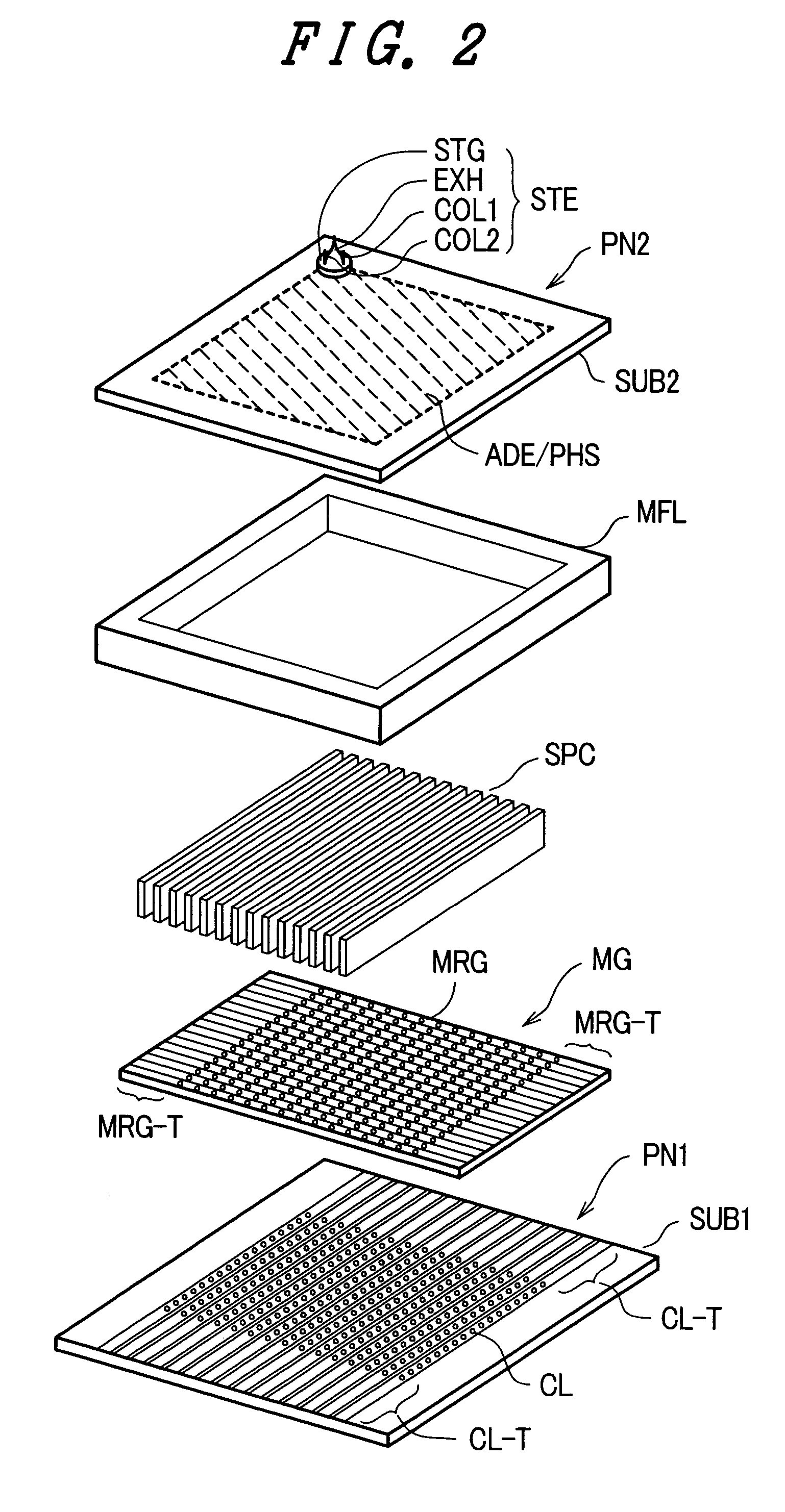

InactiveUS6172456B1Reduce in quantityIncrease in costGas filling substance selectionDischarge tube luminescnet screensField emission displayDisplay device

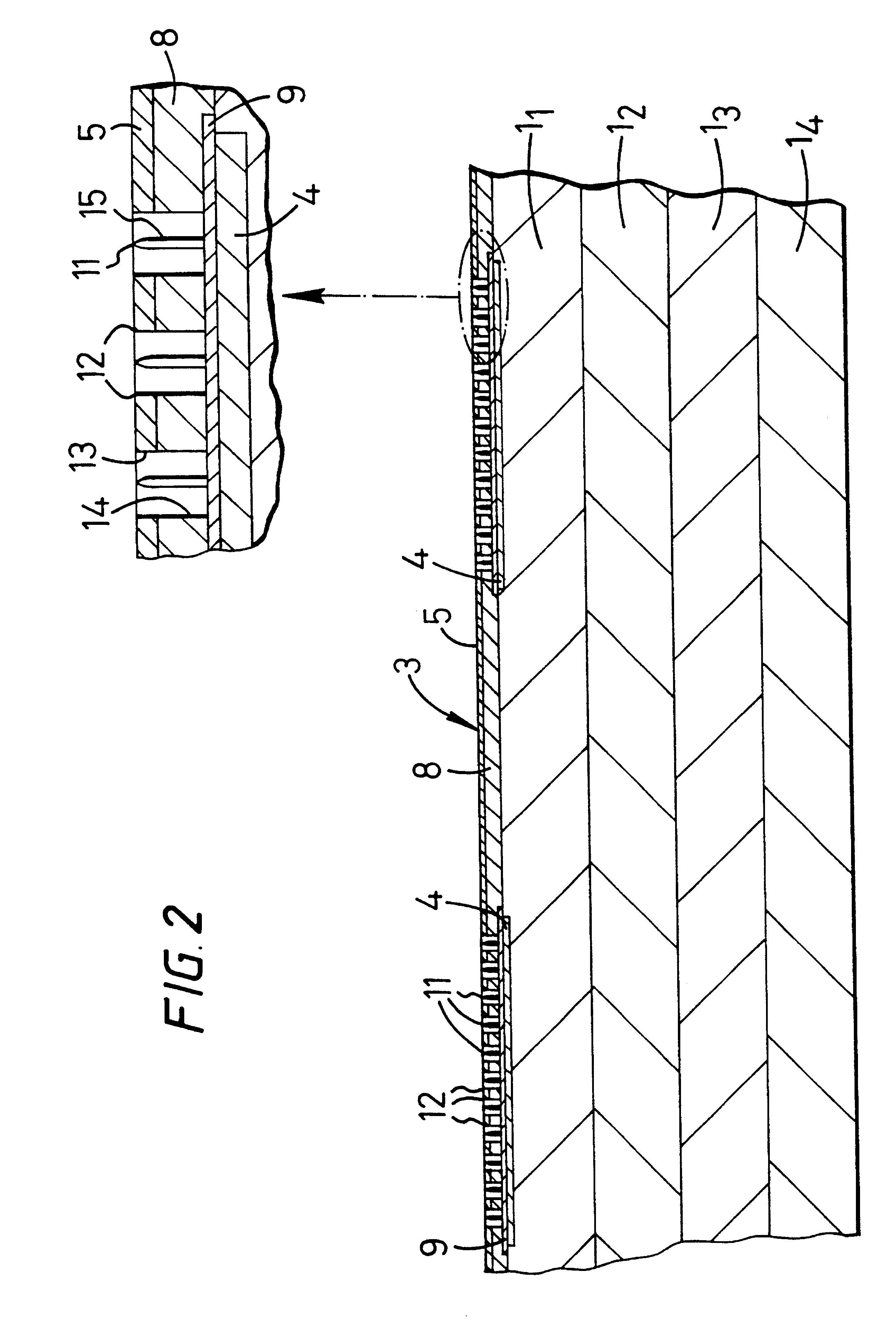

A flat-panel field emission display comprises a luminescent faceplate, a rigid backplate, and an interposed or sandwiched emitter or cathode plate. A positioning spacer or connector ridge is formed on the rear surface of the faceplate to space the cathode plate a fixed distance behind the faceplate. A peripheral seal is formed between the faceplate and the backplate. The faceplate, backplate, and peripheral seal define an evacuated internal space which contains the cathode plate. The backplate is spaced behind the cathode plate to create a rearward vacuum space in which a getter is located.

Owner:MICRON TECH INC

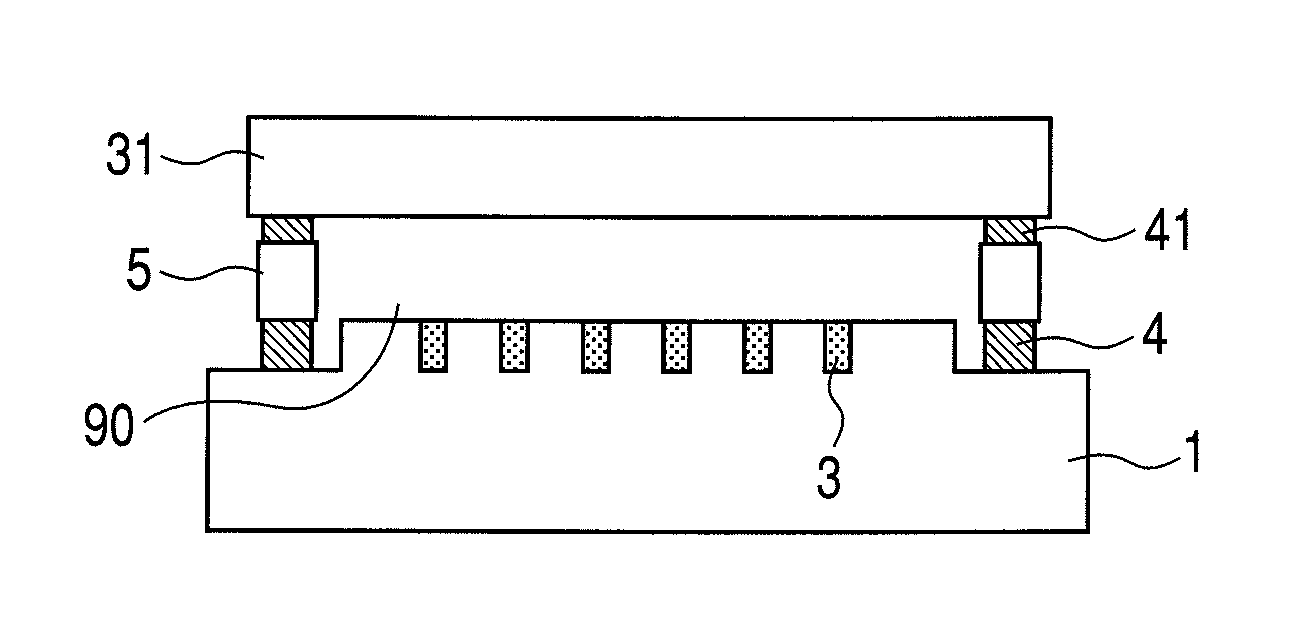

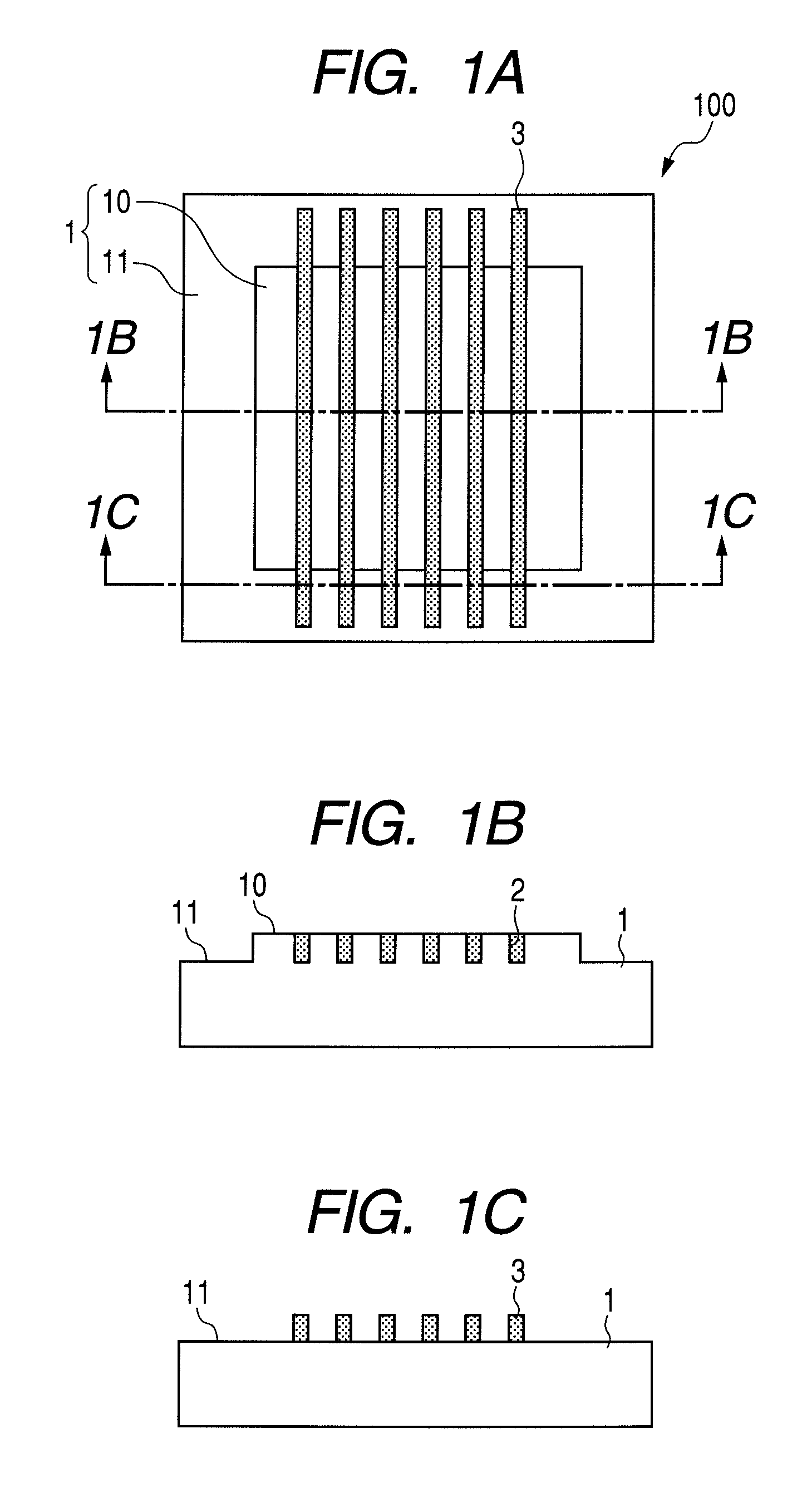

Image formation apparatus

InactiveUS20050082963A1Configuration highFulfil requirementsTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

