Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1367results about How to "Uniform wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

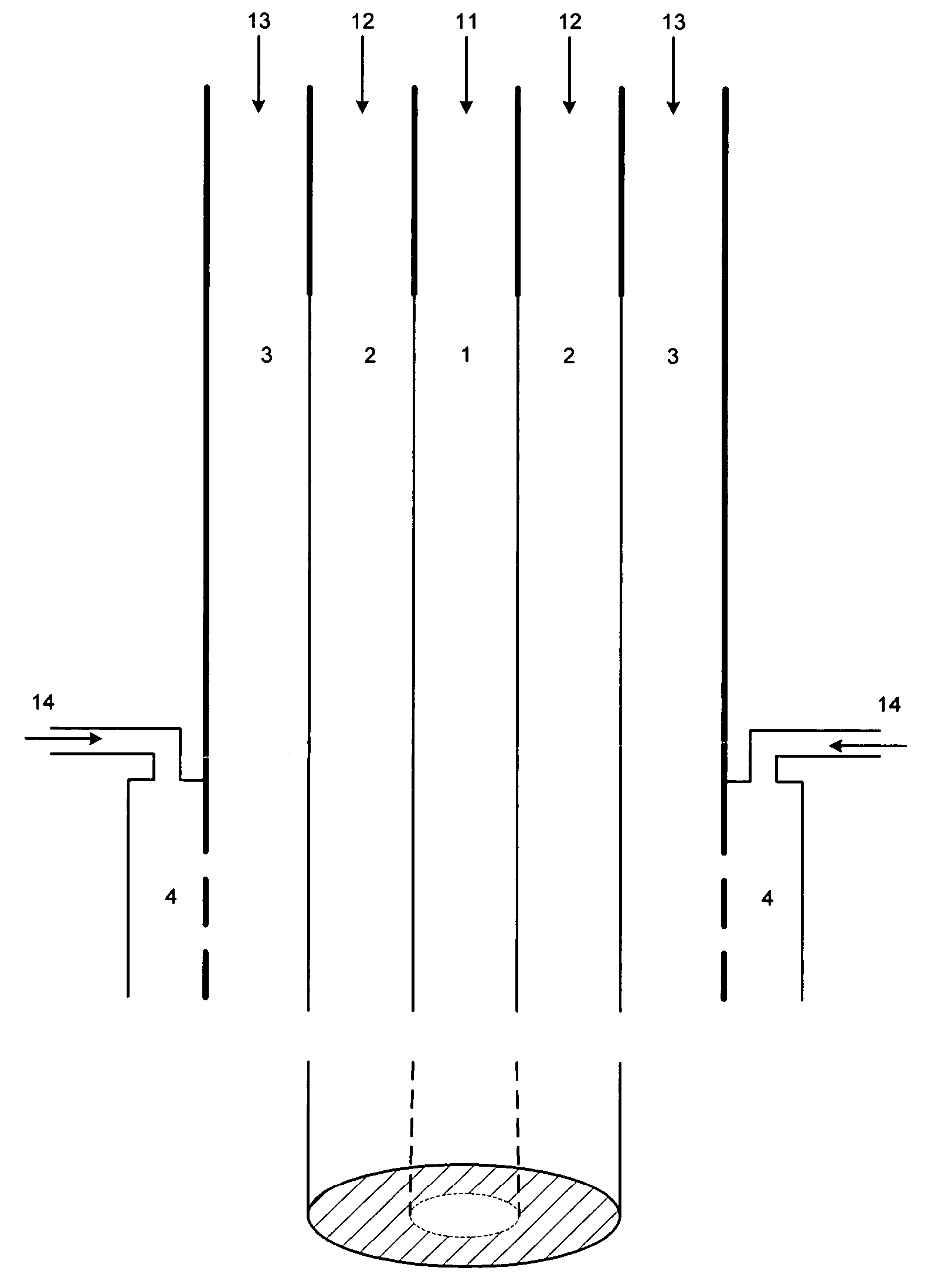

Poly(ethylene chlorotrifluoroethylene) membranes

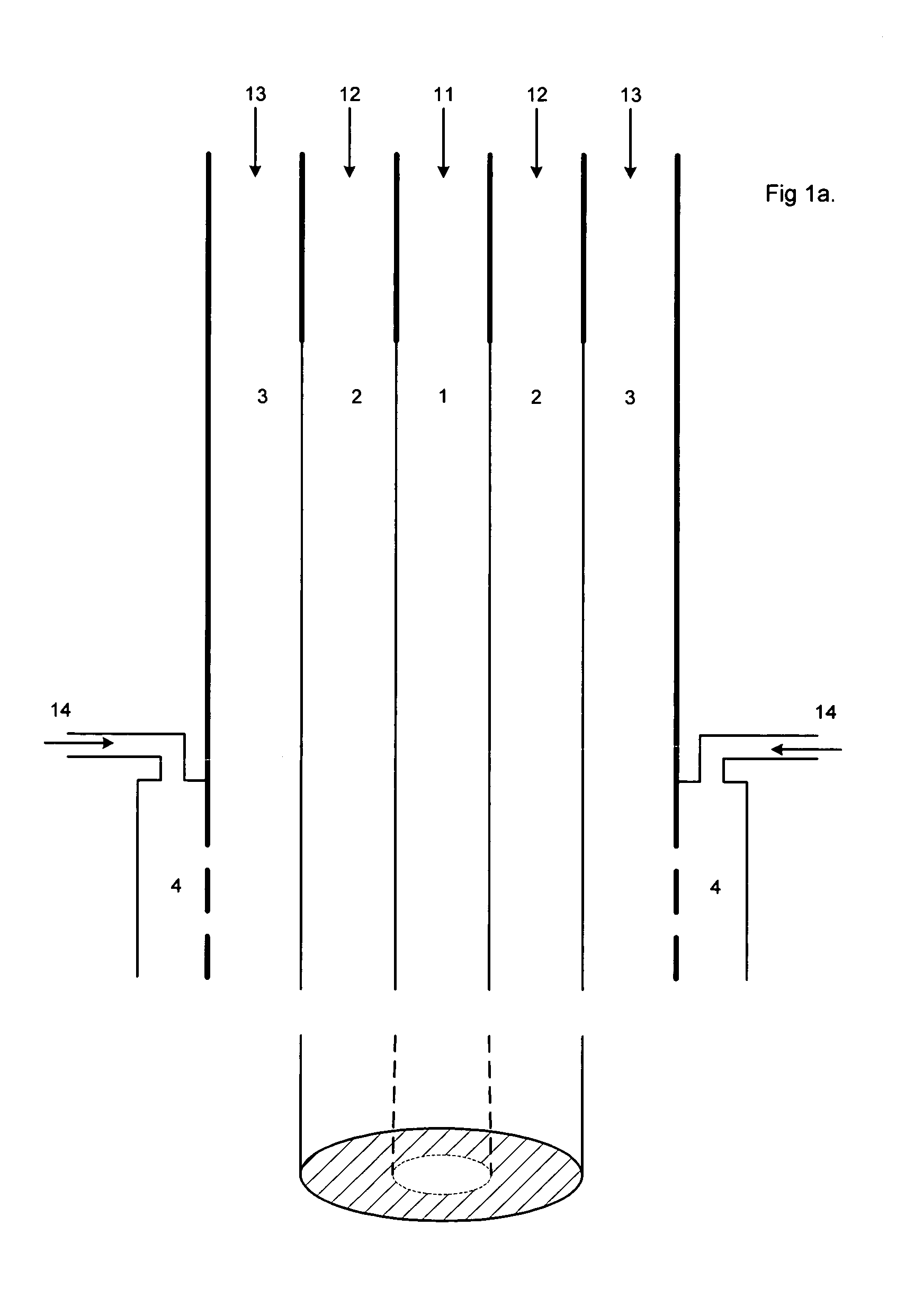

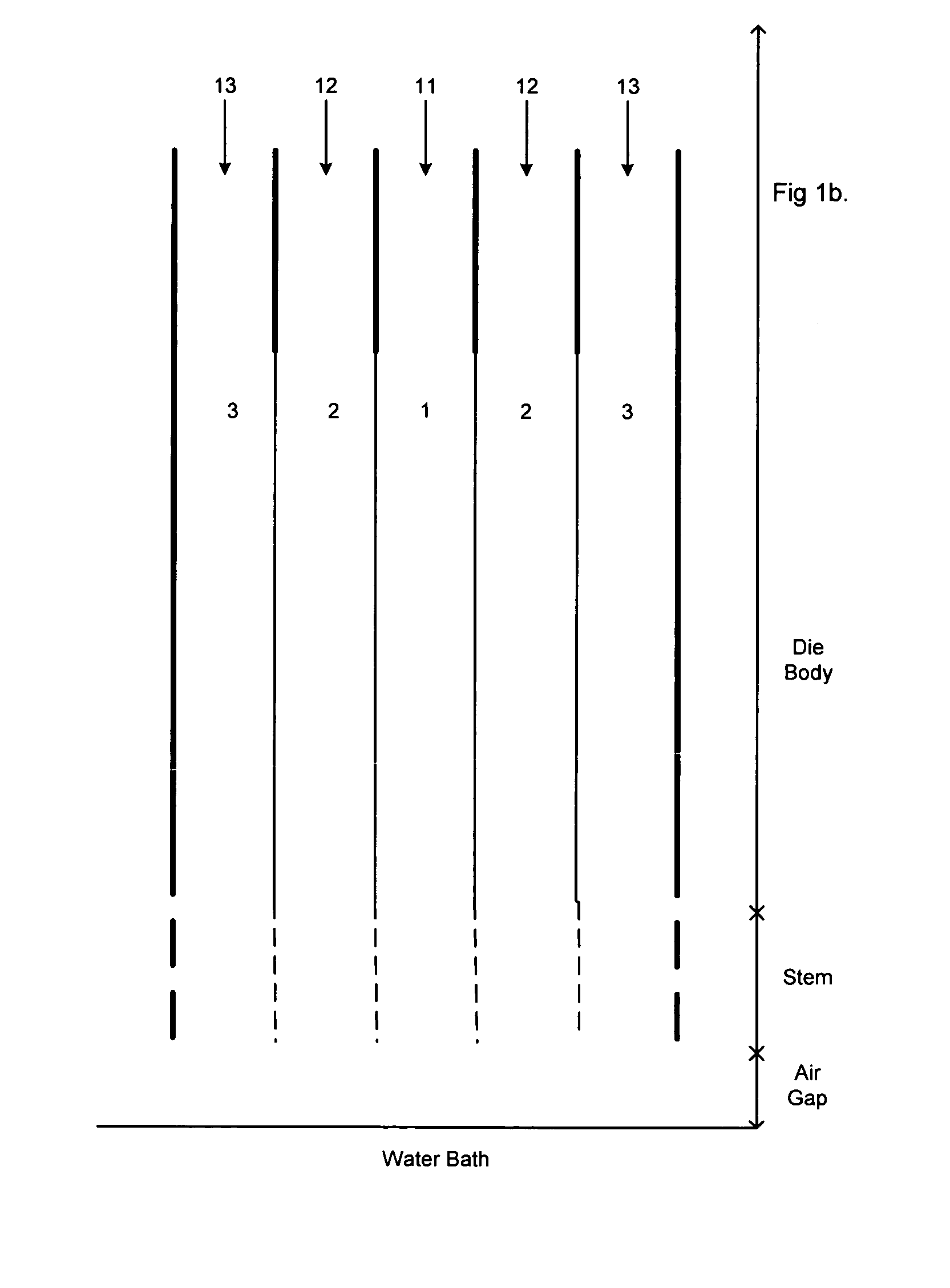

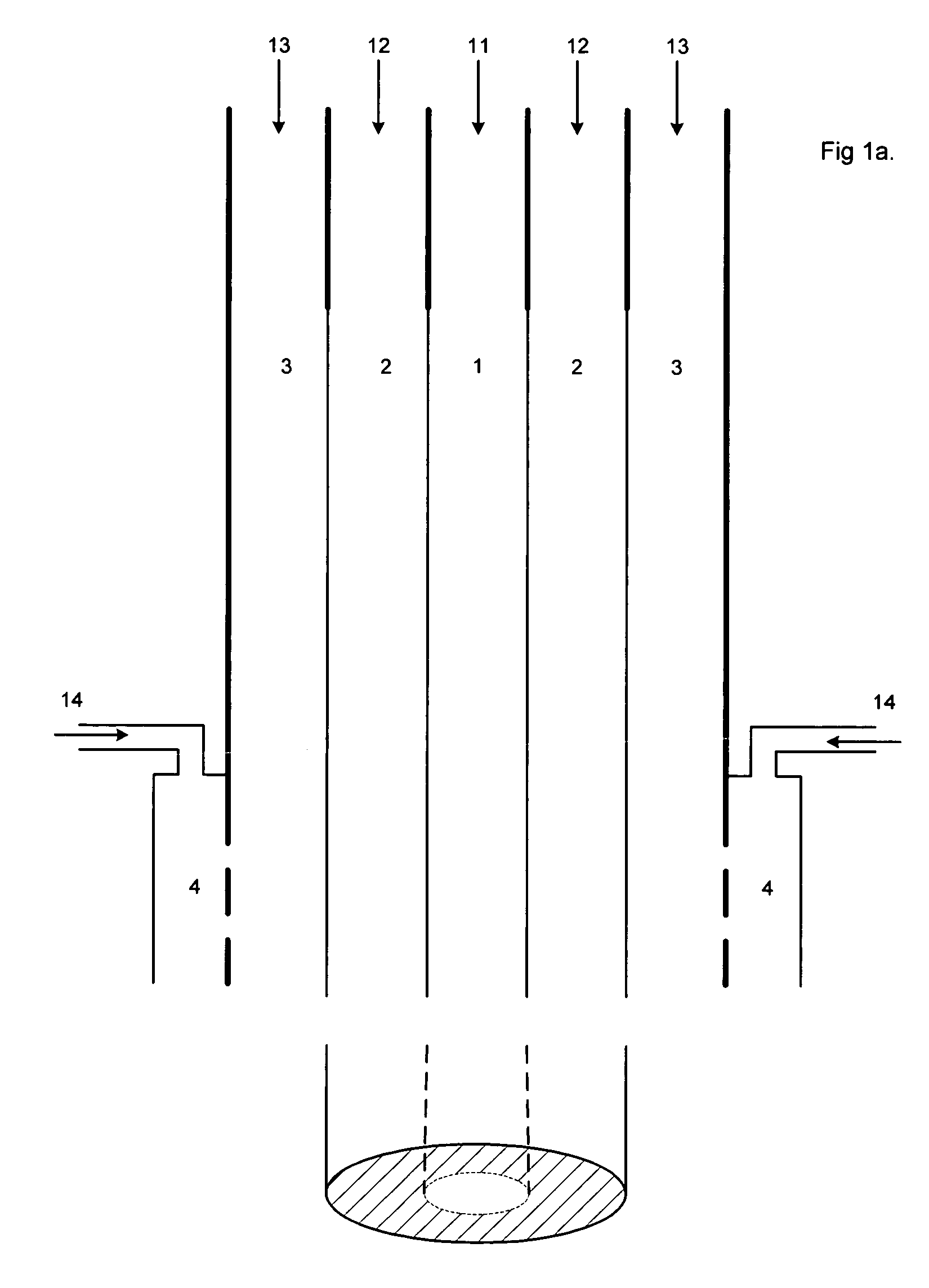

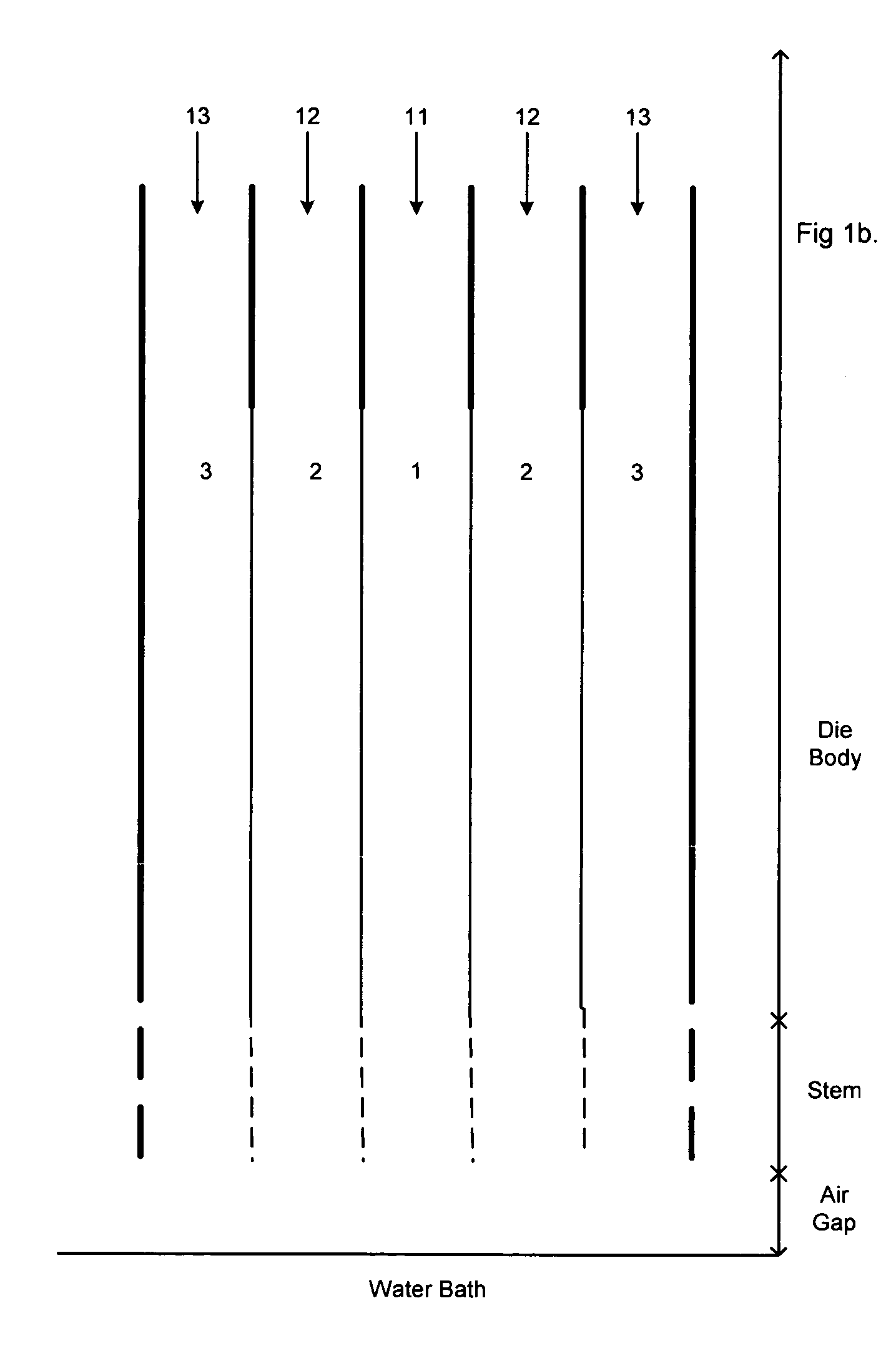

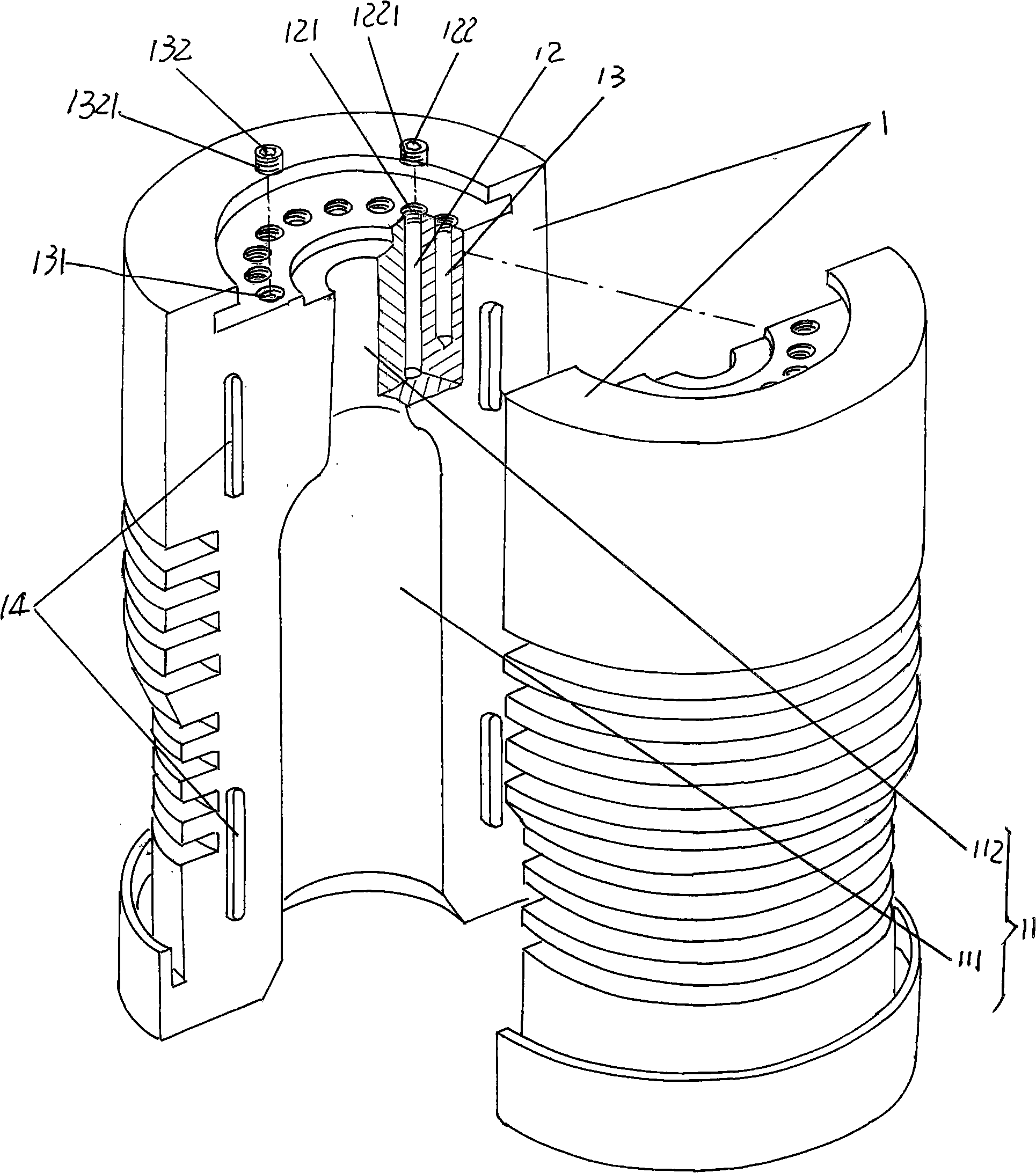

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

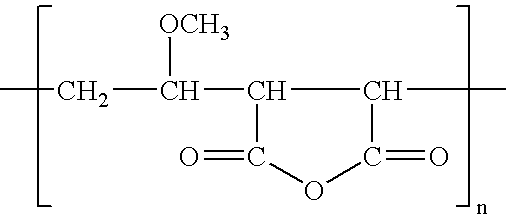

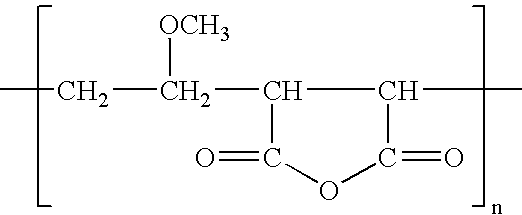

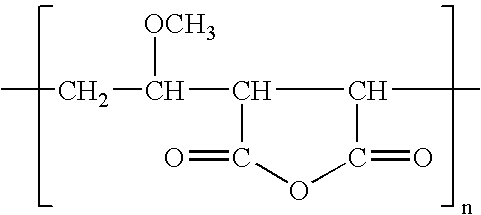

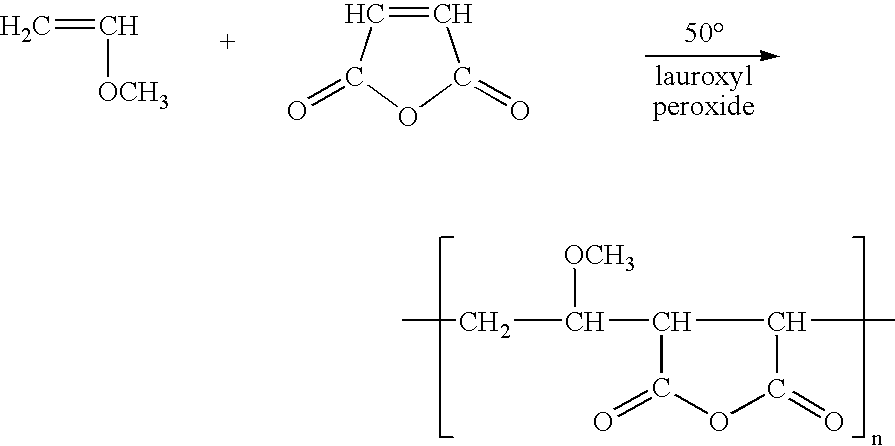

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

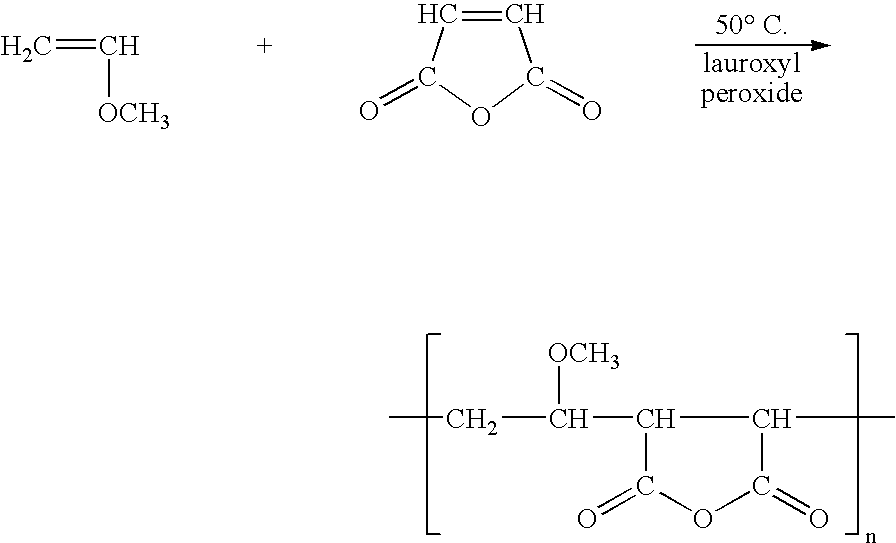

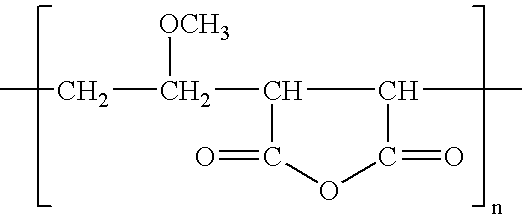

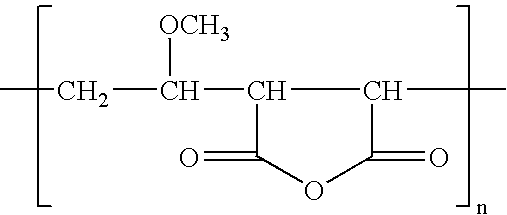

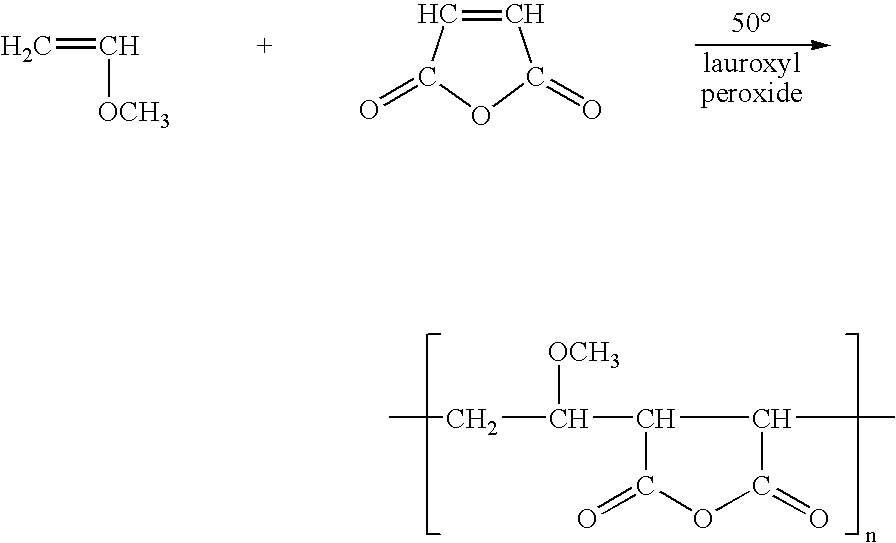

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Halar membranes

InactiveUS20050098494A1Low toxicityImprove permeabilityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fibre or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

Mould for making glass container

ActiveCN101298356AIncrease temperatureEvenly distributedVacuum and blow machinesBottleMaterials science

The invention provides a mold for producing a glass container and belongs to the technical field of mold. The mold includes a pair of half bottle molds that are opposite to each other, and a bottle die cavity is formed in the inner wall of each half bottle mold and is composed of a bottle body cavity and a bottleneck cavity. The mold is characterized in that a first heat-insulating hole and a second heat-insulating hole are alternatively distributed around the bottleneck cavity at the upper part of the half bottle mold, wherein, the depth of the two heat-insulating holes is different. The mold has the advantages that the temperature around the bottleneck cavity can be improved as the first heat-insulating hole and the second heat-insulating hole are arranged at the upper part of the half bottle mold and are corresponding to the surrounding of the bottleneck cavity, which is helpful to lead the materials to distribute evenly during the two blowing process and can guarantee that the wall thickness of the bottleneck is uniform.

