Application of carbon nanofiber and metal composite electrode in flow battery

A nano-carbon fiber and metal composite technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of high electrode cost and unsuitable for large-scale application, achieve low price, improve electrocatalytic activity and electrochemical reversibility , the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

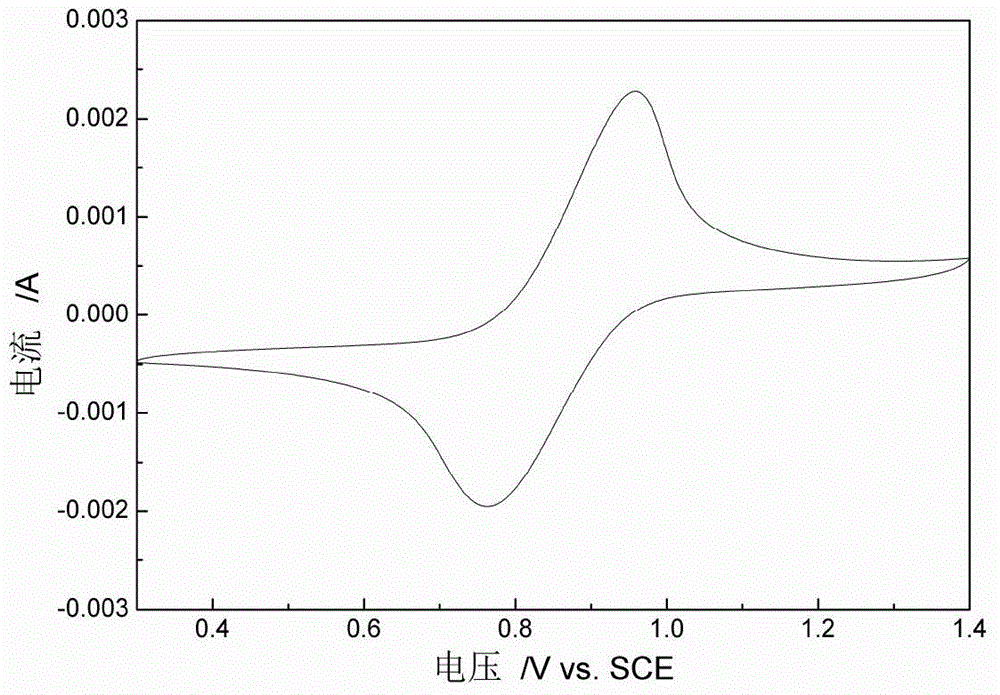

Embodiment 1

[0031] Weigh 0.5gBi(NO 3 ) 3 ·5H 2 Dissolve O in 20g of N,N-dimethylformamide, ultrasonically disperse for 1h to dissolve completely, then add 2g of polyacrylonitrile powder, stir at 70°C for 24h to fully dissolve. Then, 5 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 10KV voltage, 25° C., and 10% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 300°C for 2h, then sintered at 1200°C for 2h under argon atmosphere, the metal salt in it was reduced to metal, and then cooled to room temperature to prepare carbon nanofibers / Bi composite electrode material. Such as figure 1 As shown, the SEM image of the carbon nanofiber / metal composite electrode material shows that it is made of interlaced carbon nanofibers. The diameter of the carbon nanofibers is about 200nm. A large number of nanos...

Embodiment 2

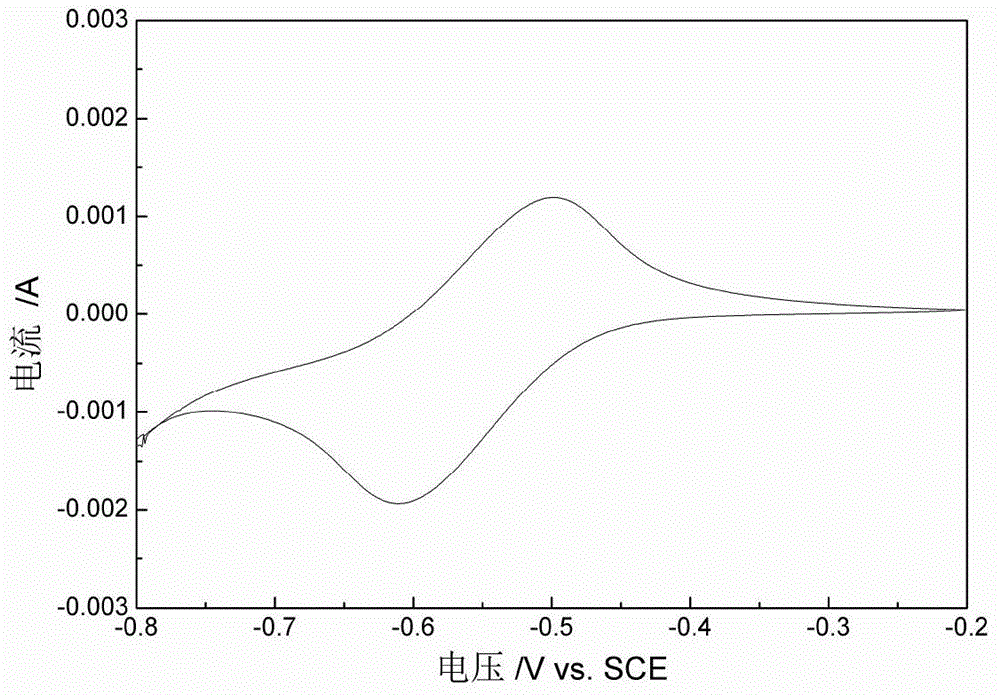

[0034] Weigh 0.4gPb(NO 3 ) 2Dissolve in 20g of N,N-dimethylformamide, ultrasonically disperse for 1h to dissolve completely, then add 3g of polymethyl methacrylate powder, stir at 50°C for 24h to fully dissolve. Then, 10 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 15KV voltage, 25° C., and a relative humidity of 20%, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 280 °C for 2 h, and then sintered at 1400 °C for 2 h under an argon atmosphere, the metal salt in it was reduced to metal Pb, and then cooled to room temperature to obtain nano Carbon fiber / Pb composite electrode material. The diameter of carbon nanofibers in the obtained carbon nanofiber film is about 100 nm, and the mass fraction of Pb is 20%.

Embodiment 3

[0036] Weigh 0.1g of bismuth subsalicylate and disperse in 20g of N,N-dimethylformamide, ultrasonically disperse for 1h to make it evenly dispersed, then add 2g of polyacrylonitrile powder, stir at 60°C for 24h to fully dissolve and mix with Bismuth subsalicylate mixed well. Then 10 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 10KV voltage, 25° C., and 10% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 280 °C for 2 h, and then sintered at 1400 °C for 2 h under an argon atmosphere, the metal salt in it was reduced to metal Bi, and then cooled to room temperature to obtain nano Carbon fiber / Bi composite electrode material. The diameter of carbon nanofibers in the obtained carbon nanofiber film is about 200 nm, and the mass fraction of Bi is 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com