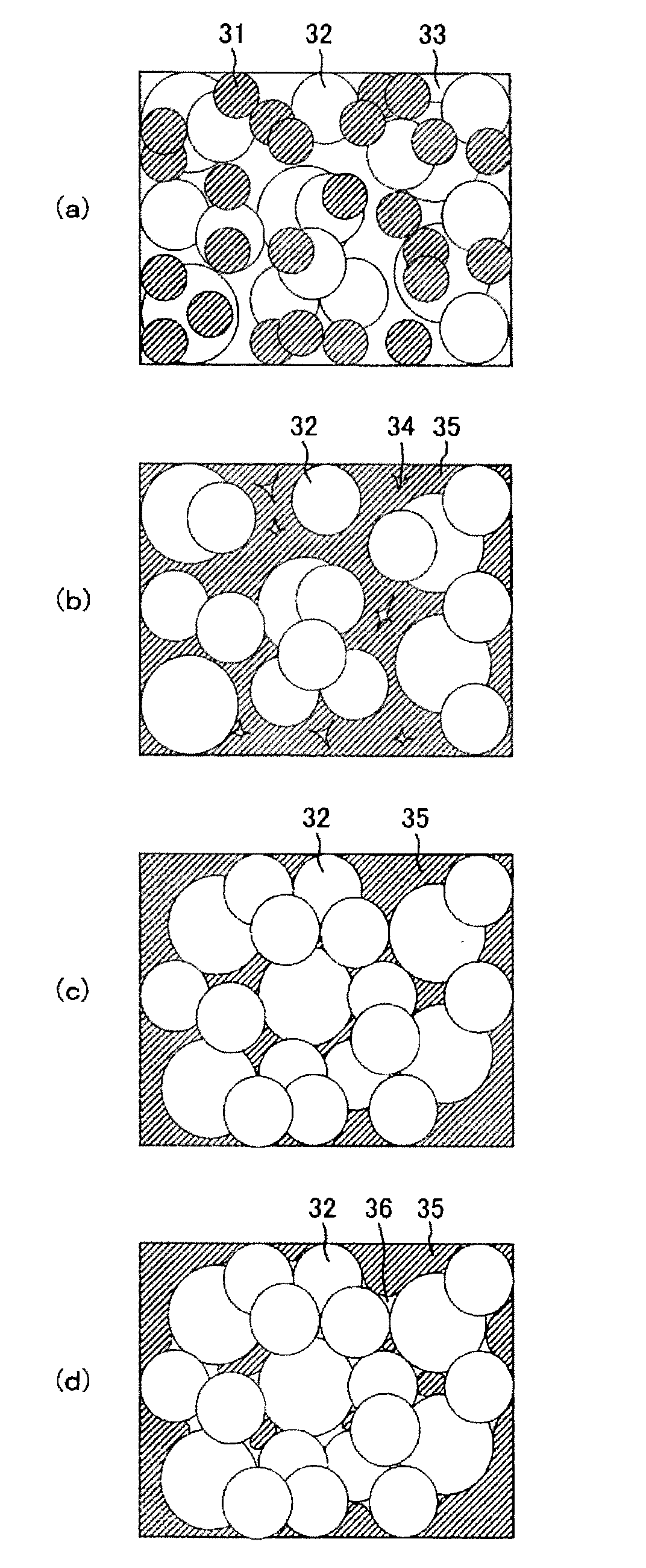

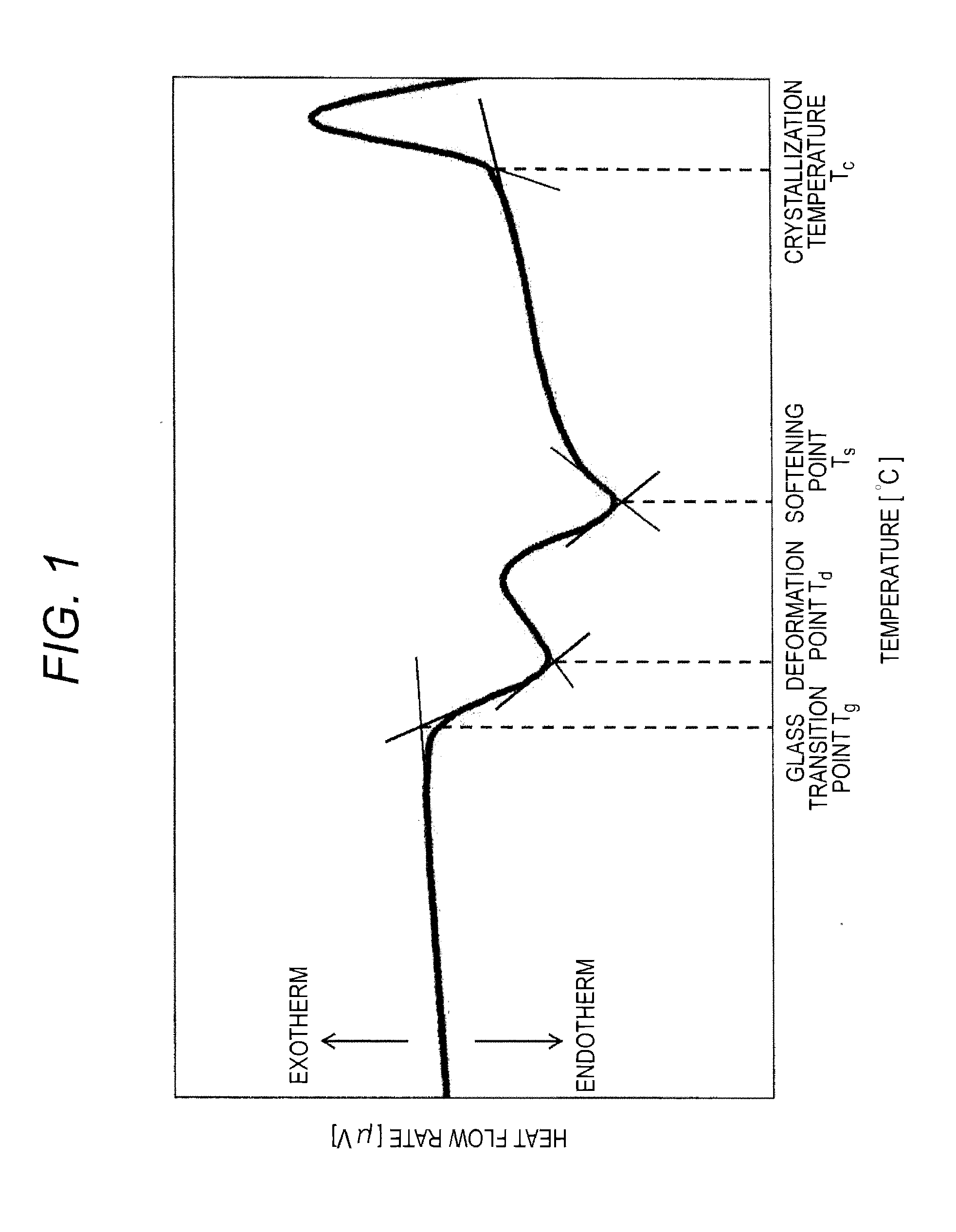

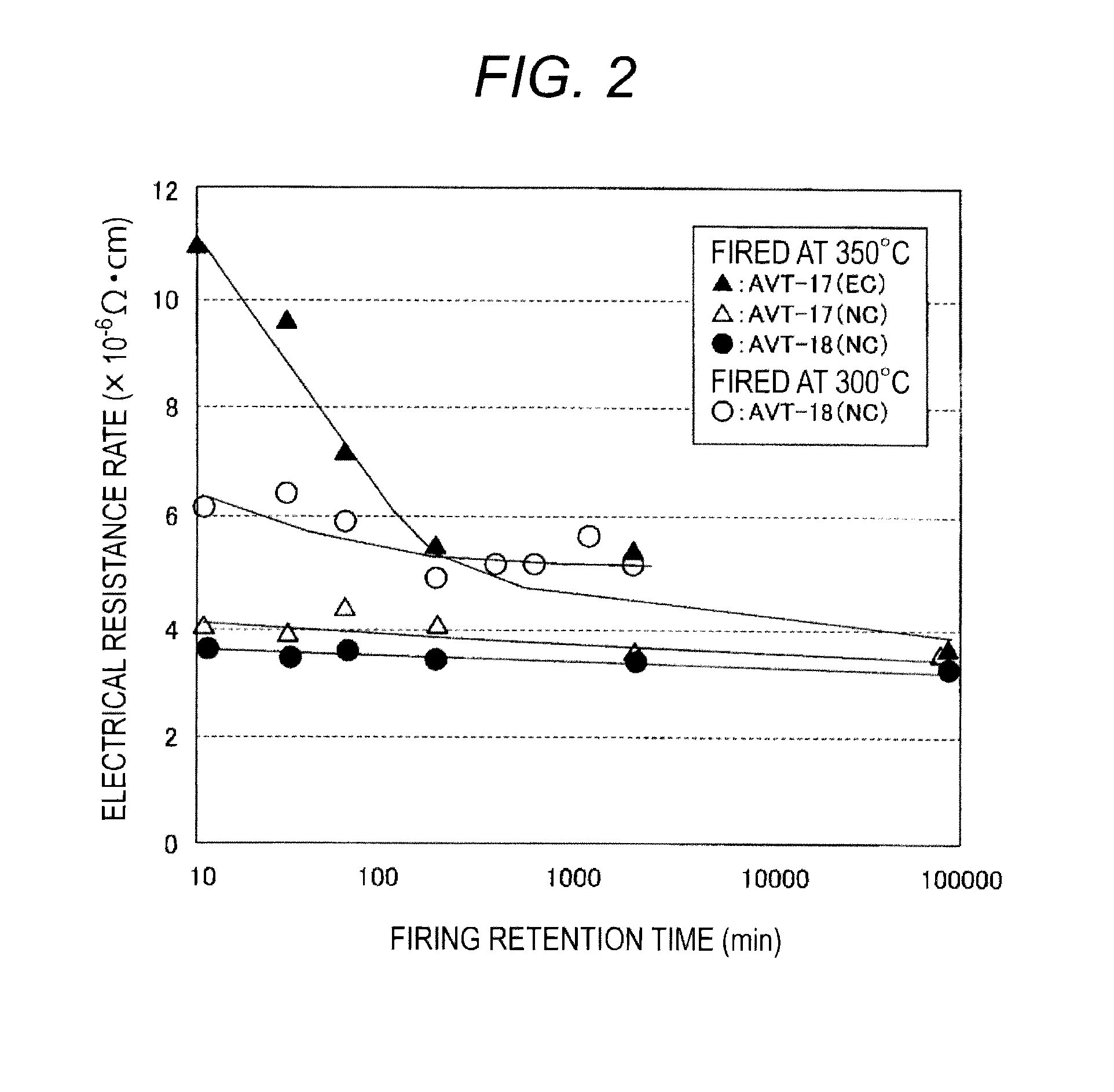

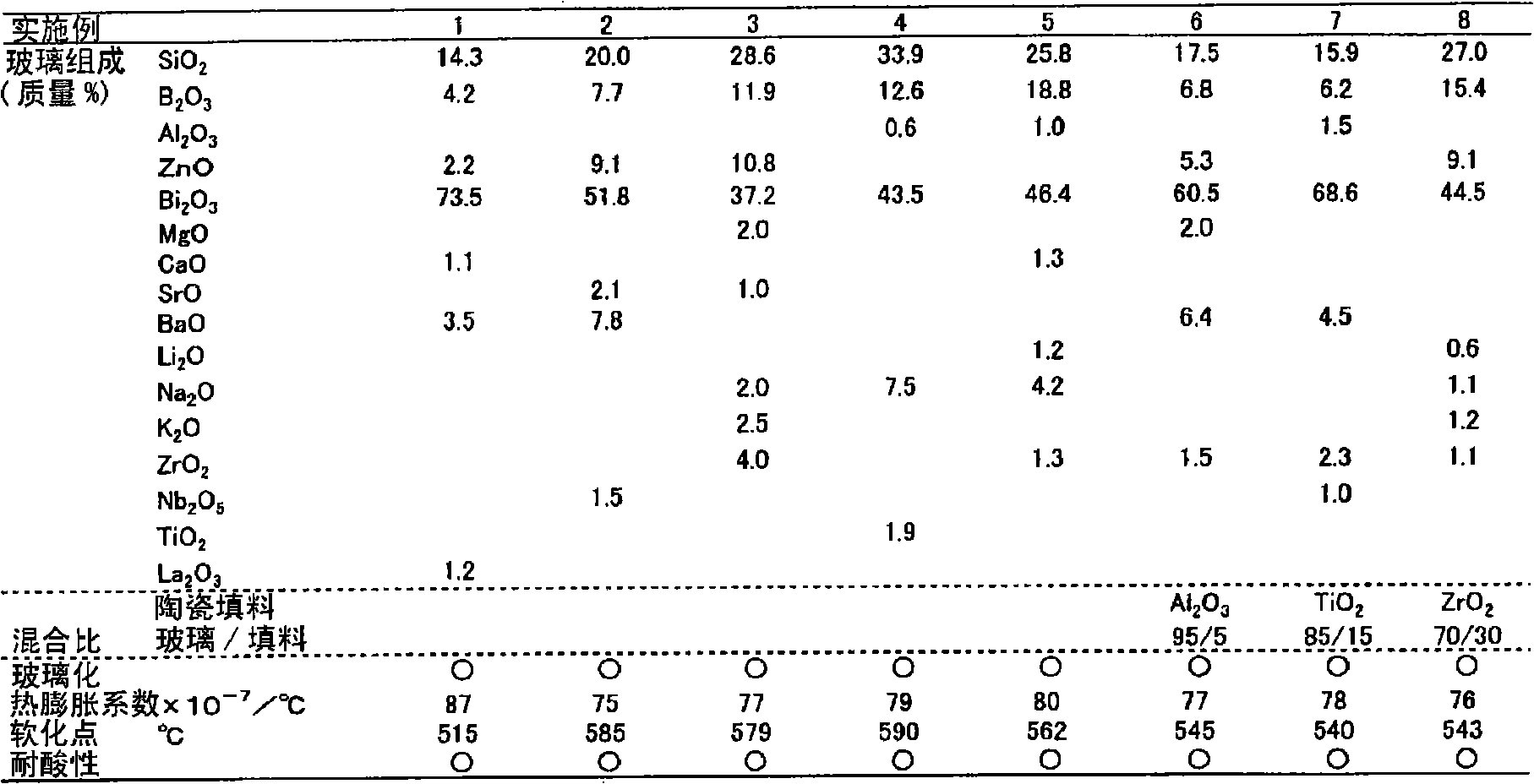

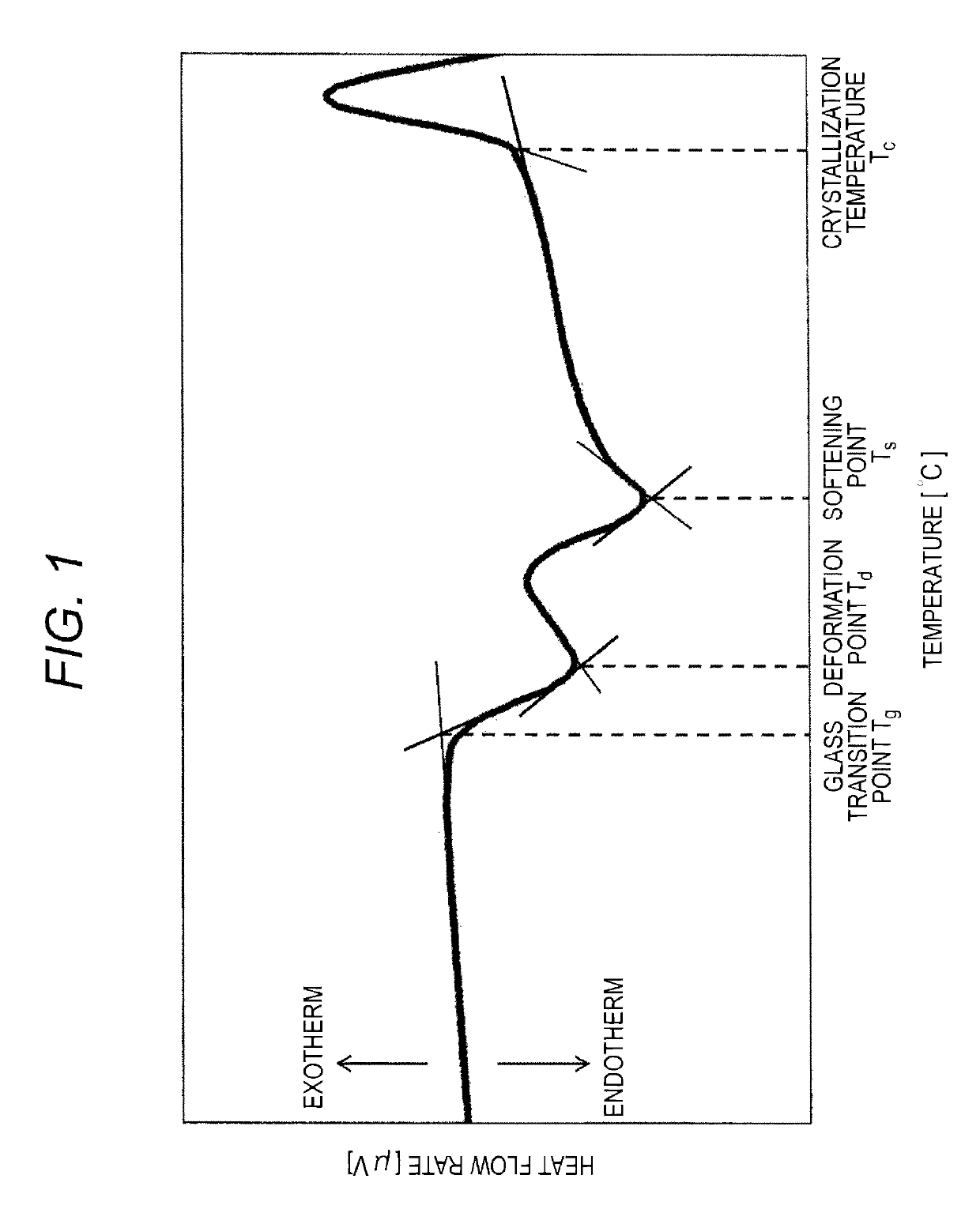

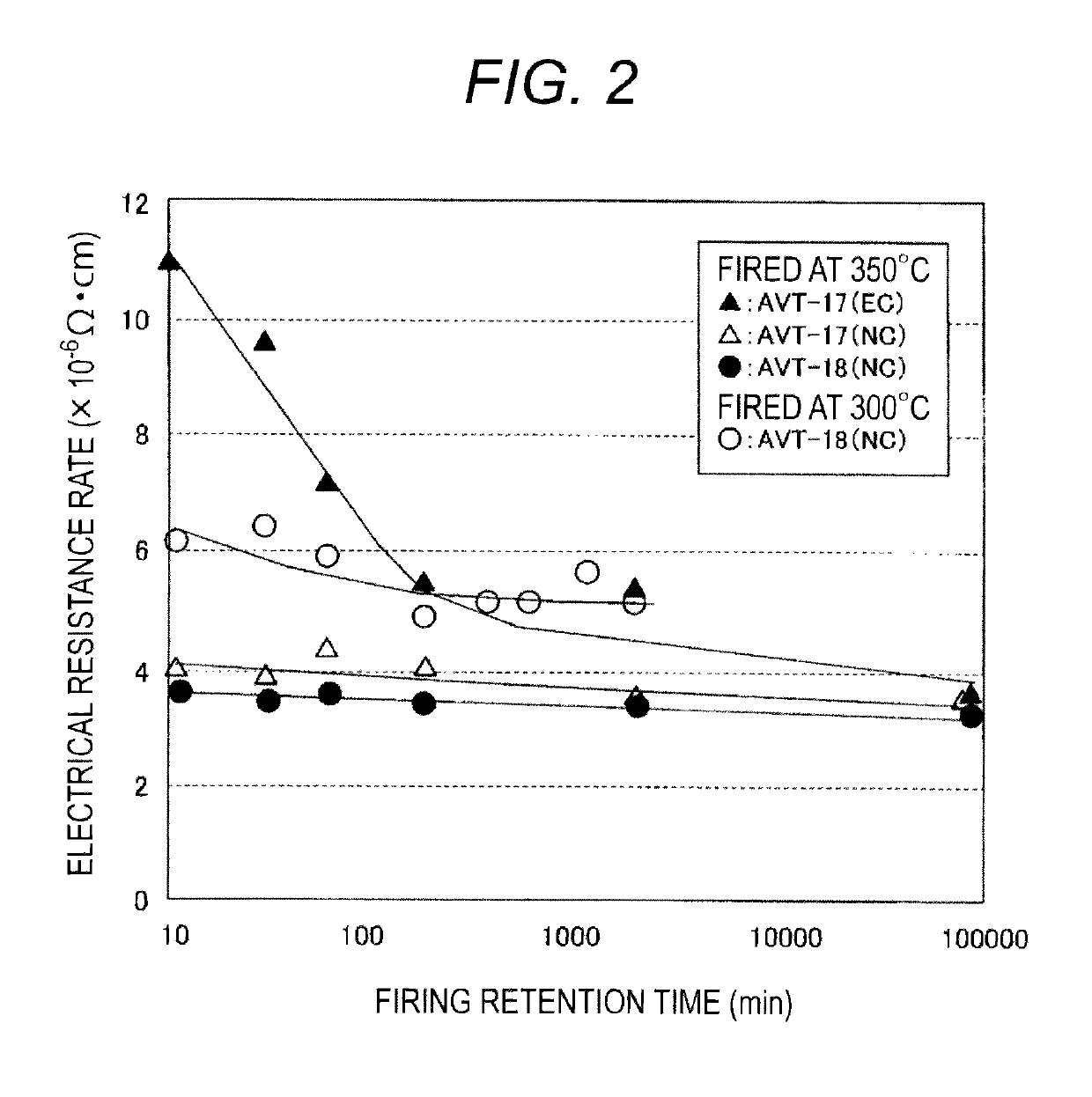

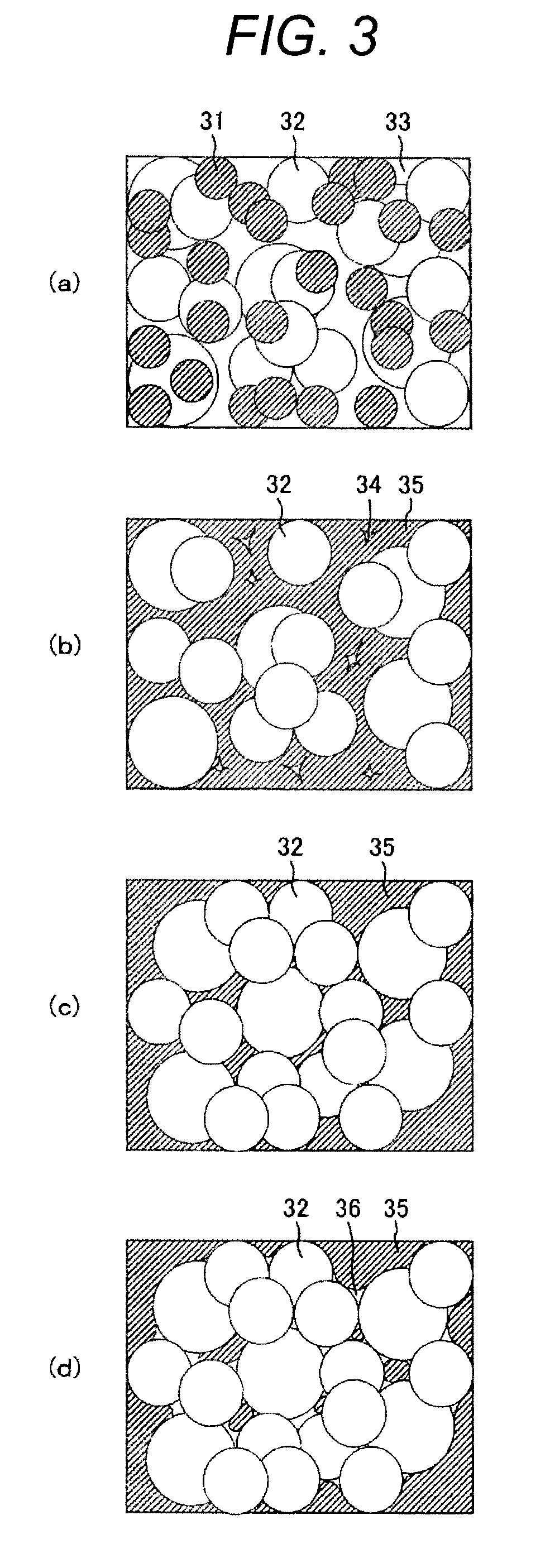

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS20140145122A1Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritThermal stability

