Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250results about "Cathode-ray/electron-beam tube electrical connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

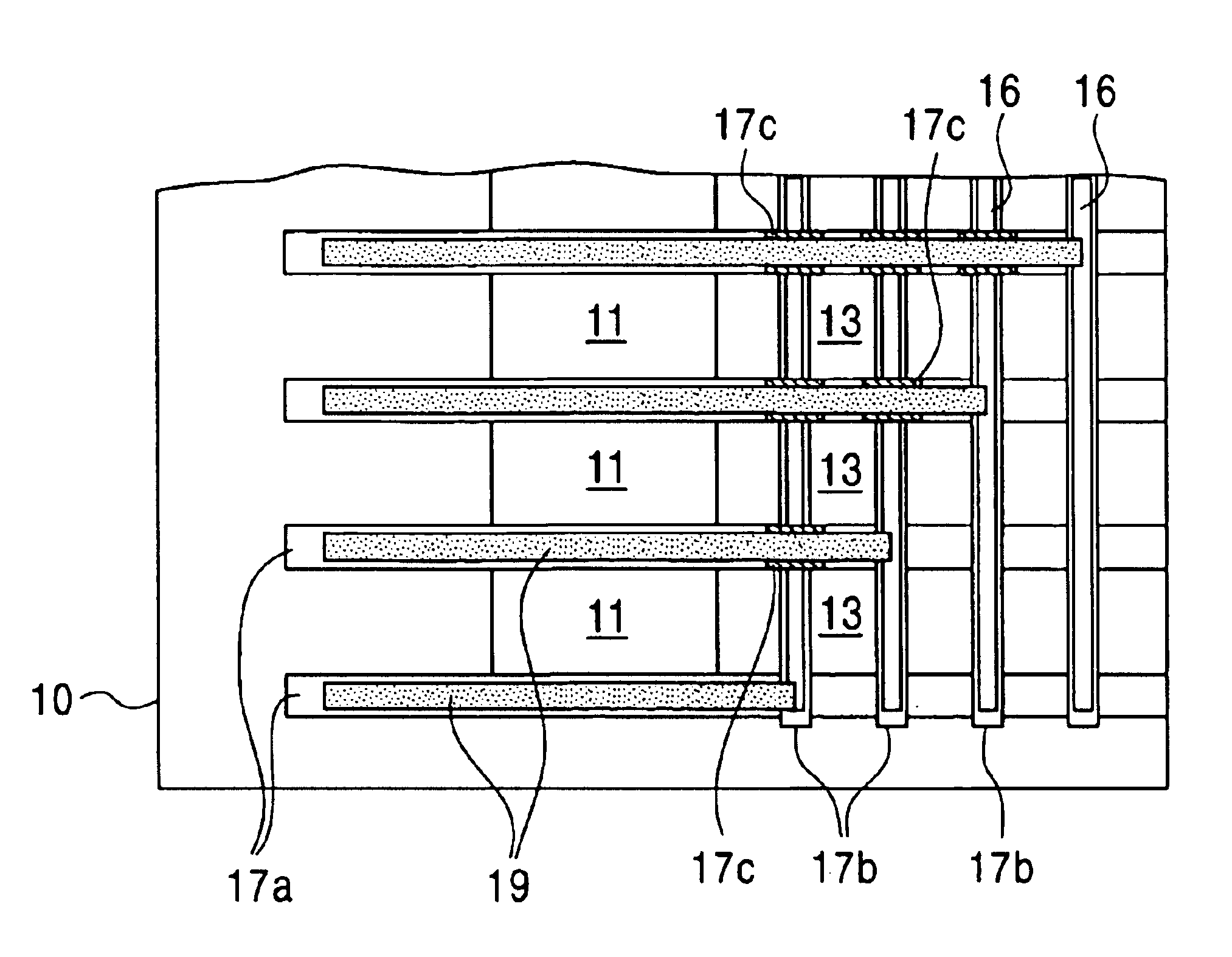

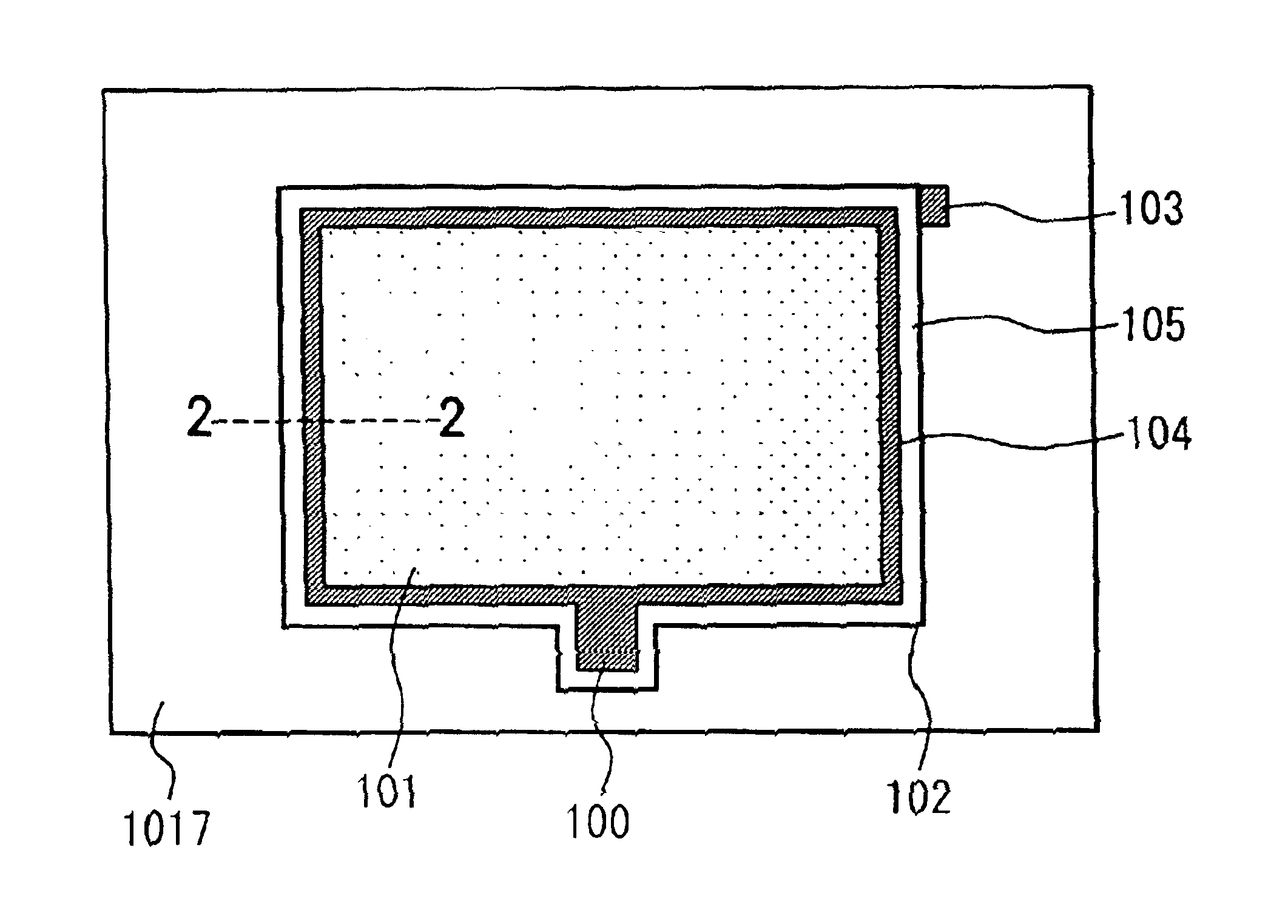

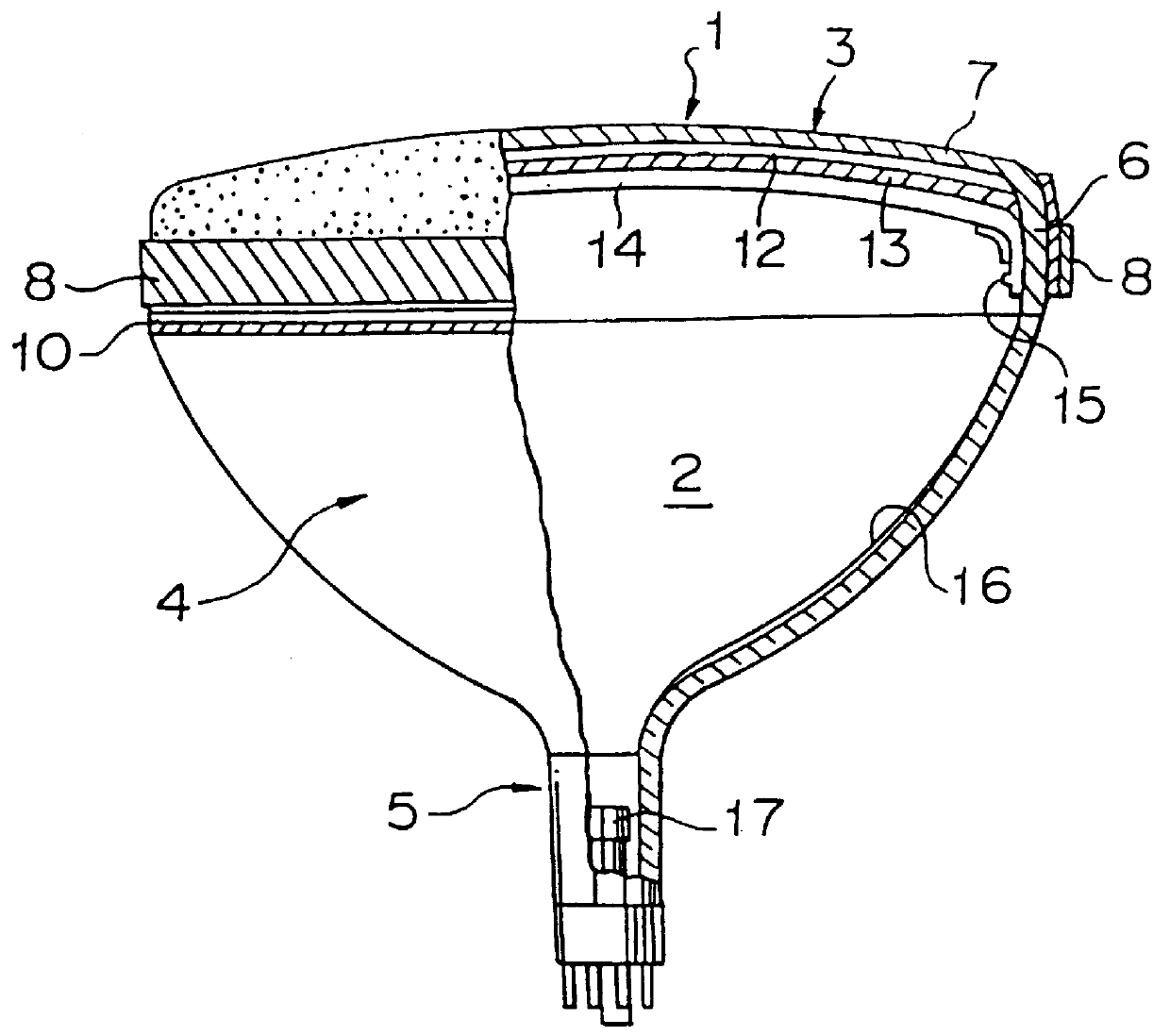

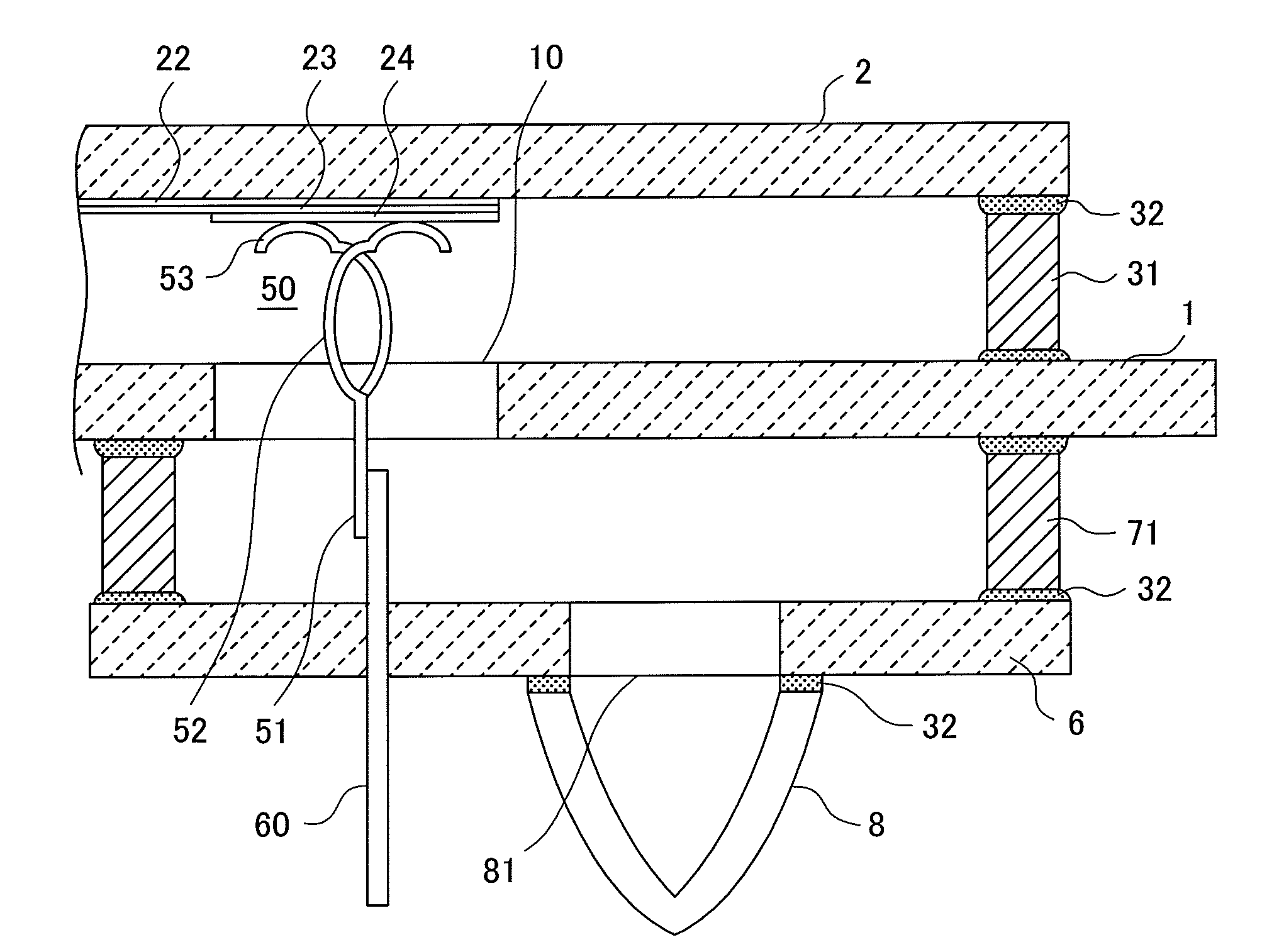

Display filter, display apparatus, and method for production of the same

InactiveUS6965191B2Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDisplay deviceEngineering

