Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about How to "Reduce solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified membranes

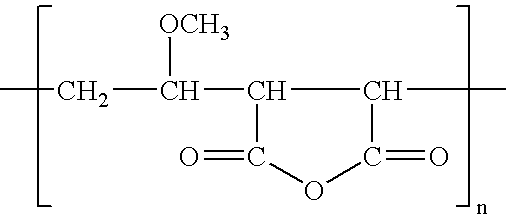

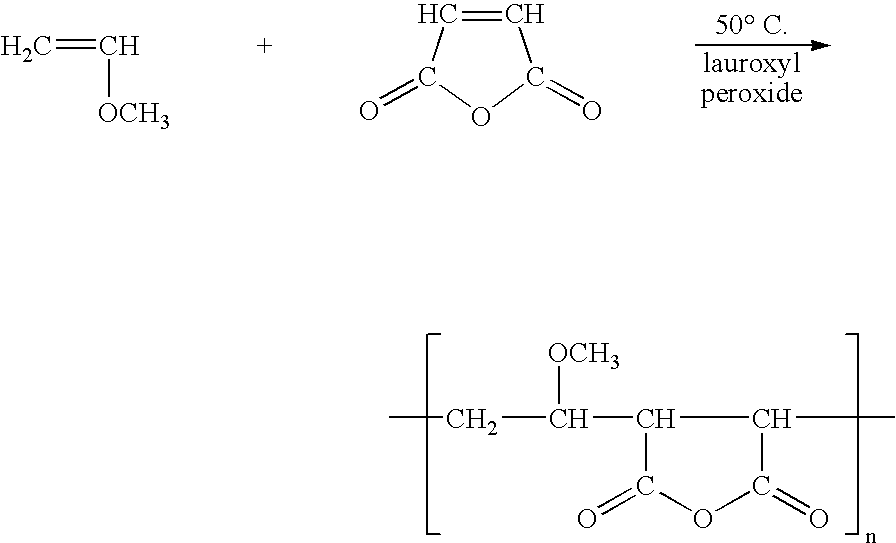

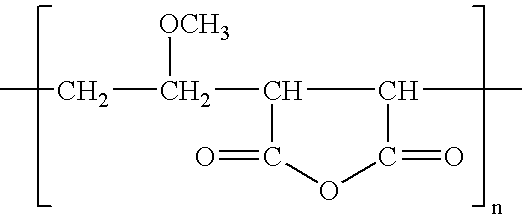

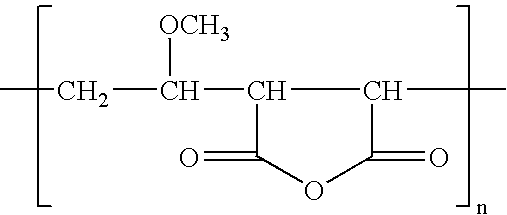

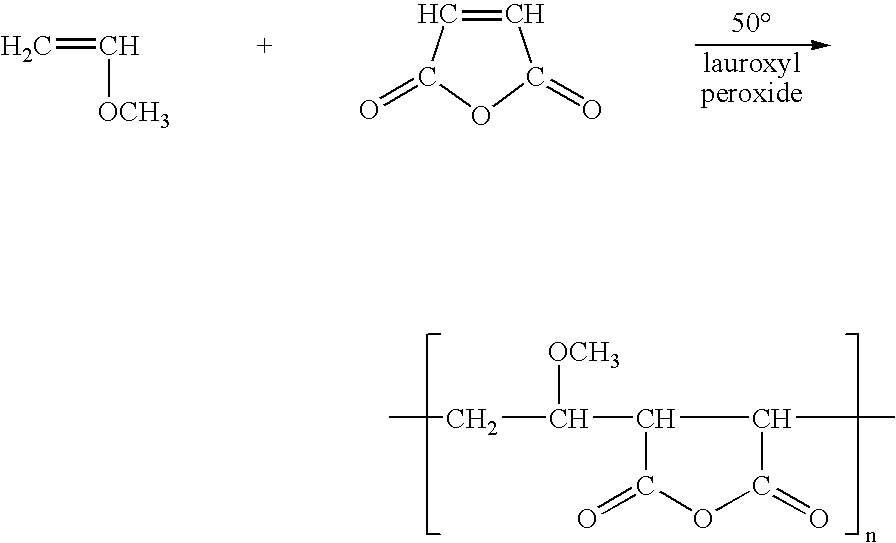

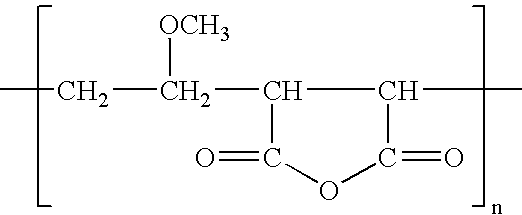

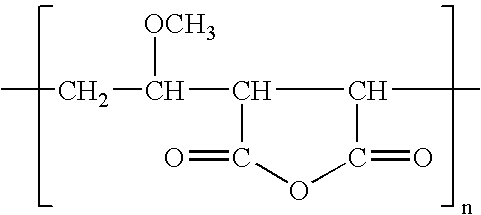

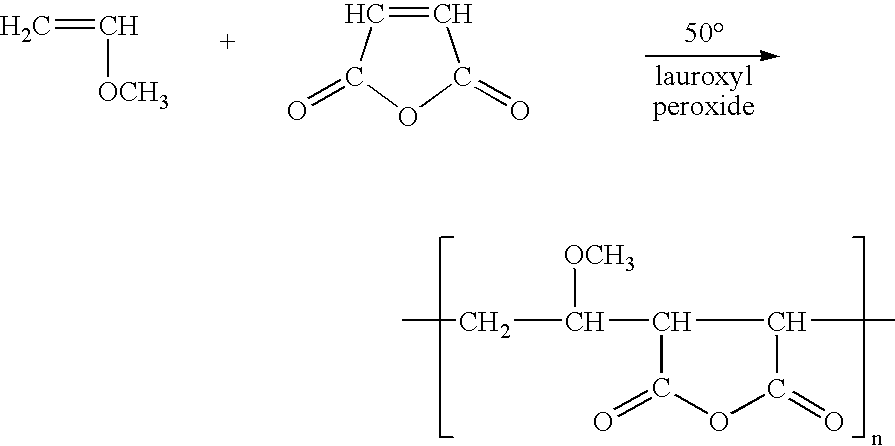

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Crack free metallic articles

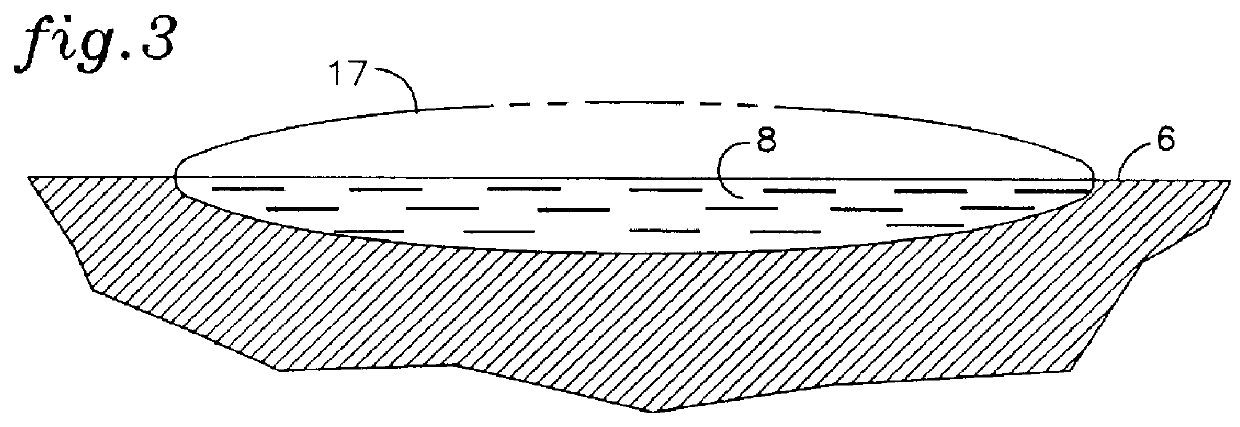

InactiveUS6103402AReduce material stressReduce solidificationTurbinesBy zone-melting liquidsCrazingClosed loop

A containerless method of producing a crack free metallic article of near-net shape includes melting a filler material into a metallic substrate or seed under conditions chosen to preclude cracking. In a preferred embodiment of the invention, a laser beam is operated at a relatively low power density and at a relatively large beam diameter at the substrate surface for an extended length of time to produce a molten pool with a low aspect ratio. Near-net shape is achieved by applying the process in a closed-loop, multi-axis material deposition system.

Owner:UNITED TECH CORP

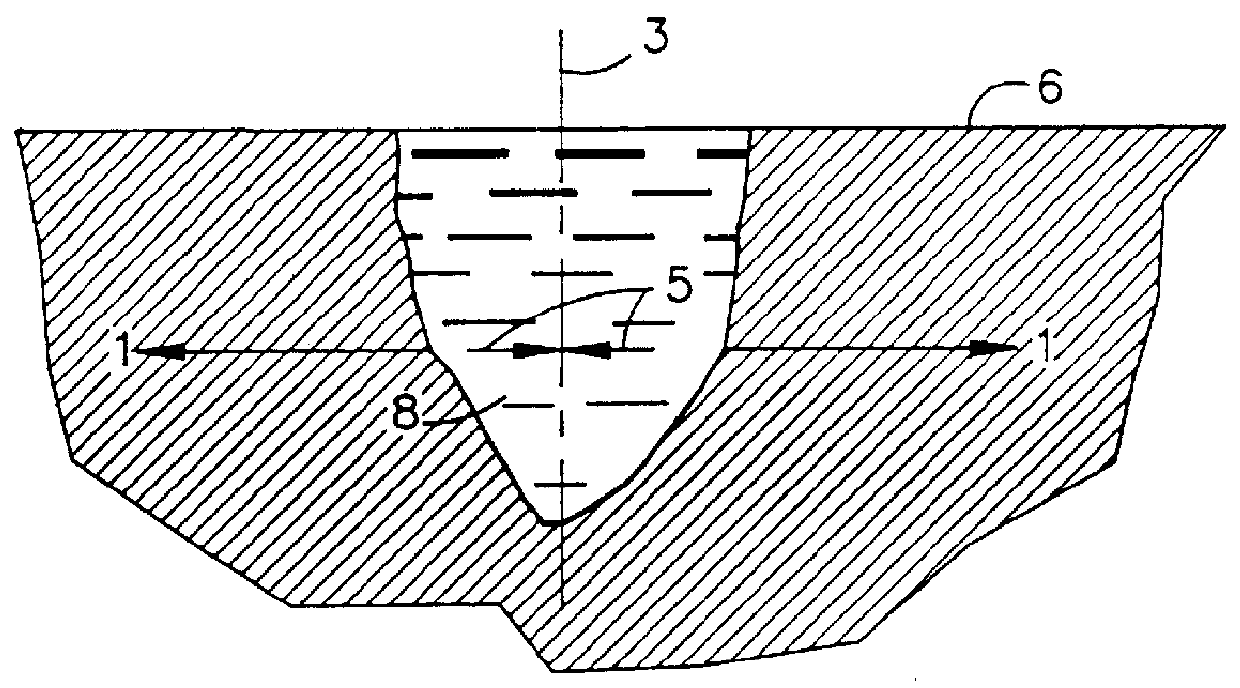

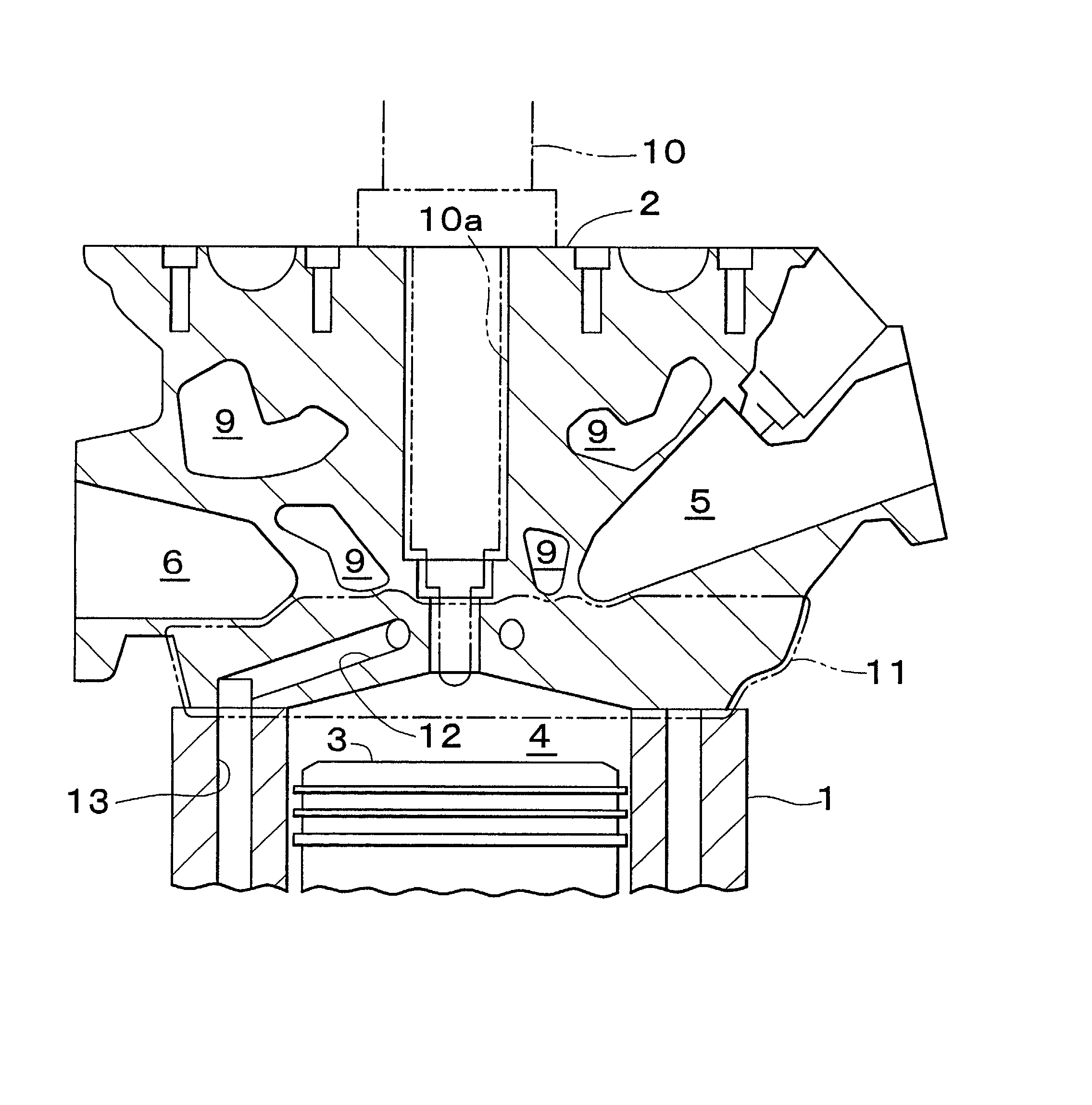

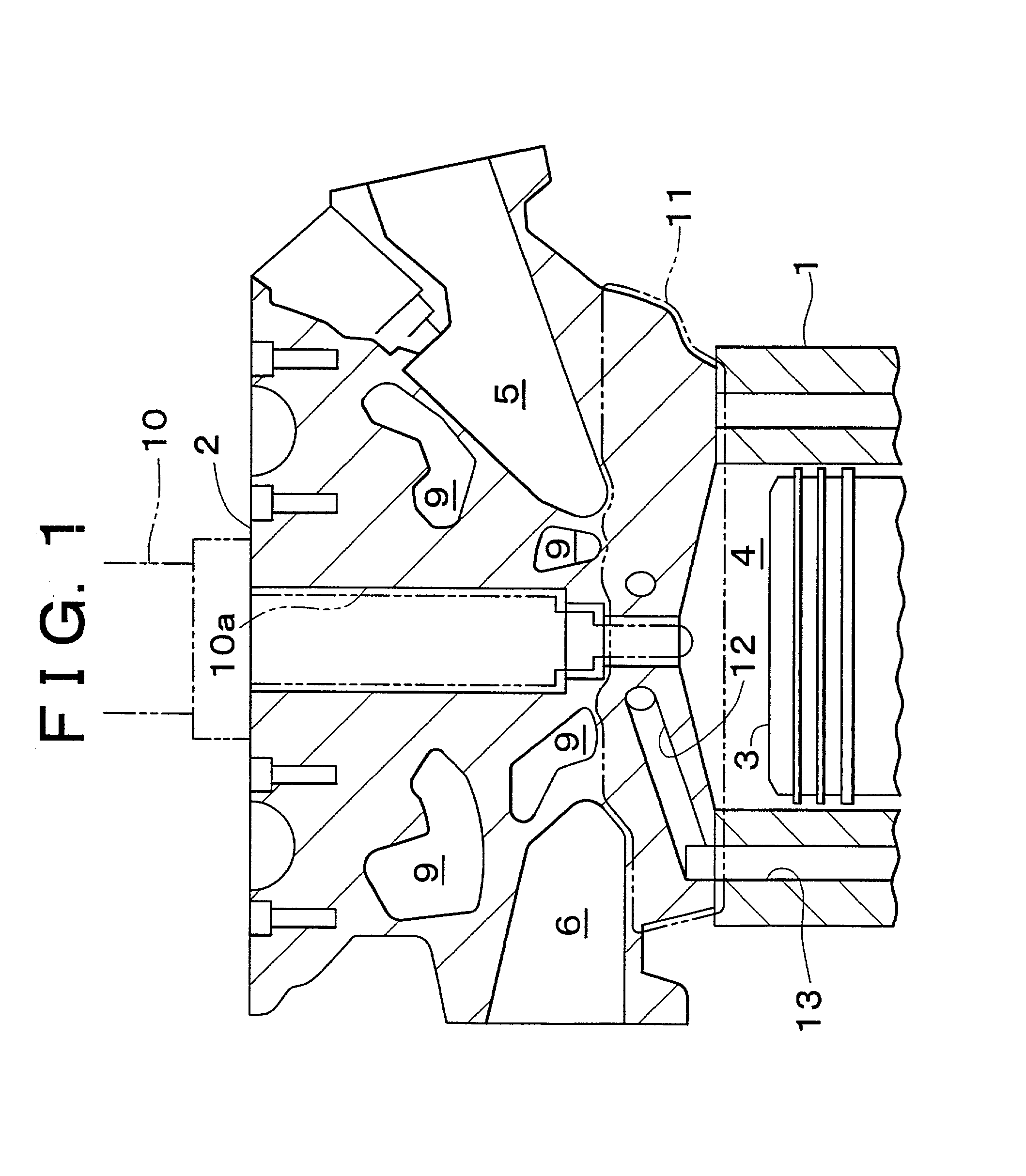

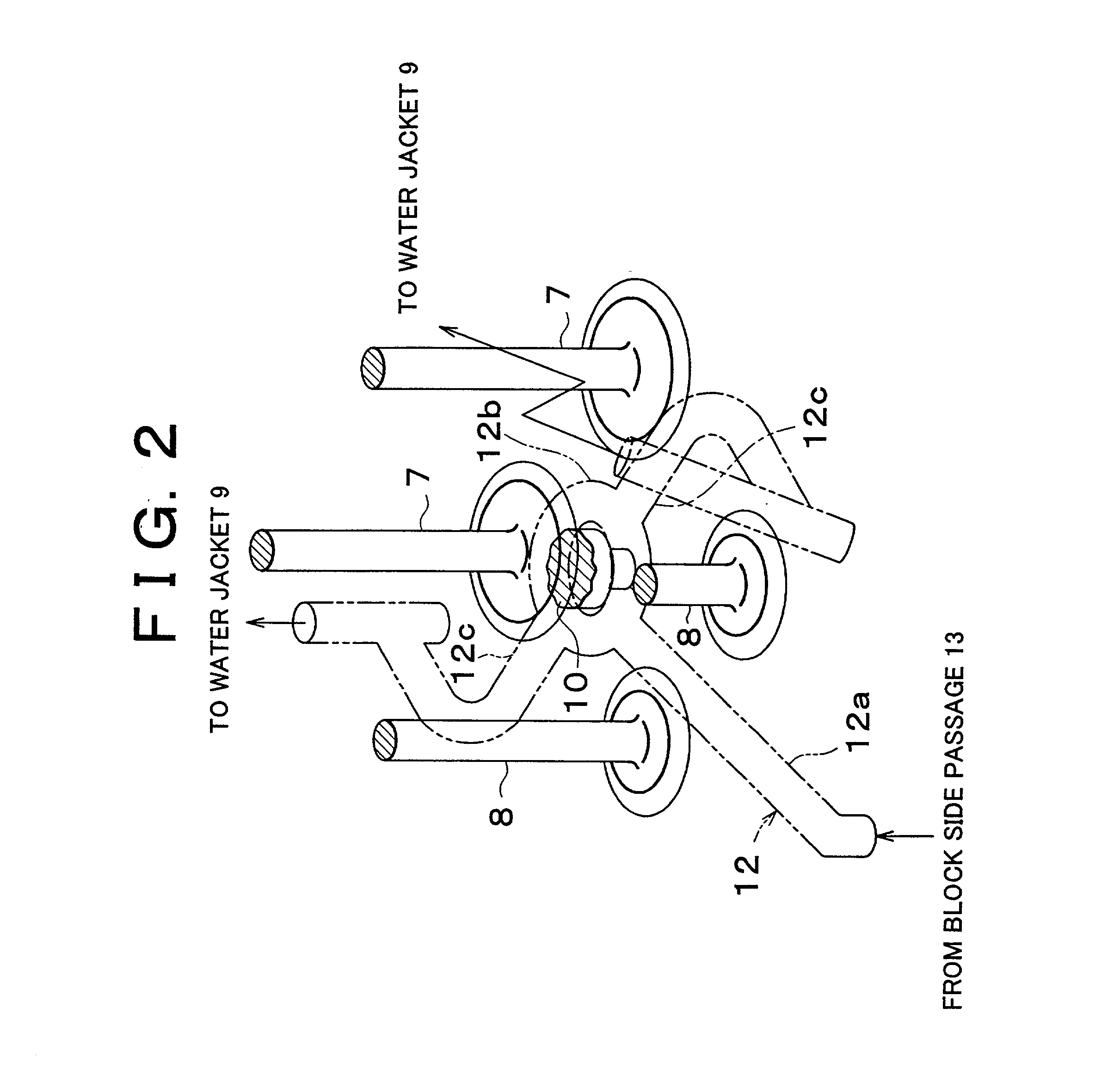

Cooling structure of cylinder head and method for manufacturing cylinder head

InactiveUS20020124815A1Improve cooling effectReduce solidificationCylinder headsCombustion enginesCombustion chamberCylinder head

In a cylinder head, a cooling water passage with a circular shape (an elliptical shape) in cross section in radial direction is formed at an area (lower layer deck) closer to a combustion chamber than a water jacket in which a cooling water flows. The cooling water passage of the cylinder head is formed by casting by providing a hollow core in a mold and removing the hollow core.

