All-vanadium flow battery porous carbon fiber felt electrode material and preparation and application thereof

A technology of all-vanadium redox flow battery and porous carbon fiber, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problem of low electrocatalytic activity of electrode materials, achieve high practical value, reduce volume, and improve electrocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

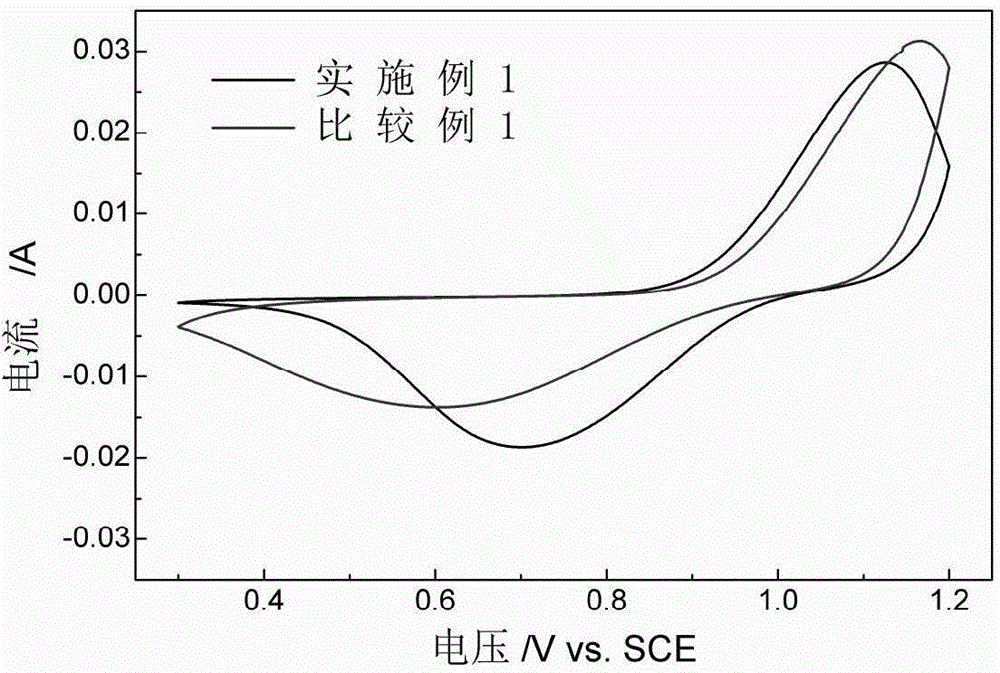

[0032] Put a certain size of polyacrylonitrile-based pre-oxidized felt into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1600°C at a heating rate of 10°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 1300°C, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates are 40ml / min and 200ml / min, respectively, and the constant temperature is reacted for 30min; then cooled to room temperature to make a porous carbon fiber felt.

[0033] In order to test the electrochemical activity of the vanadium ion redox couple on the surface of the activated carbon felt, a cyclic voltammetry test was carried out on the porous carbon fiber felt prepared in Example 1. The porous carbon fiber felt was used as the working electrode, the non-porous graphite plate was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. The electrochemical testing instrument used w...

Embodiment 2

[0046] Put a certain size of polyacrylonitrile-based pre-oxidized felt into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1400°C at a heating rate of 5°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 800°C, and water vapor and N 2 mixture of gas, water vapor and N 2 The flow rates are 10ml / min and 200ml / min, respectively, and the constant temperature is reacted for 30min; then cooled to room temperature to make a porous carbon fiber felt.

[0047] The single cell assembly evaluation conditions are the same as in Example 1, except that the difference from Example 1 is that the current density of the all-vanadium redox flow battery using the porous carbon fiber felt of this example as the electrode is 80mA / cm 2 , the voltage efficiency and energy efficiency were 90.8% and 85.4% respectively; the current density increased to 140mA / cm 2 , the voltage efficiency and energy efficiency remained at 85...

Embodiment 3

[0049] Put a viscose-based pre-oxygenated felt of a certain size into the electric furnace, 2 Under the atmosphere, the temperature was raised to 1300°C at a heating rate of 5°C / min, and the temperature was kept constant for 1h; then the temperature was kept constant, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates are 20ml / min and 200ml / min, respectively, and the constant temperature is reacted for 30min; then cooled to room temperature to make a porous carbon fiber felt.

[0050] The single battery assembly evaluation conditions are the same as in Example 1, and the difference from Example 1 is that: the all-vanadium redox flow battery adopts the activated carbon felt of this example as the electrode, and the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 89.3% and 84.4% respectively; the current density increased to 120mA / cm 2 , the voltage efficiency and energy efficiency still remain at 84.6% and 80.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com