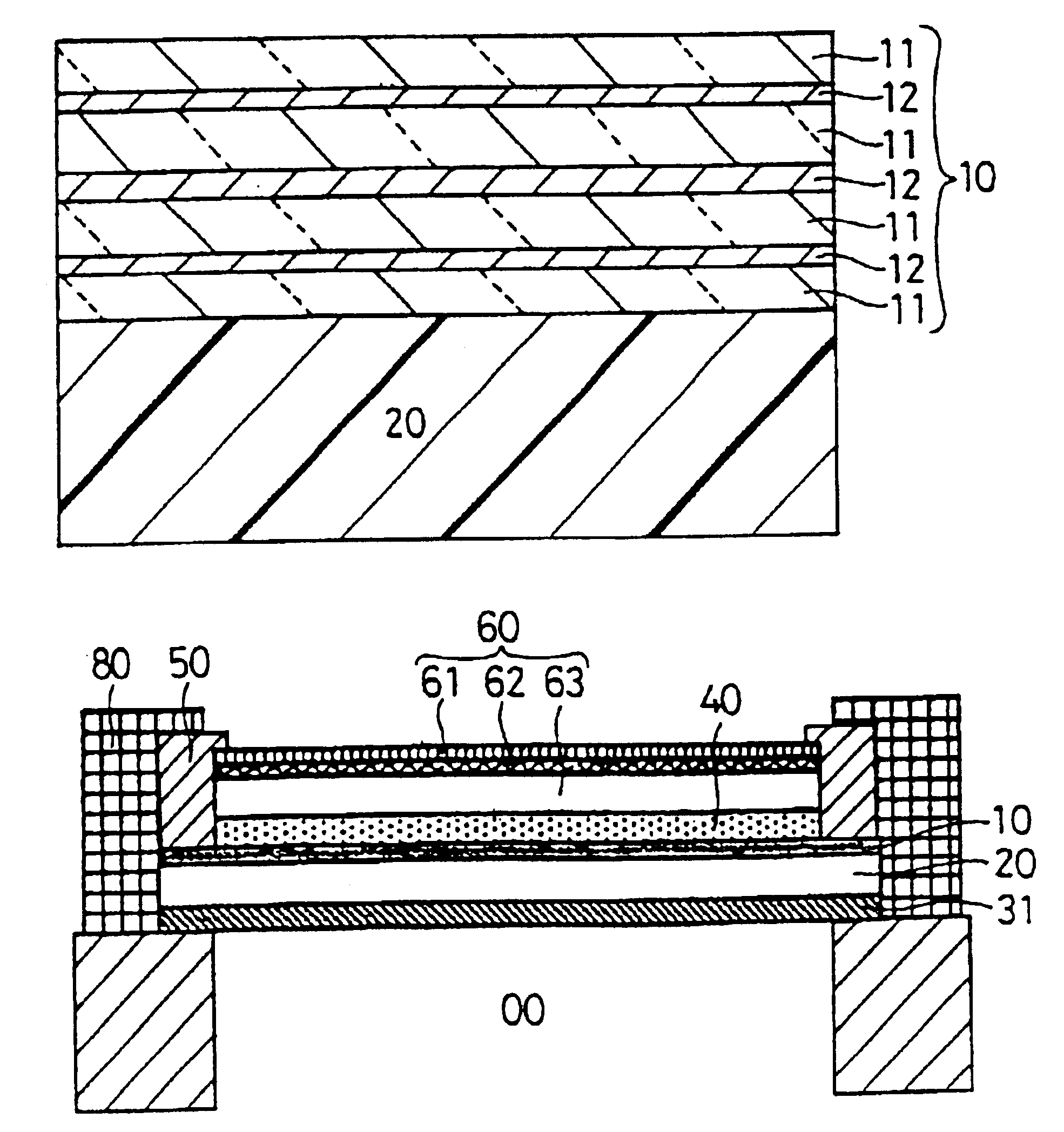

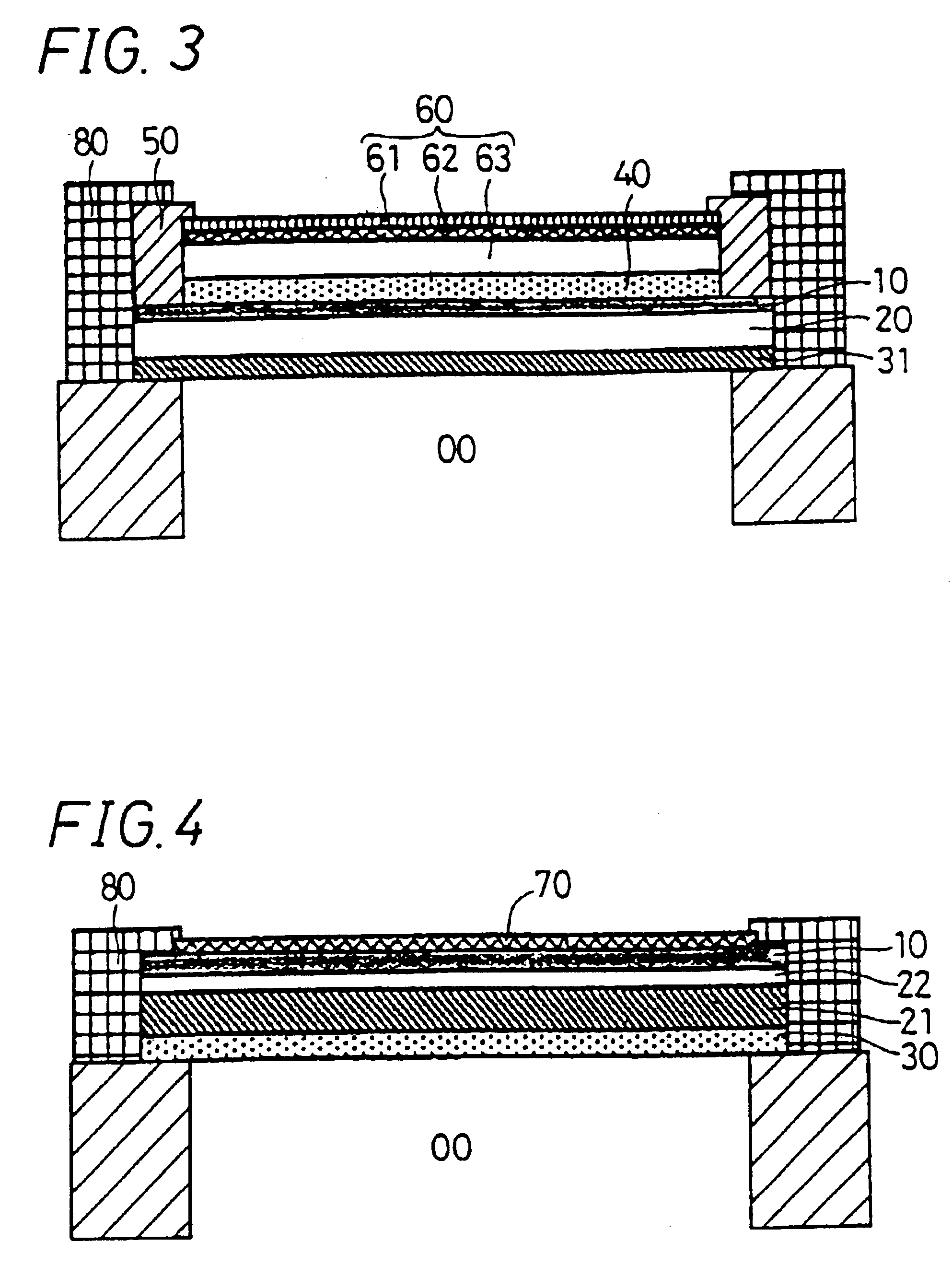

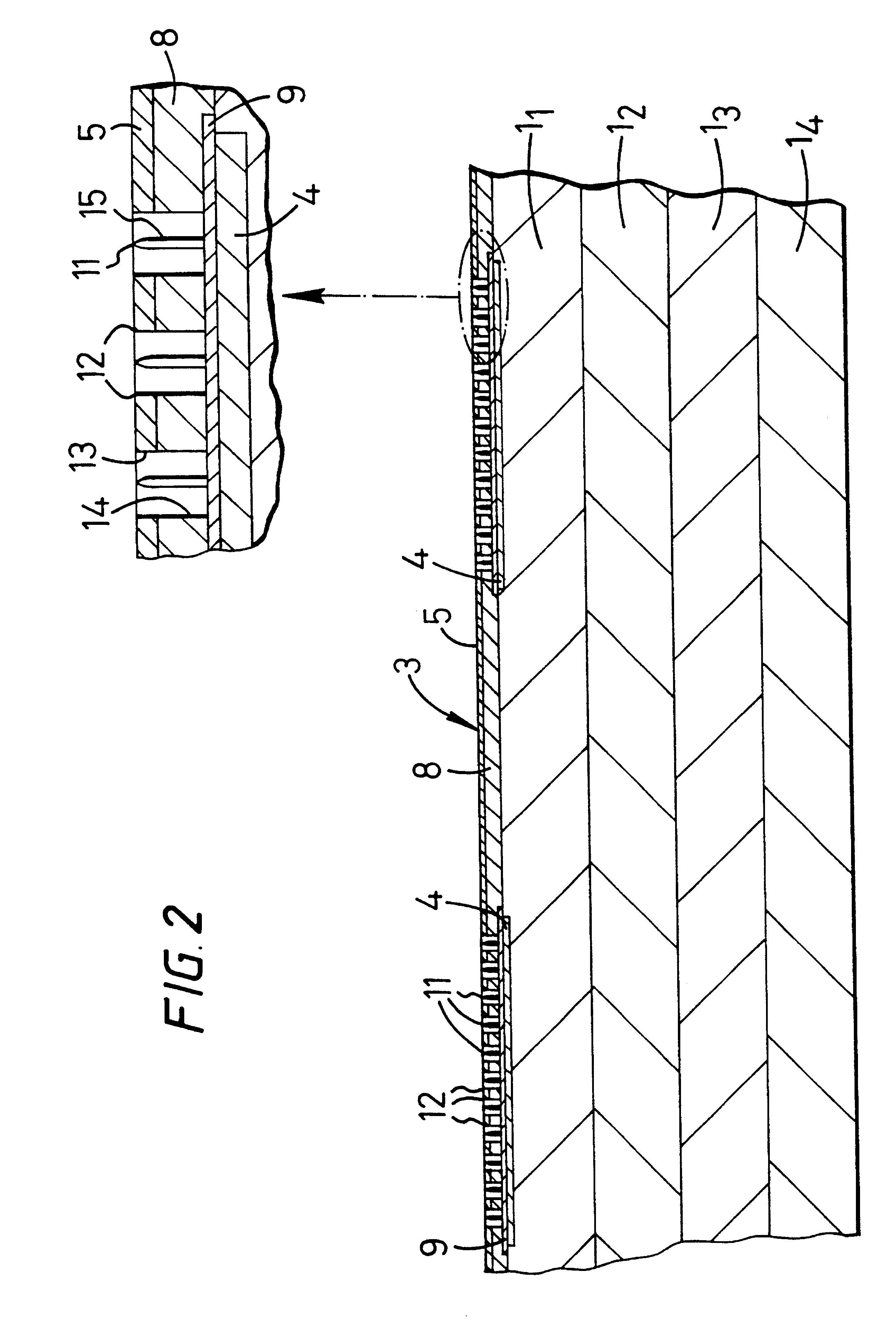

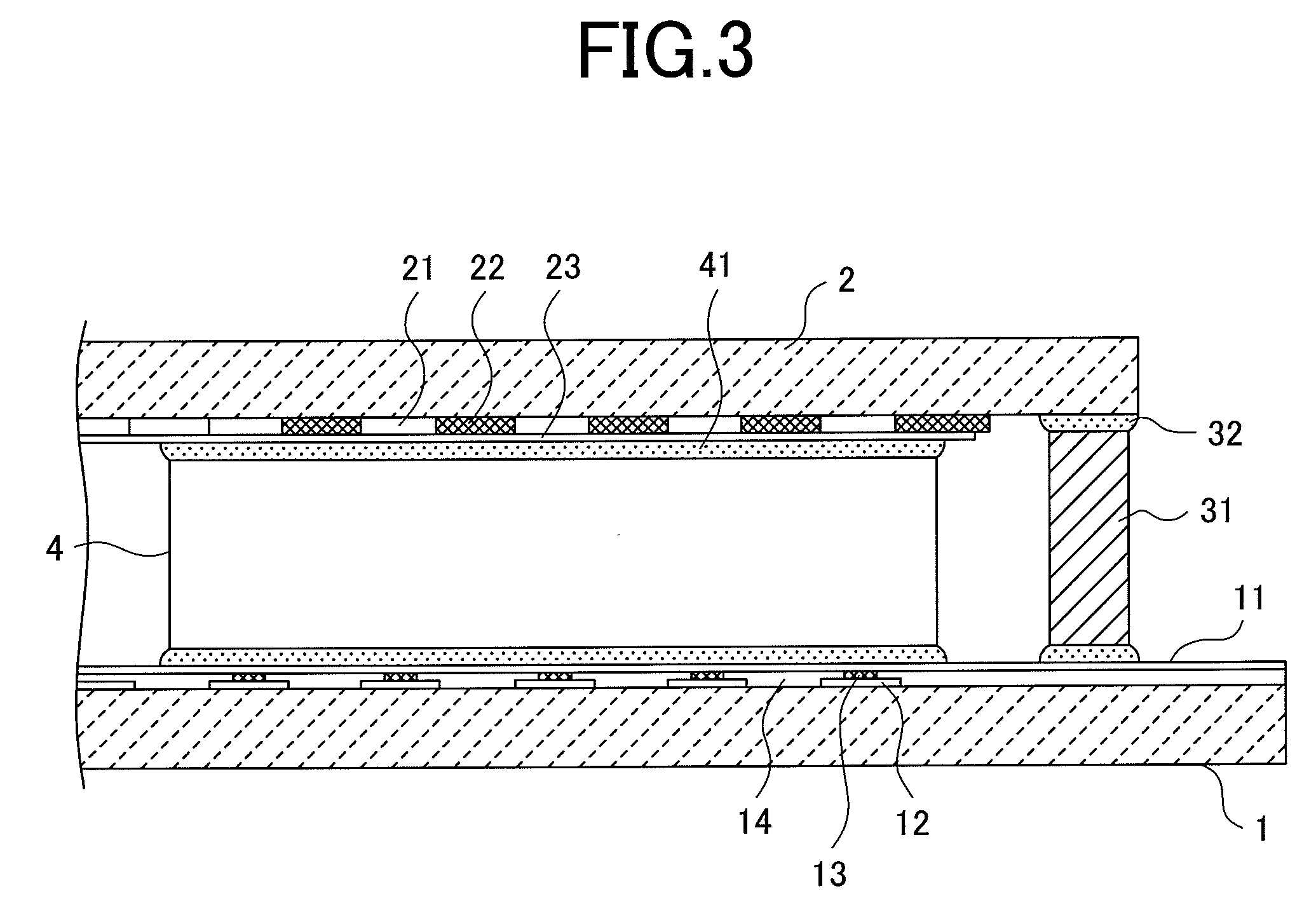

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

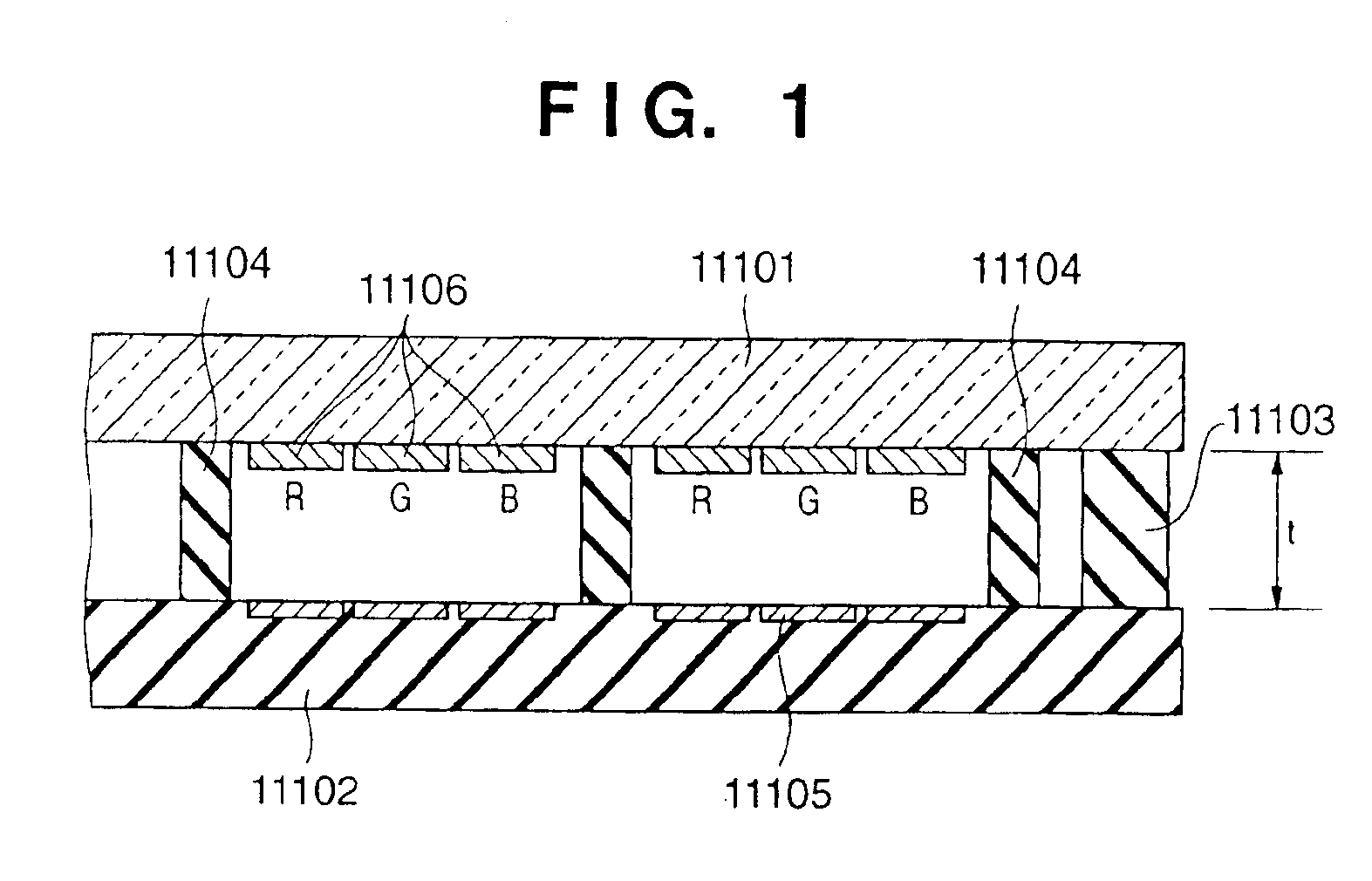

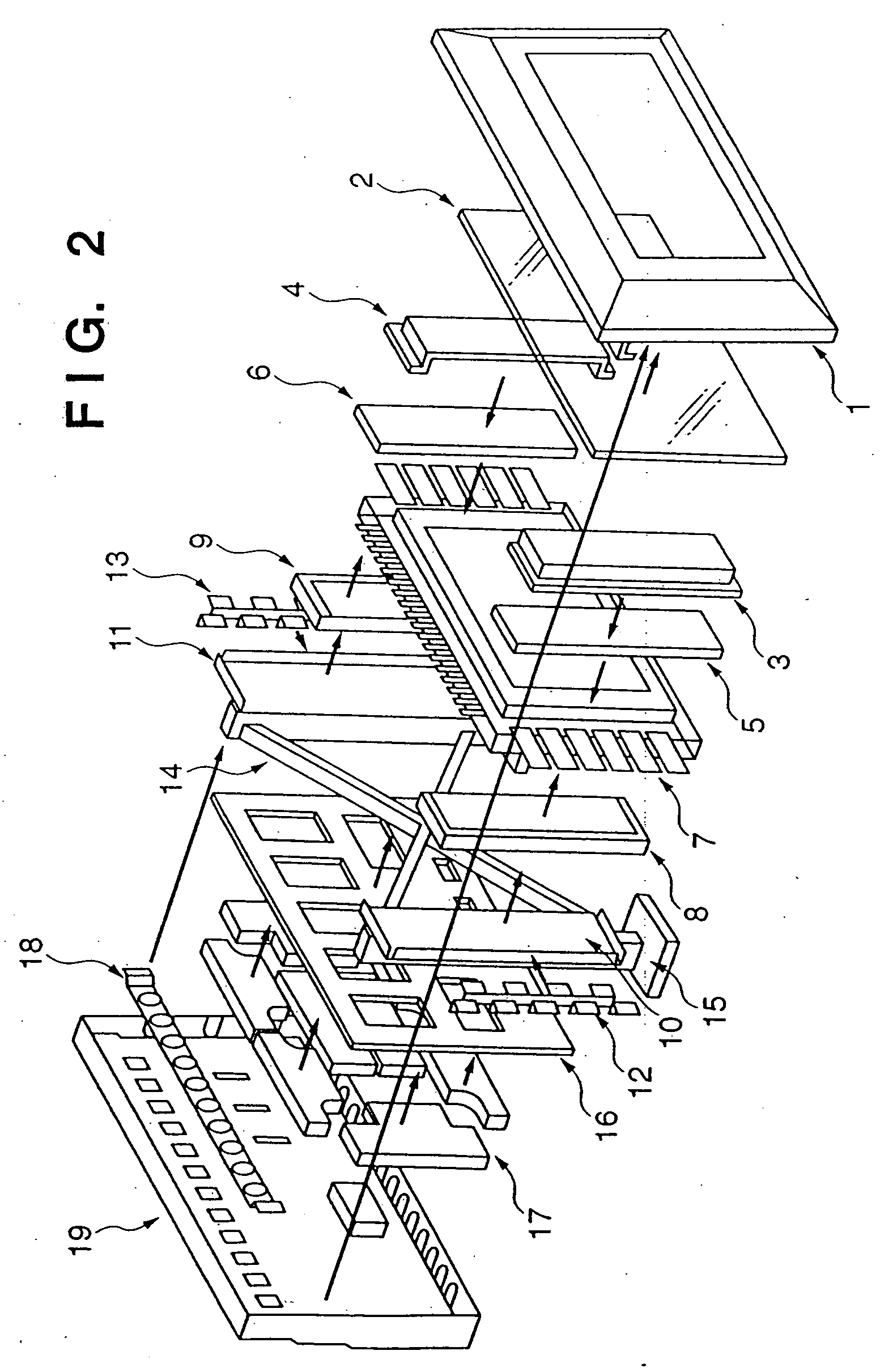

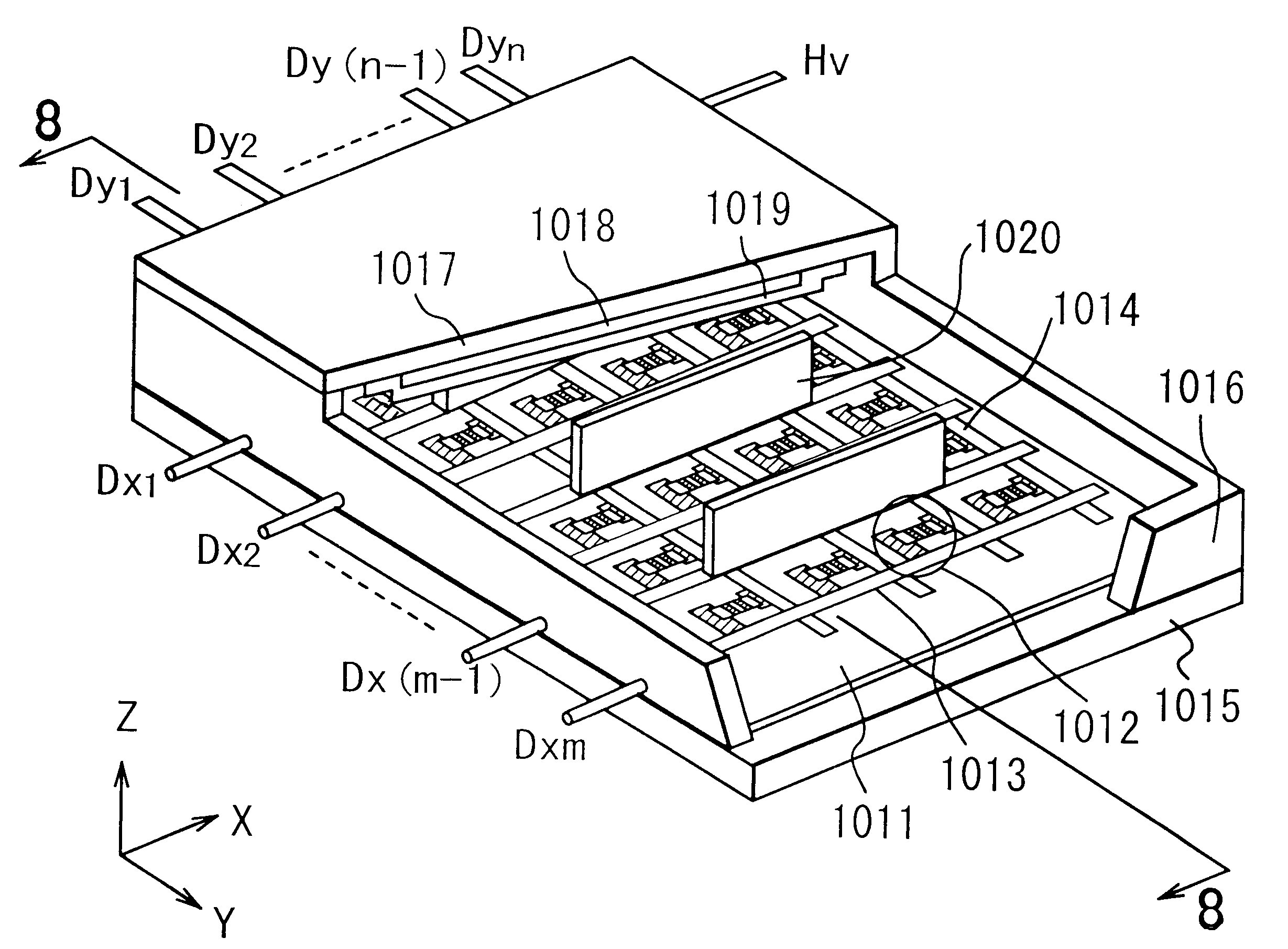

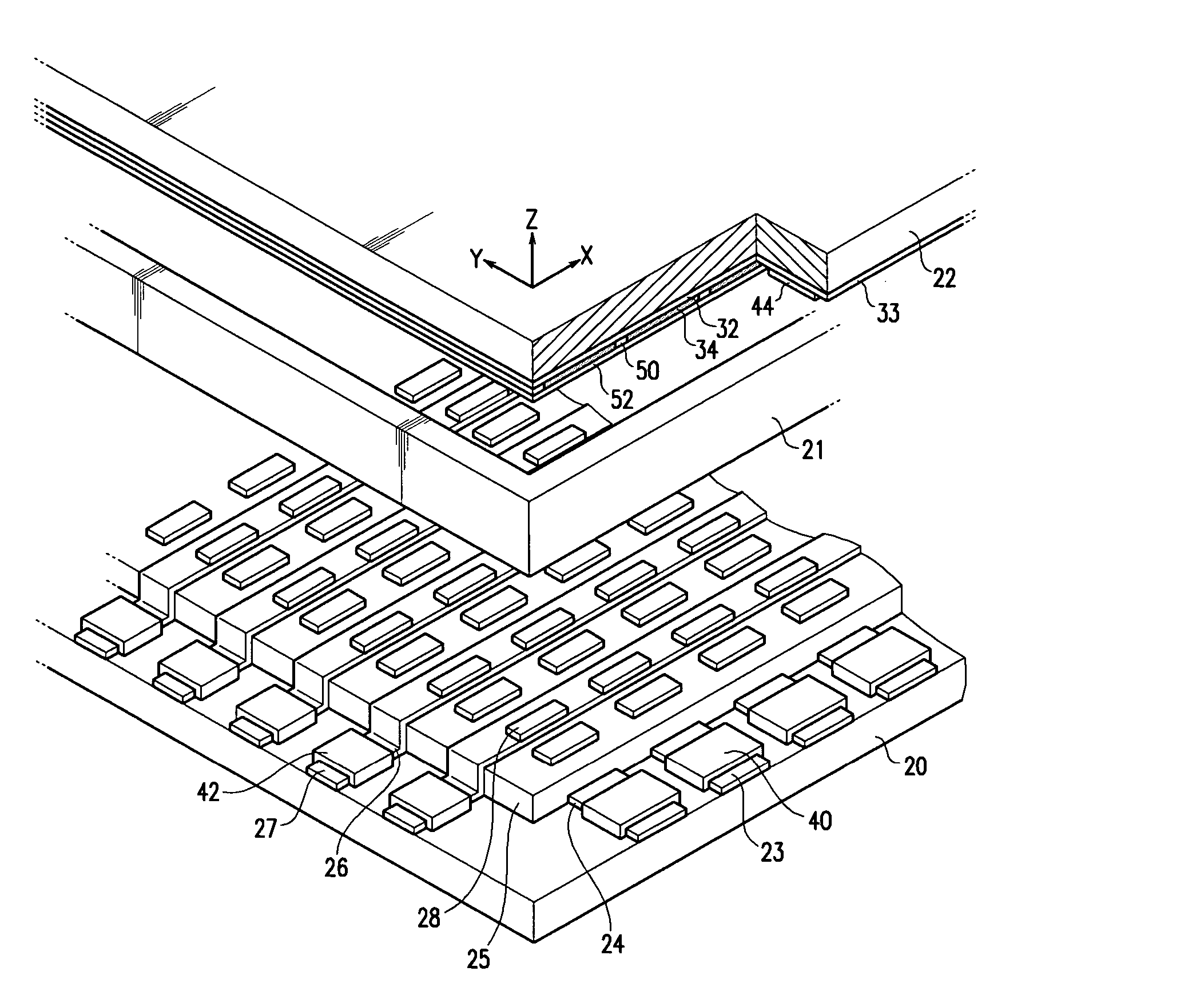

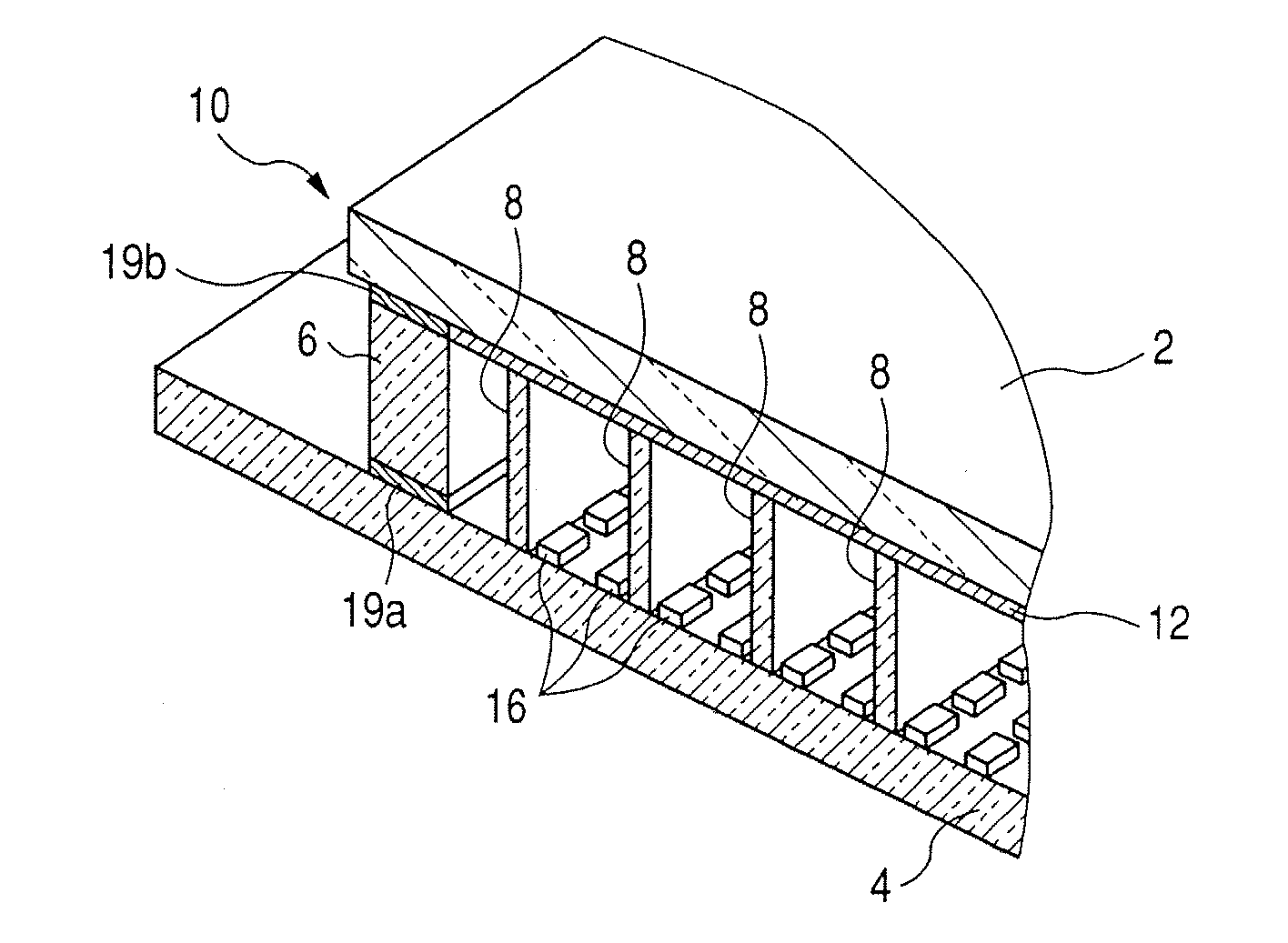

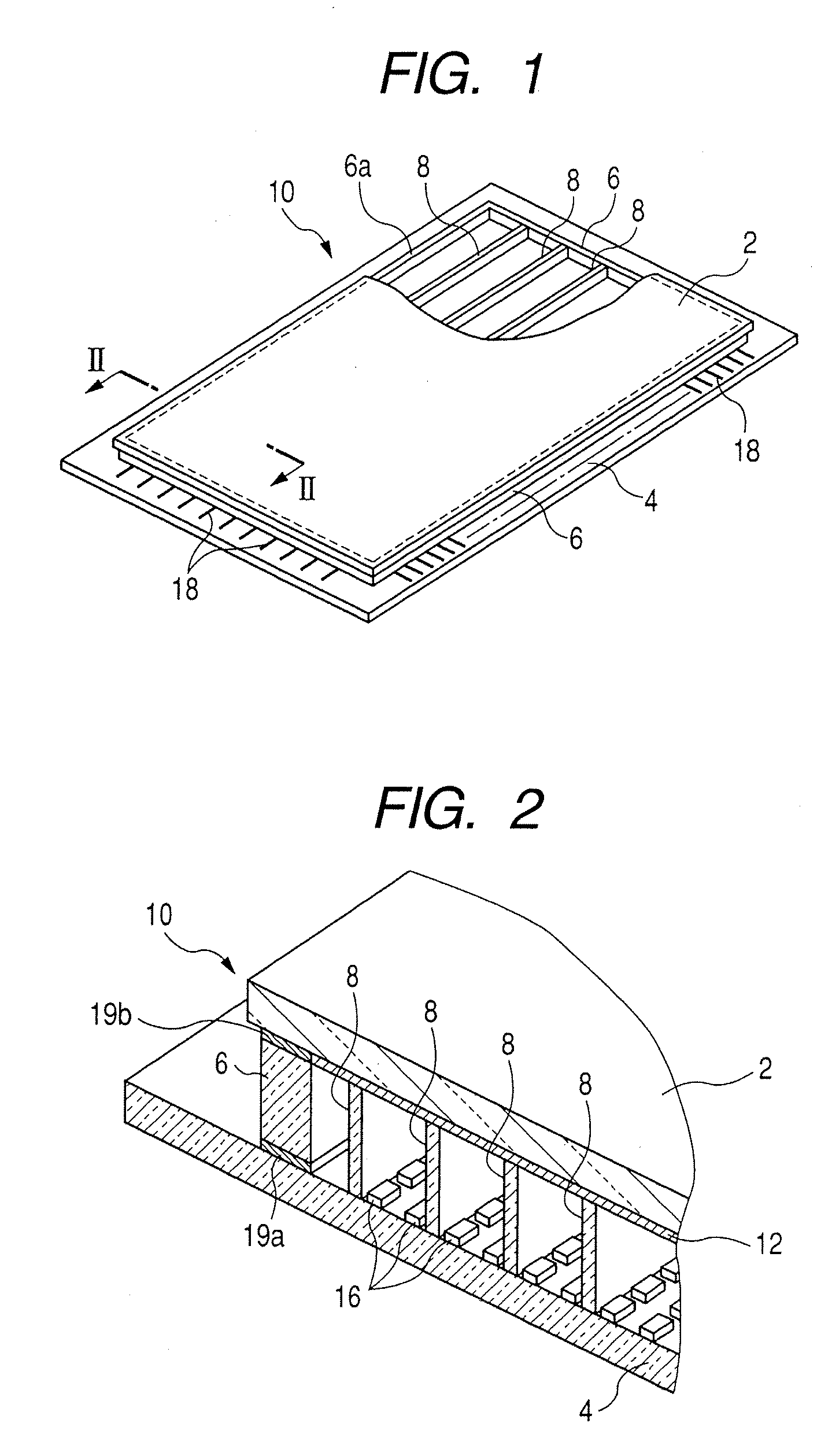

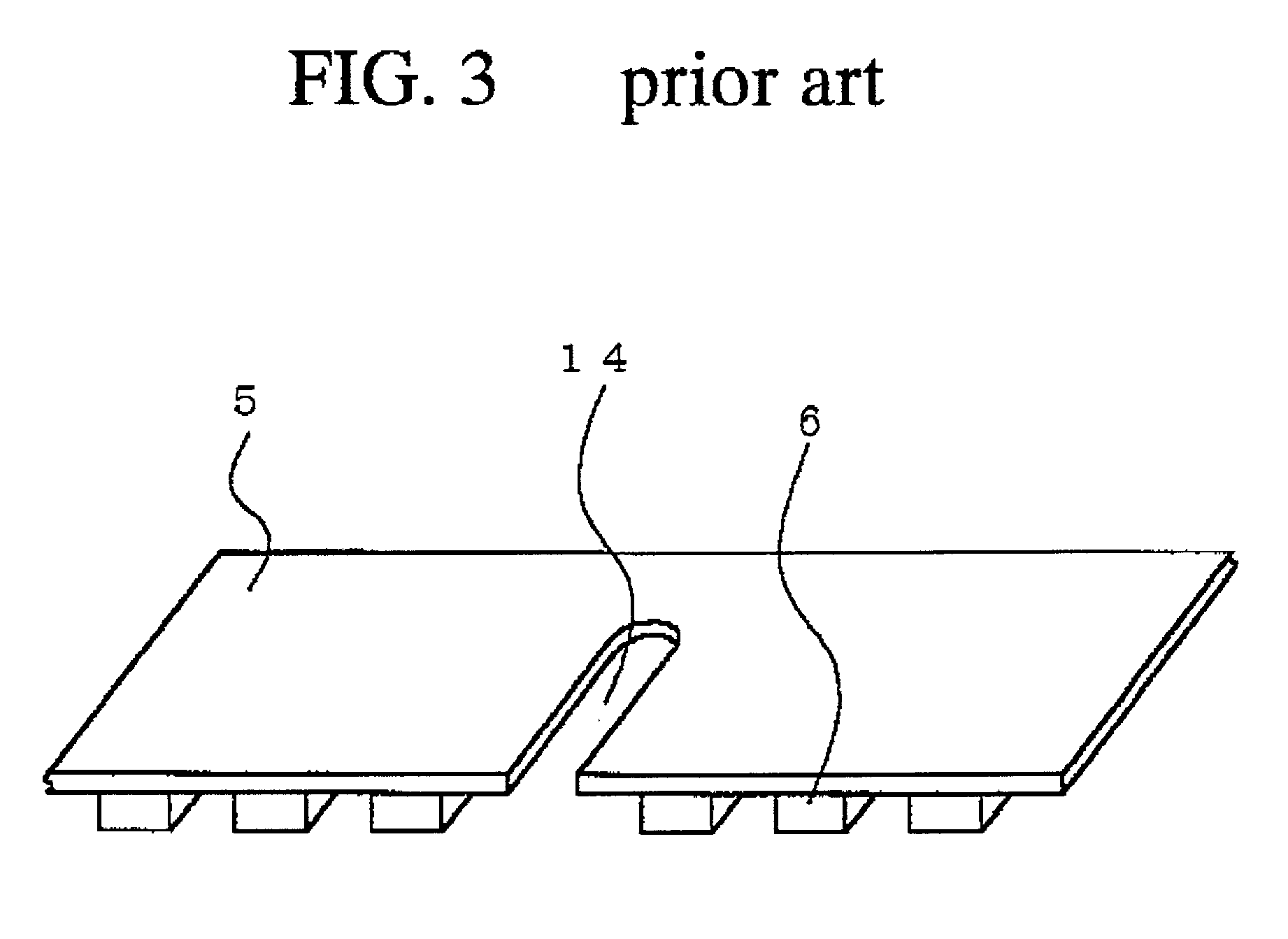

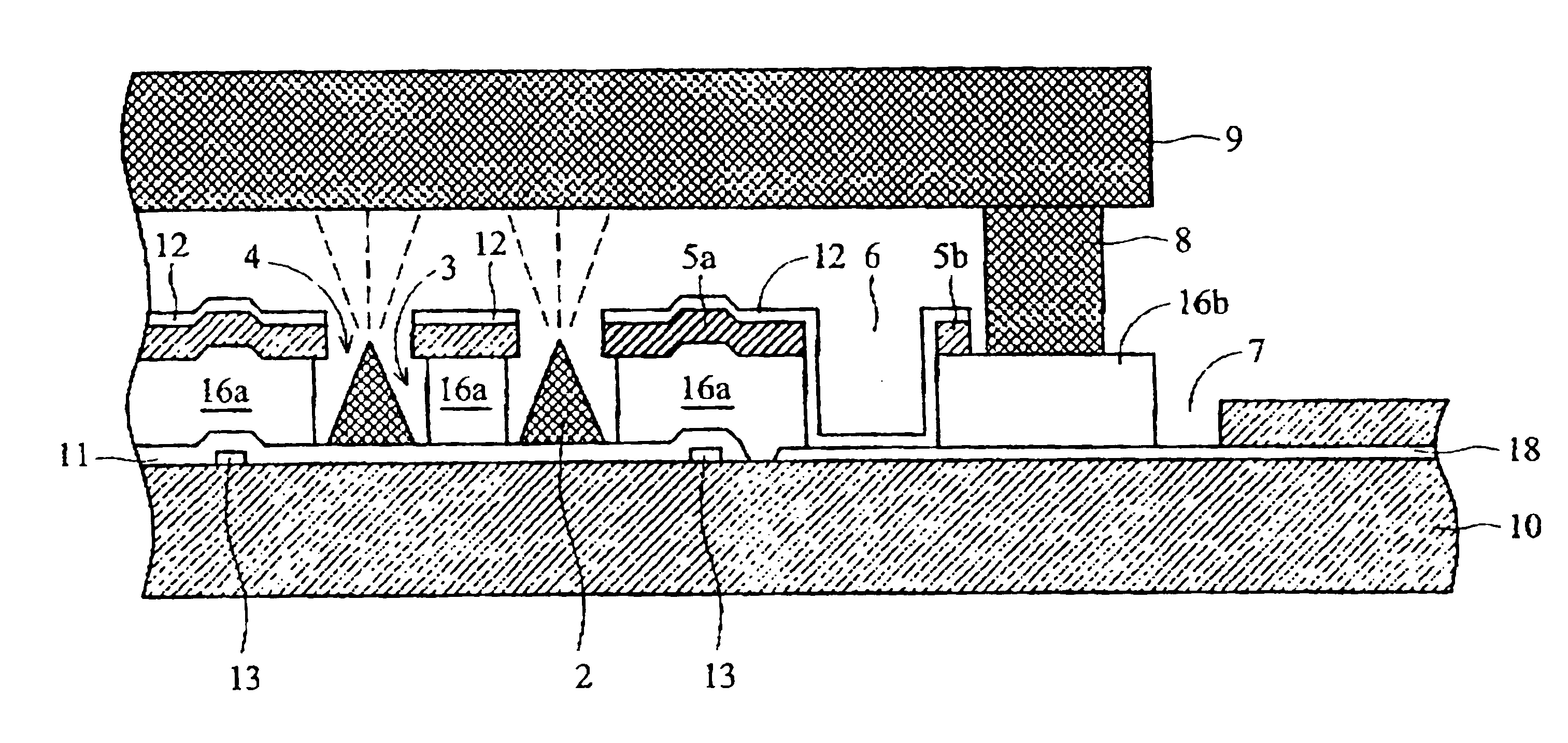

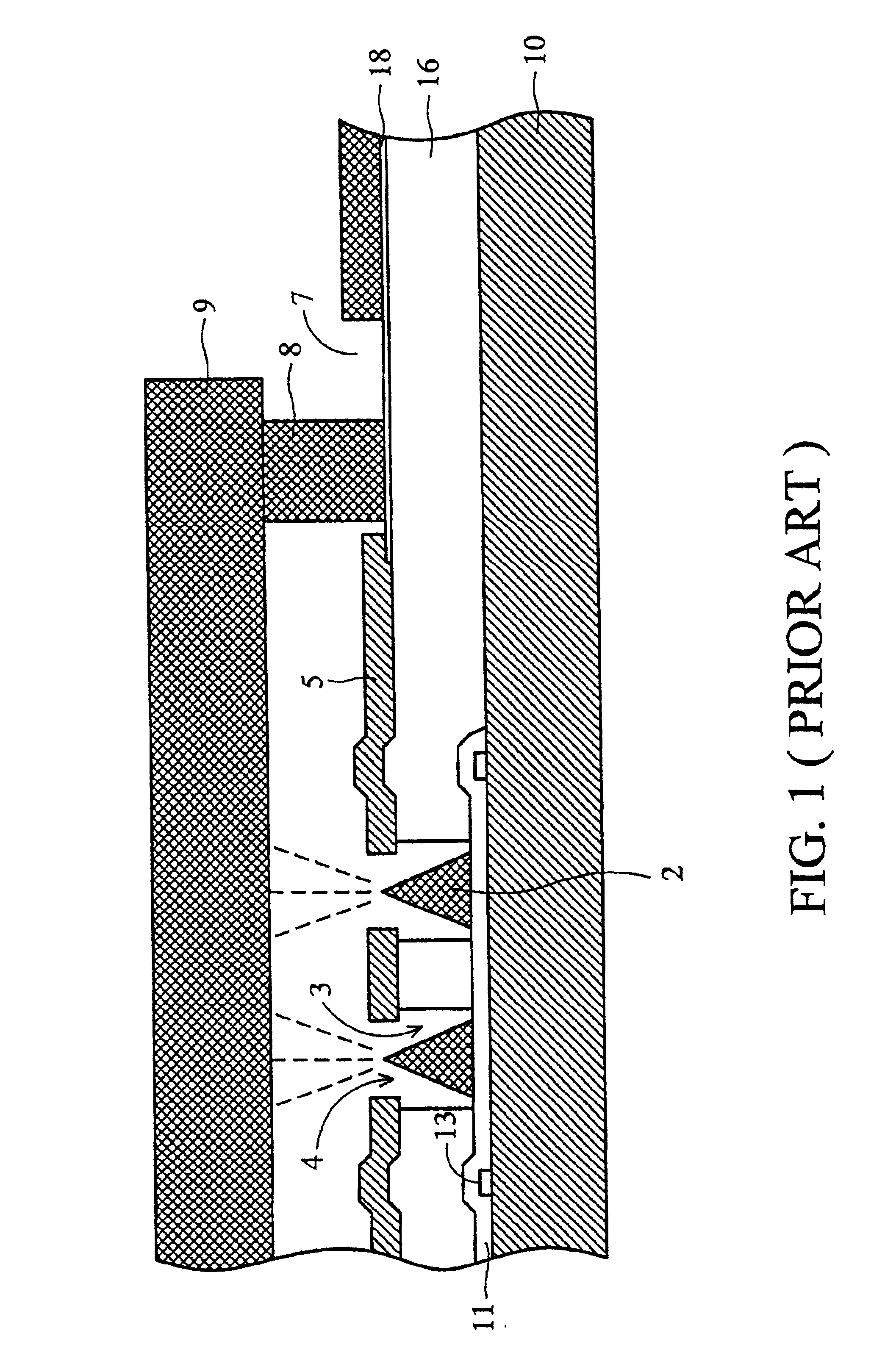

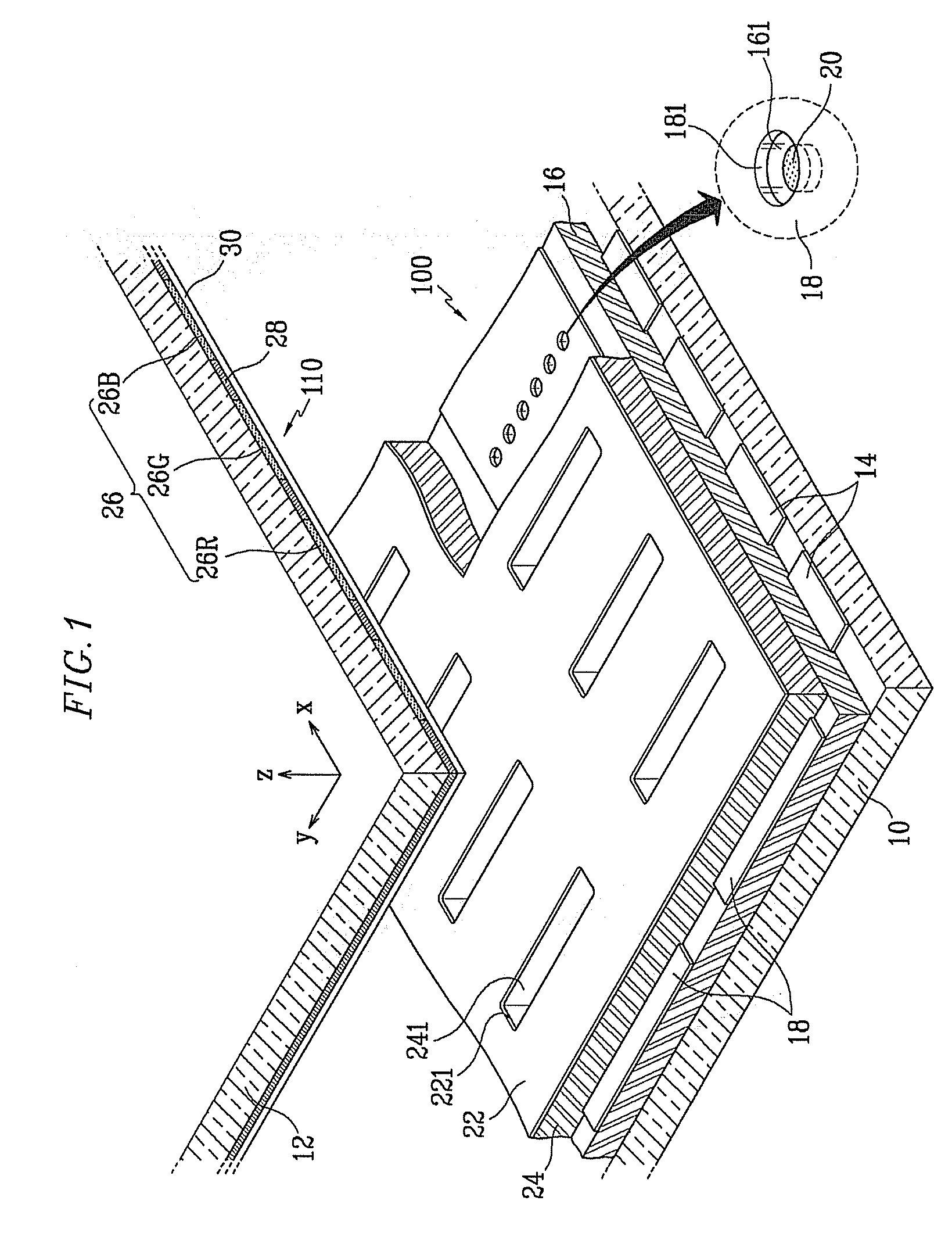

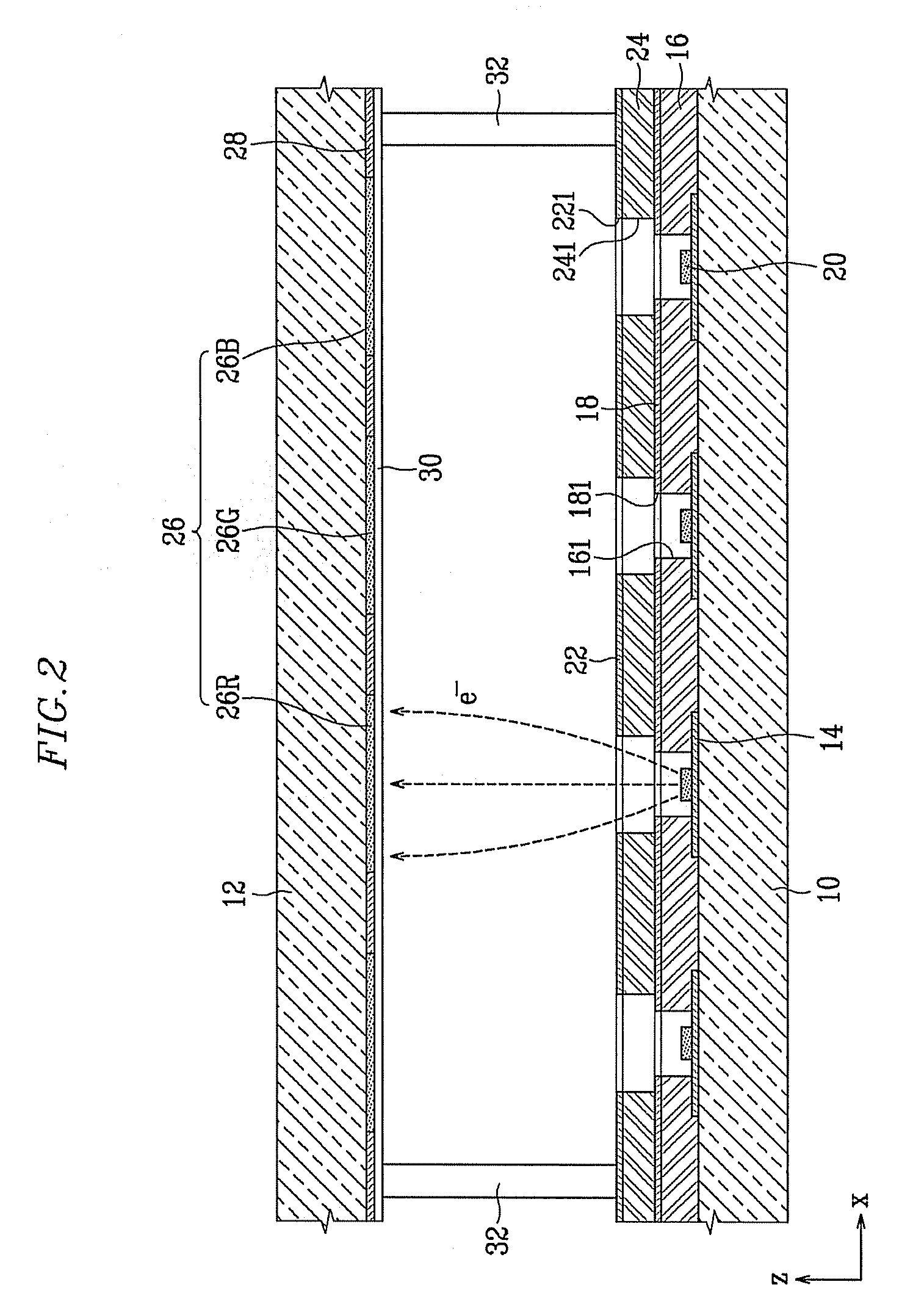

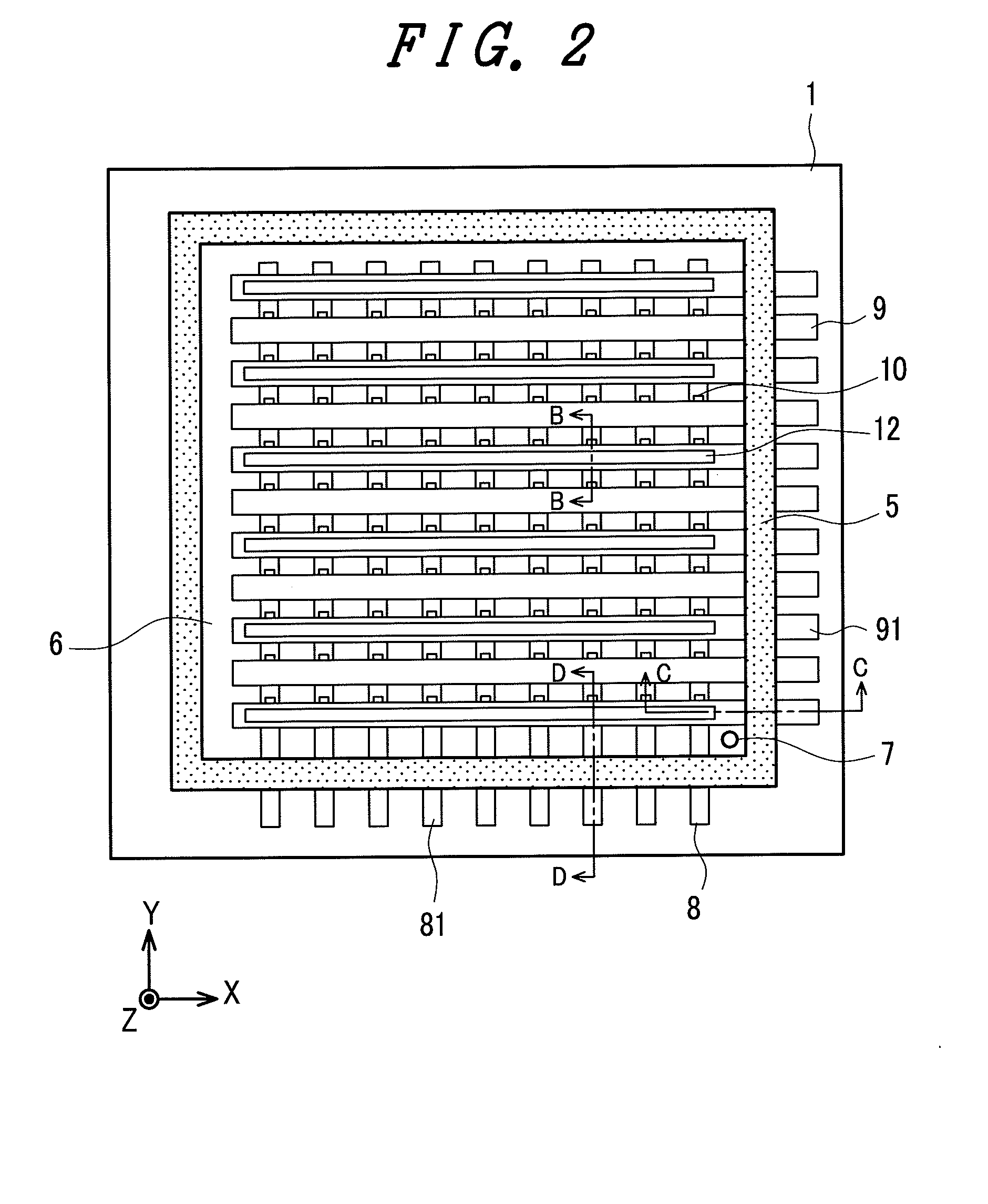

Image formation apparatus

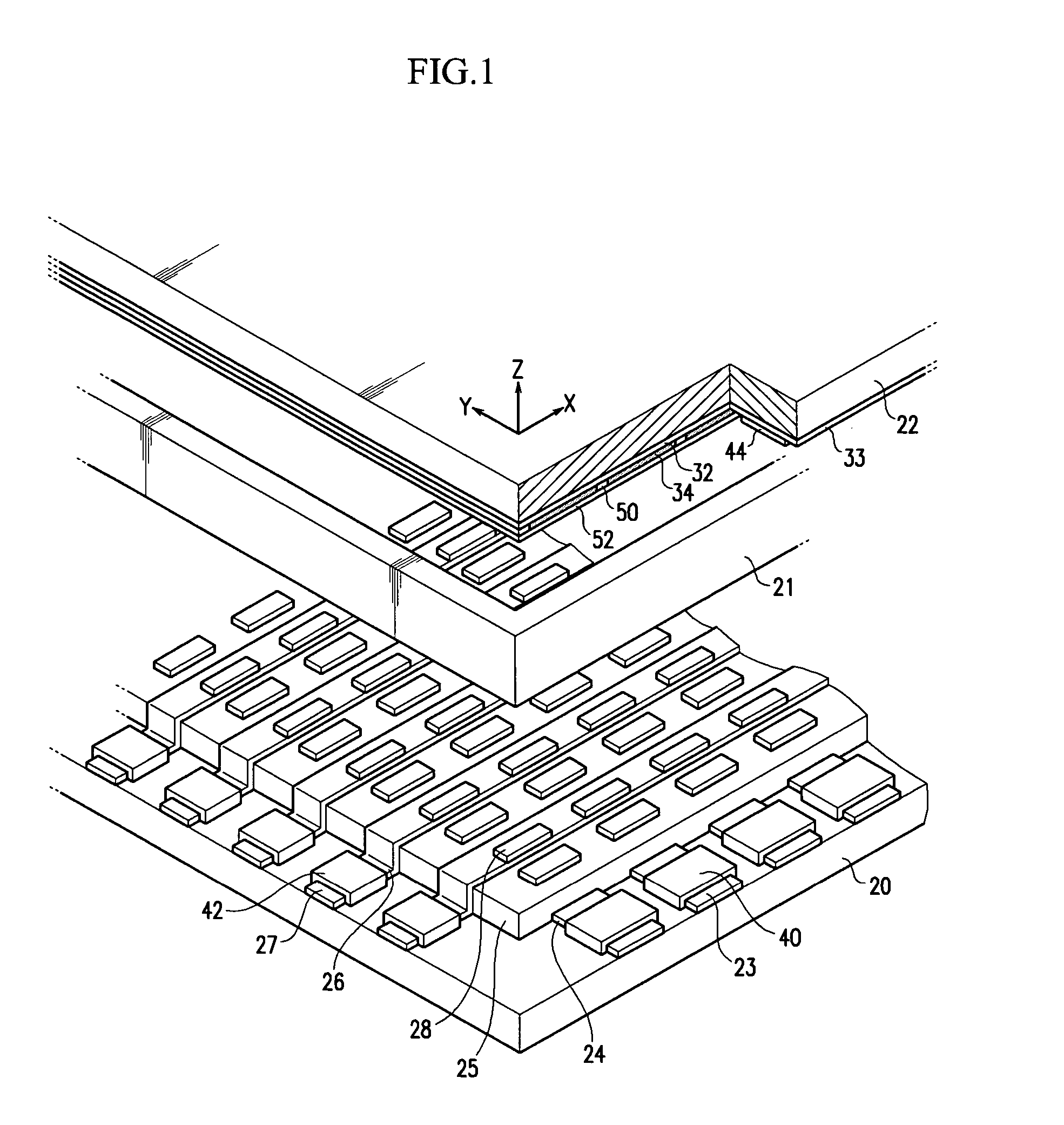

InactiveUS6879096B1High display-quality configurationSatisfies requirementTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

