Treatment method for ternary material and method for improving capacity and cycle performance of lithium battery

A technology of ternary materials and processing methods, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle stability and safety performance, achieve good electrochemical performance, simple method process, improve battery capacity and The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (2) Preparation of surface treatment materials:

[0034] Configure a cobalt salt solution with an appropriate concentration of preferably 1-10mol / L, and gradually add the cobalt salt solution to the above-mentioned LiNi with adjusted pH value under constant stirring. x co y mn z o 2 (x+y+z=1) suspension. And fully react at room temperature under constant stirring, preferably for 1-5 hours, and then preferably dry in an oven at 100-150°C.

[0035] Adding cobalt salt is in order to introduce cobalt element, so as long as all soluble cobalt salts that can be burned and removed by other elements except cobalt in the follow-up burning process can be applicable to the present invention, such as, can select cobalt acetate salt, citric acid for use At least one of cobalt salt or cobalt nitrate salt.

[0036] (3) Preparation of final material:

[0037] Add an appropriate amount of lithium salt to the dried material, mix thoroughly, and fully ignite in an air atmosphere at ...

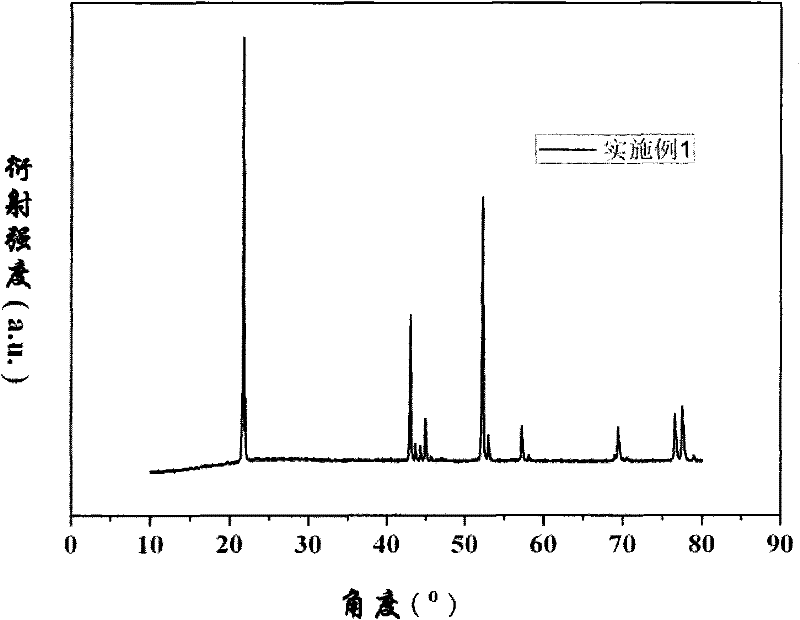

Embodiment 1

[0044] Accurately weigh 200g LiNi 0.4 co 0.2 mn 0.4 o 2 Add appropriate amount of water to the ternary powder material to adjust it to a muddy state, configure an ammonia solution with a concentration of 10mol / L, and mix 200gLiNi with constant stirring 0.4 co 0.2 mn 0.4 o 2 The pH value of the suspension was adjusted to 11.0 to make the mixture strongly alkaline, and 20g Co(NO 3 ) 2 The concentration of the solution was adjusted to 10mol / L. Under the condition of constant stirring, the cobalt salt solution was gradually added into the adjusted LiNi 0.4 co 0.2 mn 0.4 o 2 Suspension. When the cobalt salt solution is completely added to the LiNi 0.4 co 0.2 mn 0.4 o 2 When in the suspension, the reaction is continued for 5 hours at room temperature under constant stirring, and the precursor prepared by the reaction is dried in an oven at 100-150°C. Finally, 2.5g of LiOH powder was accurately weighed, and the dried precursor and LiOH powder were evenly mixed and the...

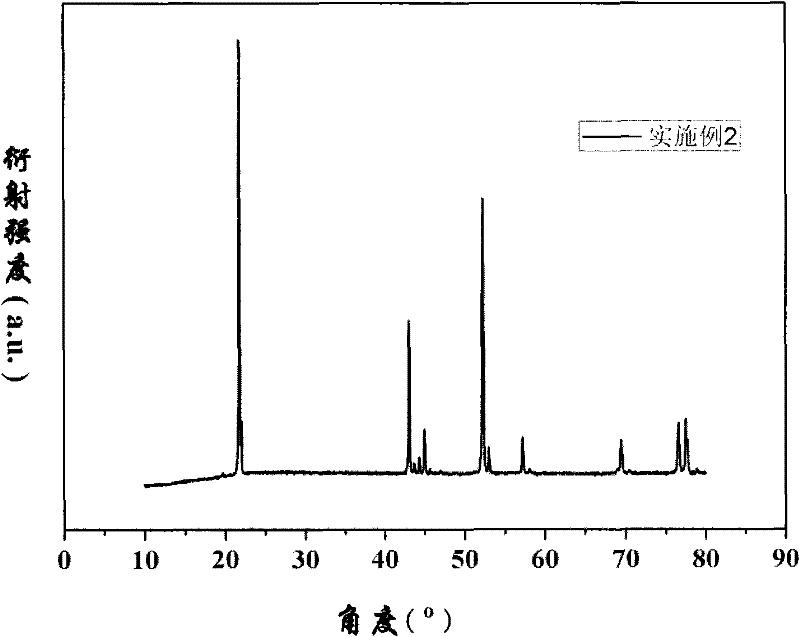

Embodiment 2

[0046] Accurately weigh 200g LiNi 0.4 co 0.2 mn 0.4 o 2 Add appropriate amount of water to the ternary powder material to adjust it to a muddy state, configure an ammonia solution with a concentration of 10mol / L, and mix 200gLiNi with constant stirring 0.4 co 0.2 mn 0.4 o 2 The pH value of the suspension was adjusted to 11.0 to make the mixture strongly alkaline, and 27.5g Co(NO 3 ) 2 The concentration of the solution was adjusted to 10mol / L. Under the condition of constant stirring, the cobalt salt solution was gradually added into the adjusted LiNi 0.4 co 0.2 mn 0.4 o 2 Suspension. When the cobalt salt solution is completely added to the LiNi 0.4 co 0.2 mn 0.4 o 2 When in the suspension, the reaction is continued for 5 hours at room temperature under constant stirring, and the precursor prepared by the reaction is dried in an oven at 100-150°C. Finally weigh 5.6gLi accurately 2 CO 3 powder, the dried precursor and Li 2 CO 3 The powder is mixed evenly and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com