Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Lower charge transfer resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pnictide containing catalysts for electrochemical conversion reactions and methods of use

ActiveUS20160233487A1Increase electrode kineticsReducing electrode charge transfer resistanceFinal product manufacturePositive electrodesLithium–sulfur batteryLithium sulfur

This patent application describes graphitic carbon nitride materials that are useful in electrochemical cells such as Lithium-Sulfur batteries. Also disclosed are lithium-sulfur batteries designed to incorporate these materials and methods of manufacturing the same. Batteries that include this material exhibit increased electrode kinetics of the lithium-sulfur electrochemical couple, phenomena that improve the specific capacity, usable lifetime and other desirable characteristics of these batteries.

Owner:RGT UNIV OF CALIFORNIA +1

Non-aqueous electrolyte for secondary battery and non-aqueous electrolyte secondary battery employing the same

ActiveUS20130330610A1Improve lithium ion conductivityIncreased durabilityCell electrodesSecondary cellsSolventNon aqueous electrolytes

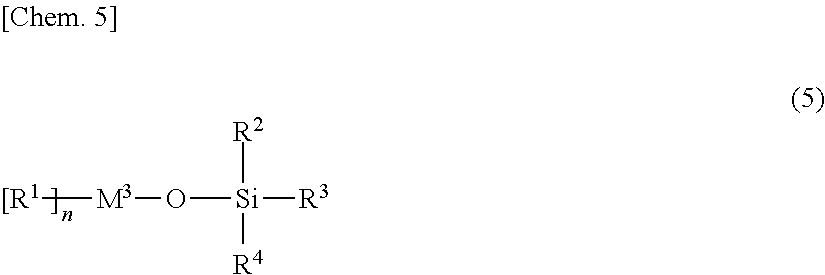

Provided are: a non-aqueous electrolyte solution for a secondary battery that exhibits both excellent low-temperature discharge characteristics and excellent cycle characteristics on a long-term basis; and a secondary battery.A non-aqueous electrolyte solution for a non-aqueous electrolyte secondary battery that has a positive electrode and a negative electrode capable of the absorbing and releasing of a metal ion, and a separator,the non-aqueous electrolyte solution comprising, in addition to an electrolyte and a non-aqueous solvent, 0.01 mass % or more to less than 3 mass % of a compound having one or more partial structure represented by the following general formula (1) and two or more isocyanate groups in the molecule:(In the general formula (1), R represents hydrogen or a C1-C12 organic group that may contain an isocyanate group and is constituted of atoms selected from the group consisting of hydrogen atom, carbon atom, nitrogen atom, oxygen atom, sulfur atom, phosphorus atom, and halogen atom).

Owner:MU IONIC SOLUTIONS CORP +1

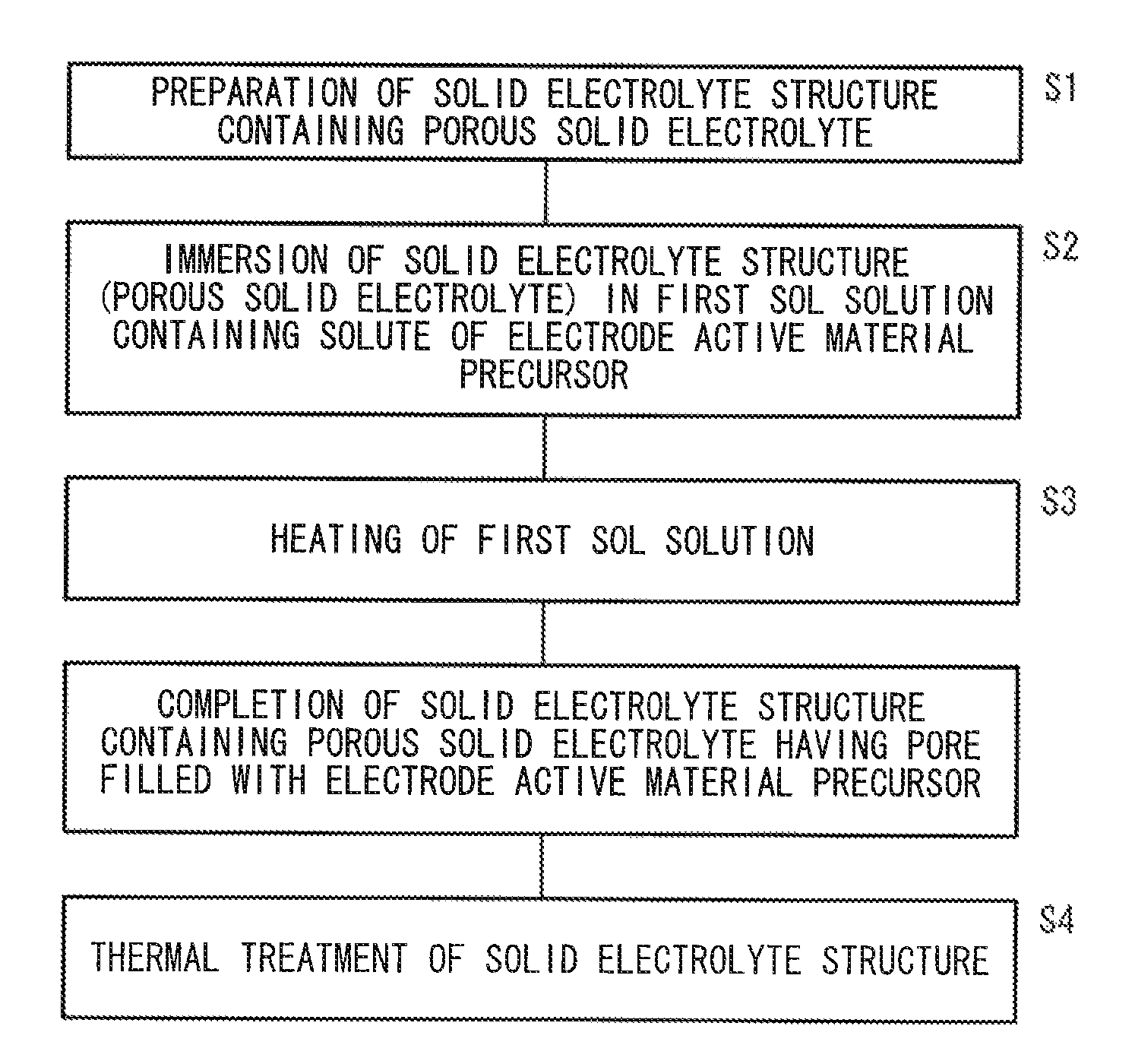

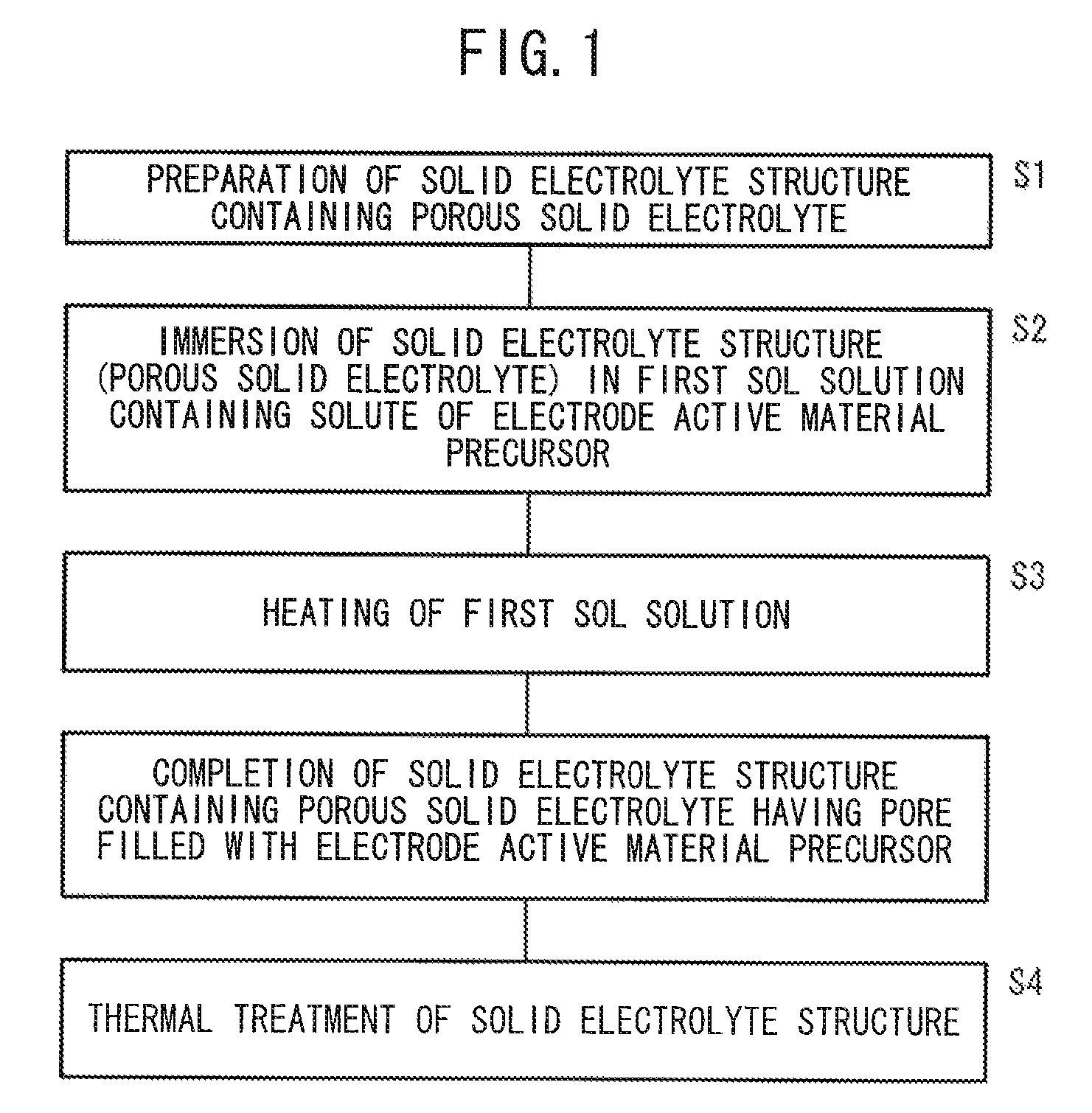

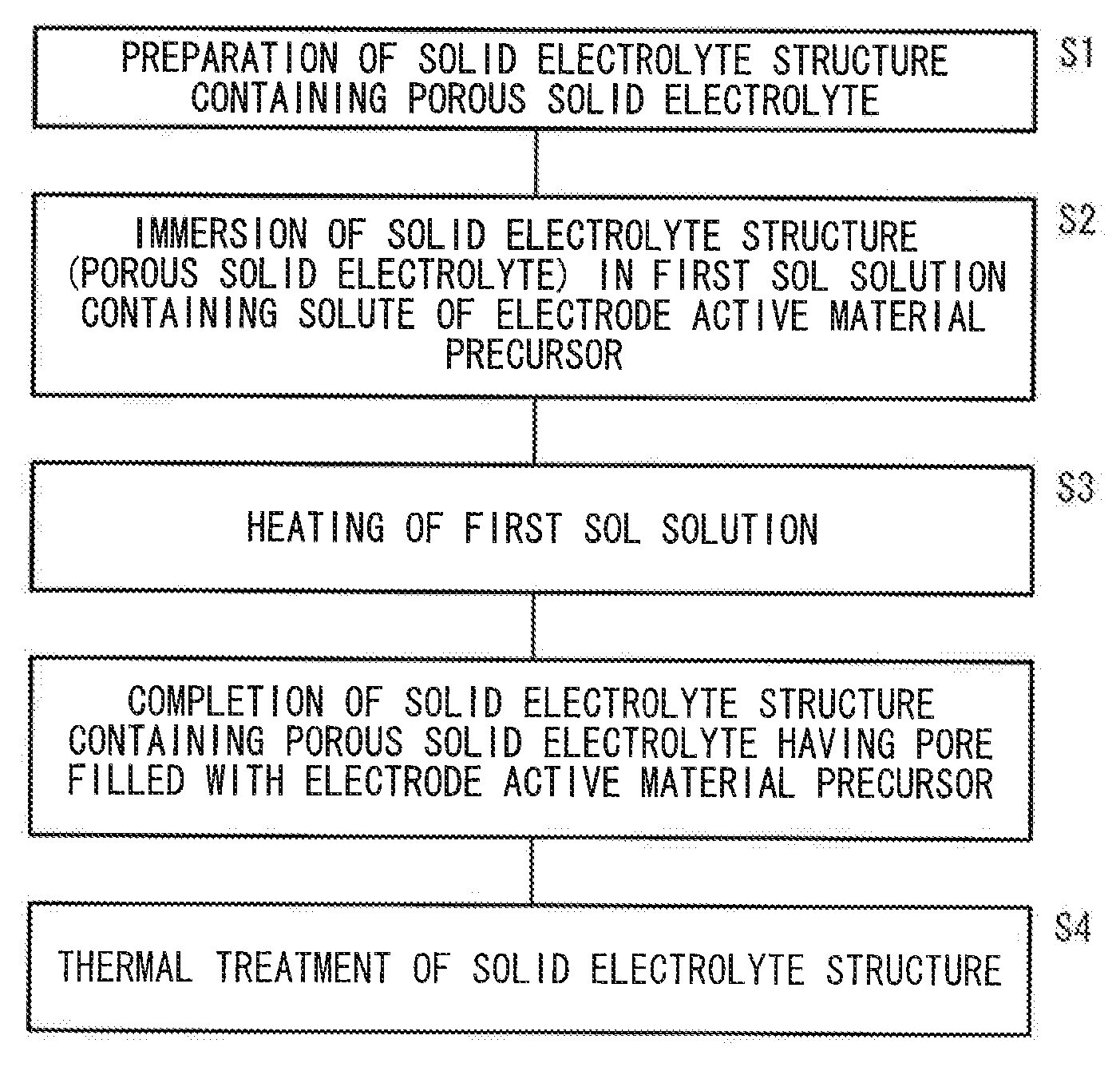

Method for filling with electrode active material and method for producing all-solid-state cell

