Lead-free low-melting-point glass composition having acid resistance

A technology of low-melting glass and composition, applied in the direction of cathode ray/electron beam tube casing/container, cathode ray/electron beam tube introduction device, gas discharge tube/container, etc. Issues such as not being able to fully function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

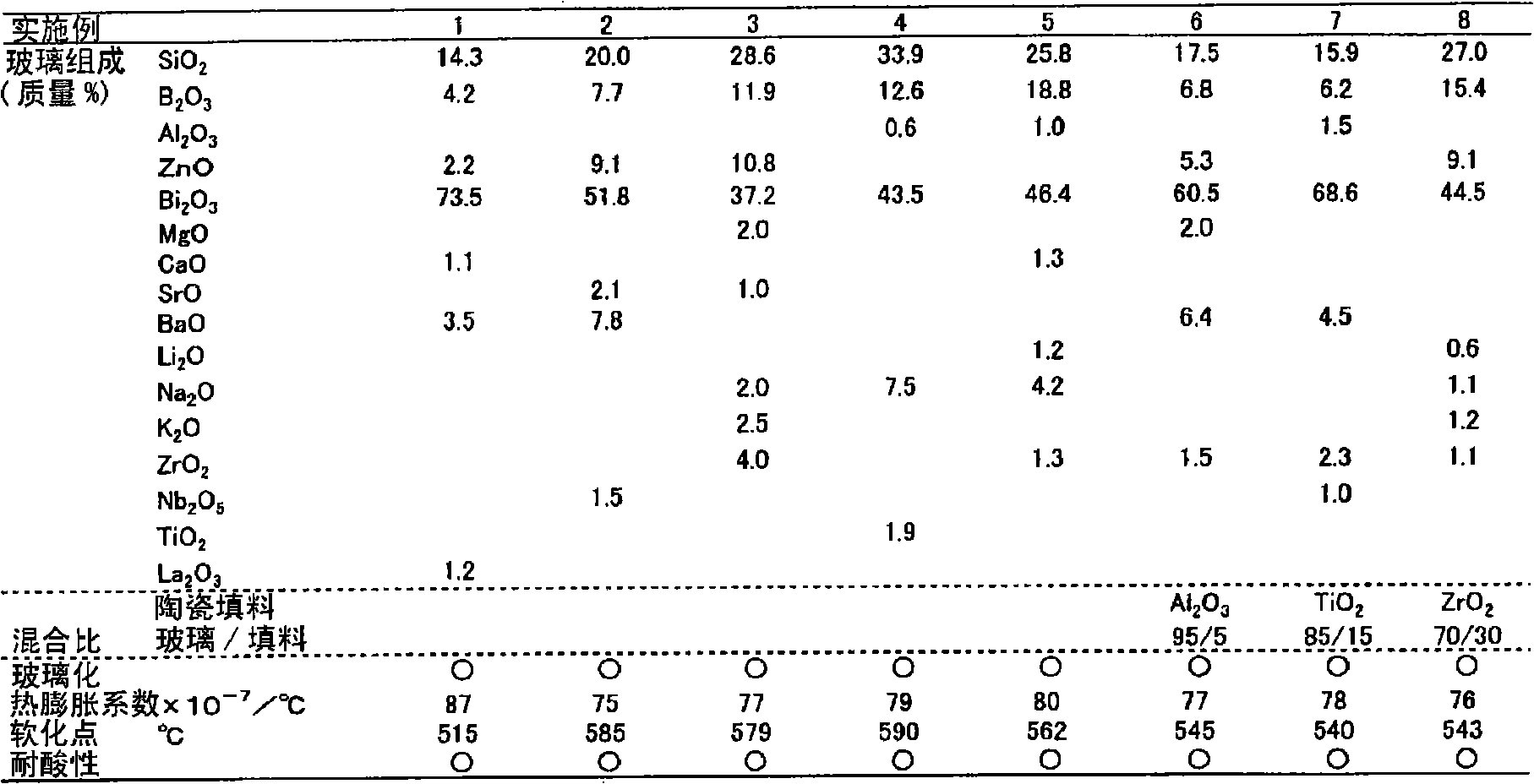

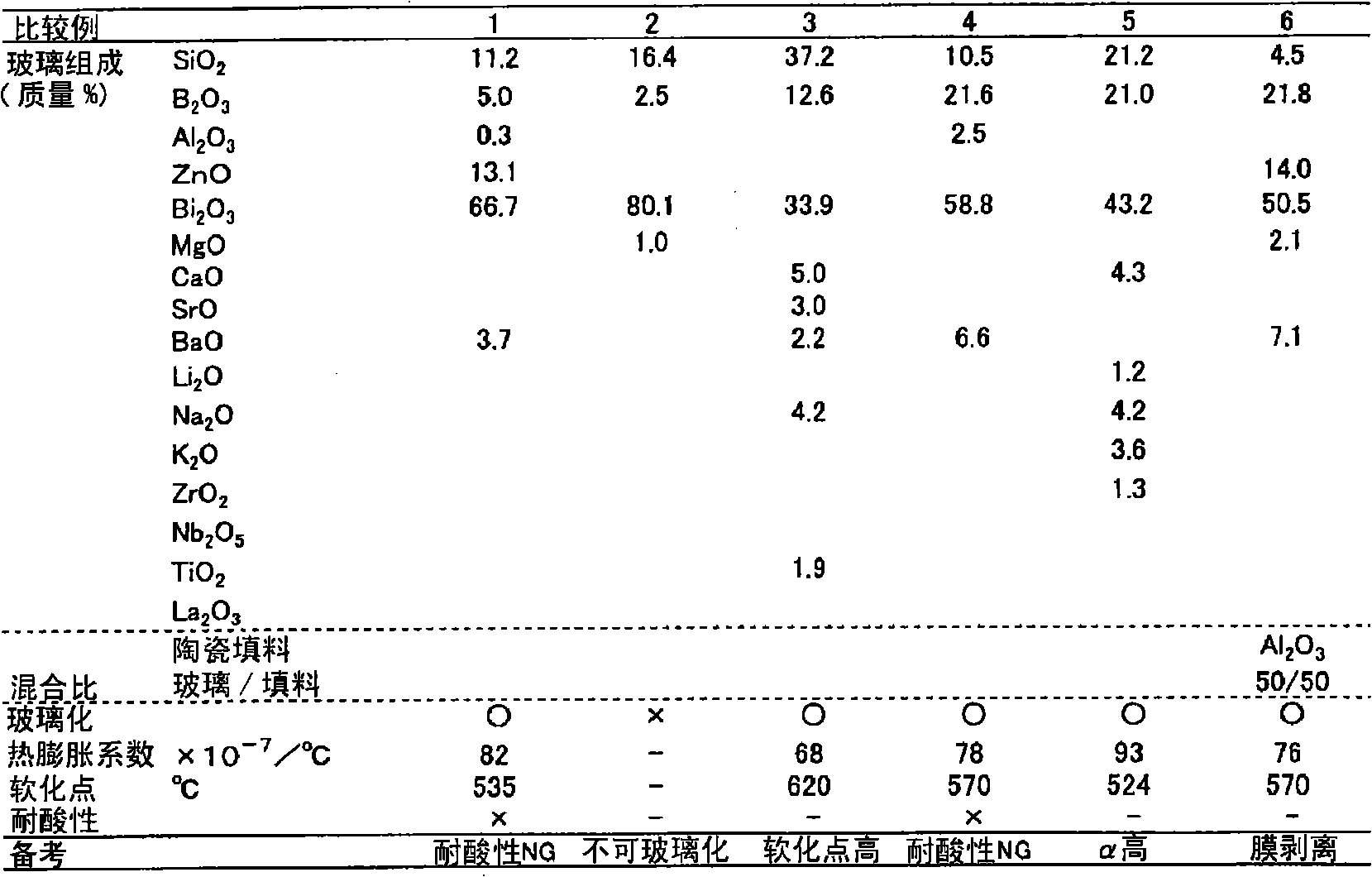

Examples

Embodiment Construction

[0015] The present invention provides a lead-free low-melting point glass with acid resistance, which is an insulating glass material for electronic material substrates represented by field emission displays, and is characterized in that the composition of the glass material contains 12 to 35 Mass% SiO 2 , 3-20% by mass of B 2 o 3 , 0 to 8% by mass of R 2 O (from Li 2 O, Na 2 O, K 2 At least one of O), 35 to 75% by mass of Bi 2 o 3 , and substantially free of lead.

[0016] SiO 2 It is a glass forming component and is an essential component for obtaining high acid resistance. In addition, by combining with another glass-forming component B 2 o 3 Coexistence can form a stable glass, so SiO can be contained in the range of 12 to 35% (mass%, the same below). 2 . If it exceeds 35%, the softening point of the glass will rise, making molding and handling difficult. On the other hand, when it is less than 12%, acid resistance will fall. More preferably, it is in the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com