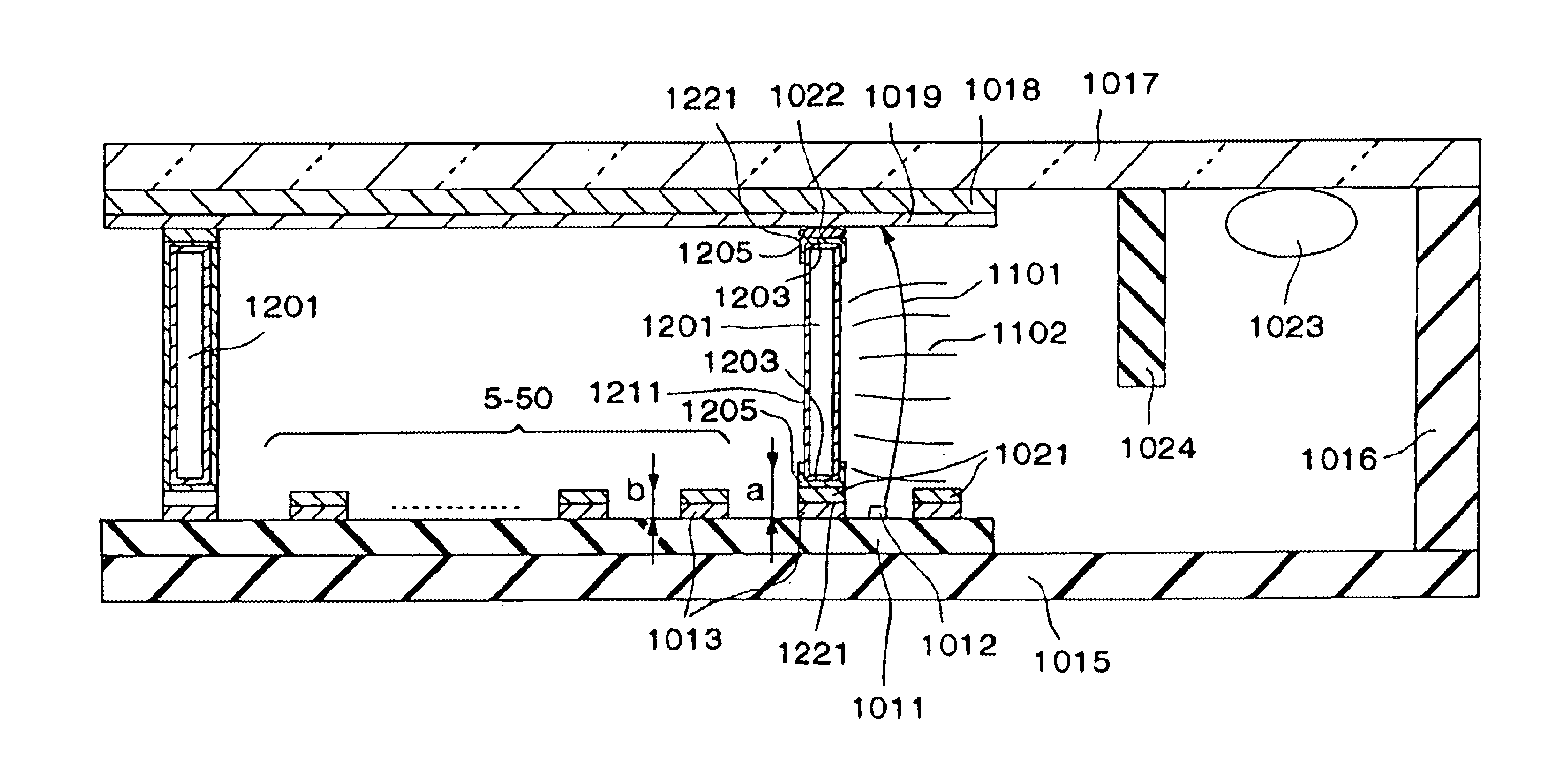

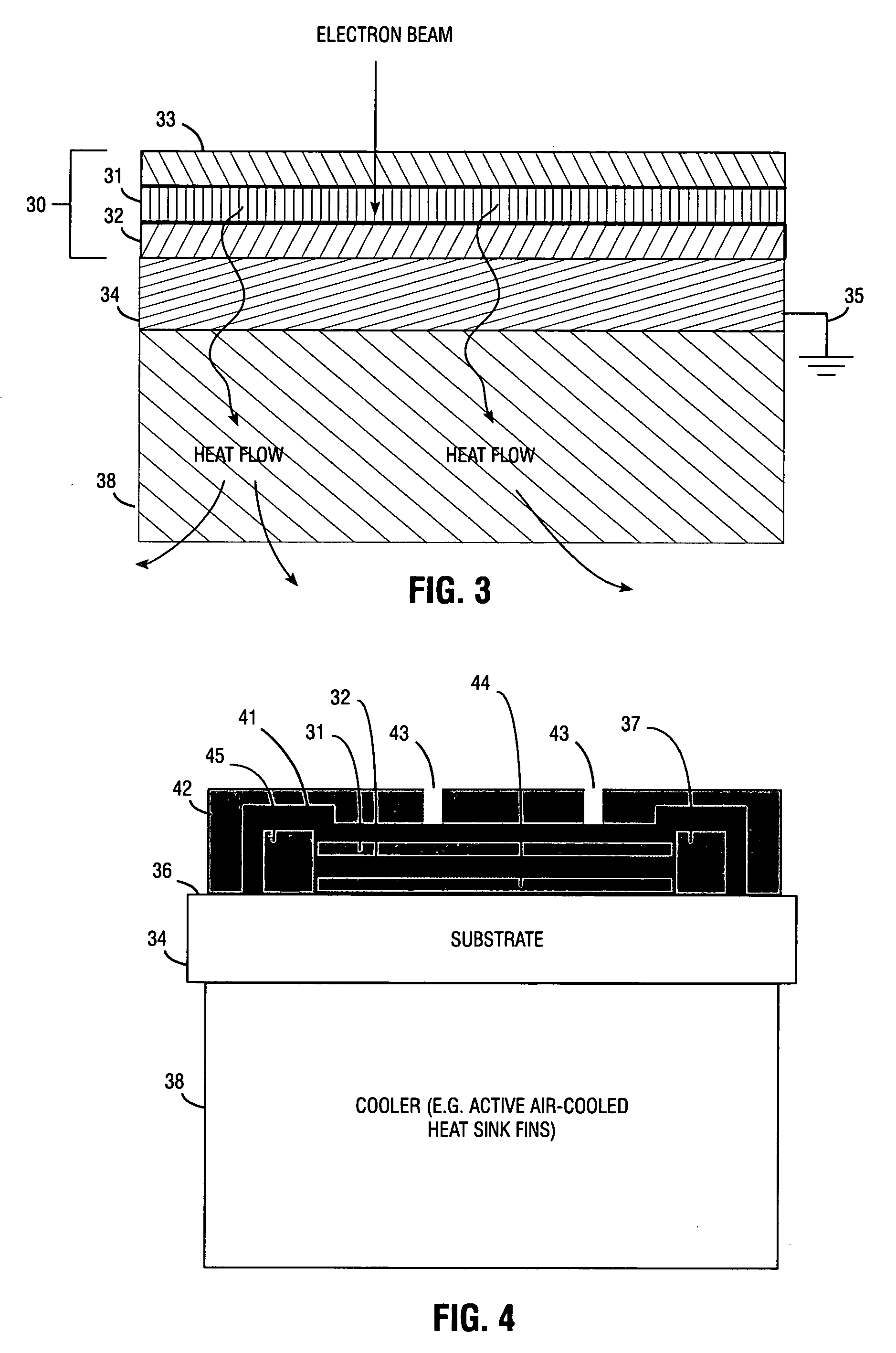

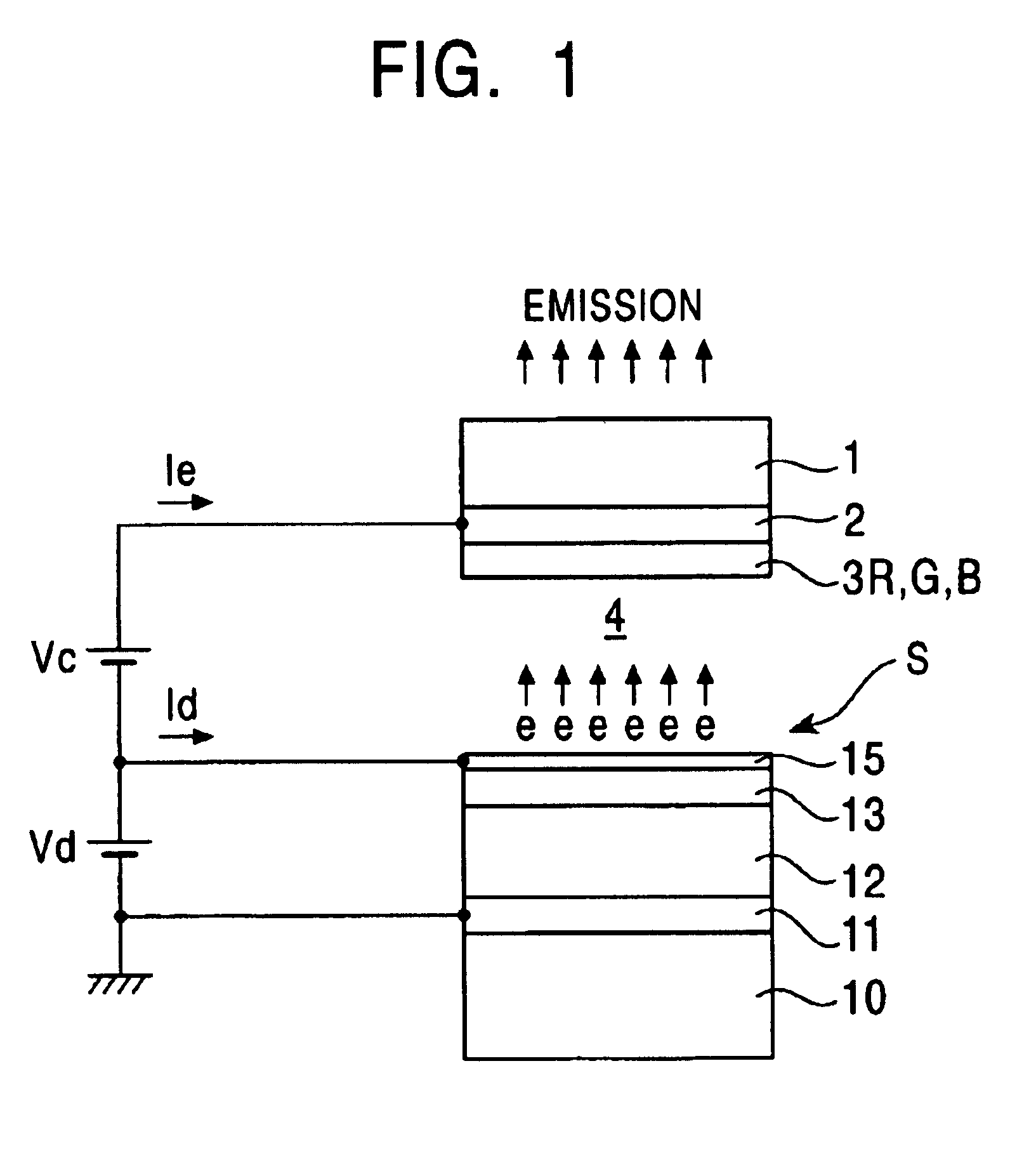

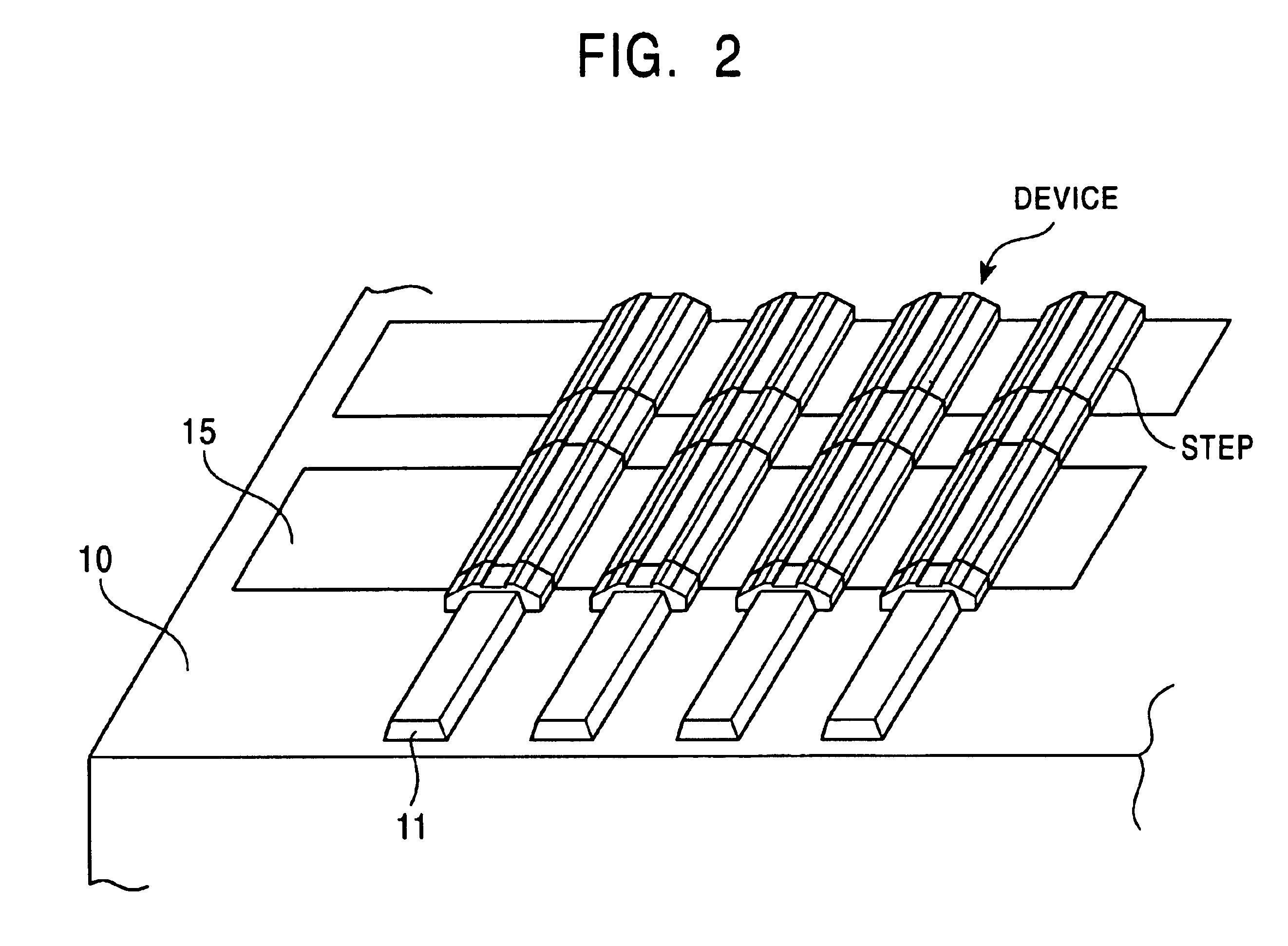

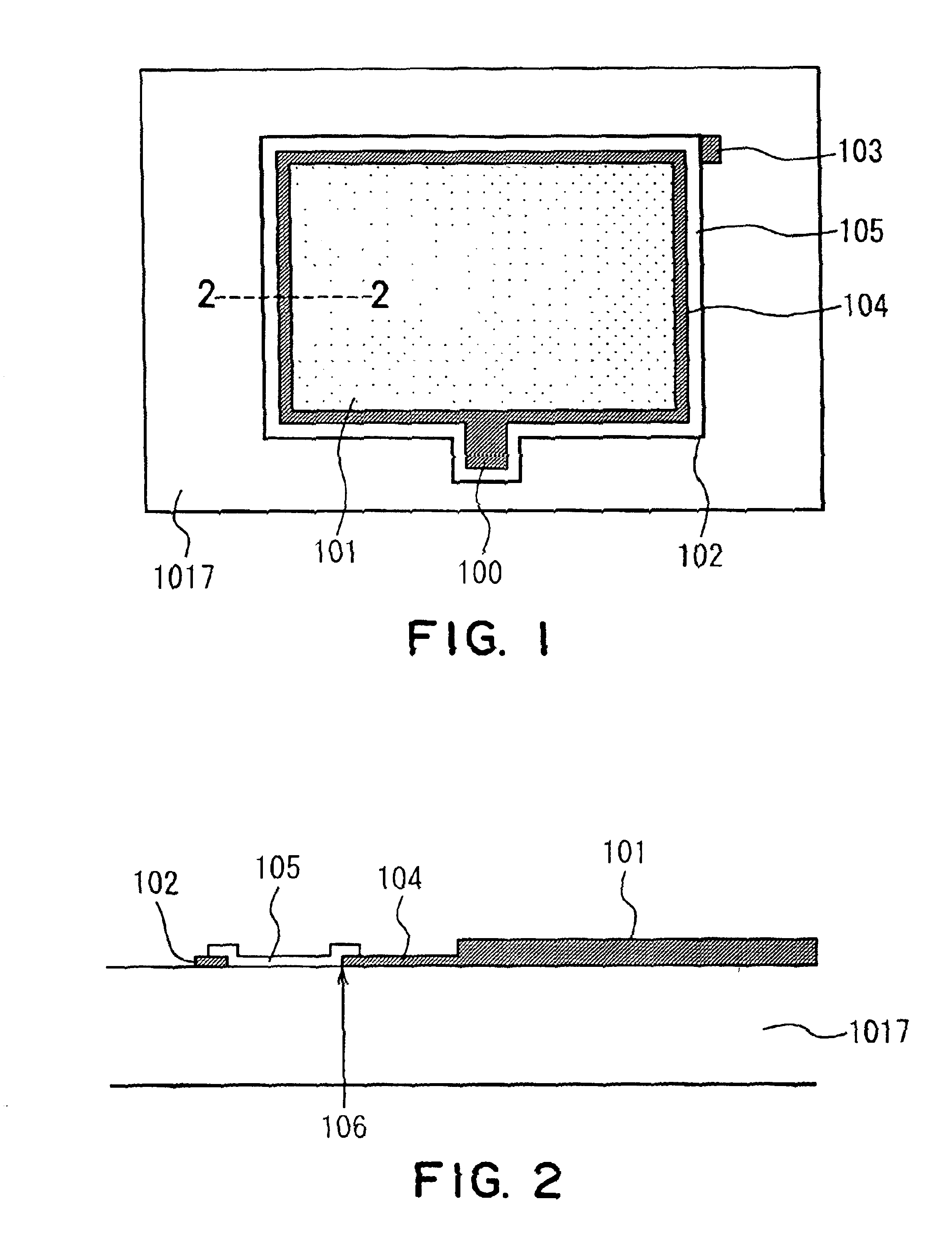

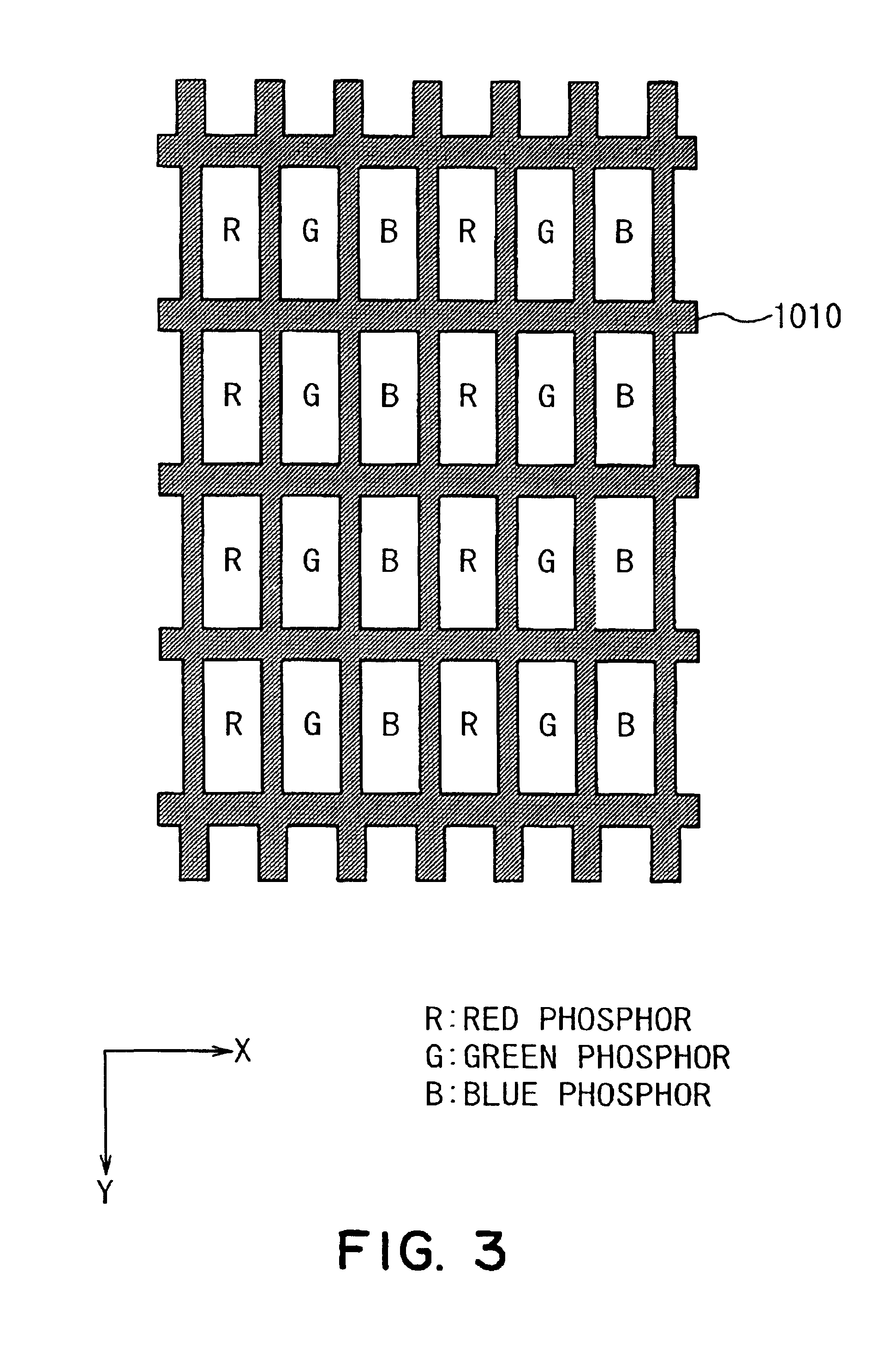

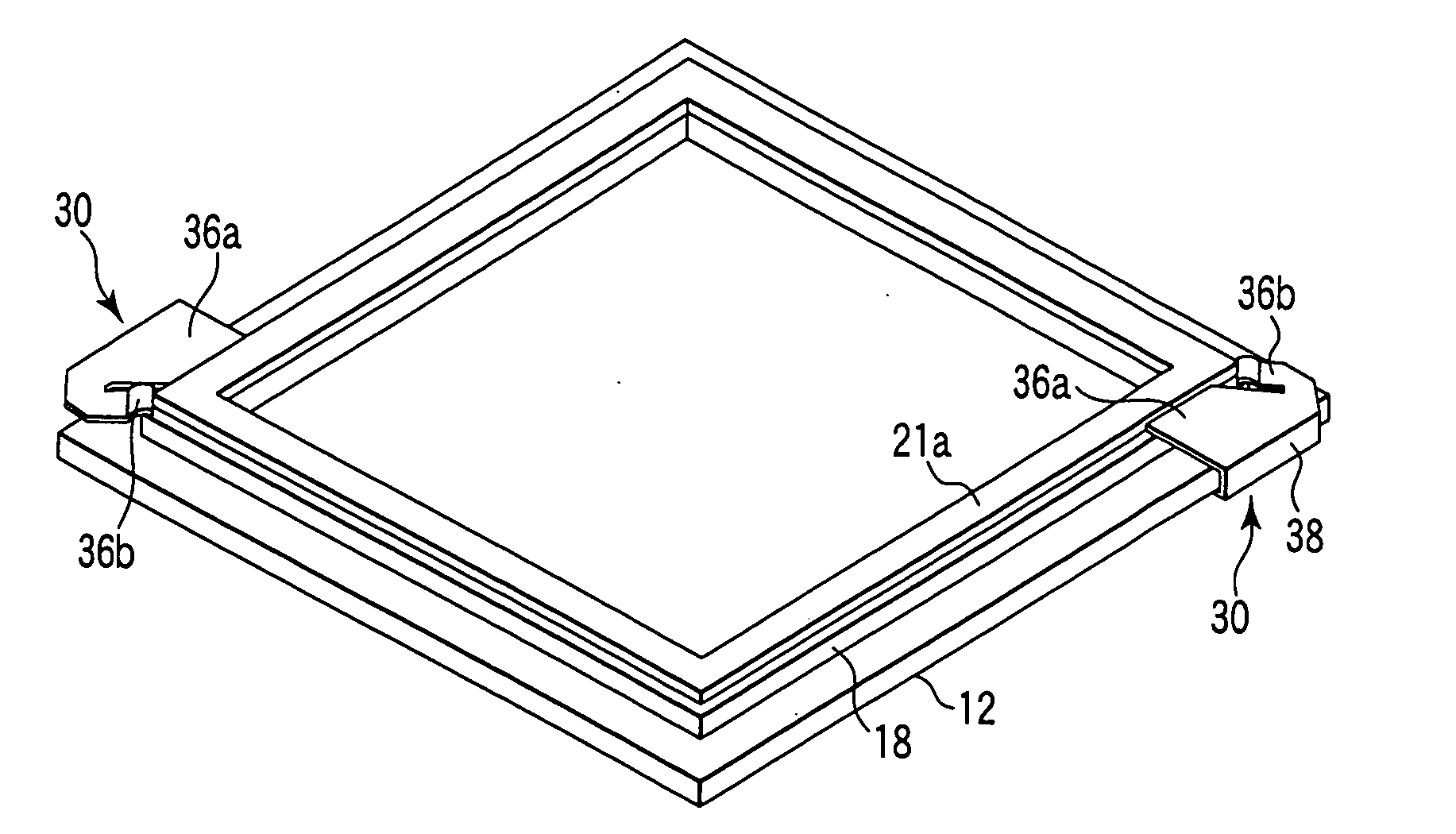

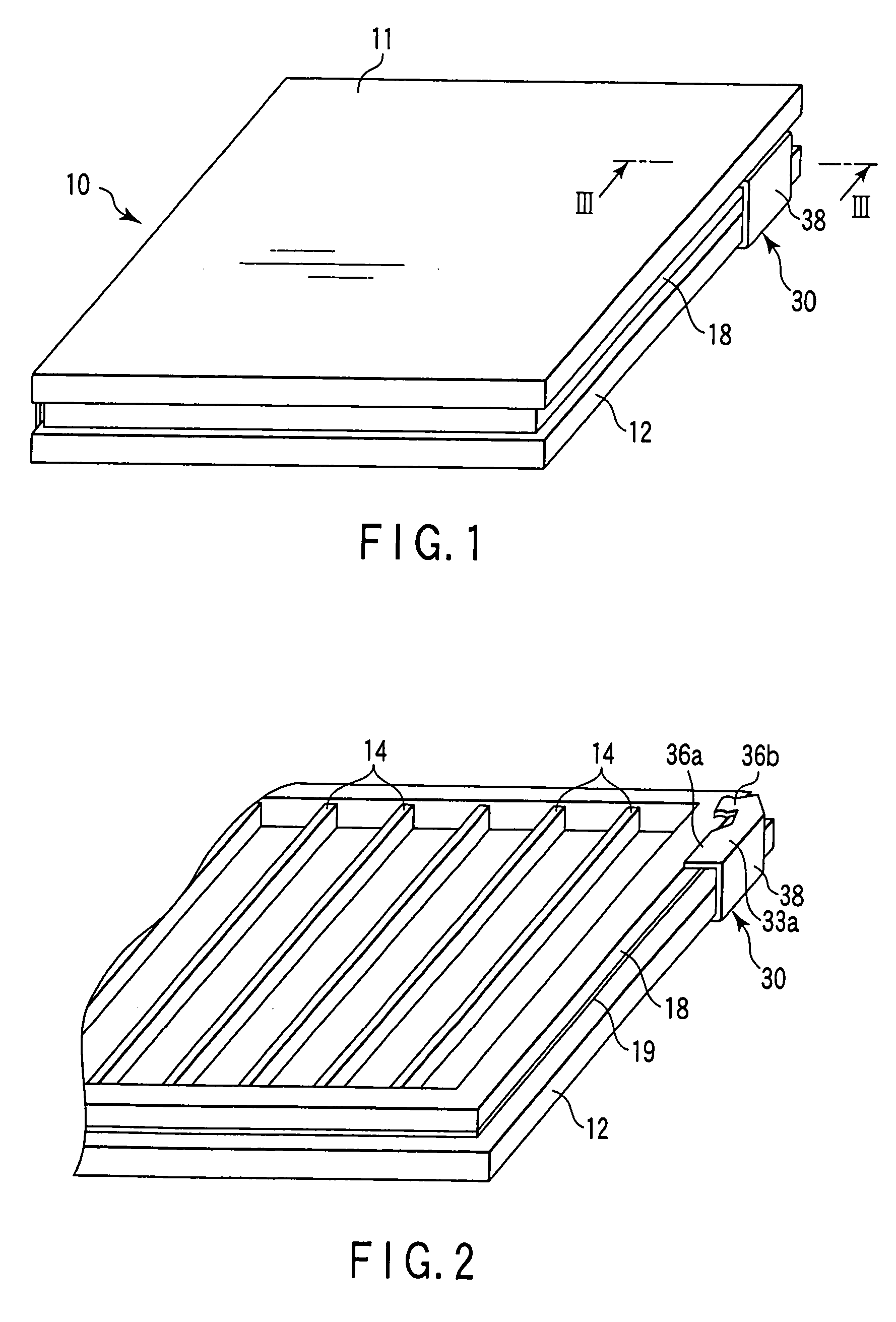

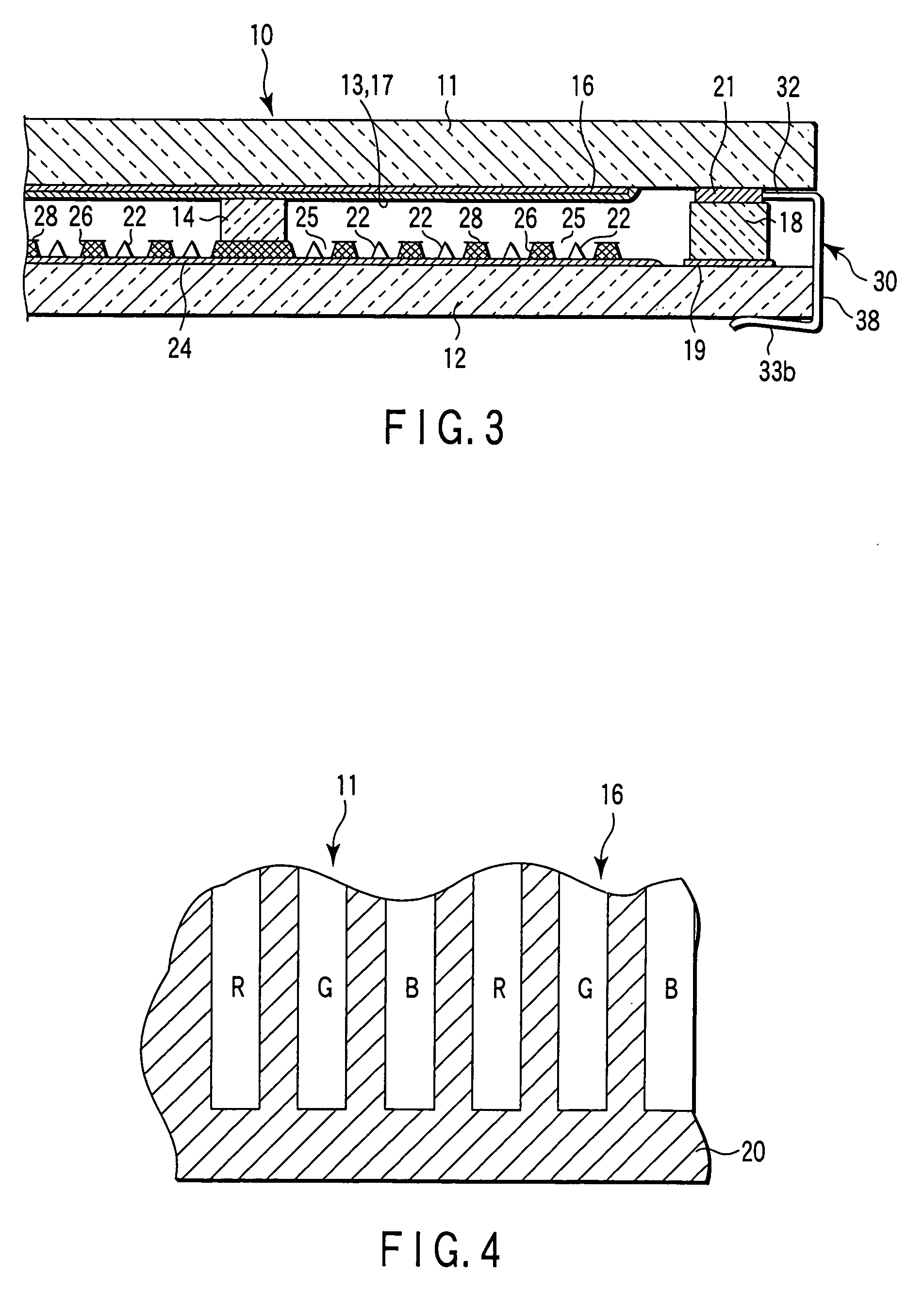

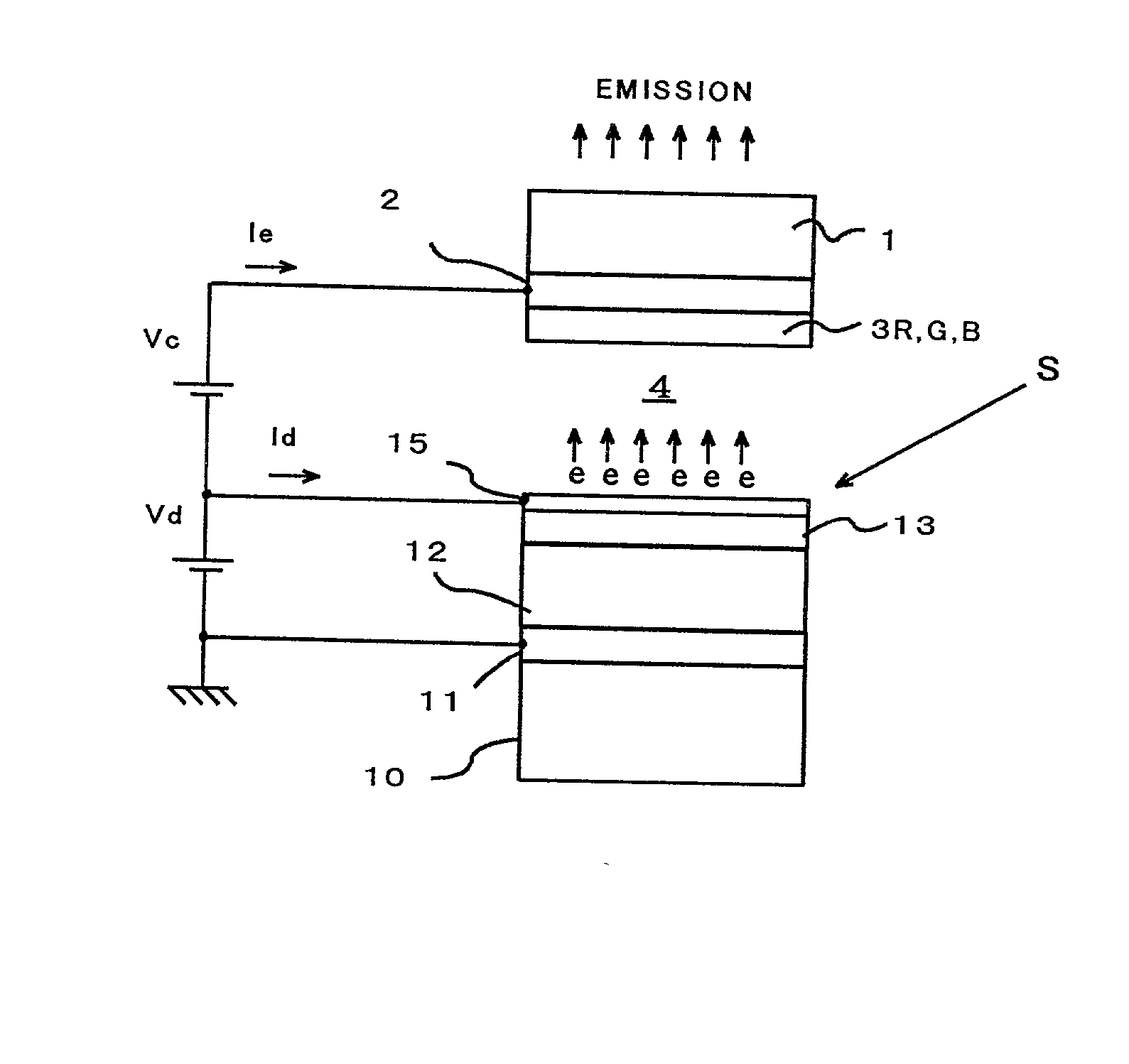

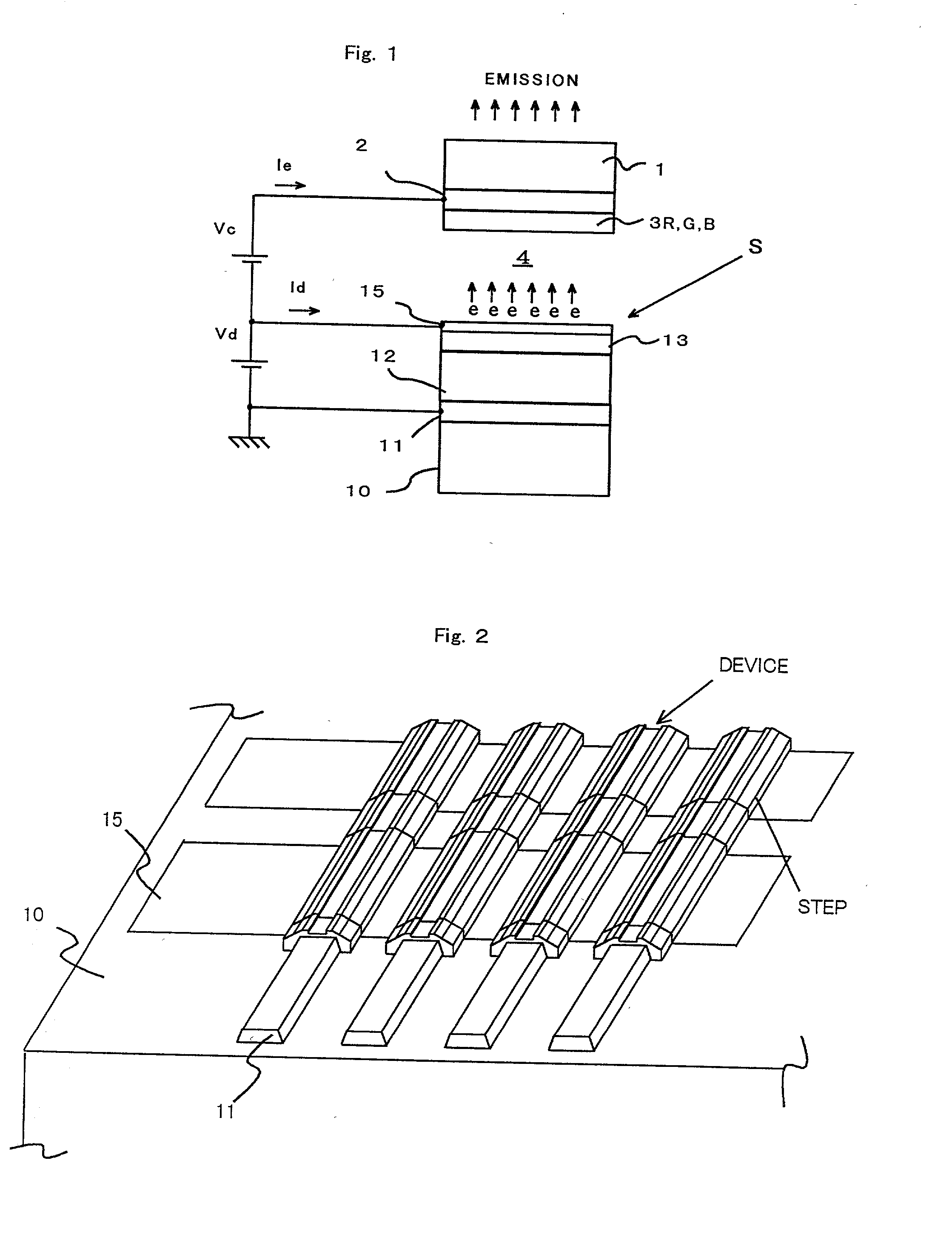

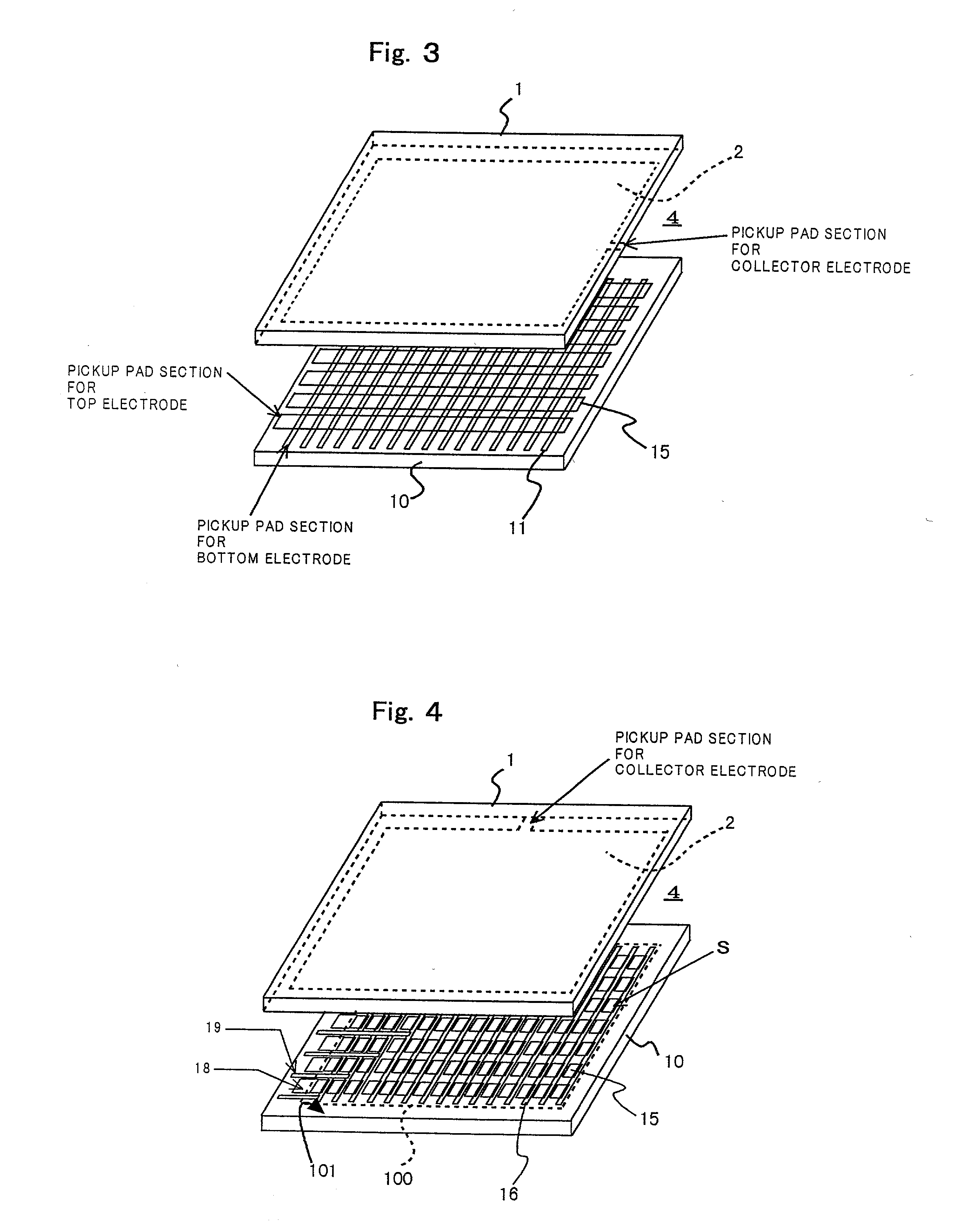

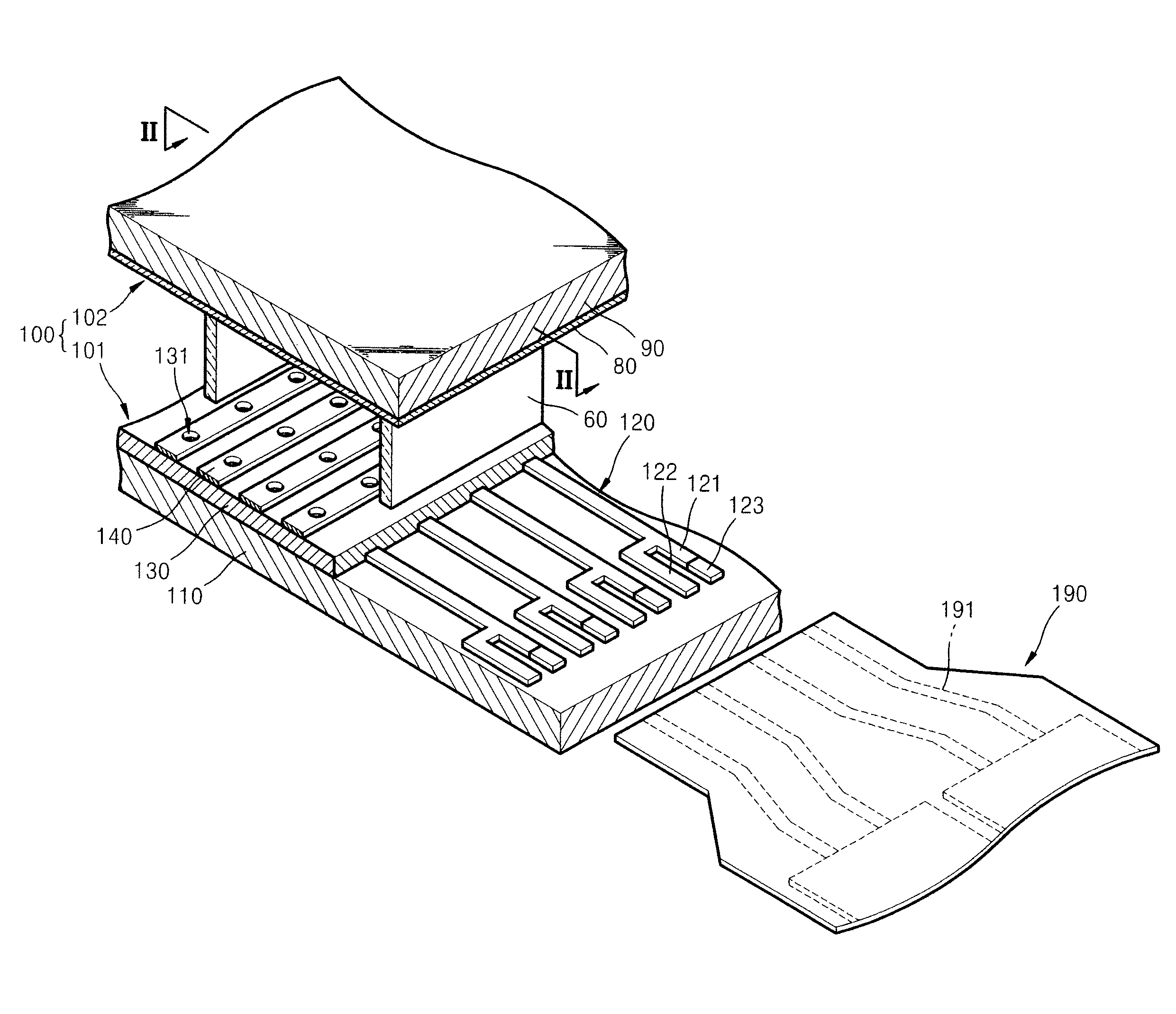

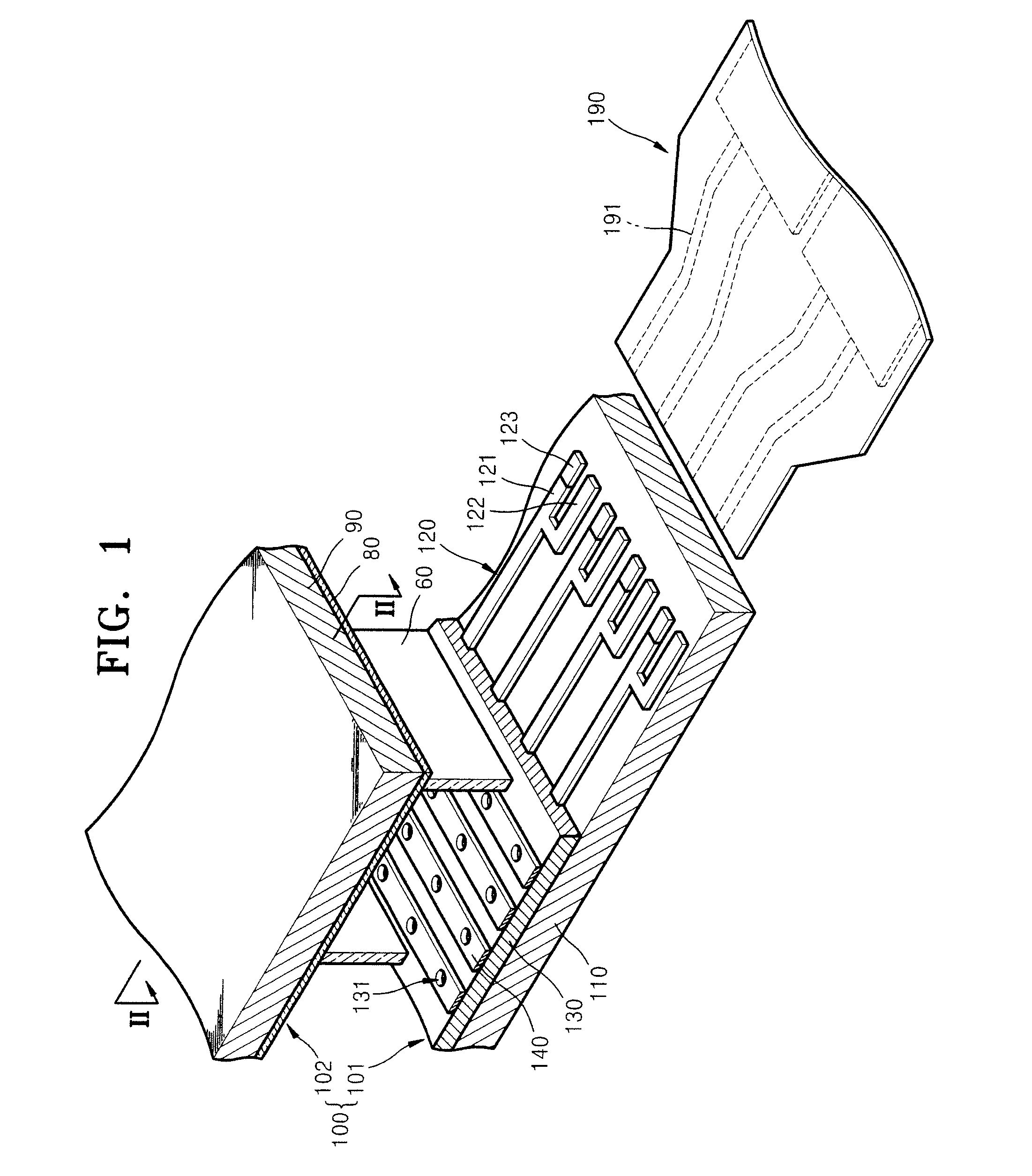

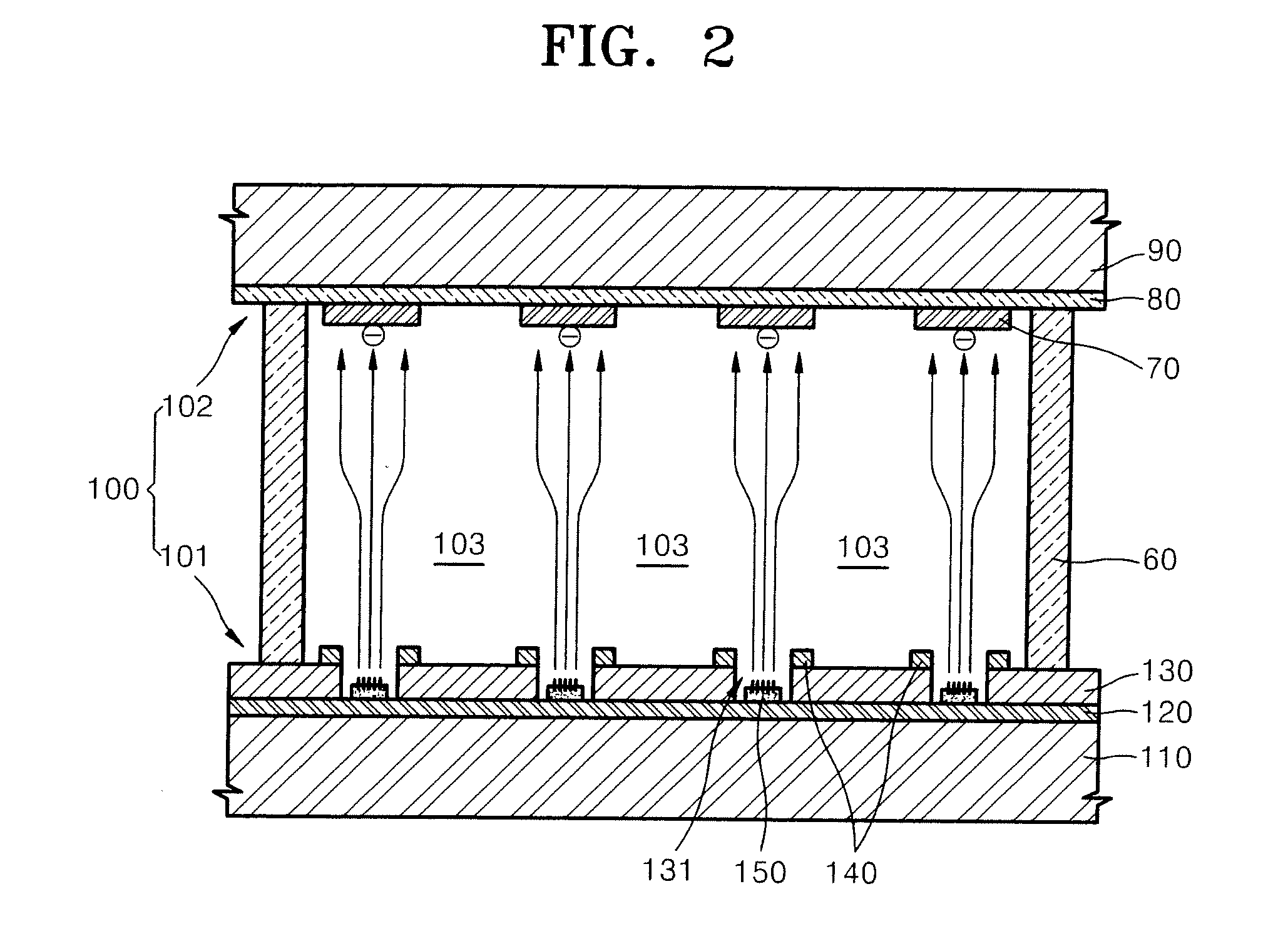

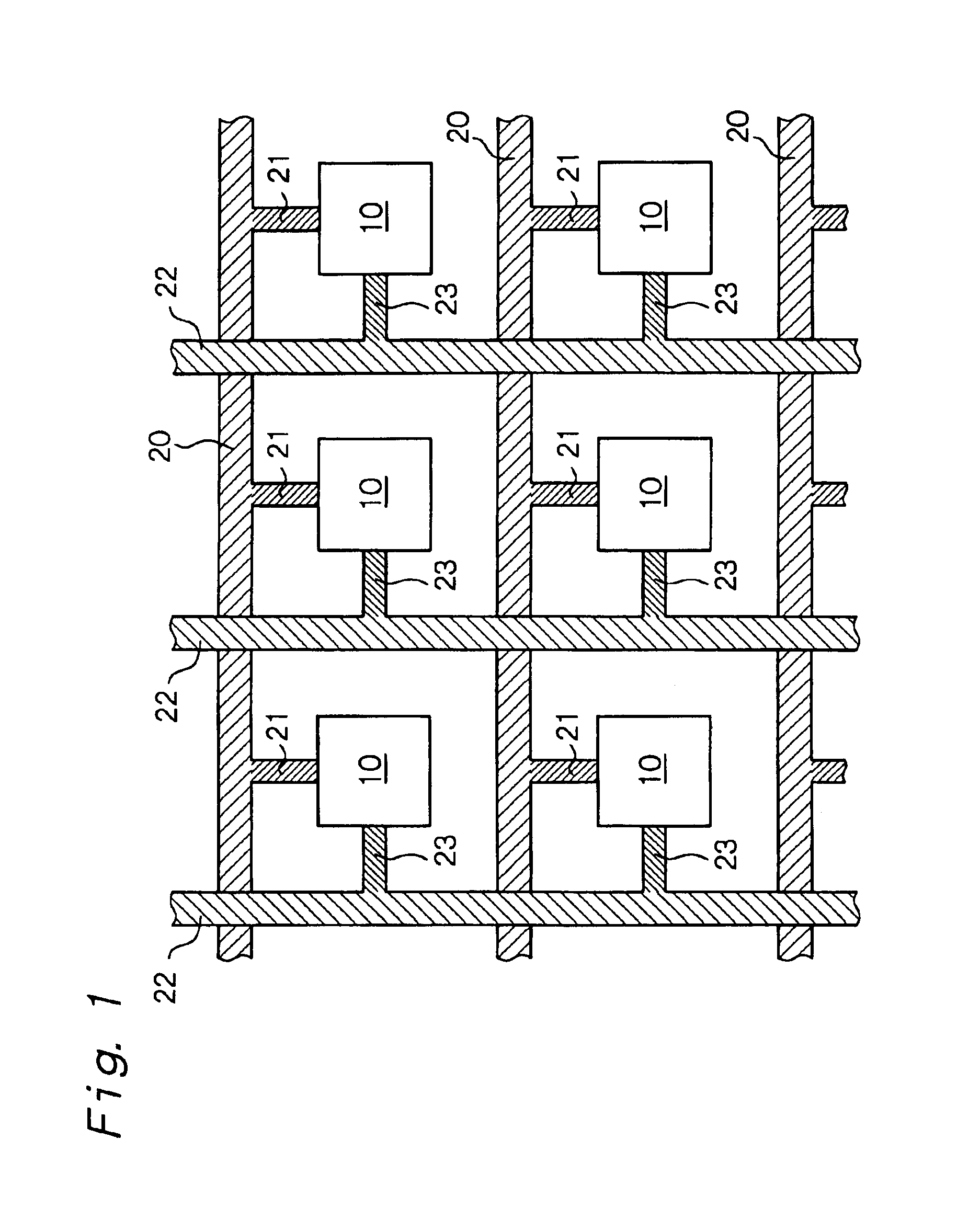

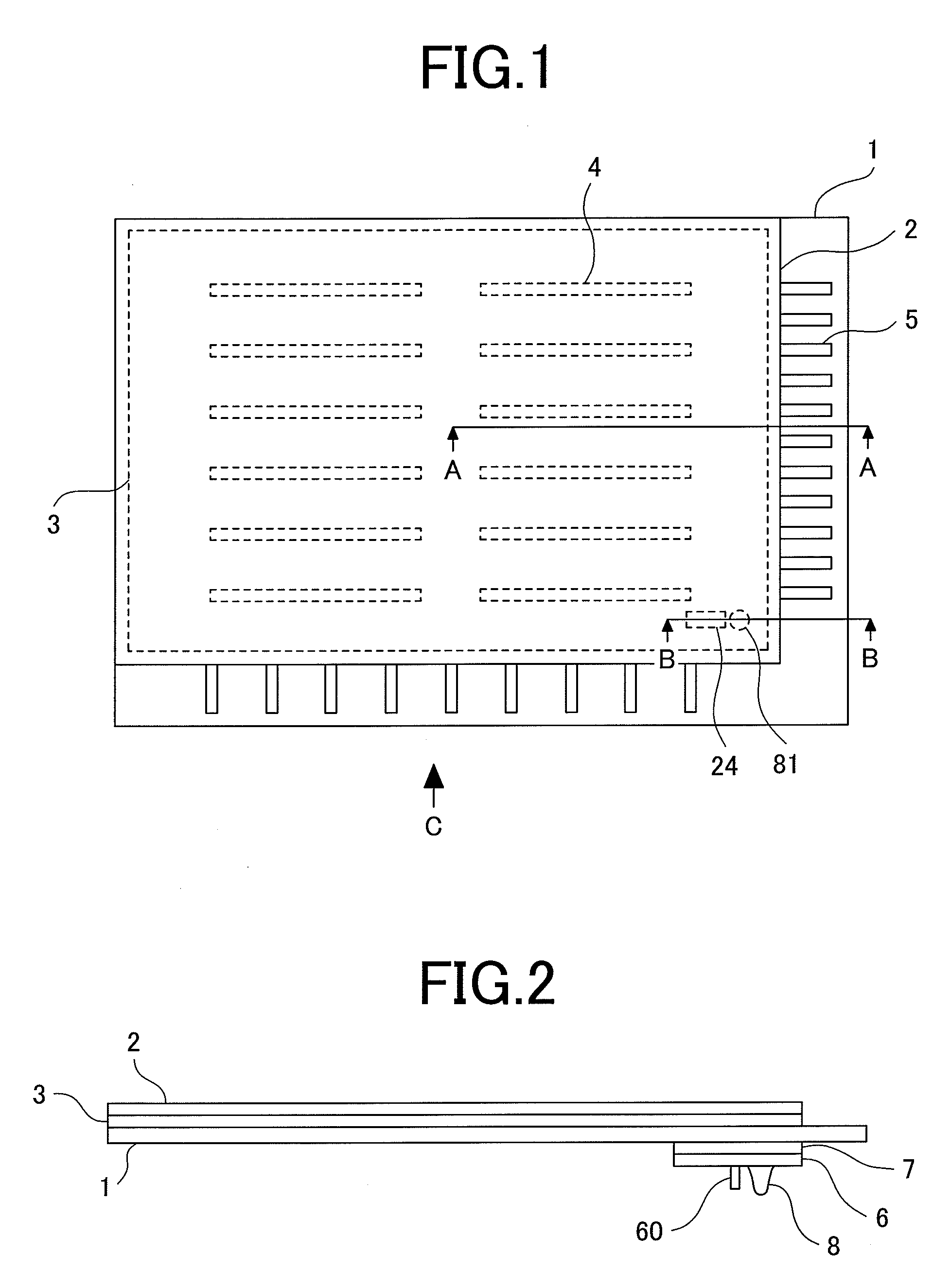

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

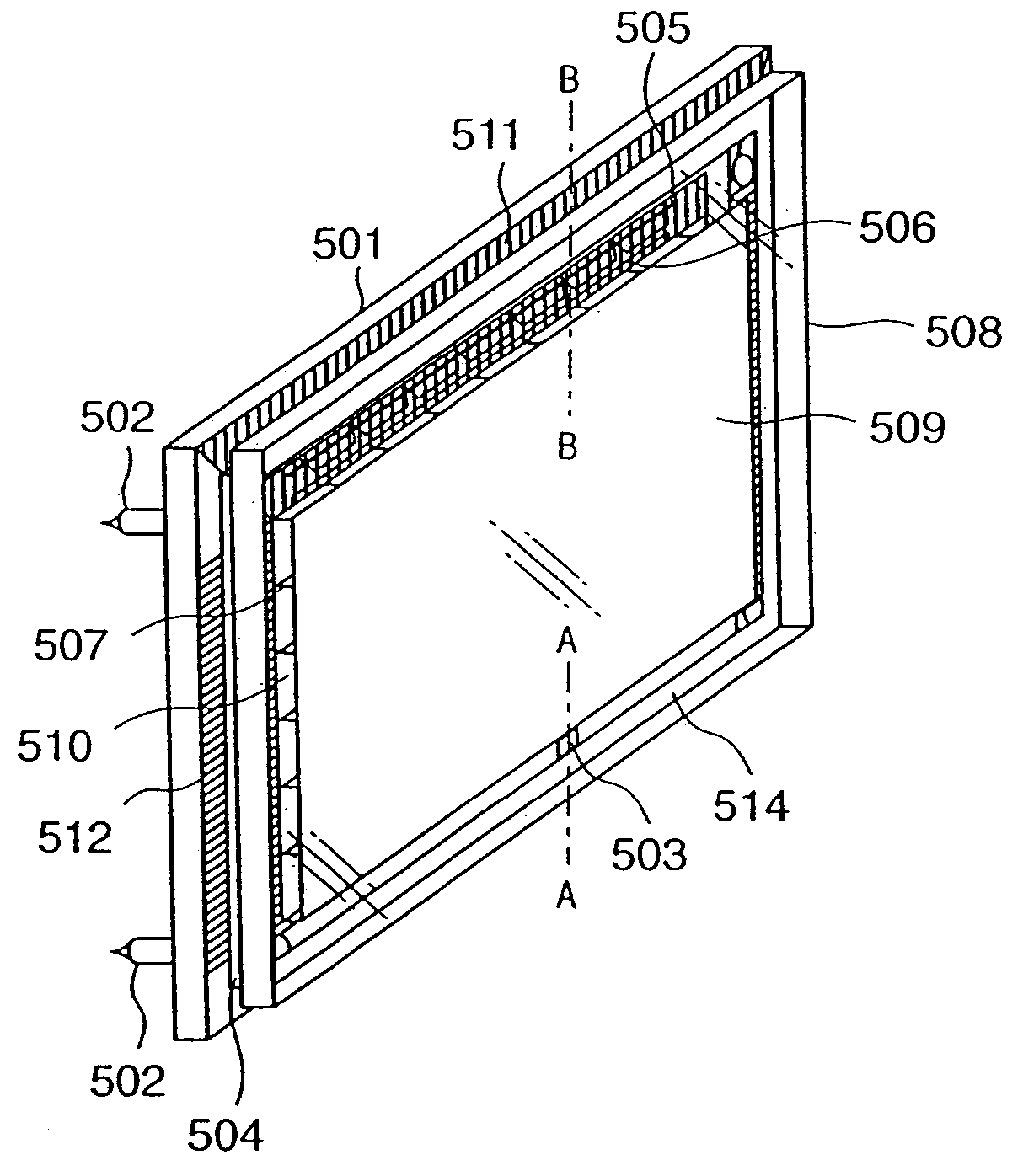

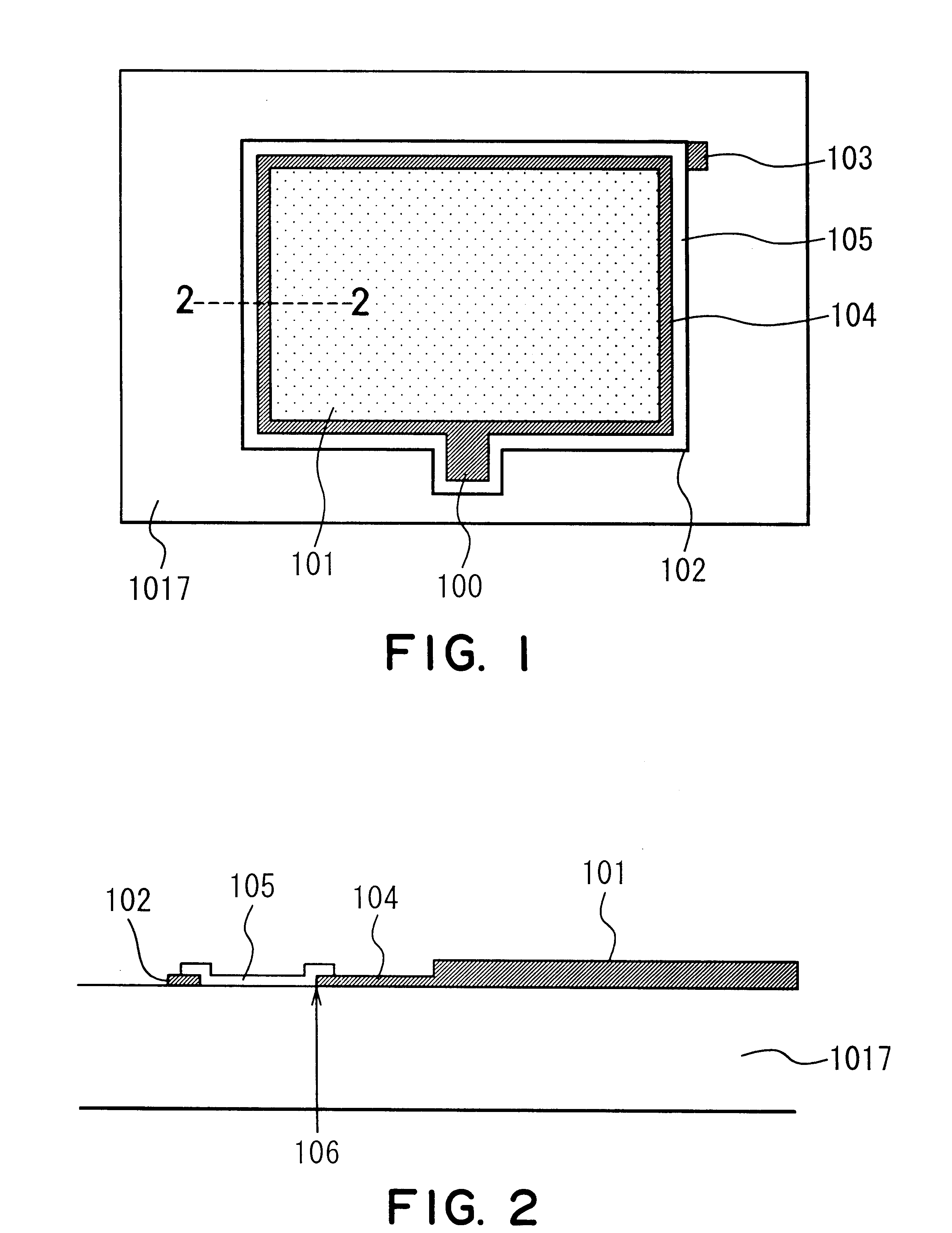

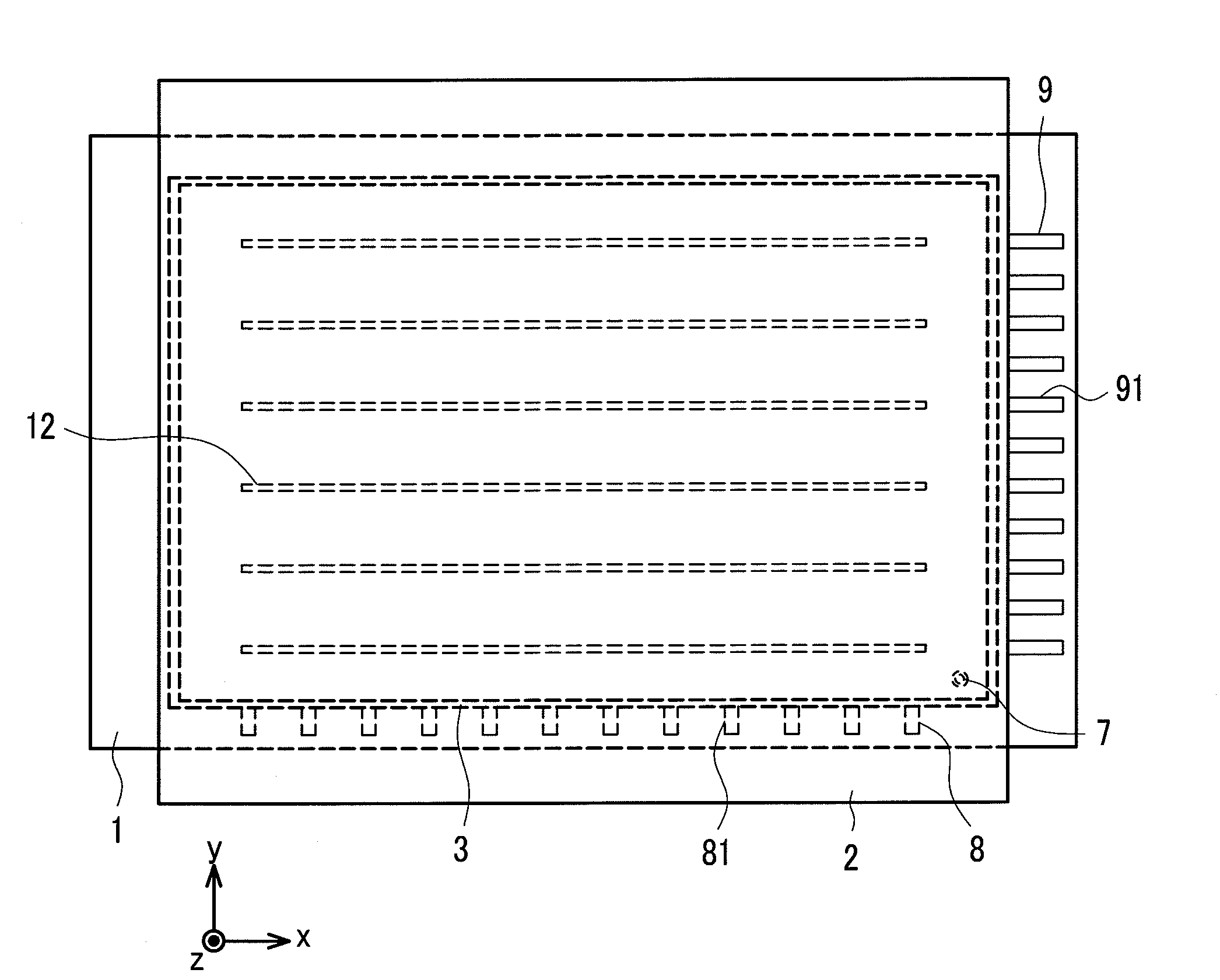

