Application method of sealing agent

A sealant and flange technology, applied in the field of sealant application, can solve the problems of pollution, gas pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

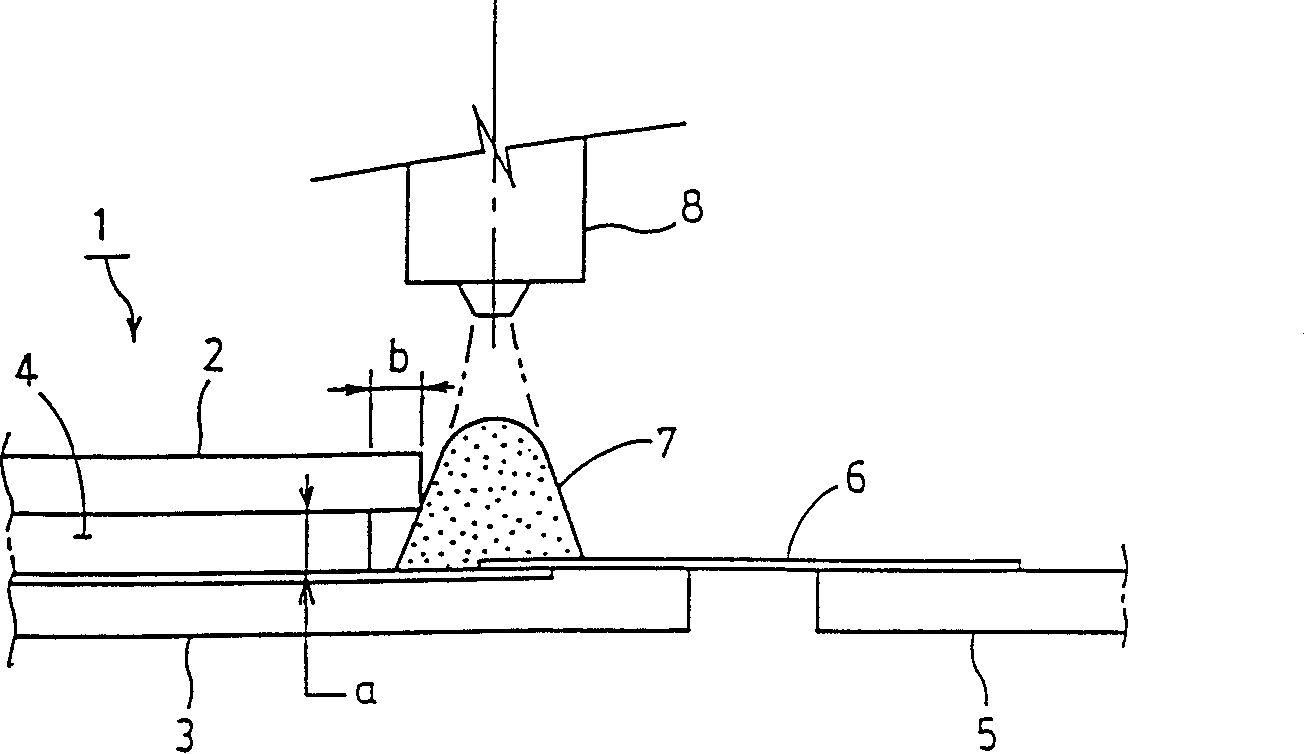

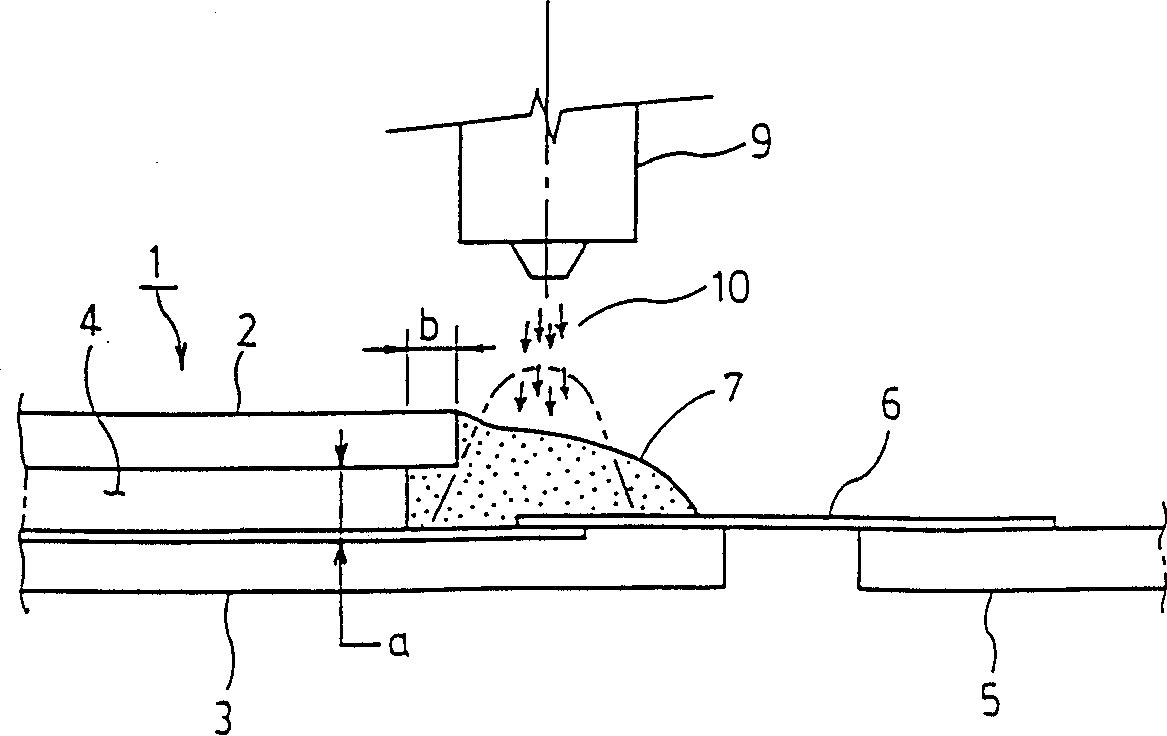

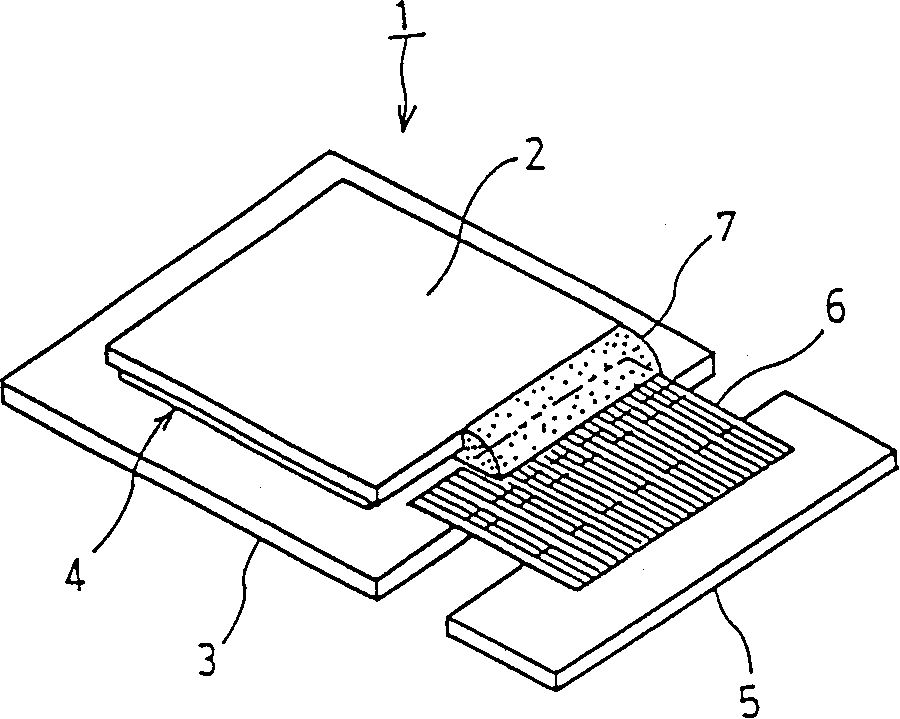

[0014] A method of applying a sealant according to the present invention will be described in detail by way of example with reference to the accompanying drawings. The invention is described in terms of a plasma display comprising glass substrates which are brought together and sealed at the end faces using known methods such as figure 2 shown and described above. Figure 1A with 1B A method of applying a sealant in the process of manufacturing a plasma display according to the present invention is briefly shown. figure 2 with 3 The same elements in are denoted by the same reference numerals. Figure 1A is a simplified view of the sealant applied in the form of a flange, Figure 1B is a simplified view of compressed gas being sprayed from a gas nozzle onto a sealant.

[0015] Referring to the drawings, a plasma display 1 includes a front glass plate 2, a rear glass plate 3, and various kinds of functional films 4 disposed between the glass plates, including electrode film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com