Recovery method of LiFePO4 positive electrode material

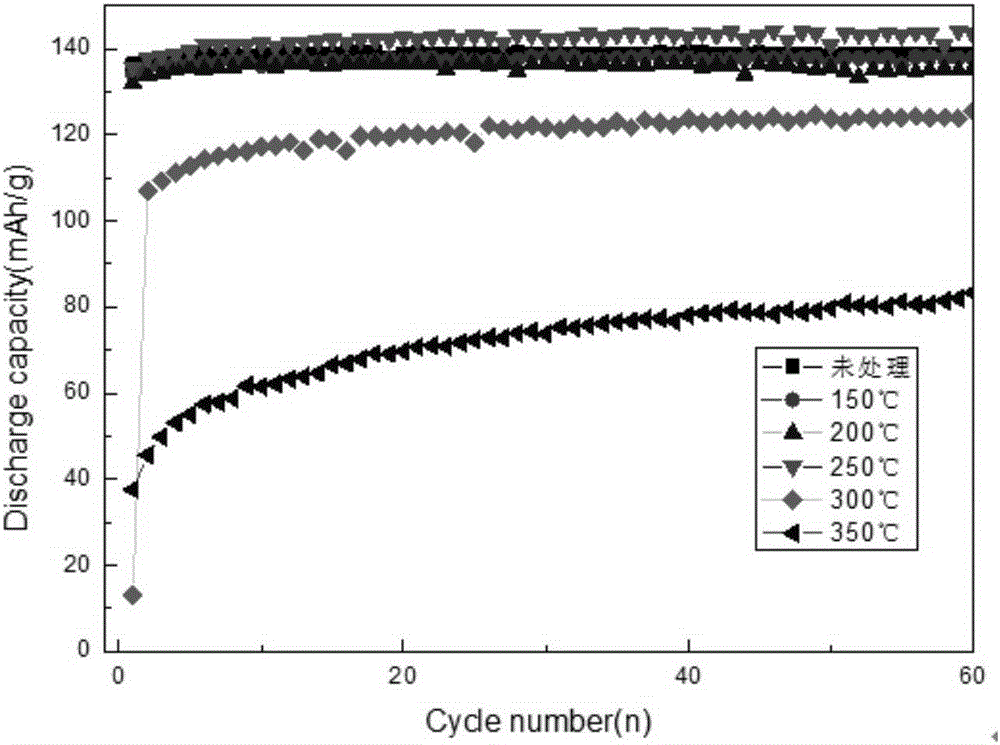

A recycling method and positive electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of high energy consumption and achieve the effects of high recovery rate, cost saving and considerable electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

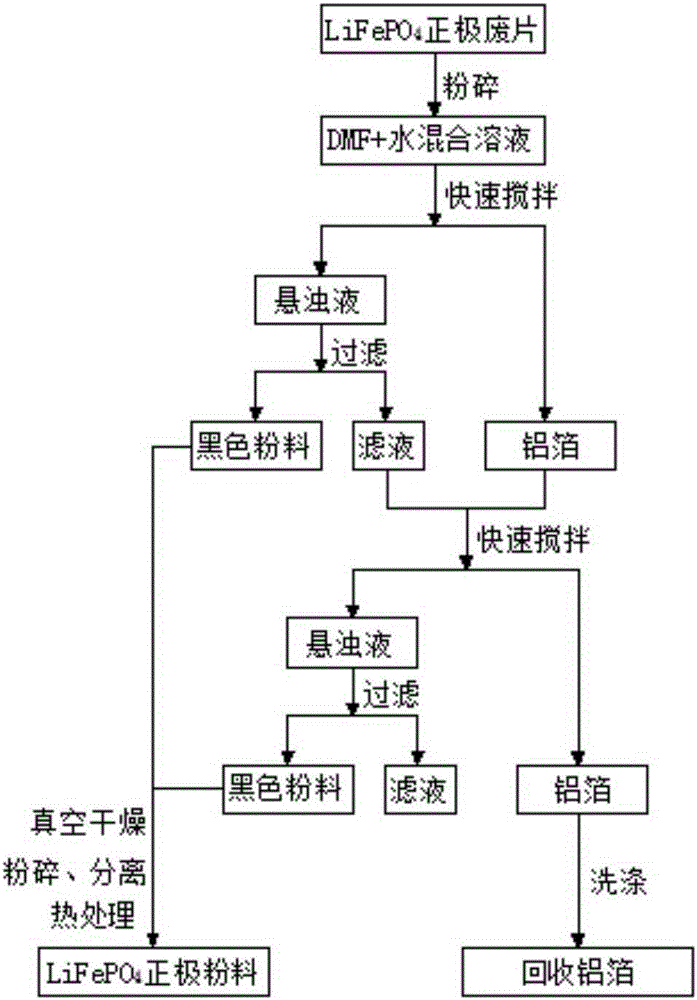

[0025] Such as figure 1 As shown, a LiFePO 4 A recovery method for positive electrode materials, comprising the steps of:

[0026] (1) LiFePO 4 After the positive electrode waste is crushed, pour it into a large beaker containing a mixed solution of 200mL DMF and water. The volume of DMF and water is 1:1. Stir rapidly for 0.5h. The black powder is separated from the aluminum foil to obtain a suspension, and vacuumize Filter to obtain black powder and filtrate, collect black powder;

[0027] (2) Add the filtrate and aluminum foil obtained in step (1) into a large beaker, stir rapidly for 0.5h, the black powder is separated from the aluminum foil again to obtain a suspension, and vacuum filtered to obtain black powder and filtrate, collect For black powder, repeat step (2) until there is little residue on the aluminum foil;

[0028] (3) Mix the black powder collected in the steps (1) and (2) and then vacuum dry, the vacuum drying temperature is 85°C, and the drying time is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com