InactiveUS8309258B2Efficient fillingLower charge transfer resistanceSolid electrolytesFinal product manufactureAll solid stateHigh concentration

A solid electrolyte structure containing a porous solid electrolyte is prepared. At least the porous solid electrolyte of the solid electrolyte structure is immersed in a first sol solution containing at least a precursor of an electrode active material as a solute. Then, the first sol solution, in which the porous solid electrolyte is immersed, is heated. A solvent of the first sol solution is evaporated by the heating, whereby a pore of the porous solid electrolyte is filled with a high concentration (a large amount) of the electrode active material precursor.

Owner:TOKYO METROPOLITAN UNIVERSITY +1

Negative electrode material and preparation method thereof, negative electrode plate and lithium ion battery

PendingCN107946561AImprove cycle performanceReduce usageNegative electrodesSecondary cellsInternal resistanceCarbon nanotube

The invention discloses a negative electrode material of a lithium ion battery. The negative electrode material comprises the following components in parts by mass: 88-105 parts of active material, 0.01-0.1 parts of single-wall carbon nanotubes, 0.01-0.5 parts of graphene nanobelt, one or less parts of super conductive carbon black, one or less parts of less-wall or multi-wall carbon nanotubes, 0.05-0.5 parts of dispersing agent, 1-3 parts of thickening agent, 1-4 parts of binder and 25-60 parts of solvent; the active material comprises a silicon oxide material SiO<x> and synthetic graphite, wherein x is greater than 0 and less than 2; and the silicon element in the negative electrode material is less than or equal to 3.5mass%. The invention provides the negative electrode material comprising the silicon oxide material and the low-dimensional carbon conductive material of the lithium ion battery; by virtue of the negative electrode material of the lithium ion battery, the problems of capacity fading and increasing internal resistance caused by losing of effective electron channels due to low electrical conductivity and an expansion effect in the use process of a silicon oxide negative electrode active material can be solved; and meanwhile, the cycle performance of the lithium ion battery applying the negative electrode material is improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Silicon-carbon composite cathode pole piece of lithium ion battery and preparation method of silicon-carbon composite cathode pole piece

InactiveCN105576185ALower impedanceImprove cycle lifeElectrode carriers/collectorsSecondary cellsCarbon compositesCarbon nanotube

The invention discloses a silicon-carbon composite cathode pole piece of a lithium ion battery. The silicon-carbon composite cathode pole piece comprises a cathode current collector, wherein one silicon-carbon cathode active material layer coats the surface of the cathode current collector; the silicon-carbon cathode active material layer is prepared from the following components by mass percent: 80%-99.5% of a silicon-carbon composite material, 0%-15% of a graphene conductive agent, 0%-15% of a carbon nano tube conductive agent, 0%-15% of a carbon black conductive agent and 0.2%-20% of a binding agent. Furthermore, the invention discloses a preparation method of the silicon-carbon composite cathode pole piece. According to the silicon-carbon composite cathode pole piece and the preparation method of the silicon-carbon composite cathode pole piece, disclosed by the invention, the silicon-carbon composite cathode pole piece can be used for effectively improving the conductive property of a silicon-based material and guaranteeing low impedance and long cycle life of the lithium ion battery applied by the cathode pole piece; the whole properties of the lithium ion battery are greatly improved, and long-time use requirements of electronic products can be met; and a market application prospect of products of battery manufacturers can be improved easily.

Owner:TIANJIN LISHEN BATTERY

Polymer-Based Solid Electrolytes and Preparation Methods Thereof

InactiveUS20120308899A1Small thermal change rate of conductivity and capacitanceStable capacitanceSolid electrolytesSolid electrolyte cellsLithiumSolvent

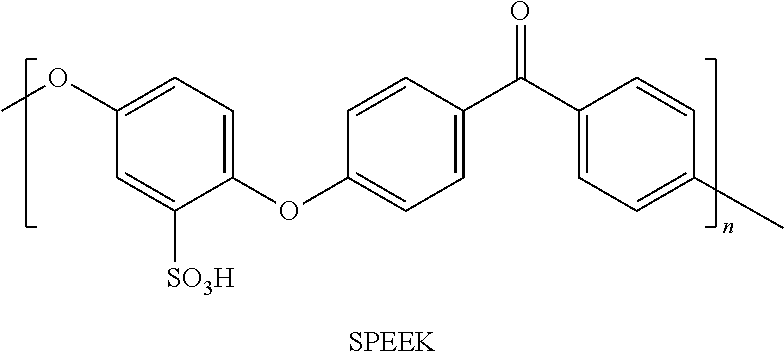

SPEEK solid electrolytes and preparation methods thereof are provided. The SPEEK solid electrolyte comprises sulfonated polyetheretherketone (SPEEK), an electrolyte, and a solvent. The electrolyte is a lithium salt.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Polymer-Based Solid Electrolytes and Preparation Methods Thereof

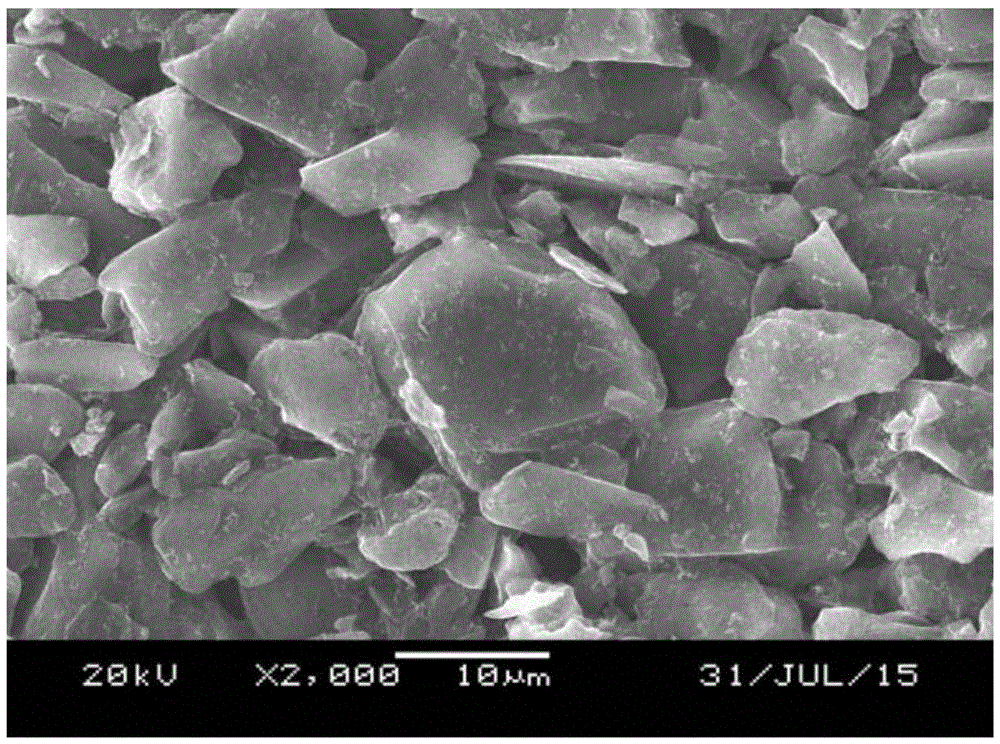

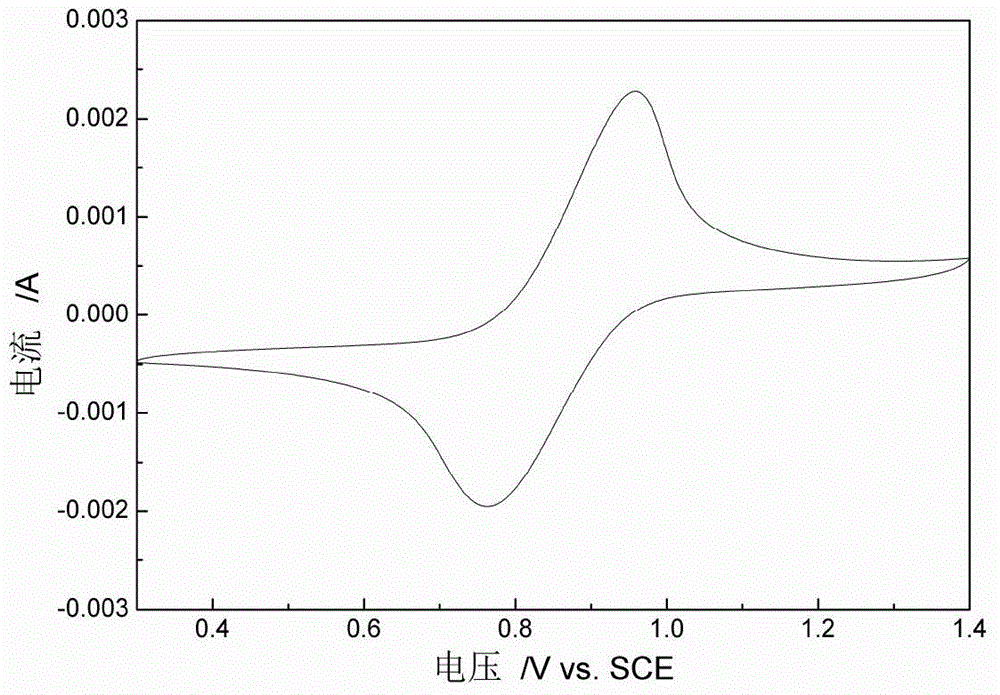

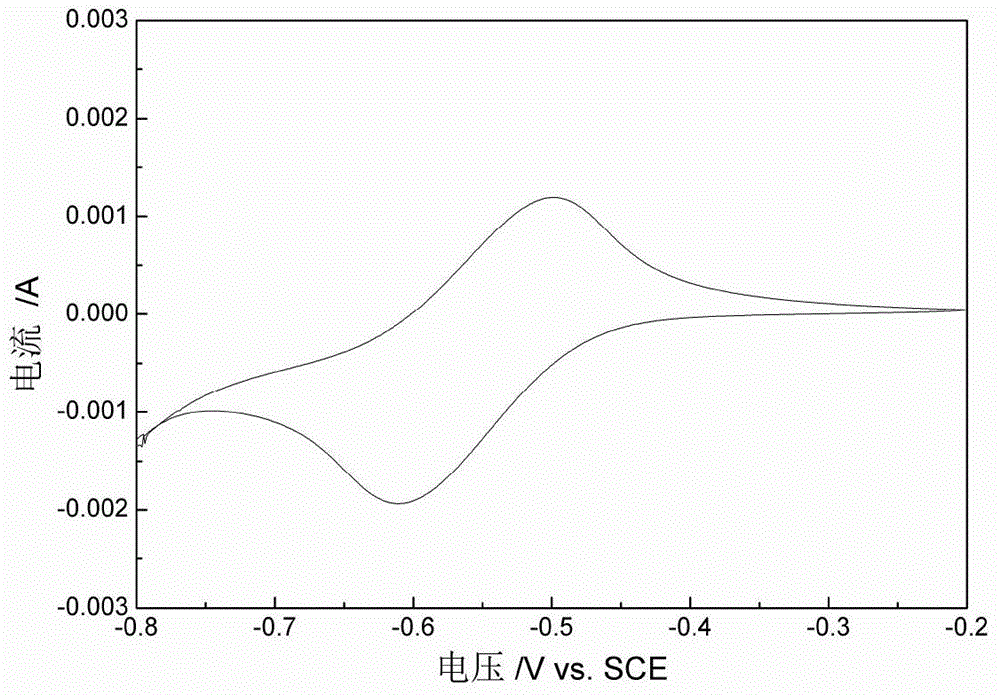

InactiveUS20120208091A1Improve ionic conductivityLower charge transfer resistanceSolid electrolytesFinal product manufactureLithiumSolvent