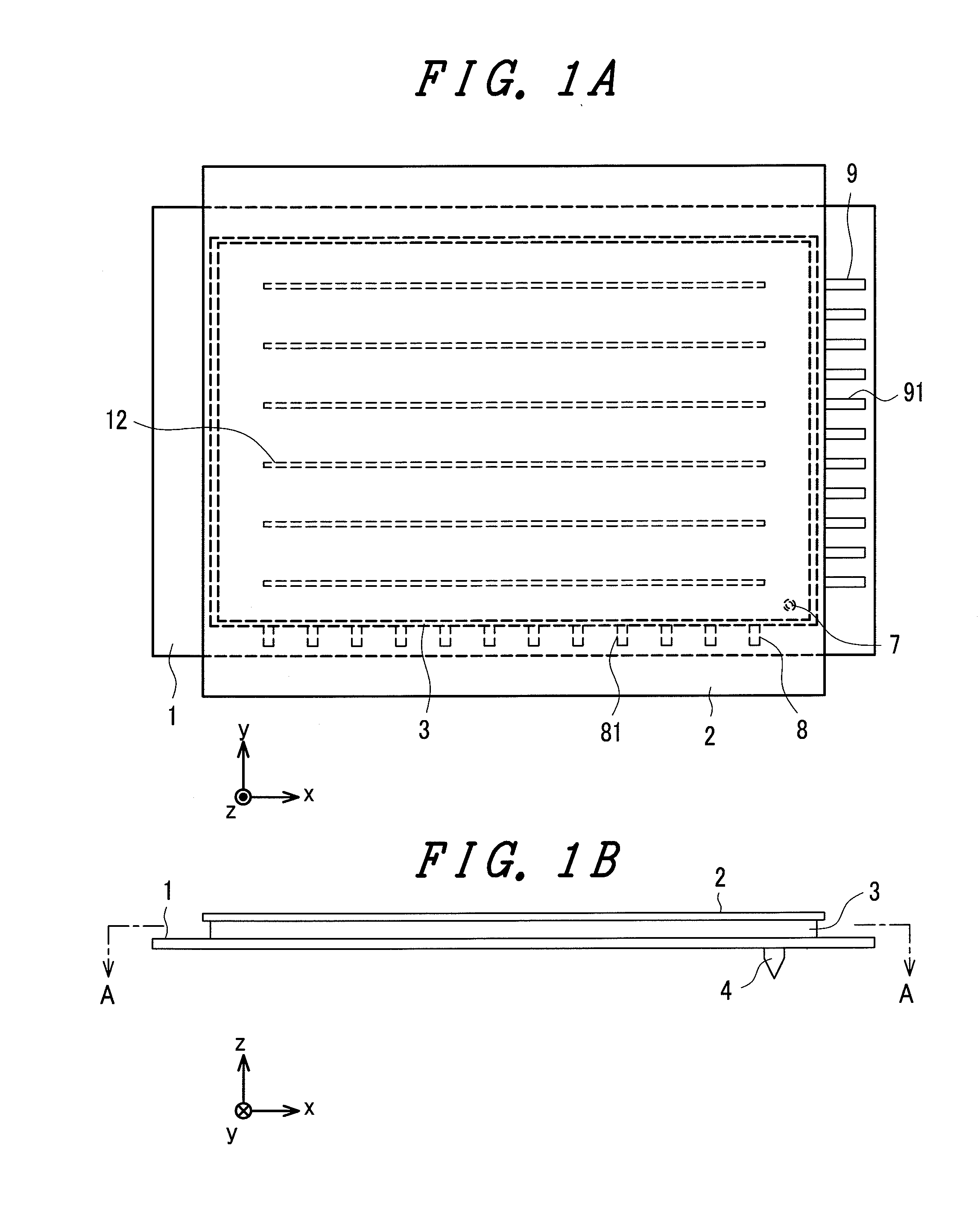

Image display device

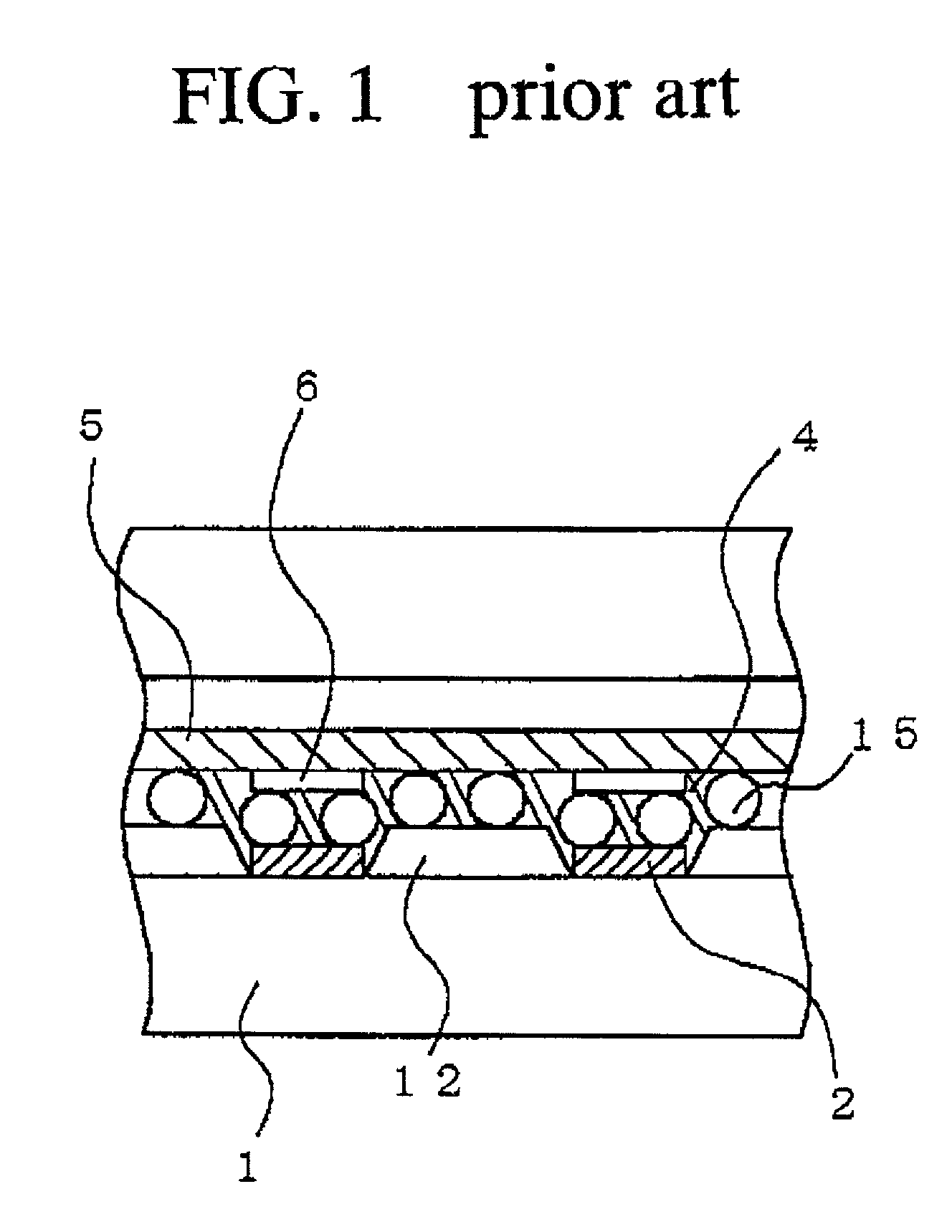

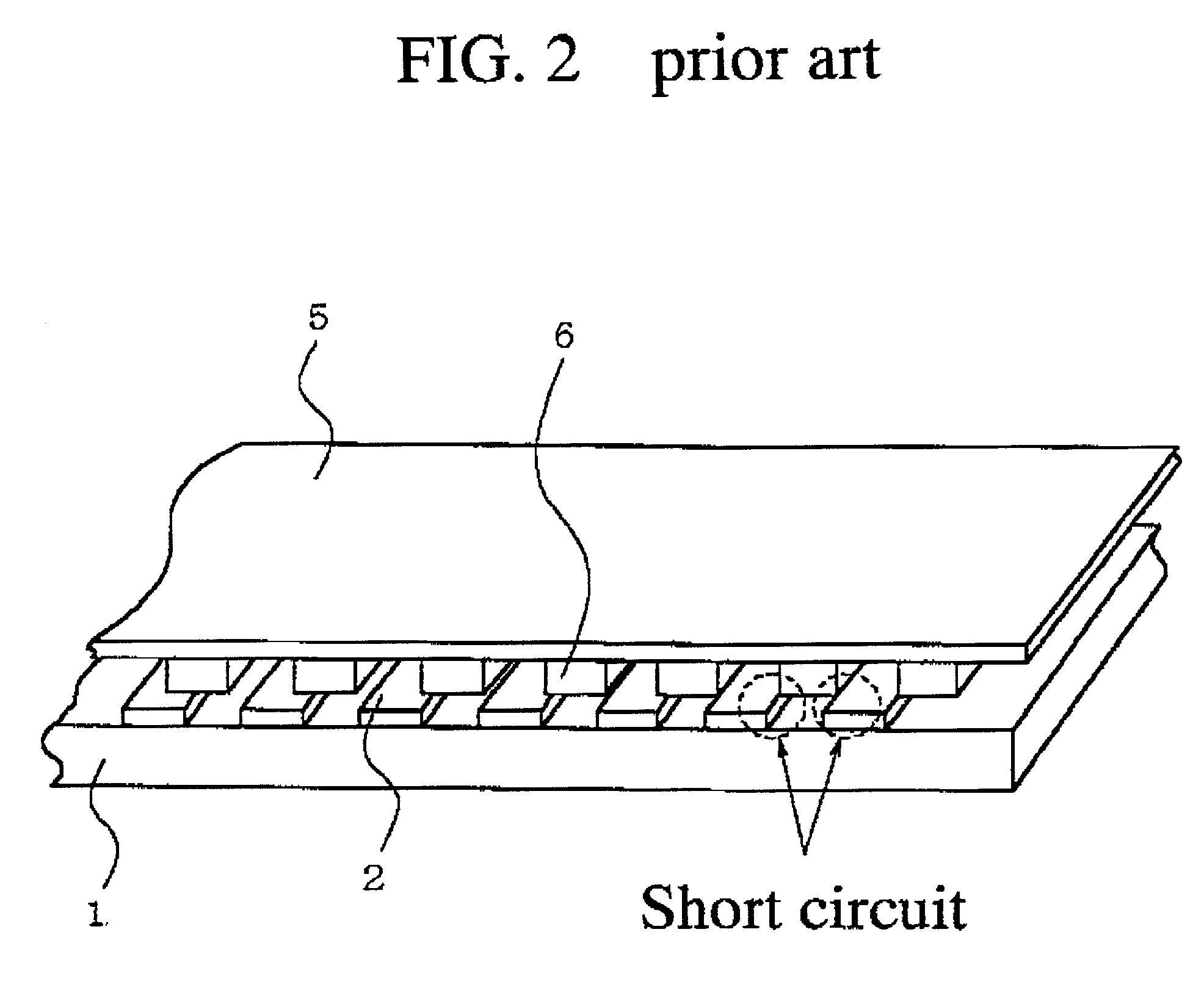

InactiveUS20020129952A1Improve working efficiencyElectrical conduction unstableTelevision system detailsCathode-ray/electron-beam tube electrical connectionConductive coatingDisplay device

There is provided an image display device including a panel of good work efficiency which can prevent the destruction of its conductive coat due to discharge and can highly efficiently reduce the leakage of unwanted radiation electric fields. The image display device includes a panel grounding electrode which connects a conductive coat and a grounding member together, and the panel grounding electrode uses a conductive adhesive material having in the whole of an adhesive layer, and an insulative protective tape.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