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

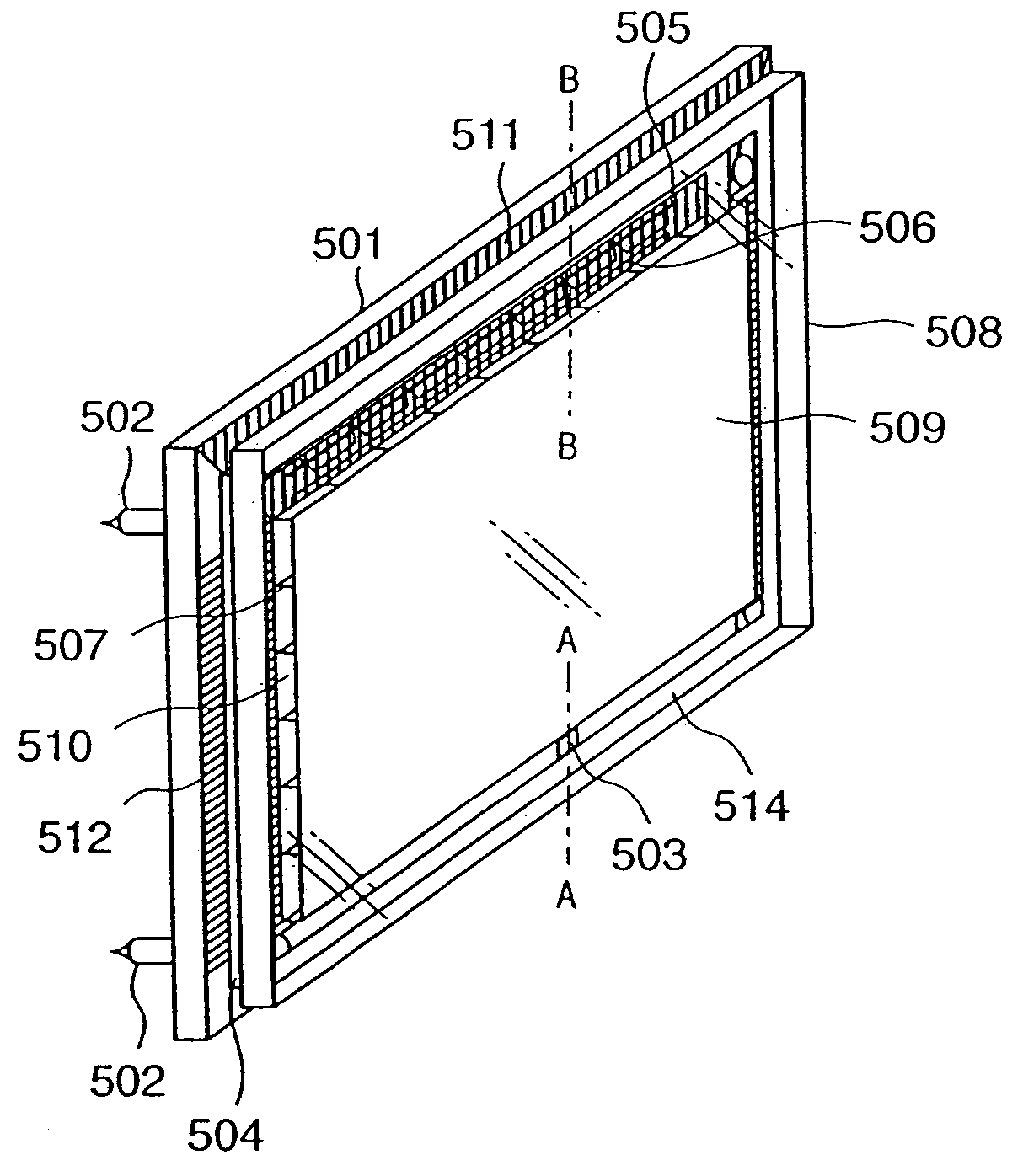

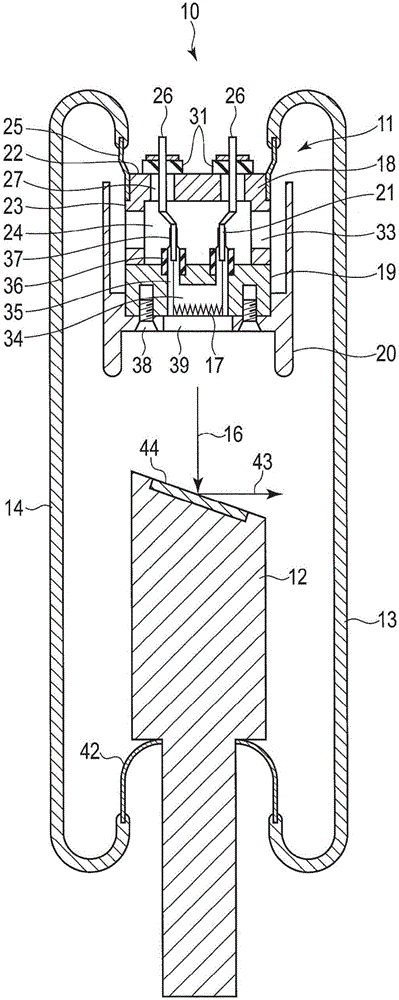

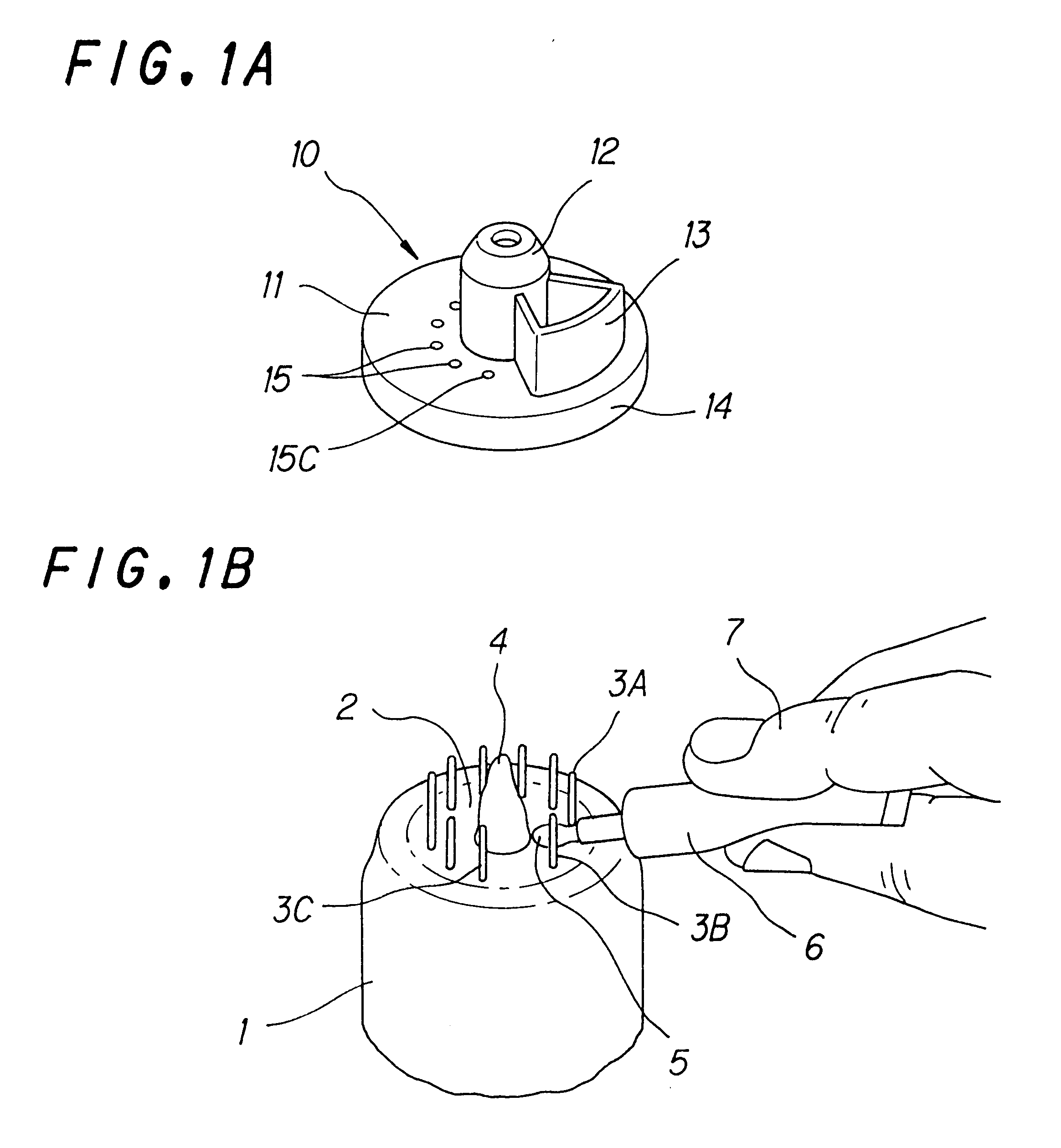

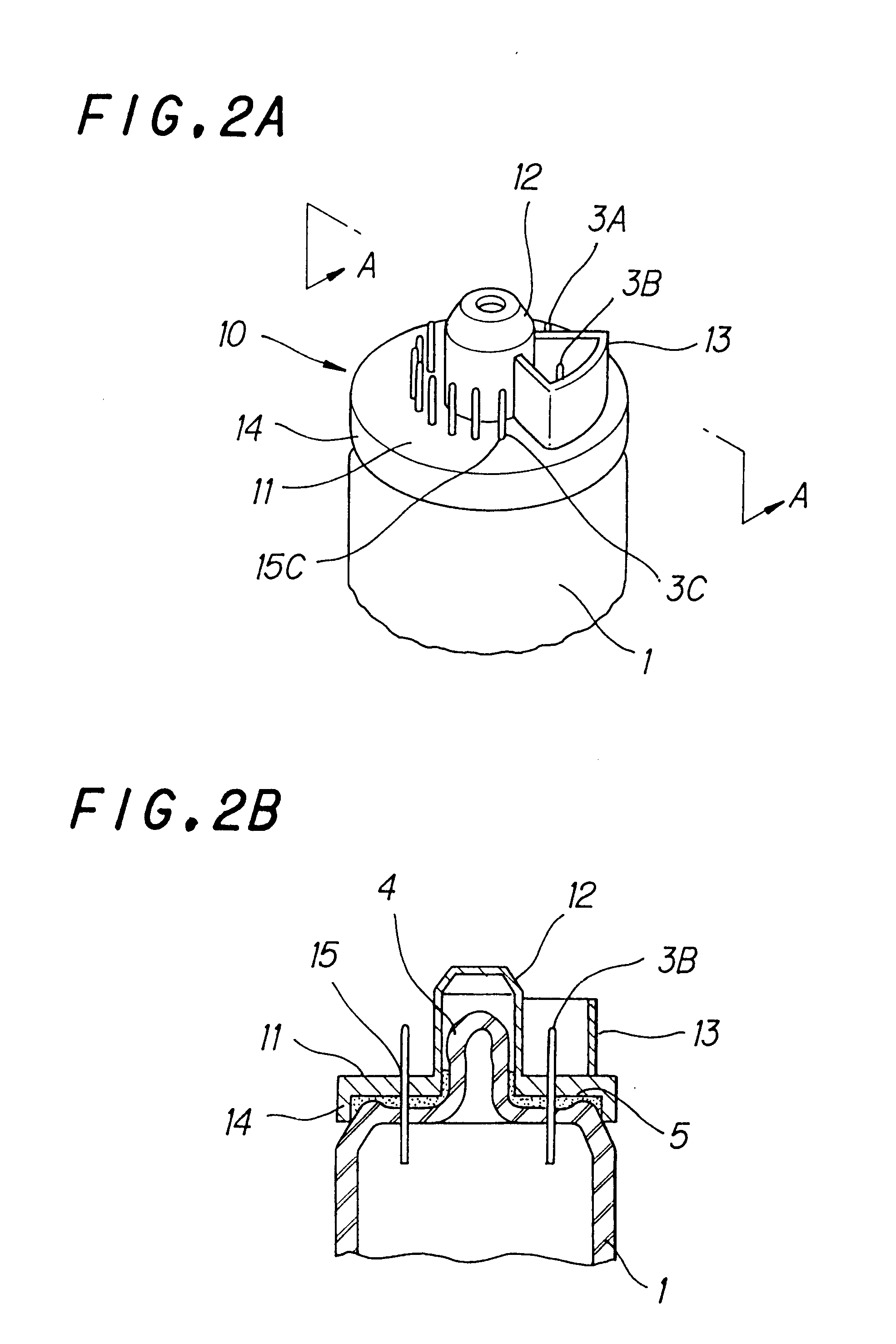

Image display device

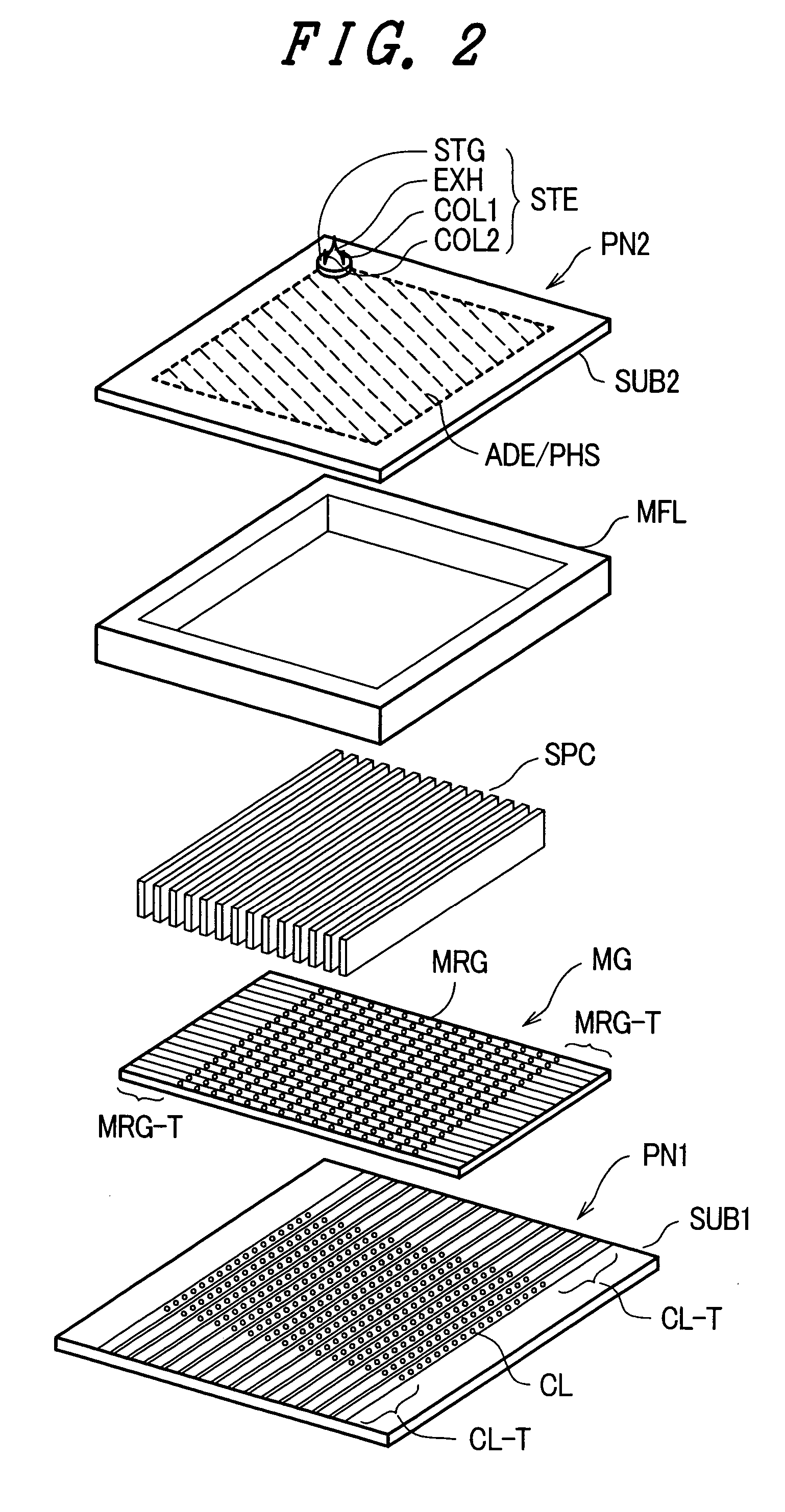

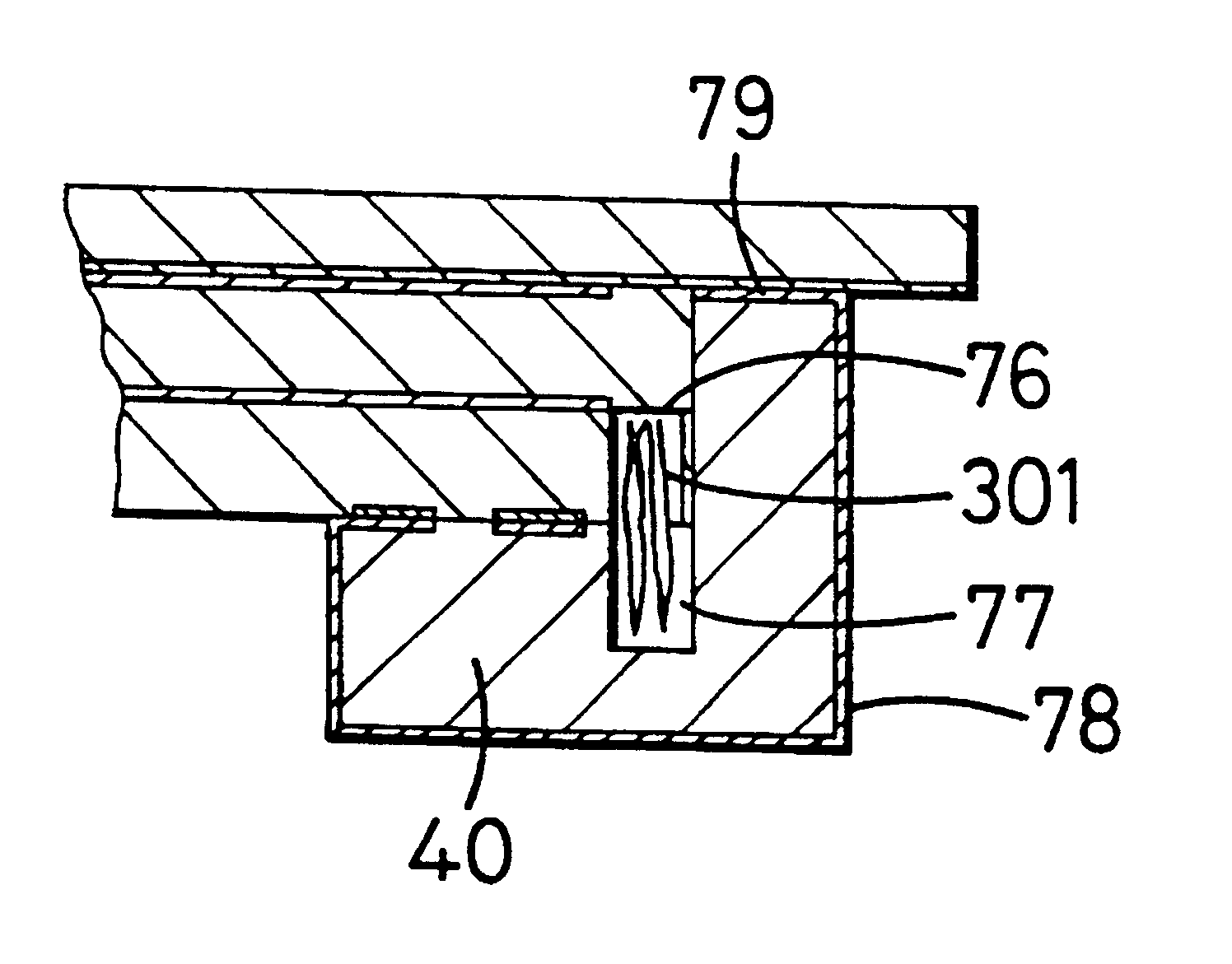

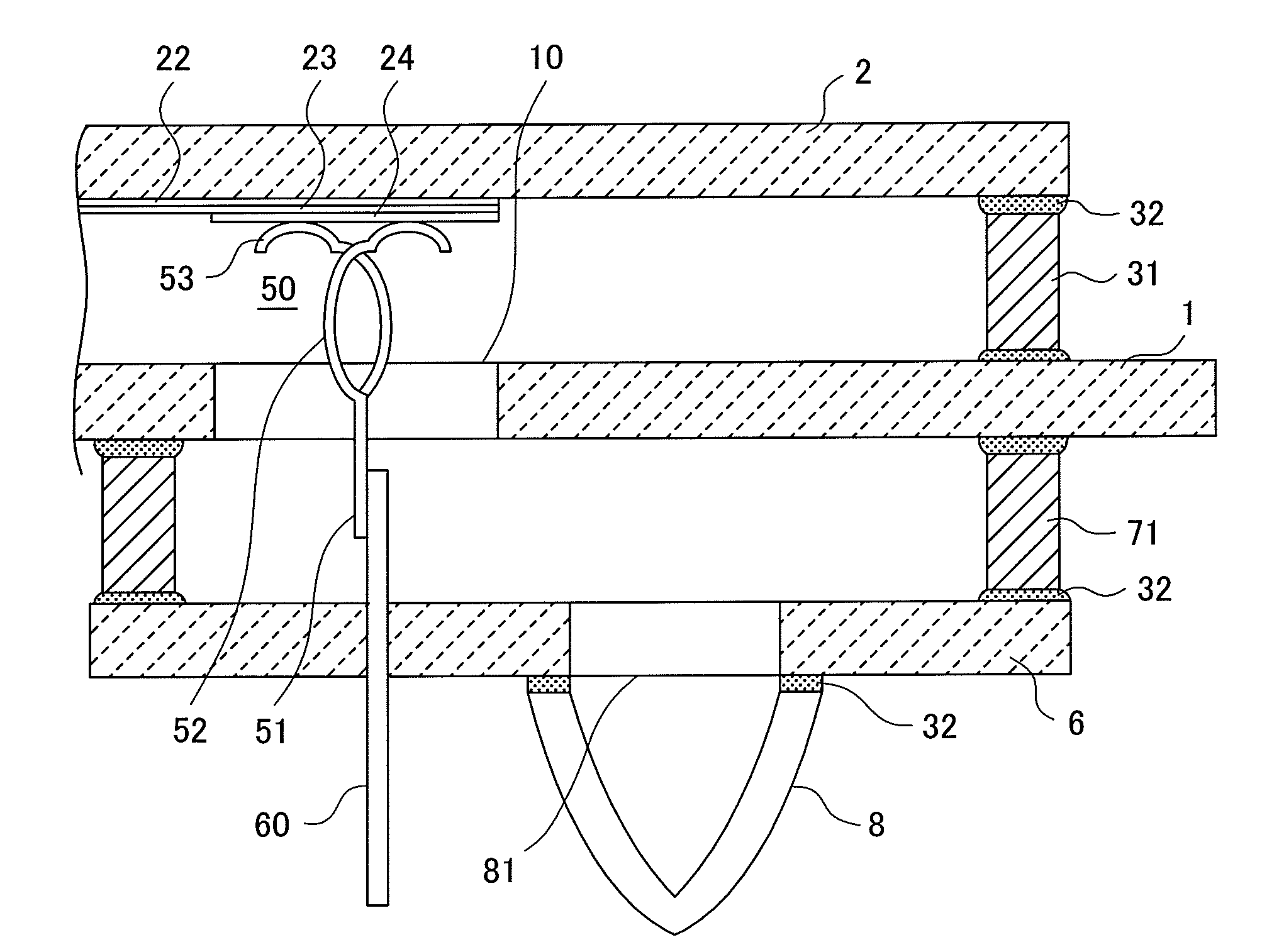

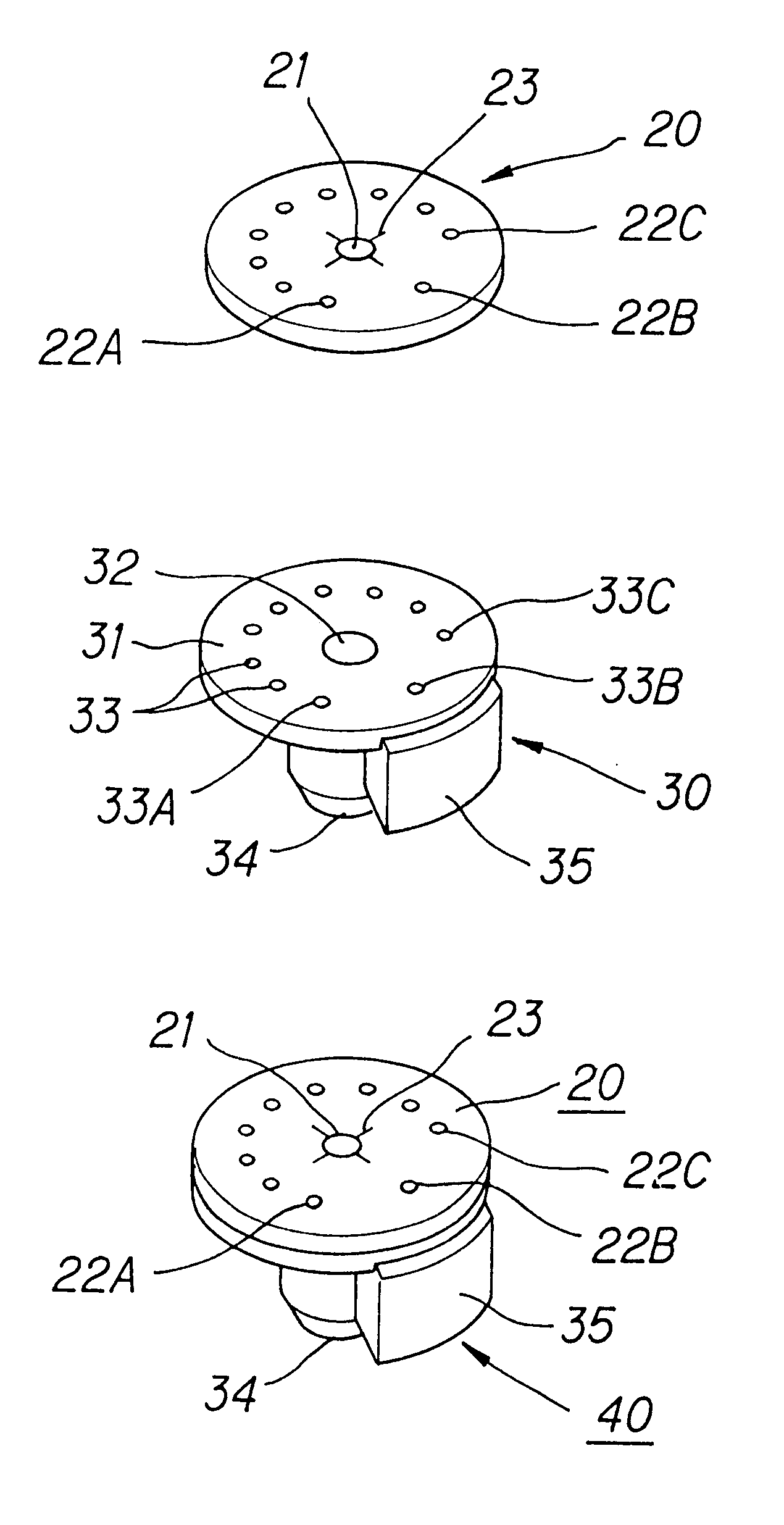

InactiveUS20050206299A1High dielectric strengthSimple structureGas filling substance selectionGas-filled discharge tubesDisplay deviceExhaust pipe

In a corner portion outside a display region of a face substrate which constitutes a face panel of a display device, an opening is formed. In the opening, a stem glass structural body, which is configured by integrally forming an exhaust pipe on a center portion of a stem glass and by forming conductive leads in a peripheral portion thereof in an embedded manner, is fixed by welding using curing by heating. The exhaust pipe is evacuated and, thereafter, tipped off, thus realizing vacuum sealing of the inside thereof. A lead line is connected to a distal end of one conductive lead by welding and another end of the lead line is electrically connected with one end portion of the anode formed on an inner surface of the face substrate using a conductive adhesive agent. Further, a getter is mounted and fixed to another conductive lead line by welding.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