Owner:TOYOTA JIDOSHA KK

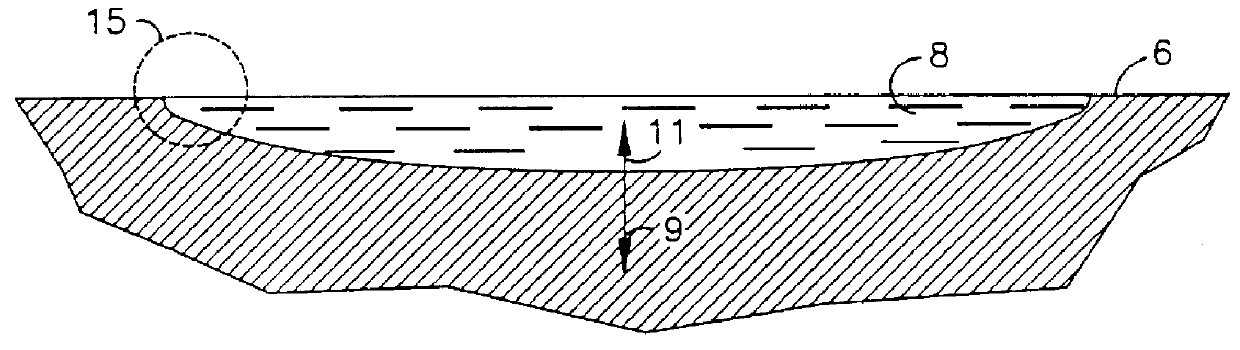

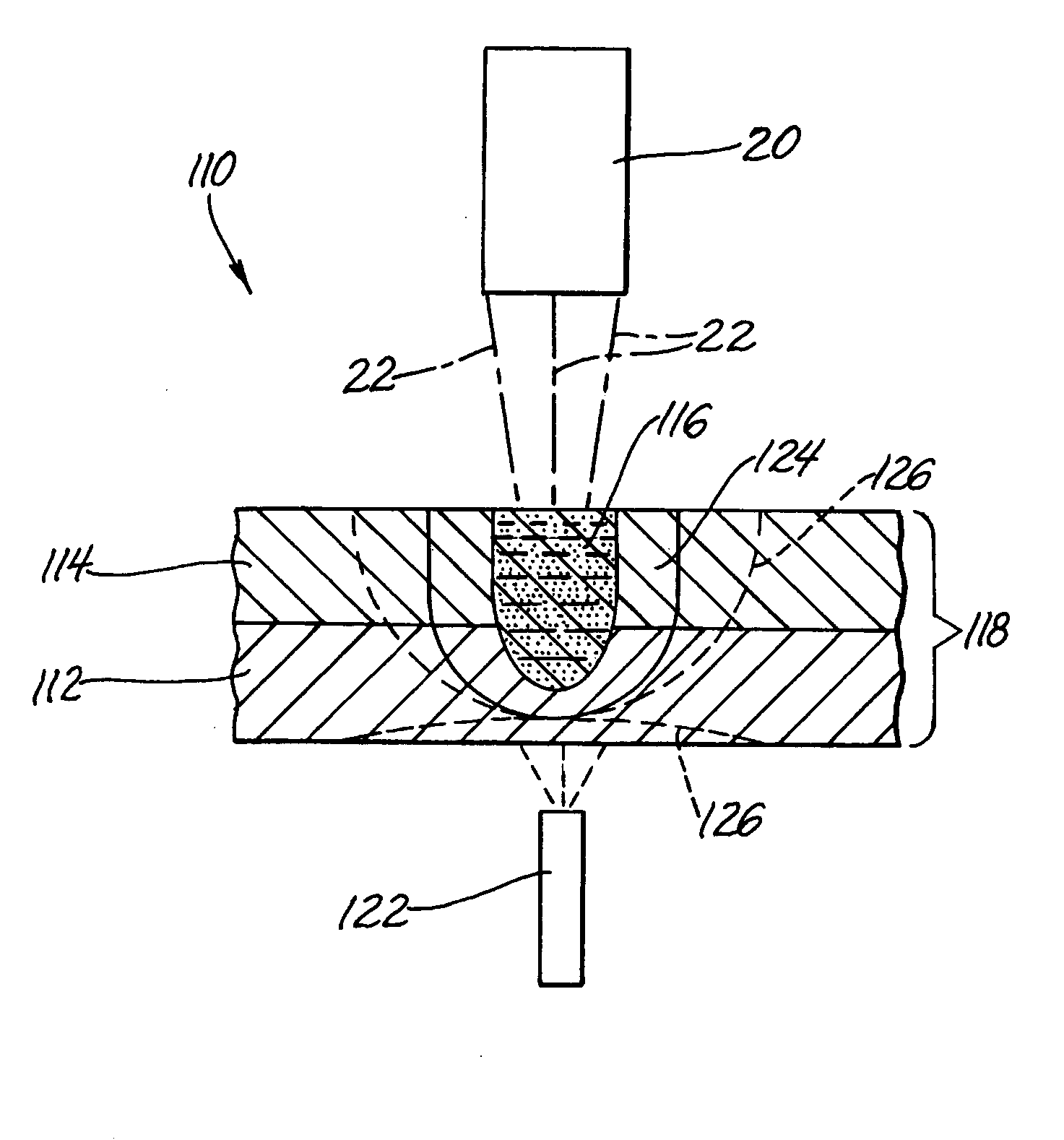

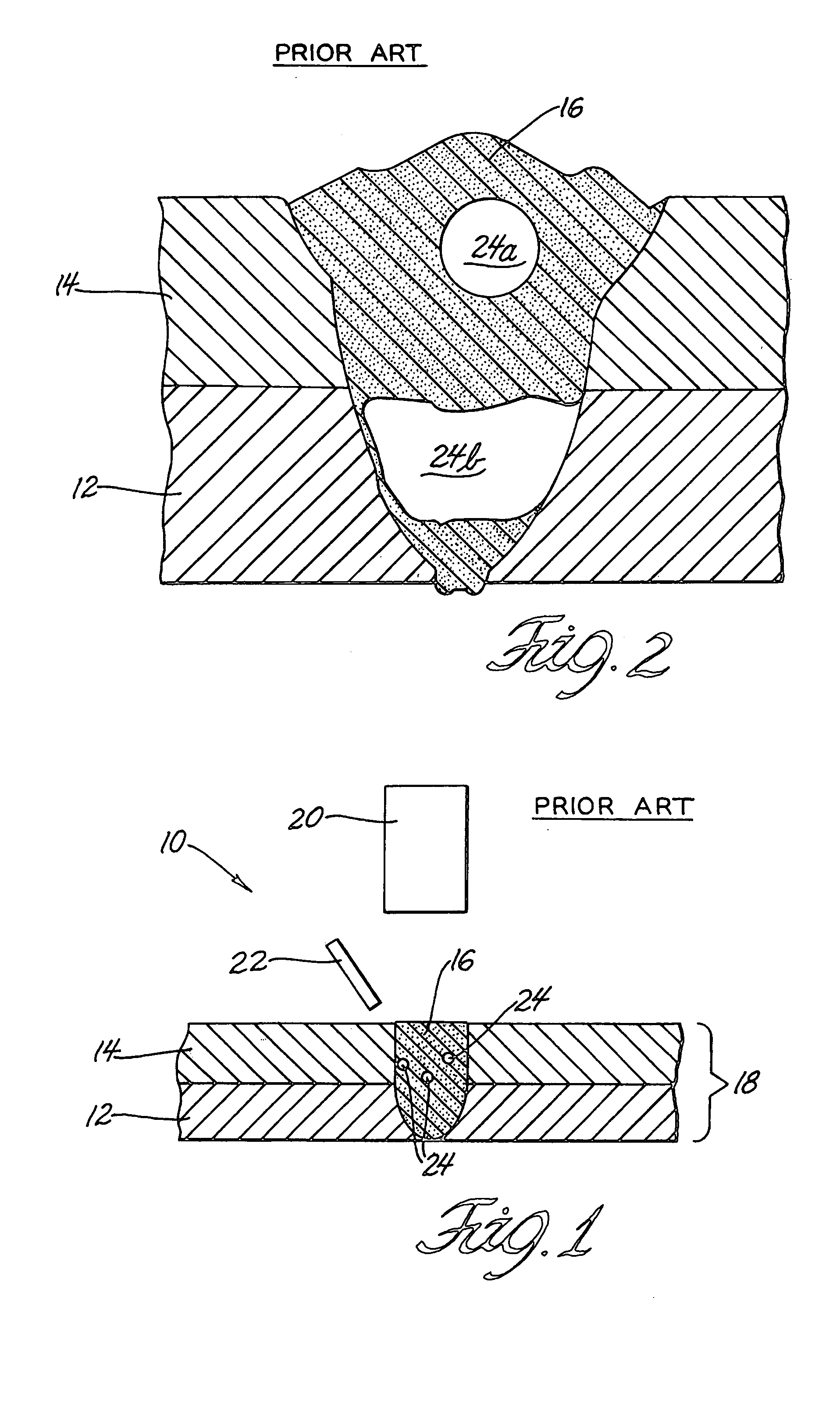

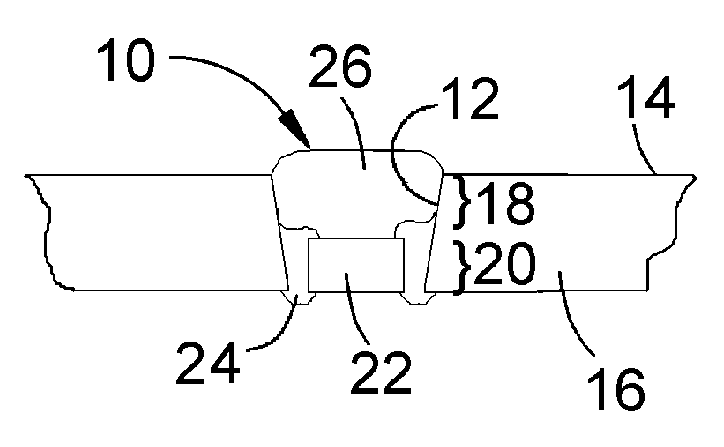

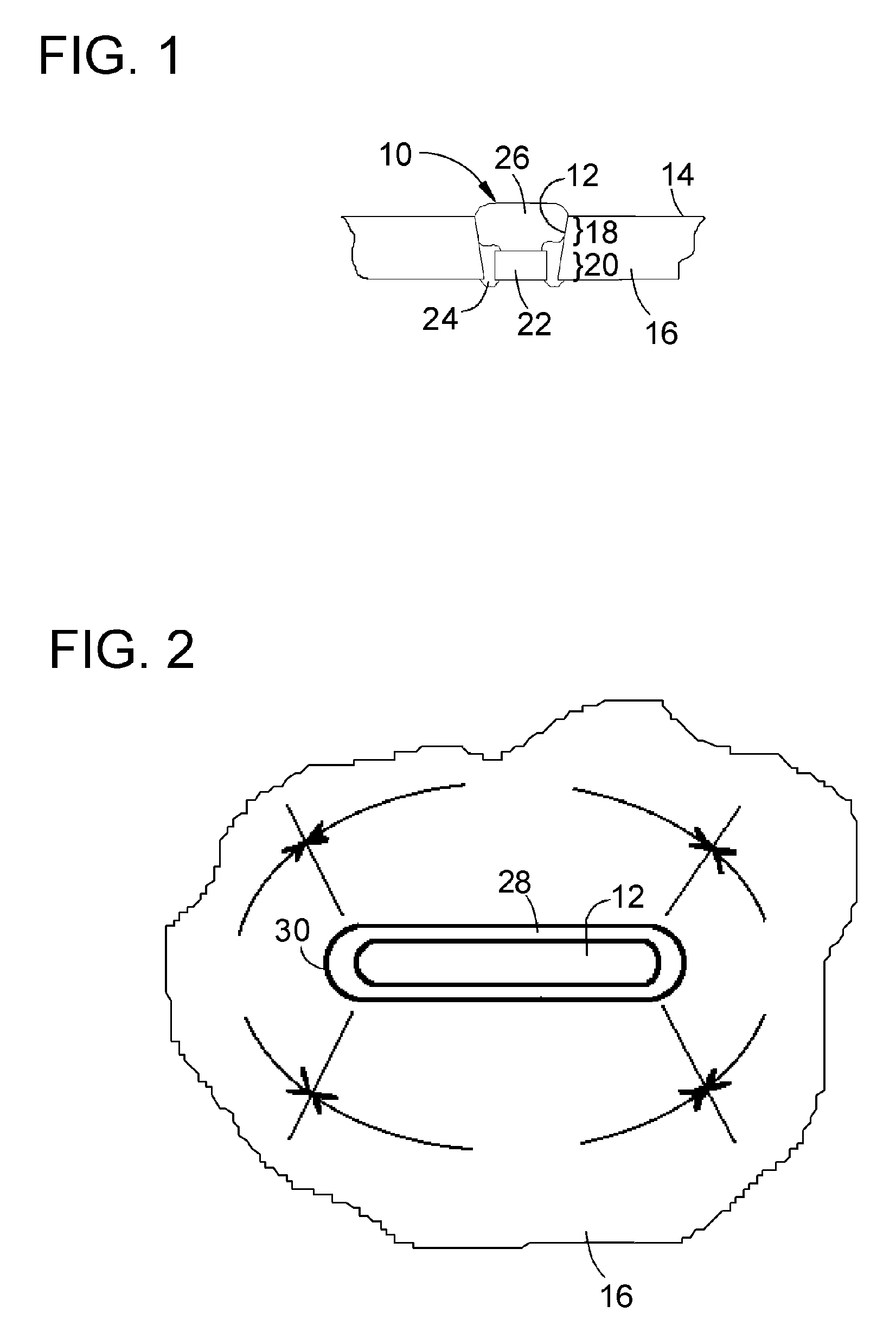

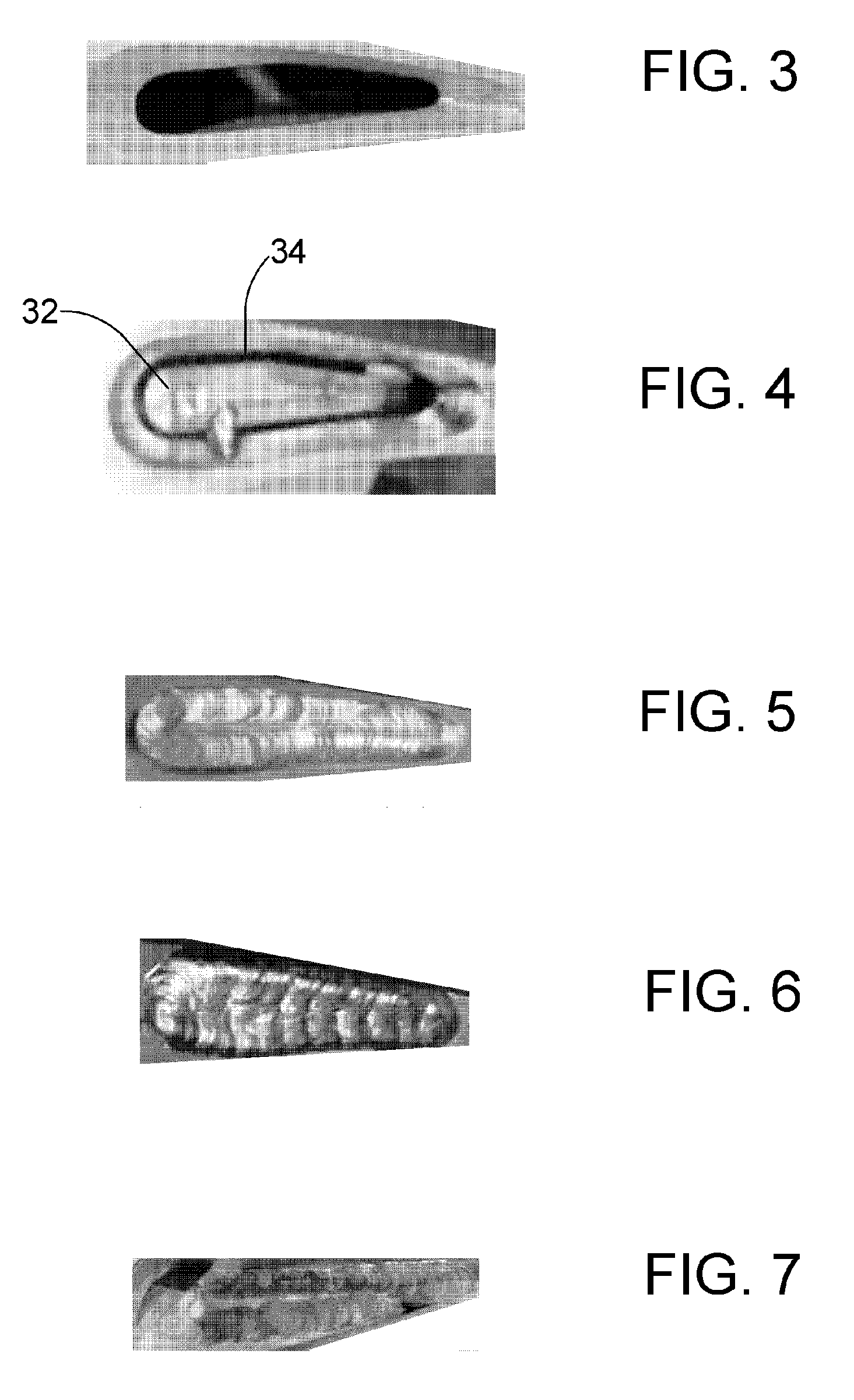

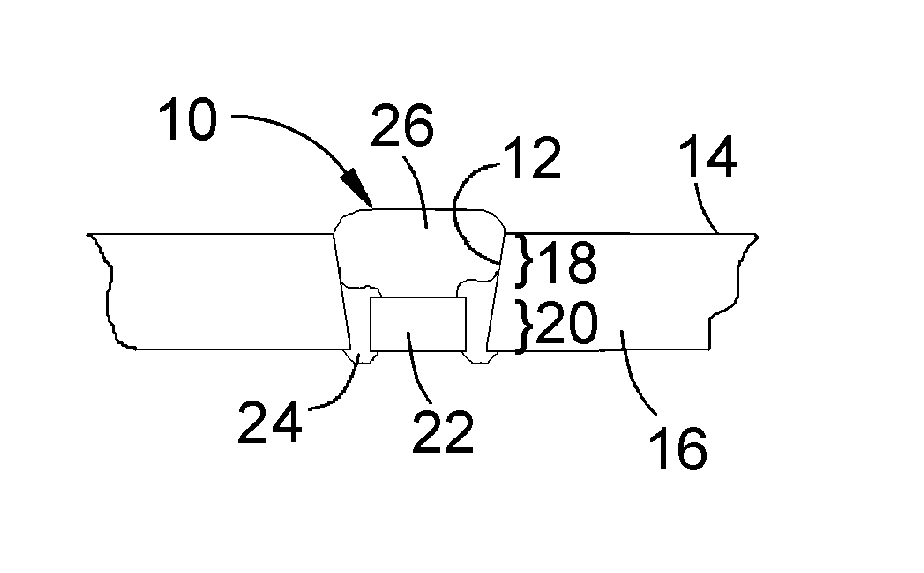

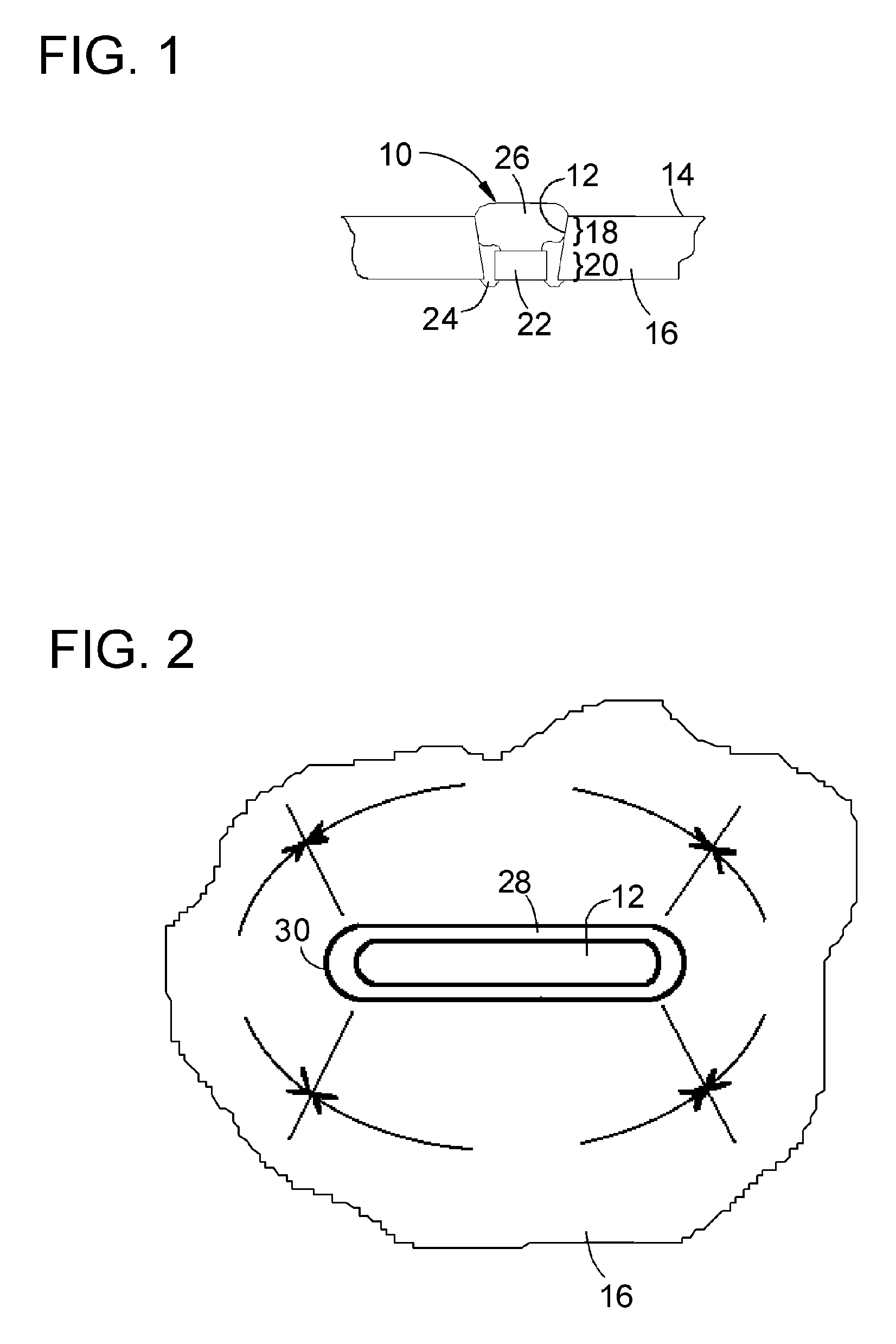

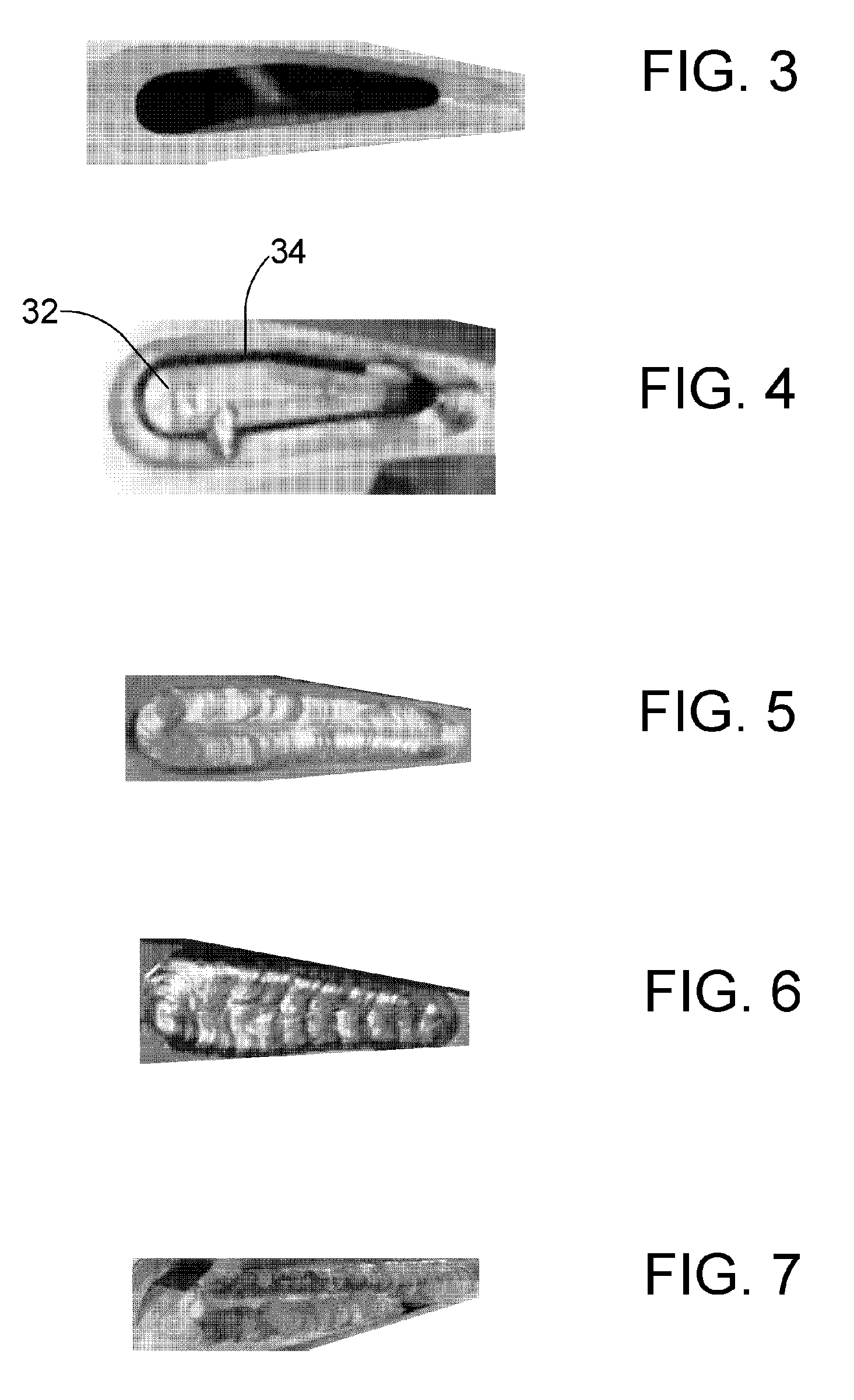

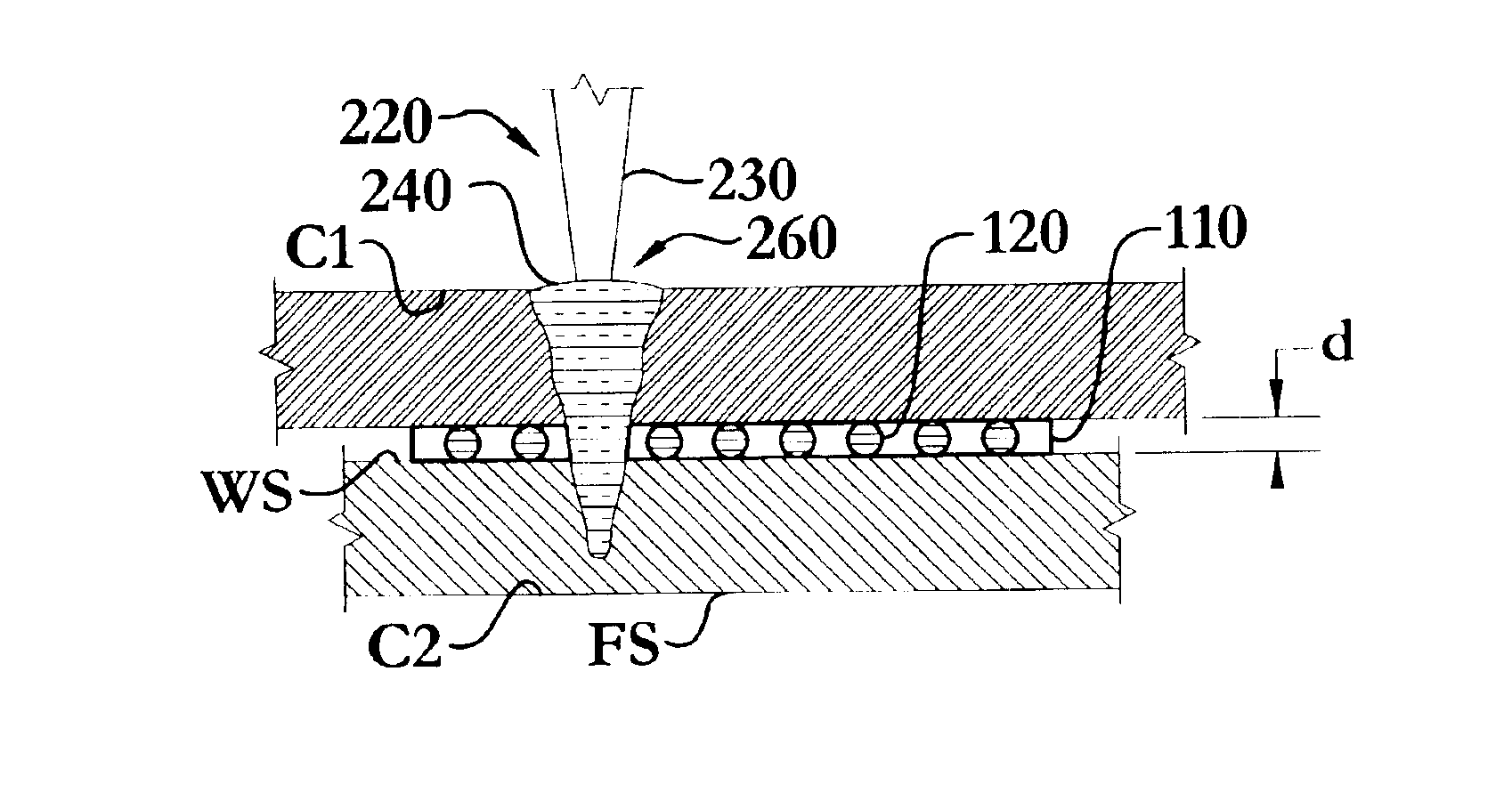

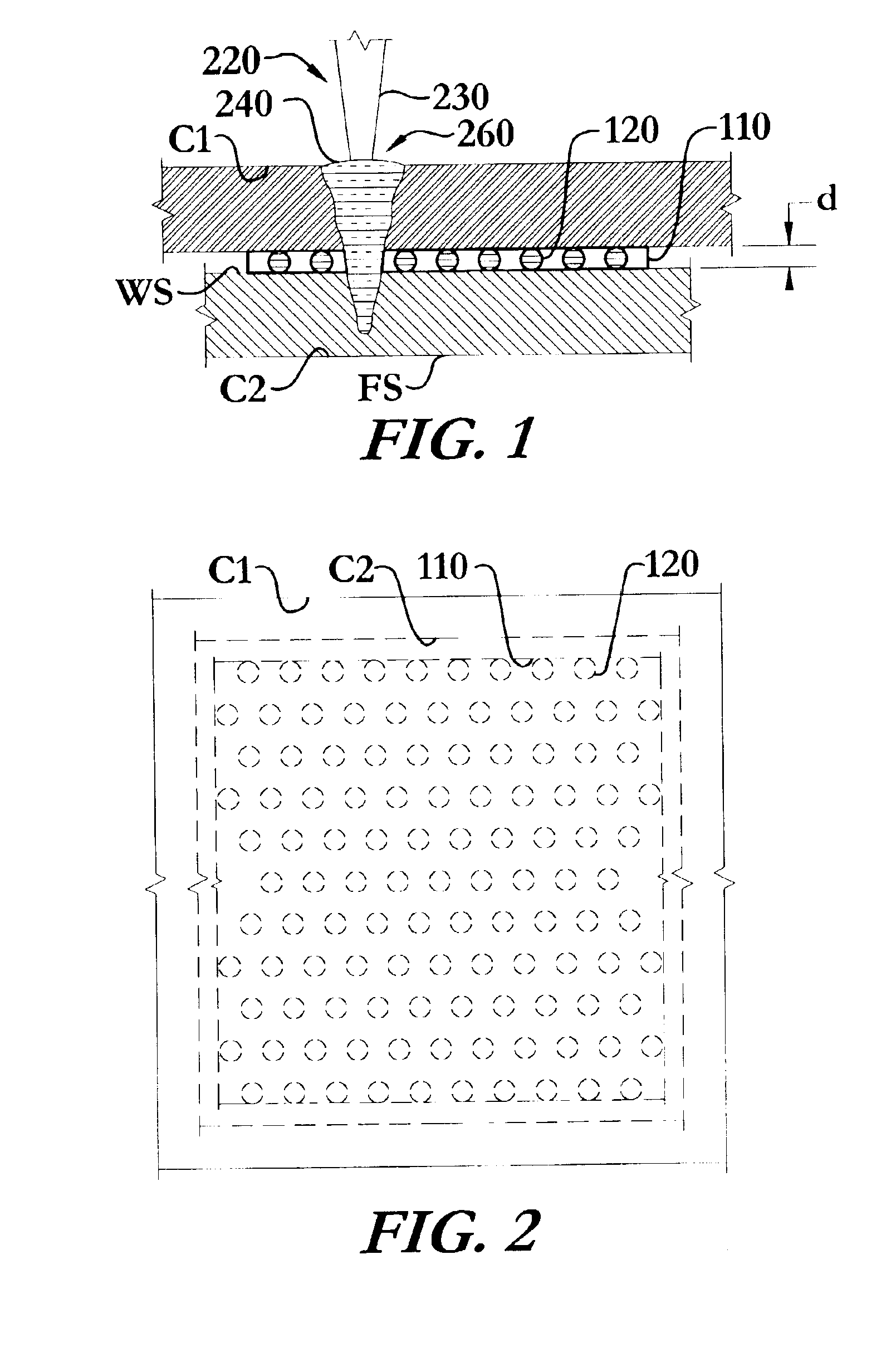

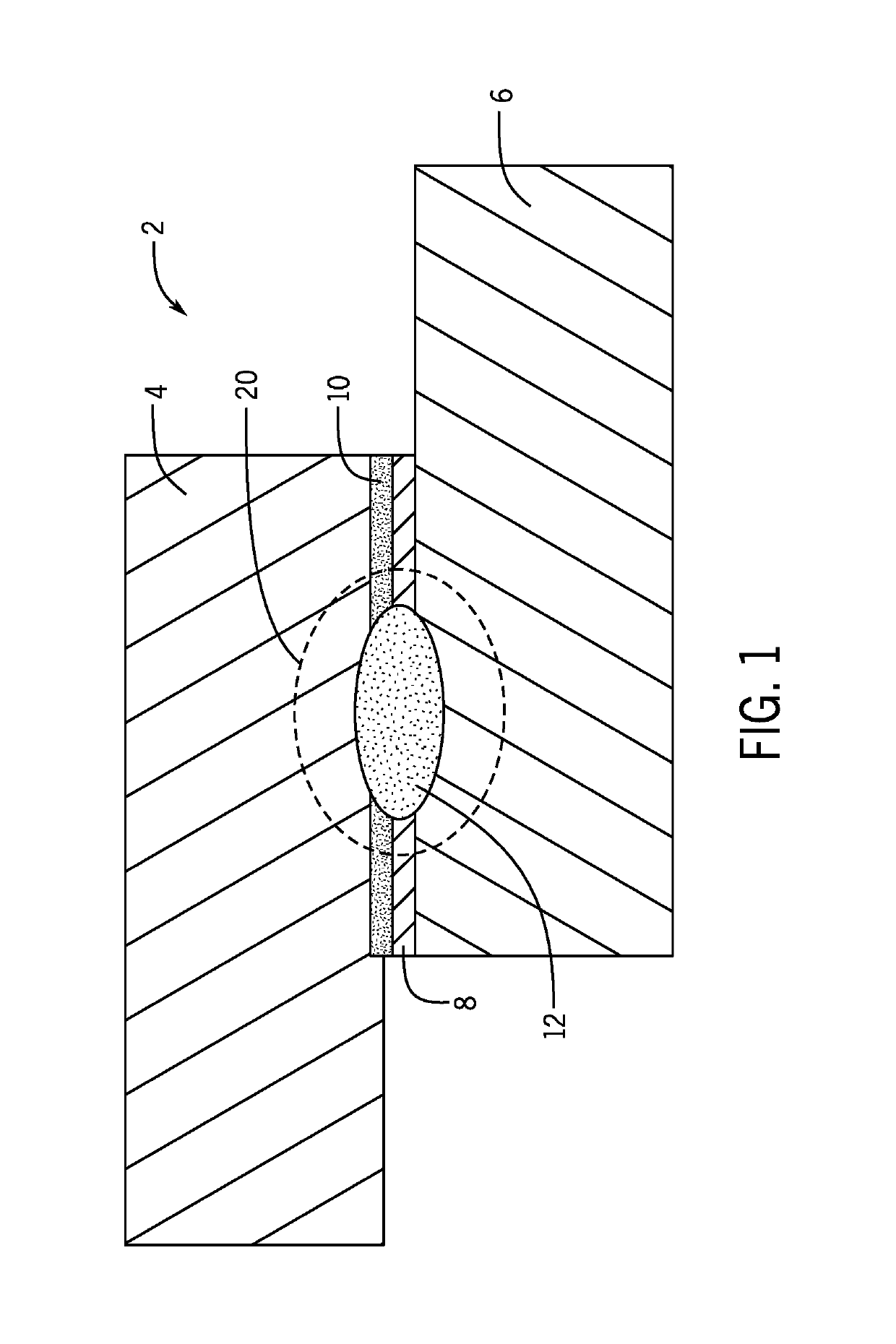

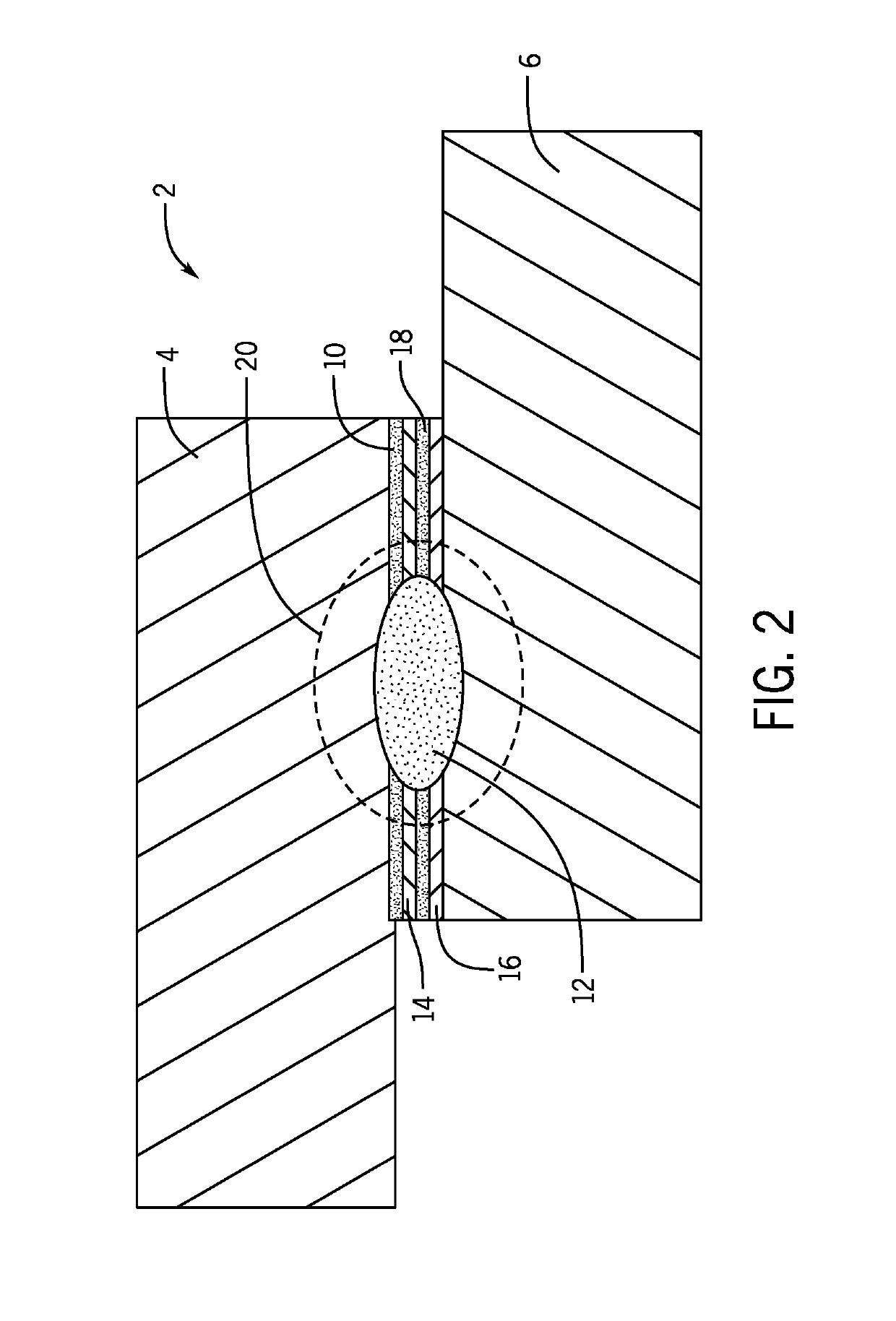

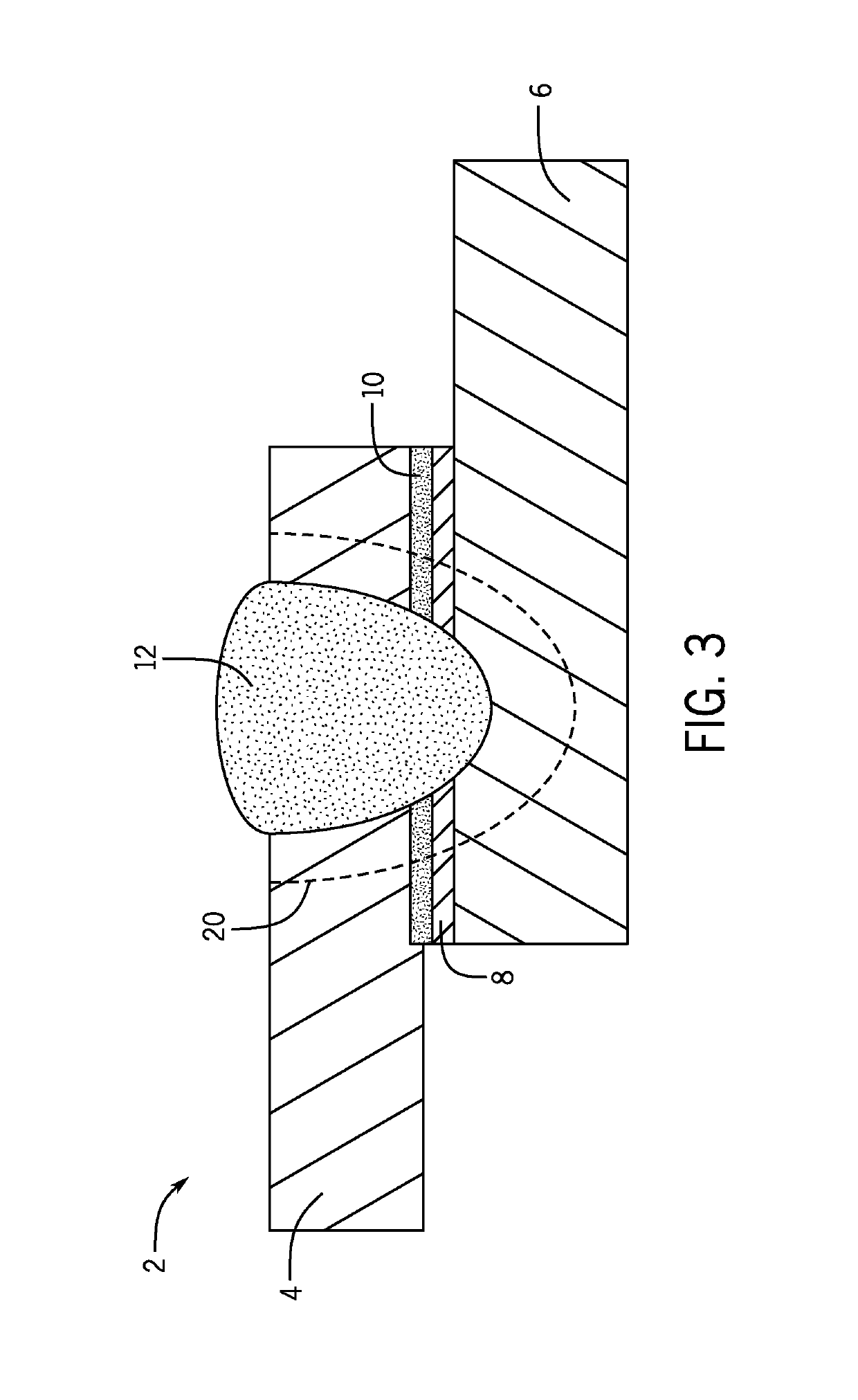

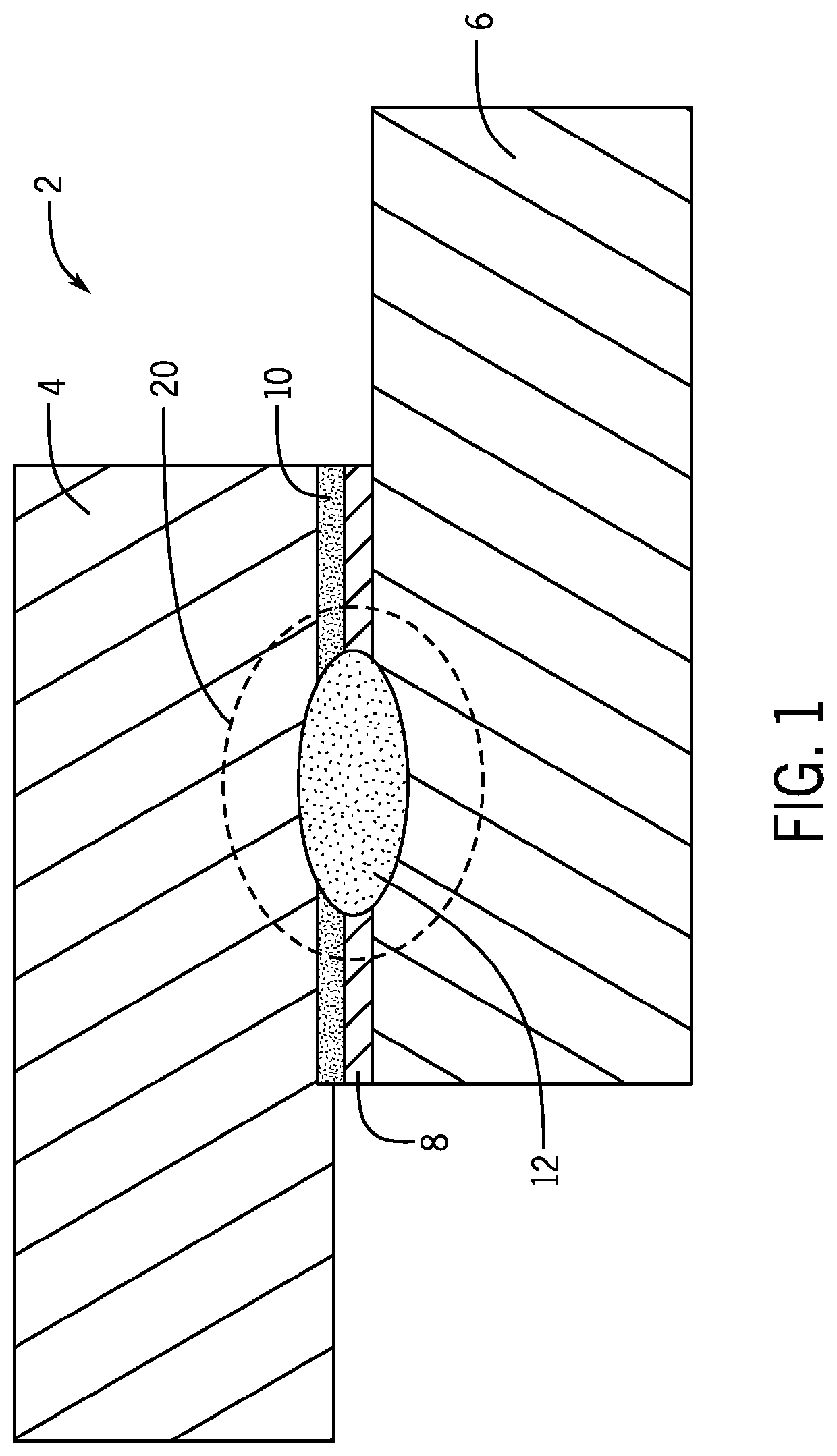

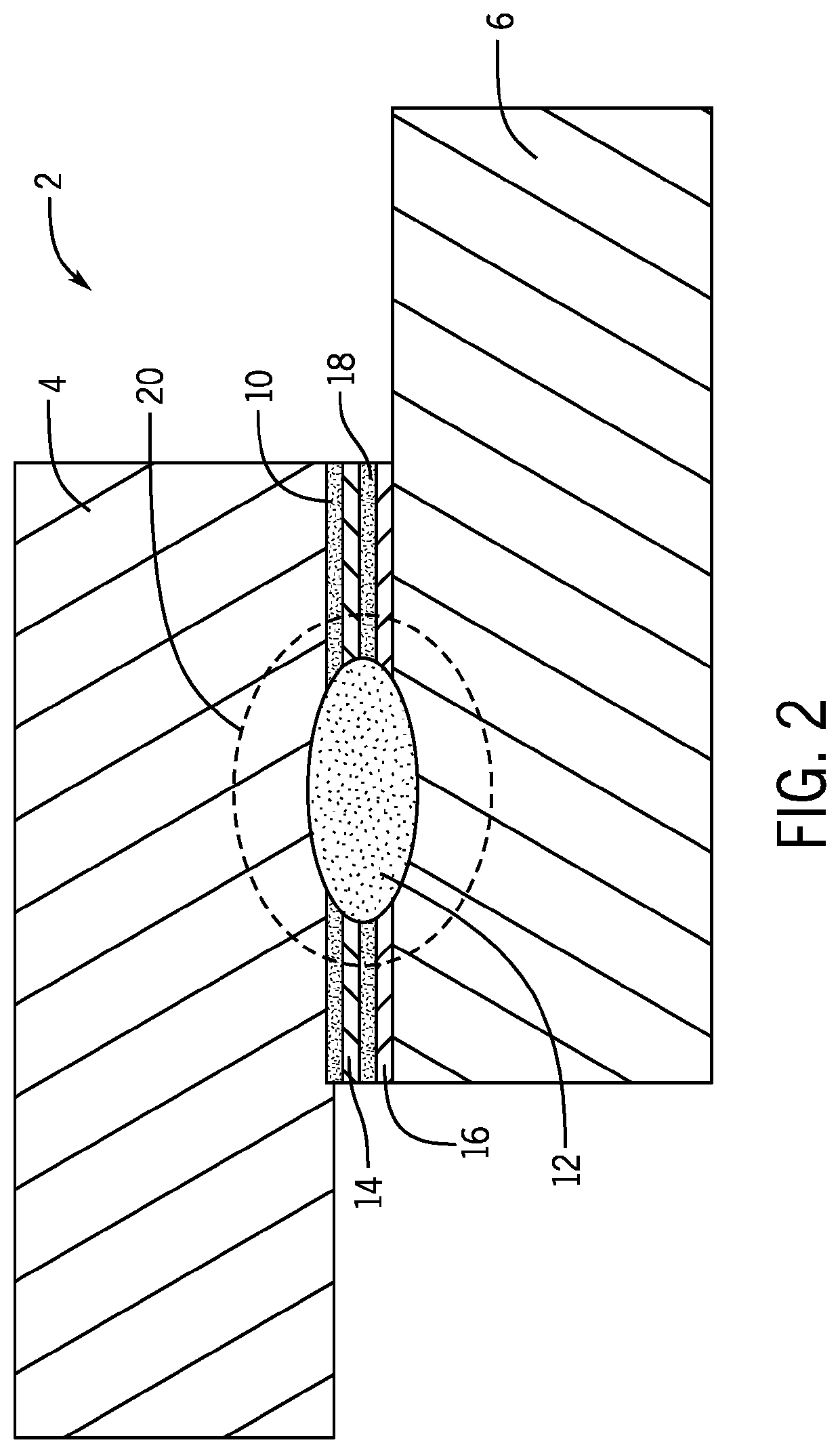

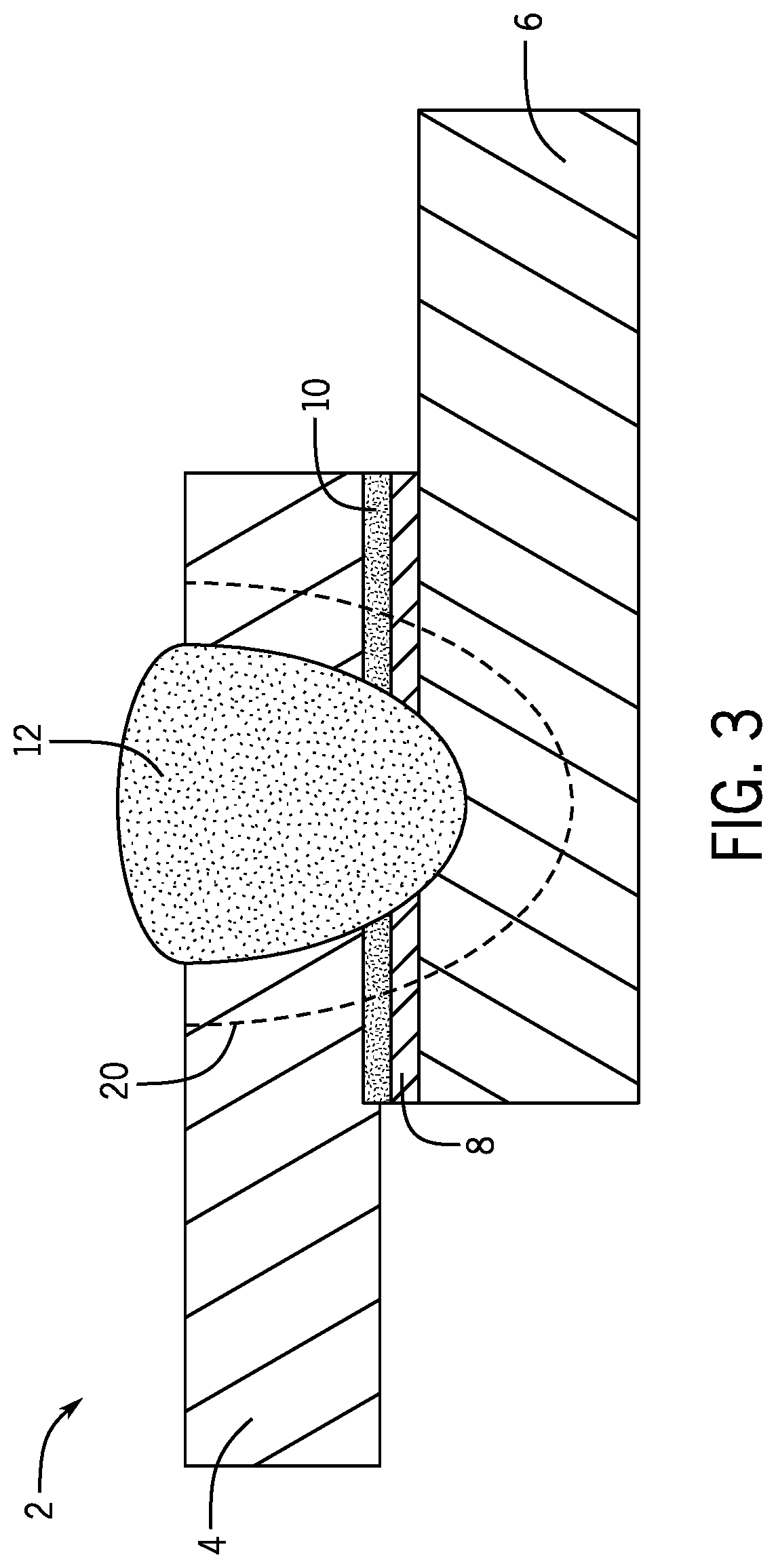

Method of improving weld quality

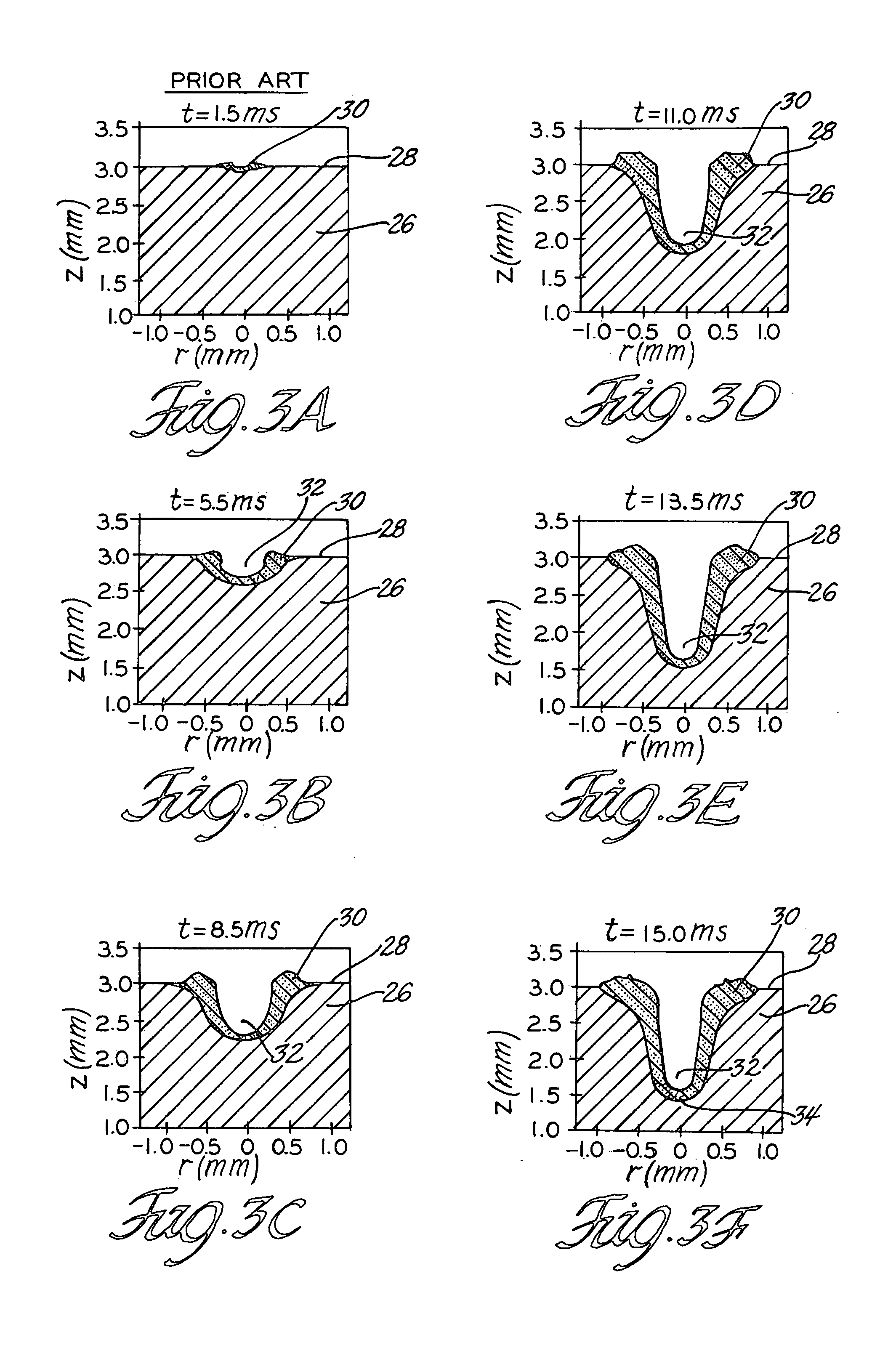

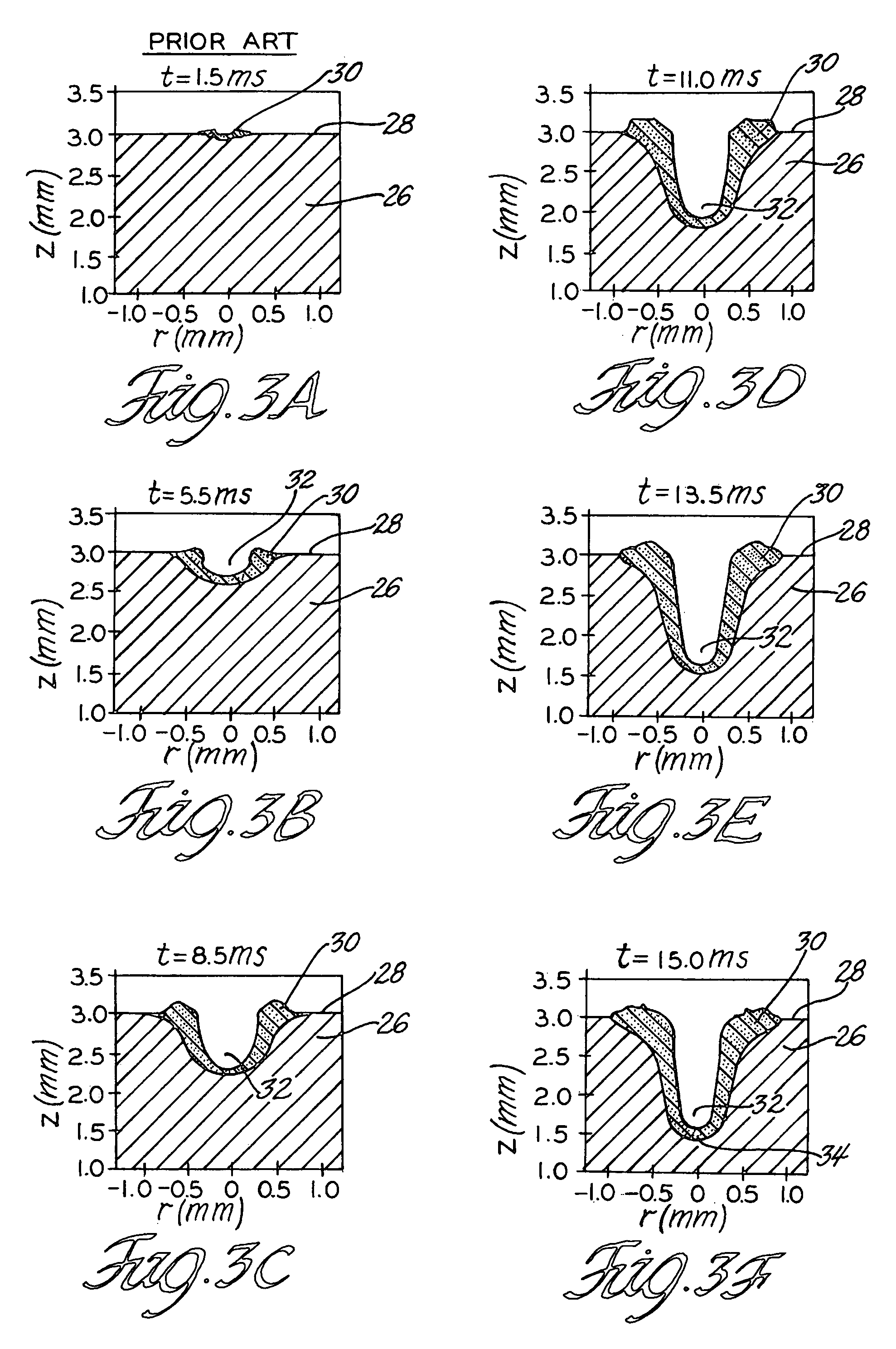

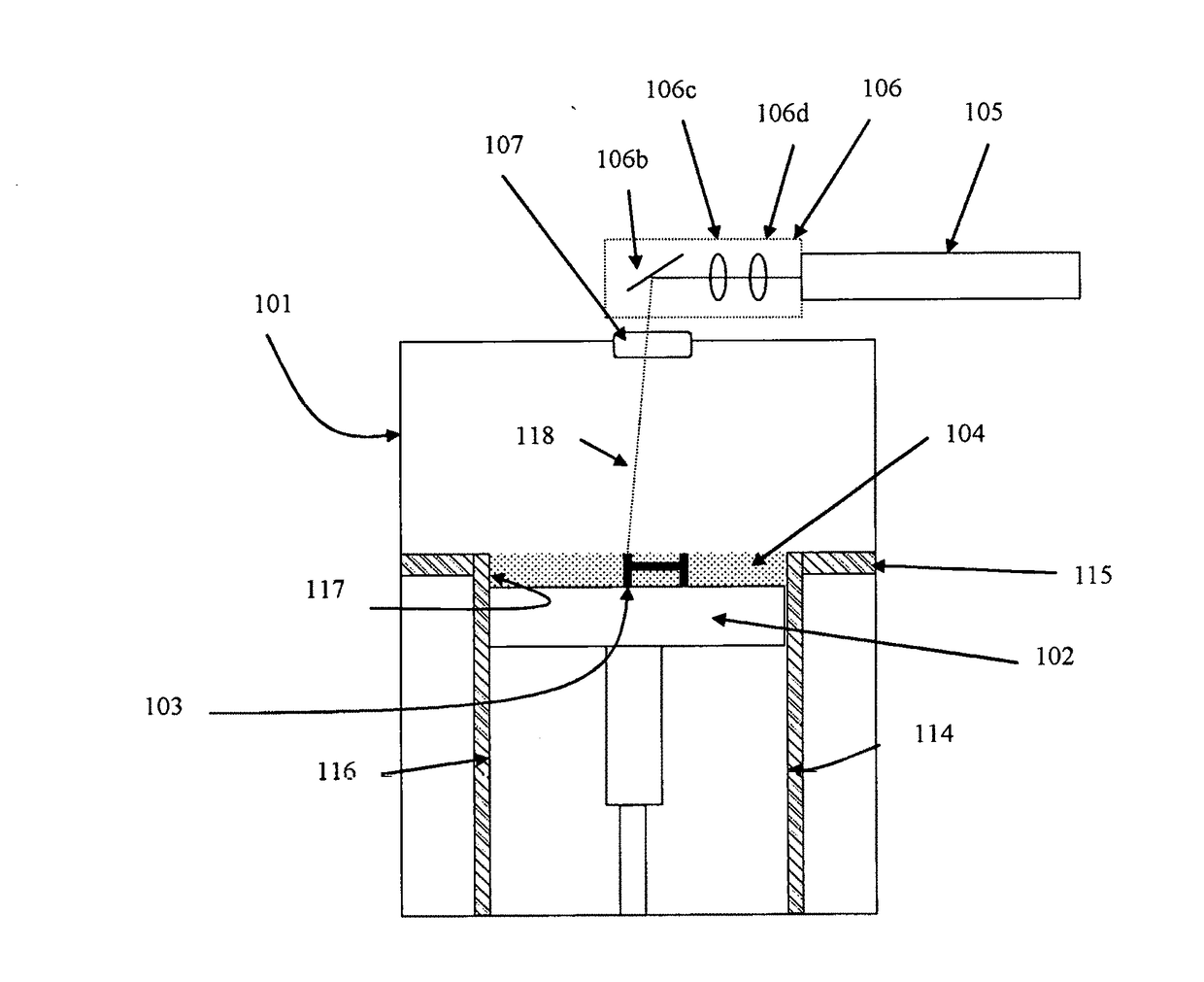

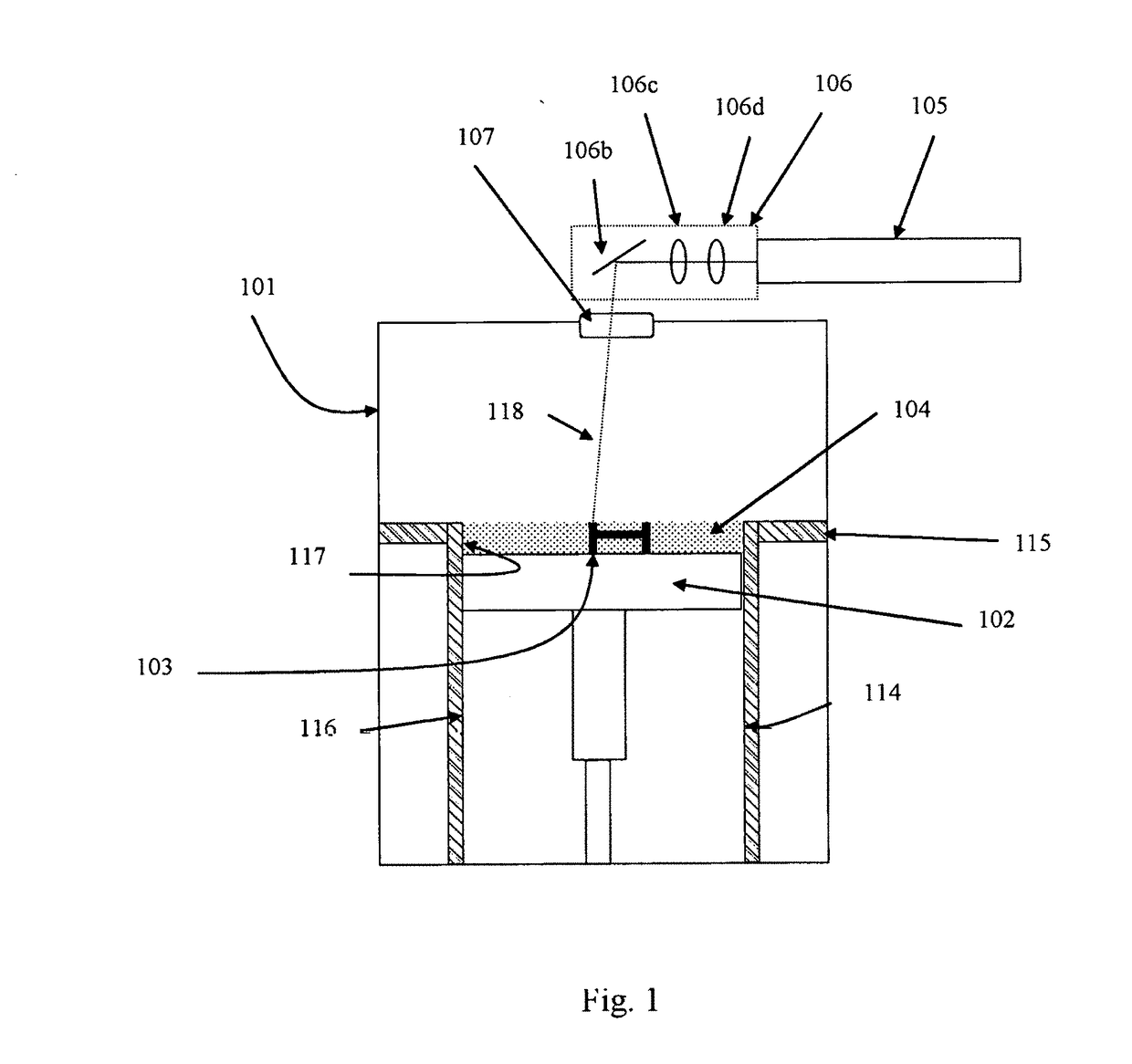

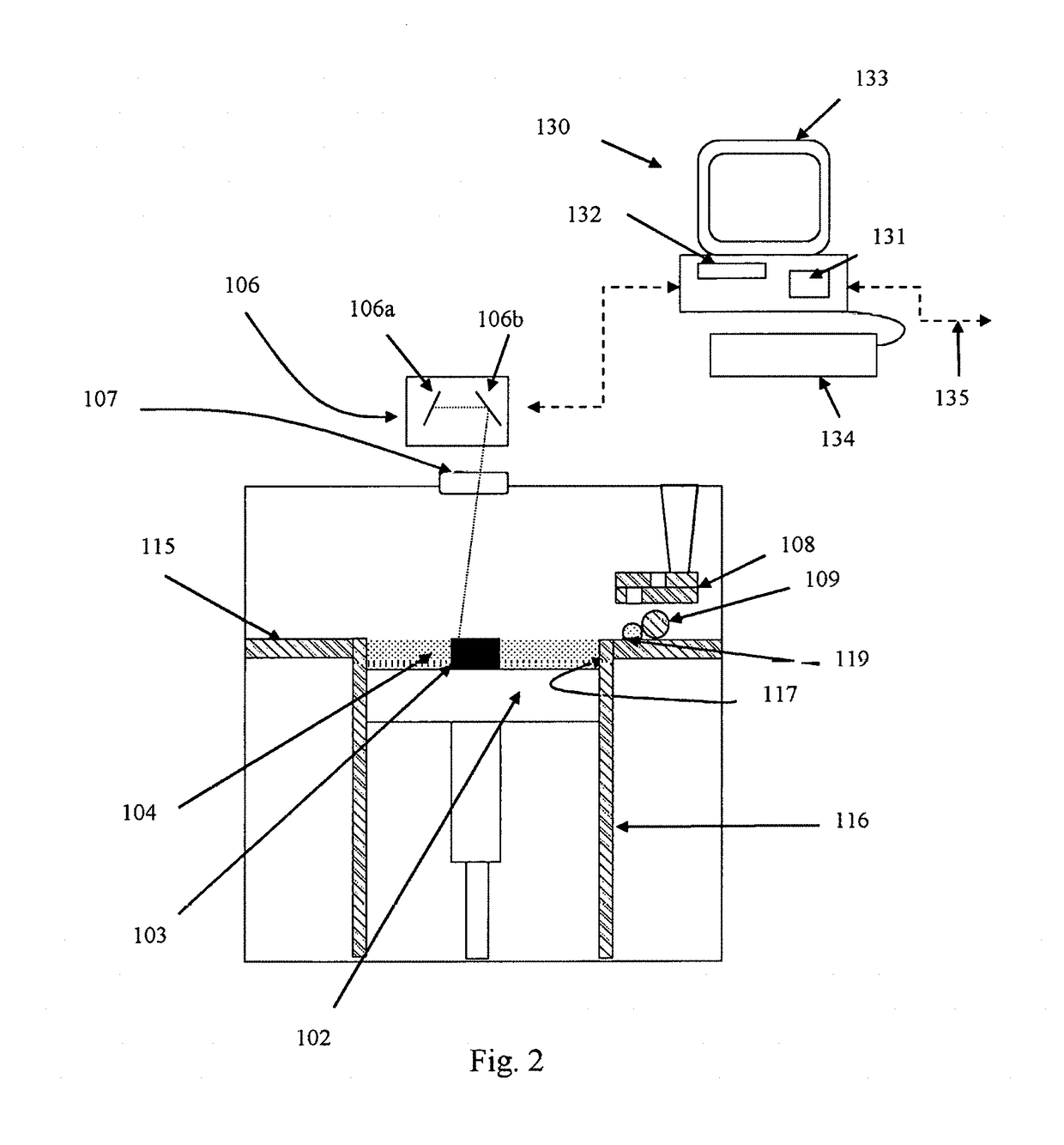

InactiveUS20050121426A1Improve temperature distributionReduce solidificationWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

A kind of beverage with anti-oxidation and immunity enhancement and preparation method thereof

The invention relates to a beverage with functions of antioxidation and immunity enhancing, and a preparation method thereof. The beverage is characterized in that: the beverage is prepared from the following raw materials: 1-3 kg of Chinese caterpillar fungus; 3-8 kg of medlar; 3-8 kg of mongolian milkvetch root; 2-6 kg of siberian solomonseal rhizome; 2-6 kg of mythic fungus; 1.5-3.5 kg of panas quinquefolium; 100-150 mg of a grape