Polymer-based solid electrolytes and preparation methods thereof are provided. The polymer-based solid electrolyte comprises a polymer, an electrolyte, and a solvent. The polymer of the solid electrolyte can be polyvinyl alcohol (PVA) or sulfonated polyetheretherketone (SPEEK). The electrolyte is a lithium salt.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

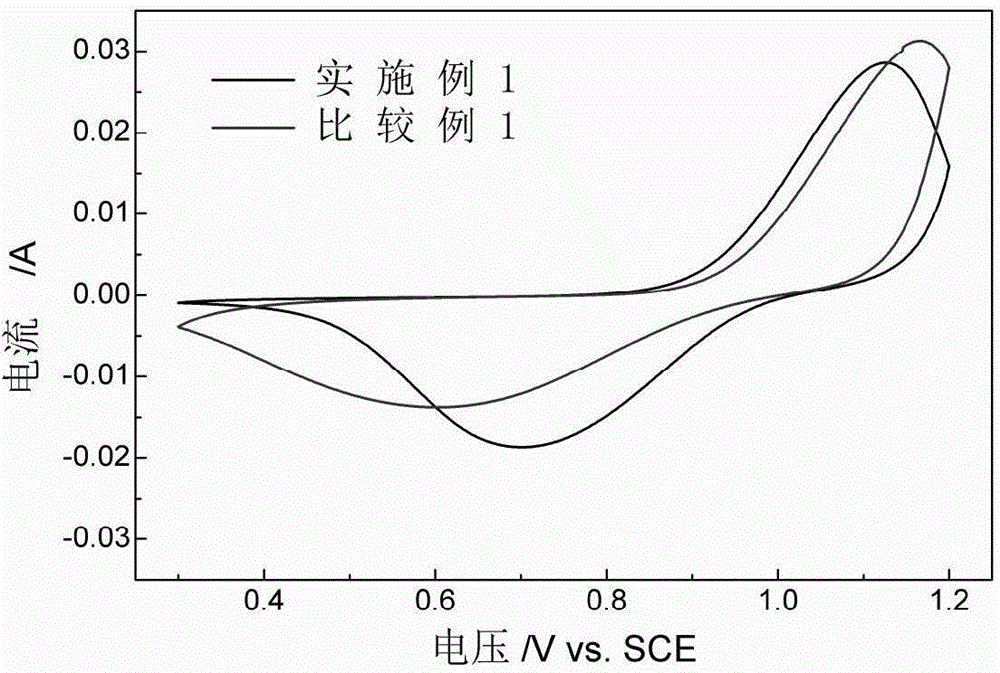

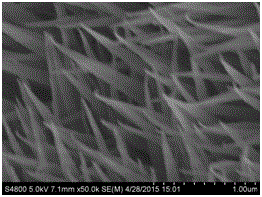

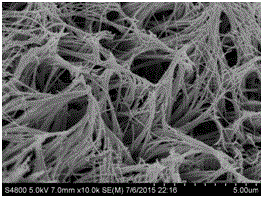

Application of carbon nanofiber and metal composite electrode in flow battery

InactiveCN105789640ALarge specific surface areaImprove electrocatalytic activityCell electrodesRegenerative fuel cellsElectricityCarbon fibers

The present invention discloses an application of carbon nanofiber and a metal composite electrode in a flow battery. An electrode material uses a mixture of high-molecular polymer and metallic salt as a precursor, nanofiber is made by a static electricity spinning method, and then carbon nanofiber is made after performing high-temperature carbonization processing on the nanofiber, wherein a diameter of the carbon nanofiber is 100-1000 nm, a diameter of a metal particle is 2-100 nm, and a mass fraction of metal / the carbon nanofiber is 1%-50%. The carbon nanofiber / metal composite electrode prepared by a preparation method has an excellent electrocatalytic activity and electrochemical reversibility when used in the flow battery, and has the advantages that the preparation method is simple, the working procedure is fewer, the raw material is readily available, the price is low and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

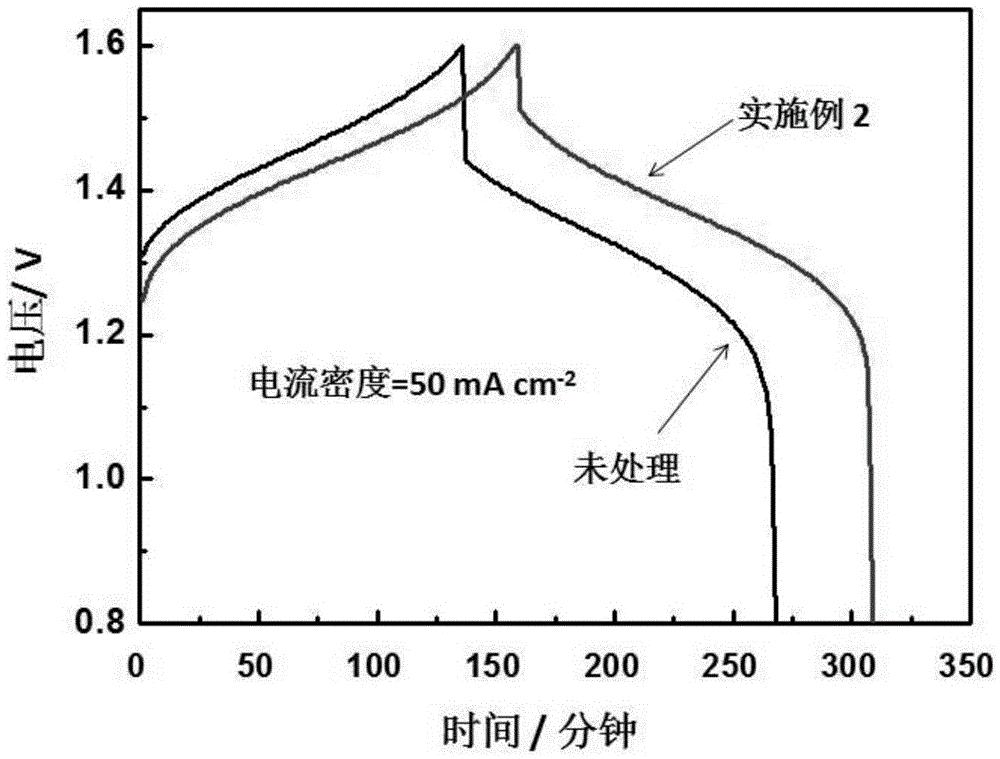

All-vanadium flow battery porous carbon fiber felt electrode material and preparation and application thereof

InactiveCN105762369AHigh specific surface areaImprove hydrophilicityCell electrodesPower flowCarbonization

The present invention relates to an all-vanadium flow battery porous carbon fiber felt electrode material comprising 5-20mum porous carbon fiber, the all-vanadium flow battery porous carbon fiber felt electrode material is prepared by introduction of an activated gas while high temperature carbonization, process is simple, and production cost is low. A prepared porous carbon fiber felt has obviously-improved specific surface area and oxygen-containing functional groups, and can significantly improve the electrocatalytic activity of a carbon fiber material to the vanadium redox reaction. The electrode material is applicable to an all-vanadium flow battery, can reduce the charge transfer resistance, improves the all vanadium flow battery voltage efficiency and energy efficiency, thus improving the working current density, and greatly reducing weight, volume and cost of the battery with the same output power.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Treatment method for all-vanadium redox flow battery electrode

InactiveCN105529471AOptimize process flowEasy to operateCell electrodesRegenerative fuel cellsHigh current densityCharge discharge

The invention provides a treatment method for an all-vanadium redox flow battery electrode. The method comprises the following steps: with carbon electrode materials of a graphite felt, a carbon felt and the like as raw materials, drying the raw materials after fully soaking in an alkali liquor; carrying out high-temperature activation under protection of an inert gas; and washing and drying the product to prepare the activated carbon electrode materials. The treatment method has the advantages of being simple, simple and convenient to operate and low in cost; the surfaces of the treated carbon electrode materials are etched; the effective reaction area of vanadium ion electron pairs on the electrode surface is increased; the charge transfer impedance of an all-vanadium redox flow battery in a charge-discharge process is greatly reduced, so that the voltage efficiency and the energy efficiency of the all-vanadium redox flow battery under high current density are greatly improved.

Owner:HUNAN YINFENG NEW ENERGY

Method for preparing bean dregs-based nitrogen-boron co-doped porous carbon material

ActiveCN109336106AIncrease contentMany typesCarbon compoundsHybrid capacitor electrodesActivation methodPorous carbon

The invention provides a method for preparing a bean dregs-based nitrogen-boron co-doped porous carbon material. The method is a one-step impregnation carbonization activation method, and comprises the following steps: (1) pretreating bean dregs: boiling, fermenting, then adding a catalyst into the fermented bean dregs for catalysis, washing and then freeze-drying; (2) adding deionized water intothe pretreated bean dregs, adding an activator and a boron source, stirring and mixing, transferring into a culture dish, and putting into a drying oven for drying; (3) heat-treating the bean dregs treated in the step (2), soaking in an HCl solution after cooling, washing, and finally drying by microwave to obtain treated bean dregs; and (4) adding a binder and a pore forming agent into the treated bean dregs in the step (3), and mixing to form a bean dregs-based porous carbon material. According to the invention, the one-step impregnation carbonization activation method is adopted; and compared with the prior art, the one-step impregnation carbonization activation method has the advantages of simple method, low energy consumption and the like.

Owner:宿州学院

Method for filling with electrode active material and method for producing all-solid-state cell

InactiveUS20090229700A1Efficient fillingLower charge transfer resistanceSolid electrolytesElectrode manufacturing processesHigh concentrationAll solid state

A solid electrolyte structure containing a porous solid electrolyte is prepared. At least the porous solid electrolyte of the solid electrolyte structure is immersed in a first sol solution containing at least a precursor of an electrode active material as a solute. Then, the first sol solution, in which the porous solid electrolyte is immersed, is heated. A solvent of the first sol solution is evaporated by the heating, whereby a pore of the porous solid electrolyte is filled with a high concentration (a large amount) of the electrode active material precursor.

Owner:TOKYO METROPOLITAN UNIVERSITY +1

Carbon nanofiber and metal composite electrode and application thereof

ActiveCN110970628ALarge specific surface areaImprove electrocatalytic activityCell electrodesRegenerative fuel cellsSpinningElectrical battery

The invention discloses a carbon nanofiber / metal composite electrode for a flow battery and a preparation method thereof. The electrode material is prepared by the following steps of: taking a mixtureof a high-molecular polymer and a metal salt as a precursor; preparing nanofibers by adopting an electrostatic spinning method; and performing high-temperature carbonization treatment, and performingsurface oxidation and etching to manufacture the electrode material, wherein the diameter of the carbon nanofibers is 100-1000 nm, the diameter of the metal particles is 2-100 nm, the metal particlesare distributed on the surfaces of the carbon nanofibers, one parts of the metal particles are embedded into the carbon nanofibers, and the other parts of the metal particles are exposed out of the surfaces of the carbon nanofibers. The carbon nanofiber / metal composite electrode prepared by adopting the preparation method has good electrocatalytic activity and electrochemical reversibility when used for the flow battery, and has the advantages of simple preparation method, few procedures, easily available raw materials, low price and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for in-situ construction of surface coating layer based on metal-organic framework material

PendingCN112397690AModerate working conditionsEasy to prepareCell electrodesSecondary cellsElectrolytic agentNanoparticle

The invention provides a method for in-situ construction of a surface coating layer based on a metal-organic network framework material, which promotes in-situ growth of nanoparticles on the surface of a core structure by regulating and controlling the dynamic process, namely nucleation and growth, of a metal organic network framework structure so as to achieve the purpose of constructing a uniform coating layer on the surface of a core. By adopting the method provided by the invention, a coating layer based on a metal organic network framework material can be constructed on the surface of a conventional positive electrode material, and the prepared positive electrode material can effectively inhibit the side reaction between the electrode material and an electrolyte, slow down the generation of surface SEI, reduce the surface film impedance and charge transfer impedance, and improve the reaction kinetic process of lithium ions; meanwhile, dissolution of transition metal ions can be inhibited, collapse of a lattice structure in the circulation process of the electrode material is effectively relieved, and the circulation stability and the rate capability of the positive electrode material are remarkably improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

