Method for continuously synthesizing precursor of lithium ion battery positive material

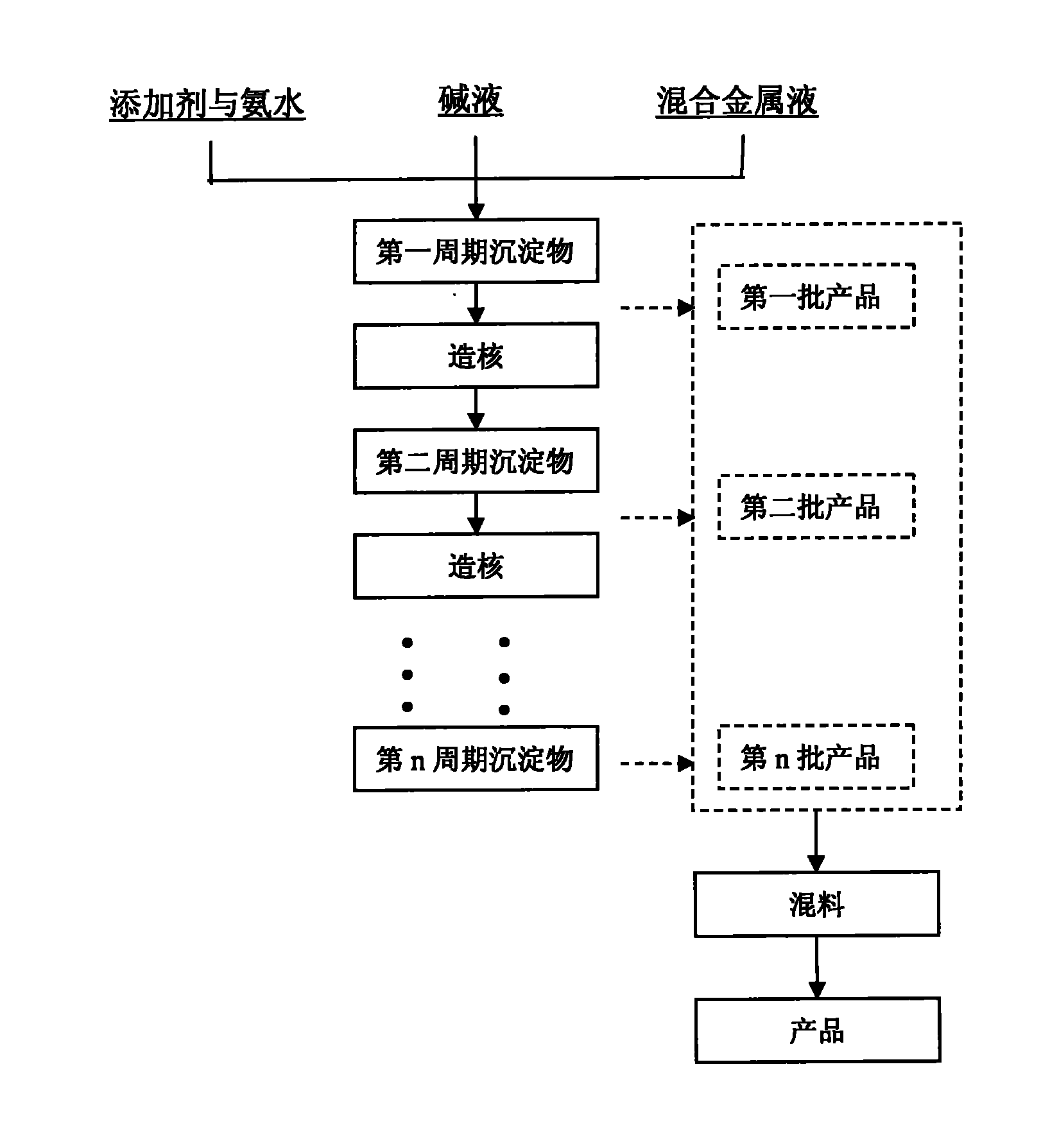

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of ineffective guarantee of product batch quality stability, low product vibration specific gravity, and low equipment utilization rate, achieving remarkable results Economic and social benefits, easy particle size distribution, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

