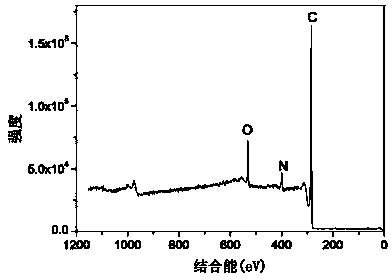

Method for preparing nitrogen-doped active carbon from nitrogen-enriched biomass raw material

A biomass raw material, nitrogen doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of pore structure damage, small amount of nitrogen doping, no visible, etc., and achieve excellent electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

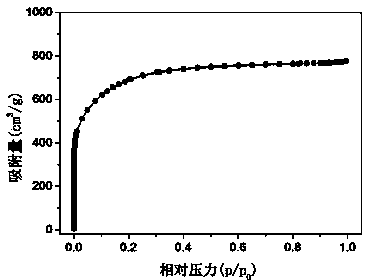

[0026] Fresh pigskin was placed in 1 mol / L sodium bicarbonate solution, soaked at 37 °C for 10 h, and washed until neutral. Sonicate in absolute ethanol for 30 min, and then oven dry at 80 °C. The dried pigskin was placed in a tubular carbonization furnace, fed with high-purity nitrogen gas at a flow rate of 120ml / min, raised to 600°C for carbonization at a rate of 5°C / min, kept for 2 hours, and cooled to obtain a carbonized sample. Grind and sieve the carbonized sample to obtain 80-120 mesh carbon. Mix this charcoal with potassium hydroxide at a mass ratio of 1:4.5, add 50 ml of deionized water, heat and stir for one hour, then dry. The dried mixture was placed in the tube furnace again, and high-purity nitrogen gas was introduced at a flow rate of 200ml / min, and the temperature was raised to 600°C at a rate of 5°C / min, and activated for 3.5 hours. After cooling to room temperature, the sample was washed with dilute hydrochloric acid and deionized water until neutral, filte...

Embodiment 2

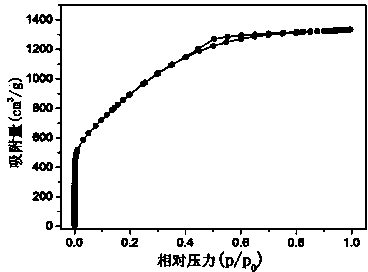

[0028]Fresh pigskin was placed in 1 mol / L sodium bicarbonate solution, soaked at 37 °C for 10 h, and washed until neutral. Sonicate in absolute ethanol for 30 min, and then oven dry at 80 °C. The dried pigskin was placed in a tubular carbonization furnace, fed with high-purity nitrogen gas at a flow rate of 120ml / min, raised to 600°C for carbonization at a rate of 5°C / min, held for 2 hours, and cooled to obtain a carbonized sample. Grind and sieve the carbonized sample to obtain 80-120 mesh carbon. Mix this charcoal with potassium hydroxide at a mass ratio of 1:4.5, add 50 ml of deionized water, heat and stir for one hour, then dry. The dried mixture was placed in the tube furnace again, and high-purity nitrogen gas was introduced at a flow rate of 200ml / min, and the temperature was raised to 800°C at a rate of 5°C / min, and the activation was maintained for 3.5 hours. After cooling to room temperature, the sample was washed with dilute hydrochloric acid and deionized water u...

Embodiment 3

[0030] Fresh pigskin was placed in 1 mol / L sodium bicarbonate solution, soaked at 37 °C for 10 h, and washed until neutral. Sonicate in absolute ethanol for 30 min, and then oven dry at 80 °C. The dried pigskin was placed in a tubular carbonization furnace, fed with high-purity nitrogen gas at a flow rate of 120ml / min, raised to 800°C for carbonization at a rate of 5°C / min, held for 2 hours, and cooled to obtain a carbonized sample. Grind and sieve the carbonized sample to obtain 80-120 mesh carbon. Mix this charcoal with potassium hydroxide at a mass ratio of 1:4.5, add 50 ml of deionized water, heat and stir for one hour, then dry. The dried mixture was placed in the tube furnace again, and high-purity nitrogen gas was introduced at a flow rate of 200ml / min, and the temperature was raised to 800°C at a rate of 5°C / min, and the activation was maintained for 3.5 hours. After cooling to room temperature, the sample was washed with dilute hydrochloric acid and deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com