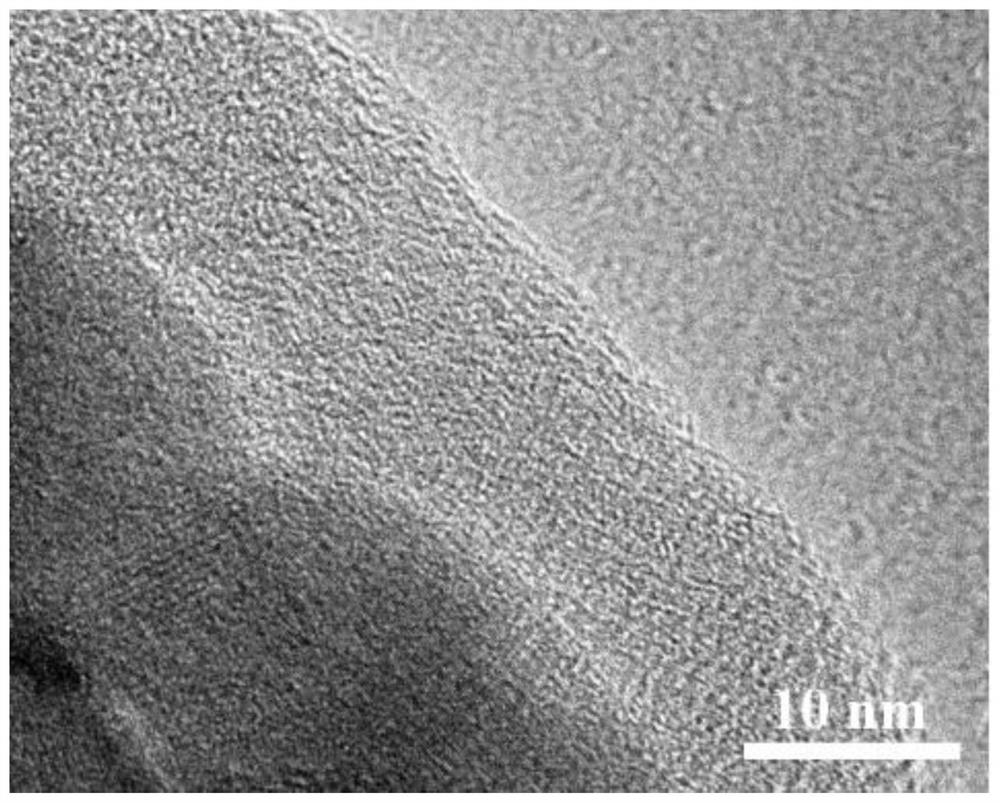

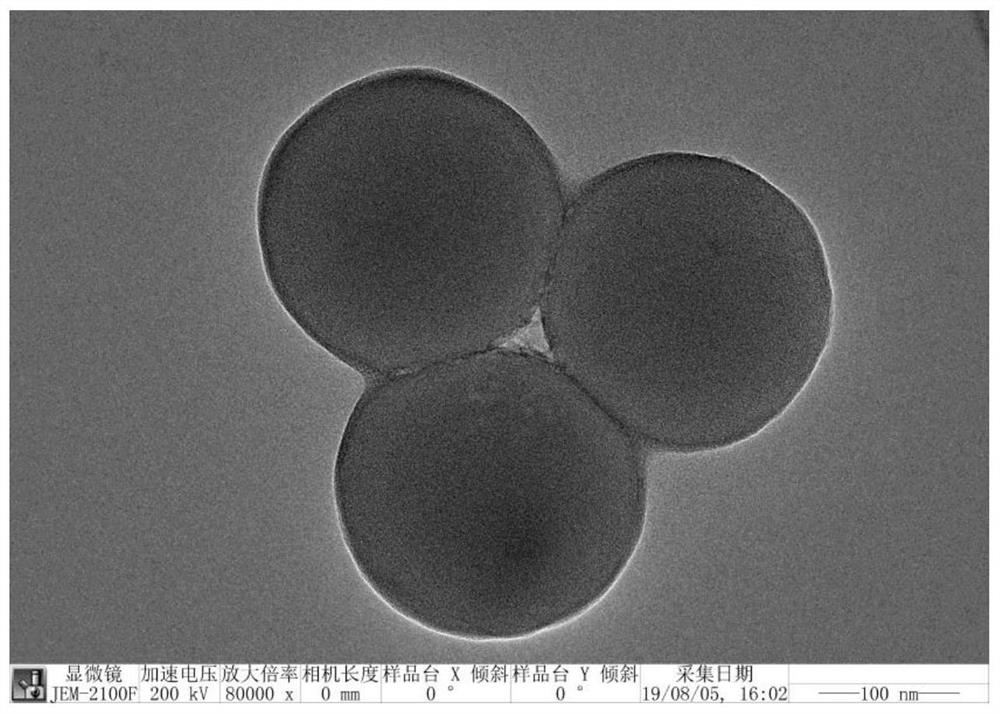

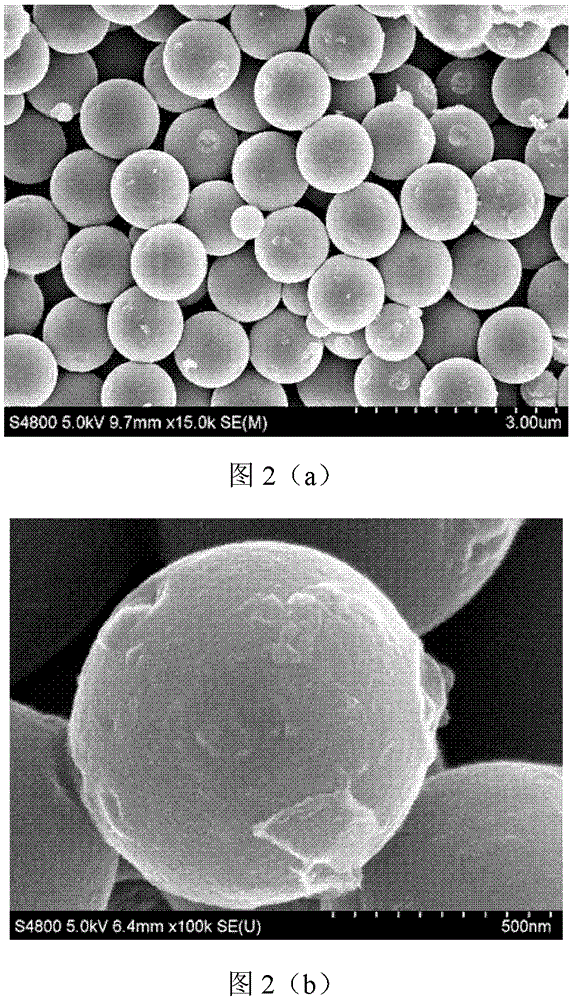

Mesopore-micropore carbon micro sphere of high specific surface area for super capacitor and preparation method of carbon micro sphere

InactiveCN105355464AHigh specific surface areaSimple preparation processHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMicrosphere

The invention relates to a mesopore-micropore carbon micro sphere of high specific surface area for a super capacitor and a preparation method of the carbon micro sphere. A polystyrene micro sphere is prepared by using styrene as a monomer, SBA-15 as a mesopore template and ammonium polyphosphate as a multifunctional auxiliary agent; and the polystyrene micro sphere is crosslinked, carbonized and etched to obtain the polystyrene-based mesopore-micropore carbon micro sphere of the high specific surface area. The preparation method is characterized in that the ammonium polyphosphate serves as the multifunctional auxiliary agent, acid and alkali activation is not needed, and the N and P codoped mesopore-micropore carbon micro sphere of the high high specific surface area for the super capacitor can be obtained; the specific surface area of the material is 1168-1476m2 / g, the pore volume is 1.069-1.341m3 / g, and when the mesopore-micropore carbon micro sphere is used as the electrode material of the super capacitor, the specific capacitance in a water system electrolyte is 132.5-175F / g; and the mesopore-micropore carbon micro sphere is very suitable for serving as the electrode material of the super capacitor.

Owner:XIAN UNIV OF SCI & TECH

Lithium ion battery negative electrode material and preparation method thereof

ActiveCN107732172AImprove cycle stabilitySafe working voltage rangeMaterial nanotechnologyCell electrodesSodium-ion batteryHydrolysis

The invention discloses a lithium ion battery negative electrode material and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: preparing Cu2O nano-cubes from copper sulfate (CuSO4), trisodium citrate, polyvinylpyrrolidone, sodium hydroxide and ascorbic acid, and coating the surface of the Cu2O with nano-TiO2 through an isopropyl titanate hydrolysis technology in order to obtain a nano-TiO2 coated Cu2O nano-cube material. The preparation method of the material has the advantages of simplicity, mild reaction conditions, no pollution to the environment, low cost and mass production. The nano-TiO2 coated Cu2O nano-cubes have remarkably improved cycle stability and charge-discharge performance as a lithium ion battery negative electrode material, and is suitable for the industrial application of the lithium ion batteries.

Owner:CHINA JILIANG UNIV

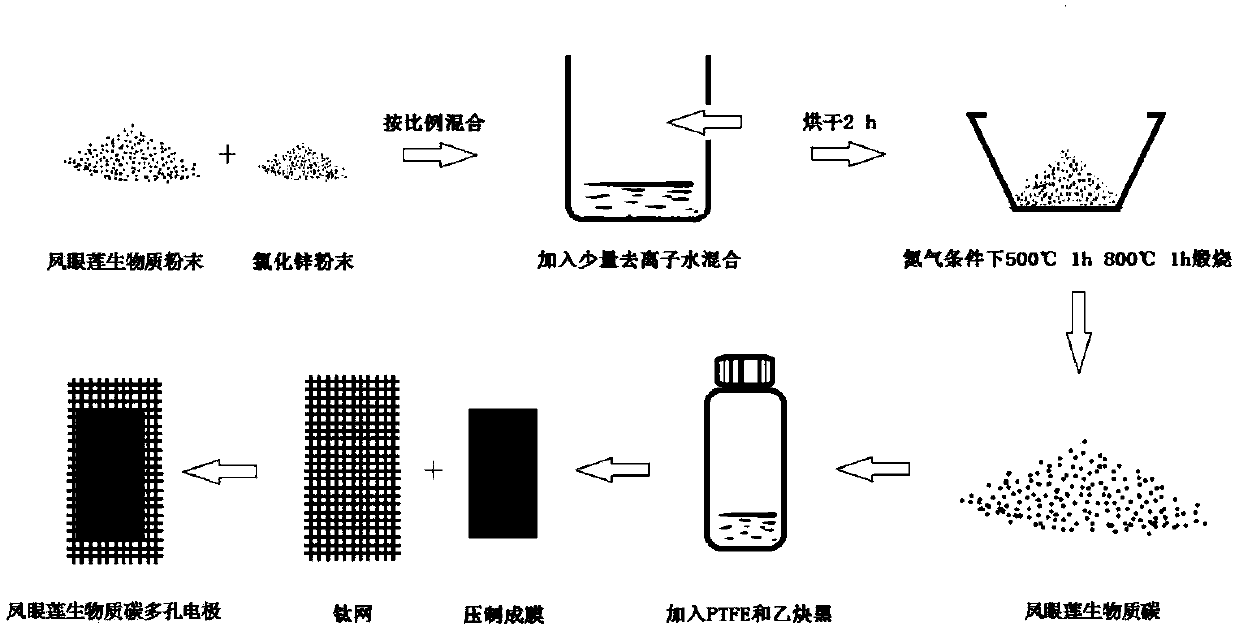

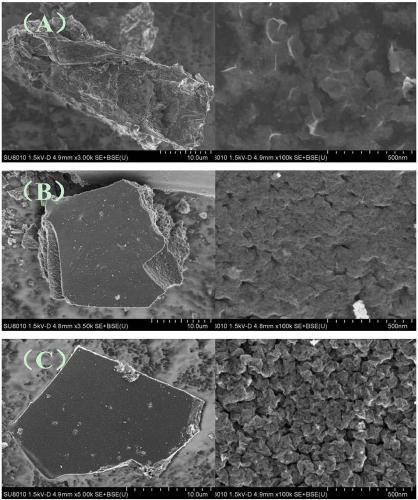

Preparation method and application of primordial water hyacinth biomass carbon porous electrode material

ActiveCN109850896ARich and well-developed pore structureGood chemical stabilityCarbon compoundsWater contaminantsPerturbateurs endocriniensPorous electrode

The invention belongs to the technical field of a preparation and application of a primordial water hyacinth biomass carbon material with a porous structure, and specifically discloses a preparation method of a novel electrode material and an application of the electrode material as a cathode in an electro-Fenton system to degrade endocrine disruptors. The electrode material takes water hyacinth biomass powder as a precursor, zinc chloride powder is added in different proportions to perform activating, the novel biomass carbon material is prepared by high temperature calcination under the protection of an inert gas, and finally a porous electrode is obtained as the cathode material for E-Fenton to degrade endocrine disruptors. The material has relatively good electrical conductivity and relatively large specific surface area. The material can be used as a novel electrode material, and a good degradation effect is especially shown in the electro-Fenton experiment.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Cobalt selenide nanometer material serving as electrode material of supercapacitor and preparation method of cobalt selenide nanometer material

InactiveCN106098393ALarge specific surface areaImprove space utilizationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNanowire

The invention discloses a Co<0.85>Se nanometer material serving as an electrode material of a supercapacitor and a preparation method of the Co<0.85>Se nanometer material. The nanometer material adopts a fibrous nanometer structure. The Co<0.85>Se nanometer material adopts a two-step hydrothermal synthesis method, and the two-step hydrothermal synthesis method comprises the steps of firstly, preparing a precursor Co(OH)(CO<3>)<0.5> nanowire by a hydrothermal reaction method; and secondly, carrying out selenization processing on the precursor by the hydrothermal reaction method to obtain the Co<0.85>Se nanometer material. When placed in a three-electrode system for test, the nanometer electrode material is endowed with high specific capacity of 1,249F / g under current density of 2A / g, the specific volume over 80% still can be maintained after 3,000 cycles of charging and discharging under 100mA current, and the charge transfer impedance is 0.32 ohm / cm<2>. The Co<0.85>Se nanometer electrode material prepared according to the method has the advantages of high specific capacitance, good cycle performance, simplicity in preparation method and low cost.