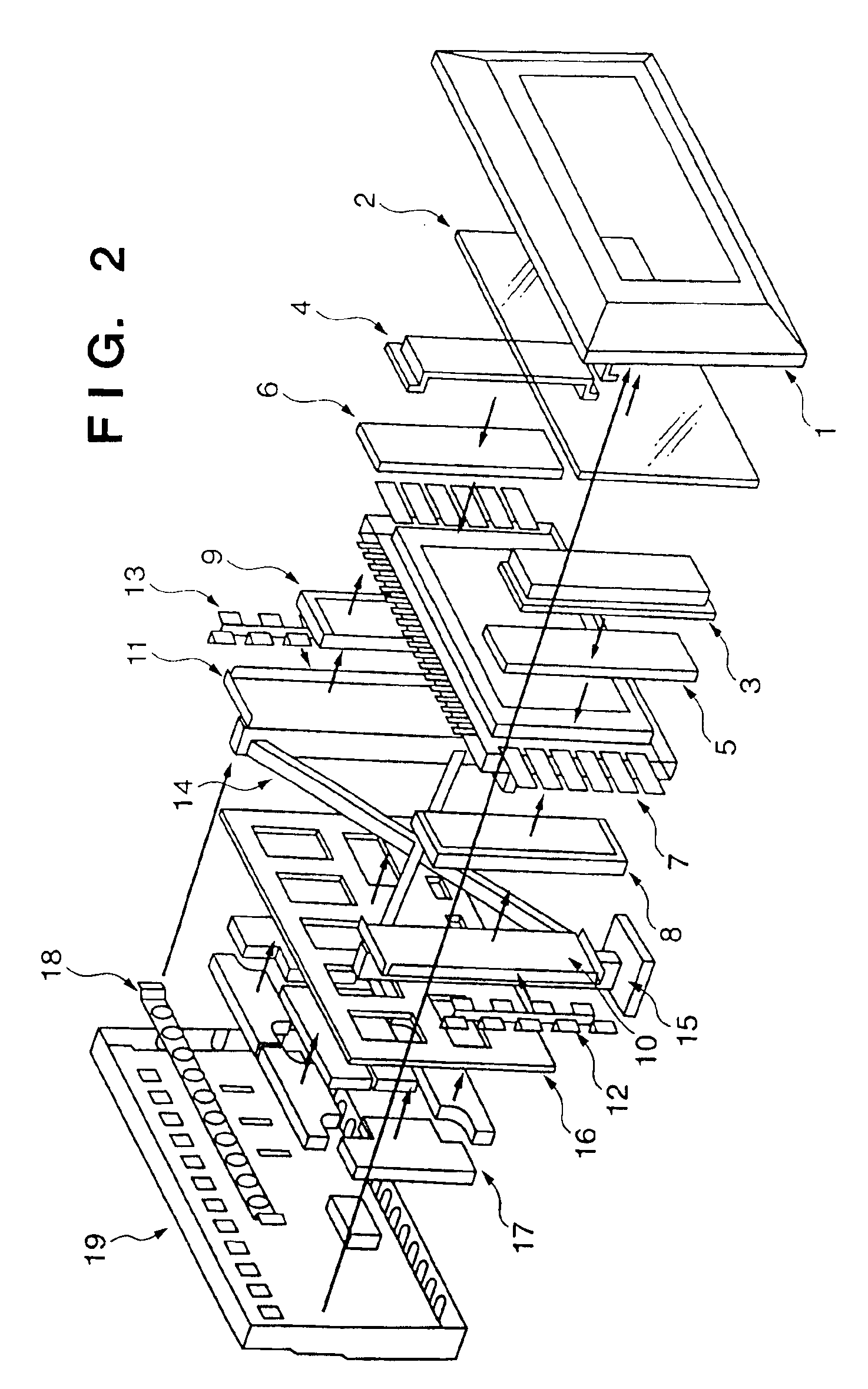

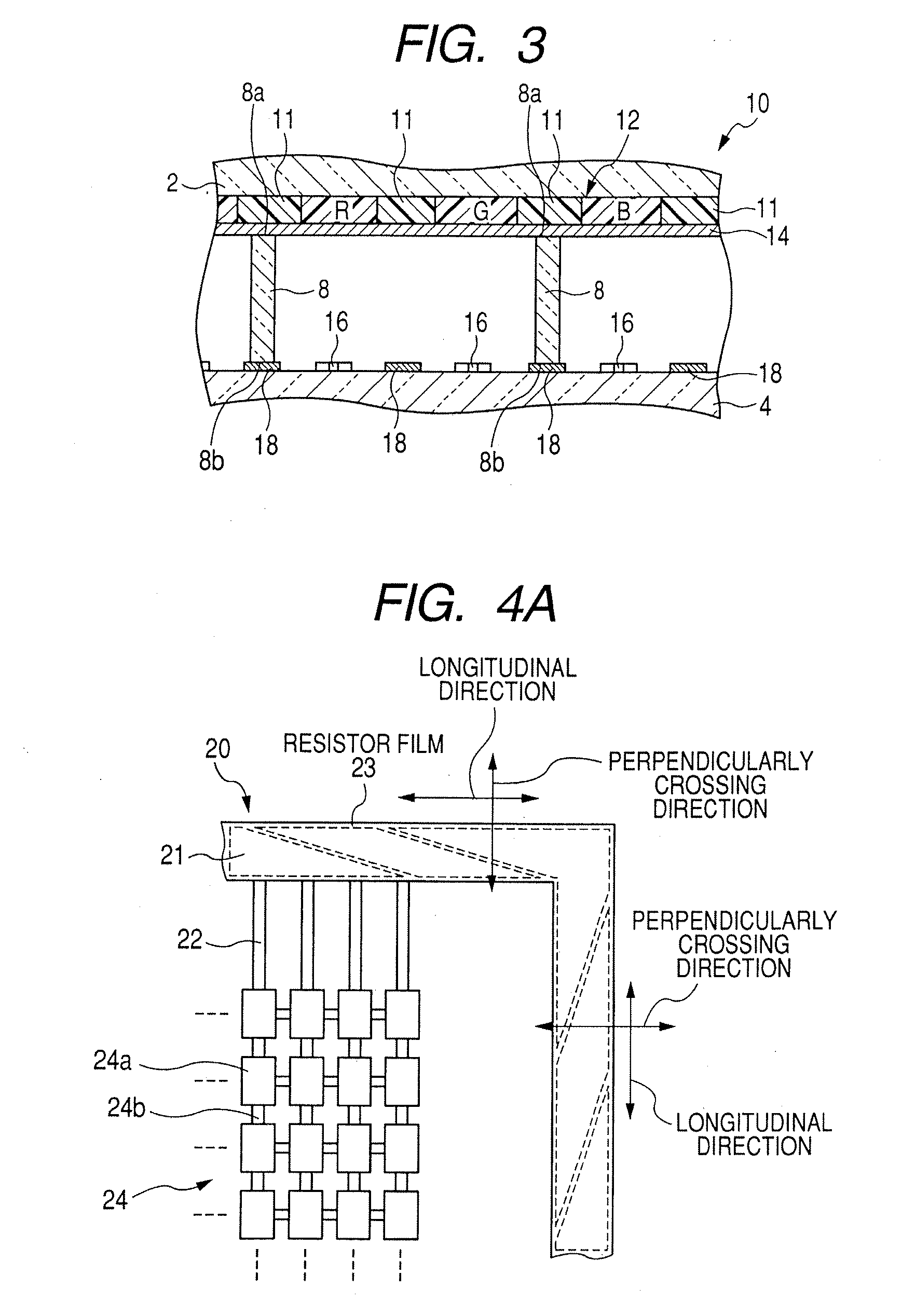

Image formation apparatus

InactiveUS20050082963A1Configuration highFulfil requirementsTelevision system detailsCathode-ray/electron-beam tube electrical connectionEquipotential surfaceElectron source

An image formation apparatus is disclosed which includes, within an enclosure configured by a pair of substrates placed face to face and an external frame placed between the substrates, an electron source placed on one of the pair of substrates, an image formation material placed on the other substrate, and spacers placed between the substrates, characterized in that the spacers and the external frame is conductive and device is provided for electrically connecting the spacers and the external frame so that the equipotential surfaces between the spacers and the external frame are quasi-parallel when driven.

Owner:CANON KK

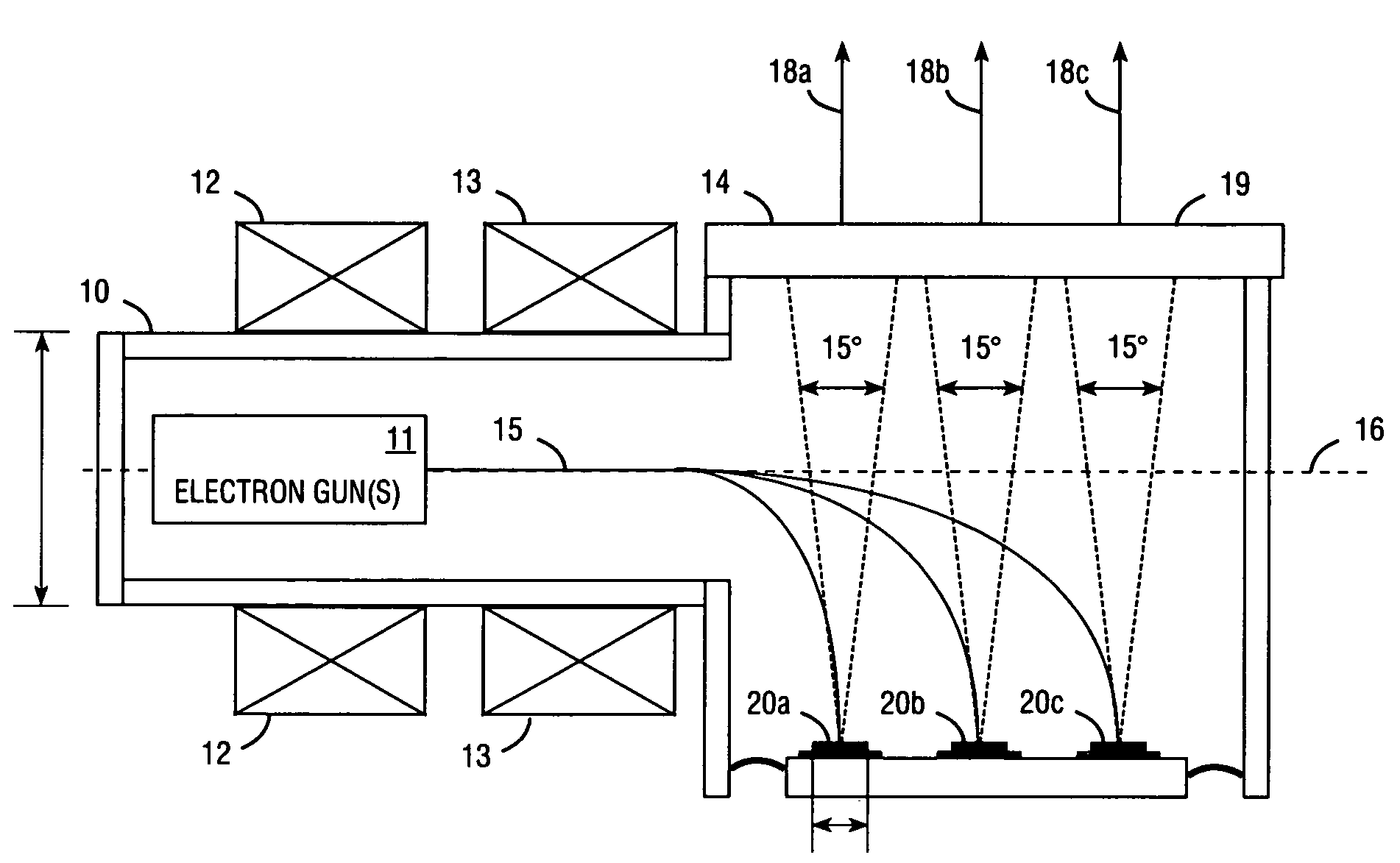

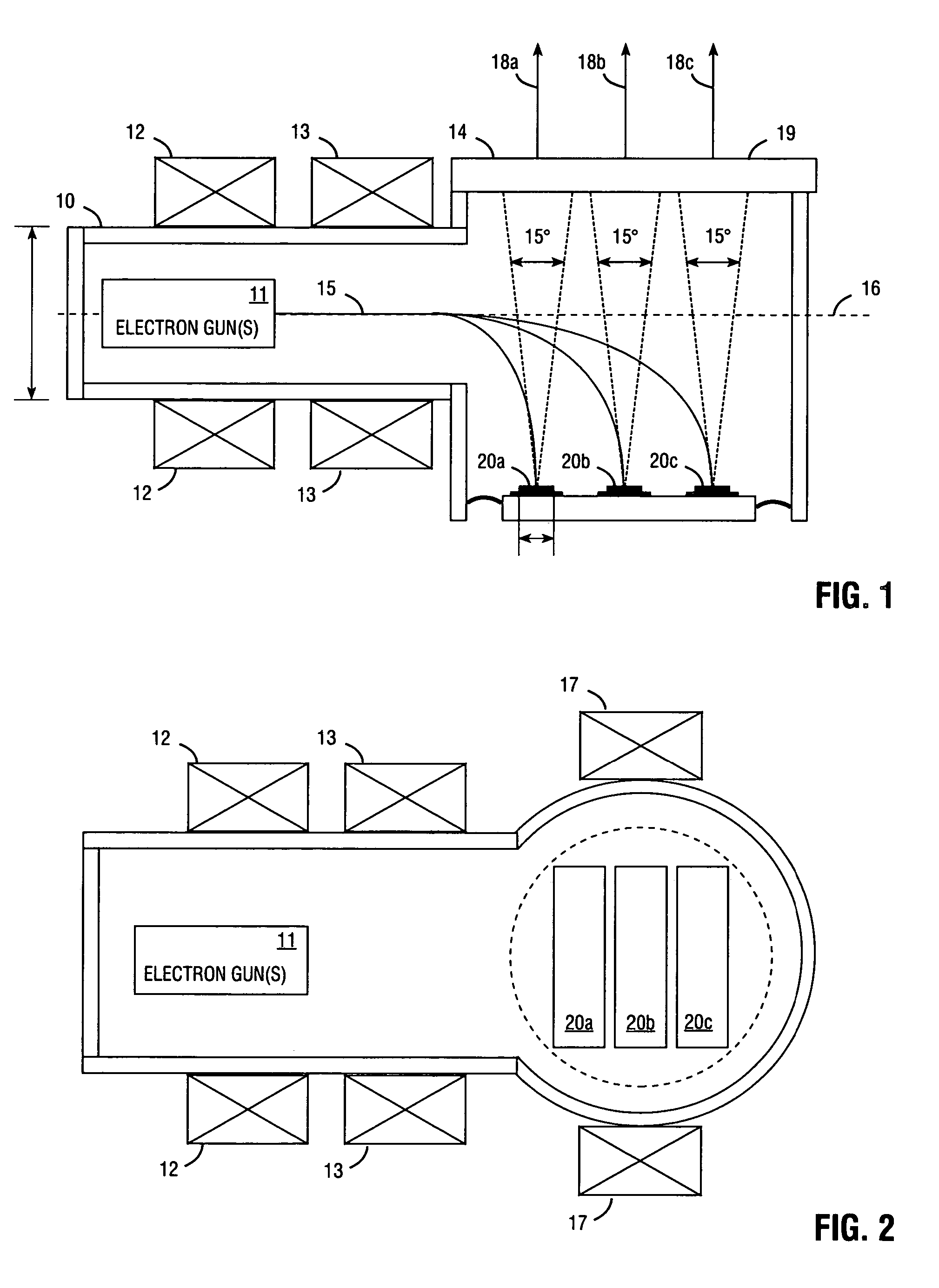

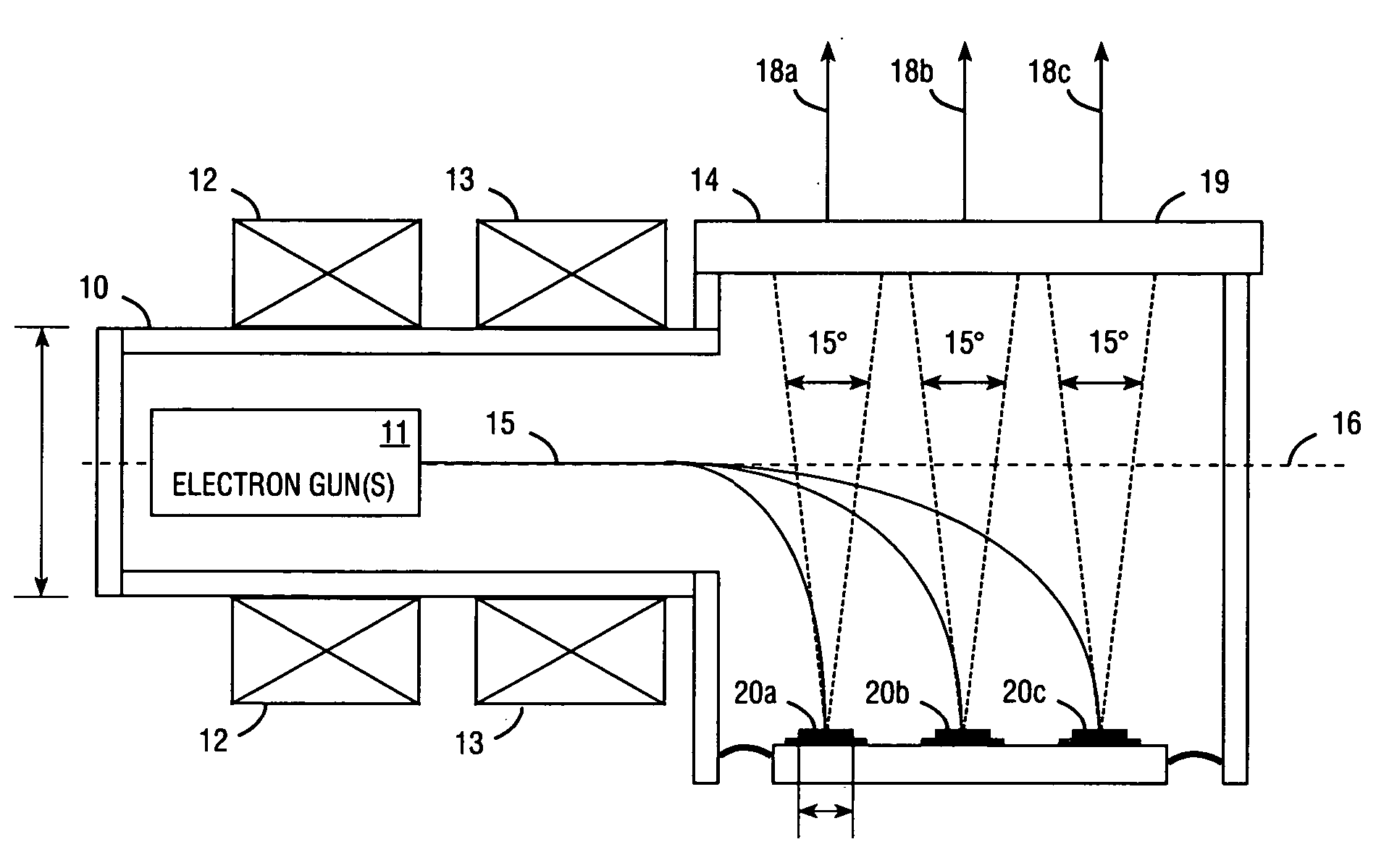

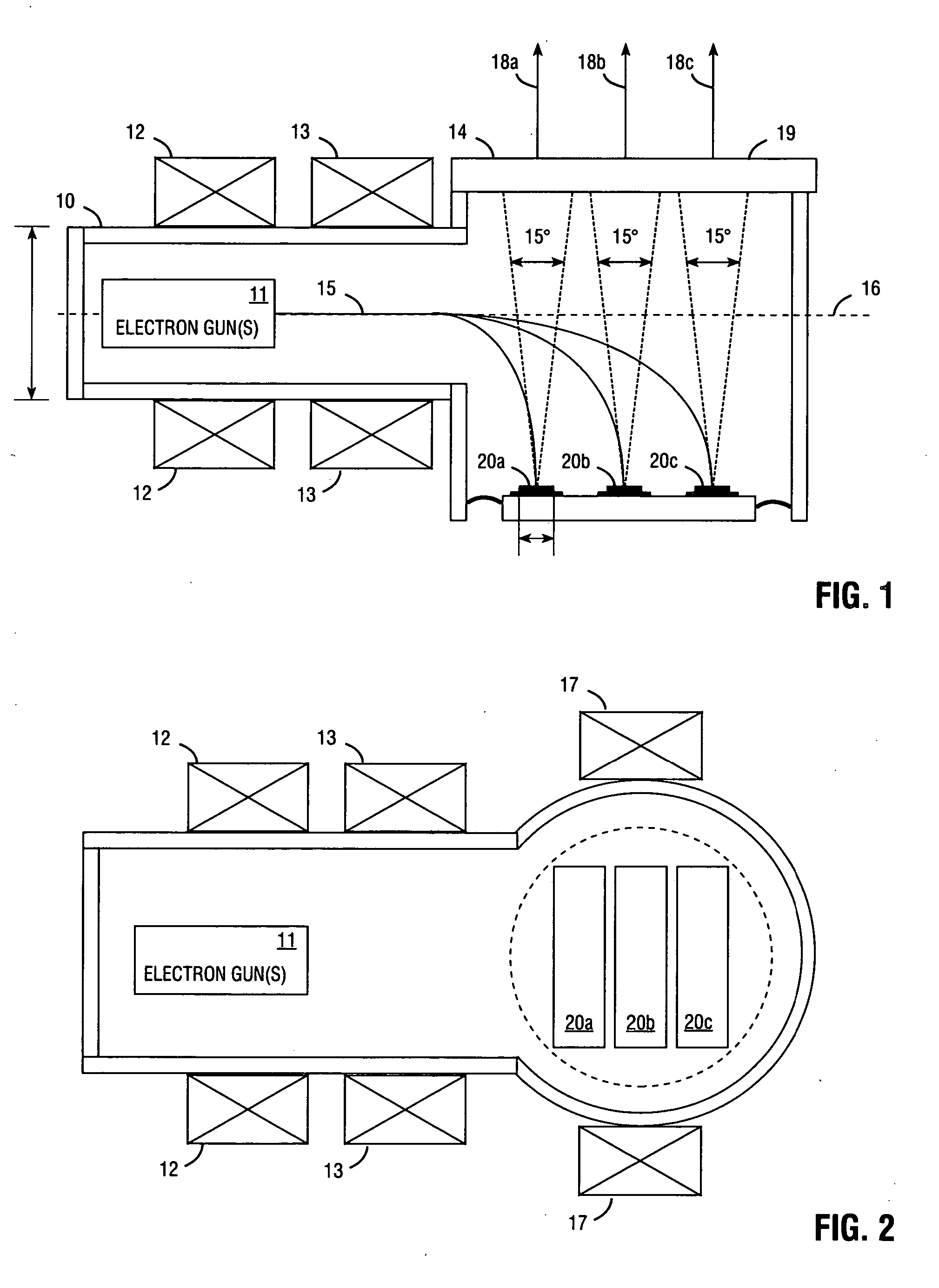

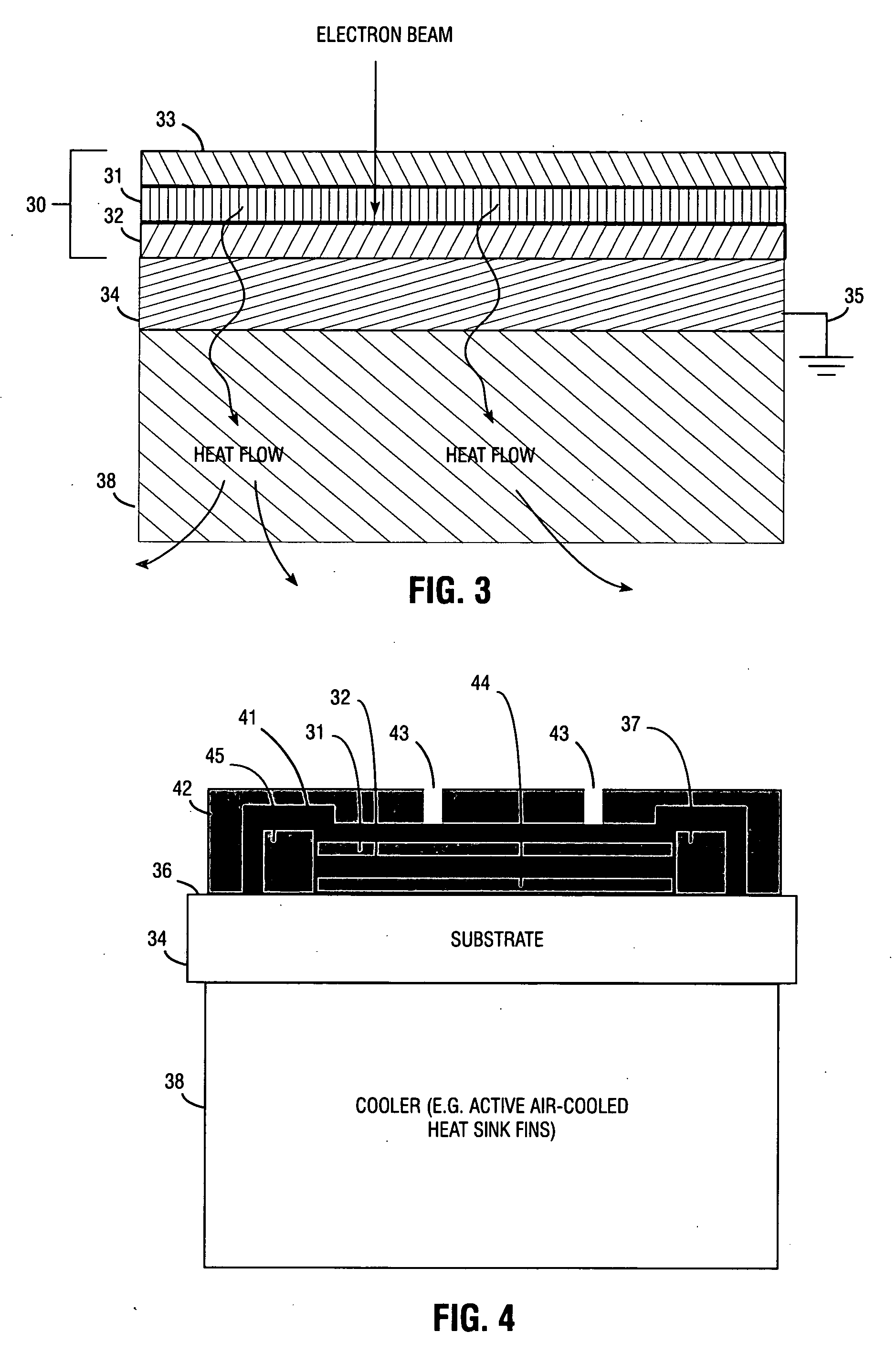

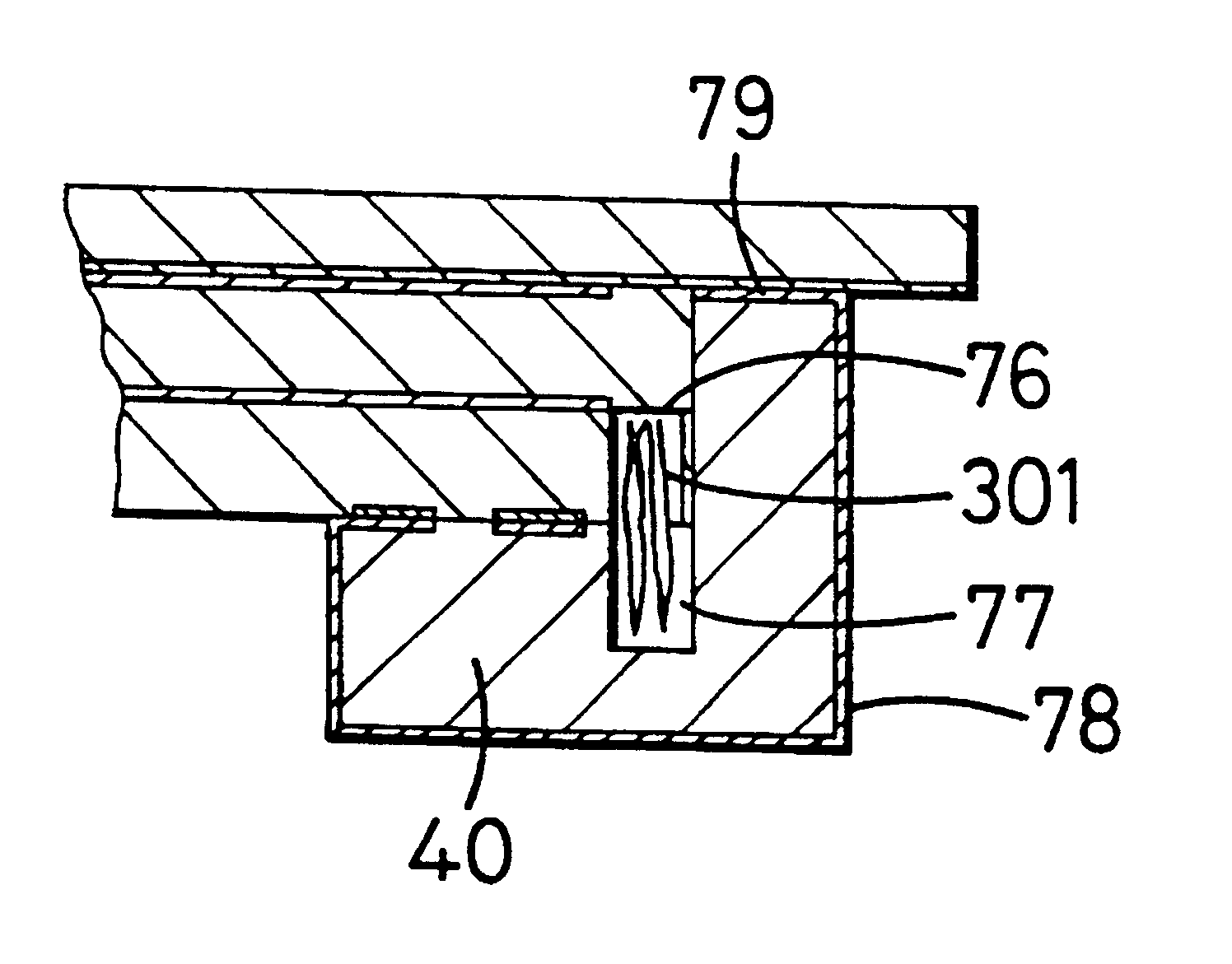

Electron beam pumped laser light source for projection television

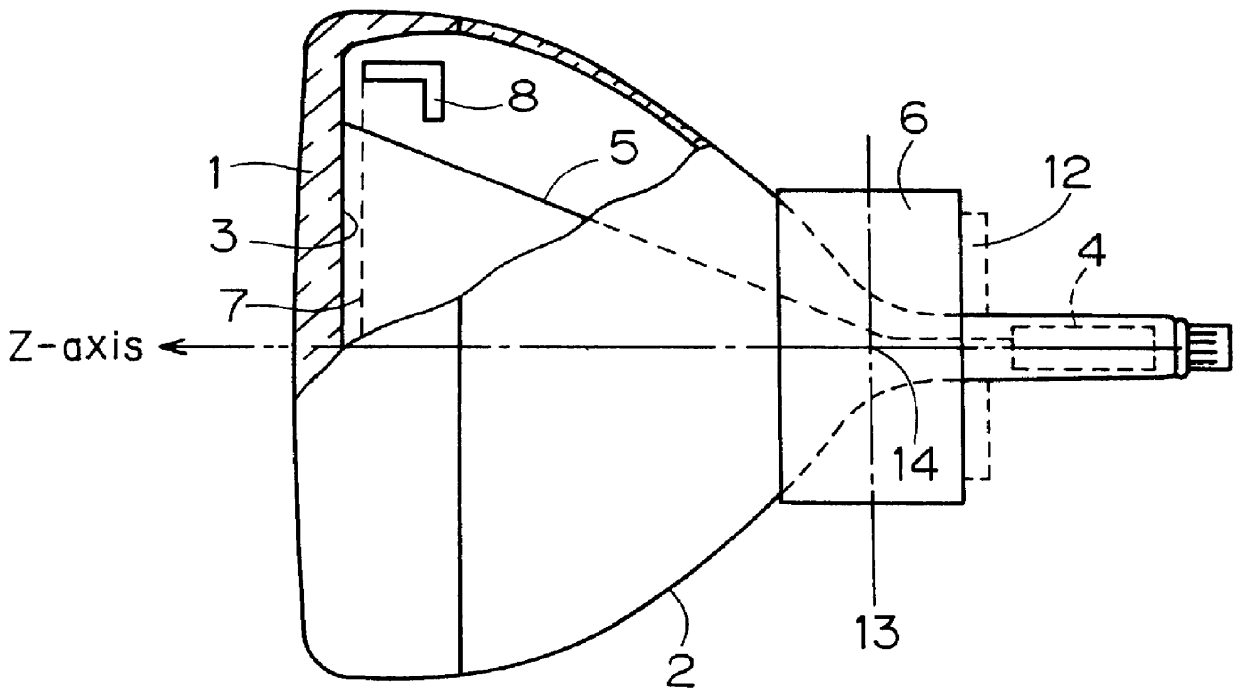

InactiveUS7309953B2Improve heat transfer performanceHigh strengthCathode-ray/electron-beam tube electrical connectionIncadescent screens/filtersContinuous lightDirect path

An electron beam pumped laser including a surface-emitting laser faceplate oriented at a non-perpendicular angle. Embodiments are described in which a bending coil bends the electron beam, or in which the faceplate is situated in the direct path of the e-beam emission but with a non-zero orientation angle. The faceplate may include a substantially opaque substrate, and an opaque heat-removing structure may be attached to the substrate to provide high heat transfer, thereby allowing high electron-beam pumping intensity and providing more light emission from a smaller package. In some embodiments the partially reflective mirror comprises a metal layer that has a plurality of openings. Multiple laser faceplates (e.g., red, green, and blue) may be placed in the same tube, to provide a continuous light source for projection television. The substrate may be connected to ground to provide an exit path for electrons from the laser gain layer.

Owner:PRINCIPIA LIGHTWORKS

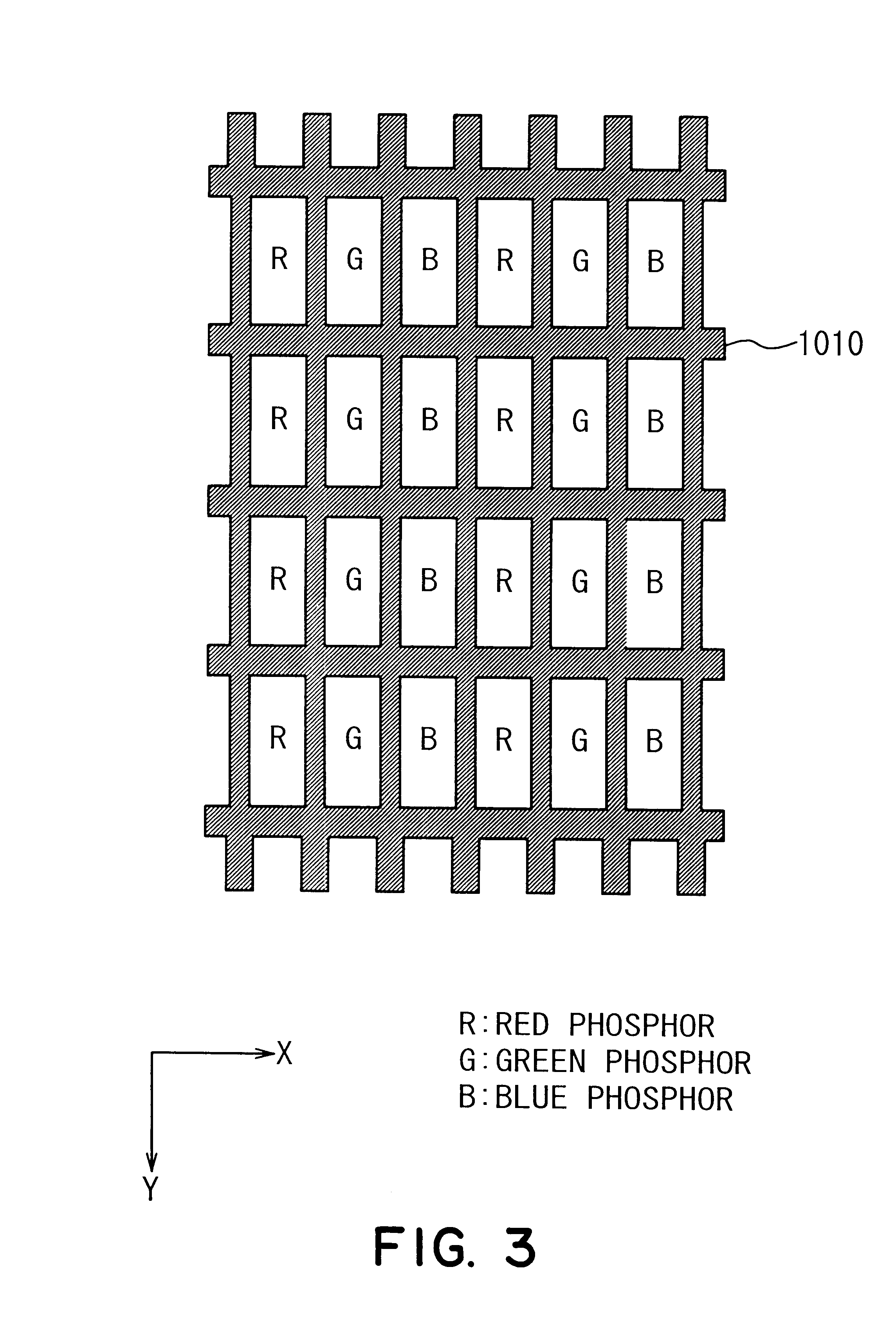

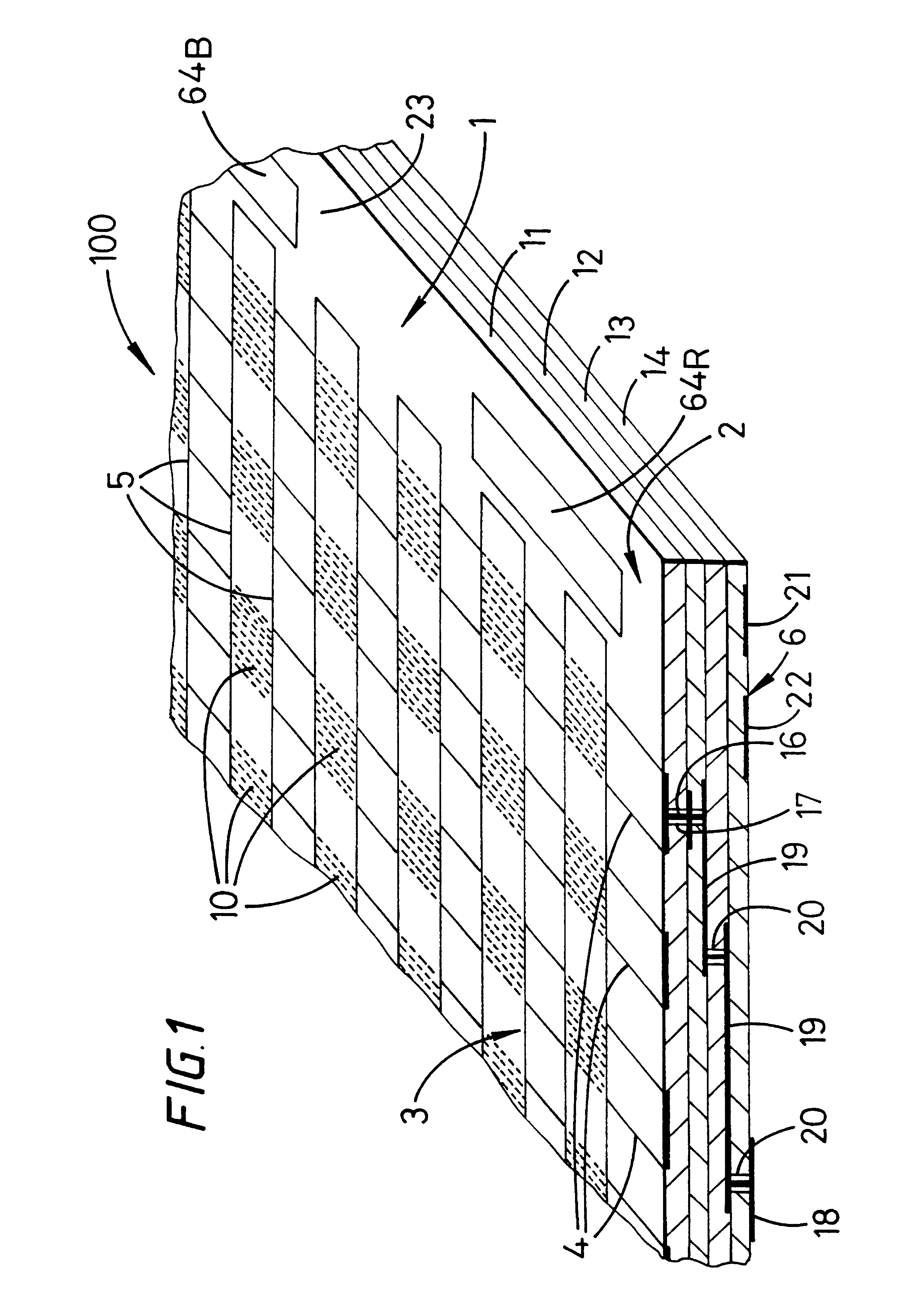

Display device of flat panel structure with emission devices of matrix array

InactiveUS6787992B2Avoid shortingUniform electric fieldCathode-ray/electron-beam tube electrical connectionNanoinformaticsDisplay deviceOptoelectronics

A display device has an emitting region constituted by a plurality of first electrodes provided on a substrate and extending in parallel, a plurality of second electrodes provided on the first electrodes and extending substantially perpendicularly to the first electrodes, and a plurality of emission sites for emitting electrons or light respectively connected to a plurality of intersections between the first and second electrodes and arranged on the substrate and has a peripheral region surrounding the emitting region on the substrate. In this display device, first and second groups of external repeating terminals for the first and second electrodes are collectively provided side by side in a part of the peripheral region.