seed extract and 45-70 g of stevioside; purified water is added to the raw materials to prepare 650 L of the beverage. According to the present invention, the combination of the raw materials used in the beverage has good synergistic reaction; the raw materials collectively provide the effects of vital energy benefiting and blood nourishing, yang reinforcingand body fluid regeneration; the beverage can act on a plurality of immune competent cells, and has functions of antioxidation and immunity enhancing; the beverage can replace drugs so as to prevent disease, such that the bitterless beverage capable of prevention of the disease is provided; the beverage is easy to be drunken, and easy to be accepted by the people.

Owner:北京卓创首机通讯科技有限公司

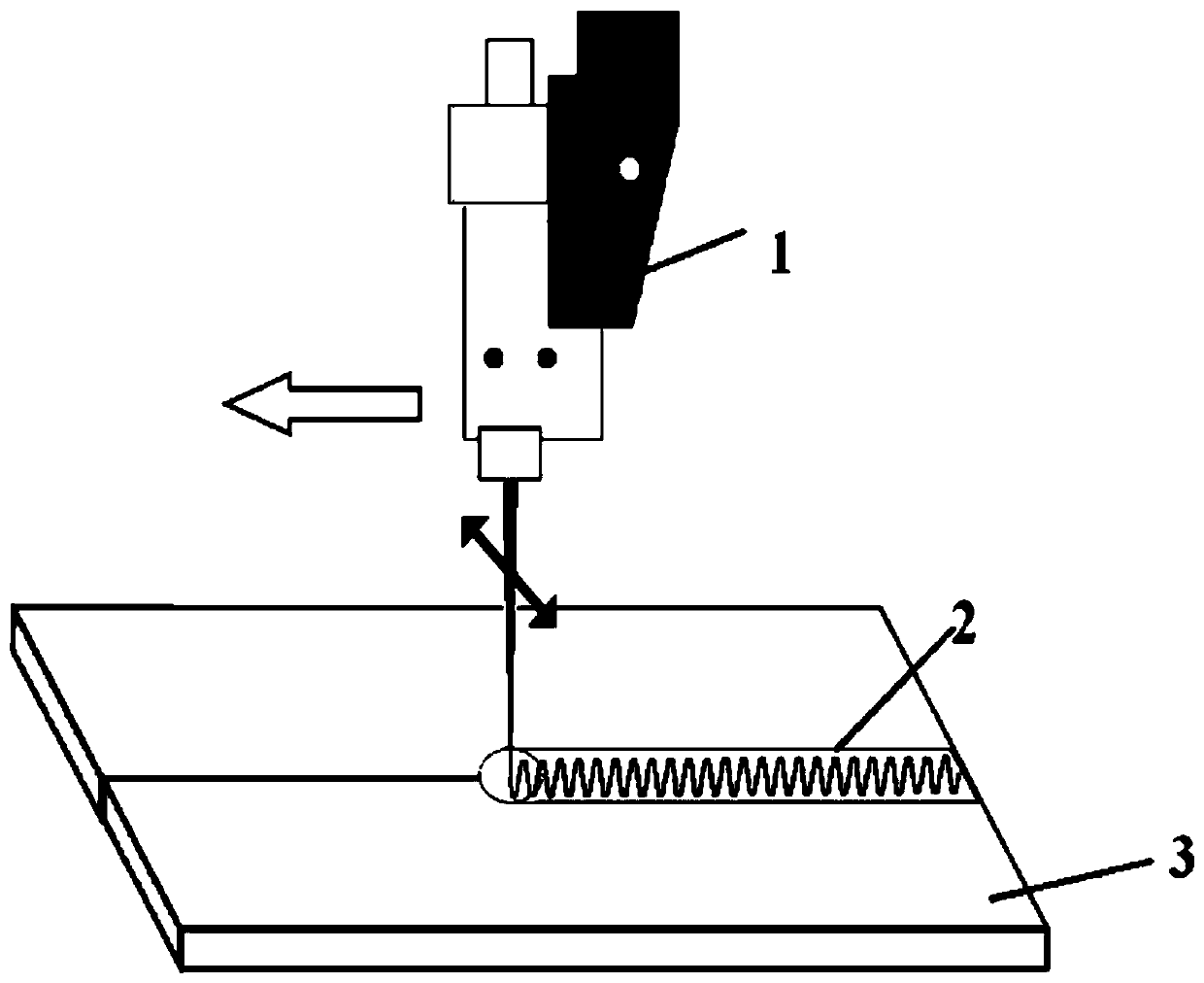

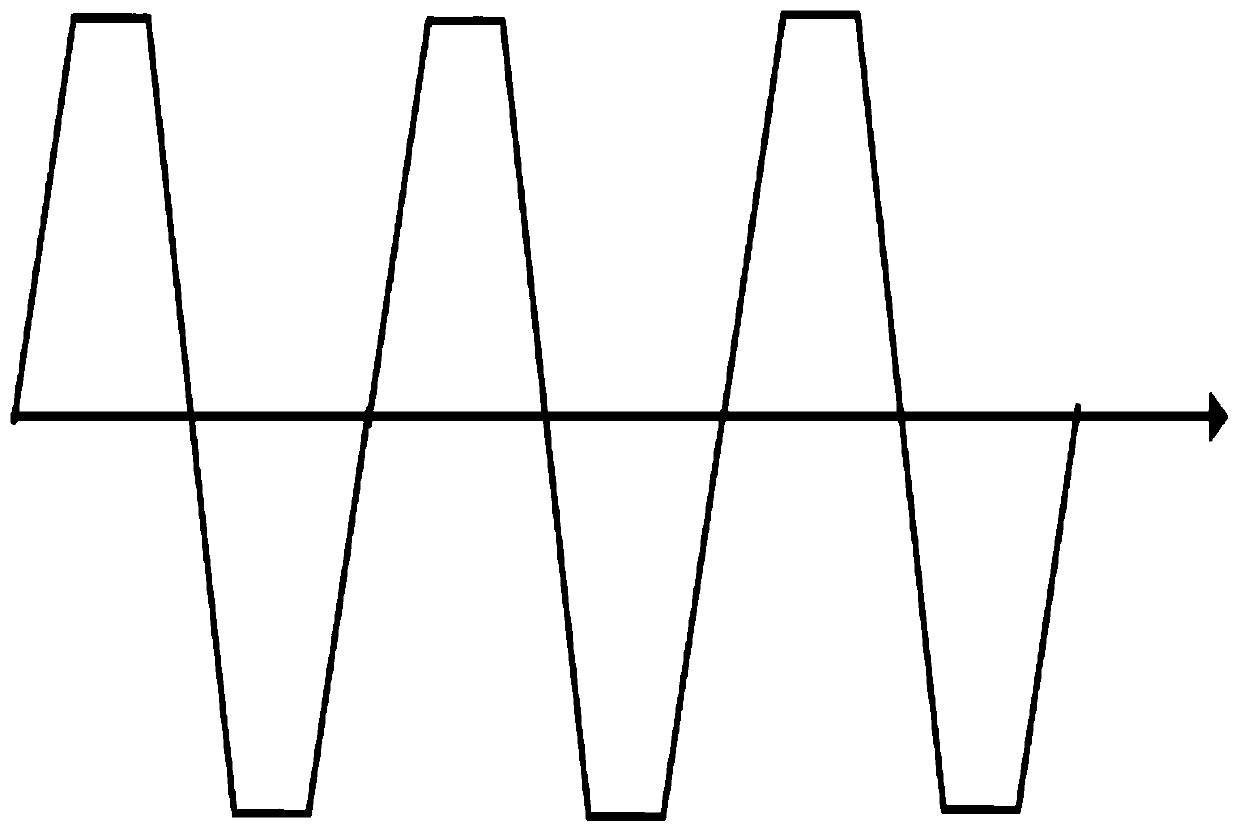

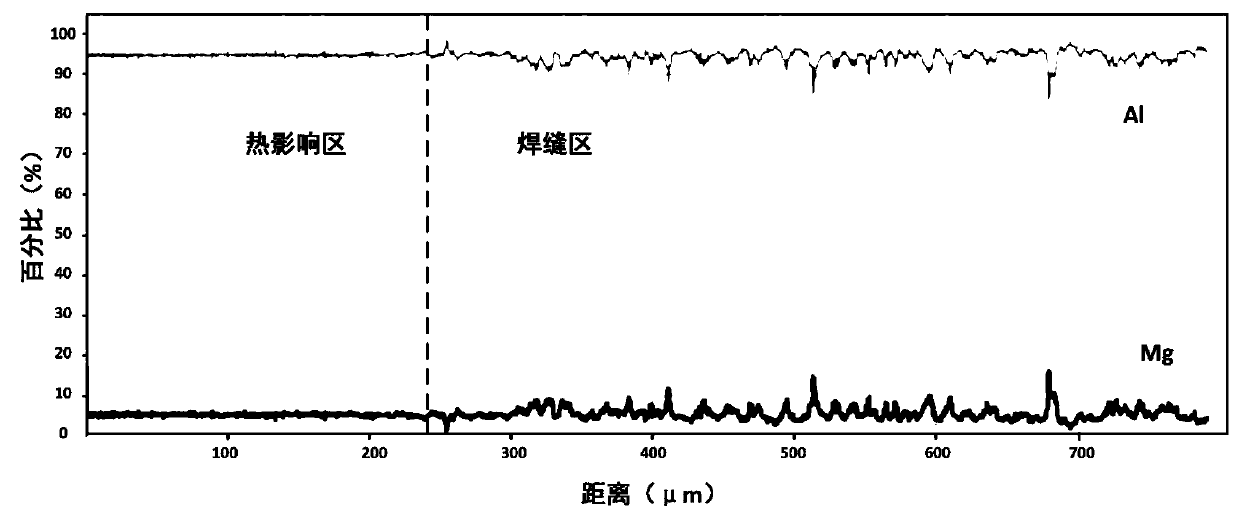

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

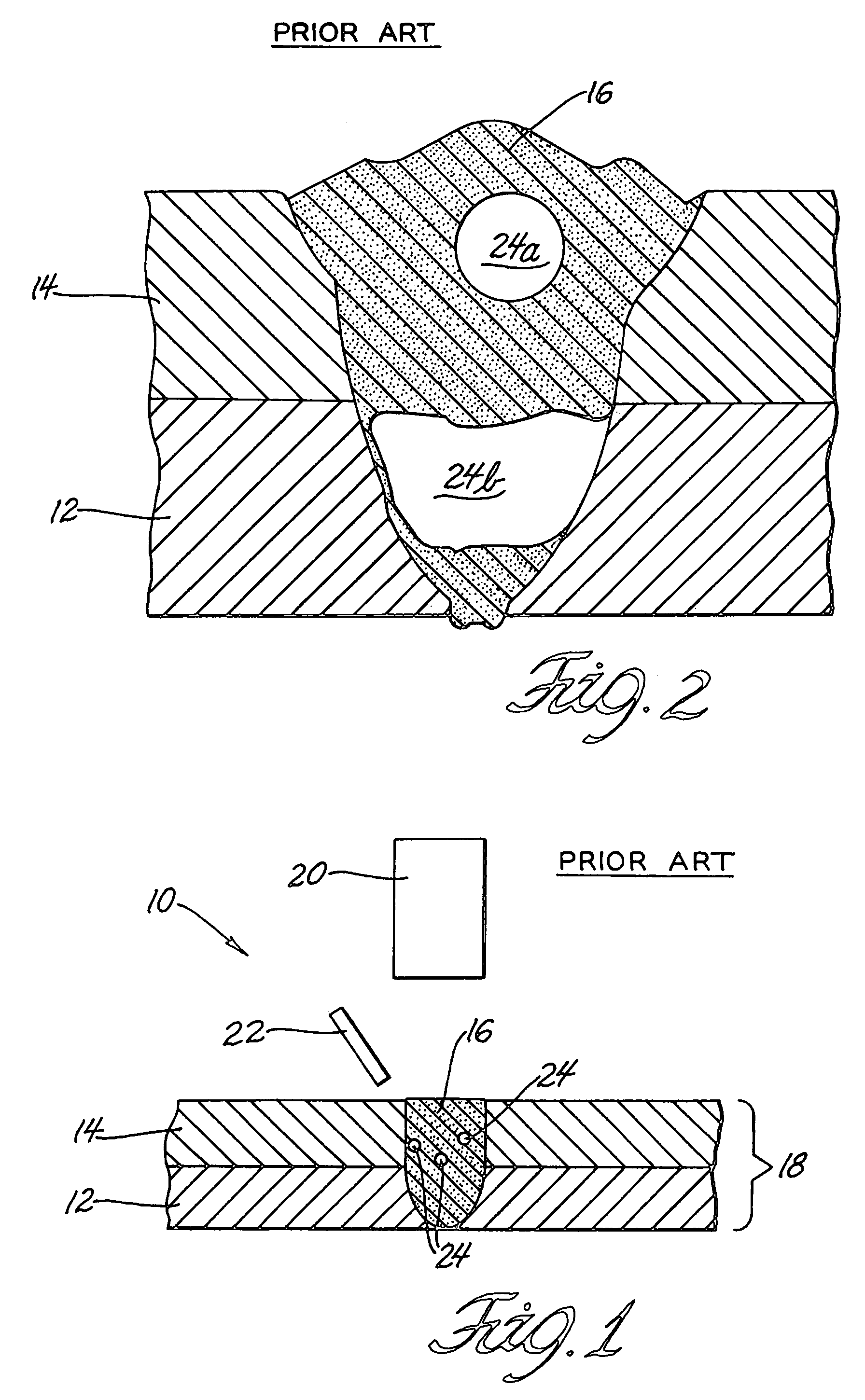

Welding process

ActiveUS20060131366A1Minimizes solidification shrinkage , incidenceMinimizes incidenceTurbinesWelding/cutting media/materialsFilling materialsSolid solution strengthening

A weld process cuitable for repairing precipitation-strengthened superalloys, and particularly gamma prime-strengthened nickel-based superalloys. The process entails forming a weldment in a cavity present in a surface of an article formed of a precipitation-strengthened superalloy. The cavity has a root region and a cap region between the root region and the surface of the article. A solid body formed of a superalloy composition is placed in the root region of the cavity so as to occupy a first portion but not a second portion of the root region. A first filler material formed of a solid solution-strengthened superalloy is then weld-deposited in the second portion of the root region. Subsequently, a second filler material formed of a precipitation-strengthened superalloy is weld-deposited in the cap region of the cavity.

Owner:GENERAL ELECTRIC CO

Method of improving weld quality

InactiveUS7154064B2Reduce solidificationReduce porosityWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Additive manufacturing apparatus and methods

ActiveUS20180290241A1Reduce delayThermal stress be avoidAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser beams

An additive manufacturing apparatus including a build chamber, build platform lowerable in the chamber so layers of flowable material can successively form across the platform, laser for generating a laser beam, scanning unit for directing the laser beam onto each layer to selectively solidify the material and a processor for controlling the scanning unit. The processor controls the scanning unit directs the laser beam to solidify a selected area of material by advancing the laser beam many times along a scan path. On each pass, the laser beam solidifies spaced apart sections of the scan path, each subsequent pass solidifying sections that are located between sections solidified on a previous pass. The processor controls the scanning unit to direct the laser beam to solidify selected area of material by solidifying sub-millimetre sized sections of non-continuously area and in an order such that consecutively solidified sections are spaced apart.