Owner:ZHEJIANG UNIV

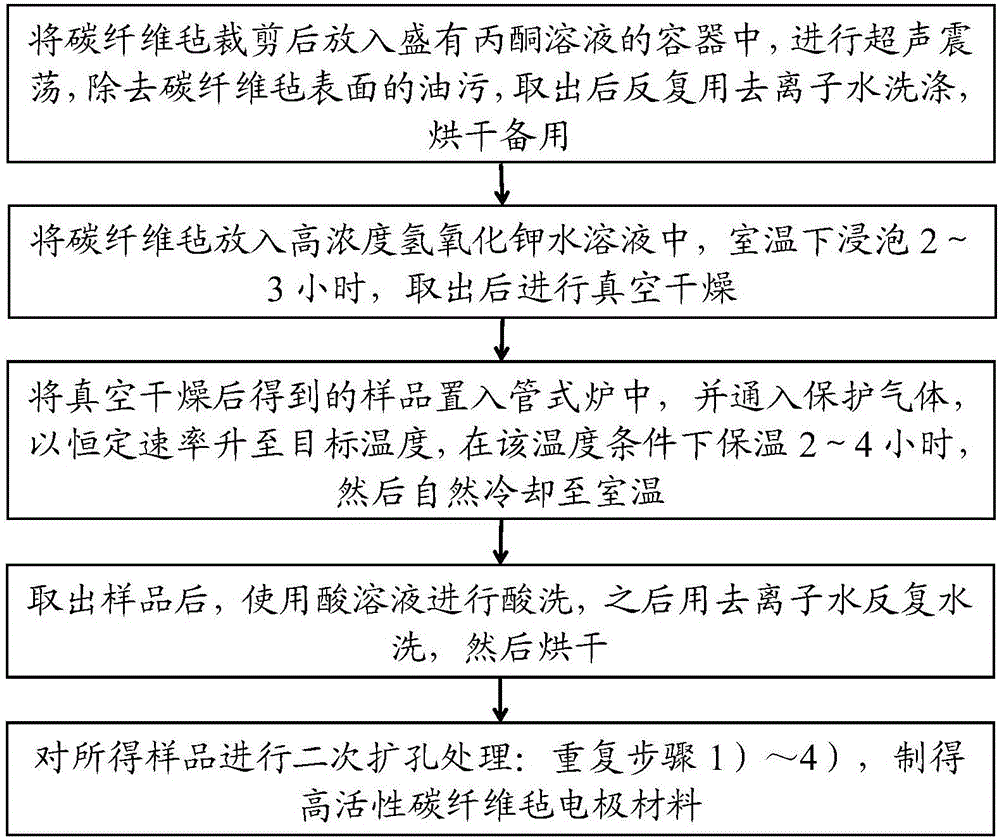

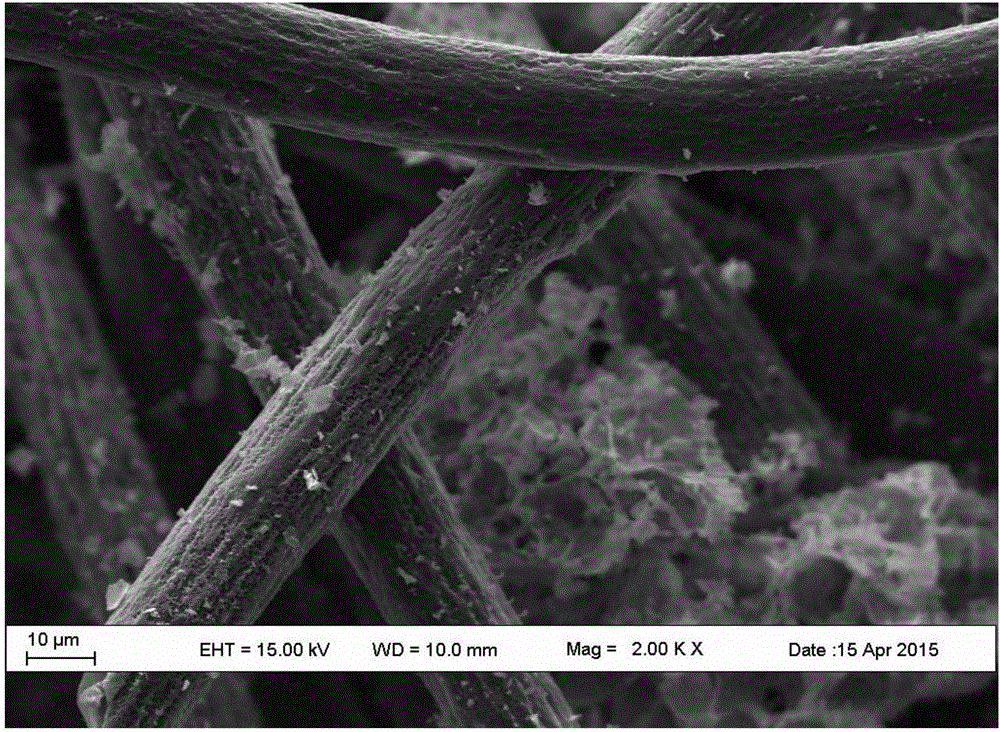

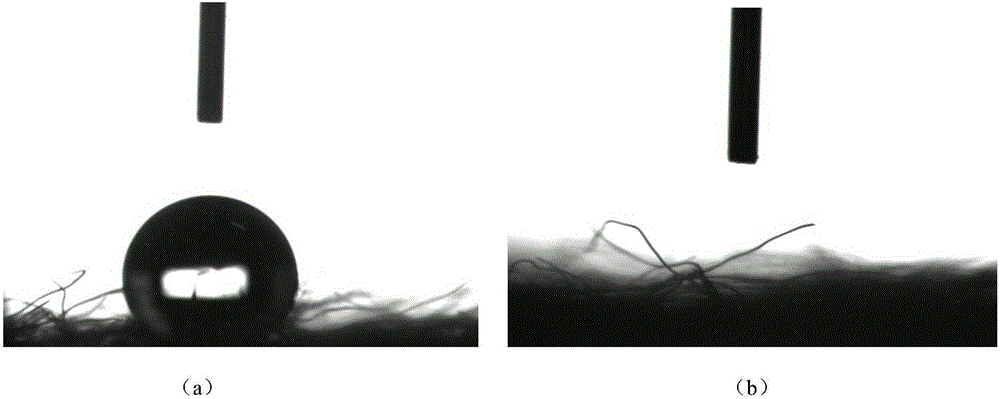

High-activity carbon fiber felt electrode material and preparation method and application thereof

The invention discloses a high-activity carbon fiber felt electrode material and a preparation method and application thereof. The preparation method includes the following steps that firstly, carbon fiber felt is placed in a container containing an acetone solution after being cut for ultrasonic concussion, greasy dirt on the surface of the carbon fiber felt is removed, and the carbon fiber felt is taken out, repeatedly washed with water and dried for use; secondly, the carbon fiber felt is placed in a high-concentration potassium hydroxide aqueous solution and soaked for 2-3 hours at room temperature, and the carbon fiber felt is taken out and subjected to vacuum drying; thirdly, the obtained sample is placed in a tube furnace, protective gas is introduced, the temperature is increased to target temperature at constant speed and preserved for 2-4 hours, and then the sample is naturally cooled to room temperature; fourthly, the sample is subjected to acid pickling by means of an acid solution after being taken out, then the sample is repeatedly washed with deionized water, and then the sample is dried; fifthly, the obtained sample is subjected to secondary pore broadening treatment, the second step, the third step and the fourth step are repeated, and the high-activity carbon fiber felt electrode material is prepared. Porousness of the carbon fiber surface is achieved through the simple and feasible method, and the material can be used as a vanadium redox battery cathode material.

