Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

A nano-lithium titanate and graphene composite technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve problems such as difficulty in realizing large-scale industrial production, limiting the wide application of composite materials, and complex synthesis processes. Achieve the effect of improving ion transport capacity, good electrochemical performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

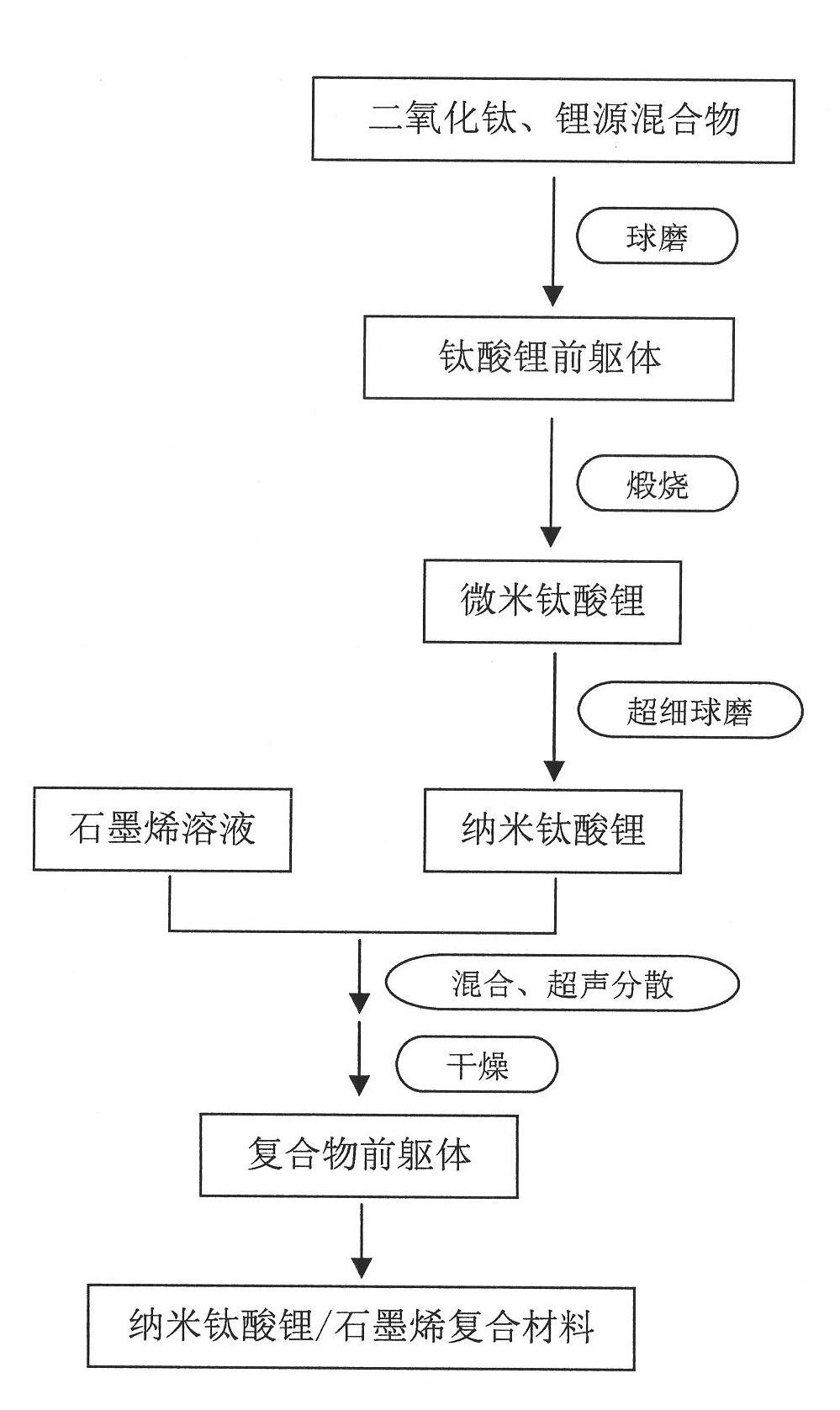

[0037] (1) Preparation of nano-lithium titanate: uniformly mix titanium dioxide and lithium source, the molar ratio of lithium to titanium is N (Li) :N (Ti) =(0.8~0.9):1, titanium dioxide and lithium source are carried out ball milling by planetary ball mill, carry out wet method ball milling, ball milling time is 1~48 hours, after drying, titanium dioxide and lithium source mixed powder in protective atmosphere Calcining at 600-1100°C for 1-48 hours, and cooling to obtain micron lithium titanate powder. Then put the micron lithium titanate obtained after calcination into an ultrafine mill, and wet ball mill it for 10 to 240 minutes under the condition of a rotating speed of 1000 to 10,000 rpm, take it out, wash it with absolute ethanol, and dry it to obtain Nano lithium titanate powder.