Owner:PIONEER CORP

Image-forming apparatus and method of manufacture therefor

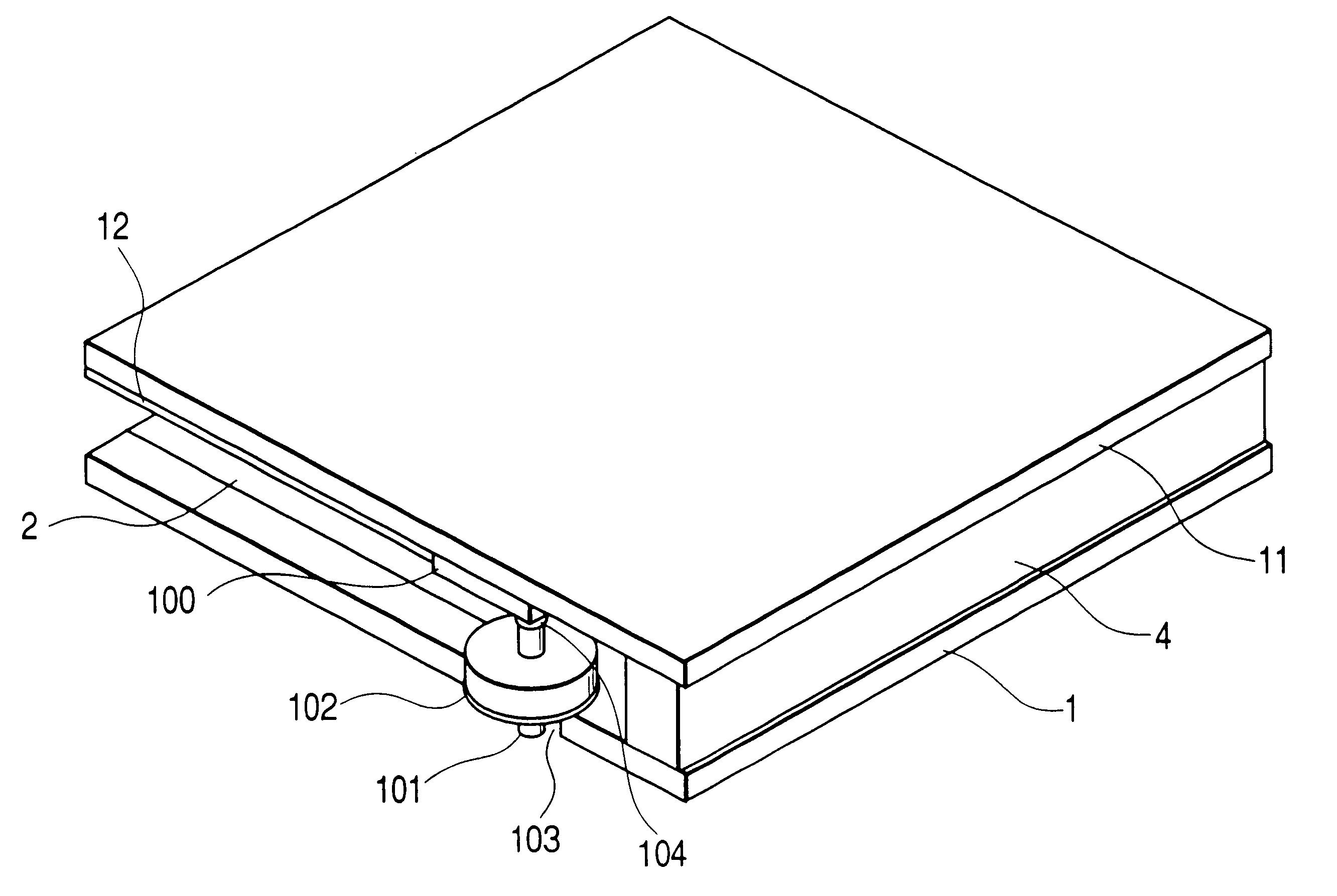

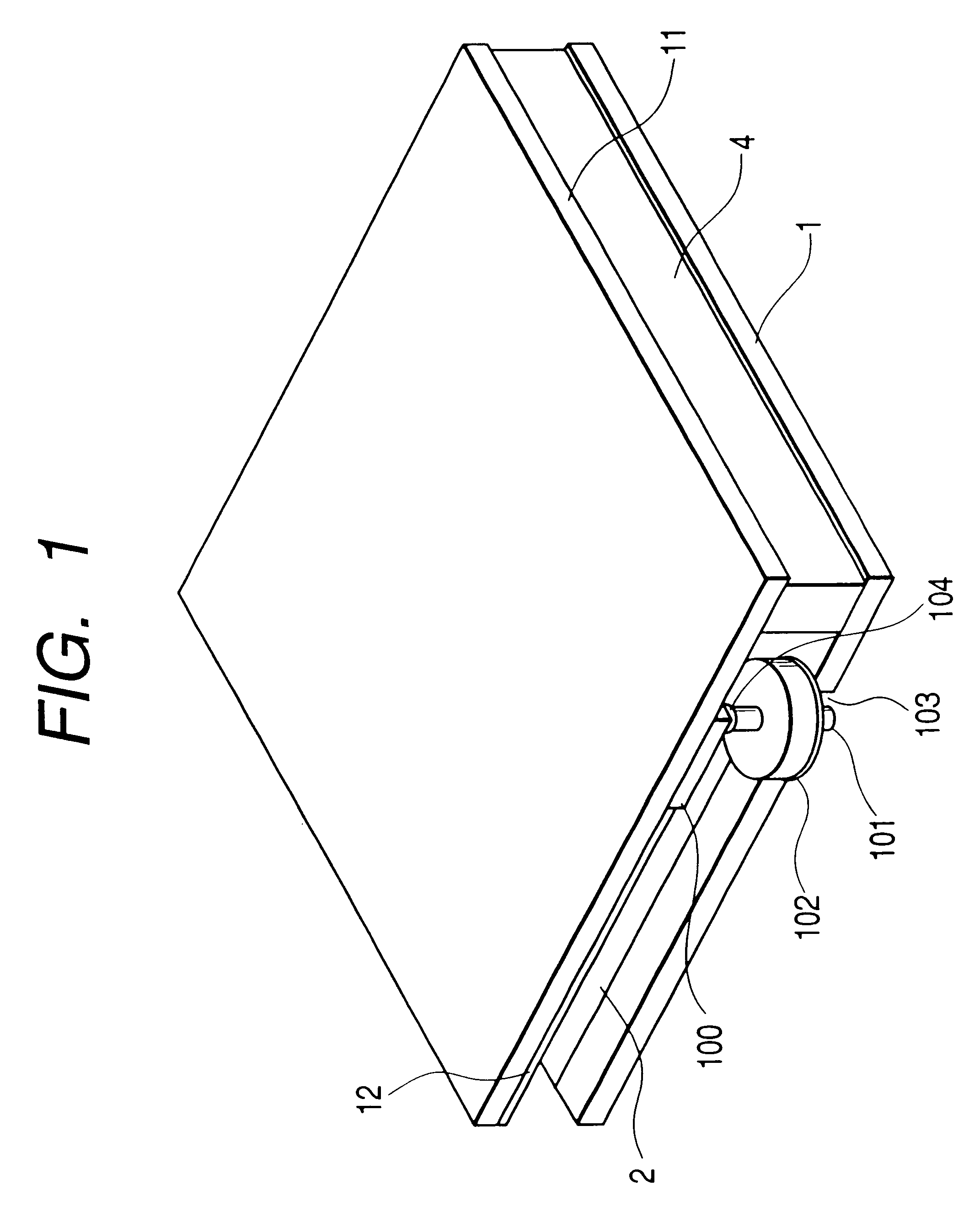

InactiveUS6528939B1Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube leading-in arrangementsElectron sourceImage formation

An image-forming apparatus includes a vacuum container having a first plate and a second plate arranged opposite to the first plate, an electron source disposed on the first plate and provided within the vacuum container, and an image-forming member disposed on the second plate within the vacuum container and irradiated with an electron emitted from the electron source. An airtight lead-in terminal has a first end in electrical contact with the image-forming member and a second end leading outside of the vacuum container through a hole in the first plate. The second end leading outside of the vacuum container is held and fixed so as not to protrude from an outer surface of the first plate.

Owner:CANON KK

Image-forming apparatus and method of manufacturing the same

InactiveUS6509691B2Cathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensElectrical resistance and conductanceElectron source

An image-forming apparatus of the present invention includes: a vacuum container constituted by disposing in opposition to each other a rear plate with an electron source formed thereon, and a face plate having an image display region provided with at least phosphors for being irradiated with electrons emitted from the electron source to form an image and anodes disposed on the phosphors; anode potential supplying means for supplying an electric potential higher than that of the electron source to the anode; at least one electroconductive member provided at a site outside of the image display region on an inner surface of the face plate; potential supplying means for supplying to the electroconductive member an electric potential at a level between a lowest electric potential of those which are applied to the electron source and an electric potential applied to the anode; first and second resistant members electrically connected between the anode and the electroconductive members, having resistances higher than that of the anode and having different resistances from each other, wherein the anode, the first resistant member, the second resistant member, and the electroconductive member are electrically connected in series.

Owner:CANON KK

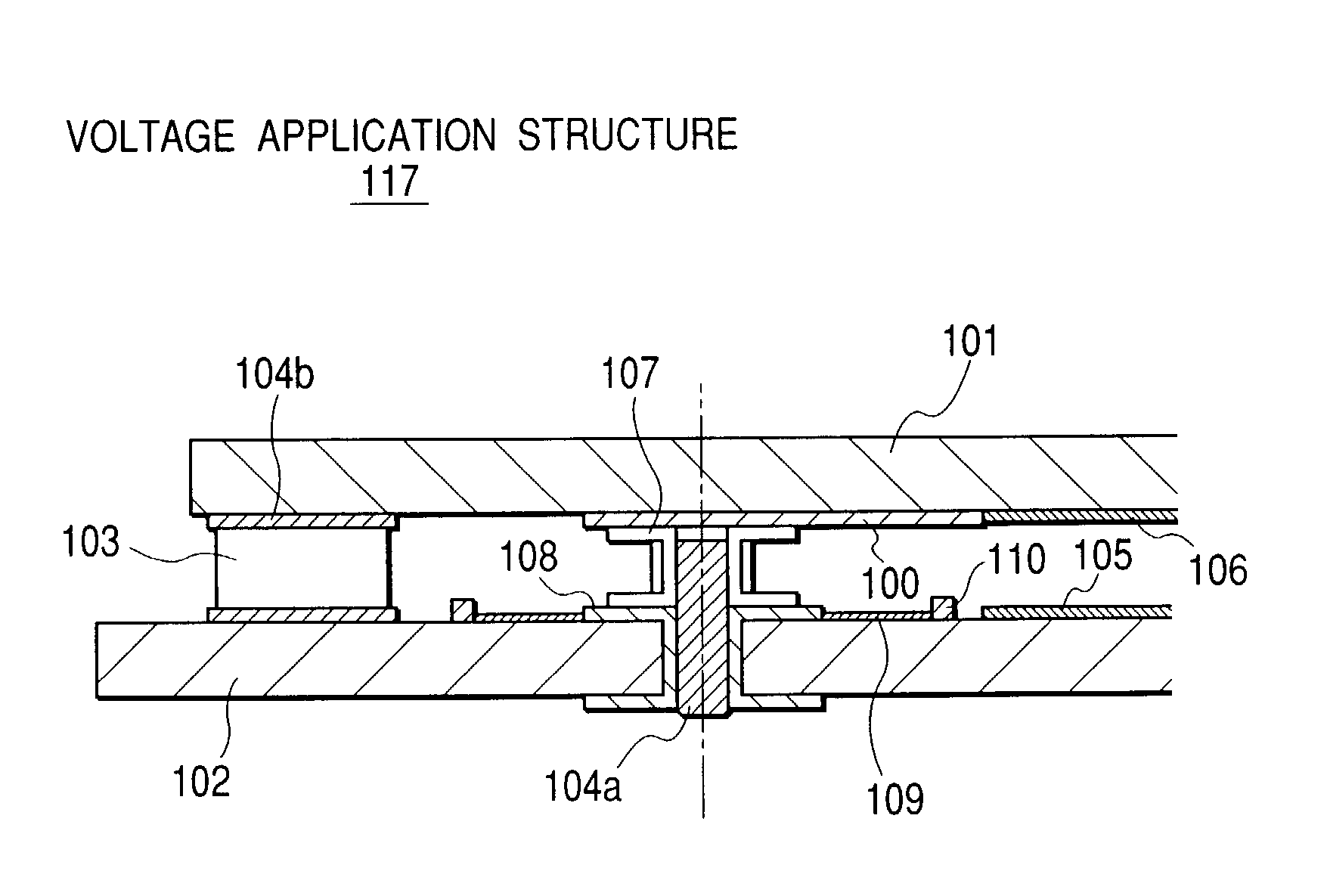

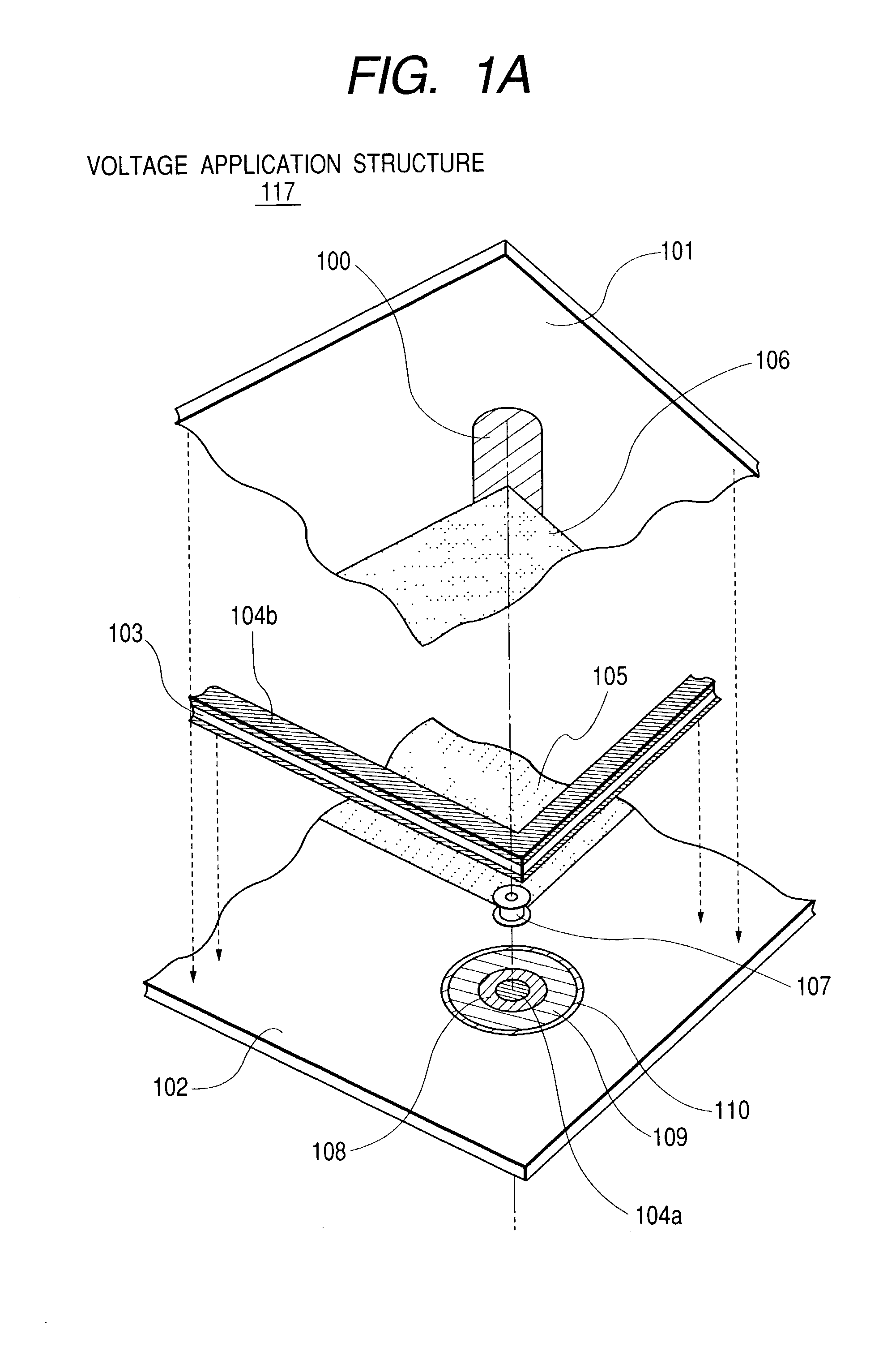

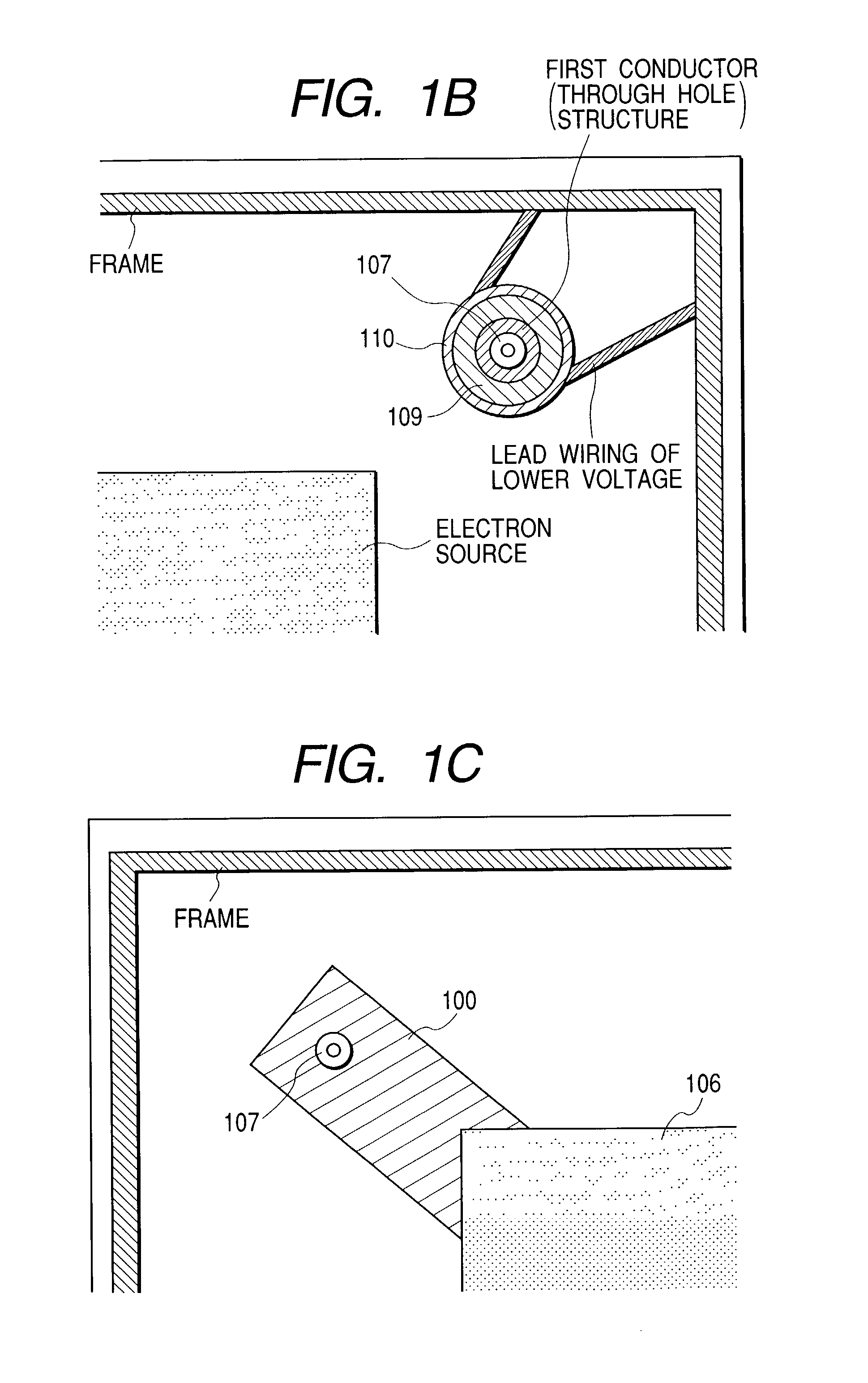

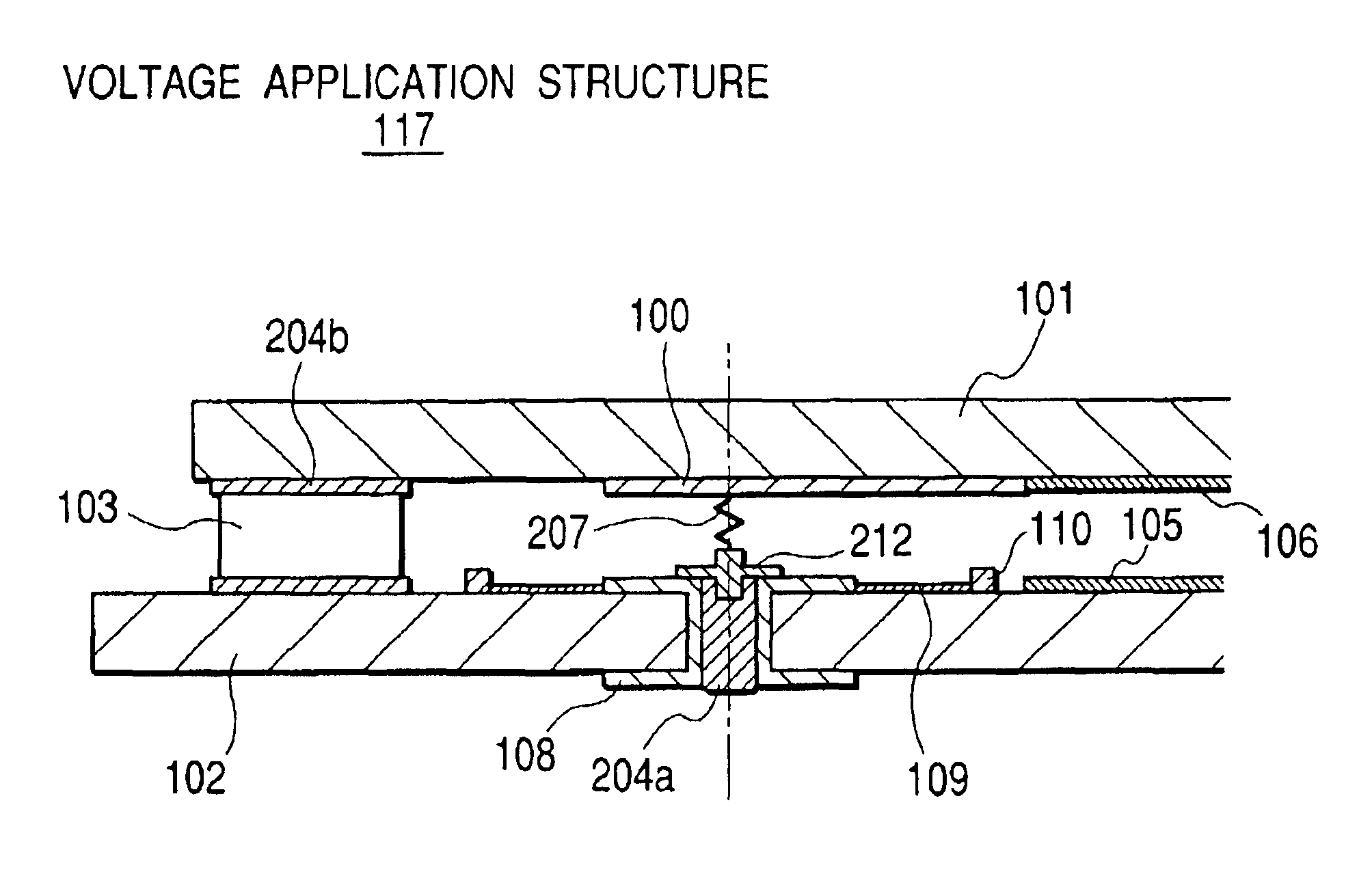

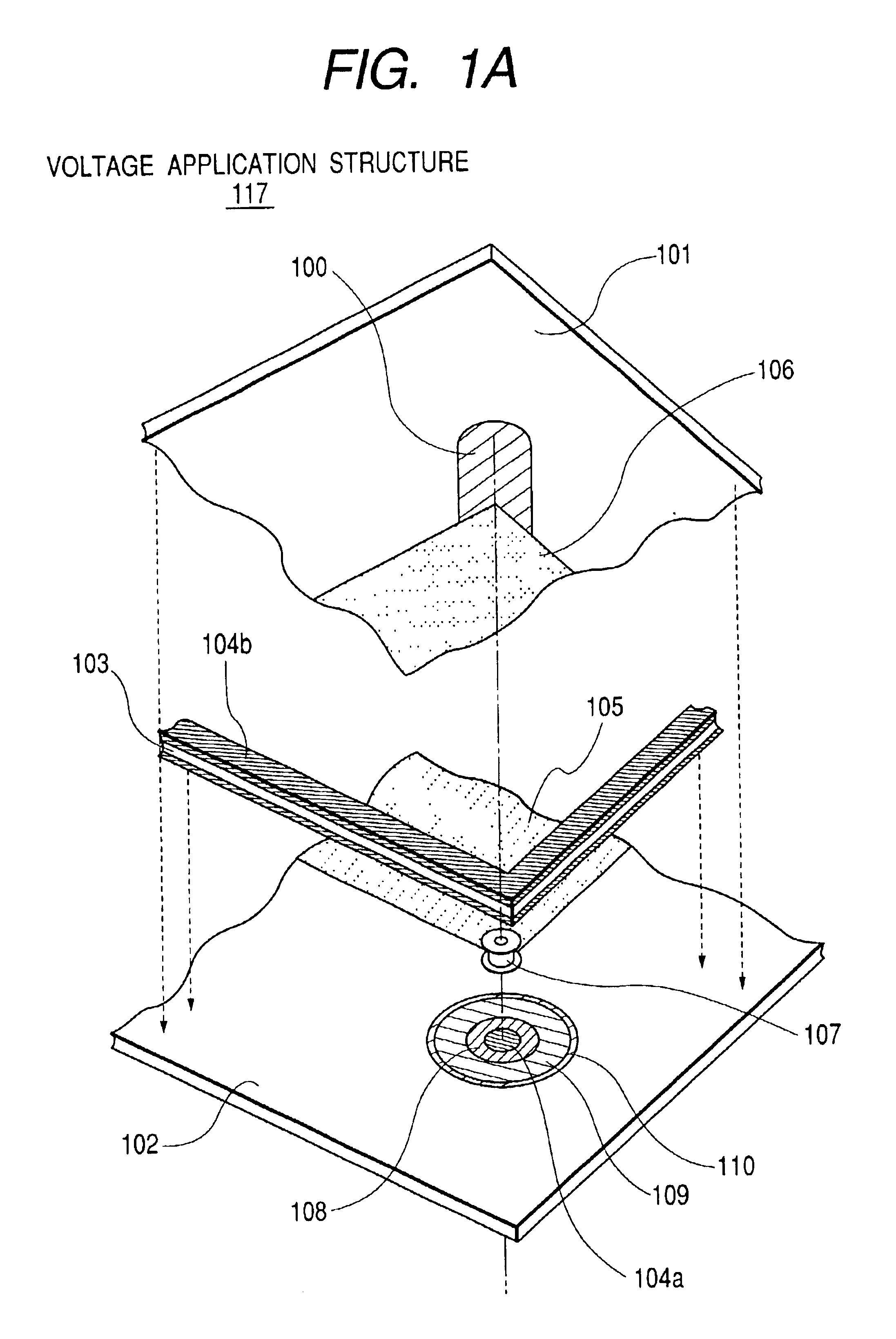

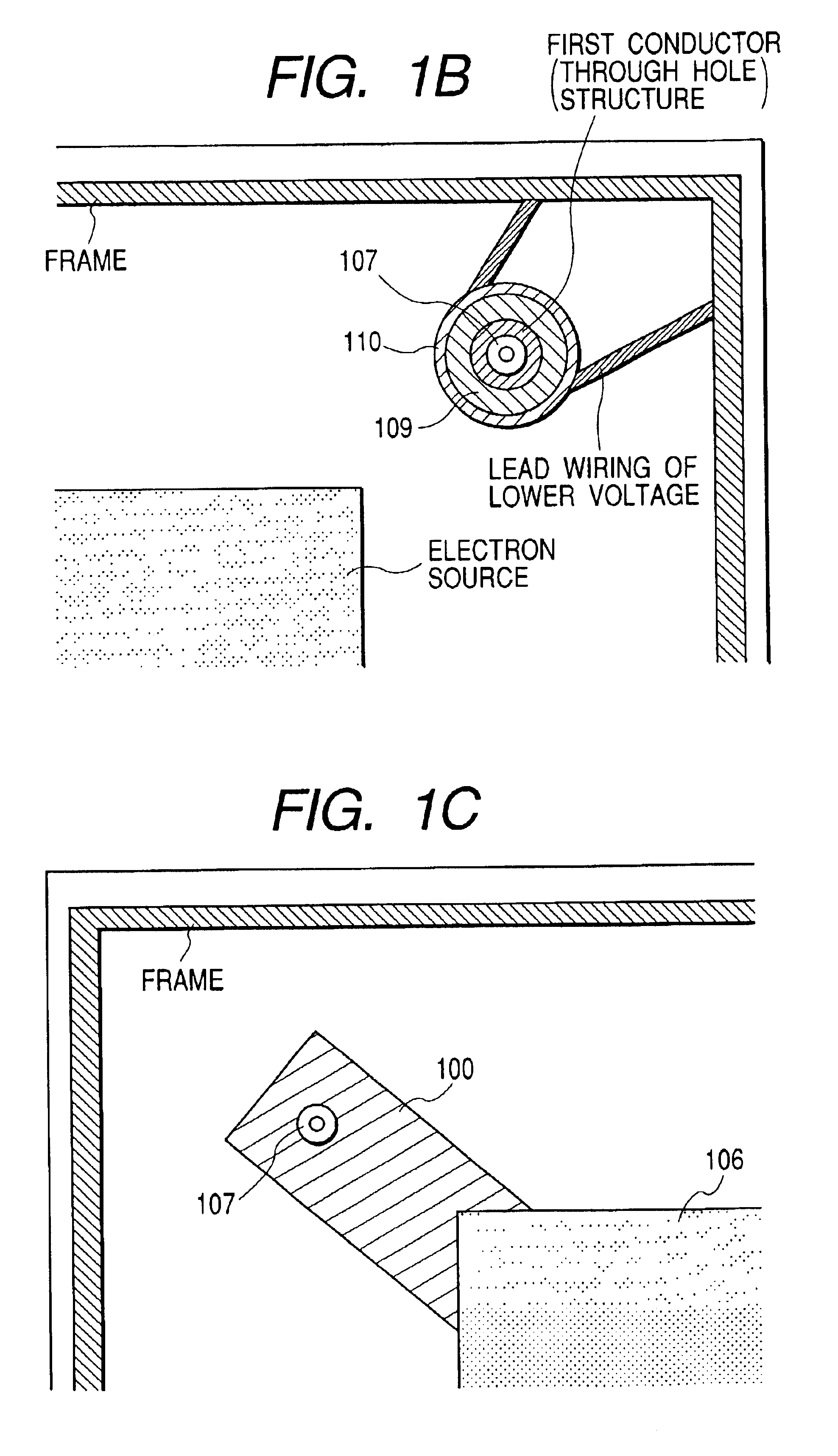

Image display apparatus having voltage application structure

InactiveUS20030025443A1Cathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensFritLow voltage

To provide a voltage application structure that is electrically stable and a display apparatus using the voltage application structure, while reducing the size, thickness, and cost of the display apparatus. A through hole structure is formed in the vicinity of a cylindrical hole established in a rear plate in advance. The through hole structure is electrically connected to lead wiring led to the outside from an anode electrode through a conductive elastic structure. A voltage to the anode electrode is applied to the through hole structure on the atmosphere side, and thus the voltage is applied to the anode electrode through the vacuum side of the through hole structure, the elastic structure, and the lead wiring. Vacuum hermeticity is maintained by filling the hole of the through hole structure with frit. Also, low-voltage wiring that is connected to the ground and regulates a potential is arranged around the through hole structure.

Owner:CANON KK

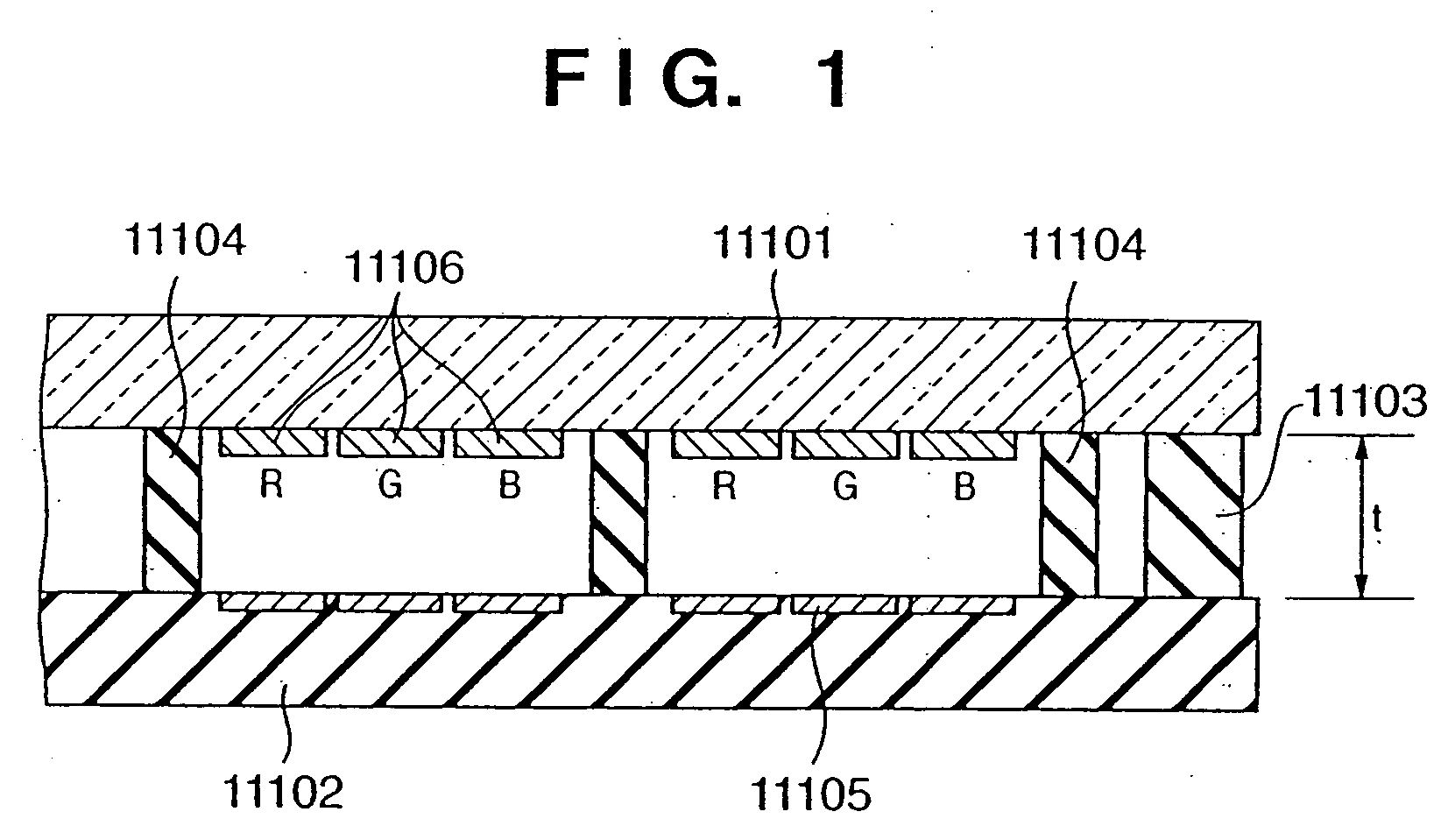

Flat panel display device and method of manufacturing the same

InactiveUS20050168129A1Increase in electrode resistance can be preventedEliminates unnecessary voltage dropCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersEngineeringFlat panel display

A flat panel display device includes a first substrate and a second substrate disposed to oppose each other with a predetermined gap therebetween. An electrode made of a transparent conductive oxide film is formed on at least one of the first substrate and the second substrate. A sealing member is disposed between the first substrate and the second substrate and bonds the first substrate and the second substrate to each other. An electrode protecting layer is formed on a portion of the electrode overlapping with the sealing member and between the sealing member and the electrode.