Owner:XUCHANG UNIV

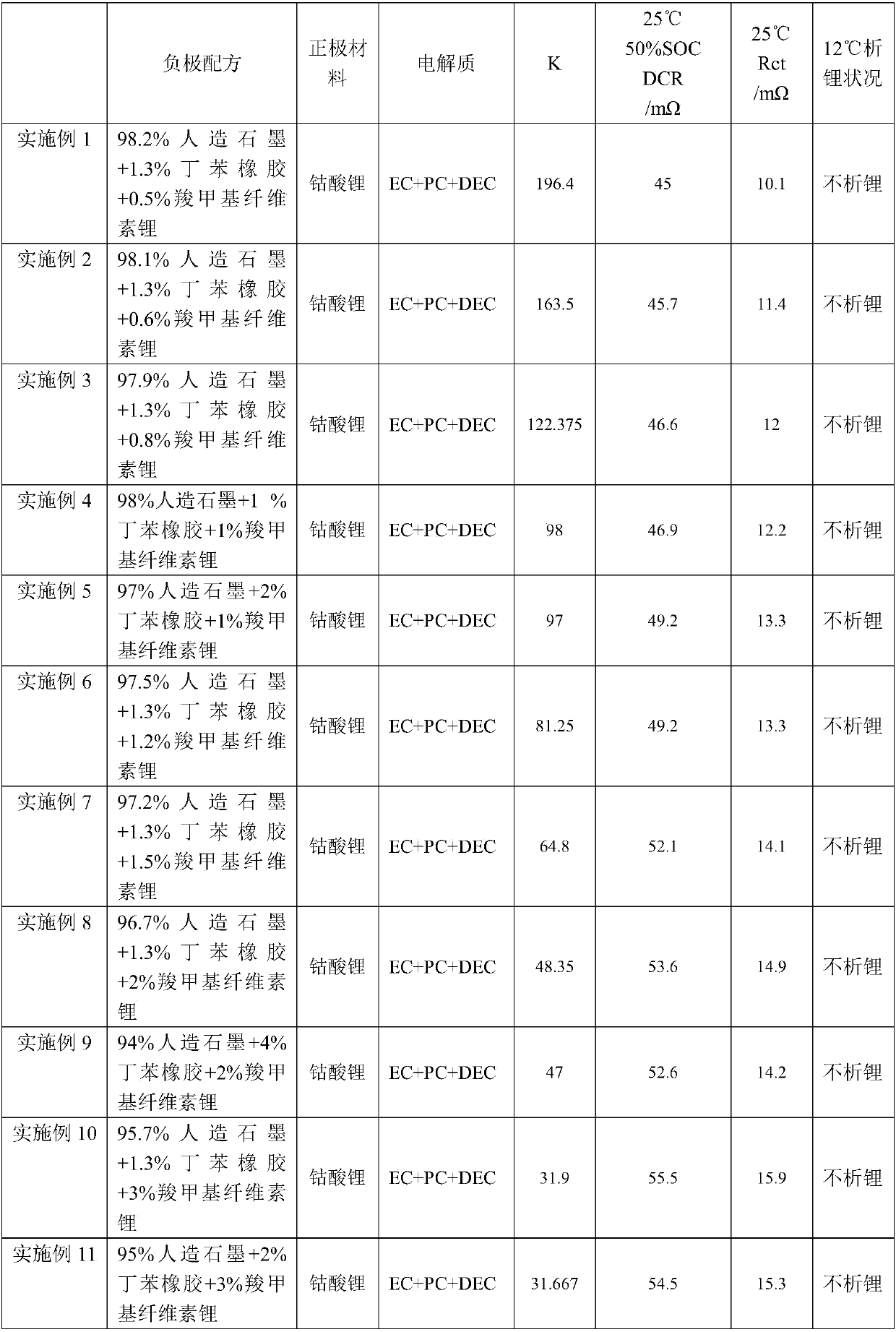

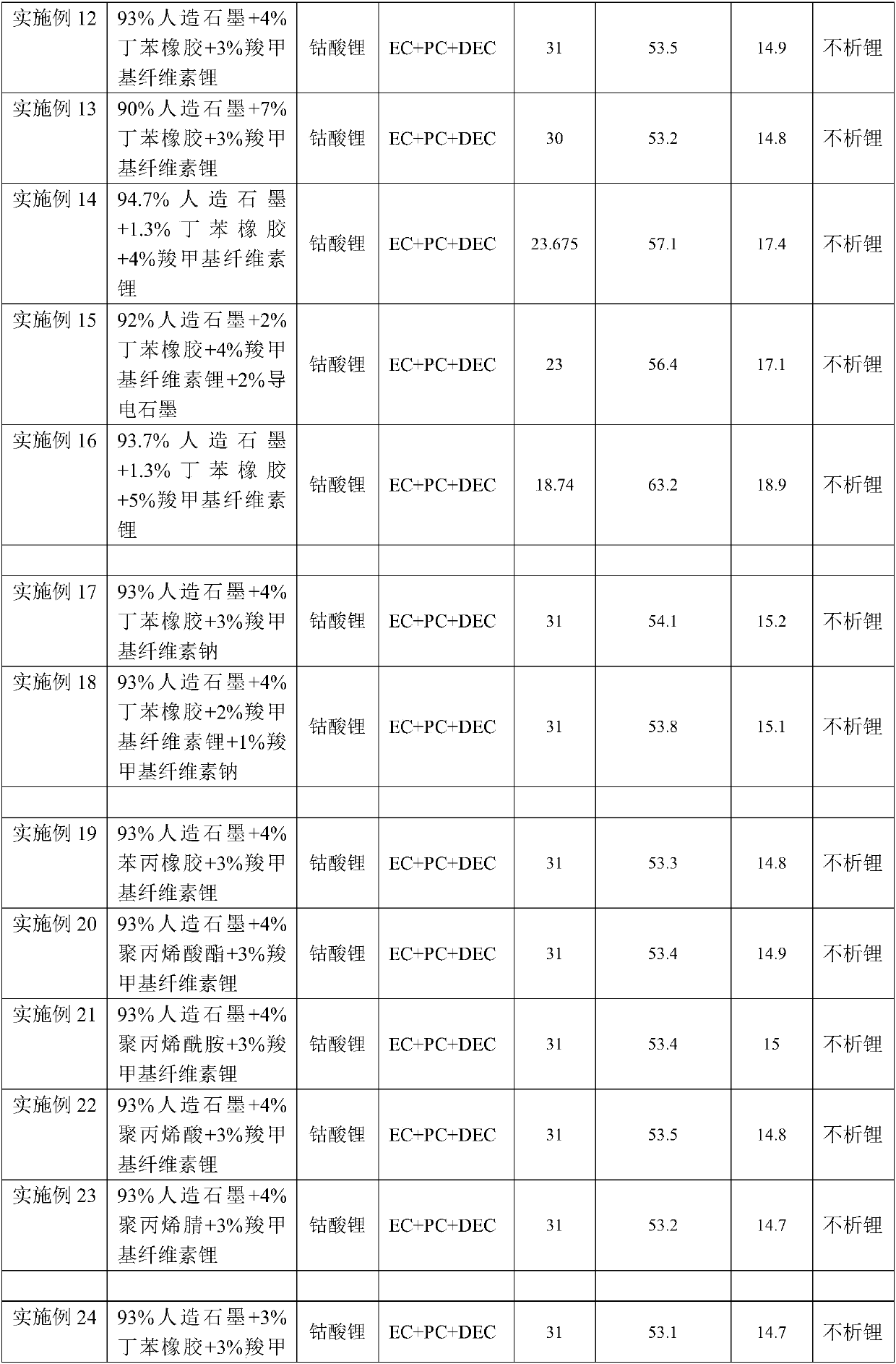

Negative electrode sheet and lithium ion battery including negative electrode sheet

PendingCN110197894ANo loss of energy densityDoes not affect cycle lifeFinal product manufactureNegative electrodesTO-18Carboxymethyl cellulose

The embodiment of the application provides a negative electrode sheet and a lithium ion battery including the negative electrode sheet. The negative electrode sheet includes a negative current collector and a negative active material layer disposed on the negative current collector, wherein the negative active material layer includes a negative active material and a dispersant, the mass ratio of the negative active material and the dispersant is greater than or equal to 18.74, and the dispersant includes lithium carboxymethyl cellulose. The negative electrode sheet, while not losing the energydensity of the lithium ion battery, not affecting the cycle life of the lithium ion battery and not causing cyclic expansion, greatly reduces the DC resistance of the lithium ion battery and the charge transfer resistance of an interface, and avoids lithium deposition of the lithium ion battery during cyclic charge / discharge process.

Owner:NINGDE AMPEREX TECH

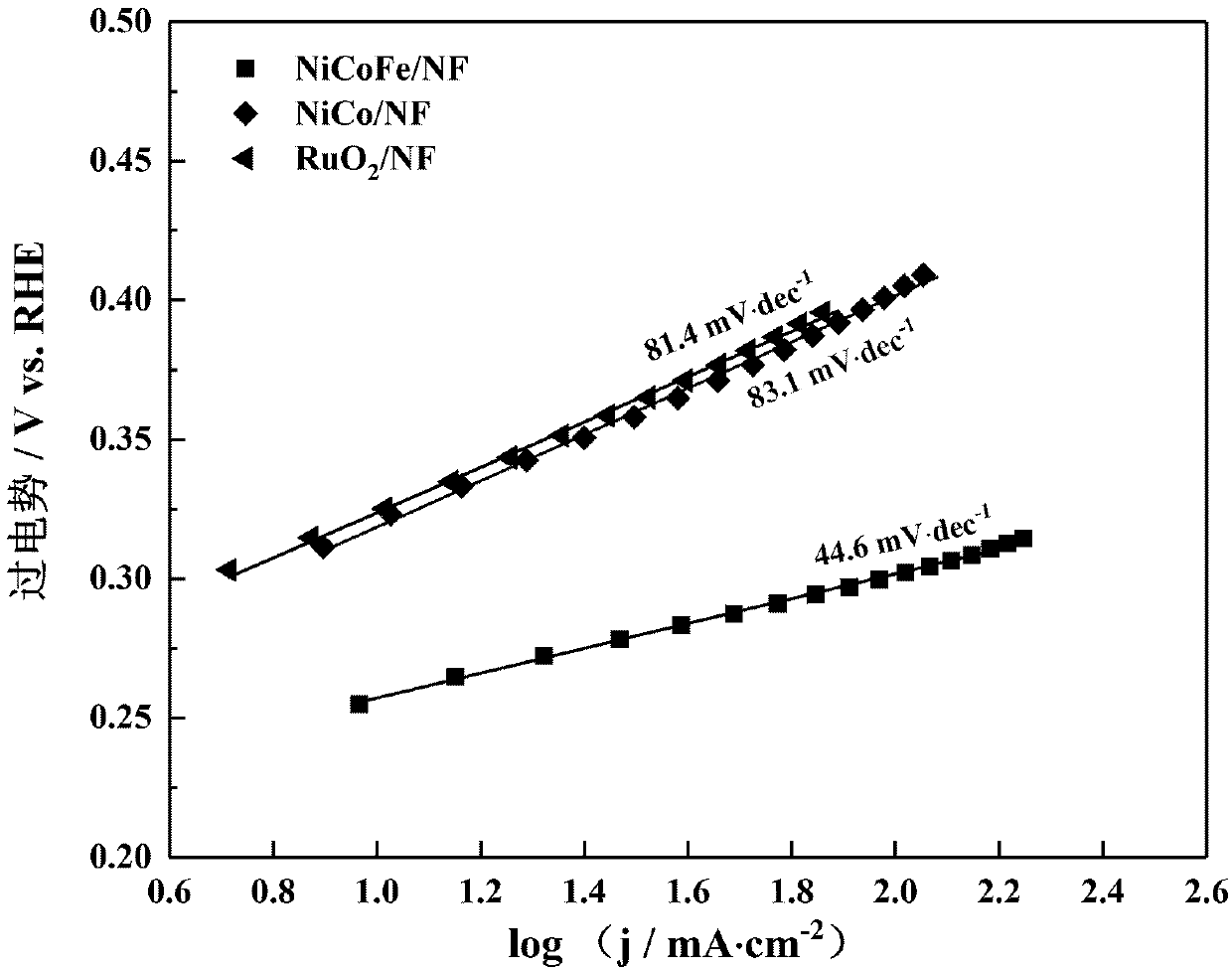

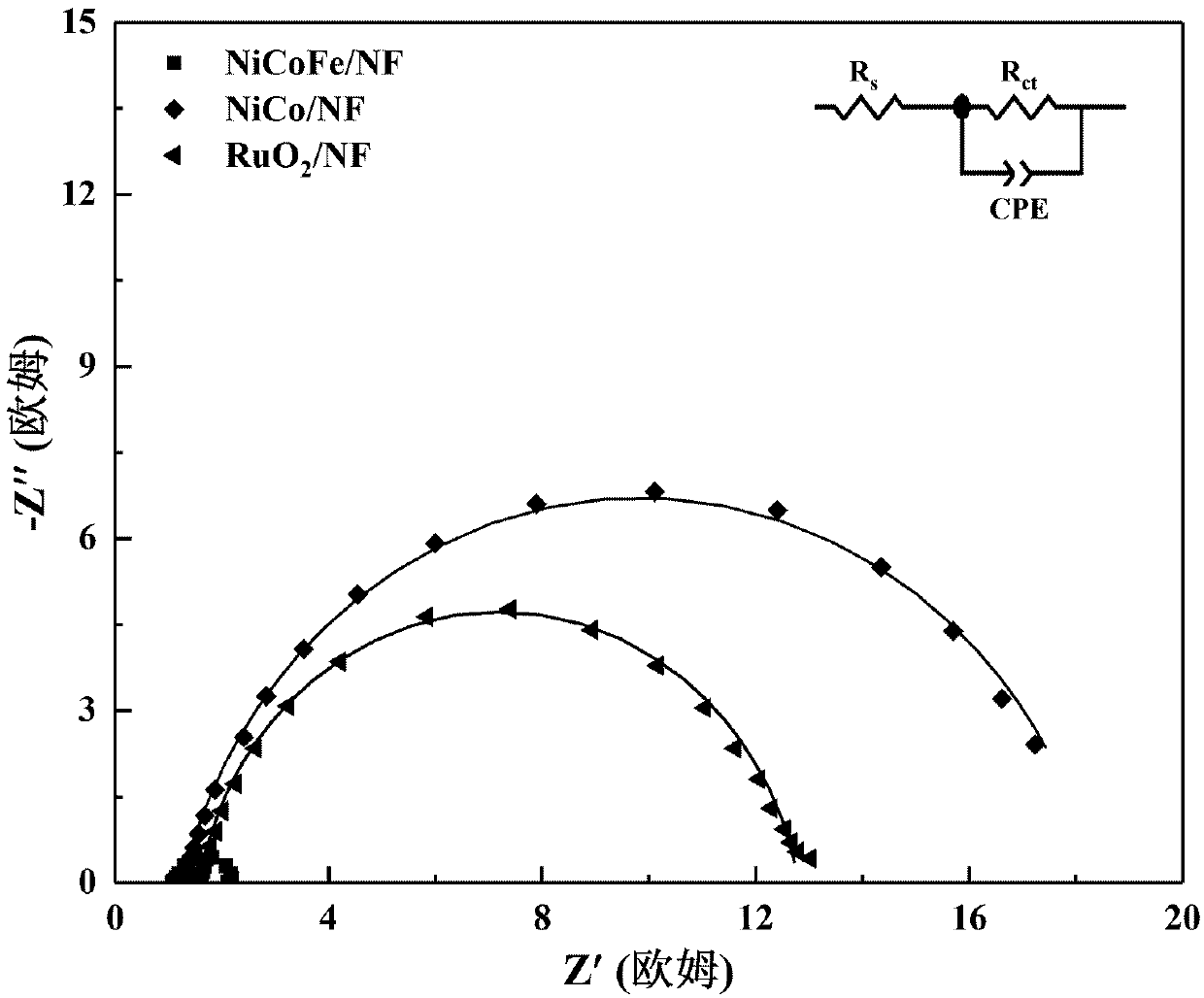

Preparation method of non-noble metal NiCoFe/NF electrocatalyst and application of electrocatalyst to oxygen evolution

ActiveCN110280249AEasy to makeRaw materials are cheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsElectrodesCation exchange reactionIon exchange

The invention belongs to the technical field of electrocatalysis, and specifically relates to a preparation method of a non-noble metal NiCoFe / NF electrocatalyst and application of the electrocatalyst to oxygen evolution. The catalyst is mainly prepared by a hydrothermal reaction and a metal cation exchange reaction at room temperature in two steps, wherein in the first step, Ni-doped Co-MOF is grown on foam nickle in situ as a precursor for the next step of reaction; in the second step, obtained NiCo / NFis immersed in an aqueous solution containing ferrous sulfate, and after drying, the NiCoFe / NF catalyst is obtained. The catalyst obtained by the method can achieve the electric current density of 10 mA / cm<2> with only 252 mV of overpotential, has excellent long-term stability at the same time, and has higher oxygen evolution activity compared with other traditional non-noble metal catalysts. The preparation method involved in the invention is simple; raw materials are abundant and easy to get; large-scale production potential is realized.