[0038] (2) Synthesis of the precursor of the composite negative electrode material: the nano-lithium titanate powder prepared in step (1) is added to the graphene solution with a concentra...

Embodiment 1

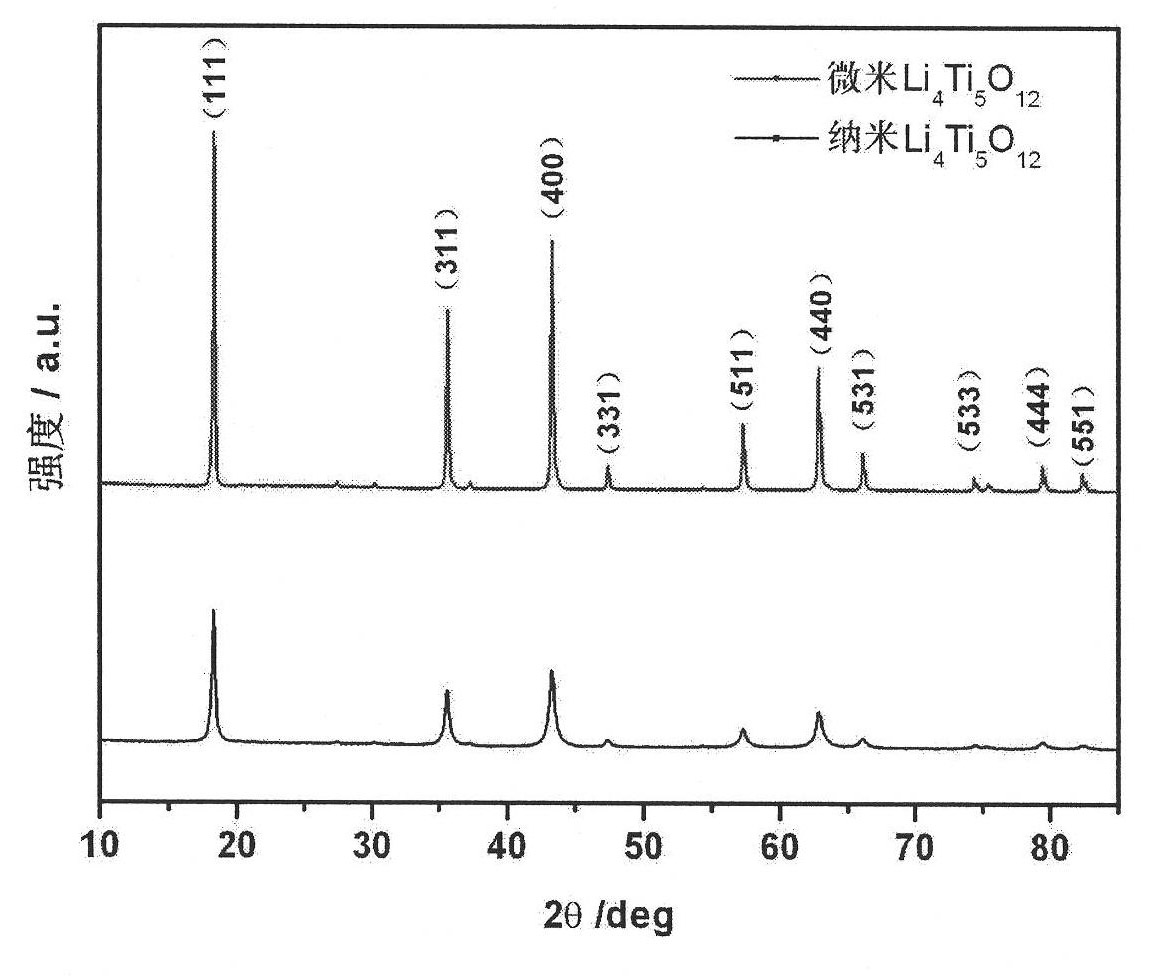

[0042] Select lithium carbonate as the lithium source, and mix lithium carbonate and anatase titanium dioxide according to the molar ratio of lithium to titanium N (Li) :N (Ti) = 0.82: 1 mixed evenly, adding absolute ethanol, the solid content was 35wt% during ball milling, ball milled on a planetary ball mill at a speed of 400 rpm for 12 hours, heated and dried at a constant temperature at 100°C, and then dried under an argon atmosphere , Calcinate the mixed powder of titanium dioxide and lithium source at 800°C for 12 hours, and take it out when it is cooled to below 100°C with the furnace to obtain micron lithium titanate powder.