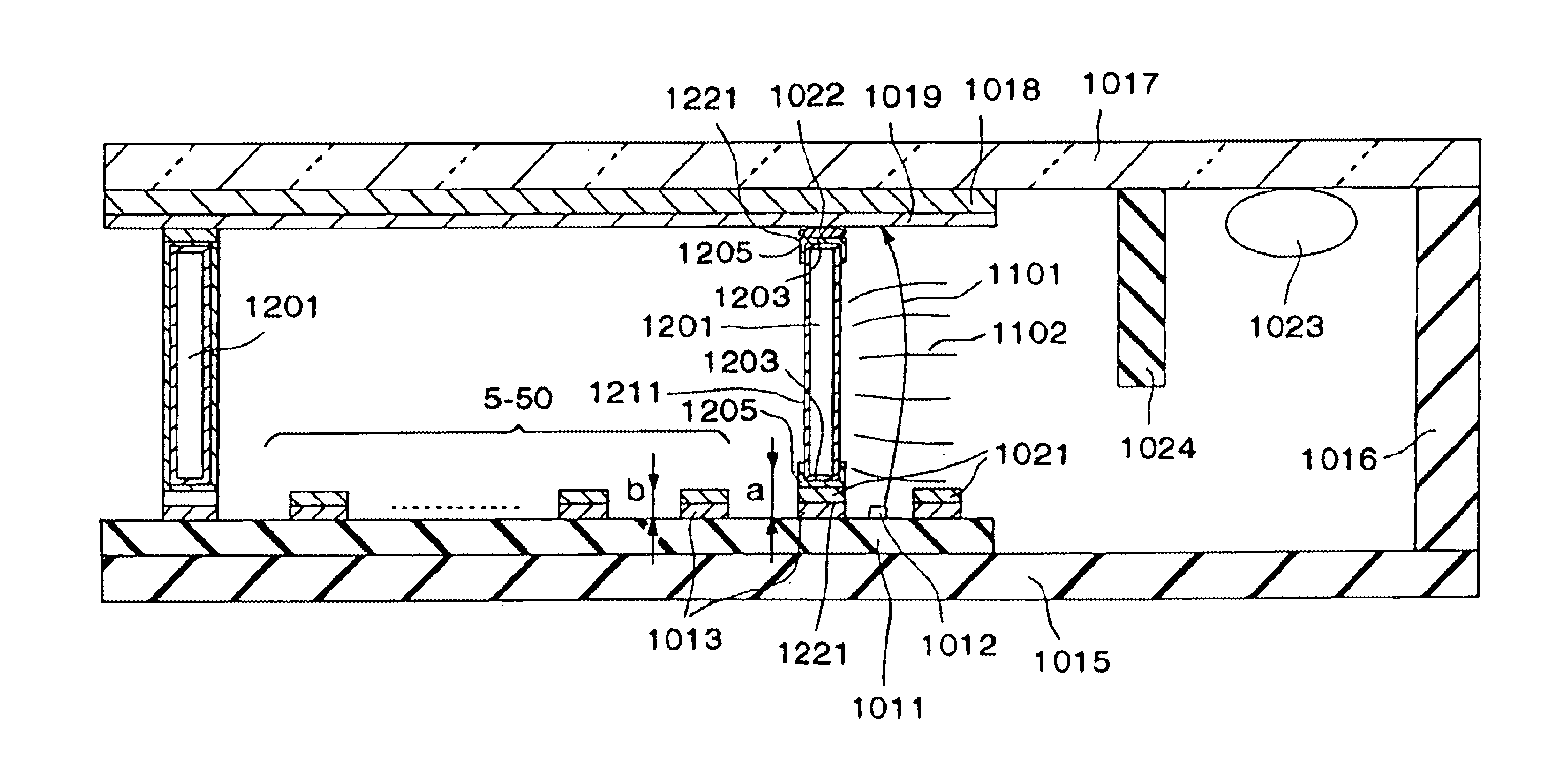

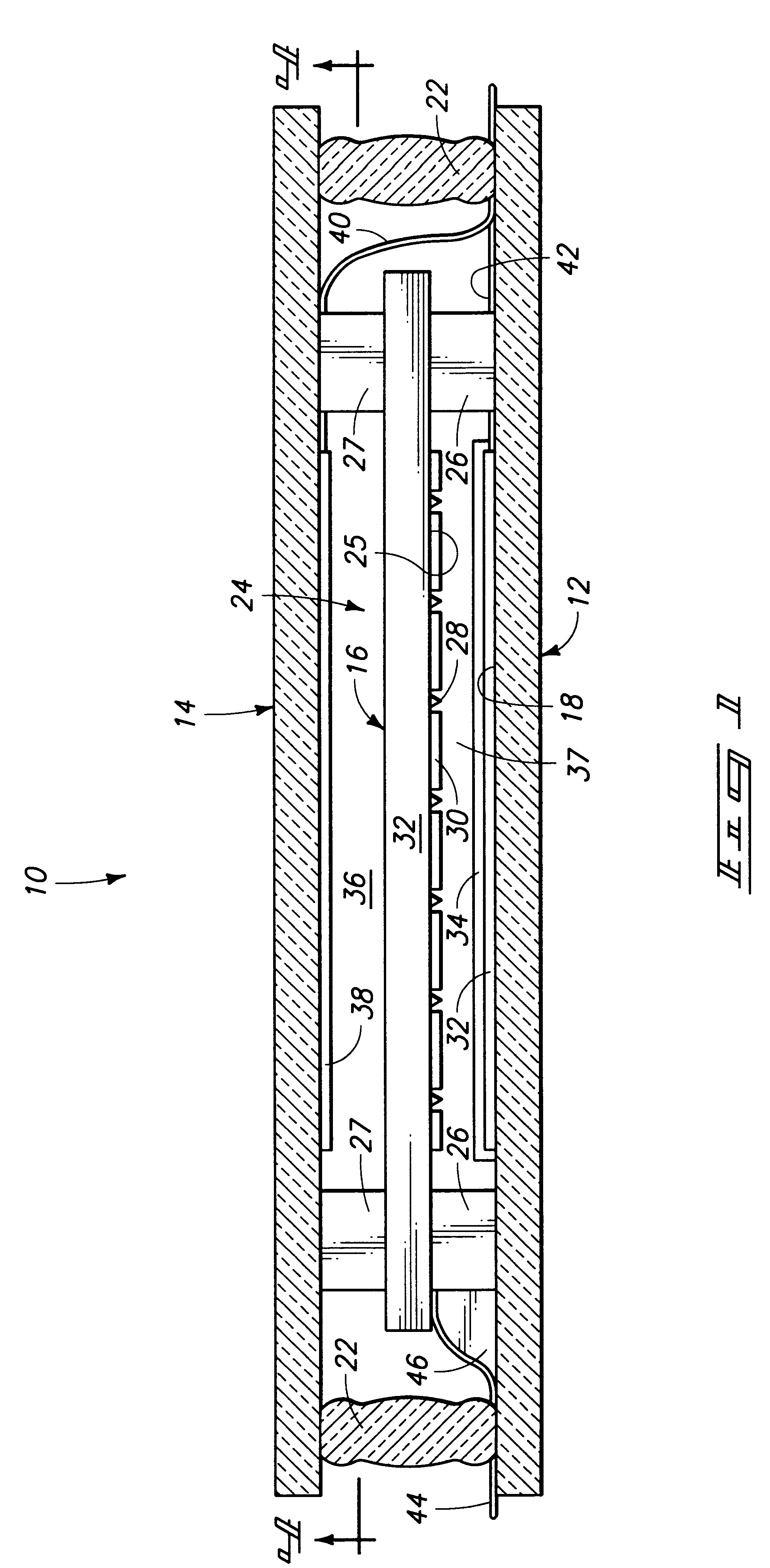

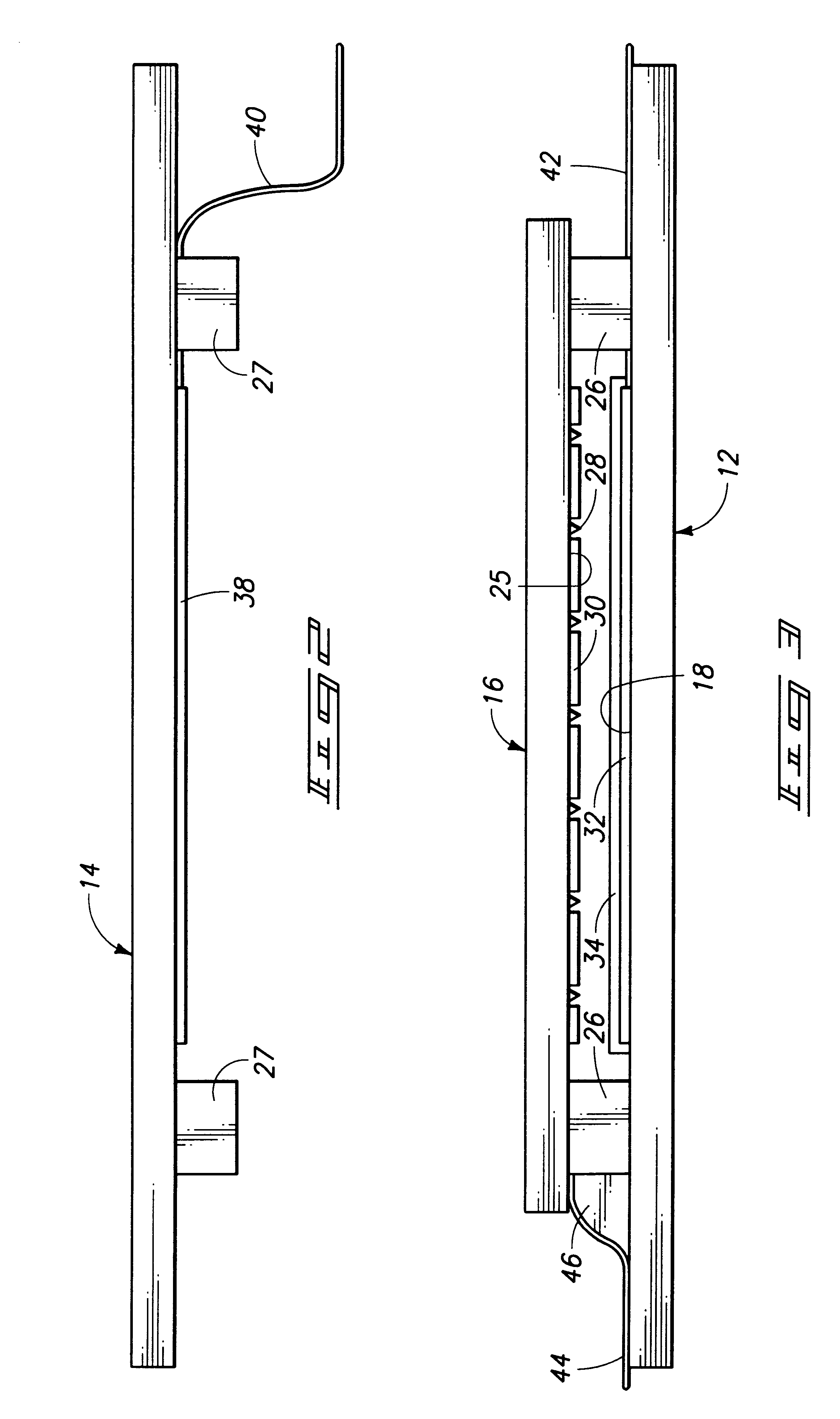

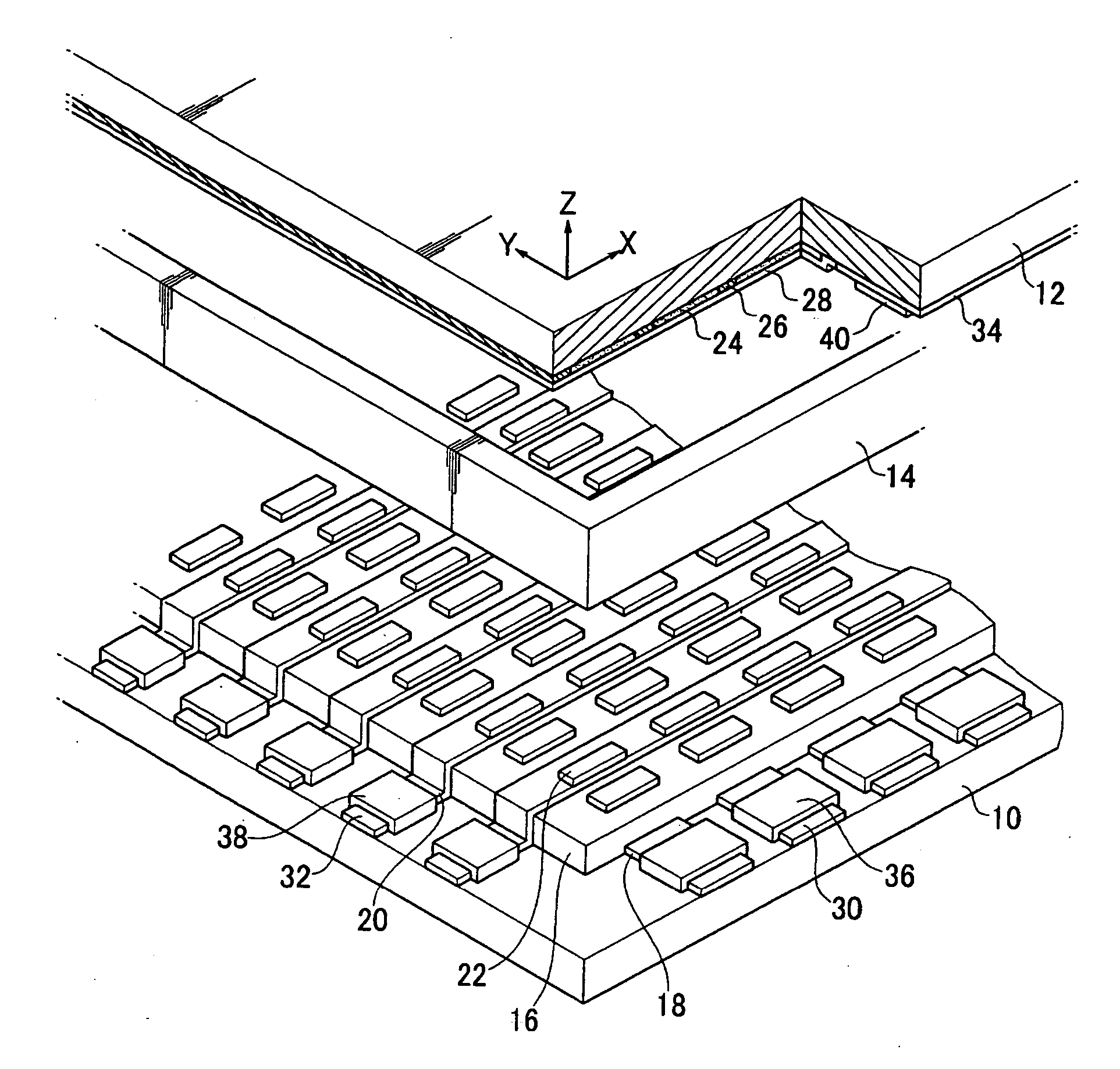

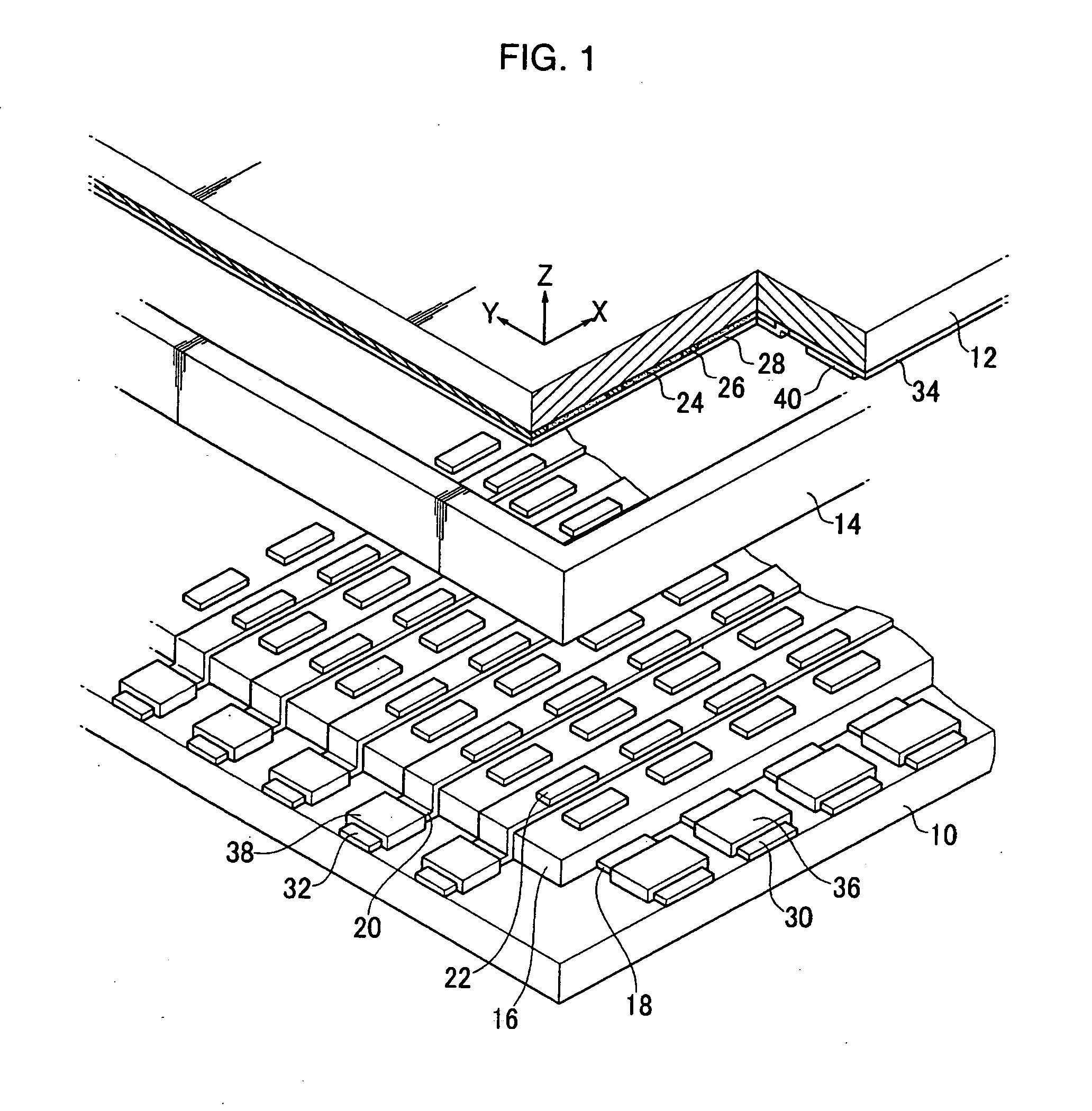

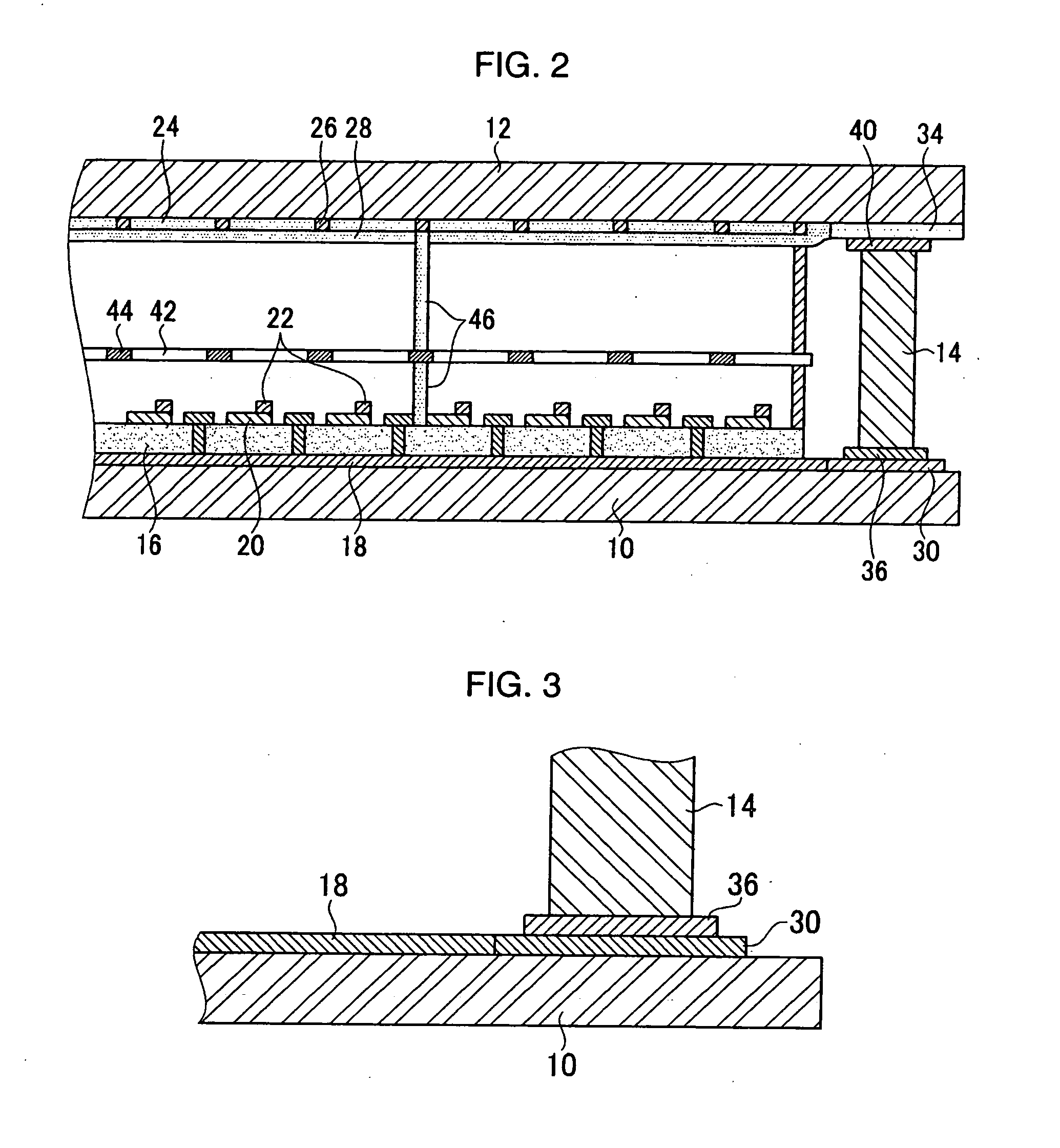

Image-forming apparatus and method of manufacture therefor

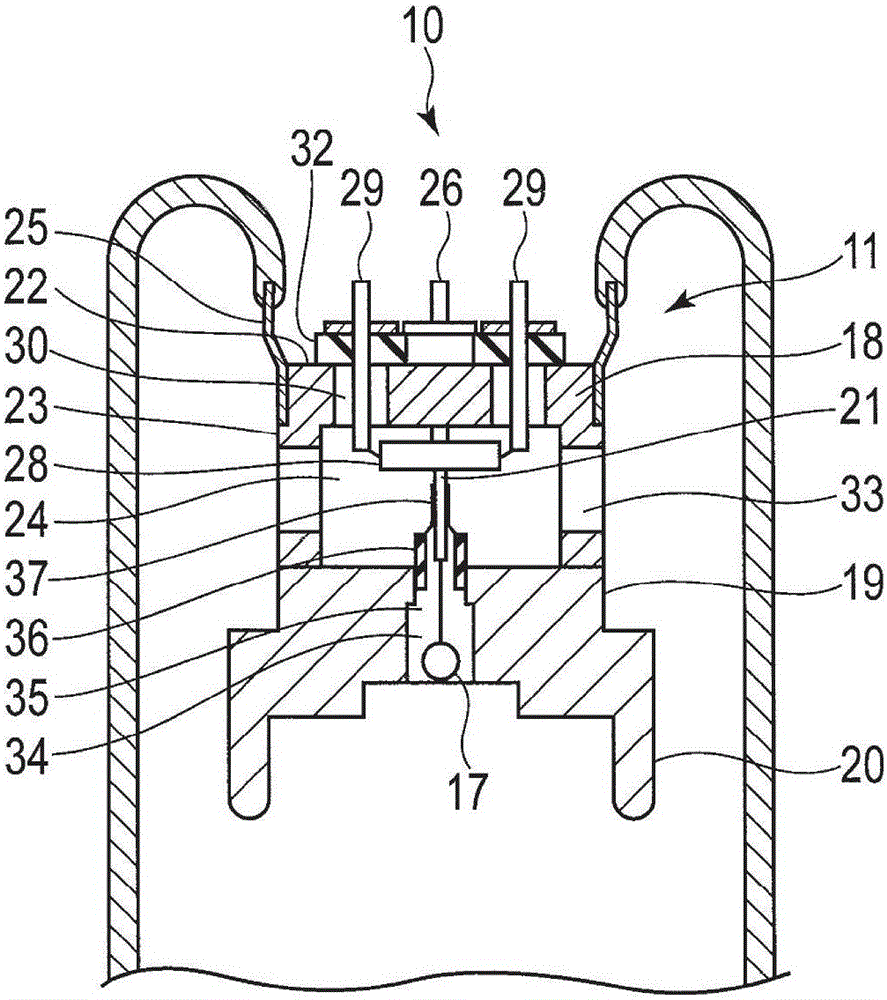

InactiveUS6528939B1Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube leading-in arrangementsElectron sourceImage formation

An image-forming apparatus includes a vacuum container having a first plate and a second plate arranged opposite to the first plate, an electron source disposed on the first plate and provided within the vacuum container, and an image-forming member disposed on the second plate within the vacuum container and irradiated with an electron emitted from the electron source. An airtight lead-in terminal has a first end in electrical contact with the image-forming member and a second end leading outside of the vacuum container through a hole in the first plate. The second end leading outside of the vacuum container is held and fixed so as not to protrude from an outer surface of the first plate.