Owner:CHANGSHU WEIHENG MOLD MFG

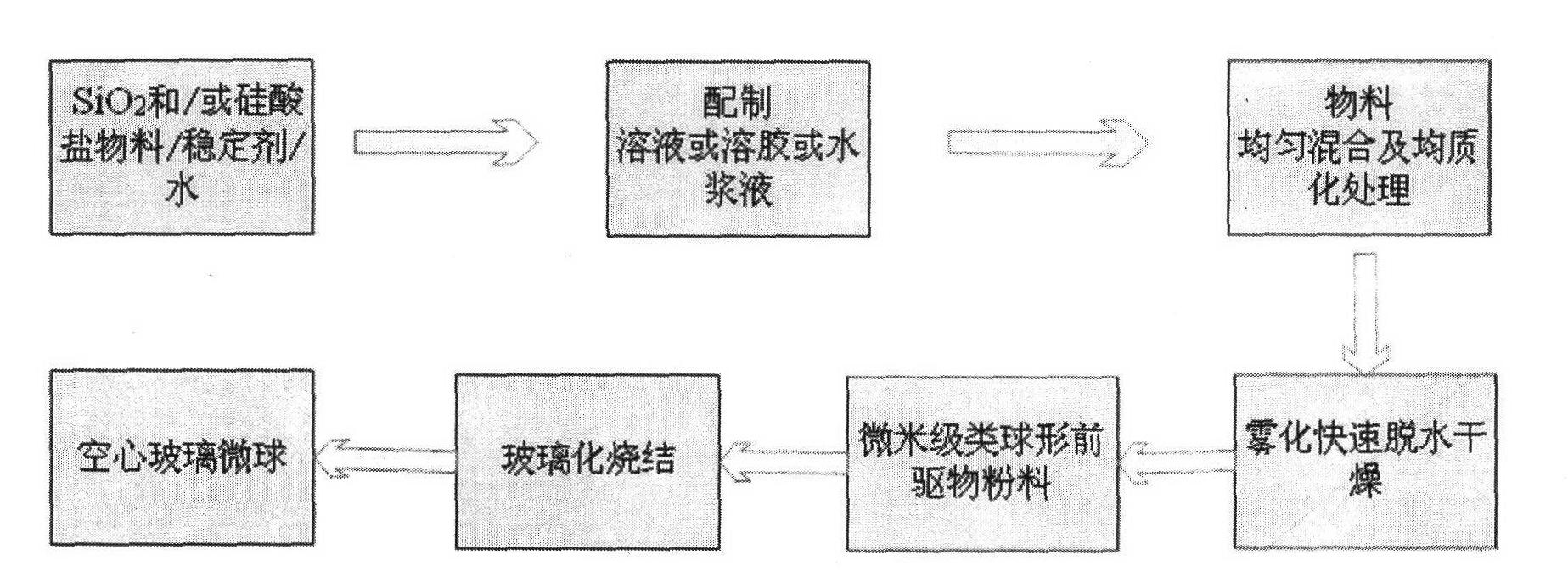

Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

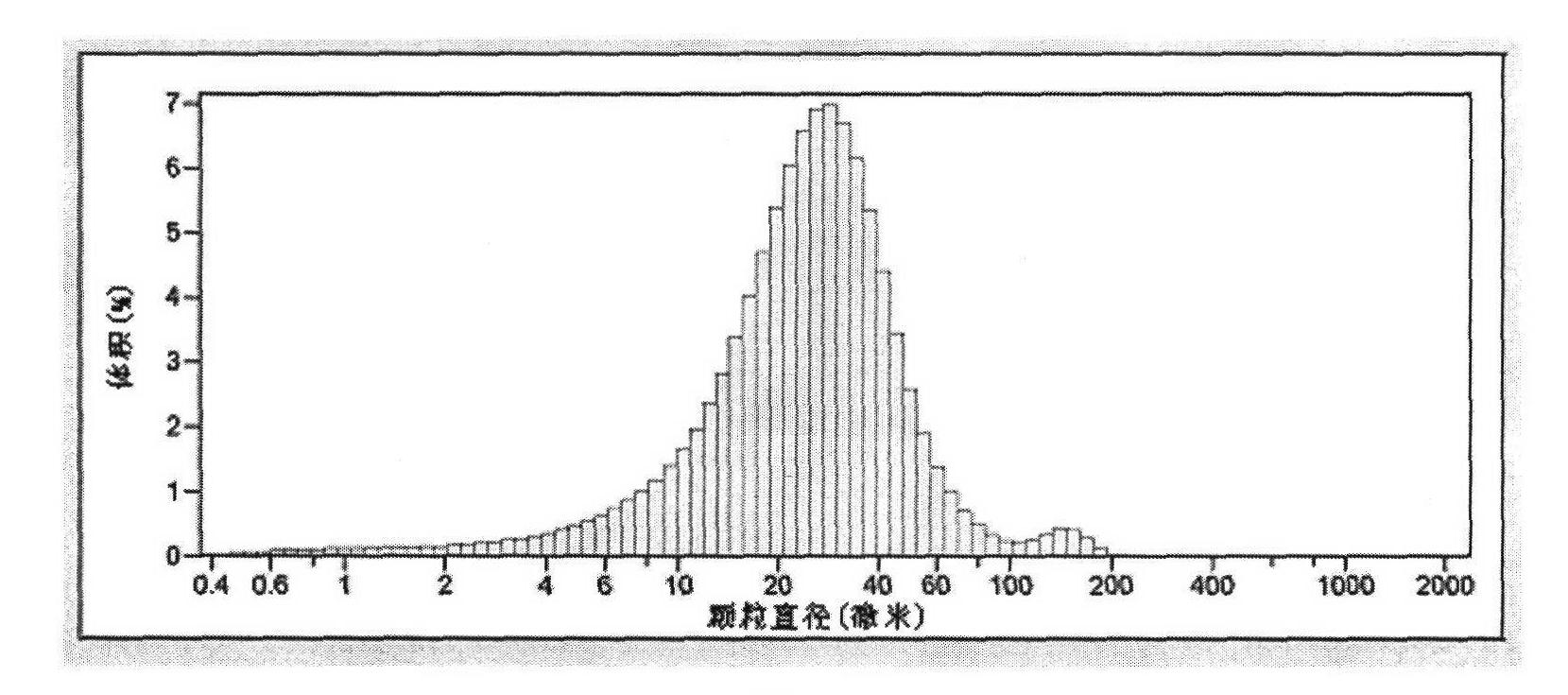

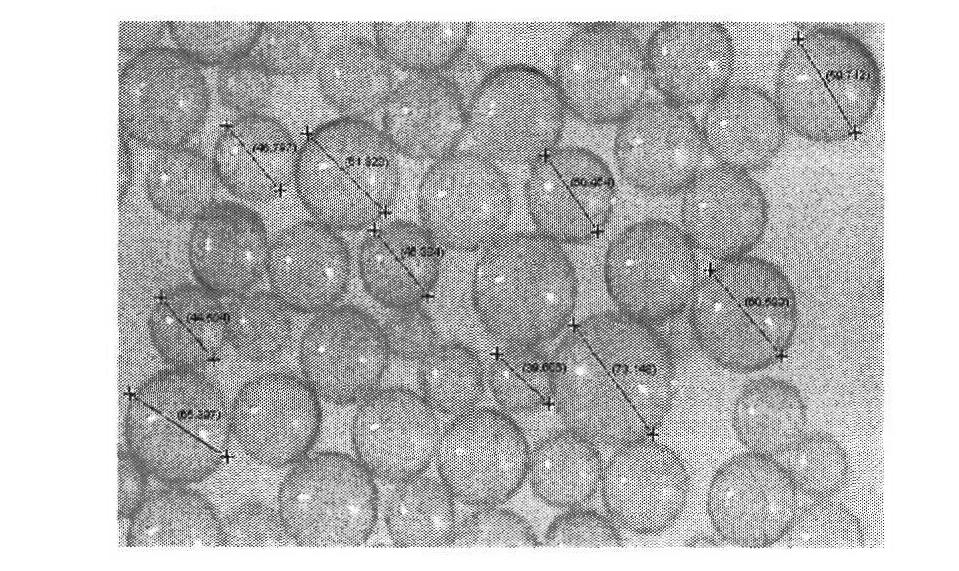

ActiveCN102583973AHigh strengthHigh compressive strengthGlass shaping apparatusMicron scalePolymer science

The invention belongs to the technical field of a soft chemical method. According to the invention, the method is used for overcoming the defects that the traditional solid-phase glass powder method for preparing a hollow glass micro-balloon is high in energy consumption, long in technical process and difficult in controlling grain size distribution and the hollow glass micro-balloon prepared according to a liquid-phase atomizing method is high in alkalinity, easy to absorb water, high in strength and easy to break, and the like. A liquid material system is compounded through a chemical reaction; after the system is homogenized, the system is quickly atomized, dewatered and dried, thereby obtaining approximate spherical precursor powder with required grain size and corresponding distribution; and the powder is treated under high temperature at 600-1100 DEG C, thereby obtaining a micron-scale hollow glass micro-balloon with the volume floating rate being above 90%, the SiO2 content (weight) being 55-88%, the true density being 0.1-0.7g / cm<3> and the compression strength being 1-50MPa. The method is low in energy consumption, free from fusion and sintering, and high in yield. The prepared hollow glass micro-balloon is high in compression strength, light in weight, low-alkali, waterproof, excellent in fluidity and dispersibility, and suitable for various high-performance light compound materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

