CoTe nanometer material applied to supercapacitor electrode and preparation method thereof

A technology of supercapacitors and nanomaterials, applied in the field of nanomaterials, can solve the problems of environmental pollution restrictions, low reserves, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

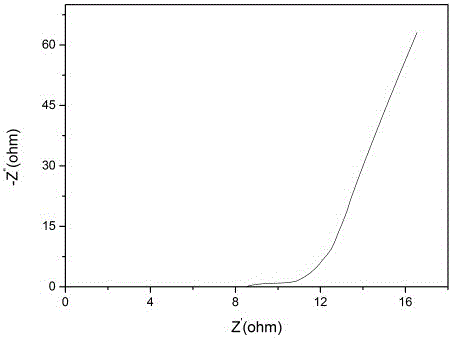

Image

Examples

Embodiment 1

[0026] 1) Put 0.3mmol Te, 0.3mmol CoCl 2 Dissolve in 24mL KOH solution with a concentration of 6M, add 6mL hydrazine hydrate, and stir at room temperature for a reaction time of 4 hours;

[0027] 2) Transfer the mixture to a 50mL polytetrafluoroethylene hydrothermal kettle, seal it, and react in a furnace at 200 degrees Celsius for 4 hours;

[0028] 3) After the reaction, the reactor was cooled with the furnace, and the black precipitate was collected by suction filtration, and washed with deionized water several times; the precipitate was baked at 70°C for 12 hours, and the obtained dry CoTe powder was used for the preparation of electrodes and test.

Embodiment 2

[0030] 1) Put 0.3mmol Te, 0.3mmol CoCl 2 Dissolve in 24mL KOH solution with a concentration of 6M, add 6mL hydrazine hydrate, and stir at room temperature for 3 hours;

[0031] 2) Transfer the mixture to a 50mL polytetrafluoroethylene hydrothermal kettle, seal it, and react in a furnace at 200 degrees Celsius for 4 hours;

[0032] 3) After the reaction, the reactor was cooled with the furnace, and the black precipitate was collected by suction filtration, and washed with deionized water several times; the precipitate was baked at 70°C for 12 hours, and the obtained dry CoTe powder was used for the preparation of electrodes and test.

Embodiment 3

[0034] 1) Put 0.3mmol Te, 0.3mmol CoCl 2 Dissolve in 24mL KOH solution with a concentration of 6M, add 6mL hydrazine hydrate, and stir at room temperature for 2 hours;

[0035] 2) Transfer the mixture to a 50mL polytetrafluoroethylene hydrothermal kettle, seal it, and react in a furnace at 200 degrees Celsius for 4 hours;

[0036] 3) After the reaction, the reactor was cooled with the furnace, and the black precipitate was collected by suction filtration, and washed with deionized water several times; the precipitate was baked at 70°C for 12 hours, and the obtained dry CoTe powder was used for the preparation of electrodes and test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com