Owner:SAMSUNG SDI CO LTD

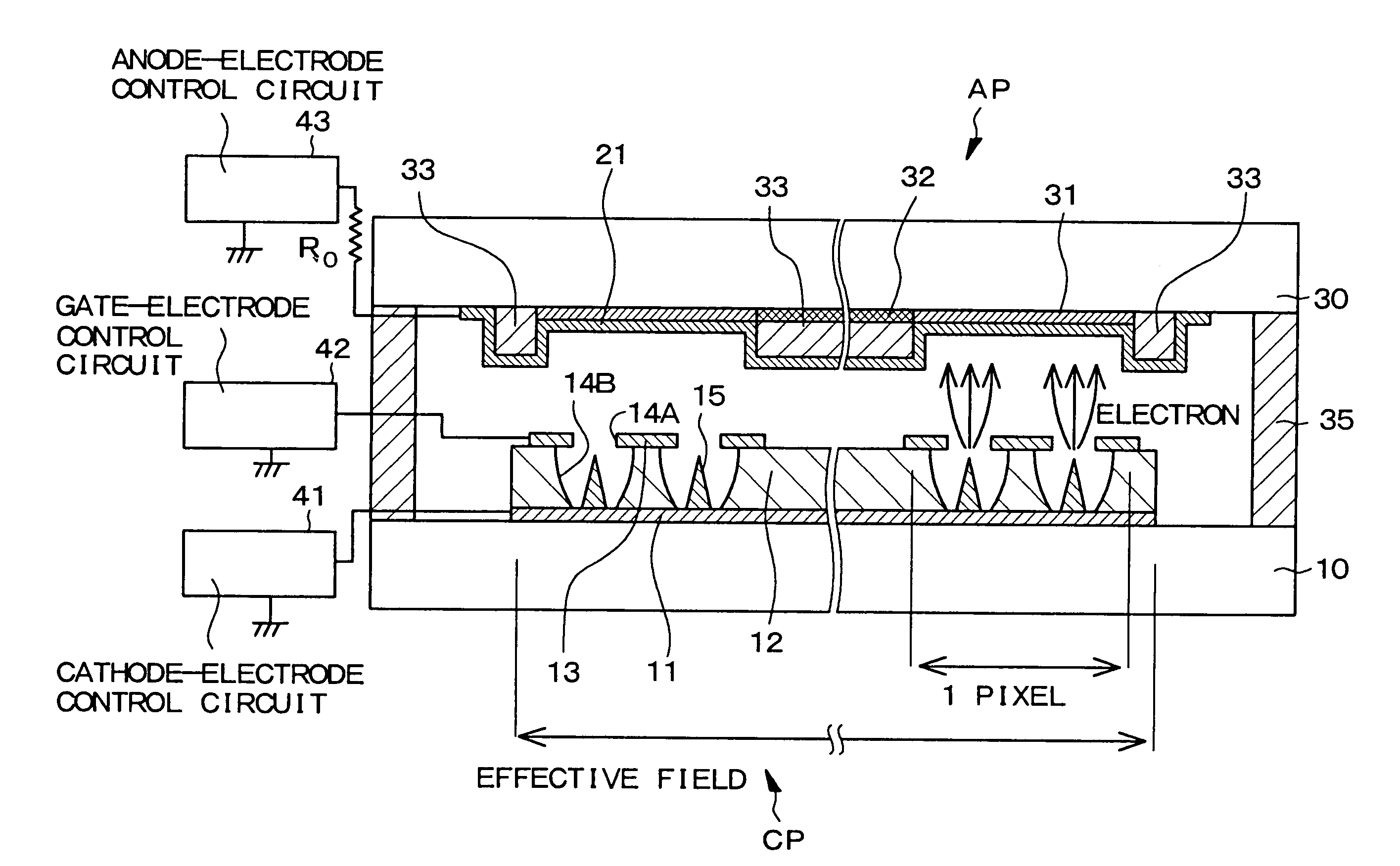

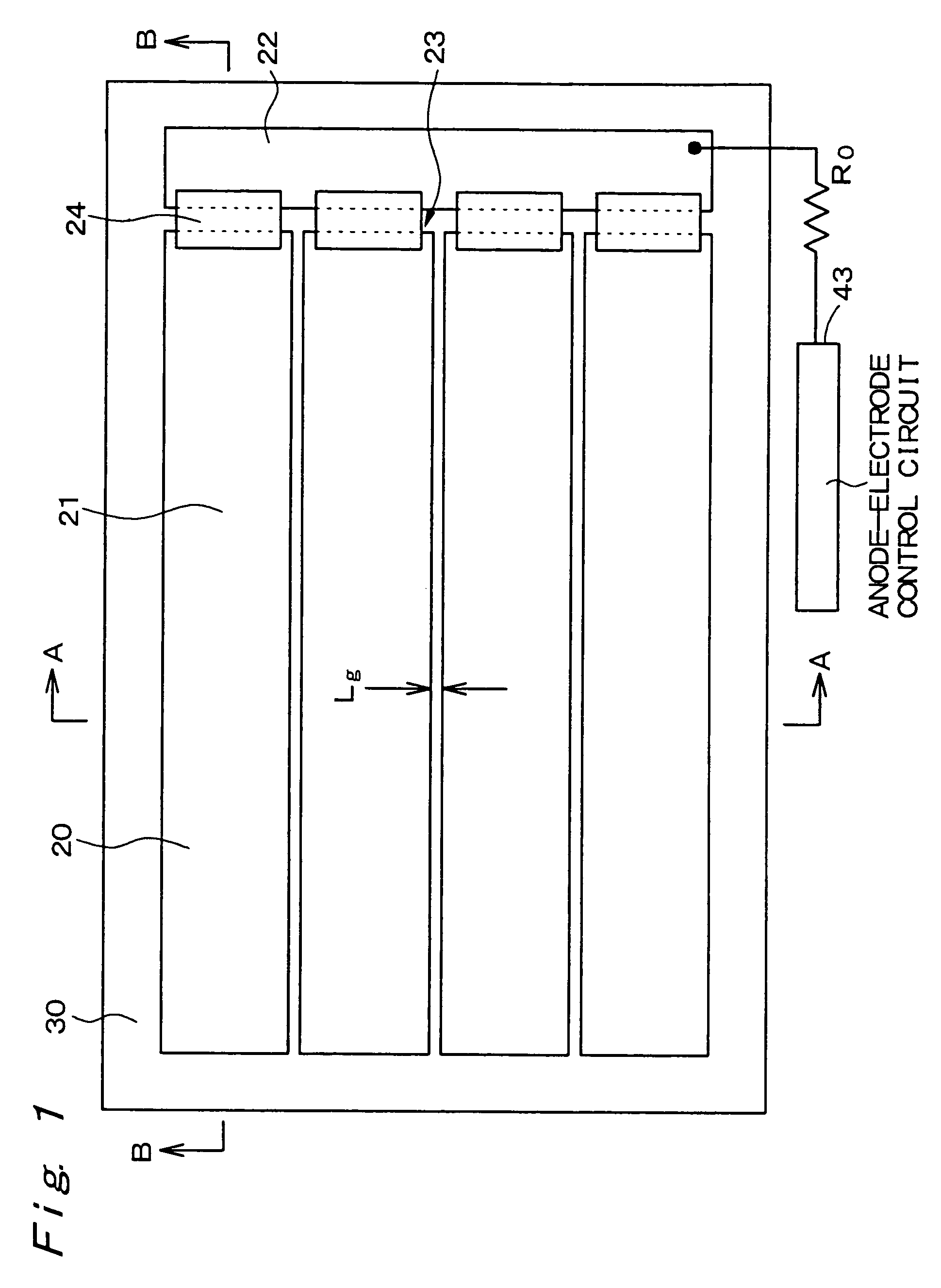

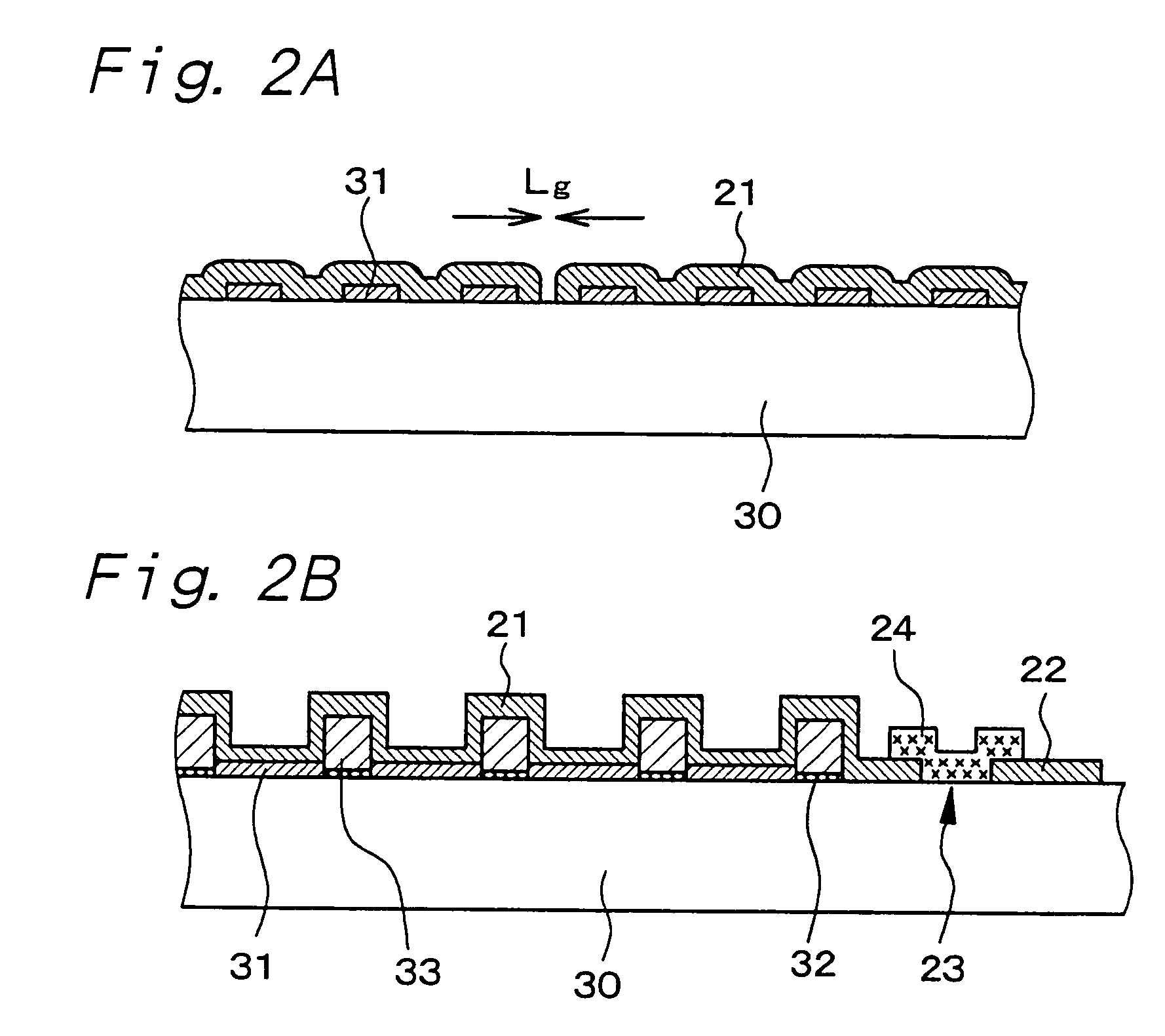

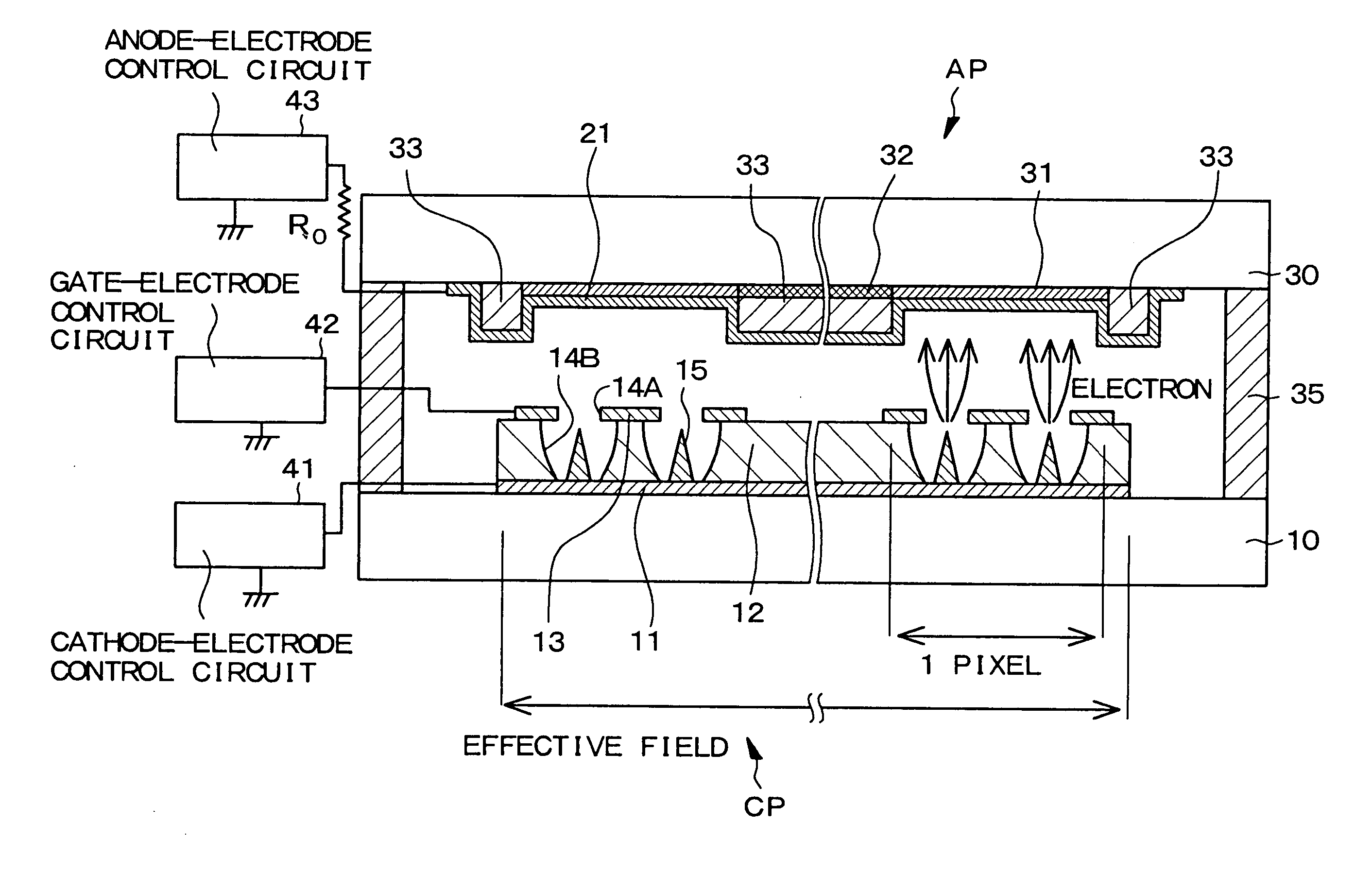

Cold cathode field emission display

InactiveUS7462979B2DischargeEasy dischargeCathode-ray/electron-beam tube electrical connectionControl electrodesField emission deviceField emission display

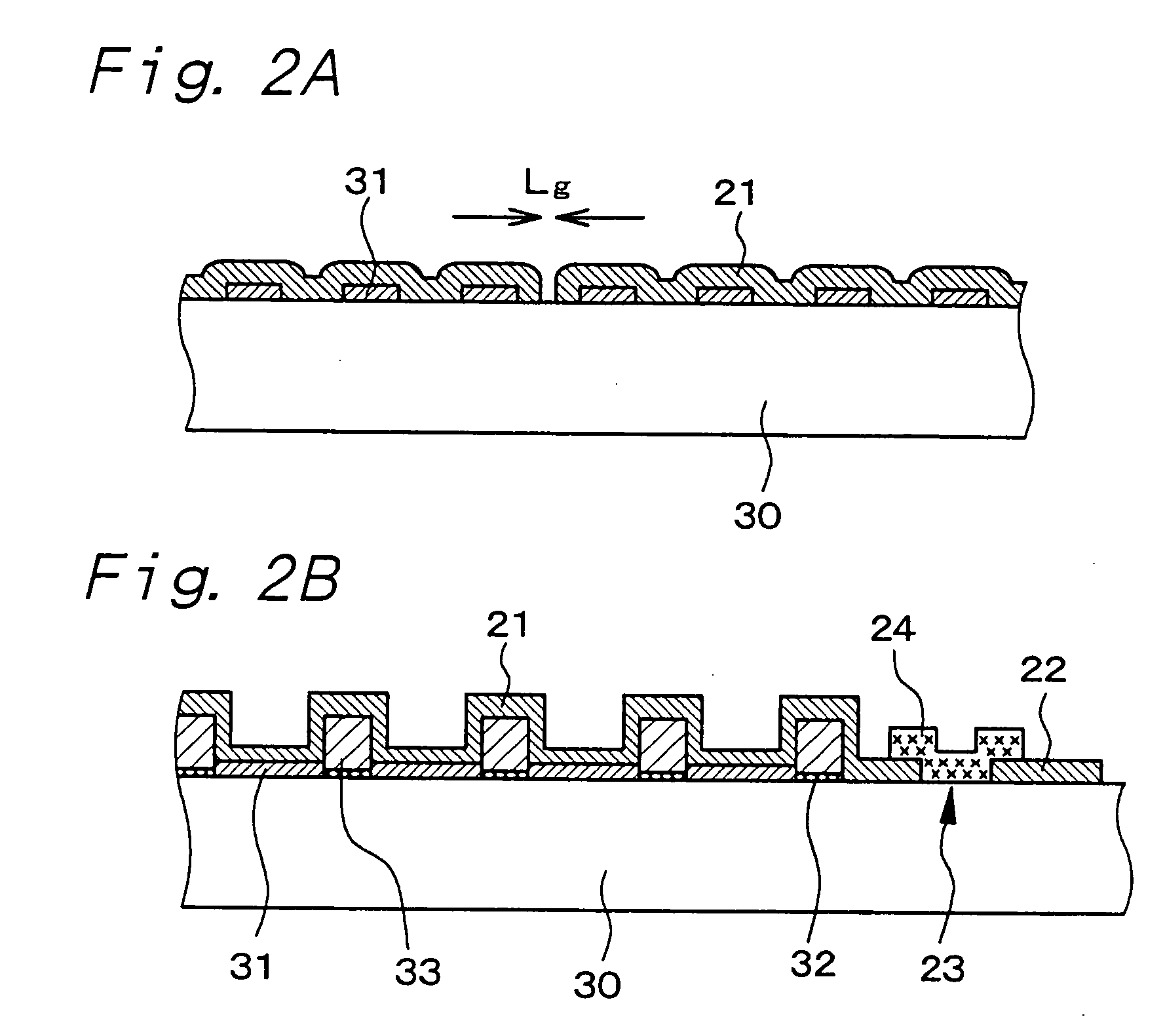

An anode electrode 20 in an anode panel constituting a cold cathode field emission display is constituted of anode electrode units 21 in the number of N (N>=2), each anode electrode unit is connected to an anode-electrode control circuit 43 through one electric supply line 22, and VA / Lg<1 (kV / mum) is satisfied in which VA (unit:kilovolt) is a voltage difference between an output voltage of the anode-electrode control circuit and a voltage applied to a cold cathode field emission device, and Lg (unit:mum) is a gap length between the anode electrode units.

Owner:SONY CORP

Electron beam pumped laser light source for projection television

InactiveUS20060163998A1Simple processImprove performanceCathode-ray/electron-beam tube electrical connectionIncadescent screens/filtersContinuous lightLaser light

An electron beam pumped laser including a surface-emitting laser faceplate oriented at a non-perpendicular angle. Embodiments are described in which a bending coil bends the electron beam, or in which the faceplate is situated in the direct path of the e-beam emission but with a non-zero orientation angle. The faceplate may include a substantially opaque substrate, and an opaque heat-removing structure may be attached to the substrate to provide high heat transfer, thereby allowing high electron-beam pumping intensity and providing more light emission from a smaller package. In some embodiments the partially reflective mirror comprises a metal layer that has a plurality of openings. Multiple laser faceplates (e.g., red, green, and blue) may be placed in the same tube, to provide a continuous light source for projection television. The substrate may be connected to ground to provide an exit path for electrons from the laser gain layer.

Owner:PRINCIPIA LIGHTWORKS

Image-forming apparatus and method of manufacturing the same

InactiveUS6853148B2Improve reliabilityReduce harmCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensElectrical resistance and conductanceElectron source

An image-forming apparatus of the present invention includes: a vacuum container constituted by disposing in opposition to each other a rear plate with an electron source formed thereon, and a face plate having an image display region provided with at least phosphors for being irradiated with electrons emitted from the electron source to form an image and anodes disposed on the phosphors; anode potential supplying means for supplying an electric potential higher than that of the electron source to the anode; at least one electroconductive member provided at a site outside of the image display region on an inner surface of the face plate; potential supplying means for supplying to the electroconductive member an electric potential at a level between a lowest electric potential of those which are applied to the electron source and an electric potential applied to the anode; first and second resistant members electrically connected between the anode and the electroconductive members, having resistances higher than that of the anode and having different resistances from each other, wherein the anode, the first resistant member, the second resistant member, and the electroconductive member are electrically connected in series.

Owner:CANON KK

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

Image display device, method of manufacturing image display device, and manufacturing apparatus

InactiveUS20050179360A1Quick and steady operationVacuum tubesCathode-ray/electron-beam tube electrical connectionEngineeringElectrical contacts

An envelope of an image display device has a front substrate and a rear substrate opposed to the front substrate, and respective peripheral edge portions of the front substrate and the rear substrate are sealed together with a sealing layer which contains an electrically conductive sealing material. An electrode for energizing the sealing layer is attached to the envelope. The electrode is formed of an electrically conductive member, is in electrical contact with the sealing layer, and has a conduction portion exposed to the outside.

Owner:KK TOSHIBA

Flat panel display device

InactiveUS20020117963A1Avoid breakingAvoid shortingCathode-ray/electron-beam tube electrical connectionNanoinformaticsDisplay deviceFlat panel display

A display device has an emitting region constituted by a plurality of first electrodes provided on a substrate and extending in parallel, a plurality of second electrodes provided on the first electrodes and extending substantially perpendicularly to the first electrodes, and a plurality of emission sites for emitting electrons or light respectively connected to a plurality of intersections between the first and second electrodes and arranged on the substrate and has a peripheral region surrounding the emitting region on the substrate. In this display device, first and second groups of external repeating terminals for the first and second electrodes are collectively provided side by side in a part of the peripheral region.

Owner:PIONEER CORP

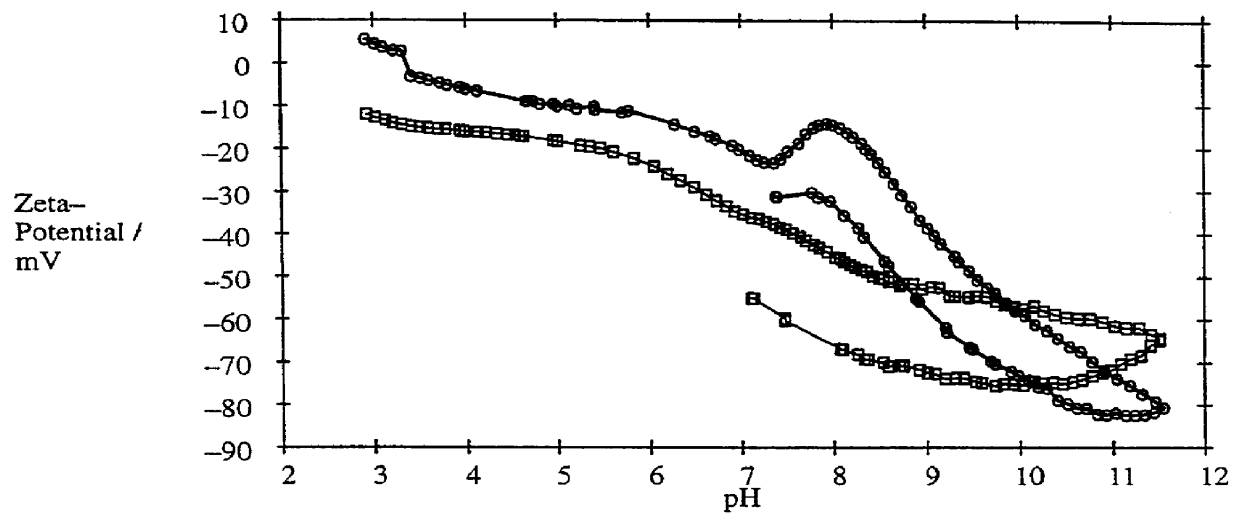

Phosphor composition with a coating of colloidal SiO2 particles and an oxygen compound of magnesium, calcium, barium, zinc, or aluminum

InactiveUS6013979AOptimal brightness and definition and adhesionMinimum level of color impurityCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersFluorescenceOxygen compound

The invention relates to a display screen having a phosphor layer of a phosphor composition of a phosphor coated with an oxygen compound of one of the elements magnesium, calcium, barium, zinc and aluminium, and with colloidal SiO2 having an average particle size of 70 nm< / =d< / =130 nm. The invention further relates to a phosphor composition of a phosphor coated with an oxygen compound of one of the elements magnesium, calcium, barium, zinc and aluminium, and with colloidal SiO2 having an average particle size of 70< / =d< / =130 nm, and to a method of manufacturing the phosphor composition.

Owner:U S PHILIPS CORP

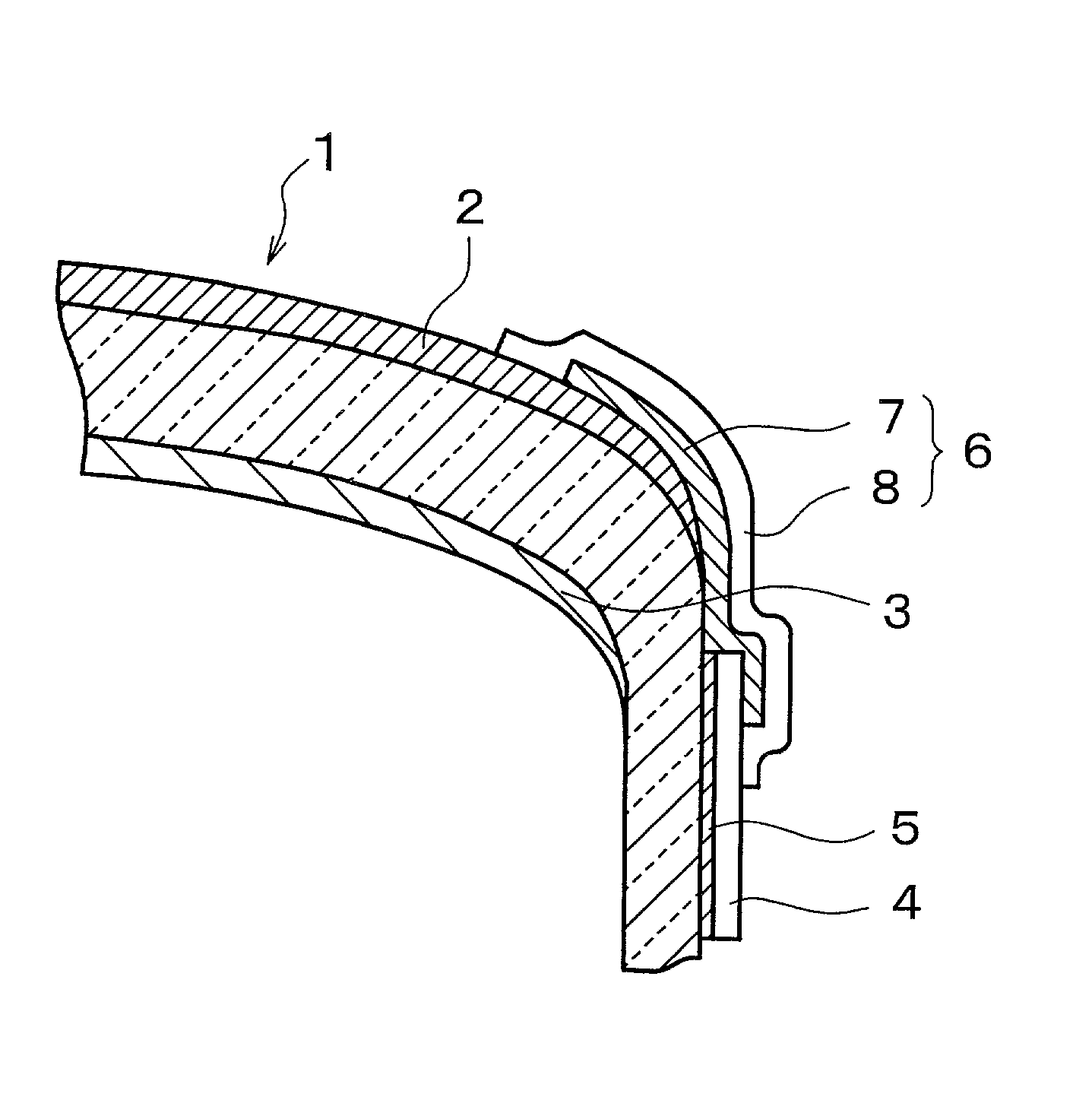

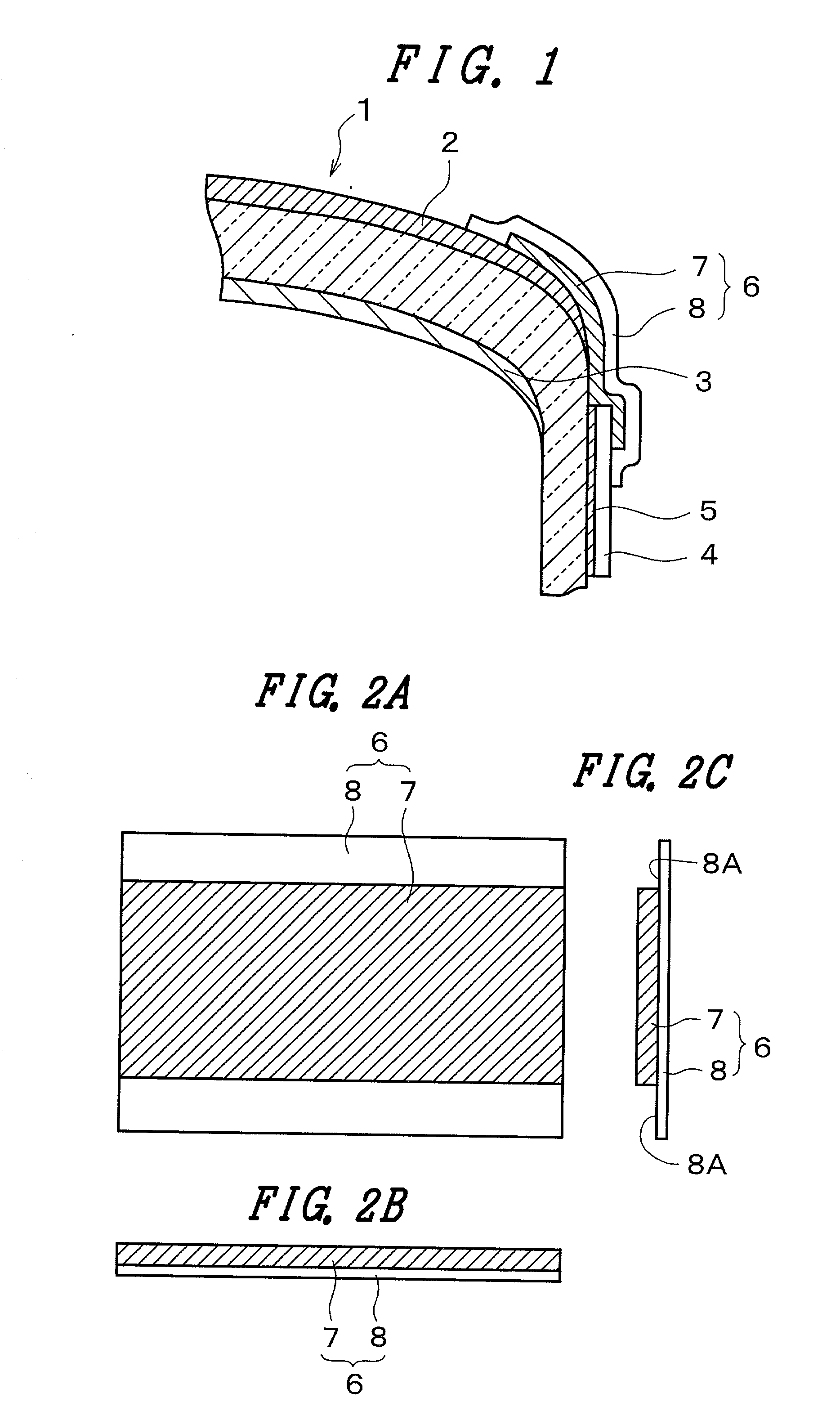

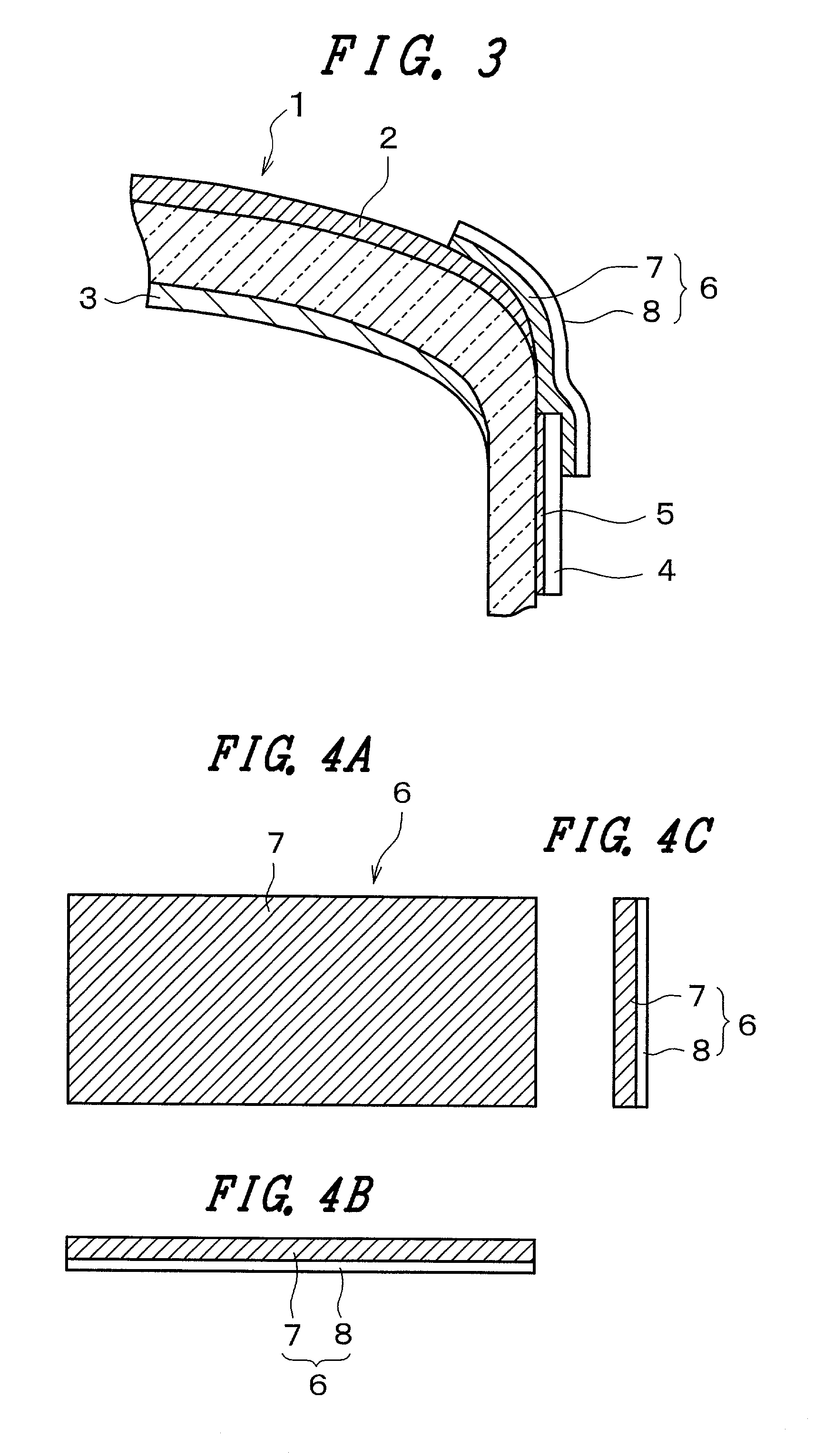

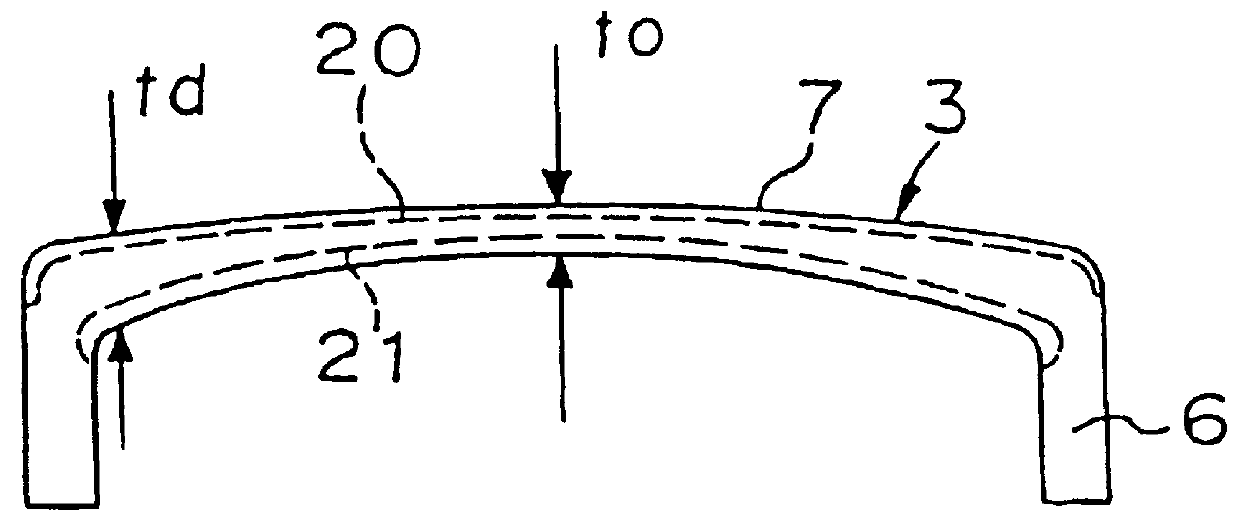

Glass bulb for a cathode ray and a method of producing the same

InactiveUSRE36838E1Inhibit the development of cracksUniform wall thicknessCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDiagonalEngineering

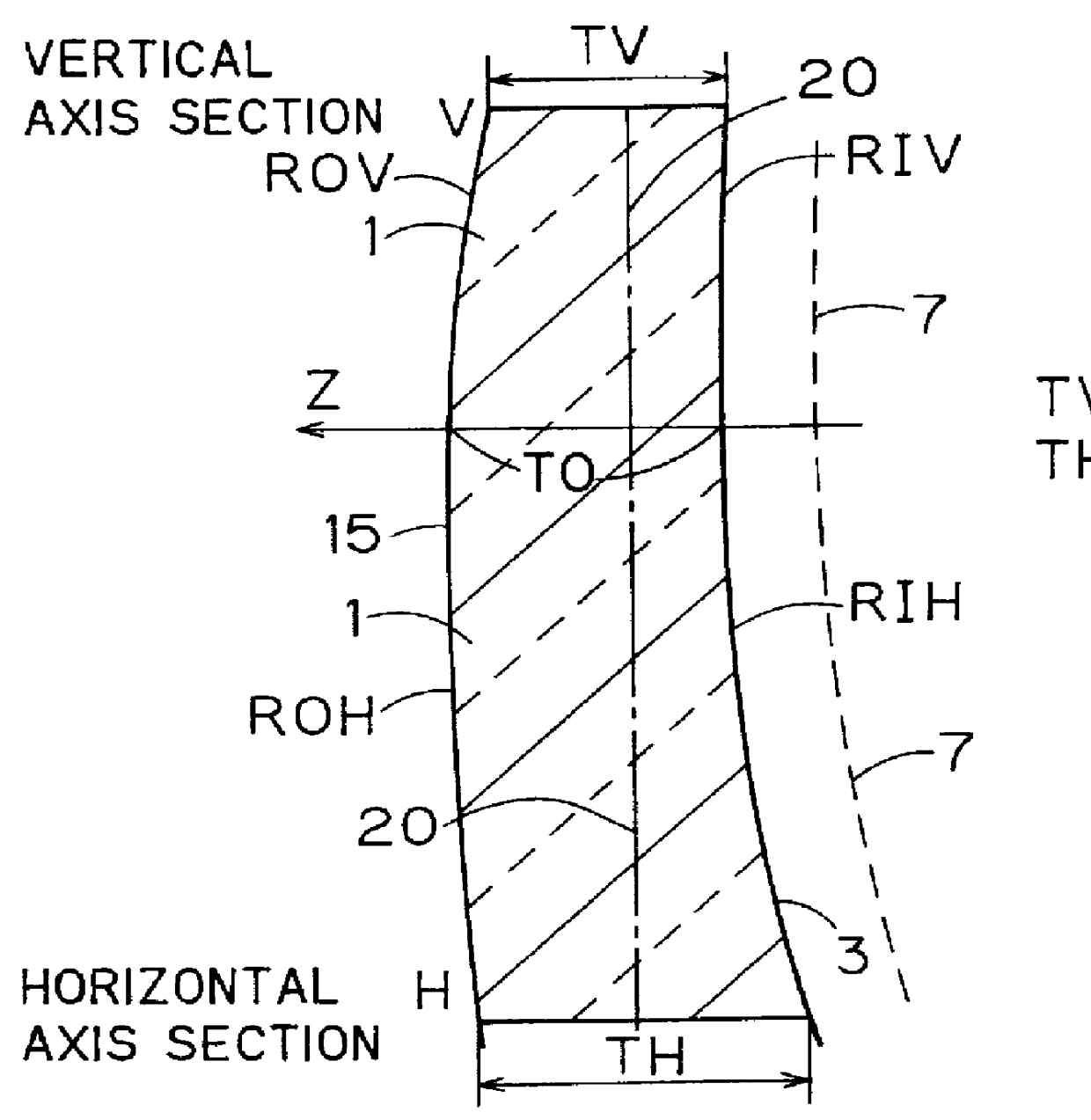

A glass panel 3 for a glass tube for a cathode ray tube has a flat panel face portion 7 and a reduced thickness while maintaining a sufficient strength without increasing a difference of brightness, and with less shrinking deformation due to the cooling and solidification of the glass panel. Compressive stress layers 20, 21 having a thickness of to / 10 or more are formed in outer and inner surfaces of the face portion 7 of the glass panel 3 respectively. The relation to the wall thickness td of the central portion of the face portion to the wall thickness to of a portion near an edge portion on a diagonal line is 1.0< / =td / to< / =1.2. Compressive stress layers 22, 23 are formed in outer and inner surfaces of a skirt portion 6 wherein the compressive stress value of the face portion 7 is larger than the compressive stress value of the skirt portion, and the compressive stress value of the outer surface 20 of the face portion is larger than that of the inner surface 21.

Owner:ASAHI GLASS CO LTD

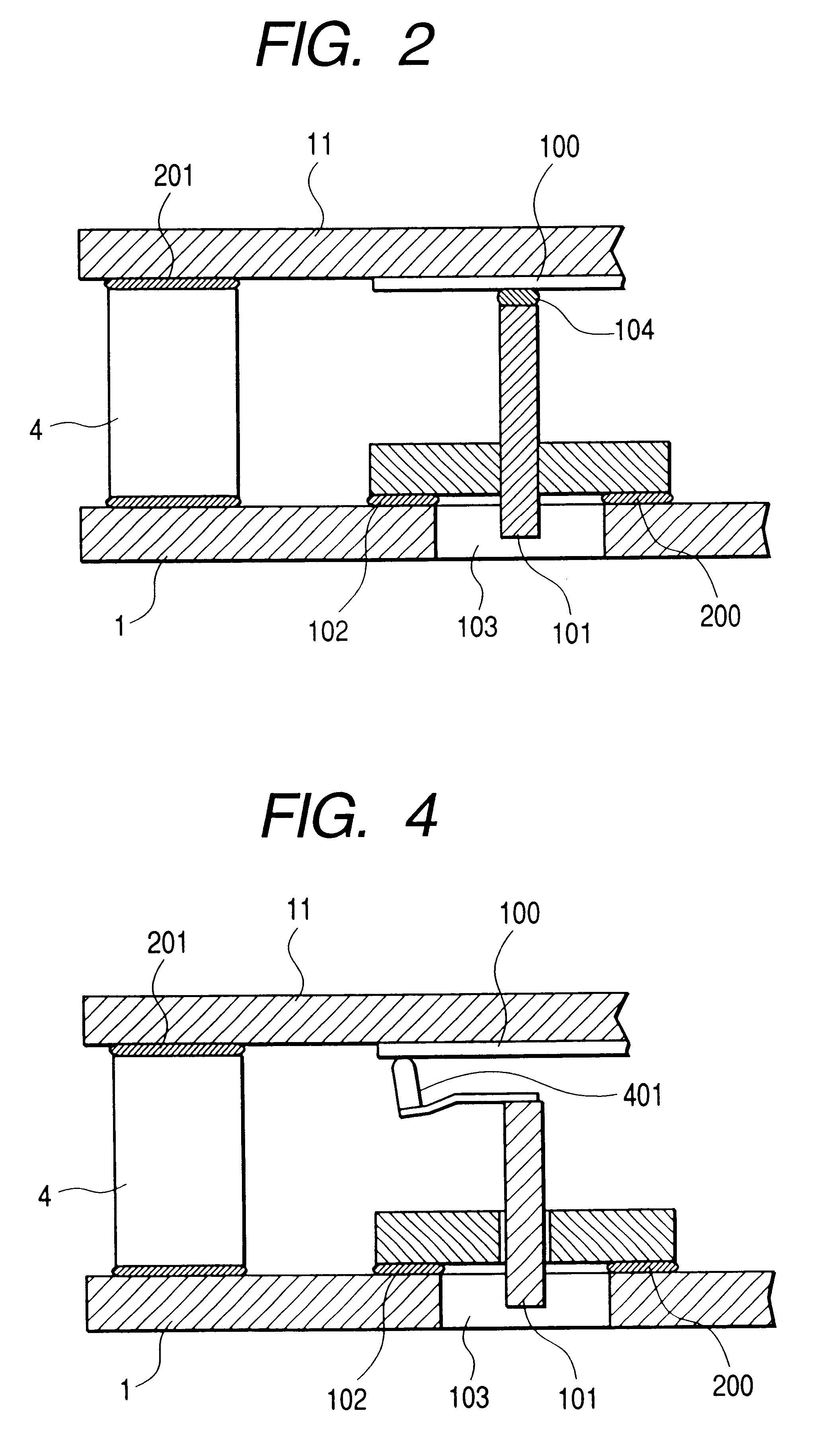

Image display apparatus having voltage application structure

InactiveUS6831402B2Cathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensLow voltageFrit

To provide a voltage application structure that is electrically stable and a display apparatus using the voltage application structure, while reducing the size, thickness, and cost of the display apparatus. A through hole structure is formed in the vicinity of a cylindrical hole established in a rear plate in advance. The through hole structure is electrically connected to lead wiring led to the outside from an anode electrode through a conductive elastic structure. A voltage to the anode electrode is applied to the through hole structure on the atmosphere side, and thus the voltage is applied to the anode electrode through the vacuum side of the through hole structure, the elastic structure, and the lead wiring. Vacuum hermeticity is maintained by filling the hole of the through hole structure with frit. Also, low-voltage wiring that is connected to the ground and regulates a potential is arranged around the through hole structure.