Owner:QUFU NORMAL UNIV

Non-aqueous electrolyte secondary battery and assembly thereof

ActiveUS20150311563A1Improve battery performanceExcellent high rate characteristicsOrganic electrolyte cellsSecondary cellsInorganic phosphateLithium metal

Provided is a non-aqueous electrolyte secondary battery combining excellent input / output performance with great durability (cycle characteristics) and an assembly thereof. The present invention provides a non-aqueous electrolyte secondary battery assembly. The positive electrode has a maximum operating voltage of 4.3 V or higher relative to lithium metal, comprising a positive electrode active material and an ion-conductive inorganic phosphate compound. The non-aqueous electrolyte solution comprises a supporting salt, an oxalatoborate-type compound, and a non-aqueous solvent. The non-aqueous solvent is formed of a non-fluorinated solvent. This invention also provides a non-aqueous electrolyte secondary battery obtained by charging the non-aqueous electrolyte secondary battery assembly.

Owner:TOYOTA JIDOSHA KK

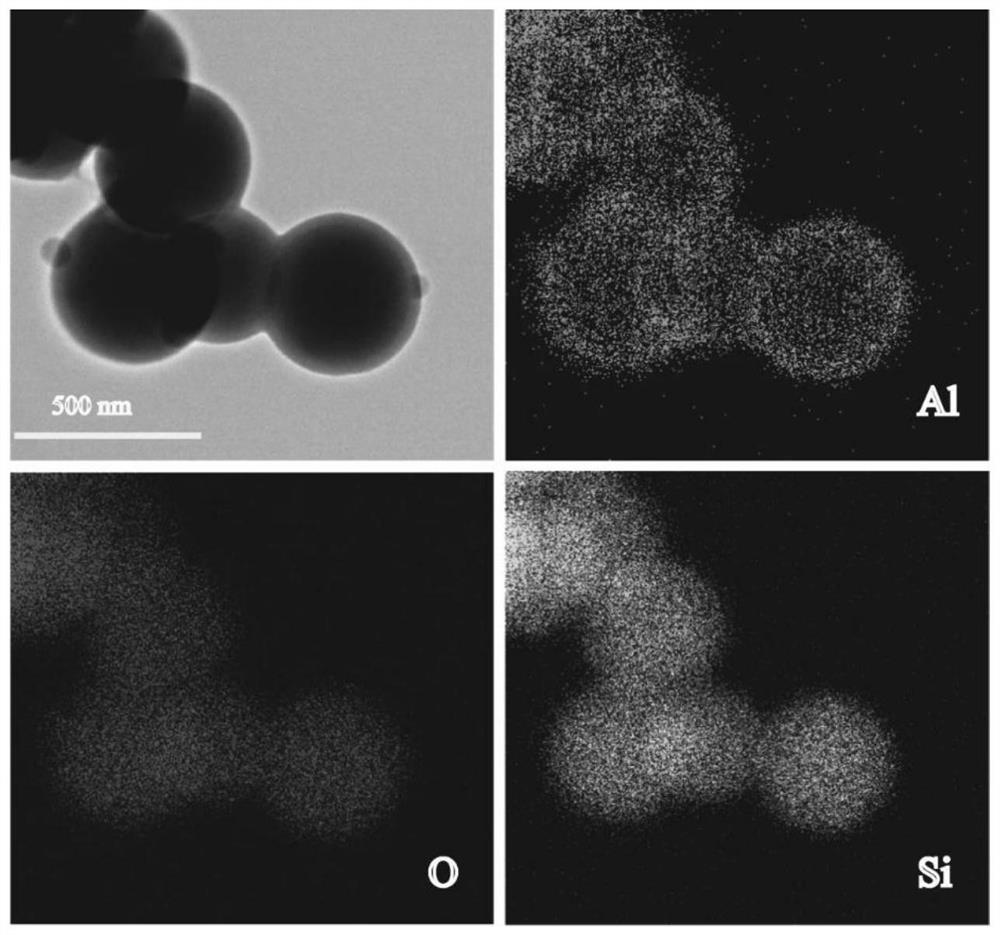

A preparation method of ternary cathode material for coated lithium ion battery

ActiveCN109037644AReduce side effectsImprove migration efficiencyCell electrodesSecondary cellsSolubilityCoprecipitation

A method for preparing ternary cathode material of coated lithium ion battery includes such steps as sequentially adding solution with different ion solubility to carry out coprecipitation reaction, adding polyacrylamide during coprecipitation reaction, pre-sintering and removing polyacrylamide to obtain porous spherical ternary material precursor; Then the precursor of porous spherical ternary material was coated with Al2O3, and sodium dodecyl benzene sulfonate was added into the coated solution. Finally, the cathode active material of lithium ion battery was obtained by sintering. A method for preparing a ternary cathode material of a coated lithium ion battery according to that present embodiment greatly improve the capacity, rate performance and cycle stability of the ternary cathode material of the lithium ion battery.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

High-low-temperature electrolyte suitable for lithium iron phosphate power battery and preparation method for electrolyte

InactiveCN107069087ASolve poor high temperature cycle performanceSolve the problem of low discharge capacity at low temperatureFinal product manufactureSecondary cells servicing/maintenancePower batteryOrganic solvent

The invention belongs to the field of an electrolyte of a lithium ion battery, and relates to a high-low-temperature electrolyte suitable for a lithium iron phosphate power battery and a preparation method for the electrolyte. The electrolyte is prepared from a lithium salt, an organic solvent and additives. By virtue of the high-low-temperature electrolyte suitable for the lithium iron phosphate power battery and the preparation method for the electrolyte, the problems of poor high-temperature cycling performance and low low-temperature discharging capacity of the lithium iron phosphate power battery can be solved, and performance requirements of the lithium iron phosphate power battery in high-low-temperature environments can be satisfied.