Owner:RENISHAW PLC

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

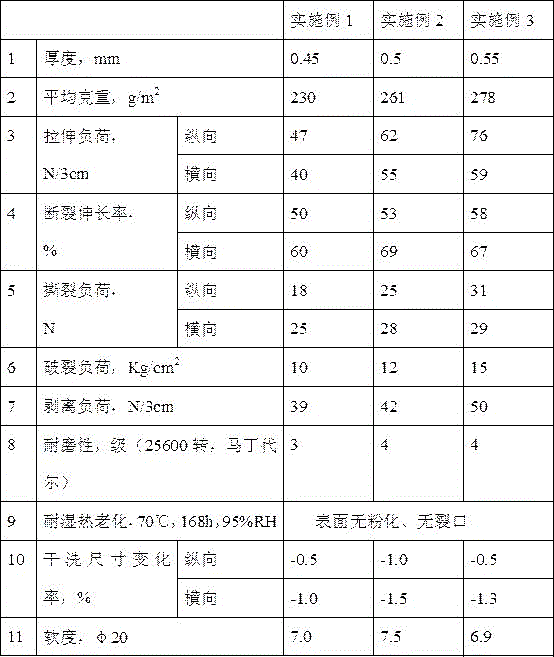

Preparation method for ultrafine fiber clothing leather

InactiveCN105568709AReduce pollutionBig pollutionHeating/cooling textile fabricsTextile treatment machine arrangementsReduction treatmentHigh density

The invention discloses a preparation method for ultrafine fiber clothing leather. The preparation method comprises the following steps that a figured or unfigured sea-island fiber is selected to be prepared into a high-density non-woven cloth, and heat setting is performed; the non-woven cloth is impregnated with polyurethane sizing and then cured to be prepared into semi-finished synthetic leather; quantity reduction treatment is performed on the semi-finished synthetic leather to strip out sea ingredients in the sea-island fiber, and then semi-finished ultrafine fiber clothing leather is prepared; the semi-finished ultrafine fiber clothing leather is treated through splitting, sanding and softening, and then the ultrafine fiber clothing leather is prepared. The ultrafine fiber clothing leather obtained through the method has the advantages that the handfeel is soft, the drape performance is good, the hot iron resisting effect is good, the effect of consistent folding grains in the warp direction and weft drection is achieved, the zigzagged folding grain or thick wrinkle phenomenon cannot occur when the leather is folded in half, the recovery effect is extremely good after the leather is folded in half, and the surface has no fold residue.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

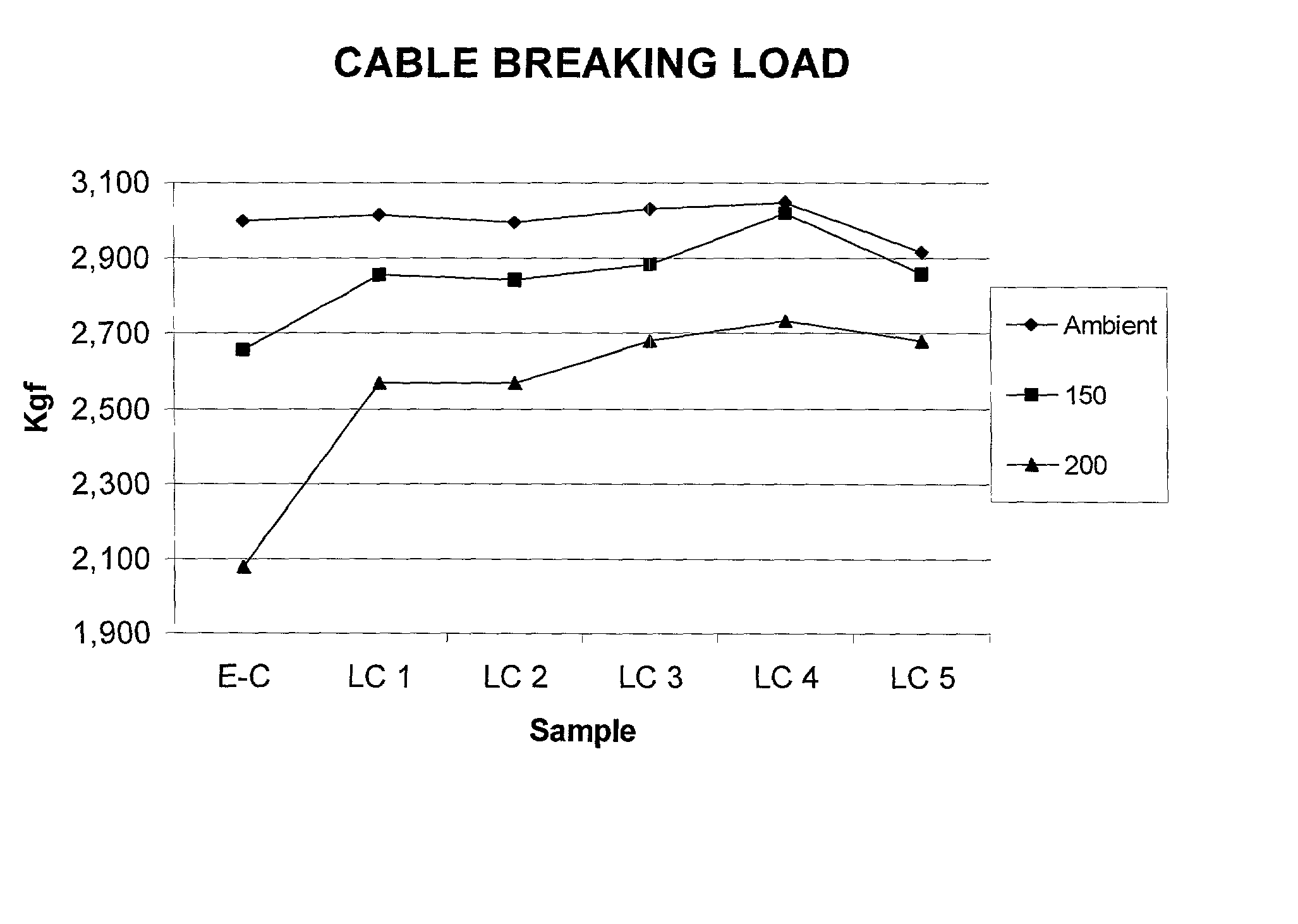

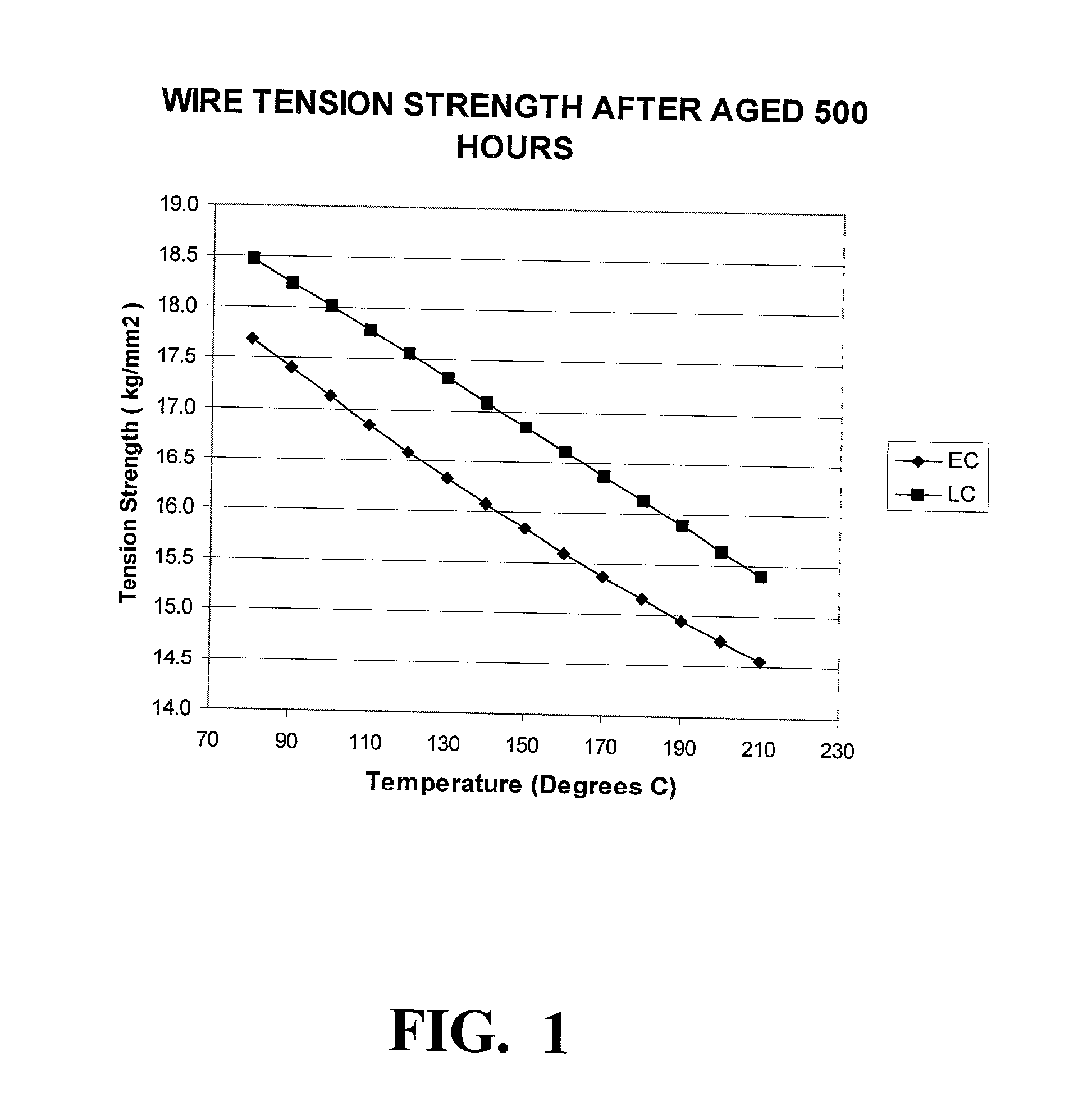

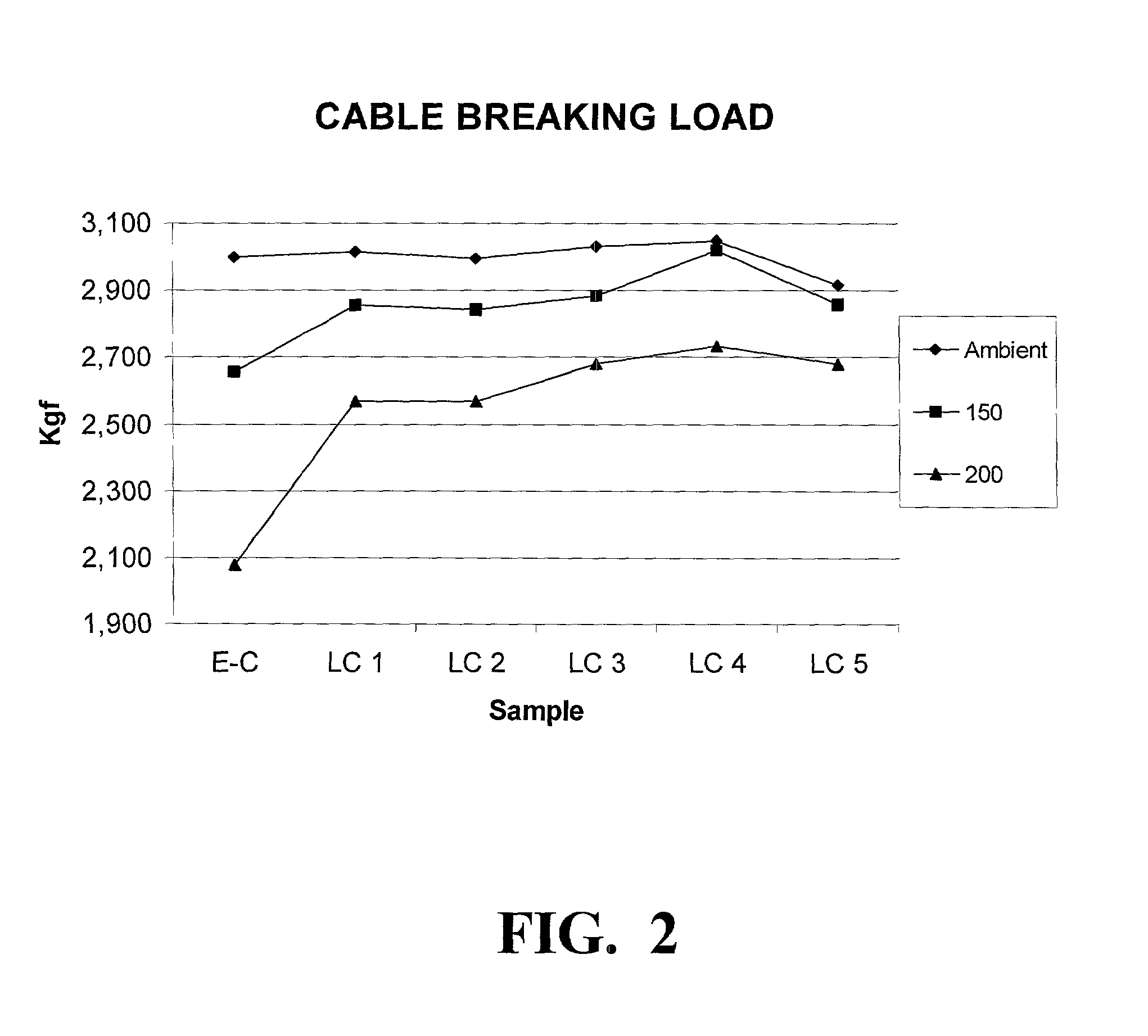

Creep resistant cable wire

InactiveUS20020162607A1Eliminate the effects ofReduce impactConductive materialMetal/alloy conductorsAlloySilicon

Owner:PHELPS DODGE IND

Welding process

ActiveUS7533795B2Minimizes incidenceMinimizes solidificationTurbinesWelding/cutting media/materialsFilling materialsSolid solution strengthening

Owner:GENERAL ELECTRIC CO

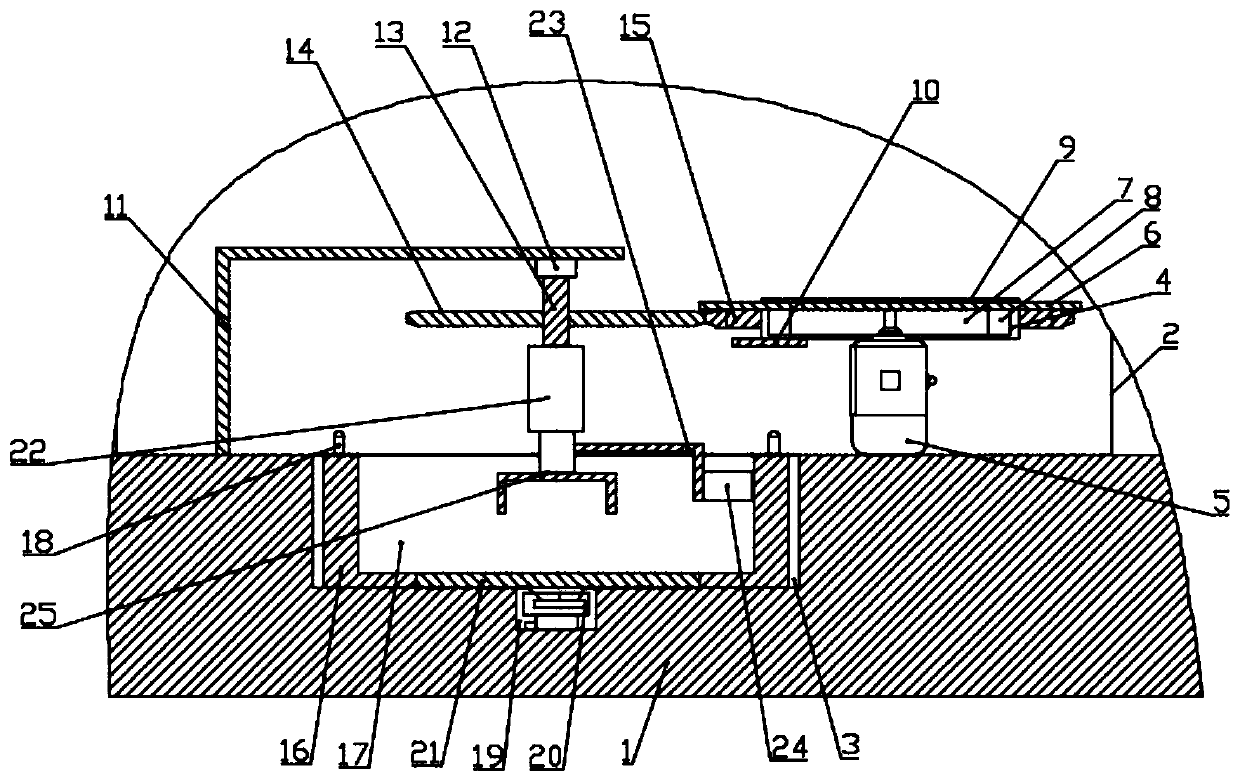

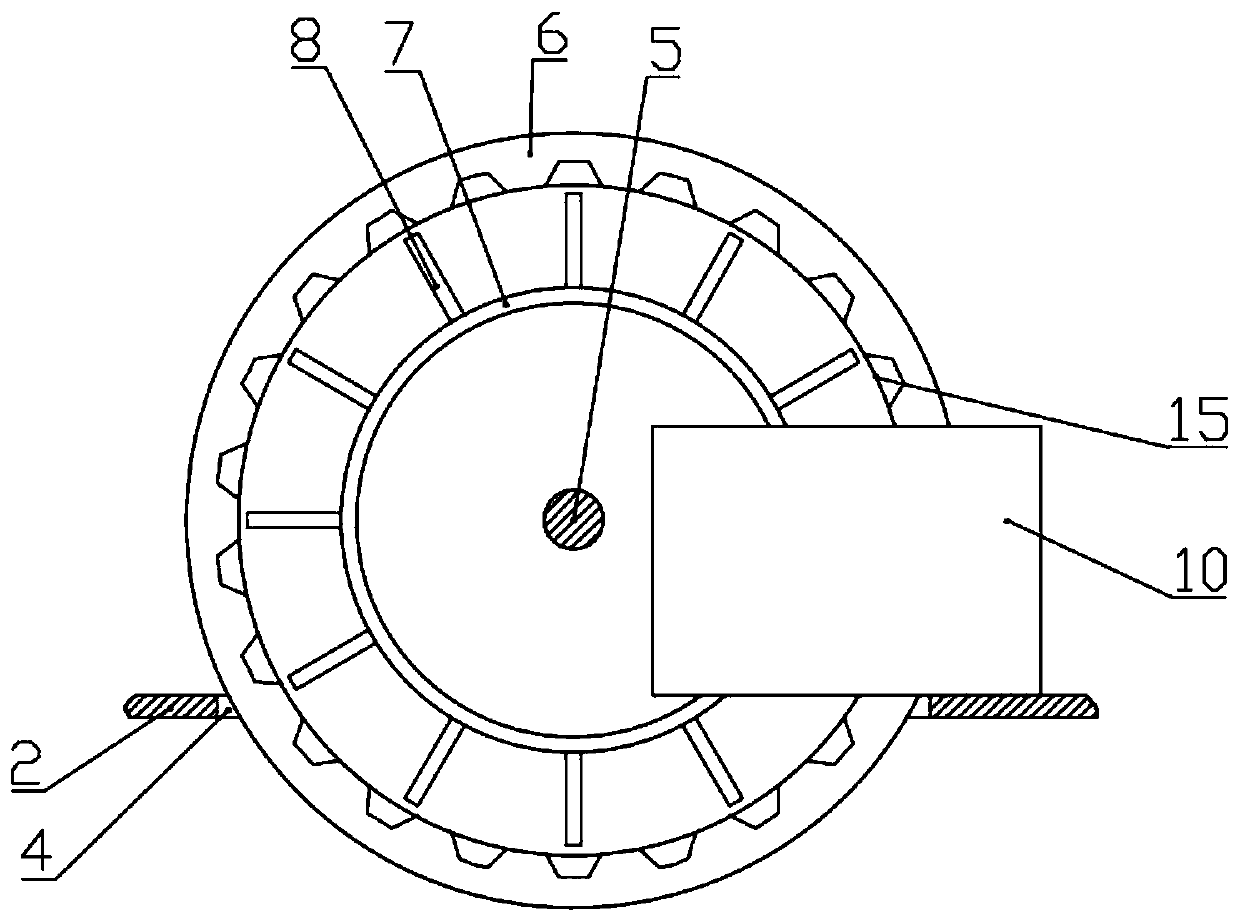

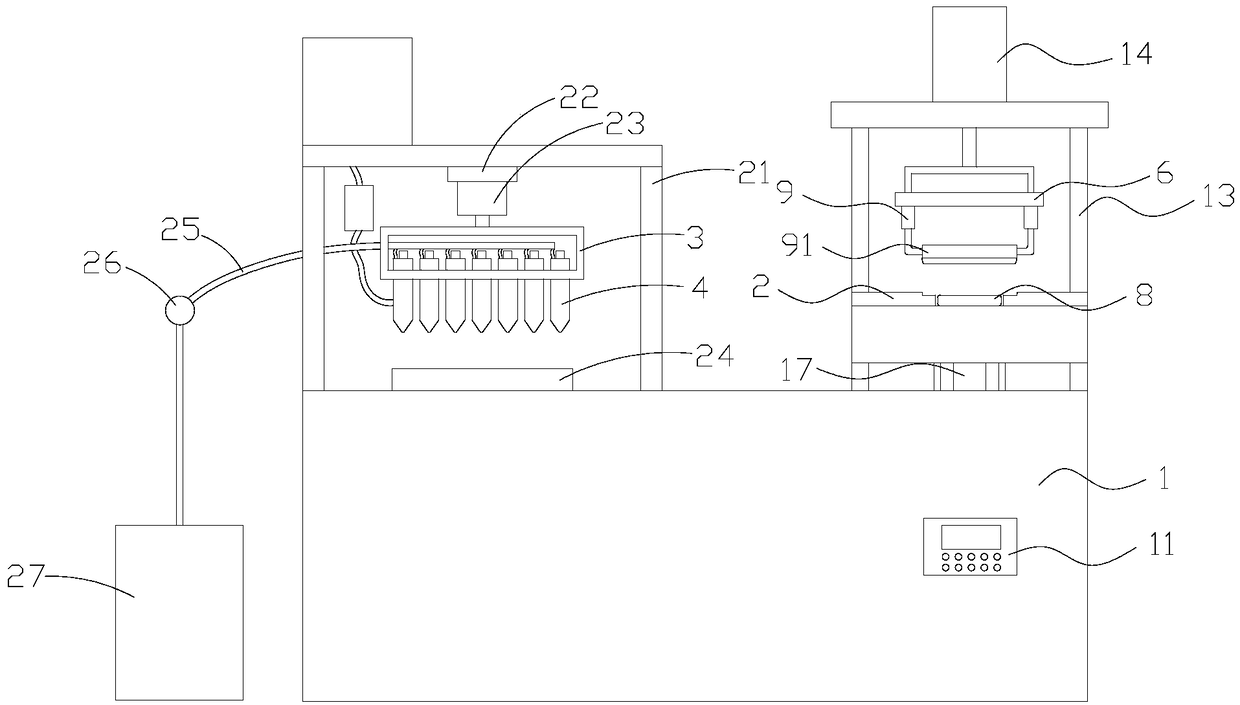

Cement mixing and quantitative adding device

ActiveCN110385788AReduce the amount of manual laborReduce wasteMixing operation control apparatusTransportation and packagingMaterials scienceC shaped

The invention discloses a cement mixing and quantitative adding device, relates to the field of building devices, and mainly solves the problem that after cement is mixed and stirred, since the amountof cement is large, when cement is added, the cement is likely to set. The cement mixing and quantitative adding device mainly comprises a moving base; a stirring mechanism, a water adding mechanism,a moving mechanism, a control mechanism and a quantitative feeding mechanism are arranged on the moving base; a rotating motor rotates to drive a baffle plate on a rotating disk to rotate, cement ina holding box is guided into a circular groove by the baffle plate to be fed, and during the feeding process, a gear is engaged to drive a C-shaped stirring shaft to rotate to stir the cement in the circular groove. The cement mixing and quantitative adding device has the beneficial effects that the cement is fed and then stirred conveniently, and feeding and cement stirring can be performed by using a motor, so that the manufacturing cost is reduced.

Owner:廊坊曲寨水泥有限公司

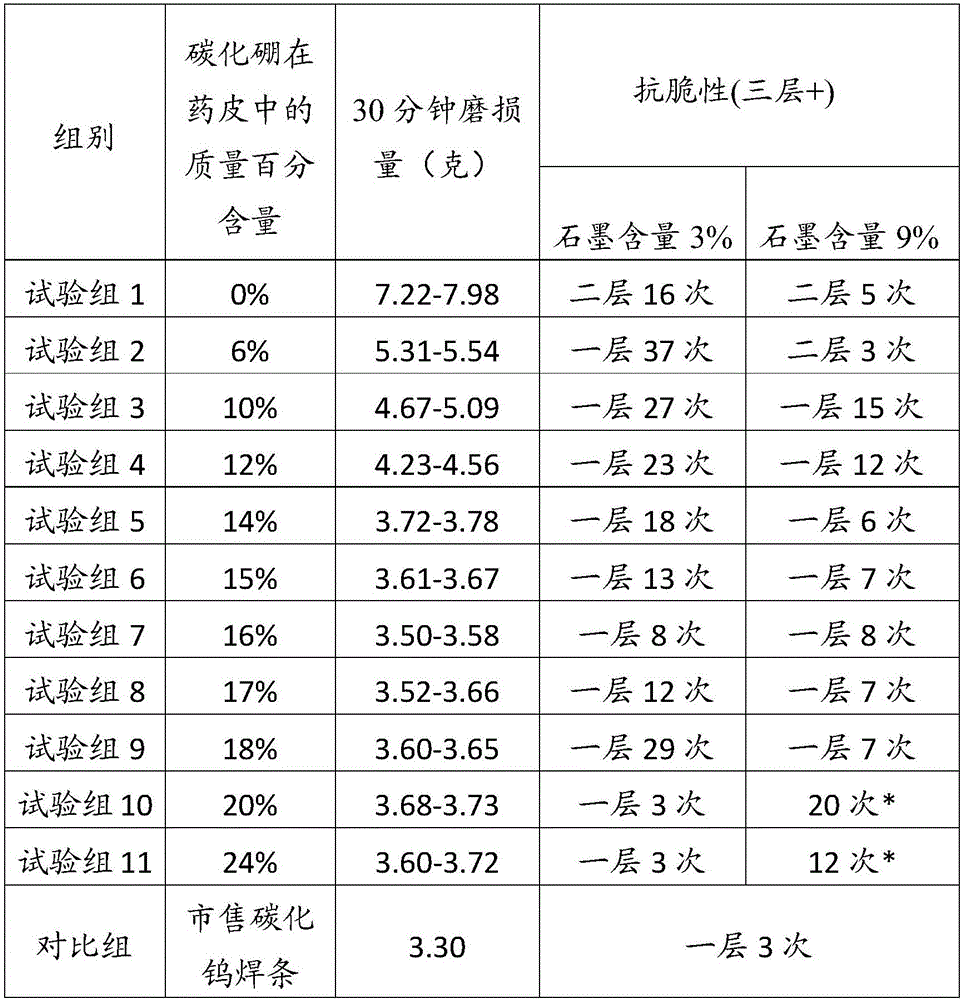

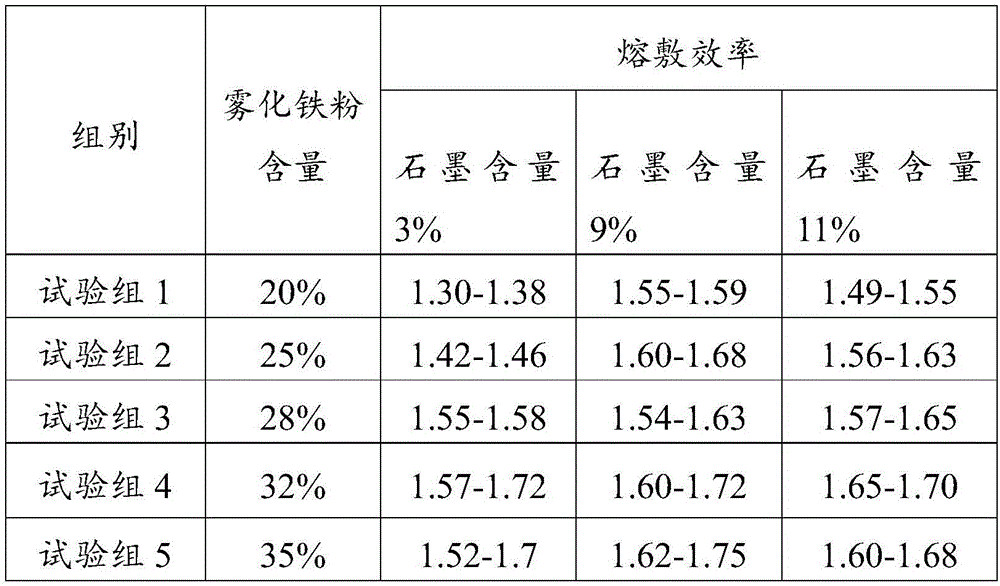

Hardfacing electrode covering and electrode containing same

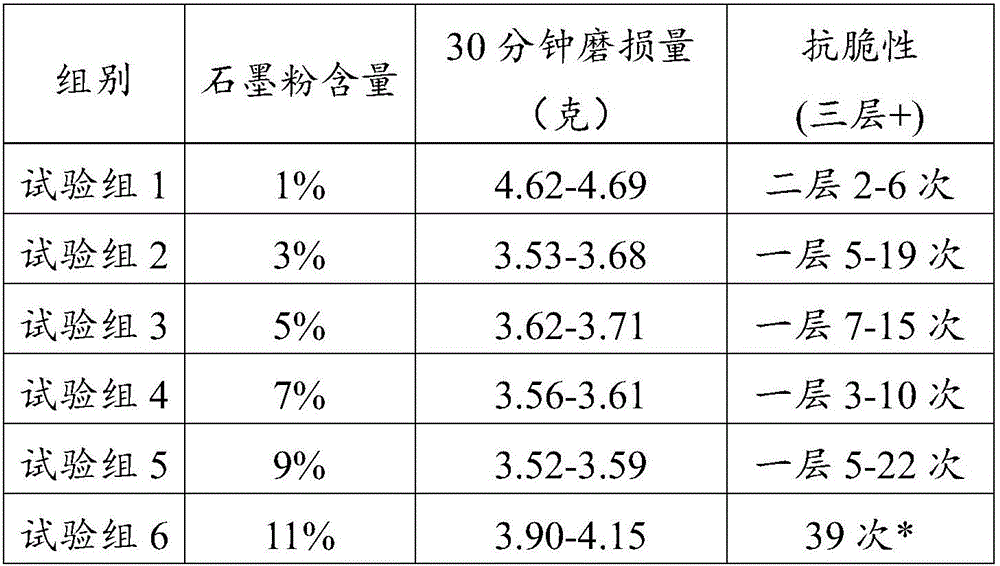

ActiveCN105689923AStrong anti-brittleImprove conductivityWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention discloses a hardfacing electrode covering and an electrode containing the same. The covering is prepared from the following components in percentage by mass: 14 to 18 percent of boron carbide, 28 percent of atomized iron powder, 0 to 6 percent of atomized ferrosilicon, 0 to 41 percent of high-carbon ferro-chrome, 0 to 33 percent of micro-carbon ferro-chrome, 0 to 20 percent of ferroniobium, 0 to 8 percent of cobalt powder, 3 to 9 percent of graphite powder, 0 to 4 percent of medium-carbon ferromanganese, 0 to 4 percent of ferrovanadium, and 0 to 20 percent of chromium metal. The hardfacing electrode covering disclosed by the invention is low in melting point, high in melting speed, convenient to perform welding and attractive in molding; metal on a surfacing layer of the hardfacing electrode covering has high hardness, high wear resistance and a certain brittleness resistance; moreover, in the using process, the hardfacing electrode covering is relatively high in cost performance. Meanwhile, the invention further discloses the electrode containing the hardfacing electrode covering and a preparation method of the electrode.