Owner:CANON KK

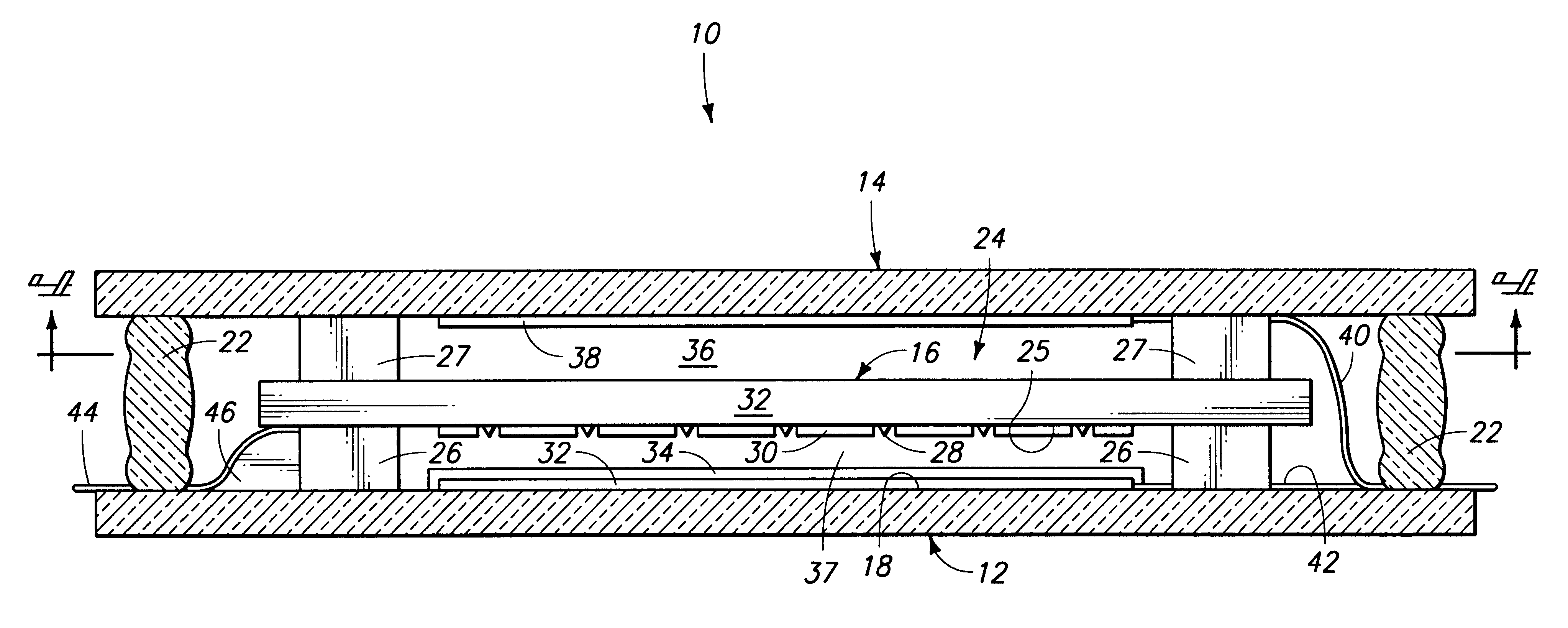

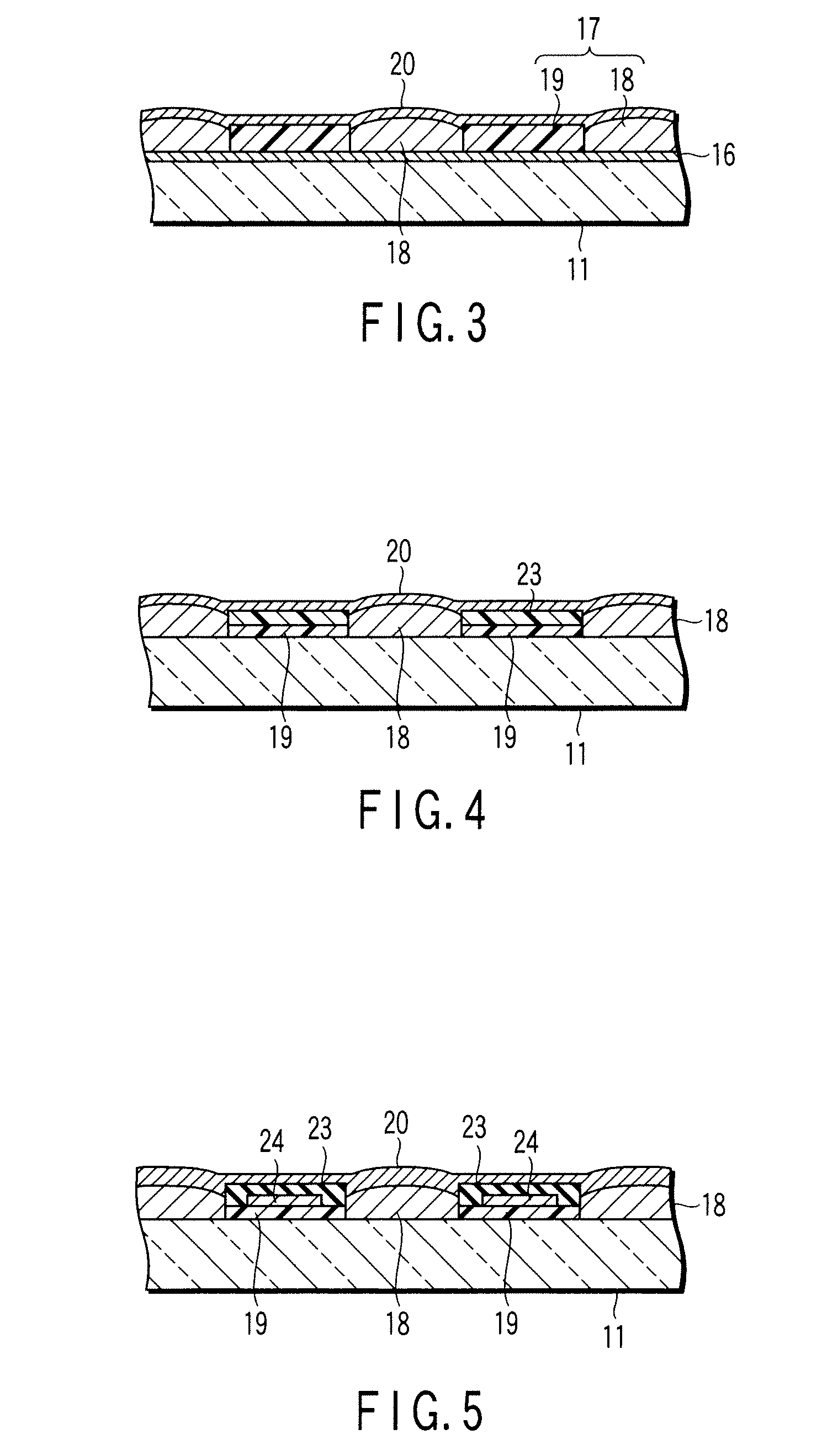

Flat panel display device and method of manufacturing the same

InactiveUS20050168129A1Increase in electrode resistance can be preventedEliminates unnecessary voltage dropCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersEngineeringFlat panel display

A flat panel display device includes a first substrate and a second substrate disposed to oppose each other with a predetermined gap therebetween. An electrode made of a transparent conductive oxide film is formed on at least one of the first substrate and the second substrate. A sealing member is disposed between the first substrate and the second substrate and bonds the first substrate and the second substrate to each other. An electrode protecting layer is formed on a portion of the electrode overlapping with the sealing member and between the sealing member and the electrode.

Owner:SAMSUNG SDI CO LTD

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

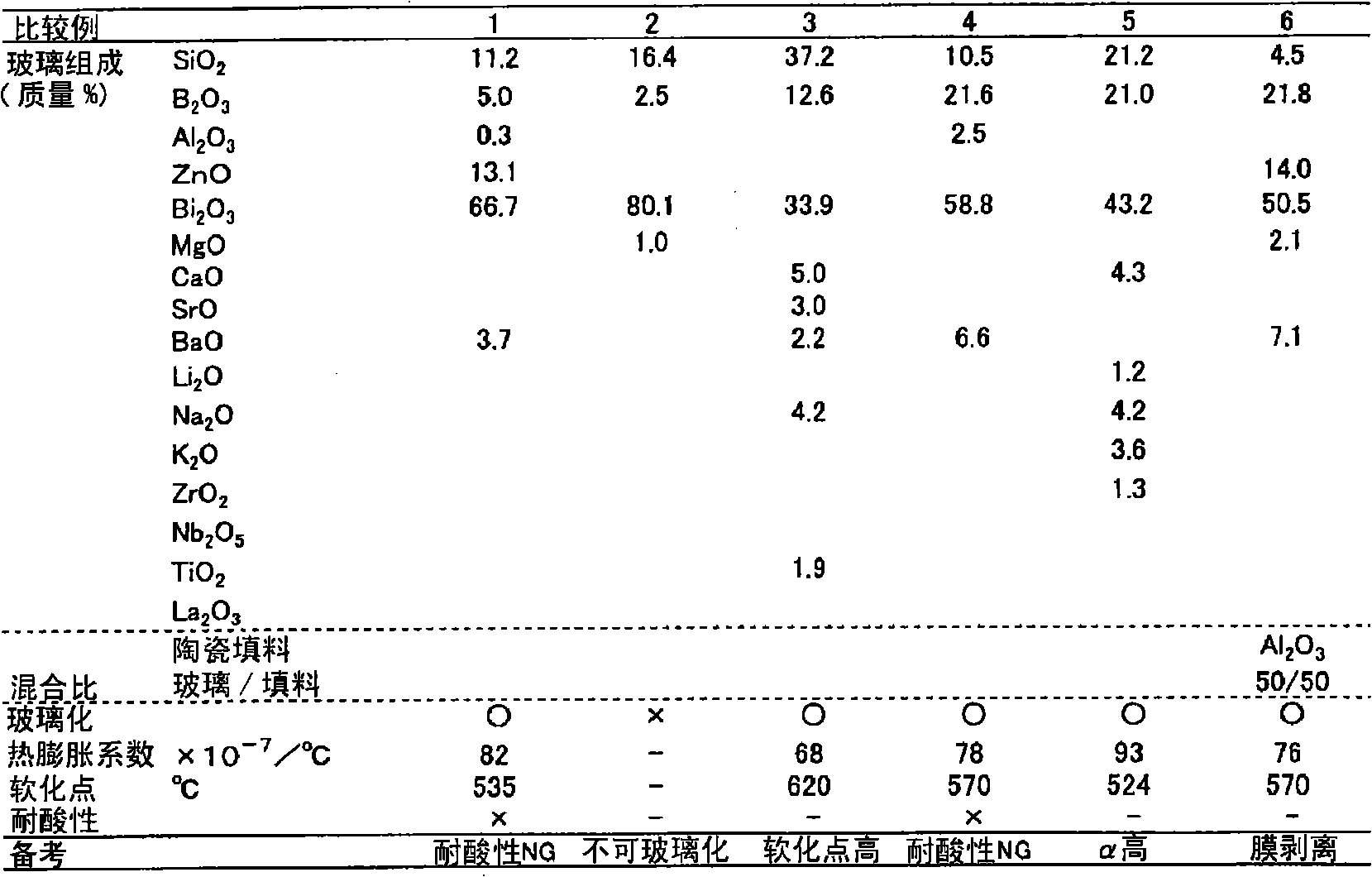

Lead-free low-melting-point glass composition having acid resistance

InactiveCN101970369ACathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersMaterials scienceLow melting point