Owner:BEIJING WANYUAN IND

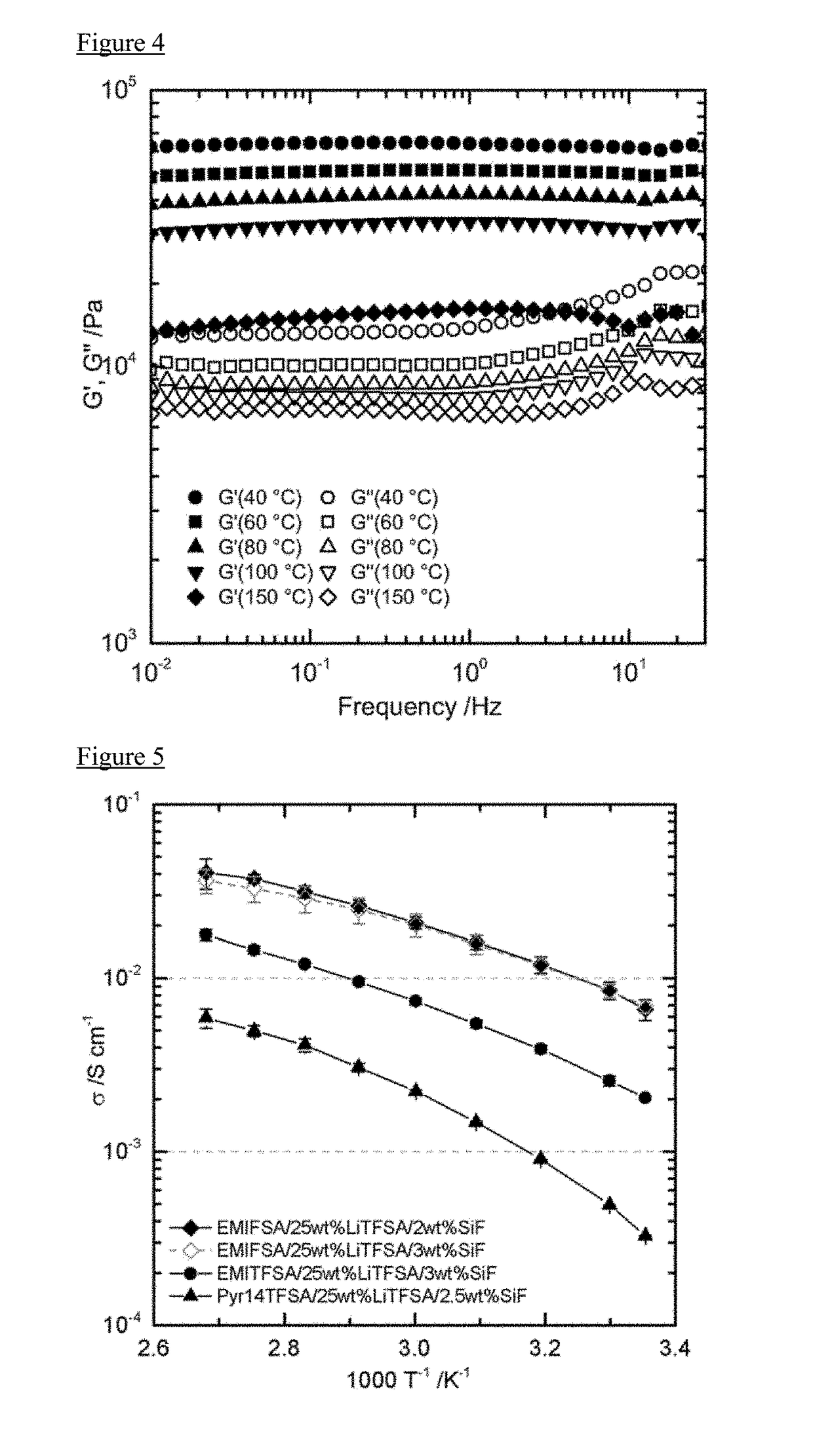

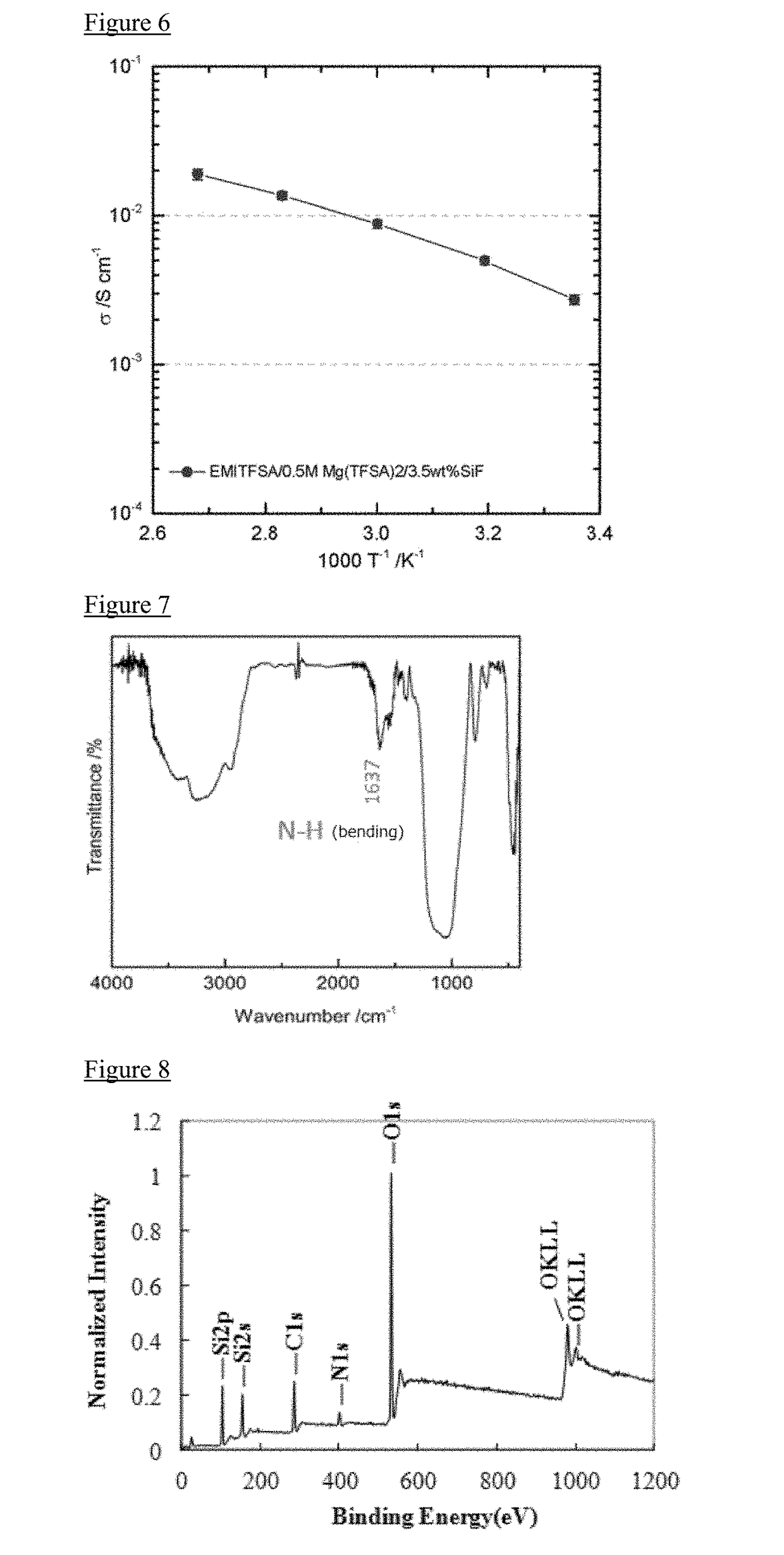

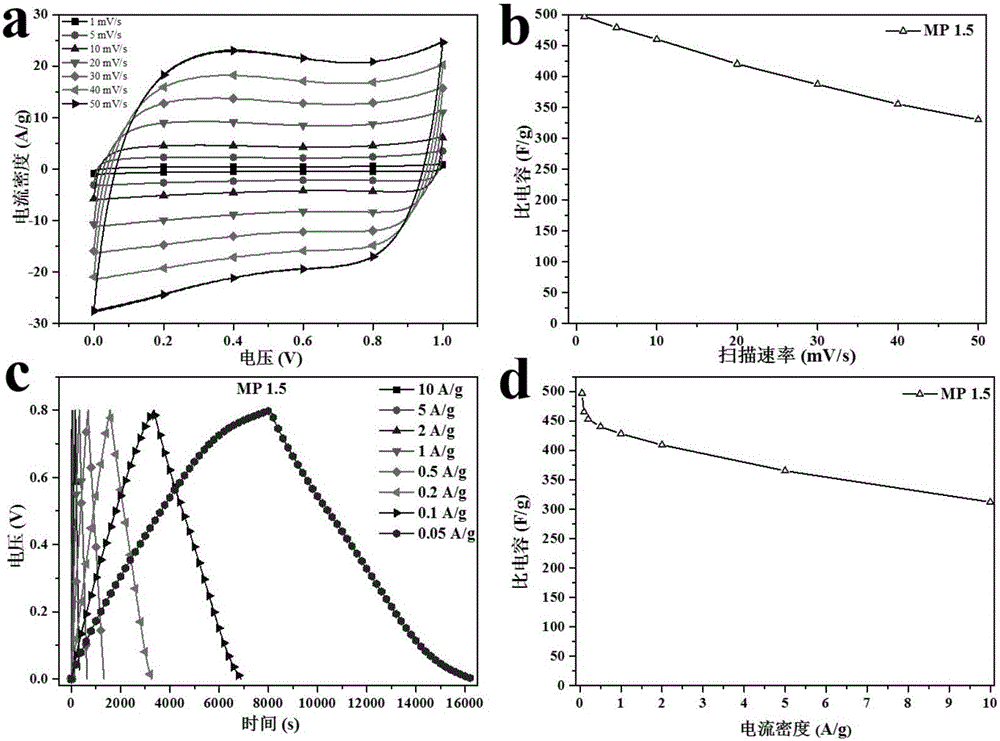

Molten salt composition, electrolyte, and electric storage device, and method for increasing a viscosity of liquid molten salt

ActiveUS20180337426A1Increase viscosityExcellent battery performanceNon-metal conductorsHybrid capacitor electrolytesIonNanometre

The object of the present invention is to provide the gelatinous, molten salt having a high ion-conductivity and an excellent heat resistance.The object of the present invention can be solved by the inorganic nanofibers having a functional group which inter-molecularly interacts with the molten salt on the surface thereof, and the molten salt composition comprising molten salt; or the method for increasing a viscosity of liquid molten salt characterized in that the inorganic nanofibers having a functional group which inter-molecularly interacts with the molten salt in the surface thereof is added to the liquid molten salt.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Preparation method for preparing nano network structure electrode materials of manganese dioxide/conductive polymers applied to super capacitor

ActiveCN106067385ALarge specific surface areaHigh specific capacityMaterial nanotechnologyHybrid capacitor electrodesPolymer capacitorDispersity

The invention provides a preparation method for preparing the nano network structure electrode materials of manganese dioxide / conductive polymers applied to a super capacitor. the preparation method comprises the steps of 1, adding 1-10 g KMnO4 in 150 mL of deionized water, and stirring till the solid KMnO4 is completely dissolved in the deionized water; 2, with the ratio of the KMnO4 raw material to be 1-10 wt%, weighing a dispersant and adding the dispersant in the KMnO4 solution; 3, weighing 0.2-5 ml of conductive polymer monomers and adding the conductive polymer monomers into the KMnO4 solution with the dispersant already added therein to obtain a suspension liquid; 4, centrifugally separating the suspension liquid, and cleaning the obtained solid to obtain a solid sample; 5, freezing and drying the solid sample to obtain the manganese dioxide / conductive polymer nano-structure electrode material. Based on the preparation method, the prepared manganese dioxide / conductive polymer nano-structure electrode material is good in dispersity, large in specific surface area and good in conductivity. Meanwhile, the prepared electrode material of the super capacitor, prepared by the above method, is high in specific capacitance, high in power density, good in rate performance and the like.

Owner:TSINGHUA UNIV

Preparation method for zinc sulfide-graphene nanocomposite

ActiveCN105347388ALower charge transfer resistanceImprove featuresMaterial nanotechnologyZinc sulfidesGraphene nanocompositesSulfur containing

The invention discloses a preparation method for a zinc sulfide-graphene nanocomposite. The preparation method is characterized by comprising the following steps: (1) preparation of a mercaptozinc complex: a step of dissolving sulfur-containing ligand and zinc salt in a proper amount of deionized water or an organic solvent for a hybrid reaction, carrying out stirring, then successively carrying out centrifugal washing with an organic solvent and deionized water, collecting a precipitate and drying the precipitate in vacuum so as to obtain the mercaptozinc complex; (2) preparation of a sintered body: weighing a certain amount of the mercaptozinc complex, sintering the mercaptozinc complex in a vacuum sintering furnace, introducing nitrogen into the vacuum sintering furnace and then carrying out natural cooling to room temperature so as to obtain black solid with white powder on its surface; and (3) acid treatment: a step of soaking the sintered body in an acid solution and then carrying out filtering and drying so as to obtain the zinc sulfide-graphene nanocomposite. The preparation method has the characteristics of simple process and synthesis equipment, a short synthesis period, good product homogeneity and easiness in realization of industrialization.

Owner:嘉兴长蒿新材料科技有限公司

Cathode additive, preparation method thereof, cathode sheet and lithium battery

ActiveCN108807860ALower charge transfer resistanceIncrease energy densityCell electrodesSecondary cellsEnergy densityTransfer impedance

The invention provides a cathode additive, a preparation method thereof, a cathode sheet and a lithium battery. The cathode additive includes a composite material formed by an inorganic lithium salt and a conductive agent. The inorganic lithium salt includes a substance with the general formula being Li<x>MNO<y>, wherein 2<=x<=8, 0<a<=1, 0<=b<1, a+b>=1, 2<=y<=6, the M is one selected from Fe, Co, Mn, Ni, Zr, V, Nb and Mo, and the N is one selected from Al, Mg, Ti, Cr, Y, Sr, Si, W, Ga and Zn. The cathode additive can improve the first discharge capacity of the lithium battery, reduce thecharge transfer impedance of the lithium battery, and improve the energy density, cycle performance and rate performance of the lithium battery.

Owner:NINGDE AMPEREX TECH

Lithium ion battery graphite negative electrode material and preparation method thereof

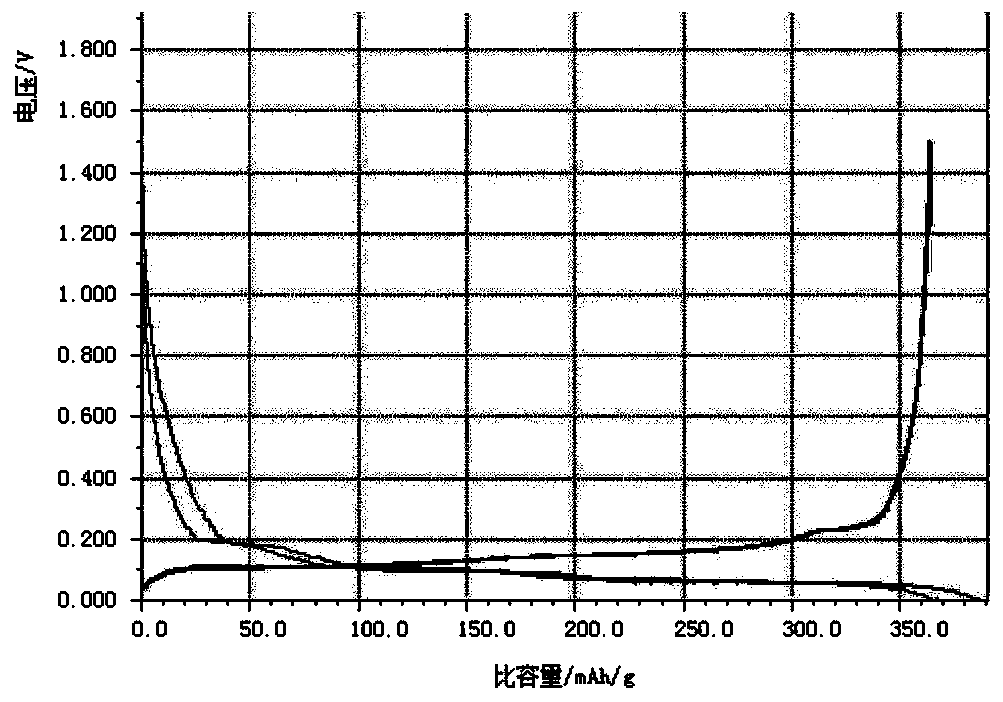

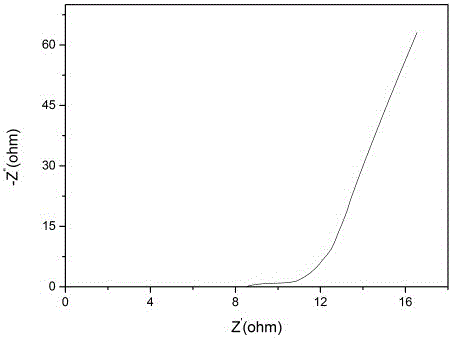

InactiveCN110931788AShorten the transmission distanceIncreased diffusion rateSecondary cellsNegative electrodesPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery graphite negative electrode material and a preparation method thereof. In the graphite negative electrode material of the lithium ion battery, D50 is 7.5-8.5 mum, D90 is 14-16 mum, and D100 is 21-26 mu-m; and the BET specific surface area of the lithium ion battery graphite negative electrode material is 2.0-2.3 m <-2-> / g, and the tap density is 1.0-1.2 g / cm <-2->. The lithium ion battery graphite negative electrode material prepared by the invention has excellent low temperature and rate capability; the primary particles with smaller particles canbe bonded through secondary granulation; the transmission distance of lithium ions in graphite crystals is shortened, the surfaces of graphite particles can be coated with copper powder and nano conductive carbon after the graphitization process, the charge transfer impedance of the surface of graphite is effectively reduced, adopted resin becomes amorphous carbon after the coating and graphitization processes, and the diffusion rate of the lithium ions is effectively increased.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

CoTe nanometer material applied to supercapacitor electrode and preparation method thereof

InactiveCN106847531AImprove electrochemical performanceLower charge transfer resistanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceThermal insulation

The invention discloses a CoTe nanometer material applied to a supercapacitor electrode and a preparation method thereof. The CoTe nanometer material is of a nanoparticle pile structure. The preparation method comprises the following steps of weighing Te powder and CoCl2 and dissolving into a KOH solution; adding hydrazine hydrate and stirring to react in room temperature; transferring an obtained mixture to a hydrothermal kettle and performing thermal insulation reaction; then naturally cooling in room temperature, collecting black precipitation, washing through deionized water for multiple times, drying the precipitation and obtaining dry CoTe. When being applied to an electrode material of a supercapacitor, the CoTe nanometer material has excellent electrochemical property, charge transfer resistance can be as low as 0.0161 ohm, specific capacitance can reach 113.4 F.g<-l> under the condition that the discharge current is 5 mA, 100% capacitance can be kept after 1000 times of circulation, and specific capacitance, rate capacity and circulation stability are all excellent.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com