Owner:CANON KK

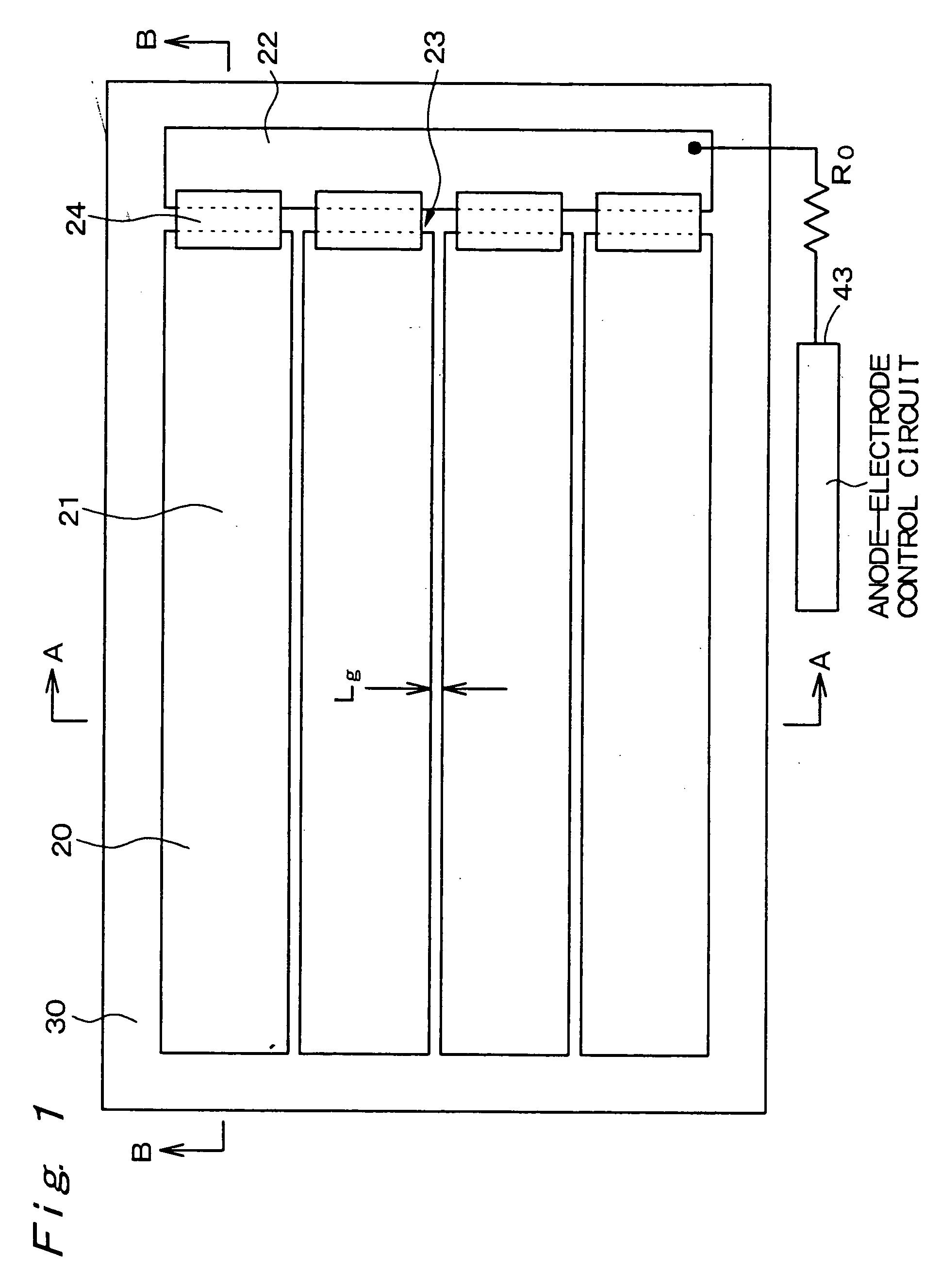

Display apparatus

InactiveUS20080174231A1Avoid resistanceCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensElectron sourceOptoelectronics

A display apparatus includes an electron source; a substrate; a light emitting body arranged on the substrate and emitting light by being irradiated by an electron emitted from the electron source; an anode disposed on the substrate and supplied with a voltage for accelerating the electron; and an electrode for supplying the voltage to the anode, the electrode being disposed along a side of the substrate, and the electrode has a plurality of electrode films, the electrode films including two electrode films adjacent to each other, and a resistor film connecting between the electrode films, and a length of the portion opposing the other electrode film in one electrode film from among the two electrode films is longer than a length of the one electrode film in a direction orthogonal to the longitudinal direction of the electrode.

Owner:CANON KK +1

Cold cathode electric field electron emission display device

InactiveUS20060087248A1Weaken energyReduce harmCathode-ray/electron-beam tube electrical connectionControl electrodesField emission deviceField emission display

An anode electrode 20 in an anode panel constituting a cold cathode field emission display is constituted of anode electrode units 21 in the number of N (N≧2), each anode electrode unit is connected to an anode-electrode control circuit 43 through one electric supply line 22, and VA / Lg<1 (kV / μm) is satisfied in which VA (unit:kilovolt) is a voltage difference between an output voltage of the anode-electrode control circuit and a voltage applied to a cold cathode field emission device, and Lg (unit:μm) is a gap length between the anode electrode units.

Owner:SONY CORP

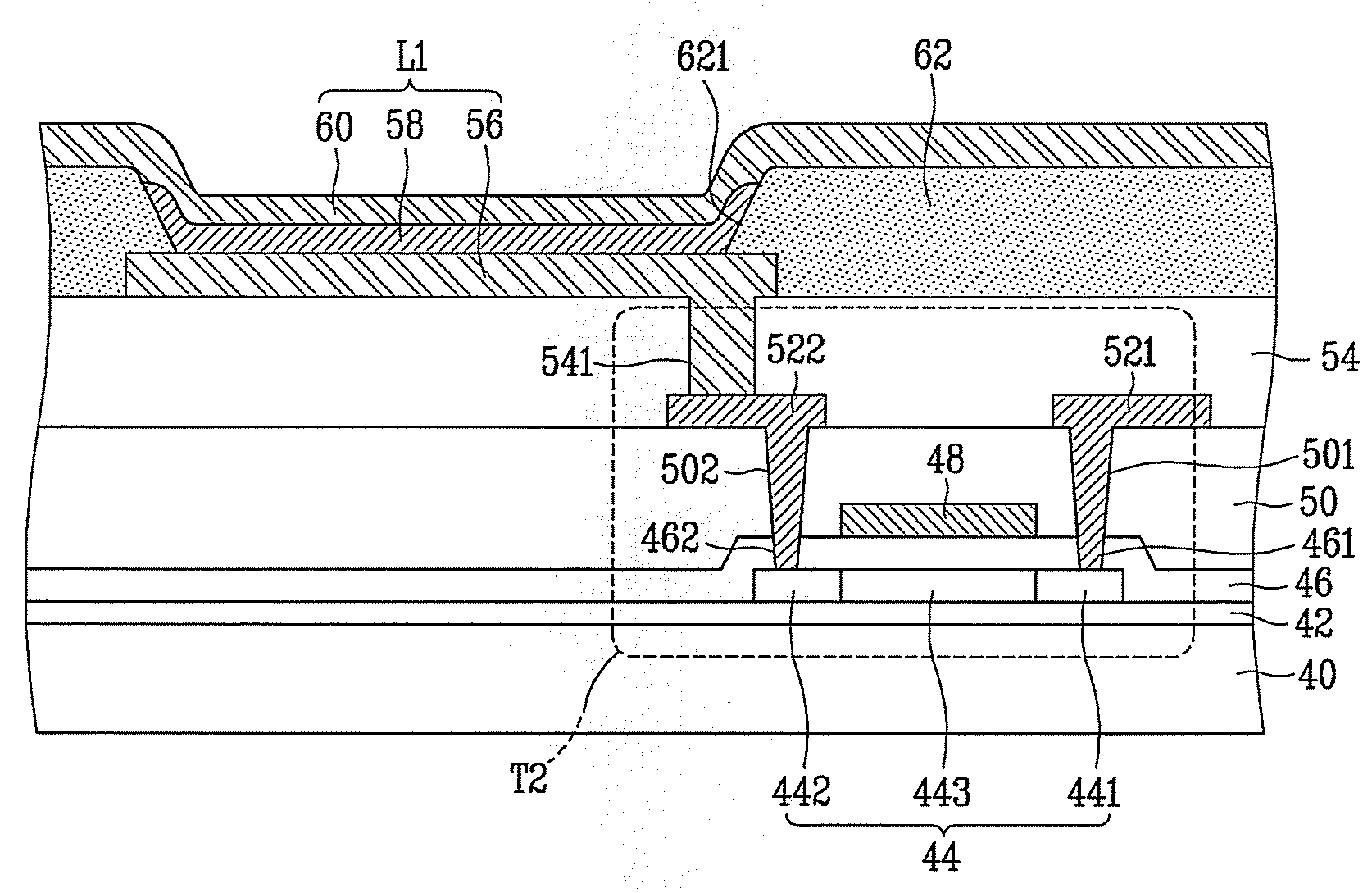

Electron emission device, electron emission type backlight unit including the same and method of fabricating the electron emission device

InactiveUS20100008068A1Improved and optimum post-processing effectImprove uniformityCathode-ray/electron-beam tube electrical connectionDischarge tube main electrodesElectricityElectrical resistance and conductance

An electron emission device, useful as a backlight unit, improves uniformity between pixels and maximizes post-processing effects. The electron emission device includes a base substrate with first electrodes extending on the base substrate, each of which includes a resistance layer formed at an end. The electron emission device also includes second electrodes electrically insulated from the first electrodes and electron emission sources formed on the first electrodes. The electron emission device is configured for current to flow through the resistance layer during a driving operation and for current to not flow through the resistance layer during an aging operation.

Owner:SAMSUNG SDI CO LTD

Plasma display apparatus and driving method thereof

InactiveUS20060290257A1Liquid crystal compositionsCathode-ray/electron-beam tube electrical connectionFlat panel displayPlasma display

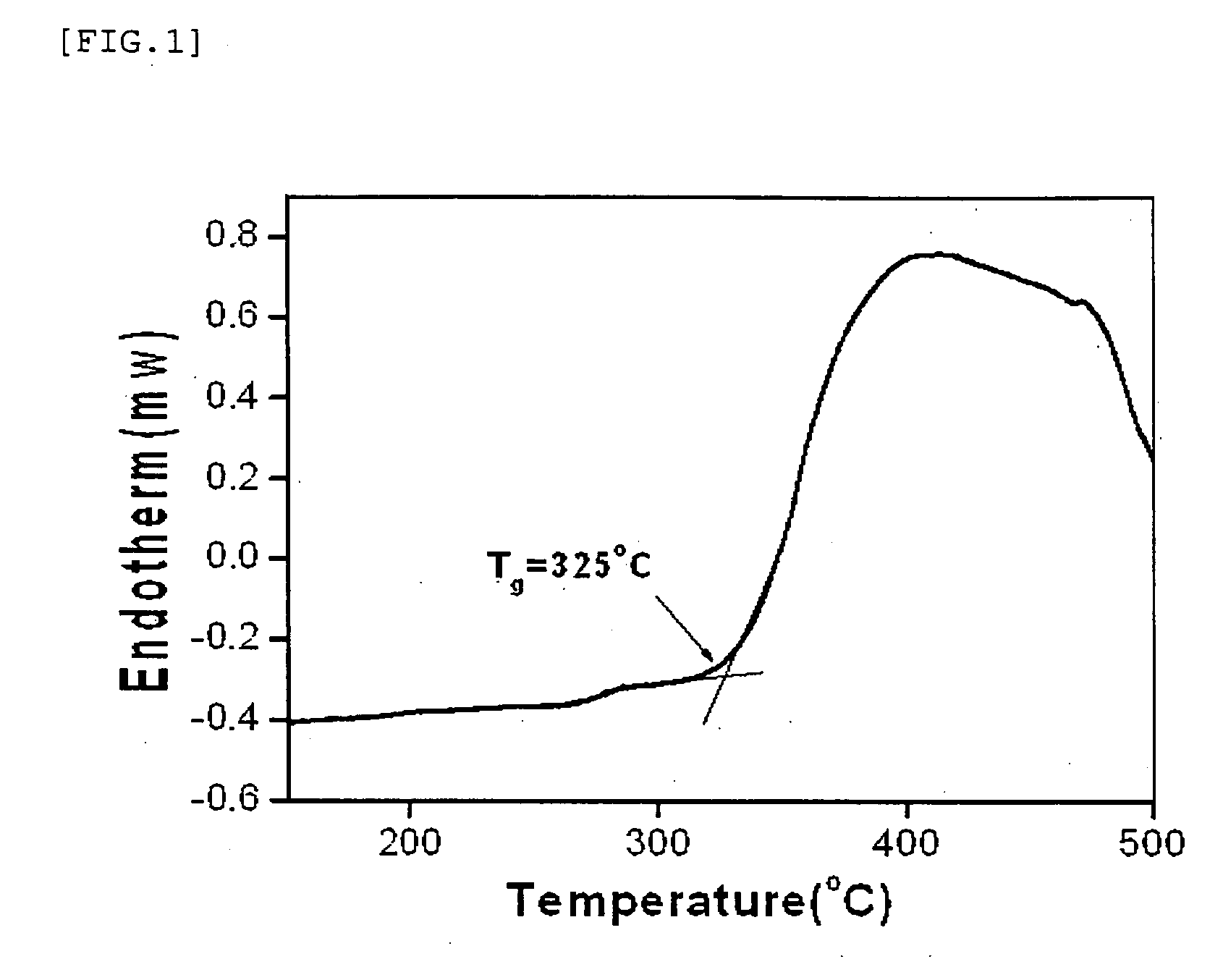

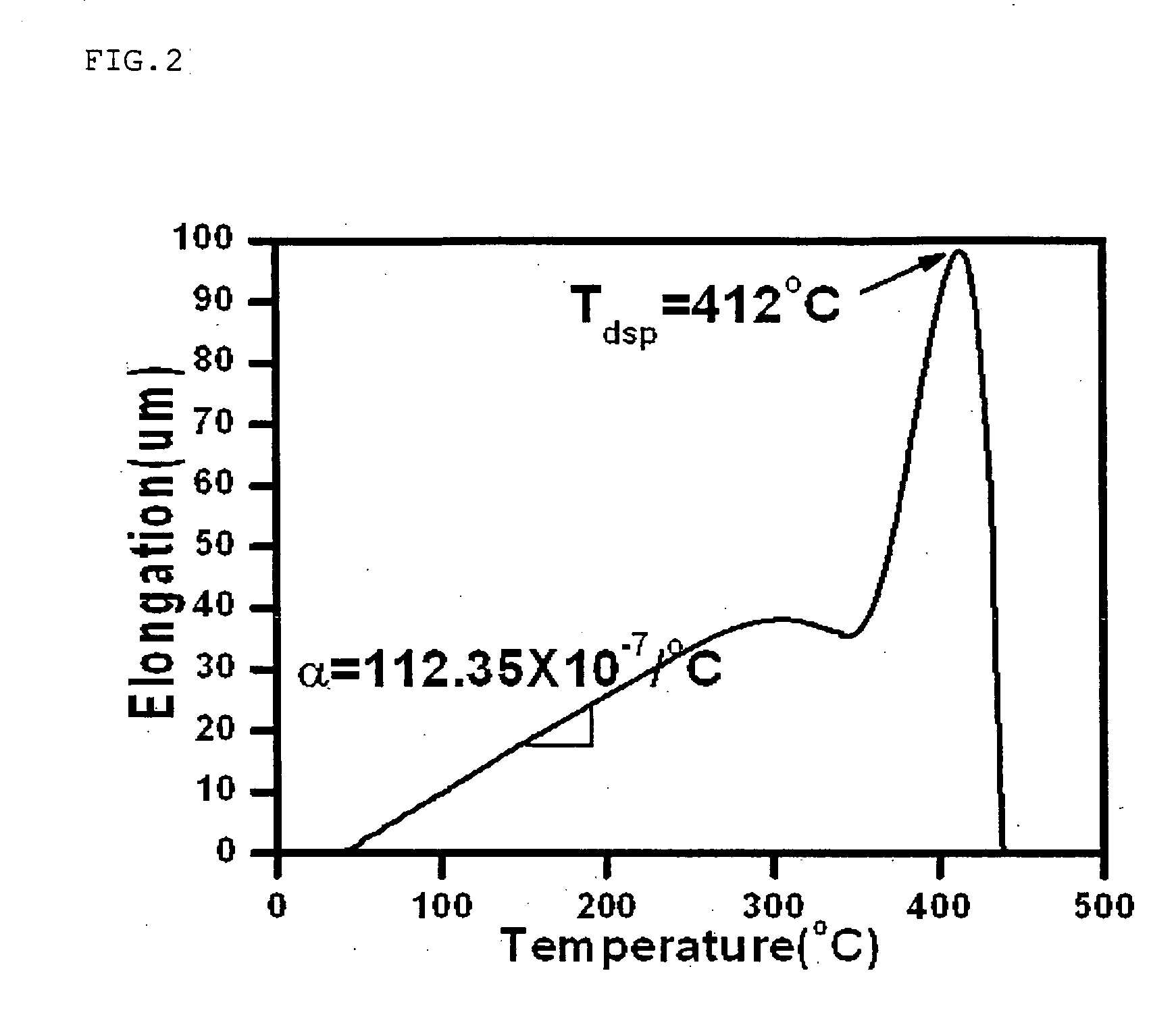

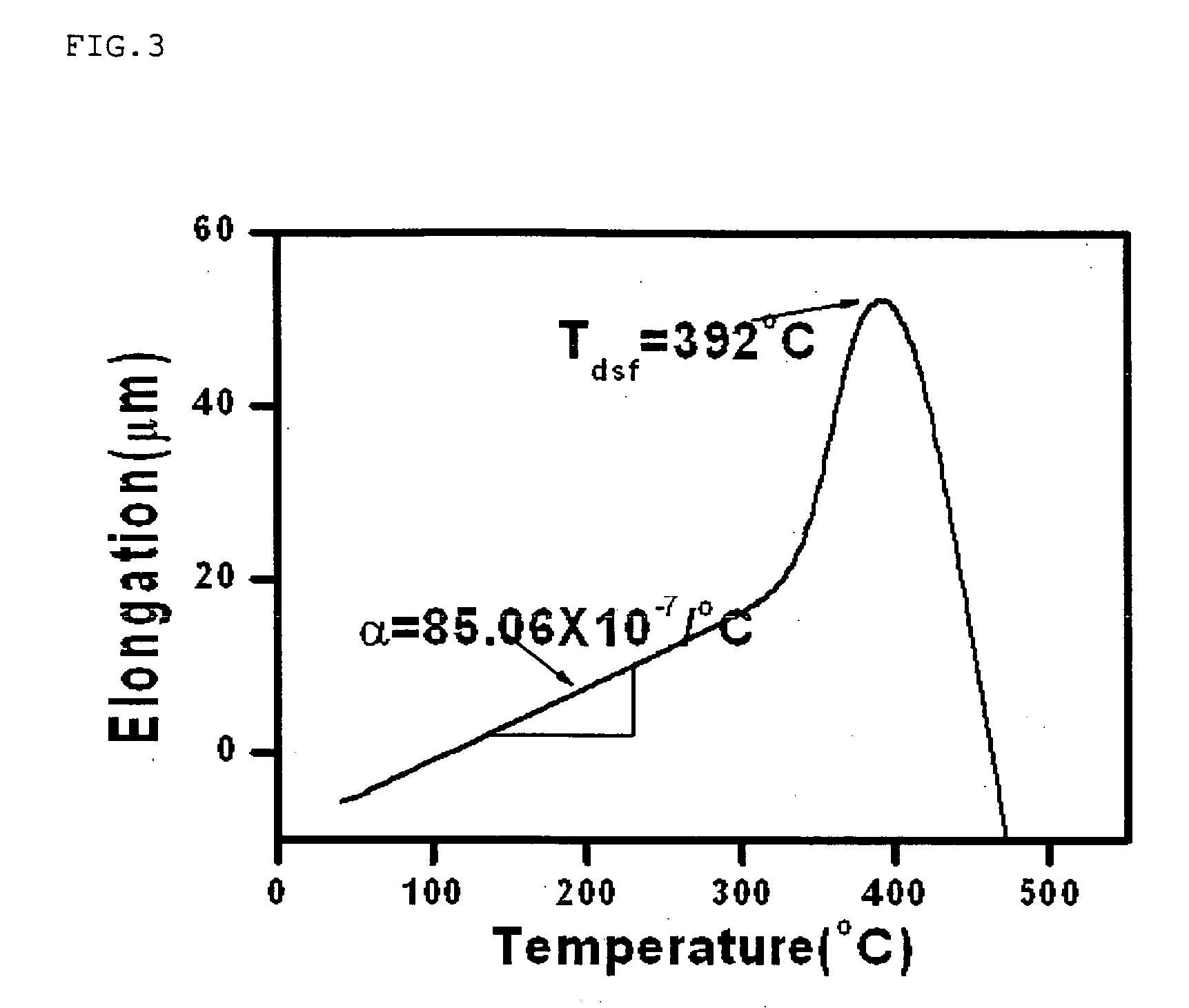

The present invention relates to a sealing glass composition that excludes Pb, i.e., an environmentally harmful material, and a flat panel display apparatus using the same. A sealing glass composition of the present invention comprises Sb2O3 of 20 mol % to 50 mol %, B2O3 of 30 mol % to 70 mol %, SiO2 of 5 mol % to 15 mol % and Al2O3 of 0 mol % to 15 mol %. The flat display apparatus of the present invention has a front panel and a rear panel, which are combined together with a sealing glass composition with a predetermined distance therebetween.

Owner:LG ELECTRONICS INC

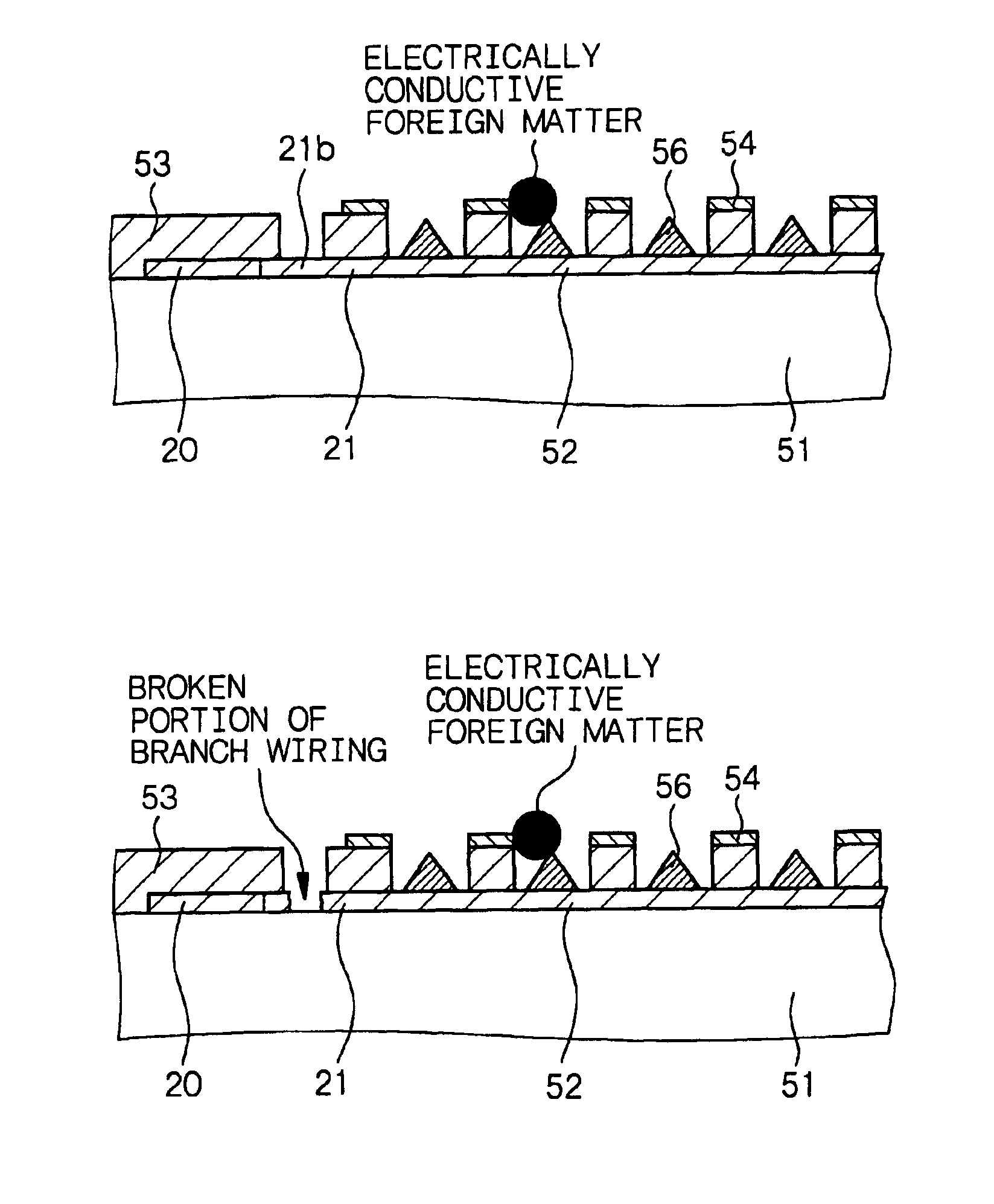

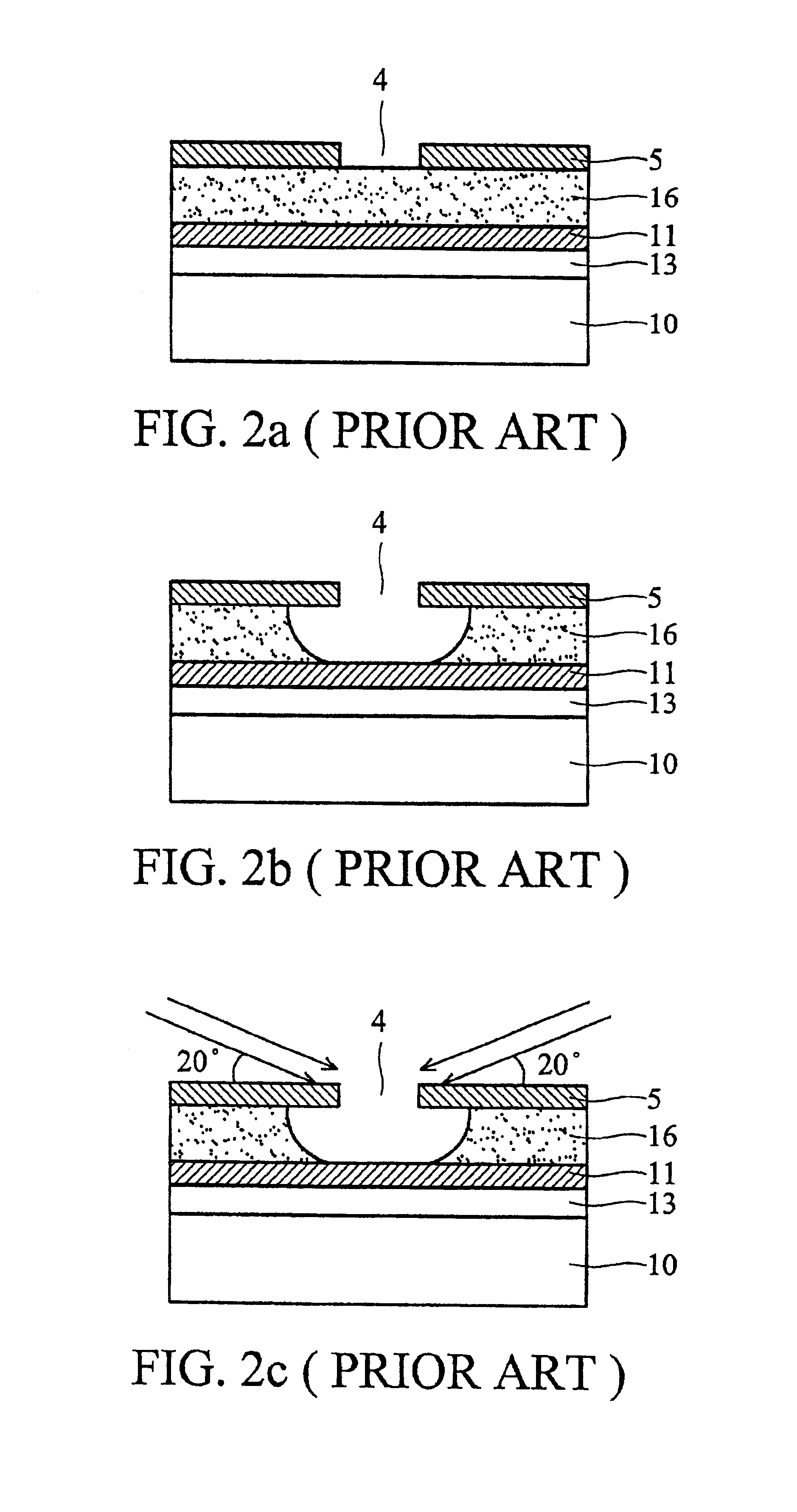

Cathode panel for a cold cathode field emission display and cold cathode field emission display, and method of producing cathode panel for a cold cathode field emission display

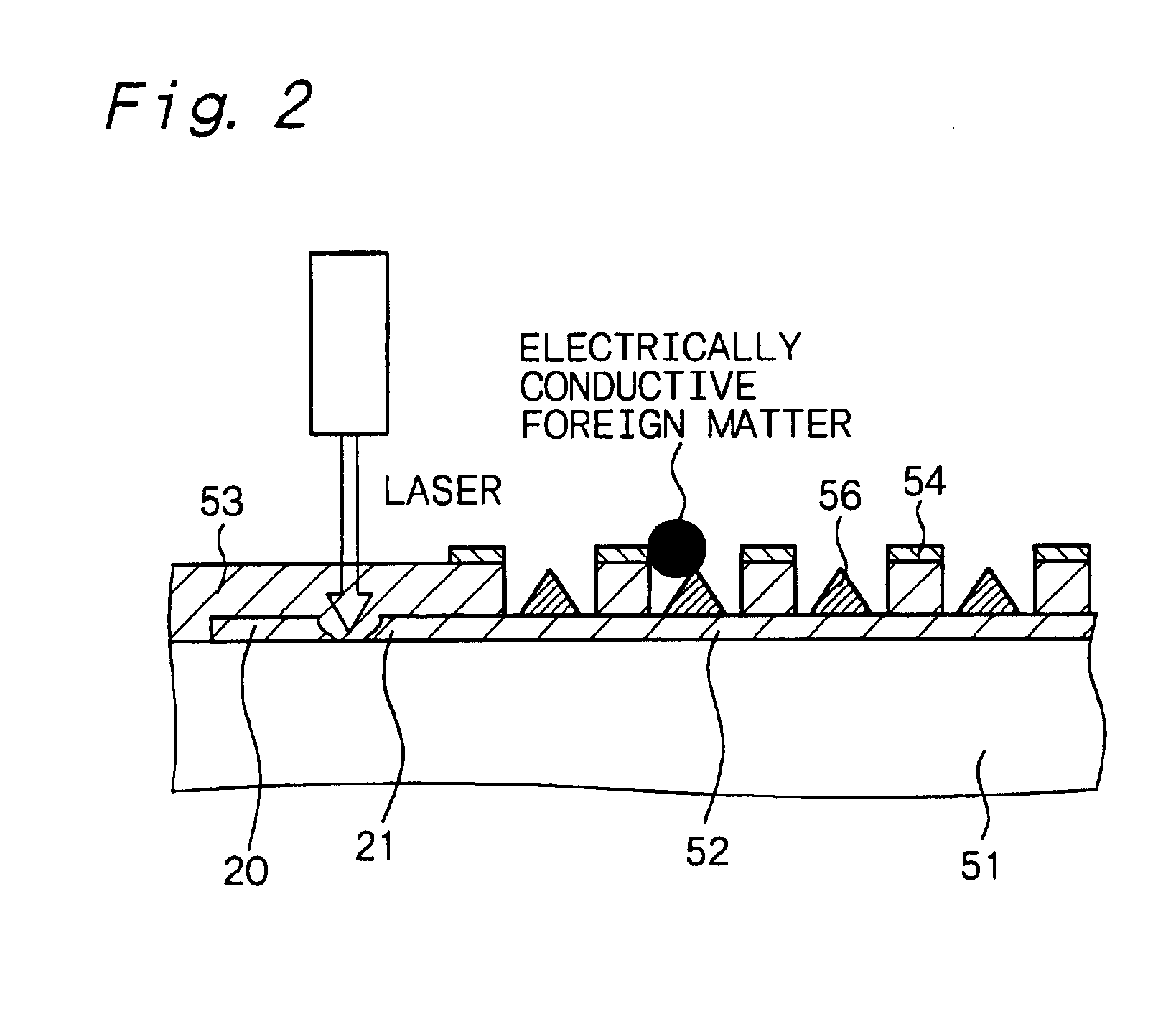

InactiveUS6917155B1Decrease in production yieldHigh melting pointCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensField emission displayCold cathode

A cathode panel for a cold cathode field emission display, comprising; (a) a plurality of main wirings, (b) a plurality of branch wirings extending from each main wiring, and (c) cold cathode electron emitting portions connected to the branch wirings, wherein a branch wiring connecting a cold cathode electron emitting portion defective in operation and a main wiring is cut off.

Owner:SONY CORP

Display panel module with improved bonding structure and method of forming the same

InactiveUS20010033127A1Cathode-ray/electron-beam tube electrical connectionIdentification meansAnisotropic conductive filmComputer module

A display panel module comprises: a substrate; a circuit board; electrode terminals aligned in a first direction over a surface of the substrate, each of the electrode terminals extending in a second direction perpendicular to the first direction; lead terminals aligned in the first direction over a confronting surface of the circuit board to the substrate; at least an anisotropically conductive film sandwiched between the electrode terminals and the lead terminals; and a plurality of first electrically insulating walls provided on the substrate and positioned in at least selected plural ones of gaps between selected ones of the electrode terminals, and the selected ones of the electrode terminals being positioned on opposite side regions of the module, and the opposite side regions are distanced in the first direction and separated by a center region, wherein the first electrically insulating walls have a first height, which is higher than a first total height of the electrode terminals and the anisotropically conductive film.

Owner:VISTA PEAK VENTURES LLC

Field emission display cathode (FED) plate with an internal via and the fabrication method for the cathode plate

InactiveUS6749476B2Improve evennessIncreased durabilityCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensAdhesiveMagnetic tape

an FED cathode plate with internal via includes an internal via; a second dielectric layer; a second gate line; a metal layer 12 covering the gate line and the internal via; and a contact. The internal via is located on a typical tape line. The second dielectric layer is located on the tape line and abutted against the internal via, thereby connecting to an anode by an adhesive. The second gate line is located on the second dielectric layer and abutted against the internal via. The metal layer is covered over the first gate line, the internal via, and the second gate line; and the contact is located on the tape line and connected adjacent to the second dielectric layer, thereby electrically connecting a lead to outside.

Owner:AU OPTRONICS CORP

Flat panel display

InactiveUS20080231165A1Same resistanceIncrease widthCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensLine widthDisplay device

A flat panel display to maintain resistance of lines at the same level to reduce a luminance difference between the lines includes a plurality of electrodes and a plurality of lead lines to respectively connect a plurality of pads to the plurality of electrodes. The lead lines are formed in a parallelogram shape in which resistivity and line width are the same for each, and a length L and a line width W of each lead line are selected such that a value obtained by dividing the length L by the line width W may satisfy an equation ofL1W1=L2W2=L3W3=…=LnWn,where L1, L2, L3, . . . , and Ln respectively refers to long side lengths, which are direct line distances between the electrode and the pad, of the respective lead lines formed in the parallelogram shape, and W1, W2, W3, . . . , and Wn respectively refers to widths, which are short side vertical distances of the respective lead lines formed in the parallelogram shape.

Owner:SAMSUNG SDI CO LTD

Display Device

InactiveUS20080315748A1High voltageImprove reliabilityCathode-ray/electron-beam tube electrical connectionGas filling substance selectionContact pressureAnode voltage

There is disclosed an FED (field emission display) capable of supplying an anode voltage, which is a high voltage, to an anode substrate with high reliability. A high voltage introduction button is sealed to a sealing plate, in which a contact spring is attached to the high voltage introduction button by spot welding. The high voltage introduction button has a flat portion connected to the contact spring, a sealing portion sealed to the glass substrate, and an external terminal to be connected to an external power source. The contact spring contacts an anode terminal of an anode substrate with an appropriate contact pressure, by a spring force from an arm portion of the contact spring. The anode terminal is formed of a conductive film containing metal particles.

Owner:HITACHI LTD

Color picture tube device having contoured panel and auxiliary coil for reducing apparent screen distortions

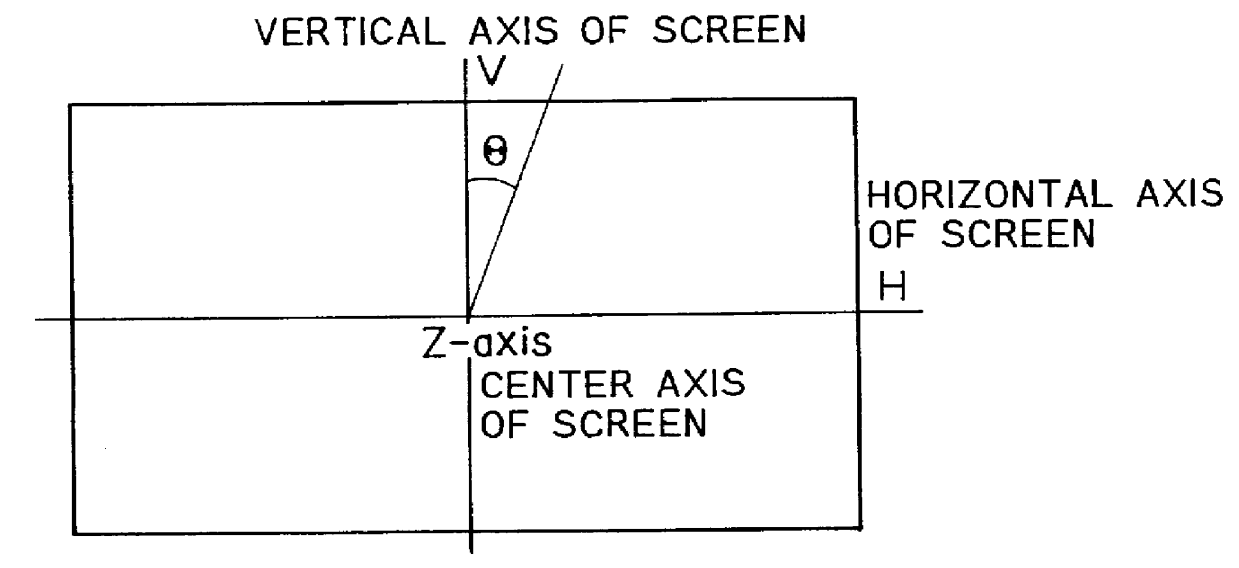

InactiveUS6133681ACathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersHorizontal axisEngineering

An object is to remove unnaturalness of the picture caused by inferior flatness of the apparent screen and provide a safety-designed color picture tube device having a flatter apparent screen without deterioration of static strength of the picture tube. The upper half of the panel (the part above the Z-axis) shows the vertical-axis (V) section and the lower half (the part below the Z-axis) shows the horizontal-axis (H) section. The outside surface of the panel is in a convex form with respect to the Z-axis in the vertical-axis (V) section with a radius of curvature of ROV and is in a convex form with respect to the Z-axis in the horizontal-axis (H) section with a radius of curvature of ROH. The inside surface of the panel is in an almost linear form in the vertical-axis (V) section with a radius of curvature of RIV and is in a convex form with respect to the Z-axis in the horizontal-axis (H) section with a radius of curvature of RIH.

Owner:THOMSON LICENSING SA

Image Display Device

InactiveUS20090002573A1Quality improvementImprove reliabilityTelevision system detailsCathode-ray/electron-beam tube electrical connectionDisplay deviceEngineering

A first translucent conductive layer is disposed on a front surface of a front substrate, a translucent insulating member is disposed on a front surface of the first translucent conductive layer, and a second translucent conductive layer held at the ground potential is disposed on a front surface of the translucent insulating member. According to the invention, an image display device, which prevents the abnormal discharge in the vacuum panel from occurring, and has high quality and reliability and long life, can be provided.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com