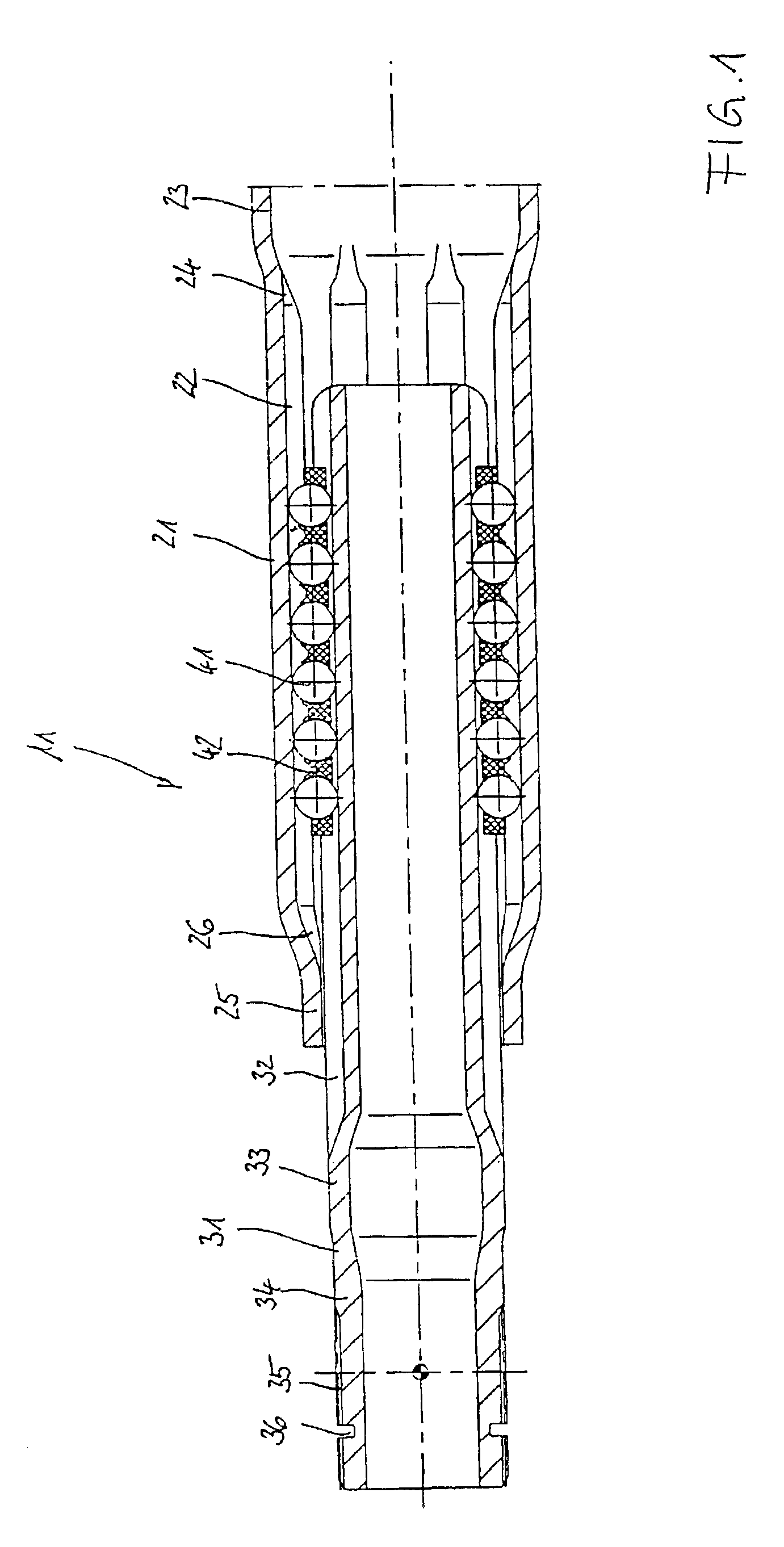

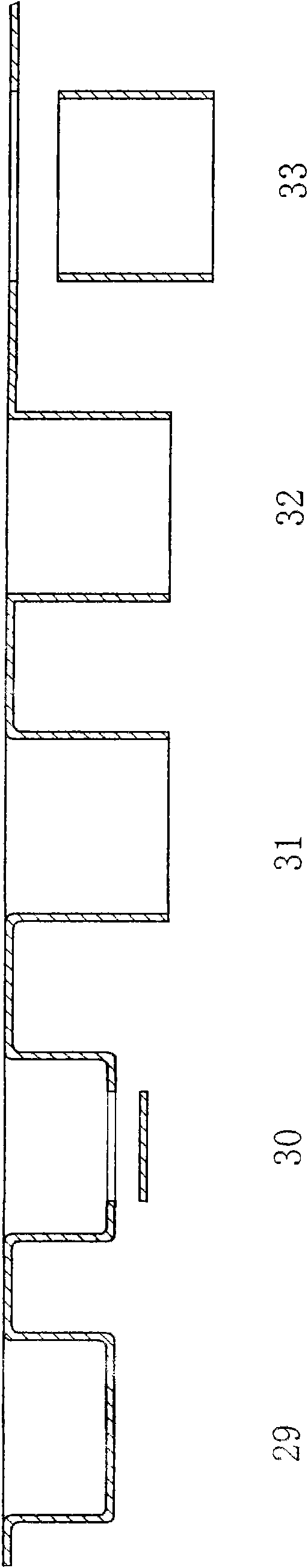

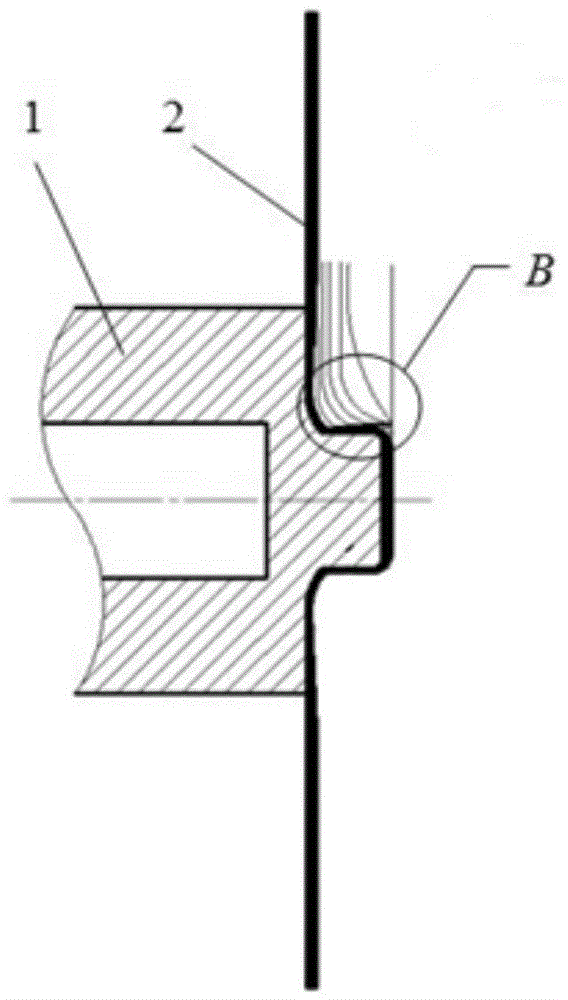

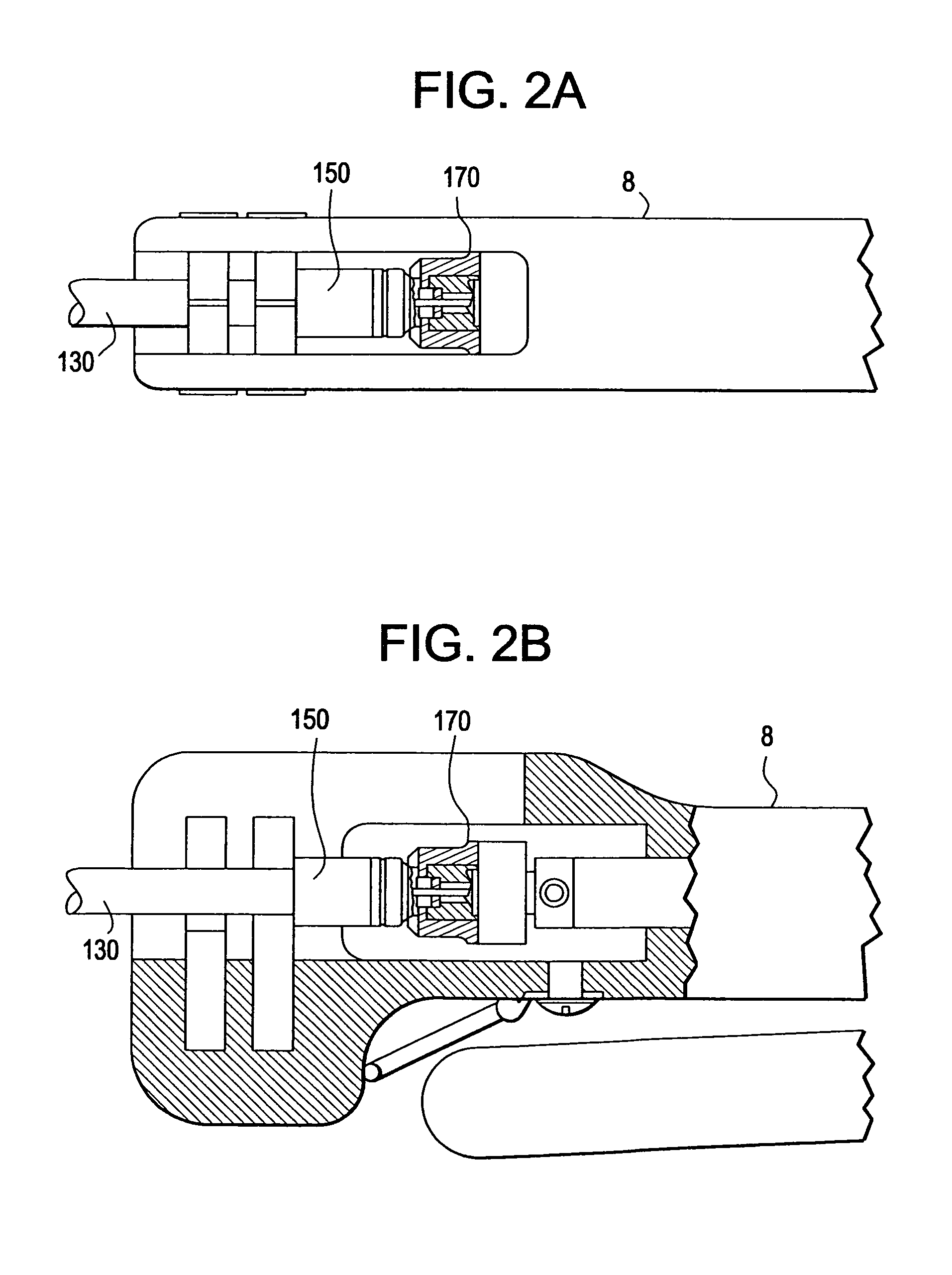

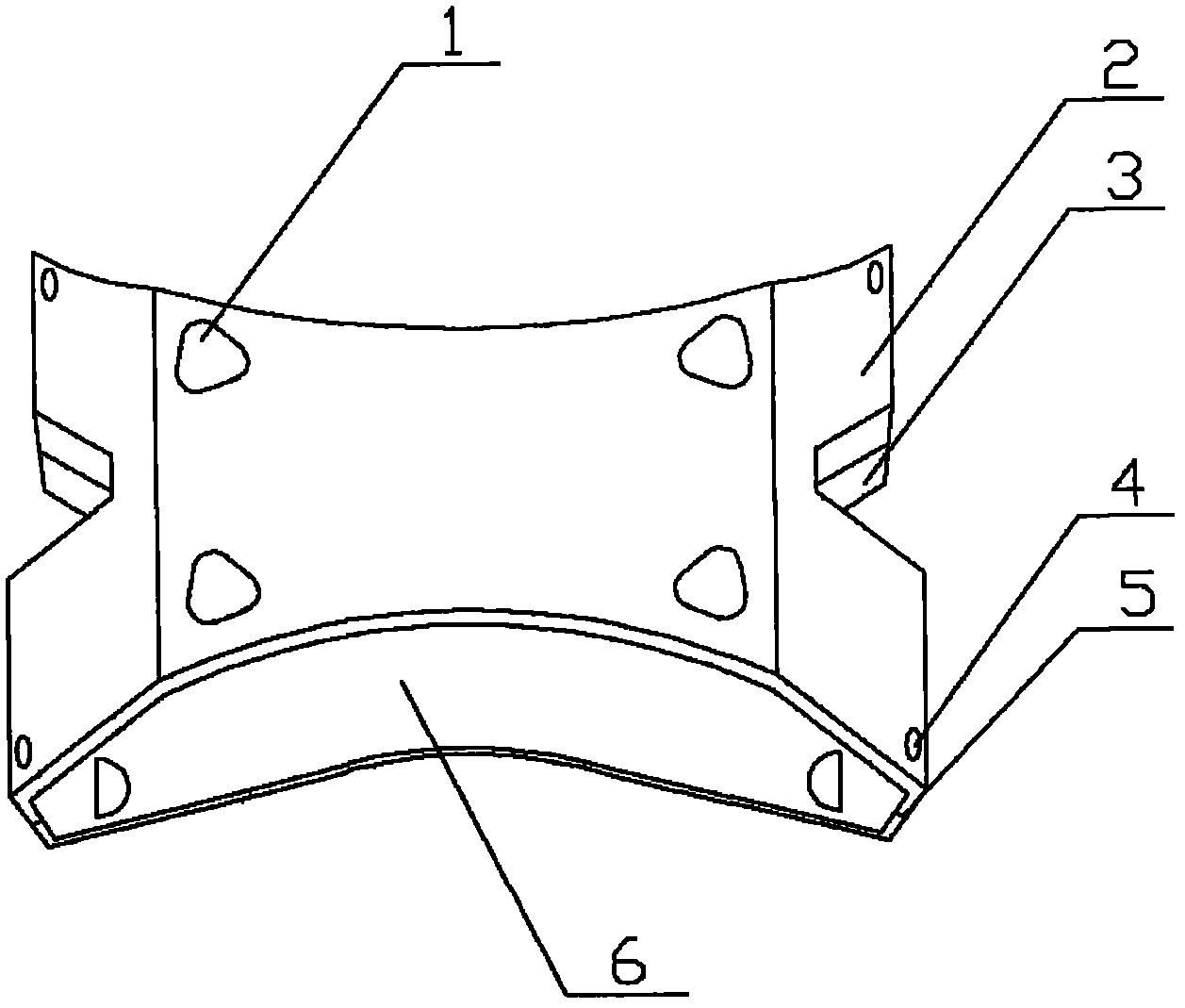

Longitudinal plunging unit with a hollow profiled journal

InactiveUS6918838B2High strengthCompact designYielding couplingShaftsEngineeringMechanical engineering

A longitudinal plunging unit (11) for torque transmitting purposes in a shaft assembly, comprising an outer profiled sleeve (21) having circumferentially distributed, inner, longitudinally extending first ball grooves (22) to be connected to a first attachment part, a profiled journal (31) positioned inside the outer profiled sleeve (21) and having circumferentially distributed, outer, longitudinally extending second ball grooves (32) to be connected to a second attachment part, groups of balls (41) arranged in pairs of first and second ball grooves (22, 32), and a sleeve-shaped ball cage (42) which is positioned in the annular space between the profiled sleeve (21) and the profiled journal (31) and which fixes the groups of balls (41) in their respective positions relative to one another. The profiled journal (31) is a hollow journal comprising a material with a substantially uniform wall thickness with a maximum deviation of ±15%.

Owner:GKN LOBRO

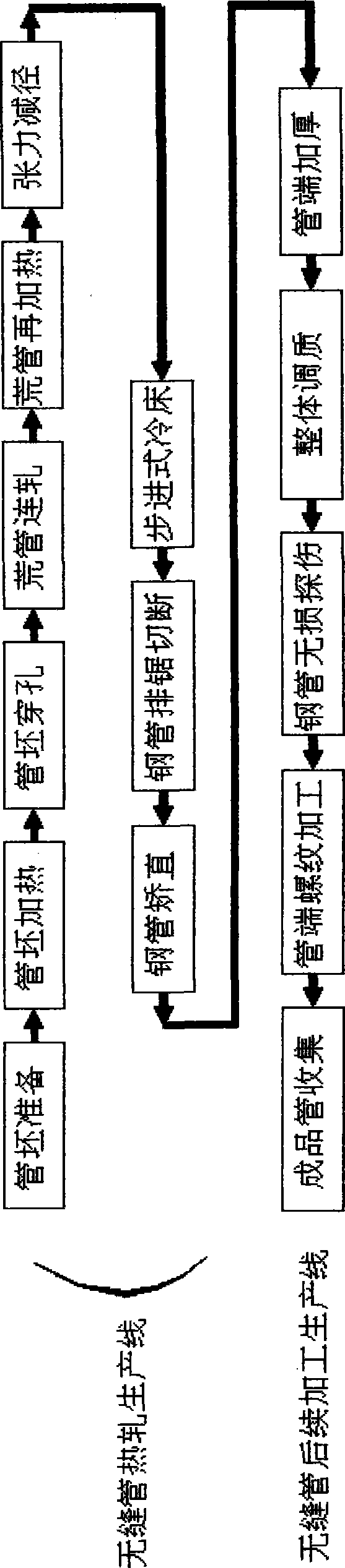

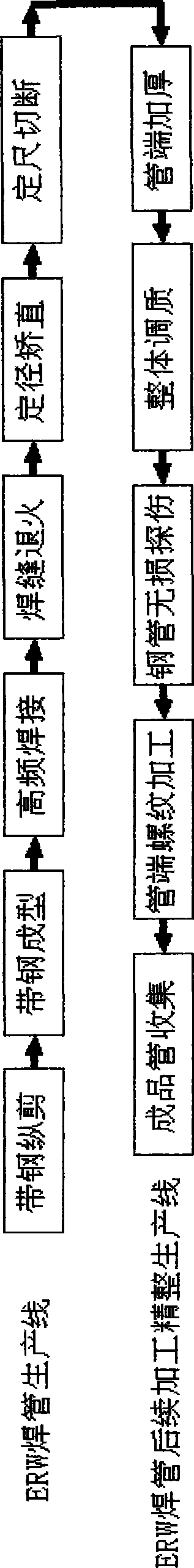

High steel level petroleum casing pipe and oil pipe manufacturing process

InactiveCN101481995AUniform wall thicknessSmooth wallDrilling rodsFurnace typesIntermediate frequencyLength measurement

The invention discloses a preparation method of high-grade steel petroleum casing pipes and oil pipes, and relates to a manufacturing method of petroleum casing pipes and oil pipes; hot rolled steel coils are taken as raw material for manufacturing the steel pipes, and ERW welded pipe material is firstly manufactured by the processes such as longitudinal-shearing striping, band steel formation, high-frequency welding, burr cleaning inside and outside of the welding seams, welding seam detection, intermediate-frequency welding seam annealing, sizing, cutting off, straightening and the like; and the processes such as post-welding finishing, end upsetting (heavy wall tubing needs the process), integral hardening and tempering, medium-temperature straightening, pipe end detection, pipe threading processing, collar screw coupling, hydraulic pressure test, path test, pipe body detection, length measurement, weighting, oiling and the like are carried out, thus producing the high-grade steel petroleum casing pipes and oil pipes. The steel grade of the steel pipe can reach the steel grade specified in API 5CT standard for manufacturing N80Q, L80, C95, P110 and Q125 with a welding method. The high-grade steel petroleum casing pipes and oil pipes manufactured by the invention has the advantages of high production efficiency, low production cost, high lumber recovery, and high product quality.

Owner:江苏嘉宝科技制管有限公司

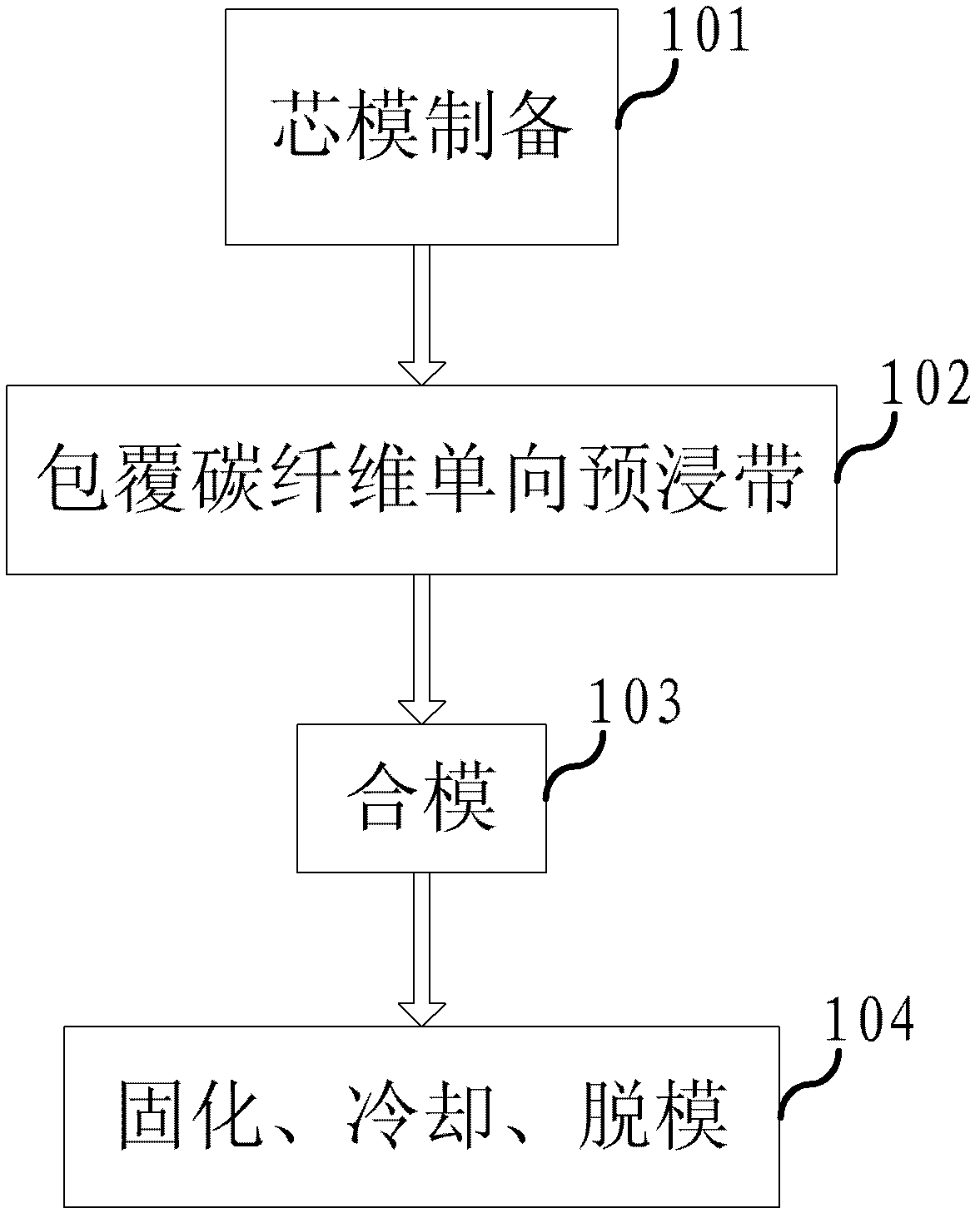

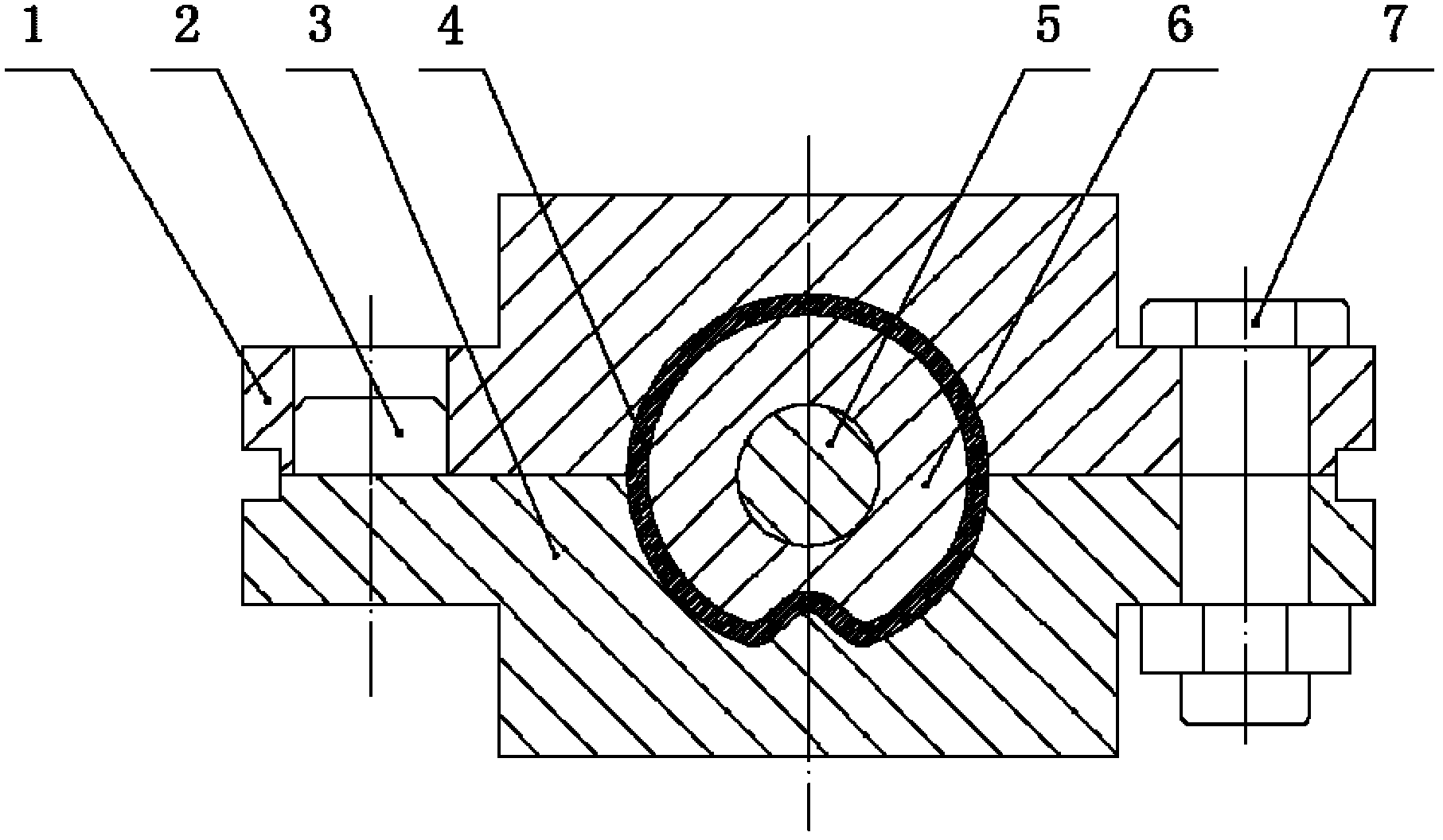

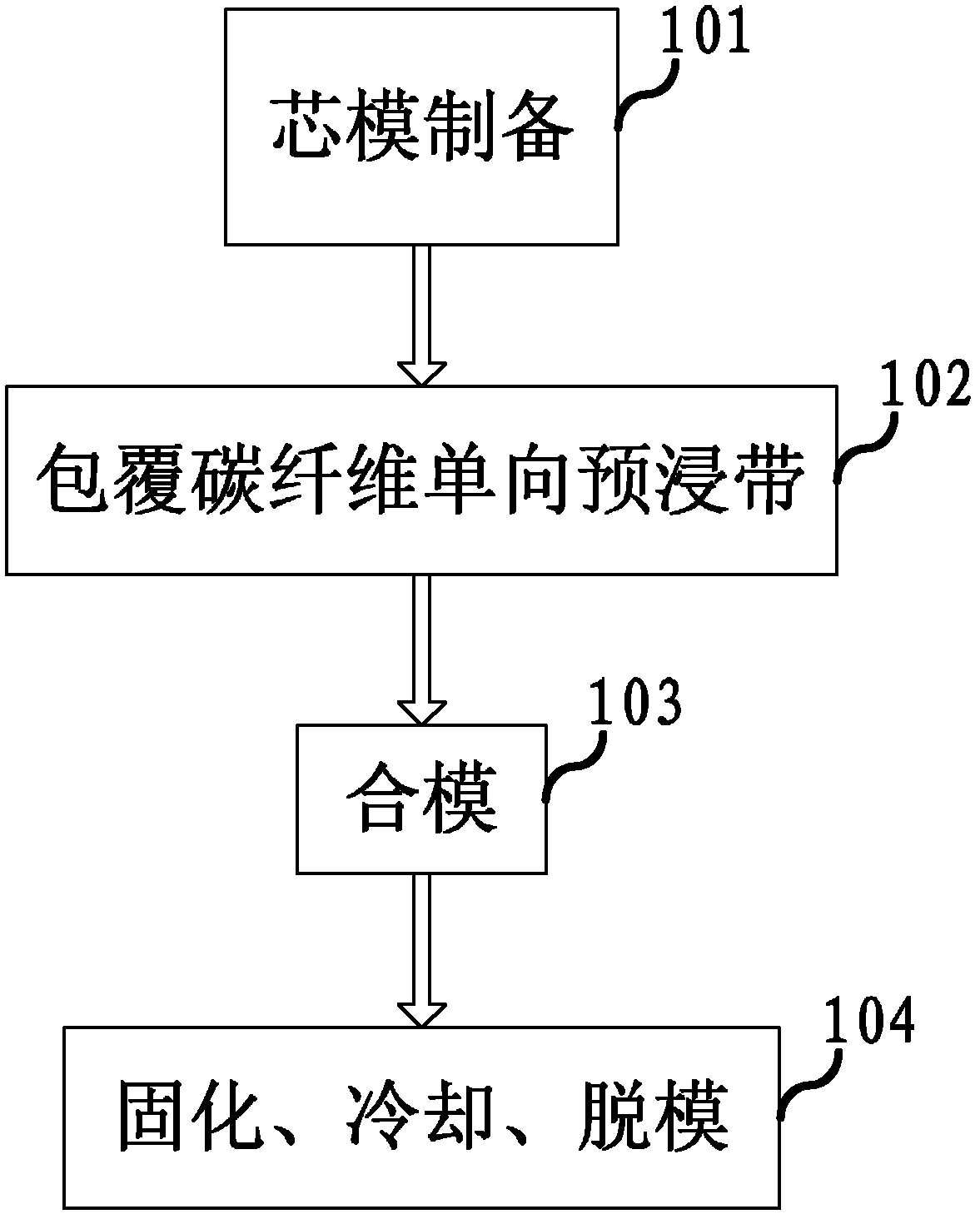

Method for forming carbon fiber pipe and die thereof

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Cast sand core for cylinder cover of diesel engine

ActiveCN104707939AUniform wall thicknessNo input requiredFoundry mouldsFoundry coresInlet channelDiesel engine

The invention discloses a cast sand core for a cylinder cover of a diesel engine. The cast sand core comprises a composite overall sand core, a base plate core, an upper cover plate core and a casting auxiliary core, wherein the composite overall sand core comprises a base plate part, an air inlet channel part, an exhaust channel part, an upper water sleeve part, a lower water sleeve part, a tappet hole part and an exhaust system channel; the exhaust system channel is formed in the composite overall sand core; a sand removal window is formed in the bottom of the composite overall sand core; the base plate core comprises a core assembly frame position, a core assembly abdicating position, a sand core exhaust channel and a casting position; the core assembly frame position is used for accommodating the composite overall sand core; the sand core exhaust channel is communicated with the exhaust system channel; a first sprue is formed in the upper cover plate core; and the casting auxiliary core comprises a second sprue and a first cross gate. According to a casting method for the cylinder cover of the diesel engine by employing the composite overall sand core, the cylinder cover with an accurate shape and a uniform wall thickness can be obtained; and according to the cylinder cover of the diesel engine, the floating core phenomenon in casting of the air inlet cannel, the exhaust channel, the upper water sleeve and the lower water sleeve is avoided, a cylinder cover water cavity is free of a joint surface, a product casting is free of a water sleeve burr, and the water cavity is high in cleanliness.