Owner:广州鑫钻新材料科技开发有限公司

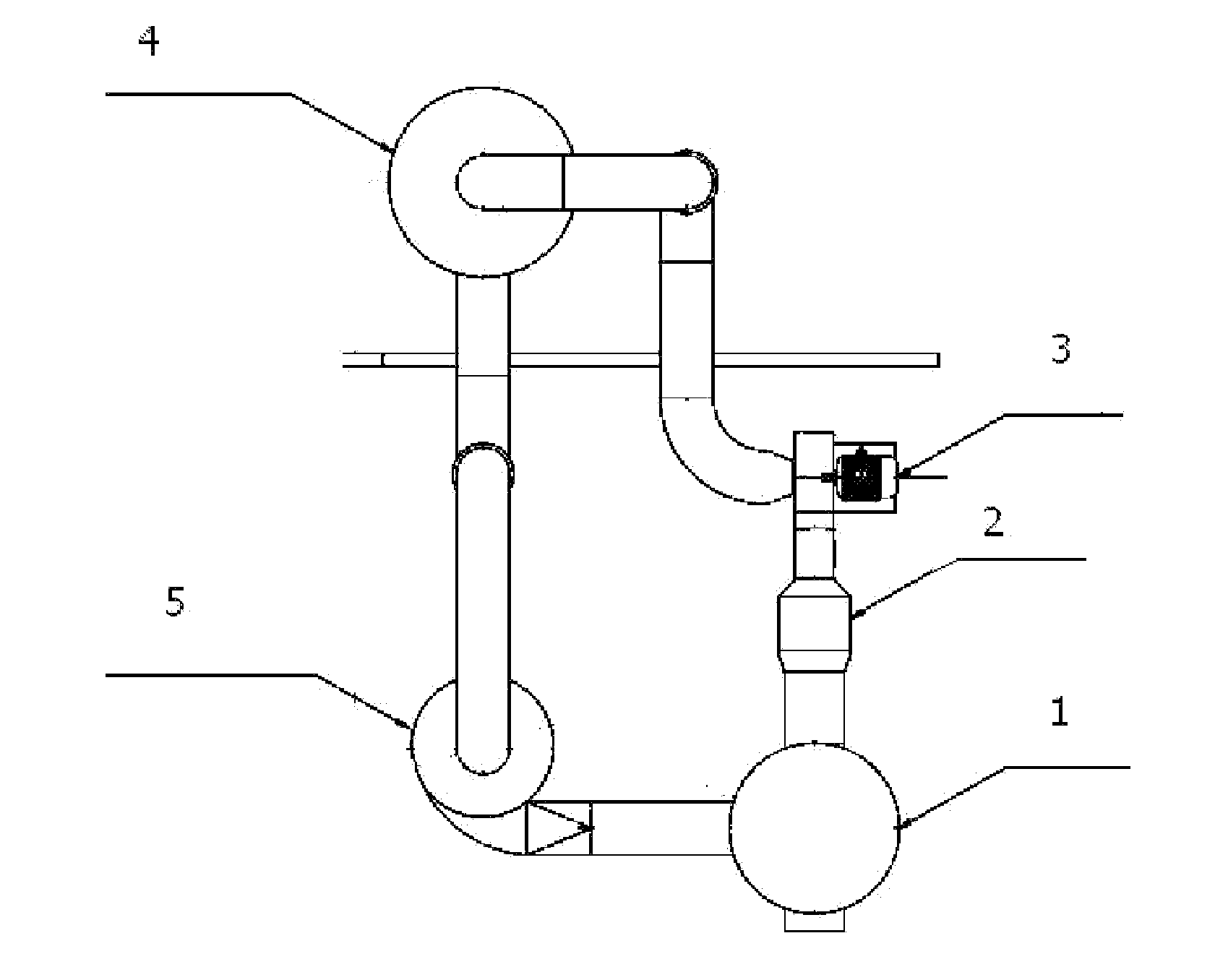

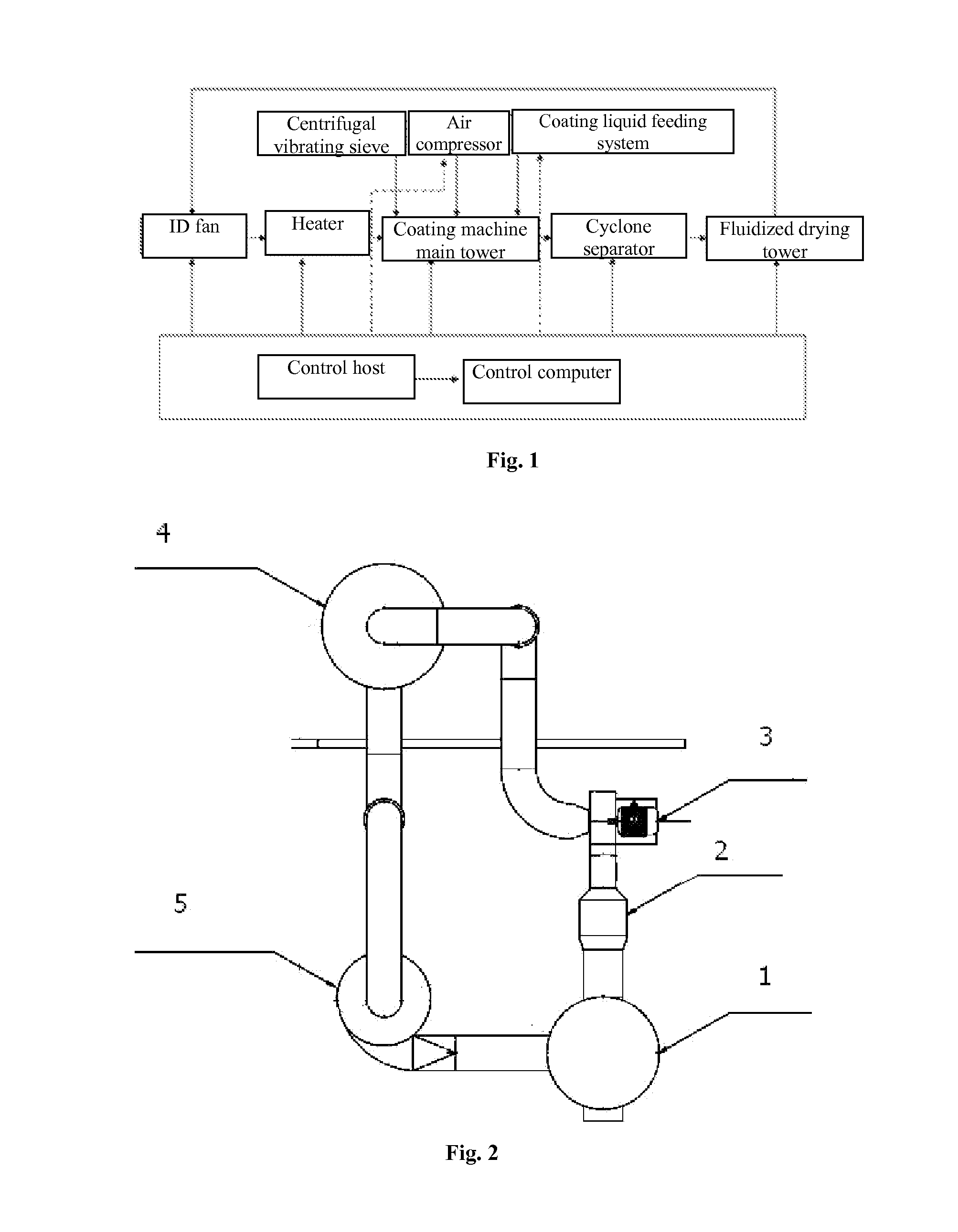

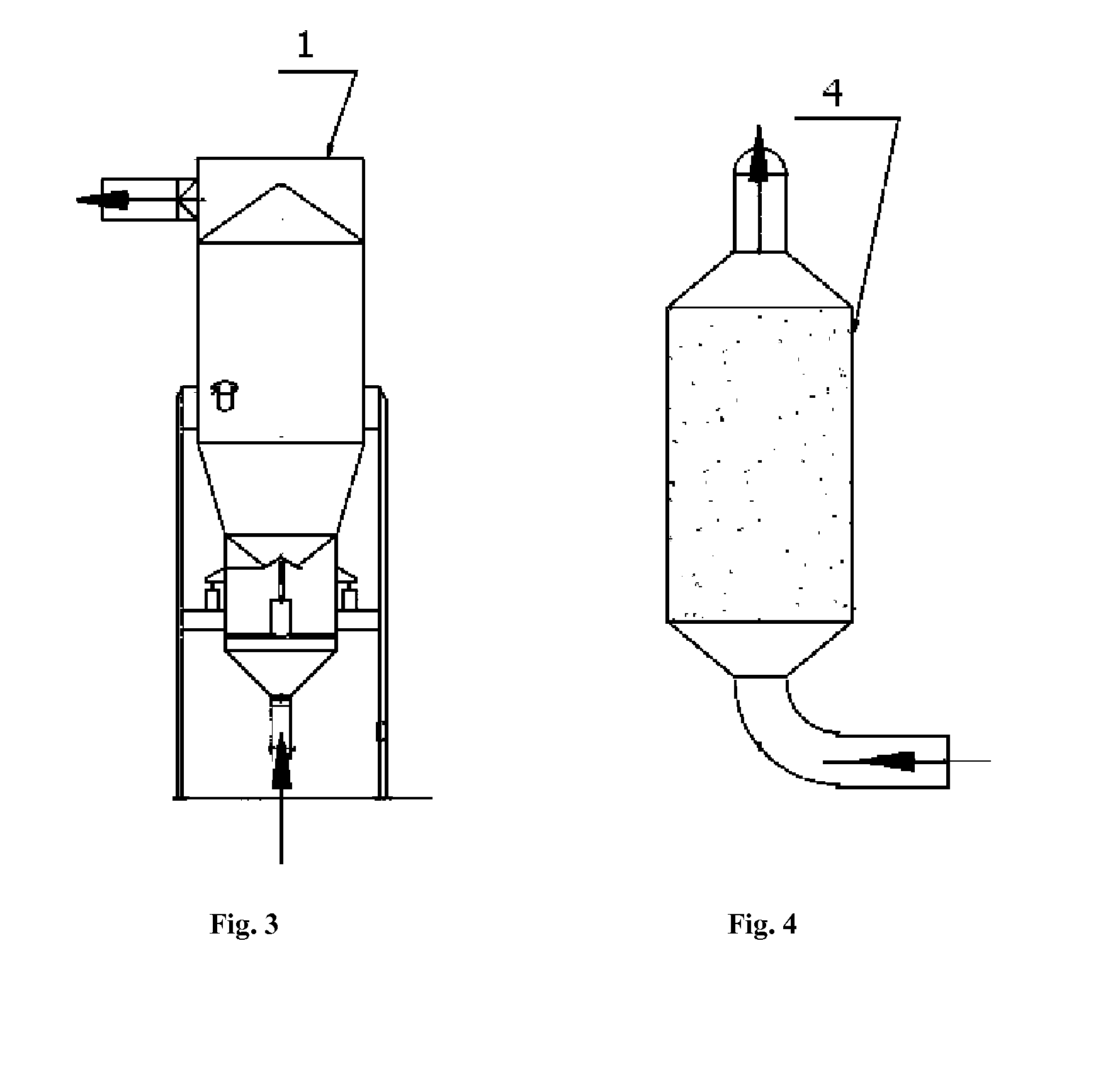

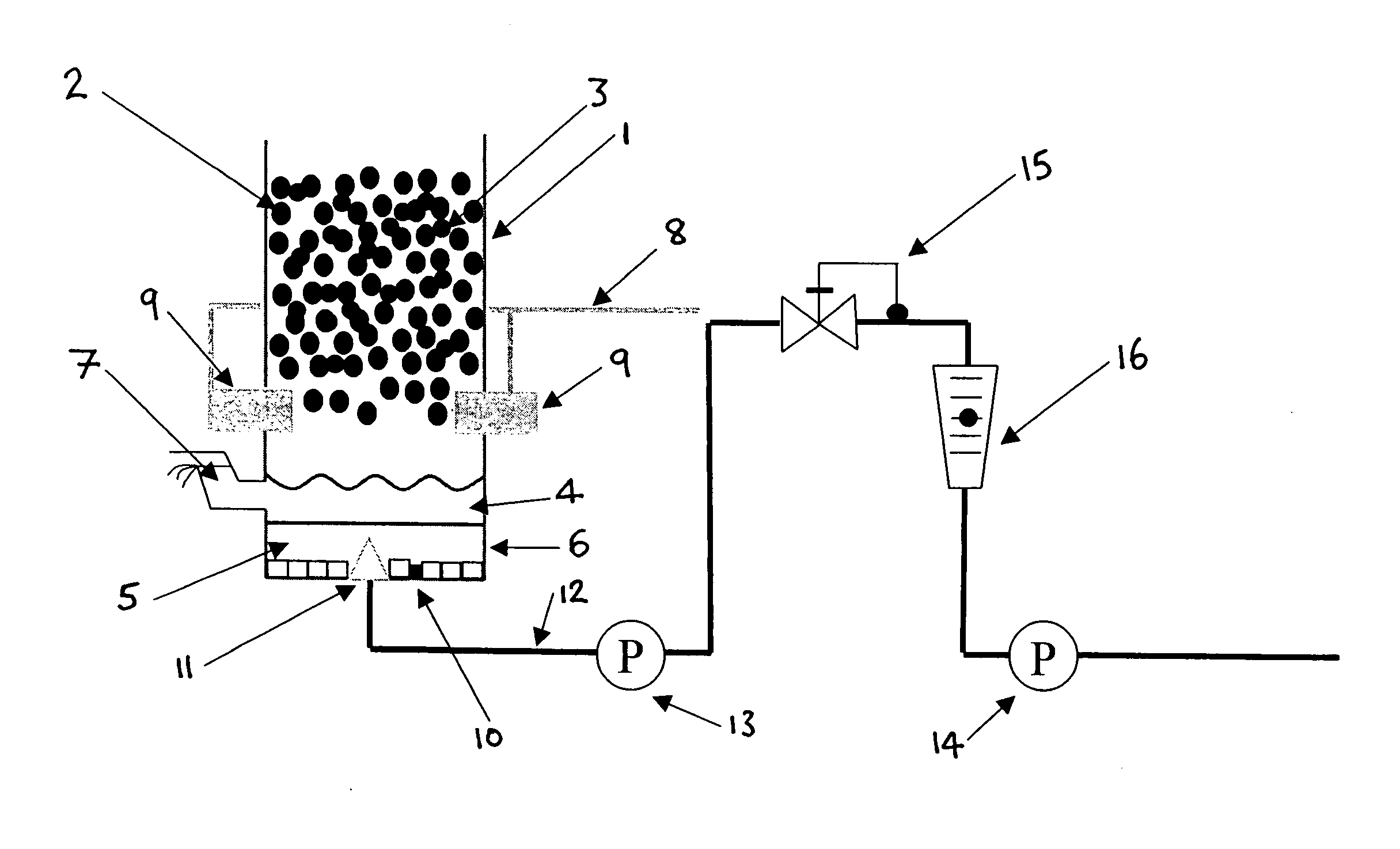

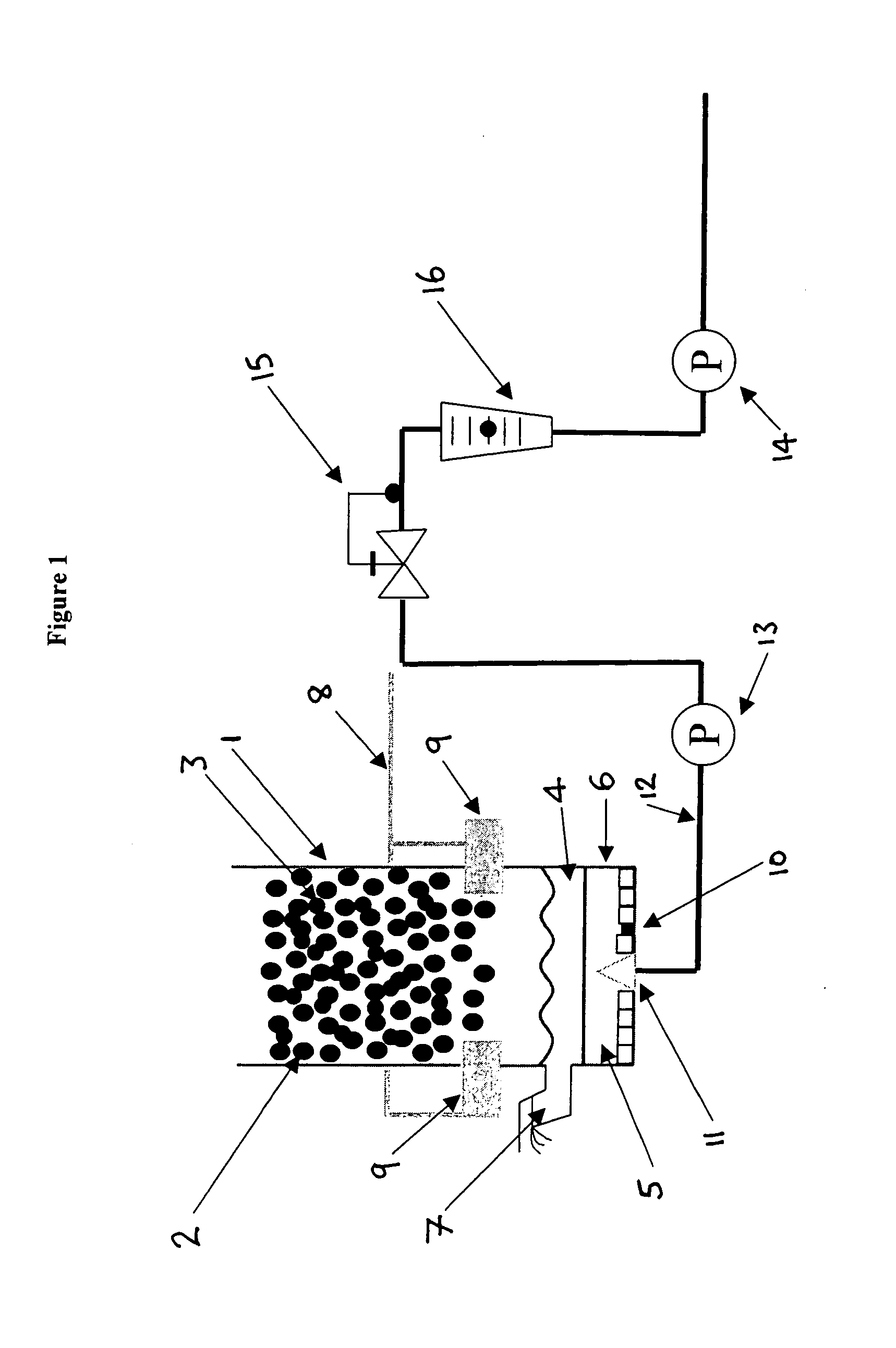

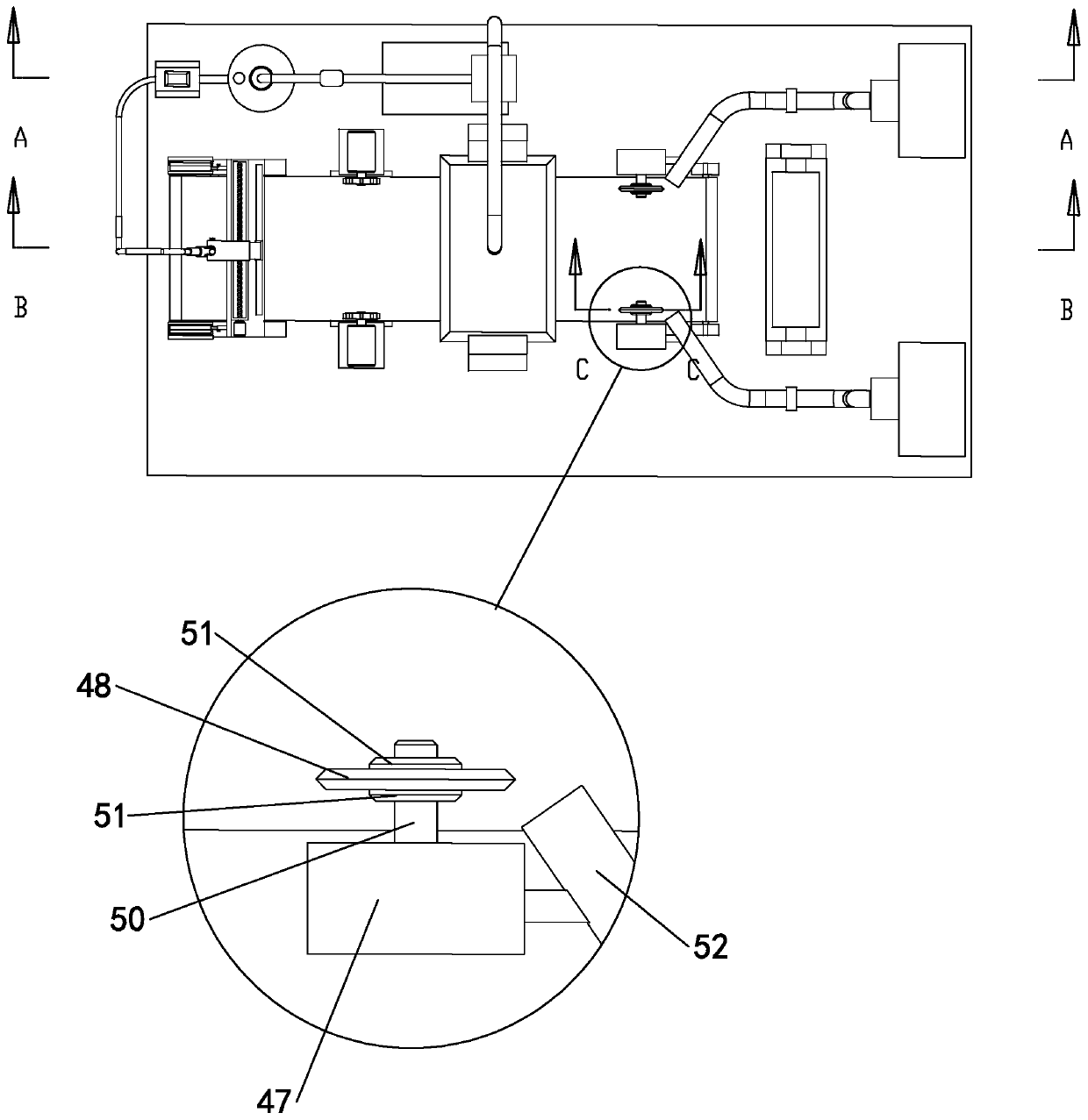

Method for Preparing Controlled Release Fertilizer with Water-Based Coating on the Basis of Closed Circulating Fluidized Bed, and Device therefor

ActiveUS20150210603A1Wasting of large amountReduce energy consumptionLiquid surface applicatorsChemical industryWater basedAir cycle

Disclosed is a method for making a controlled release fertilizer with water-based coating using a closed large numerically controlled fluidized bed and a device therefor: collecting a granular fertilizer with a suitable granule size into a barrel; sucking the same into a coating cavity by negative pressure and making the same fluid; directing a water-based coating liquid into a spray gun, then spraying the liquid onto the surface of the fertilizer granules after nebulization; collecting the impurities in the air discharged from the coating cavity by means of a cyclone separator; dehumidifying the air discharged from the cyclone separator by means of a fluidized drying tower; and then the coating is completed. The closed large numerically controlled fluidized bed coating machine has a fluidized bed coating machine main tower, a cyclone separator, a fluidized drying tower, a blower, a heater, an air compressor, a coating liquid inlet system and a control system, and is characterized in that it has a closed air circulation system, and is provided with a dehumidifying mechanism and a water condensing mechanism for the fluidized drying tower. The present invention can reduce energy consumption, increase heating efficiency and has moisture-absorbing function; it can prevent the spray gun from blocking; it has the function of automatic feeding, which improves the efficiency of coating; therefore it is important for the achievement of a water-based coating process.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

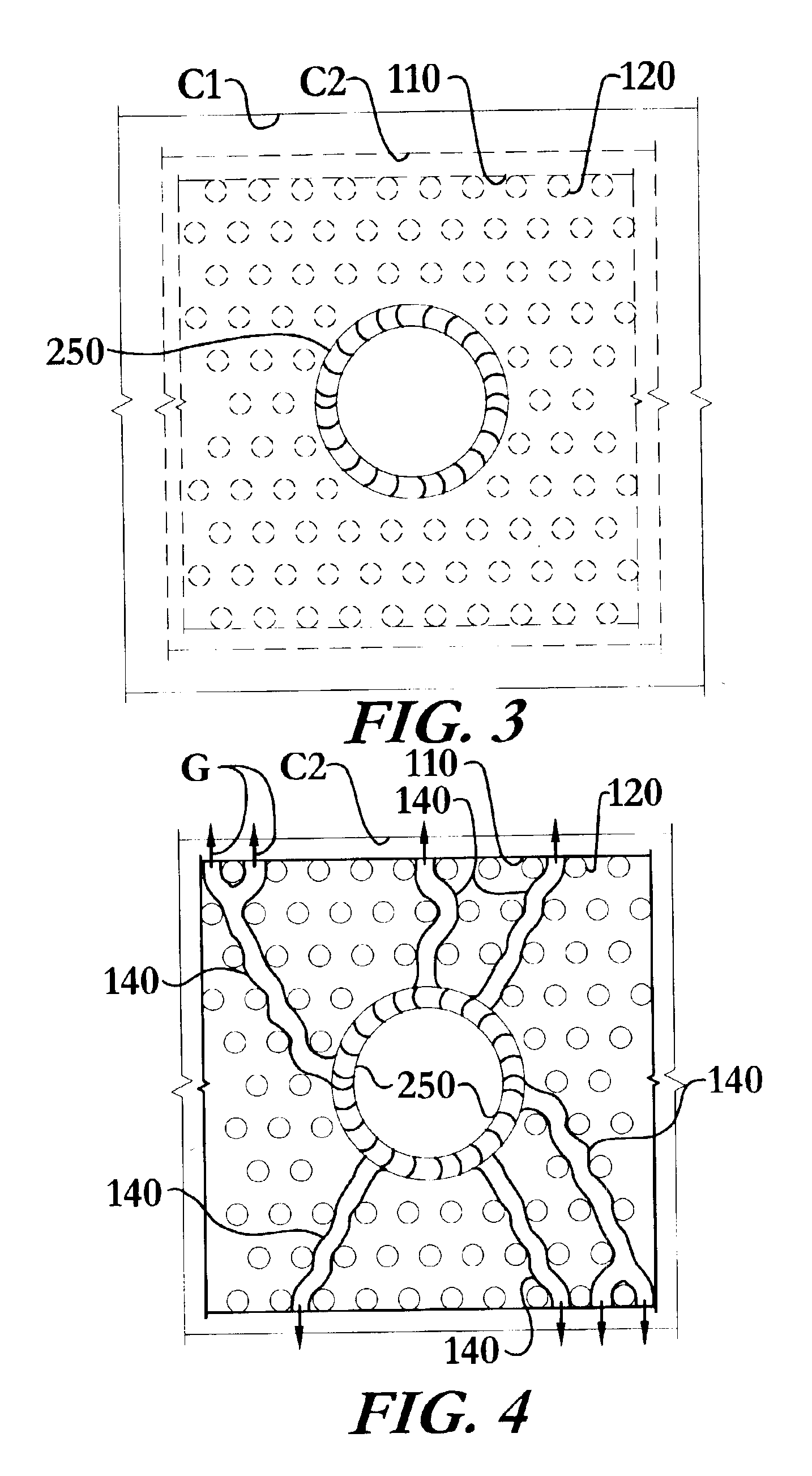

Method of weldbonding

InactiveUS6932879B2Quality improvementMinimizing adhesive flowFurnace typesBaby linensInclusion bodiesAdhesive

An improved method of weldbonding utilizing inclusion bodies, placed directly between materials to be bonded or included in a weldbonding adhesive. The inclusion bodies maintain a gap between the materials to be welded which provides a gas releasing egress route to disperse the gas and gaseous byproducts produced during welding. This egress route substantially prevents the gases and gaseous byproducts from being expelled through the weld pool and the resultant degradation of the quality of the weld pool, particularly with coated materials, partial penetration welds, and such materials as 6000 series aluminum. The method further comprises an optional step of including a crack-reducing additive, applied either directly to the materials to be welded or included in the adhesive. A laser weldbonding embodiment may use a plurality of phased heat cycles to reduce weld imperfections, and enhance the effects of the adhesive and optional crack-reducing additive.