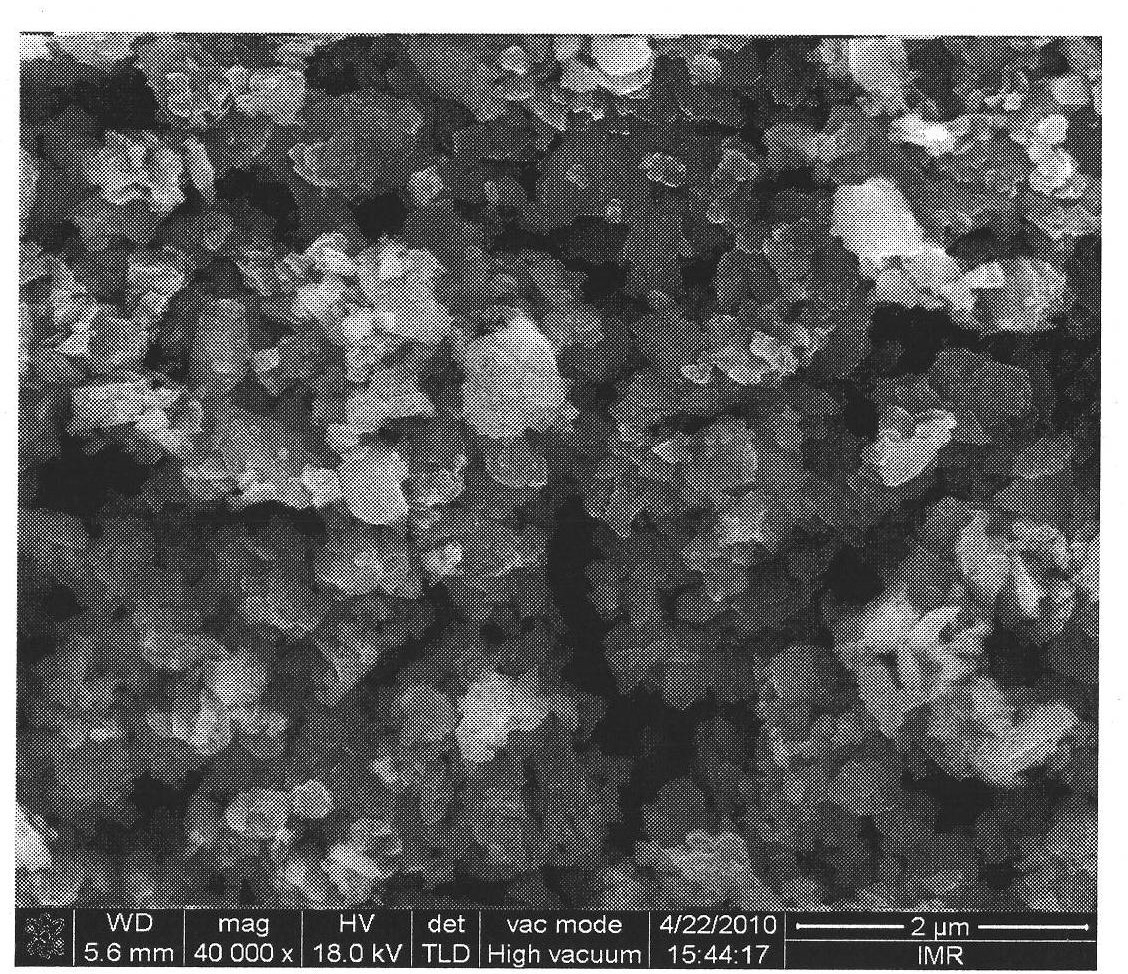

[0043] Put the above-mentioned micron lithium titanate powder into an ultrafine ball mill, add absolute ethanol, the solid content is 25wt% during ball milling, and ball mill at a speed of 2200 rpm for 90 minutes. After the ball milling, heat and dry at a constant temperature of 80°C. The nano lithium titanate powder is obtained.

[0044] Parti...

Embodiment 2

[0051] Nanoscale lithium titanate was prepared in the same manner as in Example 1.

[0052] The difference from Example 1 is that:

[0053] Weigh 60 mg of uniformly dispersed graphene solid powder, mix it with 100 ml of N-methylpyrrolidone, and disperse it ultrasonically for 10 minutes.

[0054] Weigh 1.94g of nano-lithium titanate powder and add it to the graphene solution, wherein graphene accounts for 3% of the total weight of the composite negative electrode material, and lithium titanate accounts for 97% of the total weight of the composite negative electrode material. After magnetically stirring for 30 minutes to mix evenly, the mixture solution was ultrasonically dispersed for 30 minutes. Spray drying at 200-250° C. to obtain composite negative electrode material precursor powder.

[0055] Calcining the obtained composite anode material precursor in an argon atmosphere, raising the temperature to 400° C., keeping it warm for 20 hours, and cooling in the furnace to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com