Owner:GUANGXI YUCHAI MASCH CO LTD

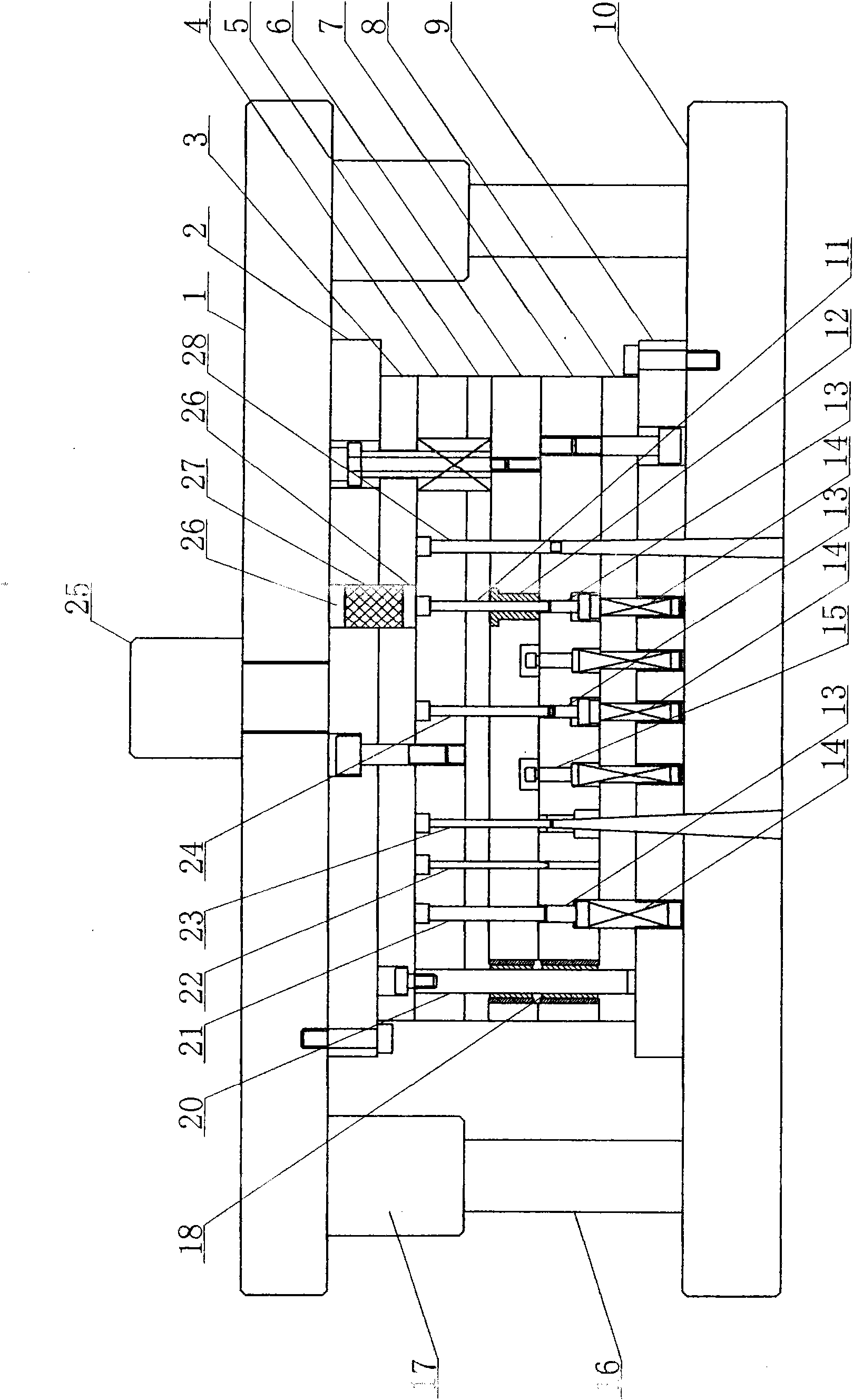

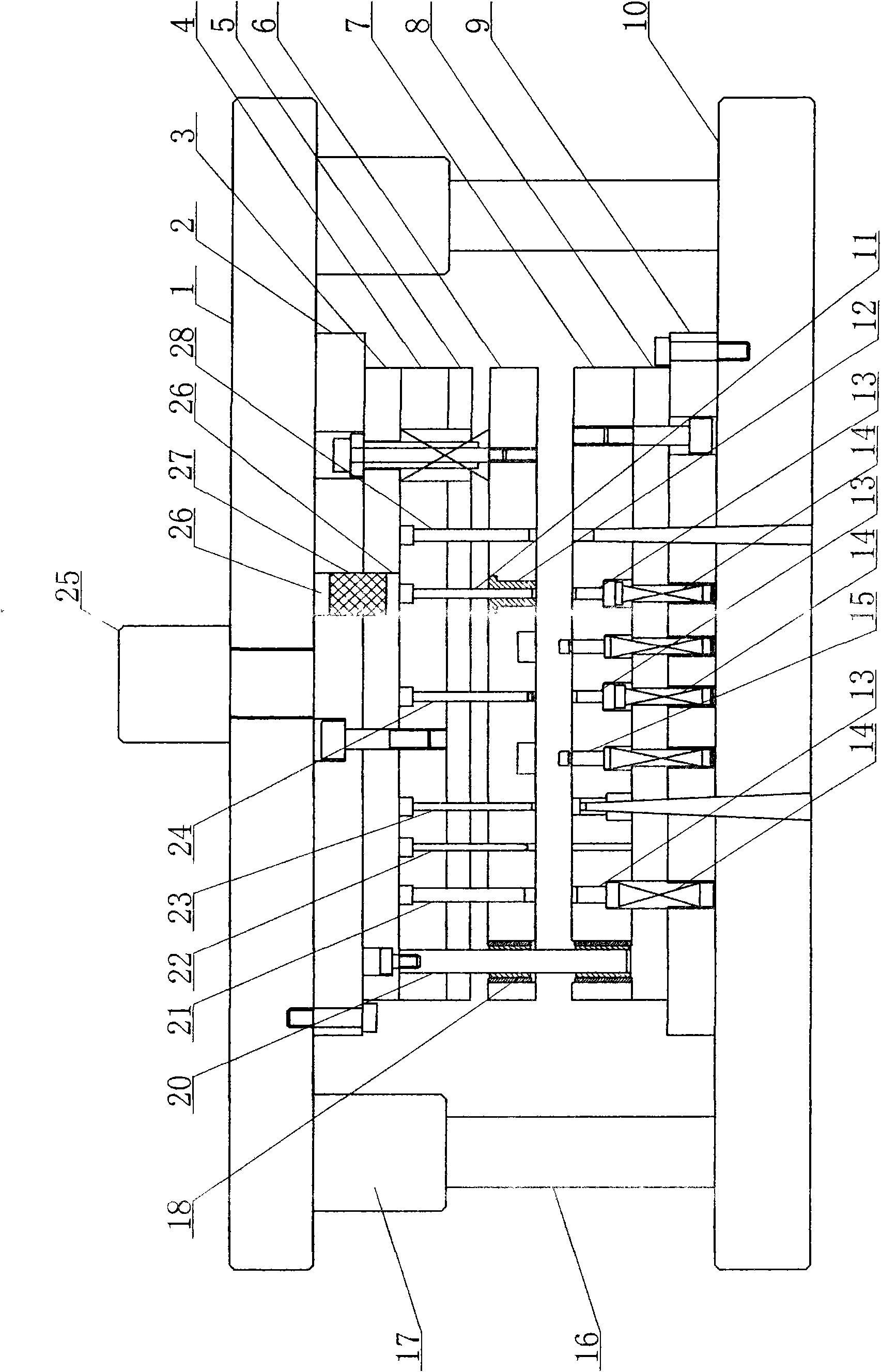

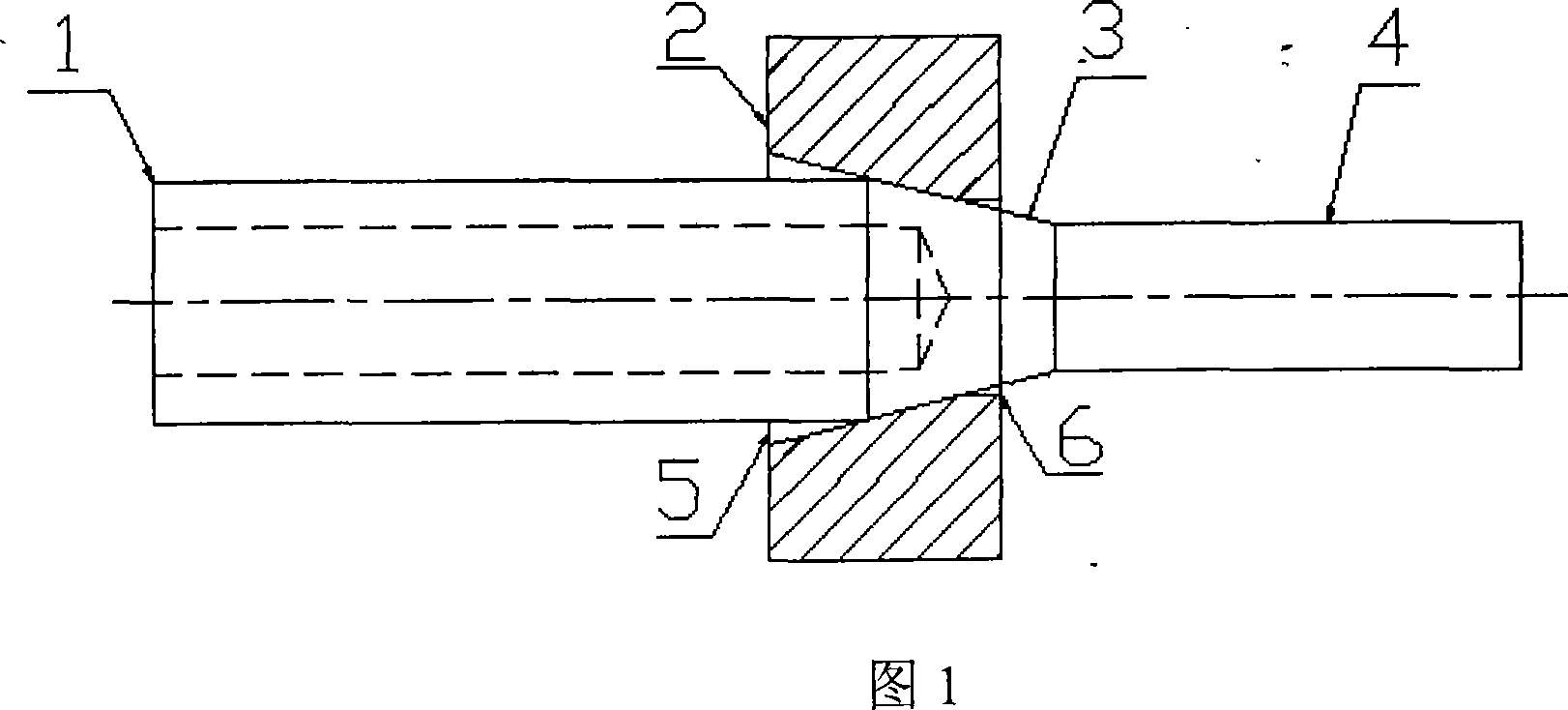

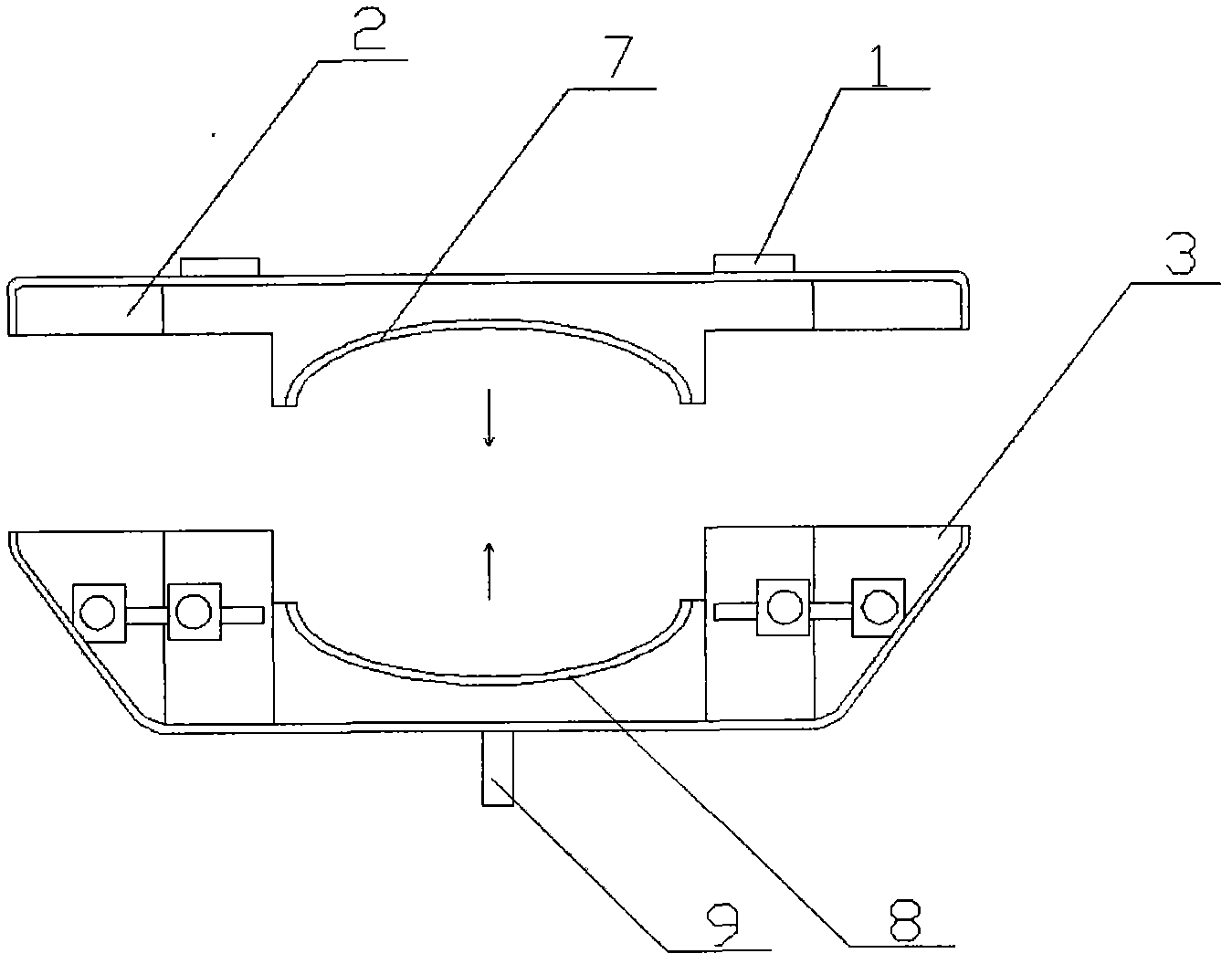

Method for producing thin-wall metal circular ring and grading stamping mould used therefor

ActiveCN101767164AIncrease productivityUniform wall thicknessShaping toolsPunchingElectronic industry

The invention discloses a method for producing a thin-wall metal circular ring, which comprises the steps of deep-drawing, punching, turning up, shaping and blanking plate materials or strip-shaped materials on a grading stamping mould. The grading stamping mould used for implementing the method mainly comprises an upper mould part and a lower mould part, wherein a deep-drawing male mould, a punching male mould, a turning-up male mould, a shaping male mould and a blanking male mould are arranged on the upper mould part sequentially; the male moulds all pass through a discharging plate; an annular convex part is arranged on the part, which surrounds the shaping male part, of the discharging plate; a deep-drawing female mould, a punching female mould, a turning-up female mould, a shaping female mould and a blanking female mould are arranged on the lower mould part sequentially; and spring-ejecting parts are arranged in the cavities of the deep-drawing female mould, the turning-up female mould and the shaping female mould. The method solves the technical problems of low processing precision and low production efficiency of the metal circular ring with two straight end faces. The method has a simple structure and is widely applied to the production manufacturing industry of the metal circular ring in electronic industry.

Owner:WEIFANG YUYUAN ELECTRONICS CO LTD

Method for precision forming of concave-bottom and thin-wall cylindrical part with large length and diameter ratio

The invention discloses a method for precision forming of a concave-bottom and thin-wall cylindrical part with large length and diameter ratio. The method comprises the following steps of firstly, calculating the size of a plate blank; then, forming the concave bottom, performing deep drawing and spinning to form a cylindrical blank, and performing spinning and thinning on the blank to reach the specified size; performing subsequent universal processing to meet the requirement of part size; in the deep drawing and spinning process of the cylindrical blank, turning the blank with the formed concave bottom, fixing between a tail jack and a code die, preparing a common spinning track by a common spinning track preparation method, enabling a main shaft to drive the blank to rotate, enabling a rotary wheel to feed according to the prepared track under the drive action of a numerical control system, using the first 6-8 passes of the spinning track as the simple reciprocating spinning, using the subsequent passes of the spinning track as the spinning track combined with the reciprocating travel, and performing the deep drawing and spinning on the blank to form the cylindrical part. The method has the advantages that by utilizing multiple times of deep drawing and spinning, the cylindrical blank is obtained, and then the spinning and thinning are performed on the blank to reach the specified size; by utilizing the characteristics of strong spinning and high accuracy, the wall thickness of the manufactured part is uniform, the surface quality is high, the compactness is good, and the number of defects is fewer.

Owner:SOUTH CHINA UNIV OF TECH

Process for forming magnesium alloy ultra-fine thin-wall tube used for degradable blood vessel bracket

The invention provides a figuration technology of superfine magnesium alloy thin-walled tube for degradable vascular bracket. The characteristics of its major technique is adding yttrium to pure magnesium, mixing RE, Al, Ca, Mn, Sb, Zn, and Zr, smelting through gas shield smelting + reduction iron solvent refining method to obtain ingot casting of magnesium alloy, performing hot extrusion, distortion and solution treatment, intercepting certain length as workpiece for subsequent processing, processing one end to tubular form and the other end to clubbed form, heating the pipe end, and tugging through multiple tracks to obtain superfine thin-walled tube with diameter of 2-10mm, wall thickness of 0.20-1mm.Its advantage is overcoming limitation of figuration technology such as pressing, has low cost, uniform wall thickness and tissue, and good mechanical property.

Owner:SHENYANG POLYTECHNIC UNIV

Method for preparing nano tube of some metalloid oxides and metals with size and shape being controllable

InactiveCN1462720AHigh yieldUniform diameterMaterial nanotechnologyPolycrystalline material growthAmphiphilePolyethylene glycol

A process for preparing the size and shape controllable ampholytic metal oxides and their metallic nanotubes features that based on the principle that under existance of excessive alkali the ampholytic metal hydroxide can become coordinate anions, under the action of surfactant as "soft template", the ampholytic metal oxide and its metallic nanotubes can be prepared by direct hydrothermal reaction or redox reaction (for example, ZnO, CuO, Al2O3, PbO2, SnO2 and relative metals). Its advantages are simple process, controllable sizes of nanotube, uniform wall thickness, and high output.

Owner:NORTHEAST NORMAL UNIVERSITY

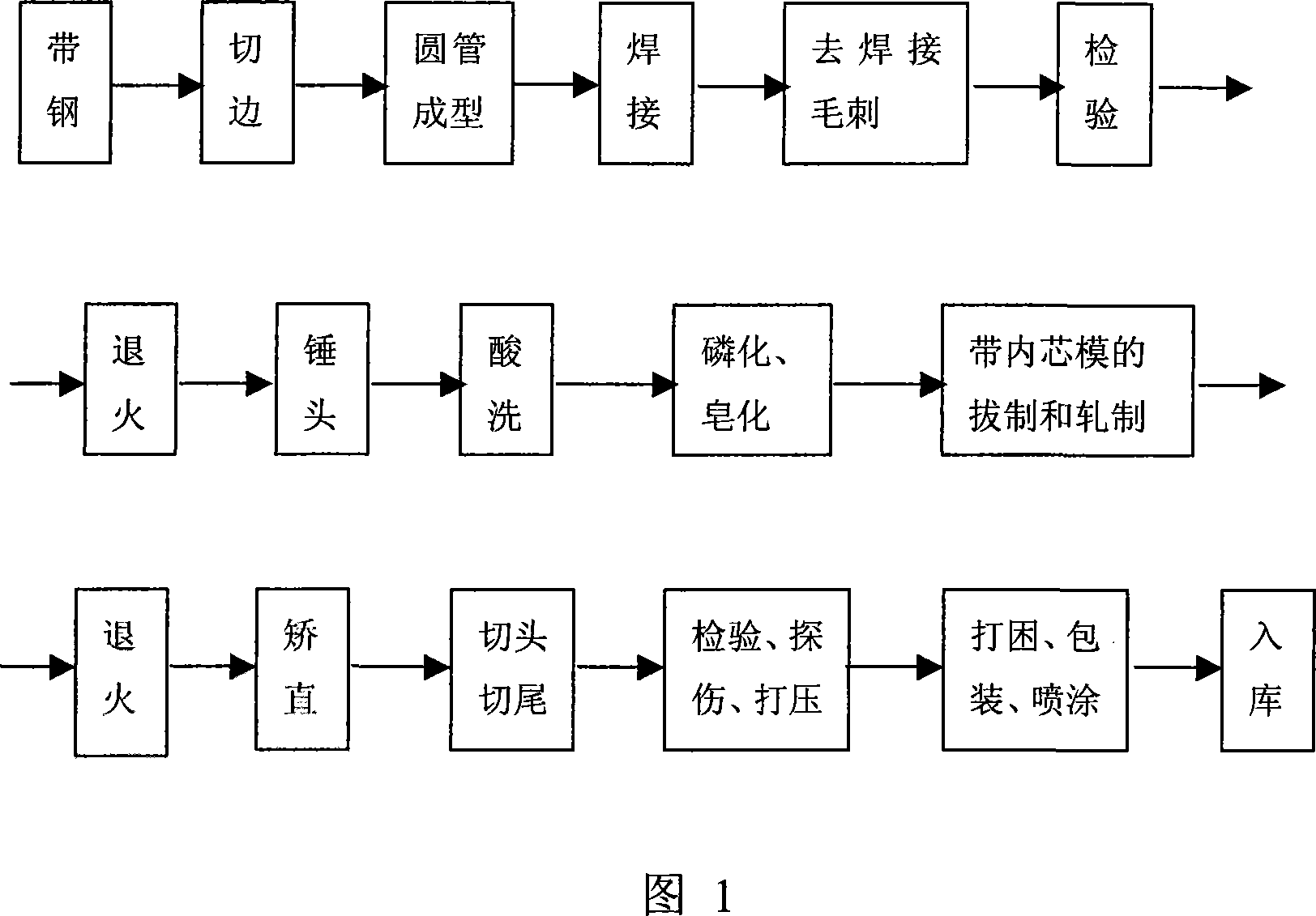

Cold drawing, cold rolling production method for high-accuracy weldless steel tube

InactiveCN101130197ASimple processLow costHigh frequency current welding apparatusChemical compositionStrip steel

The invention discloses a cold-drawing and cold-rolling manufacturing method of high-precision seamless steel pipe, which comprises the following steps: doing pipe formation procedure for the front part to cut edge of raw material steel, mould round tube, weld, remove the welded burr, detect the standard product to enter subsequent disposing procedure; doing back disposal procedure to heat, beat, wash through acid, phosphorized, saponify; rolling the mould with inner core; annealing; aligning; cutting head and tail; detecting flaw; bulging; testing; packing; storing. The invention saves energy and cost with simple operation and even wall thickness, which can replace common seamless steel pipe, low-middle pressure boiler pipe and steel pipe of the fluid completely.