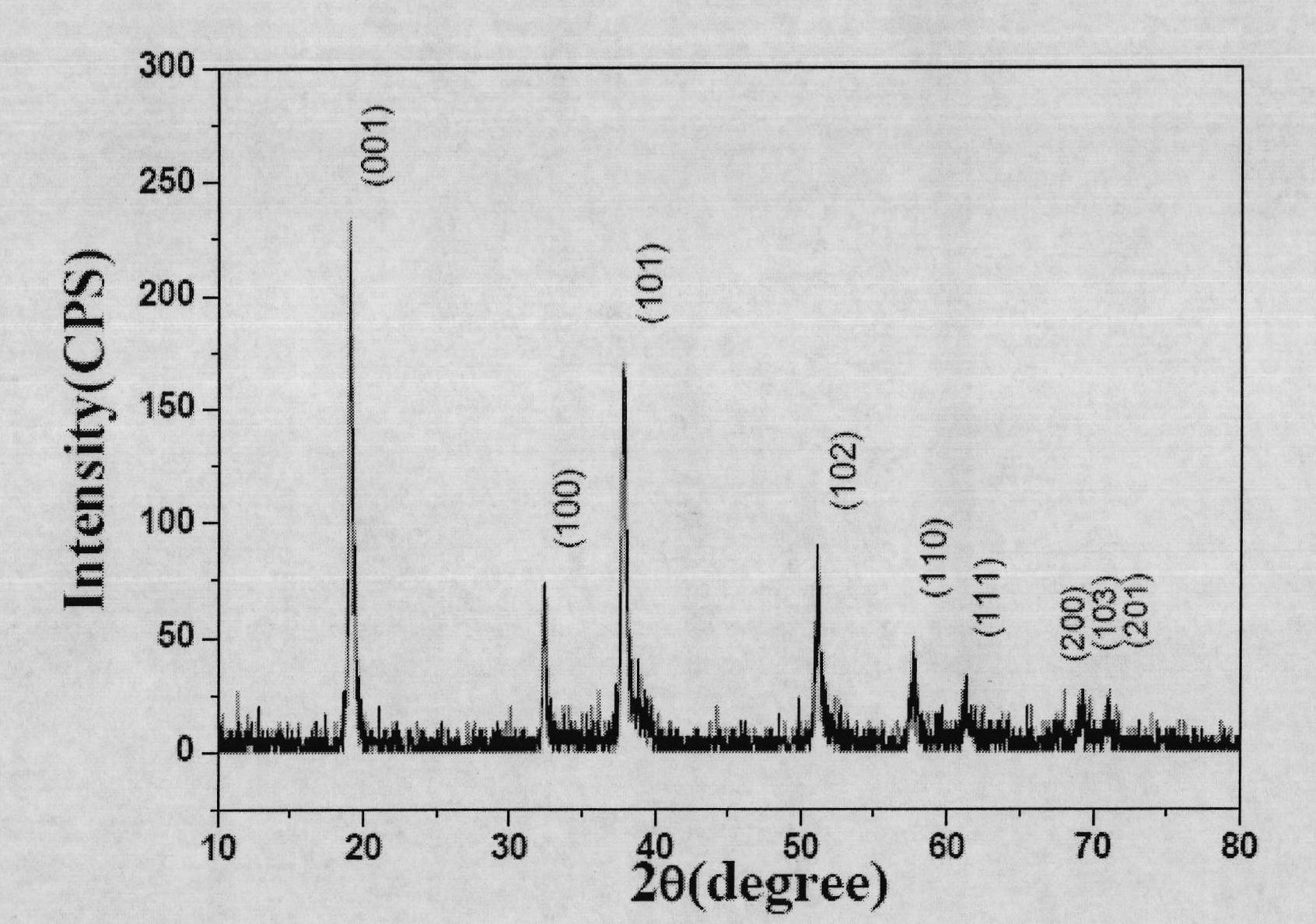

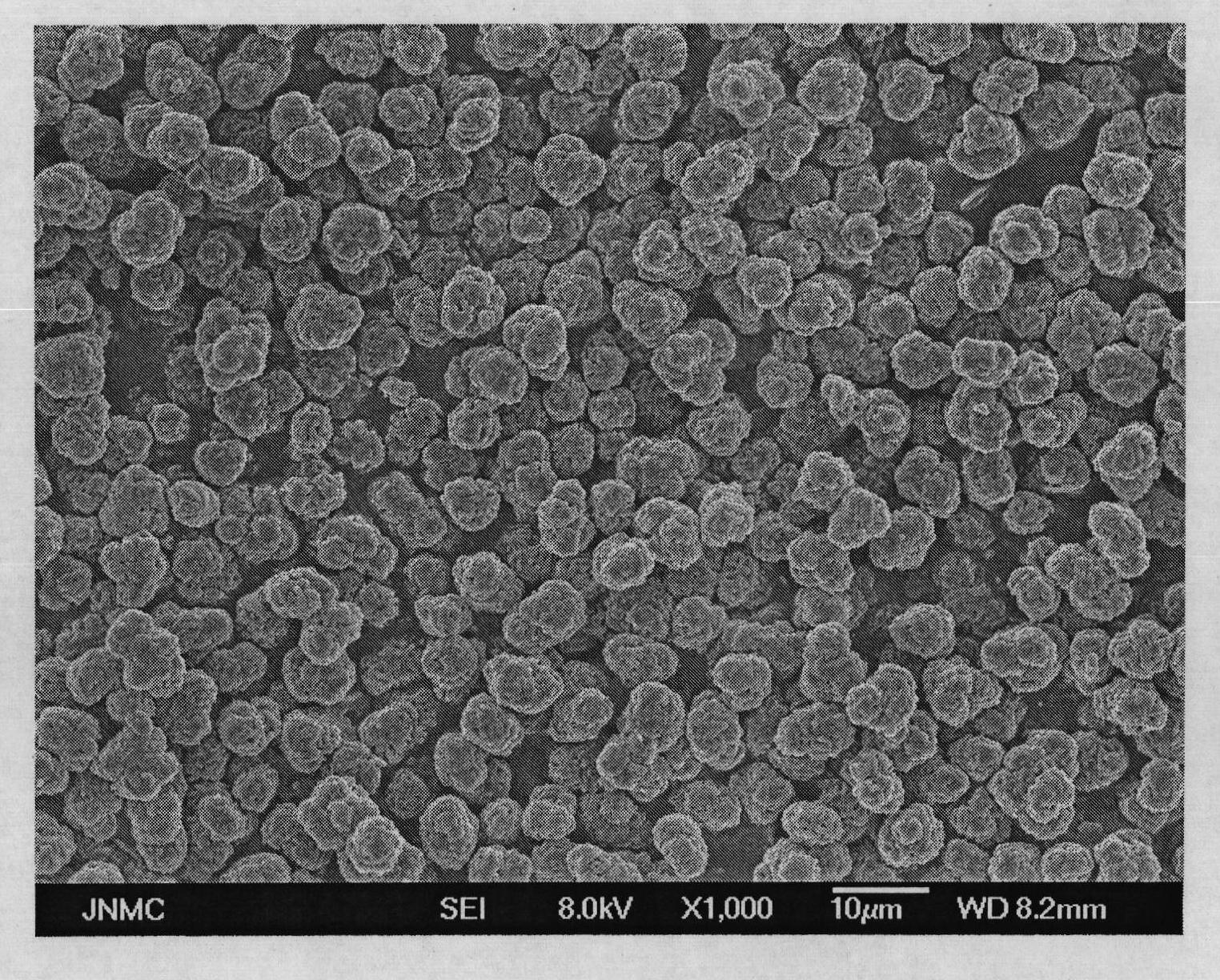

[0035] Put the nickel-cobalt-manganese mixed metal liquid with a concentration of 40-80g / L into the reaction kettle with a metering pump, the concentration of sodium hydroxide is 100-200g / L, and the concentration of ammonia water is 30-50g / L. The reaction temperature is controlled at 40-55° C., the pH value is controlled at 7-10, the stirring rate is controlled at 200-400 r / min, and the nucleation period is controlled at 25-40 hours. The overflowed solid-liquid mixture is separated and dried at 50-100°C for 12-36 hours. The particle size distribution of the obtained ternary nickel-cobalt-manganese composite hydroxide is uniform, the D50 is 6-8 μm, and the tap density is 1.8-2.0 g / cm 3 .

Embodiment 2

[0037]Put the nickel-cobalt-manganese mixed metal liquid with a concentration of 40-80g / L into the reaction kettle with a metering pump, the concentration of sodium hydroxide is 100-200g / L, and the concentration of ammonia water is 30-50g / L. The reaction temperature is controlled at 40-55° C., the pH value is controlled at 10-12, the stirring rate is controlled at 200-400 r / min, and the nucleation period is controlled at 25-40 hours. The overflowed solid-liquid mixture is separated and dried at 100-200°C for 12-36 hours. The obtained ternary nickel-cobalt-manganese composite hydroxide has a uniform particle size distribution, a D50 of 6-8 μm, and a tap density of 1.7-1.9 g / cm 3 .

Embodiment 3

[0039] Put the nickel-cobalt-manganese mixed metal liquid with a concentration of 80-120g / L into the reaction kettle with a metering pump, the concentration of sodium hydroxide is 100-200g / L, and the concentration of ammonia water is 30-50g / L. The reaction temperature is controlled at 55-80° C., the pH value is controlled at 7-10, the stirring rate is controlled at 100-200 r / min, and the nucleation period is controlled at 45-60 hours. The overflowed solid-liquid mixture is separated and then dried at 50-120°C for 12-36 hours. The particle size distribution of the obtained ternary nickel-cobalt-manganese composite hydroxide is uniform, the D50 is 9-12 μm, and the tap density is 2.0-2.2 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com