Owner:EDISON WELDING INSTITUTE INC

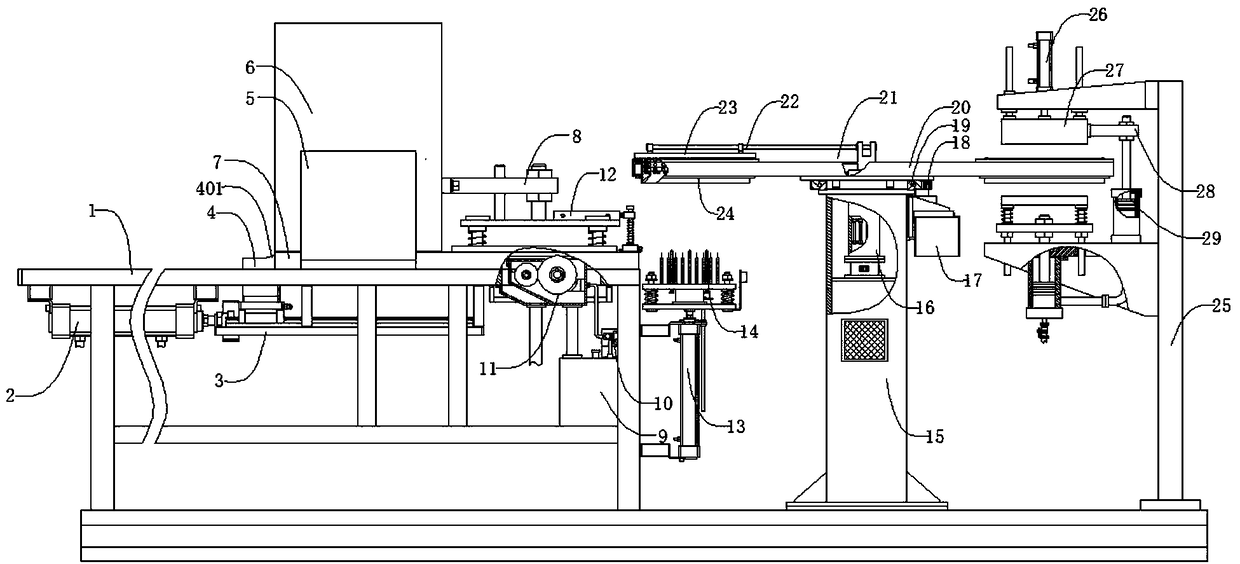

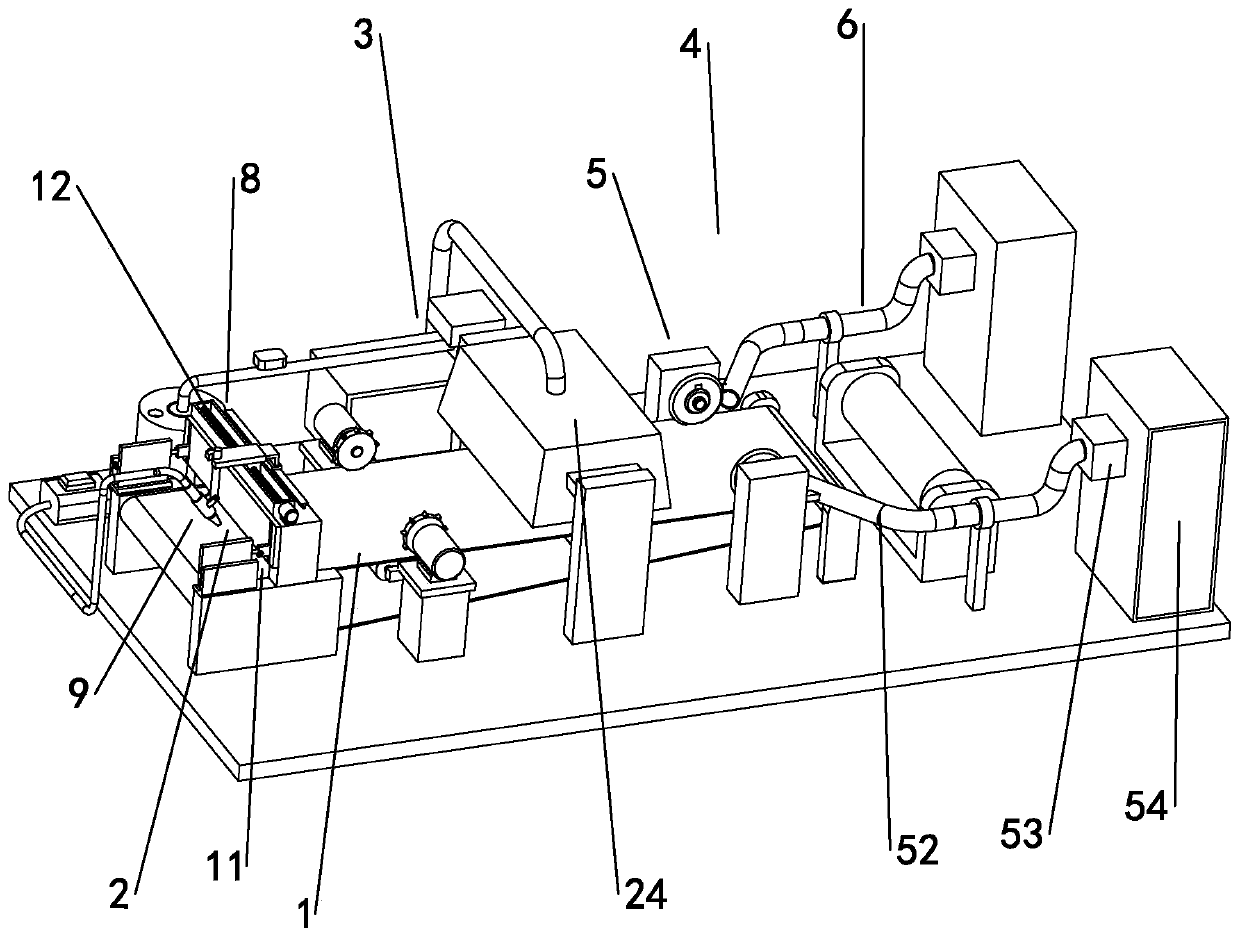

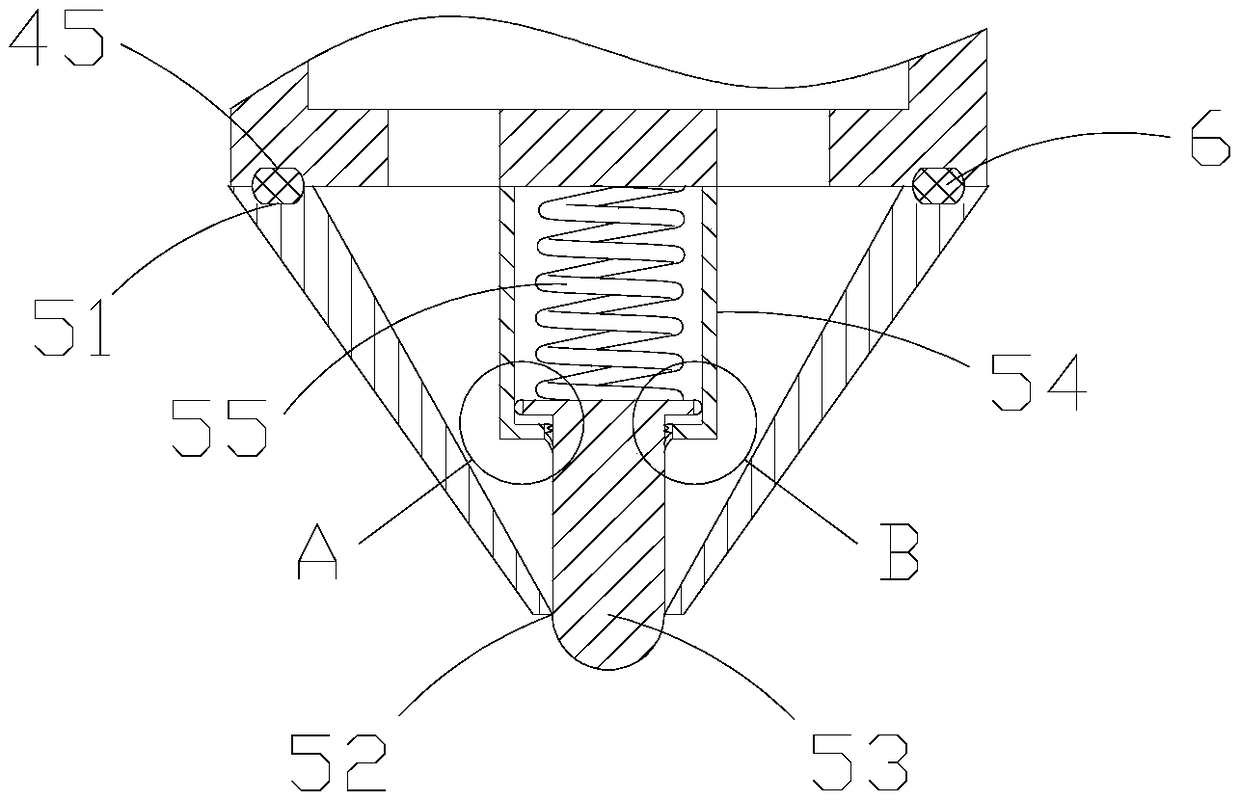

Composite board automatic gluing and laminating production line

InactiveCN108638627AAvoid shakingAvoid offsetLaminationLamination apparatusPeristaltic pumpProduction line

The invention discloses a composite board automatic gluing and laminating production line. The composite board automatic gluing and laminating production line comprises a machine frame, a pushing cylinder, a lower bearing plate, a pushing head, a support, a plate case, a plate bearing strip, a pre-pressing mechanism, a glue box, a peristaltic pump, a coating mechanism, a material taking mechanism,a jacking cylinder, a plate bearing mechanism, a vertical column, a heating mechanism, a servo motor, a gear, a slewing bearing, a round disc heating box, a bearing seat, a supporting rod, a stoppingplate, a material collecting mechanism, a vertical frame, a lower pressing cylinder, an upper die, a connection arm and a synchronous lower die mechanism. The device is simple in structure, can coatthe glue onto the surface of a base plate uniformly, the situation that the glue is not well attached due to secondary pollution can be avoided, the gluing area is accurate, the glue can be recycled,and thus glue waste is effectively avoided. Meanwhile, through floating type design, the upper die and the lower die are laminated simultaneously, uniformity of the lamination is effectively improved,the upper die and the lower die are driven by the single pressing cylinder to laminate, laminating synchronicity is effectively ensured, and the production line can meet the lamination requirement ofbase plates with different layers.

Owner:MAANSHAN JULI SCI & TECH

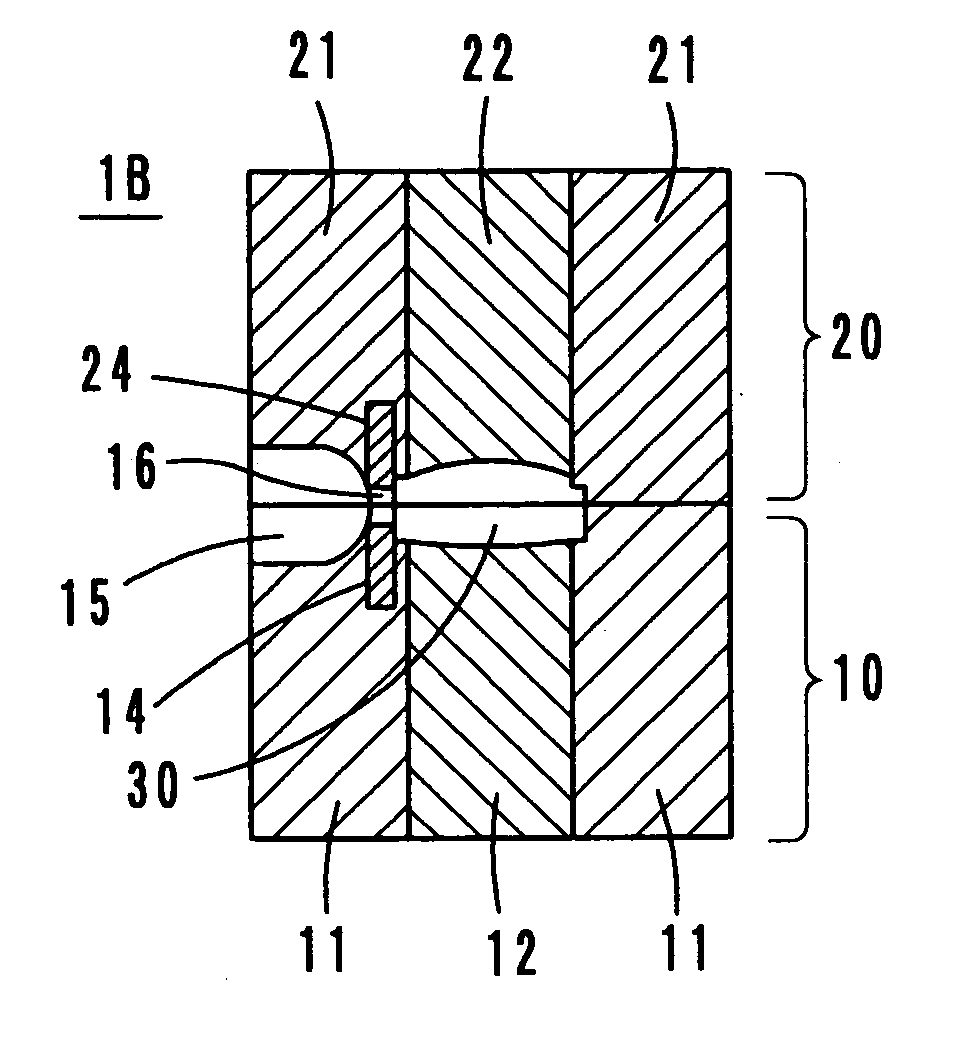

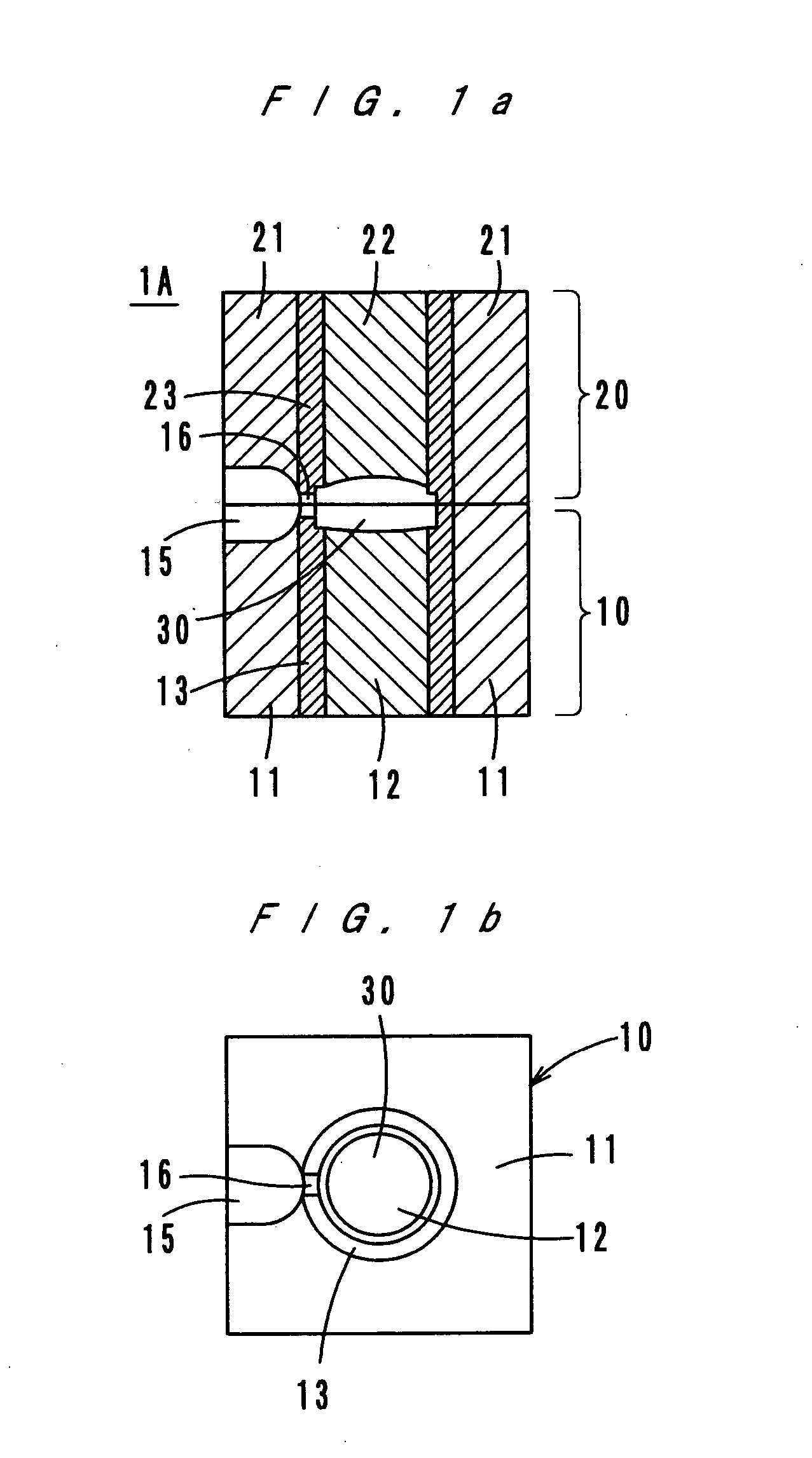

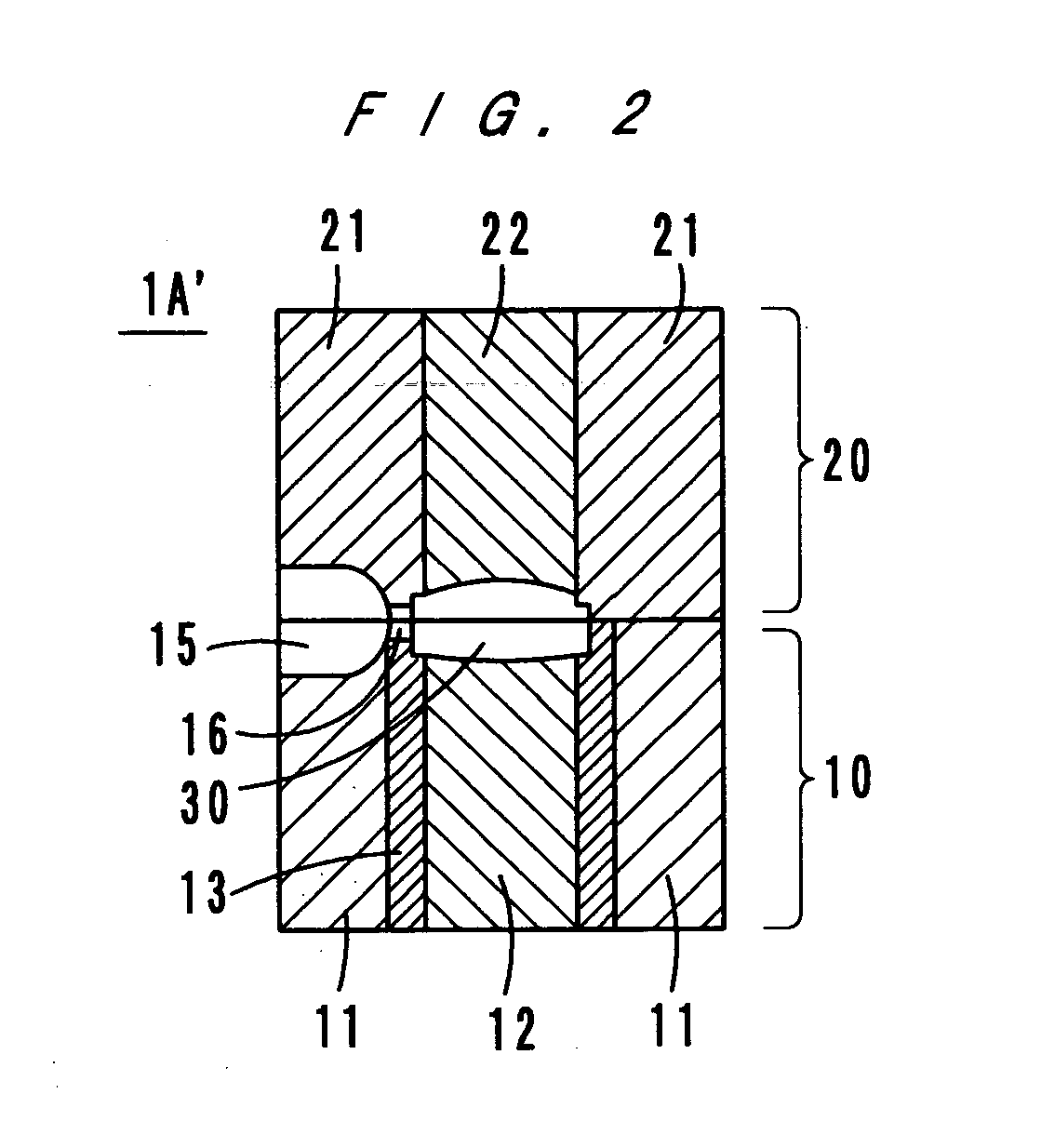

Injection mold and injection molding apparatus

InactiveUS20050287243A1High transmission accuracyRelieve stressFood shapingCoatingsMaterials science

An injection mold and an injection molding apparatus having a movable mold and a fixed mold. Each of the movable / fixed molds has bases, and a runner, a gate and a cavity are formed. The gate is composed of recesses made in mutually opposite end surfaces of sleeve-like heat insulators provided for the bases. Thereby, the gate is heat-insulated, and resin in the gate is prevented from cooling down during a pressure retention step. Thus, the resin keeps fluidity longer.