Owner:李永立

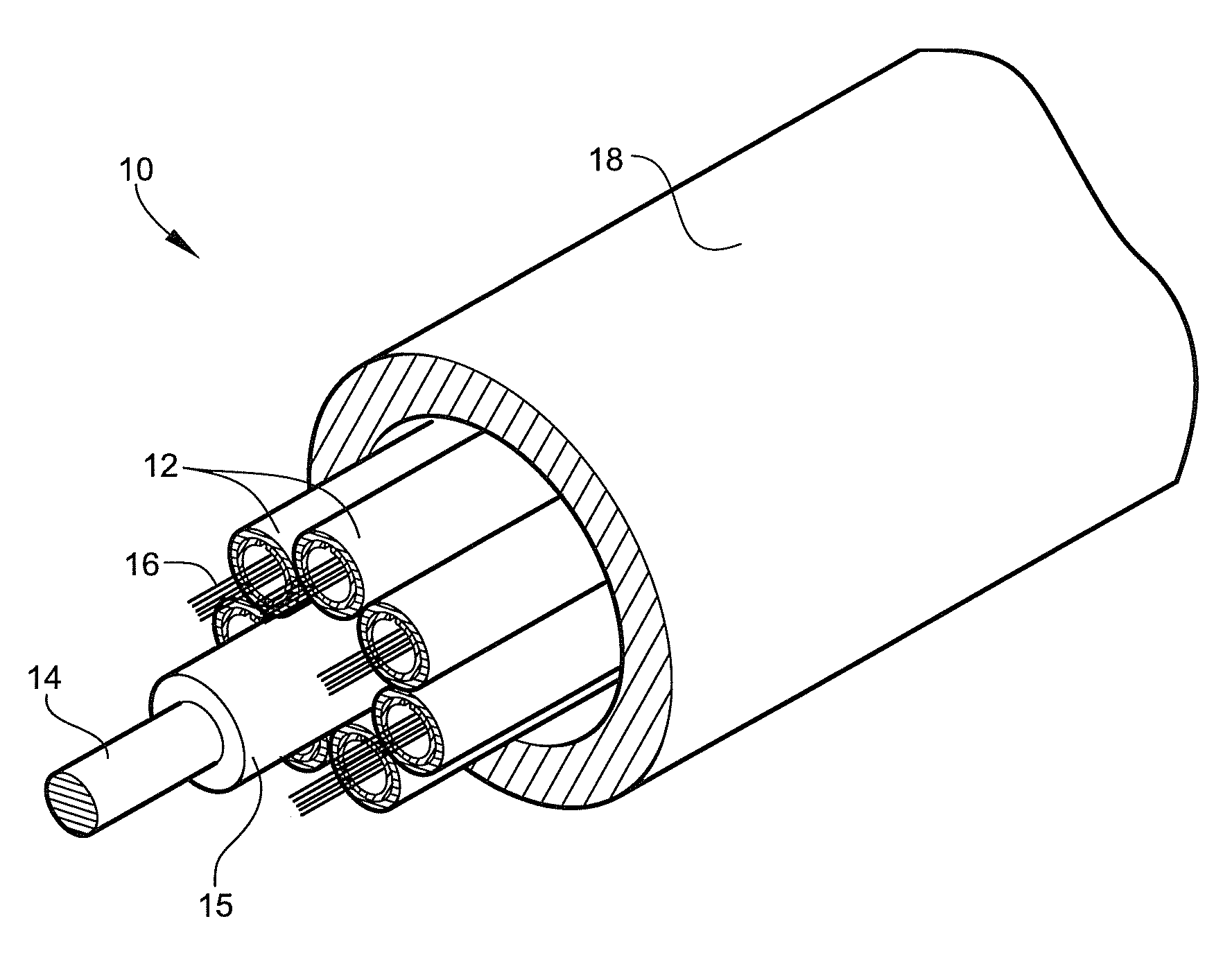

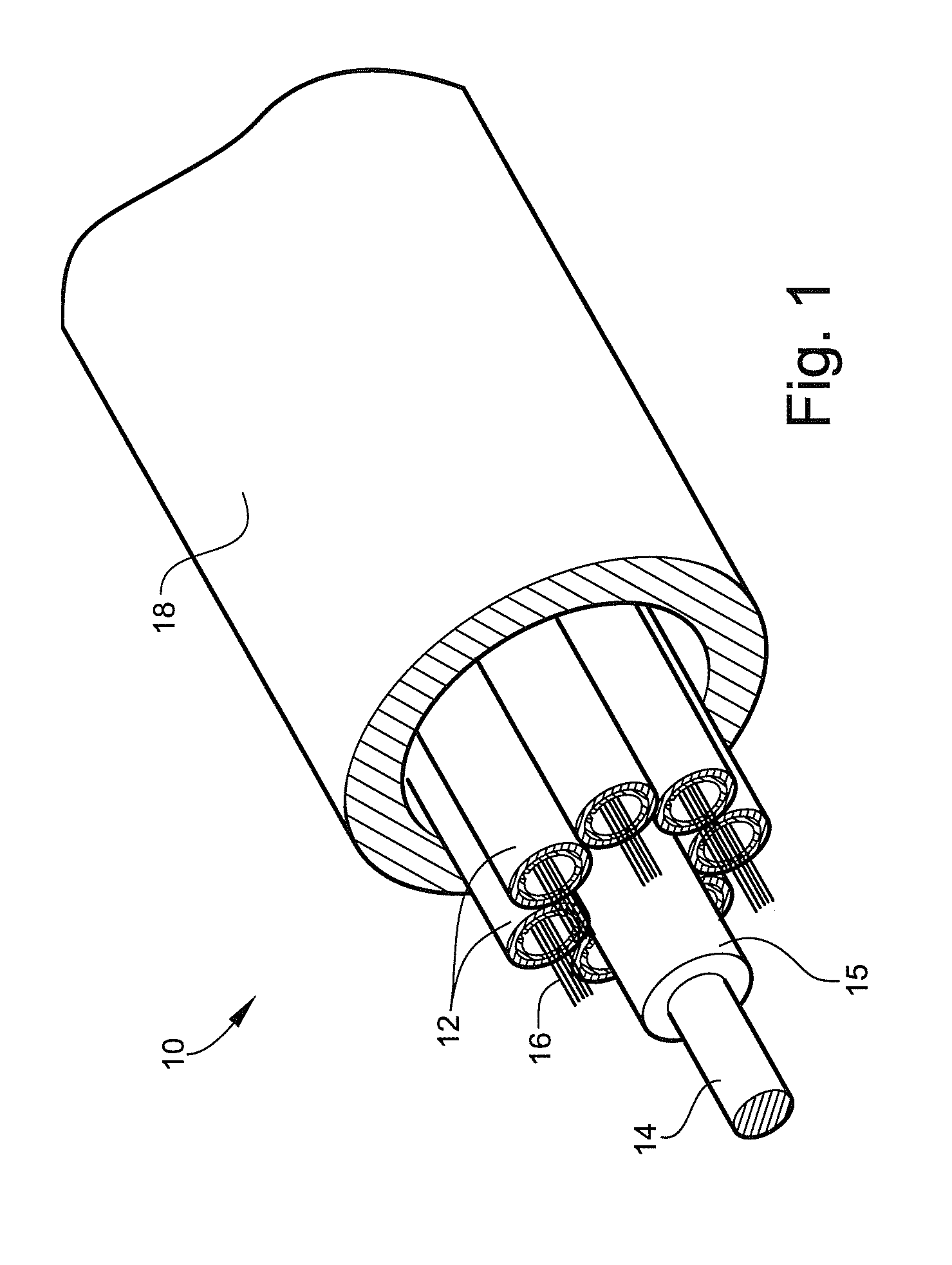

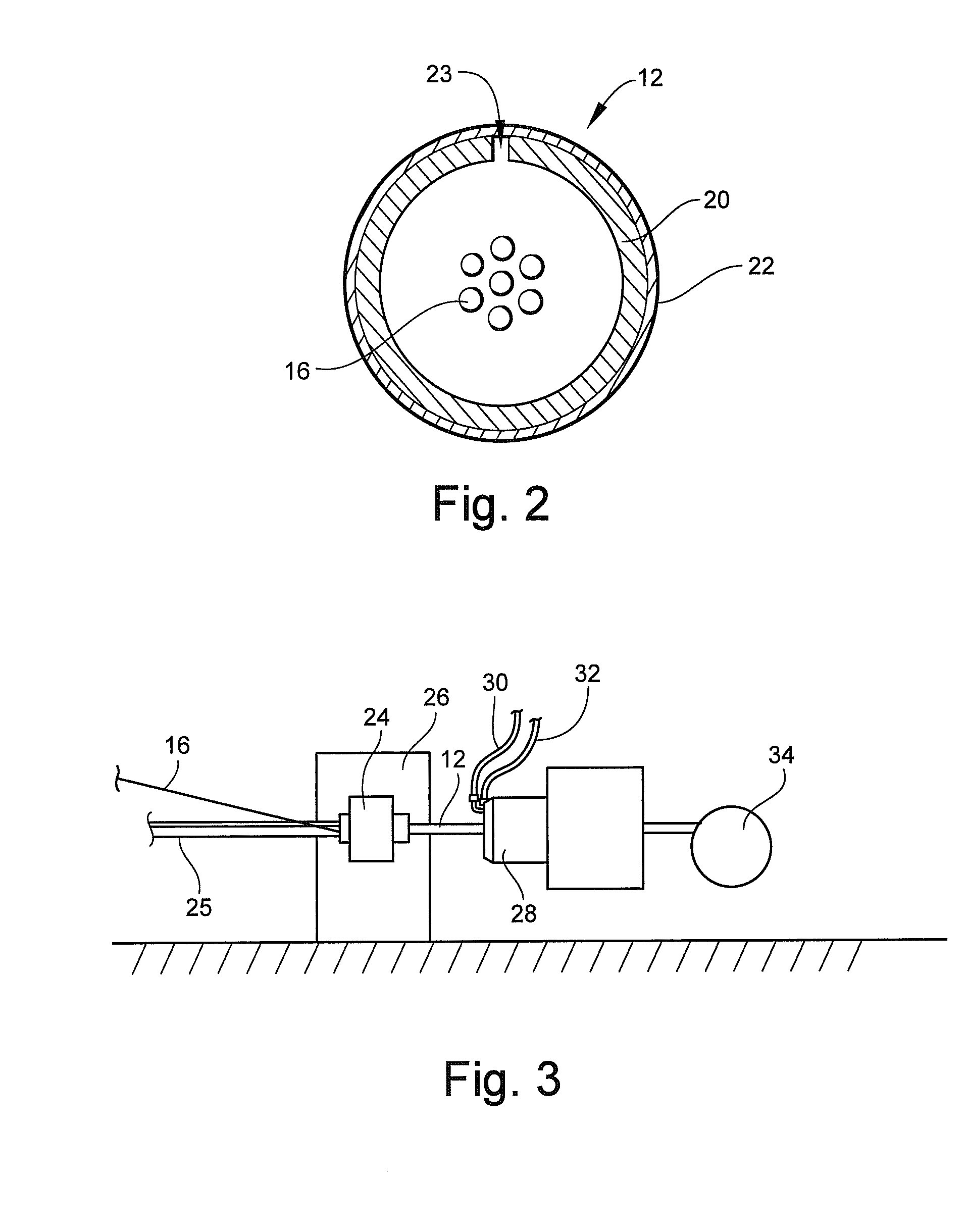

Method of forming an optical fiber buffer tube

InactiveUS20110194825A1Uniform wall thicknessLess radial controlFibre mechanical structuresCoils manufactureMaterials scienceOptical fiber

A method of forming an optical fiber buffer tube including the steps of providing a length of pre-shrunk tape having a predetermined width and thickness, forming the tape into a tube around at least one optical fiber, coating the formed tube with a molten material to close the tube, and cooling the molten material to maintain the shape of the tube. The method further includes calibrating the outer diameter of the coated tube during the cooling step by restraining the coated tube against outward radial expansion. An optical fiber buffer tube constructed according to the method is further provided.

Owner:DRAKA COMTEQ BV

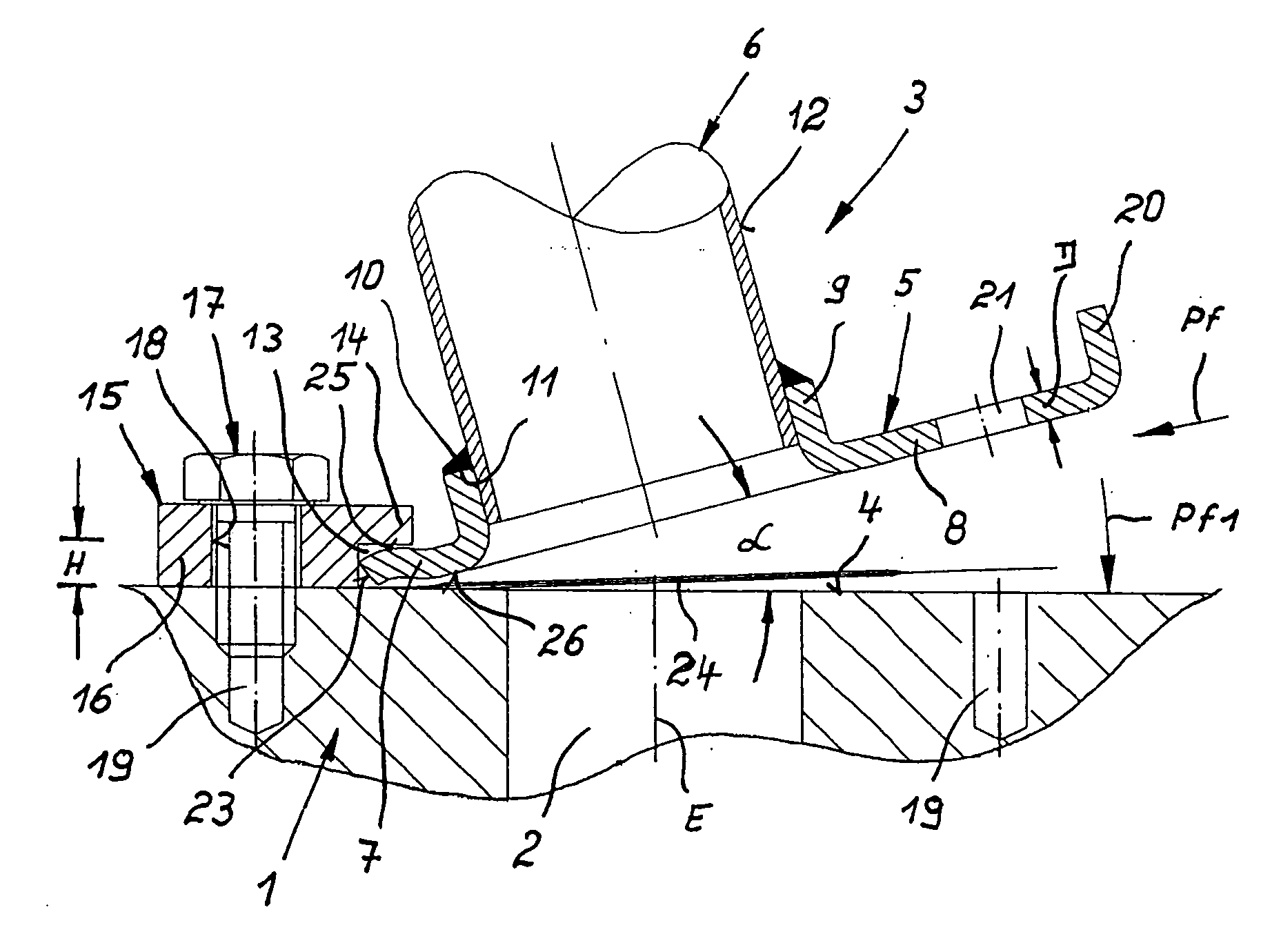

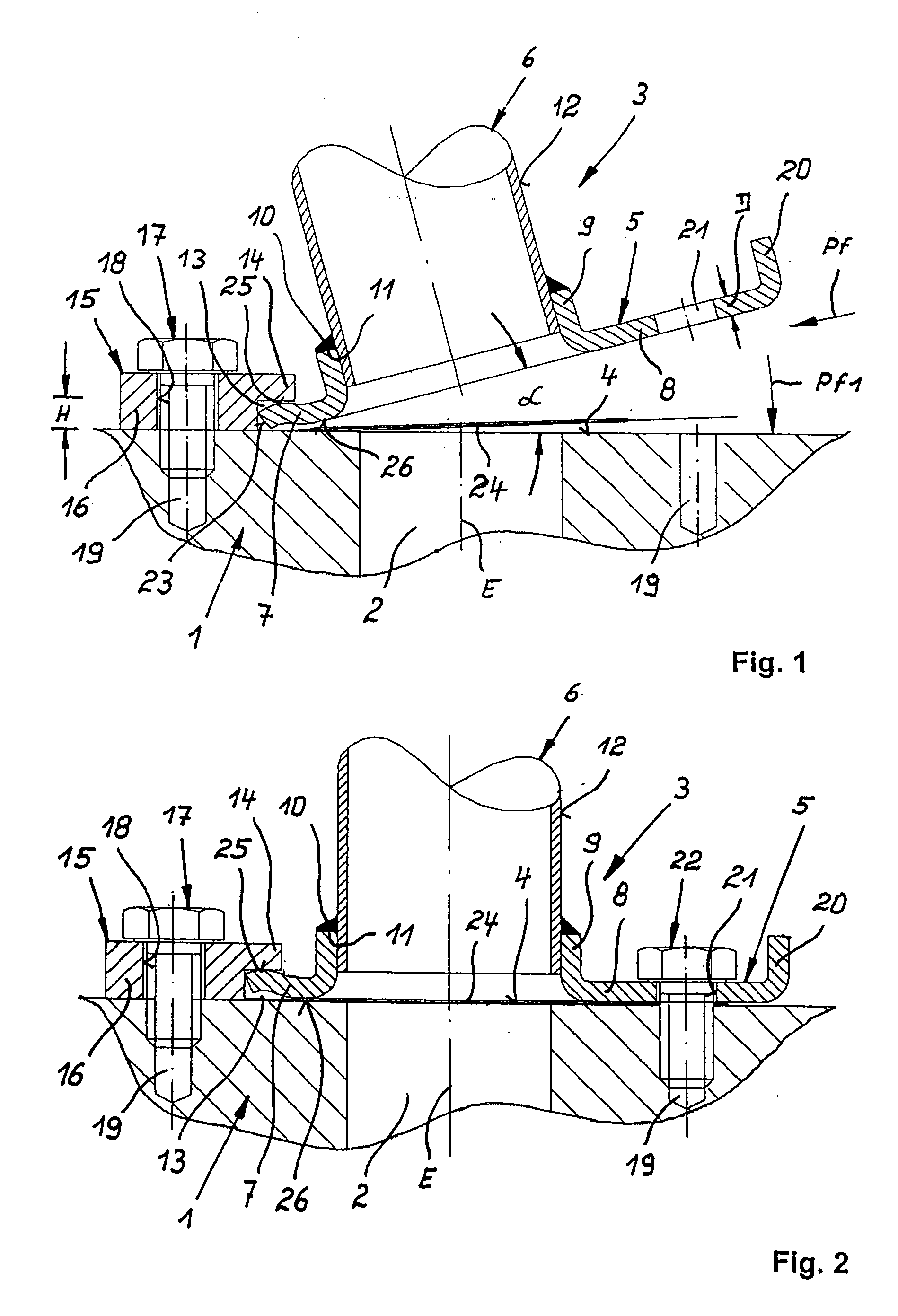

Arrangement for securely mounting an exhaust manifold to the cylinder head of an internal combustion engine

InactiveUS20050268602A1More stressProlong lifeFlanged jointsExhaust apparatusCylinder headEngineering

An exhaust manifold has a head flange constructed for receiving at least two exhaust pipes arranged side-by-side, and includes spaced apart first and second longitudinal flange portions. A mounting assembly is provided for sealingly securing the exhaust manifold to a cylinder head of an internal combustion engine and includes a mounting rail formed with a shoulder which laps over the first longitudinal flange portion and contacts the first longitudinal flange portion in a spring-elastic manner. Plural screw fasteners at least indirectly clamp the second longitudinal flange portion to the cylinder head.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

