Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

A technology of inorganic composite and isolation membrane, applied in the field of electrochemistry, can solve problems such as affecting the performance of the membrane, and achieve the effects of improving electrical conductivity, good air permeability, and improving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

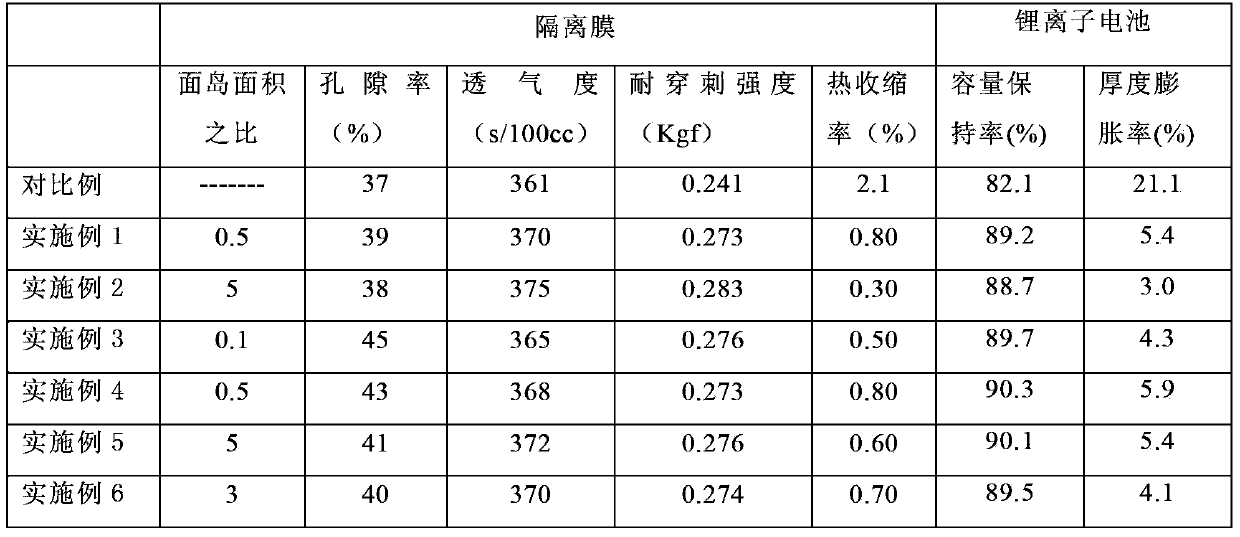

[0031] The preparation method of the organic / inorganic composite porous isolation membrane according to the second aspect of the present invention is used to prepare the organic / inorganic composite porous isolation membrane according to the first aspect of the present invention, comprising the steps of: dividing the organic particles into at least two parts; The first part of organic particles is added to the plasticizer and heated and stirred together to swell the first part of organic particles added, and then the second part of organic particles is added and stirred to swell the second part of organic particles added , and so on, according to the order of addition, the swelling degree of each part of the organic particles changes from high to low; the obtained organic particles with at least two swelling degrees are added to the solvent and mixed with the binder, stirred evenly and then added The inorganic particles are stirred evenly to obtain the organic / inorganic composit...

Embodiment 1

[0057] The positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell molding are the same as the comparative example, and only the separator is prepared in the following manner:

[0058] Add 0.06 parts by mass of ethyl acetoacetate (plasticizer) and 0.14 parts by mass of polyvinylidene fluoride (organic particles) powder into a double planetary mixer, and after stirring at 55 °C for 30 min, add another 2.66 parts by mass of polyvinylidene fluoride Stir the vinyl fluoride powder for 1 hour; then add 0.06 parts by mass of polymethyl acrylate and 68.986 parts by mass of deionized water, and mix at 55°C for 0.5 hour; then add 28 parts by mass of aluminum oxide (average particle size is 1 μm) , stirred at room temperature for 2 hours to obtain an organic / inorganic composite slurry.

[0059] The polypropylene porous substrate is coated on both sides by transfer coating, and is dried in a three-stage oven (each section is 3 meters long, and the temperature...

Embodiment 2

[0061] The positive electrode sheet, negative electrode sheet, non-aqueous electrolyte, and cell molding are the same as the comparative example, and only the separator is prepared in the following manner:

[0062] Add 0.6 parts by mass of dimethyl carbonate (plasticizer) and 0.295 parts by mass of acrylonitrile-butadiene copolymer (organic particles) powder into a double planetary mixer, and after stirring at 45°C for 30 min, add another 5.605 Parts by mass of acrylonitrile-butadiene copolymer powder were stirred for 1 hour; then 0.6 parts by mass of pure acrylic emulsion and 34.2 parts by mass of deionized water were added, and mixed for 0.5 hours at 45°C; then 59 parts by mass of magnesium oxide (average particle size is 5 μm), and stirred at room temperature for 2 hours to obtain an organic / inorganic composite slurry.

[0063] Polypropylene / polyethylene / polypropylene three-layer composite porous substrates were coated on both sides by screen printing, and dried in a three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com