Owner:CENT GLASS CO LTD

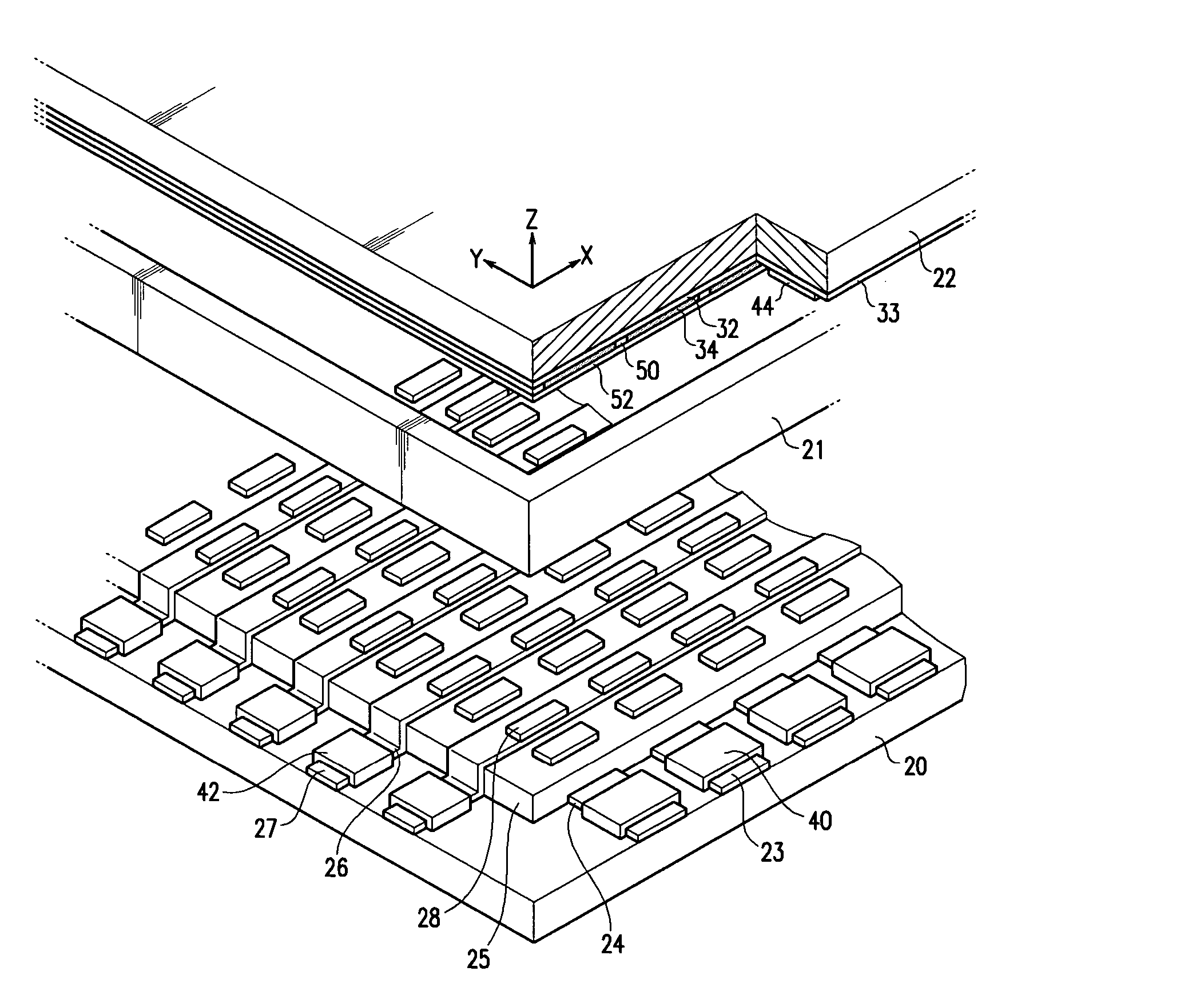

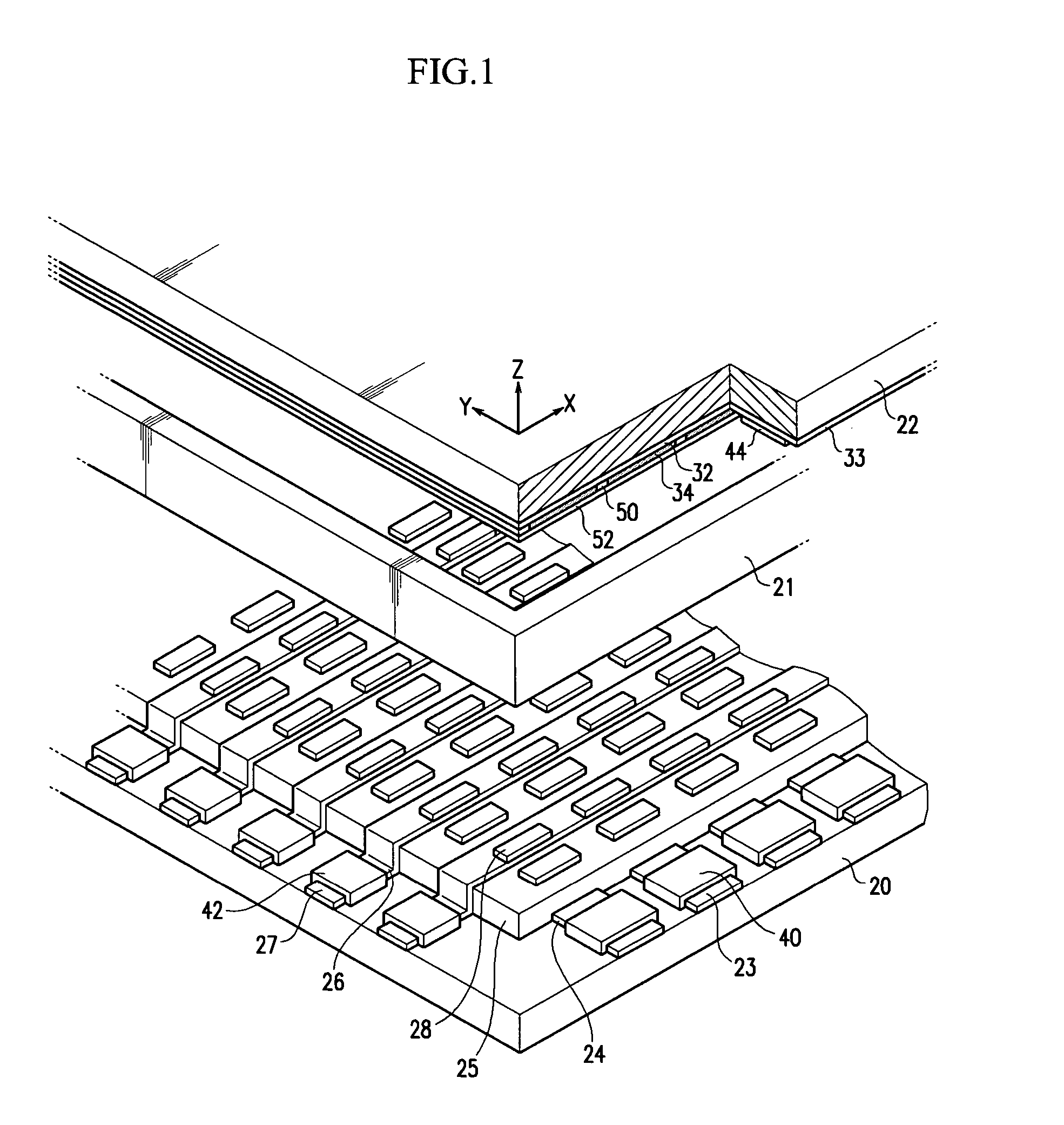

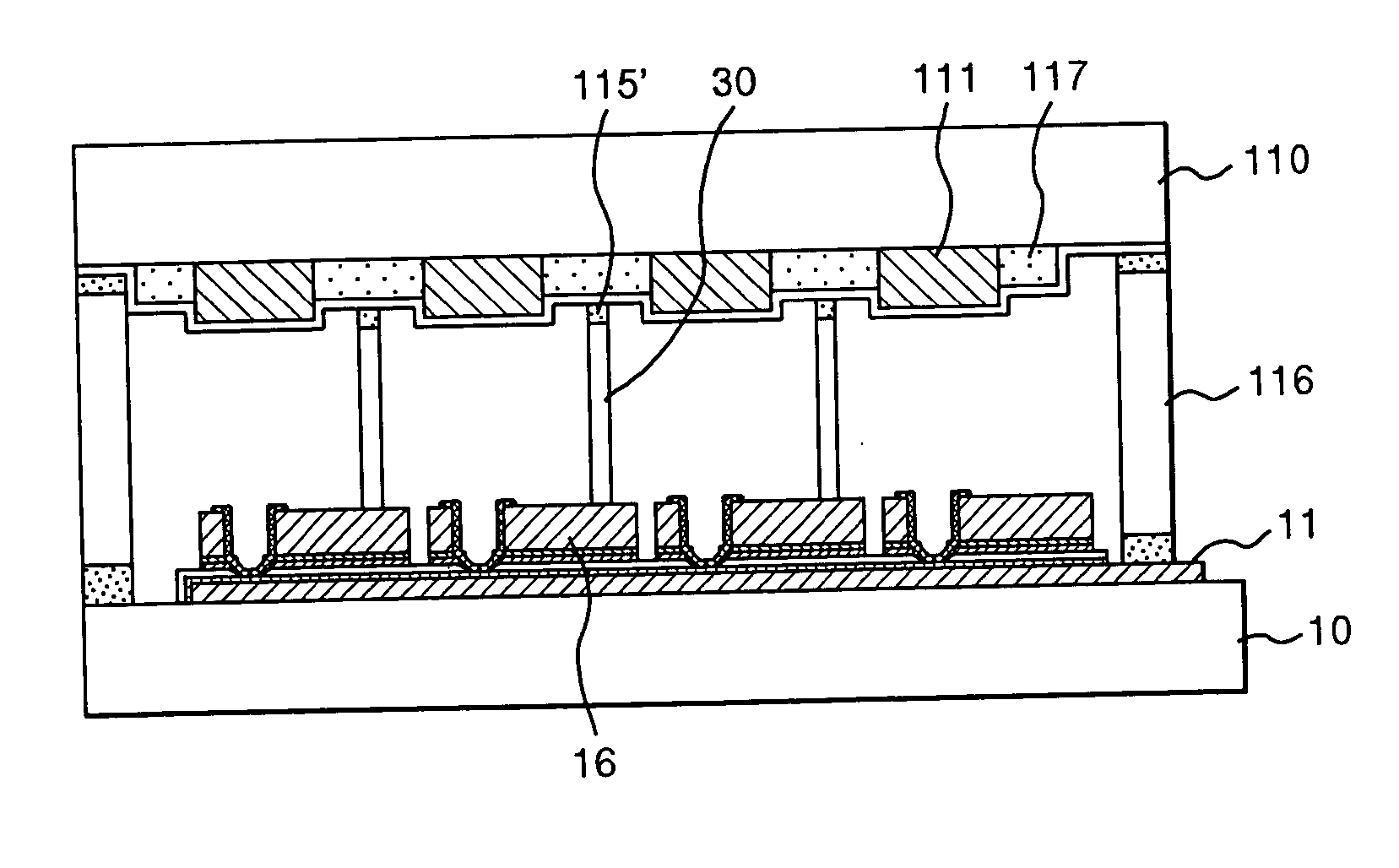

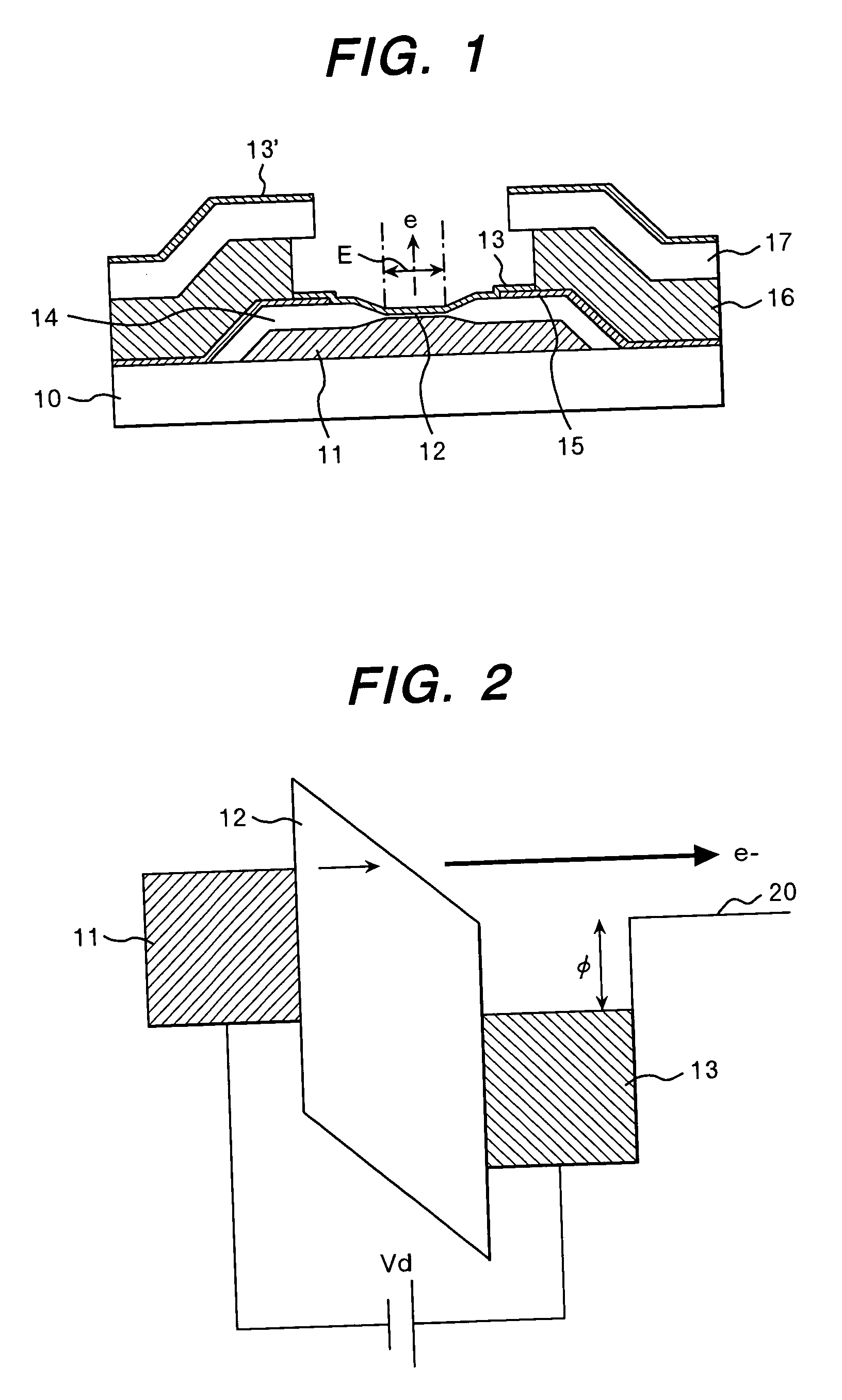

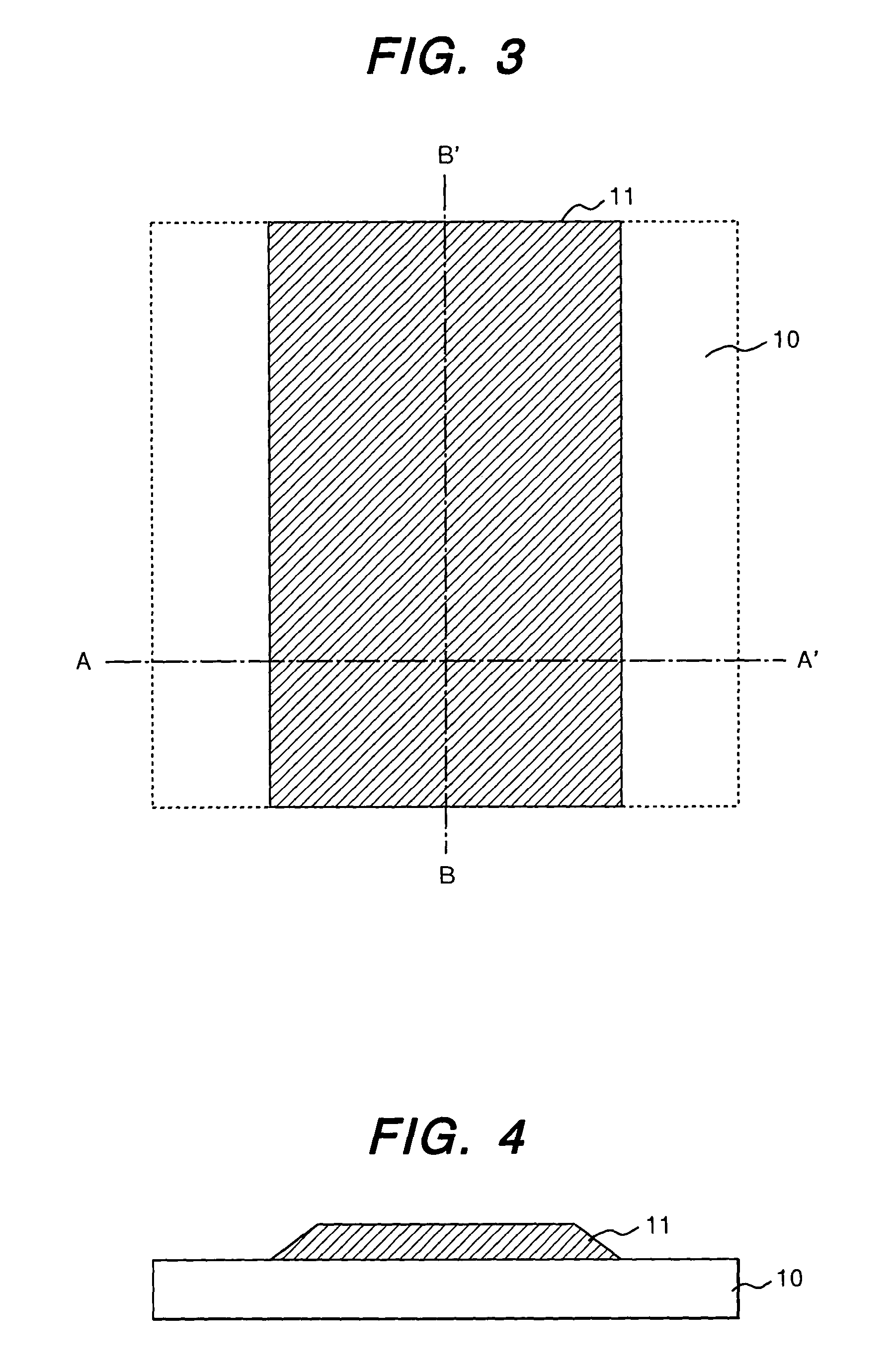

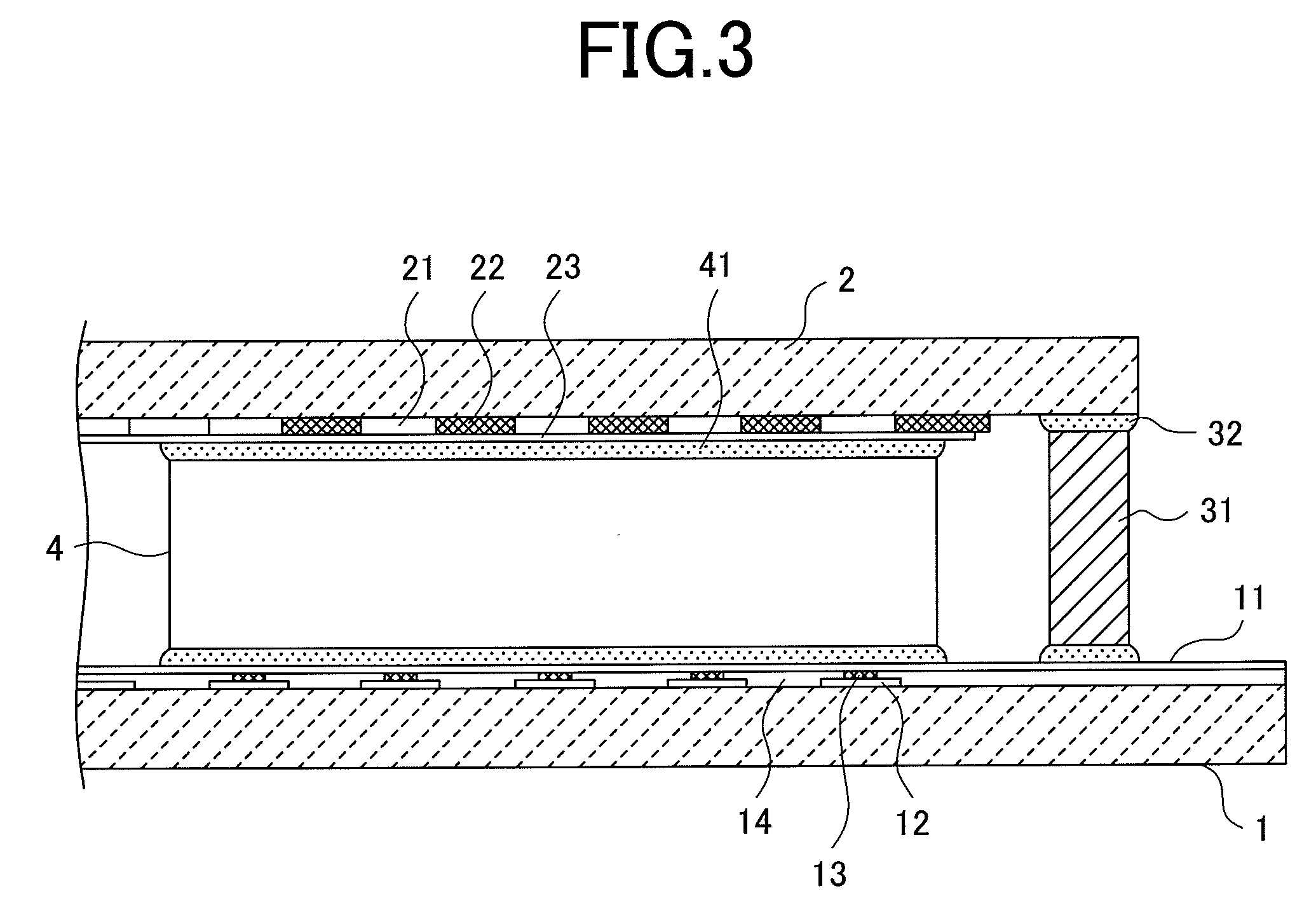

Cold cathode type flat panel display

InactiveUS20040130260A1Low production costSimple circuit structureControl electrodesDischarge tube luminescnet screensElectron sourceScan line

In a cathode substrate of an FED, spacers lines exclusive for connecting spacers to the ground were necessary besides scan lines and data lines, and a cathode substrate having a three-layer line structure was used in the prior art. The present invention realizes a high-reliable cold cathode type flat panel display which is easily produced and keeps performance that can be obtained by the three-layer line structure, using a cathode substrate having a two-layer line structure. The line structure of a cathode substrate 10 of an FED is made into a two-layer structure. Hitherto, lines of the first layer are bottom electrodes 11 which constitute electron sources and have been used as scan lines, and top electrodes 13 of the second layer have been used as data lines. In the present invention, however, the bottom electrodes 11 and the top electrodes 13 are changed to data lines and scan lines, respectively. Moreover, some parts of top electrode bus lines connected to the top electrodes 13 are used as spacer lines, too, or the top electrode bus lines 16 are divided so as to be made into spacer lines 16'.

Owner:HITACHI LTD

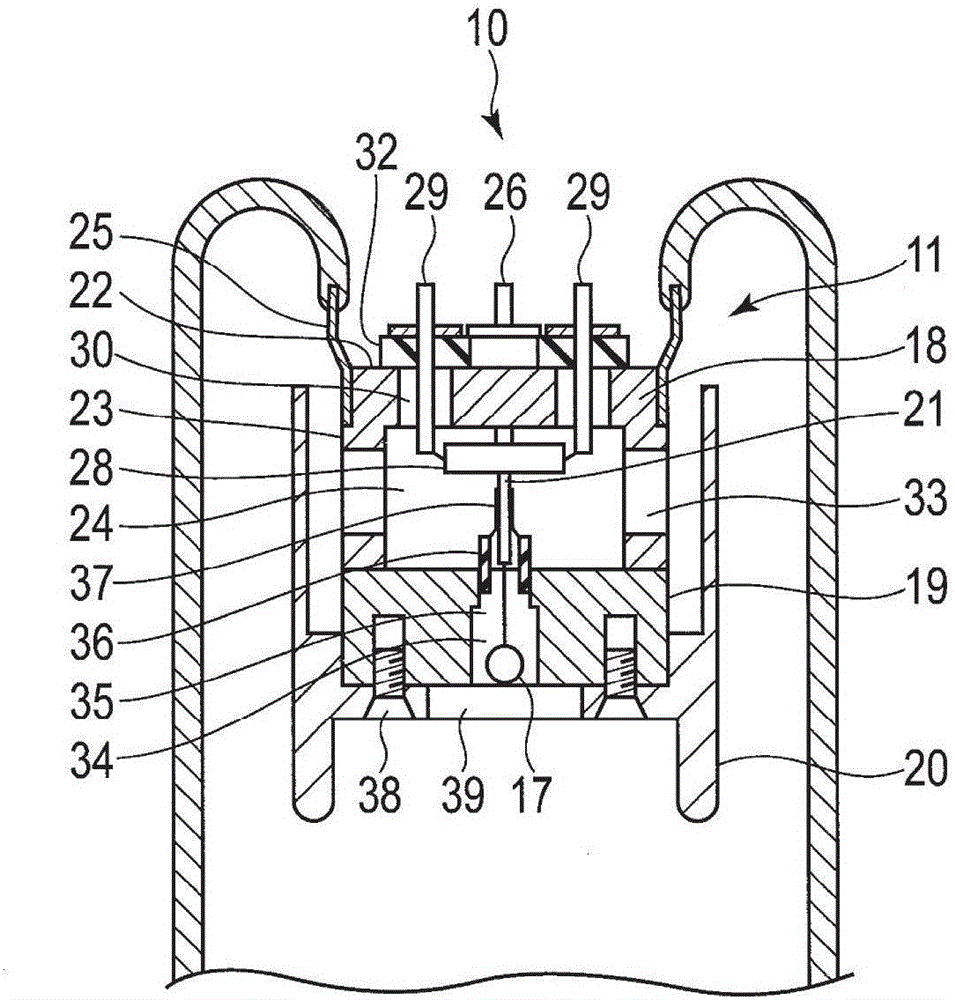

Display Device

InactiveUS20080315748A1High voltageImprove reliabilityCathode-ray/electron-beam tube electrical connectionGas filling substance selectionContact pressureAnode voltage

There is disclosed an FED (field emission display) capable of supplying an anode voltage, which is a high voltage, to an anode substrate with high reliability. A high voltage introduction button is sealed to a sealing plate, in which a contact spring is attached to the high voltage introduction button by spot welding. The high voltage introduction button has a flat portion connected to the contact spring, a sealing portion sealed to the glass substrate, and an external terminal to be connected to an external power source. The contact spring contacts an anode terminal of an anode substrate with an appropriate contact pressure, by a spring force from an arm portion of the contact spring. The anode terminal is formed of a conductive film containing metal particles.

Owner:HITACHI LTD

Self-luminous planar display device

InactiveUS20060043877A1Avoid display qualityLow reliabilityDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsDisplay deviceEngineering

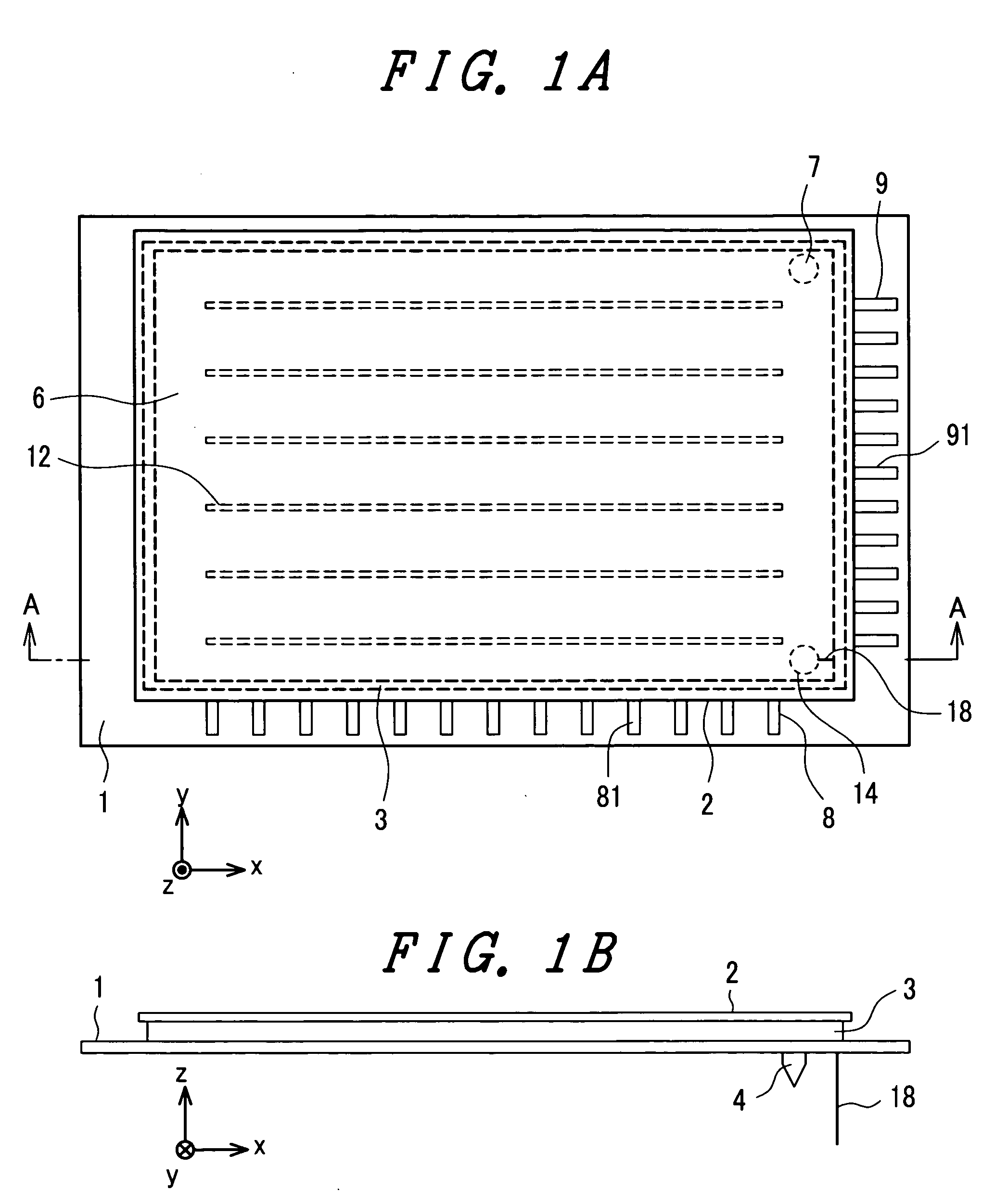

The present invention provides a self-luminous planar display device which exhibits high quality and high reliability by suppressing discharge attributed to charging of charge in a gap formed at a bent portion of a lead terminal. One of or both data line lead terminals and scanning line lead terminals are formed in parallel at least to the inner side of a sealing frame, and a gap which is formed by bent portions of the lead terminals is arranged at a position where the gap does not project to the inside from the sealing region (adhering region) of a back panel and a sealing frame.

Owner:HITACHI DISPLAYS

Airtight container and display device using the airtight container, and manufacturing method therefor

InactiveUS7928645B2Reduce airtightnessDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsDisplay deviceEngineering

Owner:CANON KK

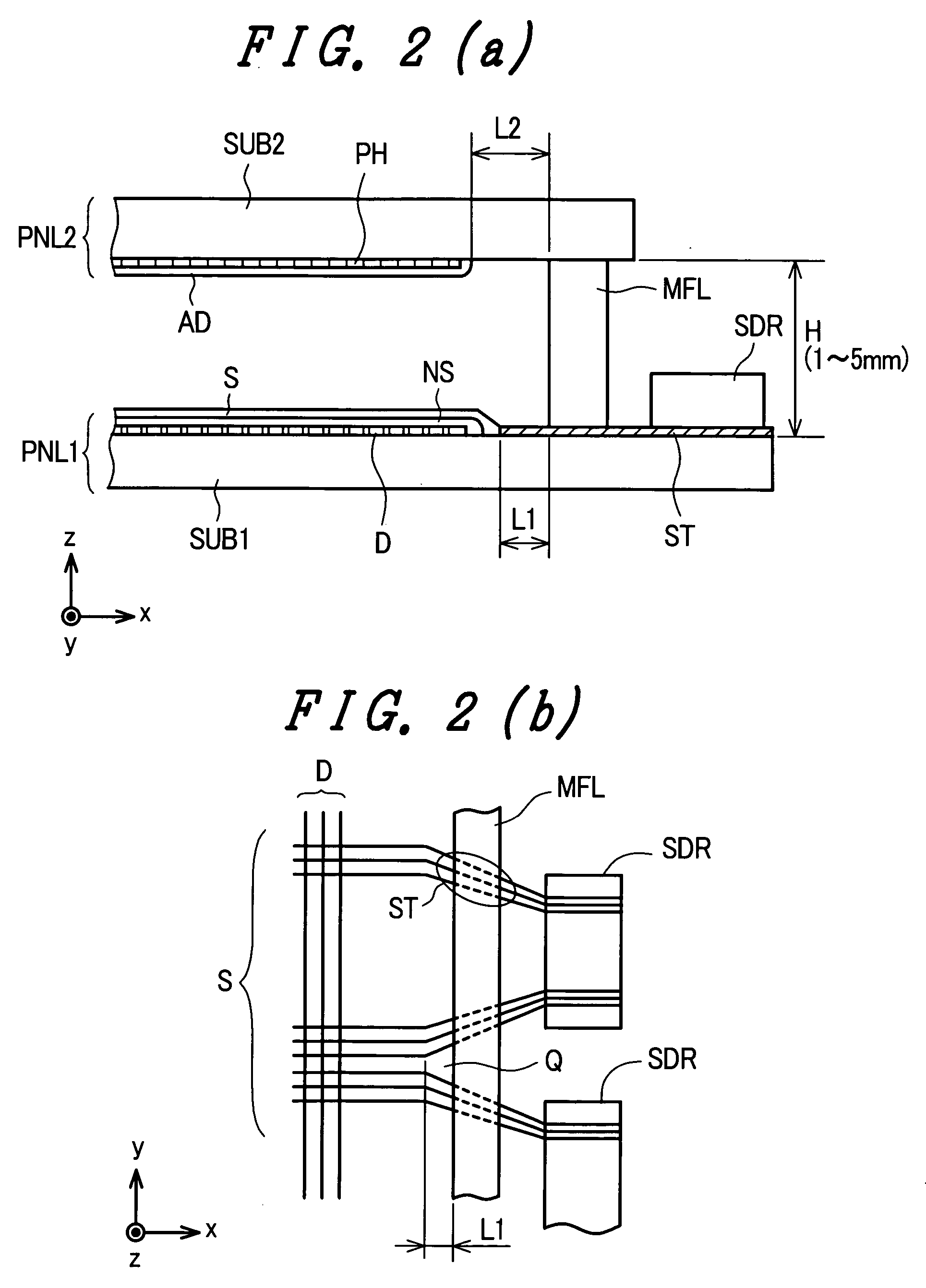

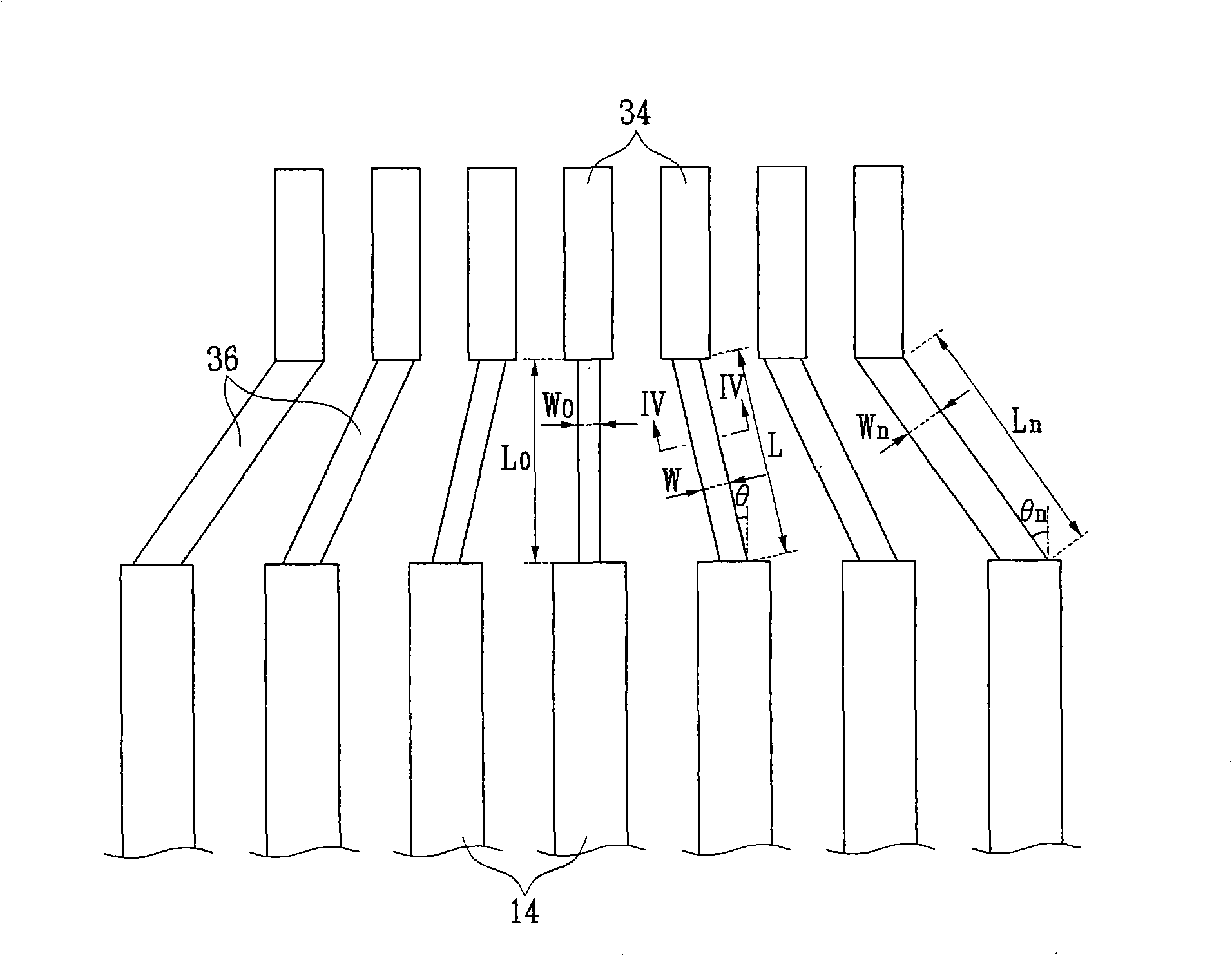

Flat panel display

InactiveCN101271802ACathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube leading-in arrangementsLine widthDisplay device

A flat panel display to maintain resistance of lines at the same level to reduce a luminance difference between the lines includes a plurality of electrodes (14) and a plurality of lead lines (36) to respectively connect a plurality of pads (34) to the plurality of electrodes (14). The lead lines (36) are formed in a parallelogram shape in which resistivity and line thickness are the same for each lead line, and a length L and a line width W of each lead line are selected such that a value obtained by dividing the length L by the line width W satisfies the equation:; L 1 W 1 = L 2 W 2 = L 3 W 3 = | | = L n W n , where L1, L2, L3, ..., and Ln respectively refers to long side lengths, which are direct line distances between the electrode (14) and the pad (34), of the respective lead lines (36) formed in the parallelogram shape, and W1, W2, W3, . , and Wn respectively refers to widths, which are short side distances of the respective lead lines (36) formed in the parallelogram shape.