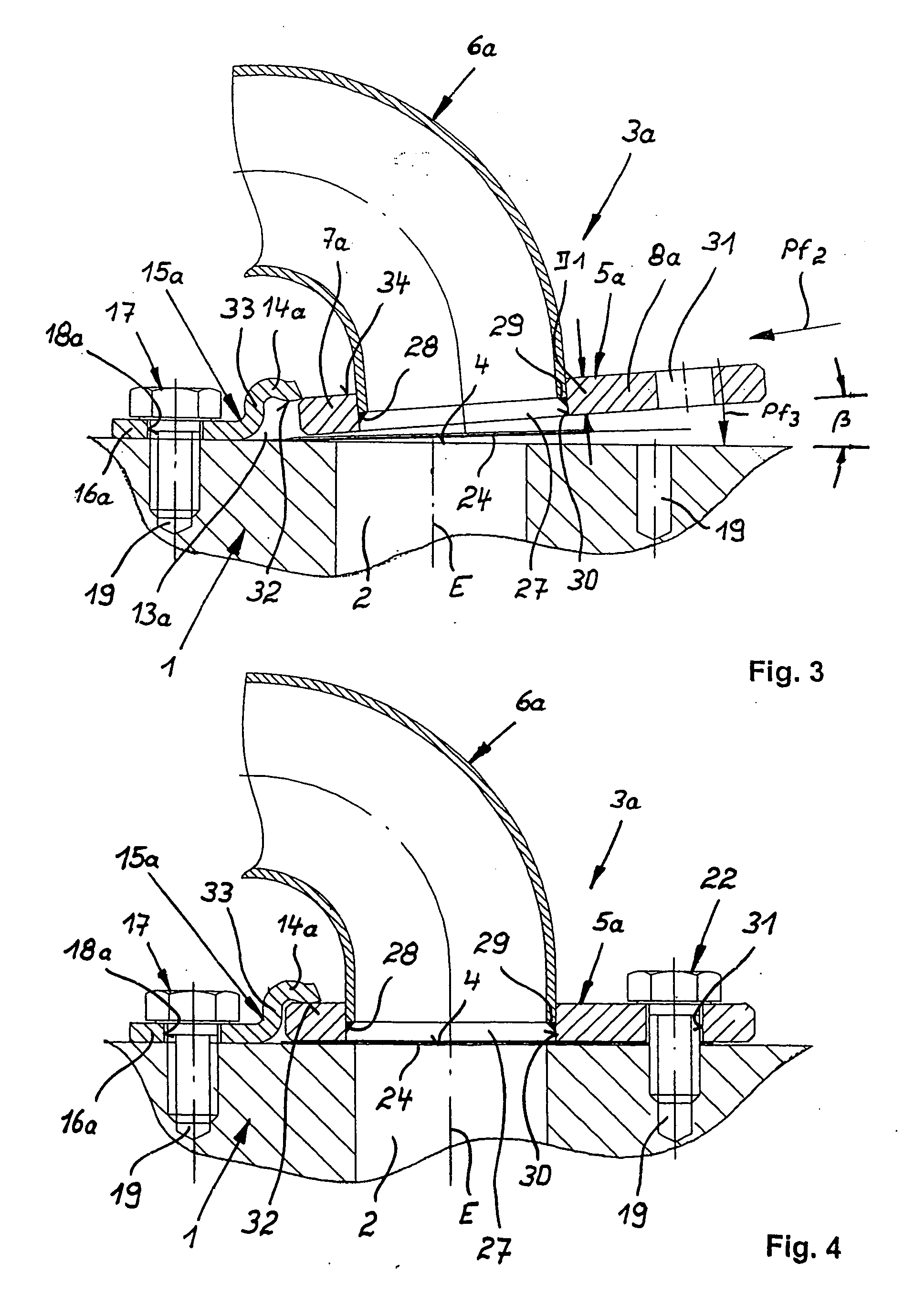

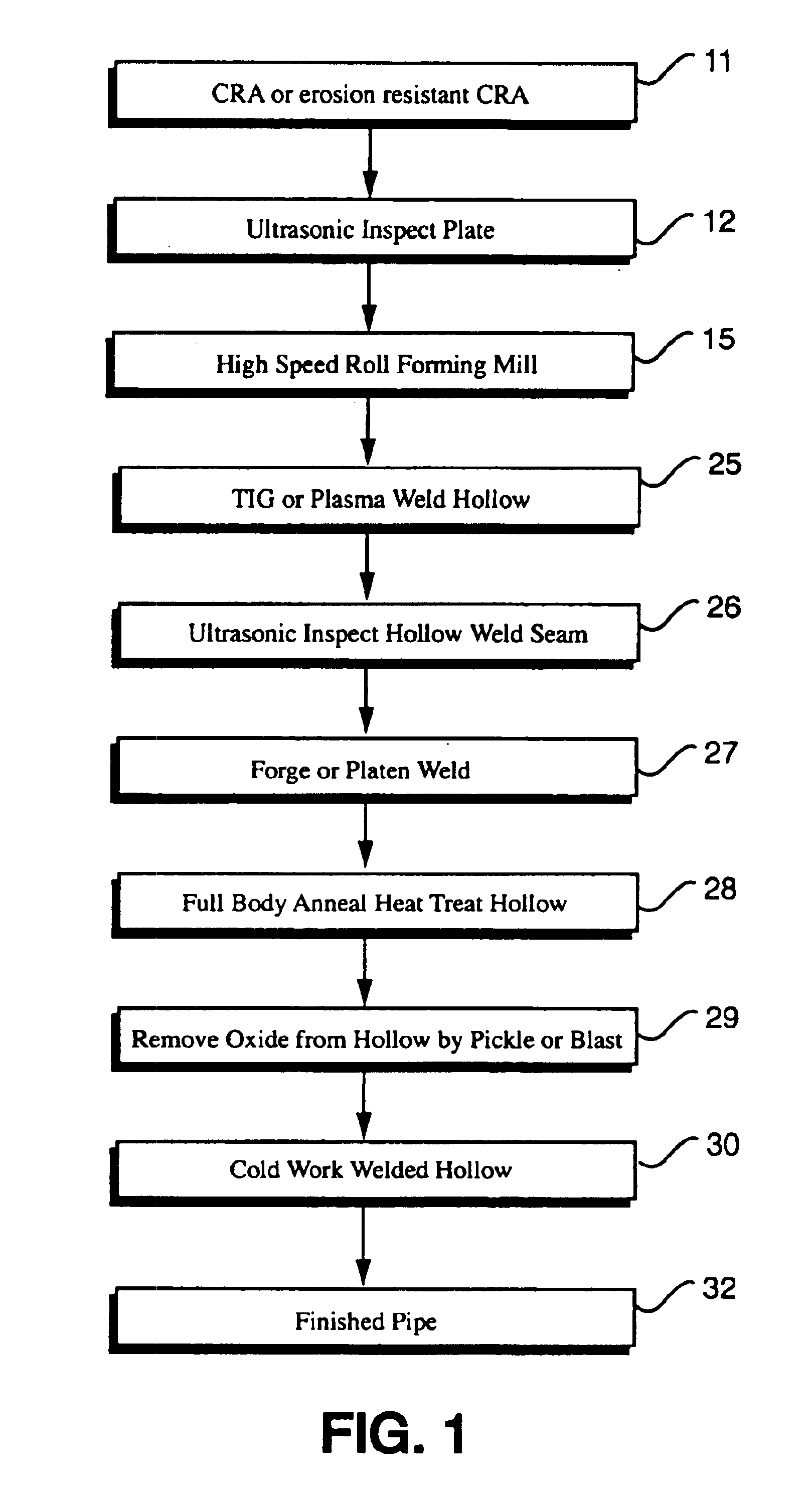

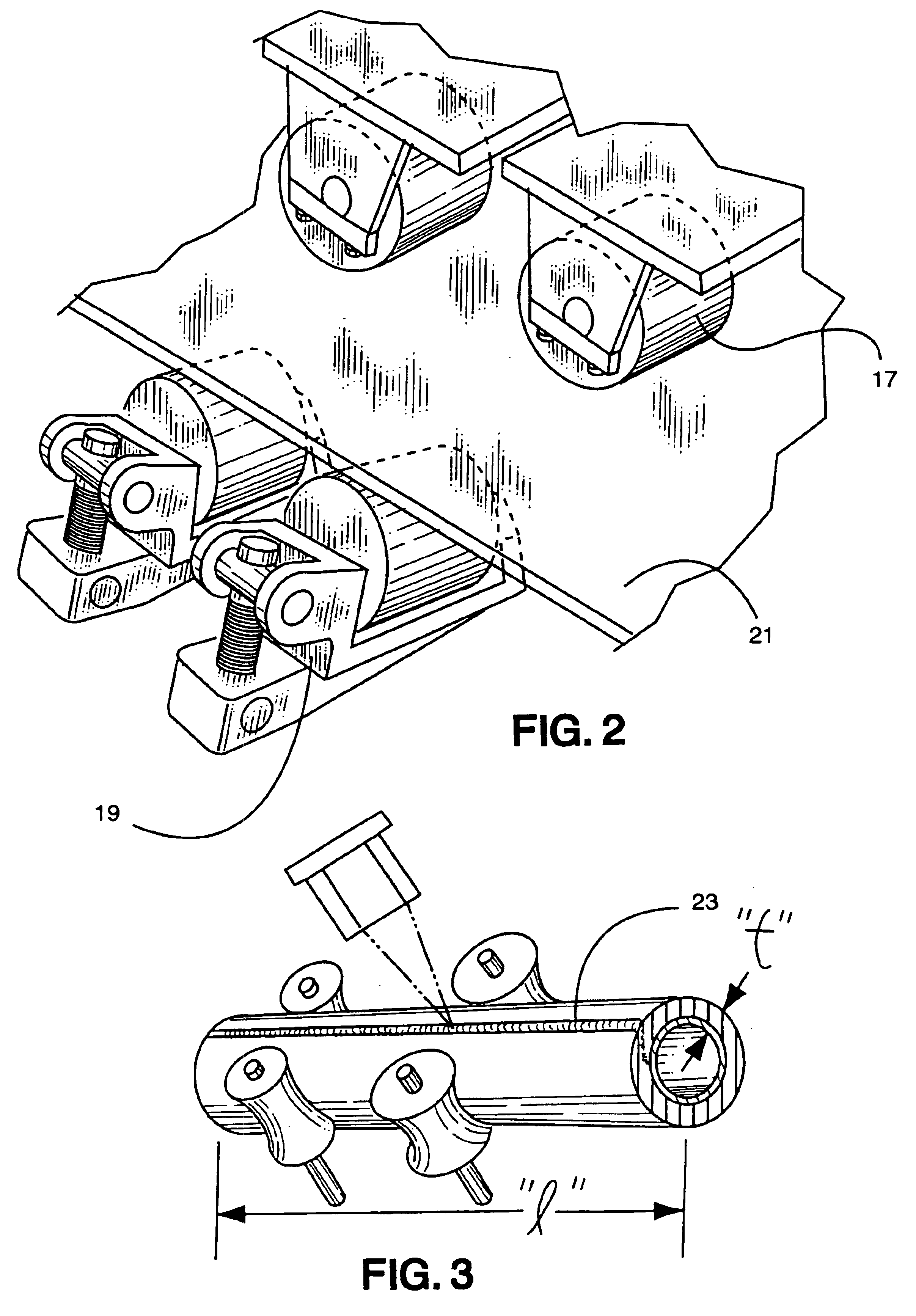

Method of manufacturing cold worked, high strength seamless CRA PIPE

InactiveUS6880220B2High tensile strengthHigh yield strengthSoldering apparatusArc welding apparatusRoll formingCorrosion

A process produces a welded seamless PIPE having good yield strength and excellent corrosion and / or erosion resistance. Up to a maximum outside diameter corrosion and / or erosion resistant CRA PIPE is cold worked from a welded hollow, rather than using the traditional seamless pierced hollow method. A high-speed roll-forming mill is also utilized, rather than using the slow traditional break press to form the welded hollow. Welded hollow dimensions can be achieved which comply with the method of cold working's capability to produce the yield strengths and dimensional tolerances required to meet the service criteria of the PIPE's intended application.

Owner:CORROSION RESISTANT ALLOYS

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

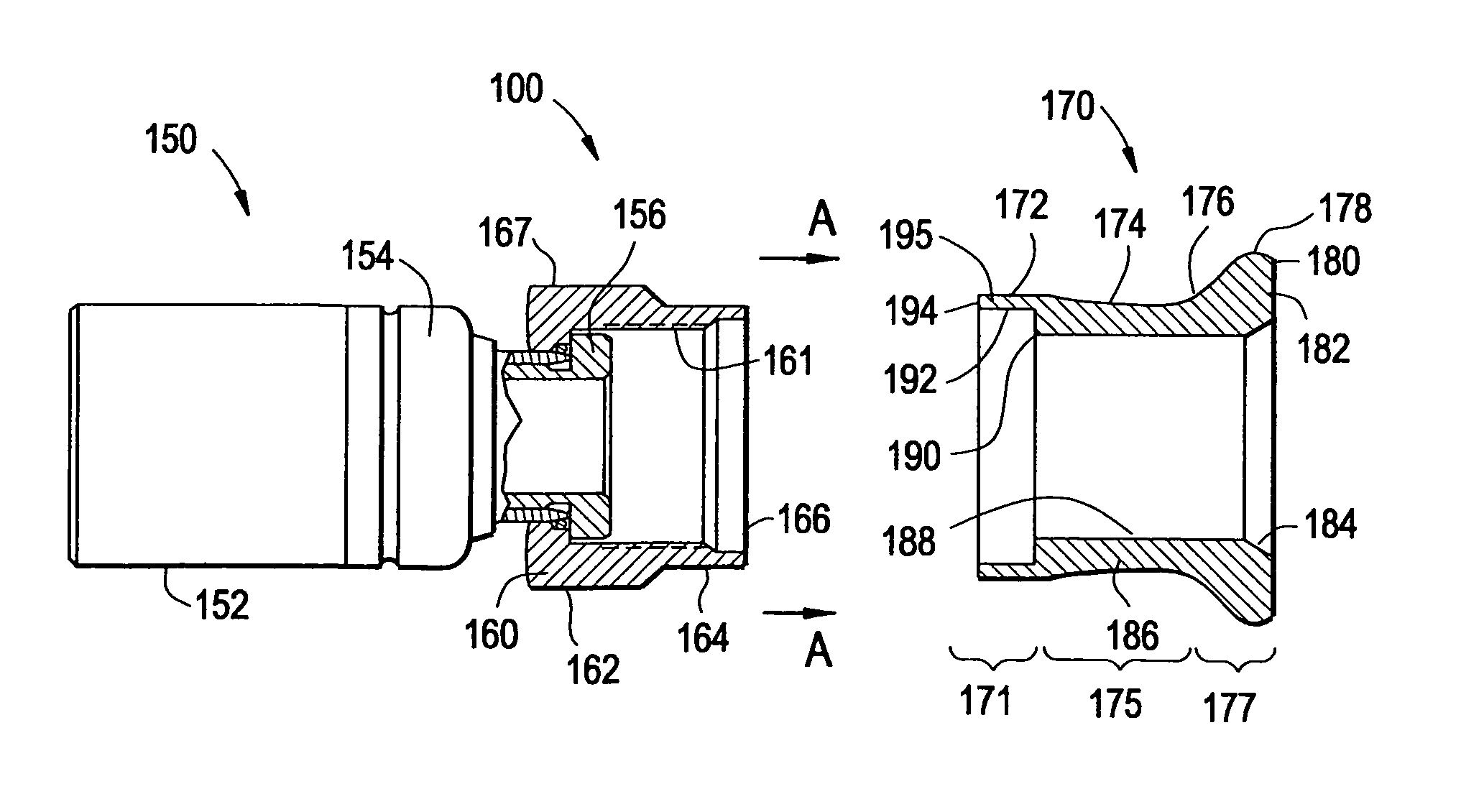

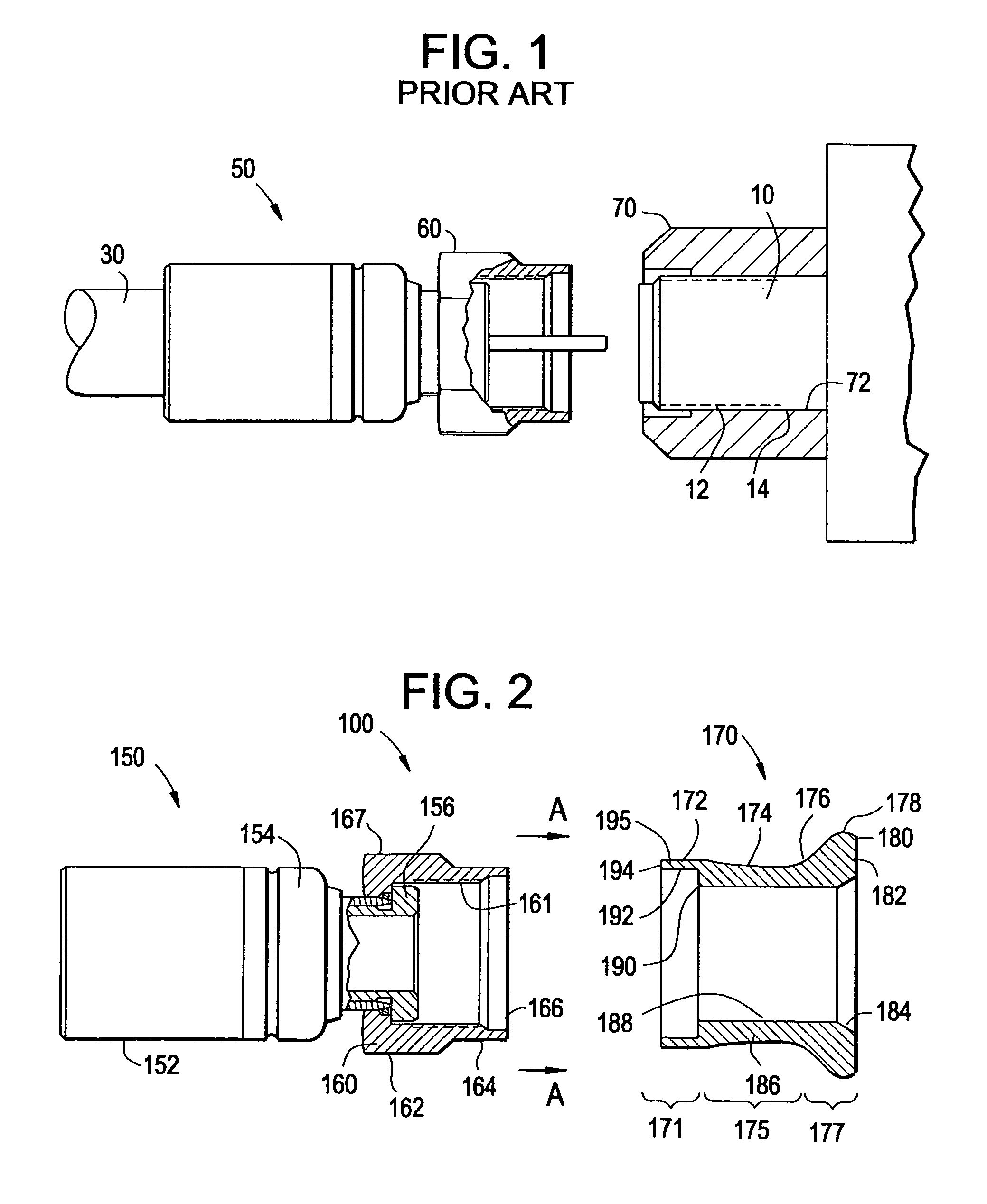

Seals and methods for sealing coaxial cable connectors and terminals

ActiveUS7938662B2Little strengthUniform wall thicknessElectrically conductive connectionsTwo pole connectionsCoaxial cableEngineering

Owner:PPC BROADBAND INC

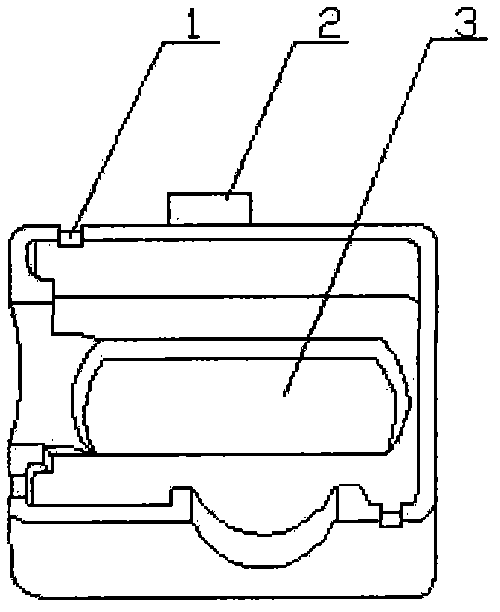

Expendable pattern for manufacturing corner fittings of container and manufacturing method and using method thereof

InactiveCN102029358ACasting high added valueSolution to short lifeFoundry mouldsFoundry coresEngineeringElectrical and Electronics engineering

The invention provides an expendable pattern for manufacturing corner fittings of a container. The expendable pattern comprises a casting latex channel, a first expendable pattern and a second expendable pattern, wherein an expendable pattern latex channel is formed on a side external wall of the first expendable pattern; a first through hole and a plurality of grooves are formed on the first expendable pattern; a second through hole and a third through hole are formed on a wall of the second expendable pattern; a plurality of connecting bumps are formed on the second expandable pattern; the grooves and the connecting bumps are in inserted joint; the expendable pattern latex channel and the casting latex channel are in glued and fixed connection; the casting latex channel is prismatic; the connection position of the grooves and the connecting bumps is provided with gummed paper which is glued and fixed with the first expendable pattern and the second expendable pattern. The process issimple; the expandable pattern has a rational pattern structure, low cost and high production efficiency; and the produced corner fittings of the container have smooth surfaces and low casting defectrate.

Owner:青岛顺联集装箱部件制造有限公司

Rotational moulding

A method of producing a plastics article having solid skin and a foam core by a rotational moulding process, comprises charging a mold with a skin-forming component and substantially simultaneously with a foam core-forming component of bulk density greater than 0.5 g / cc, providing a first heating stage in which the mold is heated to a first temperature and is rotated for a first predetermined time to form a substantially impervious skin within the mold, and providing a second heating stage in which the mold is heated to a higher second temperature and is rotated for a second predetermined time to cause foaming of said foam core-forming component, thereby forming a foam core within said substantially impervious skin.

Owner:ROTEC CHEM

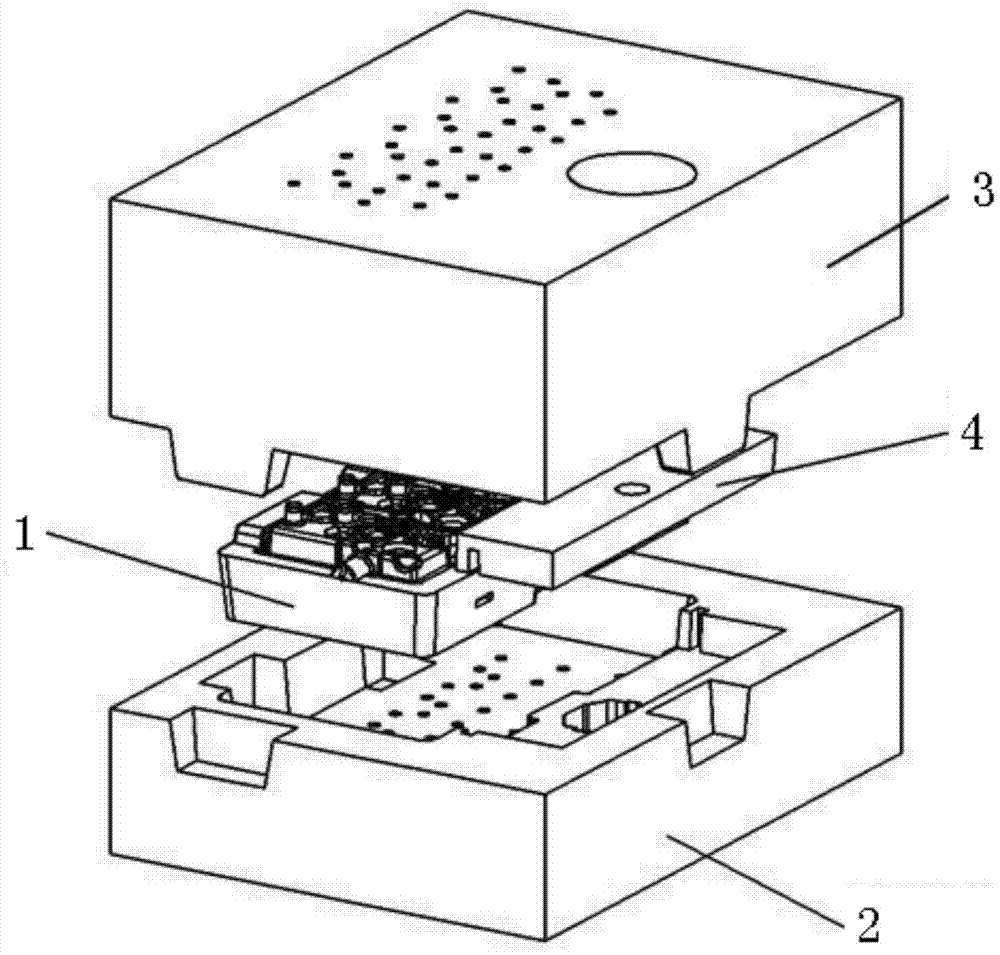

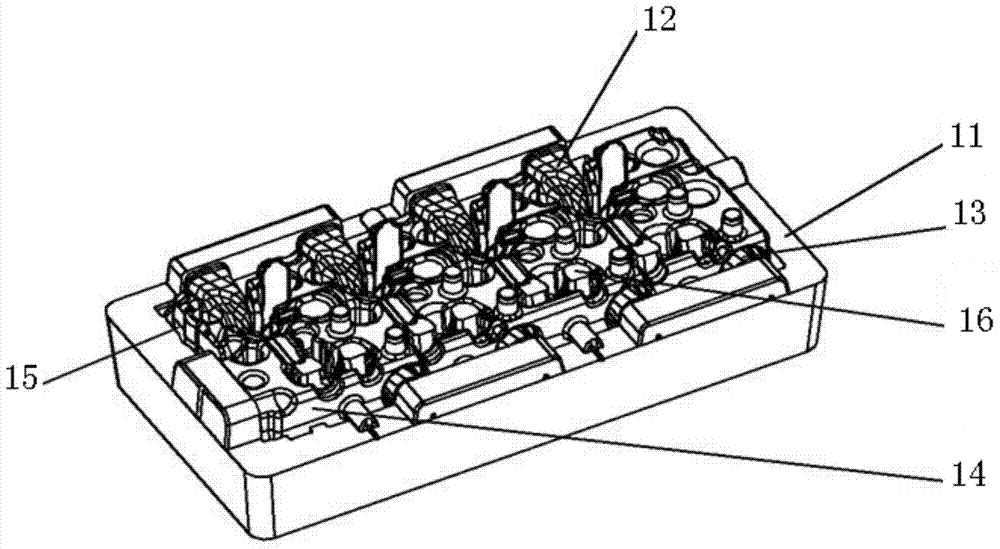

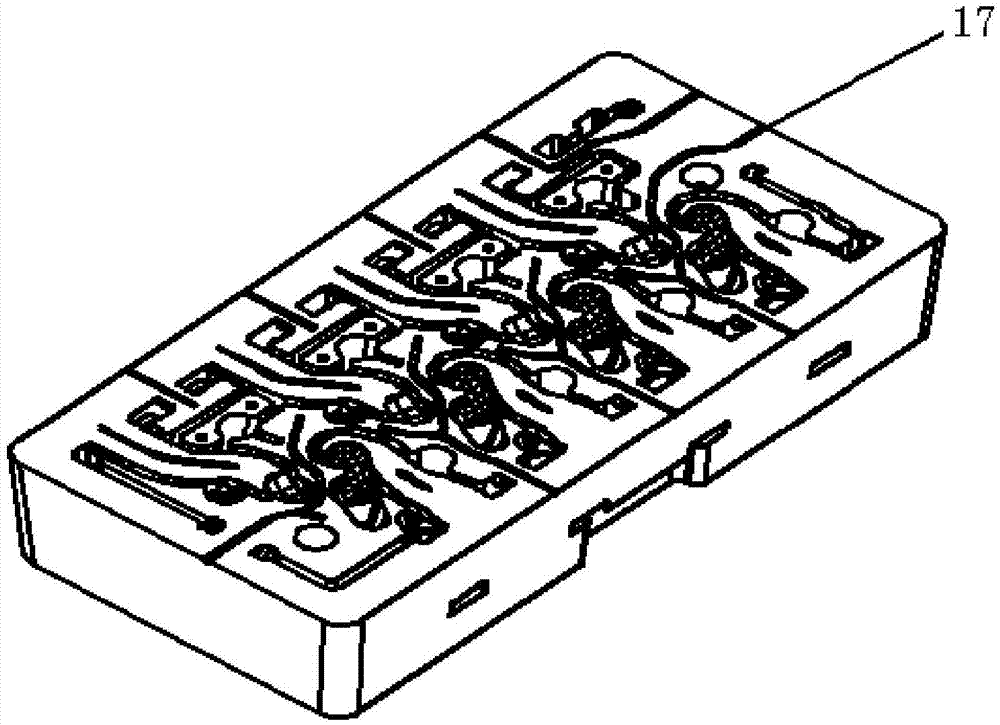

Metal-plastic composite mobile phone shell and forming method thereof

InactiveCN103722668AUniform wall thicknessBeautiful surfaceDomestic articlesCoatingsConvex structureUltimate tensile strength

The invention provides a metal-plastic composite mobile phone shell and a forming method thereof. The provided mobile phone shell has a metal surface and a plastic structure feature, wherein the external surface of the mobile phone shell is made of a sheet metal and is small in wall thickness, high in strength and beautiful in appearance; a convex structure feature of the internal surface of the mobile phone shell is made of plastics, so that the formation of a complex installation structure is facilitated, and the functional requirements on assembling and shock absorption and the like are satisfied. According to the forming method, structure features of the sheet metal and the plastic are firmly combined together and form an integral structure. Meanwhile, according to the forming method, the combination strength of plastics and metals is high, so that the mobile phone shell satisfies the assembling and application requirements of mobile phones, and also can be applied to the shell production fields of household appliances, computers and other industrial products.