Owner:KONICA MINOLTA OPTO

Giant salamander instant noodles and production method thereof

Owner:张家界金鲵生物工程股份有限公司

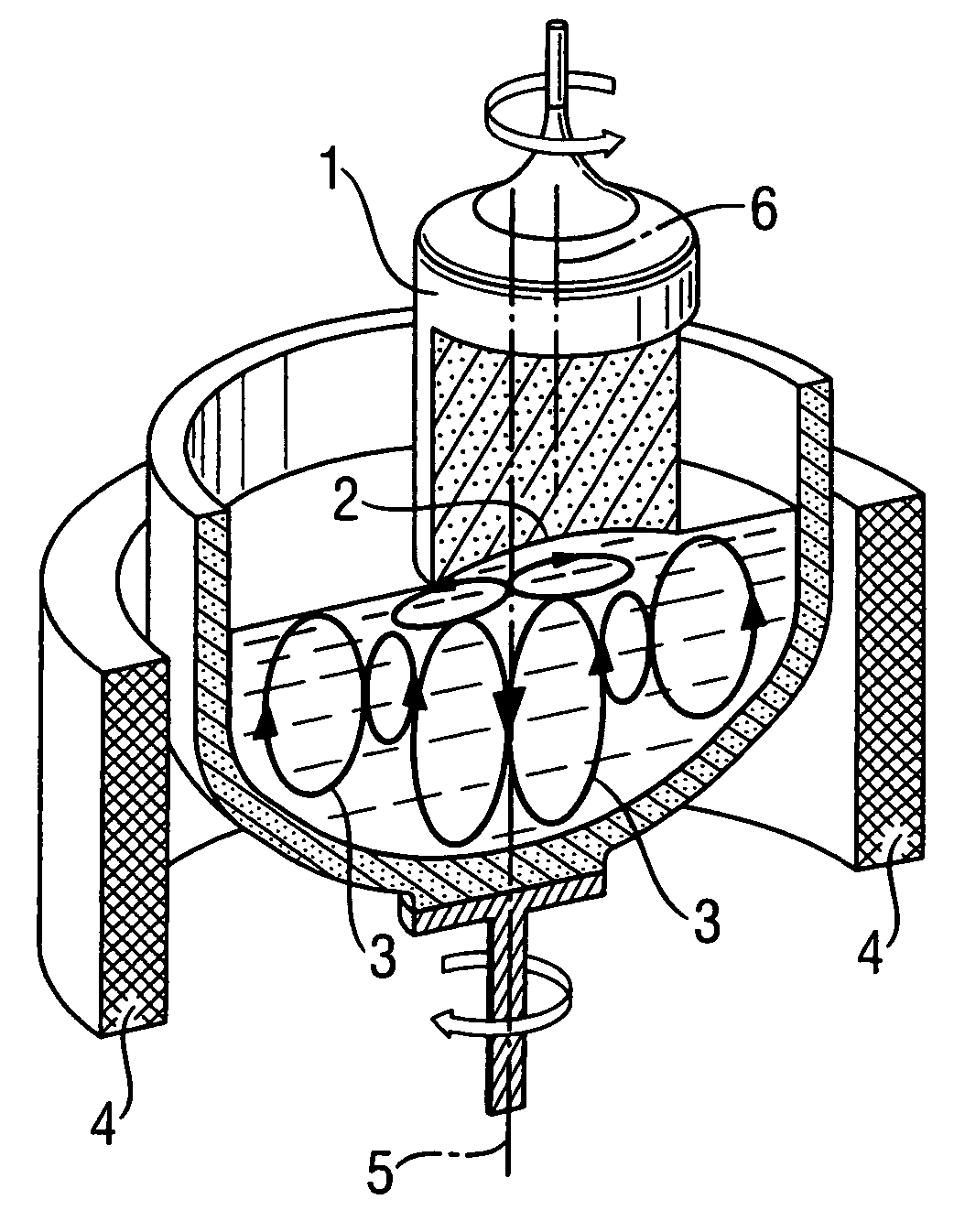

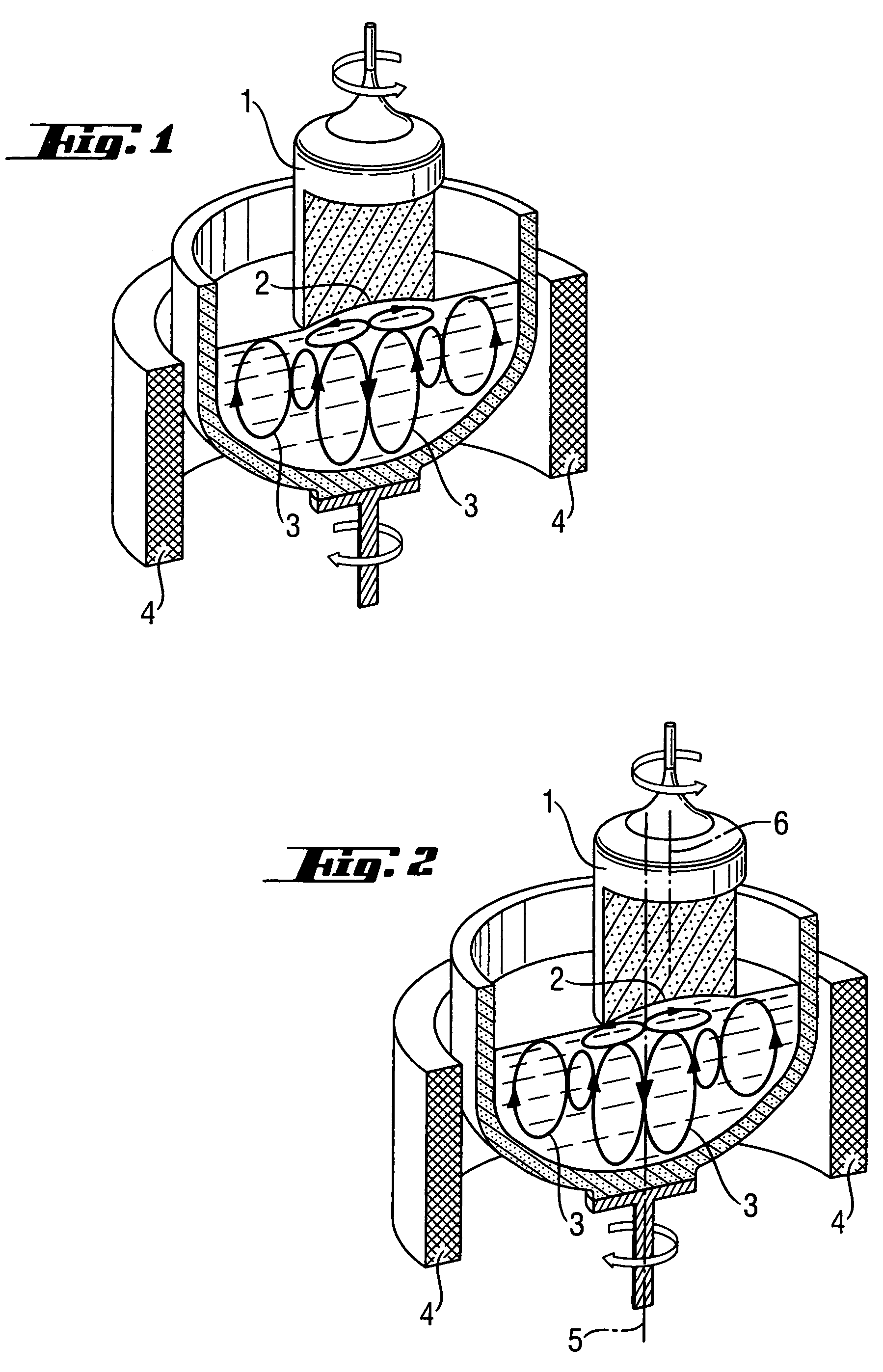

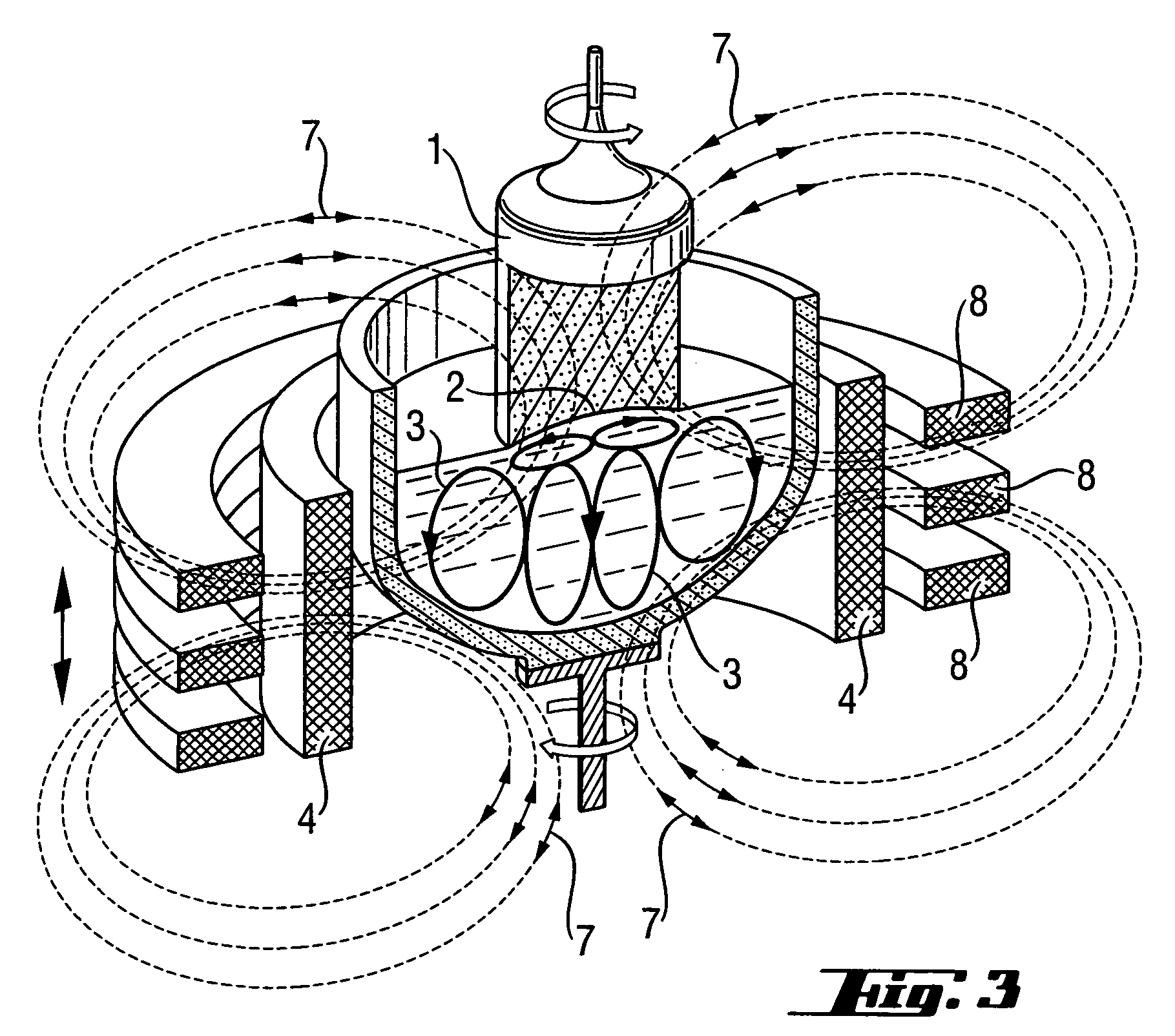

Production of mineral fibers

InactiveUS20100058810A1Reduce decreaseReduce solidificationCharging furnaceGlass furnace apparatusFiberReducing atmosphere

The present invention relates to a process for the production of mineral fibers and to an apparatus which can be used in such a process. In particular, the process of the present invention comprises: providing a furnace; charging to the furnace mineral materials which comprise iron oxides; melting the charged mineral materials in a reducing atmosphere, such that there is a base zone in the furnace in which molten iron collects, and a melt pool above the base zone where mineral melt collects; removing mineral melt from the furnace and converting it to mineral fibers; and removing molten iron from the base zone. During the process, an additive is released directly into the base zone of the furnace wherein the additive comprises one or more substances selected from oxidizing agents and non-reducing gases.

Owner:ROCKWOOL INT AS

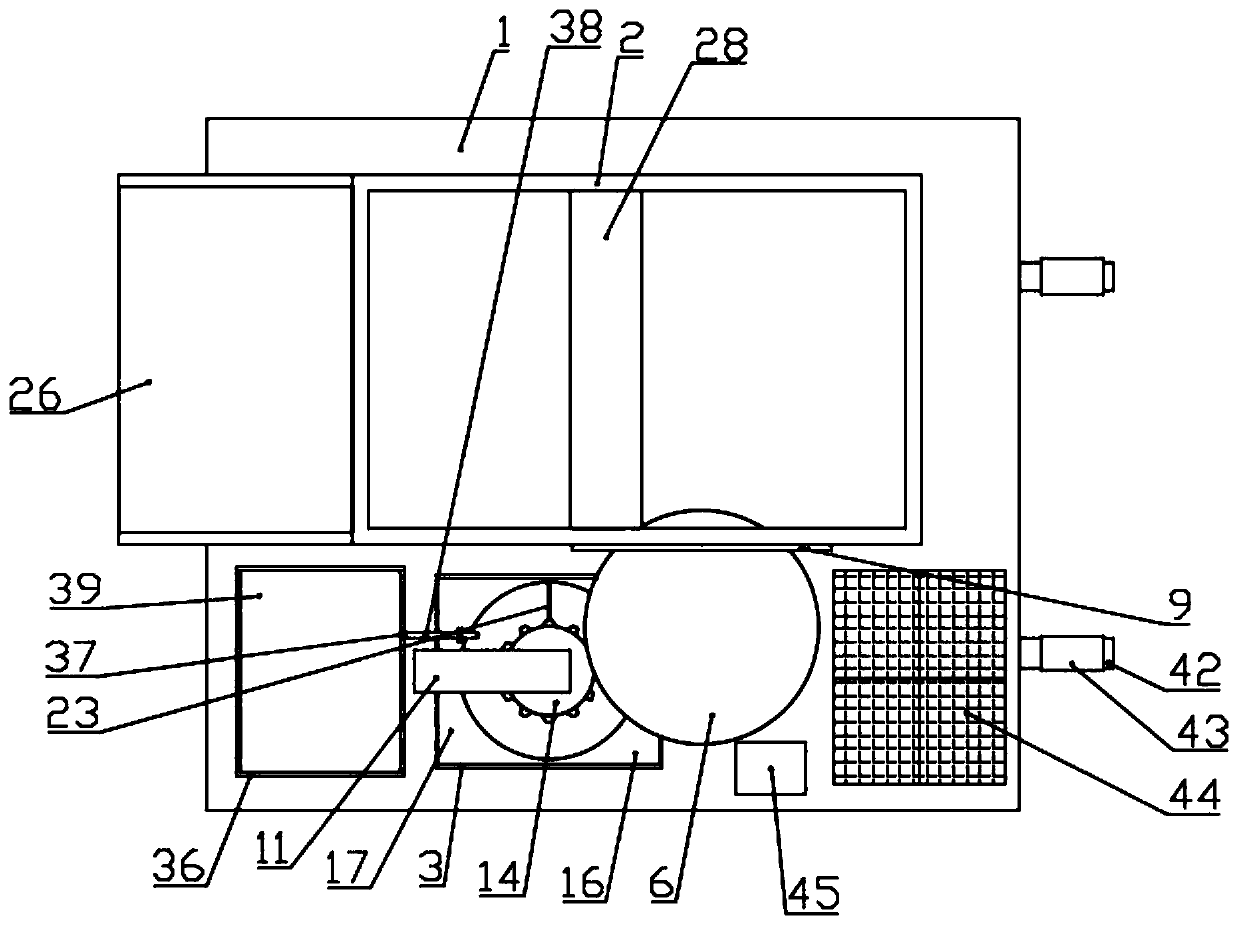

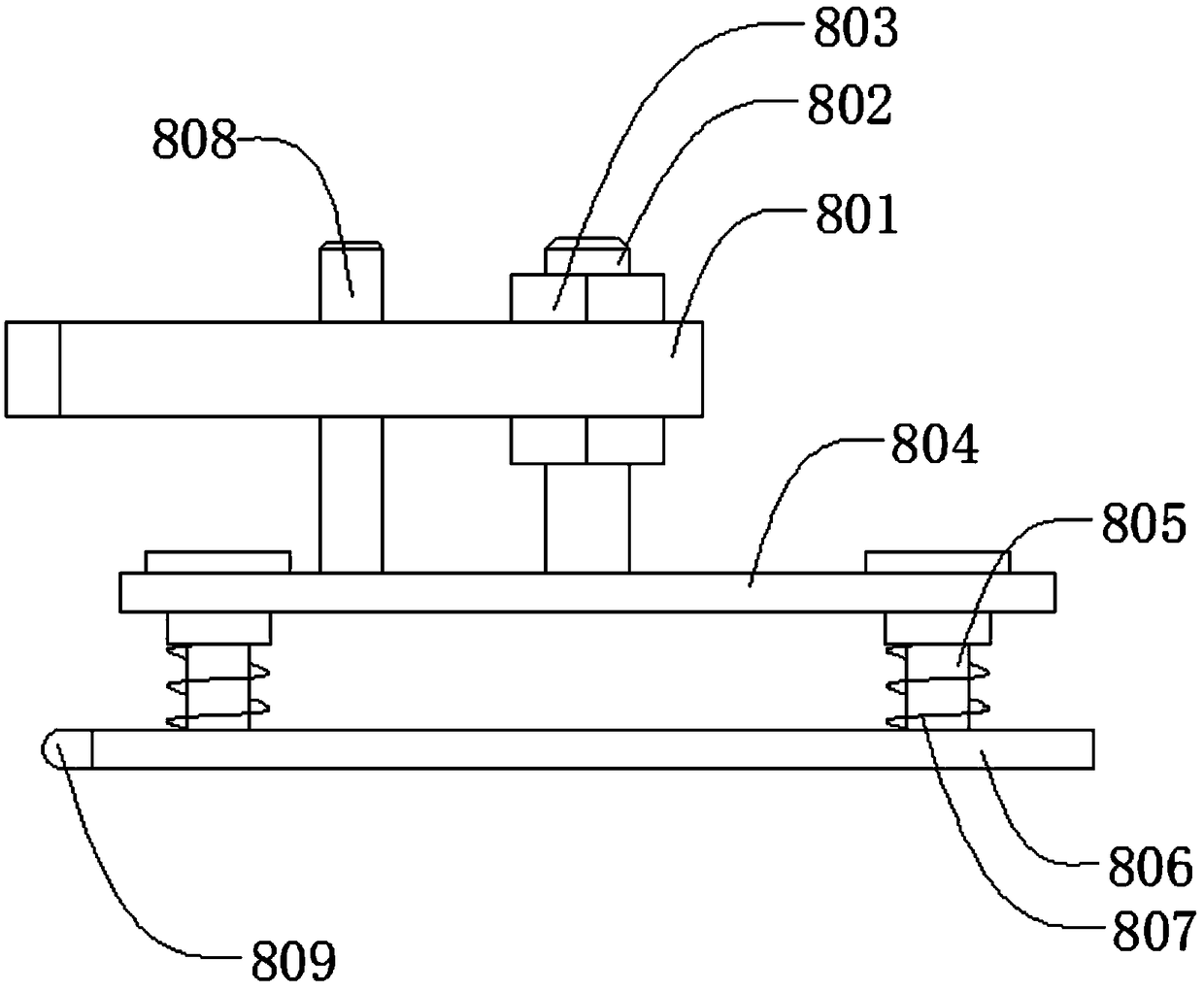

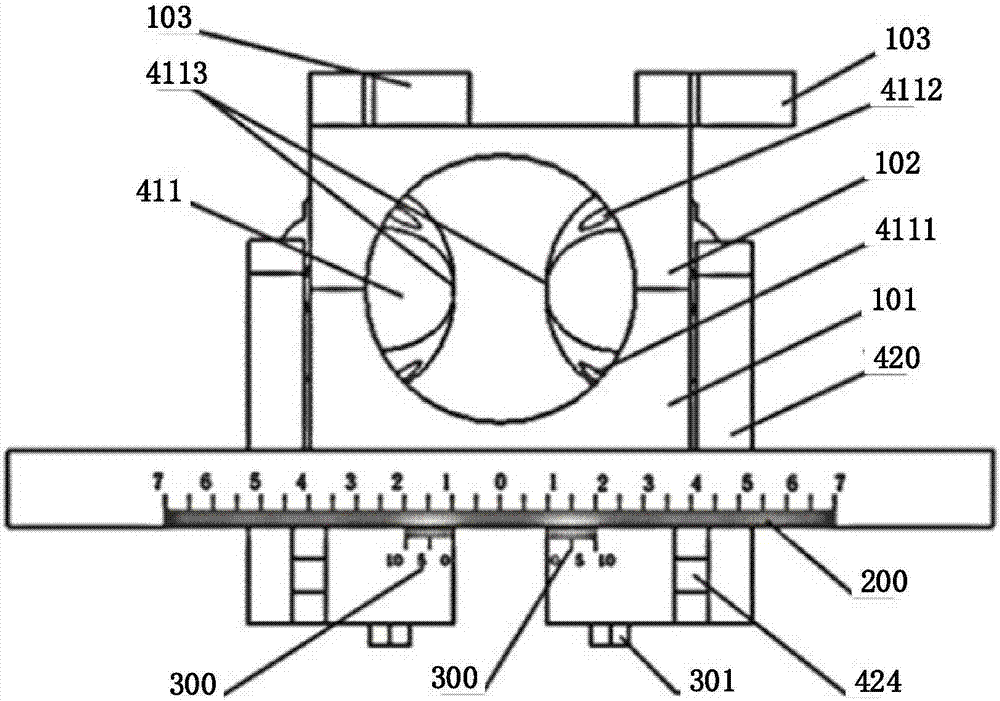

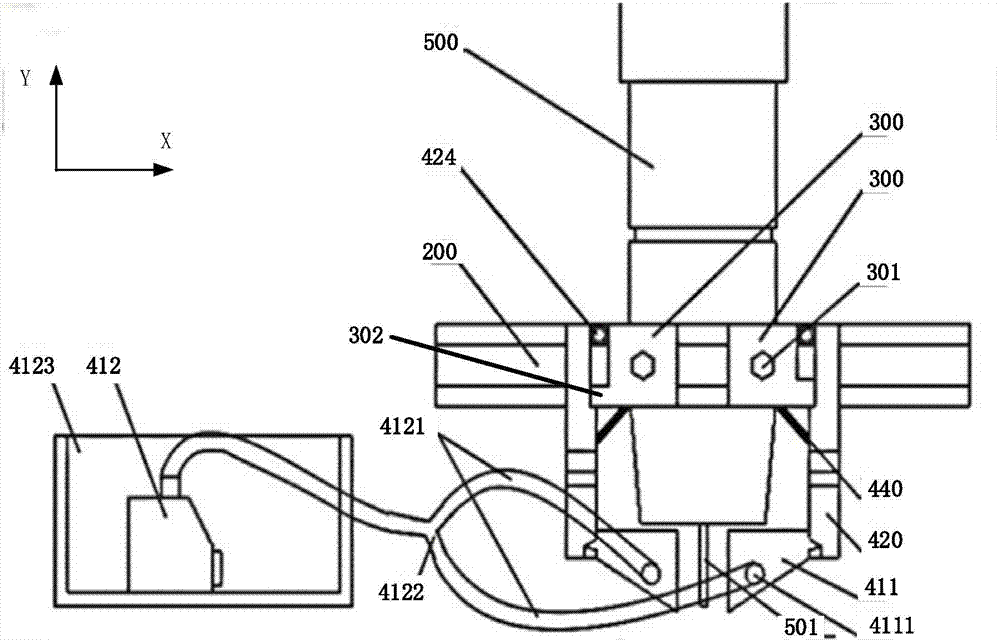

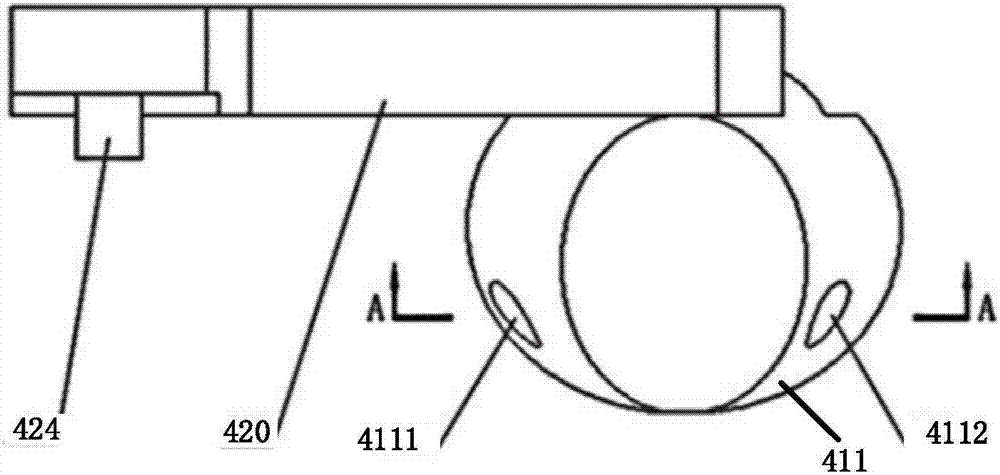

3D printing restrained forming auxiliary device and use method thereof

ActiveCN106984820AIncrease productivityHigh material utilizationAdditive manufacturing apparatusMelting tankCurrent electric

The invention discloses a 3D printing restrained forming auxiliary device and a use method thereof. The 3D printing restrained forming auxiliary device comprises a fixing portion, a sliding rail and a cooling device. The fixing portion is fixedly connected with the sliding rail and is used for being fixedly connected with a welding torch of 3D printing equipment, and the cooling device is slidably connected to the sliding rail and is used for cooling deposited metal generated in the printing process of the 3D printing equipment. The majority of heat of the deposited metal generated in the electric arc 3D printing process is brought away through cooling of a cooling block, solidification and high-temperature stay time of molten pool metal is greatly shortened, and the problems that heat accumulation of accumulated parts is serious, the heat dissipation condition is poor, a molten pool is excessively hot, an internal grain organization is thick and big, and mechanical property is low along with increase of the number of accumulated layers are solved. Besides, the 3D printing restrained forming auxiliary device is simple in structure and convenient to use and adjust, the machining margin required for a current electric arc 3D printing workblank forming piece is eliminated or reduced, production efficiency of electric arc 3D printing is improved, and the material utilization rate is increased.

Owner:HARBIN INST OF TECH AT WEIHAI

Production and processing device for composite coating

PendingCN111359821AProduce pollutionPrevent fallingSevering textilesPretreated surfacesGas burnerEngineering

The invention discloses a production and processing device for composite coating. The production and processing device comprises a cloth conveying mechanism, a paint coating mechanism, a coating drying mechanism and a leftover shearing mechanism, wherein the paint coating mechanism is arranged on the front side of the upper end of the cloth conveying mechanism, the leftover shearing mechanism is arranged on two sides of the cloth conveying mechanism and located on the rear side of the coating drying mechanism, the paint coating mechanism comprises a paint scraper, a spray gun moving mechanismand a paint spray gun assembly, the coating drying mechanism comprises a gas burner, a hot air chamber, a burning chamber and a drying cover, a cold air pipeline and a hot air outlet are arranged on the hot air chamber, an air intake fan is arranged on the cold air pipeline, a hot air channel is connected to the hot air outlet, the end, away from the hot air outlet, of the hot air channel is connected to the upper end of the drying cover, the drying cover is located right above the cloth conveying mechanism, and the far end, away from an air outlet hollow pipe, of an air delivery pipe is connected to the side wall of the cold air pipeline.

Owner:桐乡市迪诺纺织股份有限公司

LED lamp processing device

InactiveCN109351559AAvoid cloggingGuaranteed to workLiquid surface applicatorsCoatingsLED lampMechanical engineering

The invention discloses an LED lamp processing device. The device comprises a base, a crystal expanding mechanism and a glue dispensing mechanism; the crystal expanding mechanism comprises a placementplatform, a crystal expanding part, an annular cutting part and a film pressing part, the glue dispensing mechanism comprises a glue gun frame, a glue gun and a feeding device, a fixed ring is arranged on the lower surface of the film pressing part, a first channel matched with the crystal expanding part is arranged on the annular cutting part, a second channel allowing the crystal expanding partto pass through is arranged on the film pressing part, a third channel the same with the crystal expanding part in size and shape is arranged on the placement platform, a glue dispensing head is detachably connected to the glue gun, a telescopic assembly is arranged in the glue dispensing head, and the glue gun is externally connected with a liquid inlet assembly. Through the liquid inlet assembly, glue in the glue gun can be kept at the proper concentration all the time, and the problem that due to solidification of glue in the glue gun, blockage is caused is solved.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

Silicon single crystal, and process for producing it

InactiveUS7335256B2Reduce solidificationReduce curvaturePolycrystalline material growthBy pulling from meltDopantCzochralski method

A silicon single crystal which, over an ingot length of over 10 percent of the total ingot length, has a uniform defect picture and narrow radial dopant and oxygen variations. The process in accordance with the Czochralski method involves bringing about a temperature distribution in the melt in the region of the solidification interface which deviates from rotational symmetry.

Owner:SILTRONIC AG

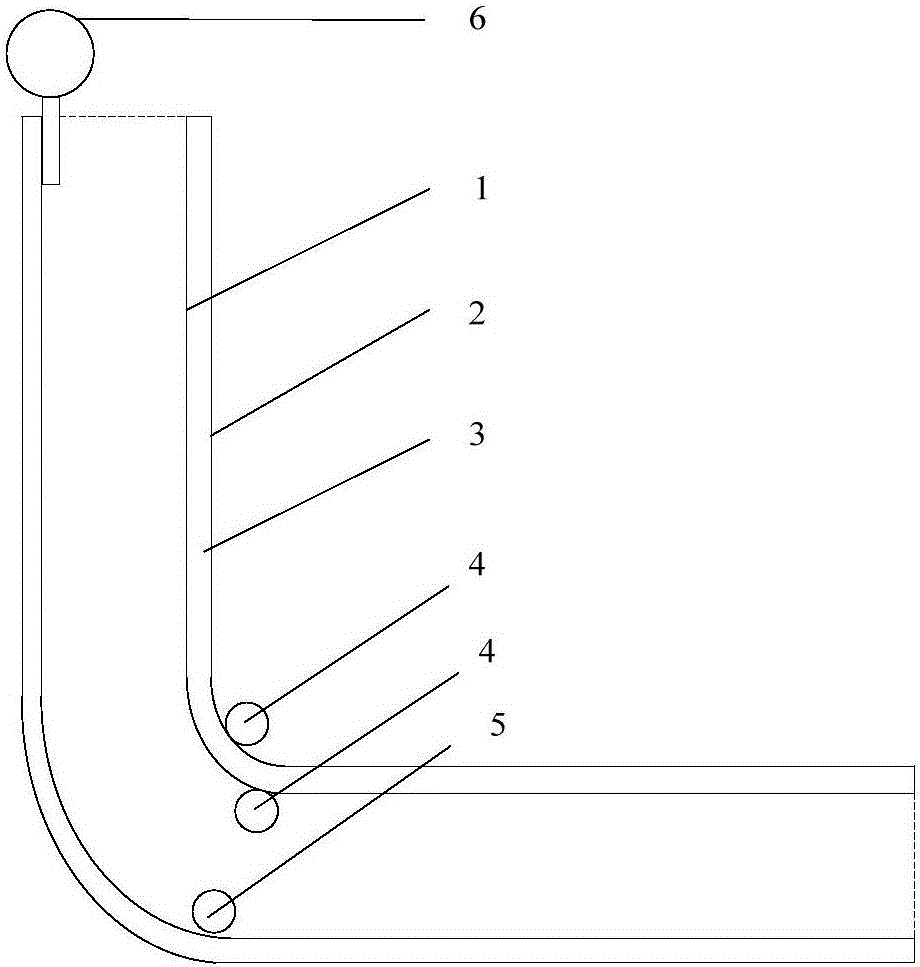

Uam transition for fusion welding of dissimilar metal parts

ActiveUS20190232419A1Reduce solidificationReduce crackingArc welding apparatusThin material handlingHigh entropy alloysMetallic materials

Welded assemblies and related methods of making the welded assemblies include a first component of a first metal material, a second component of a second metal material that is different from the first metal material, and a transition material including one or more of a high entropy alloy, a pure element, and an alloy that is not a high entropy alloy, and that is arranged between and contacting the first component and the second component. An ultrasonic weld joins the transition material to the first component, and a fusion weld joins the first component to the second component. The fusion weld contact the first component, the second component, and the transition material. The amount or level of one or more of galvanic corrosion, intermetallic compounds, and solidification cracking in the fusion weld is less than if the first component was fusion welded directly to the second component.

Owner:HONDA MOTOR CO LTD

Preheating and solidification-preventing conveying pipeline structure

InactiveCN105972339AEasy to operateShort heating timeThermal insulationPipe heating/coolingElectricityElectrical resistance and conductance

The invention relates to a preheating and solidification-preventing conveying pipeline structure which comprises an inner pipeline and an outer pipeline. The end portion of the inner pipeline and the end portion of the outer pipeline are in sealed connection. A closed cavity structure is defined by the inner pipeline and the outer pipeline. A vacuum layer is formed in the cavity structure. The inner pipeline is a steel pipeline. The preheating and solidification-preventing conveying pipeline structure further comprises an electric heating circuit used for heating the inner pipeline after being electrified. The electric heating circuit is electrically connected with the inner pipeline. The steel inner pipeline is used as a resistor, electric energy is provided for the inner pipeline through the electric heating circuit, electric energy heating is conducted on the inner pipeline, and the preheating and solidification-preventing conveying pipeline structure can reach the needed temperature within a short time. The preheating and solidification-preventing conveying pipeline structure is convenient to operate, short in heating time, even in heating effect, capable of effectively reducing solidification of the pipelines and capable of prolonging the service life of the pipelines.

Owner:江苏爱能森科技有限公司

UAM transition for fusion welding of dissimilar metal parts

ActiveUS10870166B2Reduce solidificationReduce crackingArc welding apparatusThin material handlingHigh entropy alloysUltrasonic welding

Welded assemblies and related methods of making the welded assemblies include a first component of a first metal material, a second component of a second metal material that is different from the first metal material, and a transition material including one or more of a high entropy alloy, a pure element, and an alloy that is not a high entropy alloy, and that is arranged between and contacting the first component and the second component. An ultrasonic weld joins the transition material to the first component, and a fusion weld joins the first component to the second component. The fusion weld contact the first component, the second component, and the transition material. The amount or level of one or more of galvanic corrosion, intermetallic compounds, and solidification cracking in the fusion weld is less than if the first component was fusion welded directly to the second component.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com