Owner:SAMSUNG SDI CO LTD

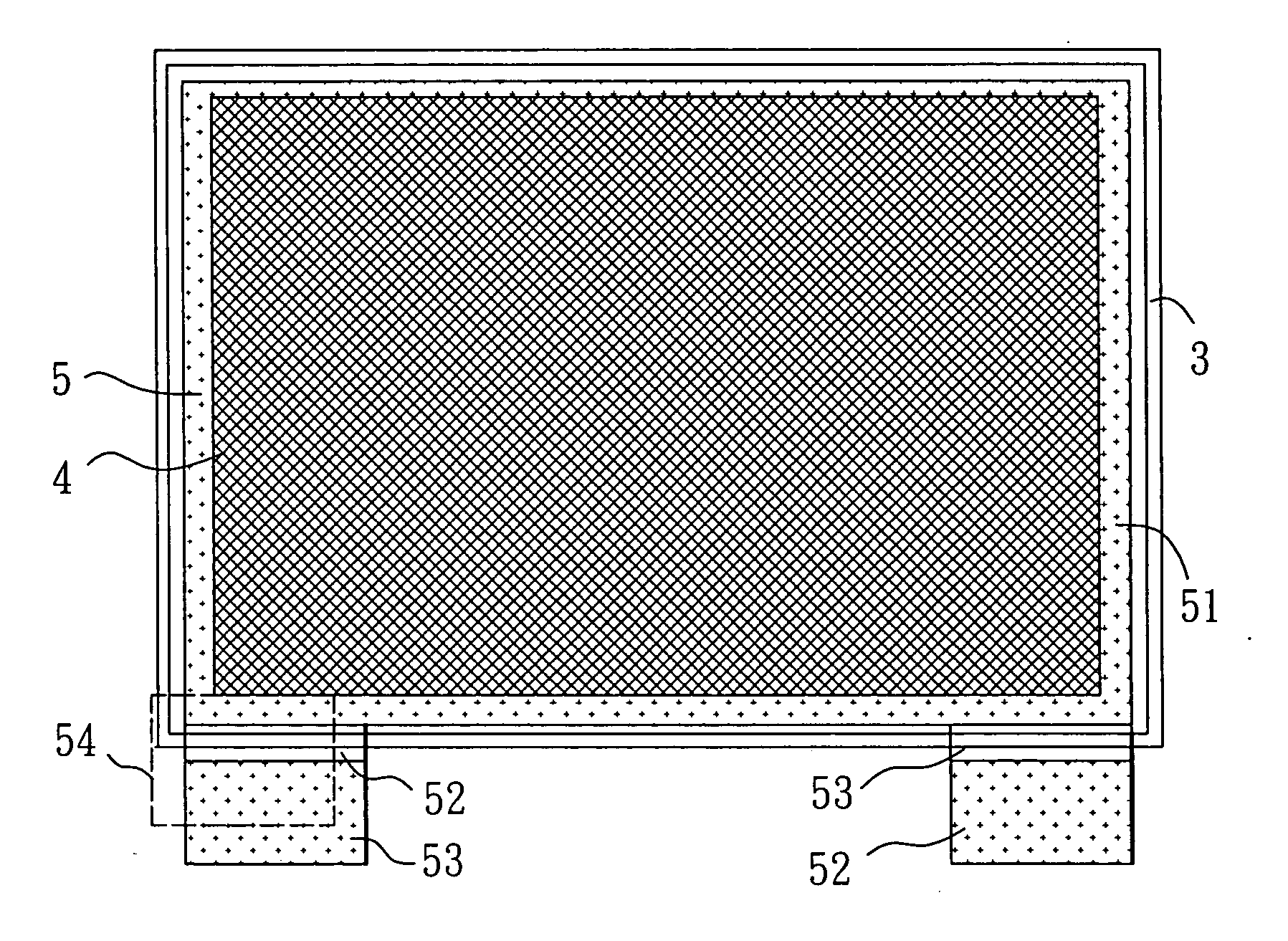

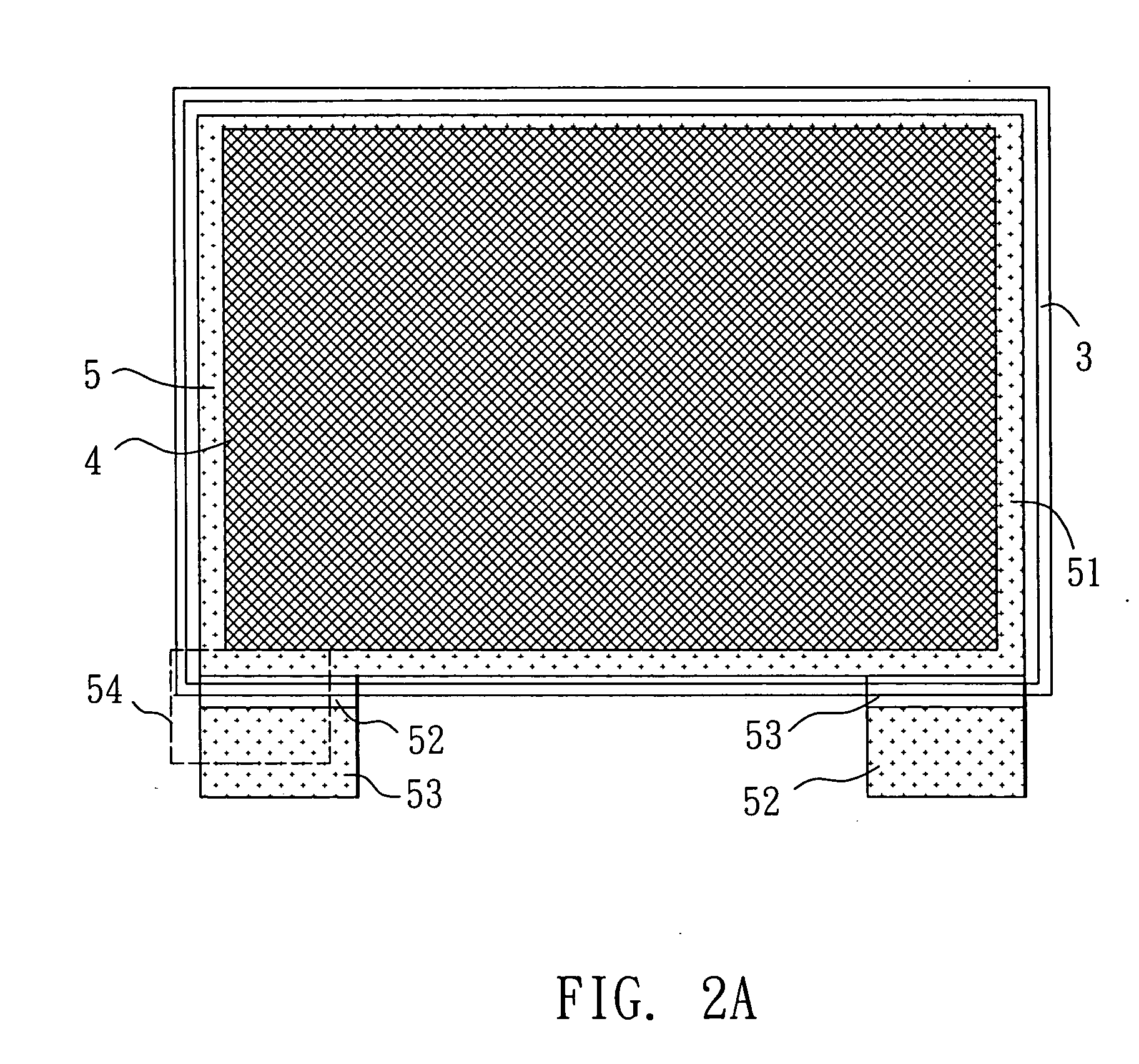

Anode plate for a field emission display device

InactiveUS20050046335A1Sealing strengthSmall sizeCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensField emission displayLuminescence

An anode plate for a field emission display device (FED) is disclosed, which has a substrate; an anode conductive layer formed on the substrate; at least one interspacing conductive band having a plurality of internal gaps for connecting the anode conductive layer and external cable lines, wherein the interspacing conductive band covers a part of the anode conductive layer; and a fluorescent layer located on the anode conductive layer, to serve as a source of luminescence for a field emission display device. The field emission display device includes the anode plate aforesaid as is also disclosed.

Owner:IND TECH RES INST

Vacuum fluorescent display

InactiveUS20050140267A1Cathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensFluorescenceDisplay device

A vacuum fluorescent display includes a display portion, filament cathode, grid, and a pair of filament support members. The display portion is arranged on a substrate and has an anode coated with a phosphor material in accordance with a pattern to be displayed. The filament cathode is applied above the anode of the display portion to be separate from the anode. The grid is arranged between the anode of the display portion and the filament cathode, and cooperates with the corresponding anode to display a predetermined pattern. The pair of filament support members are connected to an outside and extend the filament cathode. Part of the filament support members is clamped between a front glass plate and glass spacer and is extracted to outside.

Owner:NORITAKE ITRON CORP +1

Image display device

InactiveUS20070069630A1Easy to manufactureEase of mass productionDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsPhosphorVoltage source

In an image display device which includes a frame body which is arranged between a back substrate and a face substrate, a phosphor screen which is arranged on the face substrate, and an anode lead line for introducing a high voltage which is arranged between the phosphor screen and a voltage source, the anode lead line is covered with at least a portion of the frame body. According to the present invention, it is possible to obtain an image display device having a prolonged lifetime and capable of performing a high quality display while ensuring the conduction of a high voltage which is applied to a phosphor screen side.

Owner:HITACHI DISPLAYS

Flat panel display device

InactiveUS20060267479A1Increase resistanceIncrease brightnessCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersFlat panel displayMetal

Owner:SAMSUNG SDI CO LTD

Display device

InactiveUS20060038479A1Lower resistanceSmall thicknessDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsElectrical resistance and conductanceDisplay device

In the display device having a plurality of electron emitter elements and an internal circuit connected to the electron emitter elements both being formed on a substrate and sealed within a sealing member, the present invention provides a lead line passing through the sealing member to connect the internal circuit with an external circuit and forms the internal circuit smaller in resistivity (specific resistance) than the lead line by e.g. forming the lead line thinner than the internal circuit to suppress voltage drop in the internal circuit as well as to secure the predetermined sealing condition of the electron emitter elements and the internal circuit.

Owner:HITACHI LTD

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS10252938B2Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritElectronic component

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

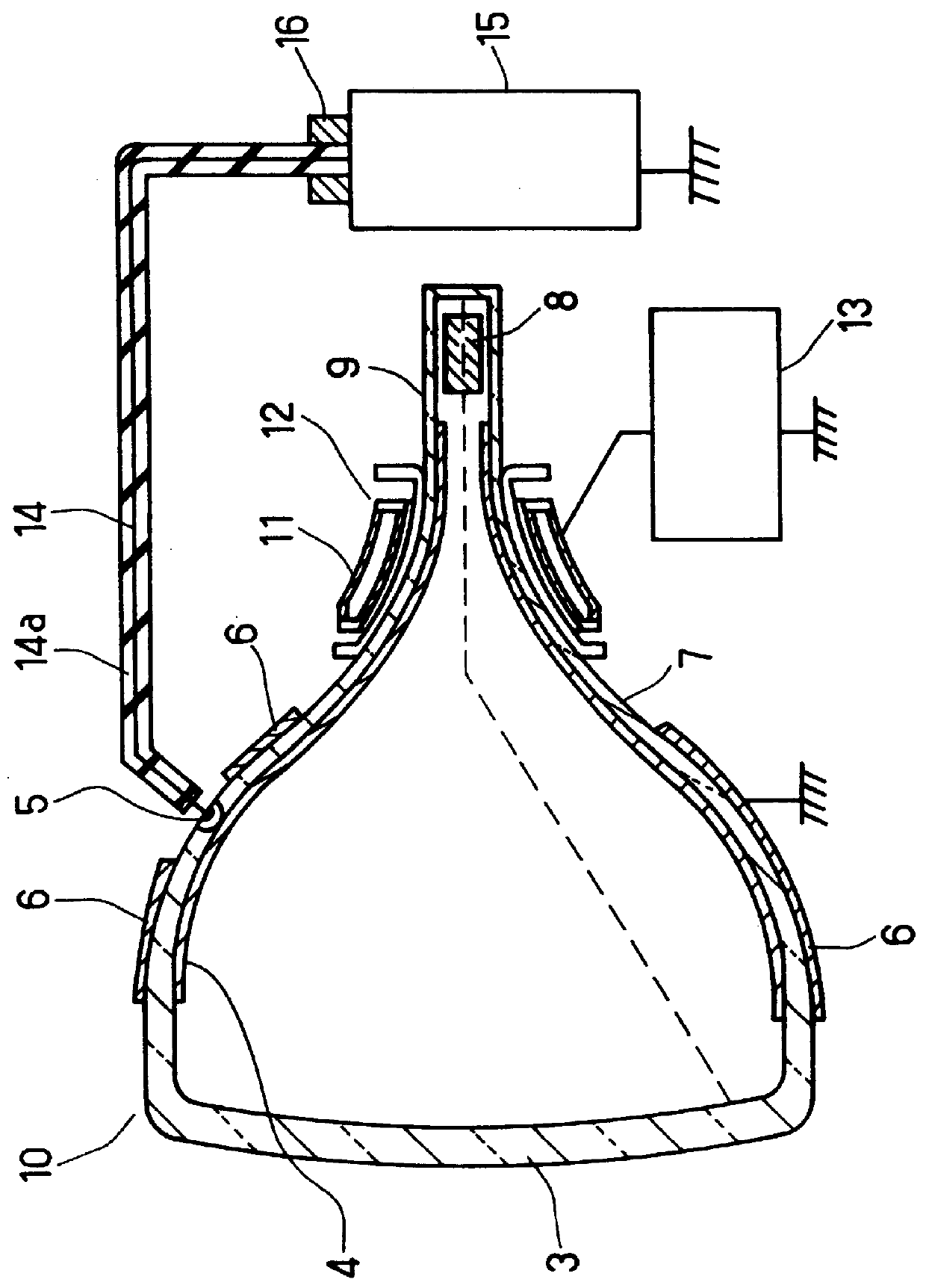

Cathode ray tube apparatus

InactiveUS6054804AReduce leakageTelevision system detailsCathode-ray/electron-beam tube electrical connectionElectrical conductorNeck parts

A cathode ray tube apparatus that can reduce the leakage extraneous electric field with low cost. The cathode ray tube apparatus comprises a front panel, a glass bulb having a funnel part including an anode terminal at the outer surface thereof and a neck part including an electron gun, a deflection apparatus comprising a horizontal deflection coil on the outer surface of the funnel part and the neck part of the glass bulb, a flyback transformer connected to the anode terminal of the funnel part via a first lead wire having an insulating coating, and a leakage extraneous electric field controller installed on the first lead wire. The controller reduces the leakage of the extraneous electric field from the first lead wire. It is preferable that the leakage extraneous electric field controller comprises a negative pulse generator generating negative pulses having a reverse polarity and a synchronized period with respect to the horizontal deflection voltage signal of the horizontal deflection coil, a conductor at least partially surrounding the insulation coated first lead wire, and a second lead wire connecting the negative pulse generator and the conductor.

Owner:PANASONIC CORP

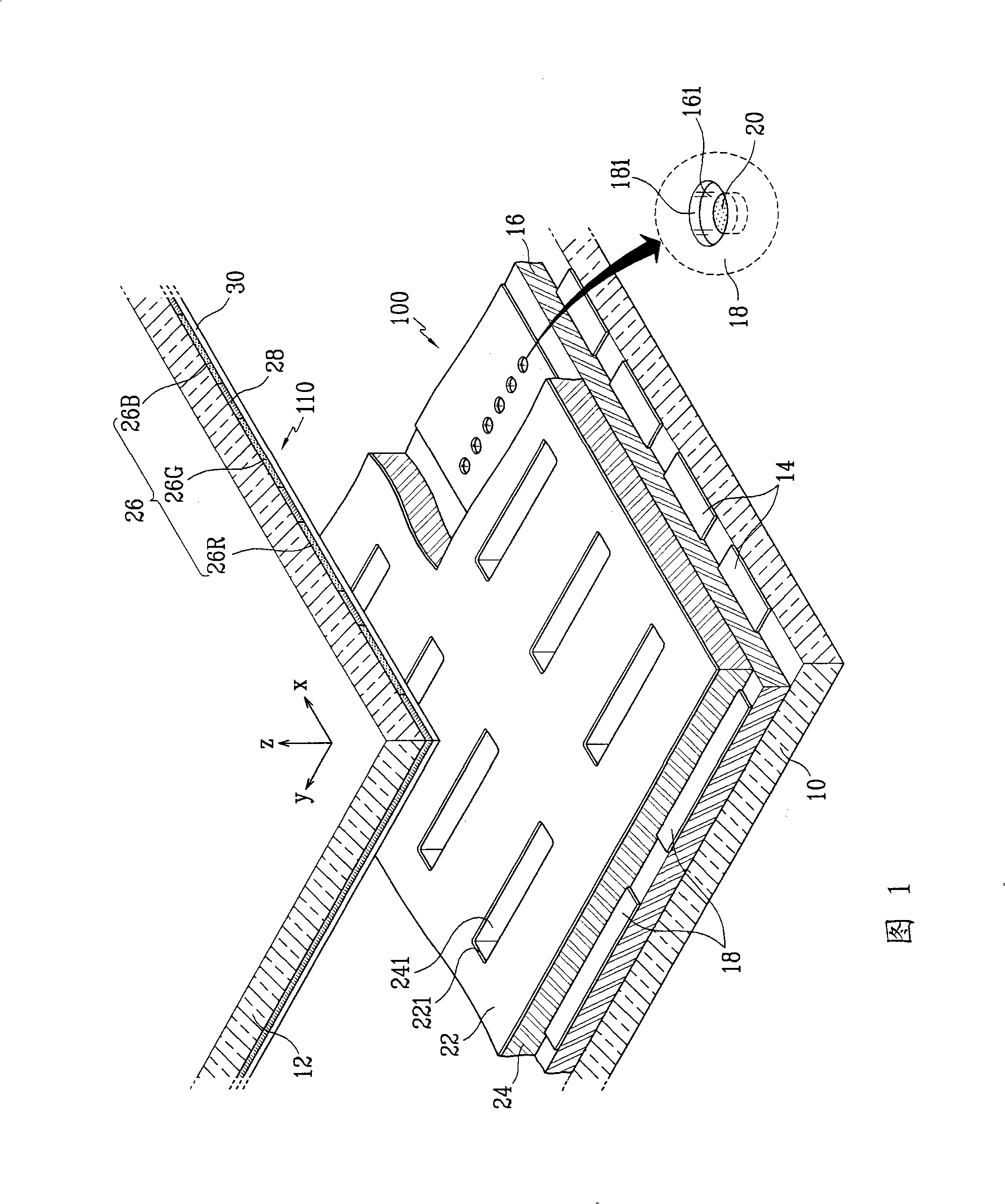

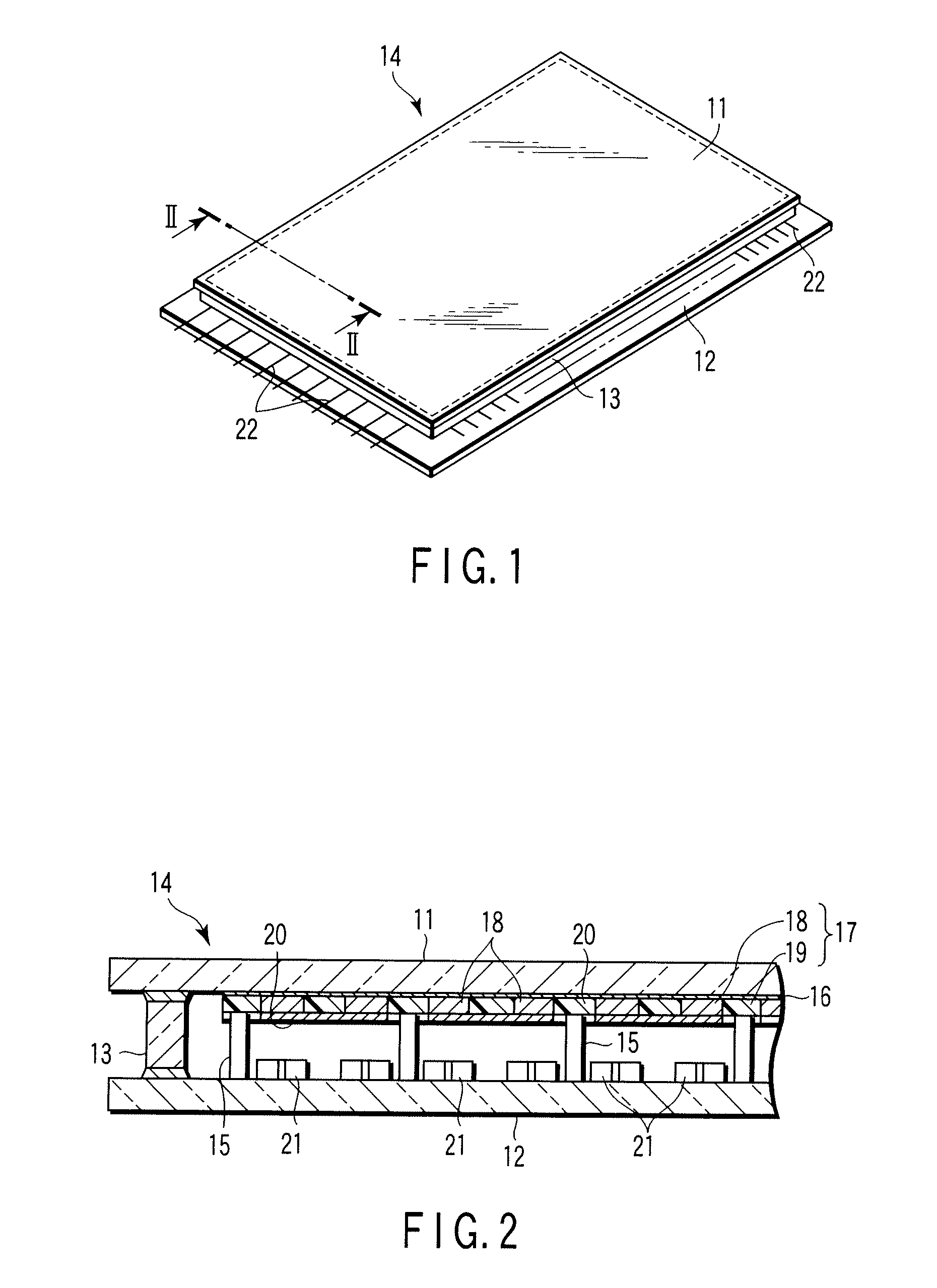

Image display device

InactiveCN101040364ABroaden your optionsAvoid voltage dropCathode-ray/electron-beam tube leading-in arrangementsImage/pattern display tubesPhosphorElectron excitation

An image display device is provided with a front plate (11) and a rear plate. The front plate is provided with a phosphor screen (17), which includes a phosphor layer and a light blocking layer, and a metal back layer (20) which is provided to overlap the phosphor screen and is an anode electrode for electron excitation of the phosphor layer. The rear plate is arranged to face the front plate with an electron emitting element arranged thereon for emitting electrons to the phosphor screen. On the front plate, an anode power supply terminal and an anode power supply wiring (16) connected to the metal back layer are formed. The anode power supply wiring (16) is formed closer to the front plate (11) than the metal back layer (20), and the anode power supply wiring (16) is connected to the metal back layer (20) through a resistant material layer (19).