Owner:ZHEJIANG NORMAL UNIVERSITY

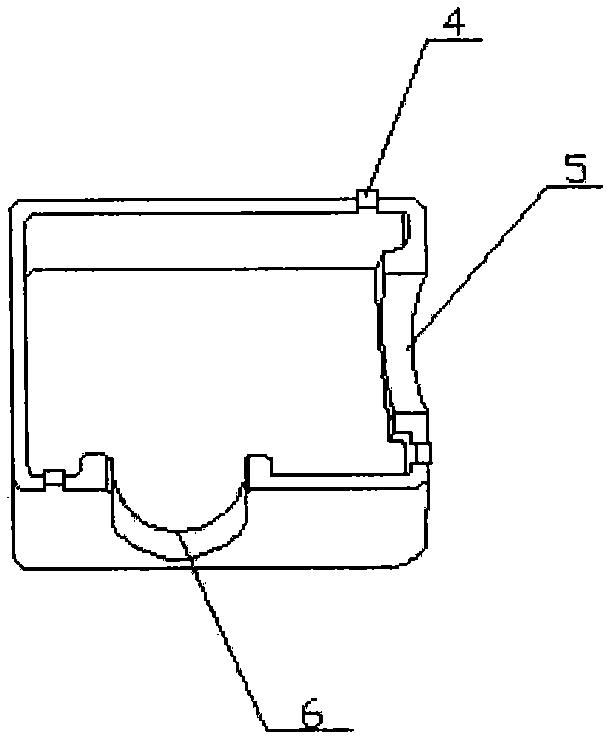

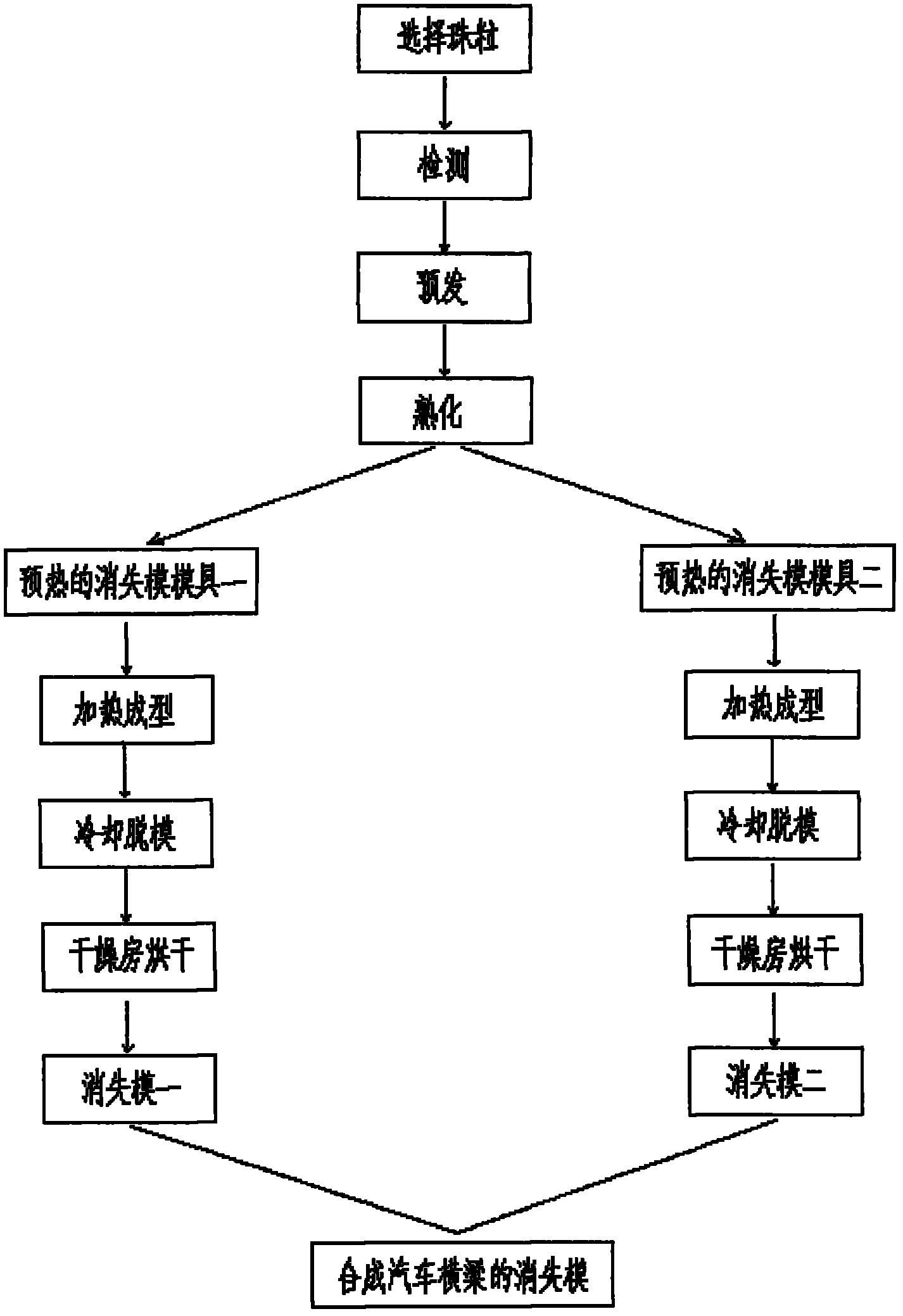

Method for manufacturing automobile cross beam lost foam and using method

InactiveCN102009123ASolution to short lifeReduce or eliminate cleanupFoundry mouldsFoundry coresCasting defectMoisture

The invention provides a method for manufacturing an automobile cross beam lost foam. The method comprises the following steps of: a, selecting proper STMMA beads, and detecting moisture and volatile content of the beads; b, pre-expanding: fully removing the redundant moisture from an intermittent steam pre-expander through a steam-water separation device, and then delivering the STMMA beads intothe intermittent steam pre-expander; c, curing: controlling the curing time of the beads to be between 12 and 48 hours; d, filling the cured beads into a lost foam die, and cooling and molding to obtain a lost foam I and a lost foam II; e, delivering the lost foams into a drying room; and f, inserting and connecting the lost foam I and the lost foam II together to synthesize the automobile cross beam lost foam. The method has simple process; the lost foam die has a reasonable structure; the method has low cost and high production efficiency; and the produced automobile cross beam has smooth surface and low casting defect rate.

Owner:青岛顺联集装箱部件制造有限公司

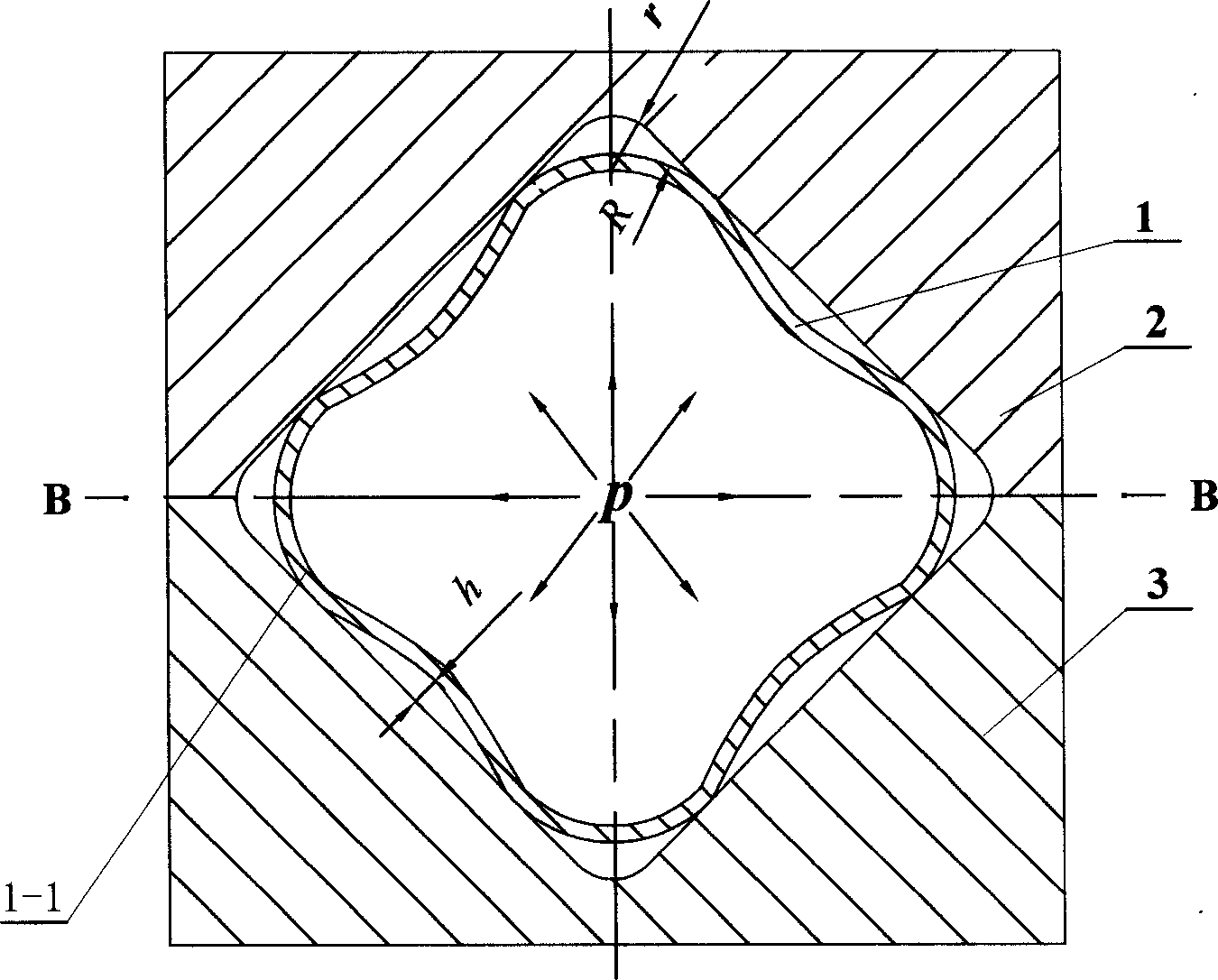

High-pressure forming method in tubular member for lowering forming pressure

An internal high pressure method for forming tubular part with decreased forming pressure includes such steps as preshaping the tubular part to make its cross-section like a multi-petal flower shape, putting it in the cavity of lower die, closing upper and lower dies, and introducing high-pressure liquid to the tubular part to expand it for plastic deformation.

Owner:HARBIN INST OF TECH

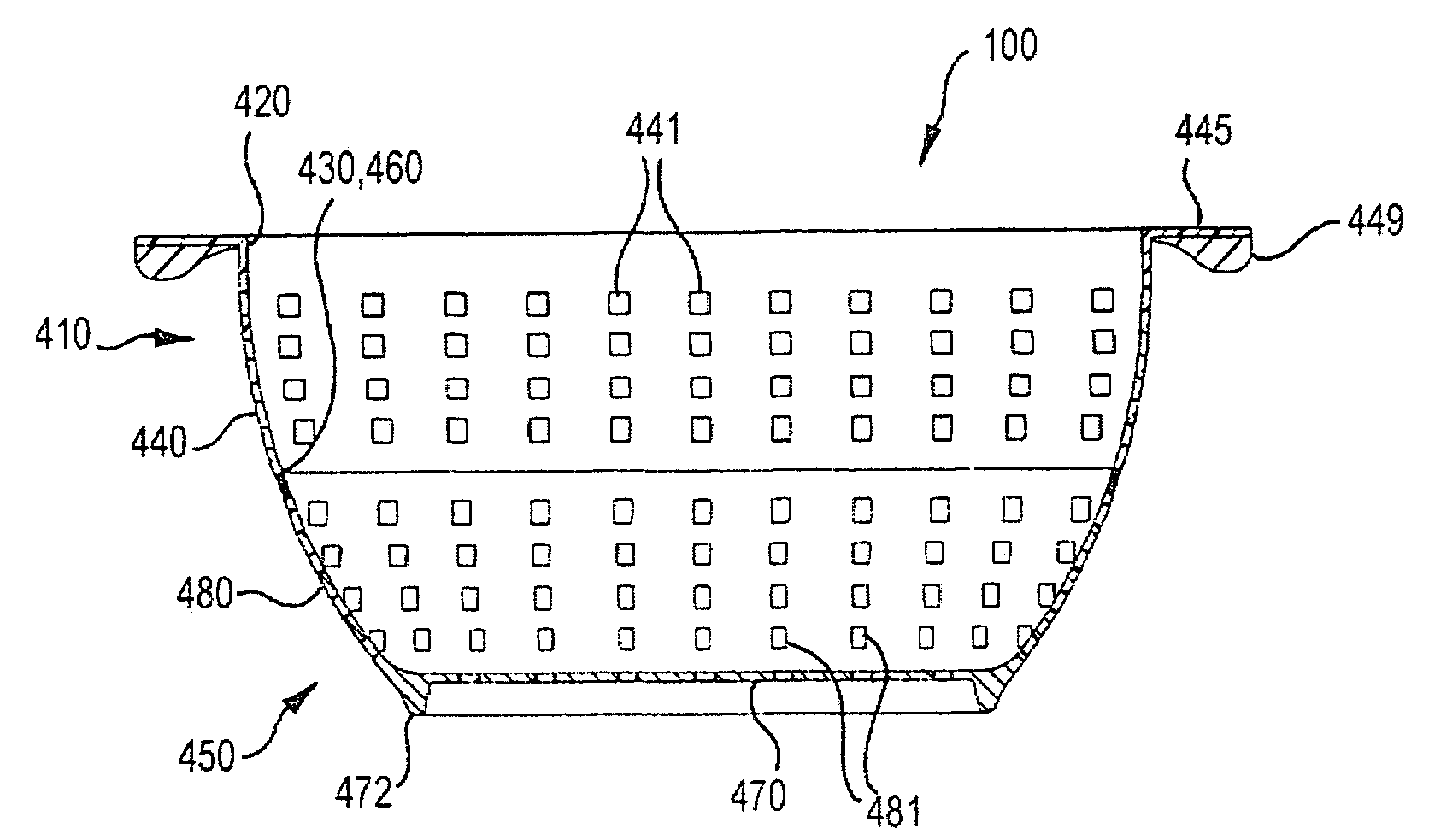

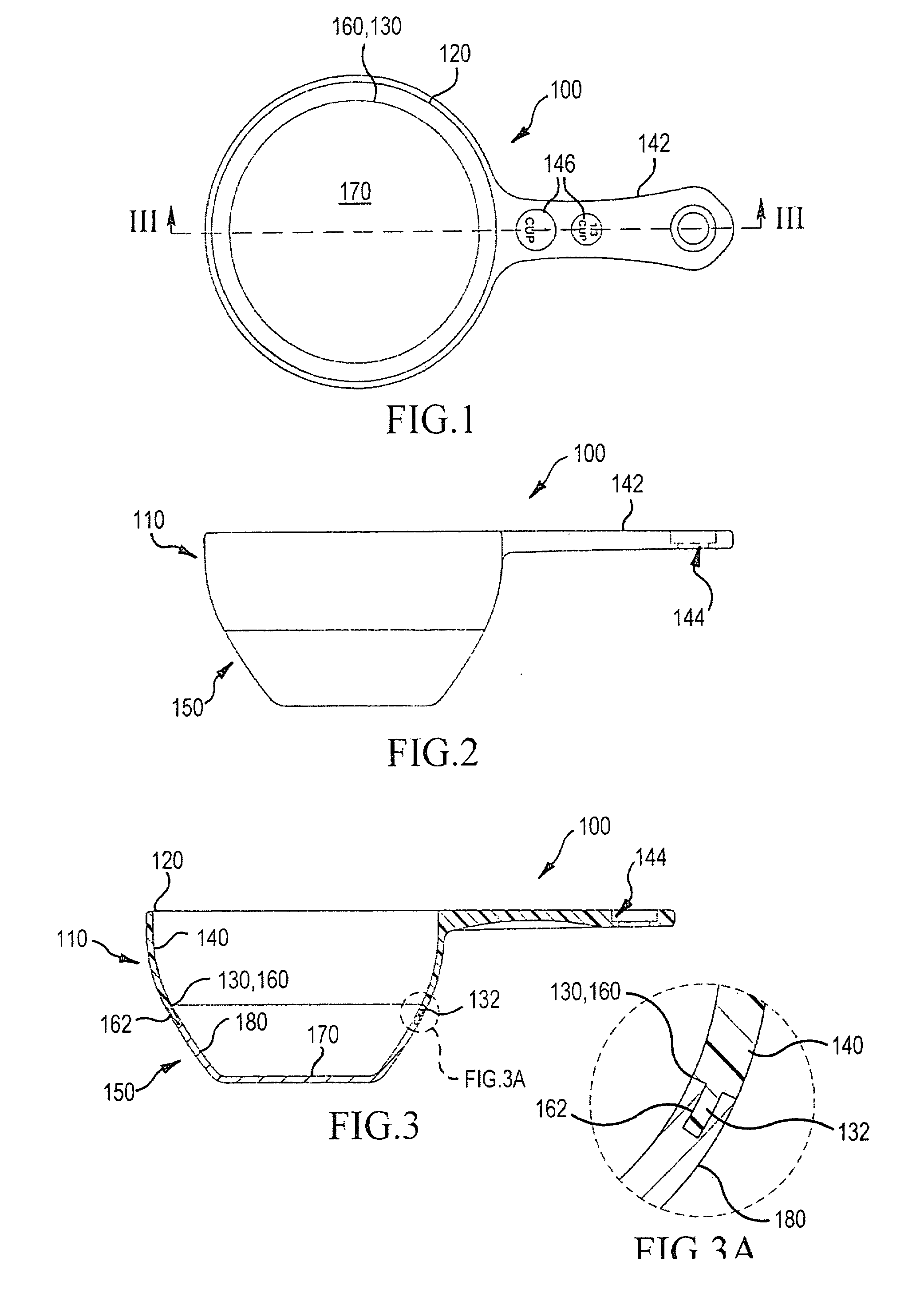

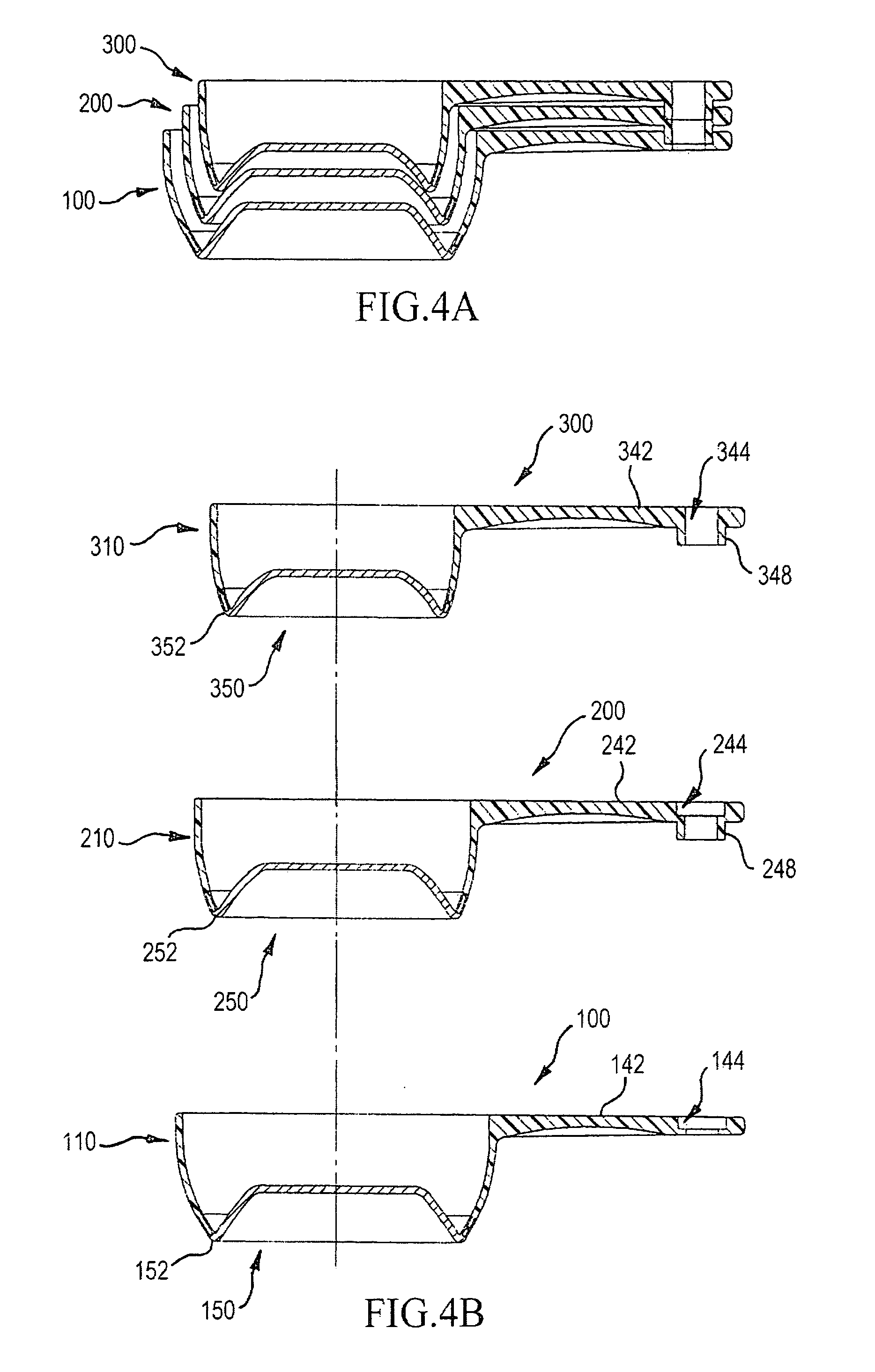

Collapsible cookware

InactiveUS20090065509A1Uniform wall thicknessAvoiding the unnecessarily complicated connection mechanismsCooking vesselsBaking vesselsMechanical engineeringEngineering