Owner:KK TOSHIBA

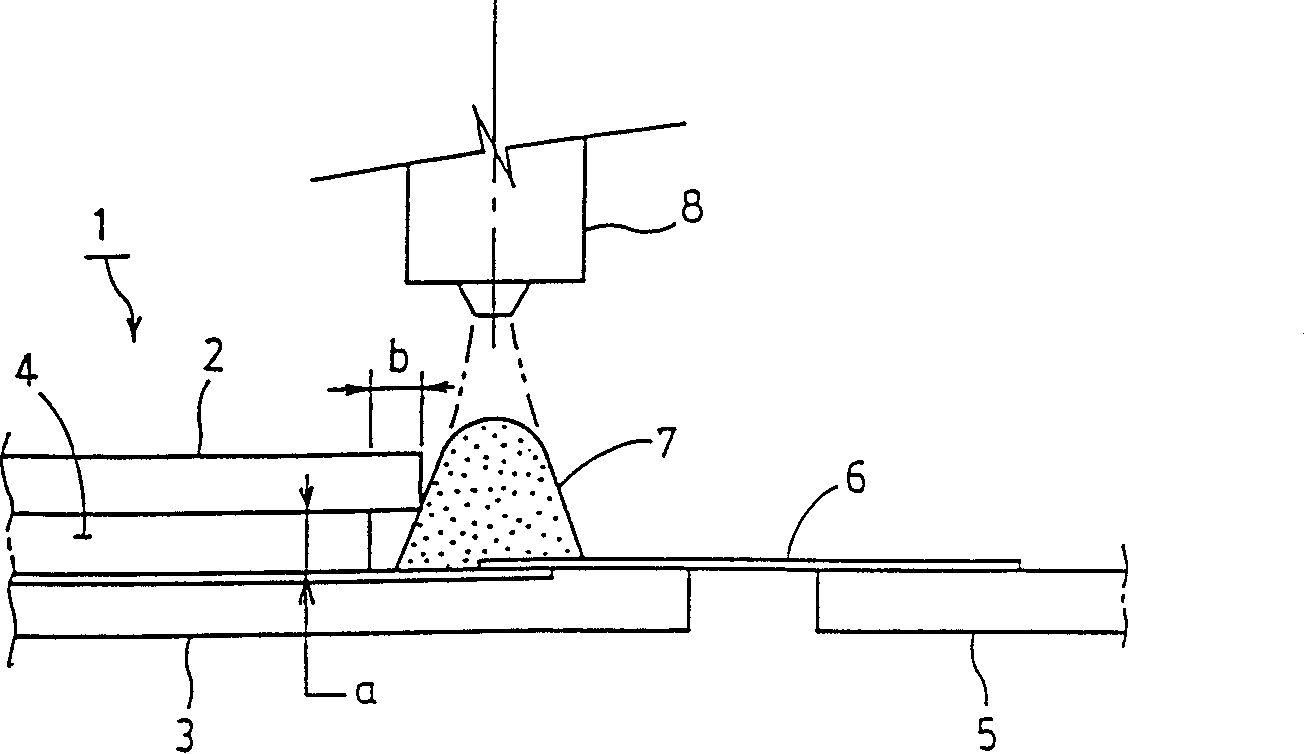

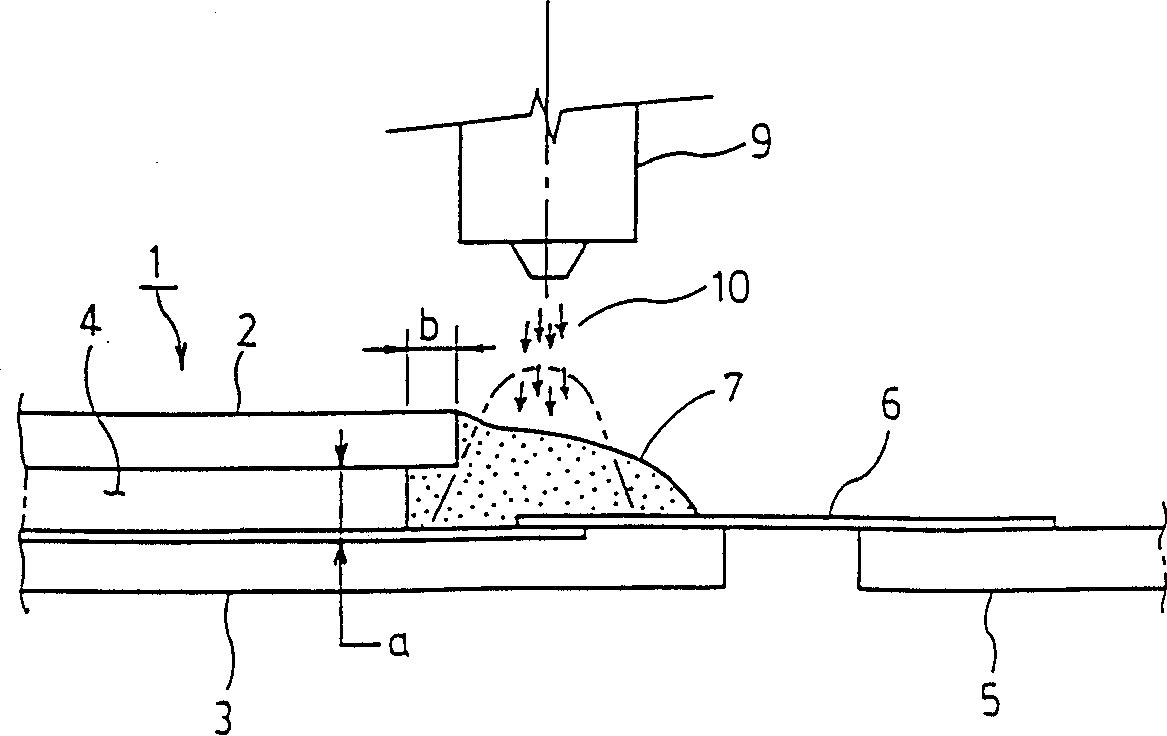

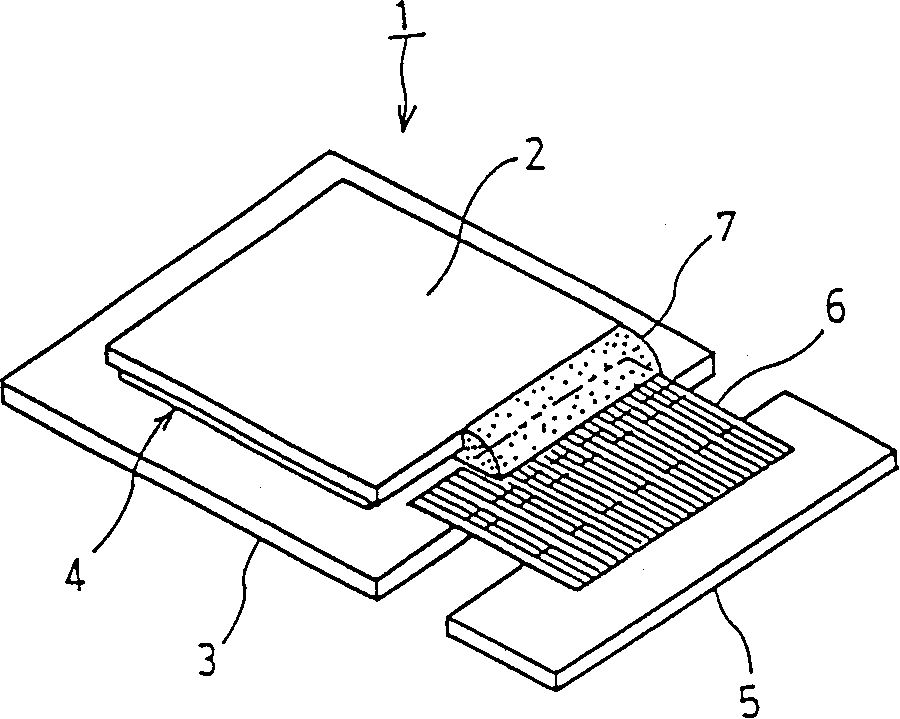

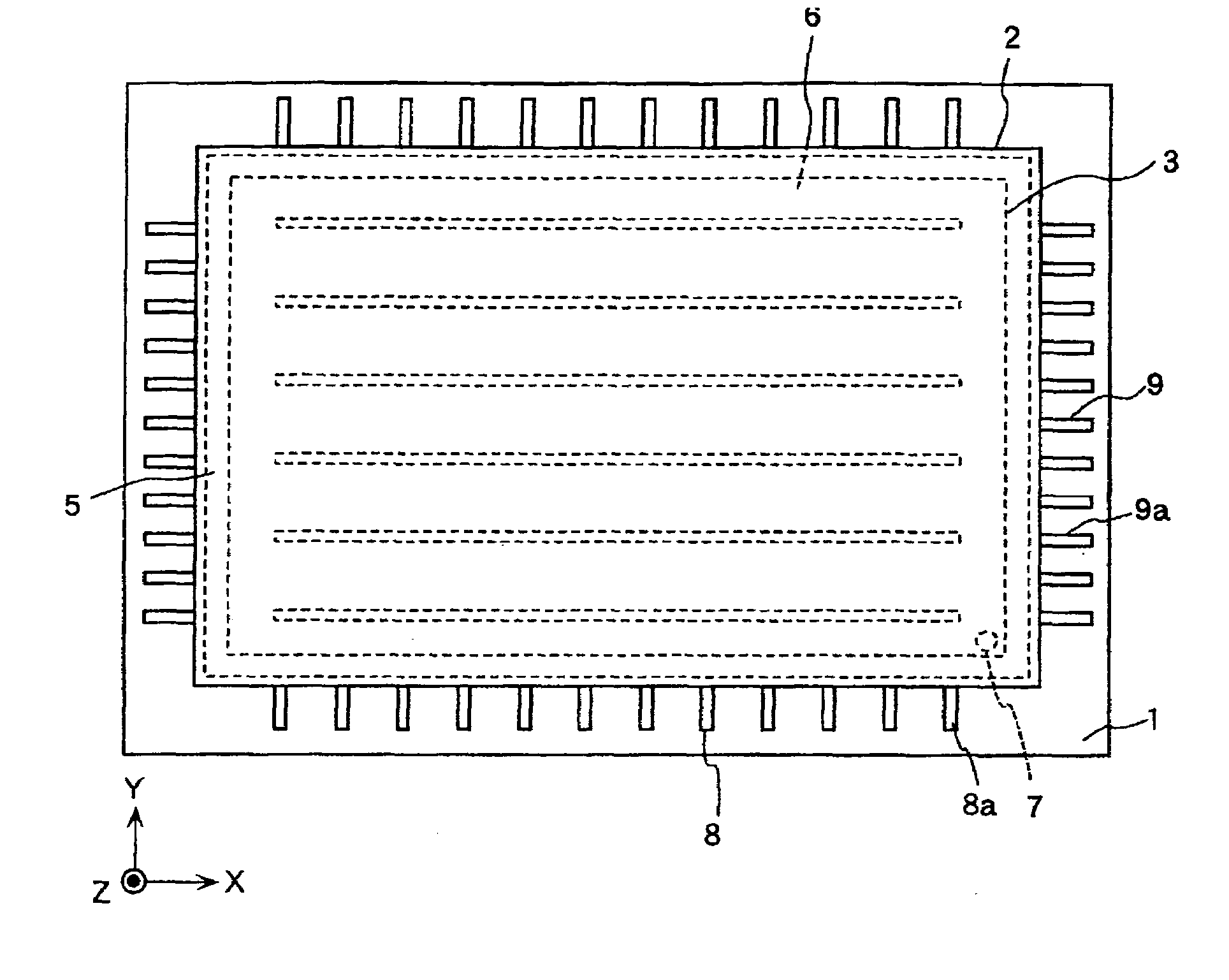

Application method of sealing agent

In the process for producing a laminated substrate (1) such as electronic substrates (2; 3), when applying a sealing agent (7) to the end face of substrates (2, 3) combined together to seal it, first the sealing agent (7) is applied to a target area in the form of successive beads (7), and then a stream of compressed gas (10) is blown against the successive beads (7) from a gas ejecting nozzle (9) so as to scan the successive beads (7). The method can effectively fill the indentation or the stepped area formed along the end face with the sealing agent (7).

Owner:NORDSON CORP

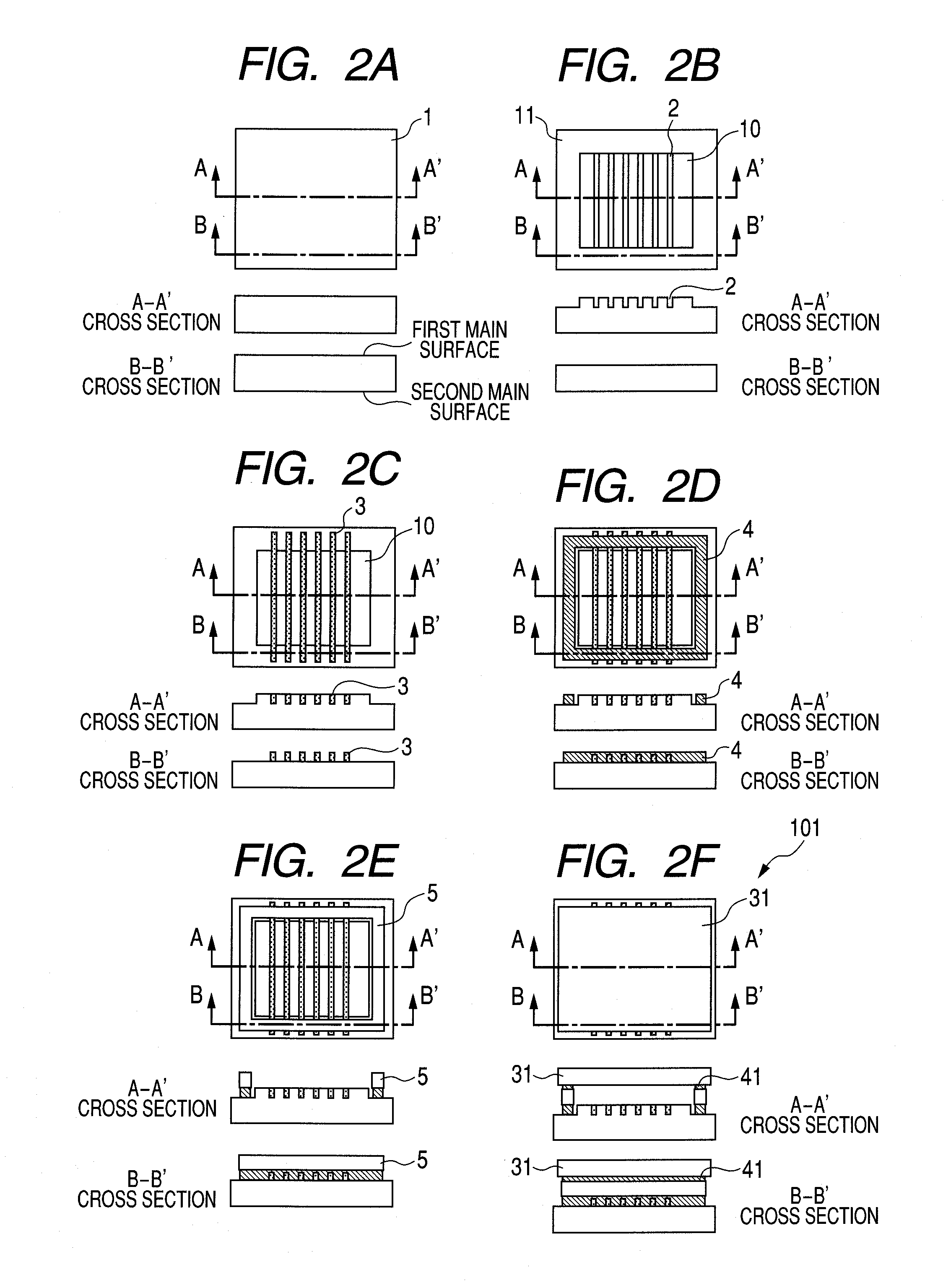

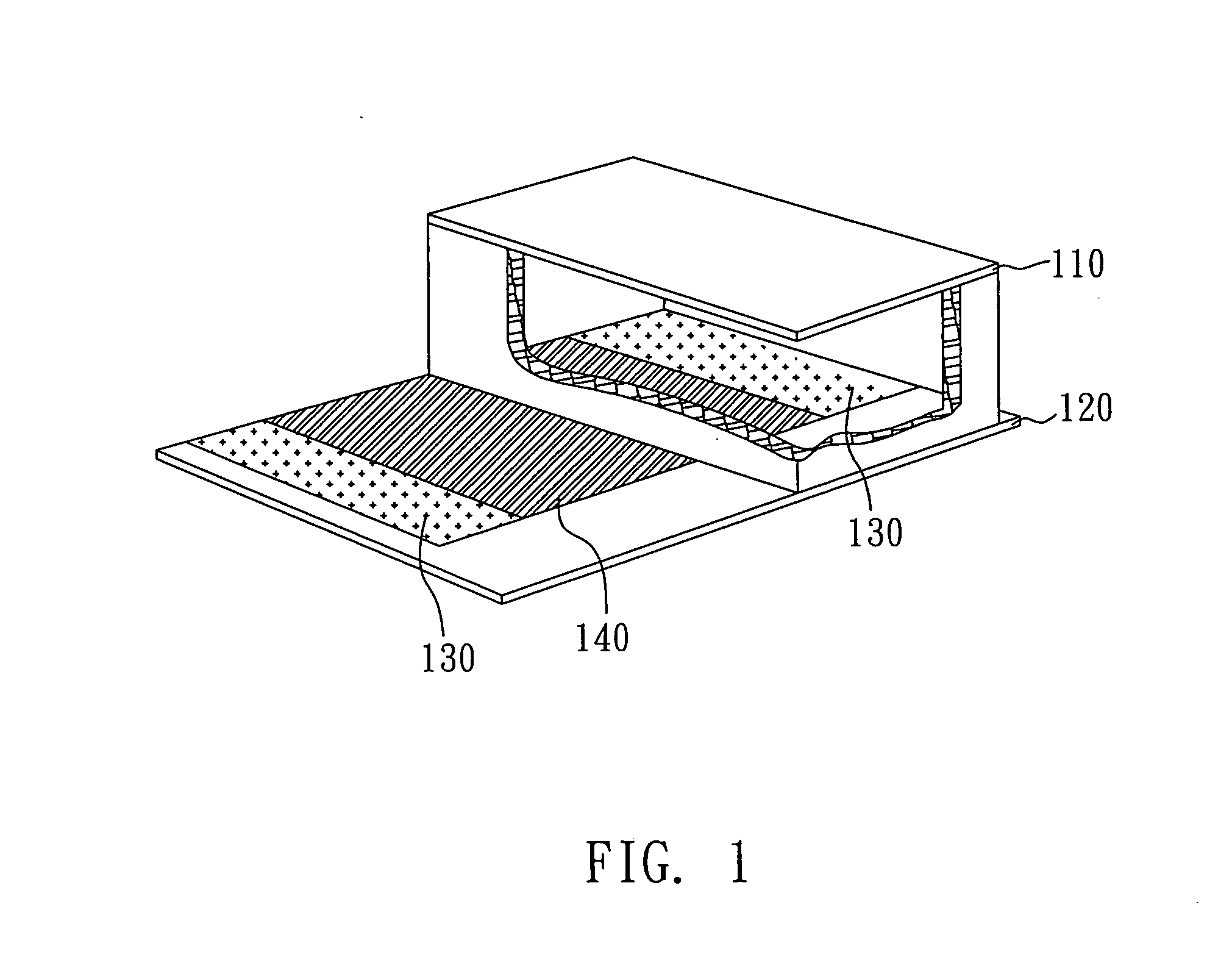

Image display device and manufacturing method thereof

InactiveUS20090001868A1Ensure reliabilityReduce resistanceDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsElectron sourceEngineering

An image display device comprising a back-surface substrate (1) having a plurality of first electrodes (8), an insulating film (14), a plurality of second electrodes (9), and an electron source (10); a front-surface substrate (2) having a fluorescent layer (15), and further having an anode for the application of an acceleration voltage; a frame (3) disposed between the front-surface substrate (2) and the back-surface substrate (1); and a sealing member (5) for sealing the frame (3) and the two substrates in an airtight manner in a sealed area (52). The second electrodes (9) cover the insulating film (14) disposed beneath these second electrodes (9) in at least the sealed area (52), and place the sealing member (5) and the insulating film (14) in a non-contact state.

Owner:HITACHI LTD

Image display device

InactiveUS20070247057A1Avoid voltage dropBright enoughDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsPhysicsEngineering

An image display device comprises a front surface substrate equipped with a phosphor screen including a phosphor layer and a light shielding layer, and a metal back layer provided by an anode electrode for allowing electrons to collide against the phosphor layer so as to excite the phosphor layer, and a rear surface substrate arranged to face the front surface substrate and having electron releasing elements arranged thereon for allowing electrons to be released toward the phosphor screen. The image display device is characterized in that an anode power supply terminal and an anode power supply wiring connected to the metal back layer are formed on the front surface substrate, the anode power supply wiring is formed closer to the front surface substrate than the metal back layer, and the anode power supply wring is connected to the metal back layer via a resistance material layer.

Owner:KK TOSHIBA

Self-luminous planar display device and manufacturing method thereof

InactiveUS20060043876A1Reduce the possibilityVacuum leakageDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsChemical reactionDisplay device

The present invention suppresses the generation of deterioration of degree of vacuum attributed to a chemical reaction between an insulation film and an adhesive agent for adhering a sealing frame. An insulation film formed between first electrodes and first electrode lead terminals and second electrodes and second electrode lead terminals on a back panel is formed except for a sealing region where the back panel and a face panel are sealed. In a second electrode lead terminal side of the sealing region, only an adhesive-agent layer which adheres the back panel and the sealing frame and the second electrode lead terminals are present between a sealing frame and a back substrate.

Owner:HITACHI DISPLAYS

X-ray tube

ActiveCN106252184ACathode-ray/electron-beam tube electrical connectionVacuum tube leading-in conductor sealsMetal filamentEngineering

According to one embodiment, an X-ray tube includes a cathode including a filament, an anode target, and an envelope. The cathode includes a metal lead wire supporter which is exposed outside the envelope, which is configured a part of the envelope, and to which a lead wire as a power supplier to the filament is attached such that the lead wire passes both inside and outside of the envelope, and a metal filament supporter fixed on the lead wire supporter, being in contact with the lead wire supporter, and supporting the filament.

Owner:CANON ELECTRON TUBES & DEVICES CO LTD

Image display device having electrical lead connections fixed through a portion of an exhausting pipe body

InactiveUS7417365B2Low costReduce manufacturing costGas filling substance selectionCathode-ray/electron-beam tube vessels/containersDisplay deviceEngineering

In a corner portion outside a display region of a face substrate which constitutes a face panel of a display device, an opening is formed. In the opening, a stem glass structural body which is configured by integrally forming an exhaust pipe on a center portion of a stem glass and by forming conductive leads in a peripheral portion thereof in an embedded manner, is fixed by welding using curing by heating. The exhaust pipe is evacuated and, thereafter, tipped off, thus realizing vacuum sealing of the inside thereof. A lead line is connected to a distal end of one conductive lead by welding and another end of the lead line is electrically connected with one end portion of the anode formed on an inner surface of the face substrate using a conductive adhesive agent. Further, a getter is mounted and fixed to another conductive lead line by welding.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Manufacturing method and apparatus for insulating member

InactiveUS6186851B1Coupling device connectionsCathode-ray/electron-beam tube electrical connectionElectricityEngineering

This invention secures the breakdown voltage between stem pins or the like for high voltage service in a cathode ray tube. This insulator formed is of a clay-like silicone compound having a tip-throughhole and pin-throughholes or a stem base with the electric insulator mounted to the stem base: A inter-stem electric insulation device is structured by mounting either one of the electric insulator or the stem base with the electric insulator to the stem of a cathode ray tube and by pressing to fix together. This structure does not occur bubble generation caused by the electric insulator, and makes the handling easy, and furthermore, accomplish an automatic mounting of the electric insulator to a stem.

Owner:SONY CORP

Structure of a vacuum display device

InactiveUS6448705B1Cathode-ray/electron-beam tube electrical connectionIncadescent body mountings/supportDisplay deviceEngineering

A structure of a vacuum display device is mainly constructed in a vacuum chamber, which is formed by the enclosure of a surface plate, a base plate, and a spacer plate. The surface plate includes a display matrix and a black matrix, the base plate includes an inner surface and an outer surface, while the spacer plate possesses a plurality of recesses in its edges. The required electrode lead wires are disposed on the inner surface of the base plate and are extended out through the recesses. A plurality of fins are disposed on the spacer plates to support the surface plate, the base plate, and the spacer plate, and are located at the black matrices. Additionally, sealing material is used to seal the connections between the surface plate, the base plate, and the spacer plate, and is also used to fill the gaps in the recesses.

Owner:DELTA ELECTRONICS INC

Popular searches

Electrode and associated part arrangements Picture reproducers using solid-state color display Electrode assembly support/mounting/spacing/insulation Lamp details Cathode-ray tube indicators Mounting/support/spacing/insulation of electrode assemblies Thermionic cathodes Discharge tube solid thermionic cathodes Discharge tube main electrodes Cold cathode manufacture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com