Owner:BRADSHAW INT

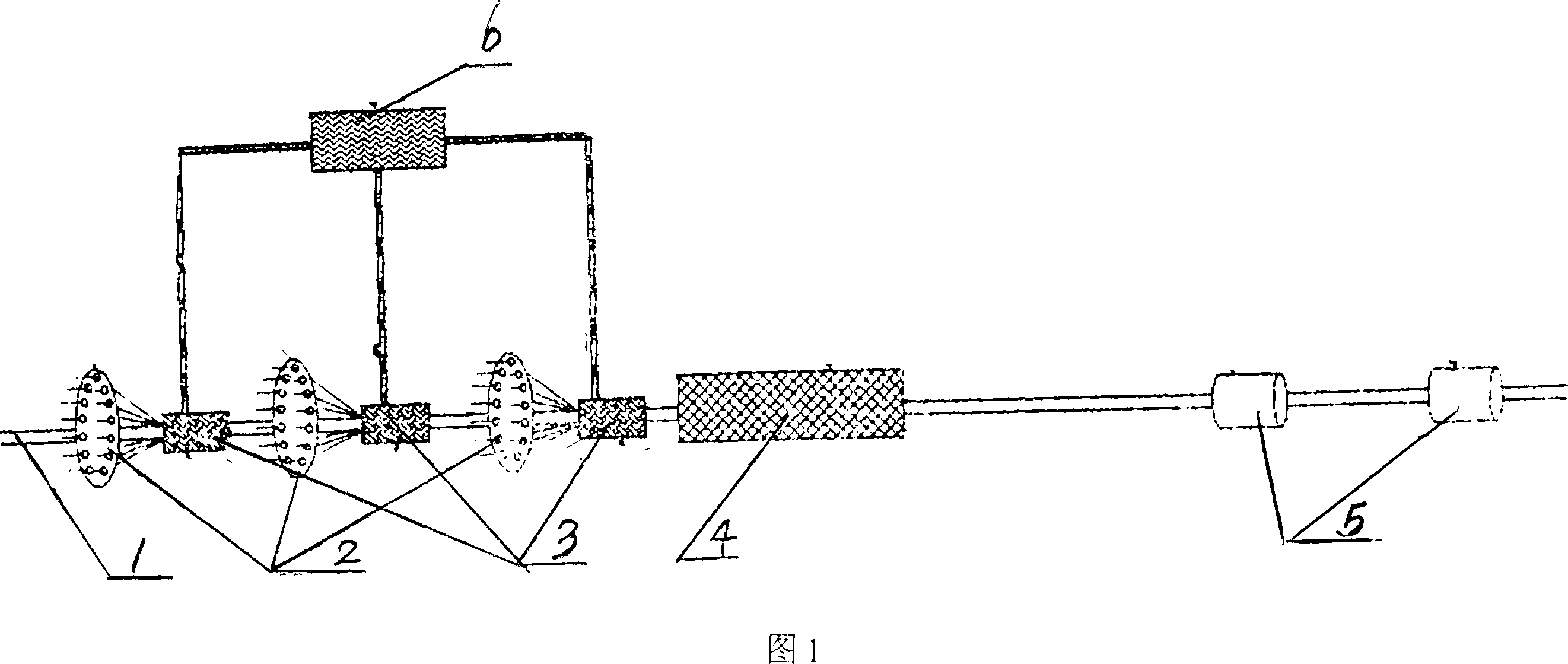

Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

InactiveCN101085551AWeave evenlyHigh precision of inner and outer diameterTubular articlesFiberMaterials science

The invention relates to the making of multi layer knitting structure on the wire pulling glass steel tube using several computers controlling the two dimensional horizontal knitter, using core mold, stretch mold, extractor synthesizing the glass steel tube, setting resin dipping slot at the back of each knitter, even direct core mold at both ends of the core mold that follows with the movement of the ring knitting layer in the direction from the first two dimensional horizontal knitter to the last knitter through the dipping slot to the stretch mold. The glass tube in and out radius has high precision, thickness of each knitting layer adjustable, even in each dipping and consistent in strength.

Owner:郝跟进

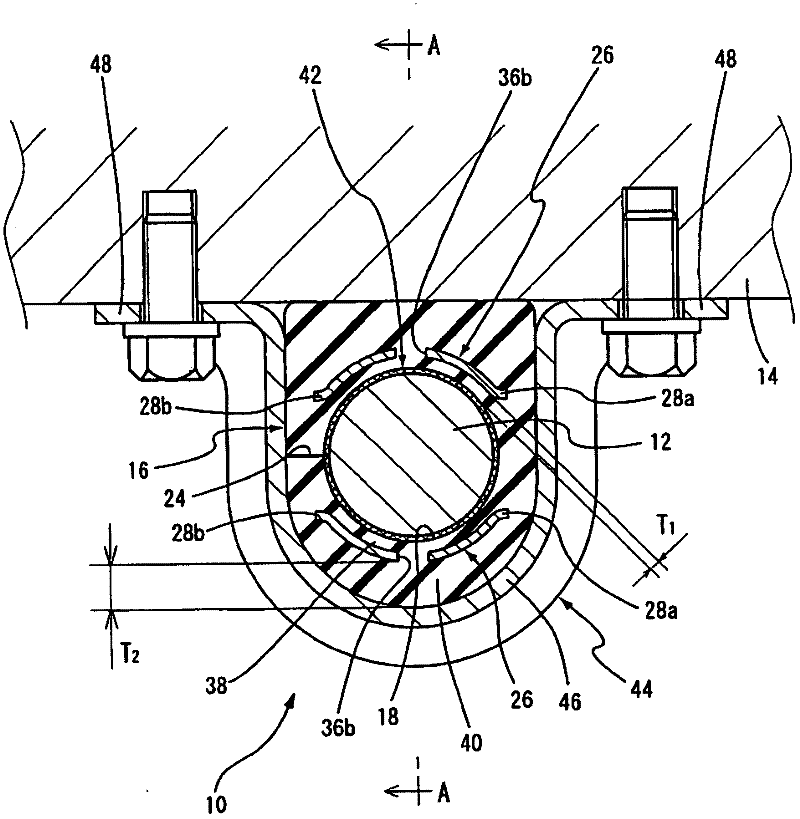

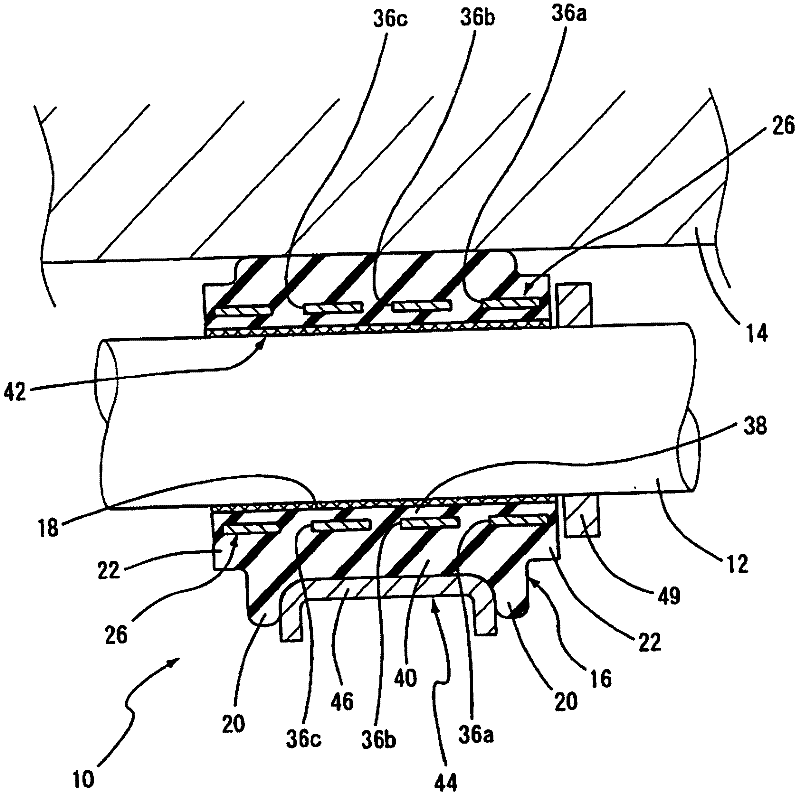

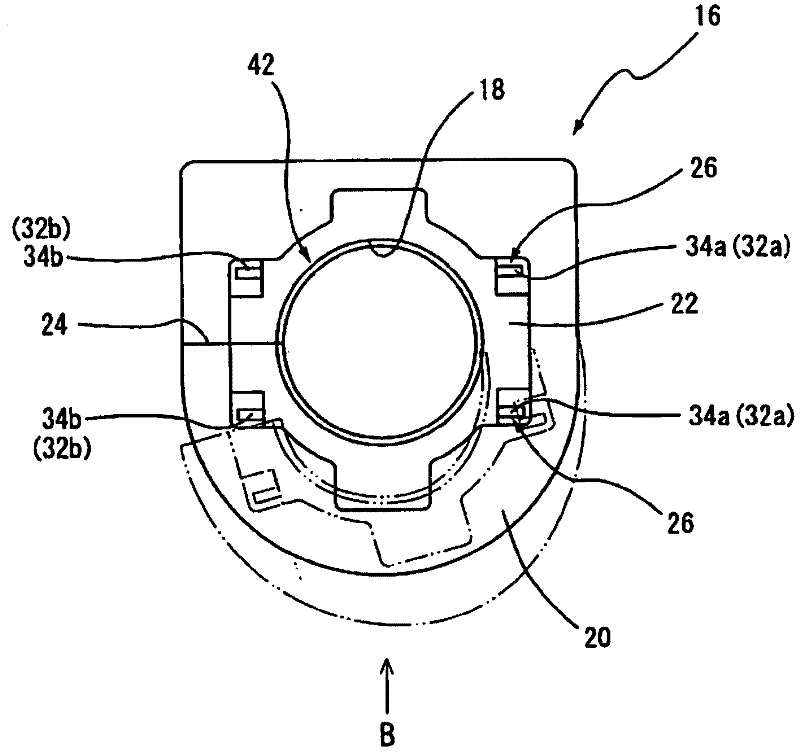

Vehicle stabilizer bushing

ActiveCN102470721AEliminate deflectionSmooth rotationSpringsNon-rotating vibration suppressionVulcanizationEngineering

Disclosed is a stabilizer bushing which more efficiently reduces torsional friction between a bushing main body and a stabilizer bar. A bushing main body (16) is formed from a cylindrical rubber elastic body to which a sliding member (42) is fixed to a surface of the inner circumference. In a middle area of the bushing main body (16) perpendicular to the axis thereof, two partition members (26, 26) are embedded so as to be positioned vertically, and are adhered by vulcanization. The bushing main body (16) is constituted from an inner rubber part (38) of a thickness so as not to allow elastic deformation by an input load, and an outer rubber part (40) thicker than said inner rubber part. Meanwhile, through-holes (36a, 36b and 36c) are formed only in positions that equally divide the partition members (26, 26) in the circumferential and axial directions.

Owner:SUMITOMO RIKO CO LTD +1

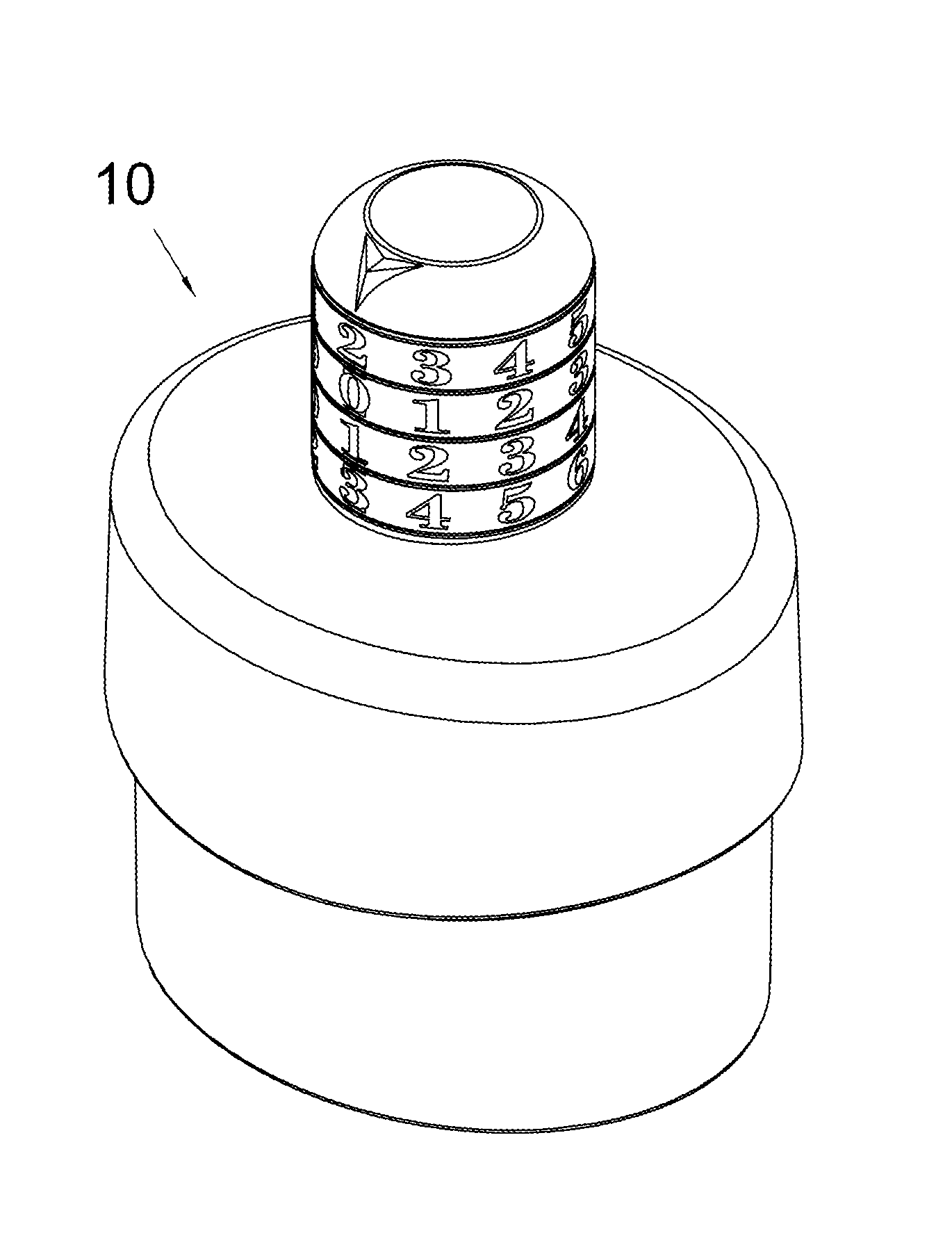

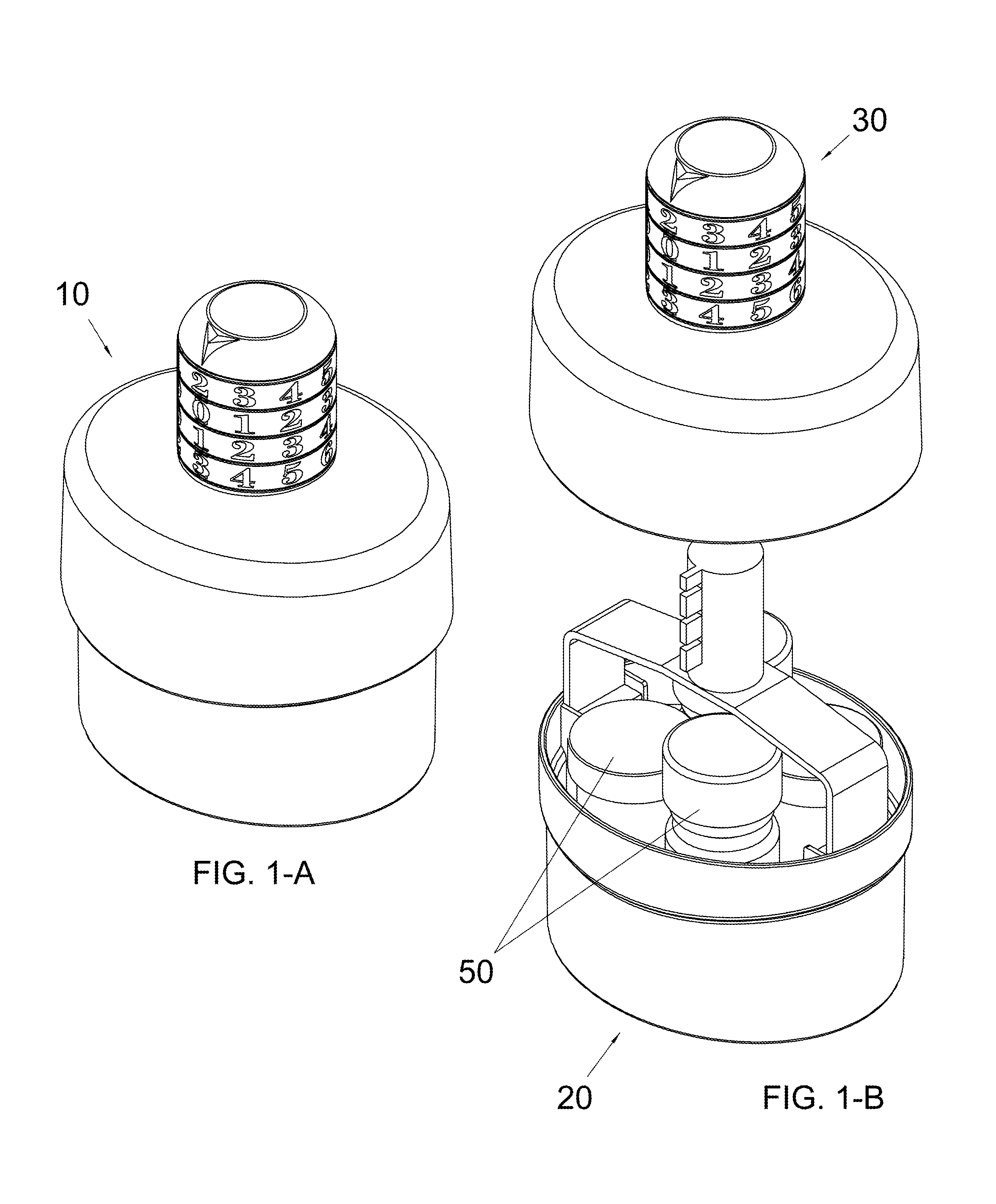

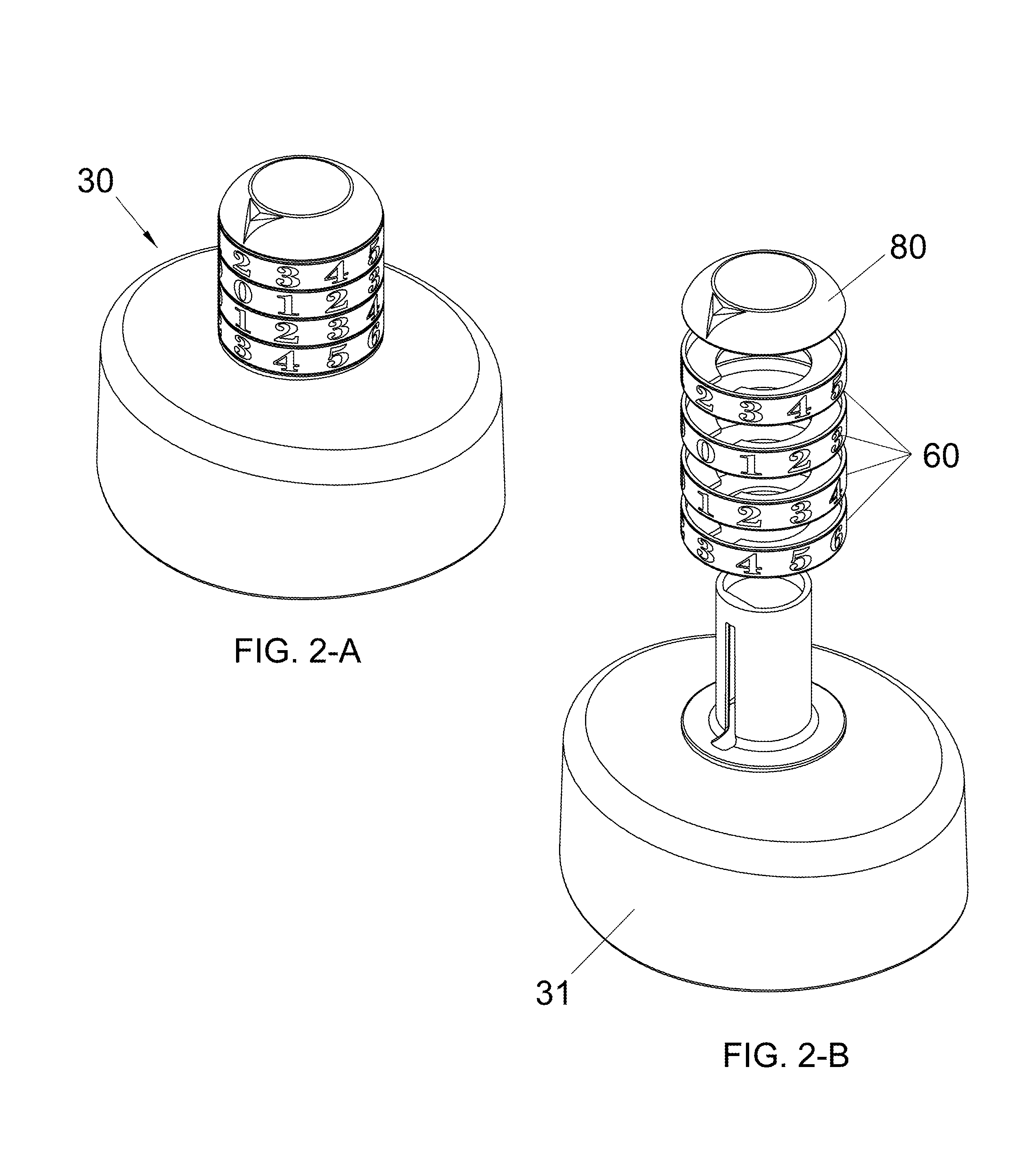

Prescription drug lock box

ActiveUS8944263B1Uniform wall thicknessHigh strengthCapsPuzzle locksPrescription drugDrugs prescriptions

This invention pertains to a prescription drug lock box consisting of a container and a detachable combination locking cover assembly used to secure the contents held within. The container has an integrally formed key post positioned above its open end. The tumblers of the cover assembly engage the key post and lock to it thus securing contents held within. When the indicia of the tumblers and correct unlocking code are in alignment with a marker, the cover assembly may be installed or removed.

Owner:SMALL STEVEN DOUGLAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com